Page 1

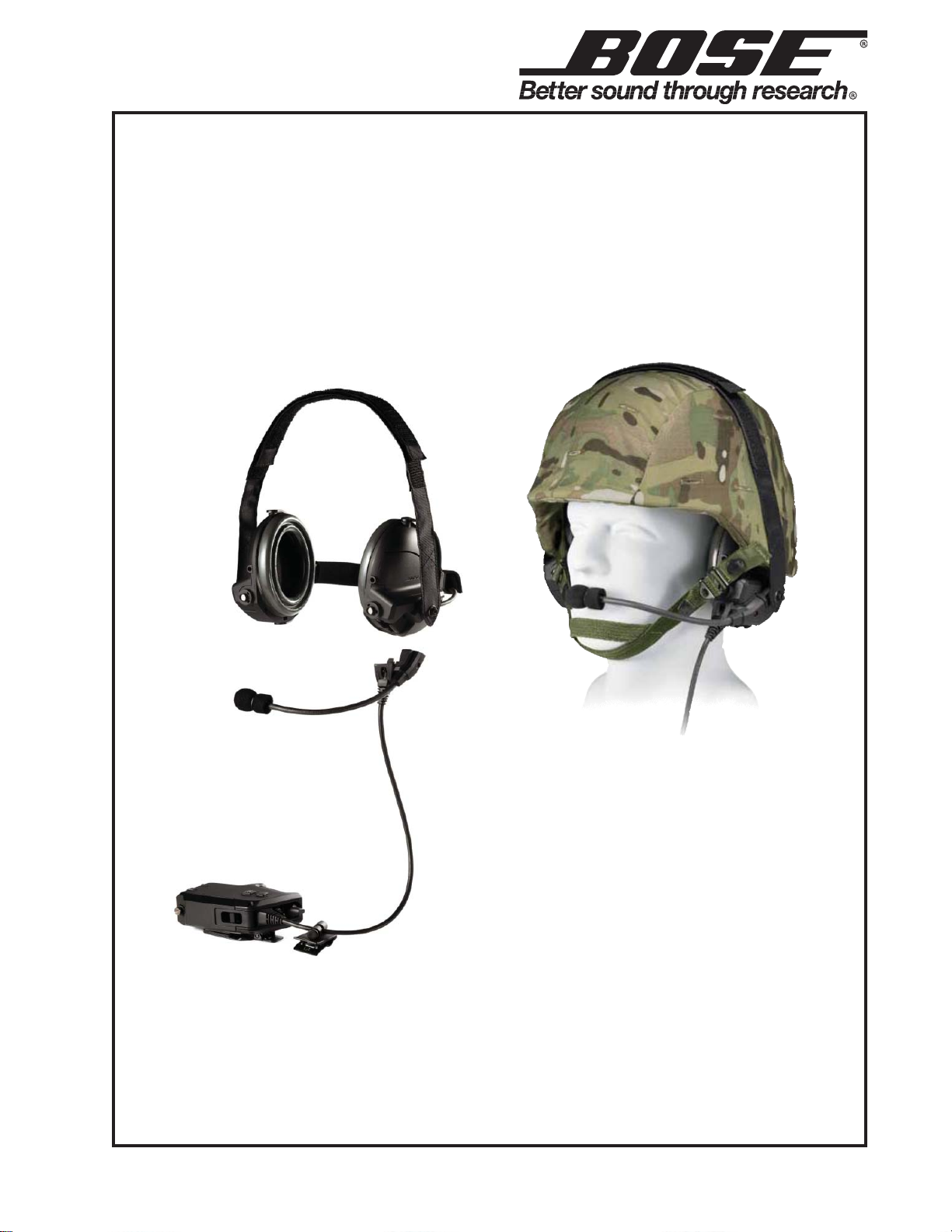

T5 Tactical Headset

©2016 Bose Corporation

Service Manual

Reference Number 350006-SM Rev. 00

Page 2

CONTENTS

Electrostatic Discharge Sensitive (ESDS) Device Handling .........................................................3

Part List Notes...................................................................................................................................3

Specifications....................................................................................................................................4

Product Description.................................................................................................................... 5-10

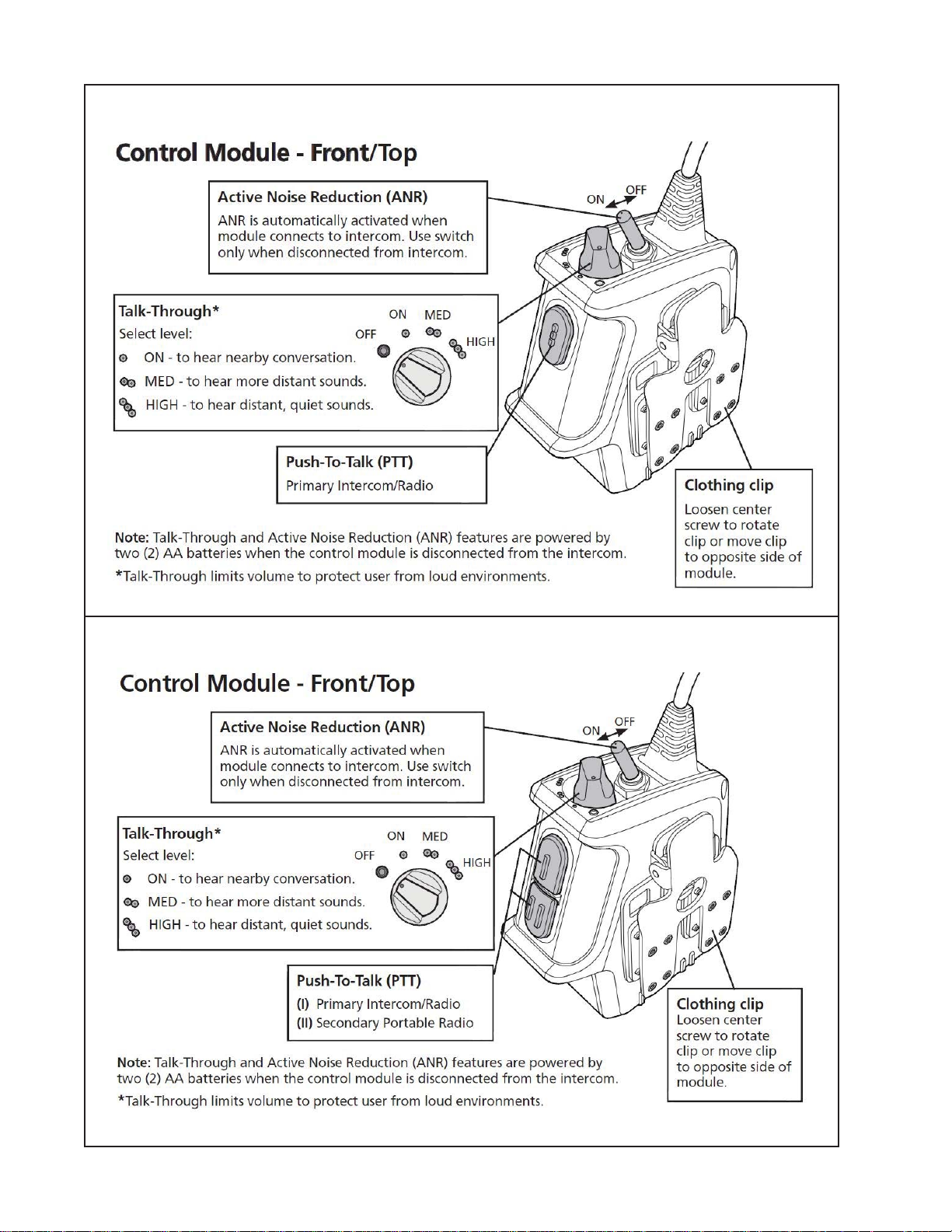

Single Comm Module Controls........................................................................................................6

Dual Comm Module Controls...........................................................................................................6

Manufactured Versions ..................................................................................................................11

Packaging Part Lists, T5 Headset, All Versions ...........................................................................11

User Replaceable Parts List...........................................................................................................11

System Configurations............................................................................................................. 12-13

Cables and Replacement Parts......................................................................................................14

Disassembly Procedures ......................................................................................................... 15-19

Test Procedures ........................................................................................................................ 20-26

Definitions........................................................................................................................................20

Troubleshooting........................................................................................................................ 27-29

Service Manual Revision History...................................................................................................30

IMPORTANT NOTE: These products are RoHS compliant. Use ONLY lead free solder when

making repairs.

®

CAUTION: The Bose

warranty infractions, refer servicing to warranty service stations or factory service.

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

FOR THE PURPOSE OF SERVICING THE IDENTIFIED BOSE

PRODUCT BY AN AUTHORIZED SERVICE CENTER AND SHALL

NOT BE REPRODUCED OR USED FOR ANY OTHER PURPOSE.

T5 Tactical Headset contains no user serviceable parts. To prevent

PROPRIETARY INFORMATION

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY

2

Page 3

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly grounded.

Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble wrap

or plastic trays.

PART LIST NOTES

1. The individual parts located on the PCB are listed in the part list.

2. This part is referenced for informational purposes only. It is not stocked as a repair part.

Refer to the next higher or lower level assembly for a replacement part.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire and/

or other hazards.

3

Page 4

SPECIFICATIONS

Bose® T5 TECHNICAL INFORMATION OVERVIEW

Mono and stereo available Single Comm and Dual Comm options

Weight (on head)

Control Module W eight

Dual Comm radio or intercom cables

Nominal Headband Clamping Force

Ear cup to Control Module Cable Length

Push-to-talk (PTT) on control module One momentary PTT switch for single comm

Live Mic Switch

ANR ON/OFF on control module 2-position (on/off) toggle type switch, powers headset in

Talk-through (TTC switch

Batter y Po w er

Current Draw

Operating noise environment Full ANR performance up to 123 dBSPL.

Earphone sensitivity 104 ± 3dB SPL (active) for a 0±0.1 dBV input

Input Impedance

Attenuation Performance will vary depending on the vehicle noise

Boom microphone Electret or Dynamic

Temperature Rating -40

EMI MIL-STD-461F

455g

300g

120g (max/each)

2.1 +/- 0.1 lbs.

420 +/- 50 mm

Two momentary PTT switches for dual comm

2-position (on/off) toggle type switch, used to transmit

continuously within the intercom

dismounted operations

User-selectable, 4 position rotary, Binaural

Position one: off

Position two: 0db gain

Positio n three: medium gain

Position four: high gain

2 AA batteries

ANR Only: 40 hours minimum

TT Only: 100 hours minimum

ANR and TT: 30 hours minimum

16 mA RMS nominal at 24v

Reduced ANR from 124dBSL u p to 130 dBSPL Max

94 ± 4dB SPL (bypass)

1000±10% per channel (binaural)

500±10% (monaural)

profile and crew position.

o

C to +65oC Operating

o

C to +71oC Storage

-57

4

Page 5

PRODUCT DESCRIPTION

OVERVIEW

The Bose® T5 Tactical Headset (T5TH) offers an unsurpassed combination of full-spectrum

noise reduction, comfort and clear audio in an ergonomic and rugged form factor that is compatible with a variety of helmets, intercoms and radio systems. The optional dual-communications

designed control module provides additional mission flexibility, which allows soldiers to easily

adapt the headset to fit specific mission needs.

The T5 Tactical Headset is designed to be used by infantry and other military personnel who are

primarily operating in and around tactical wheeled vehicles. These users engage in missioncritical communications and require effective noise reduction. Interpersonal communication and

situational awareness are paramount, so they value products that are operationally flexible for

mounted and dismounted use cases without sacrificing hearing protection.

KEY BENEFITS

• Clear, two-way communication provides increased situational awareness via intercom, radio

and Talk-Through feature.

• Reduction of both continuous and impulse noise provides hearing protection and allows for

increased focus on mission-critical tasks and information.

• Certain configurations can support simultaneous communications with two different devices.

• Improved ergonomic design supports both mounted and dismounted operations, and the

seamless transition between the two.

• Designed to fit securely and comfortably under combat helmets to support longer mission

profiles.

• Designed for rugged combat use while being intuitive and easy to use with limited training.

• Easily field-repairable and upgradeable.

5

Page 6

PRODUCT DESCRIPTION

Single Comm Module Controls

Dual Comm Module Controls

6

Page 7

PRODUCT DESCRIPTION

The T5 headset is capable of working in noise environments with sound pressure levels up to

115dB(C) SPL which means it is most useful in small and large wheeled vehicles as well as

many fixed and rotary wing aircraft.

The T5 headset consists of four main assemblies:

1. An active noise canceling headphone (two ear cups with ear cushions)

2. A suspension system (Napeband with over-the-head Velcro straps to support the weight)

3. A control cable assembly which provides power management, houses the necessary user

interface controls and adapts the headphone to the customer’s needs (by changing cables

to be compatible with desired source). The control cable assembly can be removed from the

earcups and replaced in the field.

4. A noise canceling boom microphone enabling communications. The microphone can be

easily replaced in the field.

The earcups each contain external-facing microphones and circuitry to allow Talk-Through, or

the ability to monitor external sounds such as speech without having to lift the earcups off of the

ear. This talk-through (TT) circuit limits external sounds to be no greater than 85dB at the ear.

The T5 headset has a volume control for the talk-through feature with volume settings will be

OFF; unamplified, medium amplification and high amplification. In all settings, the above mentioned 85dB limit is enabled.

The ear cushions used on the headset contribute to the performance as well as the overall

comfort of the headset. The ear cushions consist of polyurethane foam inside a polyurethane

film.

The napeband consists of a single, arc shaped spring formed to tuck behind the nape of the

user’s neck and head and to provide the desired clamping force. Two yokes connect the spring

to the earcups. The assembly is adjustable to fit most head sizes. The yokes and earcup

interface allow for rotation in 2 axes in order to allow optimum fit for performance as well as for

comfort. Additionally, the assembly includes a soft pad to provide cable routing and a comfortable fit behind the head for extended wear periods. The napeband / yoke assembly can be

completely disconnected from the earcups for replacement.

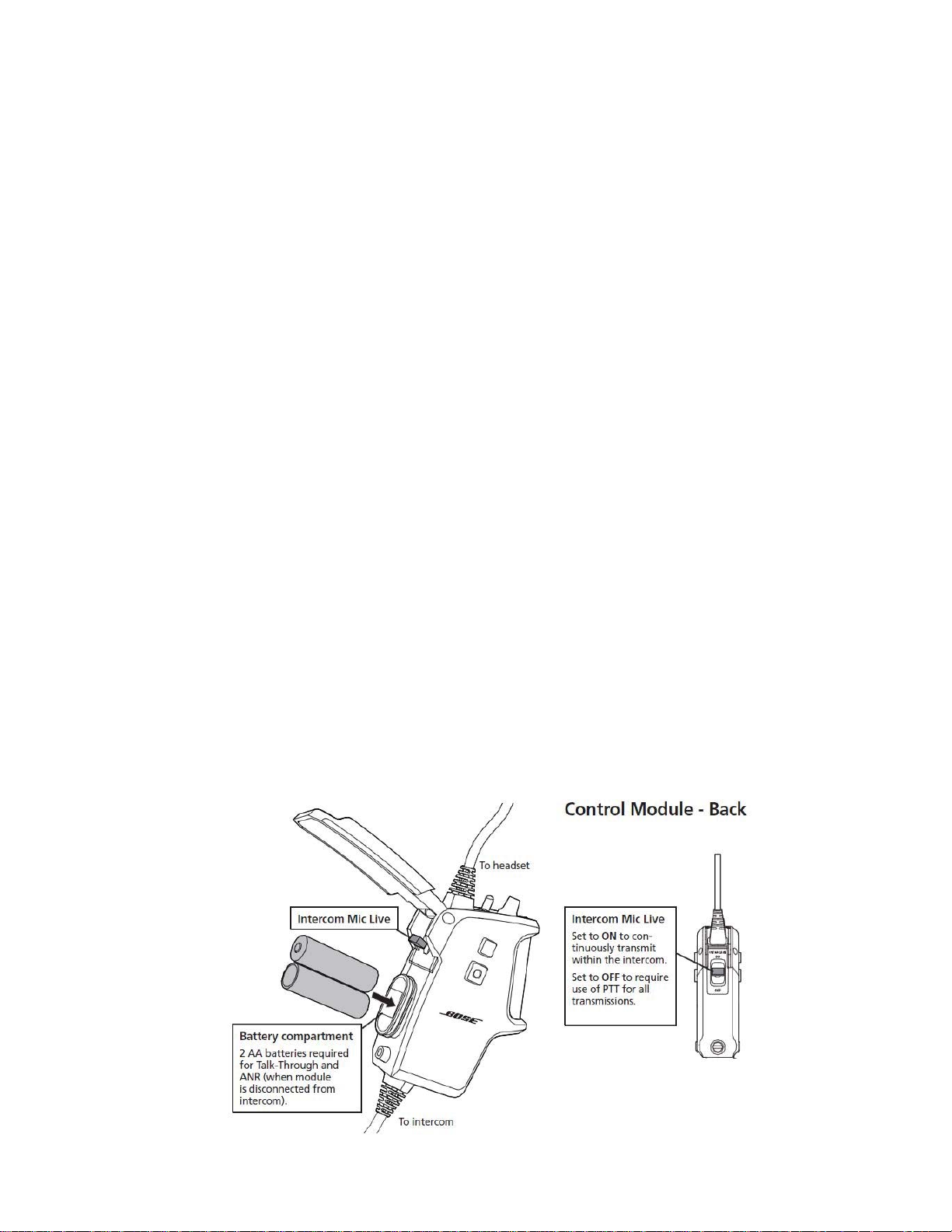

The control cable mates to the bottom of the left ear cup via a connector and housing that is

screwed to the earcup for robustness. This housing also mounts the flexible gooseneck boom

with integral noise canceling boom microphone. The control module contains a smart power

management system which can power the headset off of an external (vehicle) power source or

can use the on-board 2 AA batteries. In either case, the headset is fully functional to provide

active noise reduction (ANR), clear two way communications and talk-through capability. The

headset is also configured to provide passive noise reduction and clear two way communications when there is no power source (fail safe mode). The control module is configurable via

cable selection to enable connection of up to two input sources at any one time including intercoms, portable communication radios or other auxiliary audio or communication devices.

The control module also includes an integrated clothing clip that enables the module to be

securely mounted to a variety of clothing or equipment in a variety of orientations that best suit

the application at hand. The clothing clip can be mounted on both the front and the back face of

the control module in order to facilitate operation with either the left or the right hand or to cater

to different user preferences.

7

Page 8

PRODUCT DESCRIPTION

The control module switches and buttons are designed to be easily operated while wearing

typical work gloves with a material thickness of up to 3mm. They are also designed to provide

tactile feedback during operation and configured such that the mode of the switch can be

recognized visually or by feel.

The switches and their functions include:

1. Push to Talk (PTT) switch(es) (Momentary-Off)

2. 4-position rotary switch Talk Through (TT) control. The Talk Through circuit can be

powered by either the intercom (if applicable) or the 2-AA batteries in the control module.

3. Battery powered Active Noise Reduction (ANR) Switch (On-Off)

4. ICS Mic live Switch (Live-Mic, Mic-Off) This switch is used to enable continuous active

(latched) PTT mode for Intercom communications.

The boom microphone is serviceable and replaceable in the field. It is a dynamic microphone

which consists of a flexible gooseneck boom and a noise cancelling dynamic microphone

capsule. The Boom Microphone output is specific to the device it is attached to and is achievable by selecting the appropriate cable. Some options may include a pass-through while others

may include a +24dB gain to simulate an electret microphone’s output level. If gain is needed,

the power is provided by the input device OR from the control module depending on the specific

input cable. Some options may include a pass-through dynamic 150 ohm, single ended or

differential microphone.

Operation Modes (Power Compatibility)

The power modes listed below are determined by the combination of cables plugged into the

device as well as voltages that are present in different locations or vehicles. Any combination of

power modes based on input connections or signals can be configured within the electronics of

the control module including but not limited to the following scheme.

External Power Source

• Unpowered (0 – 6.0 VDC )

• Battery powered ANR (2-AA batteries)

• Gain switchable Talk Through only

• Selectable Output Level and Frequency Response (Both parameters follow the state

of ANR and/or Talk-Through)

• Boom Microphone Output is specific to device it the is attached to and is configured

inside the input cable. Some options may include a pass through while others may

include a +24dB gain to simulate an electret microphone’s output level. If gain is

needed, the power is provided by the input device OR from the control module

depending on the specific input cable.

Low Power (6.1 - 13.5 VDC)

• Battery powered ANR

- ANR Switch position has no effect

• Gain switchable Talk Through

8

Page 9

PRODUCT DESCRIPTION

Operation Modes (Power Compatibility) (continued)

Intercom Power (13.6 – 32.0 VDC)

• Battery powered ANR

- ANR Switch does not operate

• Selectable Gain switchable Talk Through

• Boom Microphone Output is specific to device it is attached to and is configured inside the

input cable. Some options may include a pass through while others may include a +24dB

gain to simulate an electrets level. If gain is needed, the power is provided by the input

device OR from the control module depending on the specific input cable.

Battery Power (2x 1.5V AA ;1.8 – 3.2 VDC)

• ANR Switch OFF and Talk Through Switch OFF

- ANR off

- Talk Through off

- Unpowered Output Level and Frequency Response

- Boom microphone output depends on cable and device it is attached to.

• ANR Switch ON and Talk Through Switch OFF

- ANR on

- Talk Through off

- Powered Output Level and Frequency Response

- Boom microphone output depends on cable and device it is attached to.

• ANR Switch ON and Talk Through Switch in any ON position

- ANR on

- Talk Through on

- Powered Output Level and Frequency Response

- Boom microphone output depends on cable and device it is attached to.

• ANR Switch OFF and Talk Through Switch in any ON position

- ANR off

- Talk Through on

- Powered Output Level and Frequency Response

- Boom microphone output depends on cable and device it is attached to.

Operation Modes (Audio Management) Dual Comm Versions:

The headset is designed to support multiple audio sources through ports located at the bottom

of the in-line control module. The behavior of each port has been designed to support a wide

range of applications. Any combination and presentation of input and output audio signals can

be configured within the electronics of the control module, including but not limited to the following scheme.

Port 1 is intended to be the primary communications port and can support binaural or monaural sources. When the source is monaural, the cable for that device is wired such that the

monaural signal is paralleled so that it is made compatible with the binaural connection and the

user will always hear the audio from Port 1 in both ears. Whenever Port 1 is connected, pressing PTT 1 shorts the control line to the Port 1 source which enables transmission of the boom

microphone signal to the Port 1 source. If there is no source connected to Port 1, nothing

happens when PTT 1 is pressed.

9

Page 10

PRODUCT DESCRIPTION

Operation Modes (Audio Management) Dual Comm Versions (continued):

Port 2 is intended to be a secondary communications port. The presentation of this source’s

audio to the headset depends upon the presence of a cable plugged into Port 1.

If Port 1 has a cable plugged in, the audio from the Port 2 device will only be presented to the

left earcup. In order to properly mix the audio between the multiple sources while maintaining

the dynamic range of the headset, the two signals will each be reduced by 6dB. The reduction

will occur as soon as the second cable is attached to the port on the bottom of the control

module .

If Port 1 does not have a cable plugged in, the audio from the Port 2 device will be presented to

both earcups and will not be reduced by 6dB.

Binaural devices may be connected to Port 2, however the cable connecting this type of source

to the control module will mix the two separate channels onto one signal line and present the

device as a mono device to the headset. Whenever Port 2 has a cable connected to it, pressing

PTT 2 shorts the control line to ground of the Port 2 source which enables transmission of the

boom microphone signal to the Port 2 source. If there is no cable connected to Port 2, nothing

happens when PTT 2 is pressed. The “Mic live” switch has no effect on any Port 2 device under

any configuration.

The table below describes how the headset manages the multiple audio sources based on what

cables are connected as well as how the PTT buttons function. An N/A in a cell means there is

no cable connected or there is no function. There are many variations of this that are possible.

Mode of operation Port 1 Port 2 Left Earcup Right Earcup

Unpowered X N/A Port 1 Port 1

Unpowered N/A X Port 2 Port 2

Unpowered X X Port 1 + Port 2 Port 1 + Port 2

Battery Powered X N/A Port 1 Port 1

Battery Powered N/A X Port 2 Port 2

Battery Powered X X Port 1 Port 2

ICS powered 6-32 V X N/A Port 1 Port 1

ICS powered 6-32 V X X Port 1 + Port 2 Port 1

10

Page 11

MANUFACTURED VERSIONS

V

ersion Description Material Master / SKU Number

HDST/MOD ASSY, SINGLE COMM, MONAURAL 349999-1100

HDST/MOD ASSY, SINGLE COMM, BINAURAL 349999-1200

HDST/MOD ASSY, T5, DUAL COMM 349999-2000

HDST ASSY, T5, DUAL, W/M-ICOMM/R-SEC CBLS 374120-2000

PACKAGING PART LISTS

T5 Headset, All Versions

Item

Description Part Number Qty.

Number

1 HDS T /M OD AS SY, SIN G LE C O MM , MO NA U RA L

HDST/MOD ASSY, SINGLE COMM, BINAURAL

HDST/MOD ASSY, T5, DUAL COMM

350006-1100

350006-1200

350006-2000

1

2 CARTON , RSC, 9. 00X7 .00X 5. 25, C 27 7035-01 1

3 CARTON, RSC, 19.00X15.00X12.13, C 277036-01 1

4 BAG, POLY, 16x 14 178245- 1 1

5 PKG, 3/1 6 HIGH BUBBLE COHESIVE 1 96054 2

6 BAG, POLY, 3x7 x.1 8 BUBBLE 1 49277 2

7 B AT TE R Y, AA SIZE, PAIR 263269-002 1

8 GUIDE, T5, SINGLE COMM

GUIDE, T5, DUAL COMM

355885-0010

354584-0010

1

USER REPLACEABLE PARTS LIST

Item

Number

1 CABLE, DUAL, ICOMM, T5, AMP/CONN, NF, MONO 354702-1110

2 CABLE, DUAL, RADIO, T5, NF, PRI MARY 354704-1130

3 CABLE, DUAL, ICOMM, T5, AMP/CONN, NF,

BINAURAL

4 CABLE, DUAL, RADIO, T5, NF, SECONDARY 354704-2130

5 MODULE ASSY, T5, DUAL COMM, SPARE 356190-2000

6 MODULE ASSY, T5, SINGLE COM, MONAURAL,

SPARE

7 MODULE ASSY, T5, SINGLE COM, BINAURAL,

SPARE

8 BOOM MIC ASSY, SPARE 356195-0010

9 WINDSCREEN, BOOM MIC, SPARE 280191-001 5965-01-525-1684

10 NAPEBAND/YOKE ASSY, W /COVER, SPARE 356199-0010

11 NAPEBAND, COVER, SPARE 280187-001 5965-01-525-2019

12 HEADSTRAP KIT, SPARE 277285-001 5965-01-525-1695

13 EAR CUSHION PAIR, SPARE 356202-0010

14 EARCUPS ASSY, T5, SPARE

(WITHOUT NAPE BAND / YOKE ASSEMBLY)

15 CLOTHING CLIP, SPARE 310490-0010

16 BATTERY DOOR, MODULE, SPARE 356205-0010

17 CASE, HEADSET, T5 361424-0010

18 HEADPHONE ASSY,T5,W/NAPEBAND,SPARE 370075-0010

19 MOD ASSY, W/O BOOM MIC, T5, SINGLE,

MONAURAL

20 MOD ASSY, W/O BOOM MIC, T5, SINGLE,

BINAURAL

21 MOD ASSY, W/0 BOOM MIC, T5, DUAL, COMM 370250-2000

22 HEADPHONE ASSY W/NAPEBAND, T5 370075-0010

Description Part Number NSN Number

354702-1220

356190-1100

356190-1200

356203-0010

370250-1100

370250-1200

11

Page 12

System Configurations

12

Page 13

System Configurations (continued)

13

Page 14

Cables and Replacement Parts

280191-001

277285-001

14

Page 15

DISASSEMBLY PROCEDURES

IMPORTANT NOTE: These products are

RoHS compliant. Use ONLY lead free

solder when making repairs.

1. Boom Microphone Replacement

1.1 Loosen the captive screw that retains

the boom microphone base to the left

earcup.

1.2 Gently pull the base of the boom microphone away from the earcup. Unplug the

boom microphone connector from the wiring

harness.

Note:

Reverse this procedure for installing a

replacement boom microphone.

2. Ear Cushion Replacement

2.1 Insert your fingers at the location

indicated in the photo at left and pull off the

ear cushion from the earcup.

2.2 Remove any residual glue from the

earcup assembly.

2.3 Remove and discard the tape liners

from the replacement ear cushion.

15

Page 16

DISASSEMBLY PROCEDURES

2.4 Align and press the replacement ear

cushion onto the earcup assembly until it

snaps into place. Ensure it is fully seated.

3. Nape Band Replacement

Yoke pin

Cable on outer side

3.1 Remove nape band cover

3.2 Press upward on nape band yoke until

the yoke pin clears the earcup. Disengage

the lower yoke pin from the earcup. Perform

this step on the other earcup.

3.3 Insert the replacement nape band upper

yoke pin into the earcup upper pin hole.

Press downward on the yoke and engage

the lower yoke pin in the earcup lower pin

hole.

3.4 Replace the nape band cover. Only the

middle portion secures the earcup wire to

the nape band.

Note: The cable running between the

earcups should be on the outer side of the

yoke. Remove and reuse serial number

label on replacement nape band. Attach

new product label to nape band.

4. Earcup Assembly Replacement

Note: The earcup assembly includes both

earcups, the nape band w/cover and the

head strap.

4.1 Remove the two captive screws that

secure the control module cable / boom

microphone to the bottom of the left earcup.

4.2 Gently pull the control module cable /

16

Page 17

DISASSEMBLY PROCEDURES

boom microphone assembly straight down

and away from the earcup. It should unplug

from the left earcup connector as a unit.

5. Control Module Replacement

Note: The control module is not repairable.

It is a sealed unit. The control module

cables are not replaceable separately

from the control module.

5.1 Loosen the captive screw that secures

the boom microphone assembly to the left

earcup. Gently pull the boom mic assembly

away from the earcup.

Unplug the boom microphone from the

earcup wiring harness.

5.2 Loosen the two captive screws that

secure the control module cable to the

bottom of the left earcup. Gently pull the

17

Page 18

DISASSEMBLY PROCEDURES

control module cable straight down. It

should unplug from the bottom of the left

earcup.

6. Battery Cover Replacement

6.1 On the control module, loosen the

captive screw that holds the battery door

closed over the batteries. Do not completely

remove the screw.

6.2 On the control module, remove the

screw and nut that secure the battery cover.

Take care to not lose the small nut. It is not

captive to the control module.

Reassembly Note: The small nut should be

re-installed on the same side as the clothing

clip, as shown in the photo at left.

7. Head Strap Assembly Replacement

7.1 Using a T10 Torx head wrench, remove

the screw securing the head strap to the

earcup assembly. Repeat this for the other

earcup.

7.2 Reattach the replacement head strap

using the screw removed in step 7.1.

18

Note: The replacement head strap comes

as a set. Ensure the strap loops are facing

Page 19

DISASSEMBLY PROCEDURES

outward on each earcup. When worn, the

straps should interlock without twisting.

8. Attachment Clip Replacement /

Relocation

8.1 Remove the screw securing the attach-

ment clip to the control module.

8.2 Align the square alignment holes on the

replacement clip to the alignment feature on

the control module and secure with the

screw removed in step 8.1.

Note: The clip can be installed on either

side of the control module and either

perpendicular or parallel to the cable.

19

Page 20

TEST PROCEDURES

Note: The following procedures contain two

separate test procedures.

The first test is for internal Bose

centers that have the required Bose final

audio test system.

The second test procedure is a less complex

light-up-and-play type test for repairs performed in the field.

Internal Bose Repair Center Tests

Equipment Required

The following hardware and software are

needed to perform the tests described

herein. Equivalent hardware may be substituted.

IMPORTANT NOTE: These products are

RoHS compliant. Use ONLY lead free

solder when making repairs.

®

repair

Test Setup

• Install two AA batteries into the control

module for talk through capability.

• Connect the headset to the

intercommunications system

Definitions

Background Noises Noise present in the

absence of other excitation, including the

following:

• Hum Constant low frequency signal,

caused by power line interference.

• Hiss Steady, broad mid-to-high frequency

signal caused by noise of headset electronics.

• Static Intermittent crackling signal, caused

by external electrical interference.

• Whine Sharp continuous signal, caused by

narrow overvoltage pulses on power line.

• Ripple Noises caused by interference on

power supply line at various frequencies.

Bose Final Audio Test System

This system connects to the headset and

provides all stimulus signals necessary to

excite the headset for listening tests.

The room in which tests are performed must

be within the following range of environmental conditions:

• Temperature - between 62°F and 82°F

• Humidity - between 10% and 90% R.H.

• Ambient Noise - less than 45 dB(C)SPL

• Noise Signal for noise attenuation listening.

- The test system must produce broad

band noise, 50 Hz to 10 kHz, approximately pink (third-octave spectrum flat

vs. frequency) below 1 kHz and thirdoctave spectrum weighted approximately

inversely with frequency above 1 kHz,

overall level 94 dB SPL ±3 dB. Duration

of 30 minutes or more and must not

repeat more than one time during that

interval.

Instability Noises related to acoustic leaks

or malfunctions compromising stability,

including the following:

• Squeal Mid-to-high frequency variable

tone.

• Motor-boating Lower frequency periodic

noise.

• Buzz Harmonic produced by vibration in

the presence of an audio signal. This noise

is usually related to mechanical faults.

Overload Noises related to movement,

pressure or impact on headset as well as

extremely high external noise, including the

following:

• Click Sharp transient caused by collapse

of driver diaphragm. Generally very noticeable.

• Thump Low frequency transient, caused

by saturation of headset electronics.

• Pop Low frequency transient, caused by

saturation of ANR loop.

20

Page 21

TEST PROCEDURES

1. Active Noise Reduction (ANR) Operation,

Quiet Environment

Setup Conditions:

• Talk Through (TT) swith - OFF

• Power supply input - 3.0 Volts

(2 AA batteries) in control module

• Headset microphone switch - OFF

• Headset battery ANR switch - OFF

1.1 In a quiet environment, listen to the ANR

operation as you stand still. Ensure that the

earcups are properly seated on your head.

1.2 Slowly compress the cups against your

head with your hands. Move the earcups with

your hands to simulate rapid head and jaw

movement.

1.3 Lift one of the earcups off of the ear

slightly at the back of the jaw to create a

small air leak. Listen for overload or instability conditions. Perform this step for the other

earcup.

P ASS/FAIL Criteria. Overload or instability

should not be heard under any test conditions. When creating a leak in the back of the

jaw, short term (less than 1 second) instability is allowed. If the instability is sustainable

by holding the earcup in the position where

the instability was heard, the headset has

failed this test.

2. Active Noise Reduction (ANR) Operation,

Loud Environment

Setup Conditions:

• Talk Through (TT) swith - Off

• Power supply input - 3.0 Volts

(2 AA batteries) in control module

• Headset microphone switch - Off

• Headset battery ANR switch - Off

• Sound Booth Noise Switch - On

• Sound Booth Audio Switch - Off

2.1 Listen to ANR operation as you stand

still. Ensure that the earcups are sealed to

your head.

2.2 Slowly compress the cups against the

head with your hands. Move the earcups

with your hands to simulate rapid head and

jaw movement. Listen for overload or

instability conditions.

P ASS/FAIL Criteria. ANR Operation should

be apparent. Overload or instability should

not be heard under any test conditions.

3. Talk -Through (TT) Operation, ANR OFF

This test is to verify talk-through balance

and intelligibility.

Setup Conditions:

• TT switch - Talk-through ON 0dB

• Power supply input - 3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - Off

• Sound Booth Noise Switch - Off

• Sound Booth Audio Switch - On

3.1 Talk-through Balance - Listen to the

audio signal while facing the signal source.

3.2 Block the left talk through microphone

with your hand and listen to the audio

signal through the right.

3.3 Uncover the left side and cover the

right side. Listen to the audio signal through

the left side.

PASS/FAIL Criteria. The audio signal

should be heard at the same level in both

sides of the headset and there should be

no noticeable background noise.

3.4 Talk-through Intelligibility. Listen to a

minimum of four words from the audio

signal.

PASS/FAIL Criteria. Words should be

heard clearly, and should be recognizable.

3.5 Talk-through Gain Switching. Move the

TT rotary switch to the 5dB position.

21

Page 22

TEST PROCEDURES

PASS/FAIL Criteria. Words should be heard

clearly and be recognizable.

3.6 Talk-through Compressor Operation.

Listen to the audio signal. Move the gain

switch to the +15dB position. Wait for the

sound of words to stablilize before listening

to a minimum of four words from the audio

signal.

PASS/FAIL Criteria. The level of sound

heard through the talk-through must not

increase dramatically after the sound of

the words stabilizes. If verification is

needed compare ambient sound at

increased gain level to sound heard

through the talk-through system.

If headset’s compressor takes longer than

five words to stabilize, it is a failure.

4. Talk-through Operation, Active Noise

Reduction (ANR) ON, Quiet Environment

This test verifies proper Talk-through

balance, intelligibility and compressor operation.

Set-Up Conditions:

• TT switch - Talk-through ON - 0dB

• Power supply input - 3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - Off

• Sound Booth Noise Switch - Off

• Sound Booth Audio Switch - On

5. Talk-Through Operation, ANR ON

This test is to verify Talk- through balance,

and intelligibility .

Set-Up Conditions:

• TT switch - Talk-through ON 0dB

• Power supply input - 3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - On

• Sound Booth Noise Switch - Off

• Sound Booth Audio Switch - Off

5.1 Talk-through Balance. Listen to the

audio signal while facing the signal source.

Block the left talk through microphone with

your hand and listen to the audio signal

through the right.

5.2 Uncover the left side and cover the

right side. Listen to the audio signal through

the left side.

PASS/FAIL Criteria. The audio signal

should be heard at the same level in both

sides of the headset and there should be

no noticeable background noise.

5.3 Talk-through Intelligibility. Listen to a

minimum of four words from the audio

signal.

PASS/FAIL Criteria. Words should be

heard clearly, and should be recognizable.

4.1 Talk-through Gain. Listen to the

Talk-through background noise in a quiet

environment. Exercise the TT Switch to

+5dB and +10dB positions respectively.

PASS/FAIL Criteria. The noise of the TT

circuit should increase for both earcups at

the +5dB position, and then increase for

both earcups again at the +10dB position.

The headset should not oscillate with either

+5 or +10dB gain.

5.4 Talk-through Gain Switching. Exercise

the TT Rotary switch to the 5dB position.

PASS/FAIL Criteria. Words should be

heard clearly, and should be recognizable.

5.5 Talk-through Compressor Operation.

Listen to the audio signal. Switch the gain

switch to +15 dB. Wait for the sound of

the words to stabilize before listening to a

minimum of four words from the audio

signal.

22

Page 23

TEST PROCEDURES

PASS/FAIL Criteria. The level of sound

heard through the talk-through must not

in-crease dramatically after the sound of

the words stabilizes. If verification is needed

compare ambient sound at increased gain

level to sound heard through the talkthrough system. If headset’s compressor

takes longer than 5 words to stabilize, it is a

failure.

6. Talk-Through Operation, ANR OFF,

Quiet Environment

This test is used to verify Talk-through

balance, intelligibility, and compressor

operation.

Set-Up Conditions.

• TT switch - Talk-through ON - 0dB

• Power supply input...3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - Off

• Sound Booth Noise Switch - Off

• Sound Booth Audio Switch - On

6.1 Talk-through (TT) Gain. Listen to the

Talkthrough background noise in a quiet

environment. Exercise the TT Switch to

+5dB and +10dB positions respectively.

PASS/FAIL Criteria. The noise of the TT

circuit should increase for both earcups at

the +5dB position, and then increase for

both earcups again at the +10dB position.

The headset should not oscillate with either

+5 or +10dB gain.

Field Repair Light-up-and-Play Tests

1.2 Play an audio signal to the headset.

Verify that you can hear the audio being fed

to the headset from the radio or intercomm.

1.3 Speak into the microphone. Verify that

your voice signal is being received by the

radio / intercomm.

1.4 Disconnect the headset from the radio

or intercomm and perform the battery

powered tests located after the below noise

definitions.

Definitions

Background Noises Noise present in the

absence of other excitation, including the

following:

• Hum Constant low frequency signal,

caused by power line interference.

• Hiss Steady, broad mid-to-high frequency

signal caused by noise of headset electronics.

• Static Intermittent crackling signal, caused

by external electrical interference.

• Whine Sharp continuous signal, caused by

narrow overvoltage pulses on power line.

• Ripple Noises caused by interference on

power supply line at various frequencies.

Instability Noises related to acoustic leaks

or malfunctions compromising stability,

including the following:

• Squeal Mid-to-high frequency variable

tone.

• Motor-boating Lower frequency periodic

noise.

• Buzz Harmonic produced by vibration in

the presence of an audio signal. This noise

is usually related to mechanical faults.

1. Intercomm/Radio Communications Test

After repair, connect the headset to a

compatible radio or intercomm system and

verify that all functions work properly. Once

the headset has passed test, it can be

returned to use.

1.1 Connect the headset control module

cable to the radio or intercomm.

Overload Noises related to movement,

pressure or impact on headset as well as

extremely high external noise, including the

following:

• Click Sharp transient caused by collapse

of driver diaphragm. Generally very noticeable.

• Thump Low frequency transient, caused

by saturation of headset electronics.

• Pop Low frequency transient, caused by

saturation of ANR loop.

23

Page 24

TEST PROCEDURES

2. Active Noise Reduction (ANR) Operation, Quiet Environment

Setup Conditions:

• Talk Through (TT) swith - OFF

• Power supply input - 3.0 Volts

(2 AA batteries) in control module

• Headset microphone switch - OFF

• Headset battery ANR switch - OFF

2.1 In a quiet environment, listen to the ANR

operation as you stand still. Ensure that the

earcups are properly seated on your head.

2.2 Slowly compress the cups against your

head with your hands. Move the earcups

with your hands to simulate rapid head and

jaw movement.

2.3 Lift one of the earcups off of the ear

slightly at the back of the jaw to create a

small air leak. Listen for overload or instability conditions. Perform this step for the other

earcup.

3.2 Slowly compress the cups against the

head with your hands. Move the earcups

with your hands to simulate rapid head and

jaw movement. Listen for overload or instability conditions.

P ASS/FAIL Criteria. ANR Operation should

be apparent. Overload or instability should

not be heard under any test conditions.

4. Talk -Through (TT) Operation, ANR OFF

This test is to verify talk-through balance

and intelligibility .

Setup Conditions:

• TT switch - Talk-through ON 0dB

• Power supply input - 3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - Off

4.1 Talk-through Balance - Listen to an

audio source such as spoken word.

P ASS/FAIL Criteria. Overload or instability

should not be heard under any test conditions. When creating a leak in the back of

the jaw, short term (less than 1 second)

instability is allowed. If the instability is

sustainable by holding the earcup in the

position where the instability was heard, the

headset has failed this test.

3. Active Noise Reduction (ANR) Operation, Loud Environment

Setup Conditions:

• Talk Through (TT) swith - Off

• Power supply input - 3.0 Volts

(2 AA batteries) in control module

• Headset microphone switch - Off

• Headset battery ANR switch - Off

3.1 Listen to ANR operation as you stand

still. Ensure that the earcups are sealed to

your head.

4.2 Block the left talk through microphone

on the earcup with your hand and listen to

the audio signal through the right.

4.3 Uncover the left side and cover the

right side microphone. Listen to the audio

signal through the left side.

PASS/FAIL Criteria. The audio signal

should be heard at the same level in both

sides of the headset and there should be

no noticeable background noise.

4.4 Talk-through Intelligibility. Listen to a

minimum of four words from the audio

source.

PASS/FAIL Criteria. Words should be

heard clearly, and should be recognizable.

4.5 Talk-through Gain Switching. Move the

TT rotary switch to the 5dB position.

24

PASS/FAIL Criteria. Words should be

heard clearly and be recognizable.

Page 25

TEST PROCEDURES

4.6 Talk-through Compressor Operation.

Listen to the audio source. Move the gain

switch to the +15dB position. Wait for the

sound of words to stablilize before listening

to a minimum of four words from the audio

signal.

PASS/FAIL Criteria. The level of sound

heard through the talk-through must not

increase dramatically after the sound of

the words stabilizes. If verification is

needed compare ambient sound at

increased gain level to sound heard

through the talk-through system.

If headset’s compressor takes longer than

five words to stabilize, it is a failure.

5. Talk-through Operation, Active Noise

Reduction (ANR) ON, Quiet Environment

This test verifies proper Talk-through

balance, intelligibility and compressor

operation.

Set-Up Conditions:

• TT switch - Talk-through ON - 0dB

• Power supply input - 3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - Off

6. Talk-Through Operation, ANR ON

This test is to verify Talk- through balance,

and intelligibility .

Set-Up Conditions:

• TT switch - Talk-through ON 0dB

• Power supply input - 3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - On

6.1 Talk-through Balance. Listen to the

audio source while facing it. Block the left

talk through microphone on the earcup with

your hand and listen to the audio signal

through the right.

6.2 Uncover the left side and cover the

right side microphone. Listen to the audio

signal through the left side.

PASS/FAIL Criteria. The audio signal

should be heard at the same level in both

sides of the headset and there should be

no noticeable background noise.

6.3 Talk-through Intelligibility. Listen to a

minimum of four words from the audio

source.

5.1 Talk-through Gain. Listen to the

Talk-through background noise in a quiet

environment. Exercise the TT Switch to

+5dB and +10dB positions respectively.

PASS/FAIL Criteria. The noise of the TT

circuit should increase for both earcups at

the +5dB position, and then increase for

both earcups again at the +10dB position.

The headset should not oscillate with either

+5 or +10dB gain.

PASS/FAIL Criteria. Words should be

heard clearly, and should be recognizable.

6.4 Talk-through Gain Switching. Exercise

the TT Rotary switch to the +5dB position.

PASS/FAIL Criteria. Words should be

heard clearly, and should be recognizable.

6.5 Talk-through Compressor Operation.

Listen to the audio signal. Switch the gain

switch to +15 dB. Wait for the sound of

the words to stabilize before listening to a

minimum of four words from the audio

signal.

25

Page 26

TEST PROCEDURES

PASS/FAIL Criteria. The level of sound

heard through the talk-through must not

in-crease dramatically after the sound of

the words stabilizes. If verification is needed

compare ambient sound at increased gain

level to sound heard through the talkthrough system. If headset’s compressor

takes longer than 5 words to stabilize, it is a

failure.

7. Talk-Through Operation, ANR OFF,

Quiet Environment

This test is used to verify Talk-through

balance, intelligibility, and compressor

operation.

Set-Up Conditions.

• TT switch - Talk-through ON - 0dB

• Power supply input...3.0 Volts

(2 AA Batteries) in Control Module

• Headset Microphone switch - Off

• Headset Battery ANR Switch - Off

7.1 Talk-through (TT) Gain. Listen to the

Talk-through background noise in a quiet

environment. Exercise the TT Switch to

+5dB and +10dB positions respectively.

PASS/FAIL Criteria. The noise of the TT

circuit should increase for both earcups at

the +5dB position, and then increase for

both earcups again at the +10dB position.

The headset should not oscillate with either

+5 or +10dB gain.

26

Page 27

V

Troubleshooting

Some field issues may be related to confusion regarding the different configurations and modes

of operation of the headset. Refer to the product description section of this manual for more

information regarding this before troubleshooting.

Note: No internal parts of the headset or control module are serviceable in the field.

The headset is field repairable at a higher level, i.e. control module, earcups, cables, etc. The

list of user replaceable parts is located on page 11 of this manual. Problems associated with the

headset (driver faults, earcup PCB faults, etc.) require the product to be returned to Bose

Corporation for repair.

The troubleshooting steps below describe problems that can be resolved in the field. Refer to

the list of Listening Test Defects in the Test Procedures section for additional information and

specific failure descriptions.

Symptom

No Audio

No Audio from one

Earcup

Intermittent Operation

and/or One or Both

Ears Intermittent.

One ear completely

inoperative: (No ANR

and no audio whether

switched on or off).

erification/Solution

Is ANR present? Are you connected to the vehicle? Power is

provided by the vehicle when connected to it. Connect known good

headset to same connection on the vehicle. Do you have audio now?

If so problem is with headset. Check all cables, earcups and control

module for damage. If still no audio replace earcup assembly. If not,

problem is with the connection or equipment in the vehicle.

Check sidetone. If you cannot hear your own voice, have someone

using another headset on the same intercom circuit speak. If you can

hear them, you may have a bad microphone. If still no audio, problem

could be in the cable, control module or earcups. Replace the cable.

Okay? If not, replace control module. Okay? If not, then replace

earcups.

Check Talk-Through (TT) switch setting – The TT circuits are

designed to deliver audio at a level up to 85 dB SPL at your ear. An

externally overloaded TT circuit will cause interrupted audio in the

earcups, preventing sound pressure levels of >85 dB SPL from

getting to the ear. This occurs if the TT gain setting is too high at the

rotary switch on the control module and you communicate too loudly,

overwhelming the signal and causing audio dropouts.

Check batteries - There is no LED on the product to allow monitoring

of the battery power level. Low battery when in ANR or TT mode will

cause intermittent operation or clicking every few seconds to indicate

weak batteries. Unit will continue to operate in this mode for some

time before the batteries fail entirely and the unit operation reverts to

fail-safe operation mode. ANR will be intermittent with clicking every

few seconds.

Check that all cables for damage and are fully seated. Replace cable

as needed.

Connect a known good control module and cable. Connect to a

known good source and retest. If still intermittent, replace earcups. If

audio is good with known good control module, replace original

control module.

Check all cables for damage.

Connect a known good control module and cable. Connect to a

known good source and retest. If still inoperative, replace earcup

assembly.

27

Page 28

V

Troubleshooting

Symptom

No Output from

Microphone

Low microphone

output, intermittent

microphone

transmissions or

difficult to break

intercom squelch.

No Active Noise

Reduction (ANR) or

Reduced ANR

Audio from only one

source on Dual

Comm versions

Unpowered (Fail

Safe) Mode Not

Work i n g Wh e n No t

Connected to Vehicle

erification/Solution

Check for damage or contamination, i.e. rust, chewing tobacco,

debris. If mic is damaged or contaminated, replace it.

Check microphone connection to the headset. Ensure wiring harness

is not damaged and that the connector pins are not bent and

connector is properly seated.

Replace microphone with a known good one. Retest. If okay, replace

original microphone.

Make sure unit is turned on.

Check power. Battery or external? ANR switch only controls battery

powered ANR, not external (vehicle) powered. ANR will be on all the

time when connected to vehicle power.

Check for defective cables, cracking of strain reliefs and/or bent pins.

Replace cable as needed.

Check position of Talk-Through (TT) rotary switch - The talk-through

function allows external audio from the microphone to be fed through

the headset without removing it, i.e. to speak to someone in the same

vehicle. Leaving TT on will reduce ANR and should only be used

when needed. Talk-through switch must be OFF for ANR to work

completely.

Check for low battery if not vehicle powered. There is no LED on the

product to allow monitoring of the battery power level. Low battery

when in ANR or TT mode will cause intermittent operation or clicking

every few seconds to indicate weak batteries. Unit will continue to

operate in this mode for some time before the batteries fail entirely

and the unit operation reverts to fail-safe operation mode. ANR will

be intermittent with clicking every few seconds.

Check all cables, earcups and control module for damage. Check for

damage or blockage of the microphone ports on the earcups. These

microphones are used to pick up noise in the environment in order to

cancel it. Damage or blockage will affect ANR functionality.

Check for defective switches on control module. If inoperative,

replace control module.

Connect a known good control module and cable. Connect to a

known good source and retest. If still bad ANR, replace earcups.

Port 1 is primary source and Port 2 is the secondary source. Ensure

you have correct cables and connections for the desired mode of

operation. Refer to the Dual Comm Mode of Operation table listed

previously in this manual.

Check all cables and control module for damage.

Connect known good cables from the control module to the radio.

Retest. If okay, re pla c e original cable.

Connect known good control module. If okay, replace control module.

Ensure control module switches are not intermittent. If bad, replace

control module.

Single Comm – Headset Not capable of operating in unpowered fail-

safe mode when in dismounted mode. Will allow for ANR and TT

when operating dismounted on battery power.

28

Page 29

Troubleshooting

V

Symptom

Mic Live Switch not

working on Port 2

(Dual Comm

versions)

Live Mic Button Not

Working

Talk-through (TT) Not

Working

(PTT) Button Not

Working Properly

Latched Mode of the

Push To Talk (PTT)

Button Not Working

Properly

Loud clicking/ticking

or thumping noise in

either or both ears.

Buzzing/humming

noises when touching

Electro-Luminescent

instrument panels.

Static heard through

headset

High frequency

squeal or oscillation

erification/Solution

By design, the Mic live switch has no effect on any Port 2 device

under any configuration.

Button is located on the back of the control module. This button is

only enabled while operating from vehicle power. It is disabled when

operating from portable radios.

Check switch function with vehicle power to see if it is intermittent. If

so, replace control module.

Check all cables, earcups and control module for damage. Check

control module for bad TT rotary switch.

Replace microphone with a known good one. Retest. If okay.

Replace original microphone.

Connect a known good control module and down cable and connect

to a known good source and retest. If still not working, replace

earcups.

Check vehicle radio. Connect a known good headset to vehicle

connector. If okay, problem is with headset. Check connectors and

cables for damage.

Connect a known good control module to the earcup assembly.

Retest on vehicle radio. If okay, replace control module. If still bad,

problem is in the earcup assembly.

Latched mode of PTT – Intercom mic/line switch - Enabled only in

presence of vehicle of vehicle supplied power. Used inside vehicle

over intercom. Allows comms over a radio that is connected to the

intercom. PTT allows audio pass-through to radio.

Inspect the driver for any debris such as hair or sand.

Remove ear cushion. Check the driver membrane for dimples or

creases. If found, replace the earcup assembly.

If noise is continuous and increases when your hand is moved closer

to the instrument panel, then the headset is probably receiving

interference from the lighting. This is particularly true if when you

touch grounded metal the noise goes away.

These noises will not harm the headset; however, they may be

annoying and distracting for the user.

Connect to a known good source. If okay, problem is with the source.

Check cables and earcups for damage. Check earcup driver

membrane for debris or damage such as dimples or creases.

Connect known good control module and cable. If good, replace

control module. If still bad, replace earcups.

Inspect the driver for any debris such as hair or sand.

Remove ear cushion. Check the driver membrane for dimples or

creases. If found, replace the earcup assembly.

Check for missing or deteriorated ear cushions.

29

Page 30

Service Manual Revision History

Date Revision

Level

3/2016 00 Document released at revision 00. Service manual

Description of Change Change Driven

By

release

Pages

Affected

All

30

Page 31

Specifications and Features Subject to Change Without Notice

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N: 350006-SM REV. 00; 3/2016 (M)

http://serviceops.bose.com

Loading...

Loading...