Page 1

OC-1 AWCS-II Option Card

®

©

1994 Bose Corporation Service Manual

Page 2

TABLE OF CONTENTS

1. SPECIFICATIONS.................................................................................................... 2

2. THEORY OF OPERATION....................................................................................... 3

3. EQ CURVES............................................................................................................. 5

4. BLOCK DIAGRAM.................................................................................................... 8

5. INSTALLATION INSTRUCTIONS........................................................................... 9

6. TEST PROCEDURES.............................................................................................. 12

7. PARTS LIST ..........................................................................................................

CAUTION: THE OC-1 OPTION CARD CONTAINS NO USER SERVICEABLE PARTS. TO PREVENT WARRANTY INFRACTIONS, REFER

SERVICING TO WARRANTY SERVICE STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

16

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

1

Page 3

OC-1 SPECIFICATIONS

Dimensions: .63" Hx1.29"Wx8.98"D(1.6x3.3x22.8 cm)

Weight: .09 lbs. (.042 kg.)

Input/Output: 2 audio inputs,Channel 1 and 2 high

frequency outputs, bass channnel output

Input Impedance: 482 kΩ (nominal)

(feedback input)

Output Level: 5.0 Vrms into 10 kΩ

Crossover Frequency: 125 Hz,Roll-off slope:

Output Noise: ≤ 40µV (A-weighted)

Channel Separation: 50 dB (min.) @ 5 kHz

24 dB/oct.

2

Page 4

THEORY OF OPERATION

Overview

The OC-1 is a small plug-in module for use with Bose 502™, 402™, and 802® II controllers. The

OC-1 allows the use of the Cannon™ bass loudspeaker with these controllers and their

loudspeakers. Refer to the block diagram, equalization curves and OC-1 schematic for further

information.

The OC-1 provides three major functions:

A. Low frequency equalization.

B. Crossover filtering of the high frequency signals.

C. Protection of the Cannon against excessive power.

1. Low Frequency Equalization Circuit

U5's four op-amp stages provide low-pass crossover filtering, high-pass filtering to eliminate

subsonic material, and frequency contouring to optimize the overall response.

2. High Frequency Equalization Circuit

U3, section 1 and U5, section 2 provide two channels of high-pass filtering to remove bass from

the main loudspeakers.

3. Protection Circuit

The protection circuit consists of a compressor and a mute circuit. The protection circuit is

connected so that it can monitor the low frequency voltage applied to the Cannon driver. When this

voltage exceeds the power limit defined for the driver, a compressor begins to reduce the gain in

the low frequency path so that the power does not continue to rise.

4. Compressor Circuit

The compressor consists of the following functional blocks:

A. Differential input buffer

B. Full-wave peak detector/comparator

C. Averaging circuit

D. Voltage-controlled amplifier (VCA)

The differential input buffer (U1 section 1) features protection against Radio Frequency

Interference (RFI), Electrostatic Discharge (ESD), and overvoltage. It has a gain which is much

less than 1 so that it can attenuate the high level signals coming from the Cannon (over 40 volts at

full power).

3

Page 5

U4, sections 1 and 2 form a full-wave peak detector. When the input to these stages exceeds

+/-2V peak, the outputs go high and a control voltage is created in the averaging circuit (C27, C28,

etc.). The averaging circuit captures peaks with a short attack time and holds them with a longer

release time. U2, section 2 inverts and scales the averaged control voltage and applies it to the

VCA control input.

U7 is a current-in/current-out VCA which is controlled by the voltage on pin 2.

5. Mute Circuit

The mute circuit acts as a watchdog, and prevents the Cannon™ from operating unless the

feedback signal from the Cannon is connected properly to the controller/OC-1 protection input.

When the mute circuit detects that no audio has occurred for about two minutes, it reduces the gain

in the low frequency path.

The mute circuit consists of a gain stage and a comparator. U1, section 2 amplifies the signal from

the protection circuit differential input, and U2, section 1 compares it to a reference. When the

sensed level exceeds the threshold, a control voltage (generated in U2, section 2) causes U2,

section 1 to go from high to low and reduces the compressor gain by about 40 dB.

4

Page 6

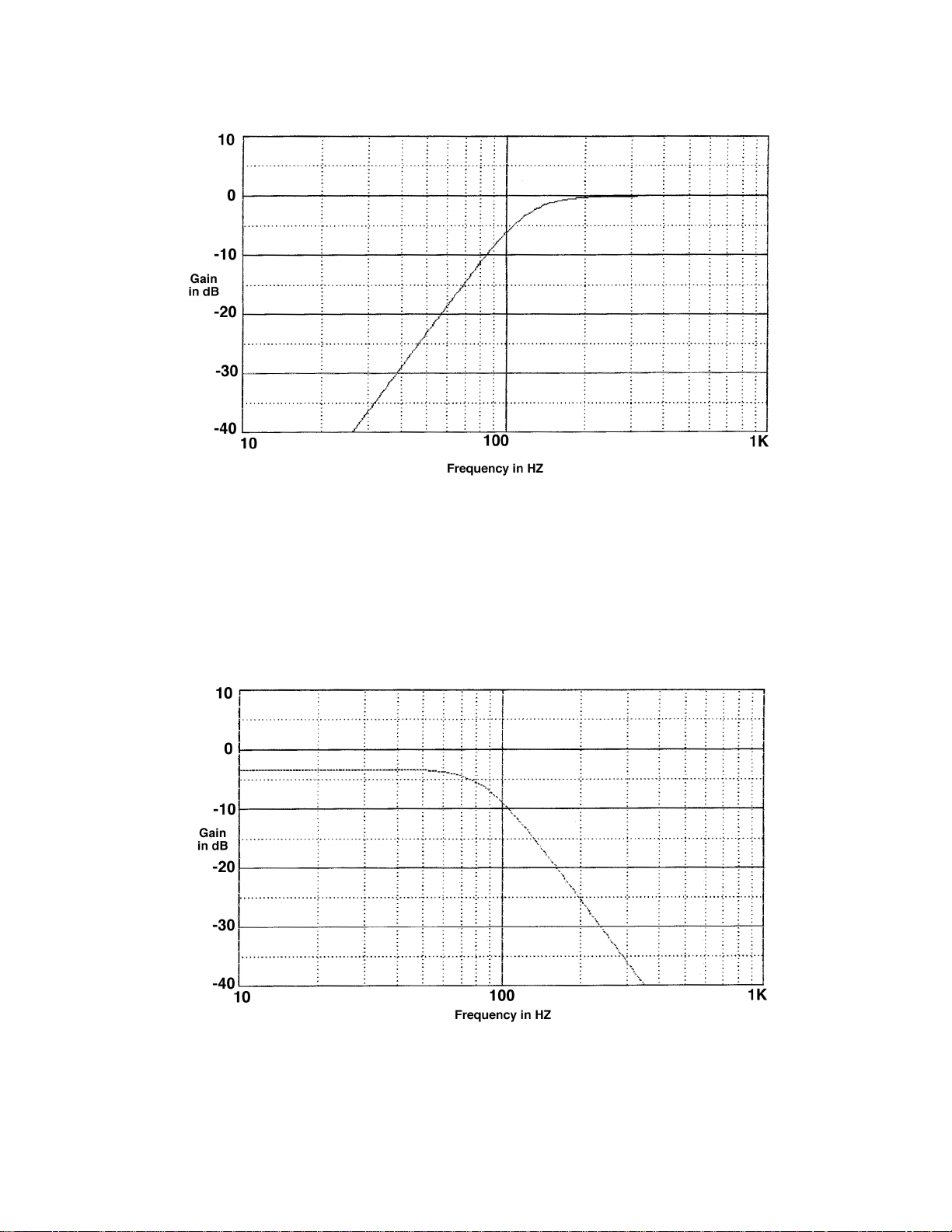

Output is measured from U3 pin 7 or U6 pin 1. Controls are set at:: Mode 4 (Option),

Output Mode: Normal, Low Frequency Level: 0 dB, and Input Level: +4 dB.

Figure 1. High Frequency EQ

Output is measured from U5 pin 14. Controls are set as in Figure 1.

Figure 2. EQA + EQB

5

Page 7

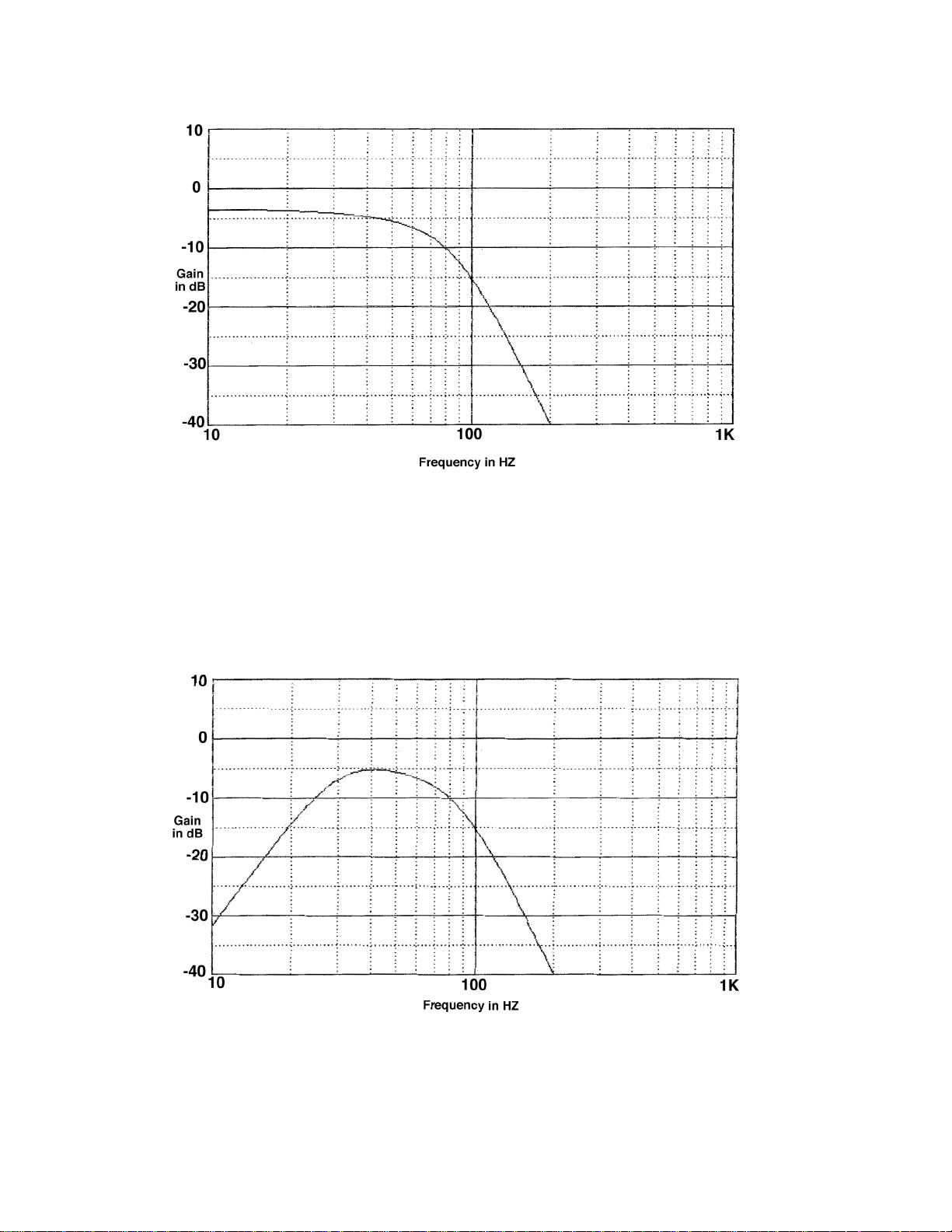

Output is measured from U5 pin 1. Controls are set as in Figure 1.

Figure 3. EQA + EQB + EQC

Output is measured from U5 pin 7. Controls are set as in Figure 1.

Figure 4. EQA + EQB + EQC + EQD

6

Page 8

Output is measured from U3 pin 1. Controls are set as in Figure 1.

Figure 5. EQA + EQB + EQC + EQD + VCA

7

Page 9

Figure 6. OC-1 Block Diagram

8

Page 10

OC-1 Installation Procedures

NOTE: The information included here is to aid

the technician in setting up the OC-1 before

doing any troubleshooting. These procedures

are provided in more depth in the OC-1 Owner's

Guide (P/N 176007).

OC-1 Option Card

Internal Protection

Circuit Harness

External Protection

Circuit Harness

Figure 7. OC-1 Option Card and Harnesses

1. Installing the Internal Protection Circuit

Harness

A. Turn the controller so that its rear panel

faces you. See Figure 8.

B. Remove 4 phillips-head screws.

C. Slide the cover towards you and lift away

from the controller.

D. Find the plastic plug in the controller's

rear panel (Figure 9). Pinch the top lock tab

and push the plug partially out (Figure 9A).

Release the tab and pull the plug completely

out.

9A

Figure 8. Cover and screw removal

Figure 9. Plastic plug removal

9

Page 11

10B

10A

Flat side of barrel

10C

Figure 10. Internal Harness Connection

E. Remove the lock nut and washer from the

harness (Figure 10A).

F. Thread the harness through the rear

panel (white connector first).

G. Turn the barrel connector so that its flat

side matches the flat side of the hole in the

controller. The connector should sit firmly

against the outside of the rear panel (Figure

10B).

H. Replace the lock nut and washer on the

harness inside the rear panel. Tighten firmly

with needle nose pliers (Figure 10C).

2. Connecting the OC-1 to the controller

NOTE: The controller's rear panel should

face you and the internal harness should be

inside.

A. Turn the OC-1 PCB so that its component

side faces you.

B. Connect the harness to J1 on the OC-1

PCB (Figure 11).

C. Plug the PCB into the connector

receptacles located on the controller's PCB.

See Figure 12 for proper orientation.

3. Installing the External Protection Circuit

Harness

A. Attach the external harness to the internal

harness connector (Figure 13) by turning

the notch on the harness to the right.

B. Hand tighten the lock nut on the external

harness.

Figure 11. System Controller Connection

Figure 12. OC-1 connected to controller PCB

10

Page 12

Figure 13. External Harness Connection

C. Connect the harness's other end to the speaker terminals on your amplifier with either screw

lugs (Figure 14A) or a banana plug (Figure 14B). Connect the red wire to the positive (+)

terminal and the black wire to the negative (-) terminal.

NOTE: Figure 15 shows a typical system hookup.

Figure 14A. Screw terminal

Figure 15. Complete system hookup

Figure 14B. Banana plug

11

Page 13

Test Setup

OC-1 Test Procedures

Input Connections: Connect an oscillator to the

positive (+) and negative (-) input terminals for

Channels 1 or 2. These procedures assume that

the person performing these tests is using test

equipment with unbalanced inputs and outputs.

See Figure 16 for connection information. Also,

refer to Figure 15 for a system hookup diagram.

Output Connections: Connect test equipment to

the positive (+) and negative (-) output terminals

for Channels 1 or 2 (low and high frequency

outputs).

All tests should be performed for both

channels.

All test equipment must be isolated from

ground (floated).

See Figure 17 for a picture of the controller's

back panel.

• Output mode switch should be set at

normal

• Input switches should be set at +4 dB

• Low frequency level potentiometer should

be set at 0 dB

**IMPORTANT NOTE**

Install the external protection circuit harness for all

tests. Otherwise, the controller's bass channel (as a

safety measure) will shut down.

1. Frequency Response of High Frequency (HF)

Output

A. Apply a 100 mVrms, 600 Hz signal to the

controllers's input terminals and reference your

dB meter to this frequency.

The controls on the back panel should be set as

follows:

• Mode switch should be set at 4 (Option)

Frequency (Hz) 402™ Controller

Response (dB)

40 -29.2 ± 1.5 dB -23.5 ± 1.5 dB -17.57 ± 1.5 dB

80 -8.3 ± 1.5 dB - 5.6 ± 1.5 dB -1.84 ± 1.5 dB

100 -3.0 ± 1.5 dB +0.8 ± 1 .5 dB +2.0 ± 1.5 dB

120 0 dB +1.6 ± 1 .5 dB +4.0 ± 1.5 dB

150 +1.83 ± 1.5 dB +1.93 ± 1.5 dB +4.7 ± 1.5 dB

180 +2.16 ± 1.5 dB +0.7 ± 1.5 dB +4.2 ± 1.5 dB

200 +2.11 ± 1.5 dB +.15 ± 1.5 dB +3.7 ± 1.5 dB

600 REF REF REF

2200 +2.12 ± 1.5 dB +3.5 ± 1.5 dB +1.61 ± 1.5 dB

5000 +7.5 ± 1.5 dB +12.5 ± 1.5 dB +7.29 ± 1.5 dB

15000 +12.85 ± 1.5 dB +19.0 ± 1.5 dB +17.02 ± 1.5 dB

B. Measure the frequency response across the

HF outputs according to the chart below. This

chart provides responses for the 402, 502, and

802 II controllers (with the option card installed).

502™ Controller

Response (dB)

802® II Controller

Response (dB)

12

Page 14

Input Connections

Audio

Oscillator

Audio

Oscillator

Output Connections

Figure 16. Unbalanced Connections

INPUT LEVEL

–10 +4

SER. NO. D.O.M.

Input

connectors

INPUT

CH 1

Input

attenuator

switches

High frequency

output

connectors

Bass level

control

HIGH FREQ OUTPUT

MODE

INPUT LEVEL

4

3

–10 +4

2

CH 2

PROTECTED BY U.S. PATENT 3,038,964

1

CH 1 CH 2

Mode

switch

LOW FREQ

LEVEL

.

0

.

OUTPUT MODE

.

.

.

.

.

NORM SUM

+3

-18

BOSE CORPORATION, FRAMINGHAM, MA 01701-9168

ENGINEERED AND MANUFACTURED IN U.S.A.

Bass mono

sum switch

Low frequency

output

connectors

LOW FREQ OUTPUT

+– +–+– +–+– +–

CH 1 CH 2

Figure 17. Typical Controller Back Panel (Barrier Strip Version Shown)

13

230V~AC

50/60Hz 12W

LISTED 411F

U

L

®

COMMERCIAL

SOUND

EQUIPMENT

Page 15

2. Frequency Response of LF Output

3. Protection Circuit Test

A. Apply a 100 mVrms, 80 Hz signal to the

controller's input terminals and reference

your dB meter to this frequency.

B. Measure the frequency response across the

LF outputs according to the chart below.

Frequency (Hz) Response (dB)

20 -10.5 ± 1.5

50 +2.25 ± 1.5

80 REF

100 -7.35 ± 1.5

120 -13.68 ± 1.5

150 -21 ± 1.5

180 -27 ± 1.5

200 -30.5 ± 1.5

NOTE: Refer to Figures 13 through 15 and the

installation instructions for connecting the

external protection circuit harness.

A. Connect a signal generator to the controller

input terminals.

B. Connect the controller LF outputs to the

amplifier input terminals.

C. Connect the external protection circuit harness

to the amplifier output.

D. Connect a voltmeter across the amplifier

output terminals.

E. Apply a 57 Hz signal to the controller input

terminals and adjust the signal generator until the

amplifier's output voltage is 40 Vrms.

F. Increase the input to the amplifier until the

output voltage is 47 Vrms. Continue increasing

the input to the amplifier. The amplifier's output

voltage should not rise above 47 volts

(compression occurs at this voltage).

14

Page 16

Notes for Future Reference

15

Page 17

OC-1 Option Card Parts List

OC-1 Packaging Parts List (Figure 16)

Item

Number

1 Cable Assembly 174147 1 1

2 Option Card PCB Assembly 145610 1 2,3

- Bag-Antistatic 174138 1 4

- Card-Owner's Registration 122157 1 4

- Envelope 122785 1 4

- Owner's Manual 176007 1 4

- Carton 145618 N/A 4

1. The cable assembly consists of both the internal and external protection circuit harnesses.

2. This part is not normally available from Customer Service. Approval from the field service

manager is required before ordering.

Description Part Number Qty.

Per

Carton

NOTES

See Note

3. The individual parts located on this PCB are listed in the Electrical Parts List.

4. This part is not illustrated.

16

Page 18

Internal Protection

Circuit Harness

Option Card (2)

External Protection

Circuit Harness

Cable Assembly (1)

Figure 16. Option Card and Cable Assembly

17

Page 19

OC-1 Electrical Parts List

Resistors

Reference

Description Part Number See Note

Designator

R1-4 475 KΩ,1%,1/4W,

52mm,MF

R6,7,41,75,76 7.5 kΩ,1%,

1/10W,0805

R8,39 100 Ω,1%,

1/10W,0805

R9,10,12,14 200 kΩ,5%,

1/10W,0805

R11,17 1 MΩ,5%,1/10W,

0805

R13,90,93 10 kΩ,1%,

1/10W,0805

R15 51 Ω,5%,1/10W,

0805

R16 4.64 kΩ,1%,

1/10W,0805

R18 12.4 kΩ,1%,

1/10W,0805

R19,25,28 20 kΩ,1%,1/10W,

0805

R22 41.2 kΩ,1%,

1/10W,0805

R24 5.1 kΩ,5%,1/10W,

0805

R26,29 7.87 kΩ,1%,

1/10W,0805

R27,30 137 kΩ,1%,

1/10W,0805

R32,37 17.4 kΩ,1%,

1/10W,0805

R33,36 100 kΩ,1%,

1/10W,0805

R34 2.43 kΩ,1%,

1/10W,0805

R35 2.94 kΩ,1%,

1/10W,0805

R38 301 Ω,1%,

1/10W,0805

R45 750 Ω,1%,

1/10W,0805

R48 1.54 kΩ,1%,

1/10W,0805

R50 35.7 kΩ,1%,

1/10W,0805

121245-2214753

133625-7501

133625-1000

133626-2045

133626-1055

133625-1002

133626-5105

133625-4641

133625-1242

133625-2002

133625-4122

133626-5125

133625-7871

133626-1373

133625-1742

133625-1003

133625-2431

133625-2941

133625-3010

133625-7500

133625-1541

133625-3572

18

Page 20

Resistors (Continued)

Reference

Description Part Number See Note

Designator

R52,58,64,65,69,

Jumper-Chip,0805 133627

77,78,83,89,94

R54,62,63 14 kΩ,1%,

133625-1402

1/10W,0805

R85 26.1 kΩ,1%,

133625-2612

1/10W,0805

R88 178 kΩ,1%,

133625-1783

1/10W,0805

R92 1.4 kΩ,1%,1/10W,

133625-1401

0805

R95 255 kΩ,1%,1/10W,

133625-2553

0805

Diodes

Reference

Description Part Number See Note

Designator

D1,4 Zener,5%,18V,1W

116995-4746A

1N4746

D2,3,9 Dual,SOT-23 147239

D5,6 1N4148,75V,

121501

300mA,Switching

or

116997

D7,8 Dual,SOT-23 147249

Integrated Circuits

Reference

Description Part Number See Note

Designator

U1-4,6 Op Amp,RC4559,

Dual

U5 Op Amp-

NJM2059,Quad

U7 VCA, 18V, SIP-8,

2155

Reference

Description Part Number See Note

Designator

J1 Header,2 pos,

Male

J4,5 Header,Rtang,

12 pos.

108568

144008

175120

Connectors

134739-02

149358

19

Page 21

Capacitors

Reference

Description Part Number See Note

Designator

C1,2,57 3300 pF,10%,50V,

X7R,0805

C3 100 µF,20%,25V,

105,Electrolytic

C4,7,13,27,28 10 µF,20%,16V,

105,Electrolytic

C5,6,8,9,18,19,

23-26,38,39,59

.022 µF,10%, 50V,

X7R,0805

C10 22 µF,20%,25V,

BP,EL

C11 1 µF,20%,50V,

105,Electrolytic

C14 100 pF,5%, 50V,

Cog,0805

C15-17,20-22 .047 µF,5%, 63V,

85,Box

C35 .18 µF,5%, 50V,

85,Box

C42 .027 µF,5%, 63V,

85,Box

C43 .47 µF,5%, 50V,

85,Box

C48,51 .22 µF,5%, 50V,

85,Box

C52,54,55 .15 µF,5%, 50V,

85,Box

133623-332

120767

137126-100

133623-223

147522-220

137126-1R0

133622-101

137127-473

137127-184

137127-273

137127-474

137127-224

137127-154

20

Page 22

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

®

Bose Corporation

The Mountain

Framingham, Massachusetts USA 01701

P/N 174786 6/94: REV.0 FOR TECHNICAL ASSISTANCE OR PARTS ORDERING,CALL 800-367-4008

Loading...

Loading...