Page 1

402

®

Series II Loudspeaker

©2009 Bose Corporation

Service Manual

Reference Number 260431-SM Rev. 02

Electronic copy only

Page 2

External dimensions:

CONTENTS

Specifications ....................................................................................................................................1

Disassembly/Assembly Procedures ........................................................................................... 2-3

Figure 1. Schematic Diagram ..............................................................................................................3

Test Procedures ................................................................................................................................4

Main Part List..................................................................................................................................... 5

Figure 2. Exploded View ......................................................................................................................5

Crossover PCB Part List ..................................................................................................................6

Figure 3. Crossover PCB Layout ........................................................................................................6

Packaging Part List ...........................................................................................................................6

Figure 4. Packaging View ....................................................................................................................6

WARRANTY

5 year limited warranty

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION

OF BOSE

ONLY FOR THE PURPOSE OF SERVICING THE IDENTIFIED

BOSE PRODUCT BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE BOSE PRODUCT, AND SHALL NOT

BE REPRODUCED OR USED FOR ANY OTHER PURPOSE.

®

CORPORATION WHICH IS BEING FURNISHED

SPECIFICATIONS

Single speaker: 23.3" H x 8.2" W x 7.8" D (59.2 x 20.8 x 19.8)cm

Packed system: 27.0" H x 12.0" W x 11.0" D (68.6 x 30.5 x 27.9)cm

Weight:

Single speaker: 17.5 lbs (7.94 kg)

Packed system: 21.3 lbs (9.66 kg)

Transducer:

Internal cabinet volume:

Port:

Type: Two rectangular ports located at the top and bottom.

Total port area: 8.84 sq. in. (57 sq. cm)

Port length: 3.23" (8.2cm)

Resonance frequency: 90 Hz

Impedance:

Power handling:

Sensitivity:

Four 4.5" environmental drivers per enclosure

1067.9 cu. In. (17.5 liters)

8 ± 2 Ohm

120W continuous per IEC-268-5

90 dB SPL, 1W, 1m

2

Page 3

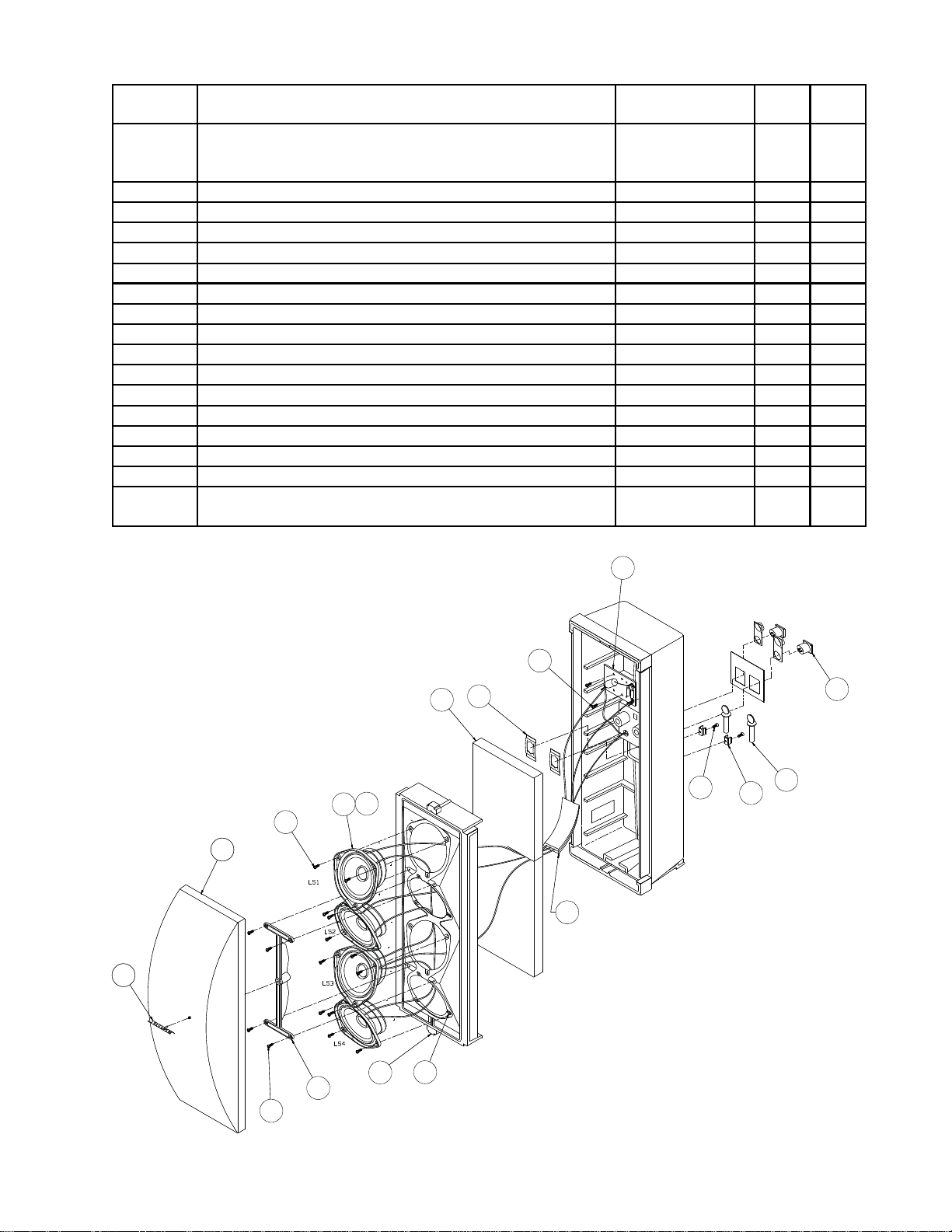

MAIN PART LIST

Item

Description Part Number Qty Note

Number

1 GRILLE, BLACK

GRILLE, ARCTIC WHITE

GRILLE, PRO GRAY

252380-001

252380-002

252380-004

1

2 SCREW, TAPP, 8 -15, HEXW, SLOT 290290-12 14

3 DRIVER ASSEMBLY, 4.5" 291020-001 4 1

4 GASKET, DRIVE R, 4. 5 " 128407 4

5 FOAM, ACOUSTIC, 19.75"x7"x1 120357 1

6 CLIP, TINNERMAN 187943 2

7 CROSSOVER ASSEMBLY 291042-001 1

8 CONN, SPEA KON, PANEL MOU NT 258213-002 2

9 SCREW, THUM B, M8x1.25x25mm 137050 2

10 CONN, FUSE CLIP, 1 POS, FEMAL E 121112 2

11 SCREW, TAPP, 6 - 20x.5, PAN, XR 290296-08 2

12 TAPE, FOAM 257555 1

13 NUT, J-TYPE, 8-32 109481 12

14 INSERT, KNURLED 290293-01 4

15 DEFLECTOR 126973-1 1

16 SCREW, TAPP, 6- 13x.625, PAN 290294-10 4

17 NAME PLATE, LOGO, BLACK

NAME PLATE, LOGO, WHITE

254458-001

254458-002

1

Note: When ordering a d river, also order a driver gasket.

17

7

2

2x

2x

2x

6

5

8

10

2x

9

12x

11

4x

4

3

2x

2

2x

1

12

12x

4x

13

14

15

16

4x

Figure 1. Exploded View

3

Page 4

Number

Qty

CROSSOVER PCB PART LIST

Item

Description

Part Num b er

Qty Note

Item

Description Part

Number

1 LAMP, AXIAL LEAD 114462 2

2 20uF, CAP, FILM, 75V, 10% 119026 1

x2

2

1

Figure 2. Crossover PCB Layout

PACKAGING PART LIST

Number

1 PACKING, FOAM, BOTTOM, EPS 258908 1

2 PACKING, FOAM, P/U, RIGHT 258927 2

3 PACKING, FOAM, P/U, LEFT 258928 2

4 MANUAL, OWNERS 256597 1

5 BAG, POLY, 13.5x 35x9.5 x1 MIL 114522 1

6 CARTON, RSC, 402 II 256591 1

3

2

1

6

4

2

3

5

Figure 3 Packaging View

4

Page 5

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Numbers in parenthesis correspond to

call-outs in figure 1.

1. Grille Removal

1.1 Rotate the Bose® logo (9) 450 to release

the grille (6).

1.2 Grasp the edge of the grill and pull it off.

0

45

2. Grille Replacement

2.1 Rotate the Bose logo (9) 450 so the

locking tabs on the logo line up with the slot

on the deflector (8). Press the grille into place.

2.2 Rotate the Bose logo horizontally, locking

the grille into place.

3. Driver Removal

3.4 Cut the wires as close as possible to the

driver’s wire terminal.

4. Driver Replacement

4.1 Referring to the schematic below, attach

the wires to the driver (1).

4.2 Line up the driver (1) to the cabinet and

secure it with three screws (7).

4.3 Line up the deflector (8) with the cabinet

and secure it with four screws (12).

5. Crossover Removal

5.1 Remove the three screws (7) securing the

top driver (1) to the cabinet. Lift out the driver.

5.2 Remove the two screws (7) securing the

crossover PCB to the cabinet.

5.3 Pull the crossover PCB through the driver

opening in the cabinet.

3.1 Perform procedure 1.

3.2 Remove the four screws (12) securing the

deflector (8) to the cabinet. Lift off the deflector.

Deflector

3.3 Remove the three screws (7) securing the

driver (1) to the cabinet. Lift out the driver.

Crossover PCB

5

Page 6

DISASSEMBLY/ASSEMBLY PROCEDURES

6. Crossover Replacement

6.1 Replace the two screws (7) securing the

crossover PCB (3) to the cabinet.

6.2 Perform procedure 4 and 2.

7. Speakon Connector Removal

7.1 Perform procedure 3.1-3.3 to remove the

two center drivers.

7.2 Using a flat-blade screwdriver, pry out the

tinnerman clip (5) securing the Speakon

connector (4) to the cabinet.

Speakon

Connector

Tinnerman Clip

7.3 Pull out the Speakon connector and

remove the wires.

8. Speakon Connector Replacement

8.1 Referring to figure 1, attach the wires to

the Speakon connector (4).

8.2 Align the Speakon connector in the

cabinet.

8.3 Reshape the tinnerman clip (5) or use a

new one. Place an appropriate size wood

block between the Speakon connector (rear

of speaker) and a hard surface. Using a flatblade screwdriver (or similar tool) and a

hammer, secure the tinnerman clip into place.

Make sure the Speakon connector is securely

fastened.

Figure 4. Schematic Diagram

6

Page 7

TEST PROCEDURES

1. Phase Test

1.1 Observing polarity, apply 9 VDC to the

input connector. Refer to the figure below.

1.2 All driver cones should move outward.

Referring to figure 4, rewire any driver that

moves inward.

1+

2-

1-

2+

Positive input

Negative input

2. Crossover Test

2.1 Connect a 0.5 Ohm resistor and amplifier

to the speaker input connector as shown in

the diagram below.

noise can be made to go away or get worse, it

is a rub or tick and the driver should be

replaced. If the noise stays the same, it is

normal suspension noise and the driver is

fine. Suspension noises will not be heard with

program material.

4. Air Leak Test

4.1 Apply a 15 Vrms, 65 Hz signal to the

speaker input connector.

4.2 Listen for air leaks around the drivers and

cabinet seam. Reposition or replace any

gasket that is found to leak. Repairs made to

the cabinet seam should not be visible from

the exterior of the speaker.

5. Sweep Test

5.1 Apply a 9 Vrms, 10 Hz signal to the

speaker input connector.

Amplifier

Speaker output

-

+

Volt meter

-

0.5 Ohm

Speaker

+

+

-

2.2 Apply a 2 Vrms, 8 kHz signal to the

speaker input connector.

2.3 Measure the voltage across the 0.5 Ohm

resistor. It should be 68-90 mVrms. If the

voltage is out of range, check the crossover

components and wiring.

3. Rub and Tick Test

3.1 Apply a 9 Vrms, 10 Hz signal to the

speaker input connector.

5.2 Sweep the signal generator from 10 Hz to

500 Hz.

5.3 Apply a 500 Hz, 2 Vrms signal to the

speaker input connector.

5.4 Sweep the signal generator from 500 Hz

to 5 kHz.

5.5 Listen for buzzes, rattles or other noises.

Redress any wire that buzzes; replace any

driver that is found to be defective.

Note: A whooshing noise from the port at its

resonance frequency of approximately 90 Hz

is acceptable.

3.2 No extraneous noises such as rubbing,

scraping or ticking should be heard.

Note: To distinguish between normal suspension noise and rubs or ticks, slightly displace

the cone of the driver with your fingers. If the

7

Page 8

SERVICE MANUAL REVISION HISTORY

Date Revision

Description of Change Change Driven By Pages

1

Level

02/01 00 Document release revision 00

02/06 01 Added RoHS part numbers This product is now built

1/07 No change Corrected part number, Driver

Assembly, 4.5”

5/09 02 - New part numbers for

speaker parts and packaging

- Layout changed to reflect

current manuals

Service manual release All

with RoHS compliant parts.

Correct part number is

254451

Part changes

Service manual layout

change

Affected

3

3

3, 4

All

8

Page 9

Specifications and Features Subject to Change Without Notice

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 260431-SM Rev. 02 05/2009 (P) For Technical Assistance or Part Orders, Call 1-800-233-4408

http://serviceops.bose.com

Loading...

Loading...