Page 1

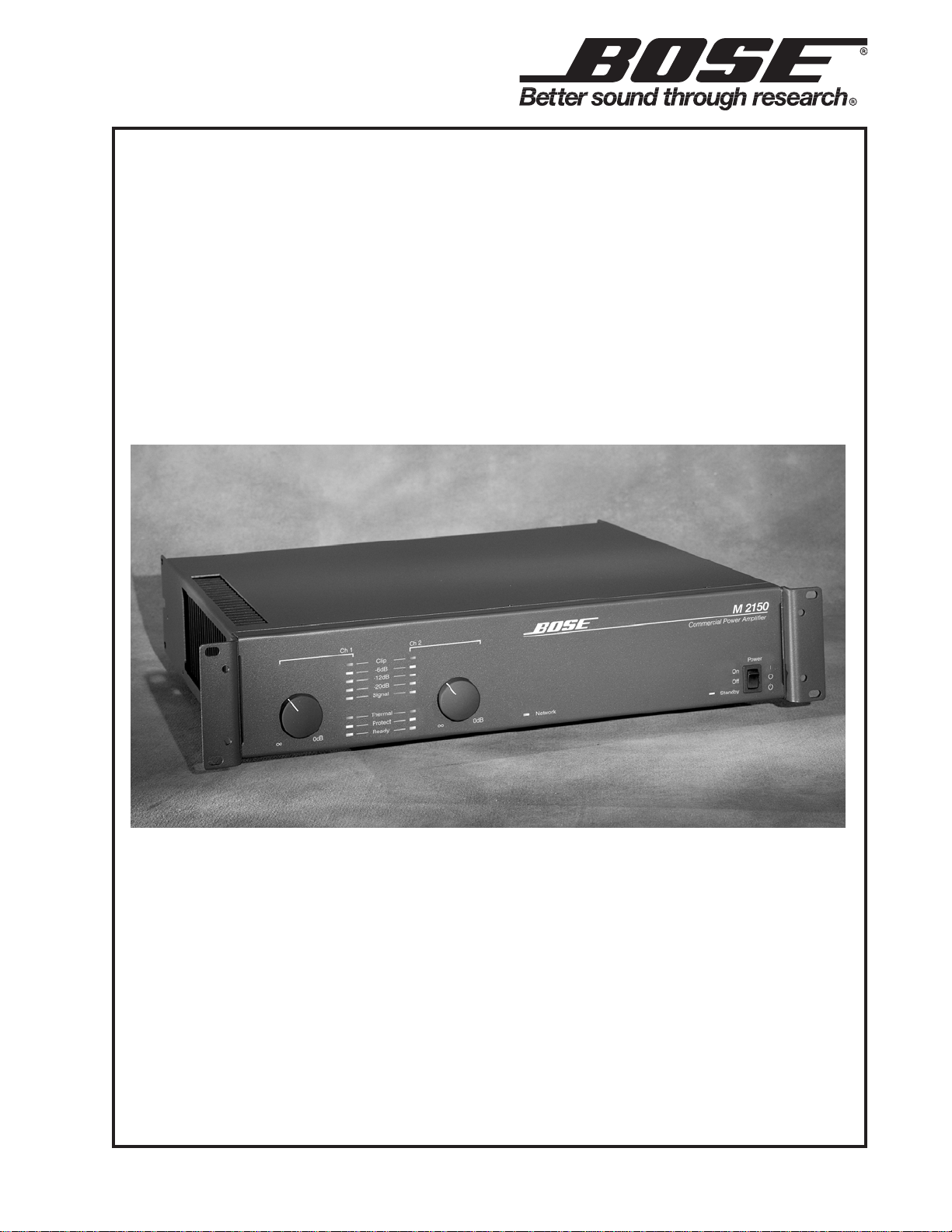

Model 2150

Commercial Power Amplifier

©2008 Bose Corporation

Service Manual

Part Number 216306 Rev . 01

Page 2

CONTENTS

Safety Information.............................................................................................................................3

Electrostatic Discharge Sensitive (ESDS) Device Handling....................................................... 3

Warranty .............................................................................................................................................3

Specifications................................................................................................................................ 4-5

Amplifier/Driver Board Version Information ...................................................................................6

Packaging Part List, Model 2150 Amplifier .....................................................................................6

Part List Notes ..................................................................................................................................7

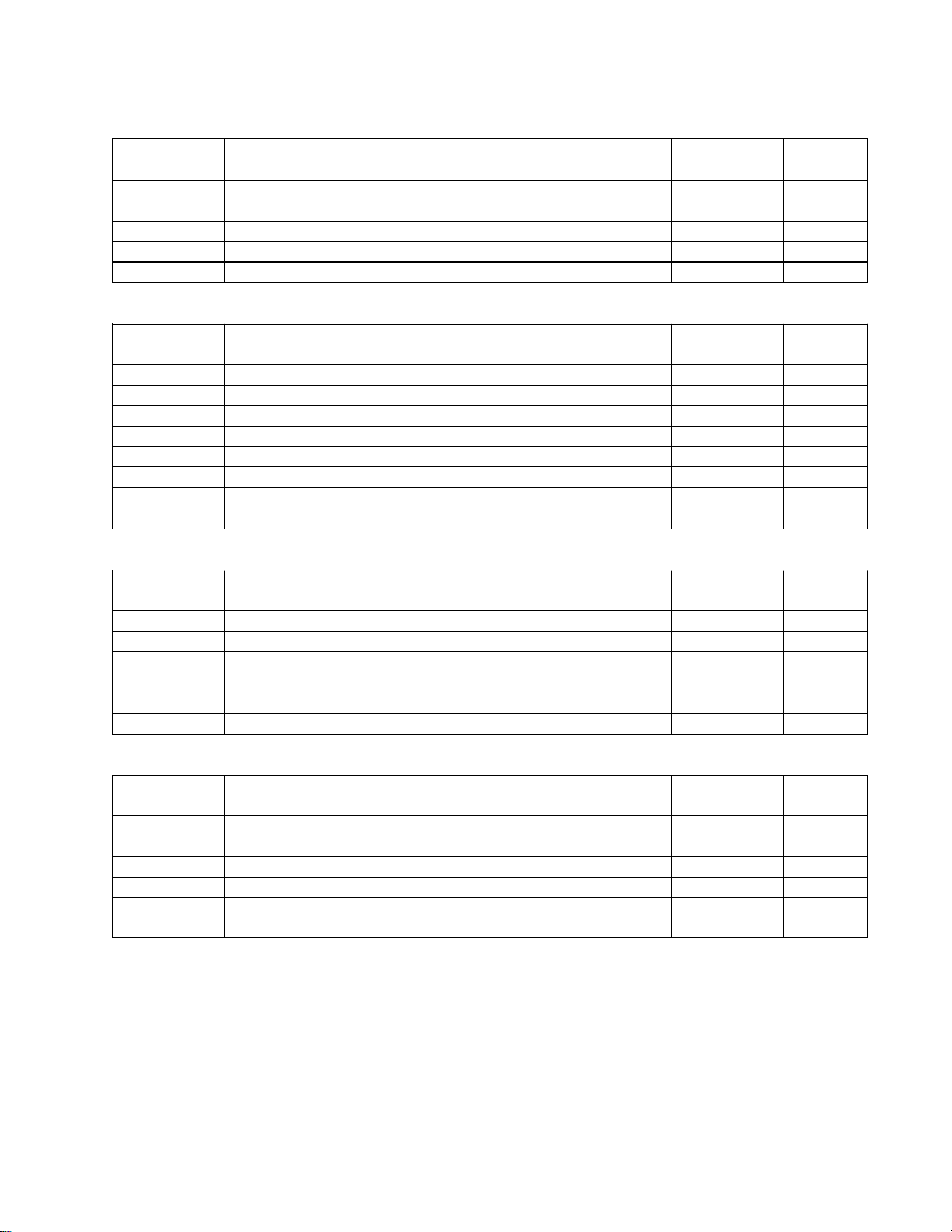

Main Part List, Model 2150 Amplifier (items not shown on a part drawing) ................................7

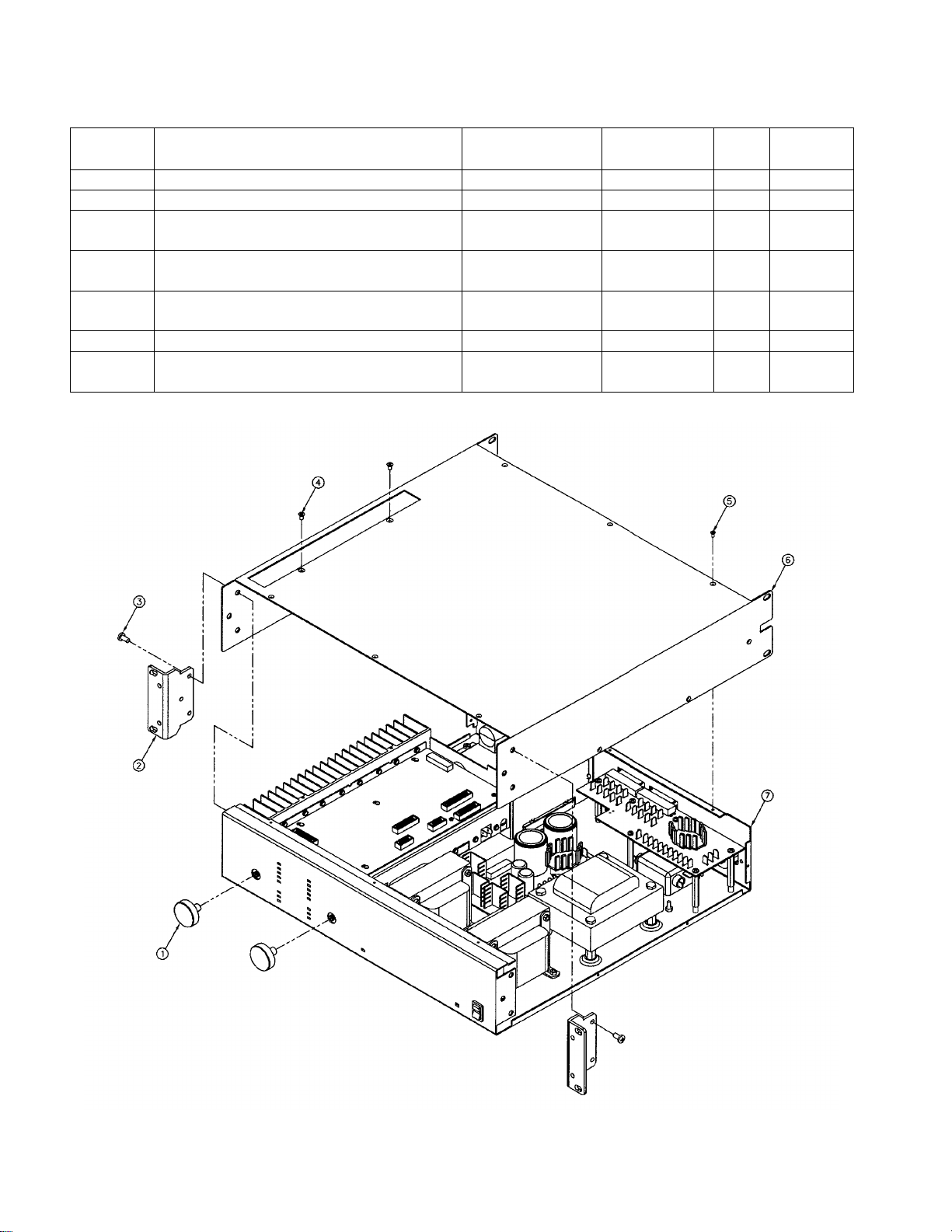

Main Part List (Continued), Model 2150 Amplifier (see Figure 1)................................................8

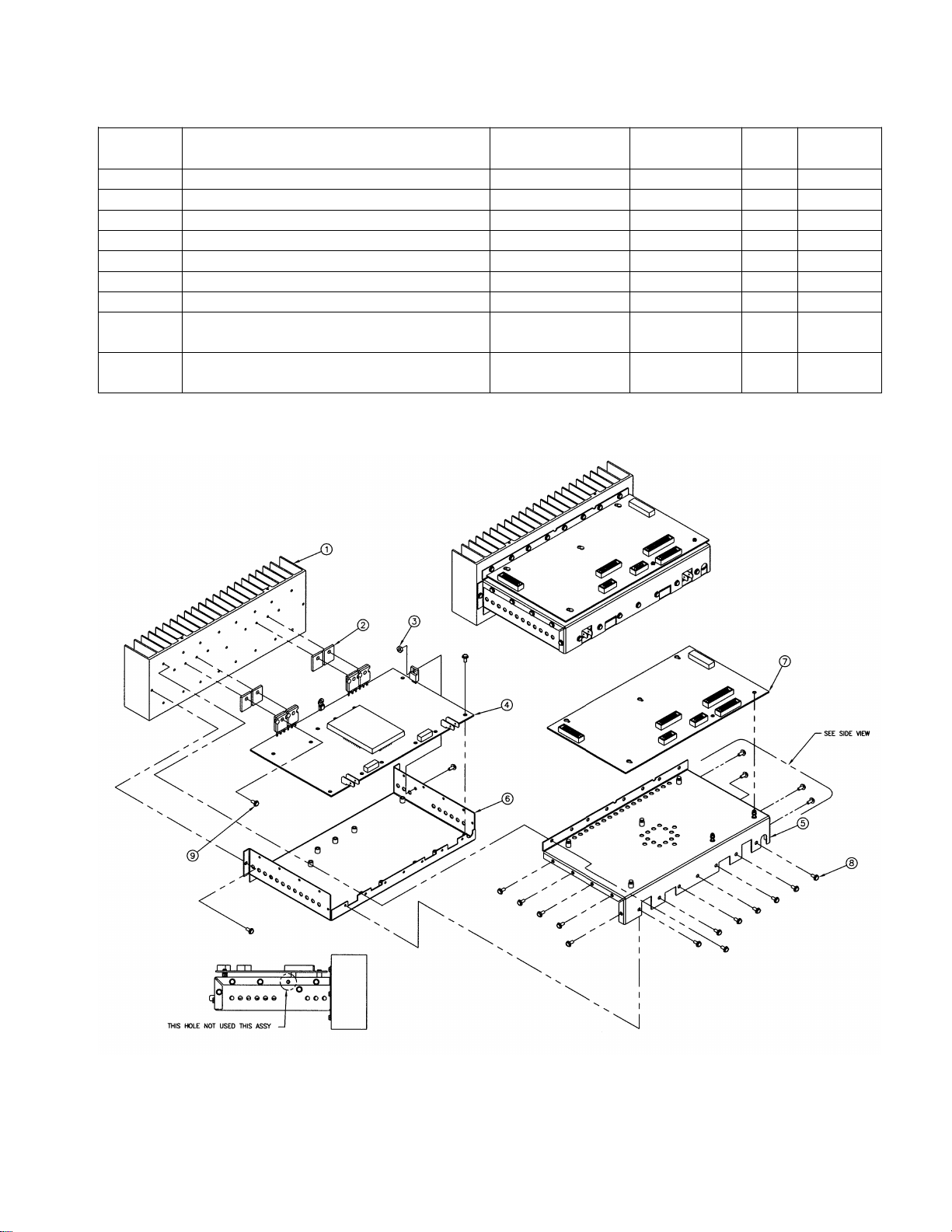

Figure 1. Model 2150 Amplifier Top Cover Removal Exploded View....................................................8

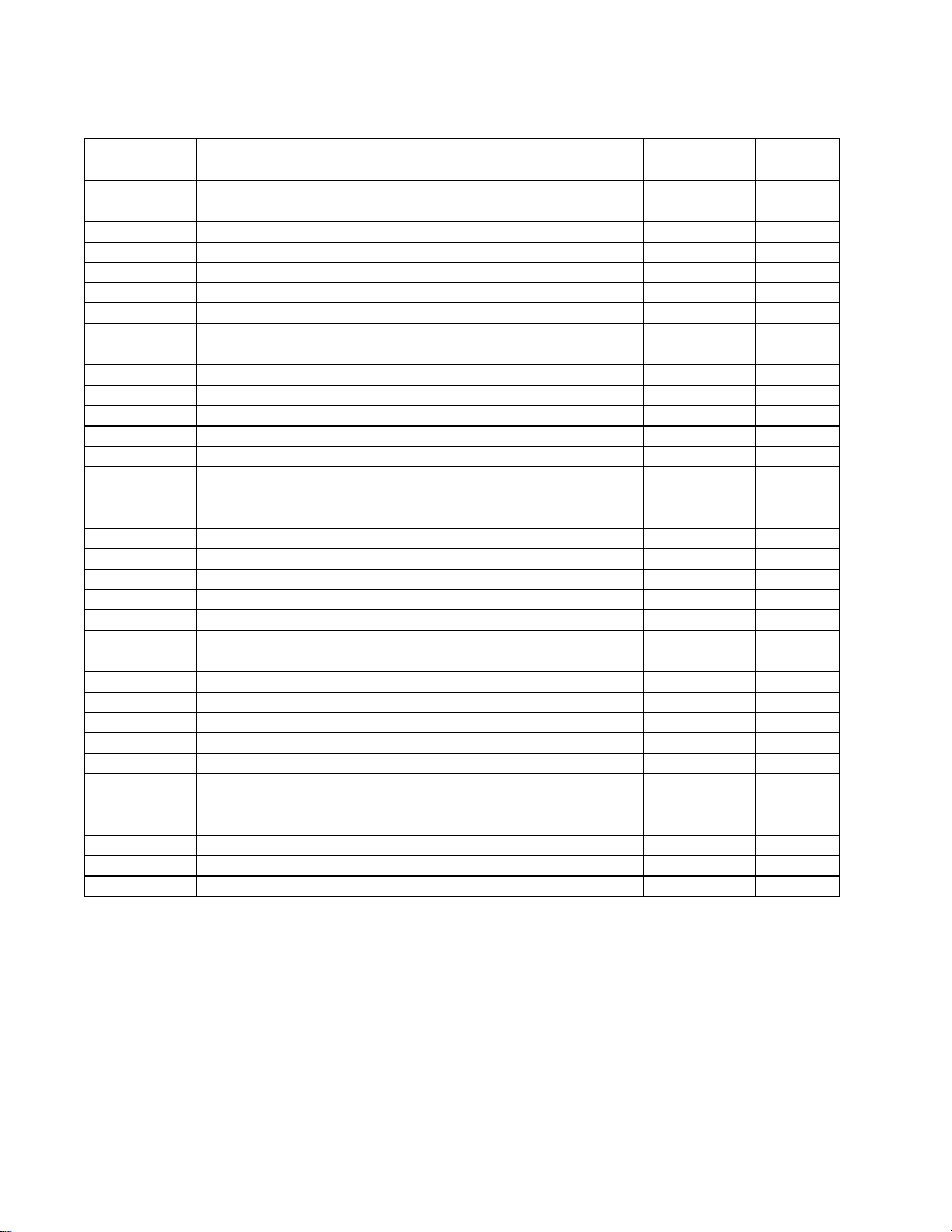

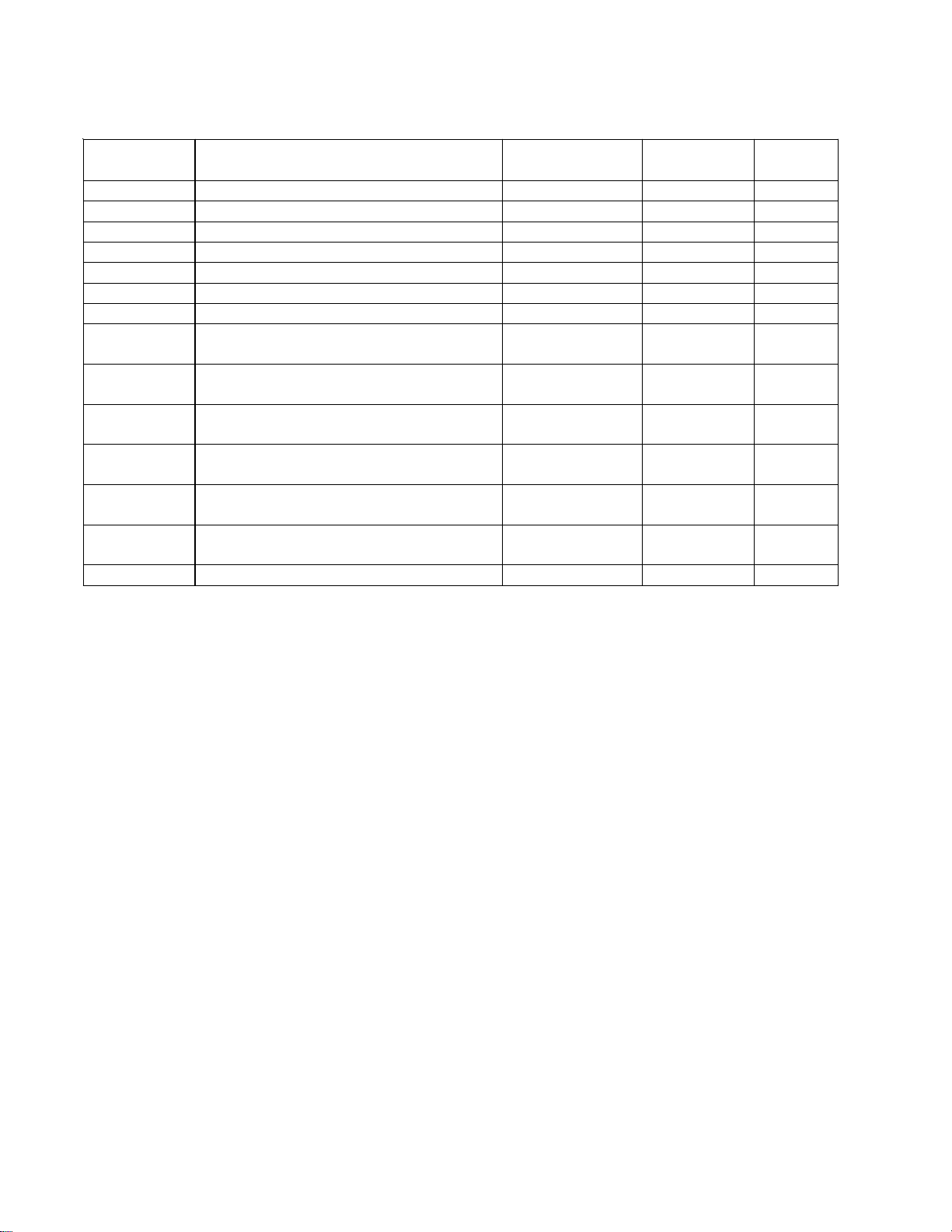

Main Part List (Continued), Model 2150 Amplifier (see Figure 2)................................................9

Figure 2. Model 2150 Amplifier Internal Assemblies Exploded V iew ..................................................10

Main Part List (Continued), Model 2150 Amplifier (see Figure 3).............................................. 11

Figure 3. Model 2150 Amplifier Module Exploded V iew...................................................................... 11

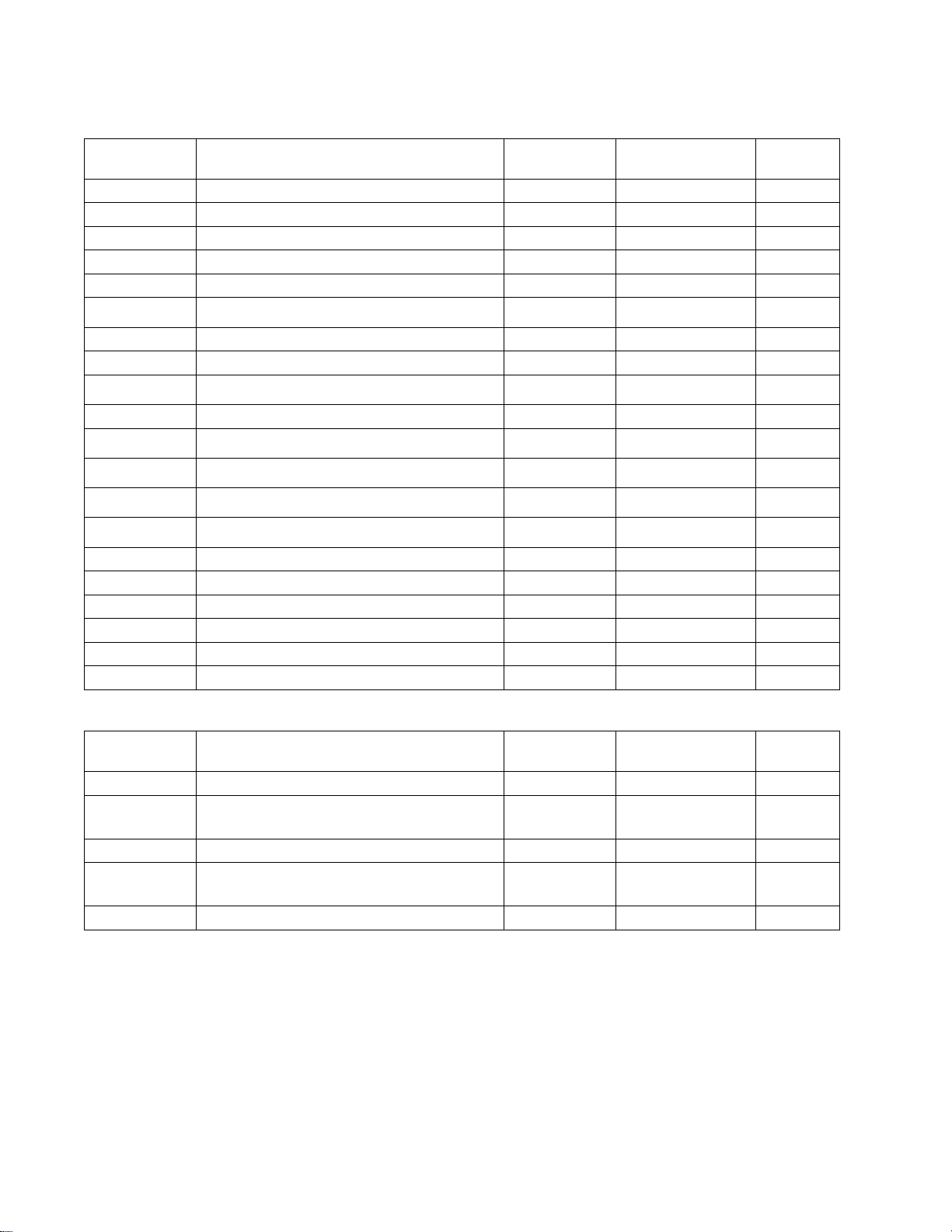

Electrical Part Lists .................................................................................................................. 12-45

Input Module Assembly ............................................................................................................ 12-14

Barrier PCB Assembly (p art of Input Module Assembly) ............................................................15

Amplifier PCB Assembly (board p art number 6000.0435)...................................................... 16-20

Amplifier PCB Assembly (board p art number 8005.0587)...................................................... 21-26

Power Supply PCB Assembly .................................................................................................. 27-29

Switch PCB Assembly............................................................................................................... 30-31

AC Input/Output PCB Assembly.....................................................................................................32

Interface PCB Assembly........................................................................................................... 33-34

Digital Signal Processor (DSP) PCB Assembly ..................................................................... 35-43

Display PCB Assembly.............................................................................................................. 44-45

Disassembly Procedures ......................................................................................................... 46-49

Test Procedures ....................................................................................................................... 50-54

Figure 4. Model 2150 amplifier rear panel .........................................................................................50

Figure 5. Test Setup Diagram ...........................................................................................................50

Figure 6. Model 2150 Amplifier Signal Flow Block Diagram ..............................................................55

Theory of Operation ................................................................................................................. 56-65

Circuit Board Layout Diagrams ............................................................................................... 66-73

Integrated Circuit Diagrams .................................................................................................... 74-78

Troubleshooting .............................................................................................................................79

Service Manual Revision History .................................................................................................80

CAUTION: The Bose® Model 2150 amplifier contains no

user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer .

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage current tester or a metering system that complies with American National Standards Institute

(ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL) UL6500 /

UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads, metallic

overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the unit

power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICA TE A POTENTIAL SHOCK HAZARD THA T MUST BE ELIMINA TED

BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resist ance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products,

the resistance measured to exposed input/output connectors should be between 4 and infinite

MOhms. If it is not within the limits specified, there is the possibility of a shock hazard, and the

unit must be repaired and rechecked before it is returned to the customer .

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only .

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

WARRANTY

The Bose® Model 2150 amplifier is covered by a five-year, transferable, limited warranty.

3

Page 4

SPECIFICATIONS

Power Output, continuous average output power, both channels driven:

150W per channel into 4 or 8 Ohms at 1kHz with 0.5% or less THD

150W per channel at 100V into a 67 Ohm load at 1 kHz with 0.5% or less THD

150W per channel at 70V into a 33 Ohm load at 1 kHz with 0.5% or less THD

Power Output, bridged-mono operation:

300W at 8 or 16 Ohms with 0.5% or less THD

300W at 100V into a 33 Ohm load with 0.5% or less THD

300W at 70V into a 16 Ohm load with 0.5% or less THD

Power Consumption:

60W or less at idle, no input, maximum gain

125W with musical program at 1/8 rated power

250W with musical program at 1/3 rated power

300W at 70V into a 41 Ohm load with 0.5% or less THD

600W at 4 Ohms with a sinewave test tone, rated continuous power at maximum gain

575W at 8 Ohms with a sinewave test tone, rated continuous power at maximum gain

560W at 70V or 100V with a sinewave test tone, rated continuous power at maximum gain

Power Requirements: 120 V AC, 60 Hz +/-20% (US and Canada)

230 V AC, 50 Hz +/-20% (Europe/UK)

240 V AC, 50 Hz +/-20% (Australia)

Output Configurations: Audio output transfomer taps per channel:

100V, 70V, 50V, 35V, 25V, 8 Ohms, 4 Ohms

Frequency Response: 30 Hz to 20 kHz (-3 dB)

Signal to Noise Ratio: > 95 dB, A-W eighted below full bandwid th power

Channel Separation: > 80 dB at 1 kHz

CMRR: > 80 dB at 1 kHz (without Bose

Slew Rate: > 10V/uSec

Sensitivity: 0.775 Vrms for rated power at 1 kHz

Input Impedance: 50k Ohms balanced, 25k Ohms unbalanced

Maximum Input: +20 dBu (7.75V)

Fusing/Protection: Mains internally fused. Amplifier thermal and

short circuit protection

®

input module)

Dynamic Headroom: 1.2 dB

Full Power Bandwidth: 30 Hz to 20 kHz at 0.5% THD

IM Distortion: 0.2%

THD: < 0.5% rated power, < 0.2% 1/8 rated power

4

Page 5

SPECIFICATIONS

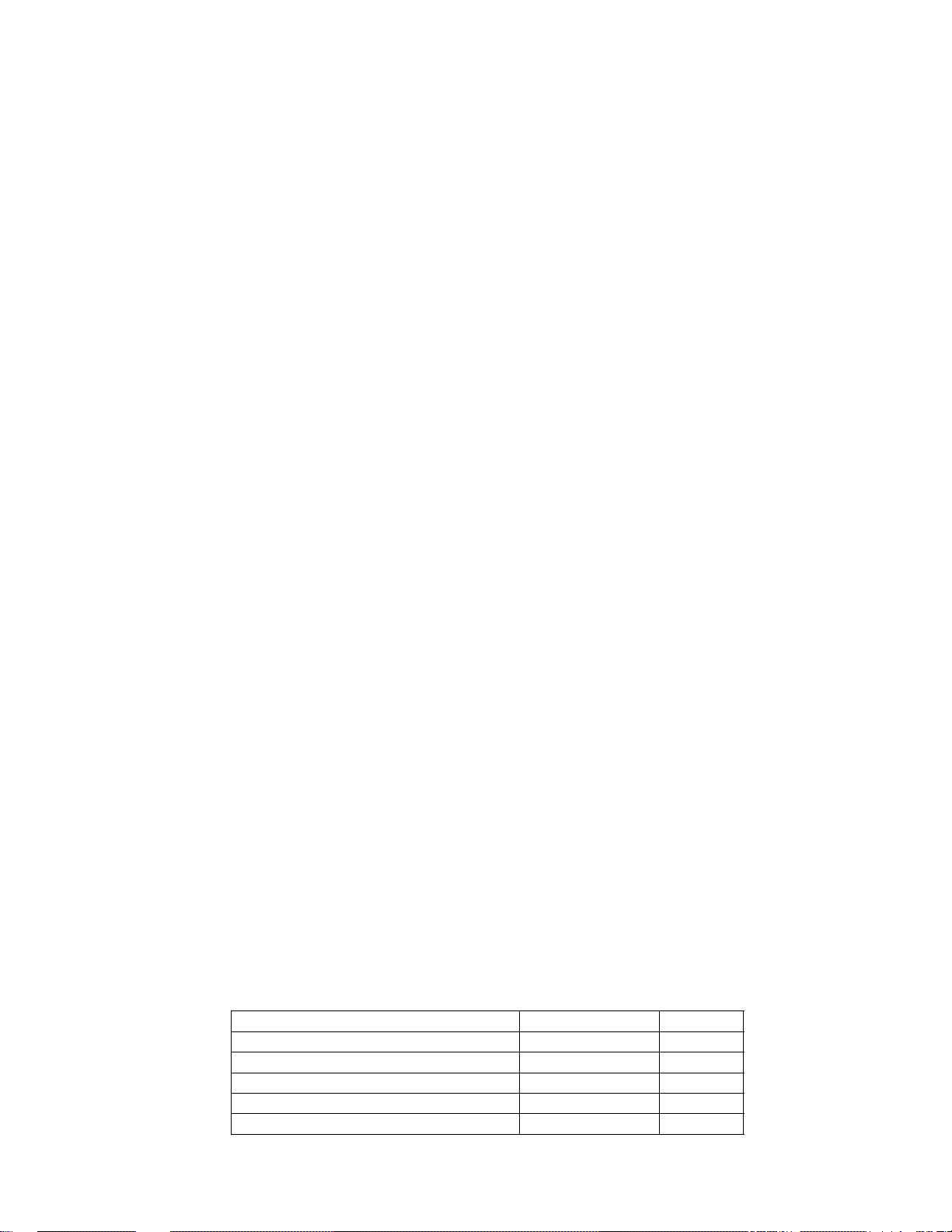

Description Product Code Voltage

Features:

• Convection Cooling

• 5-segment LED level display, per channel, including signal present and clip indicators

• 3 LED display, per channel, of power, protect and thermal overload

• St andby LED indicates the amplifier is in st andby mode

• Data LED (used with the Bose

• Level controls can be covered with caps (supplied) to prevent tampering

• Remote control of output level via Euro style connectors

• S tandard Dual Input Module with line level input s via Euro style connectors and XLR jacks,

connected in parallel

• 26 Hz High Pass Filter

• Switched 80 Hz / 120 Hz (12 dB / Octave cut) High Pass Filters

• Switched Clip Limiters

• Terminals for Sequencing Power ON/OFF

• Speaker Output via large gauge Euro style connectors (accept s 12 gauge wire)

• Power Switch, 3 positions, On, Off and Standby

• AC Line Cord (Detachable IEC Type)

• Optional Accessories:

- Computer Control and Monitoring via Bose ACM-1 amplifier control module

®

ACM-1 amplifier control module)

Physical Characteristics:

Cooling Method: Convection

Operating Environment: -10 deg C up to 55 deg C, up to 85% RH

Storage Environment: -45 deg C up to 70 deg C, up to 85% RH

Dimensions: 3.5" H (2U) x 19.0" W x 16" D

8.9cm x 48.3cm x 40.6cm

Net Weight: 43 lbs. / 19.5 kgs.

Shipping Weight: 48 lbs. / 21.8 kgs.

Regulatory Information: United States: UL6500, Canada: CAN/CSA

E60065, Europe: EN 60065, Australia/New

Zealand: AS/NZS 3250, Eastern Europe, Far

East, Pacific Rim, Americas and others: IEC

60065 + CB Scheme Certification (Worldwide)

MODEL 2150 AMPLIFIER VERSIONS

Model 2150 Amplifier, Japan 025985 100V

Model 2150 Amplifier, US/Canada 025986 120V

Model 2150 Amplifier, Euro 025987 220V

Model 2150 Amplifier, UK 025988 230V

Model 2150 Amplifier, Aus 025989 240V

5

Page 6

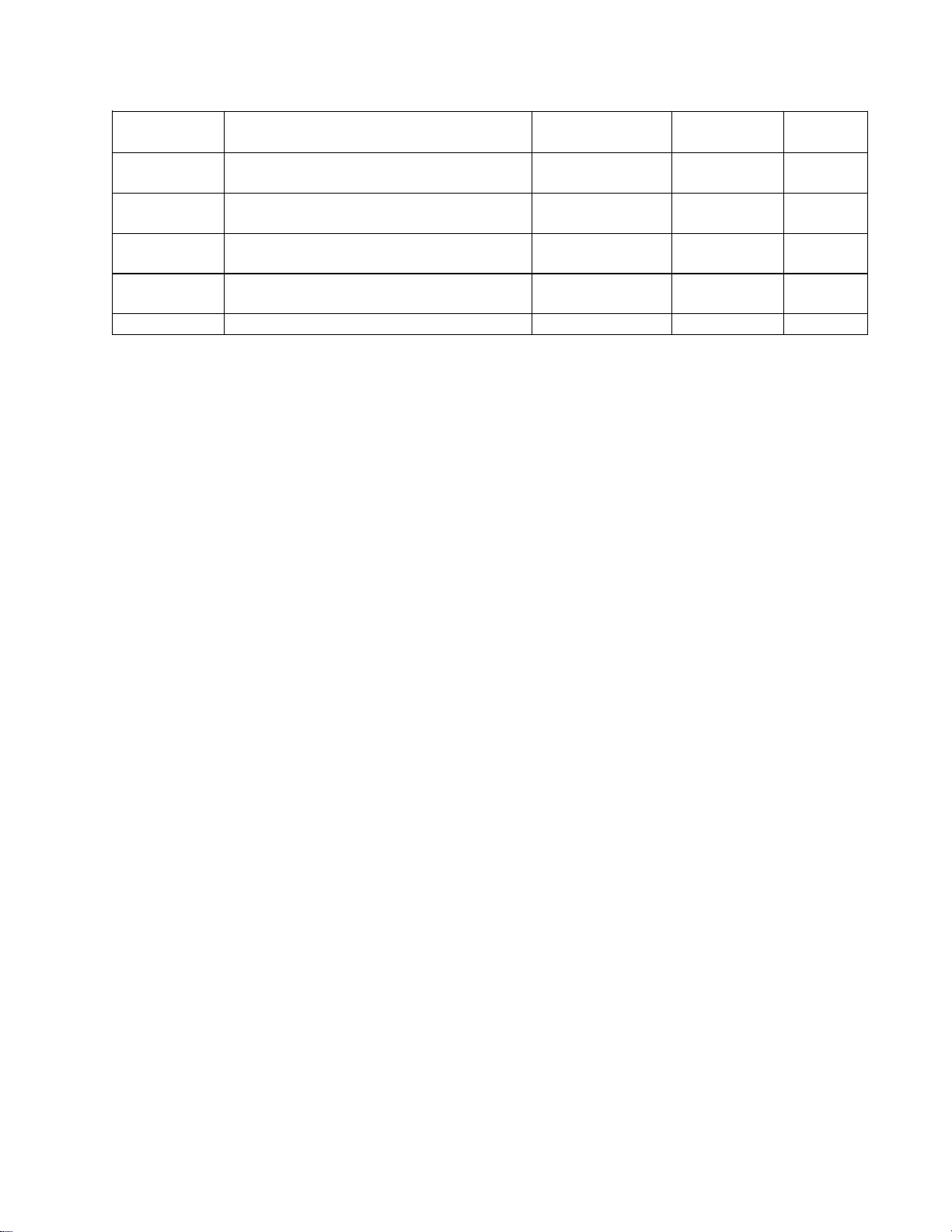

Item

Description Vendor Part

®®®®

Qty. Note

AMPLIFIER/DRIVER BOARD VERSION INFORMATION

Units built before June 2005 have the original version of the amplifier PCB assembly . Unit s built

after that date have a different version of the amplifiier PCB assembly. Units built before June

2005 use amplifier bare board part number 6000.0435. Units built after that date use bare board

part number 8005.0587. The amplifier driver modules for these boards are different as well. The

original version used the black TAO103 module. Newer versions use a PCB assembly with a

heatsink visible on the top of the board. See below .

CAUTION: The driver modules and the amplifier boards used with them are NOT compatible

with the other versions. Any attempt s to use an incorrect driver module on an incomp atible

amplifier board will result in damage to both. Be sure to use the appropriate schematic, board

layout diagram and parts list for the amplifier PCB assembly in your unit.

Original Version Driver Module, used with

the 6000.0435 Amplifier PCB

Newer Version Driver Module, used with the

8005.0587 Amplifier PCB

PACKAGING PART LIST

Model 2150 Amplifier

Bose

Number

- Bag, Plastic, 24x30

Pack amp in bag for shipment

- Bag, Poly, 10x16x4mil 8300.0023 1

- Bag, Poly, 4x6x4mil 8300.0046 1

- Foam, Corner, 2U 8700.0060 262193 4

- Carton, 2U, 23 1/4x7 1/2x20 1/8 862003 262119 1

- Manual, Owners, DK/DE/IT/ND/SW

Model 2060/2150

- Manual, Owners, EN/ FR/ SP, Model

2060/2150

- Declaration of Conformity, Bose 2150

amplifier

- Line Cord, 120V, S250AH 4150.0009 262099 1 US/CSA

- Line Cord, MOD, 3x1.0mm, 10A,

250V

- Line Cord, MOD, 3x1.0mm, 13A,

250V

- Line Cord, MOD, 3x1.0mm, 10A,

250V

- Plug, .500, Black (covers level control

shafts after knob removal)

- Foot, Rubber, BLK, .81 sq x .3 h 5740.0006 199779 4

Number

8300.0024 1

8100.0218 262210 1 EURO

8100.0219 262194 1 US/CSA

8110.0012A 262318 1 EURO

4150.0015 262117 1 AUS

4150.0016 262118 1 UK

4150.0017 262083 1 EURO

5815.0002 262319 2

Part

Number

/EURO/

UK/AUS

3

3

3

3

6

Page 7

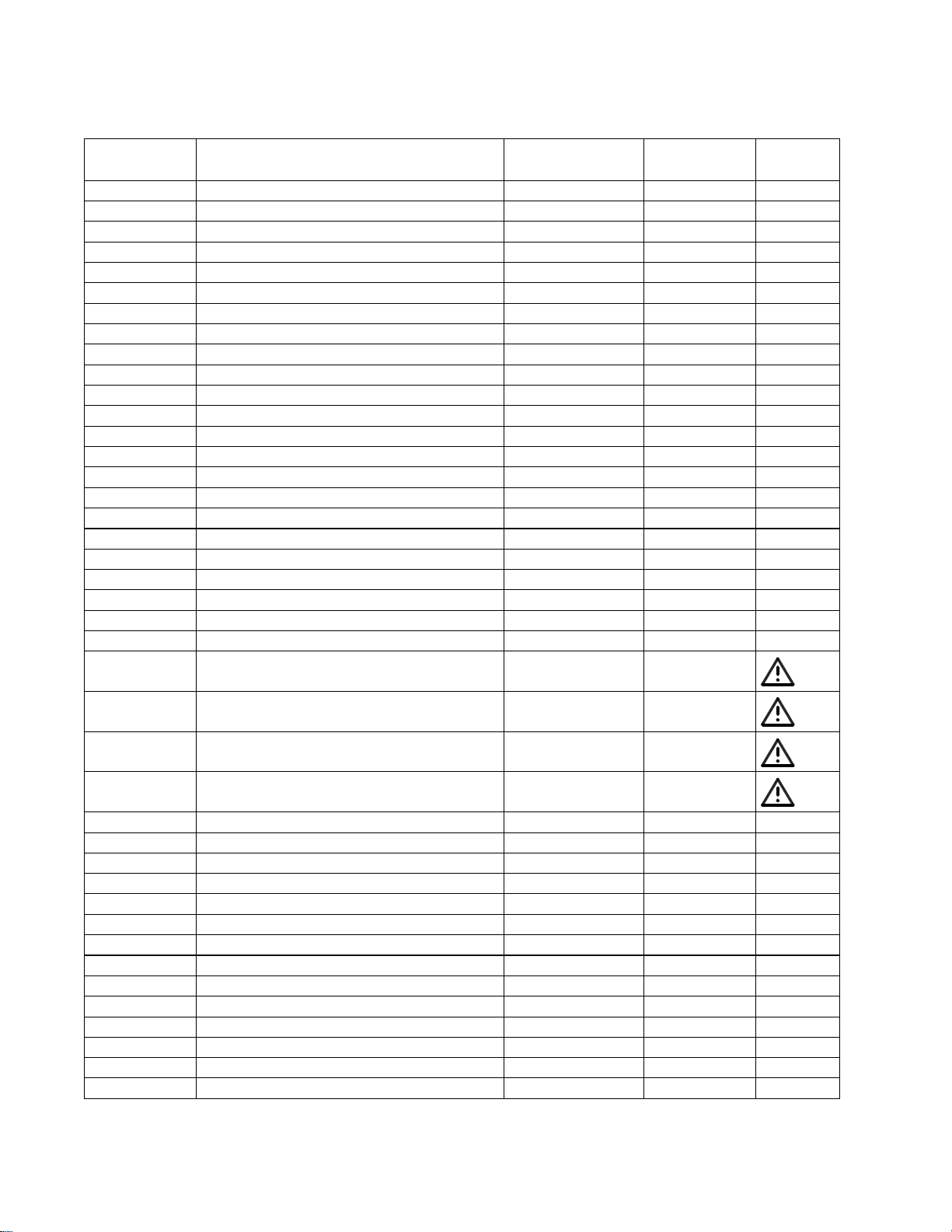

PART LIST NOTES

Item

Description Vendor Part

®®®®

Qty. Note

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part.

MAIN PART LIST

Model 2150 Amplifier (items not shown on a p art drawing)

Bose

Number

- Fuse, MDA, 8A, 250V, US/CSA

(F100 mains fuse)

- Fuse, MDA, 4A, 250V,

EURO/UK/AUS (F100 mains fuse)

- Conn, Plug, Term Block, 4 Pos, Blk

(ch1, ch2 EFX loop, remote level

connectors)

- Conn, Plug, Term Block, 3 Pos, Blk

(ch1, ch2 euroblock signal input,

power sequence connectors)

- Conn, Term Plug, Cbl Mt, 8 Pos

(ch1, ch2 speaker output connectors)

- Conn, .100 CTR, 2-Pin 160-20013-00 262317 1

- Cable, IDC, PLG/HDR, 20 Conductor,

- Harness, 2P, 22 AWG, Blind Mate

- Screw, SEMS, PHP, 6-32x1/4, BO,

16 inch (signal processor J101)

(input module power cable)

WAX (attach barrier pcb to input

module plate)

Number

315-13003-00 262208 1 3

4605.0001 262209 1 3

4227.0002 262104 3

4227.0008 262105 3

4227.0026 262106 2

4148.0017 262182 1

550-10087-01 182920 1

151-30169-01 262115 2 4

Part

Number

7

Page 8

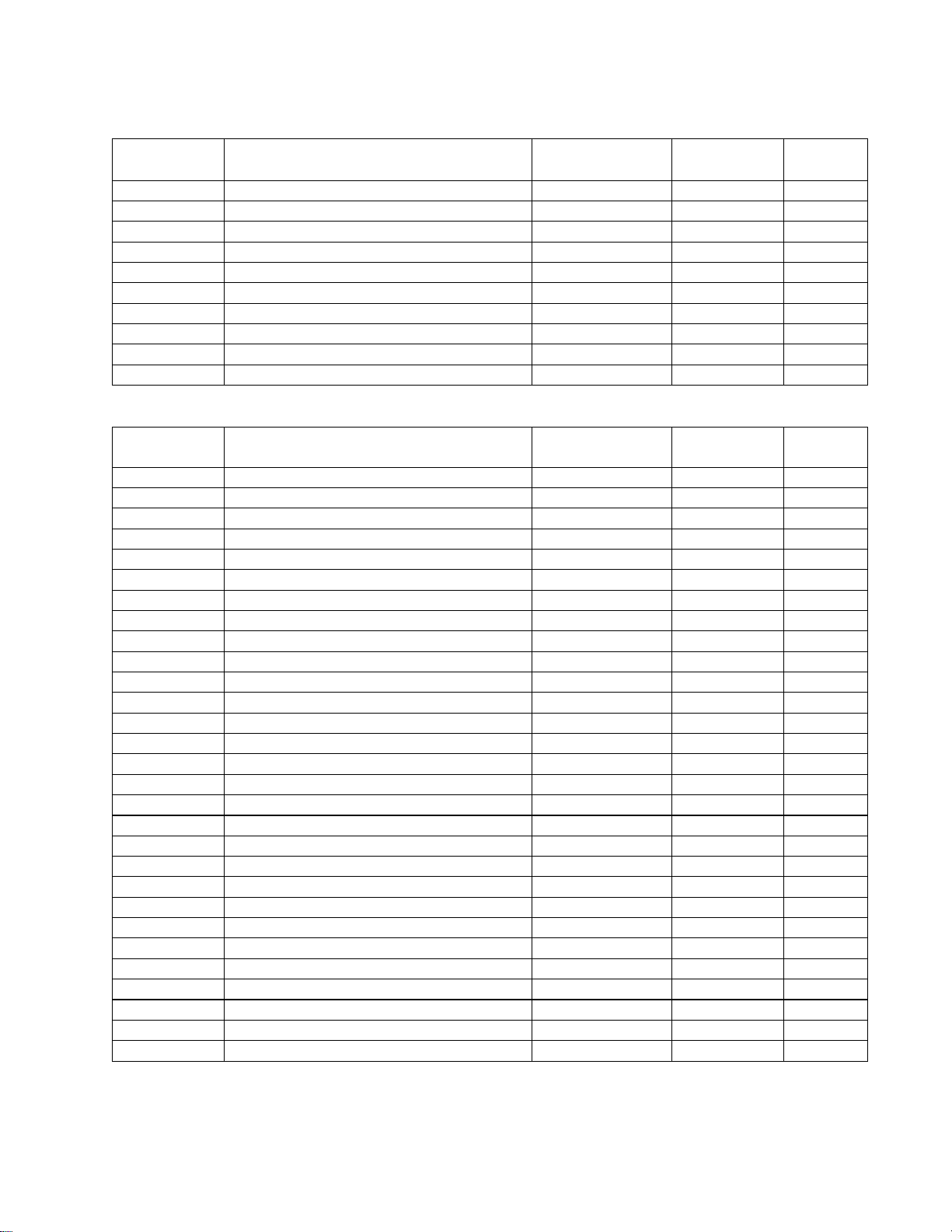

MAIN PART LIST (CONTINUED)

Item

Description Vendor Part

®®®®

Qty. Note

Model 2150 Amplifier (see Figure 1)

Bose

Number

1 Knob, Control, 1.18 OD x .5 DP Stem 5710.0001 262101 2

2 Rack Ear, 2U, Carver, Gray 700362.30 262120 2

3 Screw, SEMS, BLK OX, PHP, 10-

32x3/8

4 Screw, TF, 6-32x1/4, FHP, UC, ST,

BZ

5 Screw, TF, 4-40x1/4, FHP, UC, ST,

BZ

6 Cover, 2U, Bose 2060/2150 700487.30 262102 1

7 Amplifier Chassis Assembly

(refer to Figure 2)

Number

151-30170-01 262109 6 4

5113.0037 262113 2 4

5112.0026 199771 12 4

1

Part

Number

Figure 1. Model 2150 Amplifier Top Cover Removal Exploded View

8

Page 9

MAIN PART LIST (CONTINUED)

Item

Description Vendor Part

®®®®

Qty. Note

Model 2150 Amplifier (see Figure 2)

Bose

Number

1 Screw, TF, 6-32x1/4, FHP, UC, ST,

BZ

2 Amplifier Assembly (refer to Figure 6) 1

3 Nut, Mini STZ, 4-40 152-50004-00 182729 4 4

4 Screw, Mach, BLK OX, PHP, 4-40x1/2 151-20010-05 182717 6 4

5 Slide, Chassis, Input Module Card 159-60003-01 182731 2

6 Shield, Input Module, CV 700490 262103 1

7 Screw, TF, 4-40x1/4, FHP, UC, ST,

8 Screw, Sht Mtl, BLK OX, PHP, SERR,

9 Panel, I/O, SS, Gray, 1800V 700191.3001 199786 1 4

10 Input PCB Assembly 602-00603-02 262316 1 2

10 Barrier PCB Assembly

11 Screw, MA, 6-32x1/4, PHP, WSHR,

12 Interface PCB Assembly, CV, Dual 9000.0445.02 262086 1 2

13 AC Input/Output PCB Assembly 9000.0440.01 262085 1 2

14 Standoff, HX, M/F, 6-32x1-3/4x1/4, AL

15 Switch PCB Assembly 9000.0439.02 262084 1 2

16 Nut, 6-32, Hex, Kep, STZ 5223.0001 199774 12 4

17 Transformer, Output, 150W, CV 4554.0041 262096 2 3

18 Receptacle, IEC AC Power, Panel19 Line Filter, 16A/20A 615-00003-00 182763 1 3

20 Screw, Machine, 6-32x5/16, FHP,

21 Transformer, Power, CV, 43V/5.4A,

21 Transformer, Power, CV, 43V/5.4A,

22 Screw, SEMS, MA, 8-32x1/4, PHP,

23 Chassis, 2U, 2060/2150 700488.3001 262089 1 4

24 Switch, Rocker, Power, SPDT

25 Power Supply PCB Assembly 9000.0437.03 262082 1 2

26 Display PCB Assembly, Dual 9000.0448.02 262088 1 2

27 Nut, 4-40, Hex, Kep, STZ 5222.0001 262116 3 4

BZ

6x1/4

(part of input module)

STZ

Mount

BLK

120V (US/CSA)

230V (EURO/UK/AUS)

STBZ

ON-OFF-ON (S100)

Number

5113.0037 262113 4 4

5112.0026 199771 14 4

151-30107-01 262108 4 4

602-00533-02 182774 1 2

5113.0006 262112 18 4

5533.0046 262107 6 4

4202.0003 262093 1 3

2 4

4554.0044 262097 1 3

4554.0042 262098 1 3

5114.0012 262114 4 4

4360.0006 262095 1 3

Part

Number

9

Page 10

Figure 2. Model 2150 Amplifier Internal Assemblies Exploded View

10

Page 11

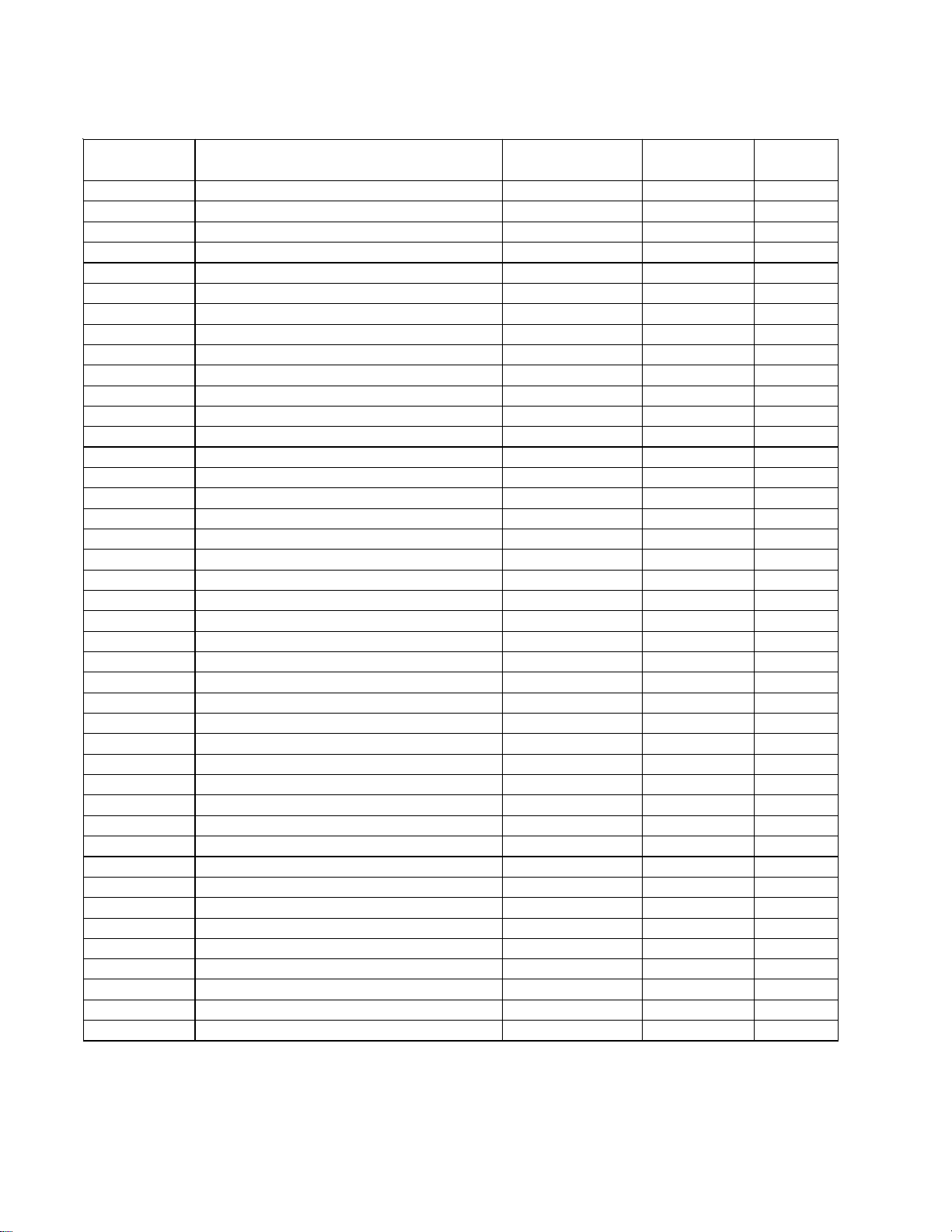

MAIN PART LIST (CONTINUED)

Item

Description Vendor Part

®®®®

Qty. Note

Model 2150 Amplifier (see Figure 3)

Bose

Number

1 Heatsink, 2U, CV 720069.31 262092 1

2 Insulator, Aluminum Oxide, TO-220 3299.0005 262100 4

3 Nut, 4-40, Hex, Kep, STZ 5222.0001 262116 1 4

4 Amplifier PCB Assembly 9000.0435.03 262081 1 2

5 Cover, Shield, Amp, CV (top) 700507 262090 1

6 Chassis, Shield, Amp, CV (bottom) 700508 262091 1

7 Signal Processor PCB Assembly 9000.0447.03 262087 1 2

8 Screw, TF, SEMS, 4-40x3/8, HWH,

ST, BZ

9 Screw, TF, SEMS, 4-40x1/2, HWH,

ST, BZ

Number

5112.0034 262111 48 4

5112.0031 262110 4 4

Part

Number

Figure 3. Model 2150 Amplifier Module Exploded View

11

Page 12

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Input Module Assembly

Resistors

Bose

Designator

R52 332k, MF, 1/4W, 1% 1226.3323 183000 4

R53 332k, MF, 1/4W, 1% 1226.3323 183000 4

R54 332k, MF, 1/4W, 1% 1226.3323 183000 4

R55 332k, MF, 1/4W, 1% 1226.3323 183000 4

R56 120 Ohm, CF, 1/4W, 5% 1224.0121 182995 4

R57 10k, CF, 1/4W, 5% 1224.0103 182789 4

R58 10k, CF, 1/4W, 5% 1224.0103 182789 4

R59 120k, CF, 1/4W, 5% 1224.0124 182996 4

R60 332k, MF, 1/4W, 1% 1226.3323 183000 4

R61 10k, CF, 1/4W, 5% 1224.0103 182789 4

R62 332k, MF, 1/4W, 1% 1226.3323 183000 4

R63 330 Ohm, CF, 1/4W, 5% 1224.0331 182998 4

R64 10k, CF, 1/4W, 5% 1224.0103 182789 4

R65 30k, CF, 1/4W, 5% 1224.0303 182852 4

R66 51 Ohm, CF, 1/4W, 5% 1224.0510 4

R69 10k, CF, 1/4W, 5% 1224.0103 182789 4

R70 10k, CF, 1/4W, 5% 1224.0103 182789 4

R72 100k, CF, 1/4W, 5% 1224.0104 182790 4

R73 47k, CF, 1/4W, 5% 1224.0473 182928 4

R74 47k, CF, 1/4W, 5% 1224.0473 182928 4

R75 47k, CF, 1/4W, 5% 1224.0473 182928 4

R76 10k, CF, 1/4W, 5% 1224.0103 182789 4

R77 10k, CF, 1/4W, 5% 1224.0103 182789 4

R78 47k, CF, 1/4W, 5% 1224.0473 182928 4

R79 100k, CF, 1/4W, 5% 1224.0104 182790 4

R80 47k, CF, 1/4W, 5% 1224.0473 182928 4

R81 47k, CF, 1/4W, 5% 1224.0473 182928 4

R82 47k, CF, 1/4W, 5% 1224.0473 182928 4

R83 47k, CF, 1/4W, 5% 1224.0473 182928 4

R84 300 Ohm, CF, 1/4W, 5% 1224.0301 182997 4

R85 100 Ohm, CF, 1/4W, 5% 1224.0101 182994 4

R86 390 Ohm, CF, 1/4W, 5% 1224.0391 182951 4

R87 300 Ohm, CF, 1/4W, 5% 1224.0301 182997 4

R88 100 Ohm, CF, 1/4W, 5% 1224.0101 182994 4

R89 390 Ohm, CF, 1/4W, 5% 1224.0391 182951 4

Number

Part

Number

12

Page 13

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Input Module Assembly

Designator

Capacitors

Bose

Number

Part

Number

C37 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C38 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C39 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C40 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C41 3300pF, Cer Disc, 100V, 10% 201-00133-00 183883 4

C42 3300pF, Cer Disc, 100V, 10% 201-00133-00 183883 4

C43 220uF, AE, RDL, 16V, 20% 205-00017-00 182993 4

C44 .1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C45 .1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C46 .1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C47 .1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C57 .01uF, CRML, Rdl, 100V, +80/-20% 201-00068-00 182780 4

C58 .01uF, CRML, Rdl, 100V, +80/-20% 201-00068-00 182780 4

C59 .001uF, PE, RDL, 100V, 10% 2458.0102 182839 4

C60 .01uF, CRML, Rdl, 100V, +80/-20% 201-00068-00 182780 4

C61 .01uF, CRML, Rdl, 100V, +80/-20% 201-00068-00 182780 4

C62 .001uF, PE, RDL, 100V, 10% 2458.0102 182839 4

Diodes

Designator

D1 1N4004, 400V 3100.0017 182811

D2 1N4148 3100.0004 182868

D3 1N4148 3100.0004 182868

D4 1N4004, 400V 3100.0017 182811

D5 1N4004, 400V 3100.0017 182811

D6 1N4148 3100.0004 182868

D7 1N4148 3100.0004 182868

D8 1N4148 3100.0004 182868

D9 1N4148 3100.0004 182868

D10 1N4148 3100.0004 182868

D15 Zener, 1N4764A, 18V, 1W 320-30037-02 183003

D16 1N4148 3100.0004 182868

D17 1N4148 3100.0004 182868

D18 Zener, 1N4764A, 18V, 1W 320-30037-02 183003

D20 1N4148 3100.0004 182868

D21 1N4148 3100.0004 182868

D22 1N4004, 400V 3100.0017 182811

D23 LED, Bi-Level, GRN/GRN 320-40010-01 182913

D24 1N4148 3100.0004 182868

D25 1N4148 3100.0004 182868

D26 1N4148 3100.0004 182868

D27 1N4148 3100.0004 182868

D28 1N4148 3100.0004 182868

D29 1N4148 3100.0004 182868

D30 1N4148 3100.0004 182868

D31 1N4148 3100.0004 182868

Number

Number

13

Page 14

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Input Module Assembly

Transistors

Part

Number

Designator

Bose

Number

Q1 NPN, MPSA06, TO-92 3200.0026 182874

Q2 PNP, MPSA56, TO-92 3200. 0003 182875

Q3 PNP, MPSA56, TO-92 3200. 0003 182875

Designator

Integrated Circuits

Number

Number

U1 Balanced Line Receiver, SSM2141 3510.2141 183005

U2 Balanced Line Receiver, SSM2141 3510.2141 183005

U3 OP-AMP W/Switch, NJM2120L 330-30062-01 183004

U4 OP-AMP W/Switch, NJM2120L 330-30062-01 183004

U5 OP-AMP W/Switch, NJM2120L 330-30062-01 183004

U6 OP-AMP W/Switch, NJM2120L 330-30062-01 183004

U7 OP-AMP, Dual, NJM072, DIP 3410. 0004 262124

Designator

Miscellaneous

Number

Number

SW1 Switch, Slide, DPTT, Right Angle 4340.0018 183002

S2 Switch, Slide, DPDT 318-40004-00 183001

P1 Jack, XLR/TRS, Right Angle 4250.0010 262125 4

P2 Phone Jack, ¼”, PC Mount 109-20002-01 182985

P3 Phone Jack, ¼”, PC Mount 109-20002-01 182985

P4 Jack, XLR/TRS, Right Angle 4250.0010 262125 4

J1 Hdr, 20 Position, Dual Row, .1 CTR 160-30051-10 182988

J2 Hdr, 4 Pos, Rt Angle, Blind Mate 160-30066-04 182991

J3 Hdr, 2 Pos, .1 CTR, Lock, ST Post 4205.0041 182921

J4 Hdr, 90 Deg, Closed End, 3 Pin 160-30064-03 182990 4

J5 Hdr, 90 Deg, Closed End, 3 Pin 160-30064-03 182990 4

J6 Hdr, 12 Pin, .098 Ctr, Shroud 160-30046-12 182987

J7 Hdr, 12 Pin, .098 Ctr, Shroud 160-30046-12 182987

JB1 Hdr, 6 Pos, Dual Row, .1 CTR, Gold 160-30054-03 182989

JB2 Hdr, 6 Pos, Dual Row, .1 CTR, Gold 160-30054-03 182989

- Conn, Mini-Link, .10”

160-20007-00 182986 Qty. 4

(used with JB1 and JB2)

- Screw, TF, 4-20x5/16, PHP, ST, BZ 5147.3202 4

14

Page 15

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Barrier PCB Assembly (p art of Input Module Assembly)

Bose

Designator

E1 Harness, Conn, 2 Position, 22 AWG,

3.5 in.

E2 Harness, Conn, 2 Position, 22 AWG,

3.5 in.

J2 Terminal Block, 2 Position, .15” CTR,

Angled

- Standoff, .25 OD, 6-32x.125, SWG,

BRS

- Standoff, Clinch, Keyhole, .25H 5533.0031 262123 4, Qty. 4

Number

550-10083-01 262121 4

550-10083-01 262121 4

101-00112-02 182967 4

118-80031-01 182828 4, Qty. 2

Part

Number

15

Page 16

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Amplifier PCB Assembly (board p art number 6000.0435)

Resistors

Bose

Designator

RT600 Thermistor, PTC, 2.2k 1200.0001 262126

R600 2. 7k , CF, 1/8W , 5% 1124.0272 4

R601 10 Ohm, MF, 1/4W, 5% 1204.0100 182937 4

R602 100k, MF, 1/8W, 1% 1126.1003 4

R603 100k, MF, 1/8W, 1% 1126.1003 4

R604 1. 00 MEG, MF, 1/8W, 1% 1126.1004 4

R605 100k, MF, 1/8W, 1% 1126.1003 4

R606 100k, MF, 1/8W, 1% 1126.1003 4

R607 1. 00 MEG, MF, 1/8W, 1% 1126.1004 4

R608 10.0k, MF, 1/8W, 1% 1126.1002 4

R609 10.0k, MF, 1/8W, 1% 1126.1002 4

R612 10.0k, MF, 1/8W, 1% 1126.1002 4

R613 10.0k, MF, 1/8W, 1% 1126.1002 4

R614 15.4k, MF, 1/8W, 1% 1126.1542 4

R615 15.4k, MF, 1/8W, 1% 1126.1542 4

R616 100k, MF, 1/8W, 1% 1126.1003 4

R617 100k, MF, 1/8W, 1% 1126.1003 4

R618 0.01 Ohm, WW, 2W, 1% 1536.0107 262127

R619 0.01 Ohm, WW, 2W, 1% 1536.0107 262127

R620 0.01 Ohm, WW, 2W, 1% 1536.0107 262127

R621 0.01 Ohm, WW, 2W, 1% 1536.0107 262127

R622 100k, MF, 1/8W, 1% 1126.1003 4

R623 100k, MF, 1/8W, 1% 1126.1003 4

R624 4.7 Ohm, MF, Fuse, 1/4W, 5% 1204.0479 182808 3

R625 4.7 Ohm, MF, Fuse, 1/4W, 5% 1204.0479 182808 3

R626 4.7 Ohm, MF, Fuse, 1/4W, 5% 1204.0479 182808 3

R627 4.7 Ohm, MF, Fuse, 1/4W, 5% 1204.0479 182808 3

R628 1. 00 MEG, MF, 1/8W, 1% 1126.1004 4

R629 1. 00 MEG, MF, 1/8W, 1% 1126.1004 4

R634 29.4k, MF, 1/8W, 1% 1126.2942 4

R639 1k, MOF, 1W, 5% 1444.0102 262142

R640 1k, MOF, 1W, 5% 1444.0102 262142

R641 27 Ohm, MOF, 2W, 5% 1544. 0270 262298

R642 27 Ohm, MOF, 2W, 5% 1544. 0270 262298

R643 10 Ohm, MF, 1/4W, 5% 1204.0100 182937 4

R644 10 Ohm, MF, 1/4W, 5% 1204.0100 182937 4

R645 10.0k, MF, 1/8W, 1% 1126.1002 4

R646 .02 Ohm, WW, 5W, 5% 1734.0207 182935

R647 .02 Ohm, WW, 5W, 5% 1734.0207 182935

R648 29.4k, MF, 1/8W, 1% 1126.2942 4

R649 10 Ohm, MF, 1/4W, 5% 1204.0100 182937 4

Number

Part

Number

16

Page 17

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Amplifier PCB Assembly (board p art number 6000.0435)

Resistors (continued)

Bose

Designator

R650 10 Ohm, MF, 1/4W, 5% 1204.0100 182937 4

R651 0 Ohm, 1/8W 1124.0000 4

R652 0 Ohm, 1/8W 1124.0000 4

R653 10 Ohm, MF, 1/4W, 5% 1204.0100 182937 4

R654 10.0k, MF, 1/8W, 1% 1126.1002 4

R655 5.11k, MF, 1/8W, 1% 1126.5111 4

R656 51. 1 Ohm, MF, 1/8W, 1% 1126.5119 4

R657 0 Ohm, 1/8W 1124.0000 4

R658 0 Ohm, 1/8W 1124.0000 4

R659 0 Ohm, 1/8W 1124.0000 4

Designator

C601 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C602 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C603 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C604 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761

C605 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C606 22uF, AE, RDL, LOW Z, 63V, 20% 2935.0226 4

C607 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C608 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C609 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C610 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C611 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C612 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C613 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C614 . 47uF, MPE, 50V, 5% 2452.0474 4

C615 . 1uF, MPE, 50V, 5% 2452.0104 4

C616 . 1uF, MPE, 50V, 5% 2452.0104 4

C617 10uF, AE, RDL, 35V, 20% 2930.0106 4

C618 . 47uF, MPE, 50V, 5% 2452.0474 4

C619 . 47uF, CRML, Z5U, 50V, 5mm, 20% 2175.0474 4

C620 . 47uF, CRML, Z5U, 50V, 5mm, 20% 2175.0474 4

C621 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C622 . 47uF, CRML, Z5U, 50V, 5mm, 20% 2175.0474 4

C623 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C624 . 47uF, CRML, Z5U, 50V, 5mm, 20% 2175.0474 4

C625 . 47uF, CRML, Z5U, 50V, 5mm, 20% 2175.0474 4

C626 100uF, AE, RDL, 25V, 20% 2930.0107 4

C627 . 22uF, MPE, 50V, 5% 2452.0224 4

C628 . 22uF, MPE, 50V, 5% 2452.0224 4

C629 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761

Capacitors

Number

Number

Part

Number

Number

17

Page 18

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Amplifier PCB Assembly (board p art number 6000.0435)

Capacitors (continued)

Bose

Designator

C630 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C631 100uF, AE, RDL, 100V, 20% 2936.0107 4

C632 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C633 100uF, AE, RDL, 100V, 20% 2936.0107 4

C634 100uF, AE, RDL, 100V, 20% 2936.0107 4

C635 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C636 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C637 100uF, AE, RDL, 100V, 20% 2936.0107 4

C638 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C641 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C642 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C645 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C646 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C651 . 1uF, MPE, 50V, 5% 2452. 0104 4

C652 . 1uF, MP, 250VAC, UL/CSA 2462.1104 182846 4

C653 . 1uF, MP, 250VAC, UL/CSA 2462.1104 182846 4

C654 . 1uF, MPE, 50V, 5% 2452.0104 4

C655 18pF, Cer Disc, NPO, 100V, 5% 2174. 0180 4

C656 18pF, Cer Disc, NPO, 100V, 5% 2174. 0180 4

C658 . 33uF, MPE, BOX, 100V, 5% 2452.2334 4

C659 . 33uF, MPE, BOX, 100V, 5% 2452.2334 4

C660 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C661 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C662 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C663 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C664 . 01uF, MPE, BOX, 100V, 5% 2452.2103 4

C665 . 01uF, MPE, BOX, 100V, 5% 2452.2103 4

C666 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C667 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C668 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C669 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C670 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C671 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C672 . 47uF, CRML, Z5U, 50V, 5mm, 20% 2175.0474 4

C673 100uF, AE, RDL, LOW Z, 25V, 20% 2392.0107 4

C674 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C675 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C676 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C677 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C678 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C679 . 1uF, CRML, X7R, 100V, 5mm, 20% 2175.0104 199761 4

C680 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

Number

Part

Number

18

Page 19

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Amplifier PCB Assembly (board p art number 6000.0435)

Inductors

Part

Number

Designator

Bose

Number

L600 330uH, .54A, RL622-331K 4500.0029 262128

L610 11uH, 9A, Filter 4500.0032 262129

L611 Jumper, 18 AWG, .5 inch, Insulated 401-30015-01 262130

L620 11uH, 9A, Filter 4500.0032 262129

L621 Jumper, 18 AWG, .5 inch, Insulated 401-30015-01 262130

Designator

Diodes

Number

Number

D600 1N4002 3100.0005 262192

D601 1N4002 3100.0005 262192

D602 1N5263B, Zener, 56V, .5W, 5% 3110.3630 262131

D603 MUR120 3100.0001 262132

D610 MUR120 3100.0001 262132

D611 MUR120 3100.0001 262132

D620 MUR120 3100.0001 262132

D621 MUR120 3100.0001 262132

Designator

Transistors

Number

Number

Q600 NPN, 2SC4793, TO-220FP 3200.0080 262133

Q601 PNP, 2N4403, TO-92 3200.0002 262134

Q610 N-CH MOSFET, STW34NB20 247 3210.0017 262135

Q611 N-CH MOSFET, STW34NB20 247 3210.0017 262135

Q620 N-CH MOSFET, STW34NB20 247 3210.0017 262135

Q621 N-CH MOSFET, STW34NB20 247 3210.0017 262135

Integrated Circuits

Designator

Number

Number

U600 Volt Reg, Switcher, LM2594N 3430.0009 262136

U602 Volt Reg, L7805CP, ISOWATT220 3430.0007 262137

U603 O P- AMP, Dual, NJM072, DIP 3410.0004 262124

U604 O P- AMP, Dual, NJM072, DIP 3410.0004 262124

U605 DRI VER, DIGITAL AMPLIFIER,

3440.0005 262138

TAO103A

19

Page 20

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Amplifier PCB Assembly (board p art number 6000.0435)

Miscellaneous

Bose

Designator

J601 Cable, I DC, PCB/PLG, 10 Cond, 4 in 4148.0018 262139

J602 Cable, I DC, PCB/PLG, 10 Cond, 4 in 4148.0018 262139

P600 Conn, Plug, HSG, 2.13mm, 4 Pin 4206.0004 262140

WL610 Conn, Tab, .250, Right Angle, PC Mnt 4200.0019 262141

WL611 Conn, Tab, .250, Right Angle, PC Mnt 4200.0019 262141

WL620 Conn, Tab, .250, Right Angle, PC Mnt 4200.0019 262141

WL621 Conn, Tab, .250, Right Angle, PC Mnt 4200.0019 262141

- Conn, Hdr, 1x8x.100, Female, 8 Pin

(sockets for U605)

- Conn, Hdr, 1x11x.100, Female, 11 Pin

(sockets for U605)

- Conn, Terminal, 2.13mm, 4 Pin

(terminals for P600)

- Heatsink, TO-220, 1.18H, Vert, PC

Mnt (Used on U602)

- Screw, MA, PHP, 4-40x3/8, BLK

(Used on U602)

- Nut, 4-40, HEX, KEP, STZ

(Used on U602)

- Grommet, 1/4ID x 9/16OD 5820.0007 262145 Qty. 1

Number

4205.0070 262320 Qty. 2

4205.0071 262143 Qty. 2

4211.0002 262144 Qty. 4

5630.0006 262155 Qty. 1

151-20002-00 262156 Qty. 1

5222.0001 262154 Qty. 1

Part

Number

20

Page 21

ELECTRICAL PART LIST

Reference

Description Bose® Part

Vendor Part

Note

Amplifier PCB Assembly (board p art number 8005.0587)

Resistors

Designator

R602 93. 1K, MF, 1/8W, 1% - 1126.9312 4

R603 93. 1K, MF, 1/8W, 1% - 1126.9312 4

R604 1. 00 MEG, MF, 1/8W, 1% - 1126.1004 4

R605 100K, MF, 1/8W, 1% - 1126.1003 4

R606 100K, MF, 1/8W, 1% - 1126.1003 4

R607 1. 00 MEG, MF, 1/8W, 1% - 1126.1004 4

R608 10. 0K, MF, 1/8W, 1% - 1126.1002 4

R609 10. 0K, MF, 1/8W, 1% - 1126.1002 4

R612 10. 0K, MF, 1/8W, 1% - 1126.1002 4

R613 10. 0K, MF, 1/8W, 1% - 1126.1002 4

R616 1. 00 MEG, MF, 1/8W, 1% - 1126.1004 4

R617 1. 00 MEG, MF, 1/8W, 1% - 1126.1004 4

R618 0.01 OHM, WW, 3W, 1% - L.1536.0107 4

R619 0.01 OHM, WW, 3W, 1% - L.1536.0107 4

R620 0.01 OHM, WW, 3W, 1% - L.1536.0107 4

R621 0.01 OHM, WW, 3W, 1% - L.1536.0107 4

R622 499K, MF, 1/8W, 1% - 1126.4993 4

R623 499K, MF, 1/8W, 1% - 1126.4993 4

R624 15 OHM, MOF, 1W, 5% - L.1444.0150 4

R625 15 OHM, MOF, 1W, 5% - L.1444.0150 4

R626 15 OHM, MOF, 1W, 5% - L.1444.0150 4

R627 15 OHM, MOF, 1W, 5% - L.1444.0150 4

R628 499K, MF, 1/8W, 1% - 1126.4993 4

R629 499K, MF, 1/8W, 1% - 1126.4993 4

R634 29. 4K, MF, 1/8W, 1% - 1126.2942 4

R639 0 OHM, 1/4W - 1224.0000 4

R640 0 OHM, 1/4W - 1224.0000 4

R641 27 OHM, MOF, 2W, 5% 262998 1544.0270

R642 27 OHM, MOF, 2W, 5% 262998 1544.0270

R643 10 OHM, MF, FUSE, 1/4W, 5% 182937 1204.0100 3

R644 10 OHM, MF, FUSE, 1/4W, 5% 182937 1204.0100 3

R645 10. 0K, MF, 1/8W, 1% - 1126.1002 4

R646 0.02OHM, WW, 5W, 5% 182935 1734.0207

R647 0.02OHM, WW, 5W, 5% 182935 1734.0207

R648 29. 4K, MF, 1/8W, 1% - 1126.2942 4

Number

Number

21

Page 22

ELECTRICAL PART LIST

Reference

Description Bose® Part

Vendor Part

Note

Reference

Description Bose Part

Vendor Part

Note

Amplifier PCB Assembly (board p art number 8005.0587)

Resistors (continued)

Designator

R649 10 O HM, MF, FUSE, 1/4W, 5% 182937 1204.0100 3

R650 10 O HM, MF, FUSE, 1/4W, 5% 182937 1204.0100 3

R651 0 OHM, 1/8W - 1124.0000 4

R652 0 OHM, 1/8W - 1124.0000 4

R653 10 O HM, MF, FUSE, 1/4W, 5% 182937 1204.0100 3

R654 10. 0K, MF, 1/8W, 1% - 1126.1002 4

R655 5. 11K, MF, 1/8W, 1% - 1126.5111 4

R656 51.1OHM, MF, 1/8W, 1% - 1126.5119 4

R660 27 O HM, MOF, 2W, 5% - 1544.0270 4

R661 27 O HM, MOF, 2W, 5% - 1544.0270 4

R666 16 O HM, MOF, 1W, 5% - L.1444.0160 4

R667 16 O HM, MOF, 1W, 5% - L.1444.0160 4

Number

Number

Capacitors

Designator

C600 220pF, CD, 10%, 1000V - L.201-0 0018-00

C601 0. 01uF, CD, 20%, 500V - L.201-00034-00

C602 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C603 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C605 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C607 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C608 0. 01uF, CD, 20%, 500V - L.201-00034-00

C609 0. 01uF, CD, 20%, 500V - L.201-00034-00

C610 0. 01uF, CD, 20%, 500V - L.201-00034-00

C611 0. 01uF, CD, 20%, 500V - L.201-00034-00

C612 0. 01uF, CD, 20%, 500V - L.201-00034-00

C613 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C614 0. 47uF, MPE, 5%, 50V - L.2452.0474 4

C615 100nF, MPE, 5%, 50V - L.2452. 0104 4

C616 100nF, MPE, 5%, 50V - L.2452. 0104 4

C617 10uF, AE, RDL, 20%, 35V - 2930.0106 4

C618 0. 47uF, MPE, 5%, 50V - L.2452.0474 4

C619 0. 47uF, CRML, 20%, Z5U, 50V - L. 2175. 0474 4

Number

Number

4

4

4

4

4

4

4

4

4

4

4

22

Page 23

ELECTRICAL PART LIST

Reference

Description Bose® Part

Vendor Part

Note

Amplifier PCB Assembly (board p art number 8005.0587)

Capacitors (continued)

Designator

C620 0. 47uF, CRML, 20%, Z5U, 50V - L.2175.0474 4

C621 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C622 0. 47uF, CRML, 20%, Z5U, 50V - L.2175.0474 4

C623 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C624 0. 47uF, CRML, 20%, Z5U, 50V - L.2175.0474 4

C625 0. 47uF, CRML, 20%, Z5U, 50V - L.2175.0474 4

C626 100uF, AE, RDL, 20%, 25V - 2930.0107 4

C627 220nF, MPE, 5%, 50V - L.2452. 0224 4

C628 220nF, MPE, 5%, 50V - L.2452. 0224 4

C630 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C631 100uF, AE, RDL, 20%, 100V - L.2936.0107 4

C632 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C633 100uF, AE, RDL, 20%, 100V - L.2936.0107 4

C634 100uF, AE, RDL, 20%, 100V - L.2936.0107 4

C635 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C636 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C637 100uF, AE, RDL, 20%, 100V - L.2936.0107 4

C638 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C641 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C642 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C645 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C646 0. 01uF, CD, 20%, 500V - L.201-00034-00

C647 220pF, CD, 10%, 1000V - L.201-00018-00

C648 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C649 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C651 100nF, MPE, 5%, 50V - L.2452. 0104 4

C652 0. 1uF, PP, BOX, 10%, 250V - 2593.0104 4

C653 0. 1uF, PP, BOX, 10%, 250V - 2593.0104 4

C654 100nF, MPE, 5%, 50V - L.2452. 0104 4

C657 22uF, AE, 20%, 160V - 2982.0226 4

C658 0. 68uF MPP, HF, 5%, 160V - L.2574.0684 4

C659 0. 68uF MPP, HF, 5%, 160V - L.2574.0684 4

C660 0. 22uF, MPP, HF, 5%, 250V - L.2594.0224 4

C661 0. 22uF, MPP, HF, 5%, 250V - L.2594.0224 4

C662 0. 01uF, CD, 20%, 500V - L.201-00034-00

C663 0. 01uF, CD, 20%, 500V - L.201-00034-00

C664 0. 01uF, CD, 20%, 500V - L.201-00034-00

Number

Number

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

23

Page 24

ELECTRICAL PART LIST

Reference

Description Bose® Part

Vendor Part

Note

Reference

Description Bose Part

Vendor Part

Note

Amplifier PCB Assembly (board p art number 8005.0587)

Capacitors (continued)

Designator

C665 0. 01uF, CD, 20%, 500V - L.201-00034-00

C666 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C667 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C668 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C669 0. 01uF, CD, 20%, 500V - L.201-00034-00

C670 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C671 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C672 0. 47uF, CRML, 20%, Z5U, 50V - L. 2175. 0474 4

C674 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C675 0. 01uF, CD, 20%, 500V - L.201-00034-00

C676 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C677 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C678 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C679 0. 1uF, CRML, 20%, X7R, 100V - L.2175.0104

C680 100pF, CD, 5%, NPO, 100V - 2174.0101 4

C681 22uF, AE, 20%, 160V - 2982.0226 4

C683 0. 01uF, CD, 20%, 500V - L.201-00034-00

C684 0. 01uF, CD, 20%, 500V - L.201-00034-00

C685 0. 18uF, MPP, HF, 5%, 250V - L.2594.0184 4

C686 0. 18uF, MPP, HF, 5%, 250V - L.2594.0184 4

Number

Number

4

4

4

4

4

4

4

4

4

4

4

Inductors

Designator

L610 INDUCTOR, FILTER, 11uH, 9A - L.4500.0032 4

L611 INDUCTOR, IRON, PWDR, 7.8uH,

10A

L620 INDUCTOR, FILTER, 11uH, 9A - L.4500.0032 4

L621 INDUCTOR, IRON, PWDR, 7.8uH,

10A

FB600 FERRITE BEAD, 133 ohm at 100mHz - L.4510.0003 4

Number

- 4500.0054 4

- 4500.0054 4

Number

24

Page 25

ELECTRICAL PART LIST

Reference

Description Bose® Part

Vendor Part

Note

Reference

Description Bose Part

Vendor Part

Note

Reference

Description Bose Part

Vendor Part

Note

Reference

Description Bose Part

Vendor Part

Note

Amplifier PCB Assembly (board p art number 8005.0587)

Diodes

Designator

D600 1N4002 262192 3100.0005

D601 1N4002 262192 3100.0005

D610 SWITCHING, MUR120, AXL - L.3100.0001 4

D611 SWITCHING, MUR120, AXL - L.3100.0001 4

D614 SWITCHING, MUR120, AXL - L.3100.0001 4

D615 SWITCHING, MUR120, AXL - L.3100.0001 4

D620 SWITCHING, MUR120, AXL - L.3100.0001 4

D621 SWITCHING, MUR120, AXL - L.3100.0001 4

D624 SWITCHING, MUR120, AXL - L.3100.0001 4

D625 SWITCHING, MUR120, AXL - L.3100.0001 4

Designator

Q601 PNP, 2N4403TO-92 262134 3200.0002

Q610 N-CH FET, STW34NB20, TO-247 - L.3210.0017 4

Q611 N-CH FET, STW34NB20, TO-247 - L.3210.0017 4

Q620 N-CH FET, STW34NB20, TO-247 - L.3210.0017 4

Q621 N-CH FET, STW34NB20, TO-247 - L.3210.0017 4

Transistors

Integrated Circuits

Number

Number

Number

Number

Designator

U602 VOLT REG, L7805CP, ISOWATT 220 262137 3430.0007

U603 O P AMP, DUAL, X072, DIP 262124 3410.0004

U604 O P AMP, DUAL, X072, DIP 262124 3410.0004

Number

Number

Amplifier Driver PCB Assembly (used with amplifier board p art number 8005.0587)

Designator

U901/U902 AMPLIFIER DRIVER SET, 300W,

TRIPATH TK2350

Number

317790-001S

Number

- 3

25

Page 26

ELECTRICAL PART LIST

Reference

Description Bose® Part

Vendor Part

Note

Amplifier PCB Assembly (board p art number 8005.0587)

Miscellaneous

Designator

H1 GROMMET, 1/4 ID x 9/16 OD - 5820.0007 4

H2 GROMMET, 1/4 ID x 9/16 OD - 5820.0007 4

H3 GROMMET, 1/4 ID x 9/16 OD - 5820.0007 4

H4 GROMMET, 1/4 ID x 9/16 OD - 5820.0007 4

J601 CABLE, IDC, PCB/PLG 10, CON, 4 IN

J602 CABLE, IDC, PCB/PLG 10, CON, 4 IN

P600 CONN, PLUG, HSG, 2.13mm, 4 PIN 262140 4206.0004

RT600 THERMISTOR, PTC, 2.2k at 60 DEG

C

WL610 CONN, TAB, 0.25", RTANG, PC MNT 262141 L.4200.0019

WL611 CONN, TAB, 0.25", RTANG, PC MNT 262141 L.4200.0019

WL620 CONN, TAB, 0.25", RTANG, PC MNT 262141 L.4200.0019

WL621 CONN, TAB, 0.25", RTANG, PC MNT 262141 L.4200.0019

- CONN, HDR, 0.1" CTR, FEM, 8-SIP

(sockets for U605)

- CONN, HDR, 0.1" CTR, FEM, 11-SIP

(sockets for U605)

- CONN, TERM, 2.13mm, 14-20 AWG,

FEM (terminals for P600)

Number

262139 4148.0018

262139 4148.0018

262126 L.1200.0001

- L.4205.0070 Qty. 2

- L.4205.0071 Qty. 2

- L.4211.0002 Qty. 4

Number

26

Page 27

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Power Supply PCB Assembly

Resistors

Part

Number

Designator

Bose

Number

R400 4. 7k , MOF, 2W, 5% 1544.0472 262299

R401 2. 2k , MOF, 1W, 5% 1444.0222 262296

R402 4. 7k , MOF, 2W, 5% 1544.0472 262299

R403 2. 2k , MOF, 1W, 5% 1444.0222 262296

Designator

C400 . 1uF, MPE, 250V, 10% 2462.0104 4

C401 . 1uF, MPE, 250V, 10% 2462.0104 4

C402 . 1uF, MPE, 250V, 10% 2462.0104 4

C403 . 1uF, MPE, 250V, 10% 2462.0104 4

C404 6800uF, AE, SNAP, 63V, 30x40 2940.0688 262861

C405 2200uF, AE, RDL, 35V, 20% 2933.0228 4

C406 6800uF, AE, SNAP, 63V, 30x40 2940.0688 262861

C407 2200uF, AE, RDL, 35V, 20% 2933.0228 4

C408 . 1uF, MPE, BOX, 100V, 5% 2452.2104 4

C409 . 1uF, MPE, BOX, 100V, 5% 2452.2104 4

C410 . 1uF, MPE, BOX, 100V, 5% 2452.2104 4

C411 . 1uF, MPE, BOX, 100V, 5% 2452.2104 4

C414 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C415 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C416 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C417 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C418 100uF, AE, RDL, 25V, 20% 2930.0107 4

C419 100uF, AE, RDL, 25V, 20% 2930.0107 4

C420 10uF, AE, RDL, 35V, 20% 2930.0106 4

C422 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C423 100uF, AE, RDL, 25V, 20% 2930.0107 4

C425 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C444 100uF, AE, RDL, 25V, 20% 2930.0107 4

C445 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C446 . 47uF, CRML, Z5U, 5mm, 20% 2175.0474 4

C447 100uF, AE, RDL, 25V, 20% 2930.0107 4

Capacitors

Number

Number

27

Page 28

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Power Supply PCB Assembly

Diodes

Bose

Designator

D400 1N4004, 400V 3100.0017 182811 3

D401 1N4004, 400V 3100.0017 182811 3

D402 Rect if ier , Bridge, 400V, 25A 3100.0025 182866 3

D403 1N4004, 400V 3100.0017 182811 3

D404 1N4004, 400V 3100.0017 182811 3

D405 1N4004, 400V 3100.0017 182811

D406 1N4004, 400V 3100.0017 182811

D407 1N4004, 400V 3100.0017 182811

D408 1N4004, 400V 3100.0017 182811

D409 1N4004, 400V 3100.0017 182811

D410 1N4004, 400V 3100.0017 182811

D411 1N4004, 400V 3100.0017 182811

D412 1N4004, 400V 3100.0017 182811

D413 1N4004, 400V 3100.0017 182811

D414 1N4004, 400V 3100.0017 182811

D415 1N4004, 400V 3100.0017 182811

Number

Part

Number

Integrated Circuits

Designator

U400 VO LT REG, +15V, NJM7815FA 3430.0005 262146

U401 VO LT REG, -15V, 7915 3430.0006 262147

U402 VO LT REG, -15V, 7915 3430.0006 262147

U403 VO LT REG, +15V, NJM7815FA 3430.0005 262146

U404 VO LT REG, +15V, NJM7815FA 3430.0005 262146

Number

Number

28

Page 29

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Power Supply PCB Assembly

Miscellaneous

Bose

Designator

WL400 Terminal, Quick-Connect, .250 TAB 4200.0017 262148

WL401 Terminal, Quick-Connect, .250 TAB 4200.0017 262148

WL402 Terminal, Quick-Connect, .250 TAB 4200.0017 262148

WL403 Terminal, Quick-Connect, .250 TAB 4200.0017 262148

WL404 Terminal, Quick-Connect, .250 TAB 4200.0017 262148

WL405 Terminal, Quick-Connect, .250 TAB 4200.0017 262148

P600 Conn, Hdr, Vertical, 2. 13mm, 4 Pin 4205.0064 262149

F400 10A, 125V, 5x20mm 4600.0001 262150 3

F401 10A, 125V, 5x20mm 4600.0001 262150 3

F402 2A, 250V, TL, 5x20mm 4600.0004 262151 3

F403 2A, 250V, TL, 5x20mm 4600.0004 262151 3

- Fuse Holder, Clip, 5x20mm

(Used on F400, F401, F402, F403)

- Cable, IDC, SKT/CONN, 20 COND,

6 in (install in J300)

- Nut, 4-40, HEX, KEP, STZ 5222.0001 262154 Qty. 5

- Heatsink, TO-220, 1.18H, Vert, PC

Mnt (Used with U400, U401, U402,

U403, U404)

- Heatsink, .75H, TO-3, Custom Hole

Used with D402

- Standoff, .25OD, 6-32x.187, SWG,

BRS (Used with D402)

- Screw, MA, PHP, 4-40x3/8, BLK

(Used on U400, U401, U402, U403,

U404)

- Screw, MA, PHP, 6-32X3/4, BLK

(Used on D402)

Number

4610.0011 262152 Qty. 8,

4148.0014 262153

5630.0006 262155 Qty. 4

5630.0009 199778 Qty. 1

118-80031-02 199749 Qty. 1

151-20002-00 262156 Qty. 5

151-20054-00 262157 Qty. 1

Part

Number

3

29

Page 30

ELECTRICAL PART LIST

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Switch PCB Assembly

Resistors

Designator

Bose

Number

Part

Number

R100 33k, MOF, 1W, 5% 1444.0333 262297 3

R101 33k, MOF, 1W, 5% 1444.0333 262297 3

Designator

C2 .01uF, Cer Disc, 250VAC, 10%,

UL/CSA

Capacitors

Number

Number

201-00035-00 3, 4

Designator

Diodes

Number

Number

D2 LED, T-1, WHT DIFF LENS, AMBER 3600.0029 262094

D3 LED, RECT, 2x5MM, YELLOW

3600.0025 262158

Standby LED

D101 1N4004, 400V 3100.0017 182811 3

Miscellaneous

Designator

- Connector, Terminal, PCMT, 1 Pos.

Mounting brackets for switch pc assy.

- Spacer, LED Standoff, .75 in.

LED standoff

30

Number

4227.0022 262159 Qty. 2

5500.0002 262160 Qty. 1

Number

Page 31

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

AC Input/Output PCB Assembly

Resistors

Part

Number

Designator

Bose

Number

R101 1k, CF, 1/8W, 5% 1124.0102 4

R102 18 Ohm, HM, CC, 1/2W, 5% 1354.0180 187934-

18R0

3

R103 8. 2 Ohm, CF, 1/2W, 5% 1324.0829 182857 3

Designator

C100 . 10uF, MP, 250VAC, UL/CSA 2462.1104 182846 3

C101 . 10uF, MP, 250VAC, UL/CSA 2462.1104 182846 3

Designator

Capacitors

Transistors

Number

Number

Number

Number

Q100 Triac, BTA41-700B, 40 Amp, 700V 3280.0005 262161 3

Integrated Circuits

Designator

Number

Number

U100 OPTO, LED/MOSFET, PS7341-1A 3610.0008 262162 3

Designator

Miscellaneous

Number

Number

J100 Conn, Hdr, .1 CTR, 2 Pin 4205.0001 262163

J101 Conn, Hdr, HZ, FEM, .2 in, 8 Pos.

4227.0027 262164 3

(Channel 2 speaker output)

J102 Conn, Hdr, HZ, FEM, .2 in, 8 Pos.

(Channel 1 speaker output)

4227.0027 262164 3

F100 8A, 250V, MDA 315-13003-00 262165 3

- Fuse Holder, Clip, .25 Dia, PC MNT

Clips for F100

- Heatsink, .75H, TO-3, Custom Hole

4610.0008 262166 Qty. 2,

3

5630.0009 199778 Qty. 1

Heatsink for Q100

- Screw, MA, PHP, 6-32x3/8, BLK

151-20052-00 262167 Qty. 1

Attach heatsink to Q100

- Standoff, .25OD, 6-32x.187, SWG,

BRS (Used on Q100)

118-80031-02 199749 Qty. 1

31

Page 32

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

AC Input/Output PCB Assembly

Miscellaneous (continued)

Bose

Designator

WL100 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL101 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL102 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL103 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL104 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL105 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL106 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL107 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL108 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL109 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL110 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL111 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL112 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL113 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL121 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL122 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL123 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL124 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL125 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL126 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL127 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL128 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL129 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL130 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL131 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL132 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL133 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL134 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL135 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL136 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL137 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

WL139 Terminal, Quick-Connect, .250 Tab 4200.0017 262148

Number

Part

Number

32

Page 33

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Interface PCB Assembly

Resistors

Bose

Designator

R801 10 Ohm, MF, Fuse, 1/4W, 5% 1204. 0100 182937 3

R802 121 O hm, MF, 1/8W, 1% 1126.1210 4

R803 121 O hm, MF, 1/8W, 1% 1126.1210 4

R804 1.02k, MF, 1/8W, 1% 1126.1021 4

R805 1. 02k, MF, 1/8W, 1% 1126.1021 4

R806 121 O hm, MF, 1/8W, 1% 1126.1210 4

R807 121 O hm, MF, 1/8W, 1% 1126.1210 4

R808 1.02k, MF, 1/8W, 1% 1126.1021 4

R809 1.02k, MF, 1/8W, 1% 1126.1021 4

R810 200 Ohm, MF, Fuse, 1/4W, 5% 1204.0201 182862 3

R811 100 Ohm, MF, Fuse, 1/4W , 5% 1204.0101 182806 3

R812 15k, CF, 1/4W, 5% 1224.0153 182848 4

R813 47k, CF, 1/8W, 5% 1124.0473 4

R814 10k, CF, 1/8W, 5% 1124.0103 4

R815 10k, CF, 1/8W, 5% 1124.0103 4

R816 51 O hm, CF, 1/8W, 5% 1124.0510 4

R817 270 O hm, CF, 1/8W, 5% 1124.0271 4

R818 68k, CF, 1/4W, 5% 1224.0683 4

R819 150k, CF, 1/8W, 5% 1124.0154 4

Number

Part

Number

Capacitors

Designator

C801 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C802 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C803 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C804 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C805 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C806 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C807 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C808 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C809 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C810 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C811 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C812 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C813 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C814 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C815 100uF, AE, RDL, 25V, 5mm, 20% 2932.0107.01 4

C816 . 1uF, MPE, 50V, 5% 2452.0104 4

C817 100uF, AE, RDL, 25V, 5mm, 20% 2932.0107.01 4

Number

Number

33

Page 34

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Reference

Description Vendor Part

Bose Part

Note

Interface PCB Assembly

Diodes

Bose

Designator

D801 1N4148 3100.0004 182868

D802 1N4148 3100.0004 182868

D803 1N4148 3100.0004 182868

D804 1N4148 3100.0004 182868

D805 1N4148 3100.0004 182868

D806 1N4148 3100.0004 182868

D807 1N4148 3100.0004 182868

Transistors

Designator

Number

Number

Part

Number

Number

Q801 PNP, 2N4403, TO-92 3200.0002 262134

Q802 NPN, 2N4401, TO-92 3200.0001 262168

Q803 PNP, 2N4403, TO-92 3200.0002 262134

Designator

Miscellaneous

Number

Number

J801 Conn, Hdr, Vert, Male, .2 in, 3 Pos 4227.0037 262169

J802 Conn, Hdr, Vert, Male, .2 in, 4 Pos 4227.0031 262170

J803 Conn, Hdr, Vert, Male, .2 in, 4 Pos 4227.0031 262170

J804 Conn, Hdr, Vert, Male, .2 in, 4 Pos 4227.0031 262170

P801 Cable, IDC, PCB/PLG, 26 Conductor,

4148.0016 262171

16 in

P802 Harness, Connector, 2 Pos, 22 AWG,

550-10083-01 262121

3.5 inch

S801 Switch, DIP, SPST, Vert Rocker, 8

4340.0031 262173

Pos

34

Page 35

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Digital Signal Processor (DSP) PCB Assembly

Resistors

Bose

Designator

RN500 22k, RES NET x8, 16 Pin, DIP, 2% 1095.1223 262174

R1 Pot, Trim, 50k, 6mm, PC Mnt 4410.0017 262175

R2 Pot, Trim, 50k, 6mm, PC Mnt 4410.0017 262175

R4 4.99k, MF, 1/8W, 1% 1126.4991 4

R5 4.99k, MF, 1/8W, 1% 1126.4991 4

R6 374k, MF, 1/8W, 1% 1126.3743 4

R425 10.0k, MF, 1/8W, 1% 1126.1002 4

R426 4.23k, MF, 1/8W, 1% 1126.4321 4

R427 10.0k, MF, 1/8W, 1% 1126.1002 4

R428 4.23k, MF, 1/8W, 1% 1126.4321 4

R429 10k, CF, 1/8W, 5% 1124.0103 4

R430 10k, CF, 1/8W, 5% 1124.0103 4

R431 10.0k, MF, 1/8W, 1% 1126.1002 4

R432 10k, CF, 1/8W, 5% 1124.0103 4

R433 10k, CF, 1/8W, 5% 1124.0103 4

R434 36.5k, MF, 1/8W, 1% 1126.3652 4

R435 16.5k, MF, 1/8W, 1% 1126.1652 4

R436 10k, CF, 1/8W, 5% 1124.0103 4

R437 100k, CF, 1/8W, 5% 1124.0104 4

R438 1. 5k , CF, 1/4W , 5% 1224.0152 4

R439 4.23k, MF, 1/8W, 1% 1126.4321 4

R440 1. 5k, MF, 1/8W, 1% 1126.1501 4

R441 1. 5k , CF, 1/4W , 5% 1224.0152 4

R442 100k, CF, 1/8W, 5% 1124.0104 4

R443 4.99k, MF, 1/8W, 1% 1126.4991 4

R444 36k, CF, 1/8W, 5% 1124.0363 4

R445 1. 5k , CF, 1/4W , 5% 1224.0152 4

R446 100k, MF, 1/8W, 1% 1126.1003 4

R447 20.0k, MF, 1/8W, 1% 1126.2002 4

R448 4.99k, MF, 1/8W, 1% 1126.4991 4

R449 100k, MF, 1/8W, 1% 1126.1003 4

R450 20.0k, MF, 1/8W, 1% 1126.2002 4

R451 36k, CF, 1/8W, 5% 1124.0363 4

R452 18k, CF, 1/8W, 5% 1124.0183 4

R453 1. 5k , CF, 1/4W , 5% 1224.0152 4

R454 47k, CF, 1/8W, 5% 1124.0473 4

R455 1k, CF, 1/8W, 5% 1124.0102 4

R456 10k, CF, 1/8W, 5% 1124.0103 4

R457 1. 5k , CF, 1/4W , 5% 1224.0152 4

R458 10k, CF, 1/8W, 5% 1124.0103 4

R459 10k, CF, 1/8W, 5% 1124.0103 4

R460 1. 5k , CF, 1/4W , 5% 1224.0152 4

R461 1k, CF, 1/8W, 5% 1124.0102 4

R462 100k, MF, 1/8W, 1% 1126.1003 4

R463 100k, MF, 1/8W, 1% 1126.1003 4

Number

Part

Number

35

Page 36

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Digital Signal Processor (DSP) PCB Assembly

Resistors (continued)

Bose

Designator

R464 10k, CF, 1/8W, 5% 1124.0103 4

R465 13.0k, MF, 1/8W, 1% 1126.1302 4

R466 4.99k, MF, 1/8W, 1% 1126.4991 4

R467 6.04k, MF, 1/8W, 1% 1126.6041 4

R468 47k, CF, 1/8W, 5% 1124.0473 4

R469 47k, CF, 1/8W, 5% 1124.0473 4

R472 22.6k, MF, 1/8W, 1% 1126.2262 4

R473 22.6k, MF, 1/8W, 1% 1126.2262 4

R474 10 Ohm, MF, Fuse, 1/4W, 5% 1204. 0100 182937 3

R476 4.23k, MF, 1/8W, 1% 1126.4321 4

R477 7. 5k , CF, 1/ 8W , 5% 1124.0752 4

R478 7. 5k , CF, 1/ 8W , 5% 1124.0752 4

R479 2.21k, MF, 1/8W, 1% 1126.2211 4

R481 100 O hm, CF, 1/8W, 5% 1124.0101 4

R483 7. 5k , CF, 1/ 8W , 5% 1124.0752 4

R484 2.21k, MF, 1/8W, 1% 1126.2211 4

R485 100 O hm, CF, 1/8W, 5% 1124.0101 4

R486 1. 5k, MF, 1/8W, 1% 1126.1501 4

R487 4.23k, MF, 1/8W, 1% 1126.4321 4

R488 7. 5k , CF, 1/ 8W , 5% 1124.0752 4

R489 1. 5k, MF, 1/8W, 1% 1126.1501 4

R490 0 Ohm, 1/8W 1124.0000 4

R491 0 Ohm, 1/8W 1124.0000 4

R500 100 O hm, CF, 1/8W, 5% 1124.0101 4

R501 100 O hm, CF, 1/8W, 5% 1124.0101 4

R502 10.0k, MF, 1/8W, 1% 1126.1002 4

R503 10.0k, MF, 1/8W, 1% 1126.1002 4

R504 10.0k, MF, 1/8W, 1% 1126.1002 4

R505 10.0k, MF, 1/8W, 1% 1126.1002 4

R506 100 O hm, CF, 1/8W, 5% 1124.0101 4

R507 100 O hm, CF, 1/8W, 5% 1124.0101 4

R508 10.0k, MF, 1/8W, 1% 1126.1002 4

R509 10.0k, MF, 1/8W, 1% 1126.1002 4

R511 10.0k, MF, 1/8W, 1% 1126.1002 4

R513 2.21k, MF, 1/8W, 1% 1126.2211 4

R514 10.0k, MF, 1/8W, 1% 1126.1002 4

R515 2.21k, MF, 1/8W, 1% 1126.2211 4

R516 47k, CF, 1/8W, 5% 1124.0473 4

R517 47k, CF, 1/8W, 5% 1124.0473 4

R518 2.21k, MF, 1/8W, 1% 1126.2211 4

R519 47k, CF, 1/8W, 5% 1124.0473 4

R520 2.21k, MF, 1/8W, 1% 1126.2211 4

R521 47k, CF, 1/8W, 5% 1124.0473 4

R522 2.21k, MF, 1/8W, 1% 1126.2211 4

Number

Part

Number

36

Page 37

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Digital Signal Processor (DSP) PCB Assembly

Resistors (continued)

Bose

Designator

R523 2.21k, MF, 1/8W, 1% 1126.2211 4

R524 1k, CF, 1/8W, 5% 1124.0102 4

R525 2.21k, MF, 1/8W, 1% 1126.2211 4

R526 2.21k, MF, 1/8W, 1% 1126.2211 4

R527 374k, MF, 1/8W, 1% 1126.3743 4

R528 1k, CF, 1/8W, 5% 1124.0102 4

R529 100k, CF, 1/8W, 5% 1124.0104 4

R531 20.0k, MF, 1/8W, 1% 1126.2002 4

R532 13.0k, MF, 1/8W, 1% 1126.1302 4

R533 100k, CF, 1/8W, 5% 1124.0104 4

R534 15.4k, MF, 1/8W, 1% 1126.1542 4

R535 13.0k, MF, 1/8W, 1% 1126.1302 4

R536 20.0k, MF, 1/8W, 1% 1126.2002 4

R537 20.0k, MF, 1/8W, 1% 1126.2002 4

R538 13.0k, MF, 1/8W, 1% 1126.1302 4

R539 9.09k, MF, 1/8W, 1% 1126.9091 4

R540 15.4k, MF, 1/8W, 1% 1126.1542 4

R541 47k, CF, 1/8W, 5% 1124.0473 4

R542 1k, CF, 1/8W, 5% 1124.0102 4

R543 47k, CF, 1/8W, 5% 1124.0473 4

R544 13.0k, MF, 1/8W, 1% 1126.1302 4

R545 20.0k, MF, 1/8W, 1% 1126.2002 4

R546 1k, CF, 1/8W, 5% 1124.0102 4

R547 47k, CF, 1/8W, 5% 1124.0473 4

R548 47k, CF, 1/8W, 5% 1124.0473 4

R549 9.09k, MF, 1/8W, 1% 1126.9091 4

R550 47k, CF, 1/8W, 5% 1124.0473 4

R551 47k, CF, 1/8W, 5% 1124.0473 4

R552 47k, CF, 1/8W, 5% 1124.0473 4

R553 47k, CF, 1/8W, 5% 1124.0473 4

R554 13.0k, MF, 1/8W, 1% 1126.1302 4

R555 1. 5k , CF, 1/4W , 5% 1224.0152 4

R556 1. 5k , CF, 1/4W , 5% 1224.0152 4

R557 13.0k, MF, 1/8W, 1% 1126.1302 4

R558 15.4k, MF, 1/8W, 1% 1126.1542 4

R559 15.4k, MF, 1/8W, 1% 1126.1542 4

R560 47k, CF, 1/8W, 5% 1124.0473 4

R561 13.0k, MF, 1/8W, 1% 1126.1302 4

R562 47k, CF, 1/8W, 5% 1124.0473 4

R563 47k, CF, 1/8W, 5% 1124.0473 4

R564 9.09k, MF, 1/8W, 1% 1126.9091 4

R565 13.0k, MF, 1/8W, 1% 1126.1302 4

R566 9.09k, MF, 1/8W, 1% 1126.9091 4

R567 47k, CF, 1/8W, 5% 1124.0473 4

R568 36.5k, MF, 1/8W, 1% 1126.3652 4

Number

Part

Number

37

Page 38

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Digital Signal Processor (DSP) PCB Assembly

Resistors (continued)

Bose

Designator

R569 10.0k, MF, 1/8W, 1% 1126.1002 4

R570 10.0k, MF, 1/8W, 1% 1126.1002 4

R571 121 Ohm, MF, 1/8W, 1% 1126.1210 4

R572 121 Ohm, MF, 1/8W, 1% 1126.1210 4

R573 36.5k, MF, 1/8W, 1% 1126.3652 4

R574 16.5k, MF, 1/8W, 1% 1126.1652 4

R575 12.1k, MF, 1/8W, 1% 1126.1212 4

R576 6.81k, MF, 1/8W, 1% 1126.6811 4

R577 4.99k, MF, 1/8W, 1% 1126.4991 4

R578 4.99k, MF, 1/8W, 1% 1126.4991 4

R579 2.49k, MF, 1/8W, 1% 1126.2491 4

R580 2.49k, MF, 1/8W, 1% 1126.2491 4

R581 12.1k, MF, 1/8W, 1% 1126.1212 4

R582 1.02k, MF, 1/8W, 1% 1126.1021 4

R583 1.02k, MF, 1/8W, 1% 1126.1021 4

R584 6.81k, MF, 1/8W, 1% 1126.6811 4

R586 5.49k, MF, 1/8W, 1% 1126.5491 4

R587 100k, MF, 1/8W, 1% 1126.1003 4

R588 100k, MF, 1/8W, 1% 1126.1003 4

R590 100k, MF, 1/8W, 1% 1126.1003 4

R591 100k, MF, 1/8W, 1% 1126.1003 4

R592 5.49k, MF, 1/8W, 1% 1126.5491 4

R593 10.0k, MF, 1/8W, 1% 1126.1002 4

R594 10.0k, MF, 1/8W, 1% 1126.1002 4

R595 3. 32k, MF, 1/4W, 1% 1226.3321 199755 4

R596 T herm, NTC, 1/2W, 1000 Ohm, 5% 1200.0006 182785 3

R599 16.5k, MF, 1/8W, 1% 1126.1652 4

R600 10k, CF, 1/8W, 5% 1124.0103 4

R601 10k, CF, 1/8W, 5% 1124.0103 4

R602 402 Ohm, MF, 1/8W, 1% 1126.4020 4

R603 402 Ohm, MF, 1/8W, 1% 1126.4020 4

R604 0 Ohm, 1/8W 1124.0000 4

R605 0 Ohm, 1/8W 1124.0000 4

R606 51. 1 Ohm, MF, 1/8W, 1% 1126.5119 4

R607 51. 1 Ohm, MF, 1/8W, 1% 1126.5119 4

Number

Part

Number

38

Page 39

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Digital Signal Processor (DSP) PCB Assembly

Capacitors

Bose

Designator

C428 1uF, AE, RDL, 50V, 20% 2930.0105 4

C431 . 1uF, MPE, 50V, 5% 2452.0104 4

C432 100uF, AE, RDL, 25V, 20% 2930.0107 4

C434 . 1uF, MPE, 50V, 5% 2452.0104 4

C435 1uF, AE, RDL, 50V, 20% 2930.0105 4

C436 . 0033uF, PE, 50V, 5% 2454.0332 4

C437 . 0033uF, PE, 50V, 5% 2454.0332 4

C438 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C439 33uF, AE, RDL, 16V, 20% 2930.0336 4

C440 10uF, AE, RDL, 35V, 20% 2930.0106 4

C441 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C448 . 1uF, MPE, 50V, 5% 2452.0104 4

C449 . 1uF, MPE, 50V, 5% 2452.0104 4

C450 . 1uF, MPE, 50V, 5% 2452.0104 4

C500 10uF, AE, RDL, NP, 100V, 20% 205-00208-00 182845 4

C501 10uF, AE, RDL, NP, 100V, 20% 205-00208-00 182845 4

C502 56pF, Cer Disc, NPO, 100V, 5% 2173.0560 4

C503 56pF, Cer Disc, NPO, 100V, 5% 2173.0560 4

C504 56pF, Cer Disc, NPO, 100V, 5% 2173.0560 4

C505 56pF, Cer Disc, NPO, 100V, 5% 2173.0560 4

C506 33pF, Cer Disc, NPO, 100V, 5% 2174.0330 4

C507 33pF, Cer Disc, NPO, 100V, 5% 2174.0330 4

C508 10uF, AE, RDL, NP, 100V, 20% 205-00208-00 182845 4

C509 33pF, Cer Disc, NPO, 100V, 5% 2174.0330 4

C510 33pF, Cer Disc, NPO, 100V, 5% 2174.0330 4

C511 10uF, AE, RDL, NP, 100V, 20% 205-00208-00 182845 4

C512 . 1uF, MPE, 50V, 5% 2452.0104 4

C513 . 1uF, MPE, 50V, 5% 2452.0104 4

C514 . 1uF, MPE, 50V, 5% 2452.0104 4

C515 . 1uF, MPE, 50V, 5% 2452.0104 4

C516 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C517 47uF, AE, RDL, 16V, 20% 2930.0476 4

C518 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C519 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C520 47uF, AE, RDL, 16V, 20% 2930.0476 4

C521 . 1uF, MPE, 50V, 5% 2452.0104 4

C522 . 1uF, MPE, 50V, 5% 2452.0104 4

C523 . 1uF, MPE, 50V, 5% 2452.0104 4

C524 . 1uF, MPE, 50V, 5% 2452.0104 4

C525 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C527 . 1uF, MPE, 50V, 5% 2452.0104 4

C528 . 1uF, MPE, 50V, 5% 2452.0104 4

C530 . 1uF, MPE, 50V, 5% 2452.0104 4

C531 . 1uF, MPE, 50V, 5% 2452.0104 4

C532 . 1uF, MPE, 50V, 5% 2452.0104 4

Number

Part

Number

39

Page 40

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Bose

Designator

C533 . 1uF, MPE, 50V, 5% 2452.0104 4

C534 . 1uF, MPE, 50V, 5% 2452.0104 4

C535 . 1uF, MPE, 50V, 5% 2452.0104 4

C536 10uF, AE, RDL, 35V, 20% 2930.0106 4

C537 10uF, AE, RDL, 35V, 20% 2930.0106 4

C538 . 1uF, MPE, 50V, 5% 2452.0104 4

C539 . 1uF, MPE, 50V, 5% 2452.0104 4

C540 . 1uF, MPE, 50V, 5% 2452.0104 4

C541 . 1uF, MPE, 50V, 5% 2452.0104 4

C542 . 1uF, MPE, 50V, 5% 2452.0104 4

C543 . 1uF, MPE, 50V, 5% 2452.0104 4

C544 . 1uF, MPE, 50V, 5% 2452.0104 4

C545 . 1uF, MPE, 50V, 5% 2452.0104 4

C546 . 1uF, MPE, 50V, 5% 2452.0104 4

C547 . 1uF, MPE, 50V, 5% 2452.0104 4

C548 . 47uF, MPE, 50V, 5% 2452.0474 4

C549 . 1uF, MPE, 50V, 5% 2452.0104 4

C550 . 1uF, MPE, 50V, 5% 2452.0104 4

C551 . 47uF, MPE, 50V, 5% 2452.0474 4

C552 . 47uF, MPE, 50V, 5% 2452.0474 4

C553 10uF, AE, RDL, 35V, 20% 2930.0106 4

C554 10uF, AE, RDL, 35V, 20% 2930.0106 4

C555 . 47uF, MPE, 50V, 5% 2452.0474 4

C556 . 1uF, MPE, 50V, 5% 2452.0104 4

C557 . 1uF, MPE, 50V, 5% 2452.0104 4

C558 10uF, AE, RDL, 35V, 20% 2930.0106 4

C559 10uF, AE, RDL, 35V, 20% 2930.0106 4

C560 . 1uF, MPE, 50V, 5% 2452.0104 4

C561 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C562 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C563 . 1uF, MPE, 50V, 5% 2452.0104 4

C564 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C565 33pF, Cer Disc, NPO, 100V, 5% 2174.0330 4

C566 33pF, Cer Disc, NPO, 100V, 5% 2174.0330 4

C567 10uF, AE, RDL, 35V, 20% 2930.0106 4

C568 . 47uF, MPE, 50V, 5% 2452.0474 4

C569 1uF, AE, RDL, 50V, 20% 2930.0105 4

C570 . 47uF, MPE, 50V, 5% 2452.0474 4

C571 1uF, AE, RDL, 50V, 20% 2930.0105 4

C572 10uF, AE, RDL, 35V, 20% 2930.0106 4

C573 10uF, AE, RDL, 35V, 20% 2930.0106 4

C578 . 1uF, MPE, 50V, 5% 2452.0104 4

C579 . 1uF, MPE, 50V, 5% 2452.0104 4

C580 . 1uF, MPE, 50V, 5% 2452.0104 4

C581 . 1uF, MPE, 50V, 5% 2452.0104 4

Number

Part

Number

40

Page 41

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Bose

Designator

C582 10uF, AE, RDL, 35V, 20% 2930.0106 4

C583 10uF, AE, RDL, 35V, 20% 2930.0106 4

C584 100pF, Cer Disc, NPO, 100V, 5% 2174.0101 4

C585 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C586 330pF, Cer Disc, COG, 100V, 5% 2174.0331 182992 4

C587 10uF, AE, RDL, 35V, 20% 2930.0106 4

C588 10uF, AE, RDL, 35V, 20% 2930.0106 4

Designator

D425 1N4148 3100.0004 182868

D426 1N4148 3100.0004 182868

D428 1N4148 3100.0004 182868

D429 1N4148 3100.0004 182868

D430 1N4148 3100.0004 182868

D431 1N4148 3100.0004 182868

D433 1N4148 3100.0004 182868

D443 1N4148 3100.0004 182868

D445 1N4148 3100.0004 182868

D446 1N4148 3100.0004 182868

D500 1N4148 3100.0004 182868

D501 1N4148 3100.0004 182868

D502 1N4148 3100.0004 182868

D503 1N4148 3100.0004 182868

D504 1N4148 3100.0004 182868

D505 1N4148 3100.0004 182868

D506 1N4148 3100.0004 182868

D507 1N4148 3100.0004 182868

D508 Zener, 1N5236B, .5W, 7.5V, 5% 3110.0002 262176

D509 Zener, 1N5236B, .5W, 7.5V, 5% 3110.0002 262176

D510 1N4148 3100.0004 182868

D511 1N4148 3100.0004 182868

D512 1N4148 3100.0004 182868

D513 1N4148 3100.0004 182868

D514 1N4148 3100.0004 182868

D515 1N4148 3100.0004 182868

D516 1N4148 3100.0004 182868

D517 1N4148 3100.0004 182868

D518 1N4148 3100.0004 182868

D519 1N4148 3100.0004 182868

D520 1N4148 3100.0004 182868

D521 1N4148 3100.0004 182868

Diodes

Number

Number

Part

Number

Number

41

Page 42

ELECTRICAL PART LIST

Reference

Description Vendor Part

®®®®

Note

Reference

Description Vendor Part

Bose Part

Note

Digital Signal Processor (DSP) PCB Assembly

Transistors

Bose

Designator

Q426 PNP, 2N4403, TO-92 3200.0002 262134

Q427 NPN, 2N4401, TO-92 3200.0001 262168

Q428 NPN, 2N4401, TO-92 3200.0001 262168

Q429 NPN, 2N4401, TO-92 3200.0001 262168

Q430 NPN, 2N4401, TO-92 3200.0001 262168

Q431 NPN, 2N4401, TO-92 3200.0001 262168

Q432 NPN, 2N4401, TO-92 3200.0001 262168

Q433 NPN, 2N4401, TO-92 3200.0001 262168

Q500 NPN, 2N4401, TO-92 3200.0001 262168

Q501 NPN, 2N4401, TO-92 3200.0001 262168

Designator

U425 COMPARATOR, QUAD, LM339 3410.0339 262177

U426 COMPARATOR, QUAD, LM339 3410.0339 262177

U427 COMPARATOR, QUAD, LM339 3410.0339 262177

U428 COMPARATOR, QUAD, LM339 3410.0339 262177

U500 OP-AMP, DUAL, NE5532P 3410.5532 262178