Page 1

TABLE OF CONTENTS

Specifications................................................................................................................................... 1

Product Description......................................................................................................................... 2

Disassembly/Assembly Procedures .............................................................................................. 3

Test Procedures ............................................................................................................................... 4

Figure 1. Test Setup Diagram ......................................................................................................... 4

Figure 2. Crossover Top Side and Etch Layout............................................................................... 5

Figure 3. FreeSpace

Figure 4. FreeSpace Model 1B Acoustimass Module Assembly Diagram ...................................... 6

Part List..........................................................................................................................................7-8

FreeSpace Model 1B Acoustimass Module (Per Figure 4)........................................................... 7

Figure 5. FreeSpace Model 1B Acoustimass Bass Module Rear Panel Label ............................... 7

FreeSpace Model 1B Acoustimass Module Crossover Assembly (Per Figure 6) ...................... 8

Figure 6. FreeSpace Model 1B Acoustimass Module Crossover Assembly ................................... 8

Packing List ...................................................................................................................................... 9

FreeSpace Model 1B Acoustimass Module (Per Figure 7)........................................................... 9

Figure 7. FreeSpace Model 1B Acoustimass Module Packing Diagram .......................................... 9

®

Model 1B Acoustimass® Module Schematic Diagram.................................. 5

SPECIFICATIONS

External Dimensions: Bass Module: 19" x 14" x 7.5"

Packed System: 26.2" x 19.8" x 10.6"

Weight: Bass Module: 18.7 lb

Transducer Complement: 2 - 5 1/4" Woofers

Power Handling: 100 Watts per channel

Usable Frequency Range: Bass Box: 55 Hz to 200 Hz

Sensitivity: Pink Noise: 76dB-spl, 1 Watt @ 1 Meter

IEC Noise: 78.6dB-spl, 1 Watt @ 1 Meter

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY

FOR THE PURPOSE OF SERVICING THE IDENTIFIED BOSE

PRODUCT BY AN AUTHORIZED BOSE SERVICE CENTER OR

OWNER OF THE BOSE PRODUCT, AND SHALL NOT BE

REPRODUCED OR USED FOR ANY OTHER PURPOSE.

1

Page 2

PRODUCT DESCRIPTION

The FreeSpace® Model 1B Acoustimass® Module is a passive bass unit with a crossover at

200 Hz. The crossover will feed four (two per channel) 8Ω impedance, or eight

(four per channel) 4Ω impedance FreeSpace Model 6 loudspeakers. It offers several

advantages over a powered bass box system.

• The FreeSpace Model 1B Acoustimass Module does not require the wiring of AC mains

during installation. This can represent a significant savings in installation costs.

• The FreeSpace Model 1B Acoustimass Module is designed to be used with the AMPlus™

Series Amplifiers. It is able to take advantage of all of the features of the amplifiers, such

as Opti-voice

selection.

• The FreeSpace Model 1B Acoustimass Module can also be used with the the Model 8,

Model 32, and Model 25 loudspeakers to form a complete extended bandwidth system.

®

paging, Dynamic EQ, Page Vectoring, Dynamic Compensation, and source

2

Page 3

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Refer to Figure 4. for the following

procedures.

1. Driver Removal

1.1 Remove the six screws (5) that secure

the rear cover (8) to the cabinet.

1.2 Slide the rear cover off far enough to

reach the woofer harness cables (10) on

the crossover assembly (9).

1.3 Unplug the woofer harness cables from

the crossover assembly. You can now

completely remove the rear cover.

1.4 Remove the four screws (3) that secure

the woofer assembly (2) to the cabinet.

1.5 Cut the wires as close to the terminals

as possible.

2. Driver Replacement

®

Note: Refer to Figure 3, FreeSpace

1B Acoustimass

®

Module Schematic

Model

Diagram, for wiring information.

3. Crossover Removal

3.1 Remove the six screws (5) that secure

the rear cover (8) onto the Acoustimass

Bass Module.

3.2 Slide the rear cover off of the bass box

until you can reach the connectors for the

woofer harness cables (10).

3.3 Unplug the woofer harness

cables from the crossover assembly (9).

3.4 Unplug the connector harness

assembly (7) from the crossover assembly.

3.5 Remove the four screws that secure

the crossover assembly to the rear panel.

4. Crossover Replacement

4.1 Mount the crossover assembly (9) to the

rear cover (8) using the four screws

removed in Procedure 3.5.

4.2 Plug the connector harness

assembly (7) onto the crossover assembly.

2.1 Observing polarity, solder the woofer

harness cable (10) leads to the woofer

assembly (2).

2.2 Secure the woofer assembly to the

cabinet using the four screws (3) removed in

Procedure 1.4.

Note: Be sure to re-align the woofer

gasket (1) with the cabinet in order to make

an airtight seal.

2.3 Plug the connectors for the woofer

harness cables onto the crossover

assembly (9) located on the rear cover (8).

2.4 Slide the rear cover back onto the

bass box, and secure it using the six screws

(5) removed in Procedure 1.1.

4.3 Plug the woofer harness cables (10)

onto the crossover assembly.

4.4 Secure the rear cover to the

Acoustimass Bass Module using the six

screws (5) removed in Procedure 3.1.

3

Page 4

TEST PROCEDURES

1. Rub and Tick Test

1.1 Perform Disassembly/Assembly

Procedure 1.1-1.4 in order to gain access to

the driver to be tested.

1.2 Apply a 10 Volt rms, 10 Hz signal to

the driver input terminals.

1.3 Replace any driver that has a rubbing

or ticking noise. Quiet ticks are acceptable

if they cannot be heard at a distance of 1

foot.

Note: To distinguish between normal

suspension noise and rubs or ticks, displace

the surround of the driver slightly with your

fingers. If the noise can be made to go

away, or get worse, it is a tick or a rub, and

the driver should be replaced. If the noise

stays the same, it is suspension noise and

the driver is fine. Suspension noises will not

be heard with program material.

3.3 Sweep the oscillator from 10 Hz to

500 Hz. Sweep rate shall be 3-5 seconds.

Listen carefully for buzzes, rattles, or other

noises.

Note: A whooshing noise from the bass

box ports at approximately 45 Hz and 110

Hz is acceptable (port tuned frequencies).

Note: A small air leak at the input/output

terminal is acceptable.

3.4 Reduce input signal to 4 Vrms, 500 Hz.

3.5 Sweep the oscillator from 500 Hz to

7 kHz. Sweep rate shall be 3-5 seconds.

Listen carefully for buzzes, rattles, or other

noises.

3.6 Repeat sweep test for LEFT channel

only, then for RIGHT channel only.

3.7 Listen for any extraneous noises.

2. Air Leak Test

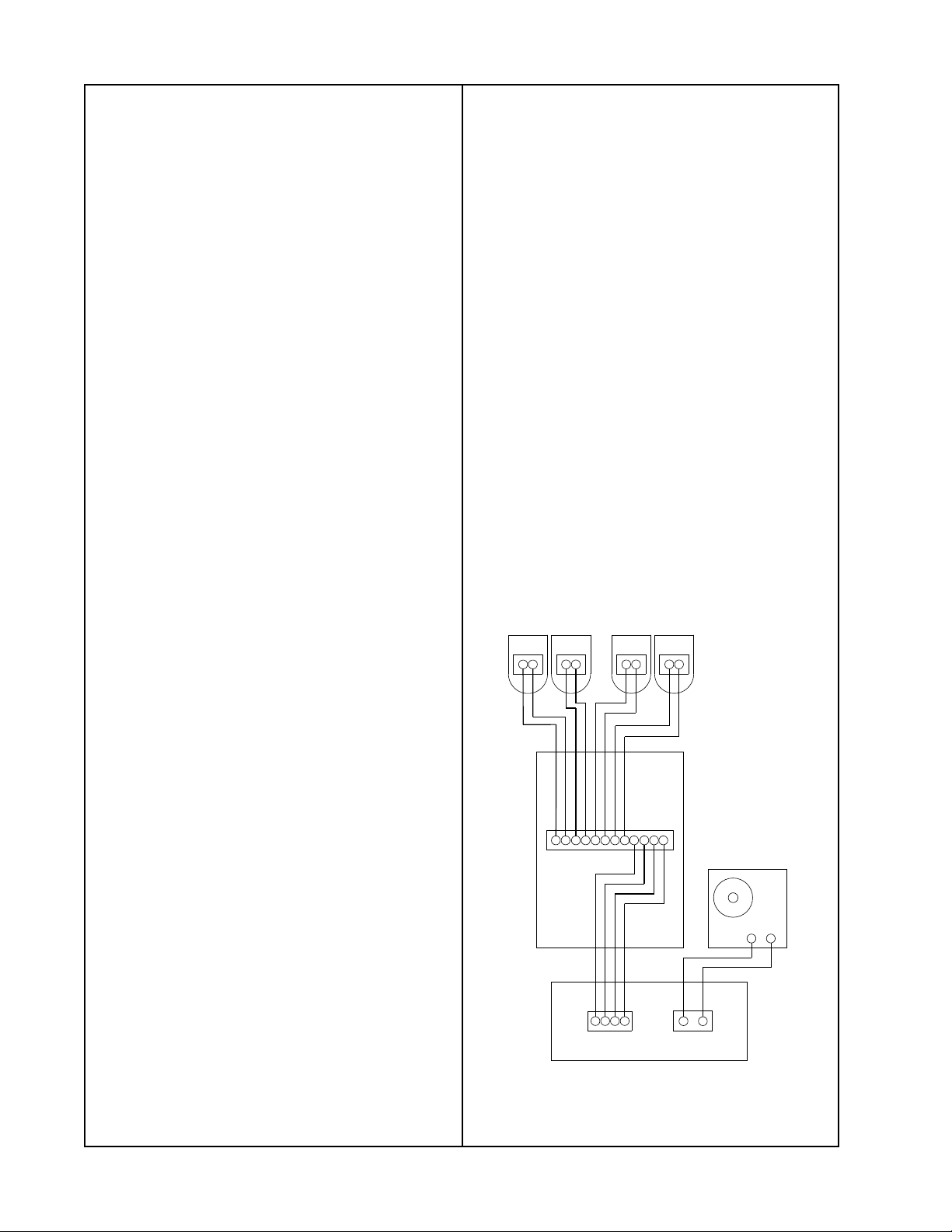

2.1 Perform test setup in Figure 1. Test

Setup Diagram, but do not connect the

satellite speakers.

2.2 Apply a 14 Vrms, 45 Hz signal to the

bass module.

2.3 Listen carefully for air leaks (audible as

a whistling or sputtering sound) at cabinet

seams. Minimum listening time should be 5

seconds/test.

3. System Sweep Test

3.1 Connect the system as in Figure 1.

Test Setup Diagram.

Note: Refer to Figure 5. for the

Acoustimass

®

Bass Module Rear Panel

Label diagram.

+

+

-

-

+-

-

+

+

-+-

++

-

-

+

-

+

+-

-

+

-

+

InputOutputs

Satellites

Bass Module

Audio Signal

Generator

-

+

-

3.2 Apply a 14 Vrms, 10 Hz signal to both

the left and right inputs.

Power Amplifier

Figure 1. Test Setup Diagram

4

Page 5

RED

INPUT FROM

AMPLIFIER

LEFT (RIGHT)

+

Figure 2. Crossover Top Side and Etch Layout

RED

C1

+

WOOFER

-

SATELLITES

BLACK

-

Figure 3. FreeSpace® Model 1B Acoustimass® Module Schematic Diagram

(one channel shown)

5

BLACK

Page 6

Front View

12

12

11

(2x)

2

(2x)

3

(8x)

1

(2x)

Top View

4

(6x)

5

(6x)

6

(2x)

7

Figure 4. FreeSpace

9

10

(2x)

Exploded View

®

Model 1B Acoustimass® Module Assembly Diagram

8

6

Page 7

PART LIST

FreeSpace® Model 1B Acoustimass® Module (Per Figure 4)

Item

Number

1 Gasket, Woofer, 6.5" 104794-08 2

2 Woofer Assy., 5.25 ", AM-5 P III 172276 2

3 Screw, Tapp, 8 - 11x .75, PAN,

XRC/SQ

4 Grommet, Grille, .635" 117995 6

5 Screw, Tapp, 8 - 11x 1.5, PAN,

XRC/SQ

6 Screw, Tapp, 8 - 11x 1.00, PAN,

XRC/SQ

7 Connector Harness Assembly 187462 1

8 Cover, Rear, Pro Grey 184885-8 1

8 Cover, Rear, White 184885-9 1

9 Crossover Assy. Model 1B 187894 1

10 Harness, Woofer 172275 2

11 Screw, 1/4 x 20, 3/4 L, Hex, BH 179114-12 4

12 Bracket, Bassbox 184892 1

Description Part Number Qty. per

172672-12 8

172672-24 6

172672-16 2

Assy.

Figure 5. FreeSpace Model 1B Acoustimass Bass Module Rear Panel Label

7

Page 8

PART LIST

FreeSpace® Model 1B Acoustimass® Module Crossover Assembly (Per Figure 6)

Reference

Designator

C1, C2 1 Cap, El, BP, 85, 50V, 20%, 100uF 142065 2

J2, J3 2 Connector, Header, Inline, 2 Position 13 3220-02 2

J1 3 Conn, Header, 12 Pin, .200, Vert 187902-12 1

- 4 Crossover PCB Assy, Bare Board 187495 1

- 5 Screw, Tapp, 8-11x.625, PAN,XRC/S 172672-10 4

- 6 Foot, .25x.50, Black 174402-1 4

(4x)

Item

Number

5

Description Part

Number

2

(2x)

4

Qty. per

Assy.

(2x)

1

3

6

(4x)

Figure 6. FreeSpace Model 1B Acoustimass Module Crossover Assembly

8

Page 9

PACKING LIST

FreeSpace® Model 1B Acoustimass® Module (Per Figure 7)

Item

Description Part Number Qty. per

Number

1 Packing, Corner Post, Bass Mod. 148044 2

2 Packing, Corner Post, Bass Insert 148364 2

3 Bag, Poly, 13.5 x 35 x 9.5 x 1 Mil 114522 1

4 Packing, Crease Sheet, S/W 190555-001 1

5 Bracket, Wallmount 184891 1

6 Bag, Poly, 14.38 x 9 .87 x 2 Mil 103351 1

7 Card, Registration 180089 1

8 Clip, Wire 187523 1

9 Sheet, Installation, FS Model 1B 187905 1

10 Packing, Crease Sheet, D/C, D/W 190554-001 1

11 Packing Tube, Joined 186732 1

12 Cover Assy, AM10, Pro Grey 187096-3 1

12 Cover Assy, AM10, Arctic White 187096-4 1

13 Carton, RSC 184 888-001 1

2

Assy.

12

1

3

10

11

6

7 8 9

5

4

13

11

Figure 7. FreeSpace Model 1B Acoustimass Module Packing Diagram

9

Page 10

FREESPACE® MODEL 1B

®

®

ACOUSTIMASS

®

MODULE

©

1997 Bose Corporation

Service Manual

Part Number 191983 REV 00

Page 11

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

®

®

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 191983 REV. 00 08/97 FOR TECH. ASSISTANCE OR PART ORDERS, CALL 1-800-367-4008

Loading...

Loading...