Page 1

Table of Contents

FreeSpace Business Music System Manual pn 181816

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) DEVICE HANDLING.................................................... 2

SAFETY INFORMATION................................................................................................................................... 3

IDENTIFICATION OF UNIT UNDER TEST....................................................................................................... 4

SPECIFICATIONS............................................................................................................................................. 5

THEORY OF OPERATION................................................................................................................................ 7

DISASSEMBLY/ASSEMBLY PROCEDURES................................................................................................. 11

Main Assembly Procedures ....................................................................................................................... 11

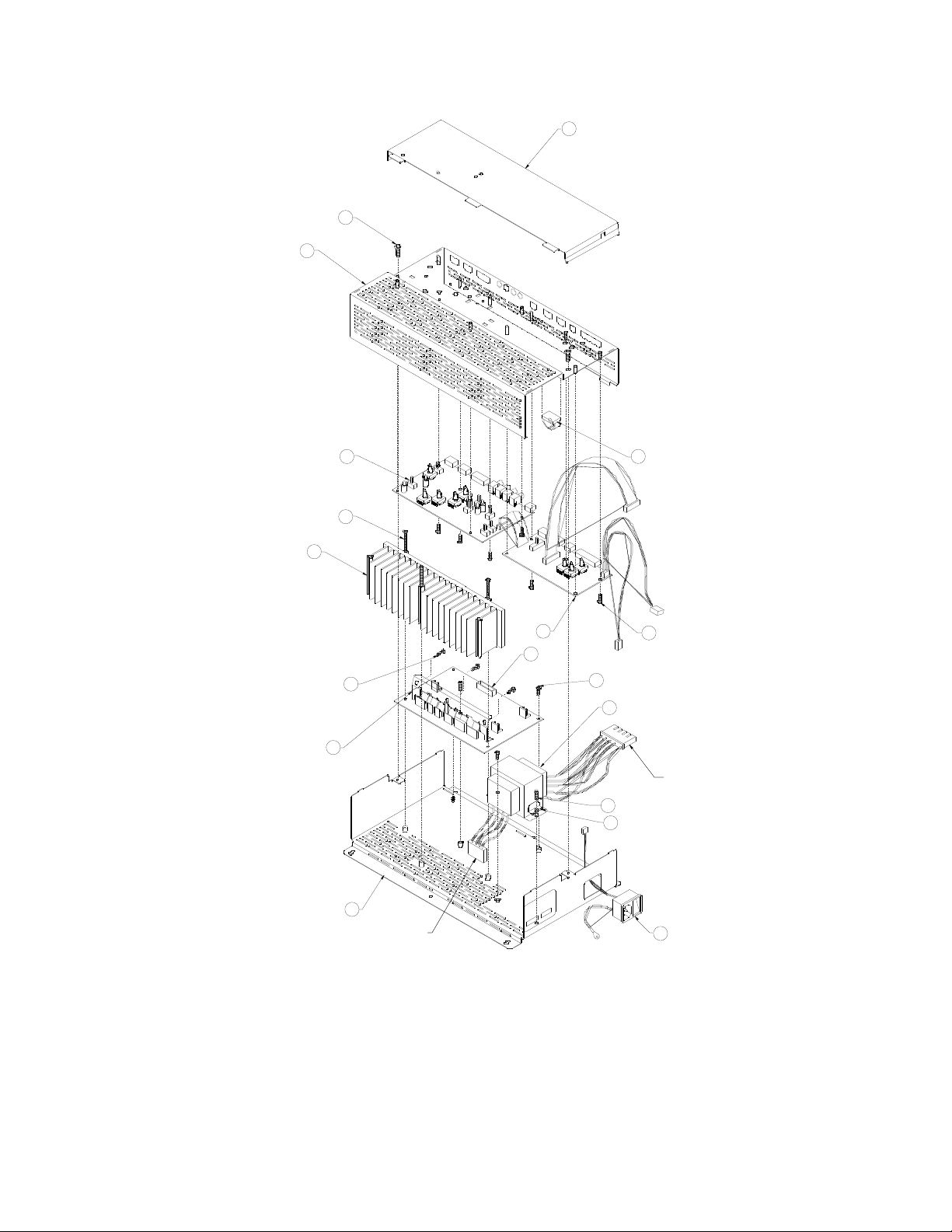

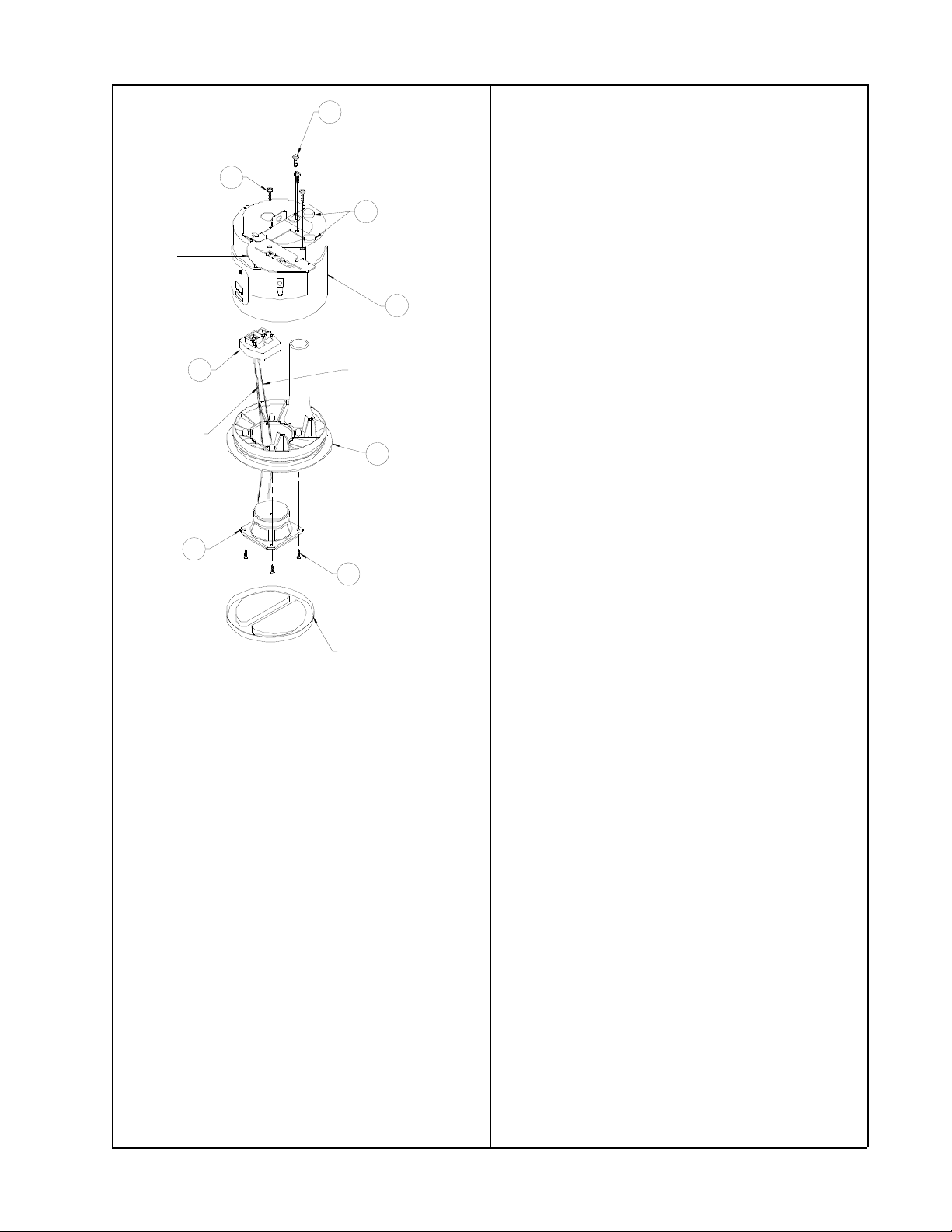

Figure 1. Main Disassembly/Assembly Exploded View............................................................................. 12

Flush-Mount Loudspeaker Procedures ..................................................................................................... 15

Figure 2. Flush-Mount Loudspeaker Exploded View .................................................................................16

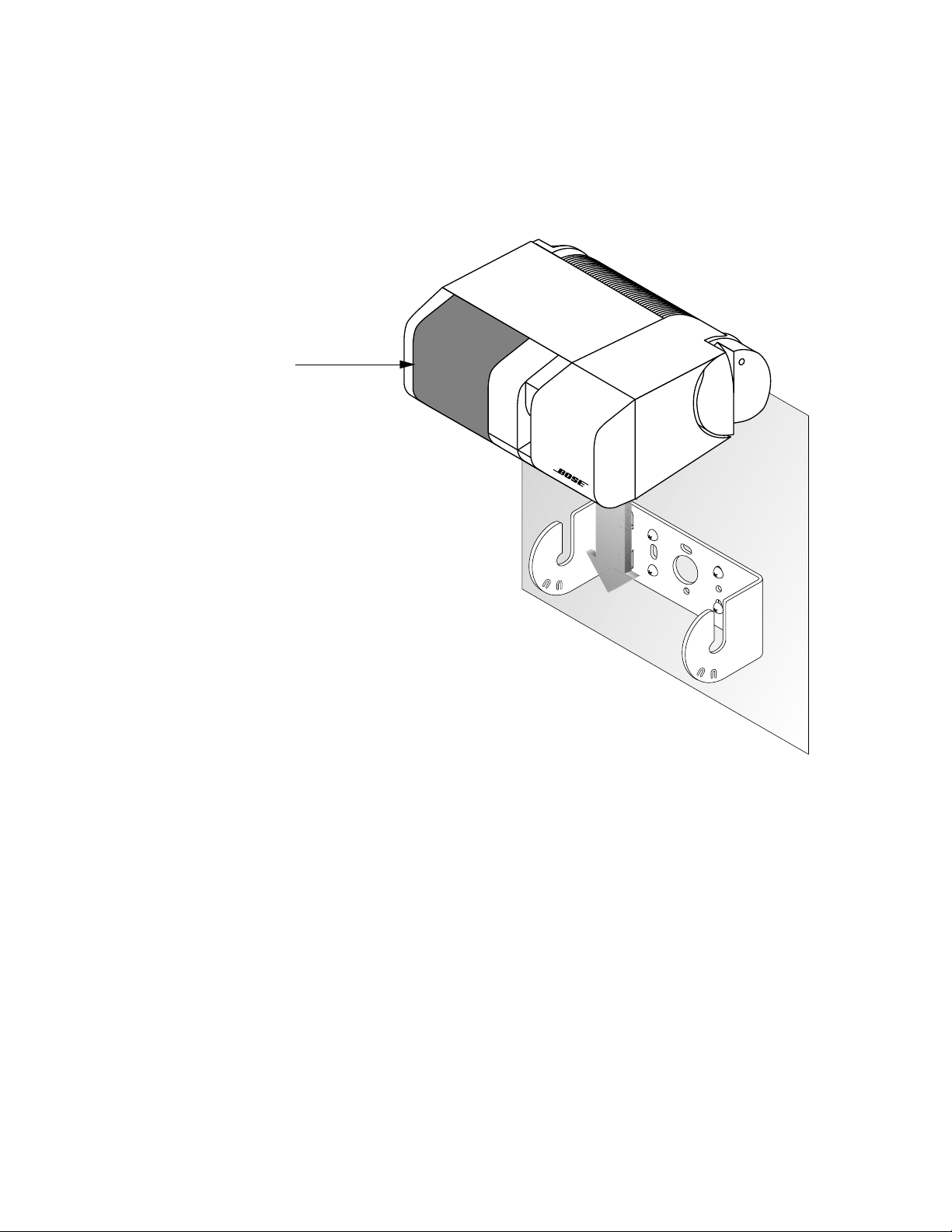

Surface-Mount Loudspeaker Procedures.................................................................................................. 16

Figure 3. Surface-mount Loudspeaker ...................................................................................................... 17

TEST PROCEDURES..................................................................................................................................... 18

Main Assembly T est Procedures................................................................................................................18

Loudspeaker Test Procedures ...................................................................................................................20

PART LISTS AND EXPLODED VIEWS........................................................................................................... 21

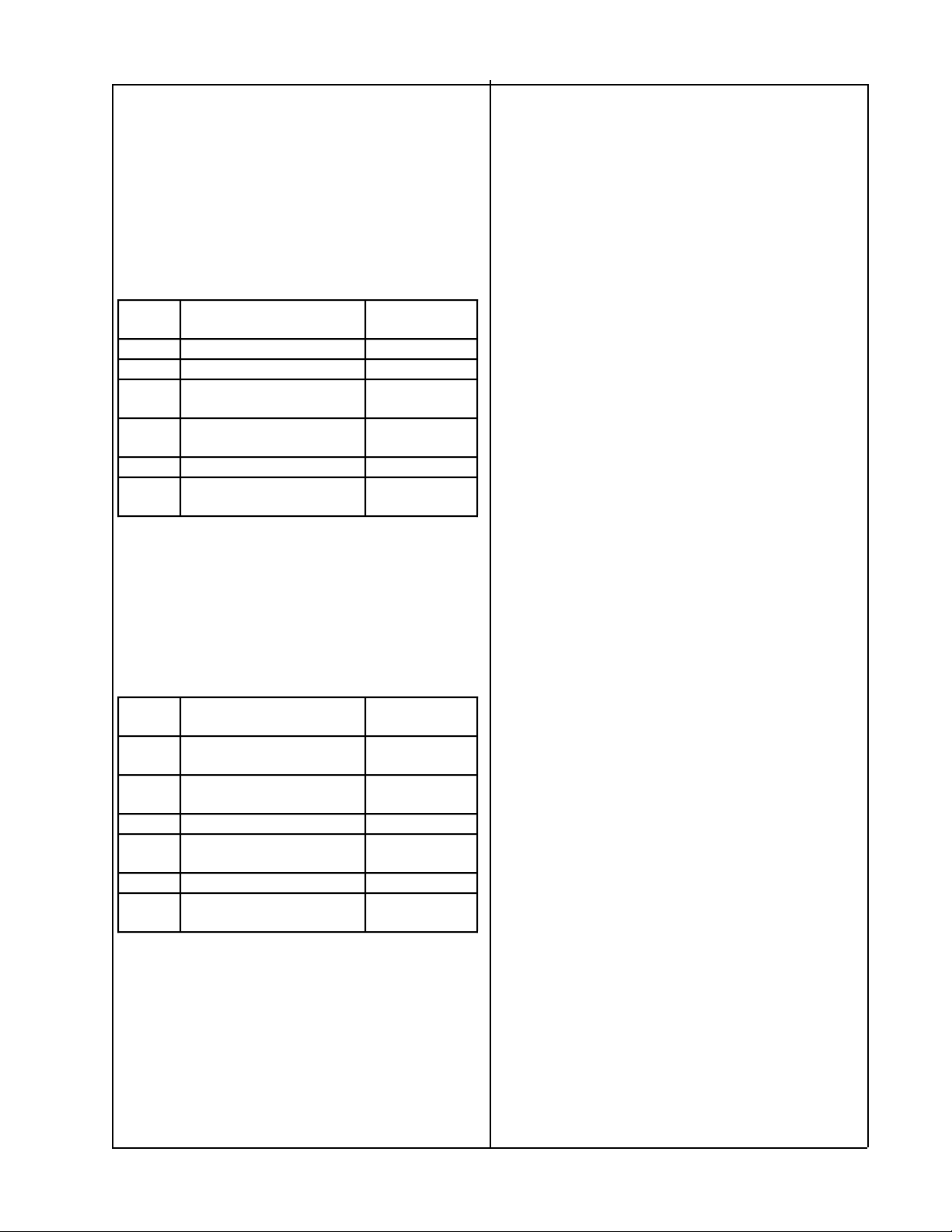

Main Assembly Part List (Figure 4)............................................................................................................ 22

Figure 4. Main Assembly Exploded View................................................................................................... 23

Remote Assembly Part List (Figure 5) ....................................................................................................... 24

Figure 5. Remote Assembly Exploded View.............................................................................................. 24

Main Assembly Packaging Part List (Figure 5).......................................................................................... 25

Figure 6. Main Assembly Packaging Exploded View .................................................................................26

Flush-mount Assembly Part List................................................................................................................ 27

Figure 7. Flush-mount Exploded View....................................................................................................... 27

Flush-mount Packaging Part List............................................................................................................... 28

Figure 8. Flush-mount Loudspeaker Packaging Illustration........................................................................28

Surface-mount Assembly Part List ............................................................................................................ 29

Figure 9. Surface-mount Loudspeaker Illustration..................................................................................... 29

Surface-Mount Packaging Part List ........................................................................................................... 30

Figure 10. Surface-mount Loudspeaker Packaging .................................................................................. 30

FreeSpace®6 Electrical Part List, PCB P/N 177300, Revision 0 .............................................................. 31

FreeSpace

SCHEMATICS AND PCB LAYOUTS............................................................................................................... 49

Sheet 1, PCB IO1 Music Inputs (PCB 177300, Revisions 0 and 1) .......................................................... 50

Sheet 2, PCB IO1 Music Compressor (PCB 177300, Revisions 0 and 1)................................................. 51

Sheet 3, PCB IO1 Board Page Processor (PCB 177300, Revisions 0 and 1) .......................................... 52

Sheet 4, PCB IO1 Board Music/Page Mixing (PCB 177300, Revisions 0 and 1) ......................................53

Sheet 5, PCB IO2 Board Line Outputs (PCB 177300, Revisions 0 and 1)................................................ 54

Sheet 6, PCB IO2 Board Remote Volume (PCB 177300, Revisions 0 and 1) .......................................... 55

Sheet 7, PCB IO2 Tone Control and Surface EQ (PCB 177300, Revisions 0 and 1)................................ 56

Sheet 8, PA Board Dynamic EQ and Limiter Processor (PCB 177300, Revisions 0 and 1)...................... 57

Sheet 9, PA Board Speaker EQ (PCB 177300, Revisions 0 and 1) .......................................................... 58

Sheet 10, PA Board Power Supply and Amp(PCB 177300, Revisions 0 and 1) ....................................... 59

Sheet 11, Remote Board (PCB 177300, Revisions 0 and 1) ..................................................................... 60

6 Electrical Part List, PCB P/N 177300, Revision 1 .............................................................. 40

1

Page 2

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESD sensitive devices. We recommend the following precautions when

repairing, replacing or transporting ESD sensitive devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble wrap

or plastic trays.

CAUTION: THE FREESPACE®6 BUSINESS MUSIC SYSTEM

CONTAINS NO USER-SERVICEABLE PARTS. TO PREVENT

WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY

SERVICE STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Perform leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug

the AC line cord directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institute (ANSI)

C101.1 "Leakage Current for Appliances" and Underwriters Laboratories

(UL) 1492 (71). With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal waterpipe,

conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket,

metal cabinet, screwheads, metallic overlays, control shafts, etc.), especially

any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliampere. Reverse the unit power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD

THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE

CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and

connect a jumper wire between the two prongs of the plug. (2) Turn on the power

switch of the unit. (3) Measure the resistance with an ohmmeter between the

jumpered AC plug and each exposed metallic cabinet part on the unit. When the

exposed metallic part has a return path to the chassis, the reading should be

between 1 and 5.2 Megohms. When there is no return path to the chassis, the

reading must be "infinite". If it is not within the limits specified, there is the possibility of a shock hazard, and the unit must be repaired and rechecked before it

is returned to the customer.

3

Page 4

IDENTIFICATION OF UNIT UNDER TEST

When servicing a FreeSpace®6 take notice of the following attributes:

• PC Board Part Number

• Revision Level Number of the PC Board

• Unit's Voltage Variation Type (100V,120V, 220V, 240V).

There are two types of FreeSpace 6 units manufactured. If the unit you are servicing has a

switch denoted by surface/flush mount speaker icons in block 12 of the front panel, then you

have a 2 EQ unit. If not, then you have a 1 EQ unit.

The EQ changes are represented on page 56 (Sheet 7, PCB Tone Control and Surface EQ)

of this manual. The 2 EQ unit will have all optional components (OPT) populated on the I02

board. The 1 EQ unit will be depopulated.

Refer to the applicable part list and schematics as follows:

• There are two Electrical Part Lists, one for Revision 0 and one for Revision 1 of PCB

177300.

• The PCB Schematics and Layout views supplied with this service manual are applicable

for Revisions 0 and 1 of PCB 177300.

NOTE: The PC board revision level number is marked on the PC board as follows:

1

4

Page 5

SPECIFICATIONS

Dimensions Module 4.0" H x 7.5" W x 15.0" D (10.16 x

19.05 x 38.10 cm)

Flush-mount Speaker Assembly: Flange Dia.: 6.25" (15.9 cm)

Hole Dia.: 5.75" (14.6 cm)

Depth: 6.5" (16.5 cm)

Surface-mount Speaker Assembly: 3.3" H x 7.6" W x 6.4" D (8.3 x 19.3 x

16.33 cm)

Weight Module: 11.3 lb. (5.14 kg.)

Flush-mount Speaker Only: 2.1 lb. (.97 kg)

(Including Mounting Hardware): 4.2 lb. (1.9 kg)

Surface-mount Speaker (Including

Mounting Hardware):

Driver Flush-mount & Surface-mount Speaker: 2.5" Full-range Driver

Beamwidth Flush-mount & Surface-mount Speaker: 150° @ -6 dB

2.5 lb. (1.2 kg)

Performance Specifications

Input Sensitivity Music Input: 200mV

Page Input: 20 0 µ V

Power Output 16W into 2Ω load

Power Requirements 120V or 220-240V ~ 50/60 Hz

Remote Volume

Control Value

Music Input Impedance Channel A: Balanced: 32kΩ

Channel A: Unbalanced: 11kΩ

Channel B: Unbalanced: 10kΩ

Page Input Impedance Balanced: 9kΩ

Unbalanced: 1kΩ

Page and Line Output

Impedance

Page Gain 0dB to 80dB adjustable

Frequency Range 80Hz - 16kHz

Noise (line into loudspeaker outputs): 20Hz - 20kHz bandwidth; -65dBV at

Frequency Response 20Hz - 20kHz, ±1dB, referenced to

10kΩ, Audio taper

400Ω

20dB gain into 10kΩ load

1kHz at line outputs

5

Page 6

Performance Specifications (Continued)

Maximum Acoustic

Output

Opti-voice® Paging

Circuitry

82dB-SPL in 20,000 cubic feet room

with a speech band RT

Ensures a constant paging level over a

30dB dynamic range by compressing

the page signal. Music gradually

returns to original level after page.

60 of 0.5 secs

6

Page 7

THEORY OF OPERATION

1. OVERVIEW

®

The FreeSpace

cial environments. The FreeSpace 6 components have been engineered to work together as a

system. The electronics have separate compressors for music and paging sources that decrease the dynamic range of the audio signal, thereby increasing the audibility of musical

passages and paging anouncements. A protective compressor in the power amplifier prevents

audible overload distortion if the user attempts to play the system too loud.The system has the

following features:

• High-fidelity sound over a large area

• Active equalization, music compression, and system overload protection

• Opti-voice® circuitry for high quality paging capability

• Remote control of volume and source selection

The circuit descriptions that follow are grouped according to the PCB section and sheet number of the schematic.

2. IO1 PCB

2.1 IO1 PCB Schematic Sheet 1

6 business music system delivers high-fidelity music and paging in commer-

Music Input A is routed through a differential input amplifier (U4) which accepts balanced

sources or unbalanced sources. The amplifier output is passed through a gain trim pot and

presented to the Music A/B selector. Music Input B is fed directly to a gain trim pot and then to

the Music Input A/B selector.

Music Selector A/B is a 2P2T analog switch, implemented with a special switching op amp

(U11,U12)). The op amp is controlled by the signal SELECTB.

The Music Selector Interface is a two transistor circuit that normally selects Music Input A. With

the Remote Selector switch open, transistor Q2 is on, which turns on D4, the Source A LED,

pulling SELECTB low. This turns off Q1, keeping its LED off. When the Remote Selector switch

is closed, Q2 is turned off, allowing Q1 and D3 (the Music B LED) to turn on. This moves

SELECTB high and turns off the Source A LED. When SELECTB is high, current is no longer

sunk from U11 and U12’s SW pin, and they select Music Input B.

2.2 IO1 PCB Schematic Sheet 2

On their way to the compressor, the left and right music signals pass through a stereo/mono

switch, S1. After the compressor (U7 and part of U6), the music signals leave this sheet. The

compressor is enabled by a logical function of SELECTB, Music Compressor A, and Music

Compressor B enable switches. The logic (U8) determines that the compressor will be enabled

only for a music source if that source is the one currently selected and if it has been enabled

for compression via its switch (S2 or S3).

The compressor offers a maximum gain of about 20dB for very low level signals and operates

at a 2:1 slope. It slowly raises the level of quiet musical passages, and quickly reduces the

level of loud passages. The two channels are cross coupled to maintain a centered stereo

image. By selecting the rectifier input source as a DC current, the compressor is disabled (U9).

7

Page 8

The two sections of U15 are used to control a bi-colored Music-Compressor LED, D2. As long

as the compressor is enabled, the LED glows green to indicate how active the compressor is.

Whether or not the compressor is enabled, the LED is also acting as a watch dog and will flash

red if the signal presented to the music compressor is too great for it to handle.

2.3 IO1 PCB Schmatic Sheet 3

The Page Input is presented to a differential amplifier (U2) that can handle a wide range

of source voltages, as well as balanced or unbalanced sources. S5 determines the gain of the

first stage (0dB or 30dB). The page signal next passes through U2, where it can be given a

gain of 0 to 30dB, as determined by R1. At S4, the page signal is routed either through

another variable gain stage (U2, gain adjustable from 0 to 20dB), or through the Opti-voice

®

compressor. The Opti-voice compressor (U5 and part of U6) provides anywhere from 20dB of

gain to 10dB of loss, depending upon the signal level.

Finally, the output of S4 is passed through the Page Muting stage (part of U10, Q3, and Q4), in

which it is muted unless the page trigger circuits have detected a signal. The Page Output

connector (J2) is driven by part of U10, acting as a buffer stage.

The two sections of U3 are used to control a bi-colored Opti-voice Compressor LED, D5. As

long as the compressor is enabled; the LED glows green to indicate how active the compressor is. Whether or not the compressor is enabled, the LED is also acting as a watch dog and

will flash red if the signals at U2’s outputs are too great for the compressor to handle.

2.4 IO1 PCB Schematic Sheet 4

The Page Trigger circuits first offer a user sensitivity adjustment, via R3, then provide up to

26dB of gain for the trigger signal. V13, Section B acts as a threshold comparator and a peak

hold circuit. For signals exceeding the threshold, the circuit changes state rapidly, and holds

the new state long enough to ride through syllabic and inter-word pauses in paging. The two

remaining sections of U13 provide a fade-back time constant for the music and adjust the

control voltage levels to suit the muting transistors Q3,4,5,6 and 7.

Two sections of U14 mix the music and page signals, while the other two sections of U14

provide the mono versions of the music signals and the music+page signals. Switch S9 enables paging in the signals fed on to the speaker outputs. R2 allows for adjustment of the page

level relative to the music.

3. IO2 PCB

3.1 IO2 PCB Schematic Sheet 5

S7, the Line Output Mode switch, selects the signals sent on to U200 and the Line Outputs.

Relay K1, controlled by Q201 and Q200, mute the Page and Line Outputs during power on

and power off transitions to prevent glitches from reaching the outputs.

8

Page 9

3.2 IO2 PCB Schematic Sheet 6

The remote volume control function is implemented on this sheet with a dual VCA, IC U201,

and its buffer, U202. (An alternate part could be used in U201A, but this is a manufacturing

alternative, not a field service alternative.) U201 is controlled by a current sourced into the

signal VCA, coming from Sheet 7. When VCA is about 2mk, gain is at its maximum, which is

unity (0dB). When the current into VCA is zero, the gain is essentially off (-80dB or so).

S4 and its related components are factory set gain trims.

3.3 IO2 PCB Schematic Sheet 7

Transistors Q202, Q203 and related components transform the variable resistance of the

remote volume control into the current source that feeds signal VCA, on Sheet 6.

U205 is a conventional bass and treble control, while U203 is an equalizer stage intended to

®

provide the EQ adjustment needed when FreeSpace

6 systems are configured with Surface-

mount loudspeakers (as opposed to the Flush-mount FreeSpace 6 speakers).

4. Power Amplifier PCB

4.1 PA PCB Schematic Sheet 8

U301, part of U300, and U302 implement a acoustically correct low frequency compensation

for more natural bass. The other two sections of U300 process the signal CD-DIA (“clipdetect-diagnostic”, see Sheet 10) into a control signal that is sent through P2A, remote volume

control circuit on Sheet 7 . CD-DIA becomes active when the power amplifiers are driven into

clipping. This in turn causes the remote volume control circuit to be turned down so that clipping ceases.

4.2 PA PCB Schematic Sheet 9

U303 combines the low frequency compensation signal with the full range signals and then

equalizes them to compensate for room acoustic and speaker driver characteristics.

4.3 PA PCB Schematic Sheet 10

U304 and U307 are power amplifiers with differential outputs. Both amplifier outputs can

deliver 16 watts into the nominal 2 ohm load of a pair of FreeSpace 6 speakers. The CD-DIA

pins are pulled low when the amplifiers begin to clip. This is used to control a compressor

implemented on Sheet 9 and Sheet 7.

D306 develops the DC power supply for the power amplifier. Q305 and associated components constitute a shunt voltage regulator which only conducts in the unlikely event of both a

high power line voltage and a low or no signal output case. It holds 18V maximum which is

presented to U304 and U307.

D305, U305, and U306 are the +/-15V supply for all the circuits except for the power amplifier.

The power transformer secondary plug can be inserted two ways; one way will handle a nomi-

nal 120VAC main, the other a nominal 240VAC main. The two orientations of this plug are

noted on the PCB.

9

Page 10

5. Remote PCB

REM PCB Schematic Sheet 11

The circuits on this sheet are contained on a small PC board inside the remote control. The

potentiometer is wired as a 10K ohm rheostat and controls the remote volume control circuits

on Sheet 6, while the SPST switch controls the Music Selector on Sheet 1.

10

Page 11

DISASSEMBLY/ASSEMBLY PROCEDURES

Main Assembly Procedures

Note: Certain parts will be referred to in

these procedures. The numbers in parentheses represent individual parts called out

in Figure 1. The callout numbers correspond to those on the part lists.

1. Chassis Cover/Top Cover Removal

1.1 Place the amplifier flat on the work-

bench with the Bose

corner.

1.2 Detach the chassis cover (1) by holding

both corners and pulling upward. Once the

cover is loosened, slide the bottom tabs out

and away from the unit.

1.3 Use a phillips-head screwdriver to

remove two silver screws (2) securing the

chassis top cover (3).

®

logo in the upper-left

2.2 Align the screw holes of the top cover

with the screw mounts located on the base.

Also align the four metal tabs on the base

with the tab slots on the cover. There are

also six metal tabs located on the bottom

edges of the cover that must be aligned

when the cover is finally seated.

2.3 Slide the cover down over the base

until the screw holes are aligned and all tab

slots are locked into place.

2.4 Secure the chassis top cover (3) by

tightening two silver screws (2) with a

phillips-head screwdriver.

2.5 Position the three bottom tabs on the

chassis cover into the slots located in the

chassis base. Press the chassis cover

down over the chasis-top cover to secure it.

3. Amplifier PCB Removal (Chassis Base)

1.4 Gently lift the right side of the chassis

top cover up at a 45° angle and pull to the

right and up. This is done to clear the left

screw mount away from the Amp PCB (8)

when the cover is lifted off.

IMPORTANT: Be careful not to pull the

three cables connected to the Amp PCB (8)

assembly. They must be disconnected

before final removal of the chassis-top

cover.

2. Chassis Cover/Top Cover Replacement

2.1 Place the chassis-top cover (3) over the

chassis base (4). Align the cover so that

the left-side screw mount of the chassis

base will slide between the IO1 PCB (8)

and the inside surface of the chassis-top

cover. Otherwise there will be difficulty

securing the cover.

3.1 Remove the Chassis Cover/ Top Cover

(Procedure 1) .

3.2 Separate the chassis-top cover from

the base by disconnecting both two-pin

cables from the Amp PCB's (8) P3A and

P3B connectors. Disconnect the eight-pin

cable from the Amp PCB's P2A connector.

3.3 Disconnect the following cables:

• Disconnect the transformer's five-pin

primary cable from the Amp PCB's P7

connector.

• Disconnect the transformer's five-pin

primary cable from the Amp PCB's P4

connector.

• Disconnect the main power two-pin

primary cable from the Amp PCB's P4

connector.

IMPORTANT: Be sure to notice the orientation of the transformer's five-pin primary

cable. Pin 1 is keyed to pin 1 of Amp PCB

connector P6 (or P7 depending upon the

unit's applicable voltage rating).

11

Page 12

CHASSIS COVER

1

2

CHASSIS

TOP COVER

COUPLER

BAR

3

IO1 PCB

7

8

6

IO2 PCB

8

8

AMP ASSY

5

9

P3B

P2

P5

P3A

5

10

12

5

CONNECT

TO P3B

BLU./GRY.

CONNECT

TO P3A

RED/BLK.

PRIMARY

5

2X

11

CONNECT

TO P5

CHASSIS

BASE

4

SECONDARY

13

Figure 1. Main Disassembly/Assembly Exploded View

12

Page 13

3.4 Remove two black screws (5) from the

Amp PCB (8) and three black screws (6)

from the Heatsink (7).

3.5 Remove the Heatsink/Amplifier PCB

Subassembly from the chassis base.

3.6 Place the subassembly on the workbench with the heatsink (7) fins down.

3.7 Remove three black decoupler bar

screws (5) that connect the heatsink to the

Amplifier PCB.

3.8 Remove the Amplifier PCB (8) from the

heatsink.

4. Amplifier PCB Replacement (Chassis

Base)

IMPORTANT: Thermal grease should be

applied to the heatsink before seating the

PCB.

4.4 Connect the following cables:

• Connect the main power's two-pin cable

to the Amp PCB's P5 connector.

• Connect the tranformer's secondary fivepin cable to the Amp PCB's P4 connector.

• Connect the transformer's primary five-pin

cable to the Amp PCB's P7 connector.

IMPORTANT: Pin 1 of the transformer's

five-pin primary cable is keyed to pin 1 of

Amp PCB connector P6 (or P7 depending

upon the unit's applicable voltage rating).

4.5 Install the Chassis Cover/Top Cover

(Procedure 2).

5. Transformer Removal

5.1 Remove the Chassis Cover/Top Cover

(Procedure 1).

5.2 Disconnect the following cables from

the transformer:

4.1 Place the Amplifier PCB (8) onto the

heatsink (7). Align the coupler bar (9) screw

holes with the screw holes of the heatsink.

The PCB should be component side up

with the power devices resting on the inner

side of the heatsink.

4.2 Secure the coupler bar and Amplifier

PCB to the heatsink by tightening three

black screws (5).

IMPORTANT: Make sure that the coupler

bar does not make contact with the metal

tab of transistor Q305.

4.3 Place the Heatsink/Amplifier PCB

subassembly solderside down into the

chassis base. Secure the upper-left hand

corner of PCB onto the standoff snap.

Secure the subassembly to the chassis

base by tightening two black screws (5) on

the Amp PCB and three black screws (6)

on the heatsink.

• Disconnect the transformer's five-pin

primary cable from the Amp PCB's P7

connector.

• Disconnect the transformer's five-pin

primary cable from the Amp PCB's P4

connector.

5.3 Remove transformer cables from cable

clamps (12) and lift the transformer from

the chassis base (4).

6. Transformer Replacement

6.1 Place the transformer (10) into the

recess of the chassis base and align it with

the chassis base mounting holes. Make

sure that the primary side is facing the IEC

Connector Assembly

(13).

6.2 Place the two transformer clips (11)

over the transformer's mounting tabs.

Secure the transformer to the chassis base

by tightening the two black screws (5).

13

Page 14

6.3 Connect the following cables:

• Connect the transformer's five-pin secondary cable to the Amp PCB's P4 connector.

• Connect the transformer's five-pin primary cable to the Amp PCB's P7 connector.

IMPORTANT: Pin 1 of the transformer's

five-pin primary cable is keyed to pin 1 of

Amp PCB connector P6 (or P7 depending

upon the unit's applicable voltage rating).

6.4 Install the Chassis Cover/Top Cover

(Procedure 2).

7. IO1 & IO2 PCB Removal (Chassis Top)

7.1 Remove the Chassis Cover/Top Cover

(Procedure 1).

8. IO1 & IO2 PCB Replacement (Chassis

Top)

8.1 Connect the 12-pin cable to connector

P1A on the larger board.

8.2 Carefully align both board's connectors

into the chassis top cover and snap them

onto the chassis standoffs.

8.3 Secure the two-pin and the eightpin cables into the cable clamps (12).

8.4 Replace six black screws (5) and

tighten to secure both boards.

8.5 Install the Chassis Cover/Top Cover

(Procedure 2).

7.2 Remove six black screws (5) from both

Amplifier IO PCB's (8). Remove the IO2

PCB board first. Grasp it by the top corners, lift up and off the chassis-top's standoffs. (Note: The IO boards are connected

by a 12-pin cable. Do not attempt to separate until both are removed).

7.3 Remove both two-pin and eight-pin

cables from the cable clamp (12) from the

inside of the chassis-top cover.

7.4 Grasp the IO1 PCB board by its top

corners, lift up and off the chassis-top's

standoffs. Position the board at a 45° angle

and carefully pull it back so that the I/O

connectors clear the top cover.

7.5 To separate boards, disconnect the 12pin cable from connector P1A on the larger

board.

14

Page 15

Flush-Mount Loudspeaker Procedures

1. Flush-mount Loudspeaker

NOTES: Certain parts will be referred to in

these procedures. The numbers in parentheses correspond to the individual parts

called out in Figure 2.

C. Use Procedure 1.2 to return the grille to

the enclosure.

1.5 Terminal Cup Removal

A. Use a phillips-head screwdriver to

remove one screw (7) from the junction-box

cover.

1.1 Grille Removal

To remove the grille (Not Shown) take a

scribe or a small flat-head screwdriver to

grasp an edge of the grille. Gently lift the

grille out from the enclosure (2).

1.2 Grille Installation

Push the grille into the enclosure (2) until it

is flush with the rim of the enclosure.

Orientation of the logo is not necessary.

1.3 Driver Removal

A. Use Procedure 1.1 to remove the grille

from the enclosure (2).

B. Use a phillips-head screwdriver to

remove four screws (3) securing the driver

(4) to the enclosure's baffle (6). Carefully lift

the driver from the enclosure and cut the

wires as close to the terminals as possible.

1.4 Driver Replacement

A. Strip the terminal wires from the terminal

cup (5) and connect them to the replacement driver (4). Connect the red wire to the

+ positive terminal and the black wire to the

- negative.

B. Swivel the junction-box cover out to

expose the terminal cup (5) in the recess of

the speaker enclosure (2).

C. Use a phillips-head screwdriver to

remove three screws (3) that secure the

terminal cup to the speaker enclosure.

D. Use Procedure 1.3 to remove the driver

(4) from the speaker enclosure (2).

E. Disconnect the terminal wires from the

driver and remove the faulty terminal cup.

1.6 Terminal Cup Replacement

A. Use Procedure 1.4 to connect the

replacement terminal cup (5) to the driver

(4).

B. Place the enclosure (2) on its side. Fit

the terminal cup into the slot at the back of

the enclosure. See Figure 2 for the proper

orientation of the terminal.

C. While holding the terminal from the

inside of the enclosure, tighten three

screws (3) with a phillips-head screwdriver.

D. Use Procedure 1.4 to secure the driver

(4) to the enclosure.

B. Align the driver so their four screw holes

align with the screw holes of the

enclosure's baffle (6). Secure the driver to

the enclosure (2) by tightening four screws

(3) with a phillips-head screwdriver.

E. Use Procedure 1.2 to secure the grille

to the enclosure.

15

Page 16

Junction-Box

Cover

7

Surface-Mount Loudspeaker Procedures

1. Surface-Mount Loudspeaker

3

NOTE: The Surface-mount Loudspeaker

8

has only two removable and replaceable

parts, the grille and the grille's scrim cloth.

Refer to the Surface-mount Assembly Part

List for the grille and scrim cloth's order

2

numbers.

1.1 Grille Removal

5

Red

4

Black

The Baffle is

6

Adhered to

Enclosure

3

Item 1 on the

Packaging Part List

Figure 2. Flush-Mount Loudspeaker

Exploded View

Grasp one edge of the grille with a small

scribe and gently pull the grille from the

enclosure. The grille's scrim cloth is behind

the grille.

1.2 Grille Replacement

1. Place the scrim cloth inside the grille.

2. Place the grille over the twiddler section

of the enclosure (Refer to Figure 3 for the

correct orientation). Press the grille until it

snaps into place.

16

Page 17

Grille

Figure 3. Surface-mount Loudspeaker

17

Page 18

TEST PROCEDURES

Main Assembly Test Procedures

Test Set-Up Parameters

Switches

All switches are referenced by their block

diagram location on the top of the unit. Set

them according to the table below.

Block

No.

10 Line Output Mode center(Music

Switch Description Setting(s)

1 Page Source Gain left (0dB)

2 Optivoice Compressor left(off)

5 Page Enables Left and

Right

7 Music Compressors A

and B

9 Music Input Mode rear(stereo)

right(on)

forward(off)

+Page)

Input Connections

Page Input

Connect the positive (+) side of an oscilla-

tor to the positive input terminal. Connect

the negative (-) side to the negative (-) and

common input terminals. Do this using

quick connectors (P/N180094) supplied

with the unit.

Music RCA Inputs A, B (Left and Right)

Connect the positive (+) side of an oscilla-

tor to the positive input terminal on the RCA

jack. Connect the negative (-) side to the

negative (-) and RCA jack ground sleeve.

Output Connections

Page and Line Outputs (Left and Right)

Potentiometers

All potentiometers are referenced by

their block diagram location on the top of

the unit. Set them according to the table

below.

Block

No.

1 Page Source Gain

3 Page Trigger

4 Page Mix Trim cw(max)

6 Music A and B Source

12 Treble and Bass Trim center(flat)

13 Volume Trim Right cw(max

Pot. Description Setting(s)

ccw(0dB)

Trim

cw(max)

Level

cw(max

Trim

gain)

gain)

Connect the positive (+) side of the test

equipment to the positive (+) output terminals. Connect the negative (-) side to the

negative (-) output terminals. Do this using

quick connectors (P/N180094) supplied

with the unit.

Speaker Output (Left and Right)

Use the same output connections as above

with a 2Ω/50Watt resistor as a load.

All test equipment should be isolated

from ground (floated).

18

Page 19

1. Page Input To Page Output Gain

6. Noise

1.1 Apply a 5 Vrms, 1KHz signal to the

Page Input.

1.2 Measure the Page Output. Should be

4.22 Vrms (+ .78 Vrms/ - .67 Vrms).

2. Page Input To Line Outputs Gain

2.1 Apply a 5 Vrms, 1KHz signal to the

Page Input.

2.2 Measure the left and right Line Output.

Should be 4.22 Vrms (+1.09 Vrms/ -.87

Vrms).

3. Music Input A to Line Outputs Gain

3.1 Apply a 500mV rms, 1KHz signal to the

Music A left and right input.

3.2 Measure the left and right Line outputs.

Should be 4.47 Vrms (+.84 Vrms/ - .71

Vrms).

Note: Repeat this test for Music Input B.

To select Music Input B, short the remote

select input.

4. Music Input A to Speaker Outputs Gain

6.1 Set the volume control to Max.

6.2 With the source off, measure the left

and right Speaker output. Should be

mVrms.

7. Full Power Distortion

7.1 Apply a 130 mVrms, 800 Hz signal to

the left input.

7.2 Measure the distortion at the left

Speaker output. Should be

7.3 Change the frequency to 95 Hz and

adjust the applied signal to get 5.66 Vrms at

the left Speaker output.

7.4 Measure the distortion at the left

Speaker output. Should be

Note: Repeat this procedure for the right

channel.

8. Separation

8.1 Apply a 100 mVrms, 800Hz to the right

Music A Input. Terminate the left Music A

Input with a 50

Ω resistor.

≤ 1% THD.

≤ 2 %.

≤ 5.6

4.1 Apply a 10 mVrms, 2KHz signal to the

left and right Music A input.

4.2 Measure the Speaker output. Should be

290 mVrms (+54mVrms/ - 46mVrms).

5. Frequency Response

5.1 Apply a 10 mVrms, 2KHz signal to the

left and right Music A Input.

5.2 Reference a dB meter to the Speaker

output and set level to 0 dBr.

5.3 Change the signal to 12.5 KHz.

5.4 Measure the left and right Speaker

output. Should be 5.1 dBr (

± 2.0 dB).

8.2 Measure the left Speaker output.

Should be

Note: Repeat this procedure for the right

channel.

19

≤ 10 mV.

Page 20

Loudspeaker Test Procedures

NOTE: These procedures apply to both Flush-mount and surface-mount loudspeakers. The surface-

mount loudspeaker is not repairable. If this loudspeaker fails the following tests contact your Bose® Field

Service Representative.

1. Rub and Tick Test

Apply a signal of 6.0 Vrms at 80 Hz to the input terminals of the loudspeaker. See Figure 1. No

extraneous noises such as rubbing or ticking should be heard. Replace any driver that has a rubbing or

ticking noise.

NOTE: There is a normal suspension noise. To distinguish between a rub or tick and suspension noise,

displace the cone slightly with your finger. If the rubbing can be made to go away or get worse, then it is a

rub or tick and the driver should be replaced. If the noise stays the same, it is a suspension noise and the

driver is fine. Suspension noise will not be heard with program material.

2. Air Leak Test

Apply a signal of 6.0 Vrms ± 1V at 80 Hz to the speaker input terminals. See Figure 1. For at least 5

seconds, listen for air leaks around the driver, speaker terminals, and along all cabinet joints. Repair air

leaks as required.

3. Sweep Test

Sweep the oscillator from 50 Hz to 5 kHz at 6Vrms. There should not be any loud extraneous sounds. If

there are any loud buzzes or distortion, replace the driver. The whooshing noise from the port at around

80 Hz is acceptable.

NOTE: There should not be any buzzes or rattles from the internal connecting wires or components.

Redress any wire or component that buzzes.

Input Terminals

Figure 1. Input Terminals

4. Phase Test

NOTE: Supply voltage should only be momentarily applied to the speaker input terminals to avoid

possible damage to the speaker.

Apply a 6 Vdc ± 1 Vdc signal to the speaker input terminals (see Figure 1). The driver should move

outward.

20

Page 21

PART LISTS AND EXPLODED VIEWS

The following section contains part lists and exploded views for the FreeSpace®6 business

music system. The part lists are broken down as follows:

• Main Assembly Part List and Main Assembly Exploded View.

• Remote Assembly Part List and Remote Assembly Exploded View

• Main Assembly Packaging Part List and Main Assembly Packaging Exploded View.

• Flush-mount Loudspeaker Assembly Part List and Exploded View.

• Flush-mount Loudspeaker Assembly Packaging Part List and Packaging Illustration.

• Surface-mount Loudspeaker Assembly Part List and Illustration.

• Surface-mount Loudspeaker Assembly Packaging Part List and Packaging View.

• Electrical Part Lists : These lists contain all electrical and mechanical parts located

on the PCB assembly 177300, Revisions 0 and 1.

PCB layouts and schematics are located in the back of the service manual.

21

Page 22

Main Assembly Part List (Figure 4)

Item

Number

Description Part Number Qty

Per

See

Note

Assy

1

Chassis,Cover,FreeSpace®6

2 Screw,Mach,8-32,Pan,Xrec/Slot 172715-08 2

3 Chassis,Top Cover,FreeSpace 6 177286 1

4 Chassis,Base,FreeSpace 6 177285 1 4

5 Screw,#8-32x.25,Pan,Xrec 179096-04 13

6 Screw,#8-32x2.75,Pan,Xrec 179096-44 3

7 Heatsink,FreeSpace 6 177283 1 4

8 Pcb Assy,FreeSpace 6,Amp,S/f 181692 1 1,3

9 Coupler Bar,FreeSpace 6 177284 1

10 Transformer,120/240V,FreeSpace 6 177278 1 2

!

Transformer,100V,FreeSpace 6 178892

177287 1

11 Clip,Transformer 179108 2

12 Clip,Cable,Dbl Face Adh,.76" 131062 3

13 Conn Assy,IEC Receptical 179064 1

14 Nut,Hex,8-32,keps 100413-2 1

Notes:

1. The individual parts located on the PCB's are listed in the Electrical Part List.

!

2. This part is critical for safety purposes. Failure to use a substitute replacement

with the same safety characteristics as the recommended replacement part might create

shock, fire and/or other hazards.

3. The PCB Assembly is divided into three parts: the Amplifier PCB, IO1 PCB, and IO2

PCB. The PCB locations are identified on the FreeSpace 6 Exploded View. This

information is provided for reference only.

4. This part is not normally available from Customer Service. Approval from the Field

Service Manager is required before ordering.

22

Page 23

CHASSIS

TOP COVER

3

IO1 PCB

7

1

CHASSIS COVER

2

LOCATE WITHIN

BOX EMBOSSED

ON CHASSIS

12

1

1

1

1

8

6

12

C43

LOCATE WITHIN

12

BOX EMBOSSED

ON CHASSIS

14

COUPLER

BAR

CHASSIS

BASE

9

5

4

IO2 PCB

SECONDARY

P3B

8

AMP ASSY

8

P2

P3A

P5

CONNECT

TO P5

5

10

5

11

5

CONNECT

TO P3B

2X

PRIMARY

13

Figure 4. Main Assembly Exploded View

TOP VIEW

23

Page 24

Remote Assembly Part List

Item

Number

Description Part Number Qty

Per

See

Note

Assy

1 PCB Assy,FreeSpace 6,AMP,S/F 181692 1

2 Cover,Remote,FreeSpace 6,Europe 178101 1

Cover,Remote,FreeSpace 6,Japan 178102 1

Cover,Remote,FreeSpace 6,Aus,Am/Can 178103 1

3 Knob,Remote,FreeSpace 6 178104 1

4 Screw,OVLHD,6-32x1.00,Am/Can 178115-16 2

Screw,OVLHD,M3.5x25mm,Aus,Europe 178116-25 2

Screw,OVLHD,M4x25mm,Japan 178117-25 2

5 Screw,TAPP,6-13x.5,PAN,XREC 173555-08 2

6 Cable Tie 135540 2

7 Bag,Poly,6x10x5 mil 147794 1

4

3

2

1

6 2 PLCS.

BLACK

YELLOW

7

5

Figure 5 Remote Assembly Exploded View

24

Page 25

Main Assembly Packaging Part List (Figure 5)

Item

Number

Description Part Number Qt y

Per

See

Note

Assy

1 Packing, Endcap, EPS, Left 177949 1

2 Polybag, 12"x8"x24" 143076 1

3 Packing, Endcap, EPS, Right 177305 1

4 Rem,RVC Walplt,Frspc 6,US/CAN 178111 1

Rem,RVC Walplt,Frspc 6,Eur 178113

Rem,RVC Walplt,Frspc 6,Japan 178112

Rem,RVC Walplt,Frspc 6,Australia 181735

5 Packing, Crease Sheet 177950 1

6 Line Cord,120V,Detachable, US/CAN 173350 1 1

!

Line Cord,230V,Detachable,UK 173351

Line Cord,230V,Detachable,Europe 173352

Line Cord,240V,Detachable,Australia 173354

Line, Cord,100V,Detachable,Japan 181690

7 Carton, RSC 177948 1

8 Lit kit Assy,FS6,F/S,Japan 181704-1 1

Lit kit Assy,FS6,F/S, Australian, Eur,UK,

181704-2

US/Can

9 Connector Kit, Assy 180094 1

Note:

!

1. This part is critical for safety purposes. Failure to use a substitute replacement

with the same safety characteristics as the recommended replacement part might create

shock, fire and/or other hazards.

25

Page 26

8

1

2

3

9

4

5

6

7

Figure 6. Main Assembly Packaging Exploded View

26

Page 27

Flush-mount Assembly Part List

Item

Description Part Number Qty See

Number

1 Grille Assy. 1

2 Enclosure Assy, Back Can, 102-F6 ----------- 1 *

3 Screw, Hilo, 8, Pan, Xrec 172721-10 7

4 Twiddler, 2.25" 149167 1

5 Cup, Terminal 176459 1

6 Baffle, 75 Cu In, White ----------- 1 *

7 Screw, Mach, 8-32, Pan,Xrec/Slot 172715-08 1

8 Foot, Clear, .312x.085, Bulk 178321-99 2

*This part was listed and illustrated for reference purposes only.

7

Note

Junction-Box

Cover

5

Red

4

3

8

2

Black

The Baffle is

6

Adhered to

Enclosure

3

Item 1 on the

Packaging Part List

Figure 7. Flush-mount Exploded View

27

Page 28

Flush-mount Packaging Part List

Item

Description Part Number Qty See

Number

1 Shield, Paint 180092 1

2 Grille Assy, 4pk, Wht 178133-2 1

3 Pan Mounting Assy, 4 Pk 178135 1

4 Spring Assy, 8 Pack, Freespace 6 178132 1

5 Carton, RSC 177752 1

6 Packing, Insert 177744 1

7 Packing, Crease Sheet, 18x21 177749 1

8 Packing, Crease Sheet, 16.07x5.75 177747 1

9 Packing, Crease Sheet, 20.75x17.0 177750 1

10 Bushing, Short,.75" 146046 1

11 Bag,Poly, 14.38x9.87x2 Mil 103351 1

12 Packing, Sheet, 8.75x8.75x.03 180023 1

Note

7

10

9

8

4

2

12

3

6

5

Figure 8. Flush-mount Loudspeaker Packaging Illustration

28

Page 29

Surface-mount Assembly Part List

Item

Description Part Number Qty See

Number

1 Knob, White 178149-02 1

Knob, Gray 178149-01 1

2 Grille, Speaker, Computer Gray 177146-01 1

Grille,Speaker, Arctic White 177146-02 1

3 Cloth, Scrim, Grille 181192 1*

*Part not illustrated

Note

23

1

Figure 9. Surface-mount Loudspeaker Illustration

29

Page 30

Surface-Mount Packaging Part List

Item

Description Part Number Qty

Number

1 Bracket, Wall, White 178146-02 4

Bracket, Wall, Gray 178146-01 4

2 Knob And Pkg Assy, Arctic White 181736-02 1

Knob And Pkg Assy, Gray 181736-01 1

3 Carton, 4 Pack 181535 1

4 Packing, End Cap, 181537 8

5 Packing, Crease Sht, 46.5x8.5 181536 1

6 Bag, Poly, 14.38x9.87x2 Mil 103351 4

2

5

Per

Pack

See

Note

1

6

4

3

Figure 10. Surface-mount Loudspeaker Packaging

30

Page 31

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Resistors

Reference

Description Part Number Reference

Designator

R1 Pot,Rotary,50kΩ,

10%,Dual

R2,3,5 Pot,Rotary,10kΩ,

10%,Single

R6-9 Pot,Rotary,10kΩ,

10%,dual

R10,11,27,3639,44,45,47,50,52,

53,55,56,61,63,64,

65,70-72,75,85,89,

96,99,101,107,110,

116,128,129,130,

135,152,202,204,

206,212,213,218,

219,221,222,240,

256,265,275,315,

319,321,322,336,

339,345, 378,379

R12,203,214,362 402Ω,1%,1/10W,

R13,18,59,76,87,94,

127, 137,291,331,

335, 355

R14-17,21,34,35,62,

66, 79,88,95,98,103,

106,109,112,136,

287,320

R19,20,86 1.54KΩ,1%,1/10W,

R22,23,311 5.62KΩ,1%,1/10W,

R24,25,28,29,31,

113,123,124,307,

310, 377

R26,253,255,267,

269,312

R32,58,74,151,257,

258,264,266,305

R33,90,92 1.2KΩ,2%,1/4W,

R40,117,200,216,

350,376

R41,208,306 301KΩ,1%,1/10W,

R42 26.7KΩ,1%,1/10W,

R43,121,143,201,

210,217,236,

10.0KΩ,1%,1/10W,

0805

0805

30.1KΩ,1%,1/10W,

0805

1.00KΩ,1%,1/10W,

0805

0805

0805

20.0KΩ,1%,1/10W,

0805

7.50KΩ,1%,1/10W,

0805

1MΩ,5%,1/10W,

0805

52mm,CF

100Ω,1%,1/10W,

0805

0805

0805

301Ω,1%,1/10W,

0805

177289-503

177290-103

177289-103

133625-1002

133625-4020

133625-3012

133625-1001

133625-1541

133625-5621

133625-2002

133625-7501

133626-1055

121243-1211222

133625-1000

133625-3013

133625-2672

133625-3010

31

Page 32

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Resistors (Continued)

Reference

Description Part Number Reference

Designator

R46,54,73,209 56.2KΩ,1%,1/10W,

0805

R51,119,120,125,12

6, 138-141,325,346

R57,91,97,102,104,

111,133,157,160,

207,224,241,277,

279,304,317,358

R60,78 68.1KΩ,1%,1/10W,

R67,83,237,301,333

353

R68 15.0KΩ,1%,1/10W,

R69 45.3KΩ,1%,1/10W,

R77,84 127KΩ,1%,1/10W,

R80 26.1KΩ,1%,1/10W,

R81 1.82KΩ,1%,1/10W,

R82,131,154 17.8KΩ,1%,1/10W,

R91,205,215,278,

326,327,347,349

R93,118,318 2.43KΩ,1%,1/10W,

R100,108 2.55KΩ,1%,1/10W,

R105,316,368, 370 47.5KΩ,1%,1/10W,

R114,357 200KΩ,1%,1/10W,

R115,134 73.2KΩ,1%,1/10W,

R122,142 4.75Ω,1%,1/10W,

R132,145,148,161,

232,242,260,262,

276,290,292,356,

374,380,381

R144,323,338,343,

363

R146,147,149,150 255Ω,1%,1/10W,

61.9KΩ,1%,1/10W,

0805

100KΩ,1%,1/10W,

0805

0805

4.12KΩ,1%,1/10W,

0805

0805

0805

0805

0805

0805

0805

15.0KΩ,1%,1/10W,

0805

0805

0805

0805

0805

0805

0805

Jumper,Chip,0805

2.00KΩ,1%,1/10W,

0805

0805

133625-5622

133625-6192

133625-1003

133625-6812

133625-4121

133625-1502

133625-4532

133625-1273

133625-2612

133625-1821

133625-1782

133625-1503

133625-2431

133625-2551

133625-4752

133625-2003

133625-7322

133625-4R75

133627

133625-2001

133625-2550

32

Page 33

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Resistors (Continued)

Reference

Description Part Number Reference

Designator

R153 27.4KΩ,1%,1/10W,

0805

R155158,239 5.11KΩ,1%,1/10W,

0805

R156,159 Pot,Rotary,10KΩ,

10%, 1/2W,Trim

R211,280,340 88.7KΩ,1%,1/10W,

0805

R220,223 11.0KΩ,1%,1/10W,

0805

R238,308,309,313,

314

R254,259,268,274 18.2KΩ,1%,1/10W,

R270-273 57.6KΩ,1%,1/10W,

R300 25.5KΩ,1%,1/10W,

R302 6.49KΩ,1%,1/10W,

R303,324,344 14.0KΩ,1%,1/10W,

R324,337,359 7.15KΩ,1%,1/10W,

R328,352 110KΩ,1%,1/10W,

R329,342 9.09KΩ,1%,1/10W,

R330,354 23.7KΩ,1%,1/10W,

R332,334,348,351 4.99KΩ,1%,1/10W,

R341,375 38.3KΩ,1%,1/10W,

R364 2.74KΩ,1%,1/10W,

R366,367,369,372 RES,CF,1/4W,5%,1

R371 Jumper,22AWG,

R373 196Ω,1%,1/10W,

R500 Pot,Rotary,10kΩ,

4.75KΩ,1%,1/10W,

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0 OHM

Non-Insul,10.0mm

0805

10%

133625-2742

133625-5111

170042-103

133625-8872

133625-1102

133625-4751

133625-1822

133625-10R0

133625-2552

133625-6491

133625-1402

133625-7151

133625-1103

133625-9091

133625-2372

133625-4991

133625-3832

133625-2741

121243-1211005

148242-100

133625-1960

177299-103

33

Page 34

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Capacitors

Reference

Description Part Number Reference

Designator

C1,2,29,123,200,

205

C3,7,23,24,25,35,

47,50,51,63,89,93,

100,103,116,117,

118,119, 120

C4,5,36,38,54,86,

90,102,105,202,217,

227,237,301,304,

309,335,348

C6,14,19,39,106,

107,112,113,

114,115,121,122

C8,11,15,18,20,27,

32,46,53,57,62,65,

76, 77,80,81,88,92,

94, 95,96,101,109,

110, 153,201,204,

206, 208,216,218,

220, 222,223,226,

238, 300,307,308,

310, 311,321,324,

501, 512

C9,43,55,79,98,207,

219,312,322

C10,41,59,224,239 10pF,5%,50V,0805,

C12,17,108,111,

242,243,244,245,

339, 340,353,354,

357,361,362

C13,314,315,329,

330

C16,320,331,355,

356, 359,360

C21,26,49,52,70,74 680pF,5%,50V,

C22,48,68,69,71,75,

84

C28 47uF,20%,16V,105,

C30,33,34,37,40,56,

58,61,66,67,83,85

C31,72,73,78,82,

333,334,349,352

C42,303 15uF,5%,50V,85,

.01uF,10%,50V,

X7R,0805

47pF,5%,50V,0805,

COG

10uF,20%,35V,85,

EL

100pF,5%,50V,

0805,COG

.022uF,10%,50V,

X7R,0805

1.0uF,20%,50V,105,

EL

COG

.10uF,80%,25V,

Y5V,0805

18uF,5%,50V,85,

BOX

1000pF,5%,50V,

0805,COG

0805,COG

4.7uF,20%,35V,105,

EL

EL

2.2uF,20%,50V,105,

EL

.1uF,5%,50V,85,

BOX

BOX

133623-103

133622-470

149948-100V

133622-101

133623-223

137126-1R0

133622-100

133624

137127-184

133622-102

133622-681

137126-4R7

137126-470

137126-2R2

137127-104

137127-154

34

Page 35

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Capacitors (Continued)

Reference

Description Part Number Reference

Designator

C44 220uF,20%,25V,85,

EL

C45,60 100uF,20%,25V,85,

EL

C64,319,327,337,

350, 351

C87 .47uF,5%,50V,85,

C104,203,341,342 22uF,20%,25V,85,

C225,240,248-250 390pF,5%,50V,0805

C228,241 .0012uF,5%,100V,

C229,230,246,247 .047uF,5%,63V,85,

C302 .068uF,5%,63V,85,

C306 1800pF,10%,50V,

C313,317,325,326 .0015uF,5%,100V,

C336,345 2200uf,20% ,50v,

C344,346,347 3300uf,20%,35v,

C363,364 1000pf,20%,250vac,

!

.22uF,5%,50V,85,

BOX

BOX

EL

,COG

85, BOX,

BOX

BOX

X7R,0805

85,BOX

105,EL

105,EL

Y-type,

149948-221E

149948-101E

137127-224

137127-474

149948-220E

133622-391

137127-122

137127-473

137127-683

133623-182

137127-152

144000-222H

144000-332V

170183

Note:

!

1. This part is critical for safety purposes. Failure to use a substitute replacement

with the same safety characteristics as the recommended replacement part might create

shock, fire, and/or other hazards.

35

Page 36

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Diodes

Reference

Description Part Number Reference

Designator

D1,3,4,6 LED,2.5v,10ma

Green,Vertical

D2,5 LED,2.5v,10ma,

Grn/Red,Vertical

D10,11,13-

Dual,SOT-23,BAV99 147239

17,22,24,107,201,

204,300

D12,20,21,200,302,

309,310

Switching,75V,

300mA

D18,19,23,202,203 Zener,18V,1W,5%,

1N4746

D25,27,29,301 Dual,SOT-23,BAV70 147249

*D305 Rectifier,Bridge,

!

100v,1.0a

*D306 Rectifier,Bridge,

!

1 00v,6a

D307 Zener,16V,1W,5%,

1N4745

Transistors

177280

177281

121501

116995-4746A

143952 *See Note 1

170214 *See Note 1

116995-4745A

Reference

Description Part Number Reference

Designator

Q1,2,202,300,304 BPLR,N,40V,200mA

,SOT23

Q3-7 BPLR,N,SOT23,2S

D2114K

Q200 BPLR,P,60V,200mA,

TO-92

Q201 BPLR,N,30V,500mA

,TO-92

Q203,301,302 BPLR,P,40V,200mA,

SOT23

Q305 DARL,NPN, Tip140 177310

Note:

!

1. This part is critical for safety purposes. Failure to use the recommended

replacement part may create shock, fire and/or other hazards.

146819

177294

119168

173476

148596

36

Page 37

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Integrated Circuits

Reference

Description Part Number Reference

Designator

U1-4,10,15,200,

202-205,301

U11,12 Switch,Active,

U201 Op-Amp,Dual,

U302 Op-Amp,Single,

U5,7 Compandor,

U6,13,14,300,303 OpAmp,Quad,

U8 Multiplexer/

U9 Multiplexer,

U302 Op Amp,Sngl,DIPU304,307 Power Amp,Mult-11,

U305 Voltage

U306 Voltage

Op-Amp,Dual,

DIP-8,RC4559

SIP-8,BA3128N

DIP-16,CN3280

DIP-8,CA3080

NE572N

DIP-14,NJM2059

Demultiplexer,8CH,

DIP-16,4051

DIP-16,CD4052

8,CA3080

45W,TDA7396

Regulator,15V,Pos.,

TO-220

Regulator,15V,Neg.,

TO-220

108568

177292

133171

119834

178894

144008

177308

147243

119834

177279

143858

143806

37

Page 38

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Miscellaneous Components

Reference

Description Part Number Reference

Designator

*F1,2 Fuse,630ma

!

5x20mm

*F3,4 Fuse,Time

!

Lag,Auto,400mA

(Inv.)

*F5 Fuse,10.0A,

!

5x20mm,Slo Blo

*F6 Fuse,3.0A,250V,

!

.60x.19,Slo Blo

FC1A,2A,5A,F61A,

Fuseclip,5mm 178548

62A,65A,FC1B,C2B,

C5B, F61B,62B,65B

JP300 Jumper,22AWG,

Non-Insul. ,10.0mm

J1,2,9,10 Connector,Rt.Ang.,

3 pos,Blk

J11,8 Connector,Rt.Ang.,

2 pos,Blk

J12 Connector,Rt.Ang.

Beau

J3 Connector,Rt.Ang.,

5 pos,Blk

J4,5 Connector,RCA,

Dual,Female

K1 Relay,24 Vdc,4PDT 144017

P1 Harness,26

AWG,Freespace 6

P1A Connector,Header,

12 pos

P2 Harness,24

AWG,Freespace 6

P2A Connector,Header,

8 pos

P3 Harness,22

AWG,Freespace 6

P3A ,3B Connector,Header,

Inline,PCB Mnt.,2p

P4 Connector,Header,

Inline,PCB Mnt.,5p

P5 Connector,Header,

2 pos

P6 Connector,Header,

High Current 8mm

pitch

140346-0630 *See Note 1

177312-0400 *See Note 1

177311-10000 *See Note 1

135677-10 *See Note 1

148242-100

177291-03

177291-02

177291-08

177291-05

177295

177298-12

148591-12

177298-08

148591-08

177296

133220-02

133220-05

143963

178742-4

38

Page 39

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 0

Miscellaneous Components

Reference

Description Part Number Reference

Designator

P7 Connector,Header,

178742-4

High Current 8mm

pitch

P9 Connector,Header,5

148591-05

pos

S1-6,S9 Switch,Slide,DPST,

176148

Vertical

S7 Switch,Slide,DPDT 176147

S10 Switch,DIP,SPST,

148777-1

4 pos.

SW500 Switch,SPST,

178108

Rocker

TP1-9,10,500, Connector,Header,

171621-0103

Test Jack,1

pos.,OR

VR300 Varistor,Met. Oxide,

!

170189

275V,75 joule

Note:

!

1. This part is critical for safety purposes. Failure to use a substitute replacement

with the same safety characteristics as the recommended replacement part might create

shock, fire and/or other hazards.

39

Page 40

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Resistors

Reference

Description Part Number Reference

Designator

R1 Pot,Rotary,50kΩ,

10%,Dual

R2,3,5 Pot,Rotary,10kΩ,

10%,Single

R6,7 Pot,Rotary,20kΩ,

10%,Dual

R8,9 Pot,Rotary,10kΩ,

10%,Dual

R10,11,27,36-39,

44,45,47-50,52,53,

55,56,61, 63-65,

70-72,75,85,89,96,

99,101,107,110,116,

128-130,135,152,

202,204,206,212,

213,218,219,221,

222,232,240,242,

256,265,275,315,

319,321,322,336,

339,345,378,379

R12,203,214,362 402Ω,1%,1/10W,

R13,18,59,76,87,94

127,137,291,331,

355

R14-17,21,34,35,62,

66,79,88,95,98103,

106,109,112,136,

229,247,287,320

R19,20,86,226,231,

249,252

R22,23 5.62KΩ,1%,1/10W,

R24,25,28,29,31,

113,123,124,155,

158,307,310,377

R26 7.50KΩ,1%,1/10W,

R32,58,74,151,257,

258,264,266,305

R33,90,92 1.2KΩ,2%,1/4W,

R40,117,200,216,

350,376

R41,208,306 301KΩ,1%,1/10W,

R42 26.7KΩ,1%,1/10W,

R43,121,143,201,

210,217,236

10.0KΩ,1%,1/10W,

0805

0805

30.1KΩ,1%,1/10W,

0805

1.00KΩ,1%,1/10W,

0805

1.54KΩ,1%,1/10W,

0805

0805

20.0KΩ,1%,1/10W,

0805

0805

1MΩ,5%,1/10W,

0805

52mm,CF

100Ω,1%,1/10W,

0805

0805

0805

301Ω,1%,1/10W,

0805

177289-503

177290-103

177289-203

177289-103

133625-1002

133625-4020

133625-3012

133625-1001

133625-1541

133625-5621

133625-2002

133625-7501

133626-1055

121243-1211222

133625-1000

133625-3013

133625-2672

133625-3010

40

Page 41

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Resistors (Continued)

Reference

Description Part Number Reference

Designator

R46,54,73,209,233,

243,

R51,119,120,125,

126,138-141,

325,328,346,352,

R57,91,97,102,104,

111,133,157,160,

207,224,241,277,

279,304,317,358

R60,78 68.1KΩ,1%,1/10W,

R67,83,237,301,

333,353

R68 15.0KΩ,1%,1/10W,

R69 45.3KΩ,1%,1/10W,

R77,84 127KΩ,1%,1/10W,

R80 26.1KΩ,1%,1/10W,

R81 1.82KΩ,1%,1/10W,

R82,131,154 17.8KΩ,1%,1/10W,

R100,108 2.55KΩ,1%,1/10W,

R105,234,244,316,

368,370

R114,357 200KΩ,1%,1/10W,

R115,134 73.2KΩ,1%,1/10W,

R118,318,93 2.43KΩ,1%,1/10W,

R122,142 4.75Ω,1%,1/10W,

R132,145,161,276,

290,292,380,381

R144,323,338,343,

363

R146,147,149,150 255Ω,1%,1/10W,

57.6KΩ,1%,1/10W,

0805

61.9KΩ,1%,1/10W,

0805

100KΩ,1%,1/10W,

0805

0805

4.12KΩ,1%,1/10W,

0805

0805

0805

0805

0805

0805

0805

0805

47.5KΩ,1%,1/10W,

0805

0805

0805

0805

0805

Jumper,Chip,0805 133627

2.00KΩ,1%,1/10W,

0805

0805

133625-5762

133625-6192

133625-1003

133625-6812

133625-4121

133625-1502

133625-4532

133625-1273

133625-2612

133625-1821

133625-1782

133625-2551

133625-4752

133625-2003

133625-7322

133625-2431

133625-4R75

133625-2001

133625-2550

41

Page 42

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Resistors (Continued)

Reference

Description Part Number Reference

Designator

R153 27.4KΩ,1%,1/10W,

0805

R156,159 Pot,Rotary,

10KΩ,10%,1/2W,

Trim

R205,215,278,326,

327,347,349

R220,223 11.0KΩ,1%,1/10W,

R230,250,303,324,

344

R235,245,330,354 23.7KΩ,1%,1/10W,

R238,308,309,313,

314

R239 5.11KΩ,1%,1/10W,

R253,255,267,269,

312

R254,259,268,274 18.2KΩ,1%,1/10W,

R270-273 57.6KΩ,1%,1/10W,

R280 56.2KΩ,1%,1/10W,

R300 25.5KΩ,1%,1/10W,

R302 6.49KΩ,1%,1/10W,

R311 5.62KΩ,1%,1/10W,

R329,342 9.09KΩ,1%,1/10W,

R332,334,348,351 4.99KΩ,1%,1/10W,

R337,359 7.15KΩ,1%,1/10W,

R340 88.7KΩ,1%,1/10W,

R341,375 38.3KΩ,1%,1/10W,

R364 2.74KΩ,1%,1/10W,

R366,367,369,372 10Ω,5%,1/4W,CF 121243-1211005

R373 196Ω,1%,1/10W,

R500 Pot,Rotary,10kΩ,

150KΩ,1%,1/10W,

0805

0805

14.0KΩ,1%,1/10W,

0805

0805

4.75KΩ,1%,1/10W,

0805

0805

8.25KΩ,1%,1/10W,

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

0805

10%

133625-2742

170042-103

133625-1503

133625-1102

133625-1402

133625-2372

133625-4751

133625-5111

133625-8251

133625-1822

133625-10R0

133625-5622

133625-2552

133625-6491

133625-5621

133625-9091

133625-4991

133625-7151

133625-8872

133625-3832

133625-2741

133625-1960

177299-103

42

Page 43

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Capacitors

Reference

Description Part Number Reference

Designator

C1,2,29,123,200,

205

C3,7,23-25,35,47,

50,51,63, 89,93,

100,103, 116-120

C4,5,36,38,54,90,

102, 105,202,217,

301, 304,309,335,

348

C6,14,19,39,106,

107,112-115,121,

122

C8,11,15,18,20,27,3

2,46,53,57,62,65,76,

77,80,81,88,92,9496,109,110,153,201,

204,206,208,216,

218,220,222,223,

226,238,300,307,

308,310,311,321,

324,501,512

C9,43,55,79,98,207,

219,312,322

C10,41,59,224,239 10pF,5%,50V,COG,

C12,17,108,111,

242-245,339,340,

343,353,354,357,

358, 361,362

C13,314,315,329,

330

C16,320,331,355,

356,359,360

C21,26,49,52,70,74 680pF,5%,50V,

C28 47uF,20%,16V,105,

C30,33,34,37,40,56,

58,61,66,67,83,85

C31,72,73,78,82,

214,235,333,334,

349,352

C22,48,68,69,71,75 4.7uF,20%,35V,105,

C42,303 .15uF,20%,50V,85,

.01uF,10%,50V,

X7R,0805

47pF,5%,50V,COG,

0805

10uF,20%,35V,85,

EL

100pF,5%,50V,

COG,0805

.022uF,10%,50V,

X7R,0805

1.0uF,20%,50V,105,

EL

0805

.10uF,80%,25V,

Y5V,0805

.18uF,5%,50V,85,

BOX

1000pF,5%,50V,

COG,0805

COG,0805

EL

2.2uF,20%,50V,105,

EL

.1uF,5%,50V,85,

BOX

EL

BOX

133623-103

133622-470

149948-100V

133622-101

133623-223

137126-1R0

133622-100

133624

137127-184

133622-102

133622-681

137126-470

137126-2R2

137127-104

137126-4R7

137127-154

43

Page 44

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Capacitors (Continued)

Reference

Description Part Number Reference

Designator

C44 220uF,20%,25V,85,

EL

C45,60 100uF,20%,25V,85,

EL

C48,68,69,71,75 4.7uF,20%,35V,105,

EL

C64,319,327,337,33

8,350,351

C86 10uF,20%,25V,85,

C87 .47uF,5%,50V,85,

C104,203,341,342 22uF,20%,25V,85,

*C209,227,232,

237

C210,231 .01uF,5%,100V,85,

C211,212,221,233 100pF,10%,50V,

C213,234 .0047uF,5%,100V,

C215,229,230,236,

246,247

C228,241 .0012uF,5%,100V,

C248-250 390pF,5%,50V,

C302 .068uF,5%,63V,85,

C306 1800pF,10%,50V,

C313,317,325,326 .0015uF,5%,100V,

C336,345 2200uf,20%,50V,

C344,346,347 3300uf,20%,35V,

.22uF,5%,50V,85,

BOX

EL

BOX

EL

0Ω,RES,Axial,.2W 139942 *See Note 1

BOX

DISC,SL

85,BOX

.047uF,5%,63V,85,

BOX

85,BOX

COG,0805

BOX

X7R,0805

85,BOX

105,EL

105,EL

149948-221E

149948-101E

137126-4R7

137127-224

149947-100E

137127-474

149948-220E

137127-103

137269-101

137127-472

137127-473

137127-122

133622-391

137127-683

133623-182

137127-152

144000-222H

144000-332V

Note:

1. These parts are screened as C209,227,232,237 on the PCB even though they are

resistors.

44

Page 45

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Diodes

Reference

Description Part Number Reference

Designator

D1,3,4,6 LED,10mA,2.5V,

Green,Vert

D2,5 LED,10mA,2.5V,

Grn/Red,Vert

D10,11,1317,22,24,25,27,29,

107,201,204,300,

301

D12,20,21,200,302,

309,310,

D18,19,23,202,203 Zener,18V,1W,5%,

*D305 Rectifier,Bridge,

!

*D306 Rectifier,Bridge,

!

D307 Zener,16V,1W,5%,

Dual,SOT-23,BAV99 147239

Switching,75V,

300mA

1N4746

100V,1.0A

100V,6A

1N4745

Transistors

177280

177281

121501

116995-4746A

143952 *See Note 1

170214 *See Note 1

116995-4745A

Reference

Description Part Number Reference

Designator

Q1,2,202,300 BPLR,N,40V,200mA

,SOT23

Q3-7 BPLR,N,SOT23,

2SD2114K

Q200 BPLR,P,60V,200mA,

TO-92

Q201 BPLR,N,30V,500mA

,TO-92

Q203,301,302 BPLR,P,40V,200mA,

SOT23

Q305 DARL,NPN,tip140 177310

Note:

!

1. This part is critical for safety purposes. Failure to use a substitute replacement

with the same safety characteristics as the recommended replacement part might create

shock, fire and/or other hazards.

146819

177294

119168

173476

148596

45

Page 46

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Integrated Circuits

Reference

Description Part Number Reference

Designator

U1-4,10,15,200,

202-205,301

U5,7 Comparator,

U6,13,14,300,303 OpAmp,Quad,

U8 Mult/Demult,8CH,

U9 Multiplexer,DIP-16,

U11,12 Switch,Active,

U201 Op-Amp,Dual,

U302 Op-Amp,Single,

U304,307 Power Amp,

U305 Voltage

U306 Voltage

Op Amp,Dual,

DIP-8, RC4559

And/Or,NE572N

DIP-14,NJM2059

DIP-16,4051

CD4052

SIP-8, BA3128N

DIP-16,CN3280

DIP-8, CA3080

Mult-11, 45W,

TDA7396

Regulator,15V,

Pos.,TO-220

Regulator,15V,Neg.,

TO-220

108568

178894

144008

177308

147243

177292

133171

119834

177279

143858

143806

46

Page 47

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Miscellaneous Components

Reference

Description Part Number Reference

Designator

*F1,2 Fuse,5x20mm,

!

630mA

*F3,4 Fuse,Time,400mA

!

*F5 Fuse,5x20mm,

!

*F6 Fuse,.60x.19, 250V,

!

FC1A,C1B,C2A,

Lag,Auto

Slo Blo,10A

Slo Blo, 3.0A

Fuseclip,5MM 178548

C2B,C5A,C5B

J1,2,9,10 Connector,Rt.Ang.,

3 Pos.,Blk.

J3 Connector,Rt.Ang.,

5 Pos,Blk.

J4,5 Connector,RCA,

Dual,Female

J8,11 Connector,Rt.Ang.,

2 Pos,Blk.

J12 Connector,Rt. Ang.,

Beau

JP300 Jumper,22AWG,

Non-Insul, 10.0mm

K1 Relay,24Vdc,4PDT 144017

P1 Harness,26

AWG,Freespace 6

P1A Connector,Header,

12 Pos.

P2 Harness,24

AWG,Freespace 6

P2A Connector,Header,

8 Pos.

P3 Harness,22

AWG,Freespace 6

P3A ,3B Connector,Header,

Inline, PCB, Mnt.,

2pos

P4 Connector,Header,

Inline,PCB Mnt,

5 Pos.

P5 Connector,Header,2

Pos.

P6 Header,High

Current 8mm. pitch

P7 Header,High

Current 8mm. pitch

P9 Connector,Header,

5 Pos.

140346-0630 *See Note 1

177312-0400C1 *See Note 1

177311-10000 *See Note 1

135677-10 *See Note 1

177291-03

177291-05

177295

177291-02

177291-08

148242-100

181702-12

148591-12

177298-08

148591-08

177296

133220-02

133220-05

143963

178742-4

178742-4

148591-05

47

Page 48

FreeSpace®6 Electrical Part List

PCB P/N 177300, Revision 1

Miscellaneous Components

Reference

Description Part Number Reference

Designator

S1-6,8,9 Switch,Slide,DPST,

Vertical

S7 Switch,Slide,DPDT 176147

S10 Switch,DIP,SPST,

4 Pos.

SW500 Switch,SPST,

Rocker

TP1-10,500 Connector,Header,

Testjack,1 Pos,OR

VR300 Varistor,Met Oxide

!

,275V,75 joule

Note:

!

1. This part is critical for safety purposes. Failure to use a substitute replacement

with the same safety characteristics as the recommended replacement part might create

shock, fire and/or other hazards.

176148

148777-1

178108

171621-0103

170189

48

Page 49

SCHEMATICS AND PCB LAYOUTS

The schematics and PC board layouts provided with this manual can be used for units built

with PC board 177300, Revisions 0 and 1.

49

Page 50

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 1, PCB IO1 Music Inputs (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

50

Page 51

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 2, PCB IO1 Music Compressor (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

51

Page 52

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 3, PCB IO1 Board Page Processor (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

52

Page 53

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 4, PCB IO1 Board Music/Page Mixing (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

53

Page 54

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 5, PCB IO2 Board Line Outputs (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

54

Page 55

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 6, PCB IO2 Board Remote Volume (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

55

Page 56

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 7, PCB IO2 Tone Control and Surface EQ (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

56

Page 57

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 8, PA Board Dynamic EQ and Limiter Processor (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

57

Page 58

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 9, PA Board Speaker EQ (PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

58

Page 59

Note: This schematic can be used for Revisions 0 and 1 of PCB 177300.

Sheet 10, PA Board Power Supply and Amp(PCB 177300, Revisions 0 and 1)

FreeSpace

®

6 Business Music System

59

Page 60