Page 1

Installation Instructions

(716) 223-4060 • (888) 289-0096 • Fax: (716) 223-9180

P/N: 43744B 09/00

DS720i Long Range Dual PIR/Microwave

Intrusion Detector

1.0 Description

The DS720i is a long range dual passive infrared (PIR)/microwave

(mW) intrusion detector that utilizes state-of-the-art signal

processing to maximize catch performance and reduce false

alarms.

2.0 Specifications

• Description: DS720i Long Range Dual PIR/Microwave Intrusion

Detector.

• Input Power: 9 to 15 VDC, 32 mA DC nominal @ 12.0 VDC (up

to 60 mA DC during walk testing, stored alarms, or trouble

conditions).

• Standby Power: There is no internal standby battery. Connect to

DC power sources capable of supplying standby power if primary

power fails. 32 mA-H required for each hour of standby time

needed. Four hours (128 mA-H) minimum are required for

Underwriters Laboratories' Certificated installations.

• Alarm Relay: Silent operating Form "C" reed relay. Contacts

rated 3 watts, 125 mA, 28 VDC maximum for DC resistive loads;

and protected by a 4.7 ohm, 1/2 Watt resistor in the common "C"

leg of the relay. Do not use with capacitive or inductive loads.

Alarm relay contacts on terminals 3,4 and 5.

• Tamper: Normally Closed (with cover in place) tamper switch.

Contacts rated at 28 VDC, 125 mA maximum. Tamper contacts

on terminals 6 and 7.

• Trouble: Normally Closed dry contact output on terminals 8 and

9. The contacts are rated at 28 VDC, 125 mA maximum. Open

during trouble condition.

• Operating Temperature: -20° to +120°F (-29° to +49°C). For

U.L. Listed Requirements, the temperature range is +32° to

+120°F (0° to +49°C).

• Microwave Frequencies:

• DS720i: 10.525 GHz

• DS720i-A: 9.9 GHz

• DS720i-B: 10.687 GHz

• Coverage:

Standard Broad: 90 ft. by 70 ft. (27 m by 21 m) (OA90)

Optional Long Range: 120 ft. by 25 ft. (37 m by 8 m) (OA120)

Standard Long Range: 300 ft. by 15 ft. (91 m by 4.6 m) (OA300)

• Options: TC6000 Test Cord and OA120 Optical Module.

• U.S. Patent Numbers: # 4,660,024, # 4,764,755, #5,077,548,

#5,083,106, # 5,208,567, # 5,262,783, and # 5,450,062.

Other patents pending.

• Dimensions: 8.25 in. L x 5 in. W x 5.19 in. H (21 cm L x 13 cm W

x 13.2 cm H)

3.0 Installation Hints

Never install the detector in an environment that causes a constant

alarm in one technology; it should never be left to operate with the

green, yellow or red LED ON.

Point the unit AWAY from outside traffic (e.g. roads, alleys, and

parking lots). Remember: Microwave energy will pass through

glass and most common nonmetallic construction walls.

Point the unit AWAY from glass exposed to the outdoors and objects

that may change temperature rapidly.

Remember: The PIR detector will react to objects rapidly changing

temperature within its field-of-view.

Avoid installations where rotating machines (e.g. ceiling fans) are

normally in operation within the coverage pattern.

If using the anti-mask feature, avoid locations where people or

objects may be moving within 3 ft. (1 m) of the detector.

4.0 Mounting

Select a location that is most likely to intercept an intruder moving

across the coverage pattern (review coverage patterns on page 6).

The recommended mounting height for the 300 ft. x 15 ft. (91 m x

4.6 m) coverage is 10 ft. (3 m). The recommended mounting height

for the 90 ft. x 70 ft. (27 m x 21 m) and 120 ft. x 25 ft. (36.6 m x 8 m)

coverages is 7.5 ft. (2.3 m). The surface should be solid and

vibration-free.

Remove the cover by inserting a flathead screwdriver or other flat

object into the slot at the bottom of the cover, and twist until the

cover snaps free of the front tabs on the base. Lift the cover up and

away to clear the rear base tabs. Do not bend or remove the

microwave antenna located on the front of the permanent reflecting

mirror.

Remove the circuit board from the base by pressing the two circuit

board retainer tabs outward while lifting the circuit board away from

the base.

Select and break away the appropriate thin wall wire entrance and

mounting hole coverings in the base.

Using the base as a template, mark the location of the mounting

holes on the mounting surface, and pre-start the mounting screws.

Route wiring as necessary to the rear of the base and through the

wire entrance, then firmly mount the base to the mounting surface.

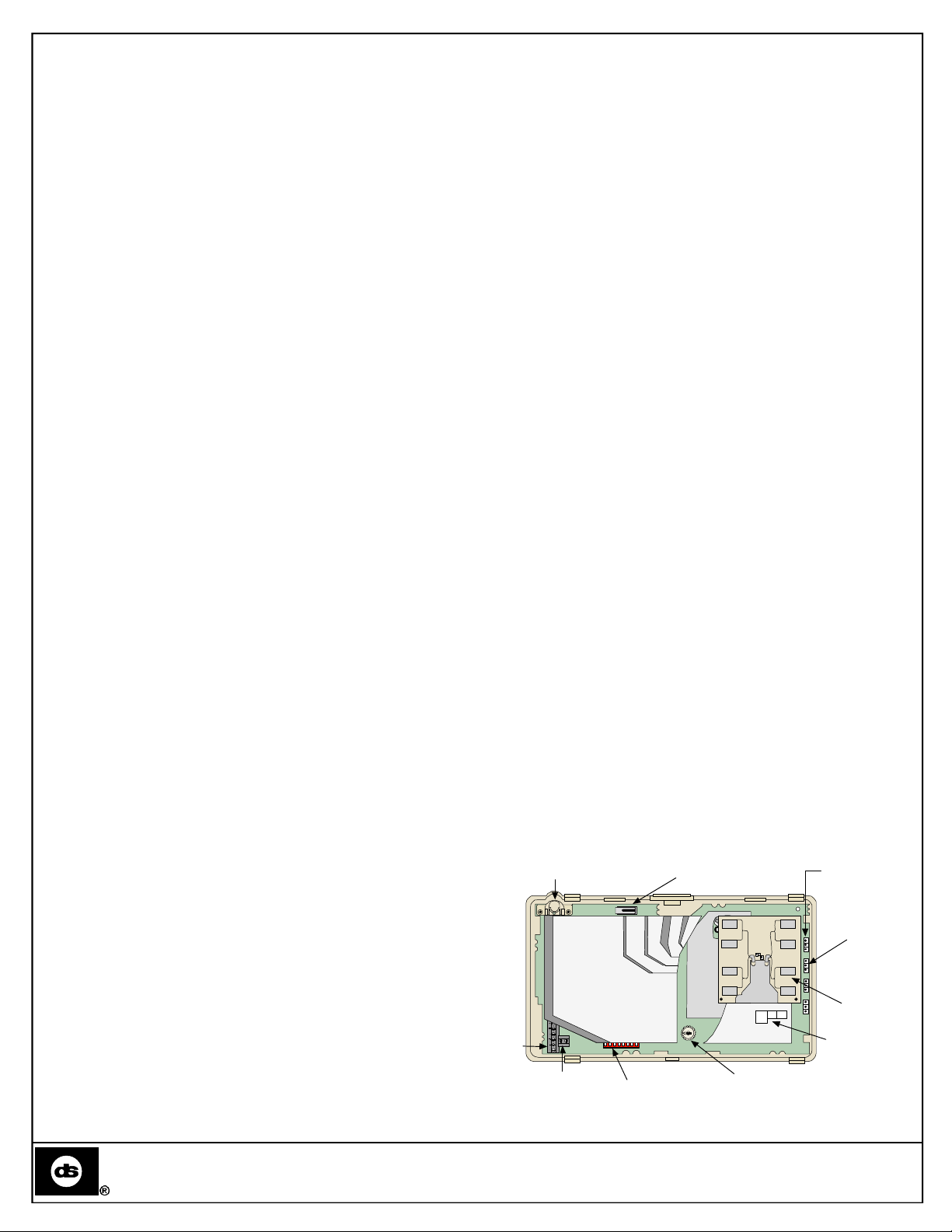

Terminal

Strip

Anti-Mask

Transmitter

1 2 3 4 5 6 7 8

Tamper Switch

MIN

MAX

PIR Noise

Voltage

Pins

Microwave

PIR

NV

Noise Voltage

MW

NV

AM

Microwave

MW

DO NOT TOUCH!

Light Pipe

Pins

Antenna

Detection Systems, Inc., 130 Perinton Parkway,

Fairport, New York, USA 14450-9199

Extra

Terminals

Set-up

Switch Bank

Microwave Range

Adjustm ent

Figure 1: Inside View of DS720i

Copyright © 2000 Detection Systems, Inc.

DS720i Installation Guide

Page 2

DS720i Installation Guide

© 2000 Detection Systems, Inc. All rights reserved.

Page 2

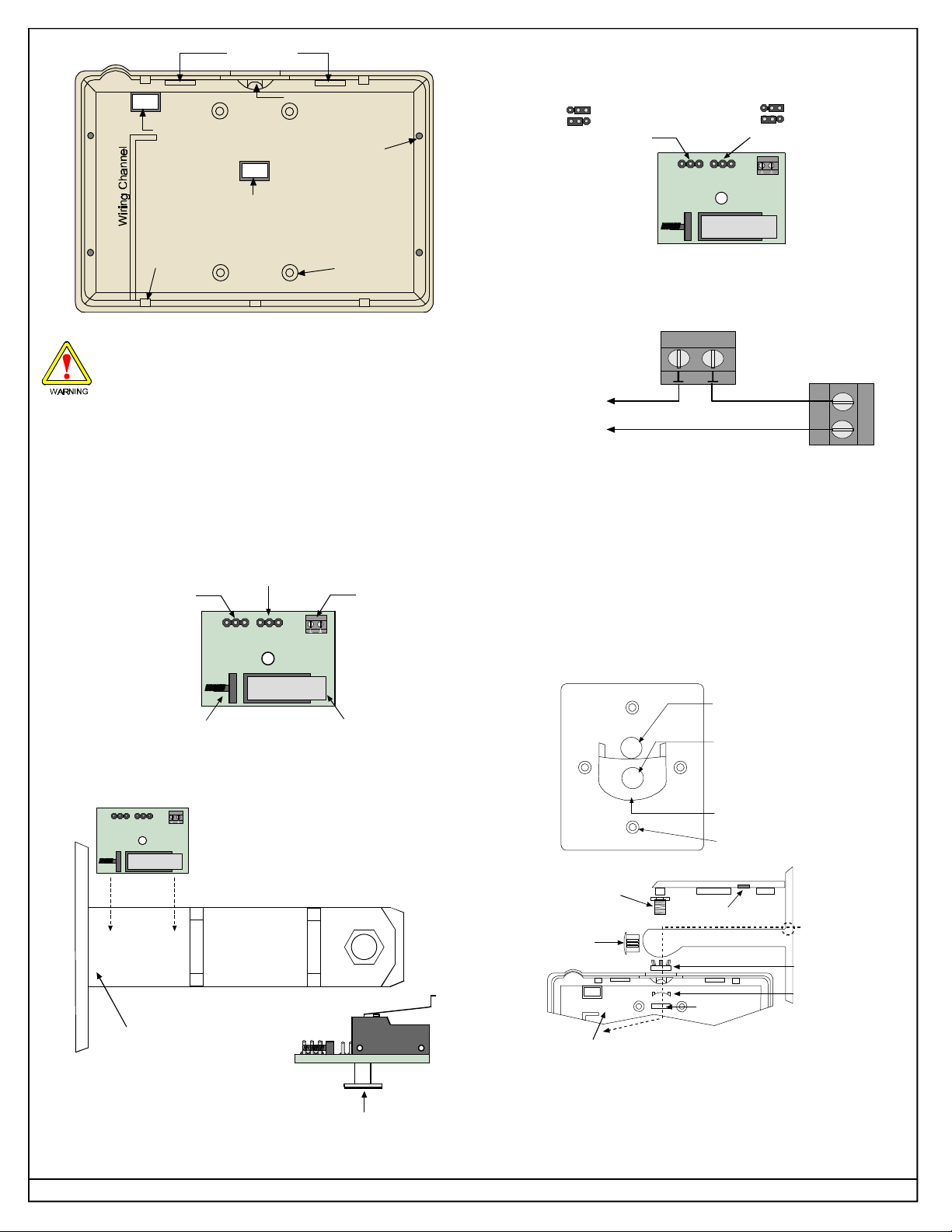

Retainer Tabs

Bracket Wire Entrance

Rear Wire Entrance

Corner Mount Holes (4)

Surface Wire

Entrance

Base

Cover Tabs

Surface Mount

Holes (4)

Figure 2: DS720i Base

Be sure all wiring is unpowered before routing.

The tamper switch's jumper pins determine whether the wall tamper

and bracket tamper features are enabled or disabled. See Figure 5

to set the jumper pins.

Enabled

Disabled

Jumper Pins for

Wall Tamper

Enabled

Disabled

Jumper Pins for

Bracket Tamper

Figure 5: Wall/Bracket Tamper Switch Jumper Pins

Figure 6 shows how to wire the tamper switch's terminals to the

control panel and the DS720i.

B334 Tamper Switch

Return the circuit board to the base by first inserting the bottom of

the circuit board into the cutouts at the bottom of the base, then

snapping the top into place.

3.1 Tamper Switch Installation

The tamper switch is designed to prevent any unauthorized opening

or manipulating of the B334 Mounting Bracket once it has been

mounted. The tamper switch mounts to the inside of the bracket

using the supplied circuit board mount.

Jumper Pins for

Bracket Tamper

Jumper Pins for

Wall Tamper

Wall Tamper

Figure 3: Optional Tamper Switch

Refer to Figure 4 when installing the tamper switch into the B334

Mounting Bracket.

Tamper

Terminal

Block

Bracket Tamper

To Panel Loop

6

7

DS720i

Figure 6: Wiring the Tamper Switch

3.2 B334 Bracket Mounting

Mount the B334 to a standard single gang switch or outlet box

using the supplied screws. If the unit is to be surface mounted, use

the wall screw/anchor assemblies or appropriate alternatives.

Slide the mirror from the black mirror mounting assembly when

feeding the power wiring through the detector base to the terminal

strip if required.

Refer to Figure 7 when mounting the DS720i to the B334 Mounting

Bracket.

Front View of B334

Wire Entrance

Stud Hole For

Ceiling Mounted

Bracket

Stud Hole

(Hidden) For Wall

Mounted Bracket

Mounting Holes (4)

Top View of

B334 Mounting Bracket

Install

Tamper Switch

Here

Fit spring through hole

in back of mounting bracket

Peel double-sided tape

Figure 4: Installing the Tamper Switch

Threaded

B334 Cover

Stud

Screwdriver Notch

Insert

B334 Body

Plug

Hex Nut

Detector Base

Figure 7: Mounting the B334 Bracket

Wiring

Route

Locking

Washer

Curved

Washer

Page 3

DS720i Installation Guide

© 2000 Detection Systems, Inc. All rights reserved.

Page 3

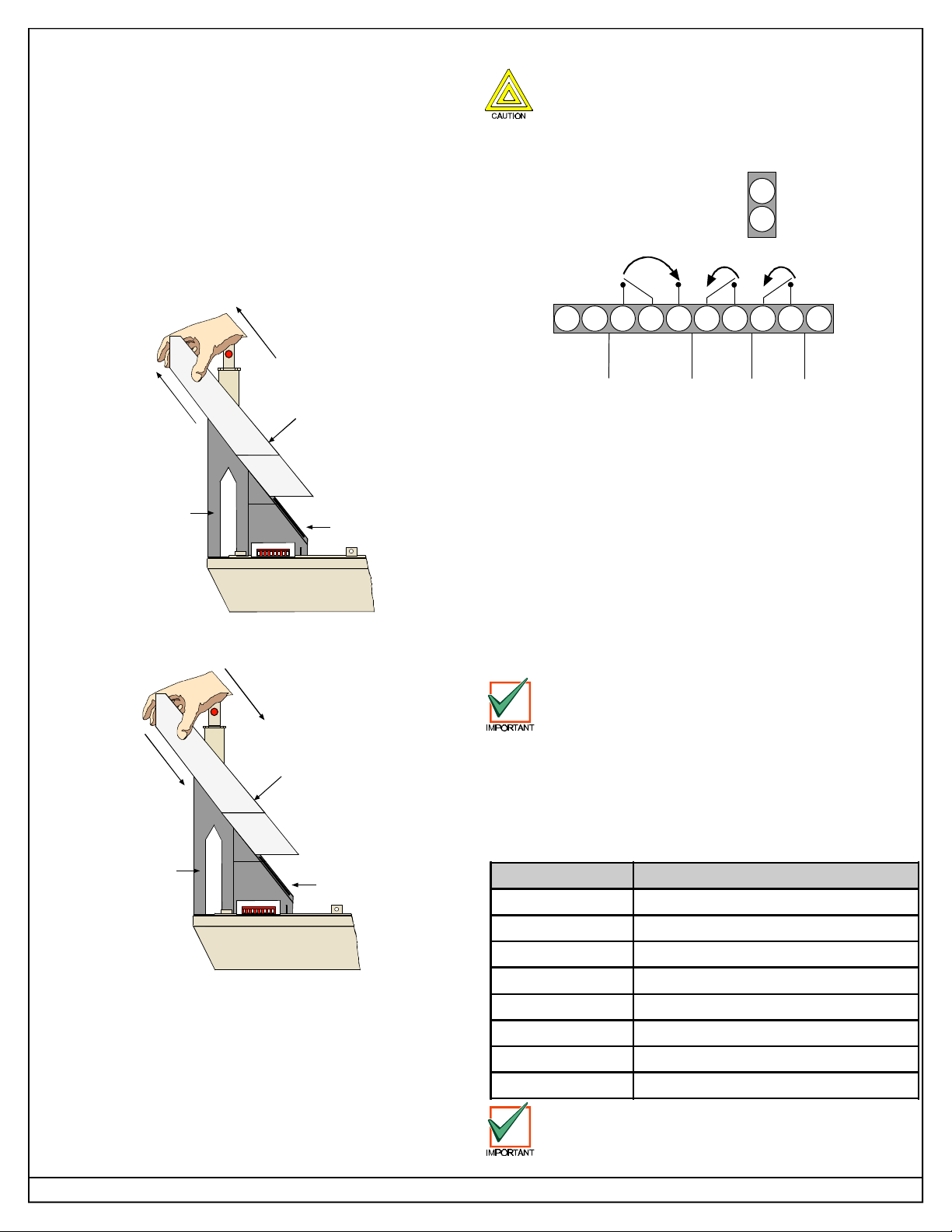

3.3 Mirror Replacement

Flashing Red 4 Microwave or PIR failure -- replace unit

The DS720i comes with two mirrors: OA300 (pre-installed), and

OA90 (optional). The mirrors slide on and off the mirror stand. To

replace the mirror, use the following steps:

1) Hold the base with one hand if the unit has not been mounted.

2) Use the other hand to pull the mirror off the mirror stand in an

upward-diagonal direction.

3) Align the runners on the inside of the mirror with the grooves on

the mirror stand.

4) Slide the mirror onto the mirror stand in a downward-diagonal

direction.

See Figure 5 for details.

Pull mirror off in an

upward-diagonal

direction.

Mirror

Mirror S tand

Slide mirror on in a

downward-diagonal

direction.

1 2 3 4 5 6 7 8

Mounting

Groove

4.0 Wiring

Only apply power after all connections have been made

and inspected.

Wire the terminal strip as shown in Figure 6.

Spare

12

Spare

11

Alarm

1 2 3 4 5 6 7 8 9 10

-

+

9-15 VDC

Input

C

NC

Alarm Relay Tamper

NO

T T

Figure 6: Wiring the DS720i Terminals

Terminals 1(–) & 2(+): Power limits are 9 to 15 VDC. Use no smaller

than #22 AWG (0.8 mm) wire pair between the unit and the power

source.

Terminals 3, 4, & 5: Alarm relay contacts rated 3 Watts, 125 mA, 28

VDC maximum for DC resistive loads and protected by a 4.7 ohm, 1/2

Watt resistor in the common "C" leg of the relay. Use terminals 3 & 4

for Normally Closed circuits. Do not use with capacitive or inductive

loads.

Terminals 6 & 7: Tamper contacts rated at 28 VDC, 125 mA.

Terminal 8 & 9: Terminals are normally closed when the detector is

not in trouble, and open when the detector is in trouble.

Terminal 10: Memory. Refer to Section 6.0 Feature Selection.

Terminals 11 & 12: Spare terminals.

Seal any openings with the foam plugs provided to

prevent drafts and insect entry. Use the (2) screws

provided to secure the detector cover to the base.

Trouble

TR

TR

Trouble

M

Memory

Input

Mirror

Mirror Stand

1 2 3 4 5 6 7 8

Figure 5: Replacing the DS720i Mirror

Align mirror with

mirror groove

5.0 LED Operation

The DS720i uses three colors to indicate the various alarm and/or

supervision trouble conditions that can exist. Refer to Table 1 for the

colors and their respective conditions.

Table 1: LED Functions

LED Function

Steady Red Unit alarm or stored alarm

Steady Yellow Intrusion detected by microwave section

Steady Green Intrusion detected by PIR section

Flashing Red 1 Warm-up calibration period after initial power-up

Flashing Red 2 Motion Monitor time-out

Flashing Green 3 IR Anti-Mask failure

Flashing Yellow 3 Microwave Anti-Mask failure

Flashing (color) 2-4: The LED flashes 2-4 times a cycle.

Page 4

DS720i Installation Guide

© 2000 Detection Systems, Inc. All rights reserved.

Page 4

The complete circuit operation of the PIR/ Microwave

30 Day

subsystems is checked every 5 hours. If the PIR or

Microwave subsystems fail two consecutive times, the

LED will flash red 4 times per cycle and the unit should

be replaced. The detector will default to PIR technology

protection if the Microwave subsystem fails. The PIR

processing will automatically be adjusted to reduce false

alarms. An intrusion alarm will reset most existing

supervision trouble conditions. There must be at least

10 seconds of no activity (no alarm) prior to the detector

alarm for a trouble clear to occur.

6.0 Feature Selection

The DS720i's features are selected using a bank of 8 DIP switches.

See Figure 1 for a location of the DIP switches.

See Figure 7 for default DIP switch positioning.

= ON (Low)

= OFF (High)

6.3 Motion Monitor

To set the Motion Monitor feature, refer to Table 2 for switches S3

and S4. The Motion Monitor Supervision feature verifies that each

technology has a clear view of the detection area. When selected,

a supervision timer is activated which gives the detector the ability

to indicate a supervision trouble condition if the time period has

elapsed since the last detector alarm. If the Memory feature is

used, the motion monitor time period will be increased by the

amount of time the detector is in the arm condition. If the detector

does not detect an alarm within the selected time period, the LED

will flash red 2 times to indicate a Motion Monitor Time-out

condition and the Trouble output will activate.

6.4 Anti-Mask/Spray Detection

The Anti-Mask feature detects attempts made to disable the

detector by covering it. The DS720i has Microwave Anti-Mask, IR

Anti-Mask and Spray Anti-Mask as standard features. When

activated, the detector will indicate an Anti-Mask supervision

trouble condition if a microwave reflective material (e.g. metal,

most plastics, etc.) is placed within one foot of the detector.

S1

The DS720i's features are assigned to the DIP switches as follows

(factory-set default settings in parentheses):

• S1: LED Operation (ON)

• S2: PIR Sensitivity: OFF - High; ON - Intermediate (ON)

• S3: Motion Monitor: see Table 2 (OFF)

• S4: Motion Monitor: see Table 2 (OFF)

• S5: mW Anti-Mask (OFF)

• S6: Anti-Mask Delay Timer (OFF)

• S7: PIR Anti-Mask (OFF)

• S8: PIR Spray Detect (OFF)

NOTE: To activate the spray detection feature, both switches S7

S2

Figure 7: Default DIP Switch Positioning

and S8 must be in the ON position.

Table 2: Motion Monitor DIP Switch Settings

S3

Motion Monitor S3 S4

Disabled OFF OFF

S4

1 Day ON OFF

4 Day OFF ON

S5

ON ON

S6 S7 S8

6.1 LED Operation

The ON position allows operation of the LED. If LED indication is not

desired after setup and walk tests are completed, place in the OFF

position. The OFF position does not prevent the LED from indicating

supervision trouble conditions.

6.2 PIR Sensitivity Selection

High Sensitivity (S2 OFF): For fast response to intruder signals.

This setting will improve your intruder catch performance.

Intermediate Sensitivity (S2 ON): Tolerates normal environments

on this setting. This setting will improve your false alarm immunity.

The anti-masking feature may interpret removal and/or

replacement of the cover as an attempt to mask the

detector and may signal a supervision trouble

condition. If this should occur, reset the detector by

removing and then reapplying its power. The trouble

condition will also be reset by the next detector alarm

after a 10 second period of no alarms from both

technologies.

This anti-mask feature also has a delay timer function that can be

turned ON or OFF with the selection of switch S6. When enabled

(switch S6 ON), this feature evaluates the anti-mask condition for

false alarms. For maximum anti-mask/spray detection performance,

this timer should be turned OFF.

The Spray Detection feature prevents accidental or intentional

blocking of the detector by detecting an object placed in close

proximity of the detector, or if the detector is sprayed with a foreign

substance. See Figure 8 for details.

Anti-Mask

Transmitter

Distance

Distance:

Approximately

1 ft. (0.3 m)

with Spray

Detect OFF

Approximately

3 ft. (0.9 m)

with Spray

Detect ON

Distance

Figure 8: Anti-Mask/Spray Detection Coverage

Page 5

DS720i Installation Guide

© 2000 Detection Systems, Inc. All rights reserved.

Page 5

6.5 Memory Operation

but less than 20 seconds)

Memory, Armed Mode and Walk Test require a supply voltage on

Terminal 10 to activate these features. This supply voltage must be

between 6 and 18 VDC. You may use a switch as shown in Figure

9:

NC C

+

-

NO T T TR TR

M

1 2 3 4 5 6 7 8 9 10

Figure 9: Alarm Memory Function

Or use an external power supply as shown in Figure 10:

-

+

NC C

NO T T TR TR

M

1 2 3 4 5 6 7 8 9 10

Control Panel

-

or

+

External DC

Supply

Figure 10: Alarm Memory Function with External Power

Supply

Control voltage: +6 to +18 volts = ON (Switch Closed); 0 volts =

OFF (Switch Open).

Day Mode: The Day Mode disables the alarm memory and allows

the LED (if activated) to operate normally.

Memory: When the DS720i is in the Night Mode the memory is

activated. This allows the detector to store an alarm for display at a

later time.

Armed Mode: The Night Mode enables the alarm memory and

disables the LED operation.

Remote Walk Test (LED Control): When the DS720i is in the

Walk Test mode, the LED will indicate the current alarm status

regardless of the setting of the LED Operation switch (Switch 1).

Table 2: Memory Operation Settings

Desired Action Control Voltage (Terminal M)

Turn ON Night Mode/

Reset Stored Alarm

Turn OFF Night Mode/

Display Stored Alarm

Turn ON Walk Test (if OFF)

Turn OFF Walk Test (if ON)

ON (for more than 20 seconds)

OFF

ON (for more than 5 seconds,

but less than 20 seconds)

ON (for more than 1 second,

7.0 Setup and Walk Tests

Place the LED switch in the ON position. If using the Memory Input

to enable the Remote Walk Test feature, it is not necessary to put

the LED switch in the ON position.

NOTE: Use a bubble level on the front of the unit to check for

proper positioning and alignment.

7.1 Establishing PIR Pattern Coverage

Turn the Microwave Range Adjust to minimum.

Replace the cover and snap it into place. This will close the tamper

switch.

During the warm-up period, the LED will flash red until

the unit has stabilized and has seen no movement for

2 seconds (approximately 1 to 2 minutes). When the

LED stops flashing, the detector is ready to be tested.

With no motion in the protection area, the LED should

be OFF. If the LED is ON, recheck the protection area

for disturbances affecting the microwave or PIR

technologies.

Walk test across the pattern at its farthest edge, then several times

closer to the detector. Start walking from outside of the intended

protection area, and observe the LED. The edge of the pattern is

determined by the first green, PIR activation of the LED (or the first

red activation if the yellow microwave LED activates first).

If the desired coverage cannot be achieved, try angling the

coverage pattern up or down to ensure the pattern is not aimed too

high or low. In a narrow aisleway, aiming the pattern slightly left or

right can also improve the detector's catch performance.

7.2 Establishing Microwave Coverage

Wait 1 minute after removing/replacing the cover so

the microwave portion of the detector can settle and to

wait at least 10 seconds between the following walk

testing procedures.

The LED should be OFF before walk testing.

Walk test across the pattern at the intended coverage's farthest

end. Start walking from outside the intended protection area and

observe the LED. The edge of the microwave pattern is determined

by the first activation of the yellow LED.

If an adequate range cannot be reached, increase the Microwave

Range Adjust slightly. Continue walk testing (waiting 1 minute after

removing/replacing the cover) and adjusting the range until the

farthest edge of desired coverage has been accurately placed.

Do not adjust the Microwave Range higher than

required. Doing so will enable the detector to catch

movement outside of the intended coverage pattern.

Walk test the unit from all directions to determine all the detection

pattern boundaries. Wait at least 10 seconds between walk tests.

7.3 Establishing Detector Coverage

All LEDs should be OFF before walk testing.

Walk test the unit from all directions to determine the detection

boundaries. A detector alarm is signaled by the first red activation

of the LED after an initial green or yellow LED activation.

Page 6

DS720i Installation Guide

© 2000 Detection Systems, Inc. All rights reserved.

Page 6

8.0 Meter Tests

An analog or digital volt meter is recommended. Use of the

TC6000 is recommended, but is not essential for meter use. Either

outside connector pin of the TC6000 may be used as common (-).

8.1 PIR Meter Readings

Connect the meter to the PIR Noise Voltage Pins. With no target

motion in the pattern, read the voltage. The base reference level for

PIR background is approximately 1.0 VDC. Installations in quiet

environments, therefore, should result in a steady meter reading

between 0.9 and 1.1 VDC.

Walk test across the farthest edge of the coverage pattern. Make

sure the detector's cover is on.

Voltage changes greater than +0.75 VDC from the reference level

during walk tests are desirable. If changes are less than 0.75 VDC,

the detector may fail to respond at this far a distance if the

temperature difference between the intruder and the background is

minimal. Try adjusting the unit up and down to maximize the voltage

change during walk tests.

Turn on all heating/cooling sources that will be in operation during

the times of protection. Stand away from the unit and outside the

protection pattern, then monitor background noise for at least 3

minutes.

Readings should not deviate more than 0.15 VDC from the

reference level. If they do, eliminate the cause or reposition the

pattern (observe readings while turning on and turning off these

sources as well as during the three minute interval).

8.2 Microwave Meter Readings

Connect the meter to the Microwave (mW) Noise Voltage Pins.

With no target motion in the pattern, read the voltage. The

background noise voltage should be steady, and should not exceed

1.0 VDC. If it does, the cause of the disturbance should be found

and eliminated.

10.0 Coverage Patterns

The protected coverage area is where the microwave and PIR

patterns overlap.

OA300 Long Range Coverage (pre-installed)

Top View

0 meters

7.5

0.0

7.5

0

10

0

C

DE

50 100 150 200

Side View

0 meters

E

C

D

0

50 100 150 200 250

B

feet

B

feet

0A90 Standard Broad Coverage (optional mirror - included)

Top View

0 meters

70

7.5

10

0

50

30

10

0

10

30

50

70

0

Side View

0 meters

K

0

I

K

J

I, J

F

G

H

E

30 50 70

feet

F - H

feet

91.4

2.3

A

2.3

300

250

76

3.1

A

0

300

24

18

A

9

B

3

C

40

°

3

D

9

18

90

A

G H

B C D E

B

A

OA300

K

F I J

C

OA90

24

3

0

90

705030

A - E

E

D

Microwaves penetrate nonmetallic surfaces.

Movement on the other side of walls and doors viewed

by the detector could cause unexpected background

noise readings.

9.0 Other Information

9.1 Maintenance

At least once a year, the range and coverage should be verified. To

ensure continual daily operation, the end user should be instructed

to walk through the far end of the coverage pattern. This ensures

an alarm output prior to arming the system.

9.2 Pattern Masking

Refer to the mirror module and pattern drawings in Section 10.0 for

masking.

Many adhesives will either destroy the mirror surface

or leave enough surface residue behind to reduce

coverage performance. Be sure to clean the mirror

surface with a mild window cleaning solution after

masking removal.

9.3 FCC Compliance Notice

This device complies with Part 15 of the FCC Rules and with RSS210 of Industry and Science Canada. Operation is subject to the

following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference that

may cause undesirable operation.

OA120 Long Range Coverage (Optional)

Top View

0 meters

20

10

G

0

I

H

10

20

0 120

20 40 60 80 100

Side View

0 meters

10

7.5

I

0

G - H

0

20 40 60 80 100

D

F

D - F

E

feet

feet

A

B

C

A - C

36

6

3

0

3

6

36

3

0

120

D G H

A

E

B

OA 120

NOTE: Use a bubble level on the front of the unit to check for

proper positioning and alignment.

I

F

C

Loading...

Loading...