Industrial PC

CPS21_3 / CPS21_4

Interface Conditions

Antriebs- und Steuerungstechnik

Edition

103

Industrial PC

CPS21_3 / CPS21_4

Interface Conditions

1070 073 825-103 (02.04) GB

E 1999 – 2002

by Bosch Rexroth AG, Erbach / Germany

All rights reserved, including applications for protective rights.

Reproduction or distribution by any means subject to our prior written permission.

Discretionary charge 6.–

Contents

Contents

1 Safety Instructions 1–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Proper use 1–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Qualified personnel 1–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Safety markings on products 1–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Safety instructions in this manual 1–5 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Safety instructions for the product described 1–6 . . . . . . . . . . . . . . .

1.6 Documentation, software release and trademarks 1–8 . . . . . . . . . . .

2 System Overview CPS21_3 / CPS21_4 2–1 . . . . . . . . . .

2.1 Components 2–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Technical Data 2–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Software 2–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Expansion Cards 2–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 BIOS Setup 2–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Rechargeable Battery Pack 2–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Operating Conditions 2–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Applicable Standards 2–12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

Page

3 Safety Functions 3–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Temperature Monitoring 3–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Function of Uninterruptible Power Supply (UPS) 3–2 . . . . . . . . . . . .

3.3 UPS Program 3–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Function 3–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Operation 3–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Parameter settings 3–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Installation 4–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Installation Positions and Clearances 4–2 . . . . . . . . . . . . . . . . . . . . . .

4.2 Dimensioned Drawing 4–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Installation with Tip/Tilt Adapter 4–5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Installation of the optional Coolkit 4–6 . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical Connections 5–1 . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Protective Earth Conductor (PE) and Screening Information 5–2 . .

5.2 Interference Suppression Information 5–3 . . . . . . . . . . . . . . . . . . . . . .

5.3 Supply Voltage 5–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 24 VDC Supply 5–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1070 073 825-103 (02.04) GB

VI

Contents

6 Interfaces and Connections 6–1 . . . . . . . . . . . . . . . . . . .

6.1 Overview 6–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Position of Interfaces 6–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Connection and Distribution Card 6–4 . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Connection of the optional Coolkit to the Connection and Distribution

Card 6–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Floppy Disk Connection 6–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 COM1 through COM4 Serial Ports, USB 6–11 . . . . . . . . . . . . . . . . . . .

6.6.1 Pin Assignment 6–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Settings 6–14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 LPT1 Parallel Port 6–15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Parallel Port for CD-ROM 6–16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Ethernet Connector 6–17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 VGA Video Port 6–18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 Keyboard ports 6–20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11 Mouse Port 6–21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12 DP-Slave Port 6–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.13 24 V out Port 6–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14 Expansion Card Interfaces 6–23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14.1 PCI_BM-xxx Card 6–23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14.2 PCI_CAN Card 6–26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Display and Control Elements 7–1 . . . . . . . . . . . . . . . . .

7.1 Display 7–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Backlight Function 7–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Keyboard 7–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Blocks of Function Keys 7–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Key Blocks ”Control” 7–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Key Block ”Machine” 7–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Number, Cursor Control and Special Keys Blocks 7–7 . . . . . . . . . . .

7.2.5 Key Mouse 7–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 LED Indicators 7–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Hardware Indicators 7–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Customer-Specific Indicators 7–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Front Panel Labeling 7–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Keyboard Controller 7–13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Scanning of Front Panel Keyboard 7–13 . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Exceptions for Simultaneously Pressed Keys 7–18 . . . . . . . . . . . . . . .

7.5.3 User-Defined Assignment of Key Codes 7–18 . . . . . . . . . . . . . . . . . . .

7.5.4 Software Download for Keyboard Controller 7–18 . . . . . . . . . . . . . . . .

8 Maintenance and Replacements 8–1 . . . . . . . . . . . . . . .

8.1 Maintenance 8–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Replacements 8–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Hard Disk 8–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Display and Backlight/Inverter 8–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Rechargeable Battery Pack 8–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Spare Parts 9–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Appendix A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Abbreviations A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Keyword index A–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1070 073 825-103 (02.04) GB

1 Safety Instructions

Before you start working with the Bosch CPS21_3 or CPS21_4 PC control,

we recommend that you thoroughly familiarize yourself with the contents of

this manual. Keep this manual in a place where it is always accessible to all

users.

1.1 Intended use

This manual contains information required for the proper use of this product.

However, for reasons of structural clarity, the manual cannot provide exhaustive details regarding all available combinations of functional options.

Similarly, it is feasible to consider every conceivable integration or operating

scenario within the confines of this manual.

Safety Instructions

1–1

The described industrial PCs serve as operating and visualization units

for Bosch proprietary application software running on Microsoft Windows 95

or Microsoft Windows NT 4.0 operating systems. They are intended as control platforms for testing, adjustment and assembly station applications.

While it is possible in principle to operate other proprietary operating systems or application software on the industrial PCs, the occurrence of unexpected effects, even with Bosch applications, cannot be entirely ruled out.

With this type of nonstandard operation, Bosch shall not assume any liability

for either hardware and/or software.

The products described hereunder

D were developed, manufactured, tested and documented in accordance

with the relevant safety standards. In standard operation, and provided

that the specifications and safety instructions relating to the project

phase, installation and correct operation of the product are followed,

there should arise no risk of danger to personnel or property.

D are certified to be in full compliance with the requirements of the

D COUNCIL DIRECTIVE 89/336/EEC of May 3rd 1989 on the approx-

imation of the laws of the Member States relating to electromagnetic

compatibility, 93/68/EEC (amendments of Directives), and

93/44/EEC (relating to machinery)

D COUNCIL DIRECTIVE 73/23/EEC (electrical equipment designed for

use within certain voltage limits)

D Harmonized standards EN 50081-2 and EN 50082-2

D are designed for operation in an industrial environment (Class A

emissions). The following restrictions apply:

D No direct connection to the public low-voltage power supply is per-

mitted.

D Connection to the medium and/or high-voltage system must be pro-

vided via transformer.

The operation of Class A devices in private residences, in business or

small-industry settings is permitted only if their operation does not produce undue interference with other devices.

1070 073 825-103 (02.04) GB

. This is a Class A device. In a residential area, this device may cause

radio interference. In such case, the user may be required to introduce

suitable countermeasures, and to bear the cost of the same.

1–2

Safety Instructions

Proper transport, handling and storage, placement and installation of the

product are indispensable prerequisites for its subsequent flawless service

and safe operation.

1070 073 825-103 (02.04) GB

1.2 Qualified personnel

Safety Instructions

1–3

This instruction manual is designed for specially trained personnel. The relevant requirements are based on the job specifications as outlined by the

ZVEI and VDMA professional associations in Germany. Please refer to the

following German-Language publication:

Weiterbildung in der Automatisierungstechnik

Publishers: ZVEI and VDMA Maschinenbau Verlag

Postfach 71 08 64

60498 Frankfurt/Germany

The present manual is designed for engineering personnel and PC specialists. These persons need special knowledge of the configuration and

commissioning of electrical equipment.

Interventions in the hardware and software of our products not described in

this instruction manual may only be performed by our skilled personnel.

Unqualified interventions in the hardware or software or non-compliance

with the warnings listed in this instruction manual or indicated on the product

may result in serious personal injury or damage to property.

Installation and maintenance of the products described hereunder is the exclusive domain of trained electricians as per IEV 826-09-01 (modified) who

are familiar with the contents of this manual.

Trained electricians are persons of whom the following is true:

D They are capable, due to their professional training, skills and expertise,

and based upon their knowledge of and familiarity with applicable technical standards, of assessing the work to be carried out, and of recognizing

possible dangers.

D They possess, subsequent to several years’ experience in a comparable

field of endeavour, a level of knowledge and skills that may be deemed

commensurate with that attainable in the course of a formal professional

education.

With regard to the foregoing, please read the information about our comprehensive training program. The professional staff at our training centre will

be pleased to provide detailed information. You may contact the centre by

telephone at (K49) 6062 78-600.

1070 073 825-103 (02.04) GB

1–4

Safety Instructions

1.3 Safety markings on components

DANGER! High voltage!

DANGER! Corrosive battery acid!

CAUTION! Electrostatically sensitive components!

Disconnect mains power before opening!

Lug for connecting PE conductor only!

Screened conductor only!

1070 073 825-103 (02.04) GB

1.4 Safety instructions in this manual

DANGEROUS ELECTRICAL VOLTAGE

This symbol warns of the presence of a dangerous electrical voltage. Insufficient of lacking compliance with this warning can result in personal

injury.

DANGER

This symbol is used wherever insufficient or lacking observance of this instruction can result in personal injury.

Safety Instructions

1–5

CAUTION

This symbol is used wherever insufficient or lacking observance of instructions can result in damage to equipment or data files.

. This symbol is used to alert the user to an item of special interest.

L This asterisk symbol indicates that the manual is describing an activity which

the user will be required to perform.

1070 073 825-103 (02.04) GB

1–6

Safety Instructions

1.5 Safety instructions for the described product

DANGER

Fatal injury hazard through ineffective Emergency-OFF devices!

Emergency-OFF safety devices must remain effective and accessible during all operating modes of the system. The release of functional locks imposed by Emergency-OFF devices must never be allowed to cause an uncontrolled system restart! Before restoring

power to the system, test the Emergency-OFF sequence!

DANGER

Retrofits or modifications may interfere with the safety of the products described hereunder!

The consequences may be severe personal injury or damage to

equipment or the environment. Therefore, any system retrofitting or

modification utilizing equipment components from other manufacturers will require express approval by Bosch.

DANGEROUS ELECTRICAL VOLTAGE

Unless described otherwise, maintenance procedures must always

be carried out only while the system is isolated from the power supply. During this process, the system must be blocked to prevent an

unauthorized or inadvertent restart.

If measuring or testing procedures must be carried out on the active

system, these must be carried out by trained electricians.

CAUTION

Only Bosch-approved spare parts may be used!

CAUTION

Danger to the module!

All ESD protection measures must be observed when using the

module! Prevent electrostatic discharges!

1070 073 825-103 (02.04) GB

Safety Instructions

1–7

Observe the following protective measures for electrostatically endangered

modules (EEM)!

D The Employees responsible for storage, transport and handling must be

trained in ESD protection.

D EEMs must be stored and transported in the protective packaging speci-

fied.

D Out of principle, EEMs may be handled only at special ESD work stations

equipped for this particular purpose.

D Employees, work surfaces and all devices and tools that could come into

contact with EEMs must be on the same potential (e.g. earthed).

D An approved earthing wrist strap must be worn. It must be connected to

the work surface via a cable with integrated 1 MW resistor.

D EEMs may under no circumstances come into contact with objects sus-

ceptible to accumulating an electrostatic charge. Most items made of

plastic belong to this category.

D When installing EEMs in or removing them from an electronic device, the

power supply of the device must be switched OFF.

1070 073 825-103 (02.04) GB

1–8

Safety Instructions

1.6 Documentation, software release and trademarks

Documentation

The present manual contains information on technical data, the operation

and configuration of the CPS21_3 / CPS21_4 PC control.

Overview of available documentation Part no.

English German

Release

Trademarks

CPS21_3 / CPS21_4 PC control

Interface conditions

1070 073 825 1070 073 815

. In this manual the floppy disk drive always uses drive letter A:, and the

hard disk drive always uses drive letter C:.

Special keys or key combinations are shown enclosed in pointed brackets:

D Named keys: e.g. <Enter>, <PgUp>, <Del>

D Key combinations (pressed simultaneously): e.g. <Ctrl> + <PgUp>

. The software version of Windows NT may be displayed as follows:

1. Click with right mouse key on the ”My Computer” icon on your

desktop

2. Select menu item ”Properties”.

All trademarks referring to software that is installed on Bosch products when

shipped from the factory represent the property of their respective owners.

At the time of shipment from the factory, all installed software is protected by

copyright. Software may therefore be duplicated only with the prior permission of the respective manufacturer or copyright owner.

MS-DOSr and Windowst are registered trademarks of Microsoft Corporation.

PROFIBUSr

tion e.V. (user organization).

is a registered trademark of the PROFIBUS Nutzerorganisa-

1070 073 825-103 (02.04) GB

System Overview CPS21_3 / CPS21_4

2 System Overview CPS21_3 / CPS21_4

2.1 Components

The CPS21_3 / CPS21_4 control unit is a complete mechanical unit consisting of:

D closed aluminum housing with

D color LC Display (CPS21_3: 13,8”; CPS21_4: 15”),

D a membrane keyboard with additional operating and display devices and

D a built-in high performance industrial PC.

The CPS21_3 / CPS21_4 is distinguished by the following:

D being largely fail-safe (e.g. shock and vibration resistant hard disk s u s -

pension , UPS – uninterruptible power supply) and

D simple maintenance.

The standard operating system Windows NT 4.0 and the Bosch application

software are preinstalled on the CPS21_3 / CPS21_4 (see section 2.3).

2–1

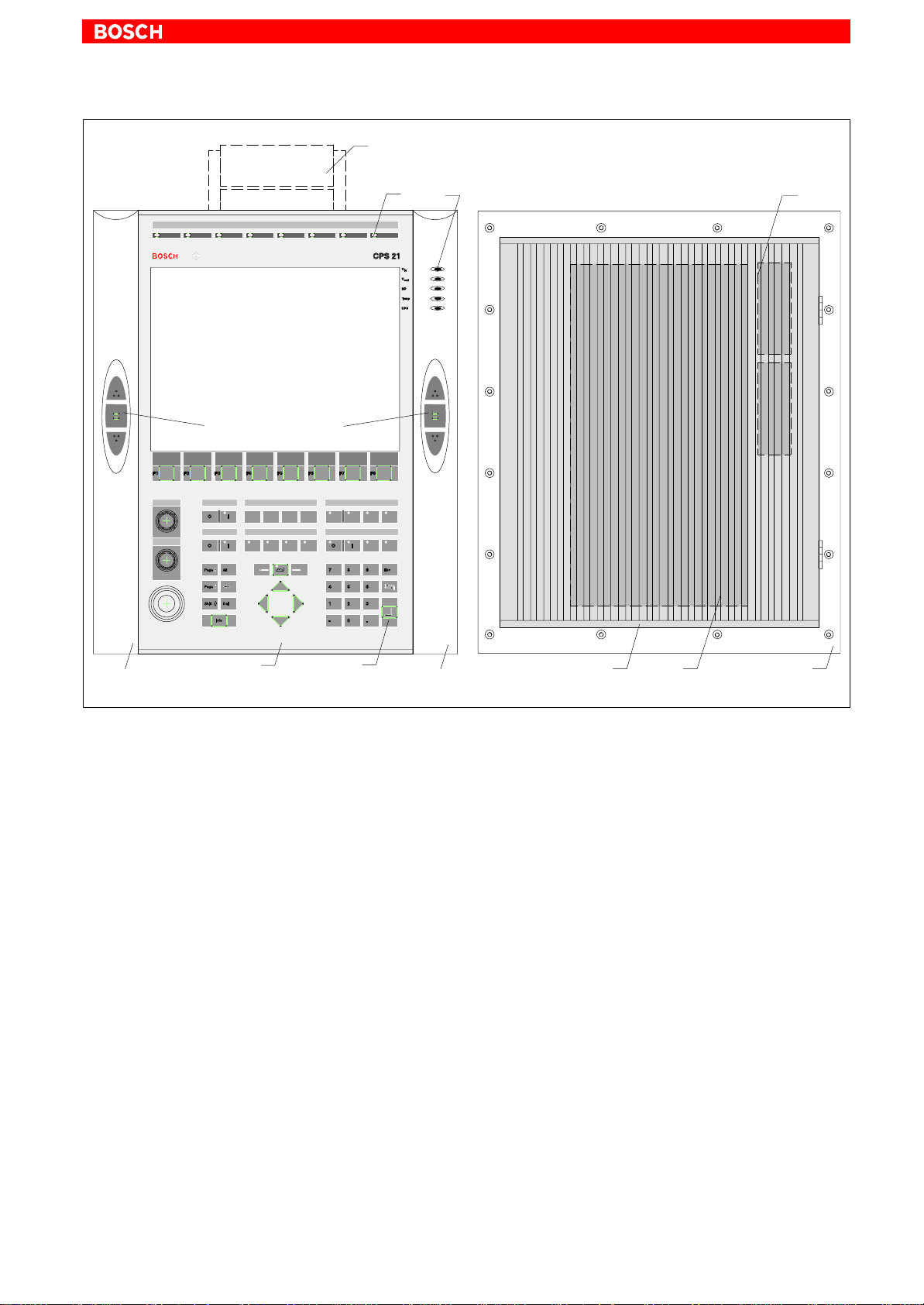

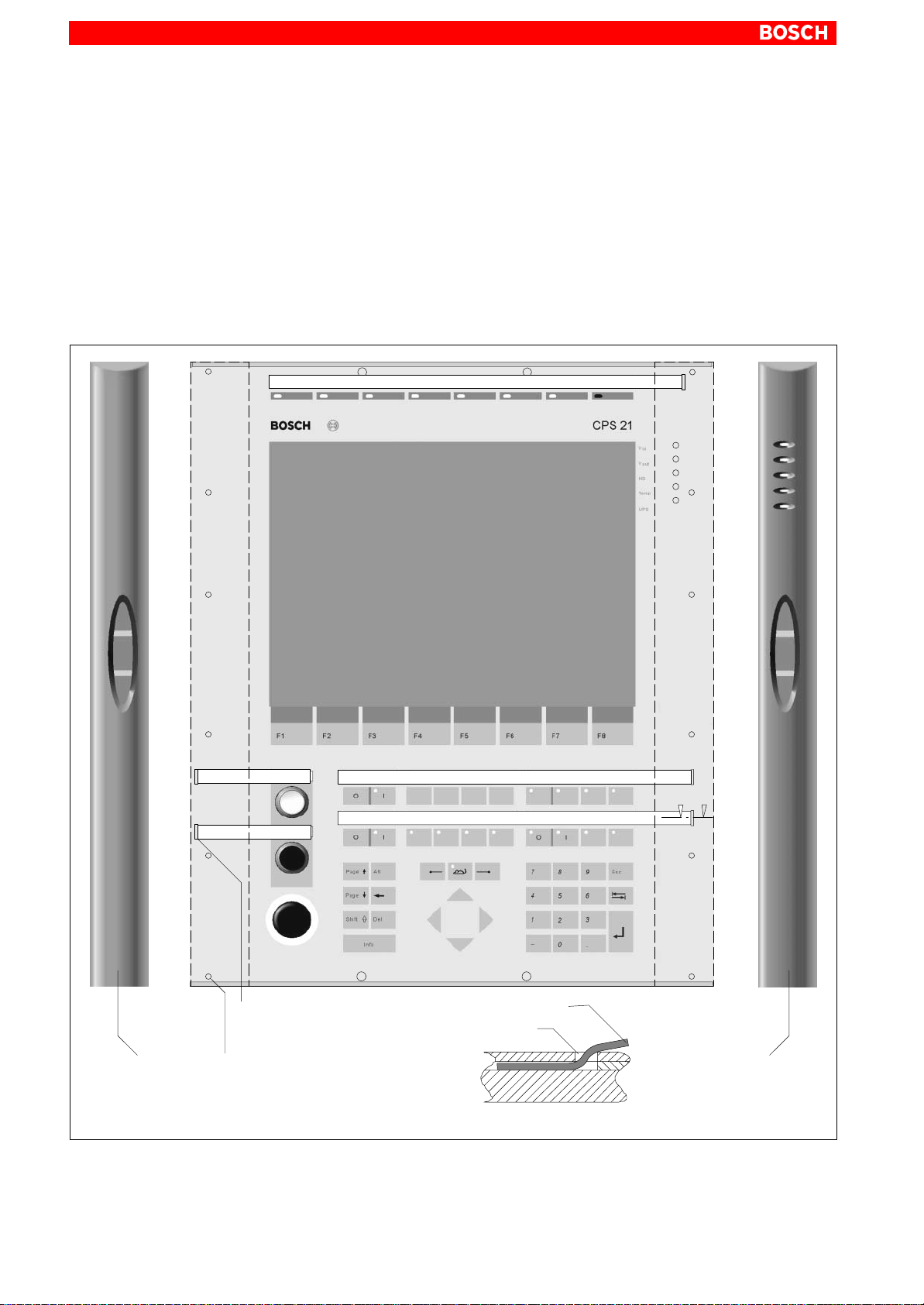

Front view CPS21_3

1070 073 825-103 (02.04) GB

2–2

System Overview CPS21_3 / CPS21_4

Front view CPS21_4

Housing:

The PC is completely covered by an anodized aluminum housing and is internally and externally equipped with cooling fins. Under the given operating

conditions (see section 2.6), this ensures passive

cooling for the integrated PC.

Frame and

Handles:

A plastic frame is connected to the housing by 2 hinges. A handlebar with three navigation buttons is fastened on each side – left and right – of the frame in

order to provide a user friendly operation. On its rear

side, the PC is fastened to the plastic frame.

Front panel: Display, membrane keyboard and the PC which, at its

rear side, is fixed to the plastic frame are fastened to

the front panel. If the frame and the front panel are

swung to the side, the display and the hard disk can

easily be replaced after the PC box has been removed (see section 8).

Insertionlabels:

Up to five labels are available for individual button

description.

Suspension: The entire unit is suitable for floor or suspended

mounting. (refer to section 4.3).

1070 073 825-103 (02.04) GB

System Overview CPS21_3 / CPS21_4

2–3

CPS21_3

13.8” Color TFT Display

Navigation keys

Tilt/tip adapter

LEDs

Battery

(internal)

Handle

Front panel

Keyboard

Handle

Aluminum housing

PC

(internal)

Plastic

frame

1070 073 825-103 (02.04) GB

2–4

System Overview CPS21_3 / CPS21_4

CPS21_4

15” Color TFT Display

Navigation keys

Tilt/tip adapter

LEDs

Battery

(internal)

Handle

Front panel

Keyboard

Handle

Aluminum housing

PC

(internal)

Plastic

frame

1070 073 825-103 (02.04) GB

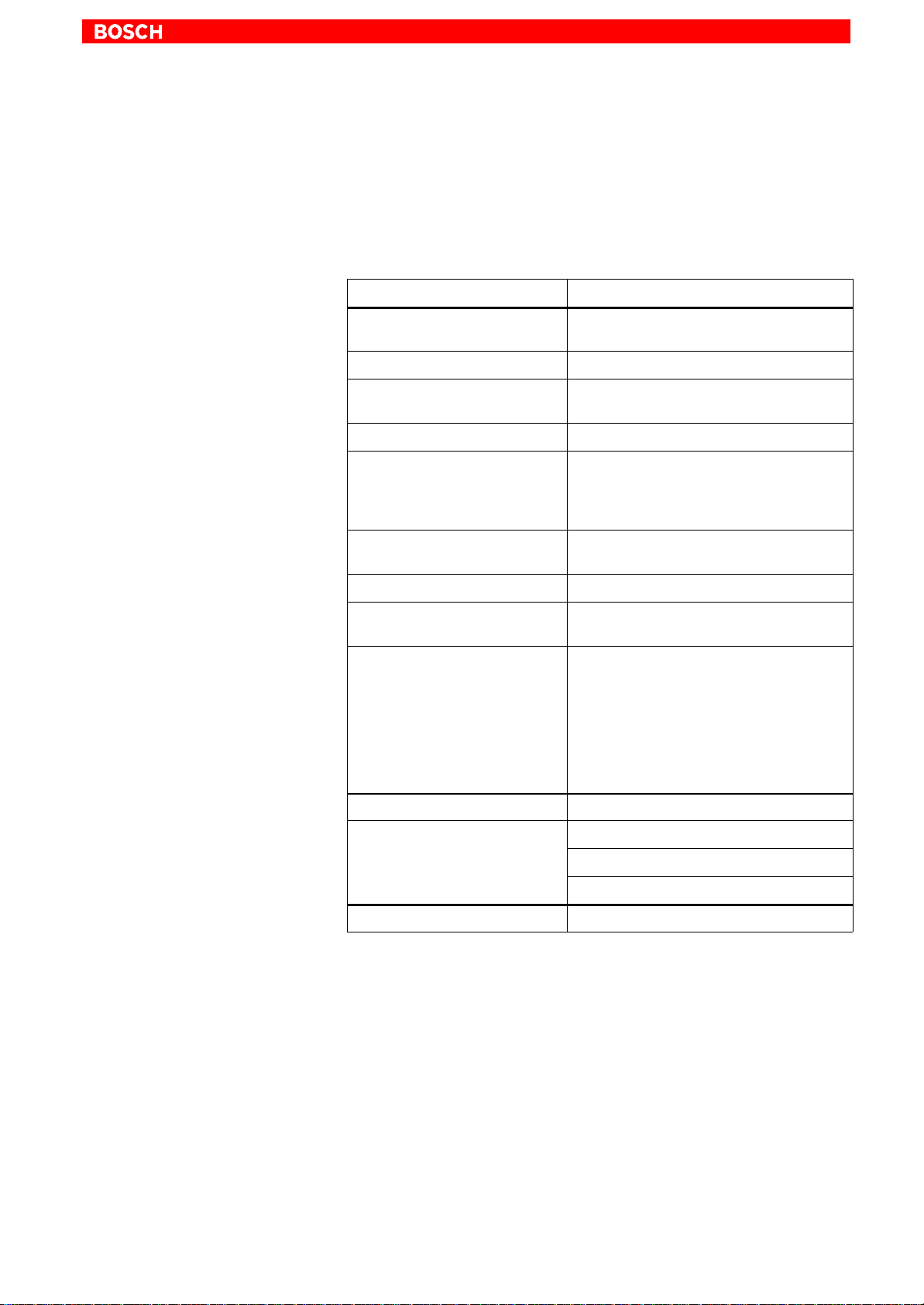

2.2 Technical Data

System Overview CPS21_3 / CPS21_4

2–5

. All specifications are subject to change as a result of technological de-

velopments. This also means that components providing higher than

the specified performance (e.g. a faster processor) may be integrated

in the devices without explicit reference in this documentation.

Feature CPS21_3 / CPS21_4

Processor ≥ Intel Pentium 266 MHz with MMXT tech-

nology (socket 7) or compatible CPU

Second level cache 512 KB

Random Access Memory

(DIMM-modules)

Hard Disk ≥ 3.2 GB (IDE)

Display 13.8” Color-TFT (CPS21_3)

3 expansion slots PCI / ISA: 3 / 0 or 2 / 1,

Power supply 24 VDC

UPS (uninterruptible

power supply)

Interfaces

(for detailed information, refer to

Section 6)

Weight: approx. 18.8 kg (without adapter)

Dimensions Housing external:509 x 432 x 177 mm

128 MB SDRAM

or 15” Color-TFT

with non–reflecting and scratch–resistant

front screen

ex works including 2 PCI cards

via integrated rechargeable battery pack

(2 series-connected 6 V battery packs)

4 x serial,

1x parallel,

PS/2-keyboard and mouse

Ethernet,

USB,

key codes via 24 V out

2 x CAN bus and 1 x busmaster

(via expansion slots)

(CPS21_4)

1070 073 825-103 (02.04) GB

PC housing: 448 x 195 x 101 mm

Front panel: 499.5 x 409.5 x 5 mm

Operating system Windows NT4.0

2–6

System Overview CPS21_3 / CPS21_4

2.3 Software

BIOS software

Operating system

. For subsequent loading of software and for data backup, a floppy disk

drive or the connection to an Ethernet network is necessary . The drive

can be purchased separately.

The BIOS software is licensed by Phoenix. With the BIOS software, the PC

boots until it finds an operating system that provides a more convenient and

user–friendly platform for running the application software.

The BIOS setup must not be altered. It is documented in the manual ”BT150,

BT200, BT250, CPS21_3 Software Configuration”.

The CPS21_3 / CPS21_4 has been equipped and tested with the following

operating systems from Microsoft Corp.:

D Windows NT (version 4.0), including possibly necessary NT service re-

leases from Microsoft Corp.

Utility programs

Application software

Additionally, the following utility program is installed:

D UPS

– Uninterruptible Power Supply Program for Windows NT

NT

(is not part of the Windows NT operating system software).

The following optional Bosch software is available:

Application CPS21_3 / CPS21_4

PCL Software PLC •

MMI-Madap Software for control and diagnosis of

plant

WinSPS PLC programming software on request

WinCan Fieldbus parameter assignment for CAN bus on request

TSWIN Programming interface for

operating terminals

• = available;

on request

on request

1070 073 825-103 (02.04) GB

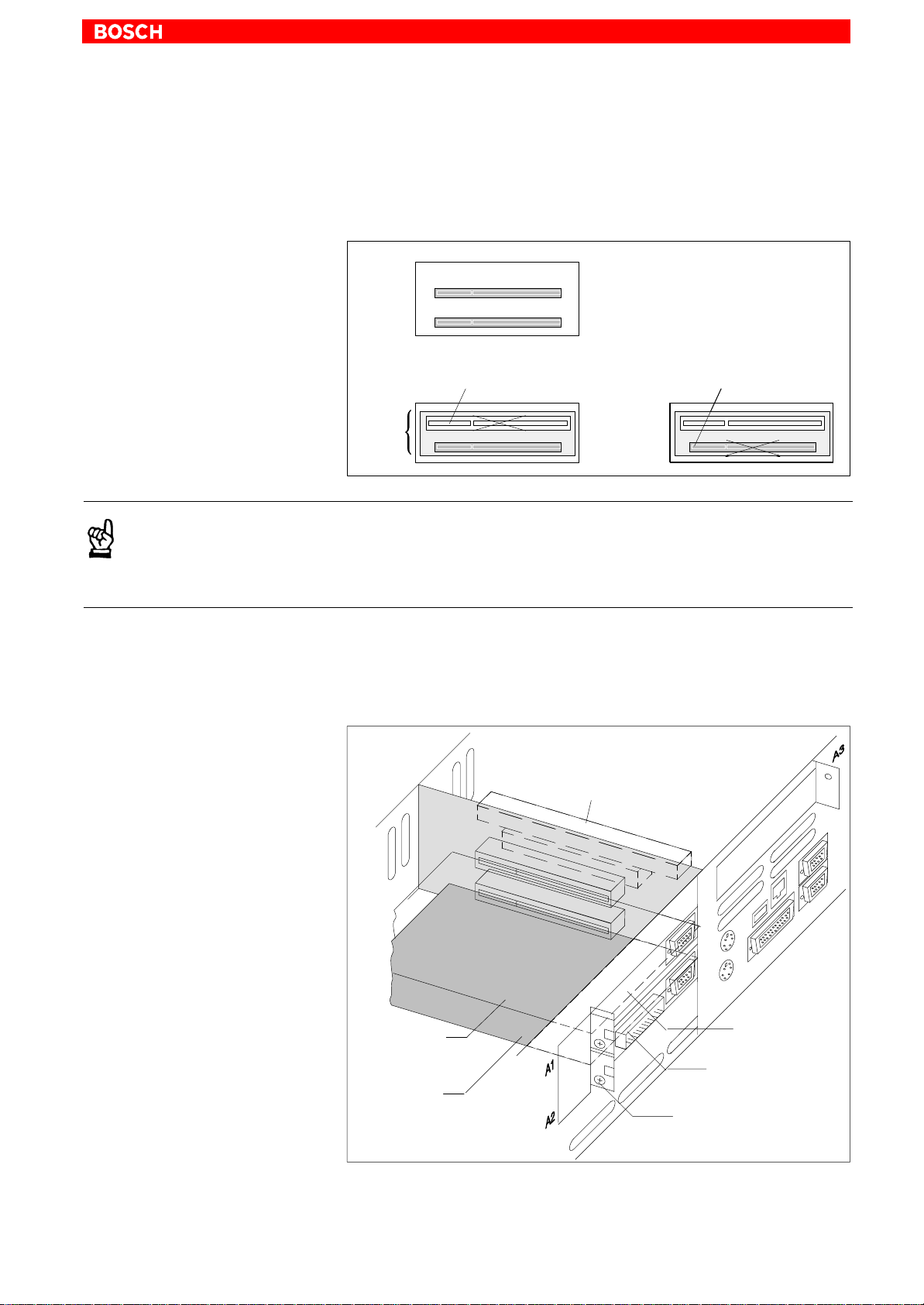

2.4 Expansion Cards

System Overview CPS21_3 / CPS21_4

2–7

The CPS21_3 / CPS21_4 has 3 slots for expansion cards with a maximum

length of 180 mm:

D 2 PCI BUS cards and

D 1 combination slot for 1 PCI or 1 ISA BUS card

Slot A1

Slot A2

must not be used if

PCI card is

inserted

Combination

slot A3

PCI bus slot

PCI bus slot

must not be used if

ISA card is inserted

ISA bus slot

PCI bus slot

CAUTION

Destruction of an expansion card or the motherboard!

PCI and ISA cards must never be inserted simultaneously in the PCI/

ISA-BUS combination slot!

The following expansion cards are used in the CPS21_3 / CPS21_4:

D PCI-CAN card: – CAN bus interface

D PCI_BM-CAN card: – CAN bus interface

– busmaster interface

ISA/PCI combination slot A3

PCI-CAN

card (on A1)

PCI-BM_CAN

card (on A2)

. For interfaces, refer to section 6.14.2

Slot cover

PCI-CAN

Slot cover

PCI_BM-CAN

Screw for fastening

slot cover

1070 073 825-103 (02.04) GB

2–8

System Overview CPS21_3 / CPS21_4

2.4.1 BIOS Setup

PCI slot x

In order to use other expansion cards, a driver software that is recommended by the card manufacturer might be necessary.

CAUTION

Using unauthorized expansion cards may result in damage to the PC

and/or the application software.

Please use only approved expansion cards, and have them installed

by a specialist.

In the BIOS submenu called “The Advanced Menu / PCI Configuration sub

menu” you can assign the interrupt request (IRQ) address to a specific PCI

slot. At the same time, the number of the IRQ address also defines the priority . I f only PnP cards are used, then the BIOS setup ”AUTO” must be main-

tained.

BIOS selection:PCI IRQ line 1, PCI IRQ line 2, PCI IRQ line 3, PCI IRQ line 4

Option: Disabled, Auto, IRQ: 3, 4, 5, 7, 9, 10, 11, 12, 14, 15,

Default: AUTO

ISA slot (IRQ)

ISA slot (UMB)

In the BIOS submenu ”The Advanced Menu / PCI Configuration sub menu /

PCI/PNP ISA IRQ Resource Exclusion / IRQx”, the IRQ Address for Legacy

ISA cards (ISA cards without plug-and-play capability) can be assigned per-

manently.

BIOS selection: IRQ:3, 4, 5, 7, 9, 10, 11, 15

Option: Available, Reserved

Default: Available

In the BIOS menu “The Advanced Menu / PCI Configuration sub menu /PCI/

PNP ISA UMB Region Exclusion” you can reserve a specific upper memory

block for Legacy ISA cards (without ”plug–and–play” capability) .

BIOS selection: C800 - CBFF, CC00 - CFFF, D000 - D3FF, D400 - D7FF,

D800 - DBFF, DC00 - DFFF

Option: Available, Reserved

Default: Available

CAUTION

Address conflicts (IRQ, memory access, I/O address) may cause

destruction of motherboard or ISA cards!

Please follow the instructions provided by the card manufacturer. I f

necessary you must make new configuration settings in the BIOS

and in the operating system (e.g. Windows NT control panel).

1070 073 825-103 (02.04) GB

2.5 Rechargeable Battery Pack

The CPS21_3 / CPS21_4 is equipped with a rechargeable battery pack

(composed of 2 series-connected 6V rechargeable batteries) that ensures a

controlled shutdown of the PC operating system by means of the uninterruptible power supply (UPS), in the event of a power failure. This prevents data

losses in the PC’s random access memory.

. UPS, refer to section 3

The rechargeable battery pack is located on the back of the front panel, next

to the PC in the aluminum housing. It is connected to the X19 connector on

the carrier board by a 2-conductor cable.

Charging function

During standard operation, the rechargeable battery pack is recharged by

means of a charging circuit. If the rechargeable battery pack (2.5 Ah) is absolutely empty, the charging process lasts 5 hours.

System Overview CPS21_3 / CPS21_4

2–9

Replacing the battery pack

The number of charging cycles that the rechargeable battery pack can withstand and therefore its useful life, depend on the ambient temperature in

which the battery pack is used. Ambient temperature here is defined as the

one in which the operating terminal is situated, e.g. the temperature in the

control cabinet or in the operating housing.

The following table can be used as a guideline:

Ambient temperature Charging cycles Maintenance interval

+ 25 °C 4000 cycles 6 years

+ 35 °C 2000 cycles 3 years

+ 45 °C 1000 cycles 1.5 years

. If there is some uncertainty concerning the temperature conditions of

the operating terminal, then we recommend exchanging the battery

pack every 1.5 years.

For position and replacement of installed battery, refer to section 8.2.3.

1070 073 825-103 (02.04) GB

2–10

System Overview CPS21_3 / CPS21_4

Charge level

With the UPSNT software program that can be called up via an icon on the

Windows NT status bar, a number of status data and settings related to the

UPS and battery operation can be read off (refer to section 3.3):

D Charging cycles: Number of previously performed charging

cycles (shutdown count).

D Checking the battery

charge level:

Presence of a rechargeable battery pack is

checked with each system startup (e.g. rechargeable battery pack not defective, no

cable break, positive plug contact)

D UPS interface: COM4

In case of an insufficient level of charge, it might be necessary to replace the

battery packs.

1070 073 825-103 (02.04) GB

2.6 Operating Conditions

The CPS21_3 / CPS21_4 is designed for continuous 24 hours/day operation. The display backlight can be switched off.

Unless stated otherwise in individual sections of this manual, the following

specifications apply:

Temperatures Storage temperature:

–20°C to +60°C

Ambient temperature: (outside the aluminum housing)

+5°C to +35°C (basic unit)

+5°C to +40°C (with external fan kit)

Ambient temperatures apply to installation conditions described in section 4.

Temperature fluctuations of up to 3°C per minute are permitted.

CAUTION

Excessive operating temperature!

Please do not expose the housing of the CPS21 to direct sunlight or

other sources of heat radiation!

System Overview CPS21_3 / CPS21_4

2–11

Humidity Climate class 3K3, to EN 60721, condensation not permitted.

Clearances and creeping distances In accordance with prEN50178 (11/96) at pollution level 2

Atmospheric pressure Operation at up to 2000 m above sea level, to DIN 60204

Degrees of Protection Front panel: IP 65, otherwise IP 54

Resistance ll surfaces are resistant to abrasion and media such as:

D Solvent naphtha (CH20V3)

D n-Heptane

D Test oil (VS15665)

D Hydraulic oil

D Lubricants

D Water

CAUTION

Conditions hazardous to the product!

The ambient air must be free of electrically conductive pollutants

(e.g., acids, alkali, corrosives, salts, metallic vapors, etc.).

Vibration resistance during operation

Frequency range: 10...150 Hz

Deflection: 0.075 mm at 10...57 Hz, according to EN 60068-2-6

Acceleration: 1 g with 57...150 Hz

Impact resistance 15 g, according to DIN IEC 68-2-27, no functional interruption

1070 073 825-103 (02.04) GB

2–12

System Overview CPS21_3 / CPS21_4

2.7 Applicable Standards

The CPS21 system components comply with the following standards:

D EN 60,204-1 Electrical systems on machines

D EN 50,081-2 Basic specification for interference emission

D EN 50 082-2 Basic technical standard, interference resistance

D EN 60,742 Tranformer for 24 V power supply, safety isolation

D EN 61,131 24 V output requirements

D EN 61,131-2 Requirements for 24 VDC power supply

D EN 418 Machine safety, EMERGENCY–OFF devices

D EN 60,529 Protection categories (incl. housings and installa-

D EN 60 721 Classification of environmental conditions

D EN 60 068-2-6 Vibration test

D EN 60068-2-27 Impact test

D .IS.114 X-ray radiation directive, as per Official Federal

(industrial environment)

(industrial environment)

tion compartments)

Gazette

. When leaving the plant, CPS21_3 / CPS21_4 complies fully with CE cer-

tification requirements.

However, the subsequent insertion of additional expansion cards will

necessitate a new CE certification.

1070 073 825-103 (02.04) GB

3 Safety Functions

3.1 Temperature Monitoring

The temperature inside the CPS21_3 / CPS21_4 must not exceed +45°C

(refer to section 2.6). For safety reasons, the PC features a temperature monitoring function that measures the temperature inside the aluminum housing.

If the temperature inside the housing exceeds +50°C, a temperature warning is issued:

D via the red flashing LED ”TEMP” on the front panel of the operating termi-

nal

D via a window displayed by the operating system.

This message must be interpreted by all application programs as well,

especially by I/O processes. Bosch application programs comply fully

with this requirement.

Safety Functions

3–1

The temperature warning function can be disabled via the program:

D UPS

If the temperature > inside the housing exceeds >65°C, the control

terminal is shut down and switched off via the UPS logic circuits (refer to

section 3.2).

for Windows NT 4.0 (refer to section 3.3).

NT

1070 073 825-103 (02.04) GB

3–2

Safety Functions

3.2 Function of Uninterruptible Power Supply (UPS)

In the event of a power failure or a temperature condition above 65 °C (refer

to section 3.1), the UPS logic circuit in the CPS21 power supply will facilitate

a safe shutdown of the PC operating system with the aid of the rechargeable

batteries.

Operating power will be drawn from rechargeable batteries (provided that

the batteries are working correctly) as soon as a voltage dip in excess of 20

ms has occurred.

. The UPS logic circuit of the CPS21 power supply is designed to ensure

the proper termination of all active application programs, followed by a

safe shutdown of the operating system. The UPS is not designed, however, to maintain the operation over a longer period of time!

DANGER

In the event that rechargeable batteries are found to be missing, defective or in a discharged condition, a voltage dip exceeding 20 ms

will trigger a RESET of the CPS21 without prior warning!

Possible consequences might be uncontrolled machine movements

and loss of data.

Users are advised to check the rechargeable batteries for proper

charge levels at regular intervals!

Power failure interval shorter than 800 ms

In the event that the mains power returns within the waiting interval of 800

ms, the power supply unit will again switch to standard operation.

V

Operating voltage

Operating voltage

restored within 800 ms

restored again

CPS21_3 is not shut down because

Operating

system

loaded

(standard

operation)

not loaded

interruption

of operating voltage is shorter than 800 ms

t0 t1 < 800 ms

t

t

1070 073 825-103 (02.04) GB

Power failure interval between 800 ms and 60 sec

A power failure interval exceeding 800 ms causes the operating system to

be shut down after a preset time (Delay Time). If the mains voltage returns

within 60 sec. the UPS will interrupt the operating voltage for an additional 8

sec. When point t3 has been reached, the operating system is again started

up.

Safety Functions

3–3

V

Operating voltage

Operating

system

loaded

(standard

operation)

not loaded

t0t1 = 800 ms

Mains voltage failure Mains voltage available

Shutdown of the

application program

Delay Time,

adjustable

Power failure interval exceeding 60 sec

When approx. 60 seconds have elapsed, the UPS will internally de-energize

the power supply.

Shutdown of the

operating system

< 60 sec

t

2

Operating

voltage

interrupted for

8 seconds

Operating

system startup

t

= t2 + 8 sec

3

t

t

Operating voltage

Operating

system

loaded

(standard

operation)

not loaded

V

Delay Time,

adjustable

t0t1 = 800 ms t4 = t1 + 60 sec

. Setting the Delay Time is done in the ”UPS

Mains voltage failure

Shutdown of the

application program

Shutdown of the

operating system

(Must not be restarted manually)

UPS de–energizes power supply

” software (refer to section

NT

t

t

3.3.2).

1070 073 825-103 (02.04) GB

3–4

Safety Functions

3.3 UPS Program

3.3.1 Function

The ”UPSNT” program (Uninterruptible Power Supply) serves to control and

monitor the integrated uninterruptible power supply. In addition, the program

checks the functioning of the rechargeable battery and controls the system’s

temperature monitoring function.

Program and UPS communicate via the COM4 serial port.

In case of a power failure, it is the UPS program’s task within a preset time

(Delay Time: max. 60 seconds)

D to provide a message to all active applications on the control terminal,

enabling them to be terminated either by the user or by means of special

application routines, and

D to shut down the operating system after expiration of the Delay Time.

When the voltage monitoring function has responded, the system shut

down can no longer be avoided.

Closing down all active applications prevents loss of data in case of sudden

power failure.

After a maximum of 60 seconds, the UPS shuts down the CPS21_3 /

CPS21_4 power supply unit if the mains voltage has not yet returned (refer to

section 3.2 Function of uninterruptible power supply).

CAUTION

Restarting the system manually leads to loss of data!

The UPS turns off the CPS21_3 / CPS21_4 in any case. Consequently

the dialog ”Restart” must not be activated after the shutdown of the

operating system.

In case of a voltage failure that lasts less than 60 seconds, the operating system restarts automatically.

During normal operation, the operator does not have access to the UPS

program. It can only be operated and parameterized by persons with special

administrator rights and after restart of the operating system.

. Modifications to the UPS

Bosch.

parameters require the prior consent of

NT

NT

1070 073 825-103 (02.04) GB

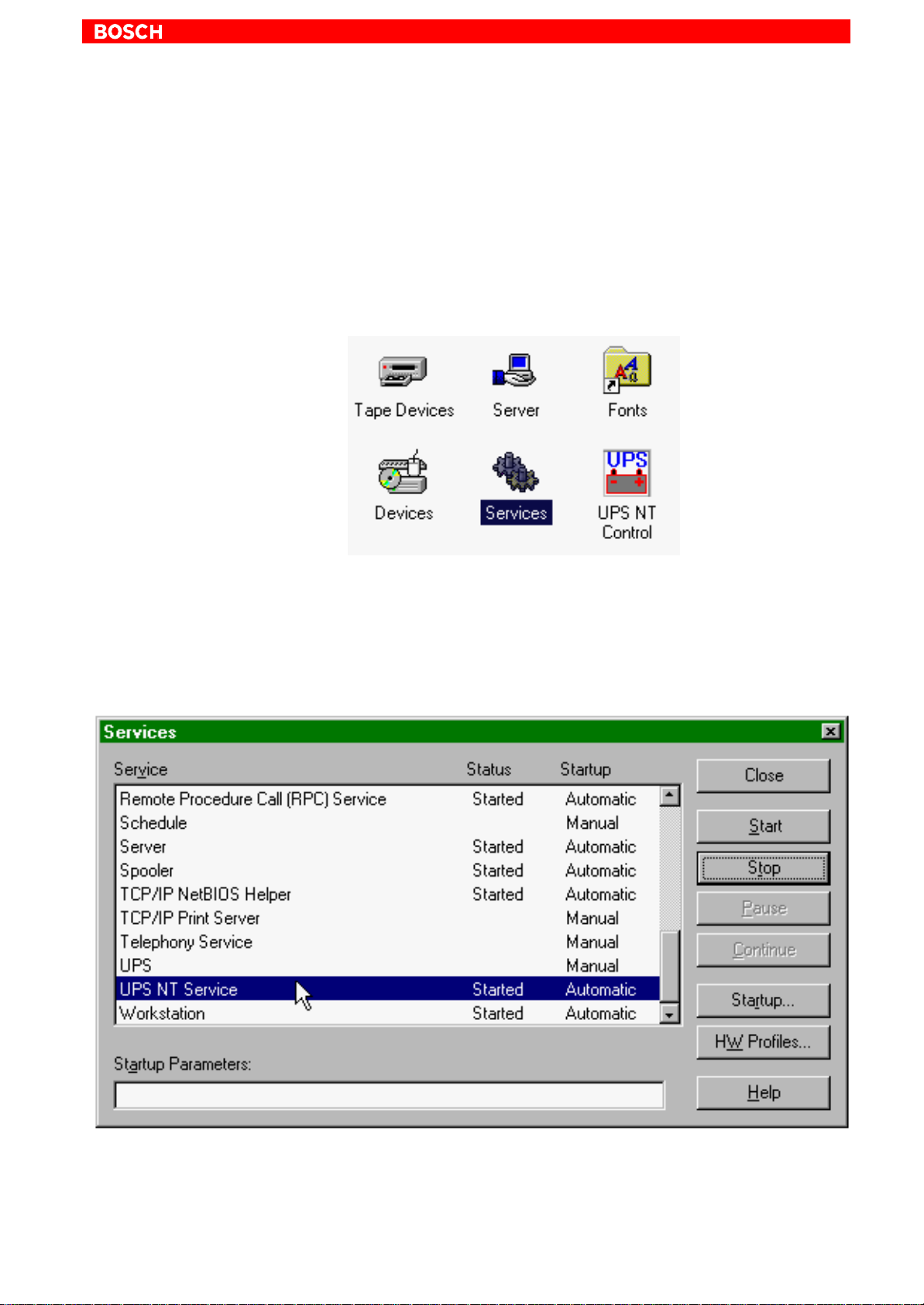

3.3.2 Operation

Start/Stop

Safety Functions

. Administrator rights are required for operation!

When starting Windows NT, the UPS

For interrupting, shutting down or restarting the service (e.g. for new installa-

tion or update), select ”Services” from the ”Control Panel” window (see the

following illustration, left of UPS

program is launched automatically.

NT

Control).

NT

3–5

In the Services window of Windows NT, the status of the UPSNT Service is

displayed:

D UPS

D UPS

Start and stop the selected entry UPS

stopped: Status column is empty

NT

started: Status column displays ”Started”

NT

Service with the Start and Stop but-

NT

tons, respectively.

1070 073 825-103 (02.04) GB

3–6

Safety Functions

Configuration

. The UPS

the user has no influence on this. A user without Administrator privileges is neither able to terminate the program nor to stop the monitoring

function.

In order to configure UPS

nel” window (see below).

The dialog ”UPS NT Configuration” determines the start and runtime behavior of UPS control.

The individual values of the configuration are stored in the Registry. The parameters can be changed at any time.

program always runs as a Windows NT service. Changing

NT

, select ”UPS NT Control” from the ”Control Pa-

NT

. After modifying the parameters, the UPS program must be stopped

and restarted in order to become operative.

This can be achieved by restarting the computer or with the help of the

Services manager.

. For details and parameter settings refer to section 3.3.3 .

1070 073 825-103 (02.04) GB

3.3.3 Parameter Settings

COM Port

UPS Shutdown Parameter

Shutdown Delay Time

Safety Functions

The UPS program is always connected to the UPS via the COM4 serial port.

Smart Shutdown

When the Power Down signal has been received from the UPS, the Delay

Time starts.

Here the time (0 to 60 seconds) for delaying the shutdown is entered. Wit-

hin this time frame, a request to close down is sent to all open windows. During this time, the user can save his data. When the Delay Time has expired,

all application programs are shut down without further notice!

3–7

Advanced Controls

When choosing the Delay Time, make sure that the time between the end of

the Delay Time and the end of the 60 seconds after the Power Down Signal is

long enough to shut down the operating system (close all Windows system

files and make backups). If the period of time chosen is too short, the shutdown process is interrupted because the UPS interrupts the power supply of

the CPS21_3 / CPS21_4. This might lead to data loss.

CAUTION

On expiry of the Delay Time, the operating system is shut down without further notice. Data from open application programs that has

not been backed up, is lost.

Enable Accu (i.e. Rechargeable Battery) Test

If this checkbox is activated, the system tests the rechargeable battery pack

with each new start.

In the case of a faulty battery pack (e.g. defective battery pack, cable break,

plug not connected), battery monitoring is disabled. The UPS program continues only with its temperature monitoring function.

If temperature monitoring is not activated, the UPS program is shut down.

1070 073 825-103 (02.04) GB

. A message that the rechargeable battery pack is empty is displayed.

3–8

Safety Functions

Enable Temp Control

If this checkbox is activated, the system temperature is monitored permanently. If the system temperature is exceeded, the following warning is displayed:

After a temperature warning, the UPS program is reactivated. During this reactivation period of about 2 seconds, voltage monitoring does not take place

although the battery pack is functioning correctly.

Info

Default Setting UPS

Disable Auto Power Off

The function ”Disable Auto Power Off” makes sense only during system

start-up or during software installation. Make sure that the checkbox is deactivated during normal operation!

CAUTION

Loss of data!

If this checkbox is activated, a regular shutdown of the operating system is not possible after a voltage breakdown. The CPS21_3 /

CPS21_4 shuts down immediately!

Shutdown count

The displayed value shows how often the system was shut down by UPS, i.e.

how many charging cycles the battery has been subjected to. More details

regarding after how many charging cycles it is necessaary to replace the rechargebale batteries is contained in section 8.2.3.

NT

With this button, the standard values of the dialog elements can be preset.

These are:

D COM port: COM4

D Shutdown Delay Time: 30 sec

D Accu Test (battery test): active

D Temp Control: active

D Disable Auto Power Off: inactive

1070 073 825-103 (02.04) GB

4 Installation

Installation

When installing, please observe the applicable standards and operating

conditions in sections 2.7 and 2.6.

CAUTION

Conditions hazardous to the product!

The ambient air must be free of electrically conductive pollutants

(e.g., acids, alkali, corrosives, salts, metallic vapors, etc.).

. Note

D The use of silicon-based sealing compounds, adhesives and

insulating agents is prohibited.

D Ensure that the installation is easy to maintain, i.e. that it provides

unrestricted access to connecting cables and fuses.

D Prior to installation, please write down the information on

equipment rating plates. In the event that rating plates are hidden

from view as a result of the installation, you will still have quick

access to this information whenever required.

4–1

1070 073 825-103 (02.04) GB

4–2

Installation

4.1 Installed Positions and Clearances

Housing: Front panel: Protection category IP 65

Aluminium housing: Protection category IP 54

Weight: approx. 18 kg

Installation

vertical, 0_ up to max. "45_ inclination

position:

Installation

type:

floor or suspended installation, sealed according to

IP 54.

. Please remember that the front panel may become dirty more readily if

installed at an angle.

100

CPS21

100

Top

mounting

device

100

Minimum 100 mm all–round

clearance for cooling required

Bottom

mounting

device

100

100

100

"45°

"45°

Install. position max. "45_ incline

D Install the CPS21 control panel, ensuring that it can be operated ergono-

mically. In addition, the operator must be provided with a permanent and

unobstructed line of sight to moving machine parts!

D To prevent reduced screen readability and additional thermal load, avoid

installation locations that are exposed to direct sunlight.

D The LEDs on the front panel must not be obstructed or concealed.

D To ensure there is sufficient ventilation space, provide an all-round mini-

mum clearance of 100 mm (see drawing).

D Allow for connecting loops in all cable routings. Use drag chain qualified

cables. Provide strain relief for all cables.

D Keep as far away as possible from sources of interference.

1070 073 825-103 (02.04) GB

Clearance

Installation

4–3

The following clearances must be maintained:

D for passive cooling of CPS21: 100 mm min. to all sides

D for maintenance procedures on the PC:400 mm min. in front of front pa-

nel,

opening angle max. 1205

Opening angle:

max. 1205

min. 400 mm

CAUTION

Excessive operating temperature!

Please do not expose the housing of the CPS21 to direct sunlight or

other sources of heat radiation!

1070 073 825-103 (02.04) GB

4–4

Installation

4.2 Dimensioned Drawing

Plastic frame

Housing bottom

Aluminium housing with

cooling fins

Housing lock

(5 double–bitkey)

Front view CPS21_3

432

Front view CPS21_4

Handle bar (plastic)

509

177

432

383

509

Housing top

151.5

1070 073 825-103 (02.04) GB

4.3 Installation with Tip/Tilt Adapter

The CPS21 is designed for:

D suspended mounting (e.g.bracket system KSE 60) or

D Floor mounting

with an adjustable tip/tilt adapter.

For this purpose, the housing top and bottom are each provided with a circu-

lar opening (70 mm in diameter with 4 bores 5 mm in diameter) for fastening

the tip/tilt adapter and through which all cables are led into the housing.

The opening that is not used is covered with a rectangular cover plate. Ex

works, the bottom opening is covered.

Installation

A

4–5

Housing

A–A

64

23

Bm5 (4X)

362

64

383

6

Bm5 (6x)

∅ 70

Installation

opening

Bezel 4 x 45_

A

151.5

1070 073 825-103 (02.04) GB

. The flange for the suspended or floor installation must be sealed suffi-

ciently in order to comply with the housing degree of protection IP 54.

4–6

Installation

Installation Instructions

L For suspended installation, please use the upper opening.

For floor installation, take off the cover from the bottom opening and close

the upper opening.

L Open the housing with a 5 mm double-bit key and swing out the PC.

L Insert the cables that lead to the PC and the distribution card through the

opening.

L Fasten the tip/tilt adapter of the swivel arm or the stand to the opening with 4

screws. Make sure the connection is impermeable (IP54).

L Connect all cables with the corresponding plugs on the PC and the distribu-

tion card.

L Close the housing.

1070 073 825-103 (02.04) GB

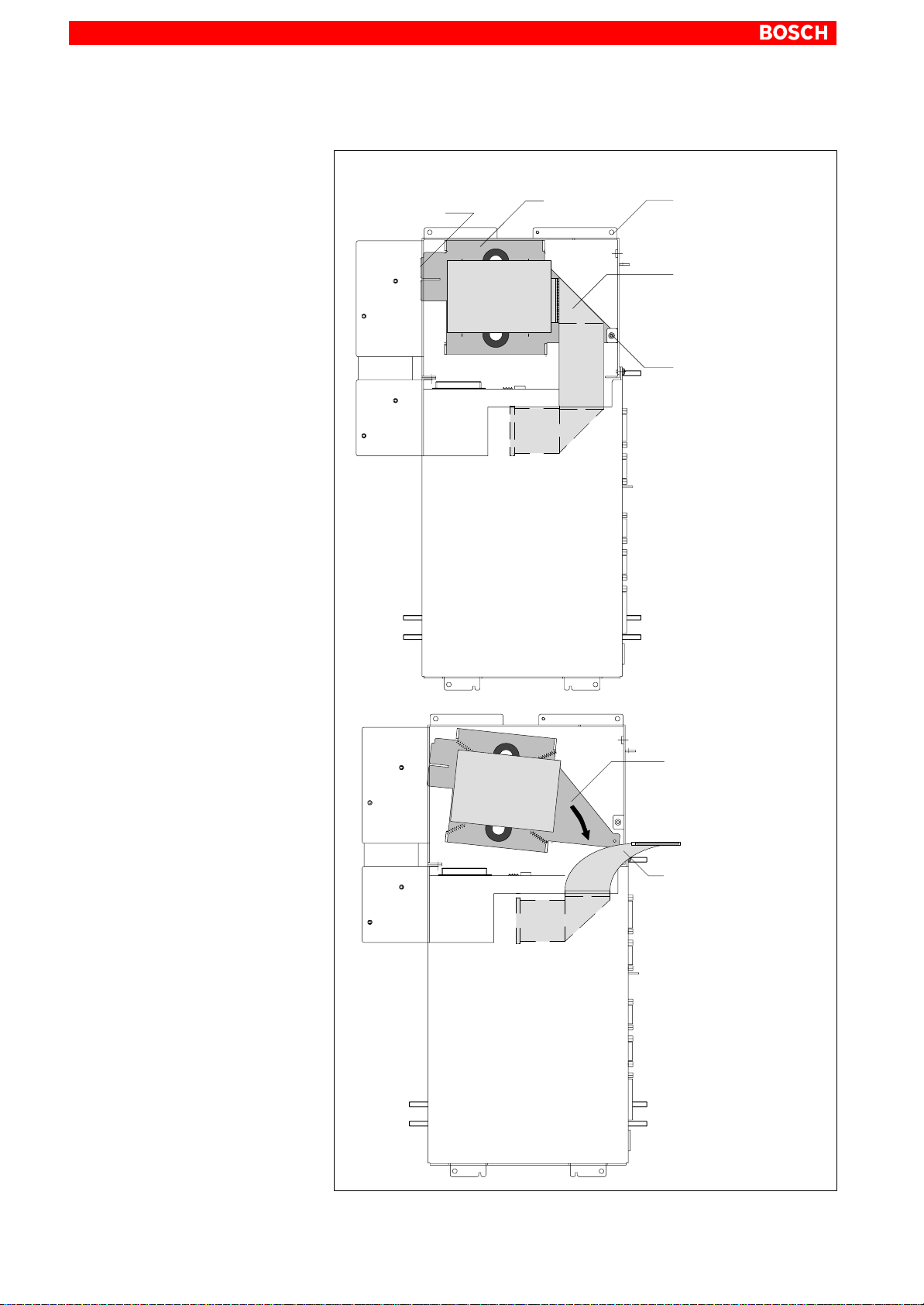

4.4 Installation of the optional Coolkit

A Coolkit can be obtained separately as an optional extra. It must be used if

the CPS21 is used under high ambient temperatures of up to + 40°C.

Installation Instructions

L Remove the existing cover from the bottom of the CPS21 by unscrewing the

4 retaining screws (see diagram).

View of CPS21 from below (with cover)

Installation

Plastic frame

Retaining screws

Base plate

4–7

CPS21 side view

(with Coolkit in place)

Cover (to be removed)

L Open the CPS21 housing and fasten the CPS21 Coolkit with the new cover

from the accessory kit to the base plate from below (see diagram).

View of CPS21 from below

(with Coolkit in place)

Plastic frame

PC box

Screw holes not used

CPS21 base plate with outlet

Coolkit

New cover

New cover from the

accessory kit with 4 threaded

holes

1070 073 825-103 (02.04) GB

L Screw the Coolkit on using the 4 long screws from the accessory kit. They

should be introduced from the top into the interior of the open CPS21 through

holes in the base plate (where the old cover that has been removed was

screwed onto) and screw them into the threaded holes of the new cover (see

diagram on next page).

4–8

Installation

Plastic frame

CPS21 housing

opened

PC box

Insert 4

retaining

screws from

here and screw

tightly into new

cover

CPS21 base plate

Coolkit

New cover with 4

threaded holes

L The 6 screw holes not used on the bottom of the Coolkit can be covered from

below with stoppers from the accessory kit.

L Instructions for making the electrical connections to the Coolkit are in section

6.4.

1070 073 825-103 (02.04) GB

5 Electrical Connections

Please note that, with respect to all electrical connections, the terminal connection plans and work instructions provided by the machine manufacturer

shall always be binding!

The system planner is also charged with providing and planning for the integration and implementation of required components, such as EmergencySTOP circuits, mains switches, etc. in accordance with current technical

standards and at the highest levels of safety attainable.

CAUTION

Risk of damage to system components caused by insertion or removal of plug connectors on energized circuits!

Connections must be made only while the system is switched off.

Observe the following to prevent malfunction:

D Provide for isolated 24 VDC and 0 V terminal strips inside the control ca-

binet. With regard to cable routing, maintain a minimum distance of 10

cm from all power cables.

D Connect the CPS21and other industrial components (e.g. CNC, PLC) in

such a way that they are always switched on simultaneously.

Electrical Connections

5–1

1070 073 825-103 (02.04) GB

5–2

Electrical Connections

5.1 Protective Earth Conductor (PE) and Screening Information

DANGER

Dangerous conditions, functional failures and equipment damage to

the system may be caused by substandard potential equalization or

inadequate screening between individual components!

Potential equalization currents must not flow across the screening

of interface cables.

L The protective earthing conductors (earthing connections) of the system

must be arranged in a tightly meshed grid. All components, control cabinet

housings and doors, including the mounting plate, must be earthed.

L The potential equalization lines / PE lines of all system components shall be

kept as short as possible, thus providing low-resistance connections.

L Install the PE lines, preferably electrically conductive, on the mounting plate

inside the control cabinet. Both sides of the insulated installed PE rails must

be connected to the mounting plate with max. 20 cm long, adequately dimensioned copper straps.

Arrange the PE lines so that the length of the outgoing protective earth conductor connections to the individual modules in the control cabinet does not

exceed 1 m.

L When specifying the PE wiring, ensure sufficiently dimensioned cross-sec-

tion. In this regard, also observe EN 60204, Part 1 (max. electrical resistance

and testing PE wiring installations).

L If at all possible, apply screening connections on both ends of a cable.

L Ensure that equipotential equalization currents do not flow across the inter-

face signal lines via the shielded conductors. Therefore, before switching on

for the first time , ensure that the potential equalization between devices

which are to be connected is correct. Do not forget the interfaces which connect devices to each other at different locations (irrespective of distance or

power supply).

DANGER

Dangerous shock currents due to poor PE connections!

The effectiveness of PE connections must not be impeded by mechanical, chemical or electrochemical influences. Connections must be

permanent and tight.

1070 073 825-103 (02.04) GB

5.2 Interference Suppression Information

When designing the plant, please observe and comply with governing regulations and s t a t u t o r y l a w w i t h r e gard to interference suppression on individual components. This will increase the operational safety of the entire

system.

DANGER

Dangerous conditions, functional failures and equipment damage to

the system may be caused by electromagnetic interference!

Install only screened signal voltage cables and at a sufficient distance from high-voltage cables. If this is not possible, separate metallic cable ducts must be used.

The following sections are designed to provide you with a brief overview of

possible interference suppression measures in the control cabinet. Among

these are, for example:

D Filters

D Spark quenching circuits

D Damping of inductive switching peaks

D Limitation of switching voltage of high-speed semiconductors

D Screening

Electrical Connections

5–3

To ensure optimum interference suppression, all of these components

should be taken into consideration because they are most effective when

working in conjunction with each other. In principle, interference suppression should be implemented as follows:

D Apply suppression measures as close to the source of interference as

possible

D Use only components that are identified as interference suppressors

D Limit leakage currents in accordance with safety regulations

D Provide touch guards

D Prevent vibration fatigue breakage by providing secure mechanical sup-

port for interference suppressors.

To ensure that interference suppression measures are successful, electrical

symmetry or asymmetry must also be taken into consideration.

Besides symmetrical components of interference voltage that occur between the mains connection cables, asymmetrical interference voltages occur as well. They are caused by capacitive coupling of the interference

source with the mains network, for example.

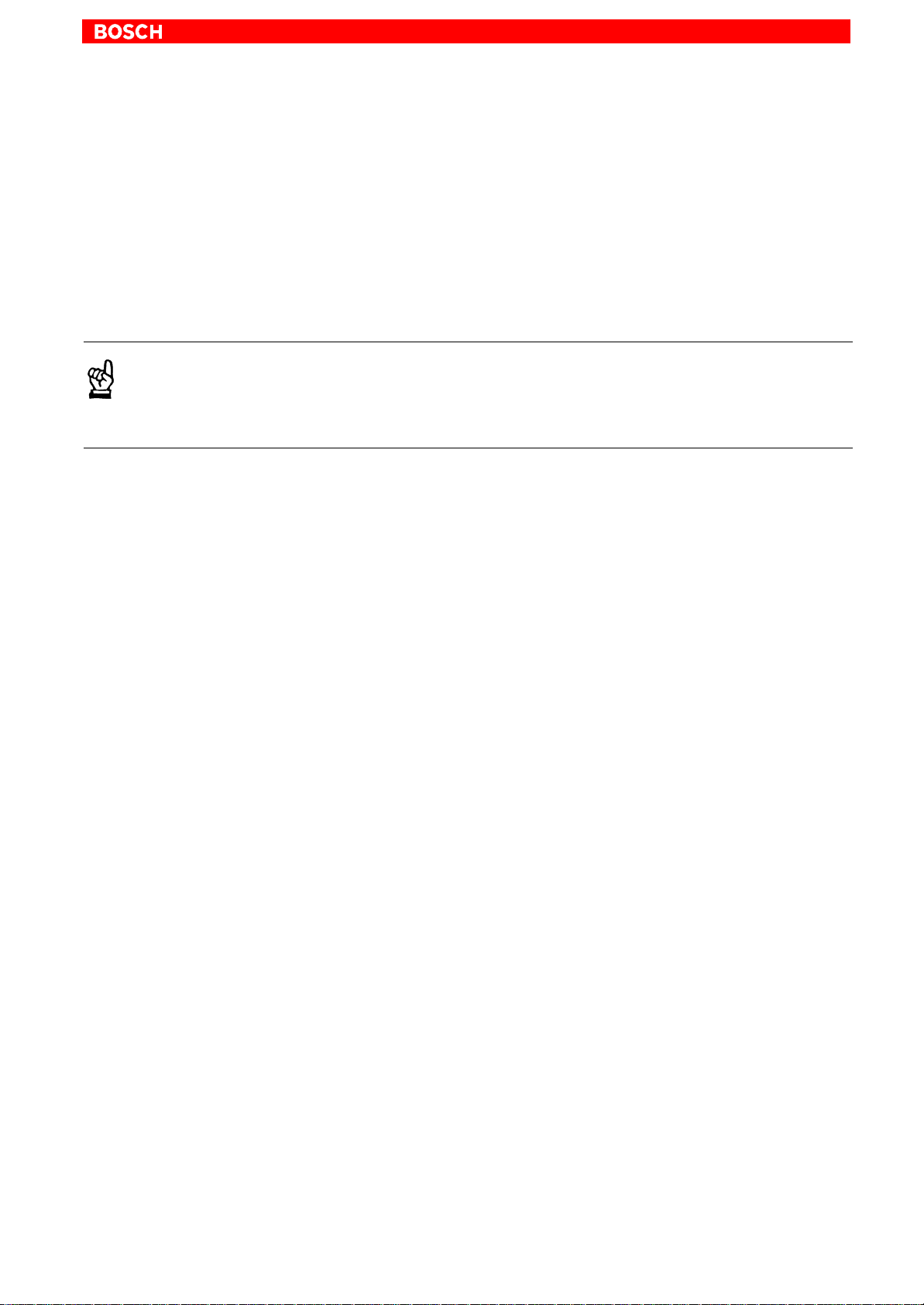

The following diagram shows a commonly used interference suppression

circuit. The asymmetrical interference voltages are discharged to the housing via C

. Cx damps the symmetrical interference.

y

C

L

y

1070 073 825-103 (02.04) GB

C

L

x

C

y

Mains

5–4

Electrical Connections

Interference suppression examples

Suppression of contacts

(Alternating current, direct current, offset DC current)

a) b) c)

R

C

R

Rp

C

VDR

to b) For sensitive contacts, residual current when contact open!

to c)

Voltage-dependent resistance, residual current when contact

open!

Suppression of an inductive load

(Motors, solenoid, relay and contactor coils)

−

a) b) c) d)

D

ZD

+

VDR

R

VDR

C

D

U

U

e)

R

C

to c)

to d)

For relay, drop-off delay.

For relay, defined drop-off delay

to e) Must be optimized for inductance!

Suppression example – mains input:

L

1

L

1

C

x

C

y

M

C

x

N

SL

~

L

2

L

3

C

x

SL

M

3

~

C

C

x

y

C

x

1070 073 825-103 (02.04) GB

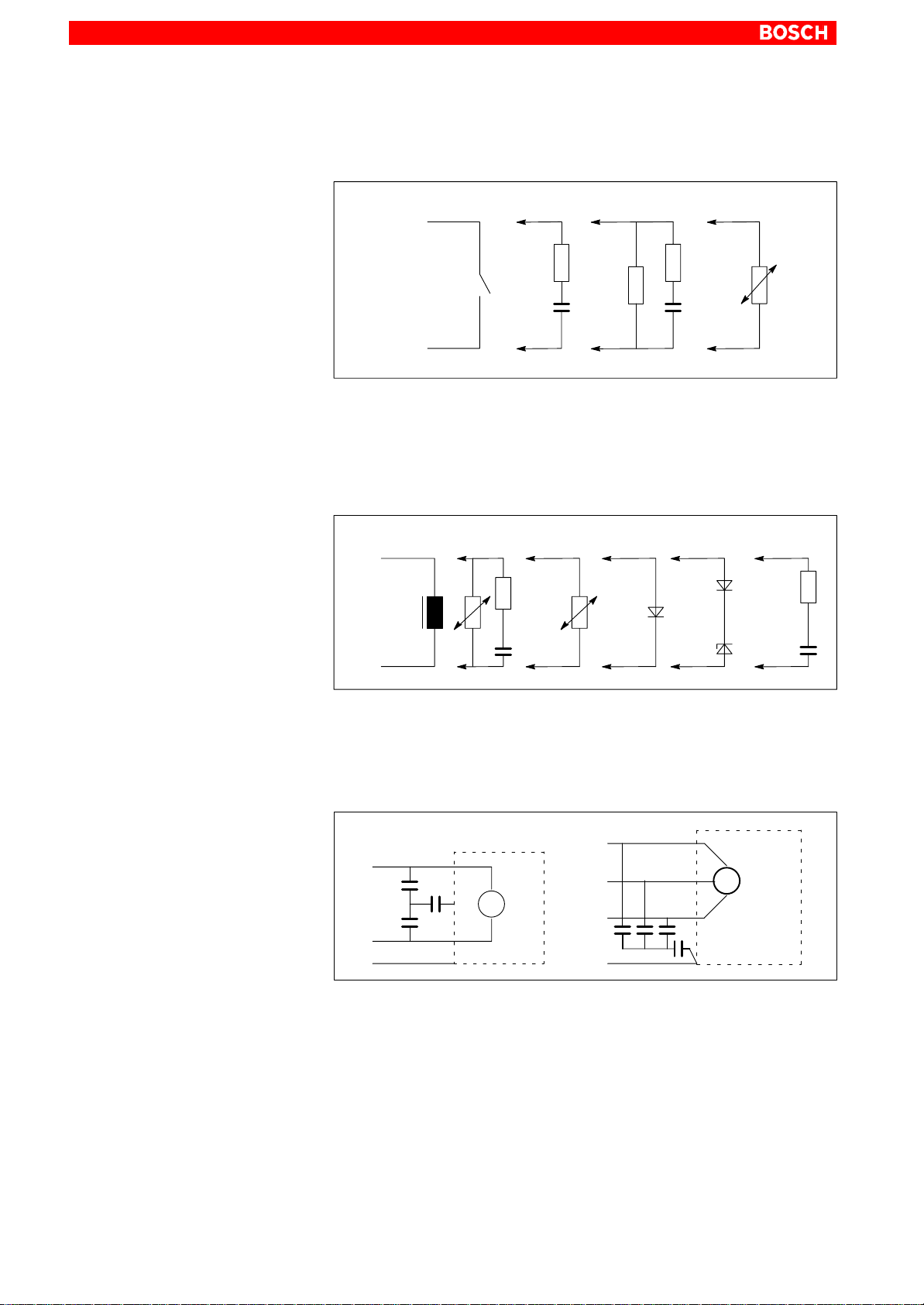

5.3 Power supply

5.3.1 24 VDC-power supply

X25 24 VDC connection

Weidmüller push-lock terminal, MSTB 1.5, 4-pin

Max. conductor

cross!section:

X25

Electrical Connections

1.5 mm

4

1

2

(refer to next page)

AssignmentPin

40 V

3

2

0 V

24 V

24 V1

5–5

Rated voltage UN: 24 VDC ; +20%, –15% with a max.

of 1.5 Vss ripple voltage

Residual ripple at U

Interference and surge immu-

: refer to figure

N

= 35 V (for t < 100 ms)

U

max

nity:

Current draw at U

: max. 5 A

N

Input fuse: M6.3A (5x20) medium time-lag fuse

(position: refer to page 6–3)

Reverse voltage protection: via decoupling diode. Polarity reversal

will blow input fuse.

DANGEROUS ELECTRICAL VOLTAGE

The 24 VDC input voltage must fulfill the requirements of ”Safety Isolation”!

Offset AC components of the type produced by an unregulated 3-phase current bridge circuit without smoothing with a ripple factor of 5% (refer to DIN

40110/10.75, Section 1.2) are permissible.

As an upper voltage limit, this produces a maximum absolute value of 30.2 V

and, as a minimum voltage limit, a minimum absolute value of 18.5 V.

U

1,05.28.8 V = 30.2 V

1070 073 825-103 (02.04) GB

Upper limit 28.8 V

0,866.30.2 V = 26.1 V

1,05.20.4 V = 21.4 V

Lower limit

0,866.21.4 V = 18.5 V

20.4 V

30 el

cos (30 ) = 0.866

0

0

0

t

5–6

Electrical Connections

Cross–sections

depend on power

demand, but min. of 4

2

mm

. For higher power

demand, 2 x 4 mm

2

L1L2L3

PE

Power supply with

safety transformer

as per

EN 60742

400 VAC

24 VDC

Max. length 4 m

A

0 V Load24 V Load

PE

102 (green/yellow)

2

6

(blue)

(1)

A B

Earth bar

A = Terminal row 4

B = Terminal row 10

: Terminals in insulated design

102 (green/yellow)

2

2

(2)

PE

102 (green/yellow)

CPS21

Display with front

keyboard and PC

Power supply

(safety isolation, as per EN

60950)

X10_1

Supply and

distribution

circuit board

X25

X26 or X27

Cross–sections

depend on power

demand, but min. of

0.5

mm

2 (3)

(1) Connection absolutely necessary.

(Easily visible and removable).

(2) Preferred installation of PE terminal

bars: electrically conductive on the

mounting plate. PE terminal bars that are

installed in an insulated design must be

connected to the mounting plate by means

of copper straps of a length not exceeding

200 mm.

The cross–section of the copper straps

must equal at least that of the supply cable.

2

(3) 0.5 mm

0.75 mm

1.5 mm

, up to 4 meters

2

, up to 6 meters

2

, up to 10 meters

Distances in excess of 10 m require

separate power supply close to load!

1070 073 825-103 (02.04) GB

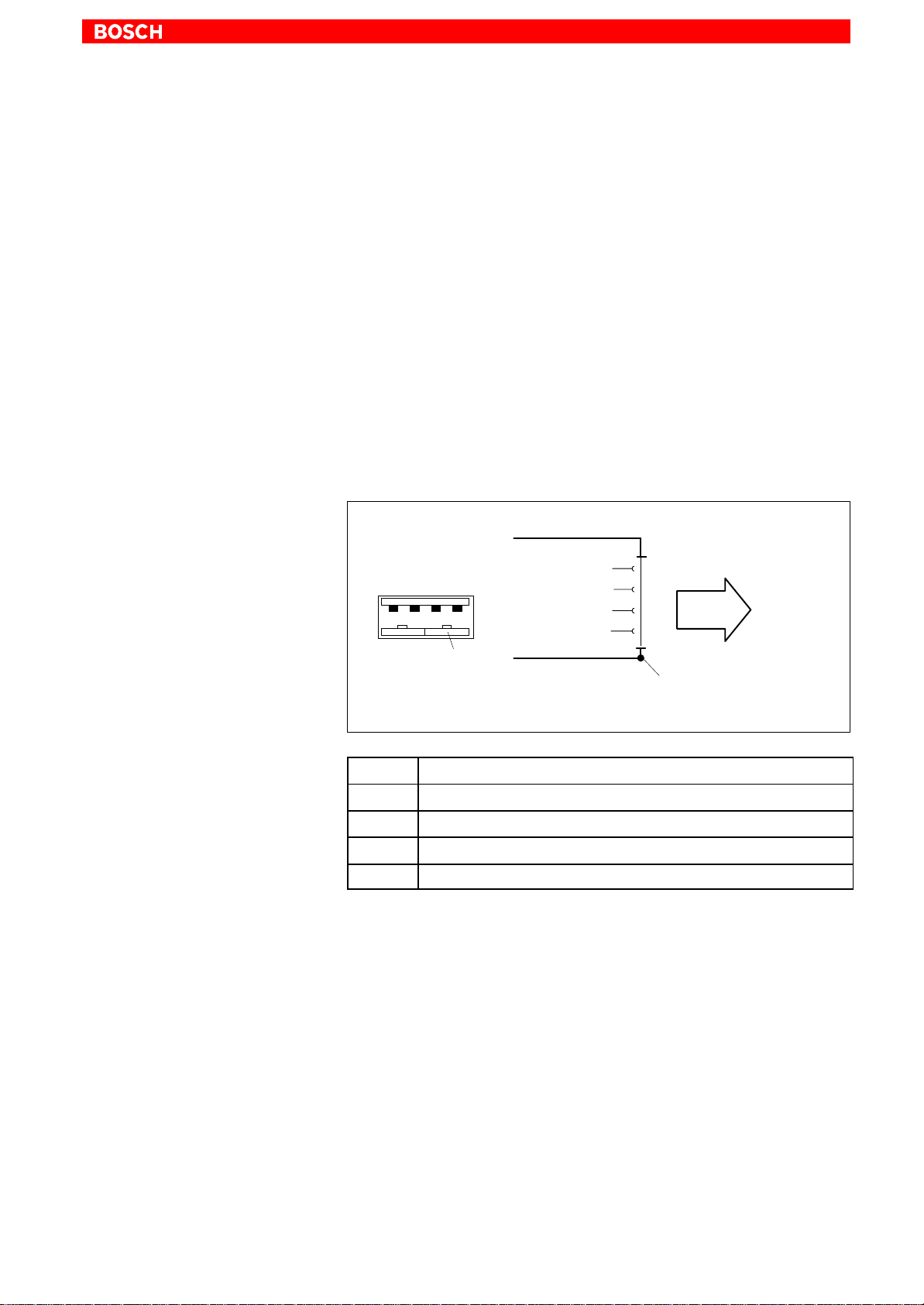

6 Interfaces and Connections

6.1 Overview

Overview of integrated connector types and their mating connectors.

Interfaces and Connections

6–1

Legend

on unit

A X24 START, STOP, EMERGENCY-STOP Weidmüller MSTB 1.5, 8–pin Female Weidmüller terminal,

A X25 Supply voltage 24 V Weidmüller MSTB 1.5, 4-pin Female Weidmüller terminal,

A X26 Supply voltage 24 V Weidmüller MSTB 1.5, 4-pin Female Weidmüller terminal,

A X27 Supply voltage 24 V Weidmüller MSTB 1.5, 2-pin Female Weidmüller terminal,

A X28 Distributor 24 Vout outputs Weidmüller MSTB 1.5, 8–pin Female Weidmüller terminal,

A X29 Distributor 24 Vout outputs Weidmüller MSTB 1.5, 8–pin Female Weidmüller terminal,

P Mouse PS/2 mini DIN mouse Female mini DIN PS/2, 6-pin Male mini DIN PS/2, 6–pin

P KBD PS/2 mini DIN keyboard Male mini DIN PS/2,

P USB USB USB socket, 4-pin USB plug, 4-pin

P 24 Vout Keyboard code output Female DB–15 Male DB–15

P Ethernet Network connection: Ethernet 10/100BaseTX Female RJ45, 8-pin Male RJ45, (8-conductor twisted pair)

P VGA VGA connection for external CRT monitor Female VGA HD connector,

P DP-Slave PROFIBUS DP

P X59 optional serial port: RS422/485 unused,

P COM1 Serial port:RS232 (UART 16550) free

P COM2 Serial port:

P COM3 Serial port:RS232 (UART 16550) kbd down-

P COM4 Serial port:

P LPT1 Parallel port:

P X10_1 PC power supply:

C X76 Floppy disk power supply +5VDC Female FDD mains connector,

C X75 Data connector for 3 1/2” floppy disk drive

C X19 Battery Male plug connector 2–pin Female connector. 2–pin, cable for in-

E X71 CAN on PCI-CAN expansion card Female DB-9 connector Male DB-9 connector

E X71 CAN on PCI_BM-CAN expansion card Female DB-9 connector Male DB 9-pin,

E X72 Busmaster on PCI_BM-CAN expansion card

Interface service Connector type

Keyboard code output (not used)

alternative to RS232; cf. COM1

alternative, optional RS485/422; cf. X59

RS232 (UART 16550) free

load or unused

RS232 (UART 16550) reserved for UPS logic

supports standard SPP, EPP, ECP mode

24 VDC

(SD, HD, ED)

(not used)

(integrated)

6–pin

15-pin.

Female DB-9 connector Male DB-9 bus connector, IP 20

no plug available because optional (male DB-9)

Male DB-9 connector Female DB-9 connector

Male DB-9 connector Female DB-9 connector

Male DB-9 connector Female DB-9 connector

Male DB-9 with plug cover –

Female DB-25 connector Male DB-25 connector (e.g., printer

Weidmüller push-lock terminal,

MSTB 1.5, 4-pin

4–pin

Male plug connector 34–pin

(IDC)

Male Weidmüller terminal,

MSTB 1.5, 10-pin

Mating connector or cable (from external device)

MSTB 1.5, 8-pin

MSTB 1.5, 4-pin

MSTB 1.5, 4-pin

MSTB 1.5, 2-pin

MSTB 1.5, 8-pin

MSTB 1.5, 8-pin

Keyboard cable with

male PS/2 mini DIN, 6-pin

Monitor cable with male VGA DB–HD,

15–pin

(Comnet DP bus system)

Female DB-9 connector

cable or parallel CD-ROM)

Female Weidmüller terminal,

MSTB 1.5, 4-pin

FDD mains cable with male 4–pin

connector

Female plug connector, 34-pin (IDC)

(data cable, floppy disk drive)

ternal battery

separate CAN bus for PLC signals

Female Weidmüller terminal,

MSTB 1.5, 10-pin

Connector

location:

1070 073 825-103 (02.04) GB

A = connection and distribution card P= PC housing side

C= on carrier board (in PC housing) E = on expansion card

6–2

Interfaces and Connections

6.2 Position of Interfaces

Connection board and carrier board interfaces

Side view (side

of hinges)

+ –

X19

Rear view

Battery

connection

Rear

covering plate

PE conductor lug

Carrier

board

Floppy disk

data connector

X75

X76

Supply and distribution

circuit board

Floppy disk

power supply

Battery

Battery connection

Supply and

distribution

circuit board

X29

X28

X27

X25

X26

DP–ADR DIP

X24

SEL COM3 DIP

Floppy disk

power supply

(accessible through opening in housing)

Floppy disk

data connector

(accessible through opening in housing)

Batter

y

1070 073 825-103 (02.04) GB

PC and PCI Expansion Cards Interfaces, Fuse

Side view (from right)

Interfaces and Connections

6–3

PCI_BM-CAN Card

Busmaster

(X72)

CAN

(X71)

CAN for PCL

(X71)

PCI-CAN Card

PE conductor lug

24 VDC connector

24 V fuse (M6.3A)

unscrewable

1070 073 825-103 (02.04) GB

6–4

Interfaces and Connections

6.3 Connection and Distribution Card

The connection and distribution card is obtainable in two models depending

on the configuration that was ordered.

D Standard distribution card with common EMERGENCY OFF and STOP

circuit

D Special distribution card with separate EMERGENCY OFF and STOP

circuits.

The connection and distribution card is to be wired in any case. The components to be connected are as follows:

D 24 VDC supply voltage of CPS21

D all buttons on the front panel

(START, STOP, EMERGENCY OFF)

D key codes of the front panel

Common EMERGENCY

OFF and STOP circuit

(Standard distribution card)

X24

X25

X26

X27

Pin

X24

8

1

4

1

4

1

2

1

X25

X26

Assignment

8

24 V (Lamp in START button)

7

6

5

4

3

2

1

4

3

2

1

4

3

2

1

Connector START key

Connection EMERGENCY OFF and OFF

button

for connection in series (1st path)

Connection EMERGENCY OFF / OFF recognition

Connection EMERGENCY OFF and OFF

button

for connection in series (2nd path)

0V

0V

24V

24V

0V

0V

24V

24V

Connection

supply voltage

Internal connection to

X10_1

X27

2

0V

1

24V

Internal connection to

fan power

1070 073 825-103 (02.04) GB

Interfaces and Connections

6–5

DANGEROUS ELECTRICAL VOLTAGE

Improperly or incorrectly installed EMERGENCY OFF circuit may

lead to life endangering situations and substantial material damages!

Please integrate the EMERGENCY OFF button of the CPS21 into the

EMERGENCY OFF circuit as well!

Supply and distribution circuit board

8

X28

1

8

X29

1

Pin Assignment

X28

8

7

6

5

4

3

2

1

X29

8

7

6

5

4

3

2

1

24VOut Bit4

24VOut Bit3

24VOut Bit2

24VOut Bit1

24VOut Bit4

24VOut Bit3

24VOut Bit2

24VOut Bit1

Internal

connection

of 24 Vout

Distributor

KeysCodes

1070 073 825-103 (02.04) GB

6–6

Interfaces and Connections

Overview of connections ex works:

Connector 24Vout

with cable

Connector X10_1

(24 VDC) with cable

X27

X24

X25

X26

X28

X29

X27 fanpower

supply

X26 to X10_1 (24

VDC) connector

X28 to connector

24 V out

Cable (10 mm2) to PE

lug, front panel and

housing

1070 073 825-103 (02.04) GB

Interfaces and Connections

6–7

Separate EMERGENCY OFF and STOP

circuits

(Special distribution card)

4

X27

1

4

X26

1

4

X25

1

3

X24

1

8

X28

1

8

X27

X26

X25

X24

X28

AssignmentPin

4

0V

3

0V

2

24V

1

24V

4

0V

0V

3

24V

2

24V

1

4

0V

3

0V

24V

2

24V

1

3

24 V (Lamp in START button)

2

1

8

7

6

5

4

3

2

1

Connector START key

24VOut Bit8

24VOut Bit7

24VOut Bit6

24VOut Bit5

24VOut Bit4

24VOut Bit3

24VOut Bit2

24VOut Bit1

Internal connection to

fan power

Internal connection to

X10_1

Connection

supply voltage

Internal

connection

of 24 Vout

X29

X31

X32

X29

24VOut Bit8

8

24VOut Bit7

7

24VOut Bit6

6

1

4

1

X31

4

1

X32

5

4

3

2

1

4

3

2

1

4

3

2

1

24VOut Bit5

24VOut Bit4

24VOut Bit3

24VOut Bit2

24VOut Bit1

Connector STOP key

for connection in series (2nd path)

Connector STOP key

for connection in series (1st path)

Connection EMERGENCY OFF

for connection in series (2nd path)

Connection EMERGENCY OFF

for connection in series (1st path)

Distributor

KeysCodes

1070 073 825-103 (02.04) GB

6–8

Interfaces and Connections

6.4 Connection of the optional Coolkit to the connection and distribution card

If the CPS21 is equipped with the optional extra Coolkit (for installation see

section 4.4), then the electrical connections for the Coolkit must be made via

the connection and distribution card.

Standard connection and distribution card

The 24 VDC Coolkit connecting cables (red = + / black = 0 V) are connected

as follows to the standard CPS21 connection and distribution card:

L Replace the existing 4 conductor cable between the X26 plug and the X10_1

connecting plug by a 2 conductor cable 2 x 0.75

2

. The cable is connected on

the one side to the X26 / Pin 2 (+ 24 V) and X26 / Pin3 (0 V), and on the PC

side to the X10_1 / Pin 2 (+ 24 V) and X10_1 / Pin 3 (0 V). Alternatively it is

also possible to clamp off the two wires that are not needed on the existing 4

conductor cable.

L Connect the Coolkit’s red connection cable to the X26 / Pin 1 and the black

cable to the X26 / Pin 4.

X10_1

4

1

red

black

to the Coolkit

Special distribution card

X26

4

X26

to the Coolkit

1

The 24 VDC connecting cables (red = + / black = 0 V) are connected to the

free pins of the X27 plug on the CPS21 special distribution card (see page

6-6) (Pin 1,2 = + 24 V; Pin 3,4 = 0V).

1070 073 825-103 (02.04) GB

6.5 Floppy Disk Connection

X75 Drive ”A” connector

Used to connect an optional floppy disk drive. The integrated floppy disk

adapter supports the following types of floppy disk drives:

D 3,5 ”

D Double density (720 kB)

D High density (1.44 MB)

D Enhanced floppy mode (2.88 MB)

. Only one type of drive can be connected at a time.

Male connector, 34–pin (on carrier

board)

Type: 3.5” HD (standard)

Cable length: Max. 0.5 m

Cable type: 34–conductor ribbon cable, screened

Interrupt (IRQ): empty

I/O address: 300H

BIOS preset: Floppy disk controller: Enabled

Interfaces and Connections

in the ”I/O Device Configuration” submenu

6–9

X75

Pin Assignment

GND

1

3

11

13

15

17

19

21

23

25

27

29

31

33

GND

GND

5

GND

7

9

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

X75

1

34

Screened ribbon cable

1

PinAssignment

24Density Select

N/C

N/C

6

Index

8

10

Motor Enable A

Drive Sel B

12

Drive Sel A

14

Motor Enable B

16

Direction

18

Step

20

Write Data

22

Floppy Write Enable

24

26

Track 0

Write Protect

28

30

Read Data

Head Select

32

Disk Change

34

No. 1 conductor

Floppy ”A”

boot drive

connector

1070 073 825-103 (02.04) GB

40

6–10

Interfaces and Connections

X76 Floppy disk drive power supply

Power supply for optional floppy disk drive.

Female coupler, 4-pin

Supply voltages: +5 V, +12 V, 0.9 A

max.

Installation

X76, socket

21334

Pin Assignment

1 +12 V

2

4 +5 V

GND

GND

. The +5 V and +12 V operating voltages are monitored for overvoltage

and undervoltage conditions. The detection of a faulty voltage causes

the PC power supply to switch off immediately. –12 V potential is not

monitored.

L Connect the ”Floppy A boot drive” connection end of the ribbon cable to the

floppy disk drive. Connect the other end of the cable to the X75 floppy disk

connector. O n the ribbon cable, observe the red marking of the no. 1 conductor which must always be connected to PIN 1 of the connected devices.

In most cases, notched connectors will provide for connections with proper

conductor alignment.

L The power supply for the floppy disk drive must also be connected. This is

accomplished by connecting the connecting cable on the floppy disk drive

(4–pin plug connector) to the X76 power supply connector.

L If the system does not recognize the floppy disk drive, the latter must be acti-

vated in the ”I/O Device Configuration” BIOS submenu by changing from

”Disabled” to ”AUTO” or ”Enabled”. If necessary, the floppy disk type must

also be selected under ”

Diskette 1

” in the main menu.

In order to start the BIOS setup function, press <F2> when the ”Press <F2>

to enter Setup” display appears during booting. Then the BIOS main menu

will be displayed. Make the above mentioned settings. Leave BIOS via the

”Exit Saving Changes” entry in the Exit menu.

T o do so, press the <Z> key if you have a keyboard with a German layout (Z =

for Yes).

Y

L If the floppy disk drive is not accessible, check the connections for

D proper seating of all cables and connectors.

D normally working supply voltage.

1070 073 825-103 (02.04) GB