Bosch WH36, TRONIC 5000C Pro WH36 Installation Manual And Operating Instructions

[en] Installation Manual and Operating Instructions 2

[es] Instrucciones de instalación y funcionamiento 21

[fr] Instructions d'installation et d'utilisation 41

Tankless Electric Water Heaters

TRONIC 5000C Pro

6720647022-00.1V

WH36

6 720 647 022 (2013/04) US

IMPORTANT: This booklet should be given to the customer after installation and demonstration.

For Service & Installation contact:

BOSCH Thermotechnology Corp.

50 Wentworth Avenue, Londonderry

NH 03053

Phone: 800-798-8161

www.bosch-climate.us

6 720 647 022 (2013/04) Tronic 5000C

2 | Table of contents

Table of contents

1 Key to symbols and safety instructions . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Safety precautions . . . . . . . . . . . . . . . . . . . . 3

2 Information about the heater . . . . . . . . . . . . . . . . . . . 3

2.1 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Technical identification code . . . . . . . . . . . . 3

2.3 Model name and number identification . . . . 3

2.4 Package contents . . . . . . . . . . . . . . . . . . . . . 3

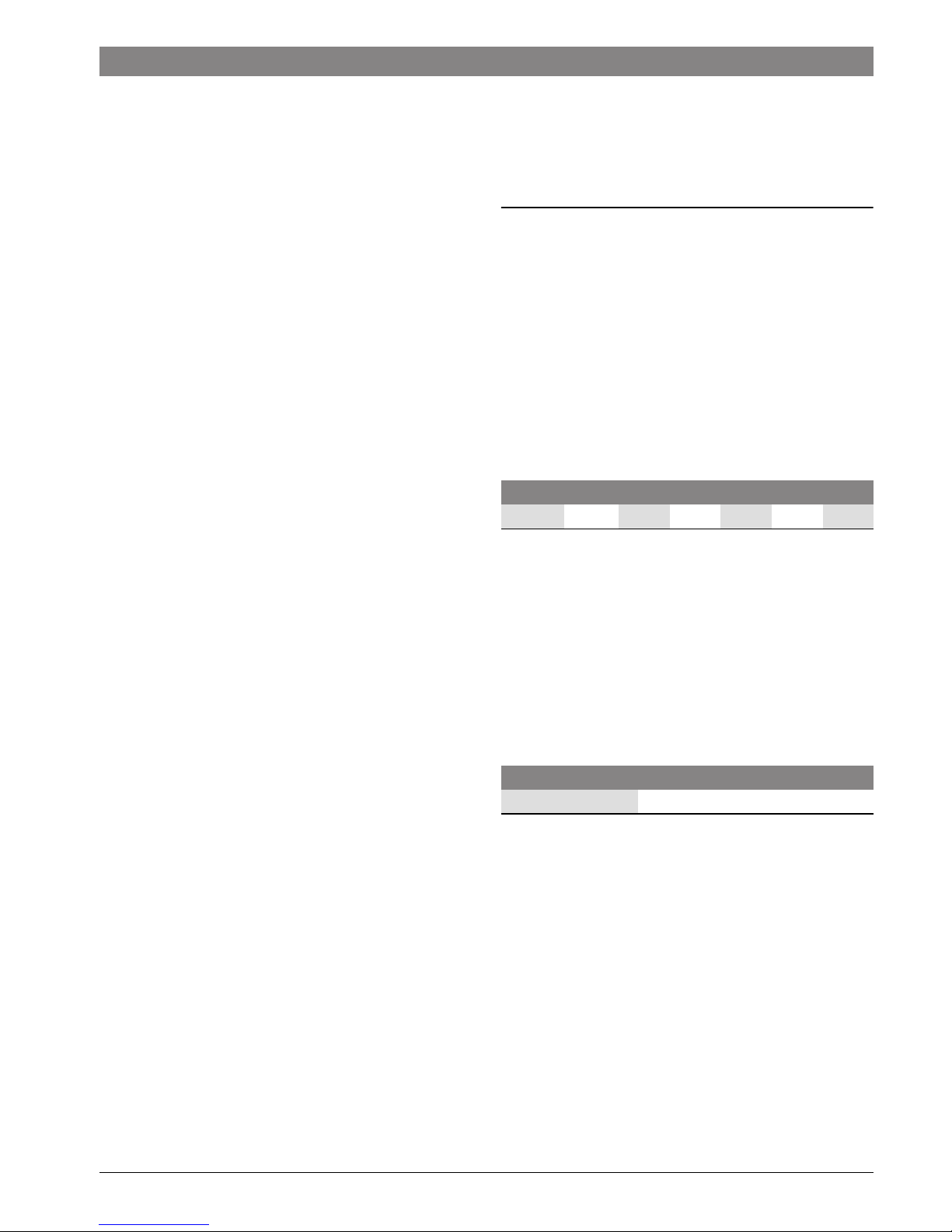

2.5 Components Diagram . . . . . . . . . . . . . . . . . . 4

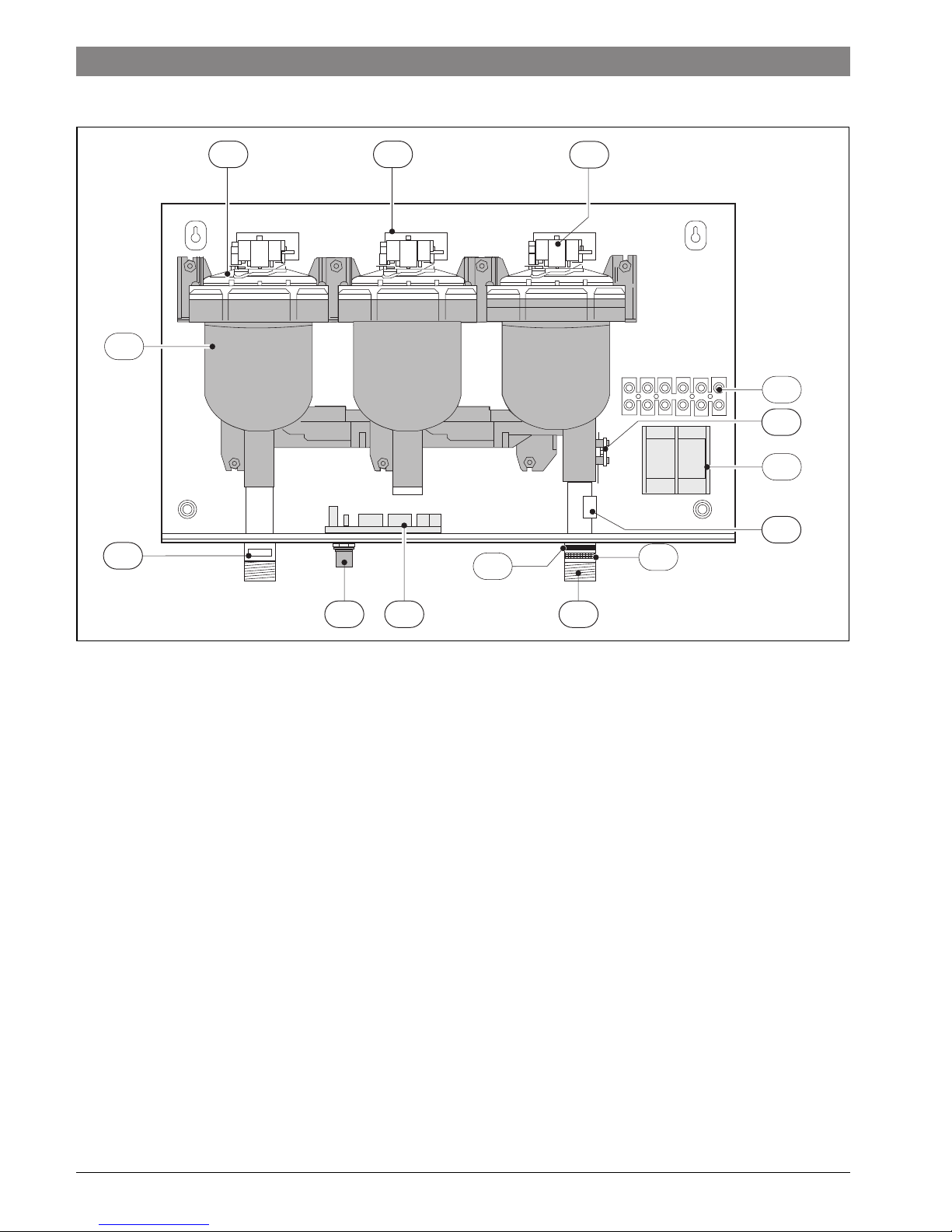

2.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . 6

2.8 Description of the heater . . . . . . . . . . . . . . . 6

2.9 Technical specifications . . . . . . . . . . . . . . . . 7

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Important information . . . . . . . . . . . . . . . . . . 8

4.2 Selection of place of installation . . . . . . . . . . 8

4.3 Mounting the water heater . . . . . . . . . . . . . . 9

4.4 Water connections . . . . . . . . . . . . . . . . . . . 10

4.5 Electrical connections . . . . . . . . . . . . . . . . . 10

4.6 Starting up . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operation instructions . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Before using the water heater . . . . . . . . . . 14

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1 Key to symbols and safety

instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

Warnings in this document are identified by

a warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the

document

• List entry

– List entry (second level)

Table 1

6 720 647 022 (2013/04)Tronic 5000C

Information about the heater | 3

1.2 Safety precautions

When using this electrical equipment, basic safety precautions

should always be followed, including the following:

▶ READ AND FOLLOW ALL INSTRUCTIONS.

▶ This appliance must be grounded.

▶ Disconnect this product from the electrical supply before

cleaning, servicing or removing the cover.

▶ To reduce the risk of injury, close supervision is necessary

when the product is used near children or elderly persons.

▶ Warning: Mount the unit onto a flat section of wall, well

away from any potential splashes of water or spray and

away from areas where direct moist or wet contact could

occur.

▶ Warning: Indoor installation only, where it will NOT be

exposed to freezing.

▶ Warning: Do not install a check valve or any other type of

back flow preventer within ten feet of the cold water inlet.

▶ The electrical installation must conform to current National

Electrical Codes.

▶ Warning: Do not switch the heater on if you suspect that it

may be frozen. Wait until you are sure that it has completely

thawed out.

▶ The Tronic 5000C Pro is designed to heat potable cold

water for domestic purposes. The heater is not designed to

accept inlet water temperatures above 86° F. Contact

Bosch Thermotechnology Corp. before specifying or

installing the appliance in any other application.

▶ Warning: Any water heater should be installed in such a

manner that if it should leak, the resulting flow of water will

not cause damage to the area in which it is installed.

National Plumbing codes require a drain pan for any water

heater installation. Failure to install one is the sole

responsibility of owner and/or installer. Reference UPC

2000 (Uniform Plumbing Code) Section 510 - Protection

from Damage or IPC 200 (International Plumbing Code)

Section 504- Safety Devices.

▶ Additional Canadian safety instructions:

– As per the Canadian Electrical Code, C22.1-02 Section

26-744, an auxiliary terminal block must be fitted to

the unit before connecting to the electrical supply (Kit

Part N° “AE Canada Kit”) (See page 10).

– A green terminal (or a wire connector marked “G,”

“GR,” “GROUND” or “GROUNDING”) is provided within

the control. To reduce the risk of electrical shock,

connect this terminal or connector to the grounding

terminal of the electrical service of supply panel with a

continuous copper wire in accordance with the

Canadian Electrical Code, Part I.

– This product shall be protected by a Class A ground

fault circuit interrupter.

▶ Keep this manual in a safe place once the unit has been

installed as it may be needed for future reference.

2 Information about the heater

2.1 Disclaimer

2.1.1 Approval number

Commonwealth of Massachusetts

In the Commonwealth of Massachusetts a licensed plumber or

electrician must perform the installation. (Approval number:

P1-09-25).

2.2 Technical identification code

[EI] Electronic Instantaneous

[36] Maximum output (kW)

[E] Electronic temperature control

[W] Wall hung

[I] Indoor

[H] Horizontal installation

[B] Water connections

2.3 Model name and number identification

2.4 Package contents

• Tankless electric water heater

• 4 screws and gaskets

EI 36 EWIHB

Table 2

Model Name Model Number

WH36 EI 36 E/M W I H B

Table 3

6 720 647 022 (2013/04) Tronic 5000C

4 | Information about the heater

2.5 Components Diagram

Fig. 1

[A] Heating module

[B] Heating element assembly

[C] Heating module PCB

[D] Hot water outlet

[E] Cold water inlet

[F] Temperature adjustment knob

[G] Flow transducer

[H] Terminal block (CANADA ONLY)

[I] 6 way terminal block

[J] Temperature sensor

[K] Control PCB

[L] Double pole thermal cut-out

[M] Inlet water filter

[N] Flow regulator

6720647022-01.1V

A

D

F K

G

E

L

J

C

B

H

I

N

M

6 720 647 022 (2013/04)Tronic 5000C

Information about the heater | 5

2.6 Dimensions

Fig. 2

[1] Outlet ¾ " NPT (hot water)

[2] Temperature knob

[3] LED

[4] Inlet ¾ " NPT (cold water)

Dimensions

(inches) WH36

A (Width) 20 "

B (Height) 12½ "

C (Depth) 4½ "

D 17 5/

8

"

E 17 5/

8

"

F2

5

/

8

"

G 3 3/

8

"

H 11 1/

8

"

I5

5

/

8

"

J1

7

/

8

"

Water connections ¾ "

Table 4 Dimensions

6 720 647 022 (2013/04) Tronic 5000C

6 | Information about the heater

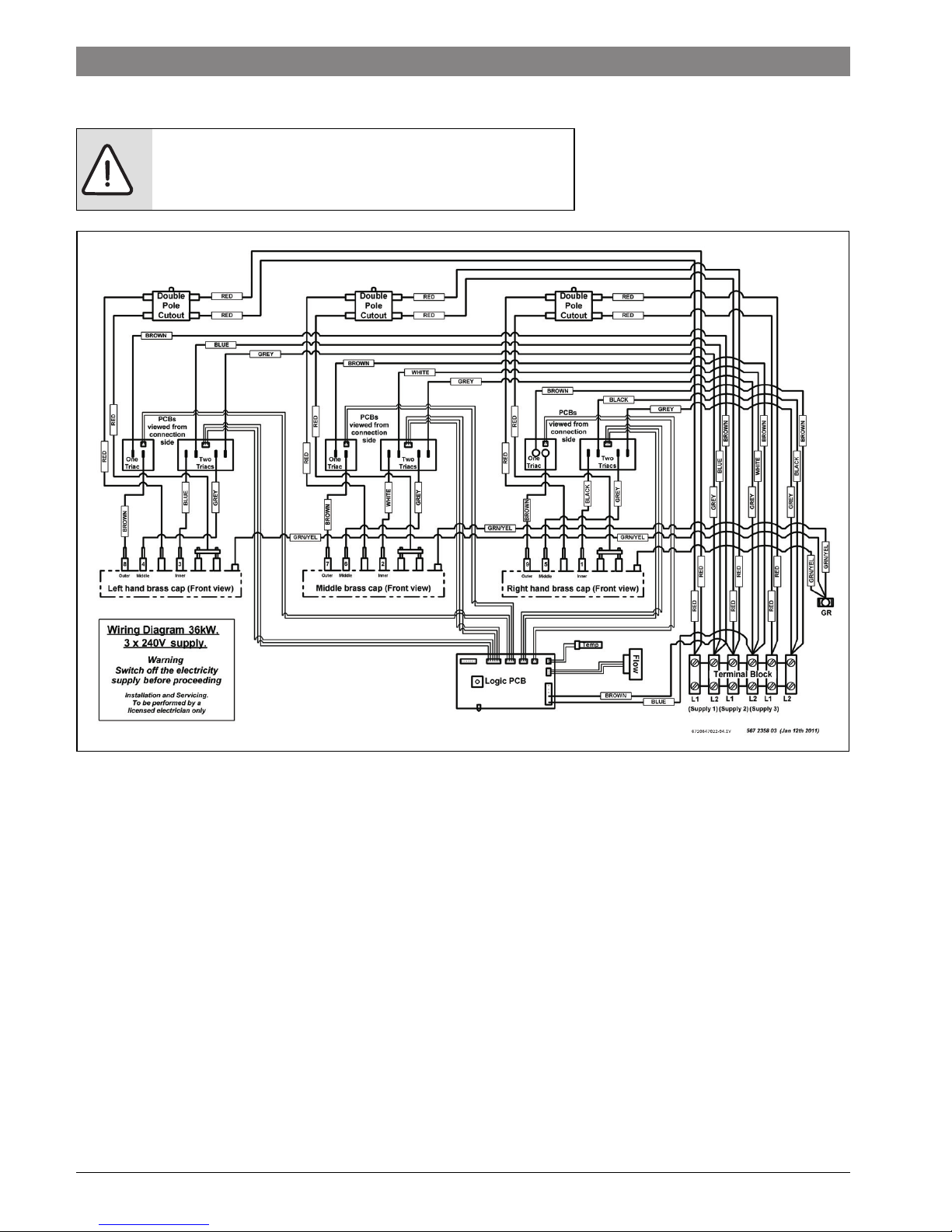

2.7 Wiring diagram

Fig. 3 Internal wiring schematic for single phase WH36 unit.

2.8 Description of the heater

How the Tronic 5000C Pro works;

• The Tronic 5000C Pro heats water continuously as it flows

through the heater modules.

• The electronic control PCB monitors the flow rate and the

incoming water temperature and then switches on the

required number of heater elements to reach the

temperature set by the temperature adjustment dial.

• As the flow rate or the incoming water temperature

changes, the electronic control adjusts the number of

heater elements used so that the outlet temperature is

maintained.

• The outlet water temperature can change slightly as the

flow rate changes due to the steps in power as different

heater elements are switched on and off.

• The outlet water temperature can also vary if the maximum

flow rate is exceeded (see Fig. 8) or if the supply voltage

changes.

• Each heater module is protected by an electro-mechanical

thermal cut-out. If the temperature of any of the heater

modules gets too high, then the cut-out will trip and cut the

power to that heater module. If the cut-out trips, it must be

reset while the circuit breakers are off. If you are not

comfortable or qualified to perform this task, consult the

original installer or a licensed electrician. This cut-out will

only trip in exceptional circumstances.

• Depending on the region of the country, the temperature of

the water supply can vary between 40°F in winter to 80°F in

summer, with an average of 55°F. The output temperature

at maximum flow of the heater is dependent on inlet water

temperature.

DANGER: Risk of electric shock!

▶ Always switch off the electricity supply to the unit before any

intervention in the heater.

6 720 647 022 (2013/04)Tronic 5000C

Regulations | 7

2.9 Technical specifications

3 Regulations

Any local by-laws and regulations pertaining to installation and

use of electric water heating appliances must be observed.

Please refer to the laws that should be attended in your

country.

• The electrical installation must conform to current National

Electrical Codes.

• As per the Canadian Electrical Code, C22.1-02 Section 26744, an auxiliary terminal block must be fitted to the unit

before connecting to the electrical supply.

• A green terminal (or wire connection marked “G”, “GR”,

“GROUND” or “GROUNDING”) is provided within the

control box. Aditional Canadian safety instructions, to

reduce the risk of electrical shock, connect this terminal or

connector to the grounding terminal of the electrical

service of supply panel with a continuous copper wire in

accordance with the Canadian Electrical Code, Part I.

• In Canada, this product shall be protected by a Class A

ground fault circuit interrupter.

• In the Commonwealth of Massachusetts a licensed

plumber or electrician must perform the installation.

(Approval number: P1-09-25).

• In the Commonwealth of Massachusetts a pressure relief

valve shall be installed on the cold water side by a licensed

plumber. (MGL 142 Section 19, Approval number P1-09-

25).

• The unit must be wired by a qualified electrician, in

accordance with the current version of the National

Electrical Code US) or Canadian Electric Code (Canada).

• When the heater is not within sight of the electrical circuit

breakers, a circuit breaker lockout or additional local

means of disconnection for all non-grounded conductors

must be provided that is within sight of the appliance. (Ref

NEC 422.31.).

• The power cable size and the installation must be in

accordance with the Canadian Electrical Code, C22.1-02.

Technical characteristics Units WH36

Voltage supply V 3 X 240 (Canada 240VAC)

Amperage A 3 x 60A (Canada 180A)

Maximum output kW 36.0kW

Temperature control range 95 °F to 131 °F

Minimum water pressure psi 15psi

Maximum water pressure psi 150psi

Minimum flow rate gal/min 0.8 US gal / min

Maximum flow rate (refer to Fig. 8)

Weight (without water) lbs 26.5 lbs

The unit will work at lower supply voltages but the following changes will apply:

Maximum output 30.2kW at 220V

27.0kW at 208V

Temperature control range 87 °F to 116 °F at 220V

82 °F to 108 °F at 208V

Maximum power

(refer to Fig. 8)

84% of maximum at 220V

75% of maximum at 208V

Table 5

WARNING:

California Proposition 65 lists chemical

substances known to the state to cause

cancer, birth defects, death, serious illness

or other reproductive harm. This product

may contain such substances, be their

origin from fuel combustion (gas, oil) or

components of the product itself.

6 720 647 022 (2013/04) Tronic 5000C

8 | Installation

4 Installation

4.1 Important information

Please follow these instructions. Failure to follow instructions

may result in:

• Damage or injury.

• Improper installation/operation.

• Loss of warranty.

4.2 Selection of place of installation

• If being used in a public place, locate the heater out of easy

reach to discourage vandalism.

• Mount the unit onto a flat section of wall, well away from

any potential splashes of water or spray and away from

areas where direct moist or wet contact could occur.

• Install the heater in a place that provides easy access for

any service or maintenance.

4.2.1 Freeze prevention

Introduction

Please note that the water heater must not be installed in a

location where it may be exposed to freezing temperatures. If

the heater must be left in a space that is likely to experience

freezing temperatures, all water must be drained from the

heater. See Section 6.

Freeze damage is not covered under the warranty.

DANGER: Risk of electric shock!

▶ For safety reasons, disconnect the

power supply to the heater before any

service or testing is performed.

WARNING:

▶ This heater must be electrically

grounded in accordance with the most

recent edition of the National Electrical

Code. NFPA 70. In Canada, all electrical

wiring to the heater must be in

accordance with local codes and the

Canadian Electrical Code, CSA C22.1

Part 1.

DANGER:

▶ The installation must only be performed

by a qualified person in accordance with

these instructions.

▶ Bosch Thermotechnology Corp. is not

responsible for improperly installed

appliances.

WARNING:

▶ The heater must only be mounted in a

vertical position with the water fittings

located at the bottom of the heater.

Under no circumstances should the

heater be mounted differently.

WARNING:

▶ The appliance should be located in an

area where leakage of the heater or

connections will not result in damage to

the area adjacent to the appliance or to

lower floors of the structure.

WARNING: Risk of freezing!

▶ Do not install the water heater in an area

where there is a chance of freezing.

Damage to the water heater as a result

of freezing will not be covered under

warranty.

WARNING:

▶ ELECTRICITY IS EXTREMELY

DANGEROUS. TAKE EXTRA

PRECAUTIONS AND ENSURE ALL

CIRCUIT BREAKERS ARE OFF BEFORE

PERFORMING ANY WORK TO THE

HEATER.

WARNING:

▶ Indoor installation only, where it will

NOT be exposed to freezing.

Use of chemical agents such as anti-freeze

are not allowed as they may cause damage to

the water heater’s internal components.

6 720 647 022 (2013/04)Tronic 5000C

Installation | 9

4.2.2 Recomended minimum clearances for servicing

Should it be necessary to service the Tronic 5000C Pro,

observe the following clearances. These are not required

clearances, but would facilitate any service work.

Fig. 4 Recommended minimum clearances

4.3 Mounting the water heater

▶ Undo the retaining screws on the front cover and take the

cover off the heater. Hold the back plate in position against

the wall and mark the four mounting holes.

▶ Drill the holes and secure the heater using the four wood

screws supplied.

Fig. 5 Vertical mounting position

WH36

Top (A) 12”

Sides 0”

Bottom (B) 6”

Front (C) 12”

Table 6 Recommended minimum clearances

WARNING:

▶ The heater must only be installed in the

orientation shown in Fig. 5 i.e., mounted

in a vertical position with the water

fittings located at the bottom of the

heater. Under no circumstances

should the heater be mounted

differently.

6 720 647 022 (2013/04) Tronic 5000C

10 | Installation

4.4 Water connections

▶ The heater must be connected directly to the main cold

water supply and not to pre-heated water. (The inlet

water temperature must not be greater than 86 °F).

▶ The heater must be installed with shutoff valves on both the

inlet and outlet connections.

▶ It is recommended that you use ¾ inch or ½ inch copper or

high-pressure flex connections.

▶ Do not use plastic piping within 3 feet on either side of

heater.

▶ Use Teflon tape for sealing pipe threads. Do NOT use pipe

dope.

▶ Remember to keep the hot water pipe runs as short as

possible.

After the heater has been plumbed, and before you wire it,

flush it with water to remove any debris or loose particles.

Heater must be full of water and air purged before power is

turned on. Failure to do so may result in damage to the

product that is not covered by warranty.

▶ After flushing and filling the heater with water, (with power

off) disconnect the inlet connection and inspect the filter

screen for any debris that may have been flushed through

the system.

▶ Check the pressure of the main water supply. To operate

correctly, the heater needs the running pressures

mentioned in 5.

4.4.1 Water quality

Water quality can have an impact on appliance longevity and

may not be covered under the manufacturer's warranty.

▶ For water analysis data call your local water department, or

if on a well, have well water analyzed periodically.

If water quality exceeds one or more of the values specified

below, Bosch recommends consulting a local water

treatment professional for water softening/conditioning

options.

4.5 Electrical connections

WARNING:

▶ Do not install a non-return check valve

within 10 feet of the inlet.

WARNING:

▶ Do not apply heat or solder to

connections or pipe if they are already

connected to the unit.

NOTICE: Disclaimer

▶ In the Commonwealth of Massachusetts

a pressure relief valve shall be installed

on the cold water side by a licensed

plumber. (MGL 142 Section 19,

Approval number P1-09-25).

The inlet and outlet connections are clearly

marked on the heater. They each have a

¾ inch NPT connector.

Description Max. Levels

pH pH 6.5 - 8.5

TDS (total Dissolved Solids) mg/l or ppm 500

Total hardness mg/l or ppm 100

(6 grains)

Aluminum mg/l or ppm 2.0

Chlorides mg/l or ppm 250

Copper mg/l or ppm 1.0

Iron mg/l or ppm 0.3

Manganese mg/l or ppm 0.05

Zinc mg/l or ppm 5.0

Table 7

WARNING:

▶ The unit must be wired by a qualified

electrician, in accordance with the

current version of the National Electrical

Code US) or Canadian Electric Code

(Canada).

When the heater is not within sight of the

electrical circuit breakers, a circuit breaker

lockout or additional local means of

disconnection for all non-grounded

conductors must be provided that is within

sight of the appliance. (Ref NEC 422.31.).

6 720 647 022 (2013/04)Tronic 5000C

Installation | 11

US wiring

• The minimum recommended wire size is 6 AWG. (The

terminal block will accept cables up to 6 AWG size).

• The cable entry is via the 1¼ inch cable entry hole on the

bottom right hand edge of the back plate.

• Strip back the insulation on the power wires about ½ inch.

Connect the live wires to the terminals marked “L1” and

“L2.” There are three pairs of live wires in the WH36. (See

Fig. 6, page 11).

• Any insulation on the ground wires should be stripped back

about ¾ inch. The ground leads must be connected. Loose

connections can cause wires to heat up.

• Make sure the terminal block screws are tightened

securely. Loose connections can cause wires to heat up.

• Make sure that the ground wires are wrapped around its

terminal stud and into the saddle washer. The nut should be

tightened securely.

• Attach the front cover and tighten the retaining screws.

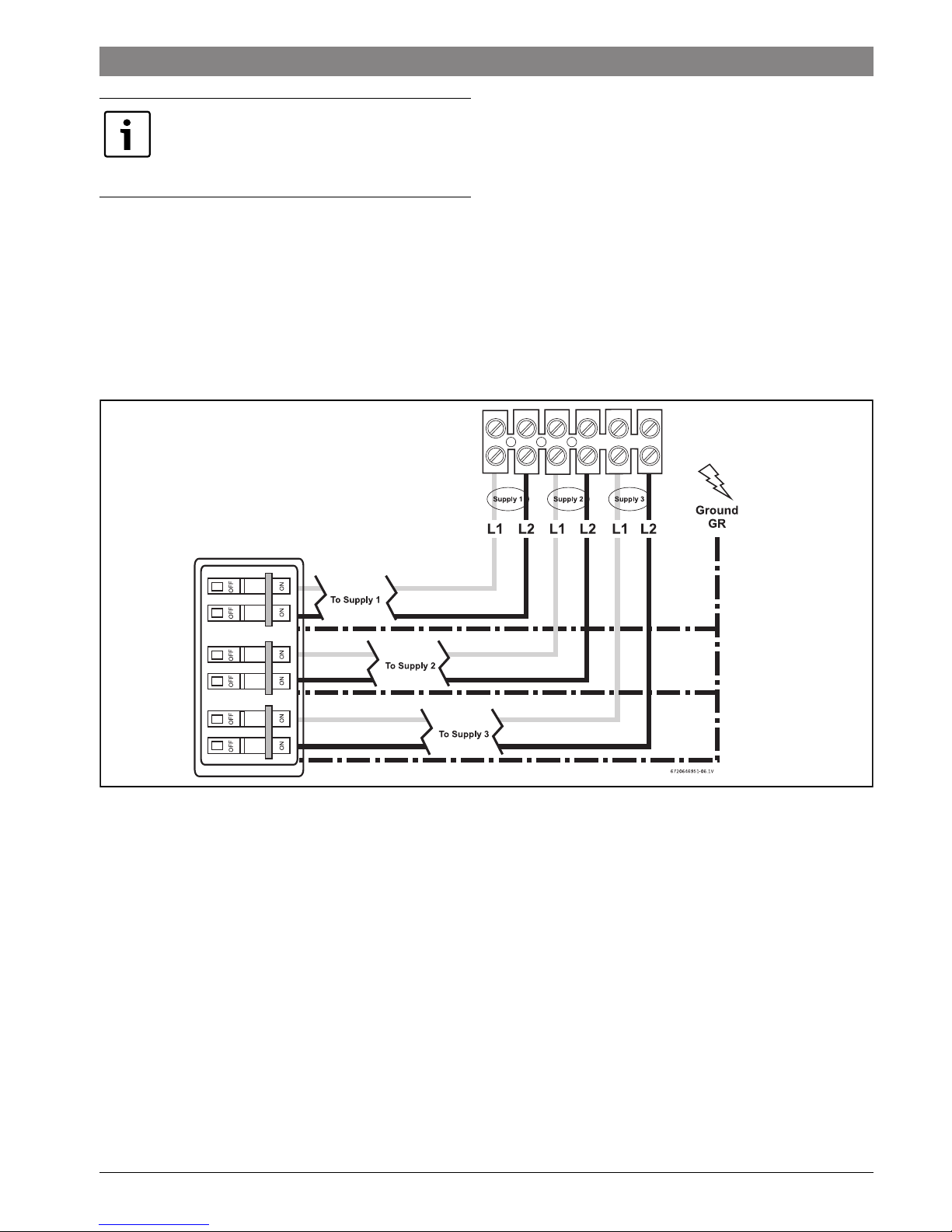

The WH36 requires three independent 240V AC circuits

protected by three separate and independent double pole

breakers (as shown) rated at least 54A each.

Fig. 6 WH36 terminal block connection (for the U.S.A.)

As per the Canadian Electrical Code, C22.102 Section 26-744, an auxiliary terminal

block must be fitted to the heater before

connecting to the electrical supply.

6 720 647 022 (2013/04) Tronic 5000C

12 | Installation

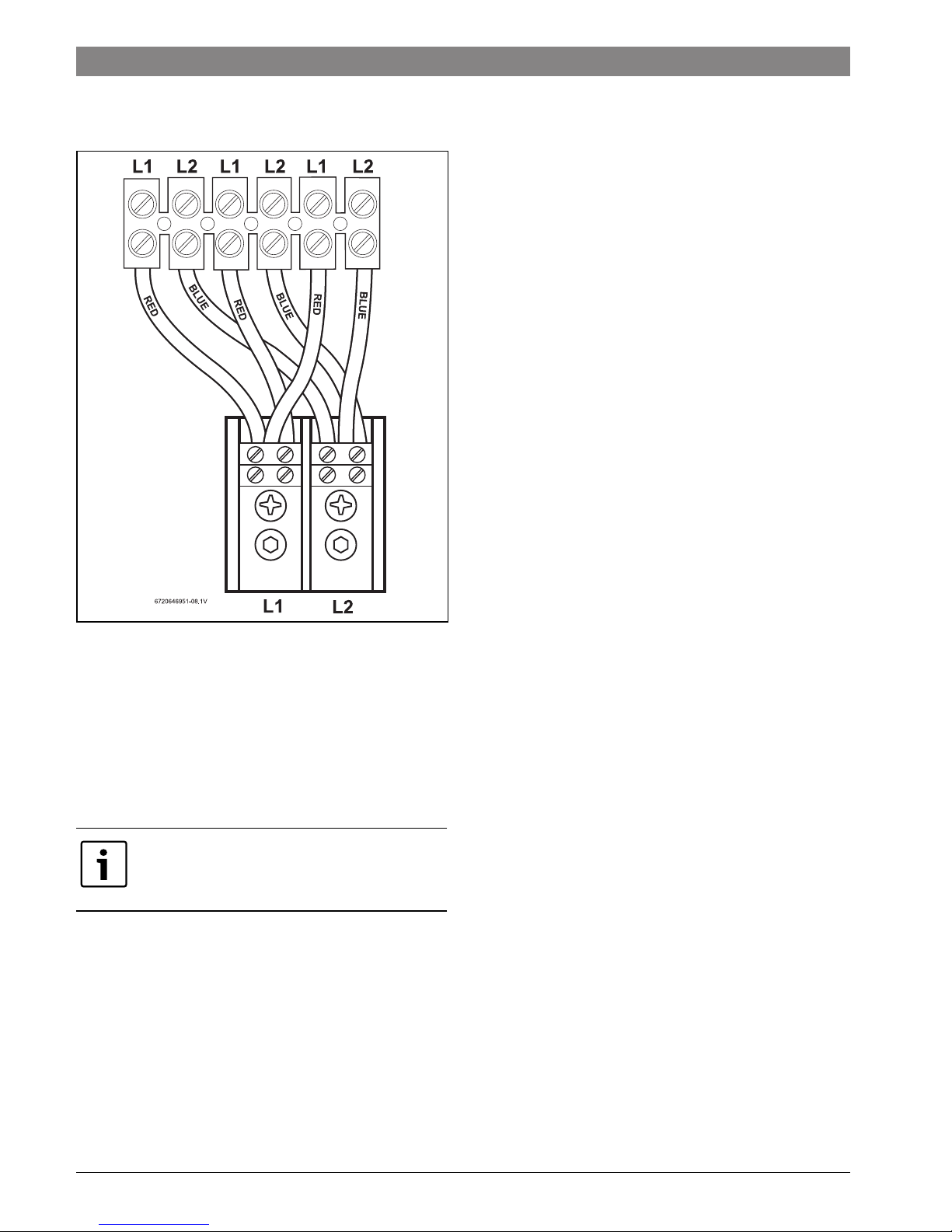

Canadian Wiring - auxiliary terminal block and connections

Fitting the auxiliary terminal block (see diagram below).

Fig. 7 For Canada only (Not for U.S.A.)

▶ Connect the red wires from the left hand terminal of the

new block to the L1 terminals in the unit.

▶ Connect the blue wires from the right hand terminal of the

new block to the L2 terminals in the unit.

▶ Push and click the auxiliary terminal block onto the

louvered rail in the backplate.

Connecting the supply cable - Canada only - not for the USA.

• The power cable size and the installation must be in

accordance with the Canadian Electrical Code, C22.1-02.

• The incoming hole diameter on auxiliary terminal block can

accept up to 1/0 AWG size cables.

• The cable entry is via the 1 ¼ inch cable entry hole on the

bottom right hand edge of the back plate.

• Strip back the insulation on the power wires about ½ inch.

Connect the ungrounded conductors to the terminals “L1”

and “L2” on the auxiliary terminal block.

• Any insulation on the ground wire should be stripped back

about ¾ inch. The ground lead must be connected to the

pillar terminal marked “GR.”

• Make sure the terminal block screws are tightened

securely. Loose connections can cause wires to heat up.

• Make sure that the ground wire is wrapped around its

terminal stud and into the saddle washer. The nut should be

tightened securely.

• Attach the front cover and tighten the retaining screws.

The WH36 requires a 180A 240V AC

single phase supply protected by a double

pole circuit breaker rated for at least 162A.

6 720 647 022 (2013/04)Tronic 5000C

Installation | 13

4.6 Starting up

4.6.1 Checking for leaks and purging air

▶ Verify all circuit breakers supplying power to the water

heater are turned off.

▶ Open all hot water taps supplied by the water heater and

inspect all water connections for leaks.

▶ With all hot water taps still open, inspect each tap to ensure

all air in the lines has been purged out.

▶ With the air purged and taps still flowing, turn on all circuit

breakers supplying the water heater.

▶ Close all hot water taps and proceed to the next section.

4.6.2 Adjusting the temperature dial

▶ The temperature adjustment is made using the dial on the

bottom edge of the unit. The adjustment is between

approximately 95 °F and 131 °F. Turning the dial clockwise

increases the temperature setting as indicated by the

marking on the unit.

4.6.3 Adjusting the flow

▶ Open fully both inlet and outlet shut-off valves at the

heater, then:

▶ Turn on fully the highest flowing hot water faucet (e.g.,

bathtub) served by the water heater.

▶ Adjust the outlet shut-off valve until the water flow rate

from the hot faucet corresponds to the value given in Fig. 8

below.

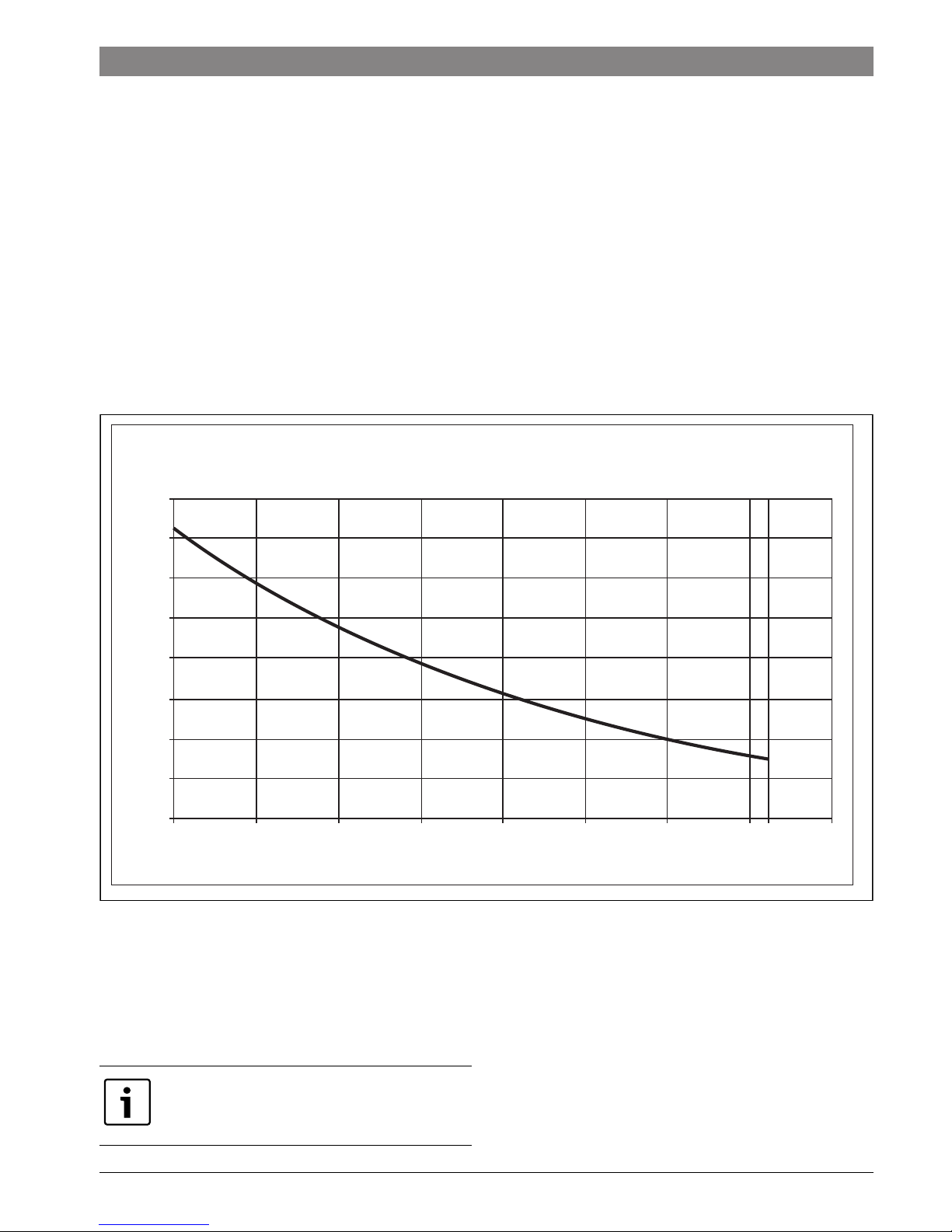

Fig. 8

These figures are based on an inlet water temperature of 55 °F

and a supply voltage of 240 volts. If the inlet water temperature

is lower than 55 °F, or if the supply voltage is less than 240

volts, then the outlet temperature will be lower than what is

shown in Fig. 8. If a higher outlet water temperature is desired,

then reduce the flow rate and/or supply the unit with 240 volts.

95 100 105 110 130115 120 125 135

2.50

Outlet temperature (ºF)

Max Flow Rate (US gal/min)

Outlet temperature vs Maximum flow rate setting

(based on incoming water temperature of 55ºF)

6720647022-03.1V

3.00

3.50

4.00

4.50

5.00

5.50

6.00

6.50

131

Before leaving the site, the installer should

demonstrate the unit to the user and give

them this guide.

6 720 647 022 (2013/04) Tronic 5000C

14 | Operation instructions

5 Operation instructions

5.1 Before using the water heater

▶ Check that the power is switched on at the circuit breaker

panel.

▶ Turn on the hot water faucet FULLY.

• There are internal safety thermal cut-outs which will trip if

the unit overheats. If the cut-out trips, it must be reset while

the circuit breakers are off. If you are not comfortable or

qualified to perform this task, consult the original installer

or a licensed electrician.

• If the unit has been used recently, run the water through for

a few seconds to let the temperature cool down. You may

initially get a short burst of very hot water that was in the

plumbing lines from previous use.

• If a second outlet connected to the unit is also turned on,

the hot water will be shared between the two.

6 Maintenance

Draining the heater

Due to the shape of the heat exchangers and connecting pipe,

it is extremely difficult to get all of the water out of the heater.

Follow the procedure below to best minimize the chance of

freezing:

▶ Disconnect electric supply.

▶ Disconnect cold and hot water pipes from fittings on

bottom of heater. Allow water to drain out (have a catch

basin ready).

▶ After allowing all water to drain out, the heater should be

blown out with low pressure compressed air to remove as

much water as possible from water heater modules. Bursts

of air work better than continuous flow.

Remember, these suggestions are only made to help minimize

the potential for freeze damage and are not to be construed as

the guaranteed method for dealing with freeze possibilities.

Check inlet water filter screen once a year

▶ Check that the power is switched off at the circuit breaker

panel.

▶ Shut off the installer supplied cold water isolation valve to

the heater. If one is not installed, install before proceeding.

▶ Open nearest hot water tap to relieve pressure in the

plumbing lines.

▶ Position a bucket under the cold water inlet connection of

the heater to catch any water that may drain.

▶ Disconnect the cold water plumbing connection from the

inlet (bottom right of heater) to access filter screen.

▶ Remove filter, clean with water and inspect for damage. If

the filter is at all damaged, it should be replaced.

▶ Replace the filter into the inlet housing

▶ DO NOT leave the filter out.

▶ DO NOT remove the flow regulator (located behind the

filter).

▶ DO NOT clear the filter by back flushing.

▶ Before switching power back on, open all hot water taps

and inspect each tap to ensure all air in the lines has been

purged out. With the air purged and taps still flowing, turn

on all circuit breakers supplying the water heater.

▶ Close all hot water taps and proceed for normal operation.

WARNING:

▶ Do not use the unit if you think it may be

frozen, as this could result in serious

damage to the unit. Wait until you are

sure that it has completely thawed out

before you switch it on.

The hot water temperature can be changed

by adjusting the temperature dial on the

bottom surface of the unit. (The dial adjusts

the temperature typically between 95°F and

131°F. The factory sets the temperature dial

at the lowest position).

6 720 647 022 (2013/04)Tronic 5000C

Maintenance | 15

Using an ohmmeter to check for premature element failure

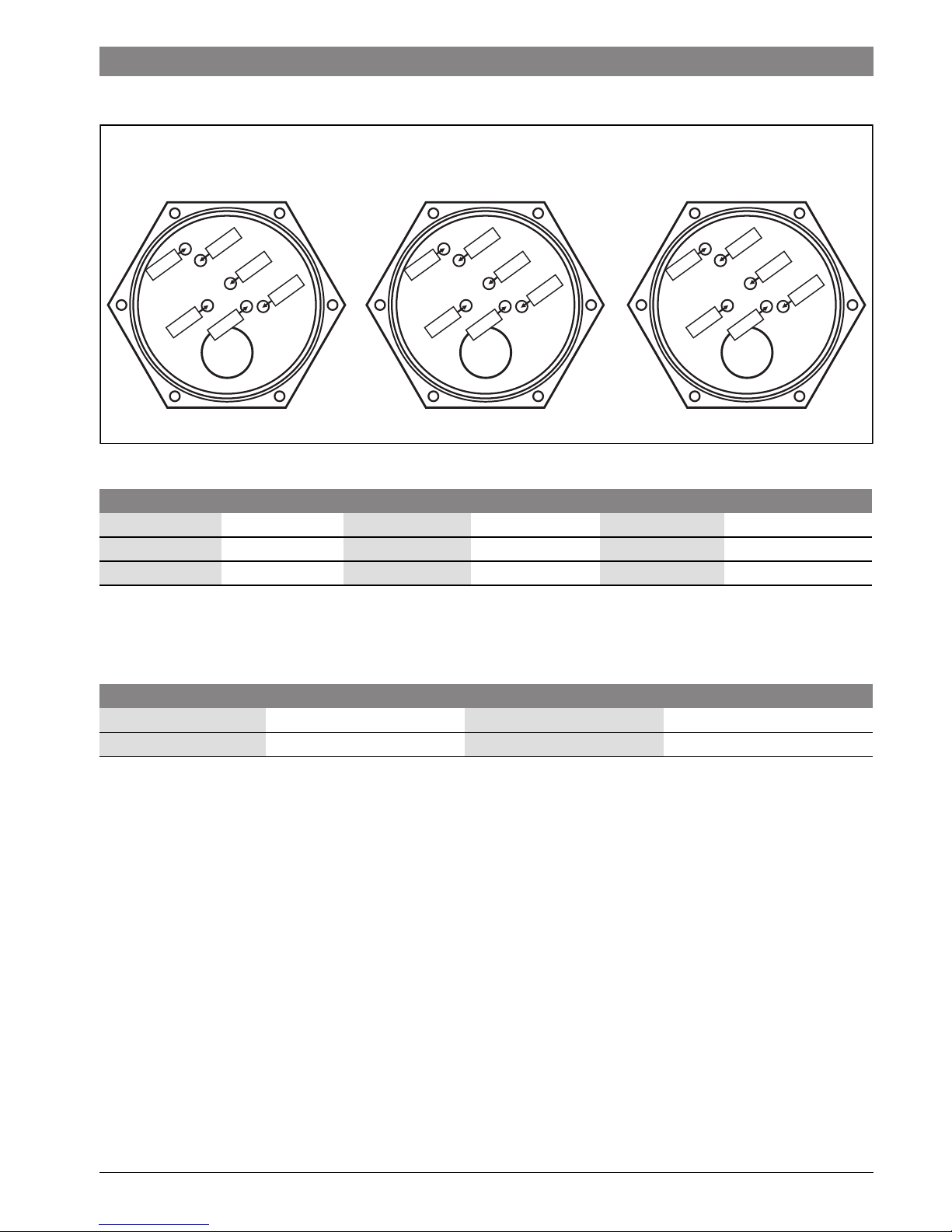

Fig. 9 Heating elements

The WH36 models are rated for 240V and will also operate at

220V or 208V with reduced output. The output will vary in

accordance with the ratios, mentioned in table 10.

Outer

Middle

Outer

Middle

Inner

Inner

Rear of Heater

Rear of Heater

Front of Heater

Front of Heater

Outer

Middle

Outer

Middle

Inner

Inner

Rear of Heater

Rear of Heater

Front of Heater

Front of Heater

Center Module Top View

Center Module Top View

RIGHT MODULE Top View

RIGHT MODULE Top View

6720647022-02.1V

Outer

Middle

Outer

Middle

Inner

Inner

Rear of Heater

Rear of Heater

Front of Heater

Front of Heater

LEFT MODULE Top View

LEFT MODULE Top View

Meter probes Ohm Readings Meter probes Ohm Readings Meter probes Ohm Readings

Outer to Outer 10.5 ± 0.8 Ohms Outer to Outer 11.4 ± 0.9 Ohms Outer to Outer 9.9 ± 0.8 Ohms

Middle to Middle 14.3 ± 0.9 Ohms Middle to Middle 12.1 ± 0.9 Ohms Middle to Middle 13.1 ± 0.9 Ohms

Inner to Inner 16.0 ± 1.2 Ohms Inner to Inner 17.8 ± 1.3 Ohms Inner to Inner 20.0 ± 1.4 Ohms

Table 8

Ratios

Volts 208V 220V 240V

Output Ratio 0.75 0.84 1

Table 9

6 720 647 022 (2013/04) Tronic 5000C

16 | Troubleshooting

7 Troubleshooting

Important: If you are unable to perform the tasks listed below,

or need additional assistance please contact your original

installer/licensed electrician.

DANGER: Risk of electric shock!

▶ Always switch off the electricity supply

to the unit before you remove the cover.

Cold water only – Neon light off

Flow rate is too low Verify the flow rate out of fixture is at or above the minimum activation rate required for the unit to

activate. (Activation rate: WH36 = 0.8 GPM).

Plumbing crossover To test for a plumbing crossover, turn off power supply to the heater. Close installer supplied cold water

shut off valve (if none installed, install before proceeding). Open all hot water taps supplied by the

heater. Wait 5 minutes and check all taps. Any water running is a sign of a plumbing crossover. Consult a

local plumber or service person for help in correcting a plumbing crossover. To return the heater to

service, reinstall cover, open the inlet water supply to the heater and open all hot water taps. Let all taps

run until there is no air coming out of the fixtures. Shut off all hot water taps. Turn power supply on to the

heater. Return heater to service. (This procedure will prevent the heating elements from burning out).

The flow transducer is

not spinning

Turn off the power supply to the heater and remove the cover. Observe if the flow transducer "spins"

when the water is turned on. Please note the flow transducer spins at a high speed and can appear to be

stopped when actually spinning. It is recommended to observe the flow transducer without water

flowing, then turn on a hot water tap while observing the flow transducer. If the flow transducer is not

spinning, remove and flush flow transducer, noting the Do's and Dont's on page 14. See the technical

support section of www.bosch-climate.us for more detailed instruction on removing the flow transducer.

No electricity at the

heater or one of the

supplies has failed

Have a licensed electrician verify proper wiring and adequate voltage on the terminal block inside the

water heater. See the “Electrical connections” section on page 10 of this manual.

Table 10

6 720 647 022 (2013/04)Tronic 5000C

Troubleshooting | 17

Cold water only – Neon light on

One or more of the

heating module thermal

cut-outs has tripped

Shut off the power to the unit, remove the cover and locate thermal cutouts on the top of each

heating module. Try resetting each cutout by pushing the reset button located in the center of the

cutout. Determine and fix the cause of the overheating. Obstructions in the water path can restrict

the flow of water through the heater causing it to overheat. Verify the heater’s inlet filter screen and

all outlets served by the heater are clear of debris. Ensure the heater is not being fed preheated

water. This water heater is designed for a cold water feed only. If thermal cut out does not reset,

check for continuity through each cutout (Less than 0.5 Ohms). If any cutout reads more than 0.5

Ohms or open, then it may be defective and should be replaced.

The power supply voltage

has dropped

This is likely an issue with the incoming power supply. Have a qualified electrician measure voltage on

the water heater’s terminal block while operating at maximum flow and maximum temperature

setting. The WH36 models are rated for 240V and will also operate at 220V or 208V with reduced

output. The output will vary in accordance with the ratios, mentioned in table 9.

The inlet water

temperature is too cold

Verify the heater is sized appropriately for it’s geographic location. Turn temperature knob located on

the bottom of the water all the way clockwise for maximum temperature setting. Ensure flow rates are

within the heater’s specifications. Refer to Fig. 8 on page 13 of the manual. Use of an isolation valve

on the hot water outlet to control flow rate is recommended.

One of the power supplies

is not on

Have a licensed electrician verify adequate voltage on the terminal block inside the water heater.

Verify circuit breakers serving the heater are not tripped. See the “Electrical connections” section on

page 10 of this manual.

Premature element failure Shut off power to the unit and remove cover. Use an ohmmeter to verify correct resistance on each

element. If readings are different than listed specifications on page 15, contact Technical Support

800-798-8161 for further instruction.

Table 11

Water not hot enough - Neon light on

The water supply is

connected to the

outlet of the unit

Verify plumbing connections are correct (See Fig. 2). Reconnect the water supply to the inlet of the unit

(marked blue).

One or more of the

heating module

thermal cut-outs has

tripped

Turn off the power to the heater, remove the cover and locate thermal cutouts on the top of each heating

module. Try resetting each cutout by pushing the reset button located in the center of the cutout.

Determine and fix the cause of the overheating. Obstructions in the water path can restrict the flow of

water through the heater causing it to overheat. Verify the heater’s inlet filter screen and all outlets

served by the heater are clear of debris. Ensure the heater is not being fed preheated water. This water

heater is designed for a cold water supply only. If thermal cut out does not reset, check for continuity

through each cutout (less than 0.5 Ohms). If any cutout reads more than 0.5 Ohms or open, then it may

be defective and should be replaced.

Temperature dial is

turned too low

Turn the temperature dial located on the bottom of the water heater clockwise for hotter temperatures.

Refer to Fig. 8 for outlet temperature vs. flow rate variance.

Water flow is too high Adjust water flow to stay within the water heater’s specifications. See Fig. 8 of this manual.

Table 12

6 720 647 022 (2013/04) Tronic 5000C

18 | Troubleshooting

Water flow too low

There are restrictions

in the plumbing

Obstructions in the water path can restrict the flow of water through the heater. Verify the heater’s inlet

filter screen, faucet aerators, showerheads and whole house filters are clear of debris. Verify proper flow

on the outlet side of the heater with the hot water pipe disconnected. Maximum flow rates for each unit

are as follows. WH36 = 3.5gpm.

Water supply pressure

too low

Verify incoming water supply is at least 30psi. For people on well systems, the recommended pressure

range is 30-50psi.

Outlet shut-off valves

are set too low

Adjust installer supplied outlet valve as described below:

• Completely open both installer supplied inlet and outlet shut-off valves at the heater. (if none

installed, install before proceeding).

• Completely open hot water on the highest flowing hot water fixture served by the heater (i.e.

bathtub).

• Slowly close the outlet shut-off valve, slowing the water flow rate until the temperature at the hot

water faucet corresponds to the values given on Fig. 8 of the manual, or desired water temperature

is reached.

Table 13

Water Temperature too Hot

Temperature dial set too

high

Turn the temperature knob located on the bottom of the water heater counterclockwise for cooler

temperatures.

There are restrictions in

the plumbing

Obstructions in the water path can restrict the flow of water through the heater causing overheating.

Verify the heater’s inlet filter screen, faucet aerators, showerheads and whole house filters are clear

of debris. Verify proper flow on the outlet side of the heater with the hot water pipe disconnected.

Opening hot water isolation valve fully may be necessary. Maximum flow rates for each unit are as

follows, WH36 - 3.5gpm.

Inlet water temperature is

too warm

Verify the heater is being feed with cold water only. This water heater is not designed for preheated

water or recirculation applications. Increase flow rate where ever possible. Replacing low flow

showerheads and aerators with higher flowing (GPM) ones may be necessary.

Table 14

Water Temperature fluctuates

Cold mix, heater deactivates If inlet water temperature is over 70°F, water may be very hot out of the tap. This requires a lot

of cold water to be added in order to get a usable hot water temperature. The addition of too

much cold water will overpower hot water demand from the water heater. This slows the flow

within the water heater, decreasing it below the activation point, which shuts off the heater.

The end result is nothing but cold water coming out of the outlet. Increase the flow rate by

cleaning or replacing fixtures and lower the setting on the temperature adjustment knob.

Fluctuating water pressure If the water pressure in the home is erratic and the water flow is not consistent while a tap is

opened, then the temperature of hot water will fluctuate. The minimum water pressure for the

home should be 30psi or greater. For people on well systems the minimum pressure range is

30-50psi. The use of a pressure reducing/regulating valve is an effective way to maintain

constant water pressure to the water heater. Watts brand 25AUB- ¾” or N35B-¾” pressure

reducing/regulating valves or equivalent is suggested.

Changing flow rate.

Water supply connected to the

outlet of the unit.

Major changes in flow rate can adversely affect the output water temperature of the heater.

Increases from one major fixture running to multiple fixtures running at one time can cause the

temperature to fluctuate. Stay within the heater’s specifications. See Fig. 8.

Table 15

6 720 647 022 (2013/04)Tronic 5000C

Spare Parts | 19

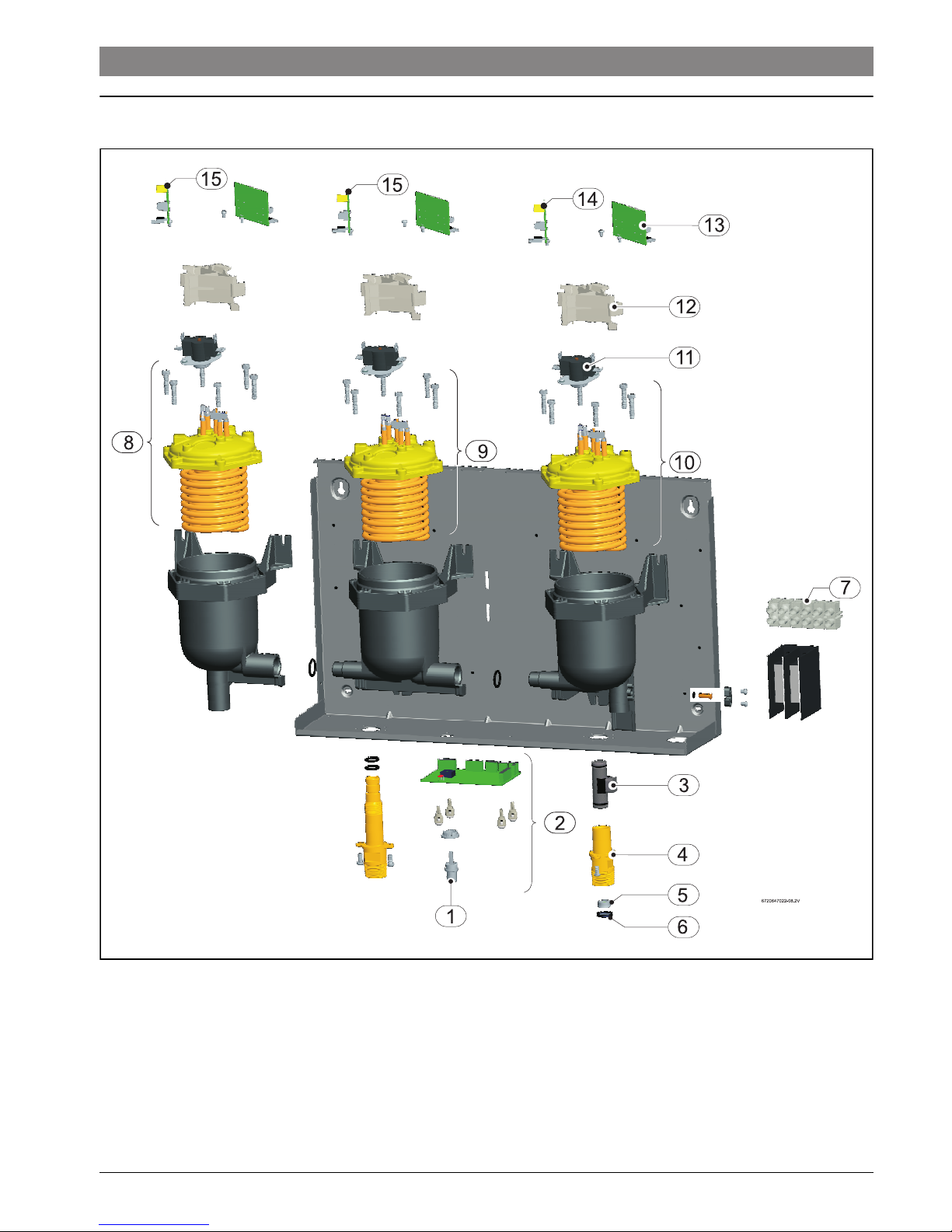

8 Spare Parts

Fig. 10

6 720 647 022 (2013/04) Tronic 5000C

20 | Spare Parts

Part number Spare part number Description

1 8-738-701-742-0 Temperature adjustment knob

2 8-738-701-744-0 Control PCB

3 8-738-701-743-0 Flow transducer

4 8-738-701-734-0 Brass Inlet

5 8-738-701-741-0 Flow Regulator

6 8-738-701-706-0 Water Filter

7 8-738-701-698-0 6 way term. block

8 8-738-701-745-0 Heater element assembly (left)

9 8-738-701-746-0 Heater element assembly (center)

10 8-738-701-747-0 Heater element assembly (right)

11 8-738-701-740-0 2 Pole Thermal Cutout

12 8-738-701-722-0 PCB Mount

13 8-738-701-723-0 Dual Channel PCB

14 8-738-701-748-0 Single Channel PCB Module 1

15 8-738-701-749-0 Single Channel PCB Module 2 and 3

Table 16

Loading...

Loading...