Page 1

i Series

Model SV Water Source

Heat Pump 1/2 to 6 Ton

Overview and Certifi cations

Engineering

Submittal

Sheet

Standard Features, Factory Installed Options, and Field Installed Accessories

Standard Features

SV Model 007 - 070

— 13 Models from 1/2 through 6 tons

— Horizontal, Vertical, and Counterflow Configurations

Cabinet

— Cabinetry is constructed using heavy-gauge, G90

galvanized steel

Quiet Operation

— All panels are insulated with ½" thick, 1.5 lb./cu.ft.

density micromat fiberglass insulation for both

thermal insulation and noise reduction

Serviceability

— All units are designed to be serviced from the front of the

unit

— Insulated bulkheads allow the unit to be serviced

during operation.

Unit Configurations

— All units are available in horizontal, vertical and

counterflow configurations

1 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Filter Racks

— Units come standard with a 1" filter rack and

construction filter

Fan Motor

— The standard motor for all SV series heat pumps is a

permanent split capacitor (PSC) motor.

Hanging Brackets

— All horizontal units come standard with hanging

bracket kits for suspending the unit from field

supplied hanger rods

Water Connections

— All water connections are heavy duty bronze FPT

fittings securely fastened to the unit corner post

Refrigerant Circuit

— SV Series units are designed using the optimum

combination of compressor, water and copper

aluminum-fin evaporator coils with capillary tubes

to provide peak performance.

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Page 2

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Standard Features, Factory Installed Options, and Field Installed Accessories continued..

Engineering Submittal Sheet

Copper Coax Coil

75 VA Transformer

Standard Range (WLS / Towers / Boiler)

Unit Protection Module

— Each SV unit is factory provided with a Unit Protection

Module (UPM) that controls the unit operation and

monitors the safety controls that protect the unit

— The UPM interfaces with the thermostat or direct digital

controller

— Water and Air coil freeze protection

— Condensate Overflow Sensor

— Brown-out Protection

— Low and High Pressure Protection

Factory and Field Installed Options

ECM Constant Torque

— The constant-torque blower motor option offers

improved effi ciency (up to 33%) over the standard PSC

motor

ECM Constant CFM (Variable Speed)

— The new high efficiency ECM motor option, available in

1/3hp to 1hp, provides constant airflow in a wide static

pressure range up to 1 in.w.g.

— Improved efficiency up to 33% over the standard PSC

motor

Optional 2" MERV 8 and MERV 13 Filter

— The MERV 8 and MERV 13 filter is a cost effective

way of upgrading air quality while maintaining low

pressure drop and sustaining long service life

Hot Gas Reheat (HGR)

— Allows the user to not only control space

temperature, but also humidity levels within the

conditioned space. Excessive moisture in the space

can promote mold growth leading to damage in the

structure or interior surfaces, as well as reducing the

air quality and creating an unhealthy environment.

Compressor Sound Blanket

— Quiets compressor sound

Smart Start (Coming Soon)

— Factory or Field installed

— Ease in starting

— Increased start-up efficiency

— Helps reduce light dimming

Cupro-nickel Coil:

— Recommended in conditions anticipating moderate

scale formation or in brackish water

Pump Interlock Relay

— Helps ensure the external flow/pump center operates

when unit is operating

Extended Range Option

Duo-Guard™ Evaporator Coil

— Duo-Guard™ Protection® - Tin Electro-Plated Copper

Tubing with High-Tech Polymer Coated Aluminum

Fins will protect the evaporator coil from all forms of

corrosive elements in the airstream

Closed Cell Foam Insulation (Coming Soon)

— Sound levels as low as 52 Db

EMS Relay

— Energy management relay to tie into a building's energy

management system

Disconnect Switch

— 40 amp external box, 1 phase, 8AWG

— 40 amp external box, 3 phase, 8AWG

Optional Filter Rack

— A 2" four-sided filter rack and pleated filter is optional

and greatly improves air filtration

2 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Two-Position Water Valve

— The optional two-position motorized water valve

opens to allow 100% fluid flow through the coaxial

heat exchanger only when there is a call for cooling or

heating

DDC Controls

— The factory and field installed DDC Controller is

preprogrammed and installed in the unit with the Unit

Protection Module

— The unit will operate in a 100% stand-alone control

mode or connect to a Building Automation System

(BAS) using open protocols BACnet, Modbus and N2

TXV (Thermal Expansion Valve)

— Improves refrigerant management and efficiencies

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 3

i Series Model SV

W

Water Source Heat Pump ½ to 6 Ton

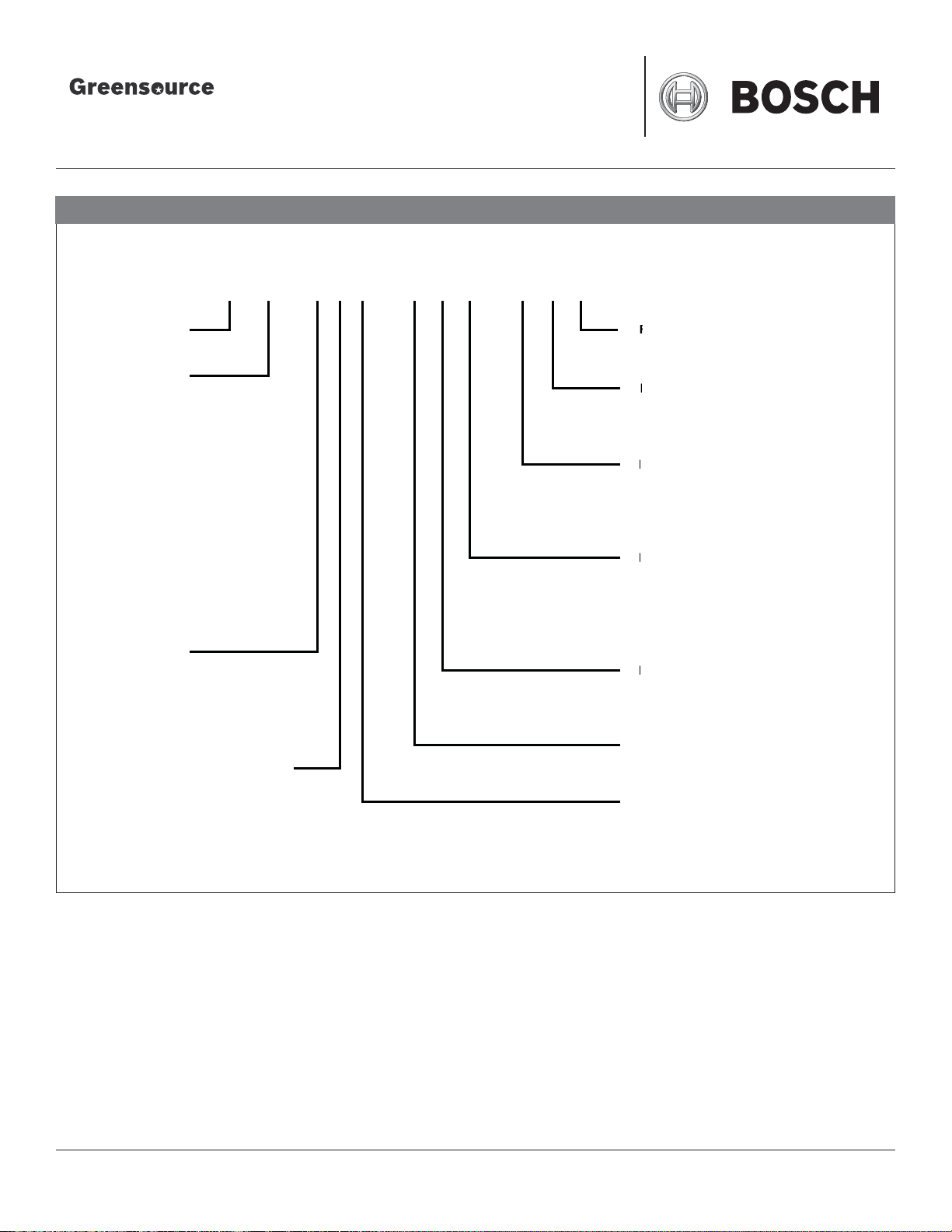

Model Nomenclature

SV 018 - 1 VT C - F L T - P U A

Engineering Submittal Sheet

SERIES

SV

SIZE

007

900

210

510

018

024

030

630

140

240

048

060

070

VOLTAGE

1 208-230/60/1

1/06/7722

3 208-230/60/3

4 460/60/3

CABINET CONFIGURATION

HZ - Horizontal

VT - Vercal

CF - Downflow/Counterflow

(sizes 015 - 070 only)

REVISION LEVEL

A - Current

EVAPORATOR COIL

U - Copper / Aluminum Fin

D - Tin Plated

FAN/MOTOR OPTIONS

CSP dradnatS - P

MCE wolfriA tnatsnoC - A

MCE euqroT tnatsnoC - T

DISCHARGE AIR CONFIGURATION

poT - T

thgiartS

- S

dnE - E

mottoB - B

RETURN AIR CONFIGURATION

tfeL - L

R - Right

WATER CONNECTIONS

tnorF - F

COAX OPTIONS

C - Copper

N - Cupro-Nickel

3 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 4

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Engineering Submittal Sheet

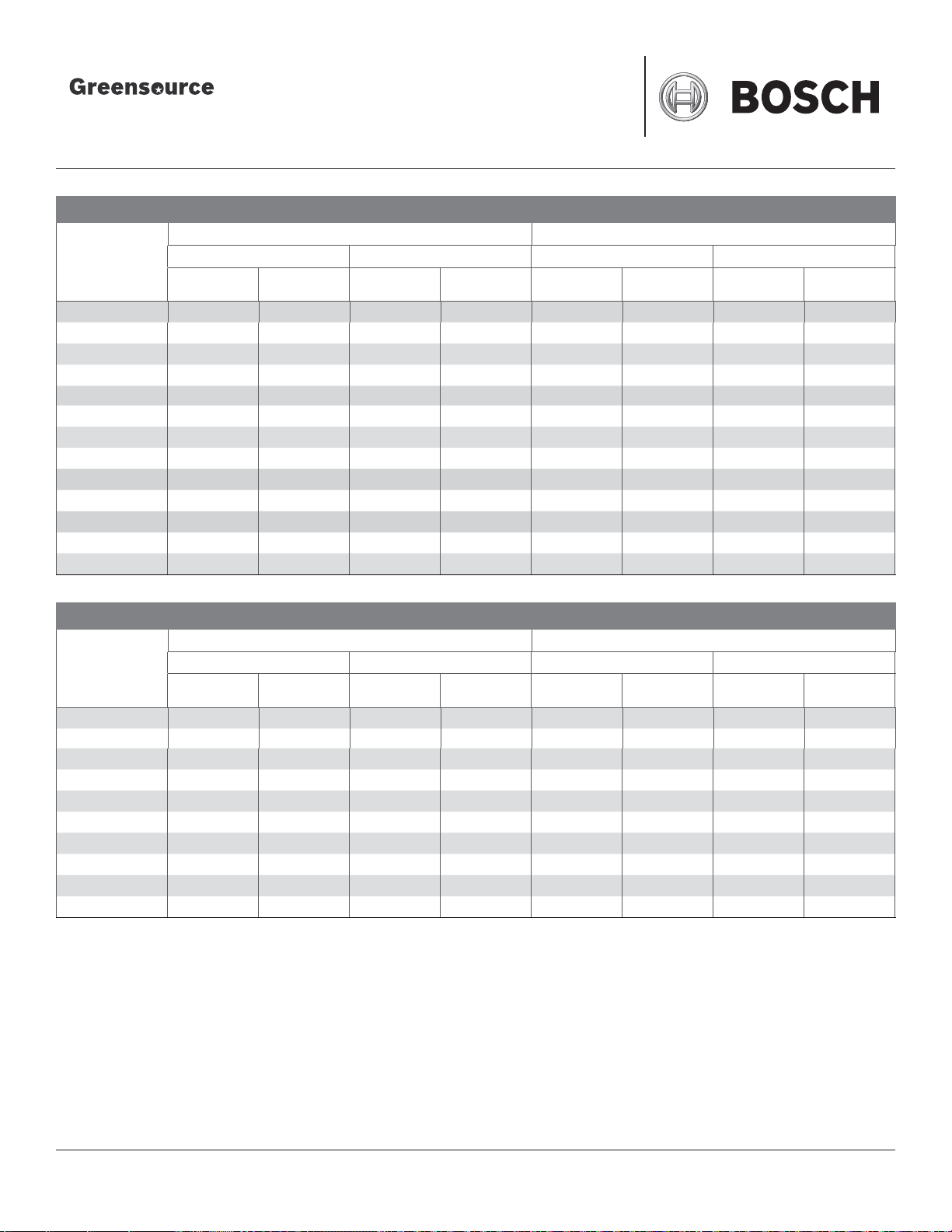

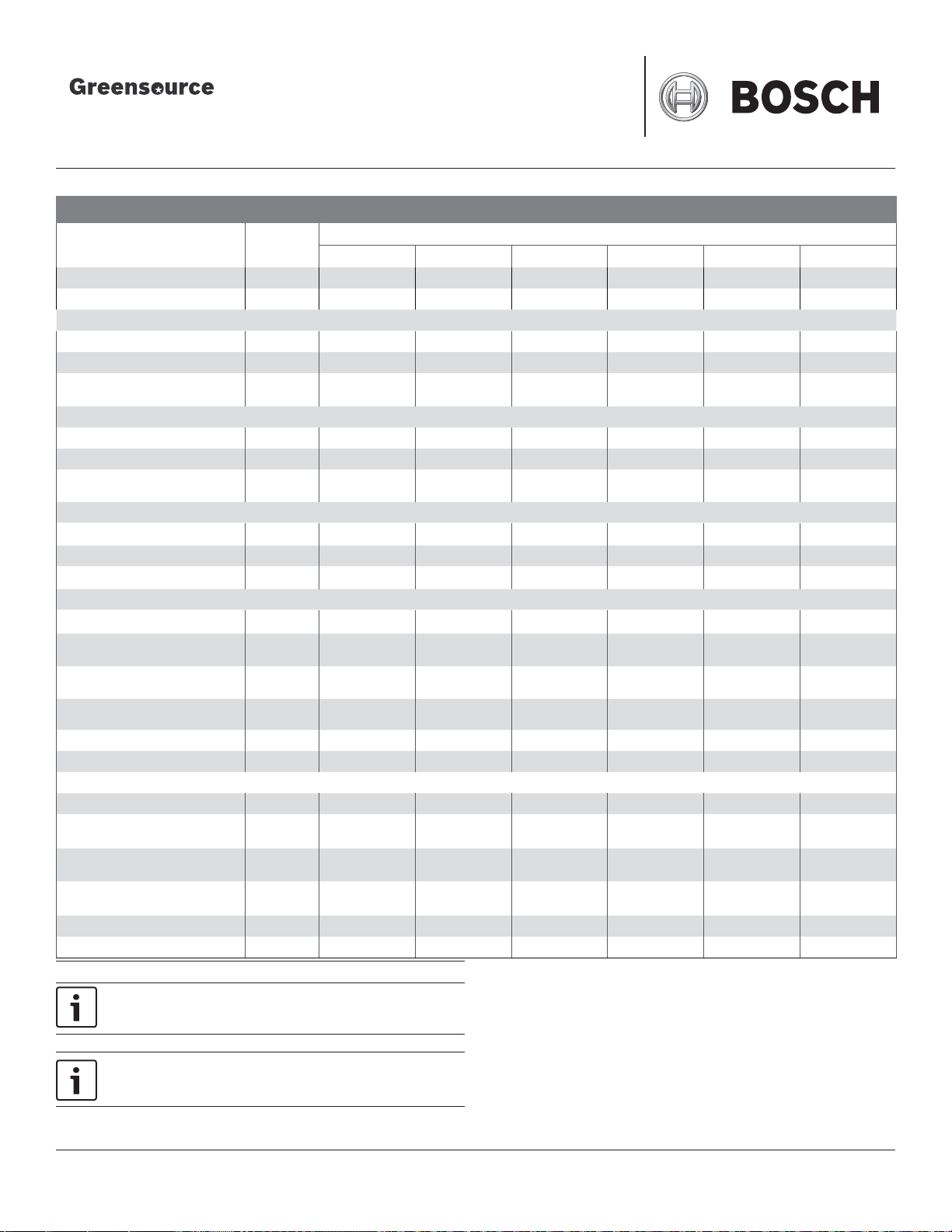

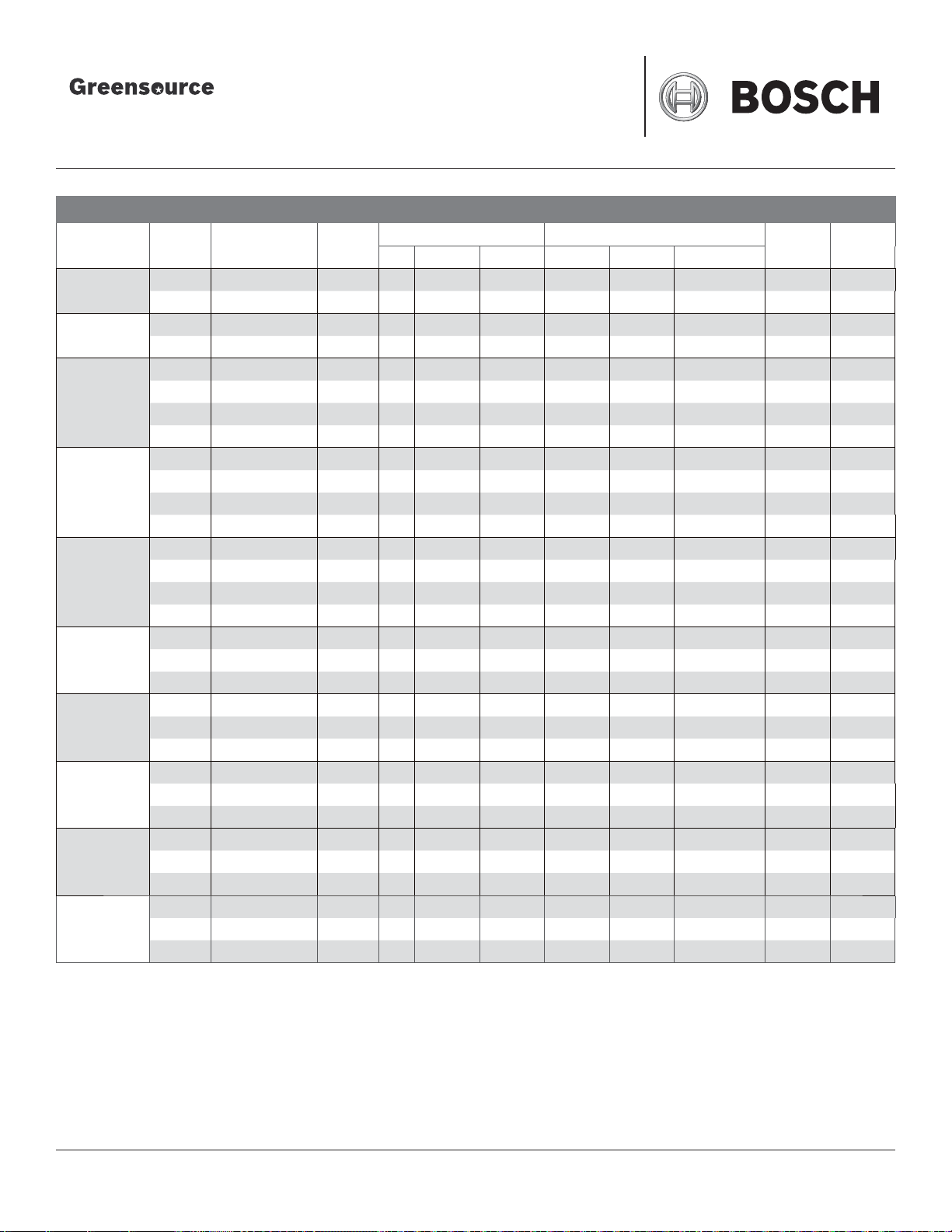

AHRI/ANSI 13256-1

Models

SV007 6100 12.2 7800 5.3 6800 15.1 4900 3.4

SV009 8200 12.4 9900 4.7 8700 14.6 5700 3.2

SV012 10900 12.2 13000 4.3 11800 14.1 8700 3.2

SV015 14200 12.8 16100 4.4 14200 14.6 11300 3.3

SV018 19400 13.4 22200 4.6 21200 15.8 14300 3.5

SV024 23400 13.4 26600 4.4 25000 15.5 17000 3.4

SV030 29200 13.2 33400 4.3 31000 14.7 20900 3.3

SV036 37900 14.7 41800 4.6 39900 16.9 26900 3.5

SV041 39500 13.1 44600 4.3 41200 14.3 29400 3.2

SV042 40000 13.7 46300 4.3 42600 14.8 31000 3.3

SV048 45900 13.0 56400 4.3 48800 14.9 35400 3.4

SV060 57900 13.0 67200 4.3 60100 14.1 46900 3.2

SV070 64000 13.3 72800 4.4 66400 15.0 50800 3.4

AHRI/ANSI 13256-1

Models

Capacity and Effi ciency Data – PSC Motor (Standard)

Water Loop Heat Pump Ground Loop Heat Pump

Cooling 86 °F Heating 68 °F Cooling 77 °F Heating 32 °F

Capacity (Btuh) EER (Btuh/W) Capacity (Btuh) COP Capacity (Btuh) EER (Btuh/W) Capacity (Btuh) COP

Capacity and Effi ciency Data – Constant Torque or Constant CFM ECM

Water Loop Heat Pump Ground Loop Heat Pump

Cooling 86 °F Heating 68 °F Cooling 77 °F Heating 32 °F

Capacity (Btuh) EER (Btuh/W) Capacity (Btuh) COP Capacity (Btuh) EER (Btuh/W) Capacity (Btuh) COP

SV015 13700 13.9 15500 4.4 14400 16.2 10700 3.3

SV018 19700 14.4 21900 4.8 21500 15.9 14100 3.7

SV024 23800 14.3 26200 4.6 25400 16.5 16700 3.5

SV030 30000 15 32800 4.6 31600 17.5 20400 3.4

SV036 38200 15.4 41400 4.7 40200 17.7 26500 3.6

SV041 40500 13.6 43700 4.4 42200 15.9 28500 3.6

SV042 40900 14.1 45300 4.4 43500 16.3 30100 3.5

SV048 46800 14.2 55600 4.5 49600 16.3 34600 3.6

SV060 59000 14.3 66400 4.3 61100 16.4 46200 3.3

SV070 65200 14.6 71800 4.6 67600 16.6 50000 3.5

Bosch Thermotechnology Corp.

4 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Londonderry, NH • Ft. Lauderdale, FL

Page 5

Engineering Submittal Sheet

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

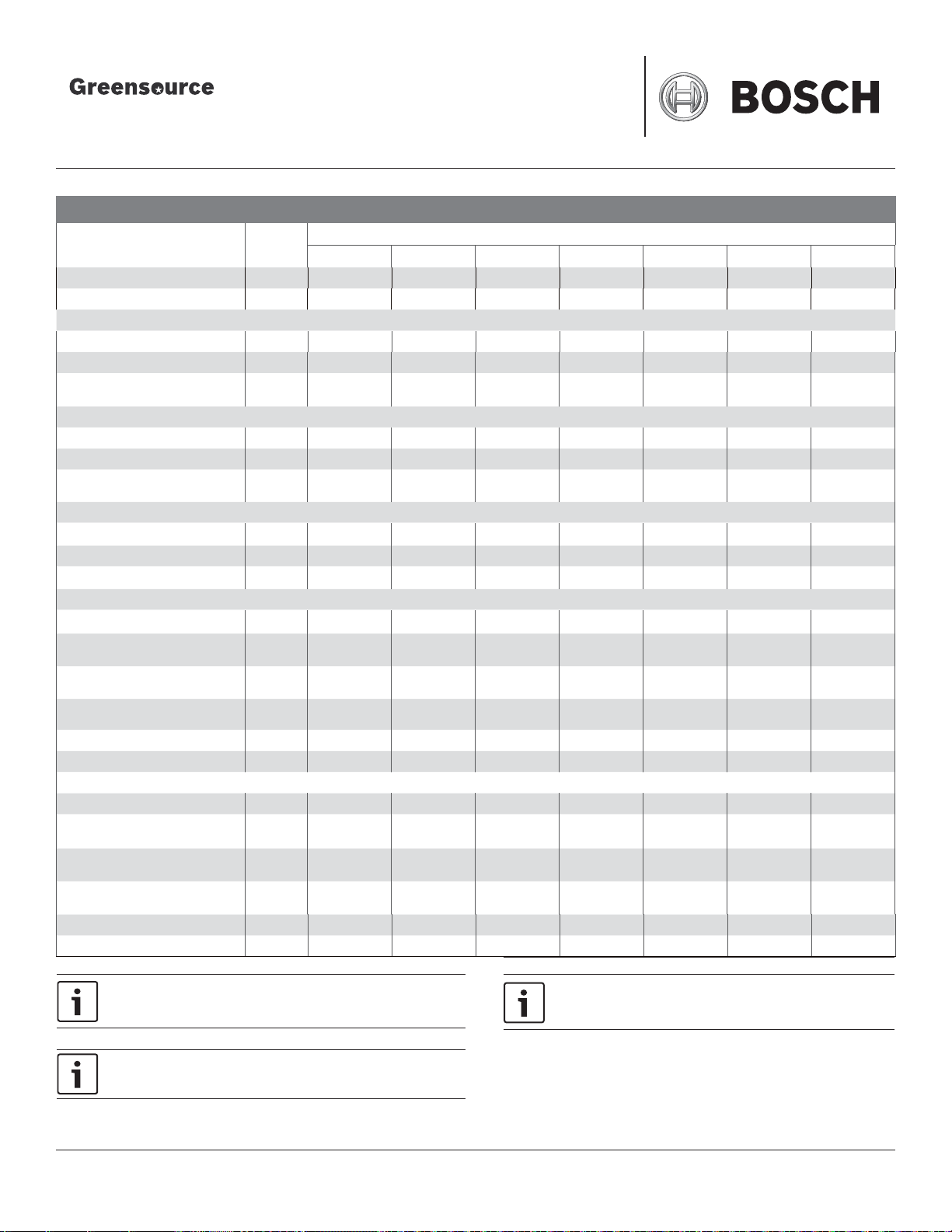

Physical Data

Description Unit

Compressor Type (Qty 1) — Rotar y Rotar y Rotar y Rotary Reciprocating Reciprocating Reciprocating

Max Water Working Pressure PSIG/kPa 400 400 400 400 400 400 400

PSC Fan Motor & Blower

Fan Motor Type/Speeds — PSC/3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3

Fan Motor HP 1/10 1/10 1/10 1/6 1/4 1/4 1/4

Blower Wheel Size

ECM Fan Motor & Blower

Fan Motor Type/Speeds — PSC/3 PSC/3 PSC/3 X13 / EON X13 / EON X13 / EON X13 / EON

Fan Motor HP N/A N/A N/A 1/3 1/3 1/3*/ 1/2 1/3*/ 1/2

Blower Wheel Size

Water Connection Size

FPT Inch

Coaxial Coil Volume Gal 0.04 0.06 0.08 0.09 0.14 0.14 0.24

Condensate Connection Inch FPT

Vertical Cabinet

Refrigeration Charge Oz 14 15 21 19 28 29 39

Air Coil Dimensions

Standard Filter - 1"

Optional Filter - 2" MERV 7 or 13

Weight - Operating lbs 98 103 105 123 173 177 190

Weight - Shipping lbs 126 130 132 151 201 205 217

Horizontal Cabinet

Refrigeration Charge Oz 17 19 19 19 29 29 37

Air Coil Dimensions

Standard Filter - 1"

Optional Filter - 2" MERV 7 or 13

Weight - Operating lbs 96 100 105 136 174 181 190

Weight - Shipping lbs

Inch

(Dia. x W)

Inch

(Dia. x W)

Inch

(H x W)

Inch

(L x H)

Inch

(L x H)

Inch

(H x W)

Inch

(L x H)

Inch

(L x H)

SV007 SV009 SV012 SV015 SV018 SV024 SV030

4.5 x 4.5 4.5 x 4.5 5.5 x 4.5 9 x 7 9 x 7 9 x 7 9 x 7

4.5 x 4.5 4.5 x 4.5 5.5 x 4.5 9 x 7 9 x 7 9 x 7 9 x 7

¾¾¾¾¾¾¾

¾¾¾¾¾¾¾

10 x 14 10 x 14 10 x 14 12 x 16.5 16 x 16.5 20 x 16.5 20 x 16.5

10 x 16 10 x 16 10 x 16 16 x 20 16 x 20 20 x 20 20 x 20

10 x 16 10 x 16 10 x 16 16 x 20 16 x 20 20 x 20 20 x 20

10 x 14 10 x 14 10 x 14 12 x 16.5 16 x 16.5 16 x 20.5 16 x 20.5

10 x 16 10 x 16 10 x 16 16 x 20 16 x 20 16 x 25 16 x 25

10 x 16 10 x 16 10 x 16 16 x 20 16 x 20 16 x 25 16 x 25

128 132 134 158 208 212 224

Value

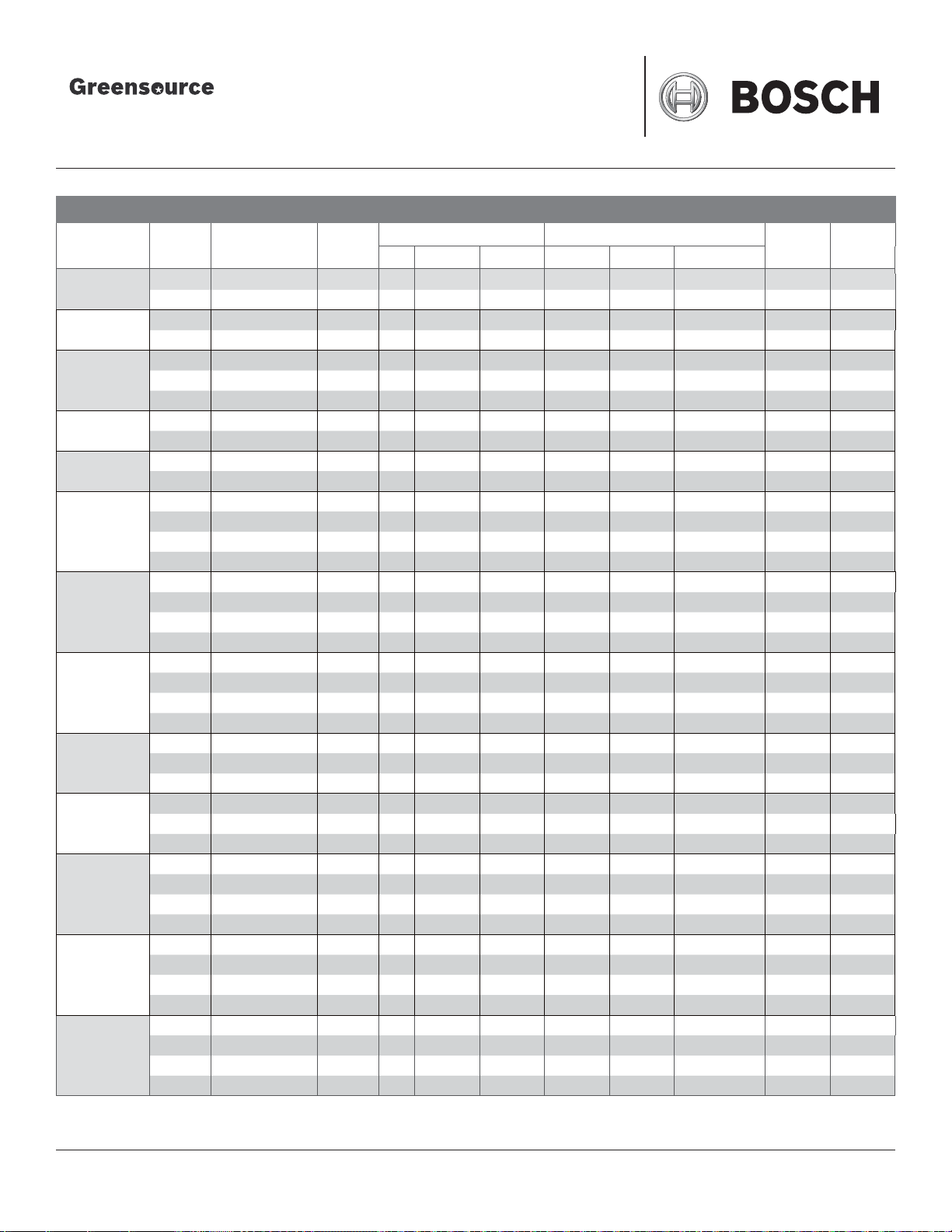

Unit sizes 024 & 030 with -4 voltage (460/3/60), the X13 motor will

be 1/2 HP rather than 1/3 HP.

460/3/60 units with a constant CFM ECM requires a neutral wire in

addition to the power wires and ground wires.

5 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

460/3/60 units with a constant Torque ECM does not require a

neutral wire.

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 6

Engineering Submittal Sheet

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Physical Data

Description Unit

Compressor Type (Qty 1) — Reciprocating Reciprocating Reciprocating Scroll Scroll Scroll

Max Water Working Pressure PSIG/kPa 400 400 400 400 400 400

PSC Fan Motor & Blower

Fan Motor Type/Speeds — PSC/3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3

Fan Motor HP 1/2 3/4 1/2 3/4 3/4 3/4

Blower Wheel Size

ECM Fan Motor & Blower

Fan Motor Type/Speeds — X13 / EON X13 / EON X13 / EON X13 / EON X13 / EON X13 / EON

Fan Motor HP 1/2 3/4 3/4 3/4 1.0 1.0

Blower Wheel Size

Water Connection Size

FPT Inch

Coaxial Coil Volume Gal 0.27 0.27 0.27 0.49 0.62 0.62

Condensate Connection Inch FPT

Vertical Cabinet

Refrigeration Charge Oz 48 48 48 52 59 73

Air Coil Dimensions

Standard Filter - 1"

Optional Filter - 2" MERV 7 or 13

Weight - Operating lbs 229 217 239 287 307 336

Weight - Shipping lbs 255 243 265 312 331 360

Horizontal Cabinet

Refrigeration Charge Oz 46 N/A 43 44 70 61

Air Coil Dimensions

Standard Filter - 1"

Optional Filter - 2" MERV 7 or 13

Weight - Operating lbs 236 N/A 231 274 288 316

Weight - Shipping lbs

Inch

(Dia. x W)

Inch

(Dia. x W)

Inch

(H x W)

Inch

(L x H)

Inch

(L x H)

Inch

(H x W)

Inch

(L x H)

Inch

(L x H)

SV036 SV041 SV042 SV048 SV060 SV070

9 x 7 10 x 8 10 x 8 10 x 8 11 x 9 11 x 9

9 x 7 10 x 8 10 x 8 10 x 8 11 x 9 11 x 9

¾¾¾ 1 1 1

¾¾¾¾¾¾

24x20.2 20x16 24x20.2 24x26.75 24x26.75 32x26.2

24x24 20x20 24x24 24x30 24x30 16x30 @2

24x24 20x20 24x24 24x30 24x30 16x30 @2

18x27.5 N/A 18x27.5 20x32 20x32 20x42

18x30 N/A 18x30 20x34.5 20x34.5 20x24 @2

18x30 N/A 18x30 20x34.5 20x34.5 20x24 @2

270 N/A 264 299 318 365

Value

460/3/60 units with a constant CFM ECM requires a neutral wire in

addition to the power wires and ground wires.

460/3/60 units with a constant Torque ECM does not require a

neutral wire.

6 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 7

Engineering Submittal Sheet

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

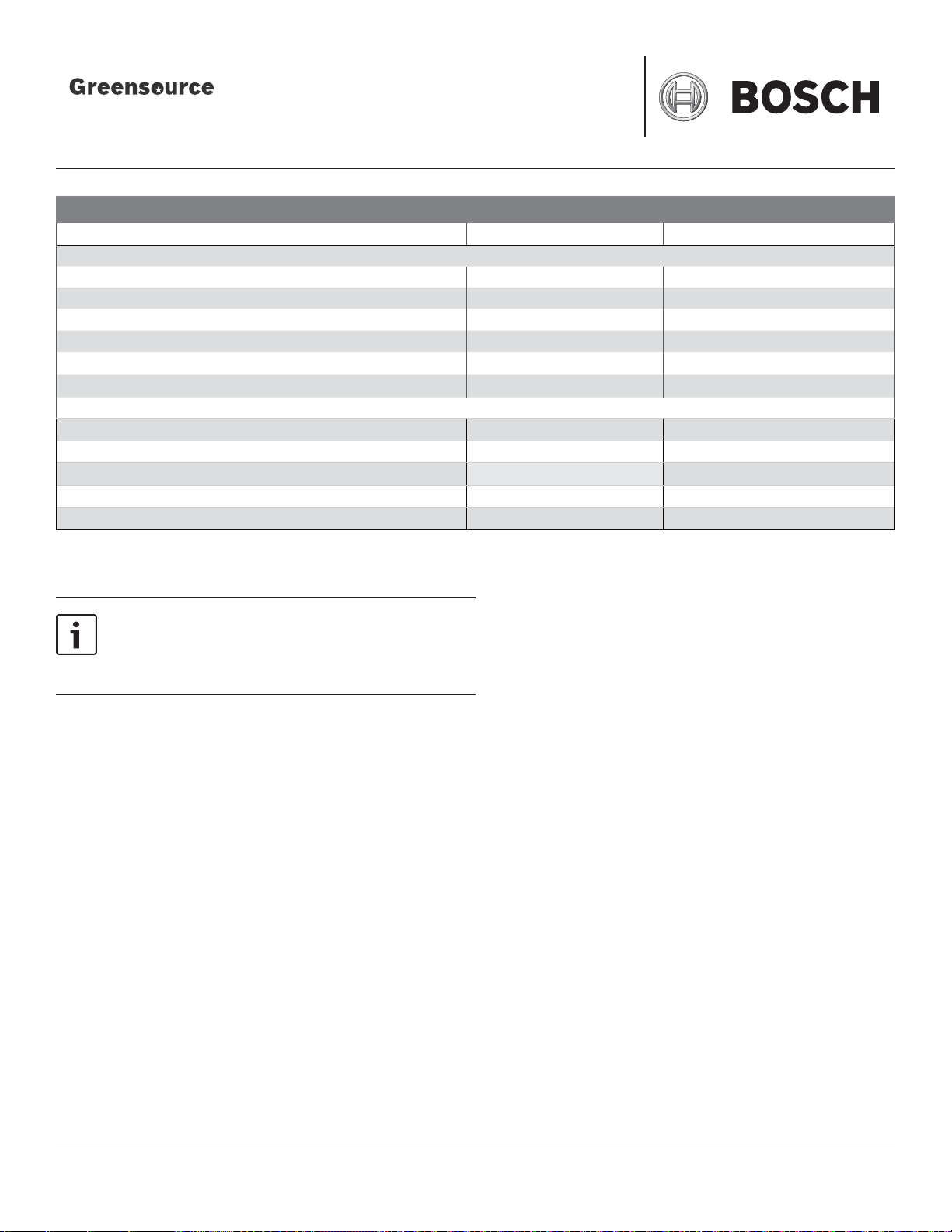

Operating Limits - Cooling & Heating

Description Standard Unit Extended Range Option

COOLING

Minimum evaporator entering air db/wb °F 68/57 68/57

Rated air coil entering air db/wb °F 80/67 80/67

Maximum evaporator entering air db/wb °F 95/85

Minimum water coil entering fl uid temperature °F 50 50

Water loop typical coil entering fl uid range temperature °F 70/90

Maximum water coil entering fl uid temperature °F 110 110

HEATING

Minimum evaporator entering air db °F 50 50

Rated air coil entering air °F 68 68

Maximum evaporator entering air db °F 80 80

Normal water coil entering fl uid range °F 50-80 25-80*

Minimum water coil entering Fluid °F 50 20*

* antifreeze solution is required at these fl uid temperatures.

95/85

70/90

Units are designed to be installed in an air conditioned space.

Maximum and minimum conditions may not be combined.

Should one value be at the maximum or minimum, the other

can not exceed the normal condition.

Maximum and minimum conditions are at rated fl ow rates.

7 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 8

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

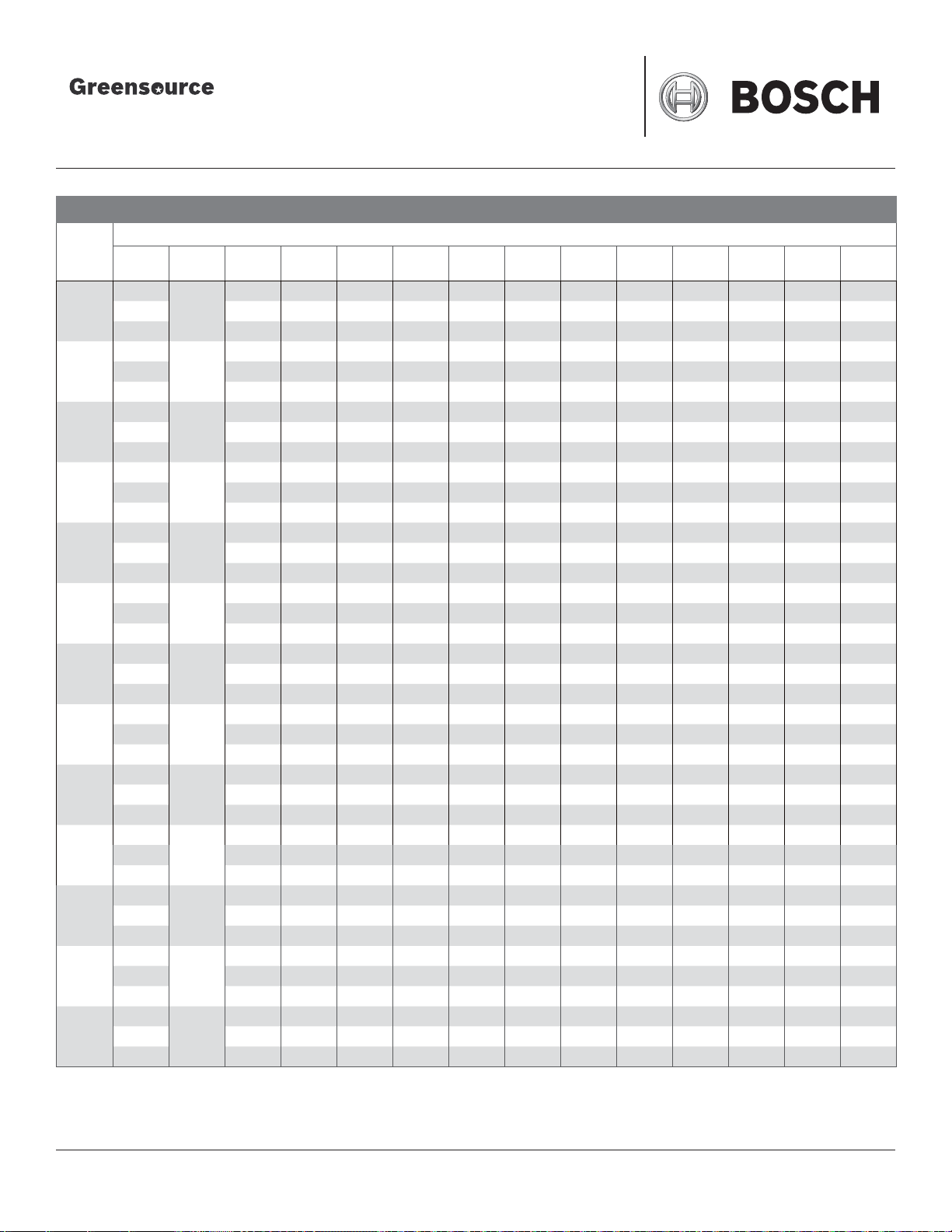

Electrical Data - PSC Standard Blower Motor

Model

SV007

SV009

SV012

SV015

SV018

SV024

SV030

SV036

SV041

SV042

SV048

SV060

SV070

All blower motors are single phase.

UNIT POWER SUPPLY: A voltage variation of +/- 10% of nameplate rating is acceptable. Phase imbalance shall not exceed 2%.

8 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

Voltage

Code

Voltage/Hz/Phase

1 208-230/60/1 197/253 1 2.6 17.7 0.96 0.1 3.6 4.2

2 265/60/1 238/292 1 2.6 13.5 0.96 0.1 3.6 4.2 15

1 208-230/60/1 197/253 1 3.4 22.2 0.96 0.1 4.4 5.2 15

2 265/60/1 238/292 1 2.9 18.8 0.85 0.1 3.8 4.5 15

0 115/60/1 103/126 1 9.6 58.4 2.2 0.1 11.8 14.2 20

1 208-230/60/1 197/253 1 4.6 28.0 0.96 0.1 5.6 6.7 15

2 265/60/1 238/292 1 3.8 22.2 0.85 0.1 4.7 5.6 15

1 208-230/60/1 197/253 1 5.6 29.0 1.10 0.17 6.7 8.1 15

2 265/60/1 238/292 1 4.6 20.0 0.90 0.17 5.5 6.7 15

1 208-230/60/1 197/253 1 6.5 43.0 1.8 0.25 8.3 9.9 15

2 265/60/1 238/292 1 5.8 46.0 1.6 0.25 7.4 8.9 15

1 208-230/60/1 197/253 1 7.4 43.0 1.8 0.25 9.2 11.1 15

2 265/60/1 238/292 1 6.7 46.0 1.6 0.25 8.3 10.0 15

3 208-230/60/3 197/253 1 5.9 63.0 1.8 0.25 7.7 9.2 15

4 460/60/3 414/506 1 2.9 30.0 0.9 0.25 3.8 4.5 15

1 208-230/60/1 197/253 1 9.9 54.0 1.8 0.25 11.7 14.2 20

2 265/60/1 238/292 1 8.5 46.0 1.6 0.25 10.1 12.2 20

3 208-230/60/3 197/253 1 6.9 63.0 1.8 0.25 8.7 10.4 15

4 460/60/3 414/506 1 5.4 30.0 0.9 0.25 6.3 7.7 15

1 208-230/60/1 197/253 1 13 74.0 4.4 0.5 17.4 20.7 30

2 265/60/1 238/292 1 11.3 67.0 3.3 0.5 14.6 17.4 25

3 208-230/60/3 197/253 1 7.8 68.0 4.4 0.5 12.2 14.2 20

4 460/60/3 414/506 1 3.9 34.0 1.8 0.5 5.7 6.7 15

1 208-230/60/1 197/253 1 13.6 88.0 4.4 0.75 18.0 21.4 35

3 208-230/60/3 197/253 1 8.8 68.0 4.4 0.75 13.2 15.4 20

4 460/60/3 414/506 1 4.4 34.0 2.8 0.75 7.2 8.3 15

1 208-230/60/1 197/253 1 13.6 88.0 4.4 0.5 18.0 21.4 35

3 208-230/60/3 197/253 1 8.8 68.0 4.4 0.5 13.2 15.4 20

4 460/60/3 414/506 1 4.4 34.0 1.8 0.5 6.2 7.3 15

1 208-230/60/1 197/253 1 15.7 84.0 4.4 0.75 20.1 24.0 35

3 208-230/60/3 197/253 1 11 88.0 4.4 0.75 15.4 18.2 25

4 460/60/3 414/506 1 5.4 44.0 2.8 0.75 8.2 9.6 15

5 575/60/3 517/633 1 4.4 36.0 2.6 0.75 7.0 8.1 15

1 208-230/60/1 197/253 1 26.3 134.0 5.5 0.75 31.8 38.4 60

3 208-230/60/3 197/253 1 15.6 110.0 5.5 0.75 21.1 25.0 40

4 460/60/3 414/506 1 7.8 52.0 2.8 0.75 10.6 12.6 20

5 575/60/3 517/633 1 5.8 38.9 2.6 0.75 8.4 9.9 15

1 208-230/60/1 197/253 1 28.3 178.0 5.5 0.75 33.8 40.9 60

3 208-230/60/3 197/253 1 19.2 136.0 5.5 0.75 24.7 29.5 45

4 460/60/3 414/506 1 8.7 66.1 2.8 0.75 11.5 13.7 20

5 575/60/3 517/633 1 6.9 55.3 2.6 0.75 9.5 11.2 15

Voltage

Min/Max

BTC 760208301 E | 10.2015

Compressor Blower Motor

QTY RLA LRA FLA HP Total Unit FLA

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Engineering Submittal Sheet

Min Circuit

Amps

Max Fuse/

HACR

15

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Page 9

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

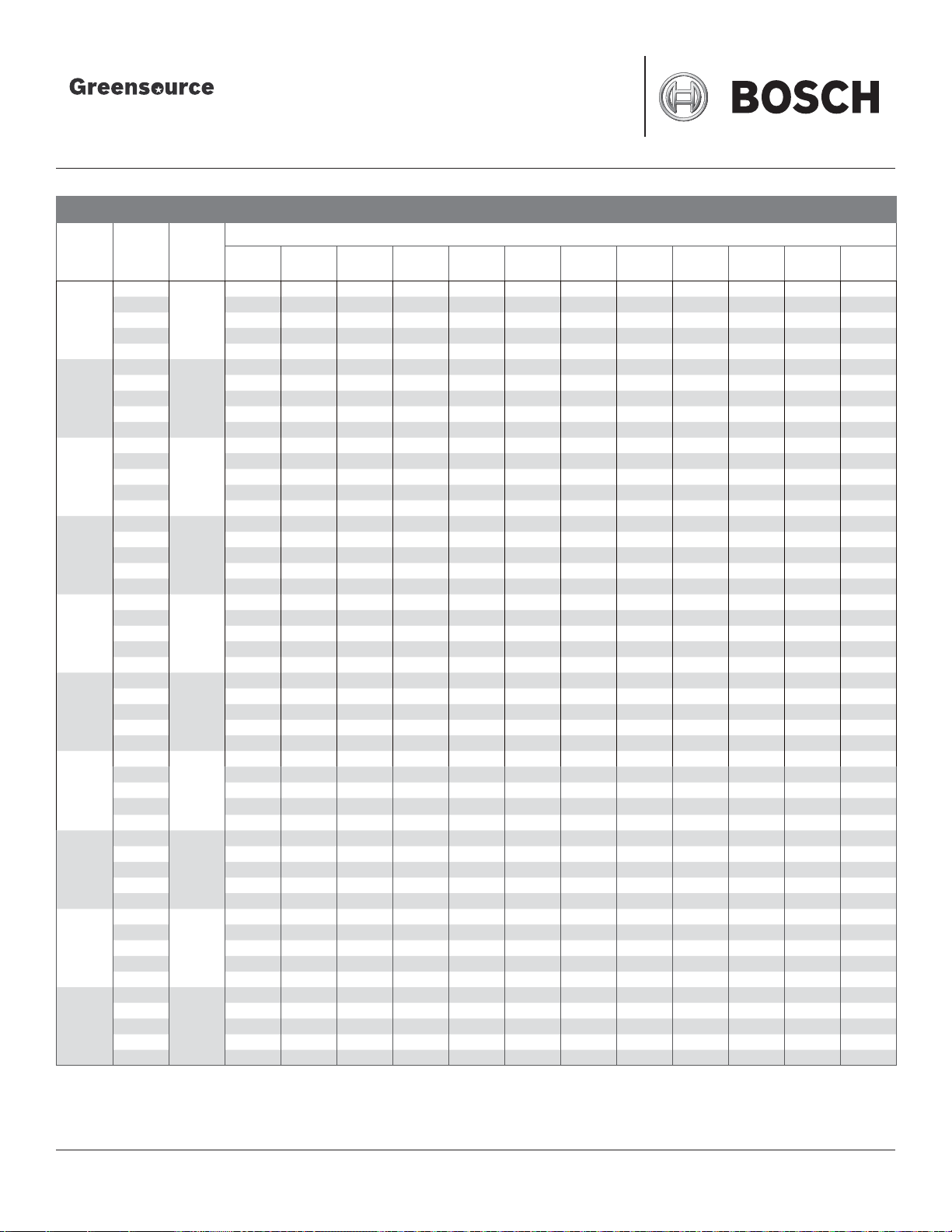

Electrical Data - Constant Torque ECM

Model

SV015

SV018

SV024

SV030

SV036

SV041

SV042

SV048

SV060

SV070

Voltage

Code

Voltage/Hz/Phase

1 208-230/60/1 196/253 1 5.6 29.0 2.8 0.3 8.4 9.8 15

2 265/60/1 238/292 1 4.6 20.0 2.6 0.3 7.2 8.4 15

1 208-230/60/1 196/253 1 6.5 43.0 2.8 0.3 9.3 10.9 15

2 265/60/1 238/292 1 5.8 46.0 2.6 0.3 8.4 9.9 15

1 208-230/60/1 196/253 1 7.4 43.0 2.8 0.3 10.2 12.1 15

2 265/60/1 238/292 1 6.7 46.0 2.6 0.3 9.3 11.0 15

3 208-230/60/3 196/253 1 5.9 63.0 2.8 0.3 8.7 10.2 15

4 460/60/3 414/506 1 2.9 30.0 2.1 0.5 5.0 5.7 15

1 208-230/60/1 196/253 1 9.9 54.0 2.8 0.3 12.7 15.2 25

2 265/60/1 238/292 1 8.5 46.0 2.6 0.3 11.1 13.2 20

3 208-230/60/3 196/253 1 6.9 63.0 2.8 0.3 9.7 11.4 15

4 460/60/3 414/506 1 5.4 30.0 2.1 0.5 7.5 8.9 15

1 208-230/60/1 196/253 1 13.0 74.0 4.1 0.5 17.1 20.4 30

2 265/60/1 238/292 1 11.3 67.0 3.9 0.5 15.2 18.0 25

3 208-230/60/3 196/253 1 7.8 68.0 4.1 0.5 11.9 13.9 20

4 460/60/3 414/506 1 3.9 34.0 2.1 0.5 6.0 7.0 15

1 208-230/60/1 196/253 1 13.6 88.0 6.0 0.8 19.6 23.0 35

3 208-230/60/3 196/253 1 8.8 68.0 6.0 0.8 14.8 17.0 25

4 460/60/3 414/506 1 4.4 34.0 4.6 0.8 9.0 10.1 15

1 208-230/60/1 196/253 1 13.6 88.0 6.0 0.8 19.6 23.0 35

3 208-230/60/3 196/253 1 8.8 68.0 6.0 0.8 14.8 17.0 25

4 460/60/3 414/506 1 4.4 34.0 4.6 0.8 9.0 10.1 15

1 208-230/60/1 196/253 1 15.7 84.0 6.0 0.8 21.7 25.6 40

3 208-230/60/3 196/253 1 11.0 88.0 6.0 0.8 17.0 19.8 30

4 460/60/3 414/506 1 5.4 44.0 4.6 0.8 10.0 11.4 15

1 208-230/60/1 196/253 1 26.3 145.0 7.6 1.0 33.9 40.5 60

3 208-230/60/3 196/253 1 15.6 123.0 7.6 1.0 23.2 27.1 40

4 460/60/3 414/506 1 7.8 70.0 4.0 1.0 11.8 13.8 20

1 208-230/60/1 196/253 1 28.3 158.0 7.6 1.0 35.9 43.0 70

3 208-230/60/3 196/253 1 19.2 155.0 7.6 1.0 26.8 31.6 50

4 460/60/3 414/506 1 8.7 75.0 4.0 1.0 12.7 14.9 20

Voltage

Min/Max

QTY RLA LRA FLA HP Total Unit FLA

Engineering Submittal Sheet

Compressor Blower Motor

Min Circuit

Amps

Max Fuse/

HACR

9 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 10

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Electrical Data - Constant CFM ECM (Variable Speed)

Model

SV015

SV018

SV024

SV030

SV036

SV041

SV042

SV048

SV060

SV070

Voltage

Code

Voltage/Hz/Phase

1 208-230/60/1 196/253 1 5.6 29.0 2.8 0.3 8.4 9.8 15

2 265/60/1 238/292 1 4.6 20.0 2.6 0.3 7.2 8.4 15

1 208-230/60/1 196/253 1 6.5 43.0 2.8 0.3 9.3 10.9 15

2 265/60/1 238/292 1 5.8 46.0 2.6 0.3 8.4 9.9 15

1 208-230/60/1 196/253 1 7.4 43.0 2.8 0.3 10.2 12.1 15

2 265/60/1 238/292 1 6.7 46.0 2.6 0.3 9.3 11.0 15

3 208-230/60/3 196/253 1 5.9 63.0 2.8 0.3 8.7 10.2 15

4 460/60/3 414/506 1 2.9 30.0 2.6 0.3 5.5 6.2 15

1 208-230/60/1 196/253 1 9.9 54.0 2.8 0.3 12.7 15.2 25

2 265/60/1 238/292 1 8.5 46.0 2.6 0.3 11.1 13.2 20

3 208-230/60/3 196/253 1 6.9 63.0 2.8 0.3 9.7 11.4 15

4 460/60/3 414/506 1 5.4 30.0 2.6 0.3 8.0 9.4 15

1 208-230/60/1 196/253 1 13.0 74.0 4.3 0.5 17.3 20.6 30

2 265/60/1 238/292 1 11.3 67.0 4.1 0.5 15.4 18.2 25

3 208-230/60/3 196/253 1 7.8 68.0 4.3 0.5 12.1 14.1 20

4 460/60/3 414/506 1 3.9 34.0 4.1 0.5 8.0 9.0 15

1 208-230/60/1 196/253 1 13.6 88.0 6.8 0.8 20.4 23.8 35

3 208-230/60/3 196/253 1 8.8 68.0 6.8 0.8 15.6 17.8 25

4 460/60/3 414/506 1 4.4 34.0 5.5 0.8 9.9 11.0 15

1 208-230/60/1 196/253 1 13.6 88.0 6.8 0.8 20.4 23.8 35

3 208-230/60/3 196/253 1 8.8 68.0 6.8 0.8 15.6 17.8 25

4 460/60/3 414/506 1 4.4 34.0 5.5 0.8 9.9 11.0 15

1 208-230/60/1 196/253 1 15.7 84.0 6.8 0.8 22.5 26.4 40

3 208-230/60/3 196/253 1 11.0 88.0 6.8 0.8 17.8 20.6 30

4 460/60/3 414/506 1 5.4 44.0 5.5 0.8 10.9 12.3 15

1 208-230/60/1 196/253 1 26.3 145.0 9.1 1.0 35.4 42.0 60

3 208-230/60/3 196/253 1 15.6 123.0 9.1 1.0 24.7 28.6 45

4 460/60/3 414/506 1 7.8 70.0 6.9 1.0 14.7 16.7 20

1 208-230/60/1 196/253 1 28.3 158.0 9.1 1.0 37.4 44.5 70

3 208-230/60/3 196/253 1 19.2 155.0 9.1 1.0 28.3 33.1 50

4 460/60/3 414/506 1 8.7 75.0 6.9 1.0 15.6 17.8 25

Voltage

Min/Max

QTY RLA LRA FLA HP Total Unit FLA

Engineering Submittal Sheet

Compressor Blower Motor

Min Circuit

Amps

Max Fuse/

HACR

10 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 11

Engineering Submittal Sheet

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Blower Performance CFM (PSC Standard Motor Blower)

Available External Static Pressure (in. wc. Wet coil and fi lter included)

Model

SV007

SV009

SV012

SV015 Medium 380 370 360 340 330 -------

SV018

SV024

SV030

SV036

SV041

SV042

SV048

SV060

SV070

Motor

Speed

Low

Medium 390 360 330 300 260 -------

High 410 380 350 315 280 210 ------

Low

Medium 390 360 330 300 260 -------

High 410 380 350 315 280 210 ------

Low

Medium 380 380 360 330 290 -------

High 420 400 380 360 340 320 ------

Low

High 520 500 480 460 430 400 340 -----

Low

Medium 810 790 760 730 680 590 ------

High 1010 970 920 870 800 680 530 -----

Low

Medium 830 820 800 770 720 620 ------

High 1050 1000 950 910 840 710 570 -----

Low

Medium 830 810 770 730 680 620 ------

High 1000 950 900 830 750 690 630 -----

Low

Medium 1410 1350 1290 1220 1150 1060 900 -----

High 1500 1440 1370 1290 1210 1120 1000 900 ----

Low

Medium 1220 1190 1150 1120 1080 1020 940 -----

High 1450 1380 1320 1250 1190 1120 1040 960 ----

Low

Medium 1460 1450 1430 1390 1330 1250 1160 -----

High 1750 1710 1670 1620 1560 1460 1330 1210 1080 - - -

Low

Medium 1700 1670 1630 1580 1530 1470 1400 -----

High 1930 1870 1810 1740 1670 1600 1520 1430 1340 - - -

Low

Medium 1890 1880 1870 1860 1825 1790 1730 1670 1590 1500 - -

High 2220 2200 2150 2100 2050 2000 1940 1870 1800 1700 1590 -

Low

Medium 1900 1890 1880 1870 1860 1825 1790 1730 1670 1590 1500 -

High 2240 2220 2200 2150 2100 2050 2000 1940 1870 1800 1700 1590

Rated

Airfl ow

300

350

400

500

650

850

950

1200

1200

1400

1600

2000

2100

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20

370340295250--------

370340295250--------

300290290300--------

320300280---------

630590560---------

650610570540510-------

740730700660610-------

1290 1250 1200 1150 1080 1000 ------

990990970950920860------

1210 1210 1190 1160 1120 1080 ------

1450 1440 1420 1400 1360 1320 ------

1560 1550 1540 1530 1505 1475 1440 1400 ----

1570 1560 1550 1540 1530 1505 1475 1440 1400 - - -

11 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 12

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

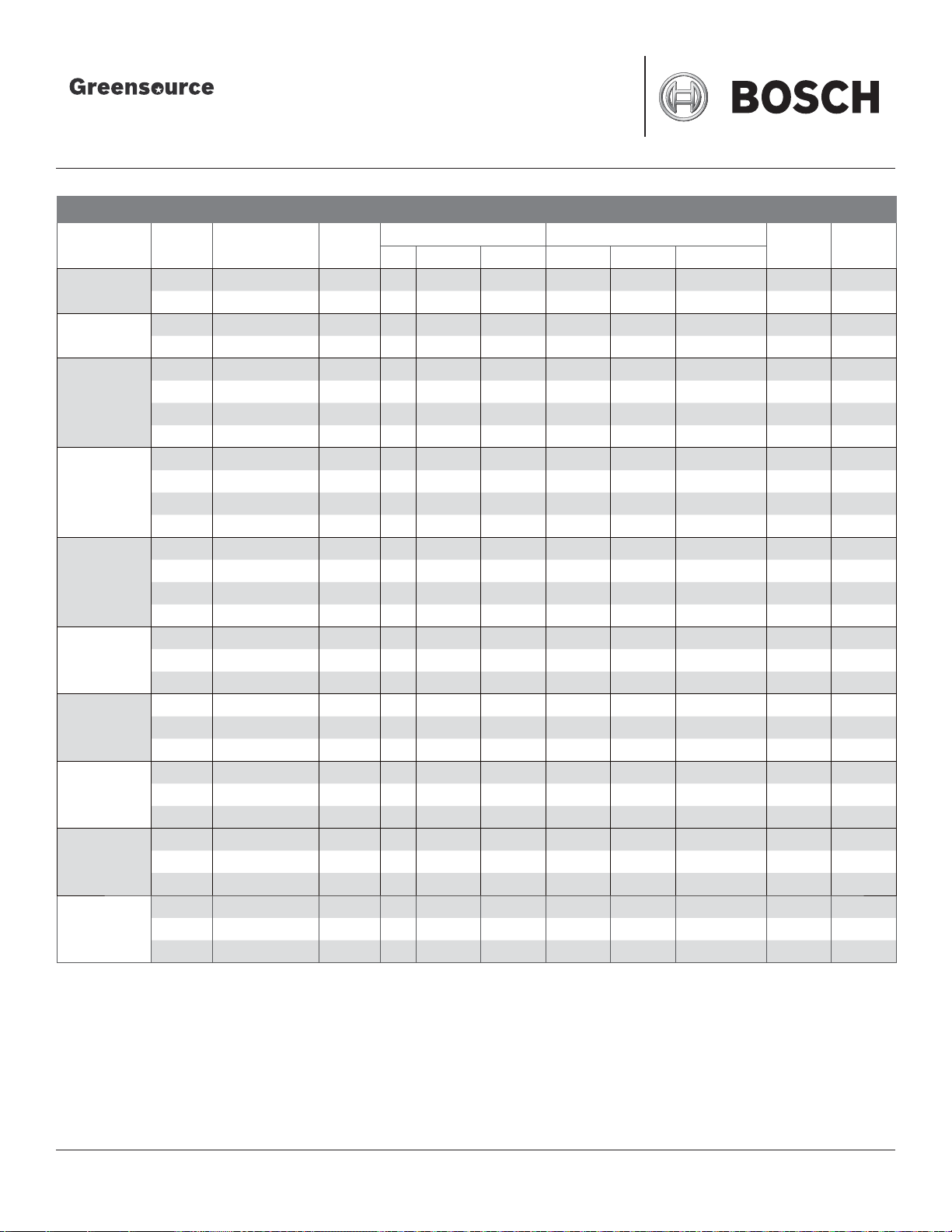

Blower Performance Constant Torque ECM

Available External Static Pressure (in. wc. Wet coil and fi lter included)

Model

SV015

SV018

SV024

SV030

SV036

SV041

SV042

SV048

SV060

SV070

Fan

Speed

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Rated

Airfl ow

500

650

850

950

1200

1200

1400

1600

2000

2100

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20

480440410370340-------

530490450420380340------

600560510470440410370-----

650600560520500480440380----

710660620580550520490470----

630590560530490-------

720700670630600560------

790770750710670620560-----

910890850810740670590520----

1010 970 920 860 810 750 660 530 ----

650610580560520-------

740720690660620570------

850830800770730690630-----

950920890870840820770650----

1160 1110 1050 990 920 800 670 560 ----

620600570540490-------

730710670640610550------

820790760740710670630-----

940910880850800740660-----

1070 1010 950 900 840 760 670 -----

1120 1090 1055 1030 1000 -------

1260 1230 1200 1170 1140 1080 ------

1330 1293 1253 1210 1167 1100 1030 -----

1400 1357 1307 1250 1193 1120 1040 963 ----

1470 1420 1360 1290 1220 1140 1050 970 890 - - -

985955920890--------

1130 1100 1070 1030 1000 -------

1210 1180 1143 1100 1060 1010 ------

1290 1260 1217 1170 1120 1050 977 -----

1370 1340 1290 1240 1180 1090 1000 920 ----

1270 1250 1230 1210 --------

1440 1420 1410 1410 1400 1380 1340 -----

1540 1530 1510 1500 1490 1470 1430 1350 ----

1650 1630 1610 1600 1580 1530 1460 1360 1240 - - -

1730 1720 1700 1670 1620 1570 1490 1380 1260 1100 - -

1390 1370 1350 1320 --------

1600 1580 1550 1530 1510 -------

1730 1700 1670 1650 1630 1600 1580 1540 ----

1830 1810 1780 1760 1740 1710 1670 1600 1520 - - -

1930 1910 1880 1860 1830 1780 1720 1640 1540 1420 - -

1900 1880 1860 1820 --------

2000 1970 1950 1920 1890 1860 ------

2110 2090 2060 2030 2010 1970 1940 1910 1880 - - -

2220 2200 2170 2140 2110 2080 2050 2060 2050 2000 1920 -

2340 2320 2290 2260 2230 2210 2180 2150 2110 2070 2000 1930

2050 2010 1970 1930 --------

2150 2120 2080 2030 1990 1960 ------

2270 2230 2200 2160 2120 2080 2040 2010 1980 - - -

2390 2350 2320 2280 2250 2200 2160 2130 2100 2070 2030 -

2520 2480 2450 2420 2380 2330 2290 2260 2220 2170 2100 2020

Engineering Submittal Sheet

12 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 13

Engineering Submittal Sheet

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Blower Performance Constant CFM ECM

Model

SV015 Norm 350 500 500 500 500 500 500 500 480 470 460 - -

SV018 650 B

SV024 850 C

SV030 950 D

SV036 1200 A

SV041 1200 A

SV042 1400 B

SV048 1600 A

SV060 2000 A

SV070 2200 B

Rated

Airfl ow

500 A

Adjust

Tap

Settings

Norm 450 650 650 650 650 650 650 640 630 610 590 - -

Norm 600 850 850 850 850 850 850 850 850 800 700 - -

Norm 650 950 950 950 950 950 950 950 950 950 950 - -

Norm 850 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 - -

Norm 840 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 - -

Norm 980 1400 1400 1400 1400 1400 1400 1400 1400 1400 1400 - -

Norm 1120 1600 1600 1600 1600 1600 1600 1600 1600 1600 1600 - -

Norm 1400 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 -

Norm 1550 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200 -

Fan

Only

- 315 450 450 450 450 450 450 450 440 440 430 - -

+ 400 580 580 580 580 580 580 580 570 560 550 - -

- 385 550 540 540 540 540 540 540 530 520 500 - -

+ 525 750 750 750 750 750 750 740 730 710 690 - -

- 500 720 720 720 720 720 720 720 700 650 560 - -

+ 675 960 960 960 960 960 960 960 960 880 790 - -

- 570 810 810 810 810 810 810 810 810 810 810 - -

+ 760 1090 1090 1090 1090 1090 1090 1090 1090 1090 1090 - -

- 715 1020 1020 1020 1020 1020 1020 1020 1020 1020 1020 - -

+ 960 1380 1380 1380 1380 1380 1380 1380 1380 1380 1380 - -

- 715 1020 1020 1020 1020 1020 1020 1020 1020 1020 1020 - -

+ 960 1380 1380 1380 1380 1380 1380 1380 1380 1380 1380 - -

- 830 1190 1190 1190 1190 1190 1190 1190 1190 1190 1190 - -

+ 1140 1630 1630 1630 1630 1630 1630 1630 1630 1630 1630 - -

- 950 1360 1360 1360 1360 1360 1360 1360 1360 1360 1360 - -

+ 1290 1840 1840 1840 1840 1840 1840 1840 1840 1840 1840 - -

- 1200 1700 1700 1700 1700 1700 1700 1700 1700 1700 1700 1700 -

+ 1550 2220 2220 2220 2220 2220 2220 2220 2220 2220 2220 2220 -

- 1300 1870 1870 1870 1870 1870 1870 1870 1870 1870 1870 1870 -

+ 1625 2330 2330 2330 2330 2330 2330 2330 2330 2330 2330 2330 -

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20

Available External Static Pressure (in. wc. Wet coil and fi lter included

13 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 14

Engineering Submittal Sheet

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Horizontal Cabinet Corner Weights

Confi guration Left Hand Evaporator Right Hand Evaporator

Model Unit Total Left Front* Right Front* Left Back Right Back Left Front* Right Front* Left Back Right Back

SV 007

SV 009

SV 012

SV 015

SV 018

SV 024

SV 030

SV 036

SV 042

SV 048

SV 060

SV 070

Lbs 98 28 21 25 24 21 28 24 25

kg 45 13 10 11 11 10 13 11 11

Lbs 103 29 23 26 25 23 29 25 26

kg 47 13 10 12 11 10 13 11 12

Lbs 105 29 24 26 26 24 29 26 26

kg 48 13 11 12 12 11 13 12 12

Lbs 127 36 28 34 29 28 36 29 34

kg 58 16 13 15 13 13 16 13 15

Lbs 177 57 36 48 37 36 57 37 48

kg 80 26 16 22 17 16 26 17 22

Lbs 181 58 37 48 38 37 58 38 48

kg 82 26 17 22 17 17 26 17 22

Lbs 194 61 41 52 41 41 61 41 52

kg 88 28 18 23 19 18 28 19 23

Lbs 237 71 49 66 52 49 71 52 66

kg 108 32 22 30 24 22 32 24 30

Lbs 231 70 47 64 50 47 70 50 64

kg 105 32 21 29 23 21 32 23 29

Lbs 268 87 60 62 60 60 87 60 62

kg 122 39 27 28 27 27 39 27 28

Lbs 288 88 65 69 66 65 88 66 69

kg 131 40 29 31 30 29 40 30 31

Lbs 316 98 72 76 70 72 98 70 76

kg 143 44 32 35 32 32 44 32 35

14 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 15

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

Vertical Unit Confi gurations

Condensate

Drain

Engineering Submittal Sheet

Access

Panels

Condenser

Water Out

Condenser

Water In

Condensate

Drain

Horizontal Unit Confi gurations

Front

Straight Through FLS

Left Hand Return

Top Discharge FLT

End Blow FLE

Electrical

Connections

Condensate

Drain

Return Air RightReturn Air Left

End Blow FRE

Right Hand Return

Top Discharge FRT

Front

Straight Through FRS

15 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

BTC 760208301 E | 10.2015

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 16

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV Vertical Unit Dimensions and Connections

0x20x1

Recommended

Nominal Filter Size

Standard Replacement

Water

Condenser

Connections

Filter

Rack

Engineering Submittal Sheet

R/A Duct

Flg Height

R/A Duct

Flg Width

Drain

Condensate

Water

Outlet

Intlet

Water

Left side to

Discharge

to Discharge

Cabinet edge

Width

Discharge

Depth

Discharge

Right Hand Return (FRT) Return Air (Filter) View

F

Electrical

Connections

Condenser

Water In

ABCDE FGH JKMNPQ

Width Depth Height

SV007 19 19 24.25 10 8 4.5 9.5 2.44 9.68 13.87 16 8 10 5.6 3/4" F.P.T. 10x 16x1

SV009 19 19 24.25 10 8 4.5 9.5 2.44 9.68 13.87 16 8 10 5.6 3/4" F.P.T. 10x16x1

SV012 19 19 24.25 10 8 4.5 9.5 2.44 9.68 13.87 16 8 10 5.6 3/4" F. P.T. 10x16x1

MODEL

16 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

SV015 21.5 21.5 32.25 10 8 5.75 12.1 2.85 8. 45 15.87 20 14 16 8.1 3/4" F.P.T. 16x 20x1

SV030 21.5 21.5 39.25 14 14 3.6 4.8 2.8 14.95 18.87 20 18 20 4.8 3/4" F.P.T. 20x20x1

SV036 21.5 26 43.25 15.5 14 6. 5 4.2 2.75 10.77 18.87 24 22 24 4.2 3/4" F.P.T. 24x 24x1

SV041 21.5 21.5 39.25 15. 5 14 2 4.2 2.8 14.95 18.87 20 18 20 4.2 3/4" F.P.T. 20x 20x1

SV018 21.5 21.5 32.25 14 14 3.6 4.8 2.85 8.45 15.87 20 14 16 4.8 3/4" F. P.T. 16x20x1

SV024 21.5 21.5 39.25 14 14 3.6 4.8 2.8 14.95 18.87 20 18 20 4.8 3/4" F.P.T. 2

SV042 21.5 26 43.25 15.5 14 6.5 4.2 2.75 10.77 18.87 24 22 24 4.2 3/4" F.P.T. 24x24x1

BTC 760208301 E | 10.2015

070 26 33. 25 58.25 18 15.5 10.8 7 2.92 13.36 25.87 30 30 32 7 1" F.P.T. 16x 30x1 (2)

SV048 24 32.5 45. 25 18 14 10 6 3.26 13.2 20.87 30 22 24 6 1" F.P.T. 24x30x1

SV060 24 32.5 45.25 18 14 10 6 3.26 13.2 20.87 30 22 24 6 1" F.P.T. 24x30x1

SV

Left Hand Return (FLT)

Condensate

Drain

Condenser

Water Out

NOTE: All dimensions within +– 0.125". All condensate drain connections are 3/4" FPT. Specications subject to change without notice.

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 17

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV Horizontal Unit Dimensions and Connections

Recommended

Nominal Filter Size

Standard Replacement

Water

Condenser

Connections

R/A Duct

Flg Height

R/A Duct

Flg Width

Top to

(FRE & FLS)

Discharge

)

End to

Straight

(

Discharge

Engineering Submittal Sheet

Left Hand Return

Straight Through

(FLS)

Right Hand Return Straight Through (FRS)

Height

Discharge

Top to

Discharge

Width

Discharge

Side to

Discharge

Outlet

Water

Intlet

Water

Front to

Cabinet

R/A Duct

Flg Width

End to

Cabinet

ABCDEFGH JKMNPQRT

(FLE & FRS)

(End)

Filter Rack

.5 34.6 18.4 2.86 18.13 7.5 10 7.7 10.86 7 2.4 33 19 1" F.P.T. 20x34.5x1

Filter Rack

Width Depth Height

SV007 19 33 11.5 1.5 16.15 15.35 2.38 9.625 5.13 5.8125 6.22 3.6 5.13 1.66 14.5 8.6 3/4" F.P. T. 10x16x 1

SV009 19 33 11.5 1.5 16.15 15.35 2.38 9.625 5.13 5.8125 6.22 3.6 5.13 1.66 14.5 8.6 3/4" F.P.T. 10x16x1

MODEL

17 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

SV012 19 33 11.5 1.5 16.15 15.35 2.38 9.625 5.13 5.8125 6.22 3.6 5.13 1.66 14.5 8.6 3/4" F.P.T. 10x16x1

SV024 22 43 17 1.5 25.15 16.35 2.86 14.13 5.7 8.6 6.36 9.15 5.2 1.5 23.5 15 3/4" F.P.T. 16x25x1

SV030 22 43 17 1.5 25.15 16.35 2.86 14.13 5.7 8.6 6.36 9.15 5.2 1.5 23.5 15 3/4" F.P.T. 16x25x1

SV036 22 54.5 19 1.5 30 23 2.85 16.13 6.9 8.63 7.75 9.8 6.4 1.46 28.5 17 3/4" F.P.T. 18x30x1

SV015 22 43 17 1.5 20.15 21.35 2.86 15.38 6.9 5.95 9.8 3.6 6.4 3.64 18.5 15 3/4" F.P.T. 16x20x1

SV018 22 43 17 1.5 20.15 21.35 2.86 15.38 5.7 8.6 6.36 9.15 5.2 1.5 18.5 15 3/4" F.P.T. 16x20x1

SV041 N/A N/A N/A N/ A N/ A N/A N/A N/ A N/ A N/A N/A N/ A N/A N/A N/A N/ A N/A N/A

BTC 760208301 E | 10.2015

SV060 25 54.5 21 1.5 34.6 18.4 2.86 18.13 7.5 10 7.7 10.86 7 2.4 33 19 1" F.P.T. 20x34.5x1

SV042 22 54.5 19 1.5 30 23 2.85 16.13 6.9 8.63 7.75 9.8 6.4 1.46 28.5 17 3/4" F.P.T. 18x30x1

SV070 25 65 21 1.5 48.1 15.4 2.86 18.13 6.5 11.26 7 12 6 1.93 46. 5 19 1" F.P.T. 20x24x1 (2)

SV048 25 54.5 21 1

Left Hand Return

End Blow (FLE)

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Right Hand Return End Blow (FLE)

NOTE: All dimensions within +– 0.125". All condensate drain connections are 3/4" FPT. Specications subject to change without notice.

Page 18

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV Counterfl ow Unit Dimensions and Connections

Size

Replacement

Nominal Filter

Water

Connections

Filter

Rack

Height

Flg

R/A

Duct

Height

Engineering Submittal Sheet

R/A

Duct

Drain

Water

Water

A B C D E F G H J K M N P Q

Width Depth Height

Flg

Width

in

out

SV015 21.5 21.5 32.25 4.1 6.4 8.7 7.6 6.7 12.3 1.0 20.0 14.0 16.0 7.6 3/4" F.P.T. 16x20x1

SV018 21.5 21.5 32.25 9.7 9.0 5.9 6.8 6.7 12.3 1.0 20.0 14.0 16.0 6.7 3/4" F.P.T. 16x20x1

SV024 21.5 21.5 39.25 9.7 9.0 5.9 6.8 3.2 15.4 1.0 20.0 18.0 20.0 6.7 3/4" F.P.T. 20x20x1

SV030 21.5 21.5 39.25 9.7 9.0 5.9 6.8 3.2 15.4 1.0 20.0 18.0 20.0 6.7 3/4" F.P.T. 20x20x1

SV042 21.5 26 43.25 11.3 10.5 7.4 5.9 7.4 15.4 1.0 24.0 22.0 24.0 5.9 3/4" F.P.T. 24x24x1

SV048 24 32.5 45.25 11.4 10.5 10.5 6.7 7.0 17.0 1.0 30.0 22.0 24.0 6.7 1" F.P.T. 24x30x1

SV060 24 32.5 45.25 12.5 11.7 10.0 6.1 7.0 17.0 1.0 30.0 22.0 24.0 6.1 1" F.P.T. 24x30x1

MODEL

18 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

SV036 21.5 26 43.25 10.3 9.2 7.8 6.2 7.4 15.4 1.0 24.0 22.0 24.0 6.2 3/4" F.P.T. 24x24x1

BTC 760208301 E | 10.2015

SV070 26 33.25 58.25 12.5 11.7 10.3 7.2 11.8 22.3 1.0 30.0 30.0 32.0 7.1 1" F.P.T. 16x30x1 (2)

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 19

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV007 (300 CFM) Capacity Data

Entering

Fluid Temp

(F)

50

60

70

80

85

90

100

110

Water Flow

(GPM)

Pressure

Drop PSI

(FOH)

1 0.3 (0.6)

2 1.2 (2.77)

3 2.5 (5.77)

1 0.3 (0.6)

2 1.2 (2.77)

3 2.4 (5.54)

1 0.3 (0.6)

2 1.1 (2.54)

3 2.3 (5.31)

1 0.3 (0.6)

2 1.1 (2.54)

3 2.3 (5.31)

1 0.3 (0.6)

2 1.1 (2.54)

3 2.2 (5.07)

1 0.3 (0.6)

2 1.1 (2.54)

3 2.2 (5.07)

1 0.3 (0.6)

2 1 (2.31)

3 2.1 (4.84)

1 0.3 (0.6)

2 1 (2.31)

3 2.1 (4.84)

Entering Air

Temp (db/

19 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

COOLING HEATING

Total

wb) F

75/63 7.0 6.3 8.3 0.42 16.9

80/67 7.5 6.5 8.8 0.42 18.1 70 4.4 3.0 0.45 2.8

85/71 7.9 6.7 9.2 0.42 19.0 80 4.3 2.8 0.48 2.6

75/63 7.5 6.5 8.6 0.37 20.3 60 4.9 3.6 0.43 3.3

80/67 8.0 6.7 9.1 0.37 21.9 70 4.8 3.4 0.46 3.0

85/71 8.5 6.9 9.7 0.36 23.5 80 4.6 3.1 0.49 2.7

75/63 7.6 6.5 8.8 0.35 21.6 60 5.1 3.8 0.43 3.4

80/67 8.1 6.8 9.3 0.35 23.4 70 5.0 3.5 0.46 3.2

85/71 8.7 7.0 9.8 0.34 25.5 80 4.8 3.2 0.49 2.8

75/63 6.6 6.1 8.0 0.45 14.6

80/67 7.1 6.3 8.5 0.46 15.7 70 5.1 3.7 0.46 3.2

85/71 7.5 6.6 8.9 0.46 16.5 80 5.0 3.4 0.50 2.9

75/63 7.1 6.3 8.3 0.41 17.4 60 5.8 4.4 0.44 3.9

80/67 7.5 6.5 8.8 0.41 18.4 70 5.6 4.1 0.47 3.5

85/71 8.0 6.8 9.3 0.41 19.8 80 5.4 3.8 0.50 3.1

75/63 7.2 6.4 8.5 0.40 18.3 60 6.0 4.6 0.44 4.0

80/67 7.7 6.6 9.0 0.39 19.8 70 5.8 4.3 0.47 3.6

85/71 8.2 6.8 9.5 0.39 21.3 80 5.6 4.0 0.51 3.2

75/63 6.2 6.0 7.7 0.49 12.7

80/67 6.7 6.2 8.2 0.50 13.6 70 5.9 4.4 0.47 3.6

85/71 7.1 6.5 8.6 0.50 14.3 80 5.7 4.1 0.51 3.3

75/63 6.6 6.1 8.0 0.45 14.7 60 6.7 5.3 0.44 4.4

80/67 7.1 6.4 8.5 0.45 15.8 70 6.5 4.9 0.48 4.0

85/71 7.6 6.6 9.0 0.45 17.0 80 6.3 4.6 0.52 3.6

75/63 6.8 6.2 8.1 0.44 15.6 60 6.9 5.5 0.44 4.5

80/67 7.3 6.4 8.6 0.44 16.8 70 6.7 5.2 0.48 4.1

85/71 7.8 6.7 9.1 0.43 18.1 80 6.5 4.8 0.52 3.7

75/63 5.9 5.6 7.4 0.53 11.2

80/67 6.3 6.1 7.8 0.54 11.8 70 6.7 5.2 0.48 4.1

85/71 6.7 6.3 8.3 0.54 12.5 80 6.5 4.9 0.52 3.7

75/63 6.2 6.0 7.7 0.50 12.6 60 7.6 6.2 0.45 5.0

80/67 6.7 6.2 8.2 0.50 13.6 70 7.4 5.8 0.49 4.4

85/71 7.1 6.5 8.6 0.50 14.4 80 7.1 5.4 0.53 3.9

75/63 6.4 6.0 7.8 0.48 13.4 60 7.9 6.5 0.45 5.2

80/67 6.8 6.3 8.3 0.48 14.2 70 7.7 6.1 0.49 4.6

85/71 7.3 6.5 8.7 0.48 15.3 80 7.4 5.7 0.53 4.1

75/63 5.7 5.5 7.3 0.55 10.4

80/67 6.1 5.8 7.7 0.56 11.0 70 7.6 6.0 0.49 4.6

85/71 6.4 6.3 8.1 0.56 11.5 80 7.4 5.6 0.53 4.1

75/63 6.0 5.7 7.6 0.52 11.7 60 8.6 7.2 0.45 5.6

80/67 6.4 6.1 8.0 0.52 12.4 70 8.3 6.8 0.49 4.9

85/71 6.9 6.4 8.4 0.52 13.4 80 8.1 6.3 0.53 4.4

75/63 6.1 5.9 7.6 0.50 12.2 60 9.0 7.6 0.45 5.9

80/67 6.6 6.2 8.1 0.50 13.2 70 8.7 7.1 0.49 5.2

85/71 7.0 6.4 8.6 0.50 14.0 80 8.4 6.6 0.53 4.6

75/63 5.5 5.4 7.1 0.57 9.7

80/67 5.9 5.7 7.5 0.58 10.3 70 8.4 6.9 0.49 5.0

85/71 6.2 6.0 8.0 0.58 10.7 80 8.2 6.5 0.53 4.5

75/63 5.8 5.6 7.4 0.54 10.8 60 9.6 8.2 0.45 6.3

80/67 6.2 6.0 7.8 0.54 11.6 70 9.3 7.7 0.49 5.5

85/71 6.6 6.3 8.3 0.54 12.3 80 9.0 7.3 0.54 4.9

75/63 5.9 5.7 7.5 0.53 11.3 60 10.0 8.6 0.45 6.5

80/67 6.3 6.1 7.9 0.53 12.0 70 9.7 8.1 0.49 5.8

85/71 6.8 6.4 8.4 0.53 13.0 80 9.3 7.6 0.54 5.0

75/63 5.1 5.1 6.9 0.62 8.4

80/67 5.4 5.4 7.2 0.62 8.8

85/71 5.8 5.8 7.6 0.63 9.3

75/63 5.4 5.4 7.1 0.58 9.3

80/67 5.8 5.7 7.5 0.59 10.0

85/71 6.2 5.9 7.9 0.59 10.6

75/63 5.5 5.4 7.1 0.57 9.7

80/67 5.9 5.7 7.6 0.58 10.3

85/71 6.3 6.0 8.0 0.58 11.0

75/63 4.7 4.7 6.6 0.66 7.2

80/67 5.0 5.0 7.0 0.67 7.5

85/71 5.4 5.4 7.3 0.68 8.0

75/63 5.0 5.0 6.8 0.63 8.0

80/67 5.3 5.3 7.2 0.64 8.4

85/71 5.7 5.7 7.6 0.64 9.0

75/63 5.1 5.1 6.8 0.62 8.3

80/67 5.4 5.4 7.2 0.62 8.7

85/71 5.8 5.8 7.6 0.63 9.3

Capacity

(MBTUH)

Sensible

Capacity

(MBTUH)

Heat of

Rejection

(MBTUH)

BTC 760208301 E | 10.2015

Engineering Submittal Sheet

Power Input

(kW)

EER

Entering

Fluid Temp

(F)

30

*

40

*

50

60

70

80

Extended Range - Anti-freeze required

*

AHRI/ISO13256-1 certified per formance is rated at entering air conditions of 80.6°F

DB and 66.2°F WB in cooling and 68°F DB in heating.

Tabulated unit performance does not include fan or pump power corrections required

for AHRI/ISO standard performance ratings.

Unit performance may be interpolated. Extrapolation is not allowed.

For conditions other than rating conditions provided, consult the FHP BST selection

software.

Ratings below 40°F are with a methanol solution.

The results reported herein are estimates based on testing by FHP. Variations in the

installation and operational environment may alter performance. Bosch disclaims all

warranties, express and implied, that the performance will be as reported, including

the warranty of merchantability and fitness for purpose. In addition, continuous

research and development may result in a change to an appliances design and

specifications, which Bosch may change without notice. Before purchase, confirm the

design specifications of the appliance.

Continuous research and development to improve our products may result in a change

to the current design and specifications without notice.

Entering Air

Temp (F)

60 4.5 3.2 0.42 3.1

60 5.3 3.9 0.43 3.6

60 6.0 4.7 0.44 4.0

60 6.9 5.5 0.44 4.5

60 7.7 6.3 0.45 5.0

60 8.6 7.2 0.45 5.6

Total

Capacity

(MBTUH)

Heat of

Absorption

(MBTUH)

Power Input

(kW)

COP

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 20

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV009 (350 CFM) Capacity Data

Entering

Fluid Temp

(F)

50

60

70

80

85

90

100

110

Water Flow

(GPM)

Pressure

Drop PSI

(FOH)

1 0.5 (1.1)

2 1.8 (4.15)

3 3.8 (8.77)

1 0.5 (1.1)

2 1.8 (4.15)

3 3.6 (8.30)

1 0.5 (1.1)

2 1.7 (3.92)

3 3.5 (8.07)

1 0.5 (1.1)

2 1.6 (3.69)

3 3.4 (7.61)

1 0.5 (1.1)

2 1.6 (3.69)

3 3.3 (7.61)

1 0.5 (1.1)

2 1.6 (3.69)

3 3.3 (7.61)

1 0.4 (0.9)

2 1.5 (3.47)

3 3.2 (7.39)

1 0.4 (0.9)

2 1.5 (3.47)

3 3.1 (7.15)

Entering Air

Temp (db/

20 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

COOLING HEATING

Total

wb) F

75/63 9.1 7.7 10.6 0.52 17.6

80/67 9.6 8 11.2 0.52 18.6 70 5.7 3.9 0.58 2.9

85/71 10.2 8.2 11.8 0.52 19.8 80 5.6 3.7 0.63 2.6

75/63 9.6 8 11 0.44 21.6 60 6.4 4.7 0.55 3.4

80/67 10.3 8.2 11.7 0.44 23.6 70 6.3 4.4 0.59 3.1

85/71 10.9 8.5 12.3 0.43 25.4 80 6.1 4.1 0.64 2.8

75/63 9.8 8 11.1 0.42 23.5 60 6.7 5 0.55 3.6

80/67 10.5 8.3 11.8 0.41 25.7 70 6.5 4.6 0.6 3.2

85/71 11.2 8.6 12.5 0.4 28.2 80 6.4 4.3 0.64 2.9

75/63 8.6 7.5 10.4 0.57 15.1

80/67 9.2 7.8 10.9 0.57 16.1 70 6.7 4.8 0.6 3.3

85/71 9.7 8.1 11.5 0.57 16.9 80 6.5 4.5 0.65 2.9

75/63 9.2 7.8 10.7 0.5 18.3 60 7.5 5.7 0.56 3.9

80/67 9.8 8 11.3 0.5 19.7 70 7.3 5.4 0.61 3.5

85/71 10.4 8.3 11.9 0.49 21.2 80 7.1 5 0.66 3.2

75/63 9.4 7.8 10.8 0.48 19.7 60 7.8 6 0.57 4.1

80/67 10 8.1 11.5 0.47 21.2 70 7.6 5.6 0.61 3.6

85/71 10.6 8.4 12.1 0.46 22.9 80 7.4 5.2 0.67 3.3

75/63 8.2 7.2 10 0.62 13.1

80/67 8.7 7.6 10.6 0.63 13.8 70 7.6 5.7 0.61 3.6

85/71 9.3 7.9 11.2 0.63 14.7 80 7.5 5.3 0.67 3.3

75/63 8.7 7.5 10.4 0.56 15.5 60 8.6 6.8 0.57 4.4

80/67 9.3 7.9 11 0.56 16.6 70 8.4 6.4 0.62 4

85/71 9.9 8.1 11.6 0.56 17.8 80 8.2 6 0.68 3.6

75/63 8.9 7.6 10.5 0.54 16.5 60 9 7.2 0.57 4.6

80/67 9.5 7.9 11.1 0.53 17.8 70 8.7 6.7 0.63 4.1

85/71 10.1 8.2 11.8 0.53 19.1 80 8.5 6.3 0.68 3.7

75/63 7.7 7 9.7 0.68 11.3

80/67 8.2 7.3 10.3 0.69 11.9 70 8.6 6.6 0.63 4

85/71 8.7 7.5 10.8 0.69 12.6 80 8.5 6.2 0.68 3.7

75/63 8.2 7.2 10.1 0.62 13.2 60 9.8 8 0.58 5

80/67 8.8 7.6 10.6 0.62 14.1 70 9.5 7.5 0.63 4.4

85/71 9.3 7.9 11.2 0.62 15 80 9.3 7 0.69 3.9

75/63 8.4 7.2 10.2 0.6 14 60 10.2 8.4 0.58 5.2

80/67 9 7.7 10.8 0.6 15 70 9.9 7.8 0.64 4.6

85/71 9.6 8 11.4 0.6 16.1 80 9.6 7.3 0.7 4.1

75/63 7.5 6.9 9.6 0.71 10.6

80/67 8 7.2 10.1 0.72 11.2 70 9.6 7.6 0.63 4.4

85/71 8.5 7.4 10.7 0.72 11.8 80 9.4 7.2 0.69 4

75/63 8 7.1 9.9 0.65 12.2 60 11 9.2 0.58 5.6

80/67 8.5 7.3 10.5 0.65 13 70 10.7 8.6 0.64 4.9

85/71 9.1 7.8 11 0.65 13.9 80 10.4 8.1 0.7 4.3

75/63 8.1 7.1 10 0.63 12.8 60 11.6 9.7 0.58 5.9

80/67 8.7 7.4 10.6 0.63 13.7 70 11.1 9 0.64 5.1

85/71 9.3 7.9 11.2 0.63 14.8 80 10.8 8.5 0.71 4.5

75/63 7.3 6.7 9.4 0.74 9.9

80/67 7.8 7 10 0.75 10.4 70 10.7 8.6 0.64 4.9

85/71 8.2 7.3 10.5 0.75 10.9 80 10.4 8.2 0.7 4.3

75/63 7.7 7 9.7 0.68 11.2 60 12.3 10.5 0.58 6.2

80/67 8.2 7.3 10.3 0.69 11.9 70 11.8 9.8 0.65 5.4

85/71 8.8 7.5 10.8 0.69 12.8 80 11.5 9.3 0.71 4.7

75/63 7.8 7 9.8 0.67 11.7 60 12.9 11.1 0.58 6.5

80/67 8.4 7.3 10.4 0.67 12.6 70 12.3 10.2 0.65 5.6

85/71 9 7.8 11 0.66 13.6 80 12 9.8 0.72 4.9

75/63 6.8 6.5 9.1 0.8 8.5

80/67 7.2 6.8 9.6 0.81 8.9

85/71 7.7 7.1 10.1 0.82 9.4

75/63 7.2 6.7 9.4 0.75 9.6

80/67 7.7 7.1 9.9 0.75 10.2

85/71 8.2 7.3 10.5 0.75 10.9

75/63 7.3 6.8 9.5 0.73 10

80/67 7.9 7.1 10 0.73 10.8

85/71 8.4 7.3 10.6 0.73 11.4

75/63 6.3 6.3 8.8 0.86 7.3

80/67 6.7 6.6 9.3 0.87 7.7

85/71 7.2 6.9 9.8 0.88 8.1

75/63 6.7 6.5 9 0.82 8.2

80/67 7.1 6.8 9.6 0.82 8.6

85/71 7.6 7.1 10.1 0.83 9.2

75/63 6.8 6.6 9.1 0.8 8.5

80/67 7.3 6.9 9.6 0.8 9.1

85/71 7.8 7.2 10.2 0.81 9.7

Capacity

(MBTUH)

Sensible

Capacity

(MBTUH)

Heat of

Rejection

(MBTUH)

BTC 760208301 E | 10.2015

Engineering Submittal Sheet

Power Input

(kW)

EER

Entering

Fluid Temp

(F)

30

*

40

*

50

60

70

80

Extended Range - Anti-freeze required

*

AHRI/ISO13256-1 certified per formance is rated at entering air conditions of 80.6°F

DB and 66.2°F WB in cooling and 68°F DB in heating.

Tabulated unit performance does not include fan or pump power corrections required

for AHRI/ISO standard performance ratings.

Unit performance may be interpolated. Extrapolation is not allowed.

For conditions other than rating conditions provided, consult the FHP BST selection

software.

Ratings below 40°F are with a methanol solution.

The results reported herein are estimates based on testing by FHP. Variations in the

installation and operational environment may alter performance. Bosch disclaims all

warranties, express and implied, that the performance will be as reported, including

the warranty of merchantability and fitness for purpose. In addition, continuous

research and development may result in a change to an appliances design and

specifications, which Bosch may change without notice. Before purchase, confirm the

design specifications of the appliance.

Continuous research and development to improve our products may result in a change

to the current design and specifications without notice.

Entering Air

Temp (F)

60 5.8 4.2 0.54 3.1

60 6.8 5.1 0.55 3.6

60 7.7 6 0.57 4

60 8.8 7 0.57 4.5

60 9.8 8 0.58 5

60 10.9 9.1 0.58 5.5

Total

Capacity

(MBTUH)

Heat of

Absorption

(MBTUH)

Power Input

(kW)

COP

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 21

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV012 (400 CFM) Capacity Data

Entering

Fluid Temp

(F)

50

60

70

80

85

90

100

110

Water Flow

(GPM)

Pressure

Drop PSI

(FOH)

1.5 1.1 (2.54)

2.5 2.8 (6.46)

3.5 5.1 (11.7)

1.5 1.1 (2.54)

2.5 2.7 (6.23)

3.5 4.9 (11.2)

1.5 1 (2.3)

2.5 2.6 (5.9)

3.5 4.8 (11.0)

1.5 1 (2.3)

2.5 2.5 (5.7)

3.5 4.6 (10.6)

1.5 1 (2.3)

2.5 2.5 (5.7)

3.5 4.5 (10.3)

1.5 1 (2.3)

2.5 2.4 (5.5)

3.5 4.5 (9.9)

1.5 0.9 (2.0)

2.5 2.4 (5.5)

3.5 4.3 (9.9)

1.5 0.9 (2.0)

2.5 2.3 (5.3)

3.5 4.2 (9.6)

Entering Air

Temp (db/

21 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

COOLING HEATING

Total

wb) F

75/63 12.5 9.7 14.6 0.67 18.8

80/67 13.3 10 15.4 0.67 19.9 70 8 5.5 0.8 2.9

85/71 14.1 10.2 16.3 0.67 21 80 7.9 5.1 0.86 2.7

75/63 12.9 9.9 14.9 0.61 21.3 60 8.6 6.2 0.75 3.3

80/67 13.8 10.2 15.8 0.6 22.9 70 8.4 5.9 0.81 3

85/71 14.7 10.4 16.7 0.6 24.6 80 8.3 5.5 0.87 2.8

75/63 13.1 10 15 0.58 22.6 60 9 6.5 0.76 3.5

80/67 14 10.3 15.9 0.57 24.4 70 8.7 6.1 0.82 3.1

85/71 15 10.6 16.9 0.57 26.6 80 8.5 5.6 0.87 2.8

75/63 11.9 9.4 14.2 0.74 16.1

80/67 12.7 9.7 15 0.75 17.1 70 9.2 6.5 0.83 3.3

85/71 13.5 10 15.9 0.75 18 80 9 6.1 0.89 3

75/63 12.3 9.6 14.5 0.69 18 60 9.9 7.5 0.77 3.8

80/67 13.2 9.9 15.4 0.68 19.4 70 9.7 7 0.84 3.4

85/71 14.1 10.2 16.3 0.68 20.8 80 9.5 6.6 0.9 3.1

75/63 12.5 9.7 14.6 0.66 18.9 60 10.3 7.8 0.77 3.9

80/67 13.4 10 15.5 0.66 20.5 70 10 7.3 0.84 3.5

85/71 14.3 10.3 16.4 0.65 22 80 9.7 6.8 0.91 3.1

75/63 11.3 9.2 13.8 0.82 13.9

80/67 12 9.5 14.6 0.82 14.6 70 10.4 7.7 0.85 3.6

85/71 12.8 9.8 15.4 0.83 15.4 80 10.2 7.2 0.92 3.2

75/63 11.7 9.4 14.1 0.76 15.3 60 11.4 8.8 0.79 4.2

80/67 12.5 9.7 14.9 0.77 16.4 70 11.1 8.3 0.86 3.8

85/71 13.3 10 15.8 0.76 17.4 80 10.9 7.8 0.93 3.4

75/63 11.8 9.4 14.2 0.75 15.9 60 11.7 9.2 0.79 4.3

80/67 12.7 9.8 15.1 0.74 17.2 70 11.4 8.6 0.86 3.9

85/71 13.6 10 15.9 0.74 18.4 80 11.2 8.1 0.94 3.5

75/63 10.7 8.9 13.5 0.89 12

80/67 11.4 9.2 14.2 0.9 12.6 70 11.8 8.9 0.87 4

85/71 12.1 9.5 15 0.91 13.3 80 11.5 8.4 0.95 3.6

75/63 11.1 9.1 13.7 0.85 13.1 60 12.9 10.3 0.8 4.7

80/67 11.8 9.4 14.5 0.85 13.9 70 12.5 9.7 0.88 4.2

85/71 12.6 9.7 15.3 0.85 14.8 80 12.2 9.1 0.96 3.7

75/63 11.2 9.2 13.8 0.83 13.5 60 13.3 10.7 0.81 4.8

80/67 12 9.4 14.6 0.83 14.5 70 12.9 10.1 0.89 4.3

85/71 12.8 9.7 15.5 0.83 15.5 80 12.6 9.4 0.97 3.8

75/63 10.4 8.8 13.3 0.93 11.2

80/67 11.1 9.1 14 0.94 11.8 70 13.1 10.2 0.89 4.3

85/71 11.8 9.4 14.8 0.95 12.4 80 12.8 9.7 0.97 3.9

75/63 10.7 9 13.5 0.89 12.1 60 14.4 11.8 0.82 5.2

80/67 11.5 9.3 14.3 0.89 12.9 70 14 11.1 0.9 4.5

85/71 12.2 9.6 15.1 0.9 13.6 80 13.7 10.4 0.99 4.1

75/63 10.9 9 13.5 0.87 12.6 60 14.9 12.3 0.82 5.3

80/67 11.6 9.3 14.4 0.87 13.3 70 14.5 11.5 0.91 4.7

85/71 12.4 9.6 15.2 0.88 14.2 80 14.1 10.8 1 4.1

75/63 10.1 8.7 13.1 0.98 10.4

80/67 10.7 9 13.8 0.99 10.9 70 14.5 11.6 0.91 4.7

85/71 11.5 9.3 14.6 1 11.6 80 14.2 11 1 4.2

75/63 10.4 8.8 13.3 0.93 11.2 60 16 13.3 0.83 5.6

80/67 11.1 9.1 14.1 0.94 11.9 70 15.6 12.6 0.93 4.9

85/71 11.9 9.4 14.8 0.94 12.6 80 15.2 11.9 1.02 4.4

75/63 10.5 8.8 13.4 0.92 11.4 60 16.6 13.9 0.84 5.8

80/67 11.3 9.2 14.1 0.91 12.4 70 16.1 13.1 0.93 5.1

85/71 12.1 9.5 14.9 0.92 13.2 80 15.6 12.3 1.03 4.5

75/63 9.4 8.4 12.6 1.06 8.9

80/67 10.1 8.8 13.4 1.07 9.4

85/71 10.8 9 14.1 1.08 10

75/63 9.7 8.5 12.8 1.02 9.5

80/67 10.4 8.8 13.6 1.03 10.1

85/71 11.1 9.2 14.3 1.03 10.7

75/63 9.8 8.6 12.9 1.01 9.8

80/67 10.5 8.9 13.6 1.01 10.5

85/71 11.3 9.3 14.4 1.01 11.2

75/63 8.8 8.1 12.2 1.15 7.7

80/67 9.4 8.5 12.9 1.16 8.1

85/71 10 8.8 13.6 1.17 8.6

75/63 9 8.3 12.4 1.11 8.1

80/67 9.7 8.5 13.1 1.12 8.7

85/71 10.4 8.9 13.9 1.13 9.2

75/63 9.1 8.3 12.5 1.1 8.3

80/67 9.8 8.7 13.2 1.1 8.9

85/71 10.5 9 13.9 1.11 9.5

Capacity

(MBTUH)

Sensible

Capacity

(MBTUH)

Heat of

Rejection

(MBTUH)

BTC 760208301 E | 10.2015

Engineering Submittal Sheet

Power Input

(kW)

EER

Entering

Fluid Temp

Extended Range - Anti-freeze required

*

AHRI/ISO13256-1 certified per formance is rated at entering air conditions of 80.6°F

Tabulated unit performance does not include fan or pump power corrections required

Unit performance may be interpolated. Extrapolation is not allowed.

For conditions other than rating conditions provided, consult the FHP BST selection

Ratings below 40°F are with a methanol solution.

The results reported herein are estimates based on testing by FHP. Variations in the

Continuous research and development to improve our products may result in a change

Entering Air

Temp (F)

(F)

30

*

40

*

50

60

70

80

DB and 66.2°F WB in cooling and 68°F DB in heating.

for AHRI/ISO standard performance ratings.

software.

installation and operational environment may alter performance. Bosch disclaims all

warranties, express and implied, that the performance will be as reported, including

the warranty of merchantability and fitness for purpose. In addition, continuous

research and development may result in a change to an appliances design and

specifications, which Bosch may change without notice. Before purchase, confirm the

design specifications of the appliance.

to the current design and specifications without notice.

60 8.2 5.8 0.75 3.2

60 9.4 6.9 0.76 3.6

60 10.6 8.1 0.78 4

60 12 9.4 0.79 4.4

60 13.4 10.8 0.81 4.9

60 14.9 12.2 0.82 5.3

Total

Capacity

(MBTUH)

Heat of

Absorption

(MBTUH)

Power Input

(kW)

COP

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 22

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV015 (500 CFM) Capacity Data

Entering

Fluid Temp

(F)

50

60

70

80

85

90

100

110

Water Flow

(GPM)

Pressure

Drop PSI

(FOH)

2 2 (4.62)

3 4.2 (9.6)

4.5 8.6 (19.8)

2 1.9 (4.3)

3 4 (9.2)

4.5 8.3 (19.1)

2 1.9 (4.3)

3 3.9 (8.9)

4.5 8.1 (18.6)

2 1.8 (4.1)

3 3.8 (8.7)

4.5 7.8 (17.9)

2 1.8 (4.1)

3 3.7 (8.5)

4.5 7.7 (17.7)

2 1.8 (4.1)

3 3.6 (8.3)

4.5 7.6 (17.5)

2 1.7 (3.9)

3 3.5 (8.0)

4.5 7.3 (16.8)

2 1.7 (3.9)

3 3.4 (7.8)

4.5 7.1 (16.3)

Entering Air

Temp (db/

22 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

COOLING HEATING

Total

wb) F

75/63 15.2 11.5 17.7 0.77 19.8

80/67 16.3 11.9 18.7 0.76 21.5 70 9.9 6.7 1 2.9

85/71 17.3 12.3 19.8 0.75 23.2 80 9.9 6.2 1.08 2.7

75/63 15.6 11.7 17.9 0.71 21.9 60 10.5 7.5 0.94 3.3

80/67 16.7 12.1 19 0.7 24 70 10.3 7.1 1.01 3

85/71 17.9 12.5 20.1 0.68 26.4 80 10.3 6.5 1.09 2.8

75/63 15.9 11.9 18.1 0.67 23.6 60 10.8 7.8 0.94 3.4

80/67 17.1 12.3 19.2 0.65 26.2 70 10.6 7.3 1.02 3

85/71 18.3 12.7 20.4 0.63 29 80 10.6 6.7 1.1 2.8

75/63 14.5 11.2 17.3 0.86 16.8

80/67 15.5 11.6 18.3 0.86 18.1 70 11.3 8 1.04 3.2

85/71 16.6 12 19.3 0.85 19.6 80 11.1 7.5 1.12 2.9

75/63 14.9 11.4 17.5 0.81 18.4 60 12 9 0.96 3.6

80/67 16 11.8 18.6 0.8 20.1 70 11.8 8.4 1.05 3.3

85/71 17.1 12.2 19.6 0.78 21.9 80 11.6 7.9 1.13 3

75/63 15.2 11.5 17.7 0.77 19.6 60 12.5 9.4 0.97 3.8

80/67 16.3 11.9 18.7 0.76 21.5 70 12.2 8.8 1.06 3.4

85/71 17.4 12.3 19.8 0.74 23.6 80 12.1 8 1.14 3.1

75/63 13.8 11 16.8 0.96 14.4

80/67 14.8 11.3 17.8 0.96 15.5 70 13.2 9.3 1.07 3.6

85/71 15.8 11.7 18.8 0.95 16.6 80 12.7 8.7 1.16 3.2

75/63 14.2 11.1 17 0.91 15.6 60 13.7 10.7 0.99 4

80/67 15.2 11.5 18.1 0.9 16.9 70 13.4 10 1.08 3.7

85/71 16.3 11.9 19.1 0.89 18.3 80 13.1 9.3 1.17 3.3

75/63 14.4 11.2 17.2 0.88 16.4 60 14.2 11.1 1 4.2

80/67 15.5 11.6 18.2 0.86 18 70 13.9 10.3 1.08 3.8

85/71 16.6 12 19.3 0.85 19.6 80 13.5 9.7 1.17 3.4

75/63 13 10.6 16.4 1.06 12.3

80/67 14 11.1 17.3 1.06 13.2 70 14.5 11 1.09 3.9

85/71 14.9 11.4 18.3 1.06 14.1 80 14.1 10.3 1.18 3.5

75/63 13.4 10.7 16.6 1.01 13.2 60 15.8 12.2 1.01 4.6

80/67 14.4 11.2 17.5 1.01 14.3 70 15.4 11.4 1.1 4.1

85/71 15.4 11.6 18.6 1 15.4 80 14.8 10.9 1.19 3.6

75/63 13.6 10.9 16.7 0.98 13.8 60 16.4 12.7 1.01 4.7

80/67 14.6 11.2 17.7 0.97 15 70 16 11.8 1.11 4.2

85/71 15.7 11.7 18.7 0.96 16.3 80 15.3 11.3 1.2 3.7

75/63 12.7 10.4 16.1 1.11 11.4

80/67 13.6 10.9 17 1.11 12.2 70 16.5 12.4 1.11 4.4

85/71 14.5 11.3 18 1.11 13.1 80 16 11.7 1.21 3.9

75/63 13 10.6 16.3 1.07 12.2 60 17.7 14 1.02 5.1

80/67 13.9 11.1 17.3 1.06 13.1 70 17.5 13 1.12 4.6

85/71 15 11.4 18.3 1.05 14.2 80 17.1 12.1 1.22 4.1

75/63 13.2 10.7 16.4 1.04 12.7 60 18 14.8 1.02 5.2

80/67 14.2 11.1 17.4 1.03 13.8 70 17.9 13.6 1.13 4.7

85/71 15.2 11.5 18.5 1.02 14.9 80 17.4 12.7 1.23 4.2

75/63 12.3 10.3 15.9 1.16 10.6

80/67 13.2 10.7 16.8 1.16 11.3 70 18.2 14.1 1.13 4.7

85/71 14.1 11.1 17.8 1.16 12.1 80 18 13 1.23 4.3

75/63 12.6 10.4 16.1 1.12 11.3 60 19.6 15.9 1.03 5.6

80/67 13.5 10.9 17 1.12 12.1 70 19.1 15 1.14 4.9

85/71 14.5 11.3 18 1.11 13.1 80 18.9 13.9 1.24 4.5

75/63 12.8 10.6 16.2 1.09 11.7 60 20.4 16.5 1.03 5.8

80/67 13.8 10.9 17.2 1.09 12.7 70 19.8 15.6 1.14 5.1

85/71 14.8 11.4 18.2 1.08 13.8 80 19.5 14.4 1.25 4.6

75/63 11.5 9.9 15.4 1.27 9.1

80/67 12.3 10.4 16.3 1.27 9.7

85/71 13.2 10.8 17.2 1.27 10.4

75/63 11.8 10 15.6 1.23 9.6

80/67 12.7 10.5 16.5 1.23 10.4

85/71 13.6 10.9 17.5 1.23 11.1

75/63 12 10.1 15.7 1.21 9.9

80/67 12.9 10.6 16.6 1.2 10.8

85/71 13.9 11 17.6 1.2 11.6

75/63 10.7 9.6 15 1.38 7.8

80/67 11.5 10 15.8 1.38 8.3

85/71 12.4 10.4 16.7 1.39 8.9

75/63 11 9.7 15.1 1.34 8.2

80/67 11.8 10.2 16 1.34 8.8

85/71 12.7 10.6 16.9 1.34 9.5

75/63 11.1 9.8 15.2 1.32 8.4

80/67 12 10.3 16.1 1.32 9.1

85/71 12.9 10.7 17 1.31 9.8

Capacity

(MBTUH)

Sensible

Capacity

(MBTUH)

Heat of

Rejection

(MBTUH)

BTC 760208301 E | 10.2015

Engineering Submittal Sheet

Power Input

(kW)

EER

Entering

Fluid Temp

(F)

30

*

40

*

50

60

70

80

Extended Range - Anti-freeze required

*

AHRI/ISO13256-1 certified per formance is rated at entering air conditions of 80.6°F

DB and 66.2°F WB in cooling and 68°F DB in heating.

Tabulated unit performance does not include fan or pump power corrections required

for AHRI/ISO standard performance ratings.

Unit performance may be interpolated. Extrapolation is not allowed.

For conditions other than rating conditions provided, consult the FHP BST selection

software.

Ratings below 40°F are with a methanol solution.

The results reported herein are estimates based on testing by FHP. Variations in the

installation and operational environment may alter performance. Bosch disclaims all

warranties, express and implied, that the performance will be as reported, including

the warranty of merchantability and fitness for purpose. In addition, continuous

research and development may result in a change to an appliances design and

specifications, which Bosch may change without notice. Before purchase, confirm the

design specifications of the appliance.

Continuous research and development to improve our products may result in a change

to the current design and specifications without notice.

Entering Air

Temp (F)

60 10.1 7.1 0.93 3.2

60 11.6 8.5 0.96 3.6

60 13.2 9.9 0.98 3.9

60 14.8 11.6 1 4.3

60 16.5 13.4 1.02 4.8

60 18.4 14.9 1.03 5.3

Total

Capacity

(MBTUH)

Heat of

Absorption

(MBTUH)

Power Input

(kW)

COP

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 23

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV018 (650 CFM) Capacity Data

Entering

Fluid Temp

(F)

50

60

70

80

85

90

100

110

Water Flow

(GPM)

Pressure

Drop PSI

(FOH)

2.5 1.2 (2.7)

4 2.9 (6.6)

5 4.3 (9.9)

2.5 1.2 (2.7)

4 2.8 (6.4)

5 4.1 (9.4)

2.5 1.1 (2.54)

4 2.7 (6.2)

5 4 (9.2)

2.5 1.1 (2.54)

4 2.6 (5.9)

5 3.9 (8.9)

2.5 1.1 (2.54)

4 2.6 (5.9)

5 3.8 (8.7)

2.5 1.1 (2.54)

4 2.5 (5.7)

5 3.8 (8.7)

2.5 1 (2.3)

4 2.4 (5.5)

5 3.6 (8.3)

2.5 1 (2.3)

4 2.4 (5.5)

5 3.5 (8.0)

Entering Air

Temp (db/

23 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

COOLING HEATING

Total

wb) F

75/63 22.3 15.9 26.1 1.24 18

80/67 24.1 16.5 27.9 1.25 19.3 70 11.6 8.3 1.15 3

85/71 25.9 17 29.8 1.26 20.6 80 10.9 7.5 1.18 2.7

75/63 23.5 16.3 27.1 1.15 20.4 60 13.1 9.8 1.14 3.4

80/67 25.4 16.9 29 1.15 22.1 70 12.3 8.9 1.18 3.1

85/71 27.4 17.4 31 1.15 23.9 80 11.6 8 1.21 2.8

75/63 23.9 16.5 27.4 1.12 21.3 60 13.4 10.1 1.15 3.4

80/67 25.8 17.1 29.4 1.12 23.1 70 12.6 9.2 1.19 3.1

85/71 27.9 17.6 31.4 1.11 25.3 80 11.8 8.2 1.22 2.8

75/63 21.1 15.3 25.1 1.33 15.9

80/67 22.8 15.9 26.9 1.34 17 70 14 10.3 1.24 3.3

85/71 24.5 16.4 28.7 1.36 18.1 80 13.3 9.5 1.28 3

75/63 22.2 15.8 26 1.25 17.8 60 15.8 12.1 1.22 3.8

80/67 24 16.4 27.9 1.26 19.1 70 15 11.2 1.27 3.5

85/71 25.9 16.9 29.8 1.26 20.6 80 14.2 10.2 1.31 3.2

75/63 22.6 16 26.3 1.22 18.5 60 16.2 12.5 1.23 3.8

80/67 24.5 16.5 28.2 1.22 20.1 70 15.3 11.5 1.28 3.5

85/71 26.4 17.1 30.3 1.22 21.7 80 14.5 10.5 1.33 3.2

75/63 19.8 14.8 24 1.42 14

80/67 21.4 15.3 25.7 1.44 14.9 70 16.8 12.4 1.32 3.7

85/71 23.1 15.7 27.6 1.46 15.9 80 15.8 11.6 1.38 3.4

75/63 20.8 15.2 24.9 1.35 15.5 60 18.9 14.5 1.3 4.3

80/67 22.6 15.8 26.7 1.36 16.7 70 18 13.4 1.36 3.9

85/71 24.5 16.2 28.7 1.37 17.9 80 17.1 12.3 1.42 3.5

75/63 21.2 15.4 25.2 1.32 16.1 60 19.1 15.2 1.31 4.3

80/67 23 16 27 1.33 17.3 70 18.5 13.8 1.37 3.9

85/71 24.9 16.4 29.1 1.33 18.7 80 17.5 12.6 1.43 3.6

75/63 18.5 14.1 22.9 1.5 12.4

80/67 20.1 14.6 24.6 1.53 13.2 70 19.5 14.8 1.4 4.1

85/71 21.6 15.3 26.2 1.55 13.9 80 18.4 13.9 1.47 3.7

75/63 19.5 14.5 23.7 1.44 13.6 60 21.6 17.5 1.37 4.6

80/67 21.1 15.1 25.5 1.46 14.5 70 20.9 16 1.45 4.2

85/71 22.9 15.6 27.4 1.47 15.6 80 19.9 14.7 1.52 3.8

75/63 19.8 14.7 24 1.42 14 60 22.1 18.1 1.39 4.7

80/67 21.5 15.3 25.8 1.43 15 70 21.5 16.4 1.46 4.3

85/71 23.4 15.8 27.7 1.44 16.2 80 20.4 15.1 1.53 3.9

75/63 17.8 13.8 22.3 1.54 11.6

80/67 19.3 14.5 23.9 1.57 12.3 70 22 17.5 1.49 4.3

85/71 20.8 15 25.6 1.6 13 80 21.1 16.3 1.56 3.9

75/63 18.8 14.2 23.1 1.49 12.7 60 25 20 1.44 5.1

80/67 20.3 14.9 24.8 1.51 13.5 70 23.9 18.6 1.53 4.6

85/71 22 15.5 26.6 1.53 14.4 80 22.8 17.2 1.61 4.1

75/63 19.1 14.3 23.4 1.47 13 60 25.3 21 1.46 5.1

80/67 20.8 14.9 25.2 1.49 14 70 24.5 19.1 1.54 4.6

85/71 22.5 15.5 27 1.5 15 80 23.4 17.7 1.63 4.2

75/63 17.1 13.6 21.7 1.58 10.8

80/67 18.6 14.2 23.3 1.62 11.5 70 24.8 20 1.56 4.7

85/71 20.1 14.7 25 1.65 12.2 80 23.8 18.7 1.65 4.2

75/63 18 13.8 22.5 1.53 11.8 60 28.1 22.9 1.5 5.5

80/67 19.6 14.6 24.1 1.56 12.6 70 26.9 21.4 1.6 4.9

85/71 21.2 15.1 25.9 1.58 13.5 80 25.5 20.1 1.7 4.4

75/63 18.3 14 22.7 1.51 12.1 60 28.5 24 1.52 5.5

80/67 19.9 14.6 24.5 1.53 13 70 27.6 21.9 1.62 5

85/71 21.6 15.3 26.3 1.55 13.9 80 25.9 20.7 1.71 4.4

75/63 15.6 13 20.3 1.65 9.5

80/67 17 13.6 21.9 1.7 10

85/71 18.5 14.1 23.6 1.74 10.7

75/63 16.5 13.3 21.1 1.61 10.2

80/67 18 14 22.8 1.65 10.9

85/71 19.6 14.5 24.5 1.68 11.7

75/63 16.8 13.5 21.4 1.6 10.5

80/67 18.3 14.1 23.1 1.63 11.3

85/71 20 14.6 24.9 1.66 12.1

75/63 14.1 12.3 18.9 1.72 8.2

80/67 15.4 12.9 20.4 1.77 8.7

85/71 16.7 13.7 21.9 1.81 9.2

75/63 14.9 12.6 19.6 1.69 8.8

80/67 16.4 13.2 21.3 1.73 9.5

85/71 17.8 13.9 23 1.77 10.1

75/63 15.1 12.8 19.8 1.68 9

80/67 16.7 13.3 21.6 1.72 9.7

85/71 18.2 14 23.3 1.75 10.4

Capacity

(MBTUH)

Sensible

Capacity

(MBTUH)

Heat of

Rejection

(MBTUH)

BTC 760208301 E | 10.2015

Engineering Submittal Sheet

Power Input

(kW)

EER

Entering

Fluid Temp

(F)

30

*

40

*

50

60

70

80

Extended Range - Anti-freeze required

*

AHRI/ISO13256-1 certified per formance is rated at entering air conditions of 80.6°F

DB and 66.2°F WB in cooling and 68°F DB in heating.

Tabulated unit performance does not include fan or pump power corrections required

for AHRI/ISO standard performance ratings.

Unit performance may be interpolated. Extrapolation is not allowed.

For conditions other than rating conditions provided, consult the FHP BST selection

software.

Ratings below 40°F are with a methanol solution.

The results reported herein are estimates based on testing by FHP. Variations in the

installation and operational environment may alter performance. Bosch disclaims all

warranties, express and implied, that the performance will be as reported, including

the warranty of merchantability and fitness for purpose. In addition, continuous

research and development may result in a change to an appliances design and

specifications, which Bosch may change without notice. Before purchase, confirm the

design specifications of the appliance.

Continuous research and development to improve our products may result in a change

to the current design and specifications without notice.

Entering Air

Temp (F)

60 12.3 9 1.11 3.2

60 14.7 11.2 1.19 3.6

60 17.6 13.4 1.26 4.1

60 20.3 15.9 1.33 4.5

60 23.2 18.4 1.4 4.8

60 26 21.1 1.46 5.2

Total

Capacity

(MBTUH)

Heat of

Absorption

(MBTUH)

Power Input

(kW)

COP

Bosch Thermotechnology Corp.

Londonderry, NH • Ft. Lauderdale, FL

Tel: 1-866-642-3198 Fax: 1-954-776-5529 www.boschheatingandcooling.com

Page 24

i Series Model SV

Water Source Heat Pump ½ to 6 Ton

SV024 (850 CFM) Capacity Data

Entering

Fluid Temp

(F)

50

60

70

80

85

90

100

110

Water Flow

(GPM)

Pressure

Drop PSI

(FOH)

3 1.8 (4.1)

5 4.5 (10.3)

7 8.2 (18.9)

3 1.7 (3.9)

5 4.3 (9.9)

7 7.9 (18.2)

3 1.7 (3.9)

5 4.2 (9.6)

7 7.7 (17.7)

3 1.6 (3.6)

5 4 (9.2)

7 7.4 (16.8)

3 1.6 (3.6)

5 4 (9.2)

7 7.3 (16.8)

3 1.6 (3.6)

5 3.9 (8.9)

7 7.2 (16.6)

3 1.5 (3.4)

5 3.8 (8.7)

7 7 (16.1)

3 1.5 (3.4)

5 3.7 (8.5)

7 6.8 (15.6)

Entering Air

Temp (db/

24 of 40

Bosch Thermotechnology Corp. reserves the right to make changes without notice due

to continuing engineering and technological advances |

COOLING HEATING

Total

wb) F

75/63 25.6 18.6 30 1.44 17.8

80/67 27.5 19.2 32 1.45 19 70 14.6 10.3 1.43 3

85/71 29.5 19.8 34 1.45 20.4 80 13.9 9.3 1.48 2.7