Bosch SV007, SV012, SV009, SV018, SV024 Installation, Operation And Maintenance Manual

...

Model SV - i Series Geothermal Heat Pump

SV007 Thru SV070

Installation, Operation and Maintenance Manual

Made in Florida

8 733 914 818 (2014/08)

2 | SV Heat PumpSeries

CONTENTS

Model Nomenclature.......................................................... 3

General Description........................................................... 4

Moving and Storage...........................................................4

Initial Inspection................................................................5

Location............................................................................ 5

Water Quality ....................................................................6

Installation........................................................................ 7

Duct Flanges ...............................................................7

Mounting Vertical Units................................................. 7

Mounting Horizontal Units .............................................7

Hanging Bracket Kit.......................................................8

Converting Horizontal Supply Air Configuration .................. 9

Condensate Connections ................................................... 9

Duct System...................................................................... 9

Piping .............................................................................10

Electrical - High Voltage ...................................................11

Models with Dual Power Supplies.................................11

460 V Models with Constant Air Flow Motors .................11

Transformer Settings for 208/230 V Units ....................11

Constant CFM ECM Blower Motor......................................30

Unit Start Up................................................................... 31

Maintenance................................................................... 31

Unit Check Out Sheet................................................. 32

Troubleshooting.............................................................. 33

Temperature/Pressure Table ........................................... 38

Waterside Pressure Drop Table........................................ 44

Water Coil Volume......................................................44

Compressor Characteristics ............................................ 45

Corner Weights (HZ) ....................................................... 46

Wiring Diagrams ............................................................. 47

Dimensional Drawings..................................................... 54

Vertical .................................................................... 54

Horizontal ................................................................ 55

Counter-Flow............................................................ 56

Notes ............................................................................. 57

Electrical - Low Voltage ....................................................11

Unit Controls - UPM ......................................................... 12

ECM Interface Board .................................................. 12

Airflow selector..........................................................13

Dehumidification Method Selector ............................... 13

Sequence of Operation............................................... 14

General ....................................................................15

Cooling and Heating Modes .........................................15

UPM Safety Features..................................................15

Options...........................................................................19

Extended Range Option ..............................................19

Unit Mounted Non-Fused Disconnect Switch.................. 19

Hot Gas Reheat.......................................................... 19

DDC Controls ............................................................19

Internal 2-Way Water Valve ......................................... 19

Application Considerations ..............................................20

Boiler/Cooling Tower Systems .....................................20

Geothermal Closed Loop Systems................................21

Certified Performance Table ............................................ 22

Fan Motor Options ...........................................................23

Permanent Split Capacitor Motors (PSC).......................23

Constant Torque Motors (ECM).................................... 24

Constant Airflow Motors (ECM).................................... 26

Standard Blower Motor ....................................................28

Constant torque ECM blower Motor....................................29

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

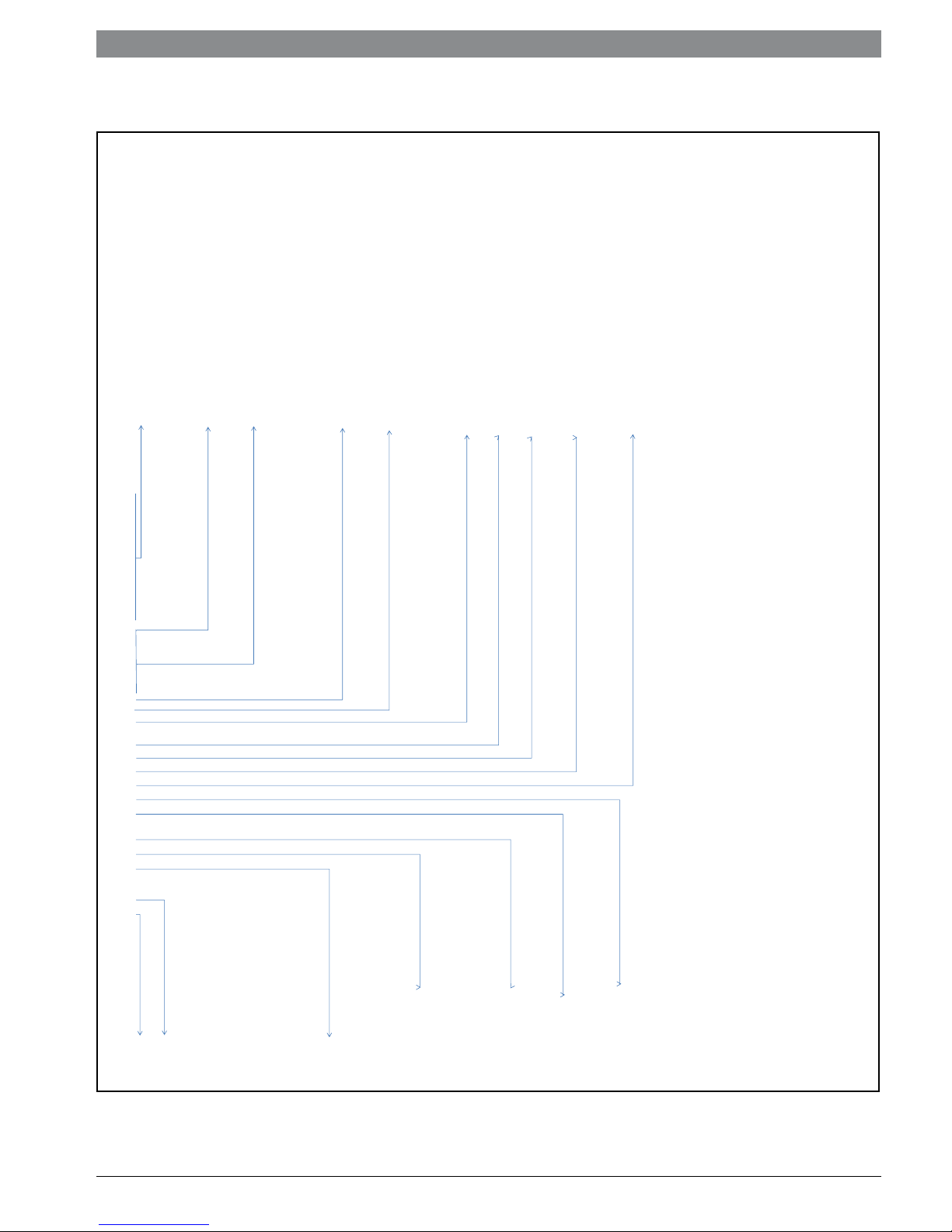

MODEL NOMENCLATURE

SV 018 - 1

VT

C - F L T P U A- XXSAMXXXX 5A X X

X

1XXX X

SV AIR FILTRATION

1 - STANDARD THROWAWAY FILTER w/

Size 2-SIDED FILTER RACK 1"

007

009

012

015

018

024

H - Hot Gas Reheat - On/Off

030 036

041

A - EMS relay

042

048

J - Disconnect Switch

060

N - Comfort Alert

07

T - Fault LED

X - As default for non used electrical codes

Voltage

1 208-230/60/1 Application

2 277/60/1 S - STANDARD RA NGE (Boiler/Tower)

3 208-230/60/3 G - EXTENDED RANGE (Geothermal)

4 460/60/3

Cabinet Construction

A - G90 Steel / 1/2" Standard 1.5LB Dual Density Fiberglass

C - G90 Steel / 1/2" Closed Cell Foam

Cabinet Configuration D - G90 Steel / 1/2" Standard 1.5LB

HZ - Horizontal Dual Density Fiberglass, Extra Quiet

VT - Vertical

F - G90 Steel / 1/2" Closed Cell Foam, Extra Quiet

CF - Downflow (Counterflow)

Electric Heat

X - None

Coax Options

A - Current

C - Copper

N - Cupro-Nickel

Air Coil

U - Uncoated

D - DuoGuard

Water Connections

F - Front Fan/Motor Options

P - Standard PSC

A - Constant Airflow ECM

T - Constant Torque ECM

Return Air Configuration

L - Left

R - Right

S - Straight

B - Bottom

4 - MERV 8 - 2" w/ 4-SIDED FILTER RACK

5 - MERV13 - 2" w/ 4-SIDED FILTER RACK

X - None

Refrigeration Circuit Options

E - Pump/valve relay

General Electrical Options (up to 5 available per unit)

Model Nomenclature | 3Revised 08/14

T - Top

Revision Level

E - End

Discharge Air Configuration

8 733 914 818 (2014/08)SV Heat Pump Series

4 | General Description SV Heat PumpSeries

SAFETY CONSIDERATIONS GENERAL DESCRIPTION

WARNING: Installation and servicing of this

equipment can be hazardous due to system

pressure and electrical components. Only

trained and qualified personnel should

install, repair, or service the equipment.

DANGER: Before performing service or

maintenance operations on the system, turn

off main power to the unit. Electrical shock

could cause personal injury or death.

CAUTION: When working on equipment,

always observe precautions described in

the literature, tags, and labels attached to

the unit. Follow all safety codes. Wear

safety glasses and work gloves. Use a

quenching cloth for brazing, and place a fire

extinguisher close to the work area.

NOTE: To avoid the release of refrigerant

into the atmosphere, the refrigerant circuit

of this unit must be serviced only by

technicians who meet local, state, and

federal proficiency requirements.

NOTE: All refrigerant discharged from this

unit must be recovered WITHOUT

EXCEPTION. Technicians must follow

industry accepted guidelines and all local,

state, and federal statutes for the recovery

and disposal of refrigerants. If a compressor

is removed from this unit, refrigerant circuit

oil will remain in the compressor. To avoid

leakage of compressor oil, refrigerant lines

of the compressor must be sealed after it is

removed.

The SV series water-to-air heat pump provides an

unmatched combination of performance, features

and flexibility for both high performance new

construction applications and replacement of

existing water-to-air heat pumps. All units are

certified by the Air conditioning, Heating and

Refrigeration Institute (AHRI) to AHRI/ANSI/

ASHRAE/ISO standard 13256-1 for water-to-air

and brine-to-air heat pumps at both Water Loop

Heat Pump and Ground Loop Heat Pump

application points.

All Water-to-Air Heat Pumps conform to UL 1995

standard and are certified to CAN/CSA C22.2 No

236 by Intertek-ETL.

These units meet all current applicable

requirements of ASHRAE 90.1.

SV series units are designed to operate with

entering fluid temperatures between 60°F and

100°F in cooling and 50°F and 80°F in heating with

the base configuration. With the extended range

option, SV series models can operate with entering

fluid temperatures between 50°F and 110°F in

cooling and between 20°F and 80°F in heating. SV

units can accommodate a wide range of air

temperatures, however, standard SV models

should not be used for 100% outside air without

consulting the factory applications group. 100%

outside air routinely requires higher levels of

dehumidification than is available from equipment

designed for return air applications.

SV series units are available in three basic

configurations: vertical top supply air (VT),

horizontal end supply air or straight through

supply air (HZ) and counter flow down supply air

(CF). Each of these configurations are available

with either left or right hand return air. HZ models

can have the supply air field converted from end

discharge air to straight through with no extra

parts required.

NOTE: To avoid equipment damage, DO

NOT use these units as a source of heating

or cooling during the construction process.

Doing so may affect the unit’s warranty. The

mechanical components and filters will

quickly become clogged with construction

dirt and debris, which may cause system

damage.

SV units are designed and rated for indoor

installation only. SV units should not be installed in

environments that fall below freezing or exceed

100°F ambient. SV cabinets are constructed of

heavy gauge G-90 galvanized steel and will resist

most common types of corrosion for the life of the

equipment.

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Moving and Storage | 5Revised 08/14

SV series units are offered with a wide range of

factory installed options including: PSC, constant

torque ECM or constant air flow ECM fan motors,

hot gas reheat, tin plated air coils, on board DDC

controls, copper or cupro nickel water coils and

more.

Some options are offered in limited sizes and/or

voltages.

On board safety features will protect the major

unit components from damage under most

foreseeable installation and operation problems.

MOVING AND STORAGE

If the equipment is not needed for immediate

installation upon arrival at the job site, it should be

left in its packaging and stored in a clean, dry area.

Units must be moved and stored in the normal

upright position at all times.

Use caution to avoid damage to filter racks and

duct flanges when storing or handling units.

NOTE: Never lift or move units by filter

racks, external piping or attached options/

accessories.

NOTE: Never stack units when

transporting them.

NOTE: When storing units:

Do not stack units larger than 6 tons

capacity!

Do not stack vertical or counter flow units

under 6 tons capacity more than 2 high

Do not stack horizontal units 6 tons capacity

more than 3 high

INITIAL INSPECTION

Be certain to inspect all cartons or crates on each

unit as received at the job site before signing the

freight bill. Verify that all items have been received

and that there is no visible damage. Note any

damage or shortage on all copies of the freight bill.

In the event of damage or a shortage it is the

responsibility of the purchaser to file the

necessary claims with the carrier. Concealed

damage not discovered until after removing the

units from packaging must be reported to the

carrier within 24 hours of receipt.

LOCATION

Locate the unit in an indoor area that allows easy

access to the filter, front access panel and blower

access panel, and has enough room for service

personnel to perform maintenance and repair

work. Provide sufficient room to make fluid,

electrical and duct work connections.

Locate the unit in conditioned space and avoid

installation in corrosive environments.

If the unit is installed in a confined space, such as

a closet, provisions must be made for return air to

freely enter the face of the unit’s air coil.

Unit condensate drains are not internally trapped.

Allow room below the unit base for horizontal and

counter flow models for an adequate condensate

trap.

NOTE: Do not locate the unit above supply

piping.

Do not locate the unit in areas subject to

freezing or in areas subject to temperature

or humidity extremes.

NOTE: SV series packaged units are not

approved for outdoor installation. Units

must be installed in conditioned space that

is not subject to extremes of temperature or

humidity to avoid cabinet sweating and/or

equipment damage.

NOTE: Do not use SV series units for

temporary heating, air conditioning or

ventilation during construction, especially

when plastering, sanding or painting. Care

should be taken to avoid introduction of

dust, paint or debris into the air coil.

8 733 914 818 (2014/08)SV Heat Pump Series

6 | Water Quality Table SV Heat PumpSeries

WATER QUALITY TABLE

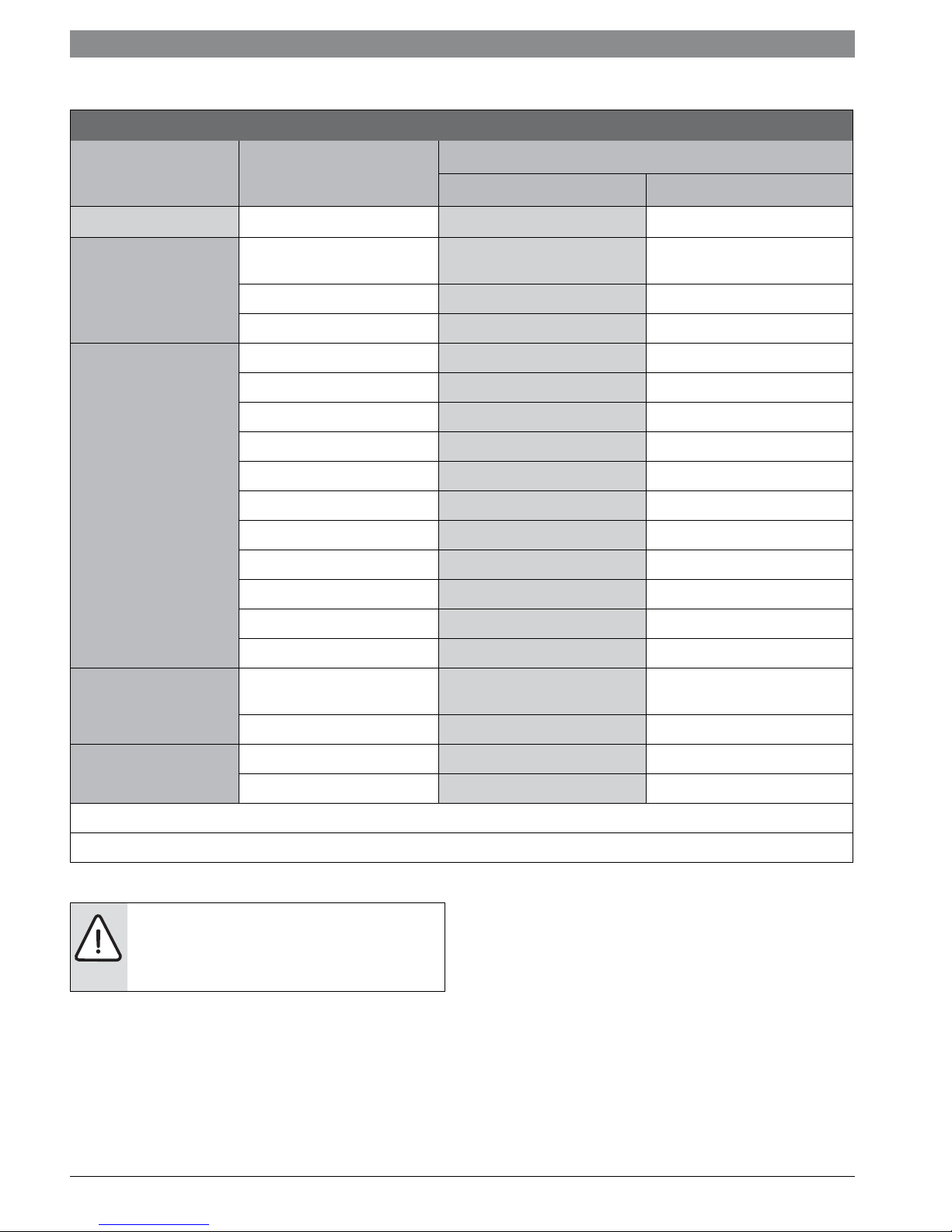

Table 1: Water Quality

POTENTIAL

PROBLEM

SCALING

CORROSION

Water Characteristic Acceptable Value

Copper Cupro-Nickel

pH (Acidity/Alkalinity) 7-9 7-9

Hardness (CaCO3,

MgCO3)

Ryznar Stability Index

Langelier Saturation Index -0.5 - +0.5 -0.5 - +0.5

Hydrogen Sulfide (H2S) < 0.5 ppm * 10-50 ppm

Sulfates

Chlorine

Chlorides

Carbon Dioxide

Ammonia

Ammonia Chloride

Ammonia Nitrate

Ammonia Hydroxide

< 350 ppm < 350 ppm

6.0 - 7.5 6.0 - 7.5

< 125 ppm < 125 ppm

< 0.5 ppm < 0.5 ppm

< 20 ppm < 150 ppm

< 50 ppm < 50 ppm

< 2 ppm < 2 ppm

< 0.5 ppm < 0.5 ppm

< 0.5 ppm < 0.5 ppm

< 0.5 ppm < 0.5 ppm

Ammonia Sulfate

Dissolved Solids

Iron (Fe2+ Iron Bacteria

IRON FOULING

EROSION

* No "rotten egg" smell present at < 0.5 ppm H2S.

** Equivalent to 30 mesh strainer

Potential)

Iron Oxide

Suspended Solids < 10 ppm, < 600 µm size ** < 10 ppm, < 600 µm size **

Maximum Water Velocity

WATER QUALITY

NOTE: Failure to insure proper water quality

and flow rates can shorten the life of the

heat pump and potentially void the unit

warranty.

Maintaining proper water quality is important for

insuring a long and trouble free service life for an

SV series heat pump.

< 0.5 ppm < 0.5 ppm

< 1,000 ppm < 1,500 ppm

< 0.2 ppm < 0.2 ppm

< 1 ppm < 1 ppm

6 ft/sec 6 ft/sec

For closed loop and boiler/tower systems water

chemistry can be checked and easily maintained to

insure that corrosive elements, dissolved oxygen

and pH levels are kept in check. It is important to

insure that any additive, antifreeze or corrosion

inhibitor that is added to the water loop is

compliant with all applicable laws and regulations

and is compatible with copper, brass and bronze

alloys. Insure that all recommended safety

precautions are followed when handling or adding

chemicals to the water loop.

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Installation | 7Revised 08/14

For open loop systems, water quality is very

important. Table #1 shows acceptable ranges for a

variety of water quality factors. The three main

concerns in open loop installations are scaling,

corrosion and fouling.

In installations with hard water, scaling due to a

buildup of carbonates on the heat exchanger wall

can gradually degrade the heat pump performance

over time. Heat pumps that are affected by scaling

may exhibit low suction pressures in heating and

high head pressures in cooling with a gradual loss

of capacity and efficiency. Scaled heat exchangers

can be cleaned by a qualified technician but care

should be taken to avoid scaling in the first place.

To limit scaling, water flow rates should be kept at

3 gallons/minute per nominal cooling ton (a 10°F

temperature rise in cooling) and care should be

taken to avoid air in the water lines from suction

side leaks. Cupro-nickel coils are generally

recommended.

In installations with high hydrogen sulfide, chlorine

or ammonia, corrosion is a potential problem. In

these installations a cupro-nickel heat exchanger is

recommended along with maintaining proper flow

and keeping air out of the system. If water quality

is outside of the values in Table #1, then a closed

loop is recommended.

Fouling due to iron bacteria can also pose

problems in some open loop installations. Iron

bacteria fouling can quickly degrade system

performance and plug heat exchangers.

Air in the water system will greatly accelerate the

fouling or corrosion process.

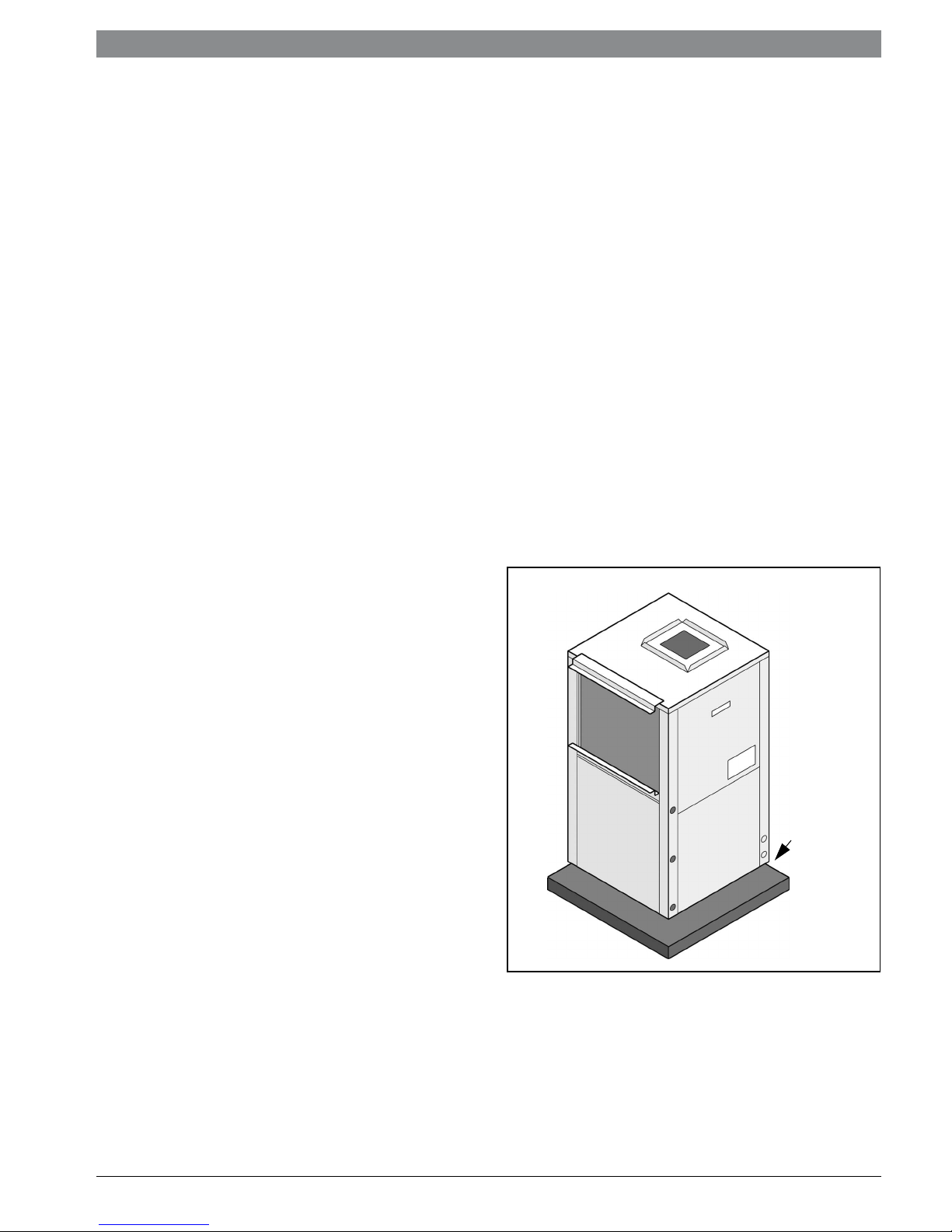

Mounting Vertical Units

SV Series vertical and counter flow units should be

mounted level on a vibration absorbing pad slightly

larger than the unit base in order to minimize

vibration transmission from the unit to the building

structure. See Figure #1. It is generally not

necessary to anchor the unit unless required by

local code.

All major service access for the SV Series vertical

and counter flow models is from the front side of

the unit. When installing the unit in a confined

space such as a closet, insure that the service

panel screws are accessible, that the filter can be

replaced without damage and that water and

electrical connections are accessible. For models

with a unit mounted disconnect switch, make sure

the switch can be easily seen and operated.

To reduce sound transmission, units should be

installed using flexible electrical conduit and hose

kits. Care should be taken to insure that no part of

the unit cabinet is touching part of the building

structure. For ducted return applications, a

flexible duct connection should be used. Refer to

Figure’s #14, #15 and #13.

INSTALLATION

The following are instructions to follow for

installation of all SV Series components.

Duct Flanges

SV heat pumps feature fold-out return and supply

air duct flanges. These fold-out flanges allow the

heat pumps to more easily fit through doorways

and other tight spaces, and also prevent damage in

shipping and handling.

It is recommended that all fold-out flanges be

folded-out once the heat pump is installed to

insure that return and supply air flow is not

obstructed. These flanges can be easily folded

using standard or duckbill pliers. Once folded out

these flanges can be used to support light duct

work loads.

Vibration

Mounting

Pad

Figure # 1 Mounting Vertical Units

Mounting Horizontal Units

While horizontal units may be installed on any level

surface strong enough to hold their weight, they

are typically suspended above a ceiling by

threaded rods. The rods are usually attached to the

unit corners by hanger bracket kits (P/N 930-008).

8 733 914 818 (2014/08)SV Heat Pump Series

8 | Hanging Bracket Kit SV Heat PumpSeries

Units larger than six tons include an integral

angle iron frame with mounting holes present.

(See unit horizontal detail drawing).

Horizontal units installed above the ceiling must

conform to all local codes. An auxiliary drain pan if

required by code, should be at least four inches

larger than the bottom of the heat pump.

Plumbing connected to the heat pump must not

come in direct contact with joists, trusses, walls,

etc. Some applications require an attic floor

installation of the horizontal unit. In this case the

unit should be set in a full size secondary drain pan

on top of a vibration absorbing mesh.

The secondary drain pan prevents possible

condensate overflow or water leakage damage to

the ceiling. The secondary drain pan is usually

placed on a plywood base isolated from the ceiling

joists by additional layers of vibration absorbing

mesh. In both cases, a 3/4" drain connected to this

secondary pan should be run to an eave at a

location that will be noticeable.

NOTE: If the unit is located in a crawl space,

the bottom of the unit must be at least 4"

above grade to prevent flooding of the

electrical parts due to heavy rains.

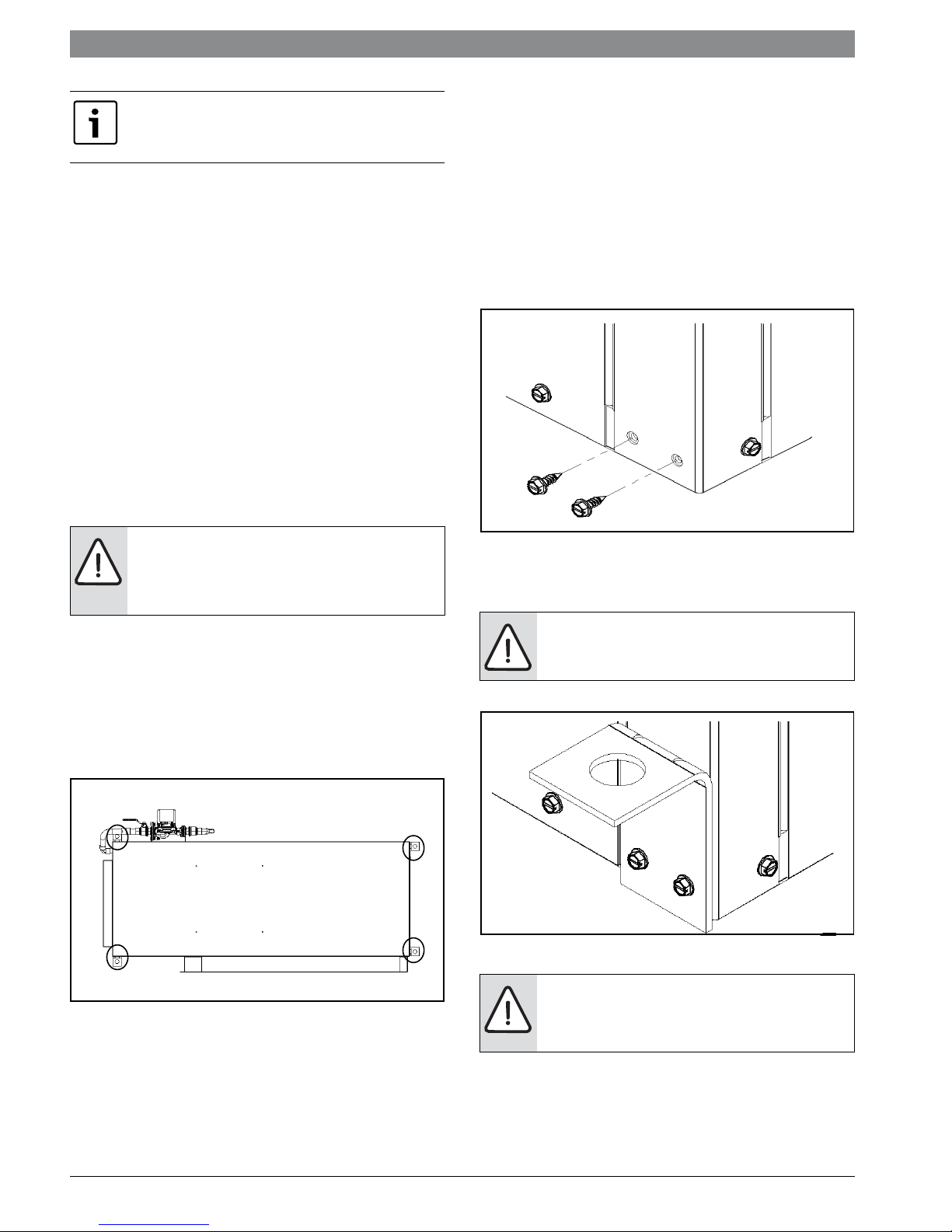

HANGING BRACKET KIT

Installation Instructions

All horizontal units come with Hanging Bracket kit

to facilitate suspended unit mounting using

threaded rod. Hanging Brackets are to be installed

as shown in figure # 2

(10) Bolts 1/4-28x1/2” Hex Bolt ( not used on this

model)

The following are needed and are to be field

provided:

Threaded rod (3/8” max dia)

Hex Nuts

Washers (1-3/4” min O.D.)

1. Remove and discard factory provided screws

from location where Hanging Brackets will be

installed shown in Figure#3

Figure # 3

2. Mount 5 brackets to unit corner post using the

bolts provided in the kit as shown on Figure # 4

WARNING: Do not re-use screws removed

from the unit on step 1 to mount the

hanging Brackets to the unit.

Figure # 2

This kit includes the following:

(5) Brackets.

(5) Rubber Vibrators Isolators.

(8) Screws # 10x1/2”

Figure # 4

WARNING: Follow all applicable codes

requirements when hanging this unit.

Selecting threaded rod material, etc.

3. Install Rubber Grommet on the Bracket as

shown in Figure#5

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Converting Horizontal Supply Air Configuration | 9Revised 08/14

4. Hang the unit and assemble the field provided

Thread Rod, Nuts and washers on to the Brackets

as shown in Figure#5

CAUTION: Rods must be securely anchored

to the ceiling.

CONVERTING HORIZONTAL SUPPLY AIR

CONFIGURATION

The supply air location on SV Series Horizontal

units can be quickly field converted from end blow

to straight through or vice-versa. To convert the

supply air direction, follow the steps below:

1. If connected to power, shut off the unit and

disconnect switch or circuit breaker.

2. Unscrew and remove the blower access panel.

3. Disconnect the wires from the unit electrical

box to the blower motor. Note which speed

taps are wired for units with PSC or constant

torque motors.

4. Unscrew and carefully remove the blower

panel with the blower and motor attached. Be

careful not to damage the refrigerant coils or

any other internal unit components.

5. Remove the blower support brackets from the

bottom of the blower housing and relocate

them to the top of the blower housing.

6. Turn the blower panel 180° so that the blower

support brackets are now at the bottom of the

blower.

7. Insert the blower panel with the blower and

motor into the desired location. Be careful not

to damage the refrigerant coils or any other

internal unit components. Screw the panel into

place.

8. Replace the wires between the blower motor

and electrical box. Make sure to connect wires

to the proper speed taps.

9. Replace the blower access panel.

10. Reconnect power to the unit.

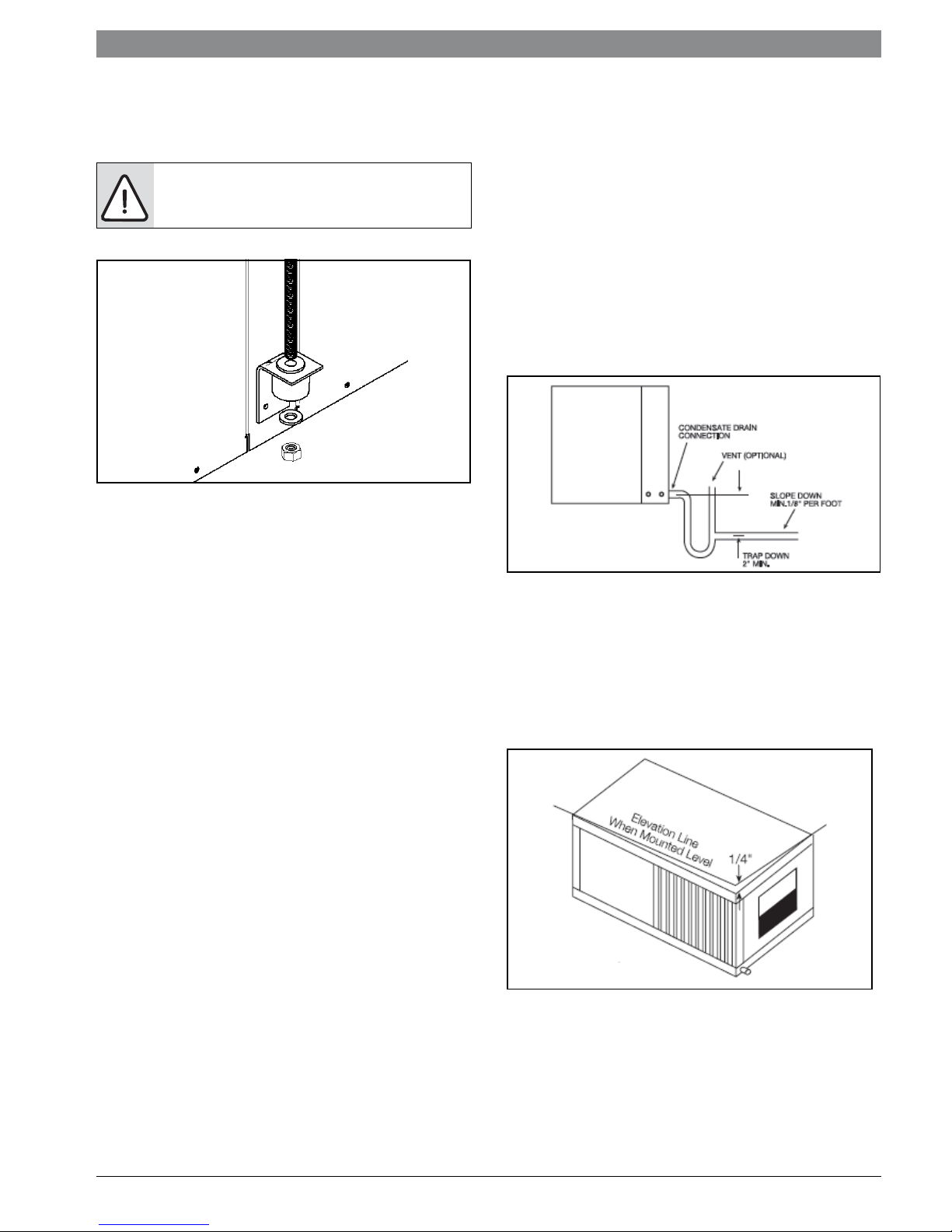

CONDENSATE CONNECTIONS

A drain line must be connected to the heat pump

and pitched away from the unit a minimum of 1/8”

per foot to allow the condensate to flow away from

the unit.

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to insure free condensate flow.

(Heat Pumps are not internally trapped).

A vertical air vent is sometimes required to avoid

air pockets.(See Figure #6).

Figure # 5 Condensate Drain

The depth of the trap depends on the amount of

positive or negative pressure on the drain pan. A

second trap must not be included.

The horizontal unit should be pitched

approximately 1/4” towards the drain in both

directions, to facilitate condensate removal. (See

Figure #6)

Figure # 6 Pitched Unit

DUCT SYSTEM

All SV Series models are provided with a return air

duct flange and supply air duct connections.

Refer to unit Dimensional Drawings for physical

dimensions of the collar and flange. (Pg#50)

8 733 914 818 (2014/08)SV Heat Pump Series

10 | Piping SV Heat PumpSeries

A flexible connector is recommended for supply

and return air duct connections on metal duct

systems. All metal ducting should be insulated

with a minimum of 1” (one inch) duct insulation to

avoid heat loss or gain and prevent condensate

from forming during the cooling operation.

Application of the unit to no insulated duct work is

not recommended as the unit’s performance will

be adversely affected.

NOTE: Do not connect discharge ducts

directly to the blower outlet.

The factory filter rack should be left in place

on a free return system.

If the unit will be installed in a new installation with

new duct work, the installation should be designed

using current ASHRAE procedures for duct sizing.

If the unit will be connected to an existing duct

system, a check should be made to assure that the

duct system has the capacity to handle the air

required for the unit application. If the duct system

is too small, larger duct work must be installed. Be

certain to check for existing leaks and repair.

The duct system and all diffusers should be sized

to handle the designed air flow quietly. To

maximize sound attenuation of the unit blower, the

supply and return air plenums should be insulated.

There should be no direct straight air path through

the air grill into the heat pump. The return air inlet

to the heat pump must have at least one 90° turn

away from the space return air grill. If air noise or

excessive air flow are a problem, the blower speed

can be changed to a lower speed to reduce air

flow.

In conditions anticipating moderate scale

formation or in brackish water a cupro-nickel heat

exchanger is recommended. Both the supply and

discharge water lines will sweat if subjected to low

water temperature. These lines should be

insulated to prevent damage from condensation.

All manual flow valves used in the system must be

ball valves. Globe and gate valves must not be used

due to high pressure drop and poor throttling

characteristics. Always check carefully for water

leaks and repair appropriately. Units are equipped

with female pipe thread fittings. Consult the

specification sheets for sizes.

Teflon tape sealer should be used when

connecting water piping connections to the units

to insure against leaks and possible heat

exchanger fouling. Do not overtighten the

connections. Flexible hoses should be used

between the unit and the rigid system to avoid

possible vibration. Ball valves should be installed

in the supply and return lines for unit isolation and

unit water flow balancing.

Pressure/temperature ports are recommended in

both the supply and return lines for system flow

balancing. The water flow can be accurately set by

measuring the water-to- refrigerant heat

exchangers water side pressure drop. See the unit

specification sheets for the water flow and

pressure drop information.

NOTE: Water piping exposed to extreme,

low ambient temperatures is subject to

freezing

PIPING

Supply and return piping must be as large as the

unit connections on the heat pump (larger on long

runs). Never use flexible hoses of a smaller inside

diameter than that of the water connections on the

unit. SV Units are supplied with either a copper or

optional cupro-nickel condenser. Copper is

adequate for ground water that is not high in

mineral content. Refer to Table #1.

Should your well driller express concern

regarding the quality of the well water available

or should any known hazards exist in your area,

we recommend proper testing to assure the well

water quality is suitable for use with water

source equipment. (Refer to Table #1)

NOTE: Never exceed the recommended

water flow rates. Serious damage or erosion

of the water to refrigerant heat exchanger

could occur.

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Electrical - High Voltage | 11Revised 08/14

ELECTRICAL - HIGH VOLTAGE

All field installed wiring must comply with the

National Electric Code as well as all applicable

local codes. Refer to the unit electrical data on the

unit name plate for wire and branch circuit

protection sizing. Supply power voltage and

phasing should match the required voltage and

phasing shown on the unit name plate. Operating

the unit below the minimum voltage, above the

maximum voltage or with incorrect phasing can

result in poor system performance or damage to

the heat pump. All field wiring should be installed

by qualified and trained personnel. Refer to the

unit wiring diagram for field connection

requirements.

NOTE: All power connections must be

properly torque to avoid the risk of

overheating.

Power wiring to the heat pump should be enclosed

in flexible conduit to minimize the transmission of

vibration from the unit cabinet to the building.

For heat pumps with unit mounted disconnect

switches, field power should be connected to the

marked terminals on the disconnect switch. For

heat pumps without unit mounted disconnect

switches (except for 460 volt units noted below

and units with dual power supply), power is

connected to the line (L) side of the compressor

contactor and the ground lug in the unit electrical

box.

Models with Dual Power Supplies

For models with dual power supplies, one power

supply feeds the compressor and a second power

supply feeds the unit fan motor and control circuit.

The compressor power supply should be

connected to the line (L) side of the compressor

contactor. The fan motor and control circuit

power supply should be connected to a provided

terminal block. Care should be taken to insure that

each power supply meets the voltage, amperage

and phase requirements of its load. Refer to the

unit nameplates for requirements.

460 V Models with Constant Air Flow

Motors (SV015-SV070)

460 volt SV heat pumps with the constant airflow

motor option require a properly sized neutral wire

with the power supply wiring in addition to the

three high voltage wires and the ground wire.

These units employ a 265 V motor that requires

power from one phase of the 460 V supply and the

neutral wire.

WARNING: The power supply ground wire

should never be used as a neutral wire.

For 460 V models with constant air flow motors

and a unit mounted disconnect switch, the power

wires and neutral wire should be connected to the

appropriate terminals on the disconnect switch

and its enclosure. For units without a disconnect

switch, power and neutral wires should be

connected to a provided 4 pole terminal block in

the unit electrical box

Transformer Settings for 208/230 V Units

As factory built, all 208/230 V units are wired for

230 V operation. For job sites with a 208 V power

supply, the primary leads on the unit transformer

will need to be changed from 240 V to 208 V. Refer

to the unit wiring diagram for details.

ELECTRICAL - LOW VOLTAGE

For heat pumps with PSC or constant torque fan

motors, all thermostat wiring is connected to a

terminal block located in the unit electrical box.

For heat pumps with a constant air flow fan motor,

thermostat wiring is connected to a removable

terminal strip located on the ECM motor control

board located in the electrical box. Refer to the

unit wiring diagram for connection details.

WARNING: Never route control wiring

through the same conduit as power supply

wiring.

Unless provided with DDC controls, the SV heat

pump can be controlled by most commonly

available single stage heat pump thermostats.

Note that the reversing valve on the SV series is

energized when the unit is in the cooling mode.

Thermostats should be located on an interior wall

away from supply ducts. Avoid locations subject to

direct sunlight or drafts, or external walls.

Thermostat wiring should be 18 AWG. Refer to the

installation instructions for the thermostat for

further details.

Exceptionally long runs of thermostat wire

should be avoided to prevent voltage drops in

the control circuit.

SV heat pumps are supplied with a 75 VA control

transformer as standard. The VA capacity of the

transformer should be considered when

connecting low voltage accessories to the heat

pump such as thermostats or solenoid valves.

8 733 914 818 (2014/08)SV Heat Pump Series

12 | Unit Controls - UPM SV Heat PumpSeries

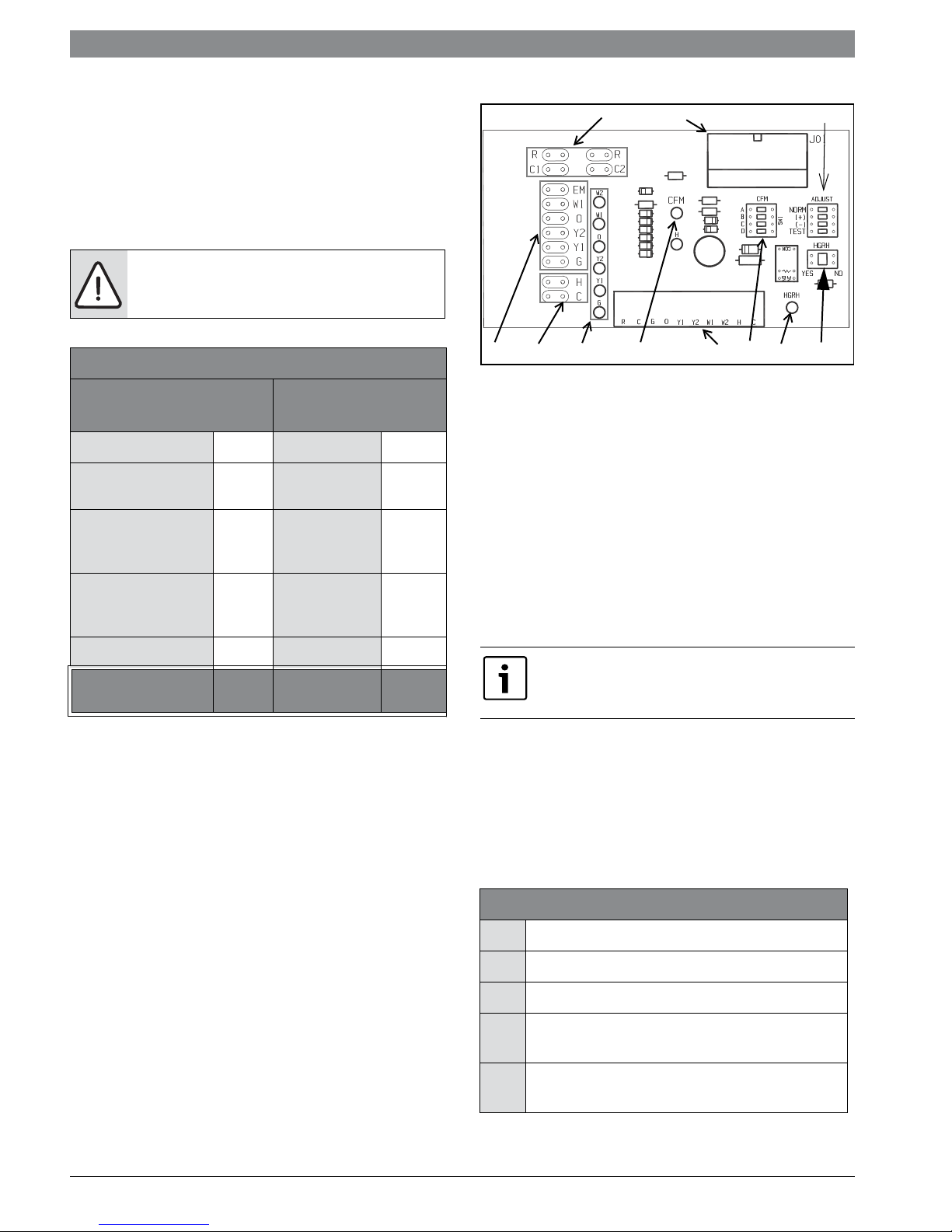

Table #2 shows the VA draw of factory mounted

components in the SV heat pump. The total VA

draw of the heat pump internal components plus

any attached accessories must be lower than the

VA capacity of the unit control transformer.

NOTE: Exceeding the transformer capacity

can result in low control voltage, erratic unit

operation or damage to the heat pump.

Table 2: Low Voltage VA Draw

Standard

Hot Gas Reheat

Construction

Component

Blower Relay

(PSC motors only)

Reversing Valve

Solenoid

Compressor

Contactor

VA

6-7

8-9

6-8

Component

Total from

‘Standard’

Additional

Control

Relays

Hot Gas

Reheat

Solenoid

VA

22-26

12-14

8-9

10

8

9

7

1

546

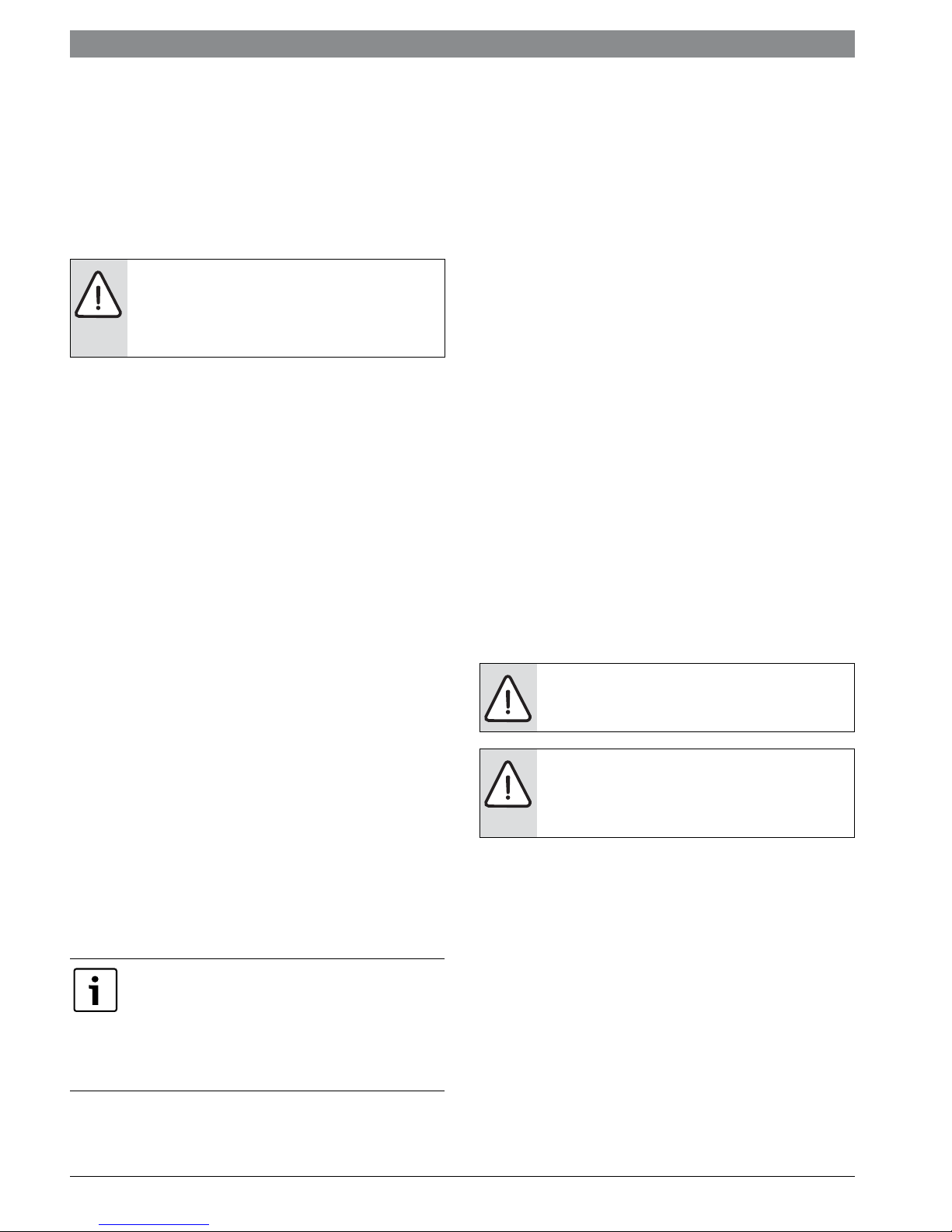

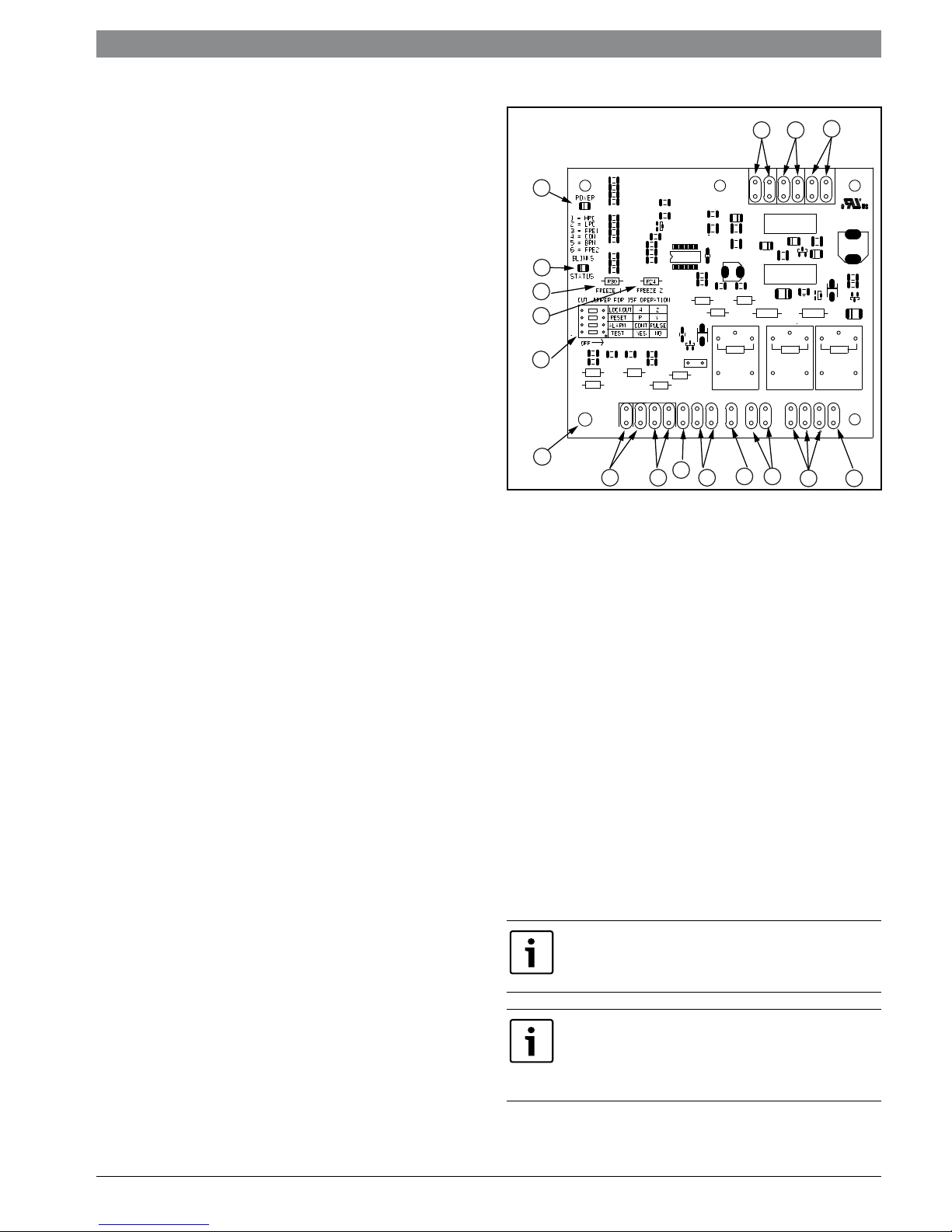

Figure # 7

[1] Motor harness plug

[2] Blower CFM adjustment

[3] Motor settings

[4] Dehumidification indication

[5] Thermostat contact inputs

[6] CFM count indicator

[7] Thermostat input status indication

[8] Reheat digital outputs

[9] Thermostat outputs

[10] 24 VAC

[11] Dehumidification method selector

3

11

UPM board

Total VA draw

2

22-26

Total VA

draw

42-49

UNIT CONTROLS - UPM

ECM Interface Board

Thermostat wiring is connected to the 10 pin

screw type terminal block on the lower center

portion of the ECM Interface Board (Refer to

Figure #7, item [5]). In addition to providing a

connecting point for thermostat wiring, the

interface board also translates thermostat inputs

into control commands for the Electronic

Commutated Motor (ECM) DC fan motor and

displays an LED indication of operating status. The

thermostat connections and their functions are as

Follows.

CFM LED indication is an approximation. Utilize

conventional Test and Balance equipment for

accurate airflow measurement.

• CFM Count Indicator (Figure #7, Item [5])

blinks to indicate approximate airflow in CFM

and may flicker when unit is off. Each blink of

the LED represents approximately 100 CFM of

air delivery, for example, if the LED blinks 12

times, pauses, blinks 12 times, etc. the blower

is delivering approximately 1200 CFM.

Thermostat Options

Y1 First Stage Compressor Operation

G Fan

O Reversing Valve (energized in cooling)

W1 Auxiliary Electric Heat (runs in

conjunction with compressor)

NC Transformer 24 VAC Common (extra

connection)

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Unit Controls - UPM | 13Revised 08/14

Thermostat Options

Y1 First Stage Compressor Operation

C1 Transformer 24 VAC Common (primary

connection)

R Transformer 24 VAC Hot

H Dehumidification Mode

Airflow Selector

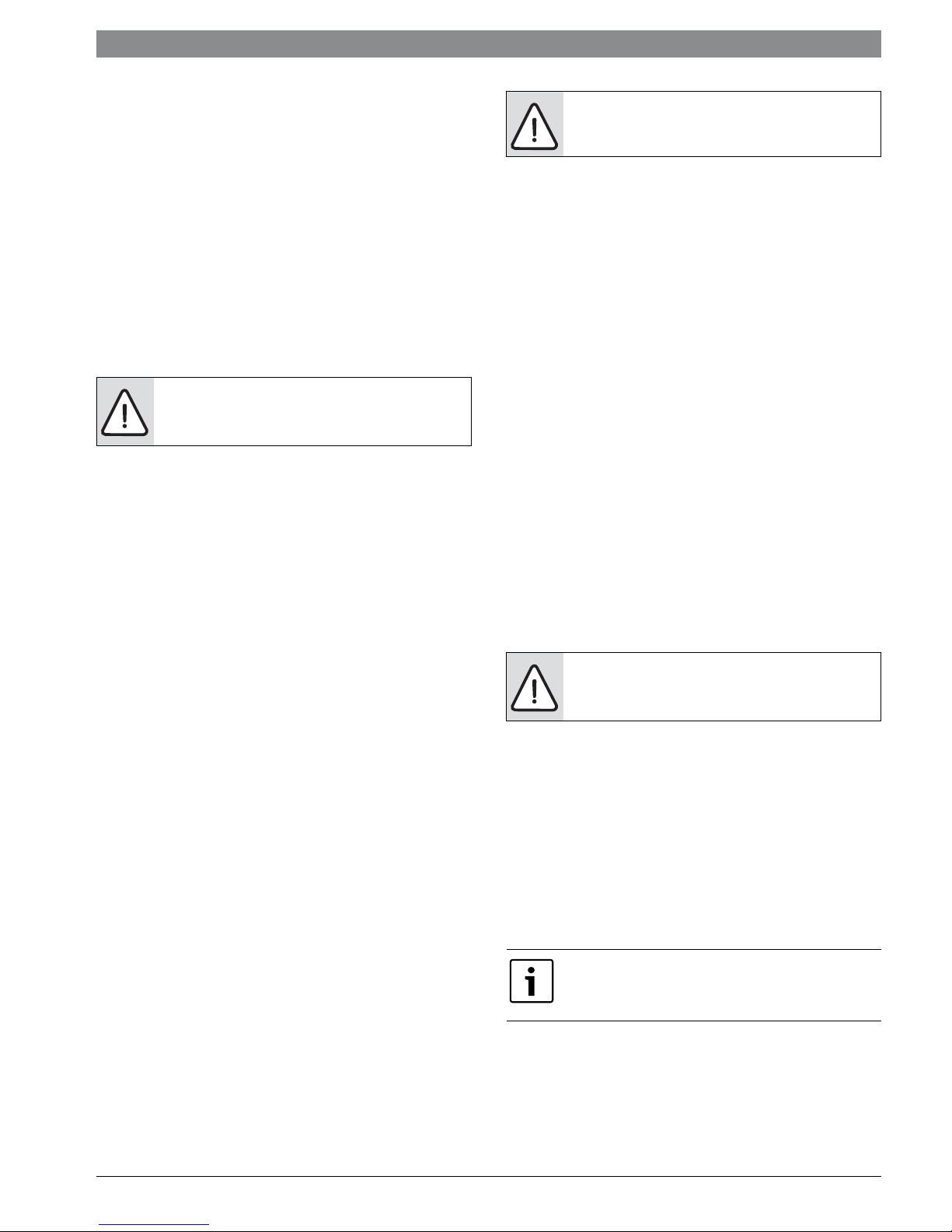

The airflow selector (Figure #7, items [2] & [3])

allows airflow adjustment to meet application

requirements and to ease troubleshooting.

Only one switch can be enabled at a time. Refer

to Figure #9 for each airflow setting.

NOTE: CFM Selector (FIg #7, Item [2]) must

remain with only “A” being enabled.

ADJUST Selector can be adjusted to NOM, (+), (-),

or TEST. NOM, (+) and (-) can be adjusted as

needed by application. TEST is used for

troubleshooting to override unit airflow to 100%

NOTE: Always disconnect power before

changing jumper positions on the interface

board and reset the unit afterward.

Dehumidification Method Selector

Dehumidification method selector (Figure #7, item

[11]) is used to select between the following two

methods:

1. Units equipped with optional Hot Gas Reheat,

on dehumidification call (the “H” terminal on

the thermostat is energized) the reheat

outputs will energize the hot gas reheat valve

in the circuit and the heat pump will start in

dehumidification mode. Dehumidification

selector (Figure #7, item [11]) should be

selected to ‘YES’.

2. Units without optional Hot Gas Reheat, on

dehumidification call, the heat pump fan will

operate at a lower speed to increase

dehumidification while cooling.

Dehumidification selector ((Figure #7, item

[11]) should be selected to ‘NO’.

In this mode, the heat pump will only dehumidify

the space when it is running in cooling mode.

Figure # 8

NOTE: Do not set the ADJ DIP switch to the

(-) setting when electric heaters are

installed. Doing so may cause the heaters to

cycle on their thermal overload switches,

potentially shortening the life of the

switches.

3. To the left of the red and green status LED’s is

a row of 1/4” male quick connects. These are

used to pass thermostat inputs on to the rest

of the control circuit. Remember to always turn

off unit power at the circuit breaker before

attaching or disconnecting any wiring from

these connections to avoid accidental short

circuits that can damage unit control

components.

Dehumidification indicator LED (Figure #7, item

[4]) will energize when dehumidification call is

present. Refer to Figure #9.

The other DIP switch bank is used to select the

proper program in the ECM motor for the unit.

Figure # 9

8 733 914 818 (2014/08)SV Heat Pump Series

14 | Unit Controls - UPM SV Heat PumpSeries

Sequence of Operation

START

YES

Y1 = ON

NO

RESET ON

Y

NO

RESET ON R

R = 24VAC

YES

POWER/ SWITCHES/SENSOR

STATUS CHECK

V > 18VAC

NO

YES

HPC =

CLOSED

NO

YES

LPC

=CLOSED

NO

YES

FRZ >TEMP

LIMIT

NO

START

TIMER

START

TIMER

YES

CLEAR FAULTS

TIME > 120

NO

TIME > 30

BLINK CODE ON STATUS LED

SOFT LOCKOUT

RECORD ALARM

START COUNTER (IF APPLICABLE)

LOCKOUT CAN BE SET

TO 4 VIA DIP SWITCH

BLINK CODE

SEC

SEC

YES

ON STATUS LED

YES

NO

COUNTER

NEEDED?

YES

COUNT = 2

OR

COUNT = 4

NO

YES

NO

HARD

LOCKOUT?

YES

BLINK CODE ON STATUS LED

DISPLAY OUTPUT = PULSE

ALR OUTPUT = ON/PULSE

NO

YES

CON > 0

YES

INITIAL

POWER UP

YES

NO

NO

NO

START

ANTI SHORT CYCLE

START

RANDOM START UP

NO

T > ASC OR

RS SEC

CC OUTPUT = OFF

YES

CC

CC OUTPUT = ON

LEGEND:

HPC - HIGH PRESSURE CUTOUT

LPC - LOW PRESSURE CUTOUT

FRZ - FREEZE PROTECTION CONDITION

CON - CONDENSATE OVERFLOW CONDITION

CC - COMPRESSOR COIL

ASC - ANTI SHORT CYCLE

RS - RANDDOM START

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Unit Controls - UPM | 15Revised 08/14

General

SV series heat pumps are designed to be

controlled by a standard 1 heat / 1 cool heat pump

thermostat. The heat pump control circuit

operates on 24 VAC control voltage regardless of

the unit supply voltage. If direct digital control is

required then the heat pump needs to be supplied

with a DDC control option.

Fan operation is controlled by the “G” terminal on

the heat pump thermostat terminal block. When

“G” is energized the unit fan motor will start

operating. For heat pumps with PSC motors, the

fan will immediately ramp up to 100% air flow. For

heat pumps with constant torque ECM motors, the

fan will ramp up to 100% air flow over a 30 second

period. For heat pumps with constant air flow ECM

motors the fan will ramp up to 70% air flow over a

30 second period if there is no call for compressor

operation (“Y”). If there is a call for compressor

operation along with a call for fan operation, then

the fan will ramp to 100% air flow.

Compressor operation is controlled by the “Y”

terminal on the heat pump thermostat terminal

block. When “Y” is energized, a signal to start the

compressor is sent to the Unit Protection Module

(UPM). The UPM checks a number of safety

features before then starting the compressor. If

any of the safety features connected to the UPM is

in a fault condition, the UPM will not start the

compressor and will flash a fault code on the red

status LED indicating the nature of the fault.

Additionally the UPM will delay compressor

operation randomly on initial start up (random

start delay) and will prevent the compressor from

restarting with less than 5 minutes of off time (anti

short cycle delay). Once all faults are cleared and

the time delays are satisfied, the UPM will energize

the compressor. The compressor will operate as

long as the thermostat calls for “Y” and there are

no faults. Refer to the troubleshooting chart for

fault diagnostics.

Cooling and Heating Modes

SV series heat pumps operate in cooling with the

reversing valve energized. When the “O” terminal is

energized, the heat pump will be in the cooling

mode, however, will not be actively cooling until

the “Y” and “G” terminals are also energized. If the

“Y” and “G” terminals are energized without the

“O” terminal, then the heat pump will operate in

the heating mode.

UPM Safety Features

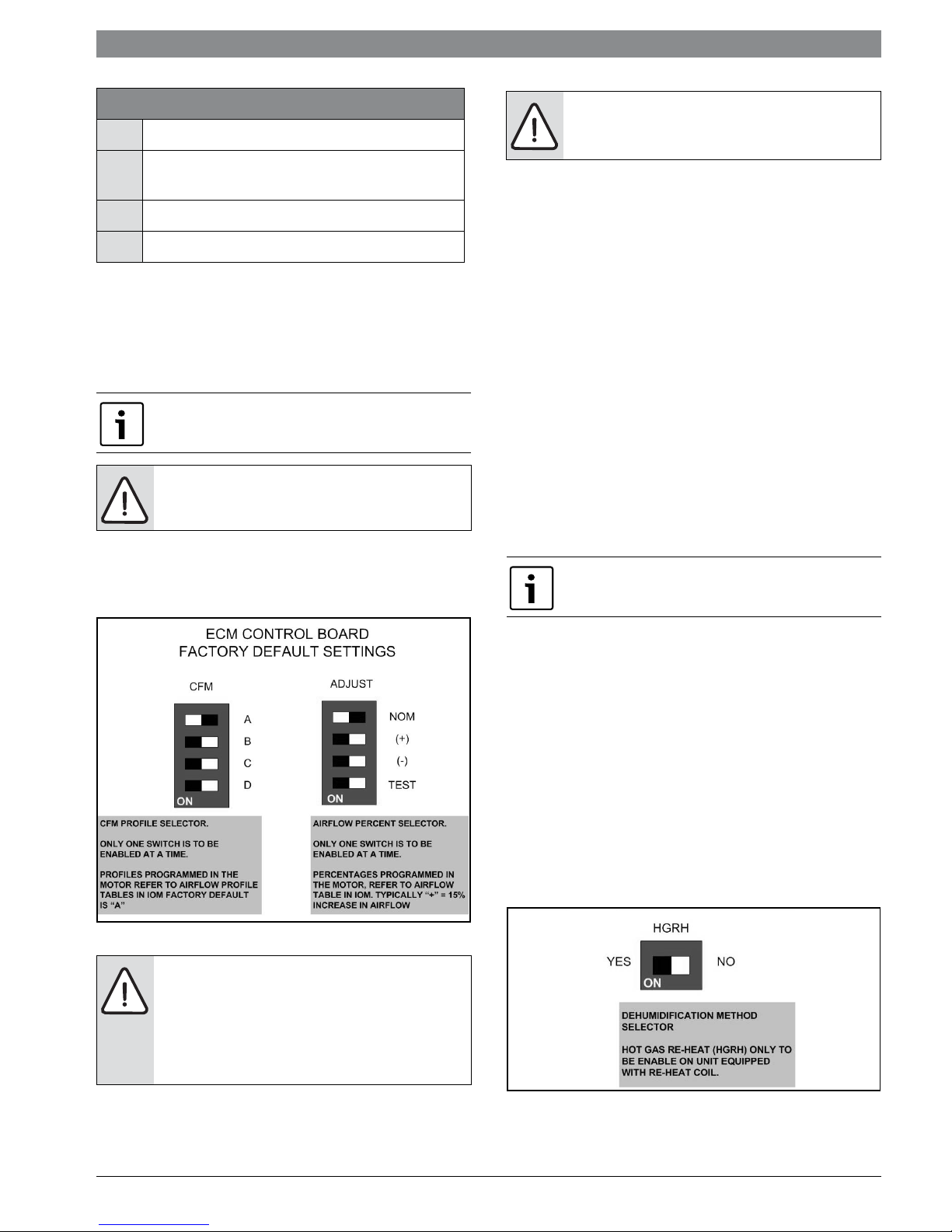

11

1213

1

2

3

4

5

17

6

[1] Board Power Indicator

[2] UPM Status LED Indicator

[3] Water Coil Freeze Protection Temperature

Selection

[4] Air Coil Freeze Protection Temperature

Selection

[5] UPM Board Settings

[6] Water Coil Freeze Connection

[7] Air Coil Freeze Connection

[8] LED Unit Display Connection

[9] 24VAC Power Input

[10] Compressor Contact Output

[11] High Pressure Switch Connection

[12] Call for Compressor Y1

[13] Low Pressure Switch Connection

[14] 24VAC Power Common

[15] Condensate Overflow Sensor

[16] Dry Contact

[17] UPM Ground Standoff

If the unit is being connected to a thermostat

with a malfunction light, this connection is made

at the unit malfunction output or relay.

If the thermostat is provided with a malfunction

light powered off of the common (C) side of the

transformer, a jumper between “R” and “COM”

terminal of “ALR” contacts must be made.

15

14

7

Figure # 10

8

16

9

10

8 733 914 818 (2014/08)SV Heat Pump Series

16 | Unit Controls - UPM SV Heat PumpSeries

If the thermostat is provided with a malfunction

light powered off of the hot (R) side of the

transformer, then the thermostat malfunction

light connection should be connected directly to

the (ALR) contact on the unit’s UPM board.

Each unit is factory provided with a Unit Protection

Module (UPM) that controls the compressor

operation and monitors the safety controls that

protect the unit.

Safety controls include the following:

• High pressure switch located in the refrigerant

discharge line and wired across the HPC

terminals on the UPM

• Low pressure switch located in the unit

refrigerant suction line and wired across

terminals LPC1 and LPC2 on the UPM.

UPM Board Dry Contacts are Normally Open

(NO)

• Water side freeze protection sensor, mounted

close to condensing water coil, monitors

refrigerant temperature between condensing

water coil and expansion valve or capillary

tube. If temperature drops below or remains at

freeze limit trip for 30 seconds, the controller

will shut down the compressor and enter into

a soft lockout condition. The default freeze

limit trip is 26°F, however this can be changed

to 15°F by cutting the R30 or Freeze1 resistor

located on top of DIP switch SW1.

• Evaporator freeze protection sensor, mounted

after the thermal expansion device and the

evaporator, monitors refrigerant temperature

between the evaporator coil and thermal

expansion valve. If temperature drops below or

remains at freeze limit trip for 30 seconds, the

controller will shut down the compressor and

enter into a soft lockout condition. The default

freeze limit trip is 26°F. (Figures #11 and #12)

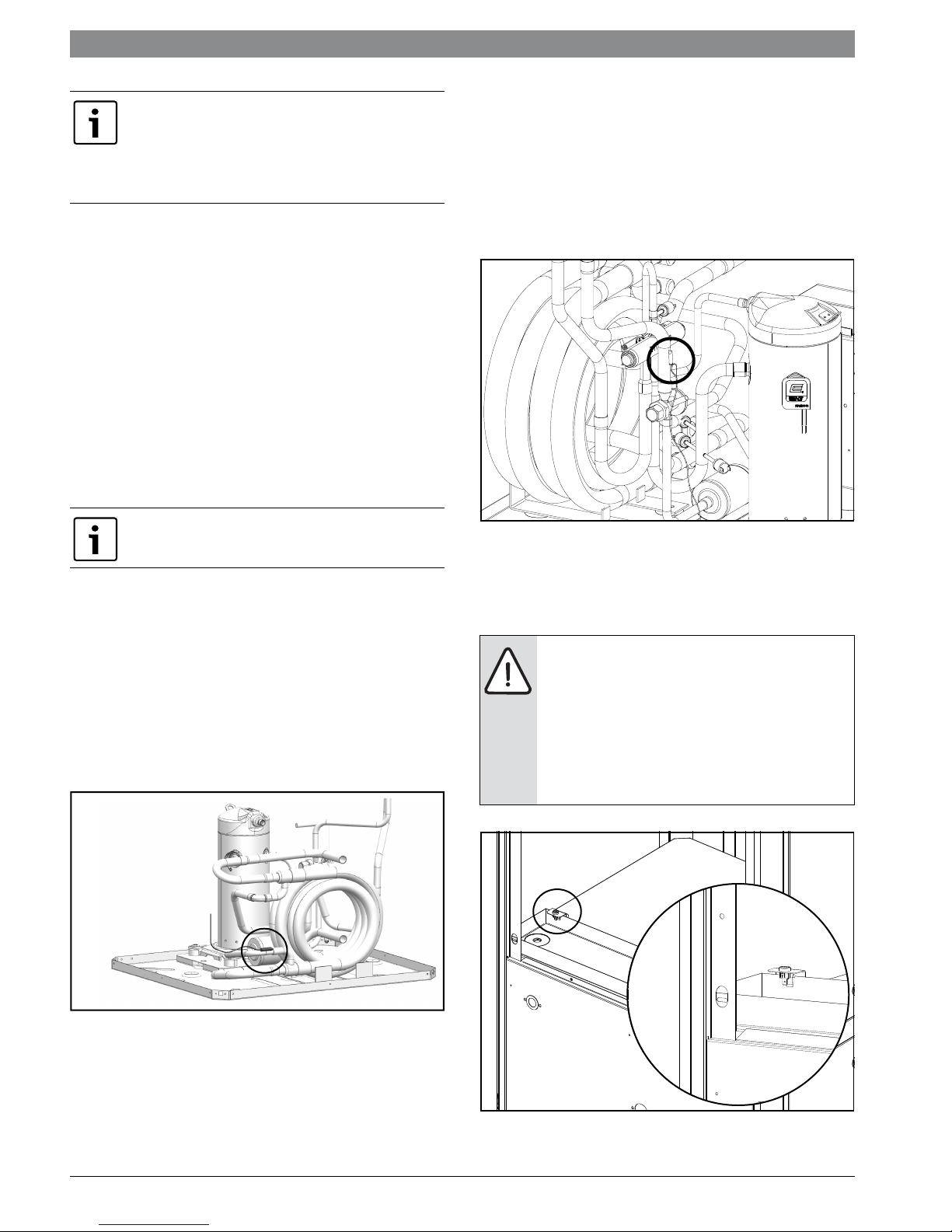

Figure # 12

• The condensate overflow protection sensor is

located in the drain pan of the unit and

connected to the ‘COND’ terminal on the UPM

board. (Figure #13)

NOTE: If unit is employing a fresh water

system (no anti-freeze protection), it is

extremely important to have the Freeze1

R30 resistor set to 26°F in order to shut

down the unit at the appropriate leaving

water temperature and protect your heat

pump from freezing if a freeze sensor is

included.

Figure # 11

Figure # 13

SV Heat Pump Series8 733 914 818 (2014?08) Subject to change without prior notice

Unit Controls - UPM | 17Revised 08/14

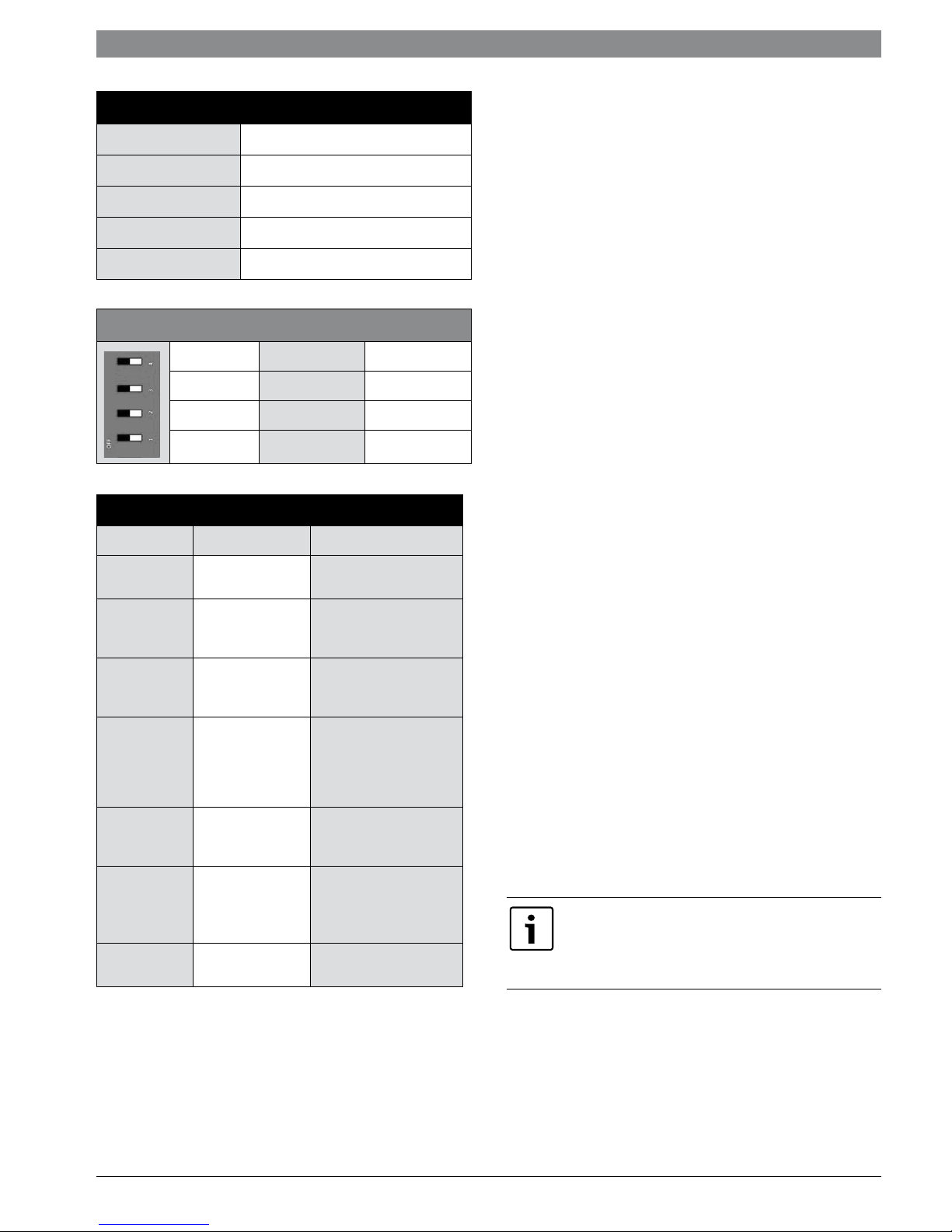

UPM Board Factory Default Settings

TEMP

LOCKOUT

RESET

ALARM

TEST

26°F

2

Y

PULSE

NO

UPM DIP SWITCH DEFAULT POSITION

lockout 42

reset

alarm

test

Table 3: UPM Fault Blink Codes

LED Blinks Fault Fault Criteria

None None

1 High Pressure

2 Low Pressure

Water Coil

Freeze

3

4

5

6 Brown Out

Condition

Condensate

Overflow

Air Coil Freeze

Condition

RY

Cont pulse

yes no

All fault conditions

nominal

Refrigerant discharge

pressure has

exceeded 600 PSIG

Refrigerant suction

pressure has fallen

below 40 PSIG

Refrigerant

temperature to the

water coil has fallen

below 30°F for 30

seconds

Condensate levels in

the unit drain pan are

too high

Refrigerant

temperature to the air

coil has fallen below

30°F for 30 seconds

Control voltage has

fallen below 18 VAC

• RANDOM START: Each controller has an unique

random start delay ranging from 270 to 300 seconds

on initial power up to reduce the chance of multiple

unit simultaneously starting at the same time after

power up or after a power interruption, thus

avoiding creating large electrical spike.

• LOW PRESSURE BYPASS TIMER: If the

compressor is running and the low pressure switch

opens, the controller will keep the compressor ON

for 120 seconds. After 120 seconds if the low

pressure switch remains open, the controllers will

shut down the compressor and enter a soft lockout.

The compressor will not be energized until the low

pressure switch closes and the anti-short cycle time

delay expires. If the low pressure switch opens 2-4

times in 1 hour, the unit will enter a hard lockout. In

order to exit hard lockout power to the unit would

need to be reset.

• BROWNOUT/SURGE/POWER

INTERRUPTION PROTECTION: The brownout

protection in the UPM board will shut does the

compressor if the incoming power falls below 18

VAC. The compressor will remain OFF until the

voltage is above 18 VAC and ANTI-SHORT CYCLE

TIMER (300 seconds) times out. The unit will not go

into a hard lockout.

• MALFUNCTION OUTPUT: Alarm output is

Normally Open (NO) dry contact.

If pulse is

selected the alarm output will be pulsed. The

fault output will depend on the dip switch

setting for "ALARM". If it is set to "CONST", a

constant signal will be produced to indicate a

fault has occurred and the unit requires

inspection to determine the type of fault. If it is

set to "PULSE", a pulse signal is produced and

a fault code is detected by a remote device

indicating the fault. See L.E.D Fault Indication

below for blink code explanation. The remote

device must have a malfunction detection

capability when the UPM board is set to

"PULSE".

If 24 VAC output is needed R must be wired to

ALR-COM terminal; 24 VAC will be available o

the ALR-OUT terminal when the unit is in the

alarm condition.

The UPM Board includes the following features:

• ANTI-SHORT CYCLE TIMER: 5 minute delay on

break timer to prevent compressor short cycling.

• DISPLAY OUTPUT: The Display output is a pulse

output connected to the Unit Diagnostic Display

(UDD) and it pulses 24VAC when the unit is in an

lockout alarm condition.

8 733 914 818 (2014/08)SV Heat Pump Series

Loading...

Loading...