Bosch SST150-40, SST250-65, SST300-80, SST450-119 Installation And Operating Manual

Indirect Fired Water Heaters

Installation and Operating Manual

Models: SST150-40

SST250-65

SST300-80

SST450-119

CAUTION

The heat transfer medium must be water or other nontoxic uid

having a toxicity rating or class of 1, as listed in Clinical

Toxicology of Commercial Products, 5th edition

The pressure of the heat transfer medium must be limited to a

maximum of 30 PSIG by an approved safety or relief valve.

®

C

US

WARNING

This manual must only be used by a trained heating installer /

service technician. Read all instructions before installing.

Perform steps in the order given. Failure to comply could result

in severe personal injury, death, or substantial property

damage.

Installation & Operating Manual

2 |

Indirect Fired Water Heaters Installation and Operating Manual

Table of Contents

1 General Information 6

Installation & Operating Manual

2 Pre-installation 7

3 Boiler Side Piping 8

4 Domestic Side (Tank) Piping 13

5 Wiring 17

6 Start-up and Check-out 18

7 Maintenance 19

8 Performance Data 21

Limited Lifetime Warranty 25

Indirect Fired Water Heaters Installation and Operating Manual

| 3

Installation & Operating Manual

Hazard Denitions

The following dened terms are used throughout this

manual to bring attention to the presence of hazards of

various risk levels or to important information concerning

the life of the product.

DANGER

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situtation

which, if not avoided, may result in minor or

moderate injury.

CAUTION

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

NOTICE

NOTICE indicates special instructions on installation,

operation, or maintenance that are important but not

related to personal injury or property damage.

4 |

Indirect Fired Water Heaters Installation and Operating Manual

Installation & Operating Manual

Please Read Before Proceeding

WARNING

Installer – Read all instructions before installing.

Perform steps in the order given. Have this indirect

water heater serviced/inspected by a qualified

service technician, at least annually. Failure to comply

with the above could result in severe personal injury,

death or substantial property damage.

NOTICE

When calling or writing about the appliance

– Please have the indirect water heater model and

serial number from the indirect water heater rating

plate.

– Consider piping and installation when determining

appliance location.

– Any claims for damage or shortage in shipment

must be filed immediately against the

transportation company by the consignee.

– Factory warranty does not apply to appliances

improperly installed or improperly operated.

HOT WATER CAN SCALD!

• Water heated to temperatures for

clothes washing, dish washing, and other

sanitizing needs can scald and cause

permanent injury.

• Children, elderly, and infirm or physically handicapped

persons are more likely to be permanently injured by

hot water. Never leave them unattended in a bathtub or

shower. Never allow small children to use a hot water

tap or draw their own bath.

• If anyone using hot water in the building fits the above

description, or if state laws or local codes require

certain water temperatures at hot water taps, you must

take special precautions:

• Use lowest possible temperature setting.

• Install some type of tempering device, such as an

automatic mixing valve, at hot water tap or water

heater. Automatic mixing valve must be selected and

installed according to valve manufacturer’s

recommendations and instructions.

• Water passing out of drain valves may be extremely

hot. To avoid injury:

• Make sure all connections are tight.

• Direct water flow away from any person

• Protection Must Be Taken Against Excessive

Temperature and Pressure! Installation of a

Temperature & Pressure (T&P) relief valve is required.

WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

This appliance MUST NOT be installed in any location

where gasoline or flammable vapors are likely to be

present.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier.

When Servicing the Indirect Water Heater -

To avoid severe burns, allow the appliance to cool

before performing maintenance.

Indirect water heater operation –

Should overheating occur or gas supply fail to shut off, do

not turn off or disconnect electrical supply to circulator.

Instead, shut off the gas supply at a location external to

the appliance.

Do not use this appliance if any part has been under

water. The possible damage to a ooded appliance can be

extensive and present numerous safety hazards. Any

appliance that has been under water must be replaced.

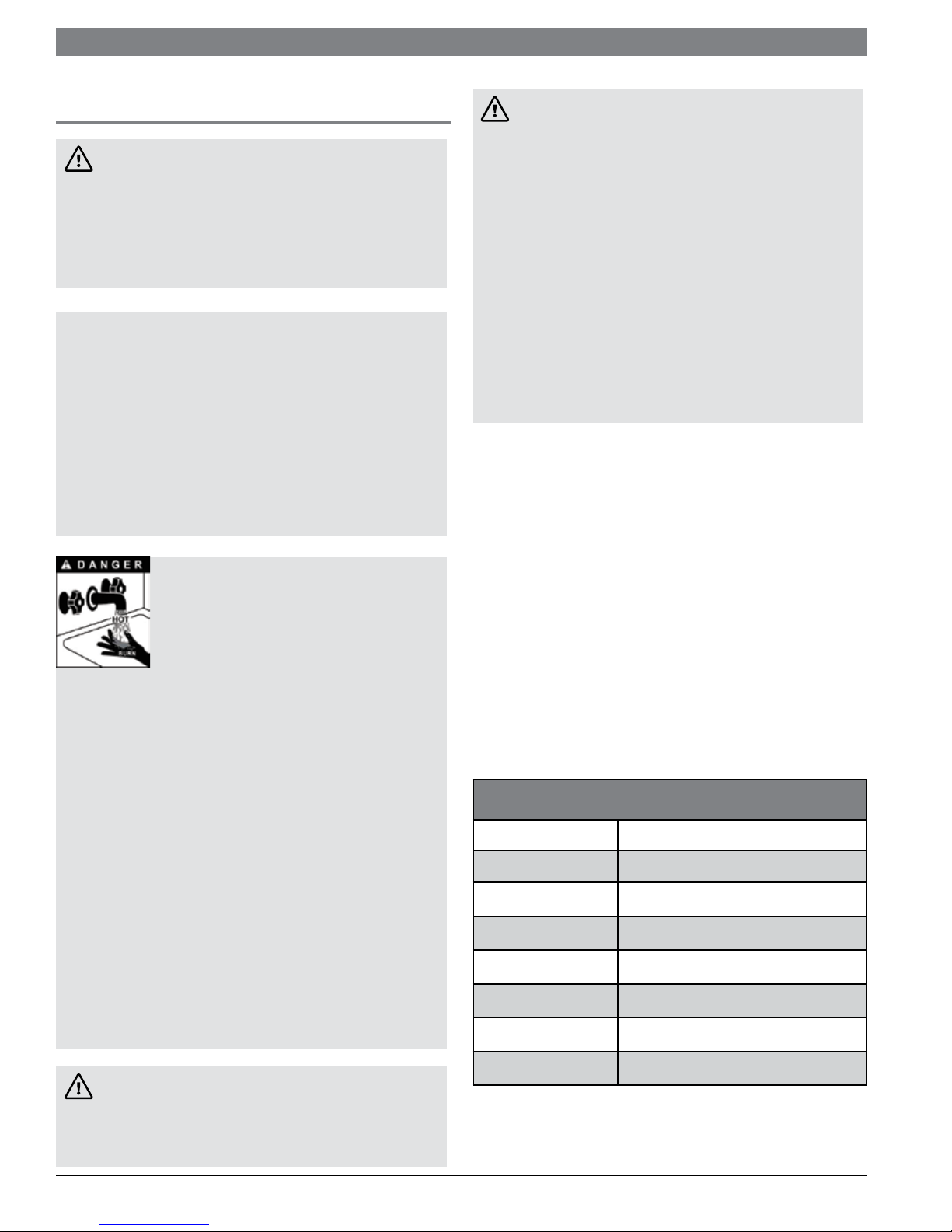

The following chart details the relationship of water

temperature and time with regard to scald injury and may

be used as a guide in determining the safest water

temperature for your applications.

APPROXIMATE TIME / TEMPERATURE

RELATIONSHIPS IN SCALDS

120° F More than 5 minutes

125° F 1 ½ to 2 minutes

130° F About 30 seconds

135° F About 10 seconds

140° F Less than 5 seconds

145° F Less than 3 seconds

150° F About 1 ½ seconds

WARNING

Failure to adhere to the guidelines on this page can

result in severe personal injury, death, or substantial

property damage.

Indirect Fired Water Heaters Installation and Operating Manual

155° F About 1 second

| 5

Installation & Operating Manual

1 General Information

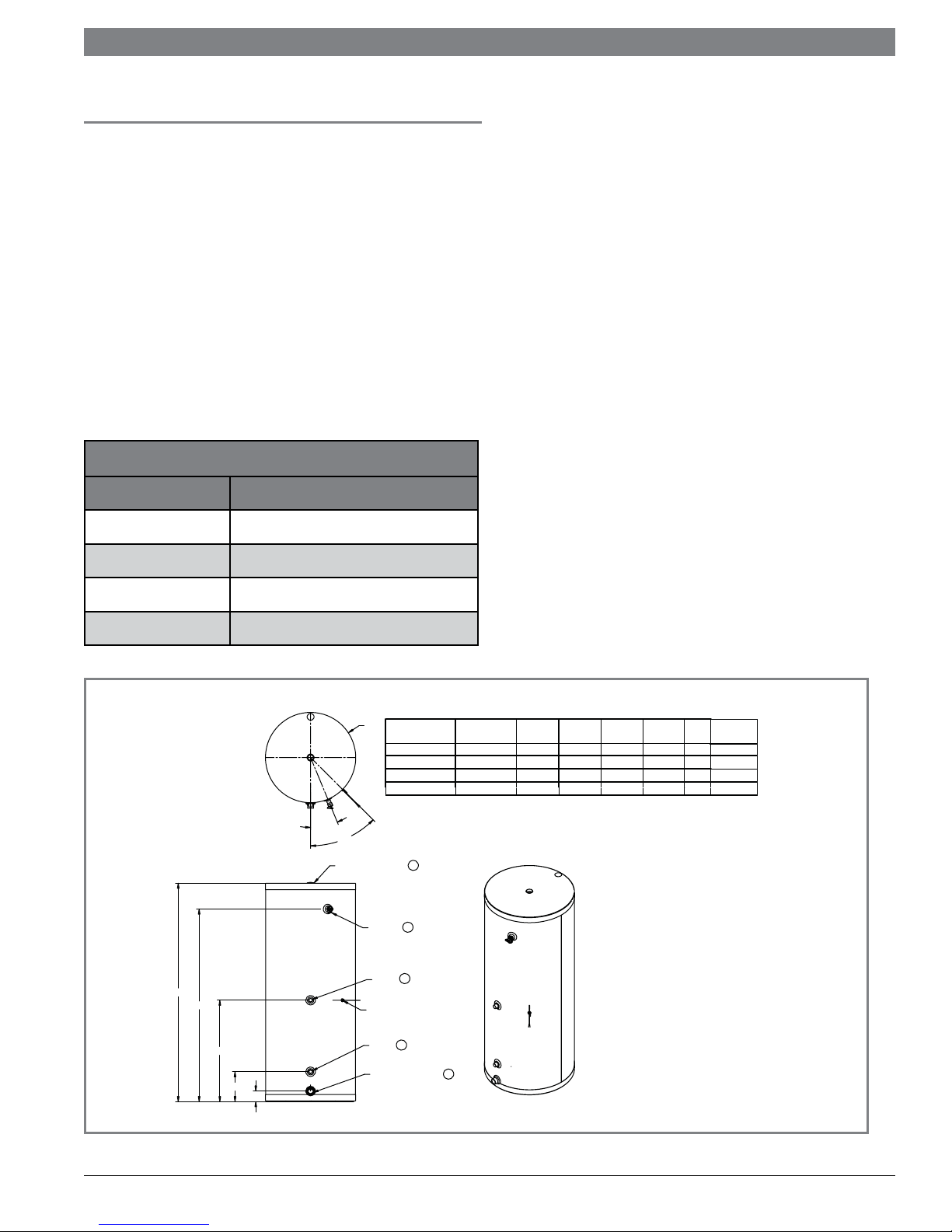

The SST series indirect water heater (FIG. 1-1) is designed

to generate domestic hot water in conjunction with a hot

water boiler using forced boiler water circulation. This

indirect water heater consists of a 316L Stainless Steel

tank in which a smooth 304L stainless steel coil is located

(Table 1A). Boiler water is pumped through the coil and

heats the water in the tank. This tank is not intended for

use in pool heating applications or for heating any uid

other than water. It is also not intended for use in gravity

hot water heating systems.

Operating Restrictions:

• Maximum domestic hot water temperature is 194°F.

• Maximum boiler water temperature is 210°F.

• Maximum working pressure for the vessel tank is 150

psig.

Component Materials Table 1A

Component Material

Tank 316L Steel Stainless Steel

Coil 304L Stainless Steel

Insulation Polyurethane

Jacket Polypropylene/ABS

Single-Wall Heat Exchanger

National Standard Plumbing Code

Single-wall heat exchangers in water heaters comply with

the National Standard Plumbing Code provided that:

• boiler water (including additives) is practically non-toxic,

having a toxicity rating or class of 1, as listed in Clinical

Toxicology of Commercial Products, and

• boiler water pressure is limited to a maximum of 30 psig

by approved relief valve.

Uniform Plumbing Code

Single-wall heat exchangers are permitted if they satisfy all

of the following requirements:

1. The heat transfer medium is potable water or contains

only substances which are recognized as safe by the

U.S. Food and Drug Administration.

2. The pressure of the heat transfer medium is maintained

less than the normal minimum operating pressure of the

potable water system.

3. The equipment is permanently labeled to indicate that

only additives recognized as safe by the FDA shall be

used in the heat transfer medium.

Other heat exchanger designs may be permitted where

approved by local code.

Figure 1-1

“F”

PART NO.

SST150-40

SST250-65

SST300-80

SST450-119

NOTES:

22.5°

45°

1” NPT (SEE NOTE 1)

“E”

“D”

“C”

“B”

“A”

1. 1-1/2” NPT ON SST MOD ELS.

2

1

3/4” NPT

3

1” NPT

AQUASTAT/SENSOR WELL

4

1” NPT

1” NPT (SEE NOTE 1)

“A”

(in.)

3

3 1/4

3 1/4

3 1/4

5

“B”

(in.)

8 1/4

9 1/4

9 1/4

9 1/4

SST150 - SST450

25 1/4

31 3/4

“D”

“C”

(in.)

(in.)

48 1/2

28

52 1/2

28

61 3/4

60 1/4

1. RELIEF VALVE CONNECTION

2. HOT WATER OUTLET

3. BOILER WATER IN

4. BOILER WATER OUT

5. DRAIN/COLD WATER INLET

“E”

(in.)

56

60

70

69

WEIGHT

“F”

FULL OF WATER

(in.)

(lbs.)

20

24

24

28

515

820

921

1268

6 |

Indirect Fired Water Heaters Installation and Operating Manual

2 Pre-installation

Installation & Operating Manual

1. The installation must conform to the instructions in this

manual and all applicable local, state, provincial, and

national codes, laws, regulations, and ordinances.

Installations in Canada must conform to B149.2

Installation Code.

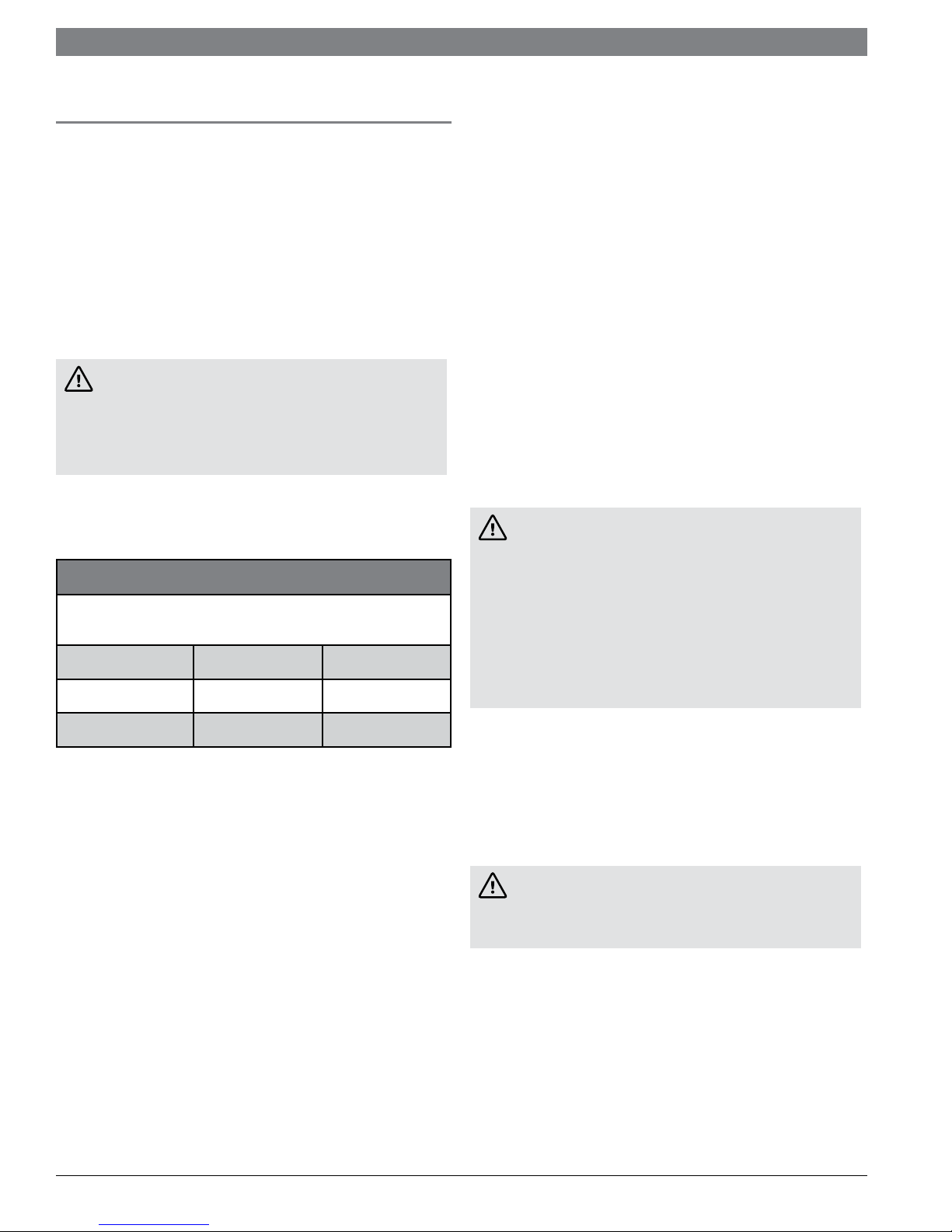

2. Be certain the domestic water supply to the tank has

physical and chemical characteristics that fall within the

limits shown in Table 2A. Where questions exist as to

the composition of the water on the job, a qualied

water treatment expert should be consulted.

CAUTION

Water with characteristics outside the limits shown in

Table 2A may severely shorten the life of the tank due

to corrosion. Damage to tanks in such cases is not

covered under warranty.

3. Read and understand all installation requirements in

this manual.

Water Chemistry Requirements Table 2A

Water used in the tank must have characteristics falling

within the following limits:

Characteristic Min. Max.

Ph 6.0 8.0

Locating the Tank

1. Choose a location for your water heater centralized to

the piping system. You must also locate the SST water

heater where it will not be exposed to freezing

temperatures. Additionally, you will need to place the

water heater so that the controls, drain, and inlet/

outlets are easily accessible. This appliance must not be

installed outdoors, as it is certied as an indoor

appliance, and must also be kept vertical on a level

surface.

2. Keep distance between boiler and water heater to a

minimum to:

a. reduce piping heat loss

b. provide minimal friction loss

3. Figure 1-1 on page 6 shows the weights of all the tanks

lled with water. Make sure that the location chosen for

the tank is capable of supporting it.

CAUTION

This appliance must be placed where leakage from

the relief valve, leakage from the related piping, or

leakage from the tank or connections, will not result

in damage to the surrounding areas, or to the lower

floors of the building. A water heater should always

be located in an area with a floor drain or installed in

a drain pan suitable for water heaters. The

manufacturer shall not be held liable for any such

water damage.

Chloride (PPM) -- 80

4. The tank may be located some distance from the boiler

provided the pump is designed to provide the ow

called for in Table 3B - Pressure Drop Values, through

the coil. Also, the further the tank is from the boiler, the

longer the response of the boiler will be to a call from

the tank zone. Insulate piping between the boiler and

the tank.

WARNING

Failure to properly support the tank could result in

property damage or personal injury.

Recommended Clearances

The installation location must provide adequate clearances

for servicing and proper operation of the water heater. A

12 inch vertical clearance is recommended from the top of

the water heater. A zero clearance is allowed for the sides

of the water heater. However, boiler and servicing

clearances must be gured when locating the water

heater.

Indirect Fired Water Heaters Installation and Operating Manual

| 7

Installation & Operating Manual

3 Boiler Side Piping

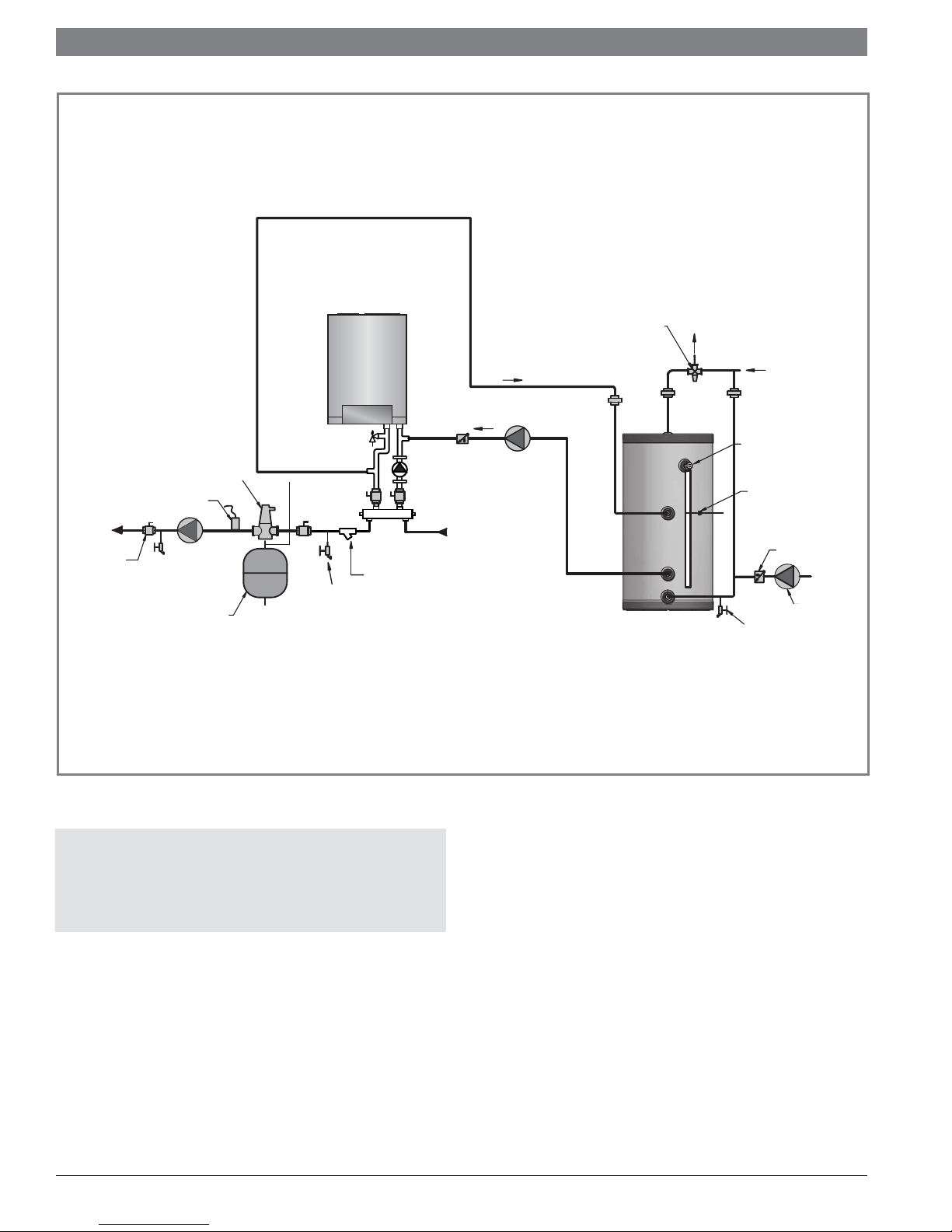

Figures 3-1 thru 3-4 show typical boiler side piping for

several common situations. Regardless of which system is

used it is imperative that the ow rates called for in Table

3B are developed through the coil. This requires properly

sized piping and a properly sized pump. The system shown

in FIG’s 3-1 thru 3-4 are described below:

DHW Prioritization

This piping system is designed to provide direct hot water

priority over the other zones in the heating system. When

there is a Domestic Hot Water (DHW) call for heat, the

controller will shut off the boiler circulator and activate

the domestic hot water circulator. Once the DHW demand

is satised, the boiler circulator will be readjusted as

demand requires. The circulator must be large enough to

move the boiler water through the coils. The

recommended piping for a DHW priority system is

depicted in FIG. 3-1

Zone with Circulator to Aquastat

This system is like the circulator zone system on a straight

heat job except that one of the zones goes to the tank

instead of radiation. As on any circulator zone system

check valves should be installed in each zone to prevent

unwanted circulation through zones which are not calling

for heat. Figure 3-2 illustrates typical circulator zone

piping.

Zone with Valve to Aquastat

As with the circulator zone system, this system is just like

a standard heating zone system except that one of the

zones is connected to the tank coil as shown in FIG. 3-3.

The system circulator must be large enough to move boiler

water through the coil regardless of the ow rate required

through the heating zones.

.

Multiple Tank Connections (Boiler Side)

Multiple tank installations must be done in the “reversereturn” manner. The reason for this is to create the same

pressure drop (and therefore, the same ow) through the

coil of each tank. The boiler manifold piping must be sized

so that each coil has the ow rate called for in Table 3B.

Because the pressure drop through tank coils varies from

size to size, it is hard to predict the ow rate that will be

developed through each coil when two tanks of different

sizes are placed in the same manifold. For this reason it is

best not to mix tanks of different sizes in the same zone if

their recovery is critical.

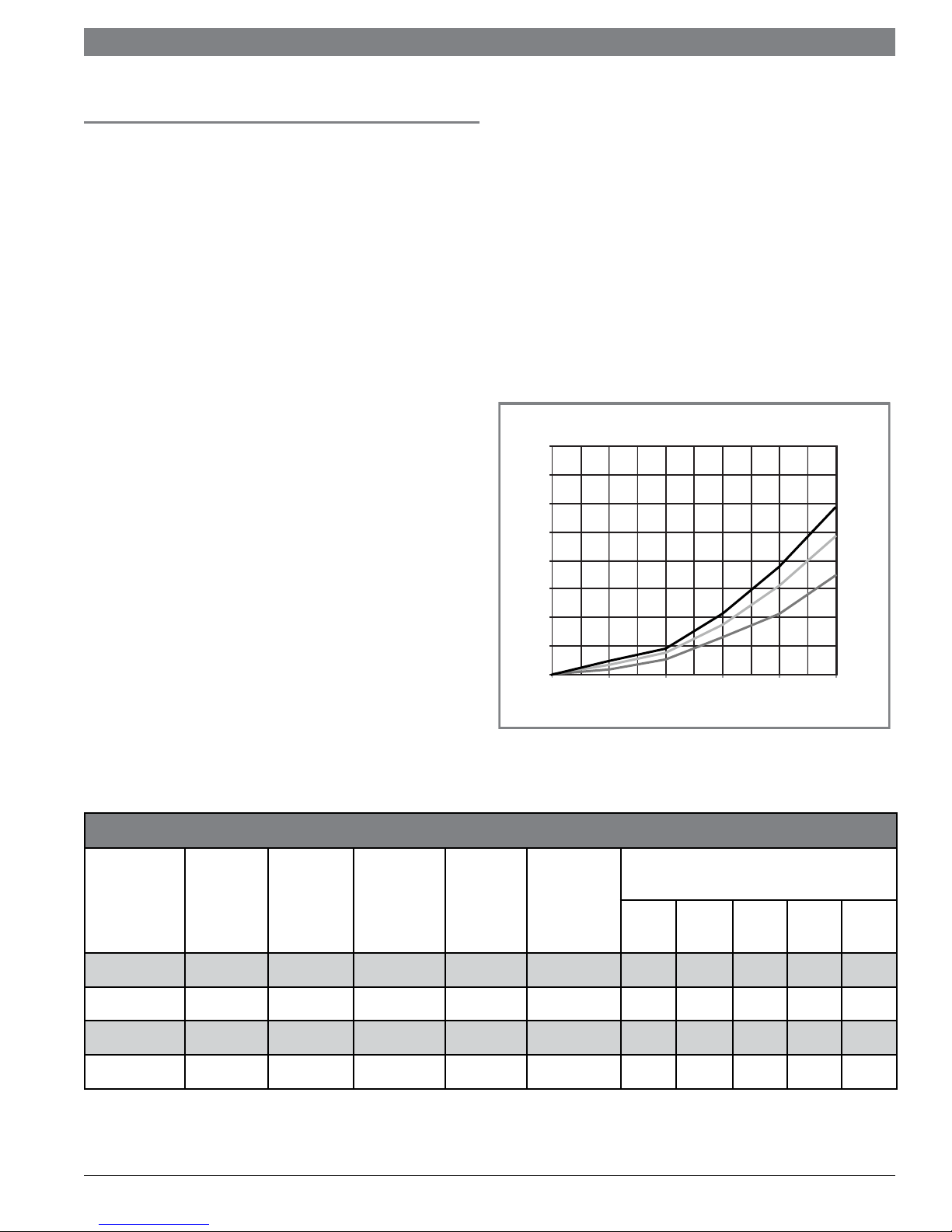

Pressure Drop Chart Table 3A

16

14

12

10

8

6

Head Loss (Ft. of Hd.)

4

2

0

0 5 8 12 16 20

SST450-119

SST250-65/

SST300-80

SST150-40

Flow Rate

Pressure Drop Values Table 3B

Water

Outlet

(IN)

Model

Water

Inlet

(IN)

SST150-40 1 1 1 30.8 10.0 0.41 1.04 2.34 4.16 6.49

SST250-65 1.5 1.5 1 41.5 13.5 0.61 1.57 3.53 6.27 9.80

SST300-80 1.5 1.5 1 41.5 13.5 0.61 1.57 3.53 6.27 9.80

SST450-119 1.5 1.5 1 67.3 22.0 0.73 1.87 4.22 7.50 11.71

8 |

Coil

Connection

(IN)

Pressure Drop (FT/HD)

Coil

Length

(FT)

Surface

area

(SQ-FT)

5

GPM8 GPM

12

GPM

16

GPM

Indirect Fired Water Heaters Installation and Operating Manual

20

GPM

TO

SYSTEM

BALL VALVE

(TYPICAL)

SEPARATOR

SYSTEM SUPPLY

SENSOR

SYSTEM

CIRCULATOR

EXPANSION

TANK

AIR

DRAIN

POINT

GB 142

BOILER

Y-STRAINER

(RECOMMENDED)

FROM

SYSTEM

Installation & Operating Manual

HOT

WATER

OUT

COLD

WATER

IN

PRESSURE RELIEF

VALVE

TANK SENSOR /

AQUASTAT

CHECK VALVE

RECIRCULATION

DRAIN

( FIELD SUPPLY )

PUMP

DOMESTIC

HOT WATER

CIRCULATOR

ANTI-SCALD

MIXING VALVE

SST series tank

Figure 3-1 GB142 Boiler Low Loss Header piping

NOTICE

Please note that these illustrations are meant to show

system piping concept only, the installer is

responsible for all equipment and detailing required

by local codes.

Indirect Fired Water Heaters Installation and Operating Manual

| 9

Loading...

Loading...