Page 1

System Checkout | 17SM CS Series Heat

SYSTEM CHECKOUT

After completing the installation, and before

energizing the unit, the following system checks

should be made:

1. Verify that the supply voltage to the heat pump

is in accordance with the nameplate ratings.

2. Make sure that all electrical connections are

tight and secure.

3. Check the electrical fusing and wiring for the

correct size.

Ensure cabinet and Electrical Box are

properly grounded.

4. Verify that the low voltage wiring between the

thermostat and the unit is correct.

5. Verify that the water piping is complete and

correct.

6. Check that the water flow is correct, and

adjust if necessary.

7. Check the blower for free rotation, and that it

is secured to the shaft.

8. Verify that vibration isolation has been

provided.

9. Unit is serviceable. Be certain that all access

panels are secured in place.

Considerations:

• Always check incoming line voltage power

supply and secondary control voltage for

adequacy. Transformer primaries are dual

tapped for 208 and 230 volts. Connect the

appropriate tap to ensure a minimum of 18

volts secondary control voltage. 24 volts is

ideal for best operation.

•Long length thermostat and control wiring

leads may create voltage drop. Increase wire

gauge or up-size transformers may be required

to insure minimum secondary voltage supply.

• FHP recommends the following guidelines for

wiring between a thermostat and the unit: 18

GA up to 60 foot, 16 GA up to 100 ft and 14 GA

up to 140 ft.

• Do not apply additional controlled devices to

the control circuit power supply without

consulting the factory. Doing so may void

equipment warranties.

• Check with all code authorities on

requirements involving condensate disposal/

over flow protection criteria.

UNIT START-UP

1. Set the thermostat to the highest setting.

2. Set the thermostat system switch to “COOL”,

and the fan switch to the “AUTO” position. The

reversing valve solenoid should energize. The

compressor and fan should not run.

3. Reduce the thermostat setting approximately 5

degrees below the room temperature.

4. Verify the heat pump is operating in the cooling

mode.

5. Turn the thermostat system switch to the

“OFF” position. The unit should stop running

and the reversing valve should de energize.

6. Leave the unit off for approximately (5)

minutes to allow for system equalization.

7. Turn the thermostat to the lowest setting.

8. Set the thermostat switch to “HEAT”.

9. Increase the thermostat setting approximately

5 degrees above the room temperature.

10. Verify the heat pump is operating in the heating

mode.

11. Set the thermostat to maintain the desired

space temperature.

12. Check for vibrations, leaks, etc.

MAINTENANCE

1. Filter changes or cleanings are required at

regular intervals. The time period between

filter changes will depend upon type of

environment the equipment is used in. In a

single family home, that is not under

construction, changing or cleaning the filter

every 60 days is sufficient. In other

applications such as motels, where daily

vacuuming produces a large amount of lint,

filter changes may need to be as frequent as

biweekly.

Equipment should never be used during

construction due to likelihood of wall board

dust accumulation in the air coil of the

equipment which permanently affects the

performance and may shorten the life of the

equipment.

8 733 920 846 (2015/01)Revised 01-15

Page 2

18 | Maintenance SM CS Series Heat Pump

2. An annual “checkup” is recommended by a

licensed refrigeration mechanic. Recording the

performance measurements of volts, amps,

and water temperature differences (both

heating and cooling) is recommended. This

data should be compared to the information on

the unit’s data plate and the data taken at the

3. Lubrication of the blower motor is not

required, however may be performed on some

motors to extend motor life. Use SAE-20 nondetergent electric motor oil.

4. The condensate drain should be checked

annually by cleaning and flushing to insure

proper drainage.

original startup of the equipment.

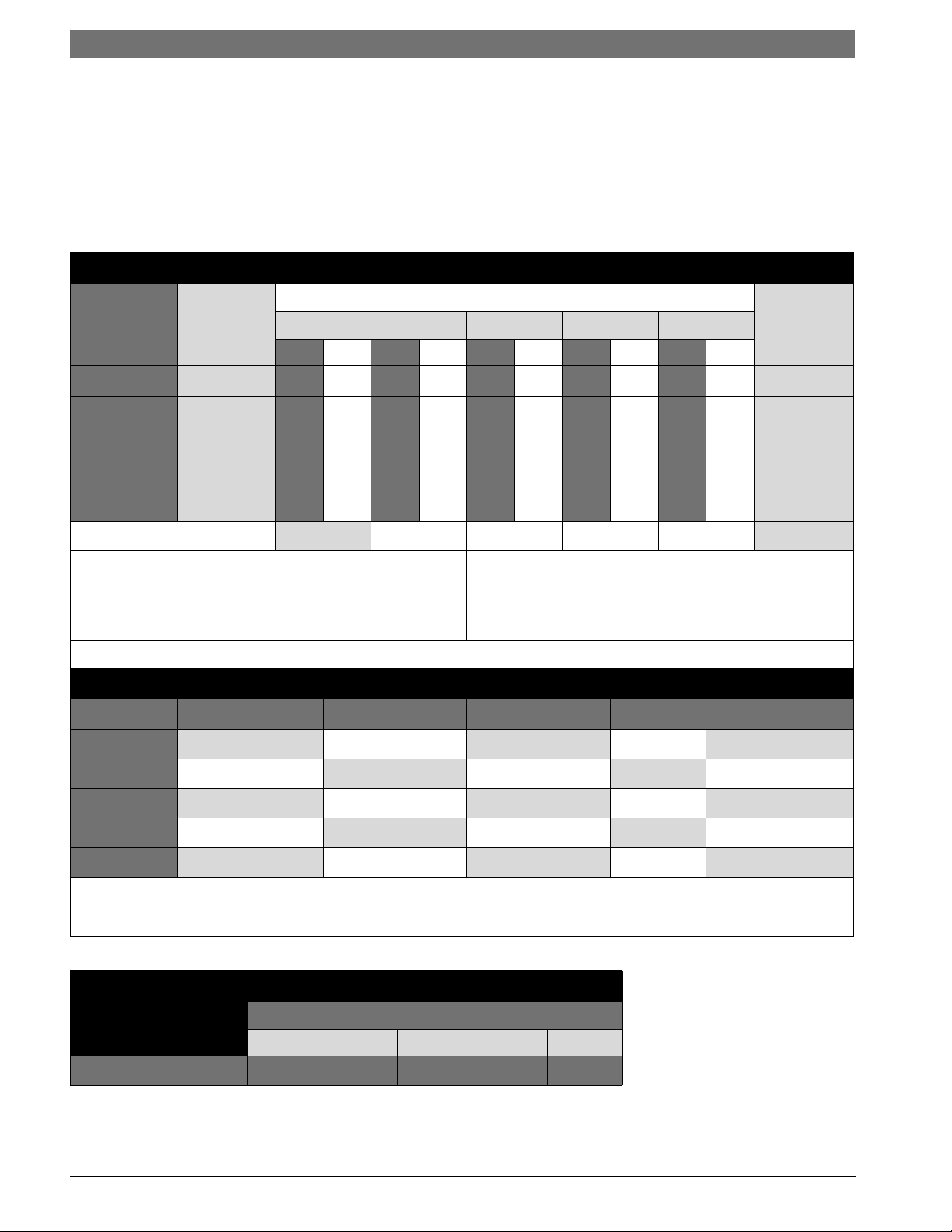

Figure 12: Refrigerant Charge, Line Sizing and Capacity Multiplier Chart

SYSTEM

MODEL

Factory

R410A

Charge

SM024

SM036

SM048

SM060

SM070

CAPACITY MULTIPLIER

(Oz)*

80

86

93

115

127

Refrigerant Line O.D. Size (Based on Equivalent Line Length)

25 FT. 35 FT. 45 FT. 50 FT. 75 FT

LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC.

3/8 3/4 3/8 3/4 3/8 3/4 3/8 3/4 3/8 7/8

3/8 3/4 3/8 3/4 3/8 3/4 3/8 7/8 3/8 7/8

3/8 7/8 3/8 7/8 3/8 7/8 3/8 7/8 3/8 7/8

3/8 1-1/8 3/8 1-1/8 3/8 1-1/8 3/8 1-1/8 3/8 1-1/8

3/8 1-1/8 3/8 1-1/8 3/8 1-1/8 3/8 1-1/8 3/8 1-1/8

1.00 .995 0.990 0.990 0.980

Suct. Line

Riser Max.

3/4

3/4

7/8

7/8

7/8

Example 1:

Model SM036 with 45ft of equivalent length of 3/8” O.D Liquid

Line. Total system charge= Factory charge + (45ft - 25 ft) x .60

oz/ft Total System Charge =86 oz + (20ft x .60 oz/ft) = 98 oz.

Additional 12 oz of R410A refrigerant required.

Note: Charge value shown for paired SM air handler.

Example 2:

Model SM060 with 10ft of equivalent length of 3/8” O.D

Liquid Line. Total system charge= Factory charge - (25ft 10ft) x .60 oz/ft Total System Charge = 115 oz - (15ft x .60 oz/

ft) = 106 oz. Removal of 9oz of R410A refrigerant required.

Charge adjustments for SM CS when paired with DX AH (oz)

Unit

SM024-1CSC

SM036-1CSC

SM048-1CSC

SM060-1CSC

SM070-1CSC

Example 3:

Model SM036 CS paired with DX049 AH with 45ft of equivalent length of 3/8” O.D Liquid Line. Total system charge = Factory

charge + (DX charge adjustments) + (45ft - 25ft) x .60 oz/ft) = 123 oz. Additional 37 oz of R410A refrigerant required.

DX025 DX035 DX049 DX061 DX071

-2 12 ---

- 025--

--22 - -

- --10 6

----0

Figure 13: Liquid Line Charge Per Linear Foot

R410A oz per foot

Liquid Line Size, O.D.

1/4 5/16 3/8 1/2 5/8

.25 .44 .60 1.15 1.95

SM CS Series Heat Pump8 733 920 846 (2015/01) Subject to change without prior notice

Loading...

Loading...