Bosch SM024, SM060, SM070, SM036, SM048 Installation, Operation And Maintenance Manual

SM Series Heat pump

SM024 | SM036 | SM048 | SMO60 | SM070

Installation, Operation and Maintenance Manual

6 720 220 406 (2015/02)

2 |

SM Series Heat Pump

CONTENTS

Key to Symbols...................................................................3

Safety Warnings ................................................................ 3

Standard package.............................................................. 3

Model Nomenclature.......................................................... 3

General Description........................................................... 5

Moving and Storage ........................................................... 6

Initial Inspection ............................................................... 6

Location............................................................................ 6

Configurability .................................................................. 7

Horizontal Configurability .................................................. 7

Required Tools ............................................................ 7

Instructions - Left-Hand Unit (SM0**-1HZ-*L*-**) ............... 7

Instructions - Right-Hand Unit (SM0**-1HZ-*R*-**) ........... 10

Counter-Flow configurability............................................ 13

Vertical Configurability.................................................... 13

Required Tools .......................................................... 15

Access to Internal Components.................................... 15

Blower Re-Configuration ............................................. 17

Condensate Drain Connection Re-configuration ............. 20

HRP Switch Relocation ............................................... 21

Electric Heat Relocation.............................................. 22

Electrical Box re-configuration ..................................... 24

Reinstall All Panels ..................................................... 25

Return and Discharge Duct Flanges .................................. 25

Pre Installation Unit Preparation ...................................... 26

Corner Cap Installation Instructions .............................. 26

DPS Water Flow Proving..............................................38

Pump Relay ............................................................... 38

Comfort Alert Module .................................................38

Smart Start Assist.............................................................39

Mode of Operation Notes............... ...............................40

Heat Recovery Package .................................................... 41

Water Tank Preparation ..............................................41

HR Water Piping.........................................................41

Water Tank Refill ........................................................42

Initial Start-Up ...........................................................42

Sequence of Operation.....................................................43

Cooling Mode ............................................................ 43

Heating Mode ............................................................43

Application Considerations ..............................................45

Well Water Systems.................................................... 45

Cooling Tower/Boiler Systems ..................................... 45

Geothermal Systems ..................................................47

System Checkout .............................................................48

Unit Start-up....................................................................48

Maintenance ...................................................................49

Unit Check-Out Sheet .......................................................50

Customer Data...........................................................50

Unit Nameplate Data................................................... 50

Operating Conditions..................................................50

Auxiliary Heat ............................................................50

Troubleshooting ..............................................................51

Electronic Thermostat Installation ....................................56

Operating Temperatures and Pressures ............................ 57

Airflow Tables..................................................................62

Mounting Vertical Units ................................................... 27

Mounting horizontal Units ................................................ 27

Hanging Bracket kit..........................................................27

Condensate Drain ............................................................ 28

Duct System.................................................................... 29

Piping ............................................................................. 29

Electrical ........................................................................ 30

Safety Devices and the UPM Controller ......................... 31

ECM INTERFACE BOARD ............................................ 35

Dehumidification Method Selector ............................... 36

Constant Torque Motors (ECM).................................... 36

Options........................................................................... 37

Hot Gas Reheat (HGRH).............................................. 37

Electric Heat ............................................................. 37

Heat Recovery Package (HRP) ..................................... 37

Constant Airflow Motor............................................... 38

Water Side Pressure Drop Table........................................64

Wiring Diagrams ..............................................................65

WIRING HARNESS DRAWINGS ..........................................72

Constant Torque Motor (SM0**-***-***-T*)........................72

Constant Airflow Motor (SM0**-***-***-A*) ....................... 73

Spare Parts List ...............................................................74

Dimensional Drawings......................................................95

Horizontal - Straight Through .......................................96

Horizontal - Hanging bracket location ............................97

Counter Flow.................................................. ...........98

CF Vertical ................................................................99

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Key to Symbols | 3SM Series Heat Pump

1

2

3

4

KEY TO SYMBOLS

Warnings

Warnings in this document are identified by

a warning triangle printed against a grey

background. Keywords at the start of the

warning indicate the type and seriousness

of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be

used in this document:

• NOTE indicates a situation that could result in

damage to property or equipment.

• CAUTION indicates a situation that could

result in minor to medium injury.

• WARNING indicates a situation that could

result in sever injury or death.

• DANGER indicates a situation that will result in

severe injury or death.

Important Information

This symbol indicates important information

where there is no risk to property or people.

SAFETY WARNINGS

NOTE: All refrigerant discharged from this

unit must be recovered WITHOUT

EXCEPTION. Technicians must follow

industry accepted guidelines and all local,

state, and federal statutes for the recovery

and disposal of refrigerants. If a compressor

is removed from this unit, refrigerant circuit

oil will remain in the compressor. To avoid

leakage of compressor oil, refrigerant lines

of the compressor must be sealed after it is

removed.

NOTE: To avoid equipment damage, DO

NOT use these units as a source of heating

or cooling during the construction process.

Doing so may affect the unit’s warranty. The

mechanical components and filters will

quickly become clogged with construction

dirt and debris, which may cause system

damage.

STANDARD PACKAGE

WARNING: Installation and servicing of this

equipment can be hazardous due to system

pressure and electrical components. Only

trained and qualified personnel should

install, repair, or service the equipment.

WARNING: Before performing service or

maintenance operations on the system, turn

off main power to the unit. Electrical shock

could cause personal injury or death.

WARNING: When working on equipment,

always observe precautions described in

the literature, tags, and labels attached to

the unit. Follow all safety codes. Wear

safety glasses and work gloves. Use a

quenching cloth for brazing, and place a fire

extinguisher close to the work area.

NOTE: To avoid the release of refrigerant

into the atmosphere, the refrigerant circuit

of this unit must be serviced only by

technicians who meet local, state, and

federal proficiency requirements.

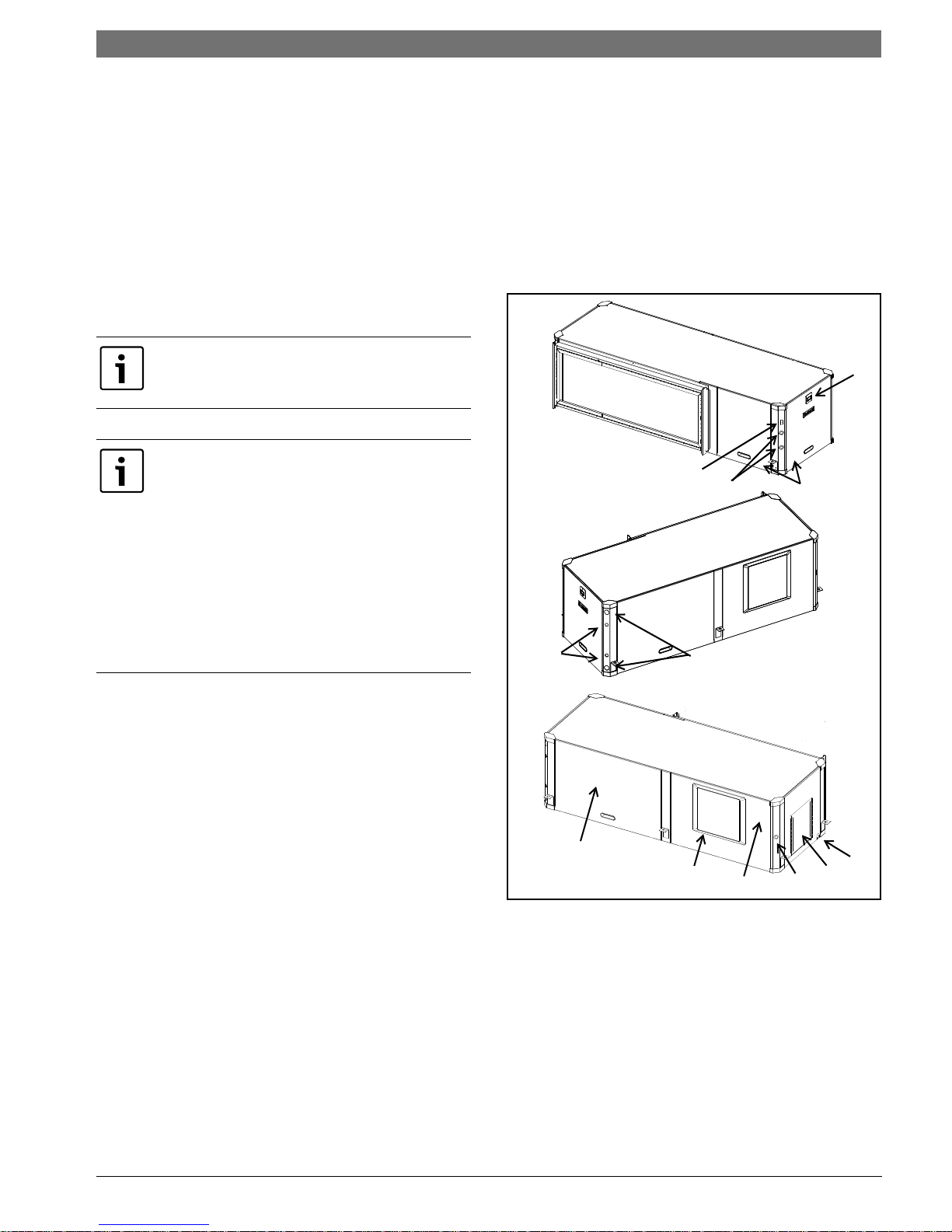

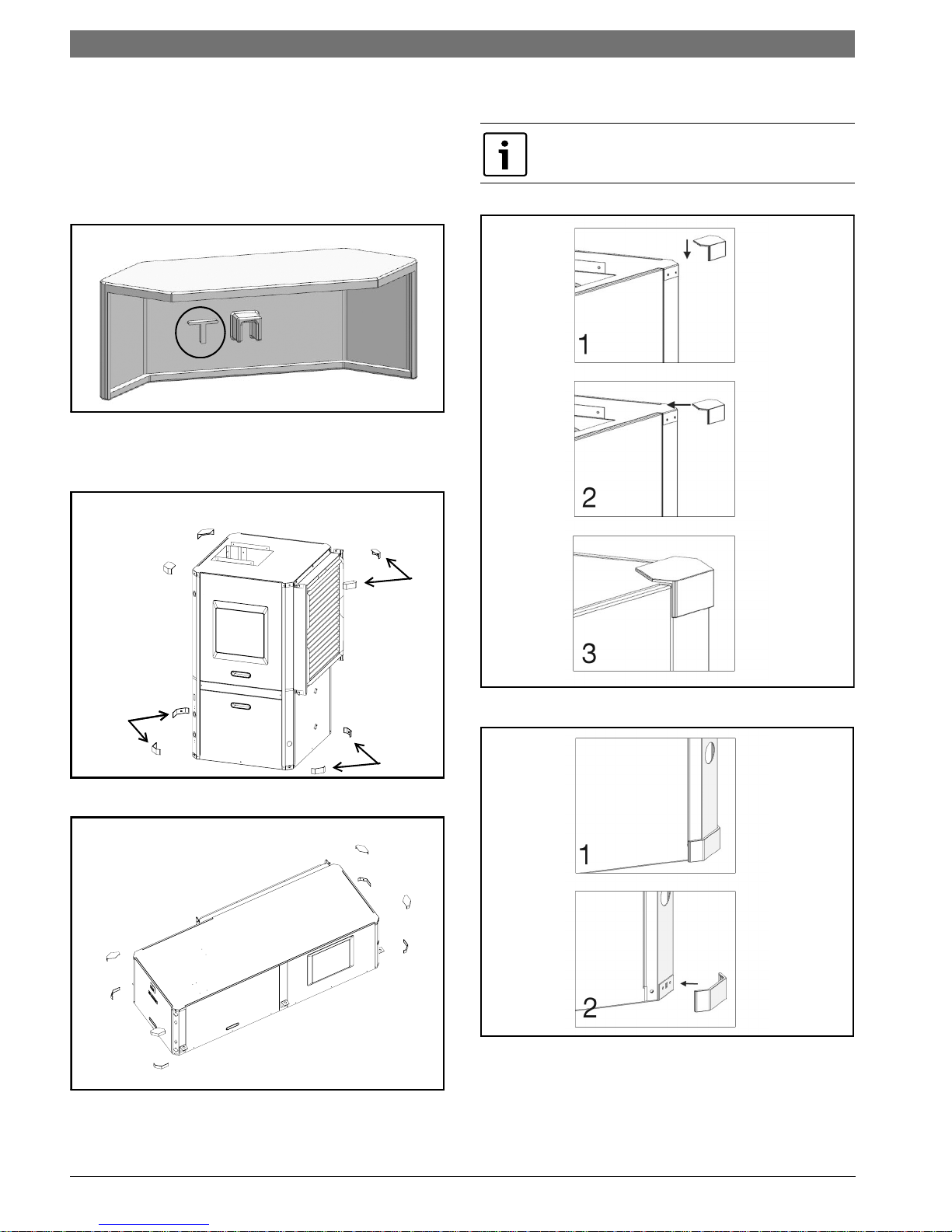

Figure # 1

[1] SM Series Water-to-Air Heat Pump

[2] Corner Caps Package

[3] Installation and Operation Manual

[4] Hanging Bracket kit (HZ unit only)

6 720 220 406 (2015/02)Revised 02-15

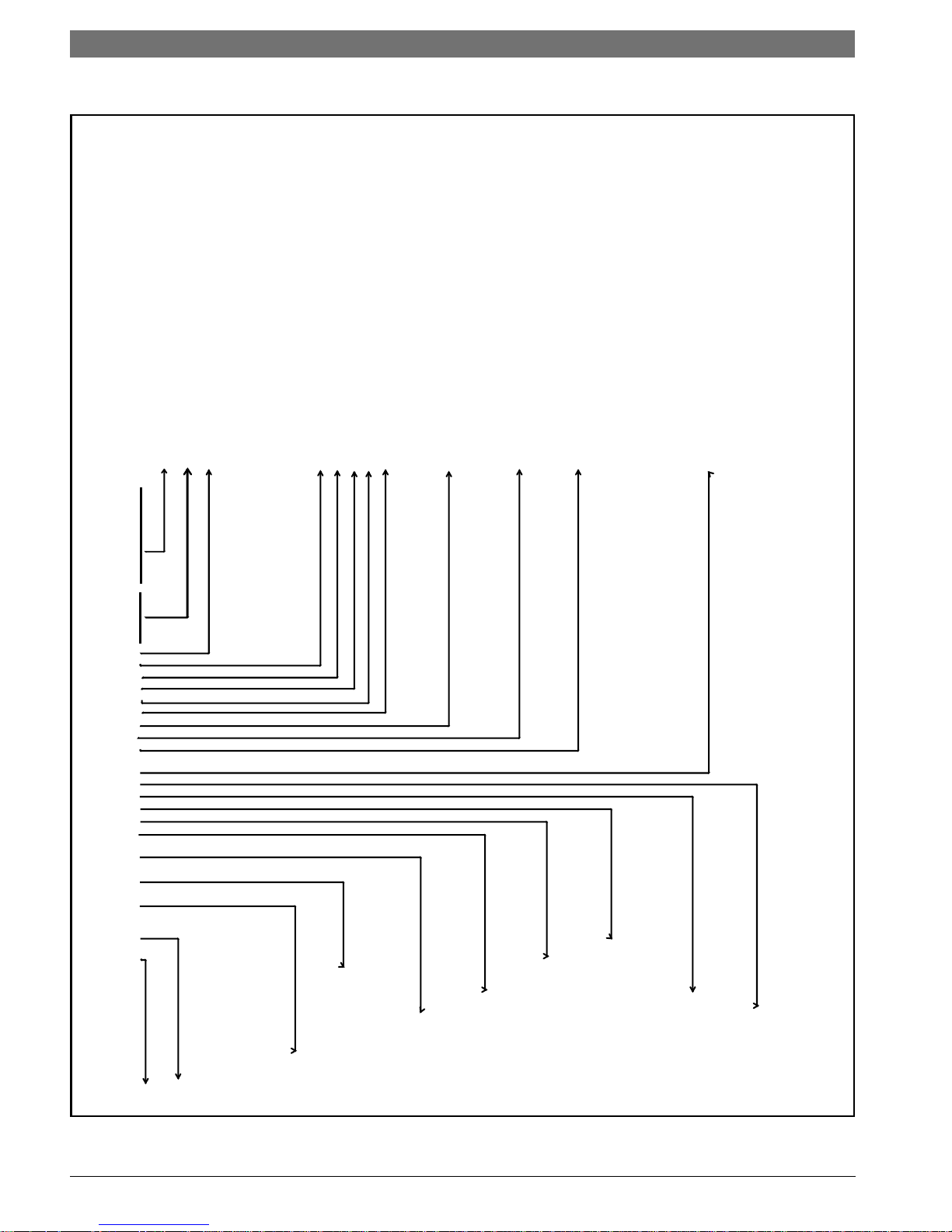

4 | Model Nomenclature

SM024 - 1 VT C - S LTATA - XXGAEXXXX7XXXX5XXXX SB A

SM

75VA Transformer +

Size

024

036 Refrigeration Circuit Options

H - Hot Gas Reheat - On/O

070 D - Heat Recovery Package

Voltage

1 208-230/60/1 General Electrical Options (up to 5 available per unit)

A - EMS relay

Cabinet Conguration E - Pump/valve relay

HZ - Horizontal H - Flow proving switch (DPS)

VT - Vertical N - Comfort Alert Module

CF - Downow (Counterow) S - Smart Start Assist

X - As default for non used electrical codes

Coax Options

N - Cupro-Nickel Application

G - EXTENDED RANGE (Geothermal)

Water Connections

y

F - Front (HZ only) Cabinet Construction

H - Painted Steel / 1/2" Closed Cell Foam

Return Air Conguration

Electric Heat (Dual power connection)

(Not Available with HGRH)

Discharge Air Conguration X - None

T - Top (VT only) A - 5 kW

E - End (HZ only) C - 10 kW

B - Bottom (CF only) D - 15 kW

E - 20 kW

Fan/Motor Options

Revision Level

T - Constant Torque ECM A - Current

Air Coil

T- Tin Plated

MERV13 - 2" w/ 4-SIDED FILTER RACK

MODEL NOMENCLATURE

SM Series Heat Pump

)

048 X - None

060

L - Left

R - Right

A - Constant Airow ECM

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

C - Copper

Figure # 2

S - Side (VT and CF onl

General Description | 5SM Series Heat Pump

1

2

3

4

5

6

7

9

10

3

8

10

GENERAL DESCRIPTION

SM Series Water-to-Air Heat Pumps provide the

best combination of performance and efficiency

available. All units are performance certified to

American Heating and Refrigeration Institute

(AHRI) ISO Standard 13256-1. All SM Water-to-Air

Heat Pumps conform to UL1995 standard and are

certified to CAN/CSA C22.2 No 236 by IntertekETL. The Water-to-Air Heat Pumps are designed to

operate with entering fluid temperature between

20°F to 90°F in the heating mode and between

30°F to 120°F in the cooling mode

NOTE: Heat Pump operating under extreme

conditions will have limitation on air/fluid flow

rates and/or temperatures.

.

NOTE: 50° F Minimum Entering Water

Temperature (EWT) is recommended for well

water applications with sufficient water flow to

prevent freezing. Antifreeze solution is required

for all closed loop applications and EWT below

45°. Cooling Tower/Boiler and Geothermal

applications should have sufficient antifreeze

solution to protect against extreme conditions

and equipment failure. Frozen water coils are

not covered under warranty. Other equivalent

methods of temperature control are acceptable.

Safety devices are built into each unit to provide

the maximum system protection possible when

properly installed and maintained. Each unit has

externally mounted LCD error code display,

allowing unit diagnosis without opening the

cabinet.

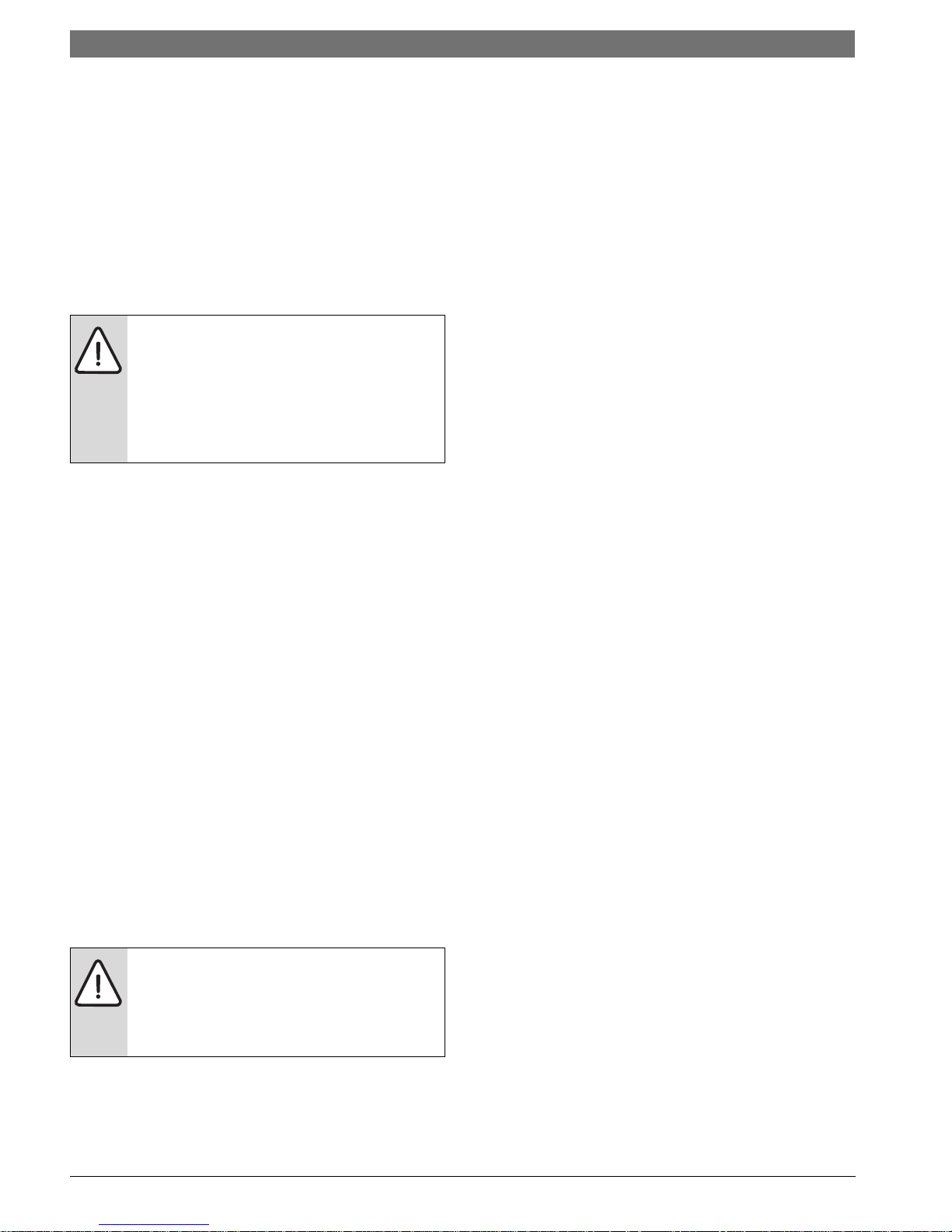

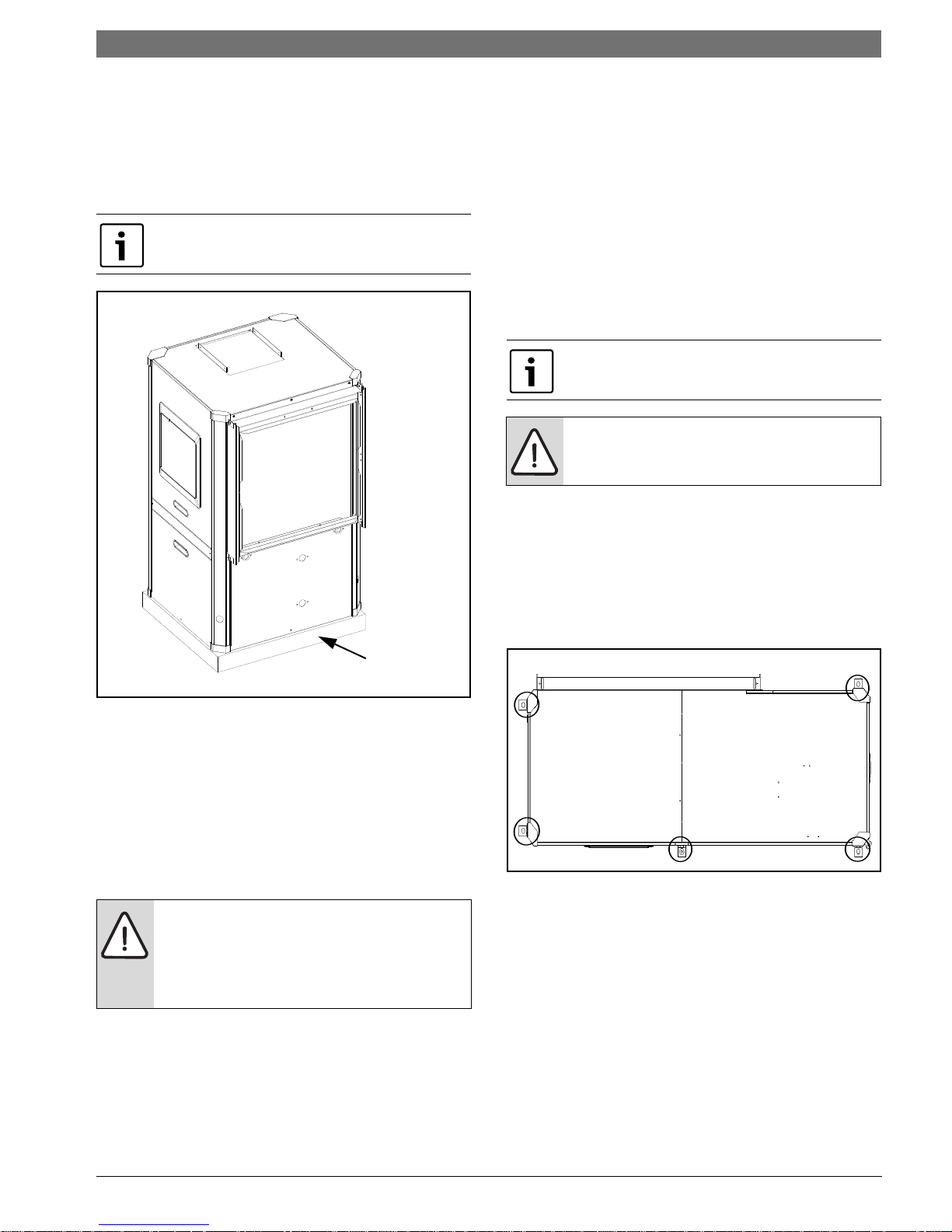

Basic Horizontal unit layout and connections are

shown in Figure #3 . Refer to Dimensional

Drawings for further detail, as well as Vertical and

Counter Flow unit details. Pg#95 through Pg#95

SM Series Water-to-Air Heat Pumps are available in

Vertical (VT), Horizontal (HZ) and Counter-Flow

(CF) configurations. VT units are field convertible

for three discharge/supply air orientations and

left-hand (LH) or right-hand (RH) return

configurations. HZ units have two field

configurable discharge/supply air orientations.

Several factory installed options are available: Hot

Gas Reheat, Electric Heat, Heat Recovery Package,

Smart Start Assist, Constant Airflow Blower Motor,

DPS Water Flow Proving Switch, Auxiliary Pump

Figure # 3

Relay, and Comfort Alert Module. Electric Heat and

Smart Start Assist are also available as field

installed accessory. See Pg#37 for more detail.

[1] LCD Error Code Display

[2] Air handler access panel

[3] Condensing section access panel

[4] Condensate drain connection

[5] Water connection

[6] Heat Recovery water connection (Optional)

[7] Heat Recovery disconnect switch (Optional)

[8] Electrical connection knockout

6 720 220 406 (2015/02)Revised 02-15

6 | Moving and Storage

[9] Electric Heat electrical connection knockout

(Optional)

[10] Blower outlet (Supply Air)

MOVING AND STORAGE

If the equipment is not needed for immediate

installation upon its arrival at the job site, it should

be left in its shipping carton and stored in a clean,

dry area. Units must only be stored or moved in the

normal upright position as indicated by the “UP”

arrows on each carton at all times.

WARNING: For storage If unit stacking is

required, stack units as follows:

Vertical units: less than 6 tons, no more

than two high.

Horizontals units: less than 6 tons, no more

than three high.

INITIAL INSPECTION

Be certain to inspect all cartons or crates on each

unit as received at the job site before signing the

freight bill. Verify that all items have been received

and that there are no visible damages; note any

shortages or damages on all copies of the freight

bill. In the event of damage or shortage, remember

that the purchaser is responsible for filing the

necessary claims with the carrier. Concealed

damages not discovered until after removing the

units from the packaging must be reported to the

carrier within 24 hours of receipt.

SM Series Heat Pump

LOCATION

Locate the unit in an indoor area that allows easy

removal of the filter and access panels, and has

enough room for service personnel to perform

maintenance or repair. Provide sufficient room to

make fluid, electrical, and duct connection(s). If

the unit is located in a confined space such as a

closet, provisions must be made for return air to

freely enter the face of unit’s air coil. On horizontal

units, allow adequate room below the unit for a

condensate drain trap and do not locate the unit

above supply piping.

NOTE: These units are not approved for

outdoor installation; therefore, they must

be installed inside the structure being

conditioned. Do not locate in areas that are

subject to freezing.

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Configurability | 7SM Series Heat Pump

1

1

2

2

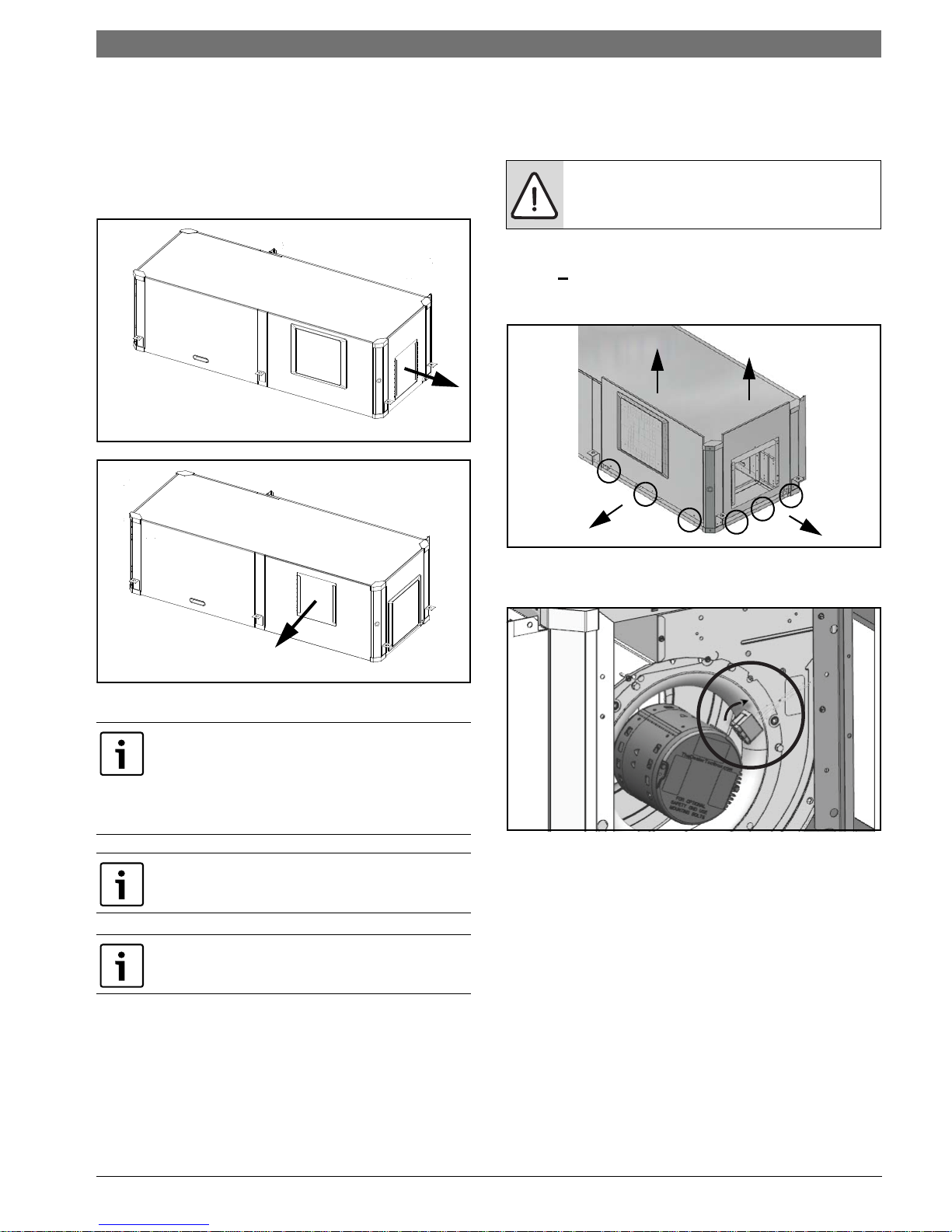

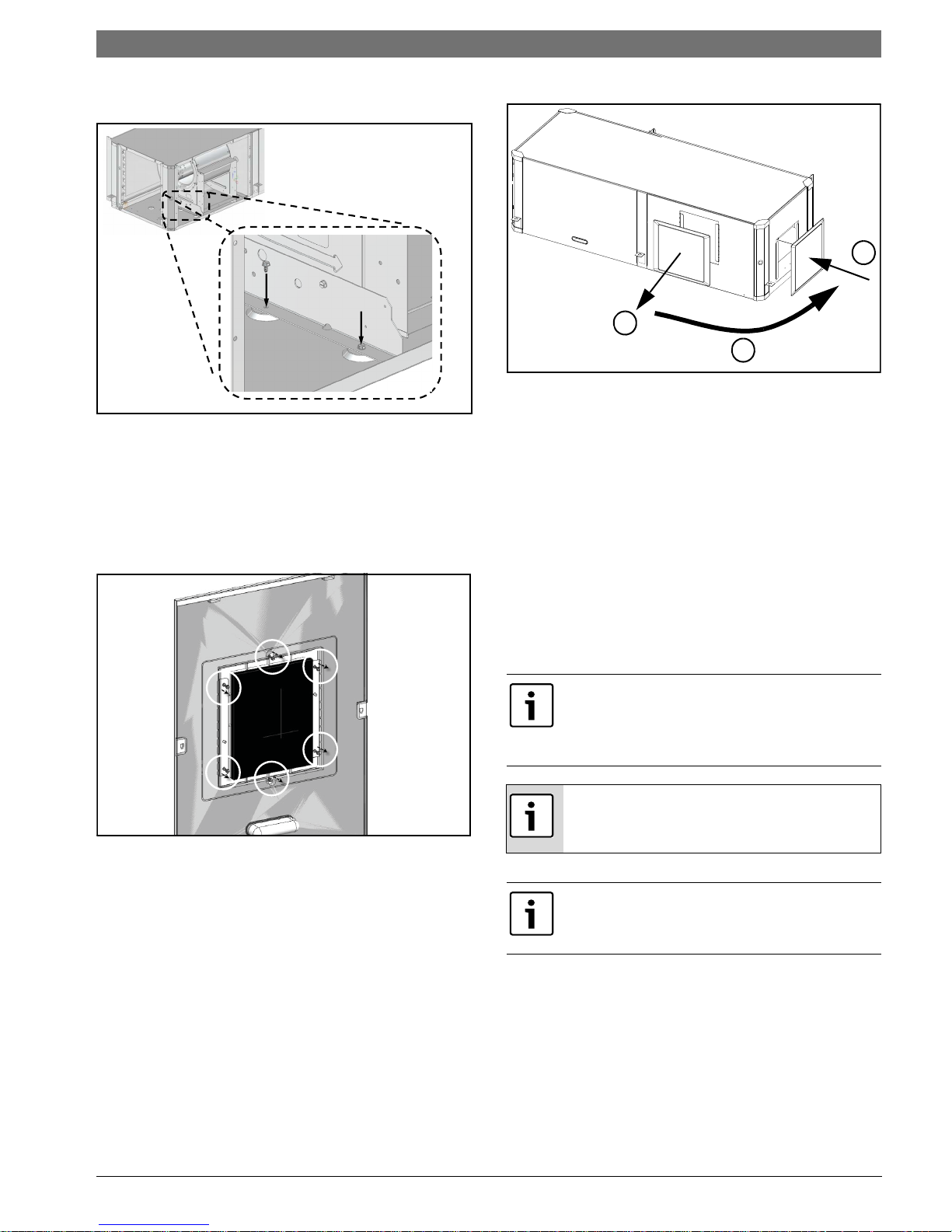

CONFIGURABILITY

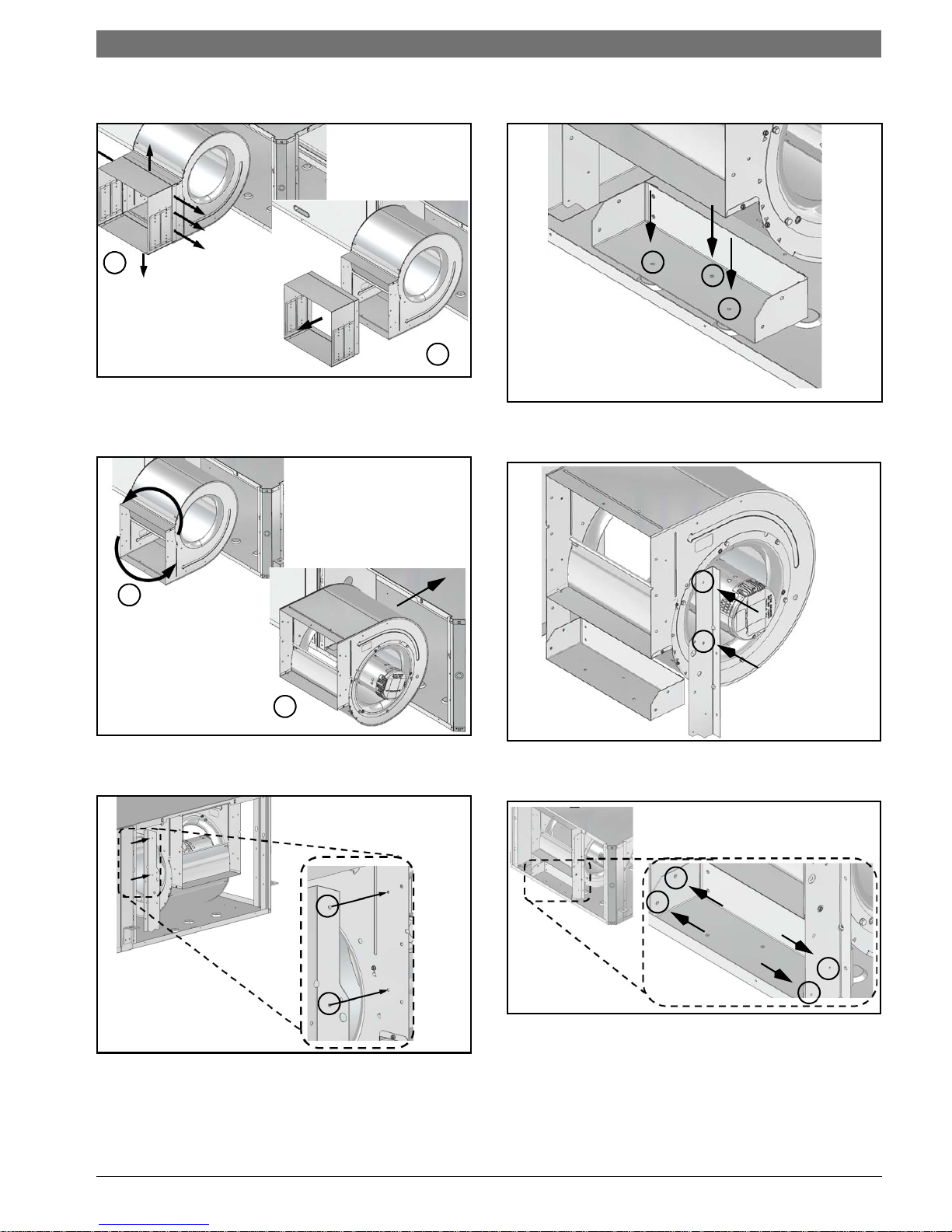

HORIZONTAL CONFIGURABILITY

The Horizontal Configuration water source heat

pump is designed to have a field configurable

blower orientation: end blow (default) and straight

through. (Figure #4 and #5)

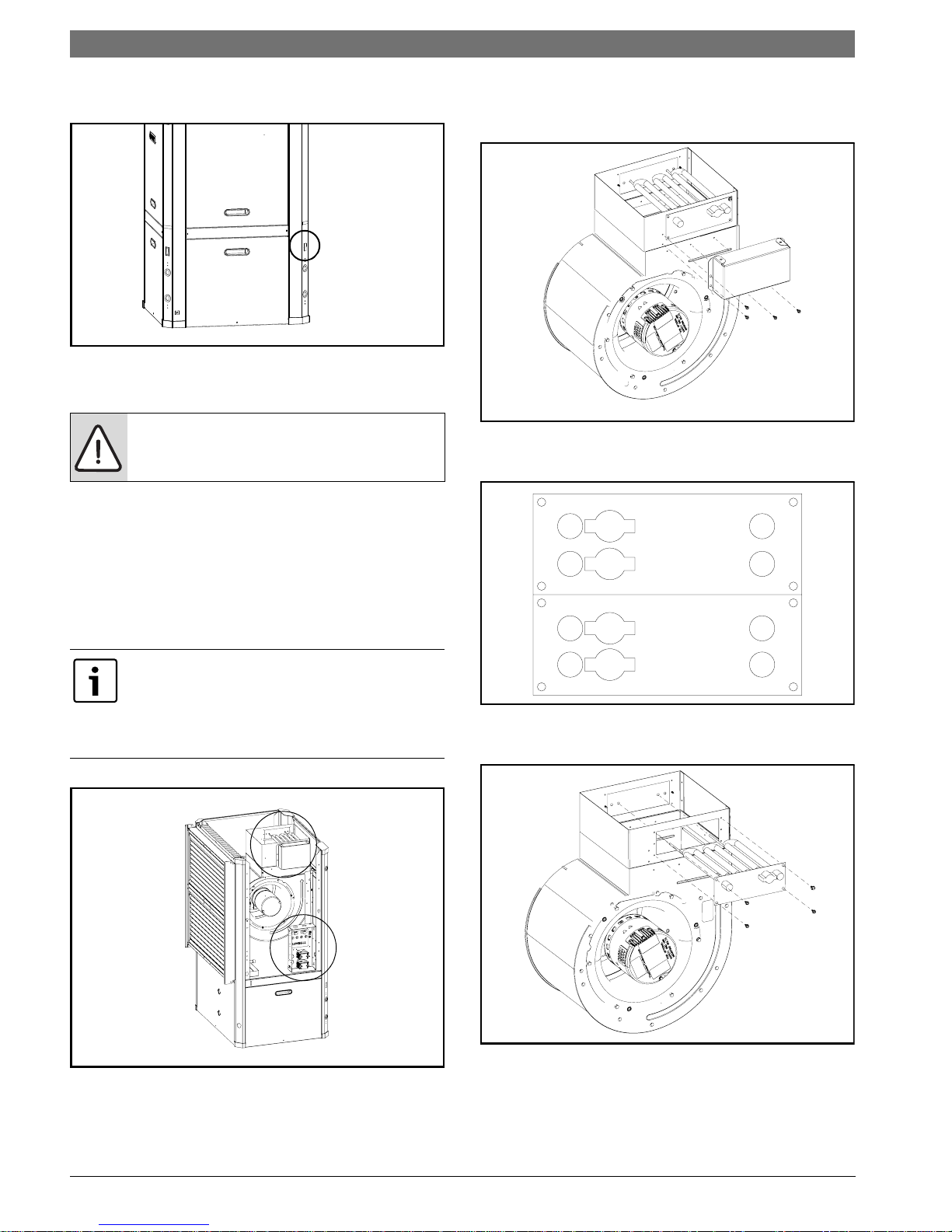

Figure # 4

• 1/4" hex head driver

• Needle nose pliers

• 5/16”-1/4” ratchet wrench

NOTE: Discharge air configuration change is

not possible on Heat Pumps equipped with

Electric Heat Option.

Instructions - Left-Hand Unit (SM0**1HZ-*L*-**)

1. Remove and retain end and side panels.(Figure

#6)

Figure # 5

Left-Hand and Right-hand Horizontal (HZ) units

have different Blower Configuration instructions.

---------------------------------------------------------------

Left- Hand unit instructions refer to Pg#7 and

Right-Hand unit instructions refer to Pg#10.

Internally mounted electric heat is only available

in End Blow configuration.

Blower configuration changes should be done

prior to unit being installed in the final location.

Figure # 6

2. Disconnect blower motor wiring and ground

wire fastened to blower housing.(Figure#7)

Figure # 7

Required Tools

• 5/16" hex head driver

•3/8" hex head driver

• 7/16" hex head driver

• Flat screw driver

• Phillips screw driver

6 720 220 406 (2015/02)Revised 02-15

8 | Horizontal Configurability

SM Series Heat Pump

3. Remove and retain bracket by removing (3)

screws. (Figure #8)

Figure # 8

4. Loosen blower assembly by removing (4)

screws. (Figure #9)

6. Rotate the blower into its new

position.(Figure#11)

Figure # 11

7. Remove and retain remaining bracket by

removing (2) screws. (Figure #12)

Figure # 9

5. Remove and retain bracket by removing (2)

screws. (Figure #10)

Figure # 10

Figure # 12

8. Remove the blower assembly by sliding it

forward. (Figure #13)

Unit top is notched to allow blower to slide

through.

Figure # 13

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Horizontal Configurability | 9SM Series Heat Pump

1

2

1

2

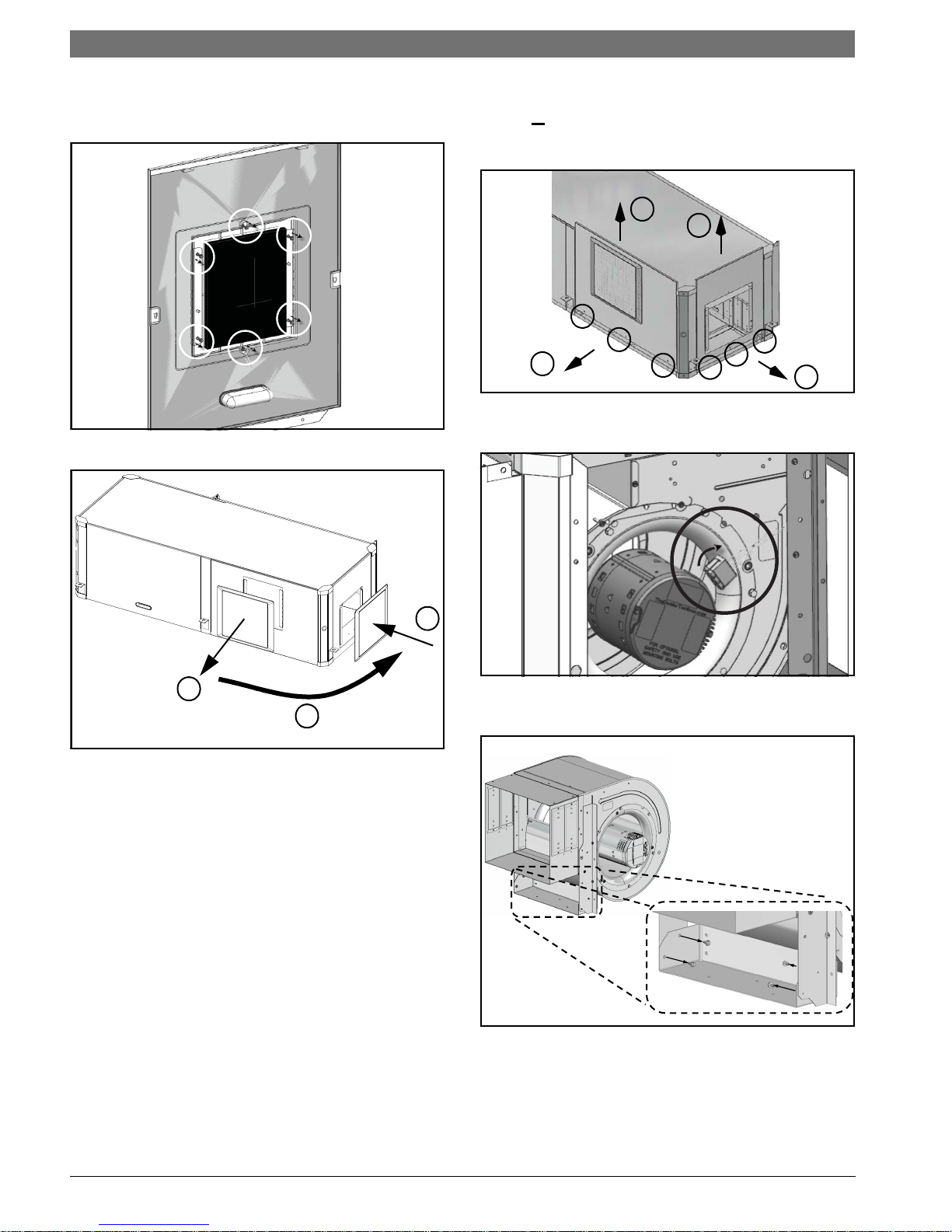

9. Remove and discard blower collar by removing

(8) screws. (Figure #14)

Figure # 14

10. Reorient the blower assembly 180 degree with

blower “belly” down and slide back into the

cabinet. (Figure #15)

12. Reinstall bracket removed in step (#3) using

(3) screws in the same location. (Figure#17)

Figure # 17

13. Reinstall remaining bracket using (2) screws.

(Figure#18)

Figure # 15

11. Reinstall bracket in the new vertical position

using (2) screws. (Figure #16)

Figure # 16

Figure # 18

14. Connect vertical and horizontal brackets by

installing (4) screws. (Figure#19)

Figure # 19

15. Reconnect blower motor wiring and ground

wire.

6 720 220 406 (2015/02)Revised 02-15

10 | Horizontal Configurability

2

1

3

1

1

2

2

SM Series Heat Pump

16. Remove and retain plastic Blower opening

cover by removing (6) screws and reinstall it in

the new location (Figure#20 and #21)

Figure # 20

Instructions - Right-Hand Unit (SM0**1HZ-*R*-**)

1. Remove and retain end and side

panels.(Figure#22)

Figure # 22

2. Disconnect blower motor wiring and ground

wire fastened to blower housing.(Figure#23)

Figure # 21

17. Reinstall all unit panels.

Figure # 23

3. Remove and retain (4) screws under the

blower collar. (Figure #24)

Figure # 24

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

NOTE: Air coil is in close proximity to the

blower. Air coil fins are easily damaged.

Great care must be taken during this step to

avoid coil damage. Shipping cardboard can

be used as protection during blower

removal and installation.

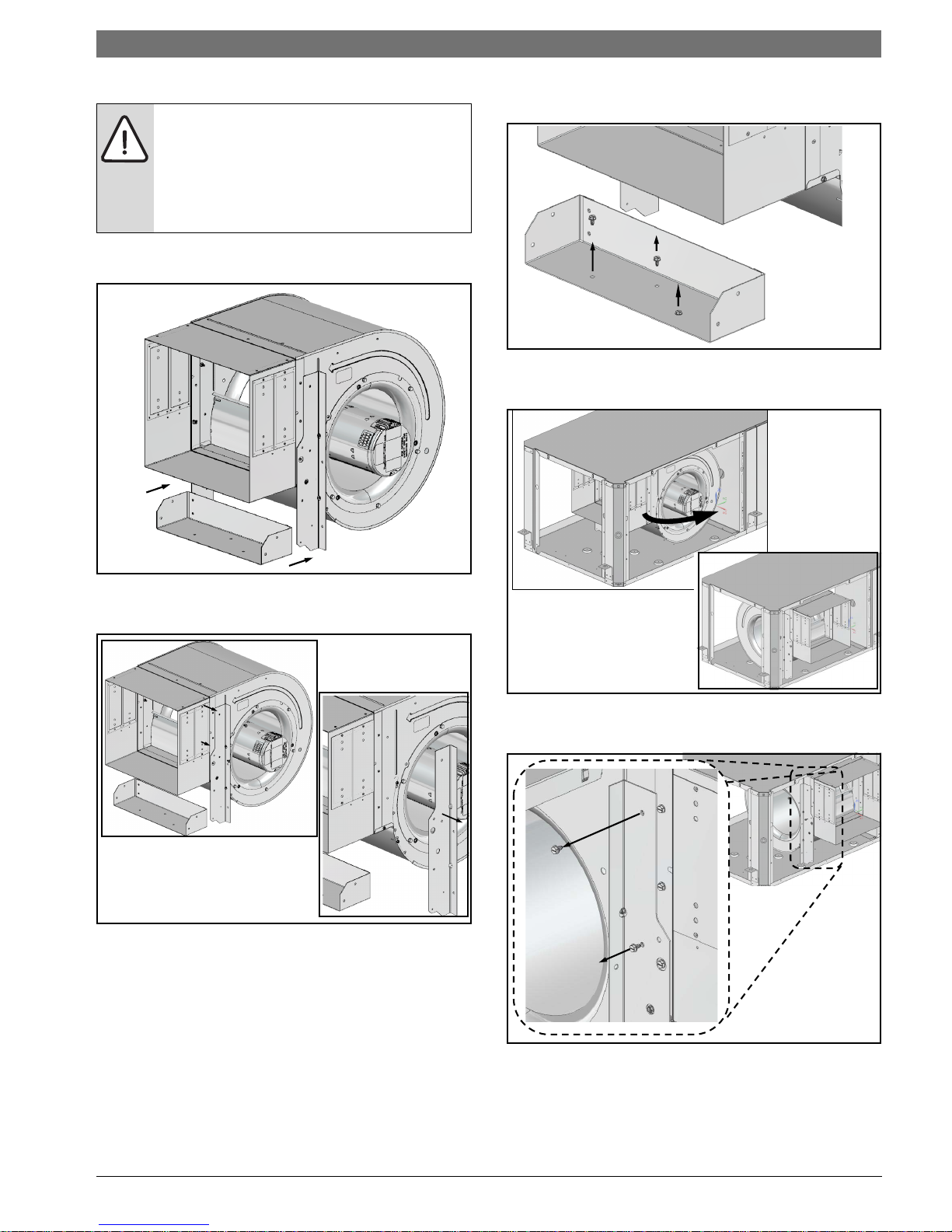

4. Slide blower assembly away from mounting

bracket. (Figure #25)

Horizontal Configurability | 11SM Series Heat Pump

6. Remove and discard horizontal blower bracket

by removing (3) screws. (Figure #27)

Figure # 27

7. Rotate the blower into its new

position.(Figure#28)

Figure # 25

5. Remove and retain (1) vertical bracket by

removing (2) screws. (Figure #26)

Figure # 26

Figure # 28

8. Remove and retain remaining vertical blower

bracket by removing (2) screws. (Figure #29)

Figure # 29

6 720 220 406 (2015/02)Revised 02-15

12 | Horizontal Configurability

SM Series Heat Pump

9. Remove the blower assembly by sliding it

forward. (Figure #30)

Unit top is notched to allow blower to slide

through.

Figure # 30

10. Remove and discard blower collar by removing

(8) screws. (Figure #31)

11. Reorient the blower assembly 180 degree with

blower “belly” up. (Figure #32)

Figure # 32

12. Move the blower back into the cabinet. (Figure

#33)

Figure # 31

Figure # 33

13. Reinstall (2) vertical blower brackets in the

new horizontal position using (4) screws.

(Figure #34)

Figure # 34

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

14. Secure (2) the now horizontal blower brackets

2

1

3

to the unit base using (4) screws. (Figure#35)

Figure # 35

15. Reconnect blower motor wiring and ground

wire.

16. Remove and retain plastic Blower opening

cover by removing (6) screws and cutting/

tearing insulation at perforations around the

perimeter of cover. Reinstall it in the new

location (Figure#36 and #37)

Counter-Flow configurability | 13SM Series Heat Pump

Figure # 37

17. Reinstall all unit panels.

COUNTER-FLOW CONFIGURABILITY

The Counter-Flow Configuration water source heat

pump is a dedicated down flow configuration.

Available from the factory in Left-hand and righthand return air configurations.

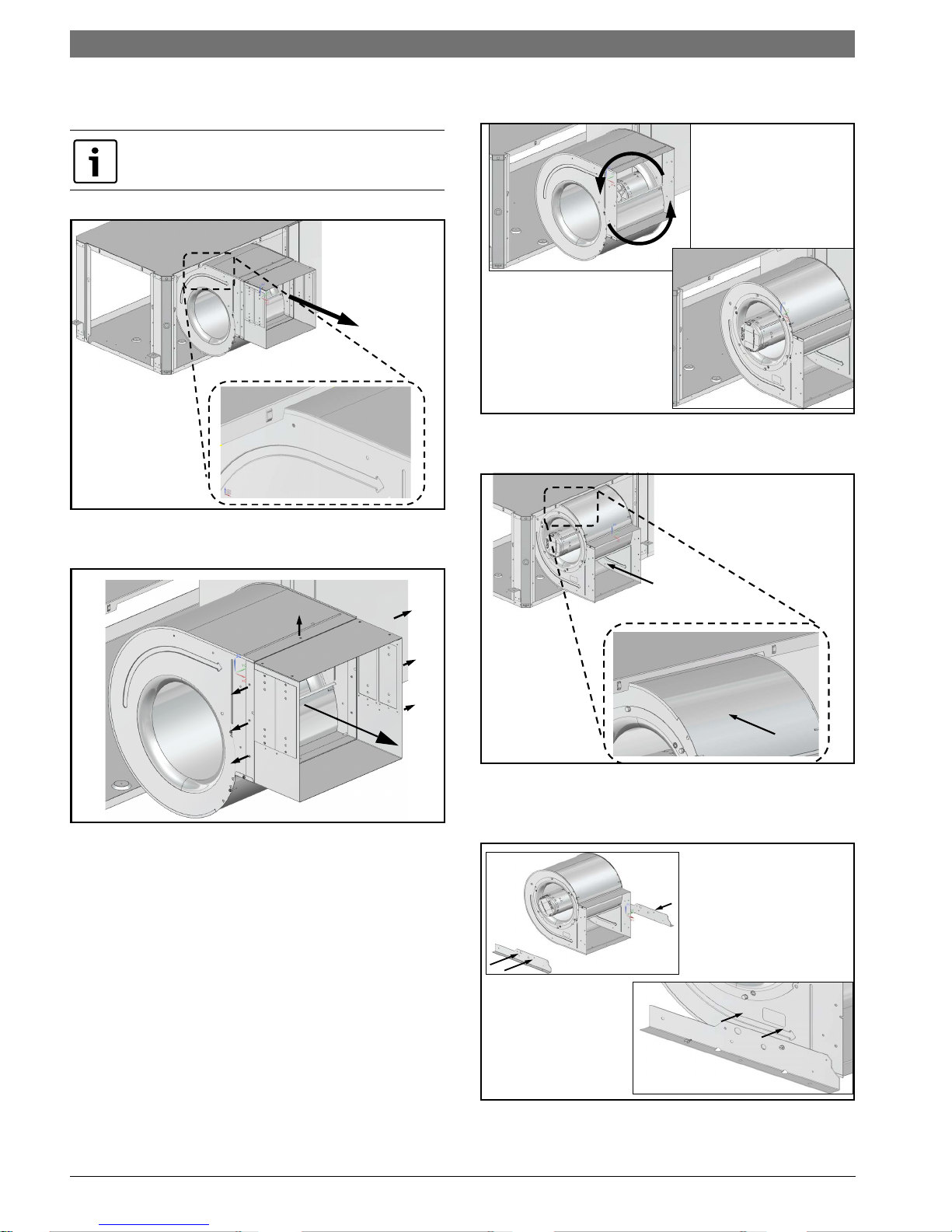

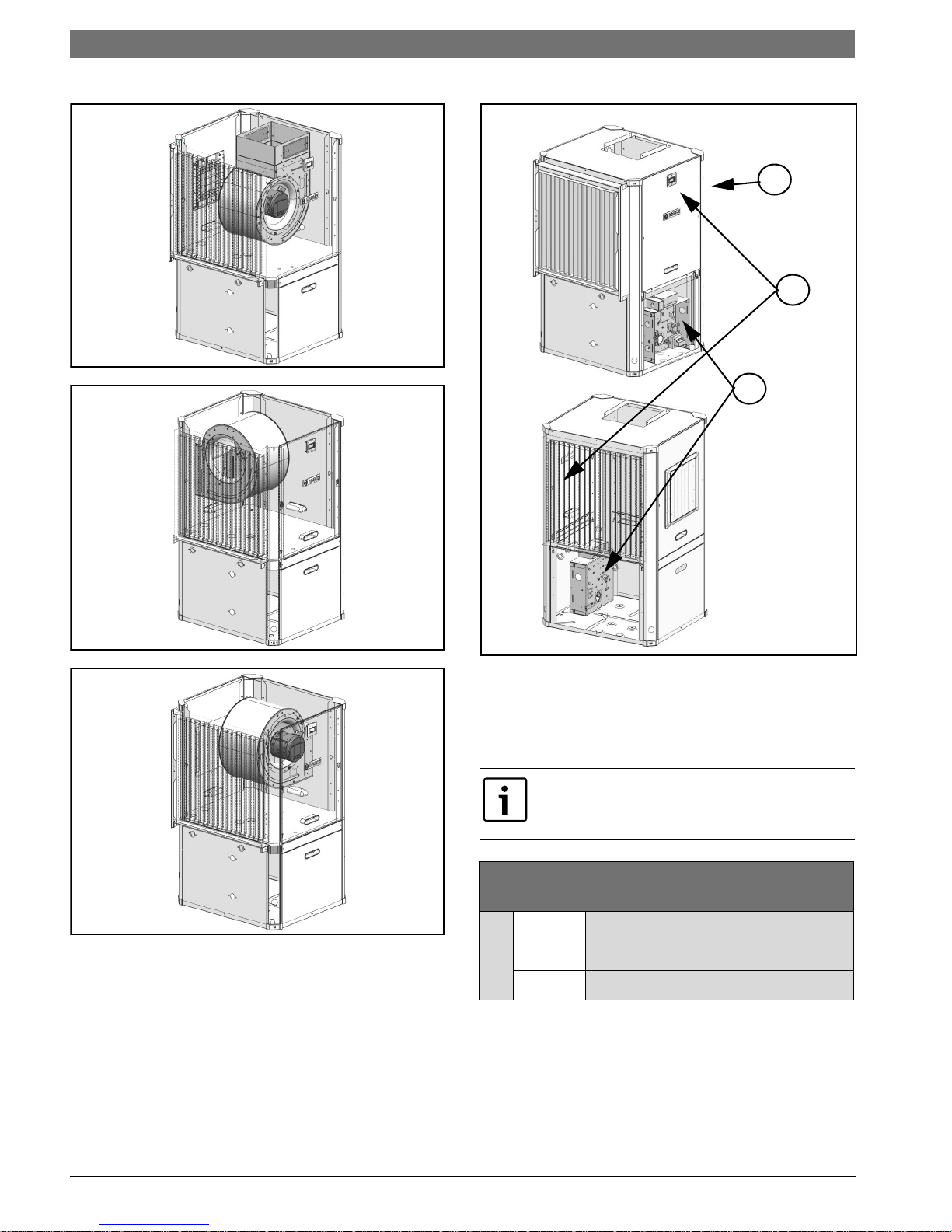

VERTICAL CONFIGURABILITY

The Vertical (VT) Configuration water source heat

pump is designed to be field configured for various

configurations. This is achieved by relocating

Electrical box (E-box), unit panels and reorienting

blower to discharge UP, BACK OR SIDE. See Figure

#37 through #41 for more detail.

The unit, as shipped from the factory, does not

have configuration on the discharge air from to

side or back, field configuration kit is requiered,

(sold as an accessory Kit).

Figure # 36

Discharge air configuration change is not

possible on Heat Pumps equipped with

Electric Heat Option.

Blower, E-box and panel configuration

changes should be done prior to unit being

installed in the final location.

6 720 220 406 (2015/02)Revised 02-15

14 | Vertical Configurability

1

2

3

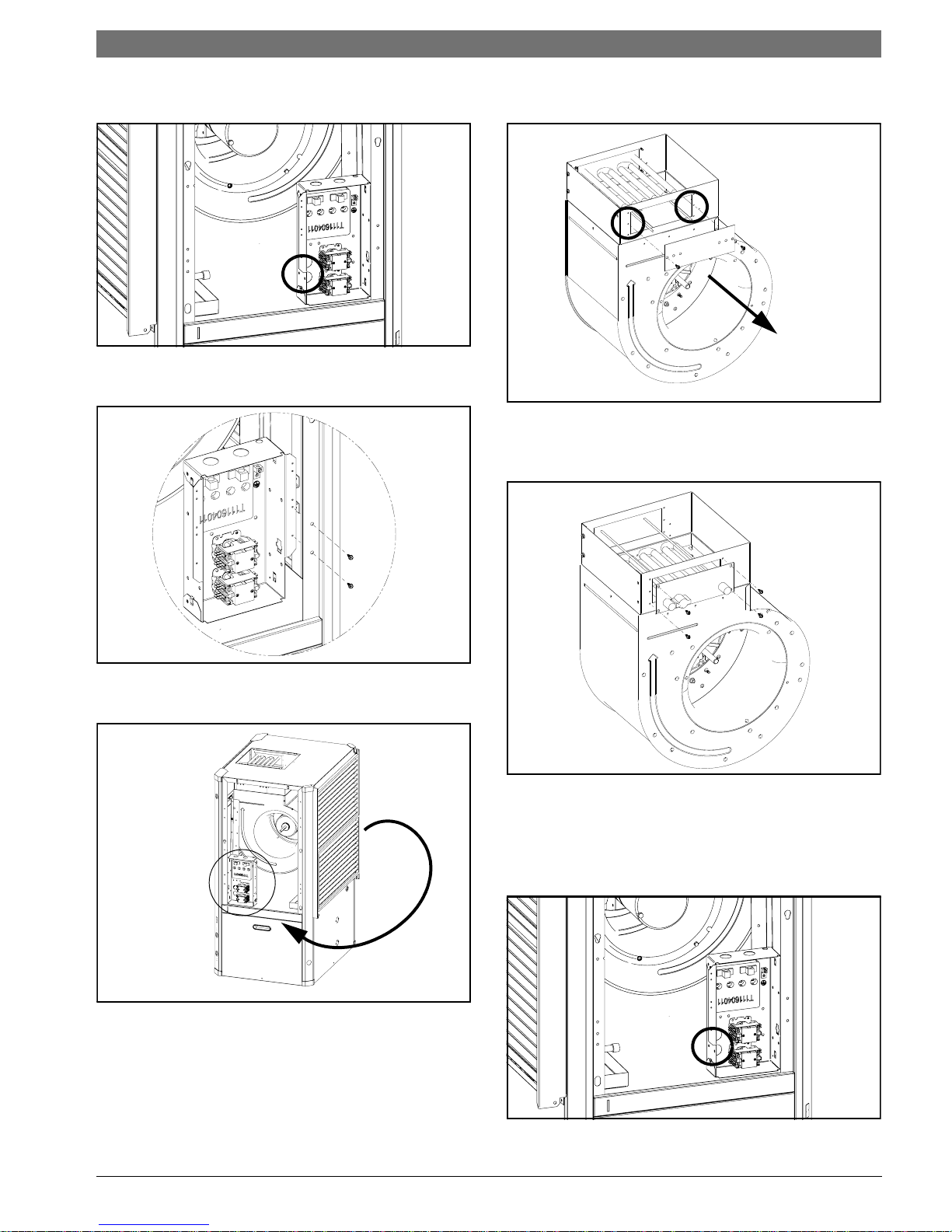

Figure # 38 Top Discharge (Default)

SM Series Heat Pump

Figure # 39 Back Discharge

Figure # 40 Side Discharge

Figure # 41

[1] Logo/Front Panel

[2] Electrical Box

[3] Default Configuration (can be ordered as either

right or left hand return)

Internally mounted electric heat is only available

in Top Discharge configuration. See table below

for details

Blower Orientation and Electric Heat

Compatibility

Up Yes Internally or Duct Mounted

Back

Blower

Side

Duct Mounted

Duct Mounted

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Required steps Possible unit configurations

How to use this table:

• Select desired configuration

from “possible unit

configurations”.

• Instructions with “X” have to

be performed to reconfigure

the unit.

Vertical Configurability | 15SM Series Heat Pump

ACCESS TO INTERNAL COMPONENTS

(PG#15)

BLOWER RE-CONFIGURATION (PG#17)

E-BOX CONFIGURATION (PG#24)

ELECTRIC HEAT RELOCATION* (PG#22)

CONDENSATE DRAIN RELOCATION

(PG#20)

HRP SWITCH* (PG#21)

REINSTALL PANELS (PG#25)

*APPLIES IF OPTION IS INSTALLED

[1] AIR COIL

[2] E-BOX (UNIT FRONT)

[3] BLOWER

X APPLICABLE STEP

All heat pumps are supplied with panel belt

which needs to be removed to access screws

for panel removal. The panels have additional

internal fasteners to prevent any air leakage.

For safety precautions two persons are

required to perform this operation.

Left return,

top discharge

Right return,

top

discharge

Left return,

rear

discharge

Right

return, rear

discharge

XXXXX

X XXX

X XX

X*

X XX

X* X* X* X*

XXXXX

Access to Internal Components

1. Using a Flat Screw driver remove and retain

Panel Belt by inserting the screwdriver into the

slot and releasing the catch.

(Figures#42and#43)

The belt is held in place by a clip on one side

and an interference fit on the other end.

Right return,

left

discharge

Left return,

right

discharge

Required Tools

• 5/16" hex head driver

•3/8" hex head driver

• 7/16" hex head driver

• Flat screw driver

• Phillips screw driver

•1/4" hex head driver

• Needle nose pliers

Figure # 42

6 720 220 406 (2015/02)Revised 02-15

16 | Vertical Configurability

1) UP

2) AWAY

1) UP

2) AWAY

Figure # 43

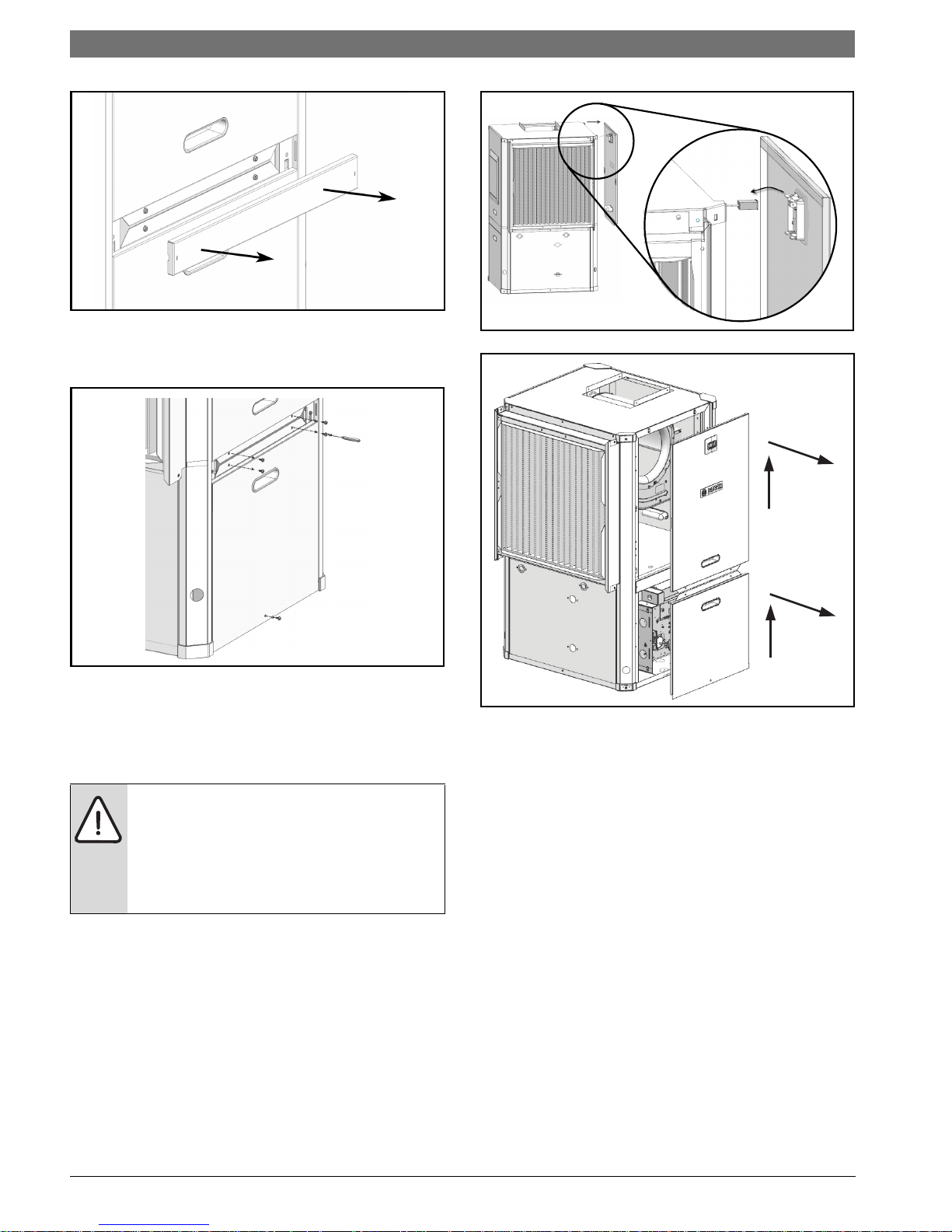

2. Remove and retain Condensing Section access

panels (bottom panel) by removing (3) screws.

(Figure #44)

SM Series Heat Pump

Figure # 45

Figure # 44

3. Remove and retain Air Handler Panel by lifting

up and out as shown in Figure #46. Remove

panel about 12" away from the cabinet and

unplug LCD screen wiring. (Figures #45

and#46)

The unit panel mounted diagnostic display

is connected to the heat pump controls with

a wire harness. Use care when removing the

display panel and carefully disconnect and

reconnect the harness when repositioning

the panel.

Figure # 46

4. Repeat steps 1–3 for all three sides.

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

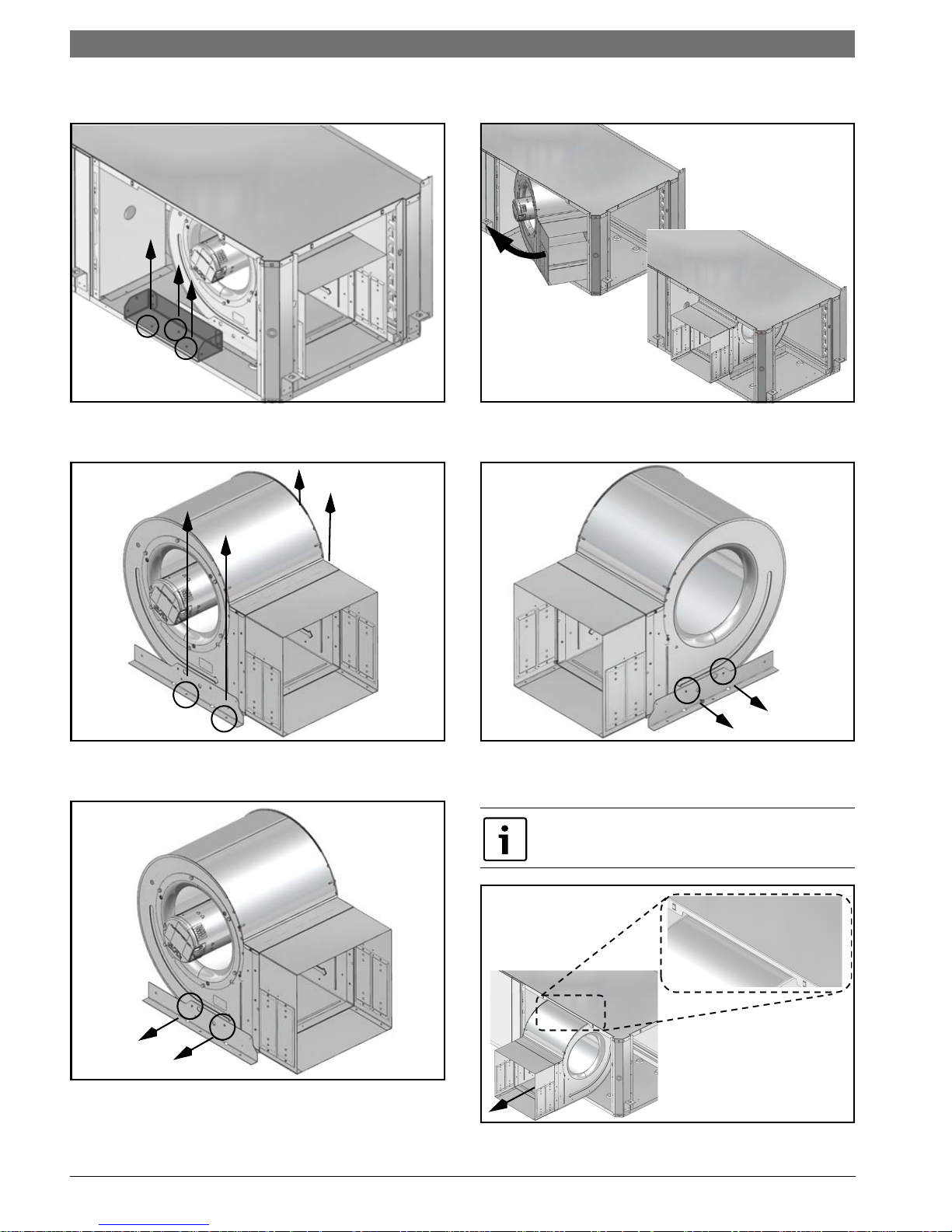

Blower Re-Configuration

This instruction details re-configuration of

blower from UP to SIDE discharge. Reconfiguration to other side uses similar steps.

1. Remove and retain diagonal support brackets

on Front and Back sides of the unit. (Figure

#47)

Vertical Configurability | 17SM Series Heat Pump

Figure # 49

4. Remove screws on both sides of the blower

securing vertical blower bracket to horizontal

support.(Figure#50)

Figure # 47

2. Unplug electrical connections of Blower motor

and ground wire connected to blower housing.

(Figure #48)

Figure # 48

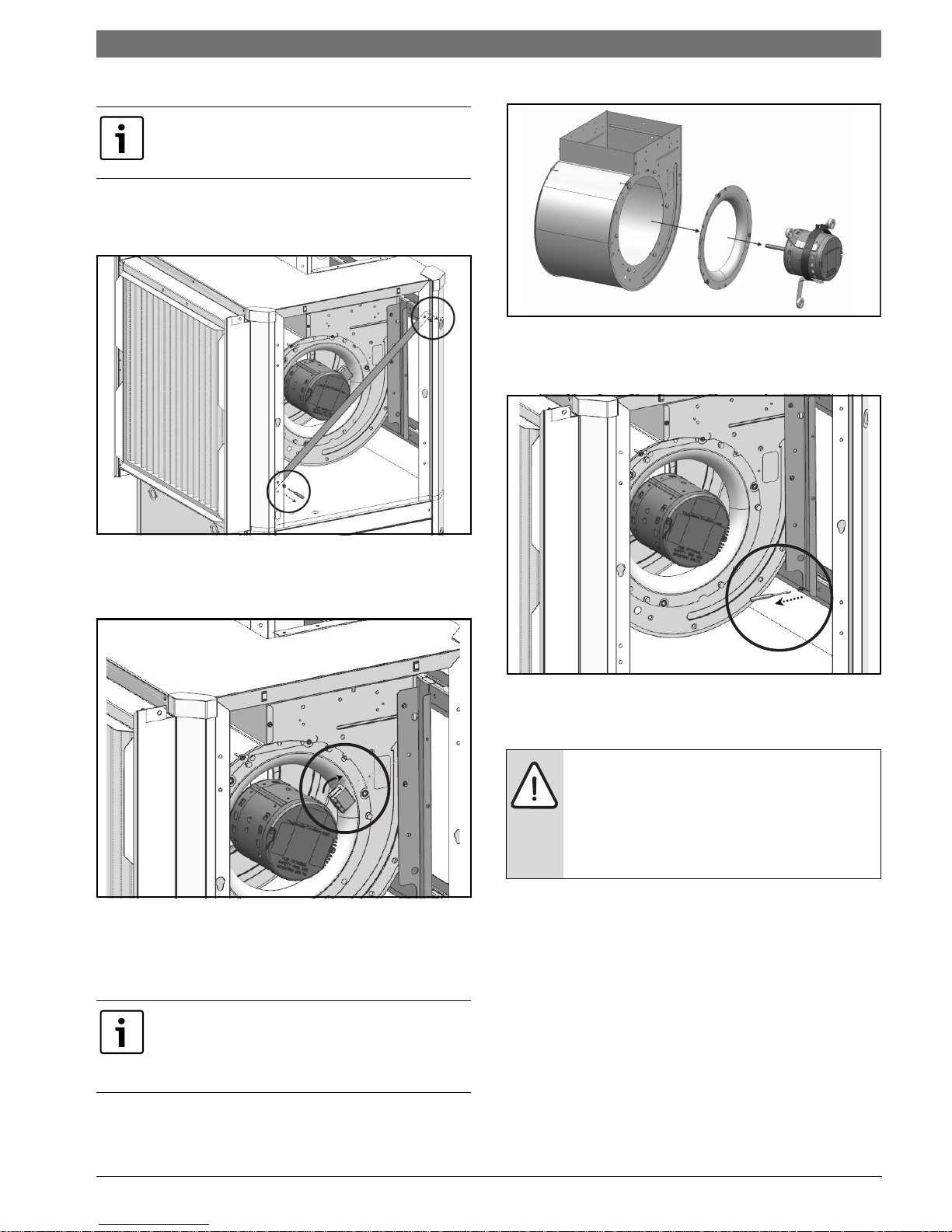

3. Remove and retain blower motor and inlet ring

assembly by removing (3) bolts securing

blower motor bracket and screws securing the

blower inlet ring. (Figure #49)

Figure # 50

5. Remove and retain blower assembly by lifting

up. (Figure #51)

Air coil is in close proximity to the blower

and air coil fins are easily damaged. Great

care must be taken during this step to avoid

coil damage. Shipping cardboard can be

used as protection during blower removal

and installation.

Removing the blower motor and blower wheel

greatly simplifies handling of the blower

assembly and reduces the chance of damaging

heat pump components.

6 720 220 406 (2015/02)Revised 02-15

18 | Vertical Configurability

1

2

FRONT OF THE PANEL VIEW

Figure # 51

6. Remove and discard blower collar. (Figure

#52)

Discharge air configuration change is not

possible on Heat Pumps equipped with

Electric Heat Option.

SM Series Heat Pump

7. Remove and retain side panel blower opening

cover by removing (6) phillips head screws and

cutting/tearing insulation at perforations

around the perimeter of cover.(Figures #53

and #54)

Figure # 53

Figure # 52

Figure # 54

8. Reinstall blower opening cover in the TOP

panel. (Figure #55)

Figure # 55

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Vertical Configurability | 19SM Series Heat Pump

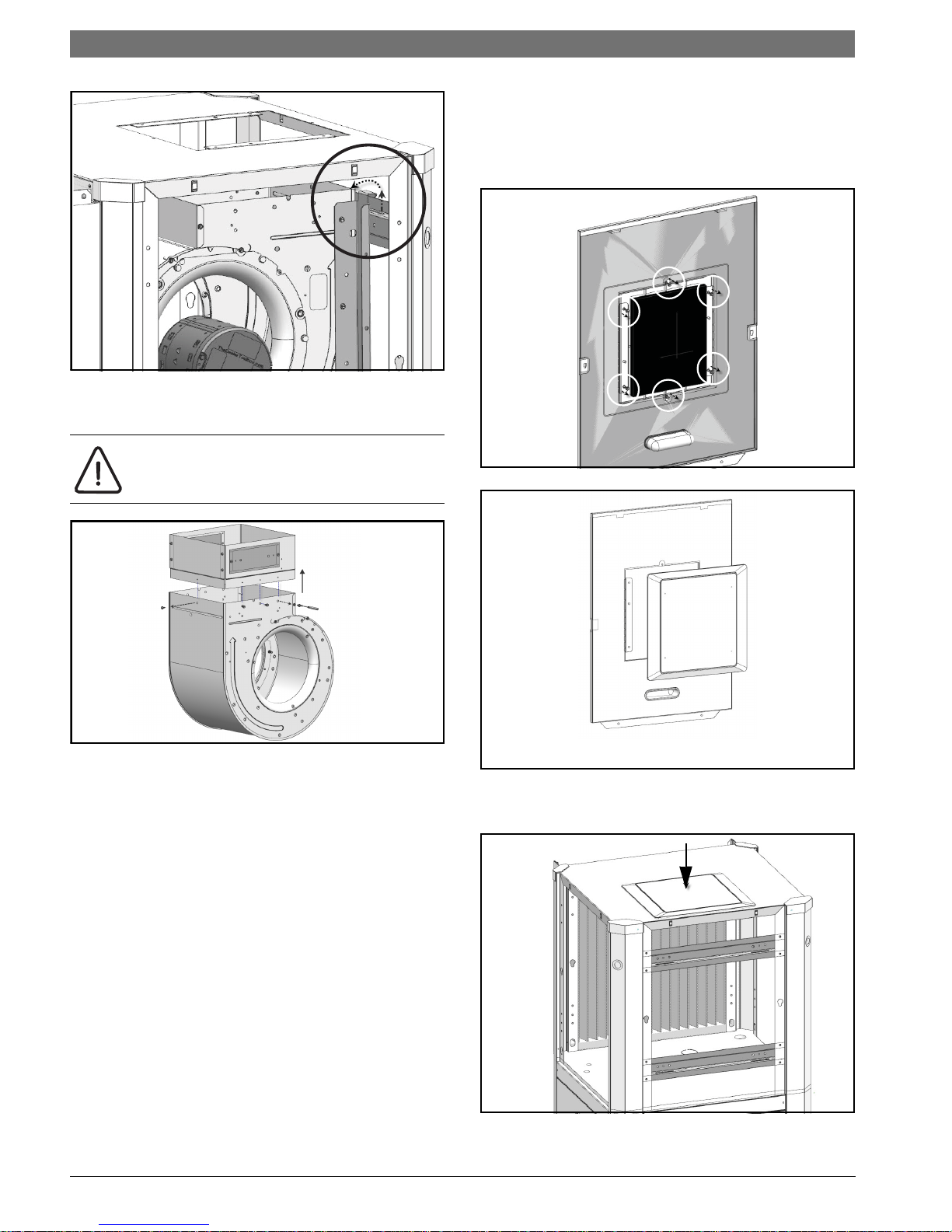

9. Remove and retain (2) horizontal blower

support brackets by removing (4) screws in

each. (Figure #56)

Upper bracket contains two push-in rubber

bump stops.

Figure # 56

10. Reinstall brackets removed in Step (9) on the

same side of the unit as the blower outlet.

(Figure #57)

11. Remove and retain vertical brackets from

blower by removing (4) screws, (2) on each

side of the blower. (Figure #58)

Figure # 58

12. Reinstall vertical brackets in new orientation.

(Figure #59)

Ensure bracket with push-in rubber bump stops

is installed in the top position.

Figure # 57

Figure # 59

13. Reinstall the blower assembly in the new

desired location, using the existing holes.

(Figure

#60)

NOTE: Be aware of blower housing

proximity to air side coil and potential for

coil damage.

Figure # 60

6 720 220 406 (2015/02)Revised 02-15

20 | Vertical Configurability

SM Series Heat Pump

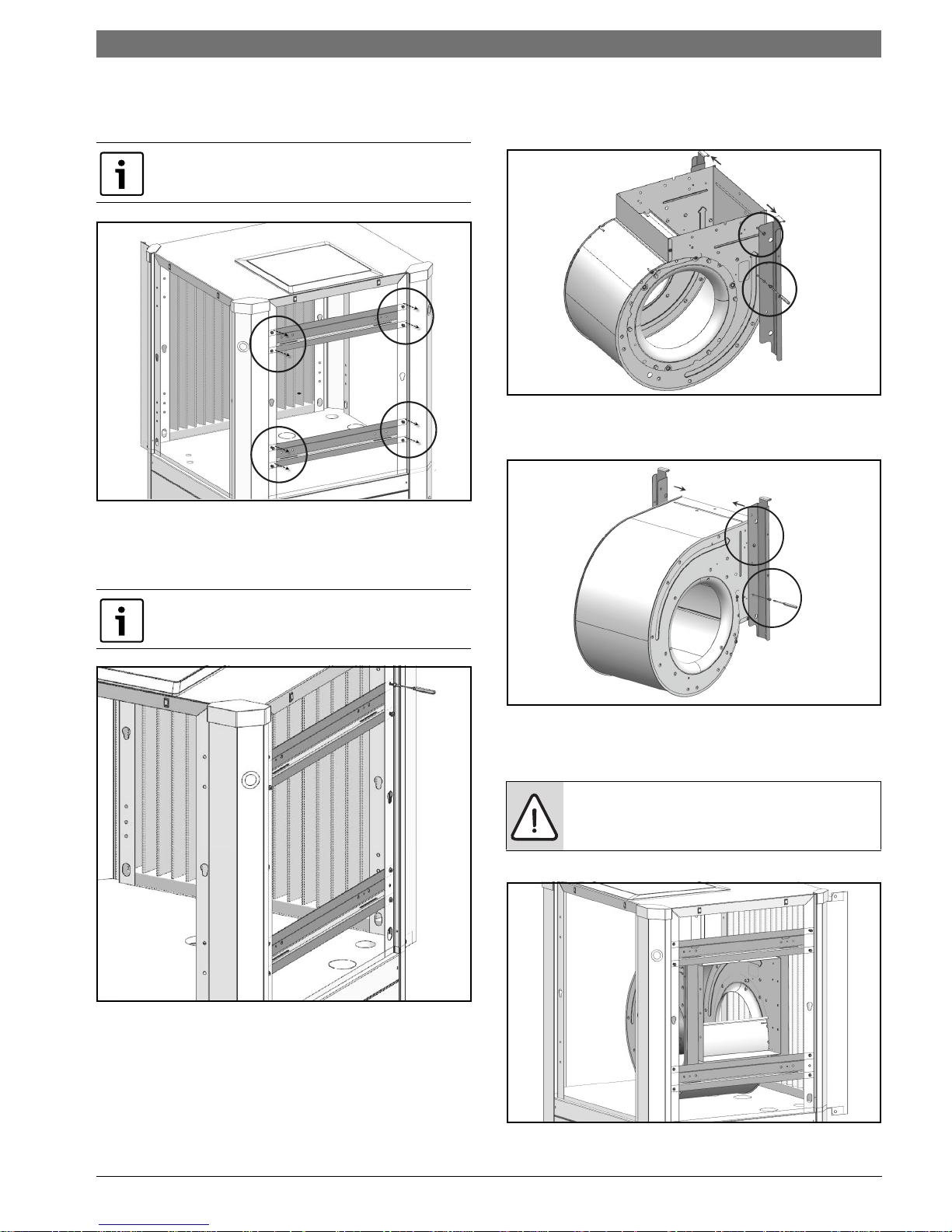

14. Reinstall blower motor and inlet ring assembly

by reversing Step #6. (Figure #61)

Figure # 61

15. Reconnect blower motor electrical plug and

ground wire.

16. Reinstall diagonal bracket(s). (Figure #62)

Condensate Drain Connection Reconfiguration

When re-configuring the unit from Left-Hand

Return to Right-Hand Return it is necessary to

relocate condensate drain connection from FRONT

left corner post to BACK left corner

post.(Figure#63)

Figure # 63

1. Cut the condensate drain hose on the inside of

cabinet.

Be sure to retain the spring

2. Remove and retain condensate drain plastic

fitting and grommet from the hose by pulling it

away from the hose (barb style connection).

(Figure#64)

Figure # 62

Figure # 64

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Vertical Configurability | 21SM Series Heat Pump

3. Locate the BACK left condensate drain and

remove and retain plastic plug covering the

cutout. (Figure#65)

Figure # 65

4. Reinstall the removed plastic plugs in the

original Condensate Drain Location.

5. Route the flexible plastic tube from FRONT left

corner post to BACK left. (Figure#66)

NOTE: Avoid kinking the hose and/or

creating a dip which could act as a second

internal p-trap. Double trapped drain lines

will not drain properly.

8. Reinstall condensate drain plastic fitting and

bushing in its new location.(Figure#67)

Figure # 67

HRP Switch Relocation

The HRP Pump Disconnect Switch is shipped loose

inside unit E-Box, to be connected to either FRONT

right corner post or BACK right corner

post.(Figure#68)

Figure # 66

6. Measure and cut the condensate drain hose to

the appropriate length.

7. Insert spring onto condensate drain hose.

Figure # 68

1. From the inside of the unit remove (2) wires

connected to HRP Pump Disconnect Switch.

6 720 220 406 (2015/02)Revised 02-15

22 | Vertical Configurability

1

2

SM Series Heat Pump

2. Identify a rectangular knockout and remove it.

Along with insulation.(Figure#69)

Figure # 69

3. Route HRP Pump Disconnect switch wires to

the new switch location.

NOTE: Do not route wiring over potentially

hot surfaces or exposed sharp edges.

Damage to wiring could result.

4. Install HRP Switch.

5. Reconnect the Switch wires.

2. Remove and retain the Electric Heat Element

cover(s) by removing (4) screws in

each.(Figure#71)

Figure # 71

3. Disconnect high voltage wiring a the Electric

Heat Elements. (Figure#72)

Electric Heat Relocation

When changing the unit from Left-Hand Return to

Right-Hand Return, it’s required to relocate

Electric Heat Components to the opposite side of

the blower in order to allow field servicing.

Electric Heat comes with (1) or (2) heating

element inserts, depending on capacity.

This instruction shows (1) heating element

insert. Perform the same steps for the

second insert, if present.

1. Identify Electric Heat components. (Figure#70)

Figure # 72

4. Remove and retain Electric Heat

Element(s).(Figure#73)

Figure # 70

[1] Electric Heat Electrical Box

[2] Electric Heat Elements.

Figure # 73

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Vertical Configurability | 23SM Series Heat Pump

5. Disconnect main Electric Heat E-box

plug.(FIgure#74)

Figure # 74

6. Remove and retain Electric Heat E-box by

removing (2) screws.(Figure#75)

8. Remove and retain Blower collar cover(s).

(FIgure#77)

Figure # 77

9. Re-install Electric Heat Elements in the new

location. Ensure High Temperature Cutouts are

located on the left side. (Figure#78)

Figure # 75

7. Re-install Electric Heat E-box in the new

location. (Figure#76)

Figure # 76

Figure # 78

10. Route the Unit E-box to Electric Heat wiring

harness to the new Electric Heat Element

location.

11. Connect wiring harness to the connector on

the side of Electric Heat E-Box. (Figure#79)

Figure # 79

6 720 220 406 (2015/02)Revised 02-15

24 | Vertical Configurability

HT-4

HT-3

HT-2

HT-1

HLS-1

HLS-2

HLS-3

HLS-4

BLACK

RED

SM Series Heat Pump

12. Reconnect high voltage wiring from Electric

Heat E-Box and Heating Element(s) matching

wire number to terminals as

shown.(Figure#80)

Figure # 80

13. Re-install Electric Heat Elements Cover(s).

(Figure#81)

CAUTION: take great care to ensure all

wires are disconnected and none of the

wires are 'snagged' on any components

Figure # 82

4. Reroute all of the disconnected wire bundles

to the opposite side of the heat pump.

Figure # 81

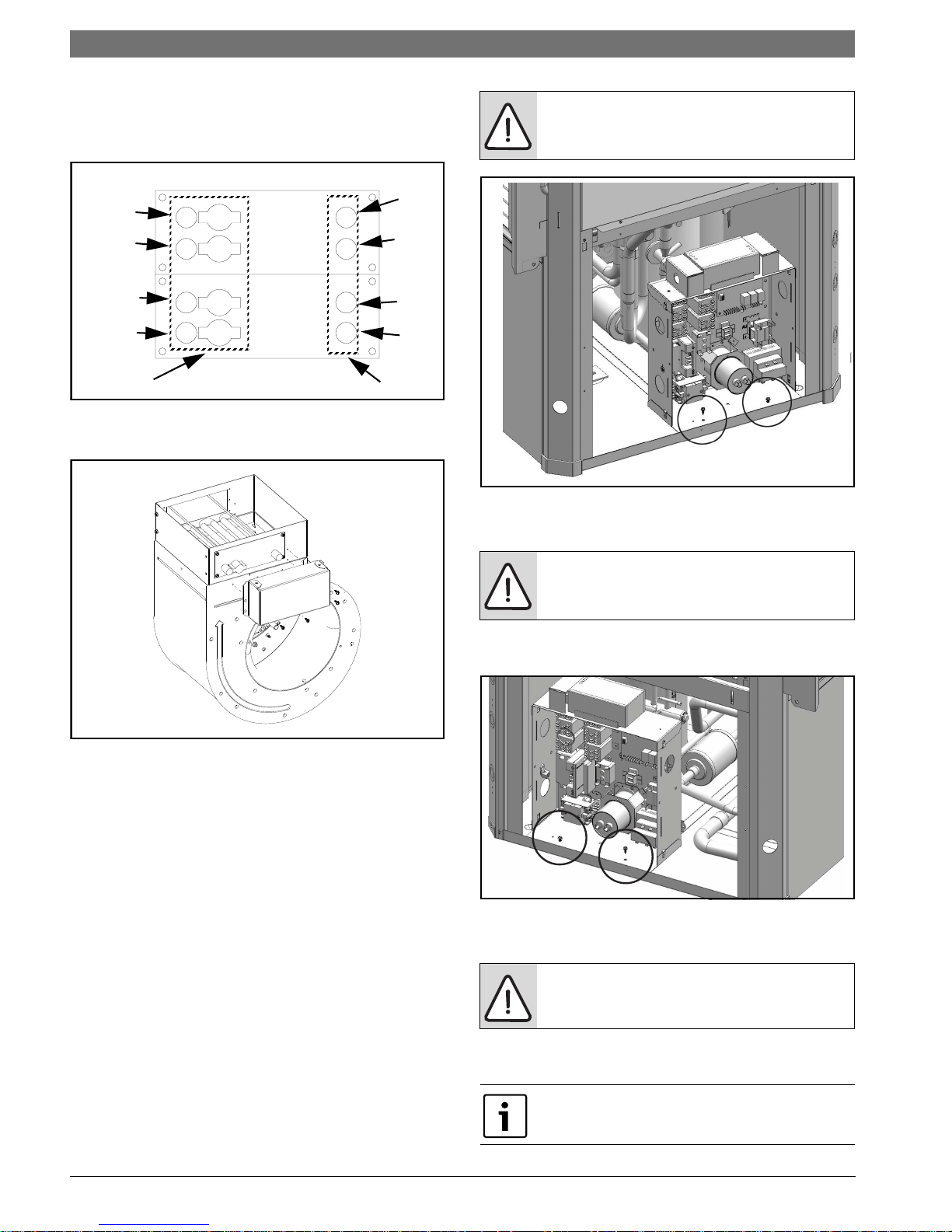

Electrical Box re-configuration

E-box is designed to be removable to support field

configuration of unit: Left-Hand Return and RightHand Return, and also to allow full access to

compressor during servicing.

The Electrical box (E-Box) has a set of plugs that

allows complete removal from the system while

keeping the majority of its internal connections.

(FIgure#123 & #124, Pg#72 and Pg#73)

1. Disconnect wiring harness by unplugging the

following plugs: P18, P19, P20 and P23 (P12 if

unit is equipped with Electric Heat).

(FIgure#123 & #124, Pg#72 and Pg#73)

2. Disconnect compressor plugs at compressor.

3. Remove and retain Electric Box by removing

(2) screws. (Figure #82)

NOTE: Do not route wiring over potentially

hot surfaces or exposed sharp edges.

Damage to wiring could result.

5. Install E-box in its new location by installing (2)

screws. (Figure #83)

Figure # 83

6. Reconnect all the wiring disconnected in Step

#1.

NOTE: Ensure all connectors are properly

oriented and are fully engaged.

7. Identify and re-route LCD wiring harness to the

new location.

Panel containing LCD always mounts on the

same side as E-Box.

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Return and Discharge Duct Flanges | 25SM Series Heat Pump

8. Swap FRONT panel (containing LCD) to the

BACK

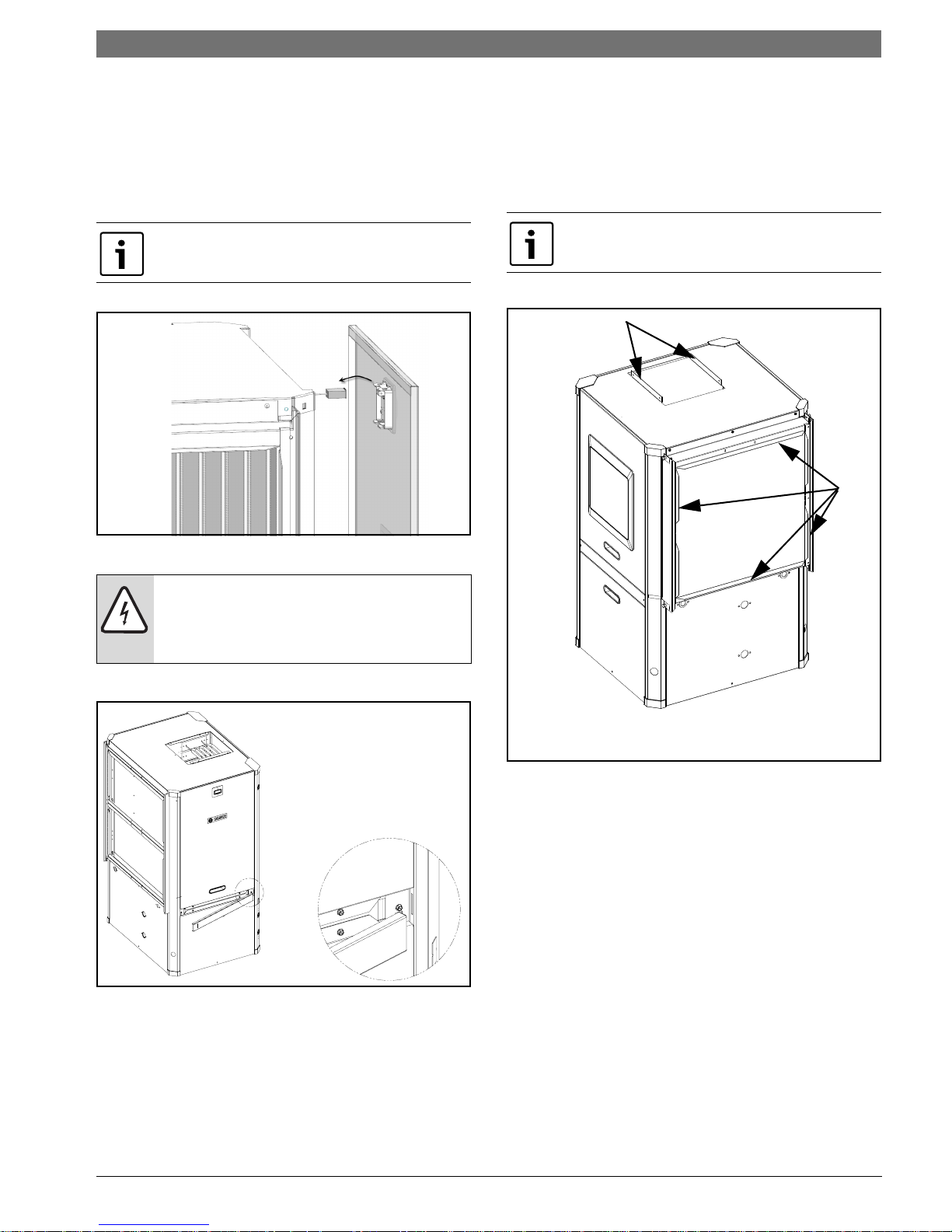

Reinstall All Panels

1. Re-route the LCD wiring to the new location

and reconnect LCD screen wiring. Reinstall

panels. (Figure #84)

Panel containing LCD and Bosch Logo must be

installed on the same side as Electrical Box.

Figure # 84

RETURN AND DISCHARGE DUCT

FLANGES

Return and discharge opening duct flanges are

shipped unfolded. Flanges bend lines are

perforated allowing easy bending using standard

sheet metal pliers or channel locks. (Figure #90)

Bend flanges one at a time.

NOTE: When re-installing panel, the “RED”

cable from the LCD connector must be

connected to the “R” terminal of the LCD

PCB. The LCD will not work any other way.

2. Reinstall belts. (Figure#85)

Figure # 85

6 720 220 406 (2015/02)Revised 02-15

26 | Pre Installation Unit Preparation

T

B

A

T2

T1

T1

T1

T2

T2

A

A

A

A

SM Series Heat Pump

PRE INSTALLATION UNIT PREPARATION

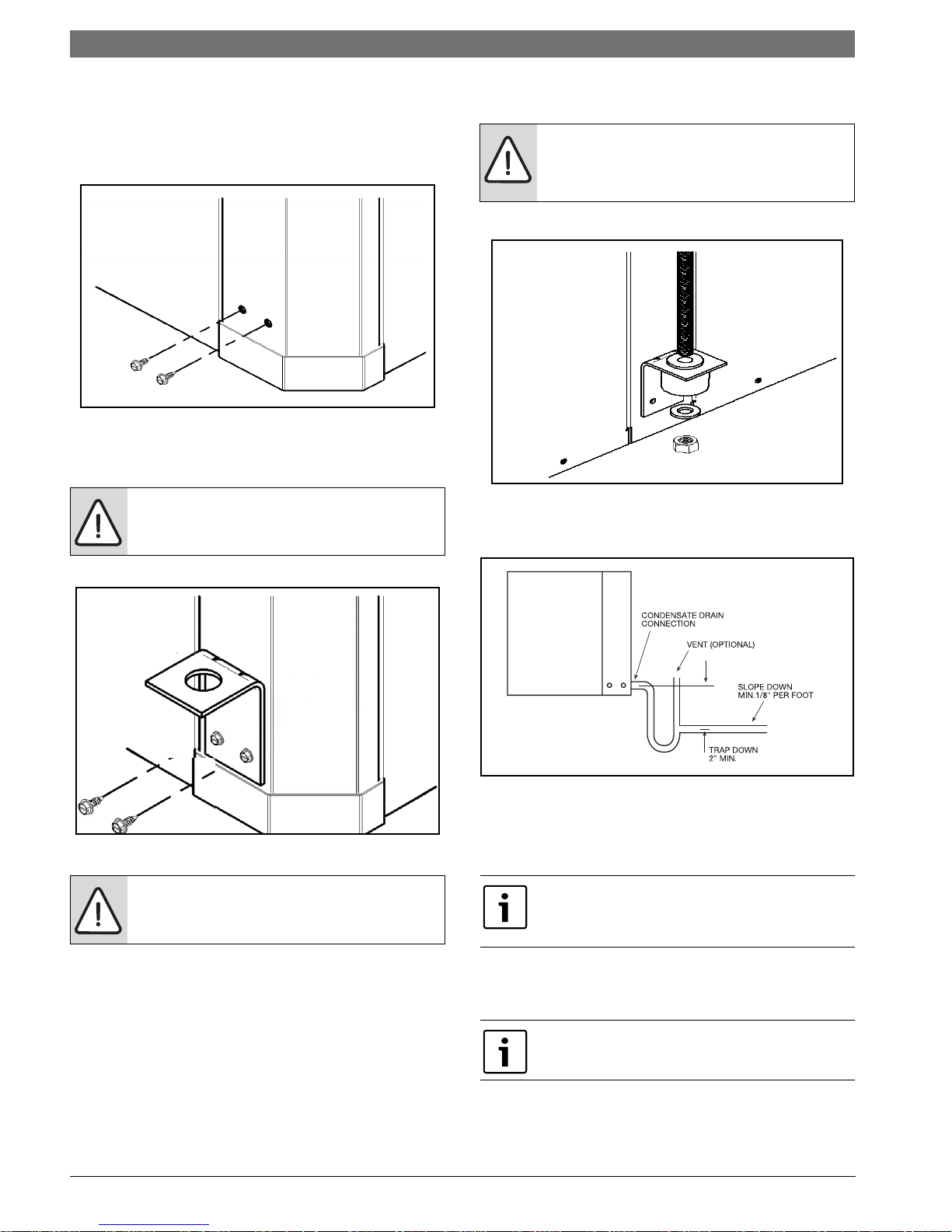

Corner Cap Installation Instructions

Each corner cap is stamped with one the following

identifiers: T, T1,T2 B, B1, B2, A.

1. Identify Letter code on each Corner Cap.

(Figure#86)

Figure # 86

2. In preparation for installation identify each

Corner Cap location. (VT & CF Figure#87 and

HZ Figure#88)

3. Remove adhesive backing and install each

Corner Cap. (Figure#89 and#90)

Ensure cabinet surface is clean and free of

debris to ensure proper Corner Cap Adhesion.

Figure # 87

Figure # 88

Figure # 89

Figure # 90

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Mounting Vertical Units | 27SM Series Heat Pump

VIBRATION

PAD FULL SIZE

MOUNTING VERTICAL UNITS

Vertical units should be mounted level on a

vibration absorbing pad slightly larger than the

base to minimize vibration transmission to the

building structure. It is not necessary to anchor the

unit to the floor. (Figure #91).

On VT and CF Units Condensate Drain pan is

internally sloped. There is no internal P-Trap.

The secondary drain pan prevents possible

condensate overflow or water leakage damage to

the ceiling.

The secondary drain pan is usually placed on a

plywood base isolated from the ceiling joists by

additional layers of vibration absorbing mesh. In

both cases, a 3/4”drain connected to this

secondary pan should be run to an eave at a

location that will be noticeable.

If the unit is located in a crawl space, the bottom

of the unit must be at least 4” above grade to

prevent flooding of the electrical parts due to

heavy rains.

HZ Units Condensate Drain pan is NOT

internally sloped.

NOTE: Horizontal (HZ) units must be

installed pitched toward the Condensate

Drain Connection 1/8” per foot.

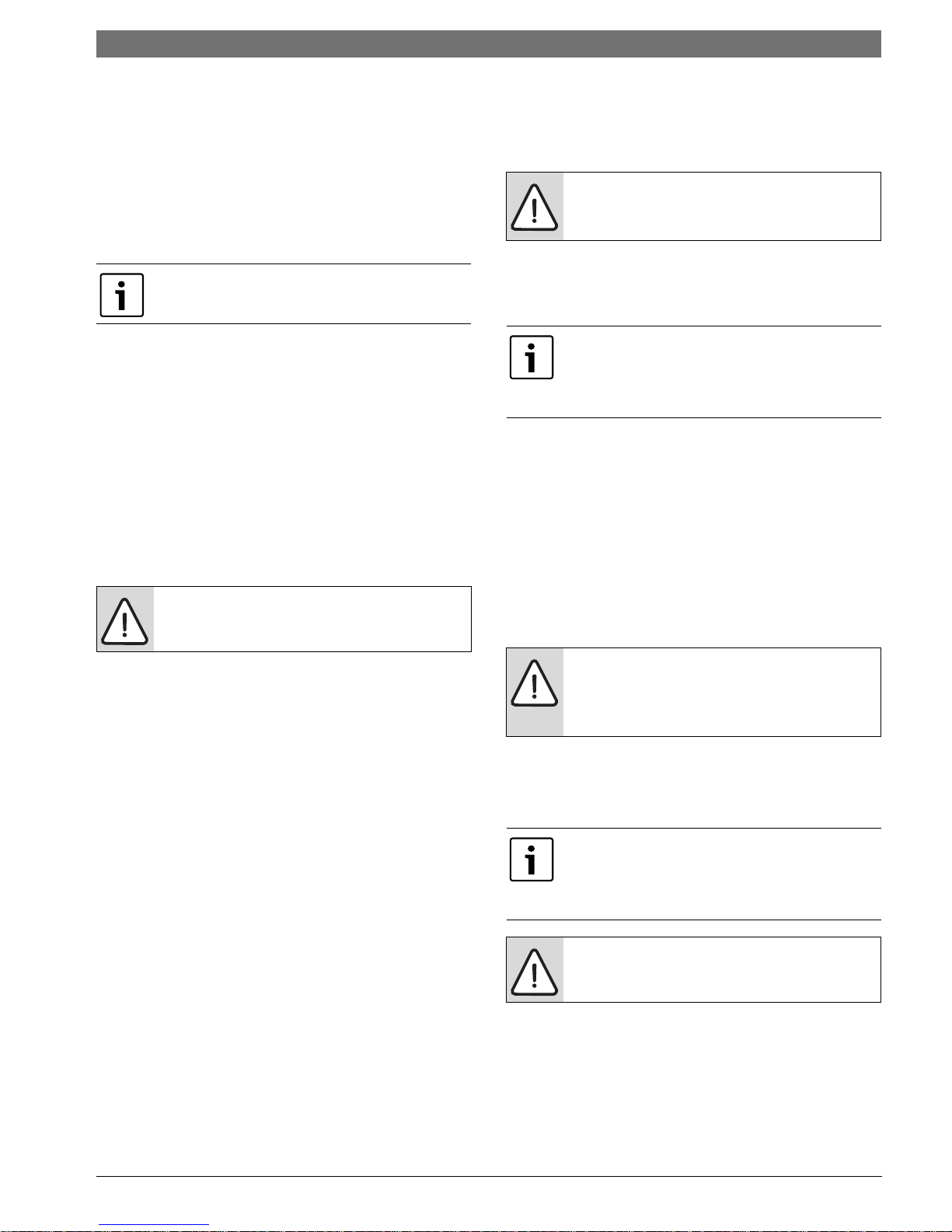

HANGING BRACKET KIT

Installation Instructions

All horizontal units come with hanging bracket

installation kit to facilitate suspended unit

mounting using threaded rod.Hanging brackets are

to be installed as shown in Figure #92.

Figure # 91

MOUNTING HORIZONTAL UNITS

While horizontal units may be installed on any level

surface strong enough to hold their weight, they

are typically suspended above a ceiling by

threaded rods. The manufacturer recommends

these be attached to the unit corners by hanger

bracket kits. The rods must be securely anchored

to the ceiling. Refer to the hanging bracket

assembly and installation instructions for details.

WARNING: Horizontal units installed above

the ceiling must conform to all local codes.

An auxiliary drain pan if required by code,

should be at least four inches larger than

the bottom of the heat pump.

Plumbing connected to the heat pump must not

come in direct contact with joists, trusses, walls,

etc. Some applications require an attic floor

installation of the horizontal unit. In this case the

unit should be set in a full size secondary drain pan

on top of a vibration absorbing mesh.

Figure # 92

This kit includes the following:

(5) Brackets

(5) Rubber Vibration isolators

(8) Screws #10x1/2 (not used for these models)

(10) Bolts 1/4-28x12” Hex bolt

The following are needed and are to be field

provided:

Threaded rod (3/8“ max dia)

Hex nuts

Washers (1-3/4“ min O.D.)

6 720 220 406 (2015/02)Revised 02-15

28 | Condensate Drain

1. Remove and discard factory provided screws

from locations where hanging brackets will be

installed shown in Figure #93

Figure # 93

2. Mount 5 brackets to unit corner post using the

Bolts provided in the kit as shown on Figure # 94

SM Series Heat Pump

WARNING:Rods must be securely anchored

to the ceiling

WARNING: Do not re-use screws removed

from the unit on step 1 to mount the

hanging brackets to the unit.

Figure # 94

WARNING: Follow all applicable codes and

requirements when hanging this unit,

selecting threaded rod material, etc.

Figure # 95

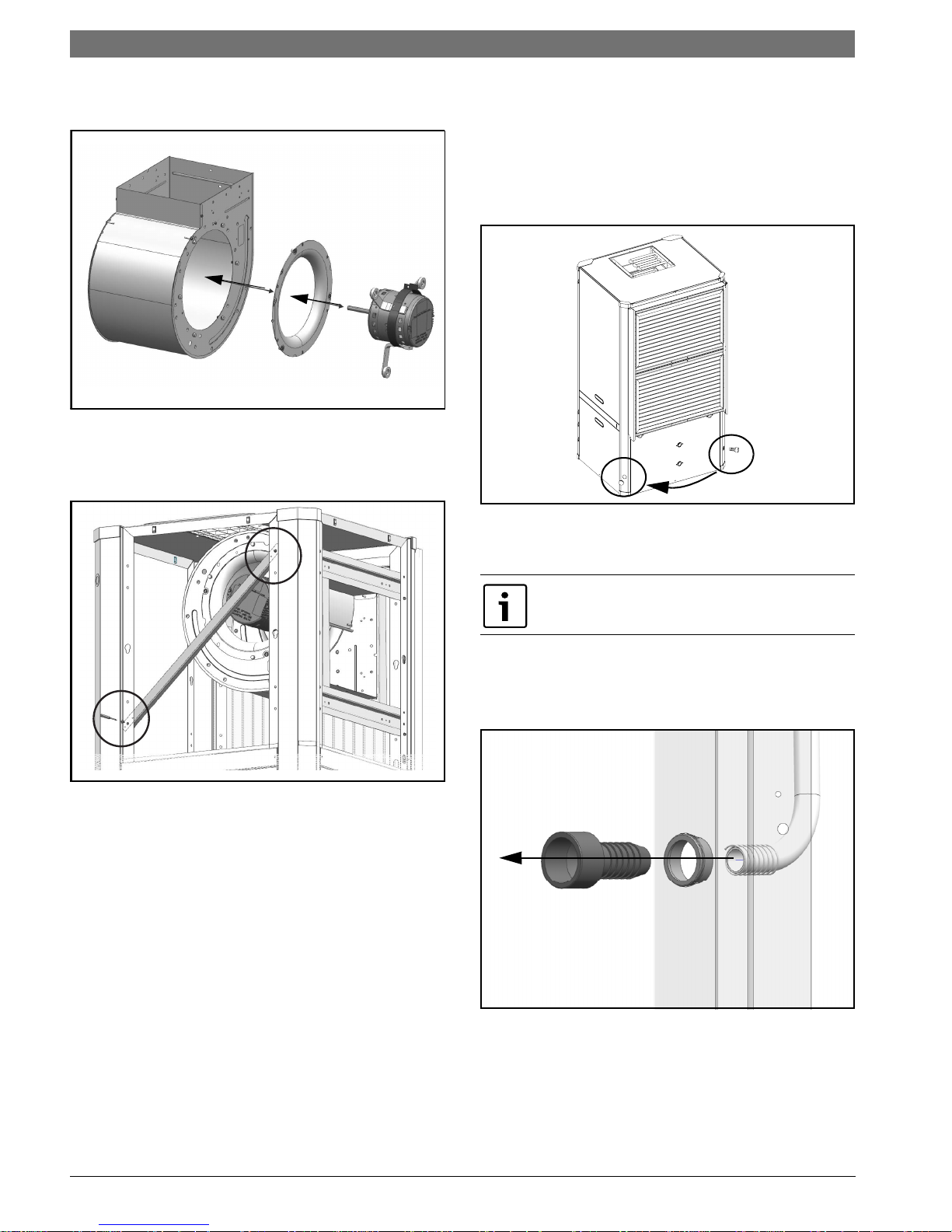

CONDENSATE DRAIN

Figure # 96

A drain line must be connected to the heat pump

and pitched away from the unit a minimum of 1/8”

per foot to allow the condensate to flow away from

the unit.

When converting unit from left-hand return to

right-hand return, condensate drain connection

must be relocated. Refer to Pg#20.

3. Install rubber grommet onto the brackets as

shown in Figure # 95

4. Hang the unit and assemble the field provided

Thread rod, nuts and washers on to the brackets as

shown in Figure # 95

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to insure free condensate flow.

HZ Heat Pump Drain Pan is not internally

sloped.

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Duct System | 29SM Series Heat Pump

A vertical air vent is sometimes required to avoid

air pockets. The length of the trap depends on the

amount of positive or negative pressure on the

drain pan. A second trap must not be included.

DUCT SYSTEM

A supply air outlet collar and return air duct flange

are provided on all units to facilitate duct

connections.

Supply air duct and return air duct flanges are

shipped unfolded with unit.

Fold the duct flange outwards along the perforated

line. Refer to unit Dimensional Drawings for

physical dimensions of the collar and flange.

(Pg#95 through Pg#95)

A flexible connector is recommended for supply

and return air duct connections on metal duct

systems. All metal ducting should be insulated

with a minimum of one inch duct insulation to

avoid heat loss or gain and prevent condensate

forming during the cooling operation. Application

of the unit to the no insulated duct work is not

recommended as the unit’s performance will be

adversely affected.

NOTE: Do not connect discharge ducts

directly to the blower outlet.

PIPING

Supply and return piping must be as large as the

unit connections on the heat pump (larger on long

runs).

NOTE: Never use flexible hoses of a smaller

inside diameter than that of the fluid

connections on the unit.

SM units are supplied with either a copper or

optional cupro-nickel condenser. Copper is

adequate for ground water that is not high in

mineral content.

Proper testing is recommended to assure the

well water quality is suitable for use with water

source equipment. When in doubt, use cupronickel.

In conditions anticipating moderate scale

formation or in brackish water a cupro-nickel heat

exchanger is recommended.

Refer to water quality table on page #30

Both the supply and discharge water lines will

sweat if subjected to low water temperature.

These lines should be insulated to prevent damage

from condensation. All manual flow valves used in

the system must be ball valves. Globe and gate

valves must not be used due to high pressure drop

and poor throttling characteristics.

The factory provided air filter must be removed

when using a filter back return air grill. The factory

filter should be left in place on a free return

system.

If the unit will be installed in a new installation

which includes new duct work, the installation

should be designed using current ASHRAE

procedures for duct sizing. If the unit is to be

connected to existing duct work, a check should

be made to assure that the duct system has the

capacity to handle the air required for the unit

application. If the duct system is too small, larger

duct work should be installed. Check for existing

leaks and repair.

The duct system and all diffusers should be sized

to handle the designed air flow quietly. To

maximize sound attenuation of the unit blower, the

supply and return air plenums should be insulated.

There should be no direct straight air path thru the

return air grille into the heat pump. The return air

inlet to the heat pump must have at least one 90

degree turn away from the space return air grille. If

air noise or excessive air flow are a problem, the

blower speed can be changed to a lower speed to

reduce air flow.

NOTE: Never exceed the recommended

water flow rates as serious damage or

erosion of the water-to-refrigerant heat

exchanger could occur.

Always check carefully for water leaks and repair

appropriately. Units are equipped with swivel

female pipe thread fittings. Consult Unit

Dimensional Drawings. (Pg#95 through Pg#95)

Teflon tape sealer should be used when

connecting water piping connections to the units

to insure against leaks and possible heat

exchanger fouling.

NOTE: Do not overtighten the connections.

Flexible hoses should be used between the unit

and the rigid system to avoid possible vibration.

Ball valves should be installed in the supply and

return lines for unit isolation and unit water flow

balancing.

6 720 220 406 (2015/02)Revised 02-15

30 | Water Quality

WATER QUALITY

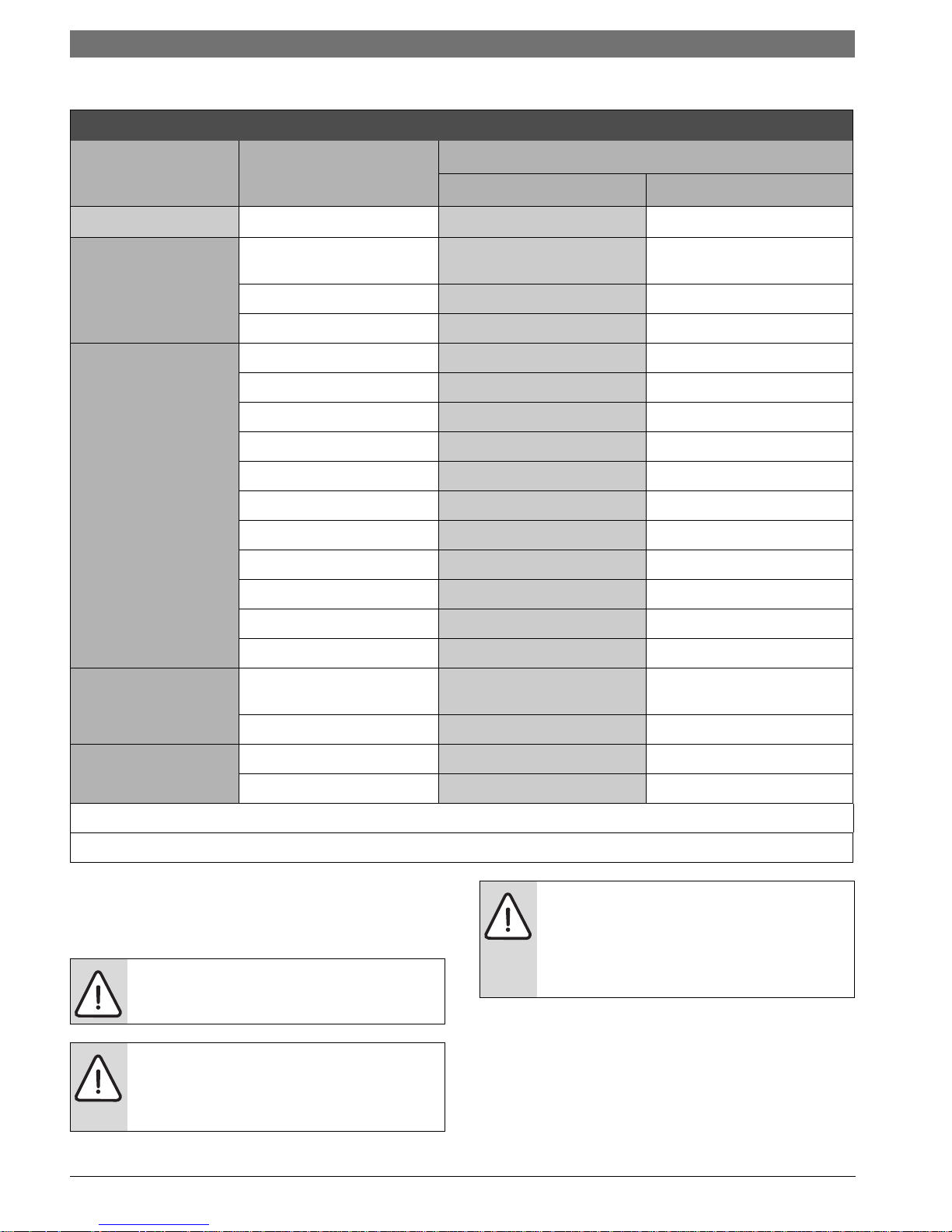

Table 1: Water Quality

SM Series Heat Pump

POTENTIAL

PROBLEM

SCALING

CORROSION

Water Characteristic Acceptable Value

Copper Cupro-Nickel

pH (Acidity/Alkalinity) 7-9 7-9

Hardness (CaCO3,

MgCO3)

Ryznar Stability Index

Langelier Saturation Index

Hydrogen Sulfide (H2S) < 0.5 ppm * 10-50 ppm

Sulfates

Chlorine

Chlorides

Carbon Dioxide

Ammonia

Ammonia Chloride

Ammonia Nitrate

Ammonia Hydroxide

< 350 ppm < 350 ppm

6.0 - 7.5 6.0 - 7.5

-0.5 - +0.5 -0.5 - +0.5

< 125 ppm < 125 ppm

< 0.5 ppm < 0.5 ppm

< 20 ppm < 150 ppm

< 50 ppm < 50 ppm

< 2 ppm < 2 ppm

< 0.5 ppm < 0.5 ppm

< 0.5 ppm < 0.5 ppm

< 0.5 ppm < 0.5 ppm

Ammonia Sulfate

Dissolved Solids

IRON FOULING

EROSION

* No "rotten egg" smell present at < 0.5 ppm H2S.

** Equivalent to 30 mesh strainer

Iron (Fe2+ Iron Bacteria

Potential)

Iron Oxide

Suspended Solids < 10 ppm, < 600 μm size ** < 10 ppm, < 600 μm size **

Maximum Water Velocity

ELECTRICAL

Refer to electrical component box layout.

(Figure #97)

WARNING: Field wiring must comply

with local and national electric codes.

WARNING: Power to the unit must be

within the operating voltage range

indicated on the unit nameplate or on

the performance data sheet.

< 0.5 ppm < 0.5 ppm

< 1,000 ppm < 1,500 ppm

< 0.2 ppm < 0.2 ppm

< 1 ppm < 1 ppm

6 ft/sec 6 ft/sec

NOTE: Operation of unit on improper

line voltage or with excessive phase

imbalance will be hazardous to the unit,

constitutes abuse and may void the

warranty.

Properly sized fuses or HACR circuit breakers must

be installed for branch circuit protection. See unit

nameplate for maximum fuse or breaker size.

SM Series Heat Pump6 720 220 406 (2015/02) Subject to change without prior notice

Loading...

Loading...