Page 1

Installation

instructions

Instructions

d'installation

Instrucciones

de instalaci6n

BOSCH

SHU (6800, 5300, 4300,

SHI (6800, 4300)

SHV (4800, 4300)

IMPORTANT: Before you begin read these instructions completely and carefully. |

INSTALLER: Please leave this manual with owner for future reference.

I

IMPORTANT: Avant de commencer, lire enti_rement et attentivement ces instructions.

OWNER: Save these installation instructions for local electrical

inspector's use and for future reference.

L' INSTALLATEUR: Remettre ce guide au propri6taire il des fins de r6f6rences.

AU PROPRH_TAIRE: Conserver ces instructions d'installation pour

l'inspecteur local en 61ectricit6 et h des fins de r6f6rences.

3000)

"3

J

1

IMPORTANTE: Antes de iniciar lea estas instrucciones completa y cuidadosamente.

TECNICO DE INSTALACION: Pot favor deje este manual con el propietario

para futuras referencias.

I

PROPIETARIO: Conserve estas instrucciones de instalaci6n para el

uso del inspector el6ctrico local y para futuras referencias

Page 2

BOSCH

Quick Reference Index

Installation Instructions

for SHU (6800, 5300, 4300, 3000)

and SHI (6800, 4300)

and SHV (4800, 4300)

INTRODUCTION

TOOLS NEEDED FOR INSTALLATION

MATERIALS YOU WILL NEED

ACCESSORY PARTS SUPPLIED

TECHNICAL DATA

CHOOSING THE LOCATION

PREPARING THE LOCATION

HOT WATER SUPPLY

DRAIN HOSE

ELECTRICAL SUPPLY

INSPECTING THE DISHWASHER

PLACING THE DISHWASHER

DRAIN HOSE 6-7

CONNECTING HOT WATER SUPPLY 7

CONNECTING ELECTRICAL SUPPLY 8

GROUNDING INSTRUCTIONS 8

PANEL INSTALLATION, SHI MODELS 8-9

PANEL INSTALLATION, SHV MODELS 9

ACCESSORY PANEL INSTALLATION, SHU 9

2

2

2

2

3

3

4

4

4

4

5

5

DOOR TENSION ADJUSTMENT

FINAL CHECK LIST

INSTALLER: Please leave this manual with owner for future reference.

I IMPORTANT: Before you begin read these instructions completely and carefully. |

OWNER: Save these installation instructions for local electrical

inspector's use and for future reference.

10

10

J

Page 3

Introduction

Please read these installation instructions completely

and carefully. They will save you time and effort and

help to ensure optimum dishwasher performance. Be

sure to observe all listed warnings and cautions.

These installation instructions are intended for use by

qualified installers. In addition to these instructions the

dishwasher shall be installed:

• In the United States, in accordance with the

National Electric Code/State and Municipal codes

and/or local codes.

• In Canada, in accordance with the Canadian Electric

Code C22.1 - latest edition/Provincial and

Municipal codes and/or local codes.

These shall be carefully followed at all times.

If the dishwasher is a new installation most of the work

must be done before the dishwasher is moved into place.

If the dishwasher is replacing another dishwasher the

connections for the dishwasher being replaced must be

checked for compatibility with the new dishwasher and

replaced as necessary.

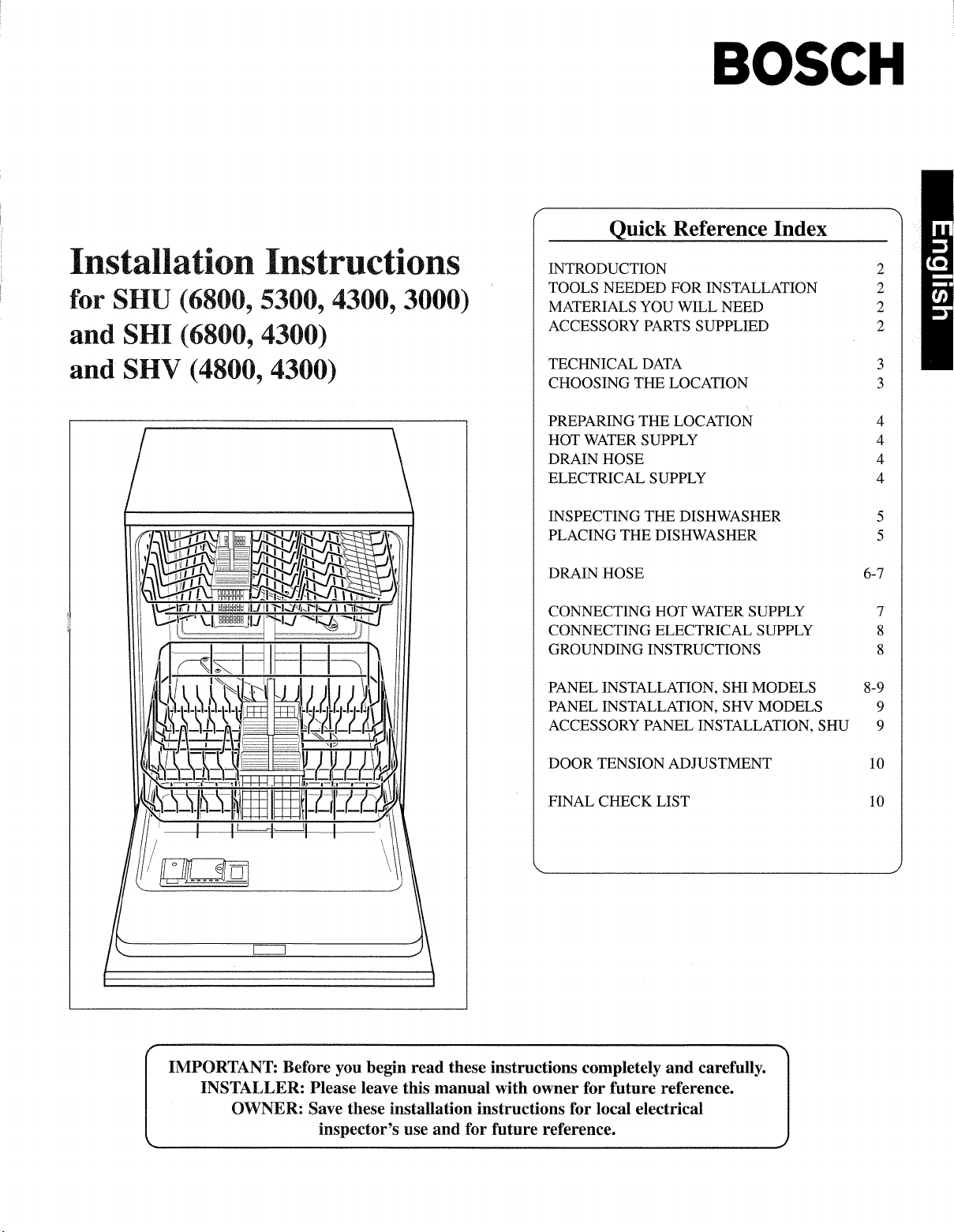

Tools Needed for Installation

Refer to Figure 1:

A. Tape Measure

B. Flat blade screwdriver

C. Phillips screwdriver

D. Torx screwdriver, #20

E. Electric Drill

K Hole saw or 1" hole cutter

G. Hammer

H. Level

I. Open end wrench

J. Adjustable wrench, 2 reqd.

K. Pipe wrench, 2 reqd.

L. Wire Cutter

M. Wire stripper

O

Figure 1.

Accessory Parts Supplied

Check to make sure that the accessory parts supplied for

your model, see Figure 2, are all there. If any parts are

missing contact your dealer immediately.

Refer to Figure 2:

O. Cover Plugs (2)

R Screws (2), for terminal box cover/toe panel

R. Mounting brackets (2)

S. Wood screws (2)

T. Drain hose clamp

U. Screws, M6 x 26 (2)

V. Mounting brackets (4) and screws (8)

W. Template sheet with instruction pictograms,

X. Screws, M4 x 42 (2) (SHV models only)

Accessory parts supplied with:

SHU models SHI andSHV models

Om@

Materials You Will Need

• Minimum 3/8" O.D. copper tubing of sufficient

length for your installation.

* Shut-off valve and fittings for hot water supply line.

• 90 ° elbow with 3/8" N.ET. external threads on one

end and sized to fit your water supply line on the

other end.

• Teflon tape or other pipe sealant.

• 3 twist-on wire connectors for 16 AWG wire.

• UL listed conduit connector or strain relief.

Additional materials may be required to comply with

local codes.

Figure 2,

Page 4

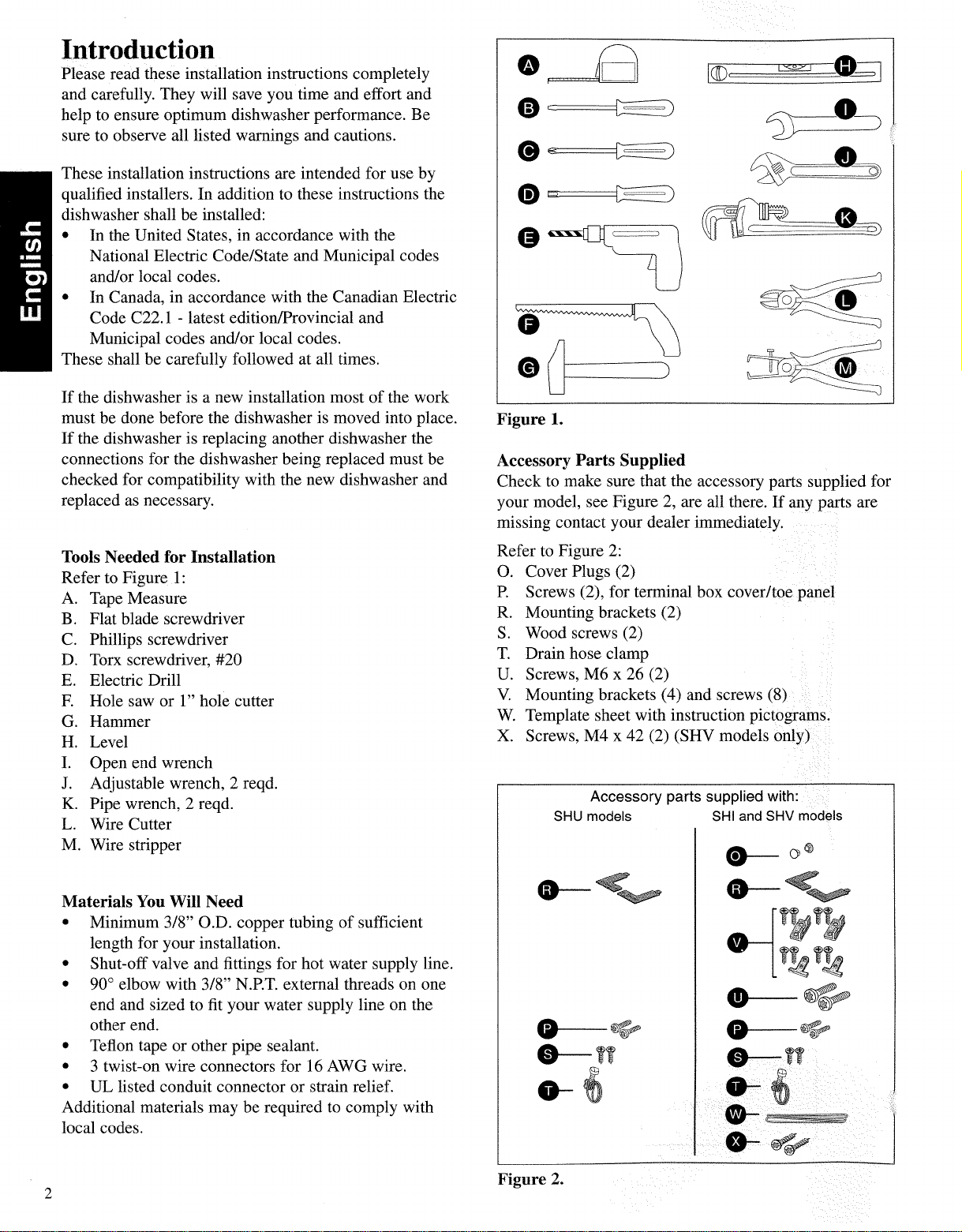

Technical Data

22-7/16"

(570 mm) _[

; ili 900

!; i_!ii:!_i:

<

1-15/16"(49mm)

Figure 3.

Dimensions

A height 33-7/8" - 35" (860 - 890 mm)

B width 23-9/16" (598 mm)

,!

C depth 22-7/16 (570 mm)

Electrical Rating

Volts Hertz Amperes Watts

120 60 12 1,450 (max)

Choosing the Location

Most of the installation work is done before the

dishwasher is moved into place. Select _alocation as

close to the sink as possible for ready access to water

and drain lines.

Any built-in dishwasher must be fully enclosed on the

top, both sides and back. Therefore the cabinet space

below your counter is probably the best location.

For proper operation and appearance of the dishwasher,

the cabinet opening should be square and have

dimensions as shown in Figure 4.

23-5/8'` - 24" (600- 610 mm)

Figure 4.

If the dishwasher is to be installed in a comer, make

sure there is adequate clearance to open the door. See

Figure 5.

Clearance

for door opening T

Door in

open Position

Figure 5.

CAUTION:

To protect against possible rapture of the fill valve,

water lines leading to the dishwasher, as well as

water lines in the dishwasher MUST be protected

against freezing. If the valve or water line freezes,

flooding may occur. Such ruptures are not covered

by the warranty.

Page 5

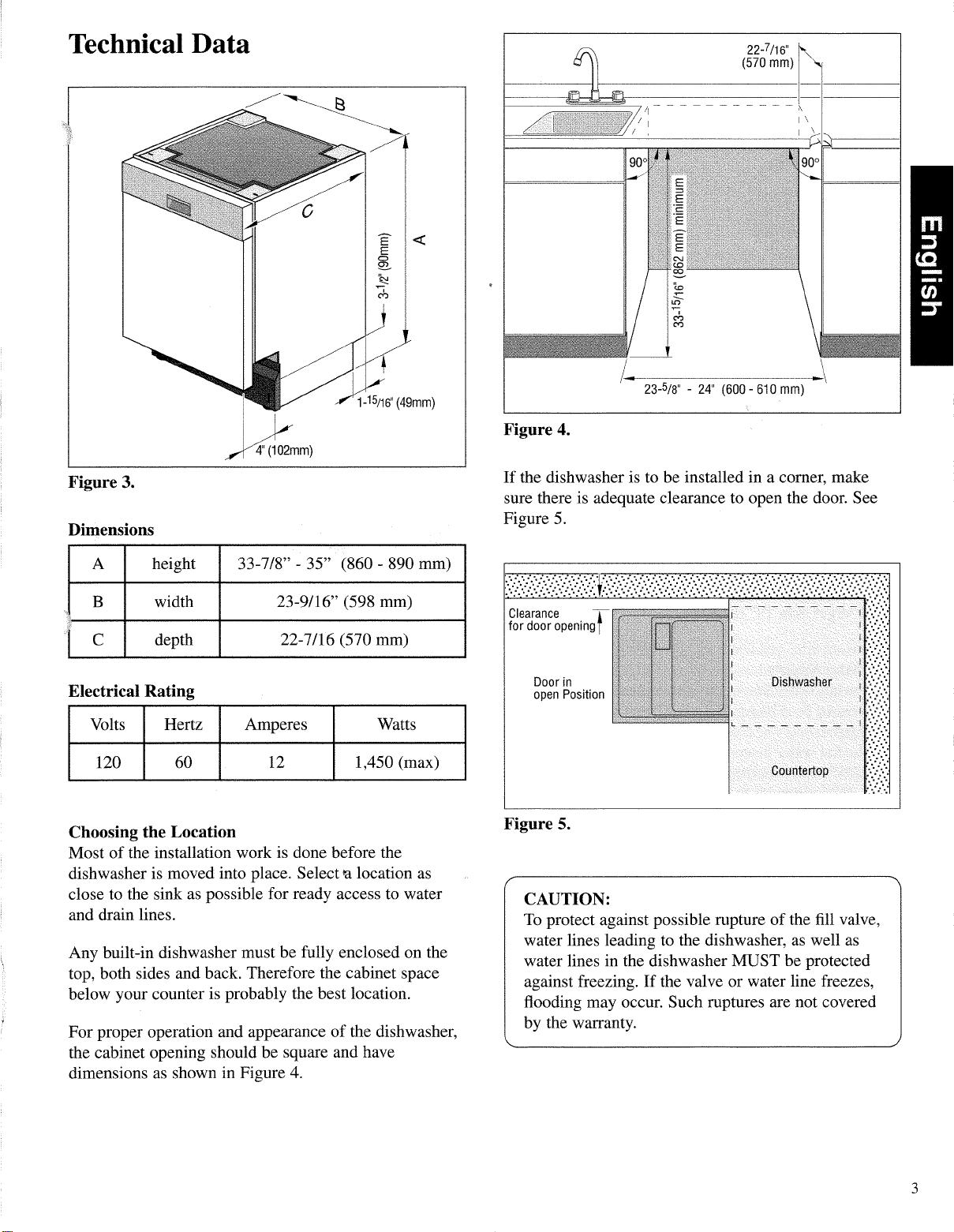

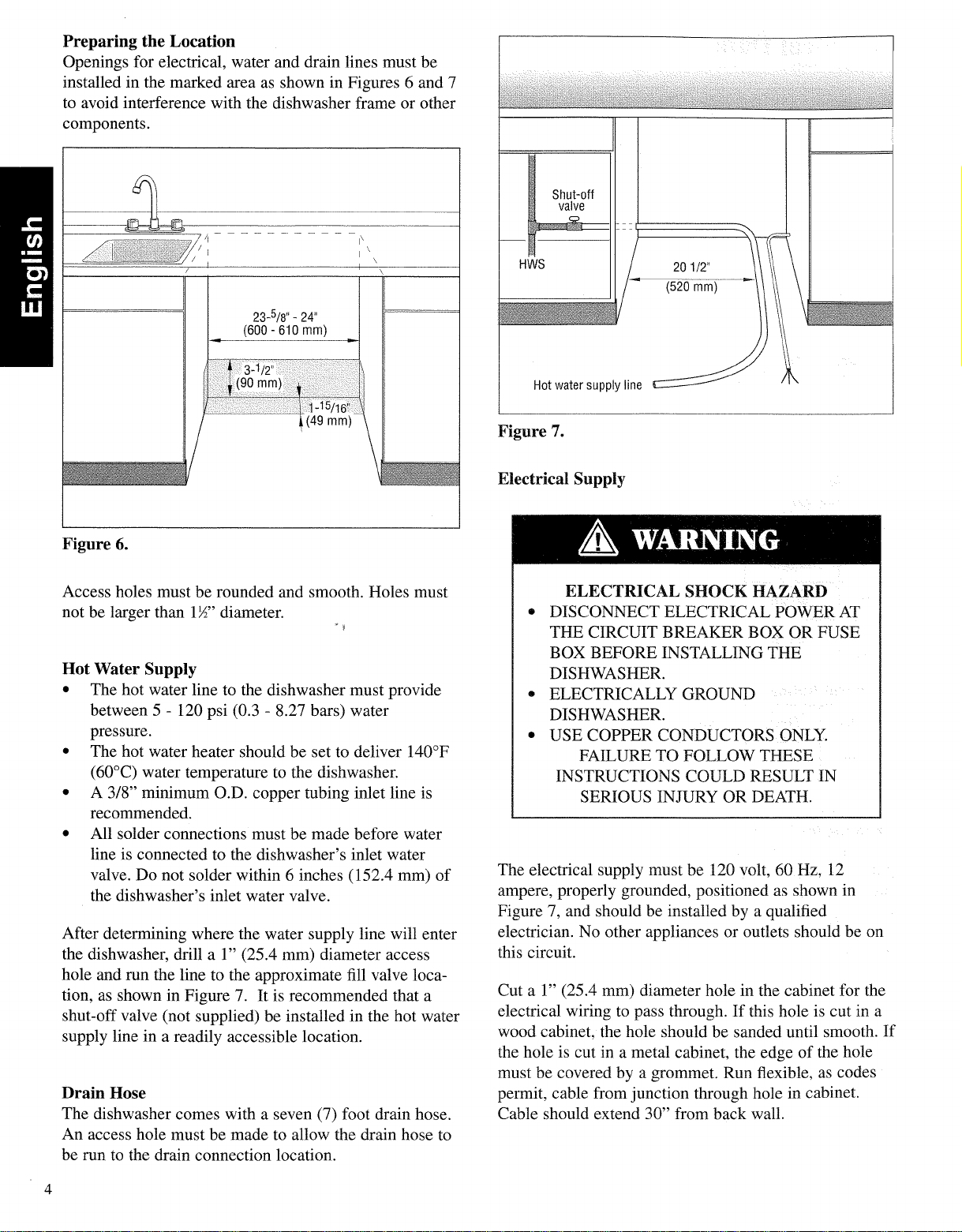

Preparing the Location

Openings for electrical, water and drain lines must be

installed in the marked area as shown in Figures 6 and 7

to avoid interference with the dishwasher frame or other

components.

&

:_ _ 7_ ..... /i I\

iiii!iiiii!iiii!iiiiii ,

'/ I I

23-5/8"- 24"

(600 - 610 rnm)

\

\

\

/

Shut-off

valve

HWS

Hot water supply line

Figure 7.

Electrical Supply

(520 mrn)

20 1/2" ;_

Figure 6.

Access holes must be rounded and smooth. Holes must

not be larger than 1/" diameter.

Hot Water Supply

• The hot water line to the dishwasher must provide

between 5 - 120 psi (0.3 - 8.27 bars) water

pressure.

• The hot water heater should be set to deliver 140°F

(60°C) water temperature to the dishwasher.

• A 3/8" minimum O.D. copper tubing inlet line is

recommended.

• All solder connections must be made before water

line is connected to the dishwasher's inlet water

valve. Do not solder within 6 inches (152.4 ram) of

the dishwasher's inlet water valve.

After determining where the water supply line will enter

the dishwasher, drill a 1" (25.4 ram) diameter access

hole and run the line to the approximate fill valve loca-

tion, as shown in Figure 7. It is recommended that a

shut-off valve (not supplied) be installed in the hot water

supply line in a readily accessible location.

Drain Hose

The dishwasher comes with a seven (7) foot drain hose.

An access hole must be made to allow the drain hose to

be run to the drain connection location.

ELECTRICAL SHOCK HAZARD

• DISCONNECT ELECTRICAL POWER AT

THE CIRCUIT BREAKER BOX OR FUSE

BOX BEFORE INSTALLING THE

DISHWASHER.

• ELECTRICALLY GROUND

DISHWASHER.

• USE COPPER CONDUCTORS ONLY.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR DEATH.

The electrical supply must be 120 volt, 60 Hz, 12

ampere, properly grounded, positioned as shown in

Figure 7, and should be installed by a qualified

electrician. No other appliances or outlets should be on

this circuit.

Cut a 1" (25.4 mm) diameter hole in the cabinet for the

electrical wiring to pass through. If this hole is cut in a

wood cabinet, the hole should be sanded until smooth. If

the hole is cut in a metal cabinet, the edge of the hole

must be covered by a grommet. Run flexible, as codes

permit, cable from junction through hole in cabinet.

Cable should extend 30" from back wall.

4

Page 6

Inspecting the Dishwasher

After unpacking the dishwasher and prior to installation

thoroughly inspect the dishwasher for possible freight or

cosmetic damage. Report any damage immediately.

Cosmetic damage must be reported within 5 days of

installation.

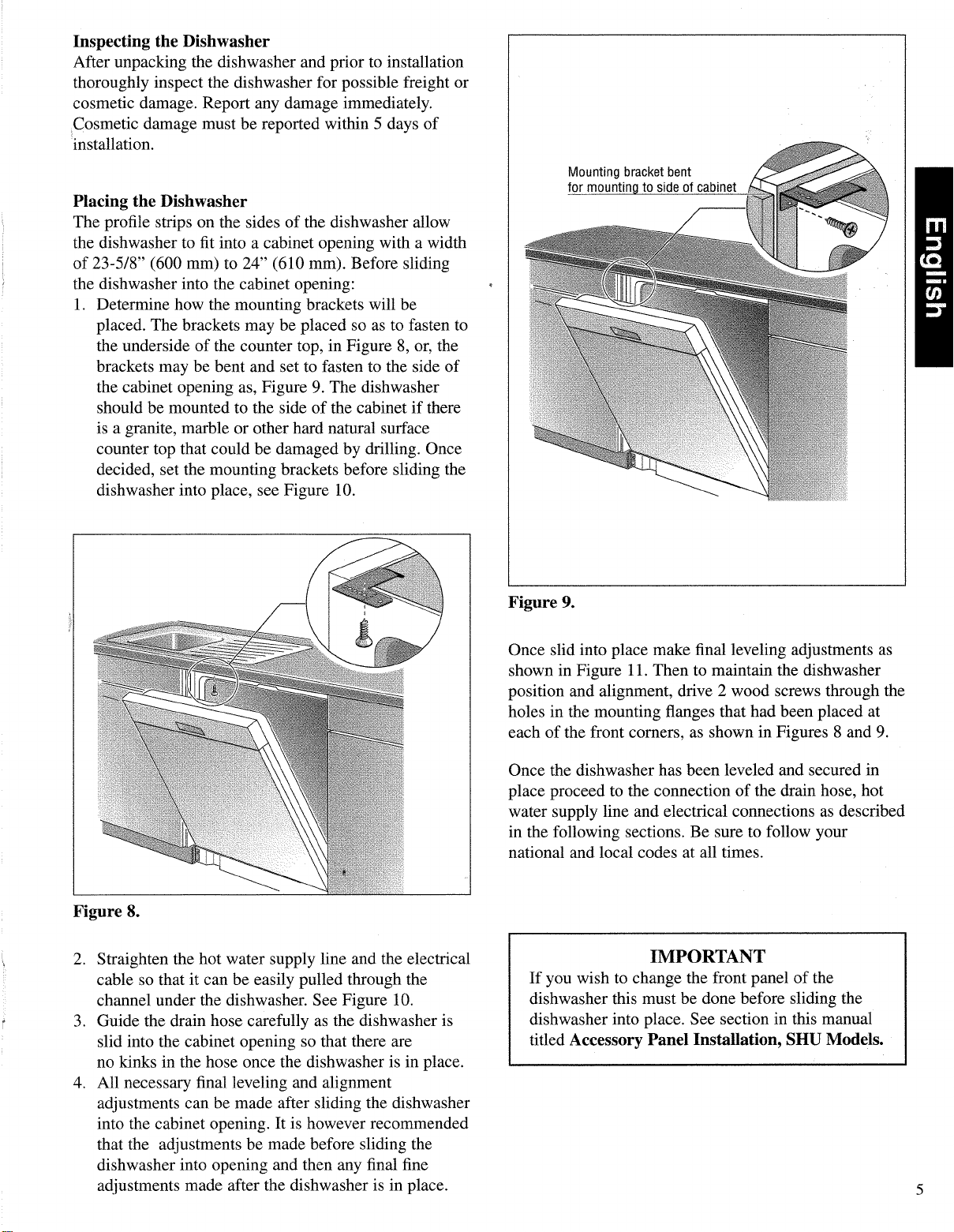

Placing the Dishwasher

The profile strips on the sides of the dishwasher allow

the dishwasher to fit into a cabinet opening with a width

of 23-5/8" (600 ram) to 24" (610 ram). Before sliding

the dishwasher into the cabinet opening:

1. Determine how the mounting brackets will be

placed. The brackets may be placed so as to fasten to

the underside of the counter top, in Figure 8, or, the

brackets may be bent and set to fasten to the side of

the cabinet opening as, Figure 9. The dishwasher

should be mounted to the side of the cabinet if there

is a granite, marble or other hard natural surface

counter top that could be damaged by drilling. Once

decided, set the mounting brackets before sliding the

dishwasher into place, see Figure 10.

Mounting bracket bent

for mounting to side of cabinet

Figure 8.

2. Straighten the hot water supply line and the electrical

cable so that it can be easily pulled through the

channel under the dishwasher. See Figure 10.

3. Guide the drain hose carefully as the dishwasher is

slid into the cabinet opening so that there are

no kinks in the hose once the dishwasher is in place.

4. All necessary final leveling and alignment

adjustments can be made after sliding the dishwasher

into the cabinet opening. It is however recommended

that the adjustments be made before sliding the

dishwasher into opening and then any final fine

adjustments made after the dishwasher is in place.

Figure 9.

Once slid into place make final leveling adjustments as

shown in Figure 11. Then to maintain the dishwasher

position and alignment, drive 2 wood screws through the

holes in the mounting flanges that had been placed at

each of the front comers, as shown in Figures 8 and 9.

Once the dishwasher has been leveled and secured in

place proceed to the connection of the drain hose, hot

water supply line and electrical connections as described

in the following sections. Be sure to follow your

national and local codes at all times.

IMPORTANT

If you wish to change the front panel of the

dishwasher this must be done before sliding the

dishwasher into place. See section in this manual

titled Accessory Panel Installation, SHU Models.

Page 7

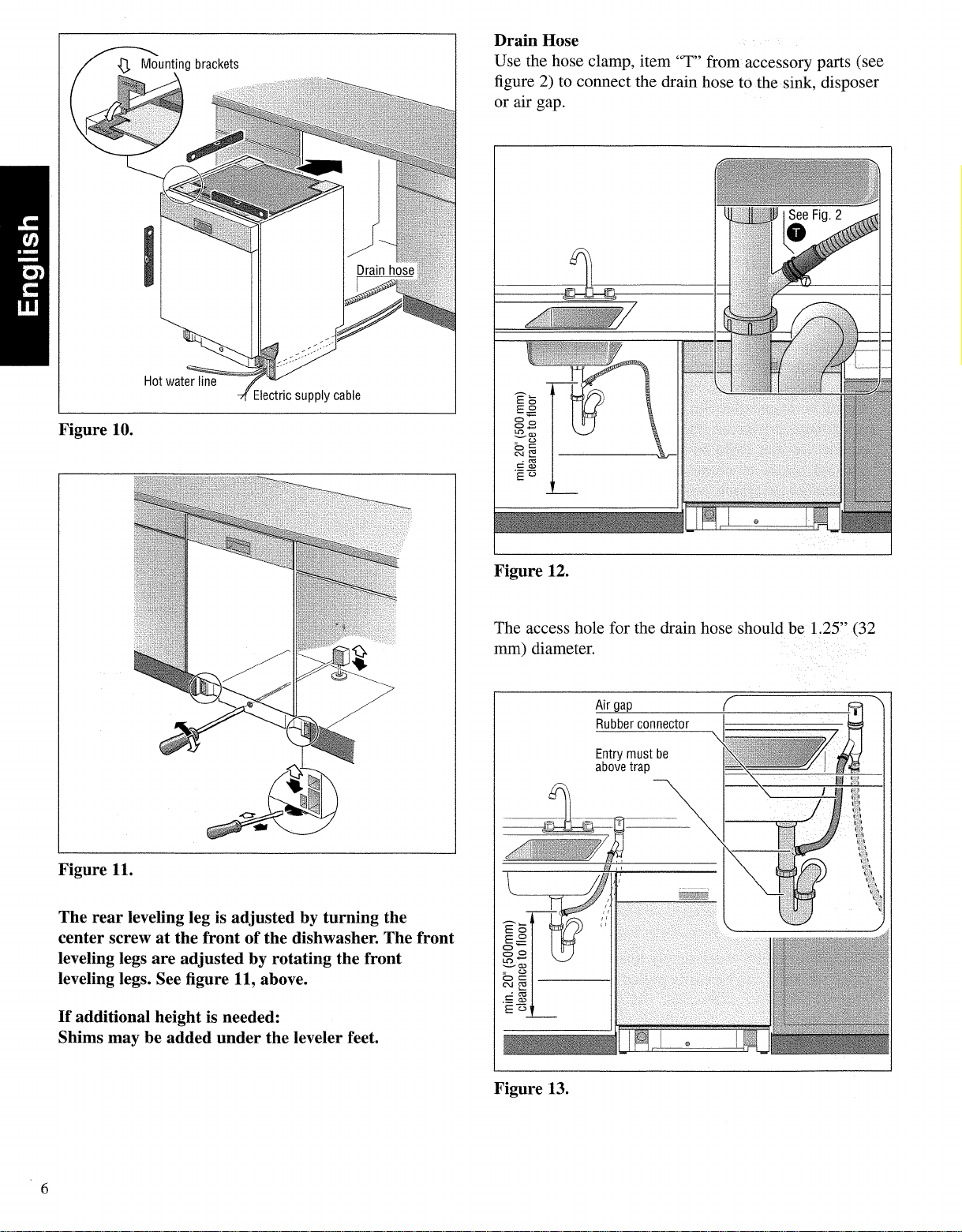

,_ Mountingbrackets

Figure10.

Drain Hose

Use the hose clamp, item "T" from accessory parts (see

figure 2) to connect the drain hose to the sink, disposer

or air gap.

&

Hotwaterline

ilectricsupply cable

Figure 11.

The rear leveling leg is adjusted by turning the

center screw at the front of the dishwasher. The front

leveling legs are adjusted by rotating the front

leveling legs. See figure 11, above.

If additional height is needed:

Shims may be added under the leveler feet.

Figure 12.

The access hole for the drain hose should be 1.25" (32

mm) diameter.

Air gap f

Rubberconnector

Entry must be

above trap

\

Figure 13.

Page 8

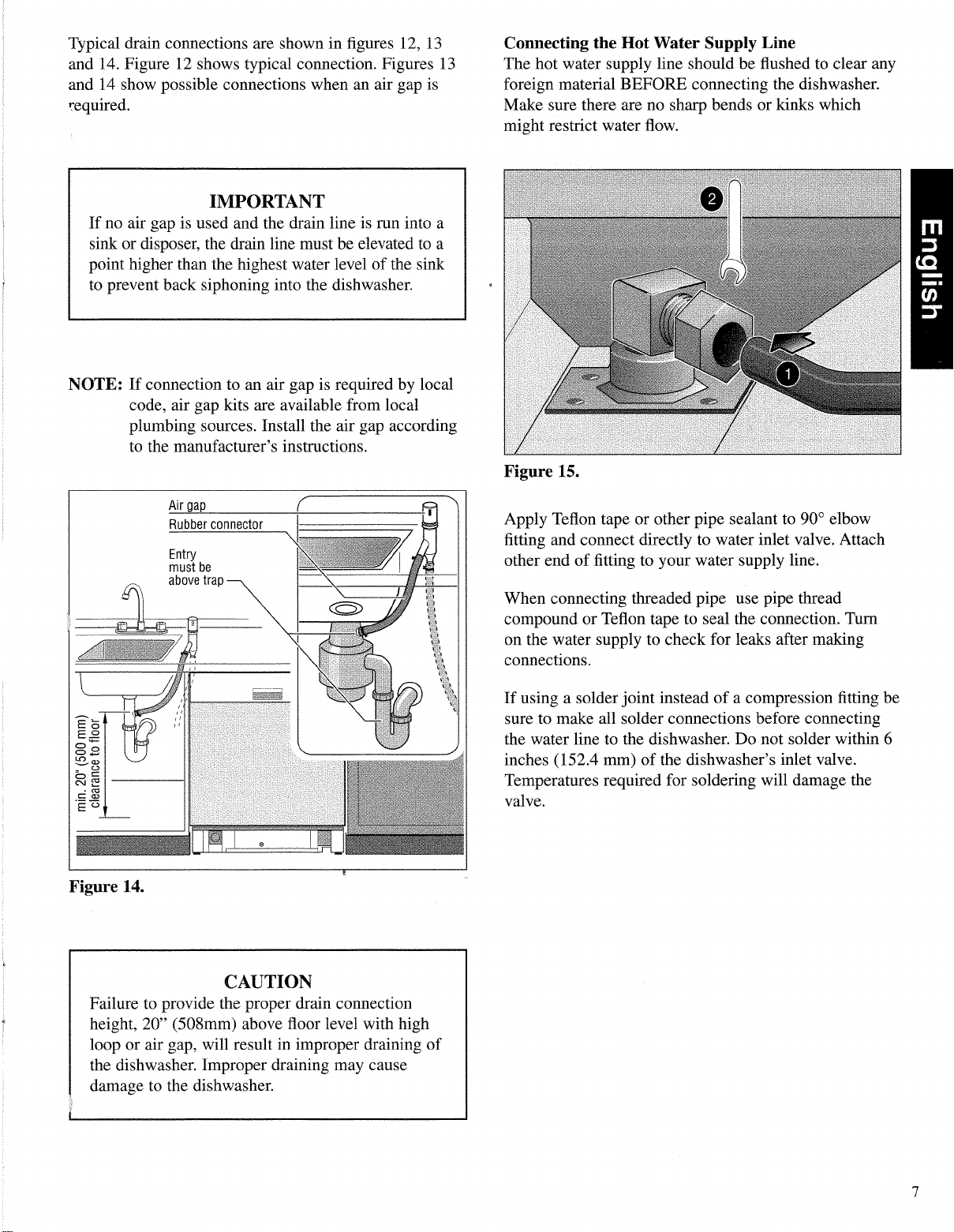

Typical drain connections are shown in figures 12, 13

and 14. Figure 12 shows typical connection. Figures 13

and 14 show possible connections when an air gap is

required.

IMPORTANT

If no air gap is used and the drain line is run into a

sink or disposer, the drain line must be elevated to a

point higher than the highest water level of the sink

to prevent back siphoning into the dishwasher.

NOTE: If connection to an air gap is required by local

code, air gap kits are available from local

plumbing sources. Install the air gap according

to the manufacturer's instructions.

Connecting the Hot Water Supply Line

The hot water supply line should be flushed to clear any

foreign material BEFORE connecting the dishwasher.

Make sure there are no sharp bends or kinks which

might restrict water flow.

Figure 15.

Figure 14.

Airgap S

Rubberconnector

Entry

mustbe

above

Apply Teflon tape or other pipe sealant to 90 ° elbow

fitting and connect directly to water inlet valve. Attach

other end of fitting to your water supply line.

When connecting threaded pipe use pipe thread

compound or Teflon tape to seal the connection. Turn

on the water supply to check for leaks after making

connections.

If using a solder joint instead of a compression fitting be

sure to make all solder connections before connecting

the water line to the dishwasher. Do not solder within 6

inches (152.4 ram) of the dishwasher's inlet valve.

Temperatures required for soldering will damage the

valve.

CAUTION

Failure to provide the proper drain connection

height, 20" (508mm) above floor level with high

loop or air gap, will result in improper draining of

the dishwasher. Improper draining may cause

damage to the dishwasher.

Page 9

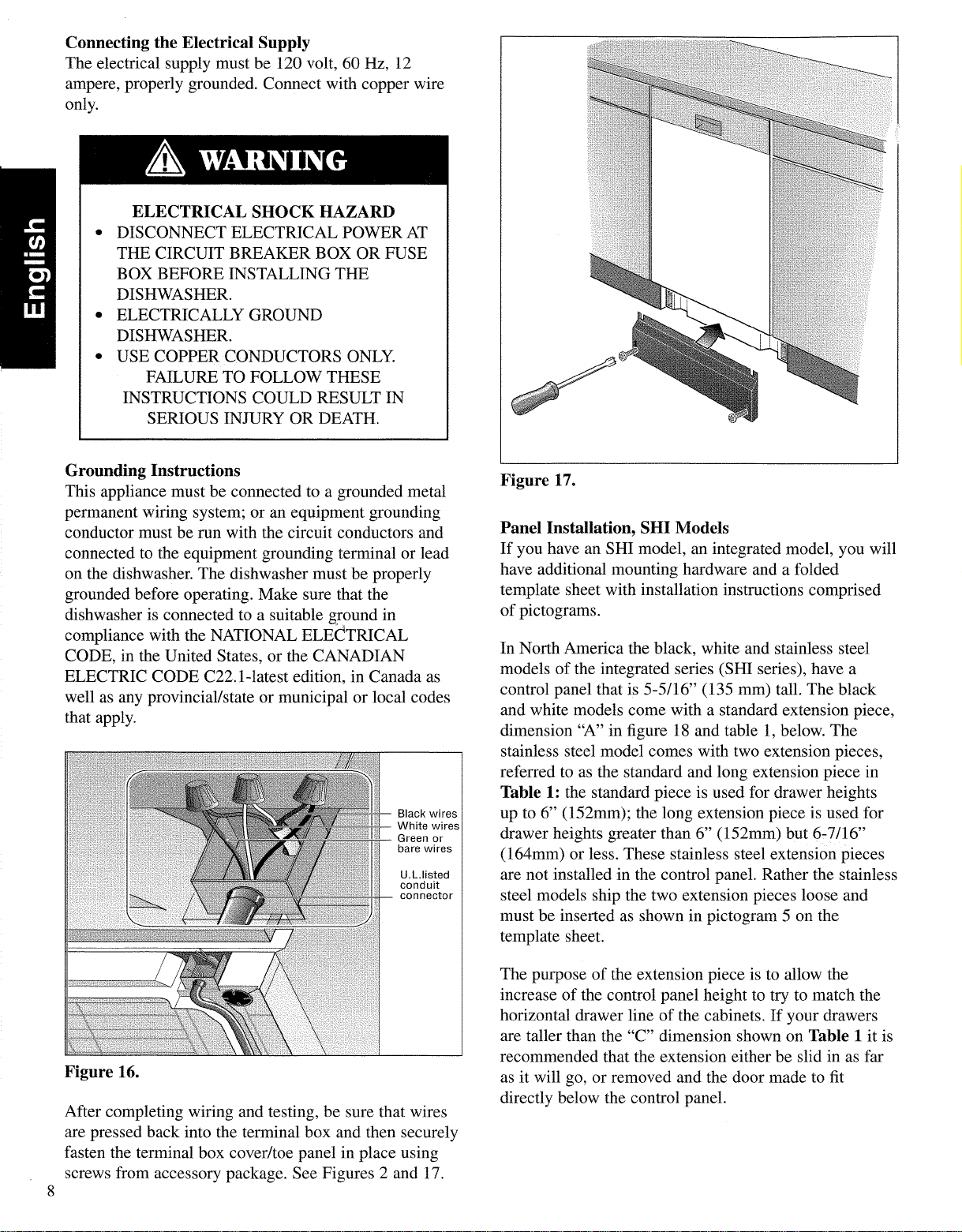

Connecting the Electrical Supply

The electrical supply must be 120 volt, 60 Hz, 12

ampere, properly grounded. Connect with copper wire

only.

ELECTRICAL SHOCK HAZARD

• DISCONNECT ELECTRICAL POWER AT

THE CIRCUIT BREAKER BOX OR FUSE

BOX BEFORE INSTALLING THE

DISHWASHER.

• ELECTRICALLY GROUND

DISHWASHER.

• USE COPPER CONDUCTORS ONLY.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR DEATH.

Grounding Instructions

This appliance must be connected to a grounded metal

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment grounding terminal or lead

on the dishwasher. The dishwasher must be properly

grounded before operating. Make sure that the

dishwasher is connected to a suitable ground in

compliance with the NATIONAL ELECTRICAL

CODE, in the United States, or the CANADIAN

ELECTRIC CODE C22.1-1atest edition, in Canada as

well as any provincial/state or municipal or local codes

that apply.

Black wires

White wires

Green or

bare wires

U.L.listed

conduit

connector

Figure 17.

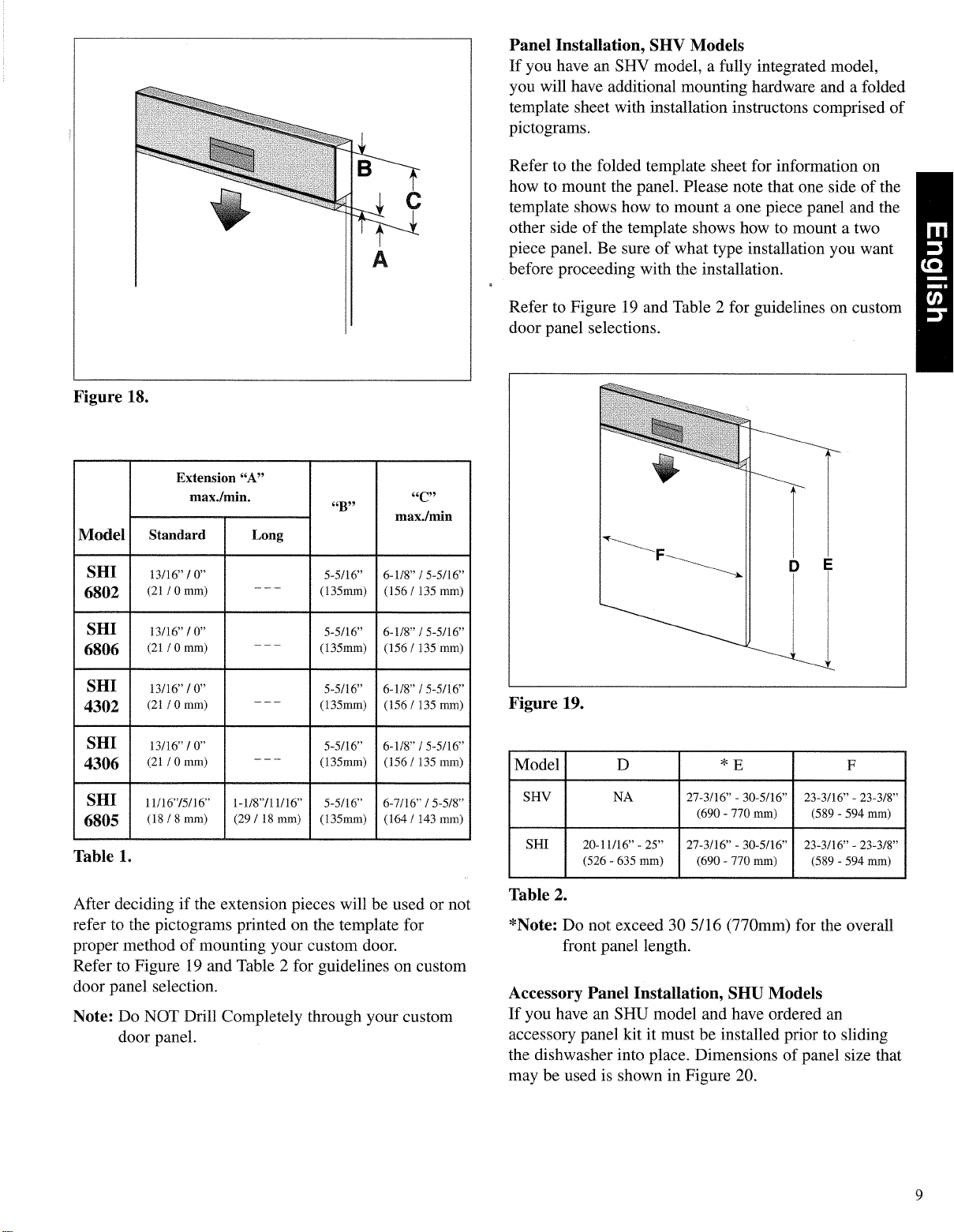

Panel Installation, SHI Models

If you have an SHI model, an integrated model, you will

have additional mounting hardware and a folded

template sheet with installation instructions comprised

of pictograms.

In North America the black, white and stainless steel

models of the integrated series (SHI series), have a

control panel that is 5-5/16" (135 mm) tall. The black

and white models come with a standard extension piece,

dimension "A" in figure 18 and table 1, below. The

stainless steel model comes with two extension pieces,

referred to as the standard and long extension piece in

Table 1: the standard piece is used for drawer heights

up to 6" (152mm); the long extension piece is used for

drawer heights greater than 6" (152mm) but 6-7/16"

(164mm) or less. These stainless steel extension pieces

are not installed in the control panel. Rather the stainless

steel models ship the two extension pieces loose and

must be inserted as shown in pictogram 5 on the

template sheet.

Figure 16.

After completing wiring and testing, be sure that wires

are pressed back into the terminal box and then securely

fasten the terminal box cover/toe panel in place using

screws from accessory package. See Figures 2 and 17.

The purpose of the extension piece is to allow the

increase of the control panel height to try to match the

horizontal drawer line of the cabinets. If your drawers

are taller than the "C" dimension shown on Table 1 it is

recommended that the extension either be slid in as far

as it will go, or removed and the door made to fit

directly below the control panel.

Page 10

Figure 18.

Extension '%"

max./rnin.

Panel Installation, SHV Models

If you have an SHV model, a fully integrated model,

you will have additional mounting hardware and a folded

template sheet with installation instructons comprised of

pictograms.

Refer to the folded template sheet for information on

how to mount the panel. Please note that one side of the

template shows how to mount a one piece panel and the

other side of the template shows how to mount a two

piece panel. Be sure of what type installation you want

befbre proceeding with the installation.

Refer to Figure 19 and Table 2 for guidelines on custom

door panel selections.

"B"

Model Standard

SHI 13/16" / 0"

6802 (21 / o mm)

SHI 13/16"/0"

6806 (21/ 0 mm)

SHI 13/16-/o"

4302 (21/ omm)

SHI 13/16"/o"

4306 (21/ omm)

SHI 11/16'75/16"

6805 (18 / 8 ram)

Long

1-1/8"/11/16"

(29 / 18 mm)

5-5/16"

(135mm)

5-5/16"

(135mm)

5-5/16"

(135mm)

5-5/16"

(135mm)

5-5/16"

(135mm)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-1/8" / 5-5/16"

(156 / 135 ram)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-7/16" / 5-5/8"

(164 / 143 mm)

Table 1.

After deciding if the extension pieces will be used or not

refer to the pictograms printed on the template for

proper method of mounting your custom door.

Refer to Figure 19 and Table 2 for guidelines on custom

door panel selection.

Note: Do NOT Drill Completely through your custom

door panel.

D

Figure 19.

Model D * E F

SHV NA 27-3/16"- 30-5/16" 23-3/16"- 23-3/8"

(690 - 770 ram) (589 - 594 mm)

SHI 20-11/16" - 25" 27-3/16" - 30-5/16" 23-3/16" - 23-3/8"

(526 - 635 ram) (690 - 770 ram) (589 - 594 mm)

Table 2.

*Note: Do not exceed 30 5/16 (770mm) for the overall

front panel length.

Accessory Panel Installation, SHU Models

If you have an SHU model and have ordered an

accessory panel kit it must be installed prior to sliding

the dishwasher into place. Dimensions of panel size that

may he used is shown in Figure 20.

Page 11

1/4" max.

(6mm)

Final check list

CHECK ELECTRICAL REQUIREMENTS.

BE SURE YOU HAVE CORRECT ELECTRICAL

SUPPLY AND RECOMMENDED GROUNDING

METHOD.

t

(586 mm

Figure 20.

Door Tension Adjustment

After installation of the dishwasher open and close the

door several times. The door should open and close

easily with very little force required to lift the door

when fully open. If the door closes too quickly, or if the

door falls open, the spring tension should be adjusted.

To adjust the spring tension obtain the gerew in Figure

21 out of the parts bag. Insert the screw as shown in

Figure 21 and adjust spring tension as shown.

Turn on the hot water shut-off valve and electrical

supply. Water temperature should be 140°F (60°C).

Operate the dishwasher through one cycle and check for

plumbing leaks.

If the dishwasher does not operate refer to the SELF-

HELP and the SERVICE and REPAIR sections in the

Use and Care Manual.

LEAVE INSTALLATION INSTRUCTIONS AND

USE & CARE MANUAL WITH OWNER.

Figure 21.

10

+

Page 12

BOSCH

INSTRUCTIONS D'INSTALLATION

pour les modules

SHU (6800, 5300, 4300, 3000)

SHI (6800, 4300)

SHV (4800, 4300)

Table des mati6res

INTRODUCTION

OUTI LS NI_CESSAI RES

MATI_RIEL REQUIS

PII_CES ACCESSOIRES FOURNIES

DONNC:ES TECHNIQUES

CHOIX DE L'EMPLACEMENT

PRE_PARATION POUR L'EMPLACEMENT

ALIMENTATION EN EAU CHAUDE

TUYAU DE DRAINAGE

ALIMENTATION #'LECTRIQUE

INSPECTION DU LAVE-VAISSELLE

INSTALLATION DU LAVE-VAISSELLE

TUYAU D'I_VACUATION

BRANCHEMENT,_ L'ALIMENTATION EN EAU CHAUDE 17

BRANCHEMENT AU SYST#ME E_LECTRIQUE 18

INSTRUCTIONS POUR LA MISE ,_ LA TERRE 18

INSTALLATION DU PANNEAU, MODI_LES SHI 18,19

INSTALLATION DU PANNEAU, MODI_LES SHV 19

ACCESSOIRE DU PANNEAU D'INSTALLATION, SHU 19

12

12

12

12

13

13

14

14

14

14

15

15,16

16,17

RI_GLAGE DE TENSION DE LA PORTE

DERNII_RE VERIFICATION

MPORTANT : Avant de commencer, lire enti_rement et attentivement ces instructions, h

A L'INSTALLATEUR : Remettre ce guide au propridtaire _ des fins de rdfdrences. |

AU PROPRIETAIRE : Conserver ces instructions d'installation pour |

I'inspecteur local en _lectricit_ et b des fins de r_f_rences. ,,,,/

20

2O

1]

Page 13

Introduction

Lireenti_rementetattentivementcesinstructions.Elles

aideront&_conomisertempseteffortetpermettront

d'assurerunfonctionnementoptimaldulave-vaisselle.

S'assurerd'observertouslesconseilsdes6curiteetles

avertissements.

Cesinstructionsd'installationsontdestin6es&un

installateurqualifie.Enplusdesinstructions,lelave-

vaisselledoit_treinstalle:

• AuxI_tats-Unis, selon le code national d'61ectricit6,

les codes municipaux et des etats et/ou les codes

Iocaux.

• Au Canada, selon le code canadien de I'electricite

C22.1 (derniere edition), les codes municipaux et

provinciaux et/ou les codes Iocaux.

Ces codes doivent etre rigoureusement observes en tout

temps.

S'il s'agit d'une nouvelle installation, la majorit_ des

travaux doit _tre effectu_e avant de mettre le lave-

vaisselle en place. S'il s'agit du remplacement d'un lave-

vaisselle, les branchements de I'ancien lave-vaisselle

doivent etre verifies afin qu'ils soient compatibles avec le

nouveau lave-vaisselle, et remplac6s si necessaire.

Outils requis pour I'installation

Voir figure I "

A. Ruban & mesurer

B. Tournevis & lame plate

C. Tournevis Phillips

D. Tournevis Torx n°20

E. Perceuse electrique

F. Scie & guichet ou & emporte-piece 1 po

G. Marteau

H. Niveau

I. Cles ouvertes 10 et 13 mm

J. 2 cl6s & molette

K. 2 cl6s & tuyau

L. Coupe-ill

M. D_nudeur de fil

O

Figure 1

Pibces accessoires fournies

S'assurer qu'il ne manque aucune piece accessoire

fournie pour ce modele, voir figure 2. S'il manque des

pieces, communiquer imm6diatement avec le d_taillant.

Voir figure 2

O. Capuchons (2)

P. Vis (2) pour couvercle de bofte de jonction et pan-

neau du bas

R. Ferrures de montage (2)

S. Vis & bois (2)

T. Collet de raccord

U. Vis, M6 x 26 (2)

V. Ferrures de montage (4) et vis (8)

W. Gabarit avec schema de montage

X. Vis, M4 x 42 (2) (modUles SHV seulement)

Pi_ces accessoires fournies avec :

ModUles SHU ModUles SHI et SHV

__®@

Matdriaux requis

• Tuyau en cuivre d'une dimension exterieure d'au

moins 3/8 po, d'une Iongueur suffisante pour I'instal-

lation.

• Valve d'arr_t et raccords pour tuyau d'eau chaude.

• Coude 90° avec 3/8 po N.P.T. (pression et tempera-

ture normales) & filetage exterieur &une extr_mit6 et

pouvant se brancher & I'alimentation en eau & I'autre

extr6mit6.

• Ruban T_flon ou autre scellant pour tuyaux.

• 3 cosses pour fil de calibre 16 AWG.

• Connecteur de tuyau approuve UL ou soupape de

pression.

D'autres mat6riaux peuvent _tre necessaires afin de

repondre aux codes tocaux.

12

0--

0-

Figure 2

Page 14

Donndestechniques

Figure 3

(102mm)

1-15/16" (49m

i \

23-5/8' - 24" (600 - 610 rnm)

Figure 4

Dimensions

A hauteur

B largeur

C profondeur

33 7/8 - 35 po (860 - 890 mm)

23 9/16 po ( 598 mm)

22 7/16 po (570 mm)

Puissance dlectrique

Volts Hertz Amperes I Watts 1120 60 12 1,450 (max.)

Choix de I'emplacement

La plupart des travaux d'installation sont effectu6s avant

que le lave-vaisselle ne soit mis en place. Choisir un

emplacement aussi pros que possible de I'evier afin

d'avoir acc_s & laconduite d'eau et au conduit de

vidange.

Pour tout lave-vaisselle & encastrer, le dessus, les deux

cSt_s et I'arri_re doivent _tre encastres compl_tement.

Par consequent, I'espace sous le comptoir est probable-

ment le meilleur endroit.

Pour un rendement appropri6 et une belle apparence du

lave-vaisselle, I'ouverture sous le comptoir devrait _tre

carree et avoir les dimensions indiquees & la figure 4.

Si I'installation doit _tre faite en coin, s'assurer d'avoir

assez d'espace pour I'ouverture de la porte. Voir figure

5.

Espacement pour T

ouverture de la porte"

Porte ouverte

Figure 5

ATTENTION :

Pour eviter toute rupture de la valve de remplissage et

des conduites d'eau allant au lave-vaisselle, ces condui-

tes d'eau DOIVENT #TRE proteg6es contre le get. Si la

valve ou la conduite d'eau gele, il peut en resulter une

inondation. Un tel bris n'est pas couvert par la garantie.

]3

Page 15

Preparationde I'emplacement

Les trous d'acces pour I'alimentation electrique, la

conduite d'eau et le systeme de vidange doivent _tre

faits tel qu'il est indiqu_ aux figures 6 et 7 de fa£on &

eviter tout probleme avec le cadre du lave-vaisselle ou

les autres 61_ments.

I Valve

!\

\

23-5/8" - 24"

(600 - 610 mm)

Figure 6

Les trous d'acces doivent 6tre ronds et lisses et ne

doivent pas avoir un diametre de plus de 1 1/2po.

Alimentation en eau chaude

• Lapression de la conduite d'eau £haude allant au

lave-vaisselle dolt _tre entre 15 et _120Ib/po2(1,03 -

8,27 barres)

• Lechauffe-eau dolt _tre r6gl_ pour fournir une

temperature de 140 °F (60 °C) au lave-vaisselle.

• Letuyau de cuivre dolt avoir un diametre d'au moins

3/8 po & I'interieur.

• Toutes les soudures doivent etre faites avant que la

conduite d'eau ne soit branch_e &la valve d'entr_e

du lave-vaisselle. Ne pas faire de soudure & moins

de 6 po (152,4 mm) de la valve d'entree du lave-

vaisselle.

Apres avoir _tabli I'endroit oQ la conduite d'eau sera

branch_e au lave-vaisselle, percer un trou d'acces de

1 po (25,4 mm) de diametre et placer le tuyau & I'endroit

approximatif de la valve de remplissage, tel qu'il est

indique & la figure 7. IIest recommand_ qu'une valve

d'arr_t (non fournie) soit installee sur la conduite d'eau

chaude, & un endroit facile d'acces.

Tuyau de vidange

Le lave-vaisselle est livr_ avec un tuyau de vidange de

sept (7) pi. Percer un trou d'acces de fa£on & ce que le

tuyau de vidange se rende au branchement du conduit

de vidange.

HWS

Conduite d'eau chaude

201/2"

(520mm)

Figure 7

Alimentation dlectrique

RISQUE DE CHOC ELECTRIQUE

• AVANT D'INSTALLER LE LAVE-VAISSELLE,

COUPER LE COURANT ELECTRIQUE AU DIS-

JONCTEUR OU A LA BOiTE DE FUSIBLES

• EFFECTUER LA MISE A LATERRE

• UTILISER UNIQUEMENT DES CONDUCTEURS EN

CUIVRE.

SI L'ON N'OBSERVE PAS CES INSTRUCTIONS,

IL PEUT EN RI_SULTER DE GRAVES BLESSURES

OU LA MORT.

L'alimentation electrique dolt _tre de 120 volts, 60 Hz,

12 amperes, correctement mise & la terre, positionnee

tel qu'il est indiqu6 & la figure 7 et installee par un

_lectricien qualifie. Aucun autre appareil ou prise ne dolt

_tre branch6 sur ce circuit.

Afin de faire passer le fil electrique, percer un trou de 1

po (25,4 mm) de diametre dans te comptoir. Si ce trou

est perc_ dans un comptoir en bois, il devrait _tre ponc_

afin d'etre lisse. Si le trou est perce dans un comptoir

de metal, les rebords devraient _tre recouverts d'un

passe-fil. Passer un c&ble flexible, tel qu'il est permis

par les codes, depuis la bofte de connexions jusqu'au

trou du comptoir. Ce c&ble dolt mesurer 30 po & partir du

tour arriere.

]4

Page 16

Vdrificationdulave-vaisselle

Apres avoir d6ball6 le lave-vaisselle et avant I'installa-

tion, verifier entierement le lave-vaisselle afin d'y deceler

d'_ventuels dommages caus6s par le transport. Signaler

immc_diatement tout dommage. Les dommages estheti-

ques doivent #tre signal,s dans les 5 jours suivants

rinstallation.

installation du lave-vaisselle

Les moulures lat6rales permettent d'ajuster le lave-

vaisselle dans une ouverture de comptoir de 23 5/8 po

(600 mm) &24 po (610 mm) de largeur. Avant de glisser

le lave-vaisselle dans I'ouverture :

,

D6terminer comment seront places les supports de

fixation. Les supports peuvent 6tre places de fagon &

Ctre fixes sous le devant du comptoir, figure 8, ou ils

peuvent _tre replies de fagon & 6tre fixes sur les

c6t6s de I'ouverture, figure 9. Si le dessus du comp-

toir est en granite, en marbre ou d'autres surfaces

naturelles tres dures, le lave-vaisselle devrait #tre fix_

sur les c6tes, sinon la surface pourrait Ctre endom-

magee par le pergage. Lorsque I'on est decid6, fixer

les supports avant de glisser le lave-vaisselle en

place, figure 10.

Support de fixation pli_ pour

t'installation sur les c6tes du corn

Figure 8

2. Aligner laconduite d'eau chaude _t le c&ble d'ali-

mentation electrique de fagon &ce que ces derniers

puissent passer facilement dans la rainure sous le

lave-vaissetle, figure 10.

3. Diriger le tuyau de vidange au fur et & mesure que le

lave-vaisselle glisse dans I'ouverture de fa_on &ce

que le tuyau Wait aucun faux pli une fois le lave-

vaisselle en place.

4. Effectuer tous les reglages de niveau et d'alignement

une fois le lave-vaisselle en place dans I'ouverture. II

est toutefois recommande que ces reglages soient

faits avant de glisser le lave-vaissetle en place, puis

une fois en place, effectuer les tous derniers

reglages.

Figure 9

Une fois glisse en place, faire les derniers r6glages de

niveau tel qu'il est indiqu_ & la figure 11. Ensuite, pour

maintenir le bon alignement du lave-vaisselle, visser 4

vis & bois dans les trous des fixations qui ont et6 places

& chacun des coins avant, voir figures 8 et 9.

Apres avoir mis le lave-vaisselle de niveau et fixe en

place, effectuer les raccords du tuyau de vidange, de la

conduite d'eau et de ralimentation electrique tel qu'il est

d_crit dans les sections qui suivent. S'assurer de

respecter en tout temps les codes Iocaux et nationaux.

]5

Page 17

Supports de fixation

Tuyau de vidange

Utitiser le cotlet de tuyau de vidange (piece <<T>>)(voir

figure 2) pour relier le tuyau de vidange & r_vier, au

broyeur ou au trou d'aeration.

I

Conduite d'eau chaude

Figure 10

Figure 11

Tuyau de vidange

C&ble d'alimentation _lectrique

Figure 12

Le trou d'acces pour le tuyau de vidange doit avoir un

diametre d'au moins ! ,25 po (32 mm).

Trou d'aeration

Raccord en caoutchouc

L'arriv_e doit #tre

au-dessus du siphon

Le pied niveleur arri_re se r_gle en tournant la vis

centrale & I'avant du lave-vaisselle. Les pieds niveleurs

avant se r_glent en les tournant. Voir figure 11 ci-des-

SUS,

Pour hausser davantage le lave-vaisselle •

Ajouter des cales sous les pieds niveleurs.

Figure 13

<

16

Page 18

Desraccordstypiquesdetuyaudevidangesontillus-

tr6sauxfigures12,13et14.Lafigure12illustreun

raccordcourant.Lesfigures13et14illustrentdes

raccordspossiblesIorsqu'untroud'aerationestneces-

saire.

IMPORTANT

S'iln'yaaucuntroud'a_rationetqueletuyaude

vidangeestreli6&1'6vierouaubroyeur,letuyaude

vidangedolt_treplus61ev_quelepointleplus_lev_

delaconduited'eauallant&I'evier;cecipoureviter

lesretoursdesiphondanslelave-vaisselle.

Trou d'a6ration S

Raccord en caoutchouc

Uarriv_e doit 6tre

au-dessus du siphon

Branchement de la conduite d'eau chaude

AVANT de brancher la conduite d'eau chaude au lave-

vaisselle, la rincer afin d'enlever tout corps _tranger.

S'assurer qu'il n'y ait aucun pli ni pincement pouvant

entraver le debit d'eau.

Figure 15

Poser un ruban Teflon ou tout autre scellant pour tuyau

sur le coude & 90° et brancher directement sur la valve

d'entr_e d'eau. Raccorder I'autre extremite & laconduite

d'eau.

Figure 14

REMARQUE :Si le branchement & untrou d'a_ration

est requis par un code local, les n6cessaires pour trous

d'aeration sont disponibles chez les plombiers. Installer

le trou d'a6ration selon les instructions du fabricant.

AVERTISSEMENT

Si ron ne respecte pas la hauteur appropriee pour le

branchement du tuyau de vidange 20 po (500 mm)

au-dessus du niveau du sol avec une grande boucle

ou un trou d'a_ration, iten r6sultera une mauvaise

vidange, ce qui pourrait endommager le lave-vaisselle.

Si I'on branche un tuyau filetS, utiliser un produit appro-

pri6 ou un ruban Teflon pour sceller le branchement.

Ouvrir la conduite d'eau afin de verifier les fuites possi-

bles.

Si I'on utilise un joint soude au lieu d'un raccord &

pression, s'assurer que toutes les soudures soient

faites avant le branchement de laconduite d'eau au lave-

vaisselle. Ne pas souder & moins de 6 po (152,4 mm) de

la valve d'entr_e d'eau du lave-vaisselle. Les temperatu-

res requises pour la soudure endommageront la valve.

17

Page 19

Branchement b I'alimentation dlectrique

L'alimentation electrique doit etre de 120 volts, 60 Hz,

12 amperes, correctement mise & terre. Faire le bran-

chement uniquement avec du fil de cuivre.

RISQUE DE CHOC E_LECTRIQUE

• AVANT D'INSTALLER LE LAVE-VAISSELLE,

COUPER LE COURANT I_LECTRIQUE AU

DISJONCTEUR OU .&.LA BO[TE DE FUSIBLES

° EFFECTUER LA MISE A LATERRE

° UTILISERUNIQUEMENTDESCONDUCTEURS

EN CUIVRE.

SI L'ON N'OBSERVE PAS CES INSTRUCTIONS, IL

PEUT EN RI_SULTER DE GRAVES BLESSURES

OU LA MORT.

Figure 17

INSTRUCTIONS POUR LA MISE A LA TERRE :

Cet appareil doit _tre relic & un systeme de c&blage

permanent, mis & la terre, ou un fil de mise & la terre

dolt 6tre prevu avec les conducteurs de circuit et relie &

la borne ou au fil de mise & la terre sur le lave-vaisselle.

Le lave-vaisselle doit etre correctement mis & laterre

avant de le faire fonctionner. S'assurer que lelave-

vaisselle soit mis & la terre selon le CODE ELECTRI-

QUE NATIONAL, aux E_tats-Unis, ou le CODE E_LECTRI-

QUE CANADIEN C22.1, derniere edition, au Canada ou

selon les codes de toute autre province ou etat ou aux

codes municipaux ou Iocaux qui s'appliquent.

Fils noirs

Fils blancs

Fils verts ou

d_nudes

de

conduit class6 U.L.

Figure 16

Apres avoir termine et verifie le branchement, s'assurer

que les ills soient repousses dans la bofte de jonction.

Ensuite, fixer solidement, de fa£:onsecuritaire, le

couvercle de la bofte de jonction et le panneau d'acces

inferieur. Voir figures 2 et 17.

Installation du panneau, modbles SHI

Pour le modele SHI, entierement integr& des supports

de fixation additionnels sont fournis et une feuille de

gabarit pliee comprenant tes instructions sur schema.

En Amerique du Nord, les modeles noirs, blancs et en

acier inoxydable de la gamme integree (SHI) sont dotes

d'un panneau de commandes de 5 5/16 po (135 mm) de

haut. Les modeles blancs et noirs sont dotes d'une

rallonge standard, dimension <,A, de la figure 18 et du

tableau 1 ci-dessous. Les modeles en acier inoxydable

sont dotes de deux rallonges; une piece standard et une

Iongue, au tableau 1. La piece standard est utilisee

pour des tiroirs jusqu'& 6 po (152 mm) de haut; la piece

Ion-gue est utilisee pour des tiroirs de plus de 6 po (152

mm) mais de 6 7/16 po (164 mm) ou moins. Ces ral-

Ionge en acier inoxydable ne sont pas installees dans le

panneau de commandes. Les modetes en acier inoxy-

dable sent livres avec tes deux rallonges separees et

ces dernieres doivent _tre inserees tel qu'il est illustre

au schema 5 de la feuille de gabarit.

La rallonge permet d'augmenter la hauteur du panneau

de comamndes afin de correspondre &ta ligne horizon-

tale du tiroir de I'armoire. Si les tiroirs sont plus hauts

que la dimension <<C>,illustreeau tableau 1, il est

recommande de faire glisser la rallonge le plus loin

possible ou de I'enlever et la porte peut _tre ajustee

directement sous le panneau de comamndes.

18

Page 20

Figure 18

Installation du panneau, modbles SHV

Si I'on possede un modele SHV, enti_rement integre,

des supports de fixation additionnels sont fournis et une

feuille de gabarit pliee comprenant les instructions sur

schema.

Consulter la feuille de gabarit pour plus de d_tails sur la

fa£on d'installer le panneau. II est & noter qu'un c6t_ de

C

la feuille montre comment installer le panneau une piece

et rautre cSte indique I'installation du panneau deux

A

pi_ces. S'assurer du type d'installation d_sire avant de

proceder.

Consulter la figure 19 et le tableau 2 concernant les

directives de s_lection du panneau de porte sur mesure.

Modble_

SHI

6802

SHI

6806

SHI

RallongeA

max.-min.

Standard

13/16 - 0 po

(20 - 0 mm)

13/16 - 0 po

(21 - 0 mm)

13/16 - 0 po

(2t - 0 mm)

Longue

55/16p0 61/8-55/16pc

(135 mm' (156 - 135 mm)

55/16pc 61/8-55/16pc

(135 mm', (156 - 135 mm)

5 5/16 po i 6 1/8 - 5 5/16 pc

(135 mm' (156 - 135 mm)

C

max.-min.

I

43O2

SH!

43O6

SHI

68O5

13/16 - 0 po

(21 - O mm)

11/16 - 5/16 po

(18 - 8 mm)

1 1/8- 11/16po

(29 - 18 ram)

55/16po 61/8-55/16pc

(135 mm) (156 - 135 mm)

55/16po 67/16-55/8pc

(135 ram) (164 - 143 mm)

Tableau 1

Apres avoir d_cid6 d'utiliser ou non ta rallonge, consulter

les schemas imprimes sur le gabarit (_oncernant la

m_thode appropriee pour installer la porte.

Consulter la figure 19 et le tableau 2 concernant les

directives sur la selection du panneau de porte sur

mesure.

Remarque : Ne PAS percer completement le panneau

de porte sur mesure.

D E

Figure 19

Mod_l_ D *E F

SHV S/O 27 3/16 - 30 5/16 po 23 3/16 - 23 3/8 po

(690 - 770 mm) (589 - 594 mm)

SHI 20 11/16 - 25 po 27 3/16 - 30 5/16 po 23 3/16 - 23 3/8 po

(526 - 635 mm) (690 - 770 mm) (589 - 594 mm)

Tableau 2

*REMARQUE : Ne pas exceder 30 5/16 po (770 mm)

pour la Iongueur hors tout du panneau avant.

Installation du panneau accessoire, modbles SHU

Si I'on possbde un modble SHU et que t'on a com-

mand6 un necessaire de panneau accessoire, ce

dernier doit _tre installe avant de glisser le lave-vaisselle

en place. Les dimensions du panneau que I'on veut

utiliser sont indiquees & la figure 20.

19

Page 21

25" (6mm)

1/4" max,

Derni_re v_rification

VI_RIFIER LES EXIGENCES I_LECTRIQUES. S'ASSU-

RER QUE LE BRANCHEMENT SUR L'ALIMENTATION

E_LECTRIQUESOIT EFFECTUE_CORRECTEMENT ET

QUE LA MISE _, LA TERRE SOIT FAITE SELON LES

RECOMMANDATIONS.

(586 mm

Figure 20

R_glage de la tension de la porte

Apres avoir installe le lave-vaisselle, ouvrir et fermer la

porte plusieurs fois. La porte devrait fonctionner facile-

ment, presque sans effort pour la refermer Iorsqu'elle est

completement ouverte. Si la porte se referme trop

rapidement ou si la porte s'ouvre d'elle-mOme, la tension

du ressort de la porte doit _tre r6gl6e. Pour r6gler la

tension du ressort, sortir la vis illustree & lafigure 21.

InsUrer cette vis tel qu'il est illustr_ & la figure 21 et

r_gler la tension du ressort.

7

Ouvrir la valve d'eau chaude et ralimentation 6tectrique.

La temperature de I'eau devrait _tre de 140 °F (60 °C).

Faire fonctionner le lave-vaisselle pour un cycle et v6rifier

les fuites possibles.

Si le lave-vaisselle ne fonctionne pas, consulter les

sections GUIDE DE DI_PANNAGE et SERVICE et

REPARATION dans le guide d'utilisation et d'entretien.

LAISSER LES INSTRUCTIONS D'INSTALLATION ET

LE GUIDE D'UTILISATION ET D'ENTRETIEN AU

PROPRII=TAIRE.

2O

Figure 21

Page 22

BOSCH

P •

Induce para referencia r@ida

Instrucciones de instalaci6n

para SHU (6800, 5300, 4300, 3000)

y SHI (6800,4300)

y SHV (4800,4300)

_i]_I;

INTRODUCCION 22

HERRAMIENTAS NECESARIAS PARA LA

INSTALACION 22

MATERIALES QUE NECESITARA 22

PARTES QUE SE INCLUYEN 22

INFORMACION TI_CNICA

ELECCION DEL LUGAR

PREPARACION DEL LUGAR

SUMINISTRO DE AGUA CALIENTE

MANGUERA DE DRENAJE

SUMINISTRO ELECTRICO

INSPECCION DE LA LAVADORA DE PLATOS 25

COLOCACION DE LA LAVADORA DE PLATOS 25

26-27MANGUERA DE DRENAJE

CONEXIONALSUMINISTRODEAGUACALIENTE 27

CONEXION AL SUMINISTRO DE

ENERGIA ELI_CTRICA 28

INSTRUCCIONF_ PARA CONECWAR A TIERRA 28

23

23

24

24

24

24

INSTALACION DEL TABLERO, MODELOS SHI 28-29

1NSTALACION DEL TABLERO, MODELOS SHV 29

INSTALACION DELTABLEROACCESORIO, SHU 29

AJUSTE DE LA TENSION DE LA PUERTA 30

TECNICO DE INSTALACION: Por favor deje este manual con el propietario

para futuras referencias.

I IMPORTANTE: Antes de iniciar lea estas instruceiones completa y cuidadosamente.

PROPIETARIO: Conserve estas instrucciones de instalaci6n para el

uso del inspector el_ctrico local y para futuras referencias

30LISTA DE REVISION FINAL

21

Page 23

Introducci6n

Por favor lea las instrucciones de instalaci6n completa y

cuidadosamente, t_stas le ahorrarin tiempo y esfuerzo y le

ayudarin a asegurar un funcionamiento 6ptimo de la lavadora

de platos. Asegdrese de seguir todas las advertencias y

precauciones que se indican.

Estas instrucciones estin destinadas para ser usadas por

personas calificadas para hacer la instalaci6n. Ademis de

seguir estas instrucciones, la lavadora de platos debe ser

instalada:

• En los Estados Unidos, de acuerdo con el Cddigo

E16ctrico Nacional / c6digos Estatales y Municipales y/o

c6digos locales.

• En Canadi, de acuerdo con la edicidn mils reciente del

C6digo E16ctrico Canadiense C22.1 / cddigos de la

Provincia y del Municipio y/o c6digos locales.

Estos se deberin seguir cuidadosamente en todo momento.

• I®

Si la lavadora de platos es una instalaci6n nueva, la mayorfa

del trabajo debe hacerse antes de que la lavadora de platos se

lleve al lugar de instalaci6n.Si la lavadora de platos esti

reemplazando a otra lavadora de platos, las conexiones para el

aparato que es reemplazado deben revisarse para que _stas

sean compatibles con la nueva lavadora de platos y si es

necesario, deben ser remplazadas.

Herramientas necesarias para la instalaci6n

Observe la Figura 1:

A. Cinta M6trica

B. Destornillador plano

C. Destornillador Phillips

D. Destomillador Torx, #20

E. Taladro E16ctrico

E Sierra o segueta de 1pulgada (25.4 mm) para cortar orificios

G. Martillo

H. Nivel

I. Llave abierta

J. Llave ajustable, se necesitan 2.

K. Llave de presi6n, se necesitan 2.

L. Pinzas para Cortar Alambre

M. Pinzas para Pelar Alambre

Figura 1.

Partes que se incluyen

Revise que est6n incluidas todas las partes que se proporcionan

para su modelo, observe la Figura 2. Si cualquiera de las partes

falta, p6ngase en contacto con el vendedor inmediatamente.

Observe la Figura 2:

O. Tapones para Cubrir (2)

R Tomillos (2), para la cubierta de la caja terminal /

base del tablero

R. Soportes de montaje (2)

S. Tornillos de madera (2)

T. Abrazadera para la manguera de drenaje

U. Tornillos, M6 x 26 (2)

V. Soportes de montaje (4) y tomillos (8)

W. Hoja de plantilla con instrucciones grificas

X. Tornillos, M4 x 42 (2) (modelos SHV dnicamente)

Partes que se incluyen con:

Modelos SHU Modelos SHI y SHV

_---- ® ®

Materiales que necesitar_i

• Tuberfa de cobre de diimetro externo mfnimo de 3/8 de

pulgada (9.5 mm), del largo suficiente para su instalaci6n.

• Vilvula y conexiones para cerrar la toma del suministro

de agua caliente.

• Url codo de 90° con rosca exterior de 3/8 de pulgada (9.5

mm) en un extremo yen el otro extremo, del tamafio que

se ajuste a la tuberfa del suministro de agua.

• Cinta de Tefl6n u otro sellador de tuberfas.

• Tres conectores de alambre retorcido para un alambre de

calibre 16.

• Un tubo para conductores registrado pot UL o un

liberador de tensidn.

Paracumplircon los cddigoslocales,puedenrequerirse matefiales

adicionales.

22

0-

0-

Figura 2.

Page 24

Informaci6n T6cnica

(570 mm)

22-7/16"

/!i

1_15/16"(49mm)

Figura 3.

Dimensiones

A alto 33-7/8" - 35" (860 - 890 mm)

;: !? / I [ \

9._0° 90°

,(

&

co

23-5/8" - 24" (600- 610 mm)

Figura 4.

Si la lavadora de platos se instalarfi en una esquina, antes

verifique que se tenga el espacio correcto para que la puerta

pueda abrir libremente. Observe la Figura 5.

B ancho 23-9/16" (598 mm)

C profundidad 22-7/16 (570 mm)

Potencia el6ctrica

Voltios Hertzios Amperes Vatios

120 60 12 1,450 (max)

Elecci6n del lugar

La mayorfa del trabajo debe hacerse antes de que la lavadora

de platos se lleve al lugar de instalaci6n. Sefeccione un lugar

lo m_is cercano posible al fregadero para tener un f_cil acceso

alas tuberfas de agua y de desagtie.

Cualquier lavadora de platos empotrada, debe estar

completamente rodeada por la parte superior, ambos lados y

la parte trasera. Por lo tanto el mejor lugar para co!ocarla, es

en el espacio entre los gabinetes de los muebles de cocina,

debajo del mostrador.

Espaciopara -_-

abrirlapuerta T !_!_i_

!ii!_

!iii_

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Puerta ab erta LavadoFade Platos ;

Figura 5.

PRECAUCION:

Para proteger contra posibles rupturas de la vfilvula de

llenado, tas tuber_as de agua que desembocan en la

lavadora de platos DEBEN estar protegidas contra

congelamiento. Si la vAlvula o las tuberia de agua se

congelan, pueden ocurrir desbordamientos de agua o

inundaciones. Dichas rupturas no est_n cubiertas por la

gaxantfa.

Para una operaci6n y apariencia adecuadas de la lavadora de

latos, la abertura del espacio deber_i ser cuadrada y tener las

dimensiones que se indican en la Figura 4.

23

Page 25

Preparaci6n del lugar

Para evitar interferencia con el armaz6n de la lavadora de

platos o de otros componentes, las tomas de agua, la corriente

el_ctrica y el desagtie deben de ser instaladas en el firea mar-

cada que se indica en las Figuras 6 y 7.

V_lvula

para cerrar

/ i f \

/

23-5/8"- 24"

(600 - 610 rnm)

Figura 6.

Los orificios de acceso deben estar redondeados y pulidos.

Los orificios no deben tener un difimetro mayor que 1 1/2

pulgada (38.1 mm). °

Suministro de agua caliente

• E1agua caliente en la tuberfa que desemboca en la

lavadora de platos, debe tener una presi6n de 5 a 120 psi

( 0.3 a 8.27 bars).

• E1calentador del agua debe fijarse para que proporcione a la

lavadora de platos agua a urla temperatura de 140 °F (60 °C).

• Se recomienda usar una tuberfa de entrada hecha de

cobre con un difimetro exterior mfnimo de 3/8 de pulgada

(9.5 mm).

• Todas las soldaduras de las conexiones deben hacerse

antes de que la mberfa de agua sea conectada a la vfilvula

de entrada de agua de la lavadora de platos. No suelde a

menos de 6 pulgadas (152.4 ram) de la v_ilvula de entrada

de agua de la lavadora de ptatos.

Despu6s de determinar en donde entrarfi a la lavadora de

platos la mberfa de agua, taladre un orificio de acceso de t

pulgada (25.4 mm) de di_hnetro y tienda la tuberfa al lugar

aproximado de la vfilvula, como se muestra en la Figura 7. Se

recomienda que una vfilvula para cerrar la toma de agua

caliente, sea instalada en un lugar de fficil acceso (la vfilvula

no se incluye en el paquete de partes).

Manguera de drenaje

La lavadora de platos incluye una manguera de drenaje de

siete (7) pies (213.5 cm). Para permitir que la manguera de

drenaje llegue al lugar de conexidn del desagtie, debe hacerse

un orificio de acceso.

24

Suministro de

agua caliente

/ 1520m / t!1

TUgbu:rita_ee_teUministro de

Figura 7.

Suministro el6ctrico

RIESGO DE CHOQUE ELI_CTRICO

• DESCONECTE LA FUENTE DE PODER

ELI_CTRICA EN LA CAJA DE INTERRUPCION

DEL CIRCUITO O EN LA CAJA DE

FUSIBLES ANTES DE INSTALAR LA

LAVADORA DE PLATOS.

• CONECTE A TIERRA LA LAVADORA DE

PLATOS.

, USE CONDUCTORES DE COBRE UNICA-

MENTE.

EL NO SEGUIR ESTAS INSTRUCCIONES

PUEDE RESULTAR EN UNA LESION

SERIA O INCLUSIVE LA MUERTE.

E! suministro el6ctrico debe ser de 120 voltios, 60 Hz, 12

amperios, conectados a tierra correctamente, colocados como

se muestra en la Figura 7 y deben ser instalados por un

electricista calificado. En este circuito no debe haber otros

aparatos conectados o salidas de corriente el6ctrica.

Corte un orificio de 1 pulgada (25.4 mm) de difimetro en el

mueble para que la instalaci6n el6ctrica pase por 61. Si este

orificio se corta en un mueble de madera, la orilla del orificio

debe ser tallado hasta que tenga una superficie suave. Si el

orificio se corta en un mueble de metal, la orilla del orificio

debe estar cubierta con un anillo de goma o caucho. Pase

cables tan flexibles como los cddigos se lo permitan, desde la

unidn al orificio en el mueble. E1 cable debe extenderse a 30

pulgadas (76.2 cm) de la pared.

Page 26

Inspecci6n de la lavadora de platos

Despu6s de desempacar la lavadora de platos y antes de la

instalaci6n, inspeccione muy bien el aparato buscando

posibles dafios cosm6ticos o de transporte. Reporte cualquier

_afio inmediatamente. Los dafios cosm6ticos deben reportarse

menos de 5 dfas de haber hecho la instalaci6n.

Colocaci6n de la lavadora de platos

Las tiras de contomo en los lados de la lavadora de platos, le permite

ajustar el aparato dentro de la abemwa en el mueble con un ancho de

23-5/8 pulgadas (600 mm) a 24 pulgadas (610 ram). Antes de

deslizar la lavadora de platos dentro de la abertura en d mueble:

1. Determine c6mo colocar los soportes de montaje. Los

soportes pueden colocarse de manera que sean atornillados

abajo de la superficie det mostrador, como se muestra en la

Figura 8; o bien, los soportes pueden doblarse y colocarse

para set atornillados a los lados de la abertura del mueble

como se muestra en la Figura 9. Si la superficie dd mostrador

es de granito, mdrmol o cualquier otro material natural que

pudiera dafiarse al ser taladrado, la lavadora de platos debe

montarse a los lados de1 mueble. Una vez que decida lo

anterior, coloque los soportes de montaje antes de destizar la

lavadora de platos a su lugar, observe la Figura 10.

Montando en el doblez del

soporte para colocaci6n lateral

Figura 8.

,

Enderece la tuberfa de suministro de agua caliente y el cable

d6ctrico de manera que pueda serjalado fficilmente por el

canal debajo de la lavadora de platos. Observe la Figura 10.

°

Con el fin de que no existan tramos retorcidos en la manguera

del drenaje una vez que la lavadora de platos est_ en su lugar,

gufe la manguera cuidadosamente mientras desliza la lavadora

de platos dentro de la abertura en el mueble.

; 4.

Todos los ajustes necesarios de nivelacidn y aJineamiento

pueden hacerse despu6s de deslizar la lavadora de platos dentro

de la abertura en el mueble. Se recomienda sin embargo que

los ajustes sean hechos antes de deslizar la lavadora de platos

dentro de la abertura y despu_s hacer cualquier ajuste final

una vez que la lavadora de platos estd en su lugar.

Figura 9.

Una vez deslizada en su lugar, haga los ajustes finales de

nivelaci6n como se muestran en la Figura 11. Despuds, para

mantener la posici6n y alineaci6n de la lavadora de platos,

coloque 2 tornillos de madera dentro de los orificios en las

pestafias de montaje que han sido colocadas en cada una de

las esquinas frontales, como se muestra en las Figuras 8 y 9.

Una vez que la lavadora de platos ha sido nivelada y asegurada

en su lugar, proceda a hacer la conexi6n de la manguera de

drenaje, y las conexiones de la tuberfa de suministro de agua

caliente y del suministro el6ctrico como se describe en la

siguiente secci6n. Verifique su c6digo nacional y local en todo

momento.

IMPORTANTE

Si usted desea cambiar el tablero frontal de la lavadora

de platos esto debe hacerse antes de deslizar el aparato

dentro de su lugar. Observe la seccidn en este manual

titulada Instalacidn del tablero accesorio, modelos

SHU.

25

Page 27

Tuberiadeagua

Figura 10.

Soportesdemontaje

Instalaci6nelectrica

Manguera de drenaje

Use la abrazaderade la manguera, parte "T" (observe la figura

2) para conectar la manguera de drenaje al fregadero, al aparato

trituradorparala etiminaci6n de basura o al hueco de aire.

VeaFig.2

Figura 11.

La pata trasera de nivelaci6n se ajusta al girar el tornillo

central en la parte frontal de la lavadora de platos. Las

patas frontales de nivelaci6n se ajustan al girar las patas

frontales de nivelaci6n. Observe la figura 11, arriba.

Si se necesita m_is altura:

Pueden colocarse cutlas para rellenar debajo del pie nivelador.

Figura 12.

E1 orificio de acceso para la manguera de drenaje debe tener

un difimetro de 1.25 pulgadas (32 mm).

Huecodeaire S

ConectordeGoma

\

Laentrada debe

estar arriba det tubo

en U

26

Figura 13.

Page 28

Enlasfiguras12,13y 14,semuestranlasconexionestfpicas

dedesagtie.LaFigura12muestraunaconexi6ntfpica.Las

Figuras13y14muestranconexionesposiblescuandoes

requeridounhuecodeaire.

IMPORTANTE

Si no se usa un hueco de aire y la tuberfa de desagtie

desemboca en un fregadero o en un aparato trimrador para

la eliminaci6n de basura, la tubeffa de desagtie debe ser

elevada a un punto mils alto que el nivel mils alto de agua

dentro del fregadero. Lo anterior sehace para evitar que el

agua se regrese como en un sifdn a la tavadora de platos.

NOTA: Si el c6digo local requiere una conexi6n a un hueco

de aire, equipos de huecos de aire est_in disponibles

en tiendas de plomerfa locales. Instale los huecos de

aire de acuerdo a las instrucciones del fabricante.

Huecodeaire (r

ConectordeGoma

La entrada

debe estar

arriba det

\

Conexi6n de la tuberia de suministro de agua caliente

ANTES de conectar la lavadora de platos,deje correr agua por la

mbeffa de suministro de agua calienteparaeliminarcualquier

materialextrafio.Verifiqueque no existen dobleces agudos o

tramos retorcidos quepuedanobstmirel flujodet agua.

Figura 15.

Aplique la cinta de Tefl6n o cualquier otro sellador de

mberfas al ajuste del codo de 90 ° y condctelo directamente a

la vfilvula de entrada de agua. Ajuste el otro extremo del codo

a la tuberfa de suministro de agua.

Figura 14.

PRECAUCION

E1no proveer la altura adecuada a la conexi6n de

desagtie, 20 pulgadas (508 mm) arriba del nivel del

suelo con un doblez etevado o un hueco de aire, resultarfi

en un desagtie inapropiado de la lavadora de platos. Un

drenaje inadecuado puede causar dafios al aparato.

Cuando conecte la tuberfa con rosca, use mezcla para tuberfa

con rosca o cinta de Tefl6n para sellar la conexi6n. Abra el

suministro de agua para revisar que no existan fugas despu_s

de hacer las conexiones.

Si usa una conexi6n de soldadura en lugar de un ajuste por

compresi6n, compruebe que todas las conexiones de soldadura

est_n hechas antes de conectar la mberfa de agua a la lavadora

de platos. No suelde a menos de 6 pulgadas (152.4 mm) de la

vfilvula de entrada de la lavadora de platos. Las temperaturas

requeridas para soldar dafiarfan la vfilvula.

27

Page 29

Conexi6n del suministro de electricidad

E1 suministro et6ctrico debe ser de 120 voltios, 60 Hz, 12

amperios, conectados a tierra correctamente. Conecte con

alambre de cobre finicamente.

RIESGO DE CHOQUE ELI_CTRICO

• DESCONECTE LA FUENTE DE PODER

ELI_CTRICA EN LA CAJA DE 1NTERRUPCION

DEL CIRCUITO O EN LA CAJA DE

FUSIBLES ANTES DE INSTALAR LA

LAVADORA DE PLATOS.

• CONECTE A TIERRA LA LAVADORA DE

PLATOS.

• USE CONDUCTORES DE COBRE IJNICA-

MENTE:

EL NO SEGUIR ESTAS INSTRUCCIONES

PUEDE RESULTAR EN UNA LESION

SERIA O INCLUSIVE LA MUERTE.

Instrucciones para la conexi6n a tierra

Este aparato debe estar conectado a un sistema de alambrado

de metal permanente conectado a tierra, o bien un conductor

de tierra del aparato debe tenderse junto con los conductores

del circuito y ser conectados a la terminal de tierra del aparato

o dirigirse a la lavadora de platos. La lavadora de ptatos debe

estar conectada a tierra correctamente antes de operar.

Verifique que ta lavadora de platos est6 conectada a tierra

correctamente y esta conexi6n cumpta en lob Estados Unidos

con el CODIGO ELF_CTRICO NACIONAL, o en Canad_ con la

edici6n m_ reciente del CODICA) ELt_CTRICO CANADIENSE

C22., asf como tambi6n con los c6digos de las provincias/del

estado o los c6digos locales odel municipio que apliquen.

Cablesnegros

blancos

Cablesverdes

osin

aislamiento

Tubopara

registradopor

UL

Figura 17.

Instalaci6n del tablero, modelos SHI

Si usted tiene un modelo SHI, un modelo integrado, usted

tendril partes adicionales para el montaje y una hoja de plantilla

con instrucciones de instalaci6n comprendidas de grdficas o

ilustraciones.

En Norte Am6rica los modelos negro, blanco y de acero

inoxidable, de las series integradas (series SHI), tienen un

tablero de control que mide 5-5/16 pulgadas (135 ram) de

alto. Los modelos blanco y negro tienen una pieza de extensi6n

estSndar, dimensi6n "A" en la figura 18 y la tabla 1, abajo. E1

modelo de acero inoxidabte tiene dos piezas de extensi6n,

referidas en la Tabla 1 como las piezas de extensi6n estindar

y larga: la pieza estdndar se usa para alturas de caj6n de hasta

6 pulgadas (152 mm); la extensi6n larga se usa para alturas de

caj6n mayores que 6 putgadas (152 mm) pero menores que

6-7/16 pulgadas (164 ram) o menos. Estas piezas de extensi6n

de acero inoxidable no vienen instaladas en el tablero de con-

trol. En lugar de esto, los modelos de acero inoxidabte

incluyen las dos piezas de extensi6n sueltas y deben ser

insertadas como se muestra en la grifica 5 de la hoja de plan-

tilla.

Figura 16.

Despu6s de terminar el alambrado y las pruebas, verifique que los

alambres est6n dentro de la caja terminal y despu_s atomille la tapa

de la caja terminal/base del tablero en su lugar usando los torrfillos

del paquete de panes que _ incluyen. Observe las Figuras 2 y 17.

28

E1 prop6sito de las piezas de extensi6n es permitir aumentar

la almra del tablero de control para tratar de igualar la lfnea

horizontal del caj6n del gabinete. Si los cajones del mueble de

cocina son mils altos de que las dimensiones "C" mostradas

en la Tabla 1 se recomienda que la extensi6n sea deslizada

hacia adentro lo mis que alcance, o que sea removida y que

puerta sea ajustada directamente abajo del tablero de control.

Page 30

!

Figura 18.

Extensi6n "A"

max./min.

_B 99

A

C

Instalaci6n del tablero, modelos SHV

Si usted tiene un modelo SHV, un modelo completamente

integrado, usted tendril partes adicionales para el montaje y

una hoja de plantitla con instrucciones de instalaci6n

comprendidas de gr_ficas o ilustraciones.

Consulte la hoja de plantilla dobtada para mils informaci6n

sobre cuinto montar el tablero. Por favor note que un lado de

la plantilla muestra c6mo montar un tablero de una pieza y el

otro lado de la plantilla muestra c6mo montar un tablero de

dos piezas. Verifique qu6 tipo de instalaci6n desea usted antes

de iniciarla.

Consulte la Figura t9 y la Tabla 2, para las direcciones en la

seleccidn del montaje a la medida de la puerta del tablero.

Modelo

SHI

6802

] SHI

6806

SHI

4302

SHI

4306

SHI

6805

Estindar

13/16" / 0"

(21 / 0 ram)

13/16" / 0"

(21 / 0 ram)

t3/16" / 0"

(21 / 0 ram)

13/16"/0"

(21 / 0 ram)

t 1/16"/5/16"

(18 / 8 mm)

Larga

1-1/8"/11/16"

(29 / 18 mm)

5-5/16"

(135mm)

5-5/16"

(135mm)

5-5/16"

(135ram)

5-5/16"

(135mm)

5-5/16"

(135mm)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-1/8" / 5-5/16"

(156 / 135 mm)

6-7/16" / 5-5/8"

(164 / 143 mm)

Tabla 1.

Despu6s de decidir si las piezas de extensi6n se usarin o no,

observe las grificas impresas en la hoja de plantilla para

conocer el m6todo apropiado para montar a la medida la

puerta del aparato.

Consulte la Figura 19 y la Tabla 2, para las direcciones en la

seleccidn del montaje a la medida de la puerta del tablero.

Nora: NO taladre completamente en la puerta del tablero.

D E

Figura 19.

Modelo D *E F

SHV NA 27-3/16"- 30-5/16" 23-3/16" - 23-3/8"

(690 - 770 ram) (589 - 594 mm)

SHI 20-11/16" - 25" 27-3/16" - 30-5/16" 23-3/16" - 23-3/8"

(526 - 635 mm) (690 - 770 mm) (589 - 594 mm)

Tabla 2.

*Nota: el largo del tablero frontal no debe exceder de 30 5/16

pulgadas (770 mm).

Instalaci6n del tablero accesorio, modelos SHU

Si usted tiene un modelo SHU y ha ordenado un juego de

tablero accesorio, 6ste debe ser instalado antes de deslizar la

lavadora de platos en su lugar. En la Figura 20 se muestran las

dimensiones del tamafio deI tablero que puede usarse.

29

Page 31

1/4" max.

(6mm)

Lista de revisi6n final

REVISE LOS REQUERIMIENTOS ELI_CTRICOS

ASEGI]RESE DE QUE CUENTA CON EL SUMINISTRO

ELt_CTRICO CORRECTO Y DE QUE EL MI_TODO DE

CONEXION A TIERRA SEA EL ADECUADO.

t

(586 mm)

Figura 20.

Ajuste de la tensi6n de la puerta

Despu6s de la instalaci6n de la lavadora de ptatos abra y

cierre la puerta varias veces. La puerta debe abrir y cerrar

fficilmente requiriendo muy poco esfuerzo para levantarla

cuando est6 completamente abierta. Si la puerta cierra

demasiado r@ido, o si la puerta se abre y cae, la tensi6n de1

resorte debe ajustarse. Para aumentar la ten_i6n del resorte,

saque del paquete de partes que se incluyen e! tornillo que se

muestra en la Figura 21 y ajuste la tensi6n como se indica.

Abra la v_ilvula de agua caliente y el suministro de electricidad.

La temperatura del agua debe ser de 140 °F (60 °C).

Haga funcionar la lavadora de platos durante un ciclo y revise

que no existan fugas en la plomerfa.

Si la lavadora de platos no funciona, lea la secci6n de

AUTO AYUDA y la secci6n de SERVICIO y

REPARACION en el Manual de Uso y Cuidado.

DEJE LAS INSTRUCCIONES DE INSTALACION Y EL

MANUAL DE USO Y CUIDADO CON EL PROPI-

ETARIO.

Figura 21.

3O

±ON_

+

Page 32

56 O0O0 3030 (7801)

Loading...

Loading...