Page 1

RF3405E

Installation Instructions

EN

Wireless (RF) Inertia

Transmitter

Page 2

RF3405E | Installation Instructions |

3

4

5

P1

P2

P3

P4

P5

P6

INERTIA LOOP

BATTERY

NeverReady Batteries, Inc.

Lost Power, NV

1

2

10 mm (0.39 in.) maximum

1

OK

12 mm (0.47 in.) nominal

3

2

OK

12 mm (0.47 in.) nominal

1.0 General Information

EN | 2

Installation Instructions

for the RF3405E

Wireless (RF) Inertia T ransmitter

1.0 General Information

The RF3405E Inertia Transmitter is a magnetic and dry

contact wireless transmitter with a built-in inertia sensor

used for monitoring doors, windows, or other dry

contact devices.

The inertia transmitter is equipped with internal reed

contacts for use with an external magnet assembly and

an inertia sensor for detecting shock. The transmitter

can also accept a dual EOL resistor supervised dry

contact input from an external device. A cover/wall

tamper switch is provided.

Supervision is provided by periodically transmitting a

supervisory signal to the receiver every 13 minutes if

there is no other activity. All transmissions from the

RF3405E send battery status information.

2.0 Mounting

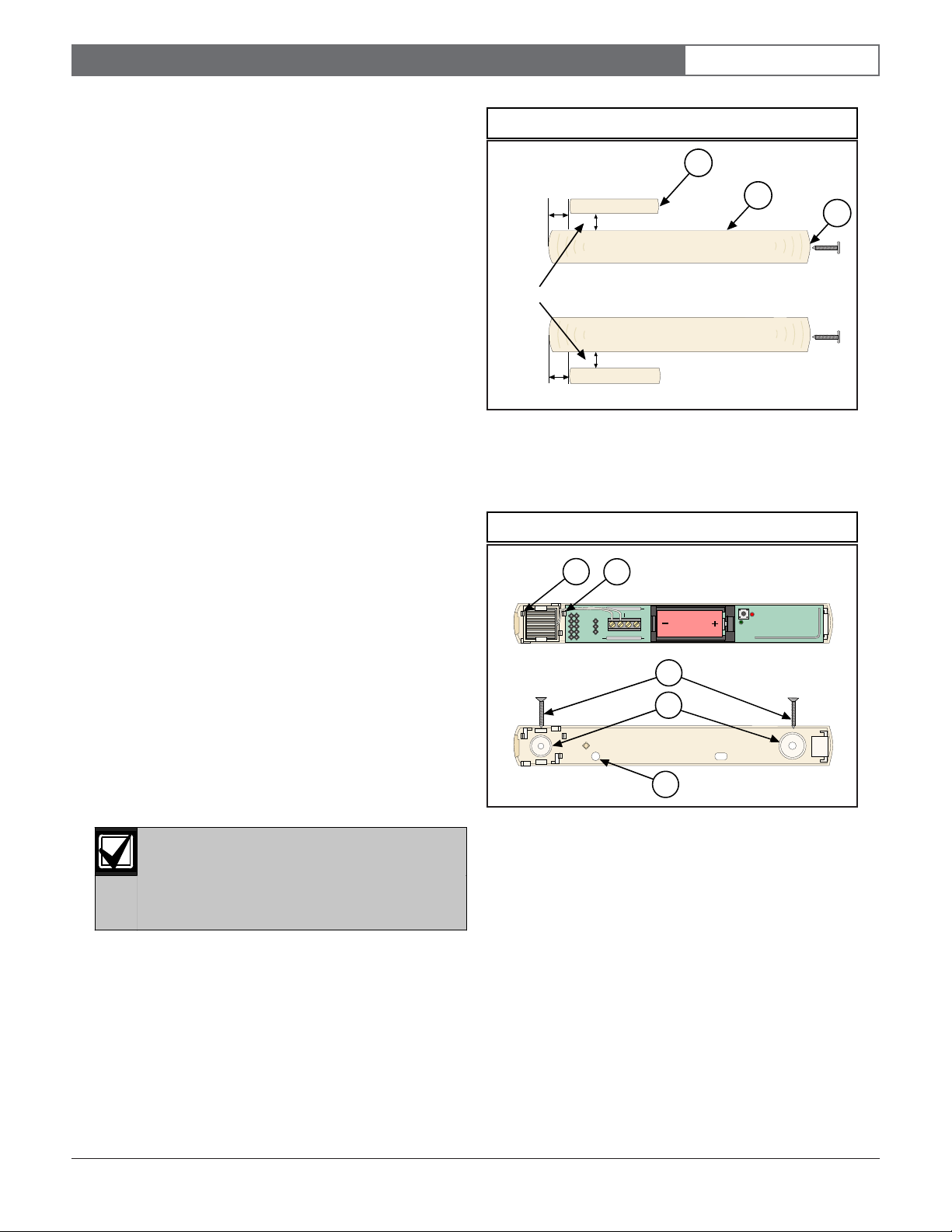

Figure 1: Magnet Location

1 - Inertia transmitter

2 - Magnet

3 - Cover screw location

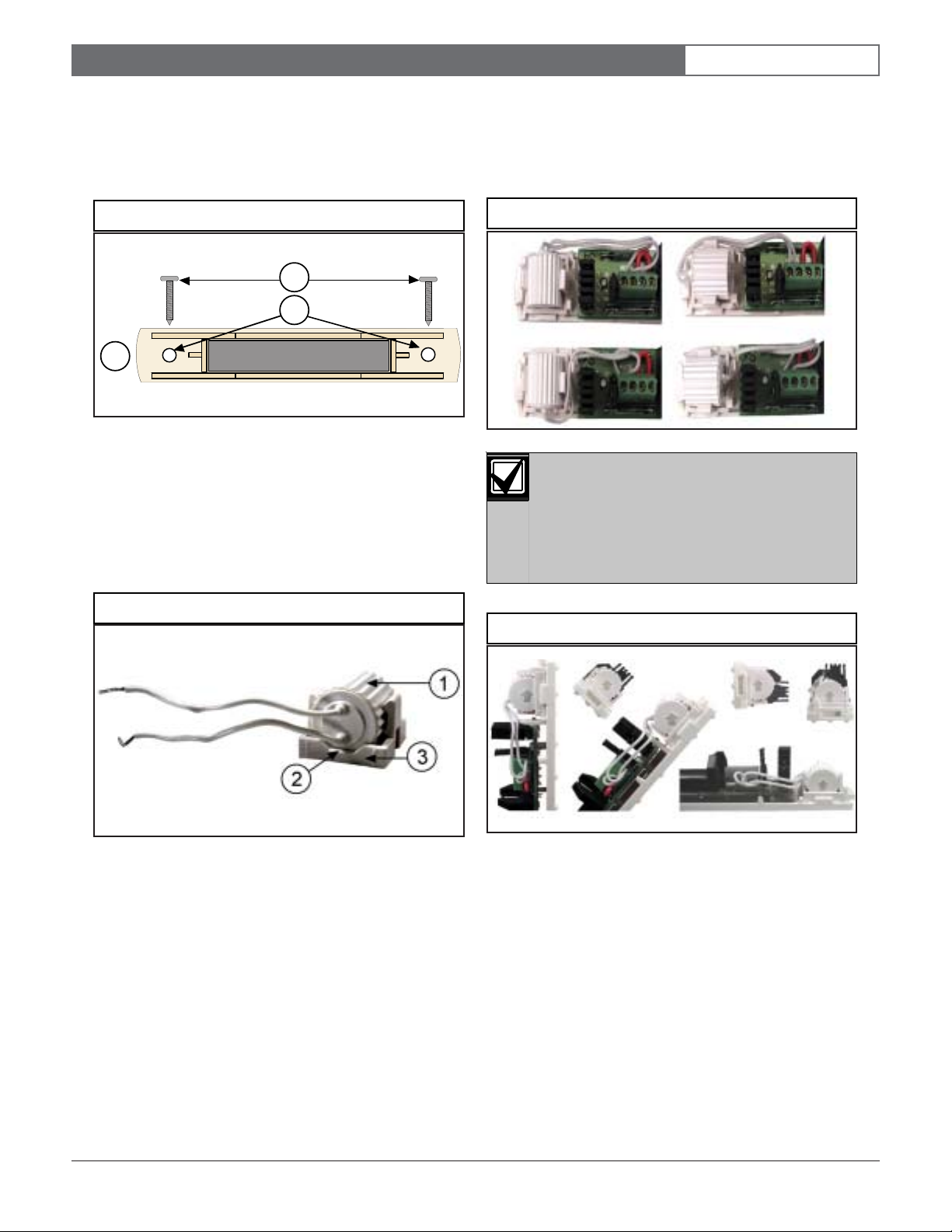

Figure 2: Base Plate

2.1 Mounting Considerations

2.2 Mounting the Transmitter

Refer to Figure 2 when mounting the inertia transmitter.

1. Position the base plate over the desired location. If

2. If the transmitter is already installed, remove the

• The maximum range of the inertia transmitter, in

open air, is approximately 300 m (98 ft.).

Typically, keep this transmitter within 100 m

(328 ft.) of the receiver to which it is assigned.

• Mounting the inertias transmitter on metal

surfaces may reduce its RF range. Mounting it on

ferrous metal (iron or steel) surfaces may affect

the operation of the internal magnetic contact.

• Mount the inertia transmitter on the door or

window frame and mount the magnet assembly

on the moving portion.

The magnet assembly must be oriented as

shown in

Figure 1

. The magnet must be no

farther away than 10 mm (0.39 in.) from the

body of the inertia sensor for normal

operation.

connecting to external contacts, position the

mounting plate so the wiring passes through the

wire entrance (callout #5).

inertia sensor bracket by pressing the inertia sensor

tab (callout #1).

1 - Inertia sensor bracket

2 - Circuit board tab

3 - 13 mm (0.51 in.) panhead mounting screws

4 - Base mounting holes

5 - Wire entrance

3. Remove the circuit board by pressing the circuit

board tab (callout #2).

4. Mount the base plate using the 13 mm (0.51 in.)

panhead screws (callout #3) through the base

mounting holes (callout #4).

5. Refer to Section 2.4 Mounting the Inertia Sensor if the

inertial sensor is used.

Bosch Security Systems | 8/03 | 47128C

Page 3

RF3405E | Installation Instructions |

Orientation of the Inertia sensor is critical to

the proper operation of the inertia detection

function.

An UP arrow, imprinted on the body of this

sensor, must always point upwards when

mounted in the transmitter base.

2.0 Mounting

EN | 3

2.3 Mounting the Magnet (if used)

Position the magnet base plate over the desired location,

using the mounting configuration shown in Figure 1.

Figure 3: Magnet Base Plate

2

3

1

1 - Magnet assembly

2 - 16 mm (0.63 in.) flathead screws

3 - Magnet assembly mounting holes

2.4 Mounting the Inertia Sensor

1. Mount the inertia sensor so the wires are over the

notched portion of the base plate (see Figure 4).

2. Press the inertia sensor all the way into the bracket.

3. You can mount the inertia sensor in four different

positions on the base plate (see Figure 5). Route the

wiring in a way that prevents crimping by the cover.

Figure 5: Inertia Sensor Mounting Positions

Figure 4: Inertia Sensor Wire Placement

1 - Inertia sensor

2 - Notch in base bracket

3 - Inertia sensor base bracket

Figure 6: Inertia Sensor: Point Up

Bosch Security Systems | 8/03 | 47128C

Page 4

RF3405E | Installation Instructions |

1

2

P1

P2

P3

P4

P5

P6

P1

P2

P3

P4

P5

P6

1

2

3.0 Wiring

EN | 4

3.0 Wiring

The RF3405E can be wired for an inertia

sensor or an external contact, but not both.

3.1 Wiring for the Inertia Sensor

Figure 7: Inertia Sensor Wiring

1

P1

P2

P3

P4

P5

1 - Inertia sensor wires

2 - Wire jumper across loop terminals

3.2 Wiring for the External Contact

INERTIA LOOP

P6

4.0 Jumper Settings

4.1 Reed Switch Enable (Jumper P2)

If Jumper P2 is removed, the internal magnetic reed

switches are enabled (see Figure 9).

Figure 9: P2 Reed Switch

2

1 - Jumper on disables internal reed switches

2 - No jumper enables internal reed switches

4.2 Setting for Inertia or External Contact

(Jumper P6)

The detector can be set to monitor the internal inertia

sensor or a set of external contacts (see Figure 10).

Figure 8: External Contact Wiring

1

P1

INERTIA LOOP

P2

P3

P6

P4

P5

2

1.5 kΩ

2.2 k

Ω

1 - Wire jumper across inertia terminals

2 - Length of contact loop can be up to 6 m (20 ft.)

3 - Normally closed (NC) contact

The wire jumper in the Loop terminals must

be ON when using the Inertia function. The

wire jumper in the Inertia terminals must be

ON when using the External contact function.

Figure 10: Set Inertia or External Contact

3

1 - External contact

2 - Inertia sensor

Bosch Security Systems | 8/03 | 47128C

Page 5

RF3405E | Installation Instructions |

4.0 Jumper Settings

EN | 5

4.3 Minor and Gross Attack (Jumper P1)

If Jumper P1 is installed, the inertia detector reacts only

to Gross Attacks (major movement). Minor movement

or a series of taps does not activate the inertia detector.

Jumper P4 and Jumper P5 settings determine the

sensitivity of the inertia detector to Gross Attack (see

Section 4.5).

Jumper P6 must be set for Inertia to enable these

settings. See Figure 11.

Figure 11: P1 Attack Monitor

1

P1

P2

2

P3

P6

P4

P5

1 - No jumper for minor and gross attacks

2 - Jumper on for gross attack only

4.4 Pulses for Minor Attack (Jumper P3)

The setting of Jumper P3 determines the number of

repetitive pulses needed to activate the inertia detector

to a Minor Attack.

If Jumper P3 is removed, the inertia detector reacts to

four repetitive pulses. This setting is only valid if

Jumper P1 is set for Minor Attack and Jumper P6 is set

for Inertia. See Figure 12.

4.5 Sensitivity for Gross Attack

(Jumpers P4 and P5)

These settings are valid only if Jumper P6 is set for

Inertia.

Figure 13: Gross Attack Jumper Settings

1

2

3

4

P4

P4

P4

P4

1 - Low sensitivity

2 - Low/Medium sensitivity

3 - Medium/High sensitivity

4 - High sensitivity

P5

P1

P2

P3

P5

P5

P5

P4

P5

P6

Figure 12: Attack Pulses

1

2

1 - Jumper on for eight repetitive pulses

2 - No jumper for four repetitive pulses

Bosch Security Systems | 8/03 | 47128C

P1

P2

P3

P6

P4

P5

Page 6

RF3405E | Installation Instructions |

Dimensions

(H x W x D)

Transmitter: 2.7 cm x 2.4 cm x 16.9 cm

(1.06 x 0.94 in. x 6.65 in.)

Magnet: 1.9 cm x 1.3 cm x 16.9 cm

(0.75 in. x 0.51 in. x 2.36 in.)

Operating

Temperature

-20°C to +60°C (-4°F to +151°F);

0% to 95% relative humidity

(non-condensing)

Frequency

Band

433.42 MHZ

Maximum RF

Power

Less than 10 mW

Operating

Voltage

Supplied by a 3 VDC lithium battery

Battery Life

A minimum of 3 years under normal

operating conditions with recommended

battery types (2 years if using the inertia

sensor).

Recommended

Battery Types

Duracell DL123A

Energizer EL123AP

Panasonic CR123A

Compatible

Receiver

RF3227E

Supervisory

Internal

13 minutes nominal

5.0 Installing the Battery

EN | 6

5.0 Installing the Battery

Be sure to observe the battery polarity (see Figure 14).

Figure 14: Battery Installation

NeverReady Batteries, Inc.

Lost Power, NV

P1

INERTIA LOOP

P2

P3

P6

P4

P5

6.0 Programming the Panel

There is a two-part ID sticker located on the housing of

the RF3405E (see Figure 15). You need the number on

this sticker to program the inertia transmitter into the

control panel.

Refer to the panel Programming Guide for programming

information on wireless type devices.

Figure 15: ID Sticker

8.0 Specifications

Table 1: Specifications

Bosch Security Systems | 8/03 | 47128C

ID: XXXXXXXXX

YYYYYYY

!

ID: XXXXXXXXX

7.0 Testing the Detector

Once the detector is mounted, you can place it in Test

Mode for 15 minutes by opening and then closing the

detector cover, or by pushing both tamper springs then

releasing one or both of them (if the cover is off). The

LED flashes once (and then continues flashing dimly) to

indicate it is in Test Mode. During the testing time, the

LED flashes twice each time a Minor Inertia Attack

occurs, a magnetic contact changes state (open or close),

or any time the external contact (if used) changes state.

The LED flashes three times for a Gross Inertia Attack.

If any jumpers are changed during Test Mode, the LED

flashes once to indicate the change.

Page 7

RF3405E | Installation Instructions |

EN | 7

Notes:

Bosch Security Systems | 8/03 | 47128C

Page 8

Bosch Security Systems

130 Perinton Parkway

Fairport, NY 14450-9199 USA

www.boschsecurity.us

Customer Service: (800) 289-0096

Technical Support: (888) 886-6189

© 2003 Bosch Security Systems

Subject to change | Printed in the USA

47128C

Loading...

Loading...