Bosch Rexroth Servodyn-D Maintenance Manuallines

Over 100 years cumulative experience

24 hour rush turnaround / technical support service

Established in 1993

The leading independent repairer of servo motors and drives in North America.

Visit us on the web:

www.servo-repair.com

www.servorepair.ca

www.ferrocontrol.com

www.sandvikrepair.com

www.accuelectric.com

Scroll down to view your document!

For 24/7 repair services :

USA: 1 (888) 932 - 9183

Canada: 1 (905) 829 -2505

Emergency After hours: 1 (416) 624 0386

Servicing USA and Canada

Industrial

Hydraulics

Electric Drives

and Controls

Linear Motion

Assembly Technologies

Pneumatics

Service

Automation

Mobile

Hydraulics

Rexroth ServodynD

Diagnostics, maintenance

Maintenance Guidelines

1070 066 032

Ausgabe 03

II Electric Drives

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

Title

Type of Documentation

Document Typecode

Purpose of Documentation

Record of Revisions

Copyright

Rexroth Servodyn-D

Diagnostics, maintenance

Maintenance Guidelines

DOK-SERV*D-DIAGNOSTICS-WA03-EN-P

The present manual informs you about the diagnostics options of the

Servodyn-D drive series.

Description Release

Date

DOK-SERV*D-DIAGNOSTICS-WA03-EN-P 07.2003 Software

Notes

releases refer

to page 1–10

E Bosch Rexroth AG, 1998 – 2003

Copying this document, giving it to others and the use or

communication of the contents thereof without express authority, are

forbidden. Offenders are liable for the payment of damages. All rights

are reserved in the event of the grant of a patent or the registration

of a utility model or design (DIN 34–1).

Validity

Published by

The specified data is for product description purposes only and

may not be deemed to be guaranteed unless expressly confirmed

in the contract. All rights are reserved with respect to the content

of this documentation and the availability of the product.

Bosch Rexroth AG

Postfach 11 62

D-64701 Erbach

Berliner Straße 25

D-64711 Erbach

Tel.: +49 (0) 60 62/78-0

Fax: +49 (0) 60 62/78-4 28

Abt.:

BRC/ESM11 (WE)

Contents

Contents

Electric Drives

and Controls

Page

1 Safety Instructions 1–1 . . . . . . . . . . . . . . . . . . . . . . .

1.1 Intended use 1–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Qualified personnel 1–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Safety markings on products 1–4 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Safety instructions in this manual 1–5 . . . . . . . . . . . . . . . . . . . . . .

1.5 Safety instructions for the described product 1–6 . . . . . . . . . . . .

1.6 Documentation, software release and trademarks 1–9 . . . . . . .

2 Mains connection at the place of installation 2–1

2.1 Earthing 2–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Earth-leakage circuit-breaker 2–3 . . . . . . . . . . . . . . . . . . . . . . . . .

IIIBosch Rexroth AGServodyn-D1070 066 032 / 03

3 Marks, certifications 3–1 . . . . . . . . . . . . . . . . . . . . . .

3.1 CE-marking 3–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 EU design type certification 3–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 UL/CSA certification 3–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Diagnostics displays at the drive 4–1 . . . . . . . . . .

4.1 VMA..KB, VMA..KE status, warning and error displays 4–1 . . .

4.2 VMA..KR, VMA..B,C,D,F status displays 4–2 . . . . . . . . . . . . . . .

4.3 VMA..KR, VMA..B,C,D,F warning displays 4–3 . . . . . . . . . . . . . .

4.4 Status displays DM and DS (without frequency inverter) 4–4 . .

4.5 VMA..KR, VMA..B,C,D,F and DM/DS error displays

(without frequency inverter) 4–5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 List of error number in parameter P-0-0095 4–14 . . . . . . . . . . .

4.6 PROFIBUS-DP errors 4–28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 DMA computer errors (without SERCOS interface) 4–28 . . . . . .

4.8 Servodyn-D frequency inverter displays 4–29 . . . . . . . . . . . . . . . .

4.8.1 Status/warning displays 4–29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 Error displays 4–31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Connection overview 5–1 . . . . . . . . . . . . . . . . . . . . .

5.1 VMA..KB, VMA..KE supply module

(with ballast switch) 5–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 VMA..KR, VMA..B,C,D,F supply module

(with current regeneration) 5–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 DMA module with analog interface or

positioning function (MC) 5–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 DMA module with SERCOS interface 5–4 . . . . . . . . . . . . . . . . . .

5.5 DMA module with CAN bus 5–5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 DMA module with PROFIBUS-DP 5–6 . . . . . . . . . . . . . . . . . . . . .

5.7 DM..8001-D frequency inverter with analog interface 5–7 . . . . .

5.8 Stand-alone module DS, supply unit 5–8 . . . . . . . . . . . . . . . . . . .

5.8.1 Overview of DS..K xxx2-D (in set–up mode) 5–8 . . . . . . . . . . .

IV Electric Drives

Contents

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

5.9 Overview of DS..K xxx1-D 5–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Replacing components 6–1 . . . . . . . . . . . . . . . . . . .

6.1 Motors 6–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Drive modules 6–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 VM...K and DM...K 6–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 DC link connection of VMA..B,C,D and DMA..A,B,D

6.2.3 DC link connection of VMW..F and DMW..F

A Annex A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Index A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with backplane modules 6–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with water cooling 6–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Instructions

1 Safety Instructions

Please read this manual before commissioning the Servodyn-D drives.

Store this manual in a place to which all users have access at any time.

1.1 Intended use

This manual contains information required for the intended use of this

product.

The described low-voltage motors are intended for use in commercial

or industrial systems. They comply with the harmonized standards of

the VDE 0530/EN 60034 series. Their use in potentially explosive atmospheres is not admissible unless expressly permitted by additional

instructions.

Electric Drives

and Controls

1–1Bosch Rexroth AGServodyn-D1070 066 032 / 03

Air-cooled designs are rated for ambient temperatures ranging between

–20 to +40 _C, and an operating altitude of v 1000 m above sea level.

Rating plate specifications deviating from this standard must be strictly

observed. Conditions at the operating site must correspond to all specifications stated on the rating plate.

Low-voltage motors comprise components intended for integration into

machines as contemplated by the EU Declaration of Conformity, as defined by Machinery Directive (98/37/EC, 98/79/EC). Before putting the

motors into operation, ensure that the machine the motors are to be

installed in meets the stipulations of the Machinery Directive (note also

EN 60204-1).

The drive inverters described

D have been developed, manufactured, tested and documented in

compliance with the safety standards. These products normally pose

no danger to persons or property if they are used in accordance with

the handling stipulations and safety notes prescribed for their configuration, mounting, and proper operation.

D comply with the requirements of

D the EMC Directives (89/336/EEC, 93/68/EEC and 93/44/EEC)

D the EMC product standard EN 61800-3 + A11

D the Low-Voltage Directive (73/23/EEC)

D the harmonized standards EN 50178 (VDE 0160) and

EN 60146-1-1 (VDE 0558-11)

D are designed for operation in industrial environments, i.e.

D no direct connection to public low-voltage power supply,

D connection to the medium- or high-voltage system via a trans-

former.

In residential environments, in trade and commerce as well as small

enterprises class A equipment may only be used if the following warning is attached:

1–2 Electric Drives

Safety Instructions

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

. This is a Class A device. In a residential area, this device may cause

radio interference. In such case, the user may be required to

introduce suitable countermeasures, and to bear the cost of the

same.

Before putting the drive inverters into operation, ensure that the machine

which the inverters are to be installed in meets the stipulations of the Machinery Directive (98/37/EC, 98/79/EC) and the EMC Directive

(89/336/EEC).

The faultless, safe functioning of the product requires proper transport,

storage, erection and installation as well as careful operation.

Safety Instructions

1.2 Qualified personnel

The requirements as to qualified personnel depend on the qualification

profiles described by ZVEI (central association of the electrical industry)

and VDMA (association of German machine and plant builders) in:

Weiterbildung in der Automatisierungstechnik

edited by: ZVEI and VDMA

MaschinenbauVerlag

Postfach 71 08 64

D-60498 Frankfurt.

The present manual is designed for drive specialists.

Programming, start and operation as well as the modification of program

parameters is reserved to properly trained personnel! This personnel

must be able to judge potential hazards arising from programming, program changes and in general from the mechanical, electrical, or electronic equipment.

Electric Drives

and Controls

1–3Bosch Rexroth AGServodyn-D1070 066 032 / 03

Interventions in the hardware and software of our products, unless described otherwise in this manual, are reserved to specialized Rexroth

personnel.

Tampering with the hardware or software, ignoring warning signs attached to the components, or non-compliance with the warning notes

given in this manual may result in serious bodily injury or damage to

property.

Only electrotechnicians as recognized under IEV 826-09-01 (modified)

who are familiar with the contents of this manual may install and service

the products described.

Such personnel are

D those who, being well trained and experienced in their field and famil-

iar with the relevant norms, are able to analyze the jobs being carried

out and recognize any hazards which may have arisen.

D those who have acquired the same amount of expert knowledge

through years of experience that would normally be acquired through

formal technical training.

With regard to the foregoing, please note our comprehensive range of

training courses. Please visit our website at

http://www.boschrexroth.com

for the latest information concerning training courses, teachware and

training systems. Personal information is available from our Didactic

Center Erbach,

Telephone: (+49) (0) 60 62 78-600.

1–4 Electric Drives

Safety Instructions

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

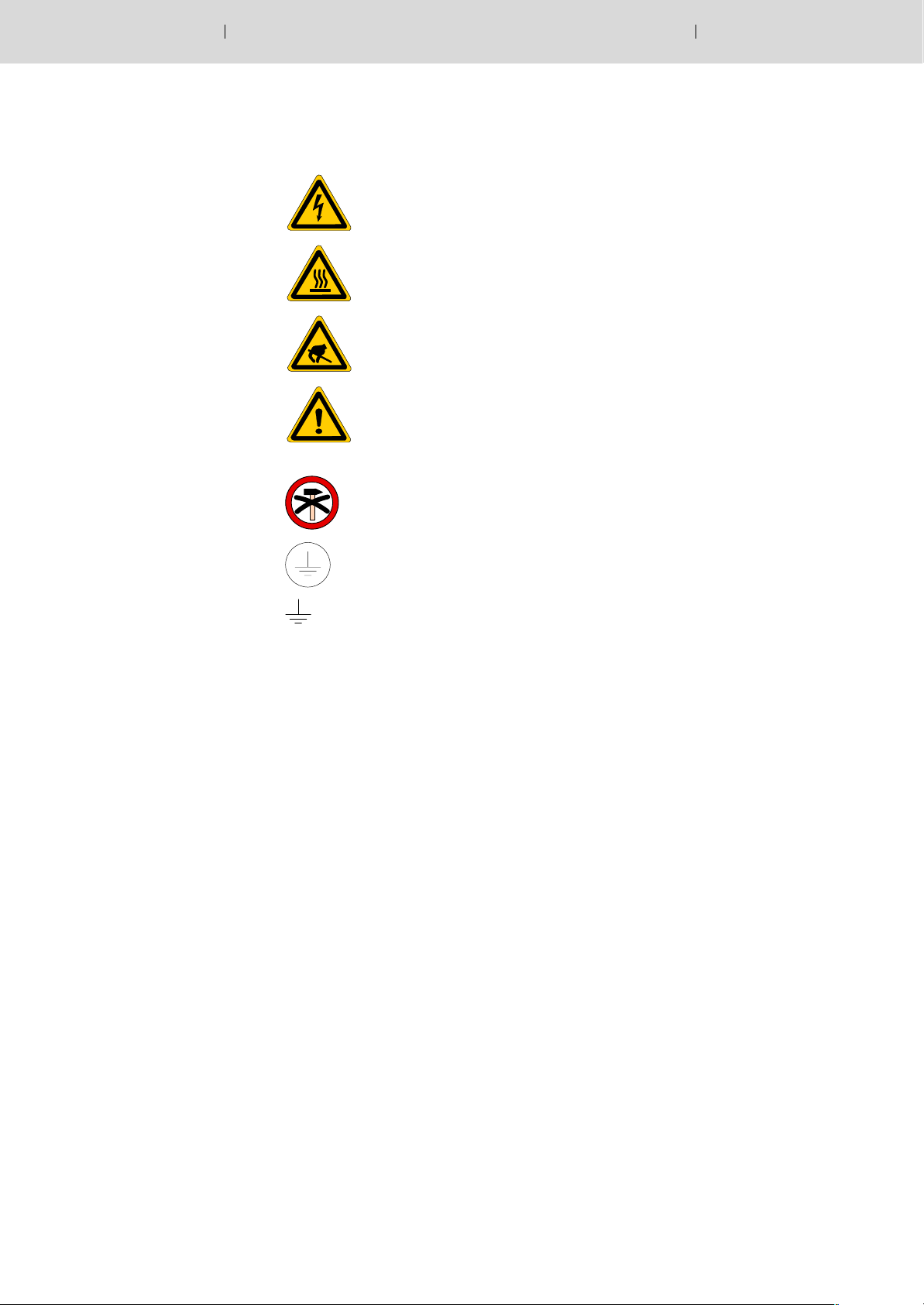

1.3 Safety markings on products

Warning of dangerous electrical voltage!

Warning of hot surface > 60 _C!

Electrostatically sensitive components!

Warning of hazardous light emissions

(optical fiber cable emissions)!

Protect against shock and impact!

Lug for connecting PE conductor only!

Connection of shield conductor only

. The hazard signs

– “Warning of dangerous electrical voltage”, and

– “Warning of hot surface”

supplied together with the motors must be attached to the motors

after installation in a visible location in accordance with the Machinery Directive (98/37/EC, 98/79/EC) if motor surfaces are exposed.

Safety Instructions

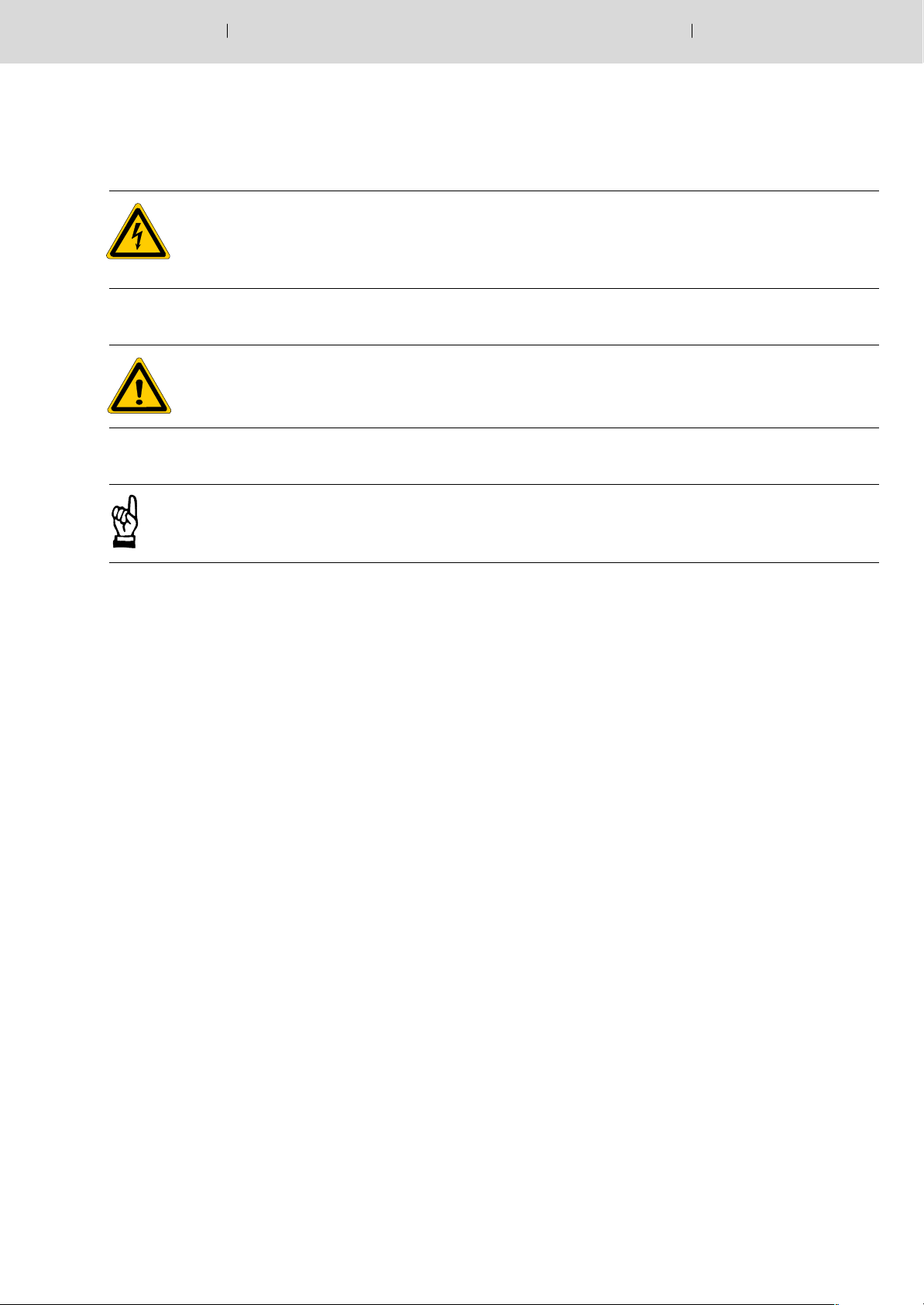

1.4 Safety instructions in this manual

DANGEROUS ELECTRICAL VOLTAGE

This symbol is used to warn of a dangerous electrical voltage. The

failure to observe the instructions in this manual in whole or in part may

result in personal injury.

DANGER

This symbol is used wherever insufficient or lacking compliance with instructions may result in personal injury.

Electric Drives

and Controls

1–5Bosch Rexroth AGServodyn-D1070 066 032 / 03

CAUTION

This symbol is used wherever insufficient or lacking compliance with instructions may result in damage to equipment or data files.

. This symbol is used to draw the user’s attention to special circum-

stances.

L This symbol is used if user activities are required.

1–6 Electric Drives

Safety Instructions

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

1.5 Safety instructions for the described product

DANGER

Danger of life through inadequate EMERGENCY-STOP devices!

EMERGENCY-STOP devices must be active and within reach in all

system modes. Releasing an EMERGENCY-STOP device must not

result in an uncontrolled restart of the system!

First check the EMERGENCY-STOP circuit, then switch the system on!

DANGER

Danger for persons and equipment!

Test every new program before starting up a system!

DANGER

Retrofits or modifications may adversely affect the safety of the

products described!

The consequences may include severe injury, damage to equipment, or environmental hazards. Possible retrofits or modifications to the system using third-party equipment therefore have to

be approved by Rexroth.

DANGER

Health hazards through destroyed electrical components!

Do not destroy any built-in components. Dispose of destroyed

components in a proper manner.

DANGER

Do not look directly into the LEDs in the optical fiber connection.

Due to their high output, this may result in eye injuries.

When the inverter is switched on, do not look into the LED or the

open end of a short connected lead.

DANGER

Please note your local, system-specific regulations and requirements as well as the proper use of tools, hoisting and transport

equipment as well as the applicable standards, regulations, and

accident prevention regulations.

Safety Instructions

Electric Drives

and Controls

1–7Bosch Rexroth AGServodyn-D1070 066 032 / 03

DANGEROUS ELECTRICAL VOLTAGE

Unless described otherwise, maintenance works must be performed on inactive systems! The system must be protected

against unauthorized or accidental reclosing.

Measuring or test activities on the live system are reserved to

qualified electrical personnel!

DANGEROUS ELECTRICAL VOLTAGE

Lethal voltages of up to 375 V DC against ground on all power connections and DC link connections!

The drives must not be switched on unless all covers have been

fitted! When the drive has been disconnected from mains, wait for

up to 5 minutes until the system is de-energized before removing

any covers.

The drive must always be examined for safe isolation from supply!

DANGER – WARNING OF HOT SURFACE!

The surfaces of motors can reach temperatures of up to approx.

100 _C.

A touch guard is to be provided where necessary.

CAUTION

Impacts and shocks applied to the shaft end will damage the rotary

encoder and ball bearings!

Drive elements such as pulleys, clutch disks, toothed wheels etc.

may only be assembled or removed by continuously heating up

the drive elements or with a suitable installation or removal tool.

Use the thread in the shaft end.

CAUTION

use only spare parts approved by Rexroth!

CAUTION

Damages to the module or inverter by removing plug-in connections.

All plug-in connections to the encoder may only be inserted or removed while the drive is switched off.

1–8 Electric Drives

Safety Instructions

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

CAUTION

Observe all precautions for ESD protection when handling modules and components! Avoid electrostatic discharge!

The following protective measures must be observed for modules and

components sensitive to electrostatic discharge (ESD)!

D Personnel responsible for storage, transport, and handling must have

training in ESD protection.

D ESD-sensitive components must be stored and transported in the

prescribed protective packaging.

D ESD-sensitive components may only be handled at special ESD-

workplaces.

D Personnel, working surfaces, as well as all equipment and tools

which may come into contact with ESD-sensitive components must

have the same potential (e.g. by grounding).

D Wear an approved grounding bracelet. The grounding bracelet must

be connected with the working surface through a cable with an integrated 1 MW resistor.

D ESD-sensitive components may by no means come into contact with

chargeable objects, including most plastic materials.

D When ESD-sensitive components are installed in or removed from

equipment, the equipment must be de-energized.

Electric Drives

and Controls

Safety Instructions

1.6 Documentation, software release and trademarks

Documentation

The present manual informs you about the diagnostics options of the

Servodyn-D drive series.

1–9Bosch Rexroth AGServodyn-D1070 066 032 / 03

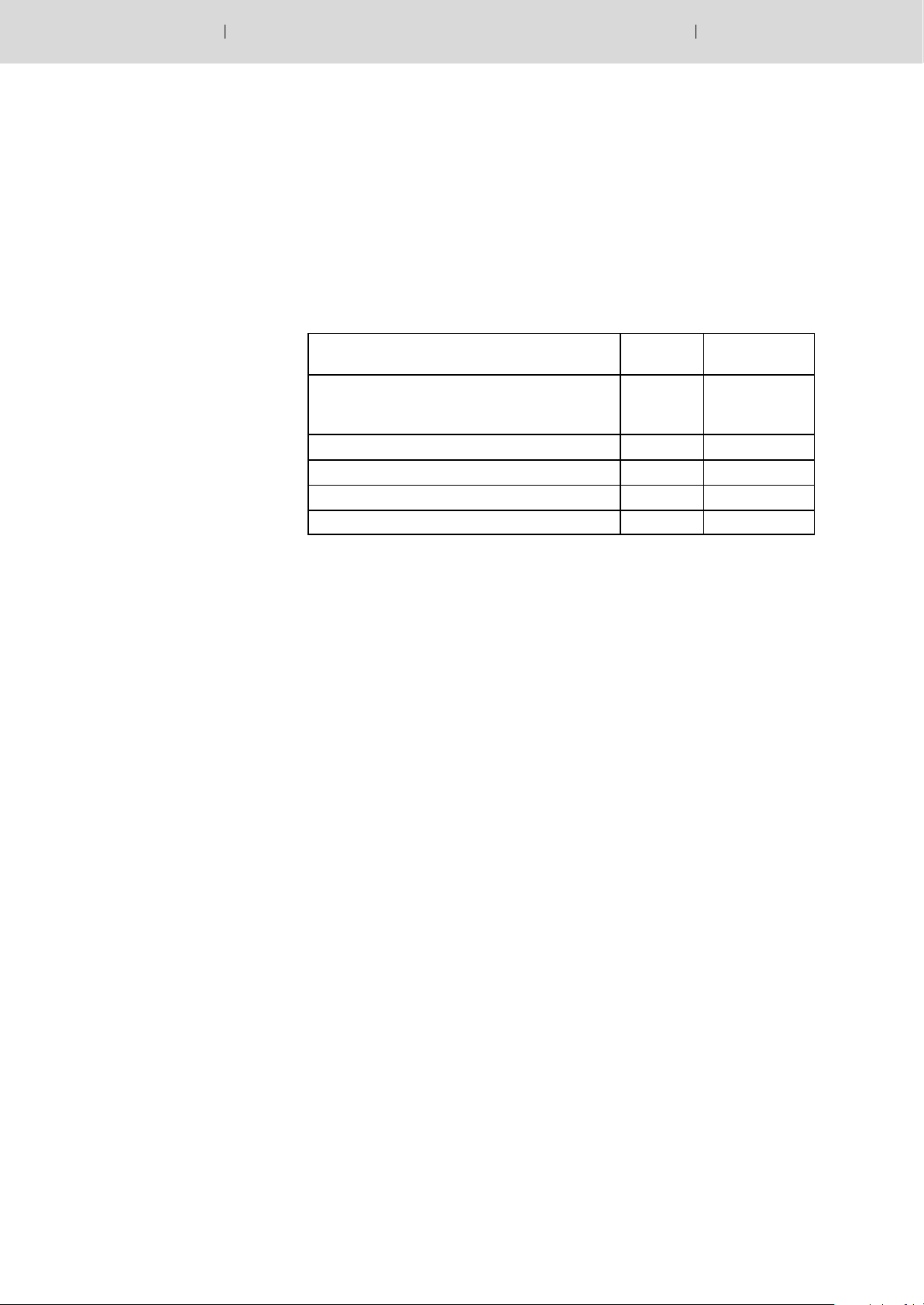

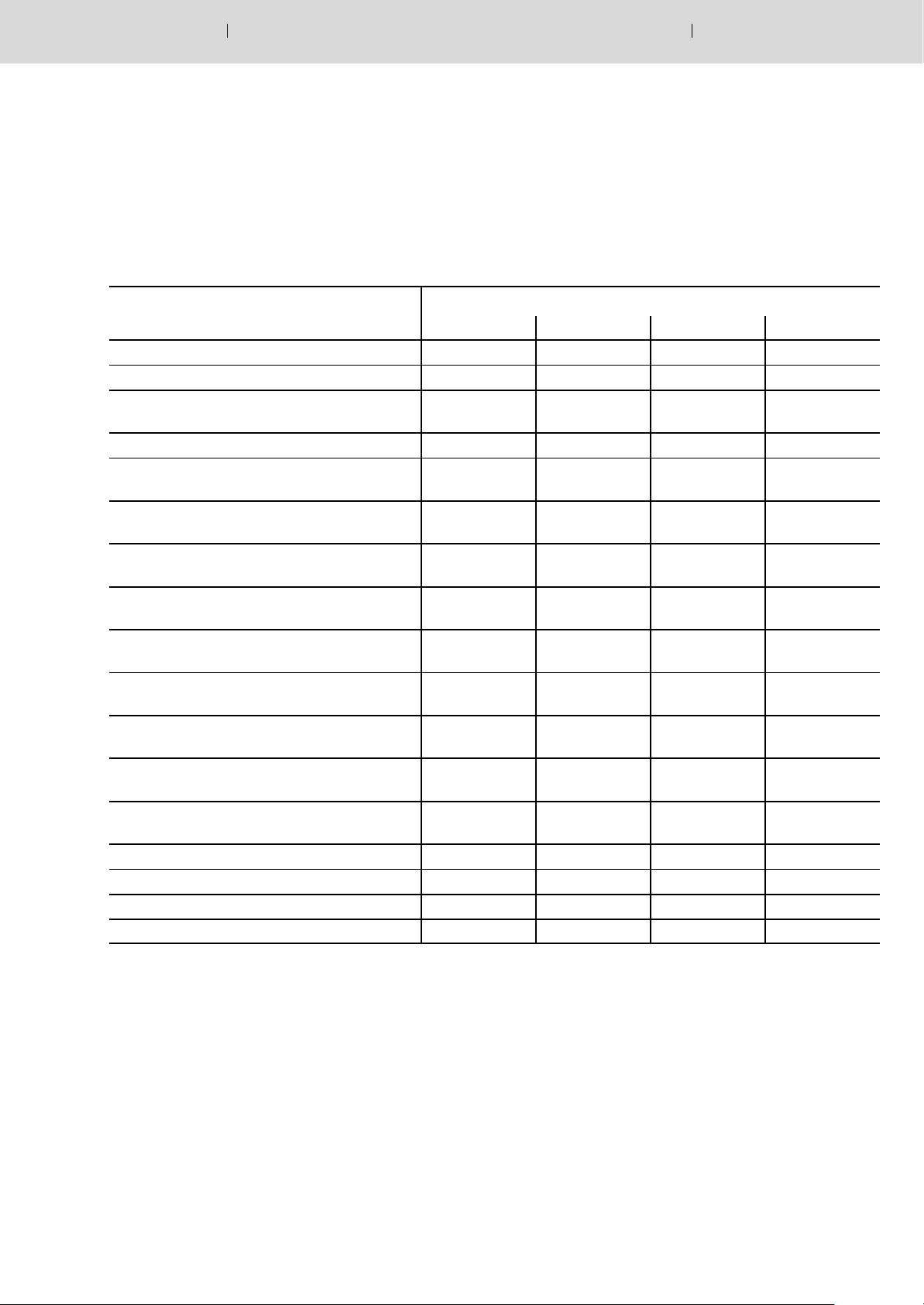

Overview of available documentation

Servo motors SF, SR 1070 066 004 1070 066 024 1070 066 048 1070 066 046

Asynchronous motors DU 1070 066 007 1070 066 027 – –

Servodyn-D, Configuration

- Manual for overview and rating

Servodyn-D, Connectivity Manual 1070 066 010 1070 066 030 1070 066 060 1070 066 050

Servodyn-D,

- Connectivity Manual - Stand alone version

Servodyn-D, Servodyn-M

- Parameter manual (without CANopen)

Servodyn-D, Servodyn-M

- Parameter manual CANopen

Servodyn-D with SERCOS interface

- Parameter and commissioning manual

Servodyn-D with analog interface

- Commissioning manual

Servodyn-D with CANrho interface

- Commissioning manual

Servodyn-D with motion control

- Commissioning manual

Servodyn-D with PROFIBUS-DP

- Commissioning manual

Servodyn-D DM/DS..8001 (ASM)

Parameter and commissioning manual

Diagnostics, maintenance 1070 066 012 1070 066 032 1070 066 062 1070 066 052

RSU, Redundant safety monitoring 1070 066 006 1070 066 026 1070 066 081 1070 066 082

EMC manual 1070 066 072 1070 066 074 1070 066 075 1070 066 076

External load switching module EBX 1070 066 077 1070 066 080 – –

Part no.

German English French Italian

1070 066 009 1070 066 029 1070 066 059 1070 066 049

1070 066 016 1070 066 036 1070 066 066 1070 066 056

1070 066 018 1070 066 038 1070 066 068 1070 066 058

1070 066 094 1070 066 095 – –

1070 066 011 1070 066 031 – 1070 066 051

1070 066 014 1070 066 034 – –

1070 066 017 1070 066 037 – –

1070 066 015 1070 066 035 – –

1070 066 090 1070 066 091 – –

1070 066 008 1070 066 028 – 1070 066 053

. In this manual the floppy disk drive always uses drive letter A:, and

the hard disk drive always uses drive letter C:.

Special keys or key combinations are shown enclosed in pointed brackets:

D Named keys: e.g., <Enter>, <PgUp>, <Del>

D Key combinations (pressed simultaneously): e.g., <Ctrl> + <PgUp>

1–10 Electric Drives

Safety Instructions

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

Release

. The present manual applies to the following releases:

DM/DS software: SERCOS interface V0.049 or higher

VM software: V0.045 or higher

D The current software release number can be viewed by selecting

parameter S-0-0030 with the DSS-D Commissioning and Service

System, or in the ”Software” field of the module configuration display

(DIAGNOSTICS " MODULE CONFIGURATION).

D For information concerning the current DSS software release, refer to

HELP " ABOUT...

CANopen/rho V0.002 or higher

Analog interface V0.17 or higher

PROFIBUS-DP V0.004 or higher

Motion Control V0.010 or higher

Trademarks

D The current software release of VMA..KR and VMA..B,C,D,F can

only be read from the 7-segment display during test operation. For

this purpose, turn dip switch ”T” on the VM’s personality module ”on”:

The following appears in a running, flashing display:

“Cxx.ZZ.ddmmyyyy“

Where: xx = software release number

ZZ = (internal)

dd = software creation day

mm = software creation month

yyyy = software creation year

All trademarks of software installed on Rexroth products upon delivery

are the property of the respective manufacturer.

Upon delivery, all installed software is copyright-protected. The software

may only be reproduced with the approval of Rexroth or in accordance

with the license agreement of the respective manufacturer.

MS-DOSr and Windowst are registered trademarks of Microsoft

Corporation.

PROFIBUSr

is a registered trademark of the PROFIBUS Nutzerorgani-

sation e.V. (user organization).

SERCOS interfacet is a registered trademark of Interessengemeinschaft SERCOS interface e.V. (Joint VDW/ZVEI Working Committee).

Electric Drives

and Controls

Mains connection at the place of installation

2 Mains connection at the place of installation

CAUTION

A reversed phase sequence or winding direction of a line reactor

will destroy the mains connection module.

Please ensure proper wiring.

2.1 Earthing

CAUTION

Inverter modules may only be operated with an earthed neutral

system.

Systems not directly earthed (IT protective system) must not be

used for operation, as air clearances and leakage paths in the

module may be overloaded.

Operation at asymmetrical mains systems (TT protective system,

one mains phase is earthed) is not permissible!

2–1Bosch Rexroth AGServodyn-D1070 066 032 / 03

DIN VDE 0100-300 defines mains systems subject to their type of earth

connection.

Accordingly, in an IT protective system, all active parts are separated

from earth, or one point is connected to earth via a resistor.

The exposed conductive parts of an electrical system are either

D earthed separately, or

D earthed jointly, or

D jointly connected to the system earth.

. Please note the information on earthing in the Servodyn-D EMC

manual, for part no. refer to page 1–9.

DANGEROUS ELECTRICAL VOLTAGE

The only permissible protective measure in accordance with

EN 50 178 is a protective earth connection.

The protective conductor must at least have the same area as the

mains feeder.

Earthing only one end of the DC link when operating by means of

an isolating transformer is prohibited!

2–2 Electric Drives

Mains connection at the place of installation

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

Earth connections in the switch cabinet must be designed in the form of a

grid mesh.

The module housing and mounting plate of the switch cabinet must be

earthed. The connection between the line filter and the supply module

should be as short as possible.

The protective earth cross-section must at least correspond to the crosssection of the line feeder of the supply module.

DANGER

Dangerous shock currents through inappropriate protective earth

connections!

Do not impair protective earth connections by mechanical, chemical or electro-chemical influences. The connection must be firm

and lasting.

Mains connection at the place of installation

2.2 Earth-leakage circuit-breaker

Inverters incorporate switched power units which are always associated

with capacitive leakage currents against earth. The leakage currents

may depend on the number of inverters, the earthing conditions as well

as the design and length of motor power cables.

Mains filters and shielded cables used to improve the electromagnetic

compatibility (EMC) increase the leakage currents further. For this reason, no earth-leakage circuit-breakers with nominal leakage currents of

less than 300 mA may be used.

DANGEROUS ELECTRICAL VOLTAGE

Personnel protection is only guaranteed if earth-leakage circuitbreakers with nominal leakage currents of less than 30 mA are

used.

Electric Drives

and Controls

2–3Bosch Rexroth AGServodyn-D1070 066 032 / 03

. Inductors and/or capacitors present in the electric circuit may lead

to spurious trips. If radio interference suppression filters are used,

spurious trips can only be avoided by installing an isolating transformer.

DANGEROUS ELECTRICAL VOLTAGE

If a pulse power current sensitive e.l.c.b. type A in accordance with

IEC-755 (VDE 0664) is used, its protective function is not guaranteed for inverters with a 3-phase mains connection (B6 circuit).

The protection of all electrical components connected together with inverters with a 3-phase mains connection to a pulse power current sensitive e.l.c.b. may be adversely affected.

Therefore, you should either install an isolating transformer with a protective device and earthing in the mains feeder, or use a universal current sensitive e.l.c.b. type B which also provides safety disconnection in

the event of DC leakage currents.

2–4 Electric Drives

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

Mains connection at the place of installation

Notes:

Marks, certifications

3 Marks, certifications

3.1 CE-marking

Low-Voltage Directive

The CE marking confirms compliance of drive modules of the ServodynD series with the Low-Voltage Directive. The rating and construction satisfy the requirements of EN 50178.

Machinery Directive

The CE marking confirms compliance of drive modules of the ServodynD series with the Machinery Directive. The rating and construction satisfy the requirements of EN 60204-1.

Electric Drives

and Controls

3–1Bosch Rexroth AGServodyn-D1070 066 032 / 03

EMC Directive

Concerning the EMC Directive, the exception stipulated in the German

EMC Act, EMVG Art. 6, Subs. (9), is applicable, cf. below.

The following must be noted with respect to the operational system (cf.

EMC manual):

D Requirements on EMC noise emission

D Conducted noise

Depending on the application (industrial environment or domestic

application), a suitable mains filter is to be provided in the power

supply line.

The cubicle construction should be designed so as to ensure the

efficiency of the mains filter to the greatest possible extent.

D Radiated noise

Depending on the application (industrial environment or domestic

application), a suitable switch cabinet with EMC shielding has to

be provided.

For the motor leads, shielded cables should be preferably used

which are grounded on both ends of the shield.

D Required interference immunity

The rating and construction satisfy the requirements of the EMC

product standard EN 61800-3 for application in industrial environments.

EMVG 18.09.1998

Art. 6 Exceptions and special determinations

(9)Apparatuses, systems, and components covered by Subs. 3, which

are exclusively manufactured and designed as accessories or spare

parts for further processing by companies or persons with expert

knowledge in the field of electromagnetic compatibility, are exempted

from compliance with the protection requirements and the requirements of Art. 4 Subs. 1 Nos. 1 to 3 and 5. The operational unit which

contains apparatuses, systems or components defined in the 1

tence above, shall satisfy the provisions of this law.

st

sen-

3–2 Electric Drives

Marks, certifications

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

3.2 EU design type certification

The certification covers Servodyn-D with redundant safety monitoring

RSU. RSU complies with the requirements concerning:

D Safety-relevant parts of controllers in accordance with EN 954-1

Category 3, as required by

D EN 12415 (safety of turning machines)

D EN 12417 (safety of machining centres)

D Control functions in the event of a fault according to EN 60204-1

In the special mode, the integrated 2-channel safety structure monitors

all axis and spindle movements. It is available for:

D Three-phase modules with SERCOS interface

(firmware release as of V0.040)

D in connection with supply modules with energy recovery capability

(firmware release as of V0.040) and

D mains connection module NAA

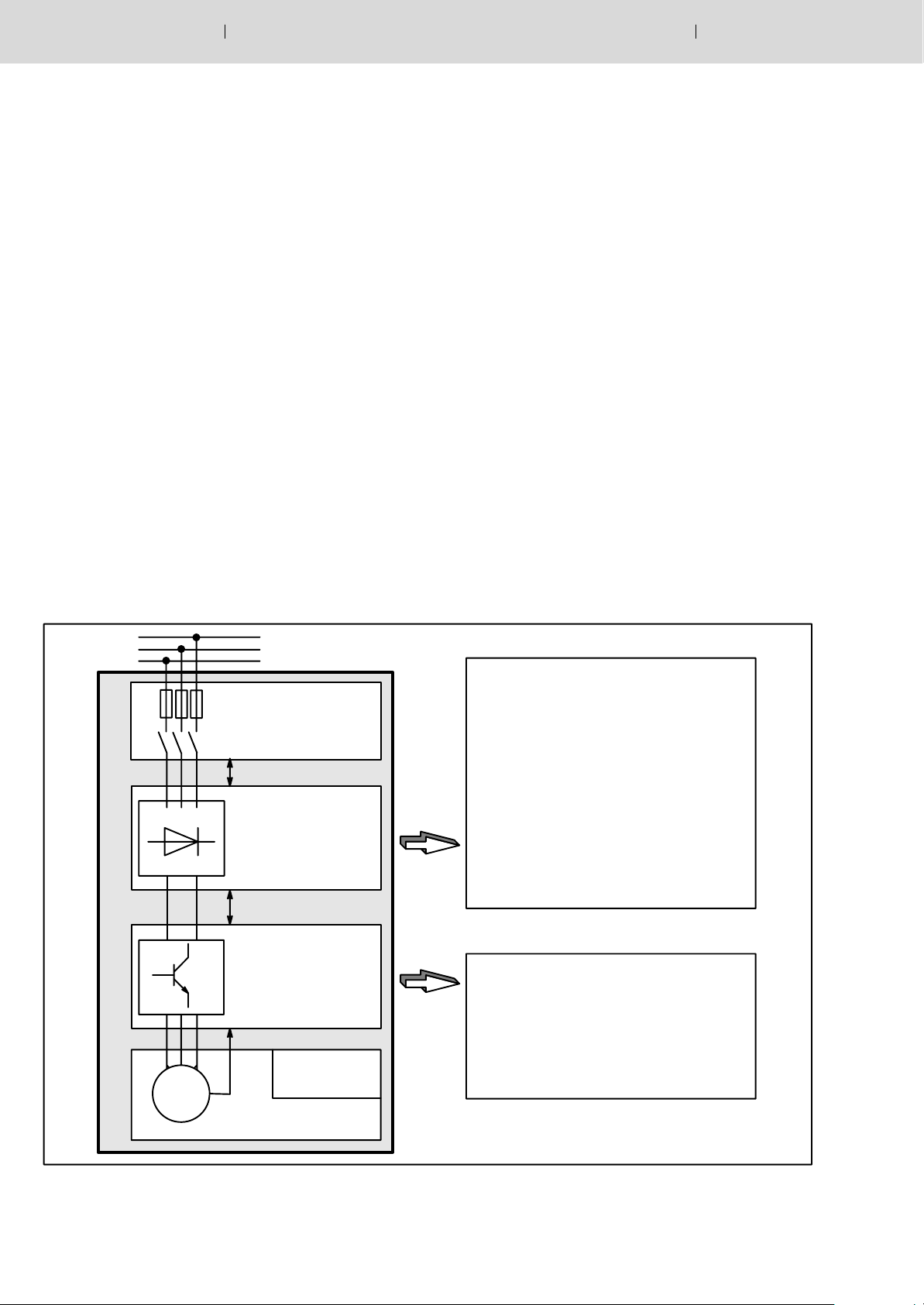

NAA mains connection module

Mains contactor control

Supply module VM

with sinusoidal infeed

and recovery

Sercodyn-D concept

Three-phase current

module DM

This concept has been certified, i.e. additional monitoring equipment is

not necessary.

. For more information, refer to Servodyn-D with Redundant Safety

Monitoring manual, part no. in Section 1.6.

Three-phase mains

D Integration of an EMERGENCY-

STOP switch

D Connection and monitoring of a

mode selector switch

D Connection and monitoring of a

dead-man’s key

D Integrated line monitor for single

and multiple phase mains failures

D Integrated control and monitoring

of the protective door tumbler

Module crosscon

nection

D Safe reduced speed in special mode

Motor

Safety

tumbler

Separating protective

device

D Safe standstill in special mode

D Monitoring of the maximum speed

Marks, certifications

3.3 UL/CSA certification

For a number of Servodyn-D modules in compact mechanics, a UL/CSA

certification is available for the U.S. and Canada. They are marked by

adhesive labels. These modules are listed in the ”Product Identity 23

MB”, File No. E214694.

Installation in compliance with UL/CSA

In order to obtain a UL/CSA-compliant installation, the following must be

noted in addition to the use of the certified components:

D Systems may only be used in environments with pollution severity 2.

D Note tightening torques of the connection terminals as specified in In-

terface Conditions manual, for part no. refer to page 1–9.

D The insulated wires must be specified for 60/75_C as a minimum.

D Only insulated Class 1 wires or equivalent may be used,

e.g. to UL Style 1015 (on motor side, H07: U

Style 1007 or 1569 (on supply side, H05: U

D Suitable for installation in symmetrical supply networks with a short-

circuit current of x 10 kA with max. 460 V +10 %.

Electric Drives

and Controls

/U: 600/1000 V) and UL

0

/U: 300/500 V)

0

3–3Bosch Rexroth AGServodyn-D1070 066 032 / 03

Operation in compliance with UL/CSA

For UL/CSA-compliant operation, the bimetal function (I

must be activated in the inverters using parameter P-0-0053 in order to

provide motor protection.

of the motor is automatically retrieved from the electronic rating

D I

N

plate to the I

D P-0-0053 is only used to set the desired time constant:

Factory setting: 0.0 (disabled)

Customary setting range: 100...150

2

t monitoring function.

(corresponds to release characteristics of

bimetal relay)

2

t monitoring)

3–4 Electric Drives

Bosch Rexroth AG Servodyn-D 1070 066 032 / 03

and Controls

Marks, certifications

Notes:

Loading...

Loading...