Bosch Rexroth Rho 4.0 System Description

Industrial

Hydraulics

Electric Drives

and Controls

Linear Motion and

Assembly Technologies Pneumatics

Service

Automation

Mobile

Hydraulics

Rexroth Rho 4.0

System description

1070072367

Edition 04

Project planning

II Electric Drives

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Title

Type of Documentation

Document Typecode

Purpose of Documentation

Record of Revisions

Rexroth Rho 4.0

System description

Project planning

DOK-RHO*4*-RHO4.0*SYSB-PR04-EN-P

The present manual informs about:

D structures, functionalities and

D programming of the rho4.0

Description Release

Date

DOK-RHO*4*-RHO4.0*SYSB-PR03EN-P

DOK-RHO*4*-RHO4.0*SYSB-PR04EN-P

10.2003 Valid from VO07

01.2005 Valid from VO08

Notes

Copyright

Validity

Published by

E Bosch Rexroth AG, 1998 − 2005

Copying this document, giving it to others and the use or

communication of the contents thereof without express authority, are

forbidden. Of fenders are liable for the payment of damages. All rights

are reserved in the event of the grant of a patent or the registration

of a utility model or design (DIN 34−1).

The specified data is for product description purposes only and

may not be deemed to be guaranteed unless expressly confirmed

in the contract. All rights are reserved with respect to the content

of this documentation and the availability of the product.

Bosch Rexroth AG

Postfach 11 62

D-64701 Erbach

Berliner Straße 25

D-64711 Erbach

Tel.: +49 (0) 60 62/78-0

Fax: +49 (0) 60 62/78-4 28

Abt.:

BRC/ESH (KW)

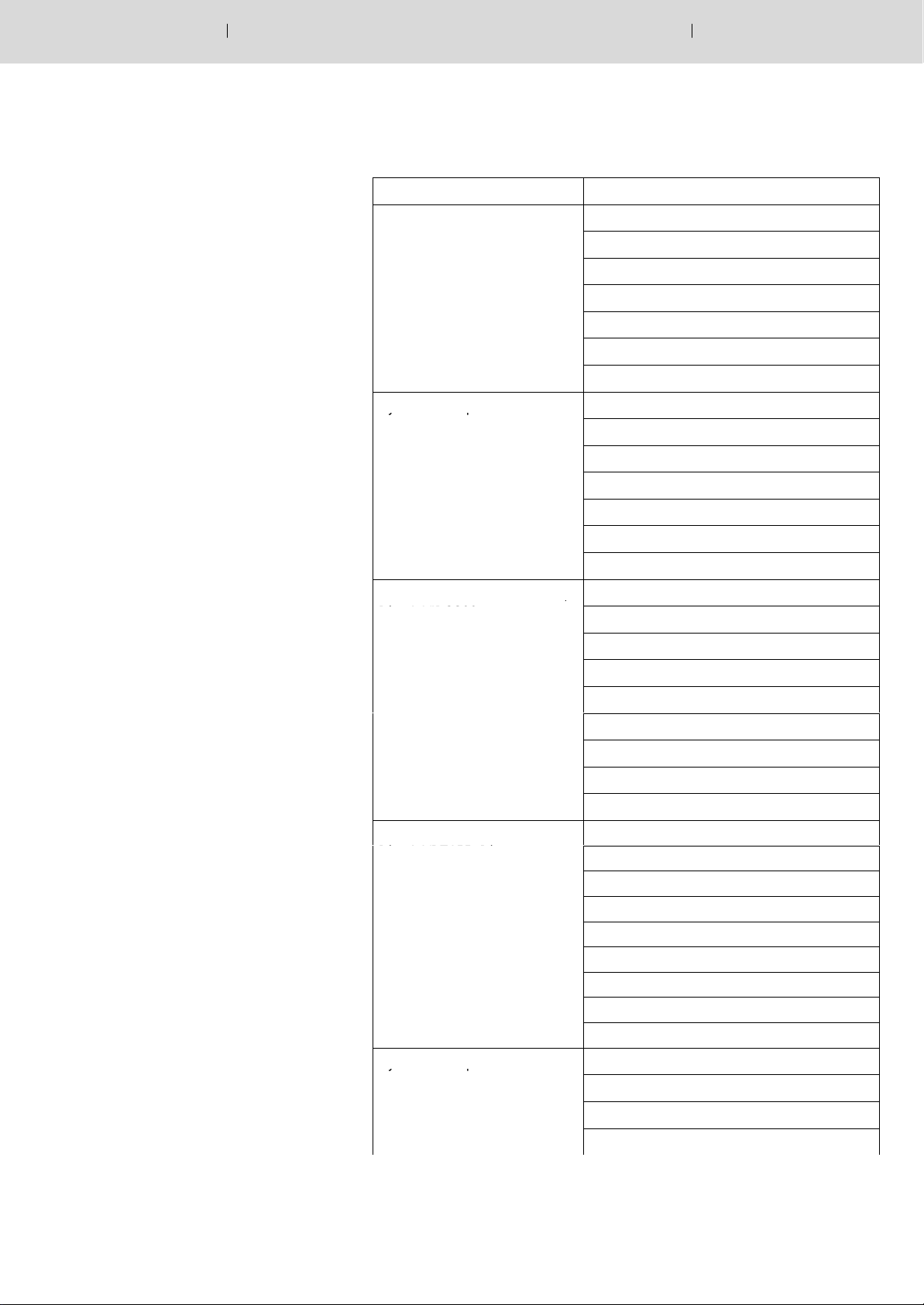

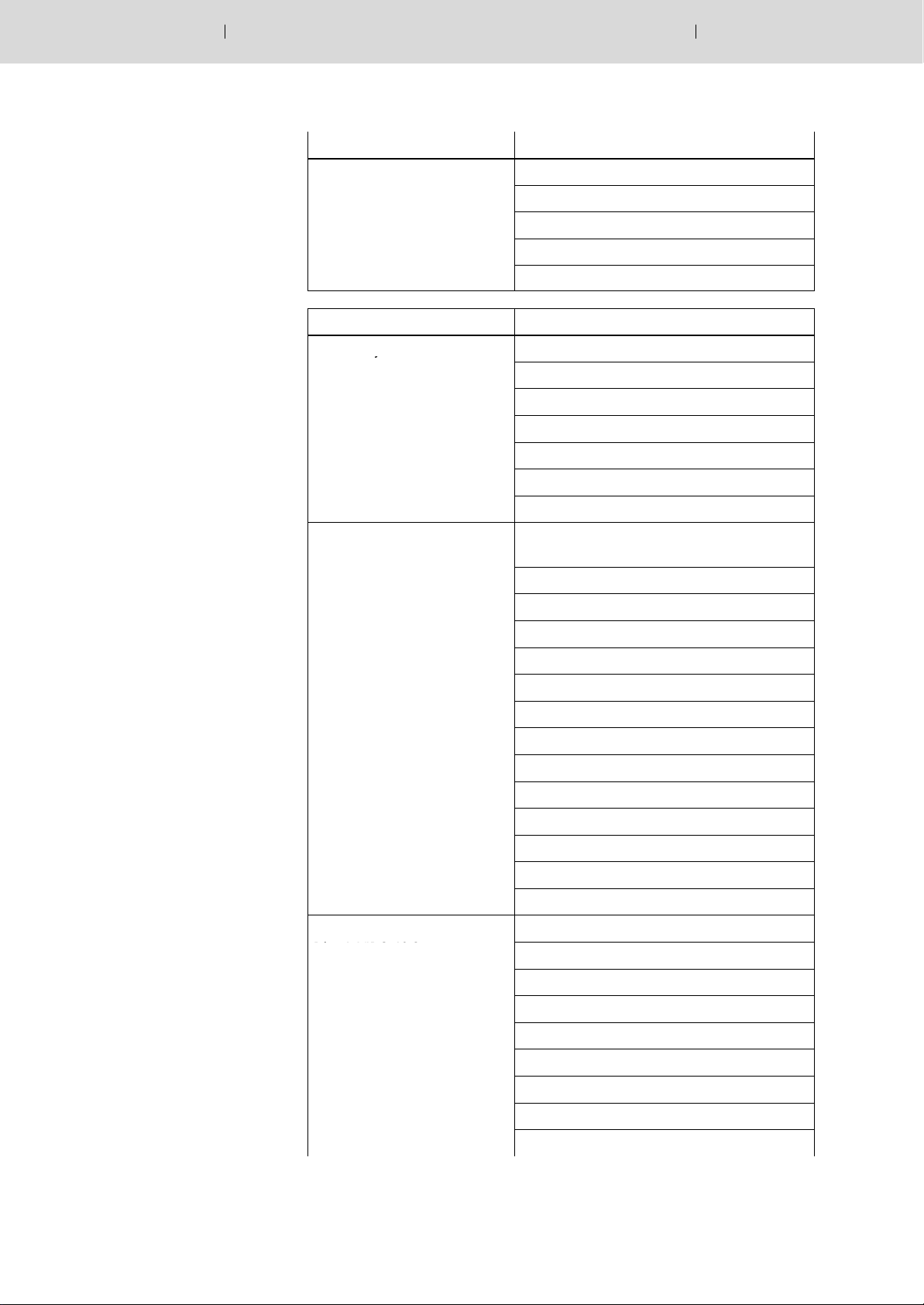

Overview of all manuals

Connection conditions Rho 4.0

System description Rho 4.0

Connection conditions Rho4.1,

Connection conditions

4.1/BT155T, Rho 4.1/BT205

System description Rho 4.1

Overview of all manuals

Manual Contents

Electric Drives

and Controls

IIIBosch Rexroth AGRhoMotion1070072367 / 04

Connection conditions Rho 4.0

System description Rho 4.0

Connection conditions Rho4.1,

Rho 4.1/IPC300

2 System overview

3 Installation

4 Electrical connection

5 Interfaces

6 LED display

7 Maintenance and replacement

8 Order numbers

2 System overview

3 Structure of the rho4.0

4 PCLrho4.0

5 CAN-Bus peripheral unit

6 SERCOS interface

7 Software

8 File management

2 System overview

3 Security functions

4 Installation

Connection conditions

Rho 4.1/BT155, Rho

System description Rho 4.1

5 Electrical connection

6 Interfaces

7 LED display

8 Maintenance and replacement

9 Software

10 Order numbers

2 System overview

3 Security functions

4 Installation

5 Electrical Connections

6 Interfaces

7 Display and Operating Controls

8 Maintenance and Replacemant

9 Software

10 Order numbers

2 Structure of the rho4.1

3 PCL

4 CAN-Bus peripheral unit

5 SERCOS interface

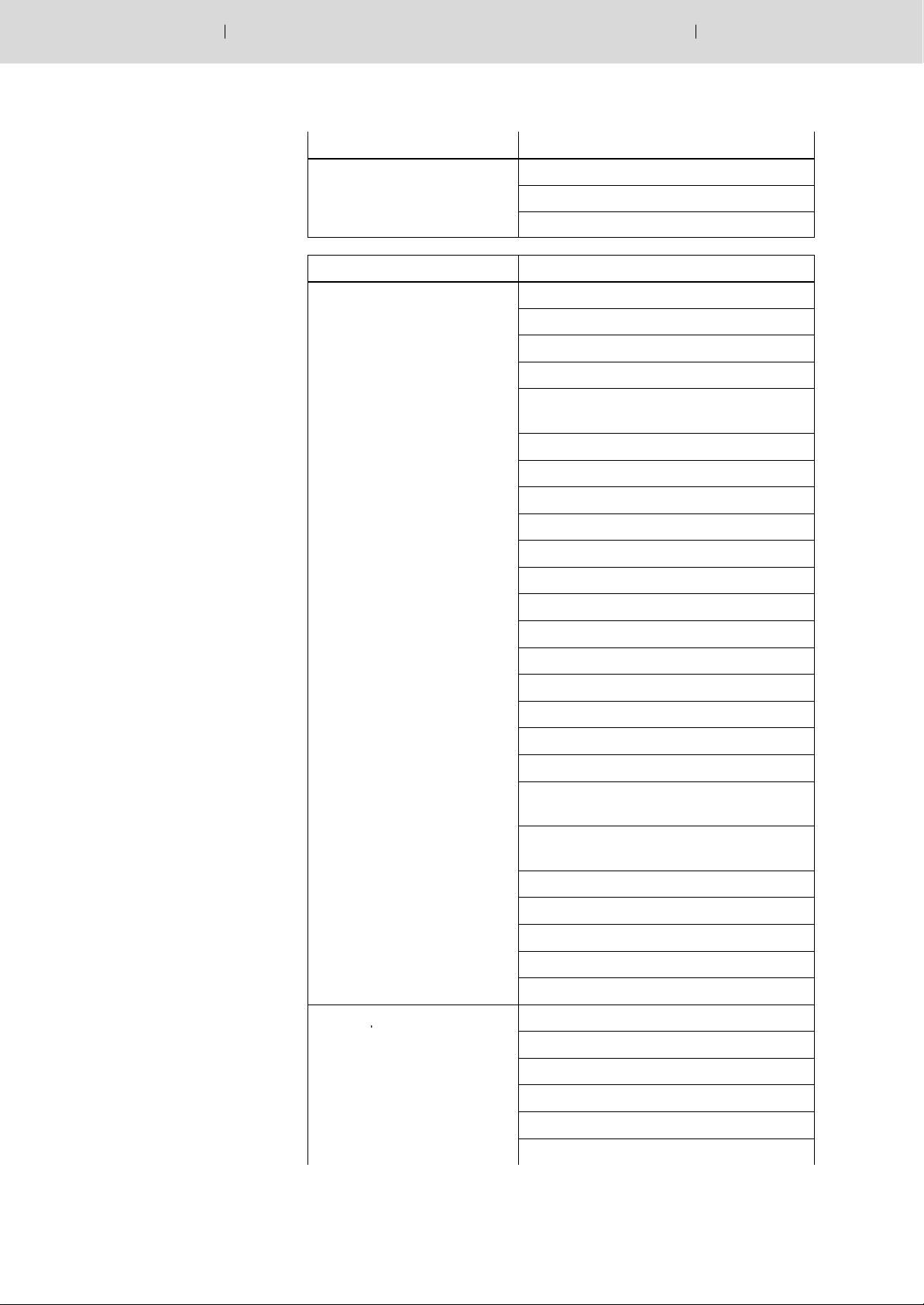

IV Electric Drives

Control functions

Machine parameters

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Overview of all manuals

Manual Contents

6 Software

7 File management

8 Scope of the rho4.1 Software

Manual Contents

Control functions

2 Survey of special functions

3 Accurate position switching

4 Setting the machine position

5 Calling operating system functions

6 Parameterization of the belt characte-

ristic

7 Selecting a point-file

8 Mirroring

9 Belt type

10 System date and time

11 System counter

12 WC main range

13 Setting the belt counter

14 Recording of reference path

15 Flying measurement (rho4.1 only)

16 MOVE_FILE

17 Setting the block preparation

18 Exception−Handling

Machine parameters

19 Belt counter current value

20 Automatic velocity adjustment for PTP

movements

21 Belt-synchronous working area belt

kind 4

22 Current belt speed

23 Changing the belt simulation speed

24 General functions

25 Process-oriented functions

26 BAPS3 keywords

2 General information

3 Application of the machine parameters

4 General system parameters

5 Speeds

6 Positions

7 Kinematic parameters

Overview of all manuals

BAPS3 Programming manual

BAPS3 Short description

Signal descriptions

Status messages

ROPS4/Online

Electric Drives

and Controls

Manual Contents

8 Measuring system parameters

9 Belt parameters

10 Drive parameters Servodyn-GC

11 Drive parameter Servodyn-D

12 Table of parameters

Manual Contents

VBosch Rexroth AGRhoMotion1070072367 / 04

BAPS3 Programming manual

BAPS3 Short description

2 Program structure

3 Constants

4 Variables

5 Program control

6 Value assignments and combinations

7 Functions

8 Movement statement

9 Write/read functions

10 BAPS3 keywords

2 Program structure

3 Constants and variables

4 Program structure

5 Value assignments and combinations

6 Standard functions

7 Movements and speeds

8 Belt synchronous

9 Workspace limitation

Signal descriptions

Status messages

and warnings

ROPS4/Online

10 Write/read functions

11 Special functions

12 Library functions

13 Fix files

14 BAPS3 keywords

2 rho4 interface description

3 Signal description of PCL inputs

4 Signal description of PCL outputs

2 rho4 status messages

3 Warnings

4 CANopen error codes

2 General information

3 Activation and functions of Online

4 The function key box

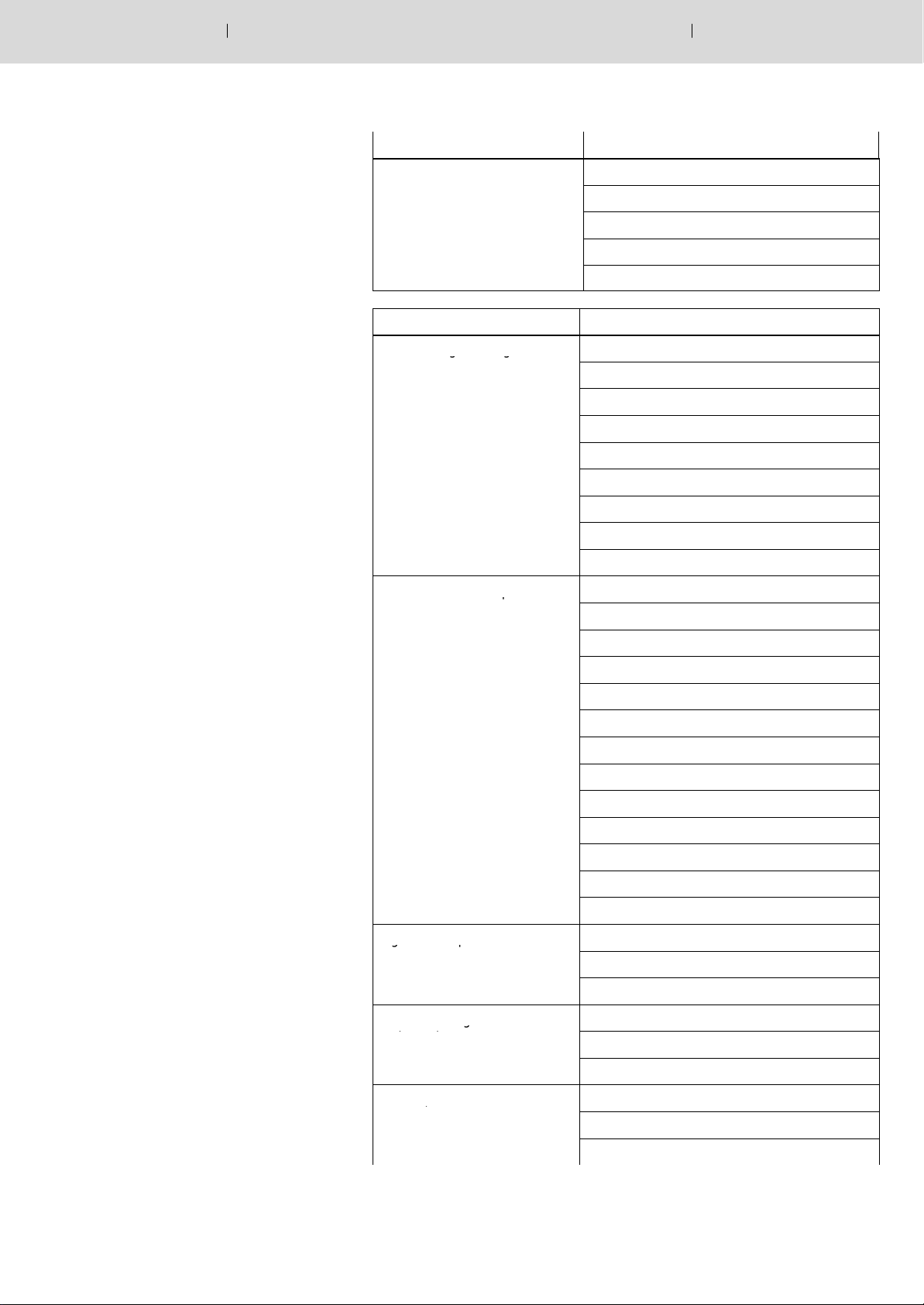

VI Electric Drives

DLL library

Connection conditions

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Overview of all manuals

Manual Contents

5 Function key assignment

6 The marker box

7 File ROPS4WIN.ini

8 Selection of a file

9 TCP/IP settings for ROPS4

Manual Contents

DLL library

PHG2000

2 Library functions

3 Calling library functions in BAPS

4 Block structure of the rho4.1

5 Library server

6 Application development

7 rho4 library functions

8 Variable access per DLL

2 Hand-held programming unit

PHG2000

3 PHG2000 system variables

4 Selection of PHG functions

5 Info function of the PHG

6 Controlling the PHG2000 output

7 Define/Teach

8 SRCAN functions

9 File and User Memory Functions

10 File list

11 Process info

Connection conditions

Rho 4.1/IPC 40.2

12 Restoring the PGH display

13 Variable assignment of PHG keys

14 Select point file and point name

15 BDT editor

2 System Overview

3 Security Functions

4 Installation

5 Eelectrical Connections

6 Interface Ports & Connectors

7 Display- and Operating Components

8 Maintenance and Replacement

9 Software

10 Ordering Informations

Overview of all manuals

DDE-Server

Electric Drives

and Controls

Manual Contents

VIIBosch Rexroth AGRhoMotion1070072367 / 04

DDE-Server

2 Introduction

3 Hardware and Software

4 Operation

5 Items of Server 4

6 Scope of function

VIII Electric Drives

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Overview of all manuals

Notes:

Contents

Contents

Electric Drives

and Controls

1 Safety Instructions 1−1 . . . . . . . . . . . . . . . . . . . . . . .

1.1 Intended use 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Qualified personnel 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Safety markings on products 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Safety instructions in this manual 1−4 . . . . . . . . . . . . . . . . . . . . . .

1.5 Safety instructions for the described product 1−5 . . . . . . . . . . . .

1.6 Documentation, software release and trademarks 1−7 . . . . . . .

2 System overview 2−1 . . . . . . . . . . . . . . . . . . . . . . . . .

3 Structure of the rho4.0 3−1 . . . . . . . . . . . . . . . . . . .

3.1 Description of the structure 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Outline structure 3−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 rho4.0 block diagramm 3−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Operating system of the rho4.0 3−4 . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Floppy operation 3−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Digital I/O 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Digital inputs 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Digital outputs 3−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operation with I/O-Gateway 3−14 . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 rho4.0 without PCL field bus card 3−14 . . . . . . . . . . . . . . . . . . . .

3.3.2 Examples of B~IO M-CAN bus connections 3−15 . . . . . . . . . . .

3.3.3 rho4.0 with PCL field bus card 3−32 . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Example of a B~IO M-DP Profibus connection 3−33 . . . . . . . . .

3.3.5 Example of a B~IO M-IBS bus connection 3−34 . . . . . . . . . . . . .

3.3.6 Example of a B~IO M-CAN bus connection 3−34 . . . . . . . . . . . .

3.4 Fixed IP addresses 3−36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Small linking with switches 3−37 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Cabling 3−37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Linking of two rho4.0 3−37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Smallest linking of up to 6 rho4.1 with 8-fold switch 3−38 . . . . .

3.5.4 Small linking of several rho4.0 with 8-fold switch 3−39 . . . . . . .

3.5.5 Remote control with ROPS4 and virtual PHG 3−41 . . . . . . . . . .

IXBosch Rexroth AGRhoMotion1070072367 / 04

Page

4 PCLrho4.0 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PCLrho4.0 programming with WinSPS from version 3.1

(build 1406) 4−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 PCLrho4.0 configuration with WinDP from version 2.10

(build 677) 4−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PCLrho4.0 configuration with WinCAN 1.1 (build 92) 4−11 . . . . .

4.4 Operation of the PCLrho4.0 with INTERBUS-S 4−13 . . . . . . . . . .

X Electric Drives

Contents

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

5 CAN-Bus peripheral equipment 5−1 . . . . . . . . . . .

5.1 CANopen-Interface 5−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Functions 5−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Machine parameters 5−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CANopen-encoder 5−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Functions 5−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Machine parameter 5−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 CAN belts 5−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Functions 5−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Machine parameters 5−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 CAN Interface X53 (only rho4.0L) 5−13 . . . . . . . . . . . . . . . . . . . . .

5.5 Analog I/O with CAN B~IO modules 5−14 . . . . . . . . . . . . . . . . . . .

5.5.1 Bus switching 5−14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Analog I/O modules 5−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Machine parameter settings 5−16 . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.4 Analog I/O parameter 5−22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.5 Example 5−24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.6 BAPS-Program 5−28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 SR-CAN module 5−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Analog In-/Outputs of the SR-CAN module 5−35 . . . . . . . . . . . . .

5.7.1 CAN-bus switching 5−35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Measuring ranges and data formats 5−35 . . . . . . . . . . . . . . . . . .

5.7.3 Machine parameter settings 5−36 . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Assignment of the CAN-Bus interfaces 5−40 . . . . . . . . . . . . . . . . .

5.8.1 Examples 5−42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 CAN-ID assignments 5−43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Servodyn-D-rho4 interface 5−46 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.1 Control data rho4 −> Servodyn-D 5−46 . . . . . . . . . . . . . . . . . . . .

5.10.2 Status messages Servodyn-D −> rho4 5−47 . . . . . . . . . . . . . . . .

6 SERCOS interface 6−1 . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Data exchange via SERCOS bus 6−1 . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Service channel 6−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Cyclic data exchange 6−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Data size of position set-values and actual values 6−4 . . . . . .

6.2 Machine parameter 6−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 SERCOS specific control parameters 6−5 . . . . . . . . . . . . . . . . .

6.2.2 SERCOS specific drive parameters 6−7 . . . . . . . . . . . . . . . . . .

6.3 Referencing 6−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 RC-controlled referencing 6−9 . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Drive-controlled referencing 6−9 . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Status messages and warnings 6−11 . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Status messages at the startup of the SERCOS interface 6−11

6.4.2 SERCOS specific state messages for running time 6−12 . . . . .

6.4.3 Warnings 6−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Transmission of cyclic drive data to the PCLrho4.0 6−13 . . . . . . .

6.5.1 Definition of the cyclic axis telegrams (AT) 6−13 . . . . . . . . . . . .

6.5.2 Treating of the axis telegrams in the rho4.0 6−14 . . . . . . . . . . . .

6.5.3 Transmission of the axis telegrams to the PCLrho4.0 6−15 . . .

6.5.4 Transmission of the rho4.0 system counter 6−16 . . . . . . . . . . . .

6.5.5 Representation of the ATs in the PCLrho4.0 6−17 . . . . . . . . . . .

Contents

Electric Drives

and Controls

6.6 Belt input via external encoder at EcoDrive/IndraDrive 6−19 . . .

6.6.1 General 6−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Function 6−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 Parameter at the EcoDrive 6−19 . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.4 Parameter at the IndraDrive 6−22 . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.5 Machine parameter at rho4 6−25 . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.6 Restrictions 6−26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Software 7−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 ROPS4/Online 7−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Server/Client functionality 7−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 File management 8−1 . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 File management function 8−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Options for accessing file management 8−3 . . . . . . . . . . . . . . . .

8.3 File attributes 8−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XIBosch Rexroth AGRhoMotion1070072367 / 04

A Appendix A−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Abbreviations A−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Index A−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XII Electric Drives

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Contents

Notes:

Safety Instructions

1 Safety Instructions

Please read this manual before you startup the rho4.

Store this manual in a place to which all users have access at any time.

1.1 Intended use

This instruction manual presents a comprehensive set of instructions

and information required for the standard operation of the described

products. The described products are used for the purpose of operating

with a robot control rho4.

The products described

D have been developed, manufactured, tested and documented in

compliance with the safety standards. These products normally pose

no danger to persons or property if they are used in accordance with

the handling stipulations and safety notes prescribed for their configuration, mounting, and proper operation.

D comply with the requirements of

D the EMC Directives (89/336/EEC, 93/68/EEC and 93/44/EEC)

D the Low-Voltage Directive (73/23/EEC)

D the harmonized standards EN 50081-2 and EN 50082-2

D are designed for operation in industrial environments, i.e.

D no direct connection to public low-voltage power supply,

D connection to the medium- or high-voltage system via a trans-

former.

The following applies for application within a personal residence, in

business areas, on retail premises or in a small-industry setting:

D Installation in a control cabinet or housing with high shield attenu-

ation.

D Cables that exit the screened area must be provided with filtering

or screening measures.

D The user will be required to obtain a single operating license is-

sued by the appropriate national authority or approval body. In

Germany, this is the Federal Institute for Posts and Telecommunications, and/or its local branch offices.

Electric Drives

and Controls

1−1Bosch Rexroth AGRhoMotion1070072367 / 04

. This is a Class A device. In a residential area, this device may cause

radio interference. In such case, the user may be required to introduce suitable countermeasures, and to bear the cost of the same.

The faultless, safe functioning of the product requires proper transport,

storage, erection and installation as well as careful operation.

1−2 Electric Drives

Safety Instructions

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

1.2 Qualified personnel

The requirements as to qualified personnel depend on the qualification

profiles described by ZVEI (central association of the electrical industry)

and VDMA (association of German machine and plant builders) in:

Weiterbildung in der Automatisierungstechnik

edited by: ZVEI and VDMA

MaschinenbauVerlag

Postfach 71 08 64

D-60498 Frankfurt.

The present manual is designed for RC technicans. They need special

knowledge on handling and programming robots.

Interventions in the hardware and software of our products, unless described otherwise in this manual, are reserved to specialized Rexroth

personnel.

Tampering with the hardware or software, ignoring warning signs attached to the components, or non-compliance with the warning notes

given in this manual may result in serious bodily injury or damage to property.

Only electrotechnicians as recognized under IEV 826-09-01 (modified)

who are familiar with the contents of this manual may install and service

the products described.

Such personnel are

D those who, being well trained and experienced in their field and famil-

iar with the relevant norms, are able to analyze the jobs being carried

out and recognize any hazards which may have arisen.

D those who have acquired the same amount of expert knowledge

through years of experience that would normally be acquired through

formal technical training.

With regard to the foregoing, please note our comprehensive range of

training courses. Please visit our website at

http://www.boschrexroth.com

for the latest information concerning training courses, teachware and

training systems. Personal information is available from our Didactic

Center Erbach,

Telephone: (+49) (0) 60 62 78-600.

Safety Instructions

1.3 Safety markings on products

Warning of dangerous electrical voltage!

Warning of danger caused by batteries!

Electrostatically sensitive components!

Warning of hazardous light emissions

(optical fiber cable emissions)!

Electric Drives

and Controls

1−3Bosch Rexroth AGRhoMotion1070072367 / 04

Disconnect mains power before opening!

Lug for connecting PE conductor only!

Functional earthing or low-noise earth only!

Connection of shield conductor only

1−4 Electric Drives

Safety Instructions

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

1.4 Safety instructions in this manual

DANGEROUS ELECTRICAL VOLTAGE

This symbol is used to warn of a dangerous electrical voltage. The

failure to observe the instructions in this manual in whole or in part may

result in personal injury.

DANGER

This symbol is used wherever insufficient or lacking compliance with instructions may result in personal injury.

CAUTION

This symbol is used wherever insufficient or lacking compliance with instructions may result in damage to equipment or data files.

. This symbol is used to draw the user’s attention to special circum-

stances.

L This symbol is used if user activities are required.

Electric Drives

and Controls

Safety Instructions

1.5 Safety instructions for the described product

DANGER

Danger of life through inadequate EMERGENCY-STOP devices!

EMERGENCY-STOP devices must be active and within reach in all

system modes. Releasing an EMERGENCY -STOP device must not

result in an uncontrolled restart of the system!

First check the EMERGENCY-STOP circuit, then switch the system on!

DANGER

Danger for persons and equipment!

Test every new program before starting up a system!

1−5Bosch Rexroth AGRhoMotion1070072367 / 04

DANGER

Retrofits or modifications may adversely affect the safety of the

products described!

The consequences may include severe injury, damage to equipment, or environmental hazards. Possible retrofits or modifications to the system using third-party equipment therefore have to

be approved by Rexroth.

DANGER

Do not look directly into the LEDs in the optical fiber connection.

Due to their high output, this may result in eye injuries.

When the inverter is switched on, do not look into the LED or the

open end of a short connected lead.

DANGEROUS ELECTRICAL VOLTAGE

Unless described otherwise, maintenance works must be performed on inactive systems! The system must be protected

against unauthorized or accidental reclosing.

Measuring or test activities on the live system are reserved to

qualified electrical personnel!

1−6 Electric Drives

Safety Instructions

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

CAUTION

Danger to the module!

Do not insert or remove the module while the controller is

switched ON! This may destroy the module. Prior to inserting or

removing the module, switch OFF or remove the power supply module of the controller, external power supply and signal voltage!

CAUTION

use only spare parts approved by Rexroth!

CAUTION

Danger to the module!

All ESD protection measures must be observed when using the

module! Prevent electrostatic discharges!

The following protective measures must be observed for modules and

components sensitive to electrostatic discharge (ESD)!

D Personnel responsible for storage, transport, and handling must have

training in ESD protection.

D ESD-sensitive components must be stored and transported in the

prescribed protective packaging.

D ESD-sensitive components may only be handled at special ESD-

workplaces.

D Personnel, working surfaces, as well as all equipment and tools

which may come into contact with ESD-sensitive components must

have the same potential (e.g. by grounding).

D Wear an approved grounding bracelet. The grounding bracelet must

be connected with the working surface through a cable with an integrated 1 MW resistor.

D ESD-sensitive components may by no means come into contact with

chargeable objects, including most plastic materials.

D When ESD-sensitive components are installed in or removed from

equipment, the equipment must be de-energized.

Electric Drives

and Controls

Safety Instructions

1.6 Documentation, software release and trademarks

Documentation

The present manual provides information on the structures and functionalities, as well as the programming of the rho4.0.

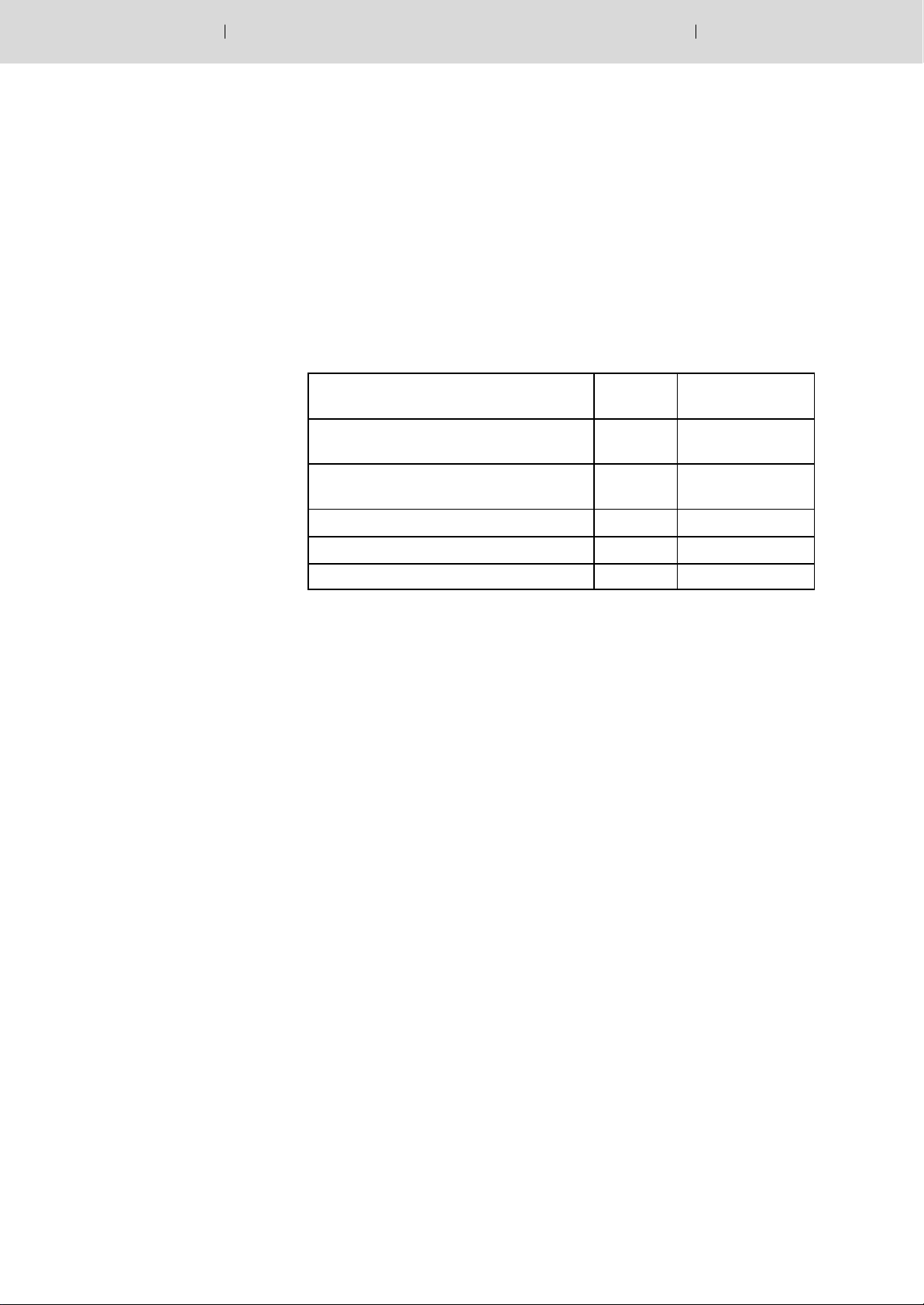

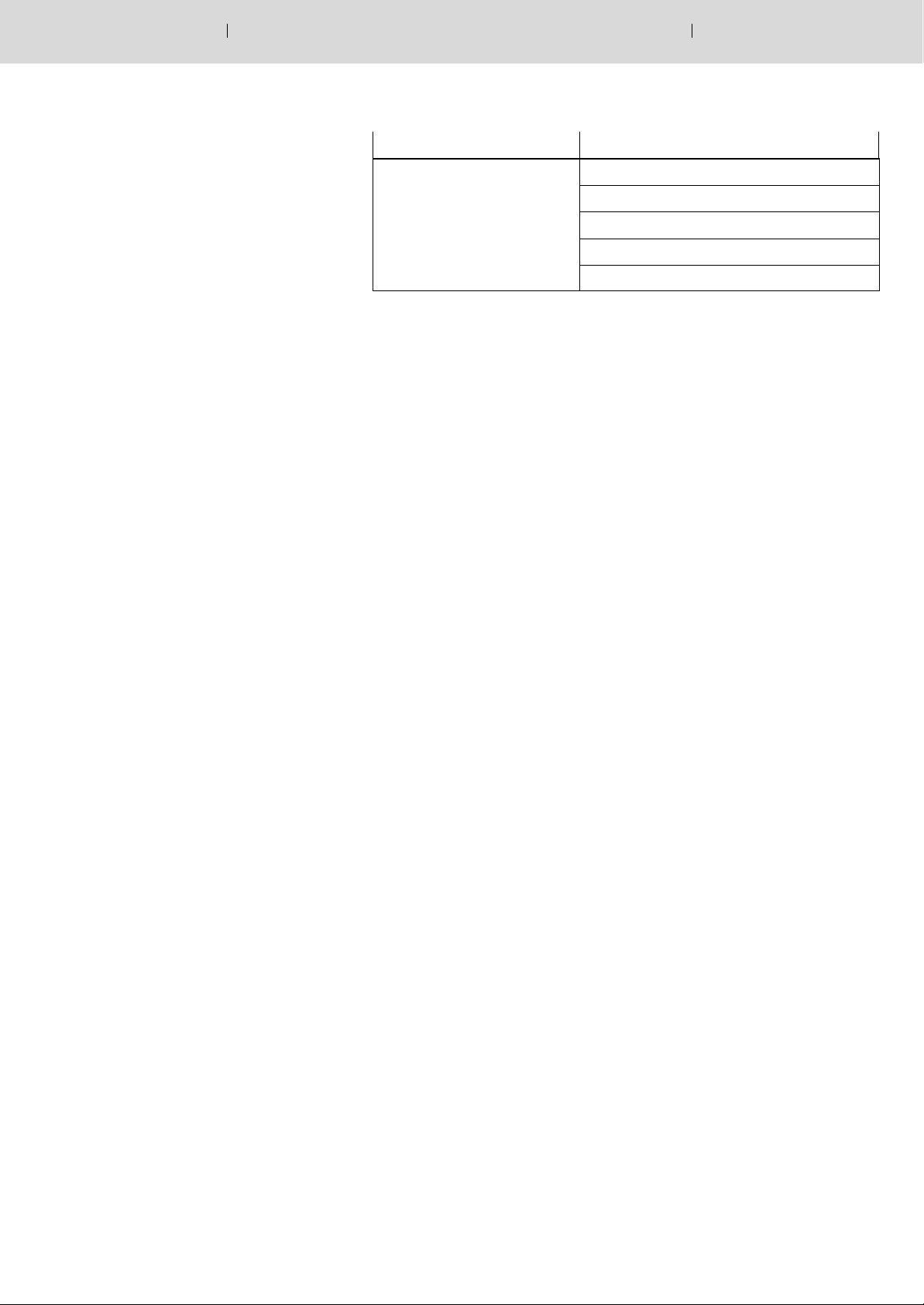

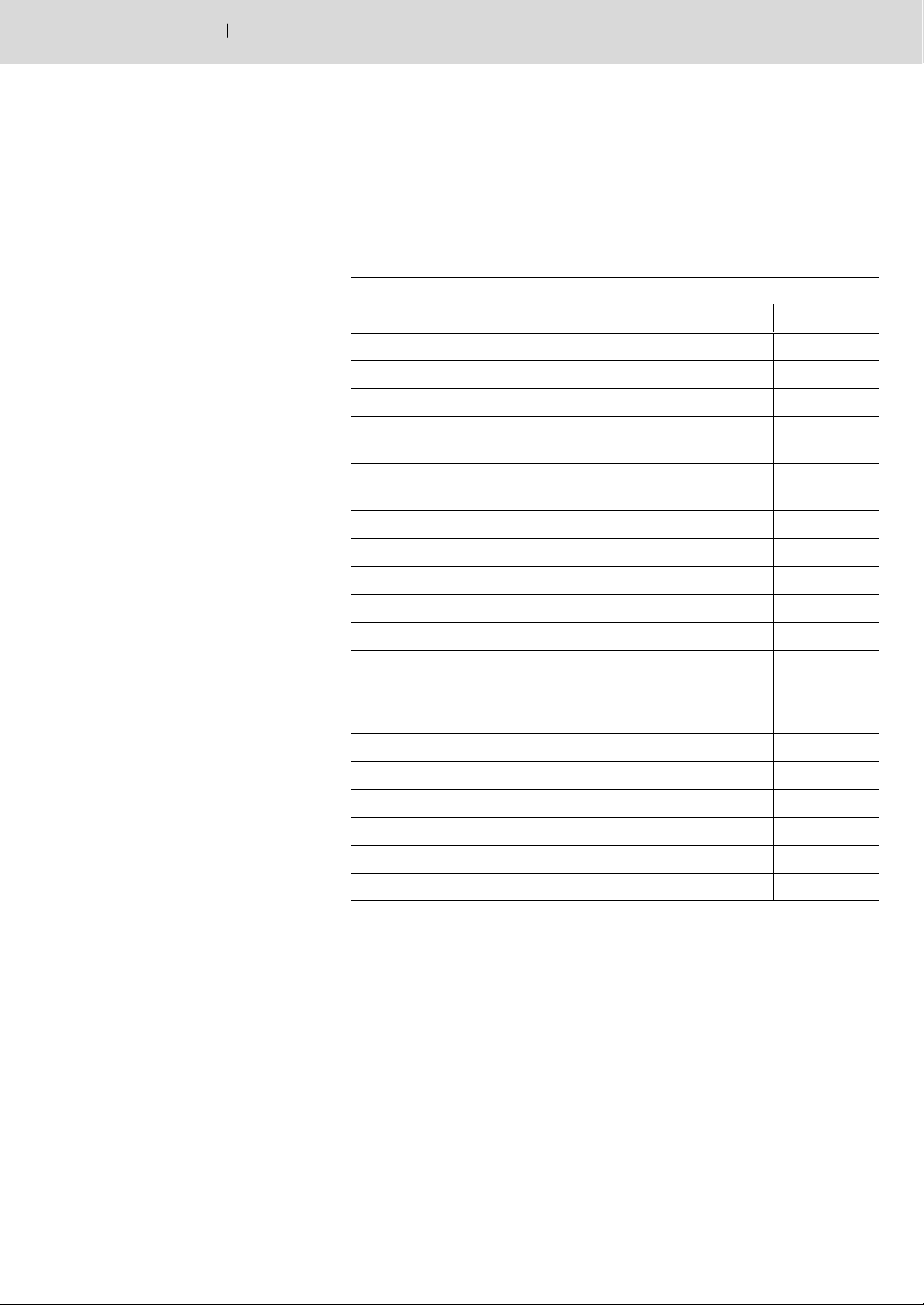

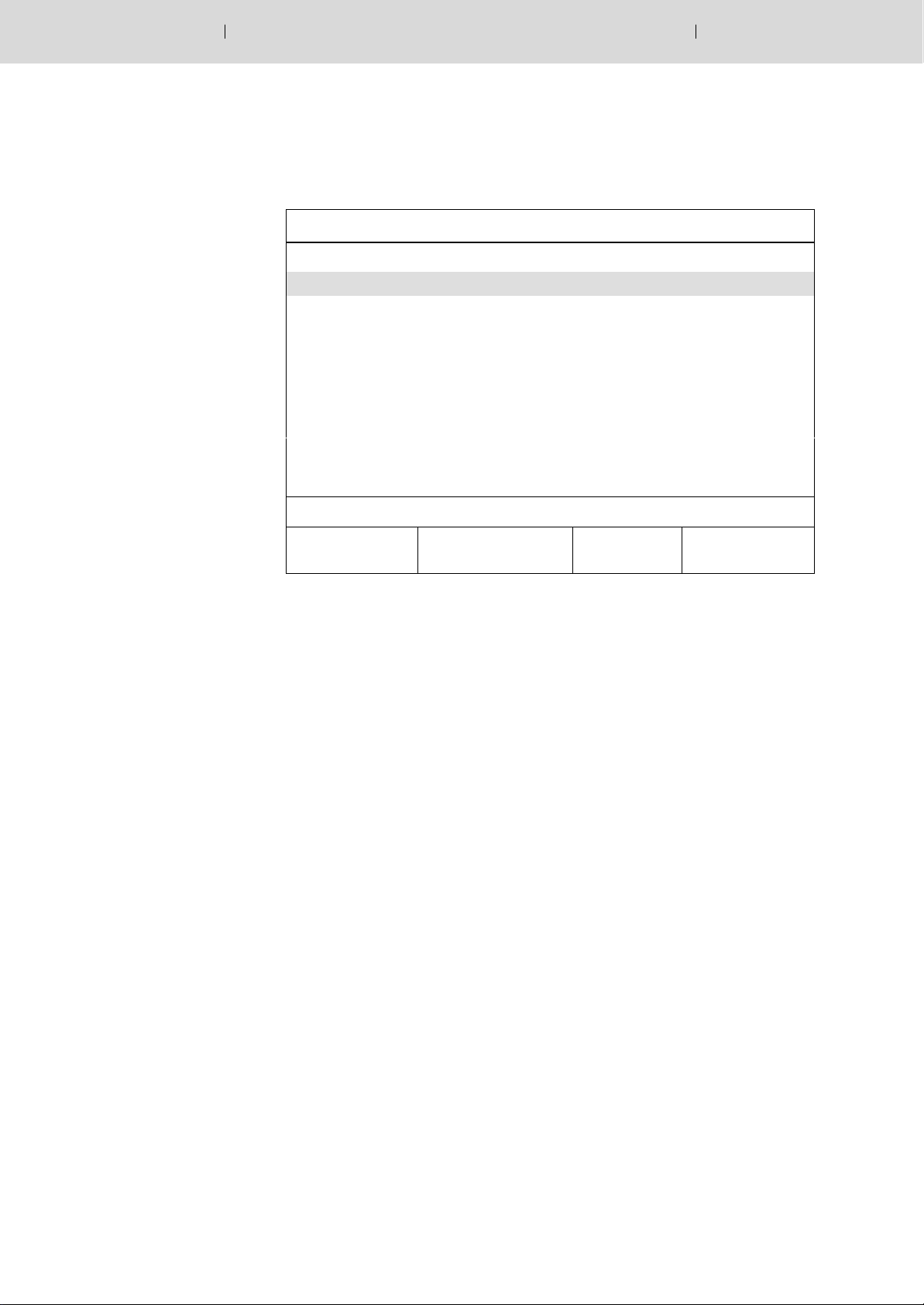

Overview of available documentation Part no.

German English

Rho 4.0 Connectivity Manual 1070 072 364 1070 072 365

Rho 4.0 System description 1070 072 366 1070 072 367

Rho 4.1/IPC 40.2 Connectivity Manual R911308219 R911308220

1−7Bosch Rexroth AGRhoMotion1070072367 / 04

Rho 4.1/BT155, Rho 4.1/BT155T, Rho

4.1/BT205 Connectivity manual

Rho 4.1, Rho 4.1/IPC300 Connectivity man-

ual

Control panels BF2xxT/BF3xxT, connection 1070 073 814 1070 073 824

Rho 4.1 System description 1070 072 434 1070 072 185

ROPS4/Online 1070 072 423 1070 072 180

BAPS plus 1070 072 422 1070 072 187

BAPS3 Short description 1070 072 412 1070 072 177

BAPS3 Programming manual 1070 072 413 1070 072 178

Control functions 1070 072 420 1070 072 179

Signal descriptions 1070 072 415 1070 072 182

Status messages and warnings 1070 072 417 1070 072 181

Machine parameters 1070 072 414 1070 072 175

PHG2000 1070 072 421 1070 072 183

DDE-Server 4 1070 072 433 1070 072 184

DLL-Library 1070 072 418 1070 072 176

1070 072 362 1070 072 363

1070 072 360 1070 072 361

Rho 4 available documentation on CD ROM 1070 086 145 1070 086 145

. In this manual the floppy disk drive always uses drive letter A:, and

the hard disk drive always uses drive letter C:.

Special keys or key combinations are shown enclosed in pointed

brackets:

D Named keys: e.g., <Enter>, <PgUp>, <Del>

D Key combinations (pressed simultaneously): e.g., <Ctrl> + <PgUp>

1−8 Electric Drives

Safety Instructions

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Release

. This manual refers to the following versions:

Hardware version: rho4

Software release: ROPS4

Trademarks

All trademarks of software installed on Rexroth products upon delivery

are the property of the respective manufacturer.

Upon delivery, all installed software is copyright-protected. The software

may only be reproduced with the approval of Rexroth or in accordance

with the license agreement of the respective manufacturer.

MS-DOSr and Windowst are registered trademarks of Microsoft

Corporation.

PROFIBUSr

is a registered trademark of the PROFIBUS Nutzerorga-

nisation e.V. (user organization).

MOBYr is a registered trademark of Siemens AG.

AS-Ir is a registered trademark of AS-International Association.

SERCOS interfacet is a registered trademark of Interessengemein-

schaft SERCOS interface e.V. (Joint VDW/ZVEI Working Committee).

I

NTERBUS-Sr is a registered trade mark of Phoenix Contact.

DeviceNetr is a registered trade mark (TM) of ODVA (Open DeviceNet

Vendor Association, Inc.).

System overview

2 System overview

The rho4.0 is a robot, handling and movement control for which the

whole processor capacity for the real time part is available since it can

run without Windows. VxWorks is used as Task Scheduler.

The hardware core of the rho4.0 is PC-based and extended by the hardware required for a real-time control.

8 axes and 8 kinematics can be controlled in the base function scope.

The rho4.0 consists of a power pack unit, a carrier board, a PC board

and a PCI plugging place, in which one of the 3 BOSCH field bus cards

(CAN, INTERBUS-S and PROFIBUS-DP) can be operated.

The PC Board is equipped with a 266- or 400 MHz processor and

32-MB-SO-DIMM. A compact flash card is used as hard disk.

There are 2 types of housing: one in the form of a drive module and another one as 19”-rack.

Electric Drives

and Controls

2−1Bosch Rexroth AGRhoMotion1070072367 / 04

The drive housing is located vertically besides a drive module. The

19”-housing is 1 HE ( 44mm) high and fitted horizontally in a 19”- control

cabinet.

The 19” variant is available with extended remanence.

2−2 Electric Drives

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

System overview

Notes:

Structure of the rho4.0

3 Structure of the rho4.0

3.1 Description of the structure

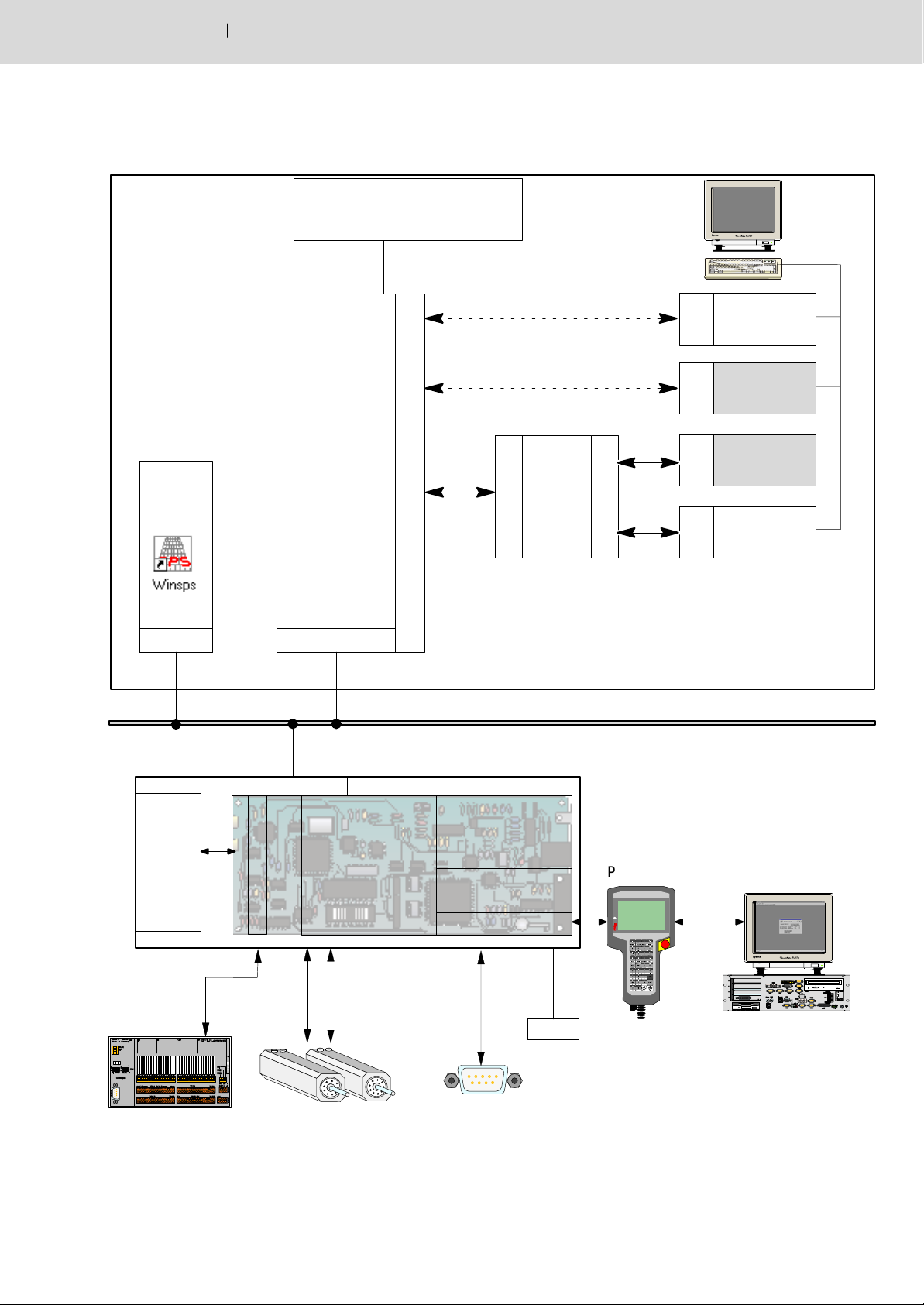

The following notes refer to point 3.1.2 Block structure of the rho4.0.

Via an external PC it is possible to communicate with the rho4.0 in Win-

dows via both a DDE server and DLL libraries. Various library functions

are available.

For the connection of the library functions the OEM has four parallel

channels available. The library functions are represented on Windows

side as DLL.

There is one common transmission channel available for ROPS4 and

DDE linking.

Electric Drives

and Controls

3−1Bosch Rexroth AGRhoMotion1070072367 / 04

Four Win channels are available in BAPS for communication with the

rho4.0 (Win_1 to Win_4). In addition, BAPS incorporates the capability

of creating one or more BAPS clients using library functions.

Coupling to a PCLrho4.0 (PC-programmable logic control), which may

run on the same computer, is provided through an internal TCP/IP connection. A data channel to the PCL is provided in the same way. The PCL

is programmed using the WIN-SPS software.

The rho4.0 provides three serial channels.

The PHG2000 is the default operating device for the rho4.0. In addition

to the default operating interface, it is possible to customise the interface

of the PHG2000 as desired using the BDT editor. Drivers and functions

are available for this purpose.

The rho4.0 incorporates a CAN interface to the digital drive amplifiers

(Bosch Servodyn D, Servodyn GC).

In addition, an interface for SERCOS drives is available.

A CAN interface is also used for the coupling of digital I/O. The

PCLrho4.0 gives the possibility of communicating by means of PROFIBUS-DP, CAN or INTERBUS-S by using a PCI field bus card.

ROPS4 can communicate with the rho4.0 via a TCP/IP or a serially connection.

BAPS plus uses the DDE Server4.

3−2 Electric Drives

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

Structure of the rho4.0

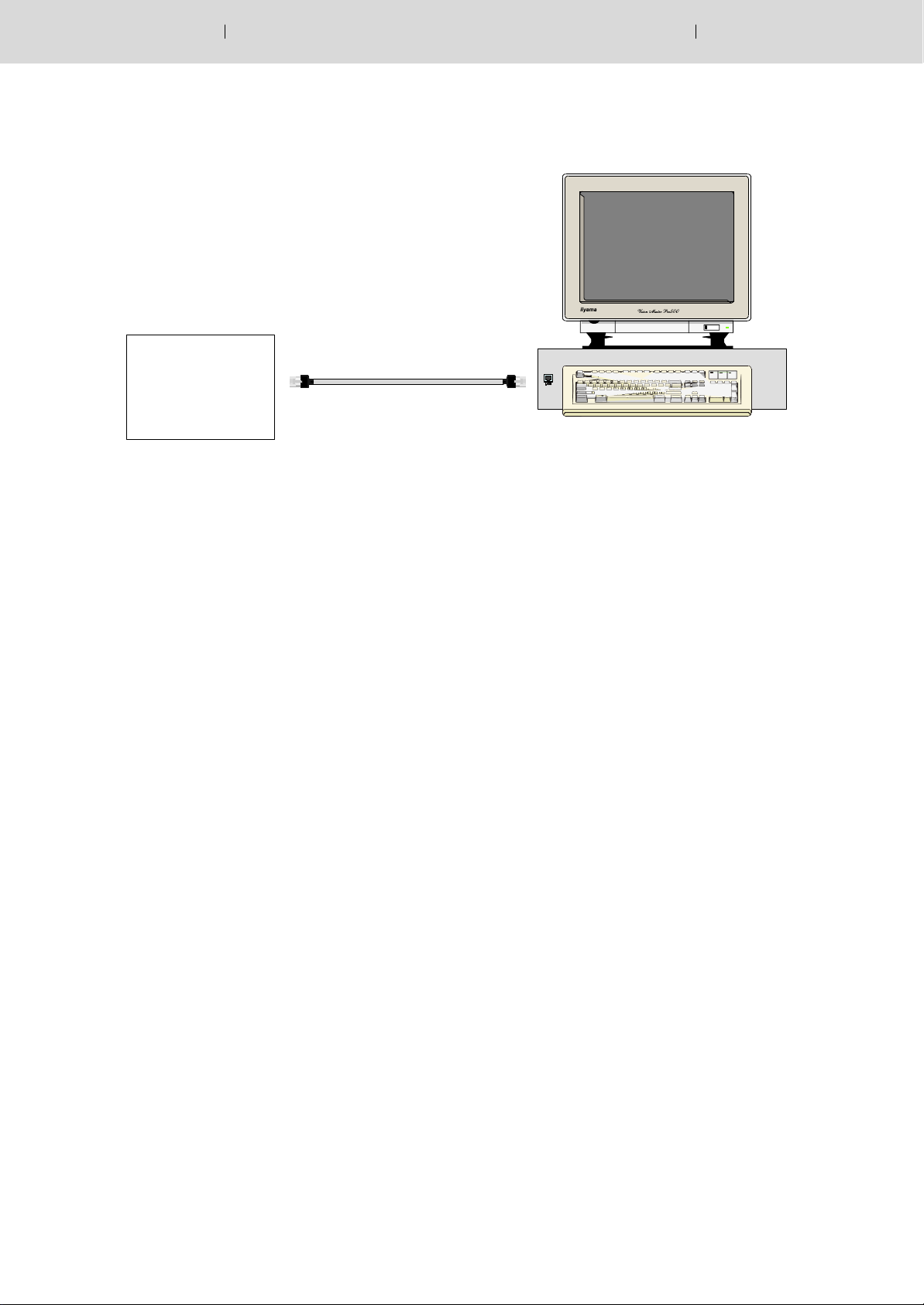

3.1.1 Outline structure

rho4.0

task management

file management

record preparation

interpolation

transformation

Windows

applications

Ethernet

TCP/IP

Standard-PC

Structure of the rho4.0

3.1.2 rho4.0 block diagramm

Electric Drives

and Controls

3−3Bosch Rexroth AGRhoMotion1070072367 / 04

External PC

WIN-PCL

Driver

V24/printer/power/

Hard disk/floppy/CD-ROM

Static link

ROPS4fkt.dll

ROPS4

Library

functions

D

Dyna-

L

mic

link

L

rho4fkt.dll

rho4

Library

functions

Dynamic link

Dynamic link

D

DDE-

L

Server

L

win.exe

D

ROPS4

L

Win.exe

L

D

L

L

D

D

D

E

OEM

Win.exe

(Switcher)

OEM

Win.exe

D

E

D

BAPS

D

plus

E

Driver

Driver

PCL

rho4.0

Driver

Ethernet

TCP/IP

T

C

P

/

I

P

C

A

N

Driver

I

nt

e

r

f

a

c

e

rho4.0

Real time core

Task administration

File administration

Record preparation

Interpolation

Transformation

S

E

R

C

O

C

A

N

Converter

rho4fkt.lib

rho4

Library

functions

PHG data

supply

Driver

V

2

4

PHG2000

BDT-editor

S

Floppy

I/O

Drives V24/20mA

3−4 Electric Drives

Structure of the rho4.0

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

3.1.3 Operating system of the rho4.0

The operating system is saved and secured against voltage loss on a

plug-in and an exchangeable compact flash disc (CF).

The change of a CF is only allowed when it is switched off by pulling the

rho4.0 component. The CF is internally mounted on the component for

safety reasons and can therefore not be removed from outside without

intention.

In the case of change of the operating system, after the exchange of the

CF, the previously saved machine parameters are to be loaded with

ROPS4 and the previously saved PCLrho4.0 program with WinSPS.

3.1.4 Floppy operation

PHG2000 display

As an option an external floppy drive can be connected to the control

rho4.0 as a storage medium supporting 3.5’ ’ disks with 1.44 MB and FAT.

The disks can be read or described from the control unit as well as from

Windows. On the disk, the file attribute may not be restricted, i.e. all files

have the attribute A(rchiv) allocated as default.

From the control side (real-time core), the operation is made via the

PHG2000.

As default the following display selection is activated:

D with the PHG mode 9.2 (list files), 9.3 (delete files), 9.4 (print files) and

9.9 (file attributes) one comes into the PHG2000 display ’Memory

management’.

D with the PHG mode 9.8 (floppy management) one comes into the

PHG2000 display ’Floppy management’.

Via an option byte (addr. 400062 = 1), it is possible to keep the display of

the modes 9.2, 9.3, 9.4, 9.9 in the PHG3 mode.

The operating mode ’File management’ gives the possibility of displaying up to 10 files of the user memory or the floppy disk at the same

time on the PHG2000 display.

The file names are limited to the format 8.3. Any extension with 3 signs is

allowed. Files that do not correspond to this format will be not displayed.

Directory structures of the floppy disk are not supported. All files that are

in the root directory of the floppy disk are displayed. Files are copied from

the control unit into the root directory of the floppy disk. Up to 224 files

can be filed into the root directory. An access to subdirectories is not possible.

Structure of the rho4.0

Electric Drives

and Controls

PHG2000-Display ’Memory management’

3−5Bosch Rexroth AGRhoMotion1070072367 / 04

The PHG2000 display ’Memory management’ is switched on with mode

9.2, 9.3, 9.4, 9.9.

Memory management

GrdStell.ird 1864331 20.09.00 10:06 RWD

GrdStell.pkt 64322 18.09.00 18:12 RWD

GrdStell.qll 4313 17.06.00 19:34 RWD

Palpos01.ird 64394 10.11.99 09:54 RWD

Palpos02.ird 84385 11.11.99 11:11 RWD

Palpos05.pkt 5376 05.09.00 17:09 RWD

Pal1 .pkt 5376 05.09.00 17:09 RWD

Pal2 .pkt 6357 08.11.00 13.08 RWD

Pal12 .pkt 12356 12.10.99 16.16 RWD

Pal22 .pkt 23466 04.05.98 15.43 RWD

MB total: 4.000 occupied: 3.052 free: 0.044

Delete

rho

Print

rho

Attributes

rho

Copy

rho −> FD

If the PHG2000 display ’Memory management’ is active, the uppermost

key row of the PHG2000 is used as function keys in the standard key assignment.

The following functions are started with it:

D ”Delete rho file“ (key code ’MOVE’)

D ”Print rho file’” (key code ’LINEAR’)

D ”Attributes rho file” (key code ’VIA’)

D ”Copy file from rho onto floppy” (key code ’TO’)

3−6 Electric Drives

Structure of the rho4.0

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

PHG2000-Display ’Floppy management’

With the PHG mode 9.8 (Floppy management) the following PHG2000

display is switched on:

GrdStel2.ird 2664331 20.09.00 10:06

GrdStel2.pkt 64322 18.09.00 18:12

GrdStel2.qll 4313 17.06.00 19:34

Palpos01.ird 64394 10.11.99 09:54

Palpos02.ird 84385 11.11.99 11:11

Palpos05.pkt 5376 05.09.00 17:09

Pal1 .pkt 5376 05.09.00 17:09

Pal2 .pkt 6357 08.11.00 13.08

Pal12 .pkt 12356 12.10.99 16.16

Pal22 .pkt 23466 04.05.98 15.43

Floppy management

MB total: 1.406 occupied: 1.354 free: 0.002

Delete

FD

Copy

MP −> FD

Copy

XMP −> FD

Copy

FD −> rho

If the PHG2000 display ’Floppy management’ is active, the uppermost

key row of the PHG2000 is used as function keys in the standard key assignment.

The following functions are started with it:

D ”Delete FD file” (key code ’MOVE’)

D ”Copy machine parameters from rho onto floppy” (key code ’LI-

NEAR’)

D ”Copy extended machine parameters from rho onto floppy”) (key

code ’VIA’)

D ”Copy files from floppy onto rho”) (key code ’TO’)

Structure of the rho4.0

Electric Drives

and Controls

Key assignment for selection

3−7Bosch Rexroth AGRhoMotion1070072367 / 04

The following key combinations correspond to the cursor movements

within the file list of the display:

Standard keyboard assignment

<up arrowl> : move cursor up <Shift> <5>

<down arrow> : move cursor down <Shift> < . >

< ’<’ > : move cursor up by a page <Alt> <7>

< ’>’ > : move cursor down by a page <Alt> <8>

<BEGIN> : position cursor at the beginning

<BEGIN>

of the file list

<END> : position cursor at the end of the

<END>

file list

<’[’> : set mark (beginning of an area) <Alt> <WENN>

<WDH> : Update display (Refresh list) <WDH>

<left arrow> : Quit operating mode

<Shift> <1>

file management

The inversely represented file(s) is/are selected for the function key to be

confirmed. Any large, coherent area over several pages can be selected. The processing of a selected area (file list) is interrupted with <left

arrow>.

CAUTION

The disk may not be removed from the drive during a write access.

It can destroy (logically) the disk.

3−8 Electric Drives

Structure of the rho4.0

Bosch Rexroth AG RhoMotion 1070072367 / 04

and Controls

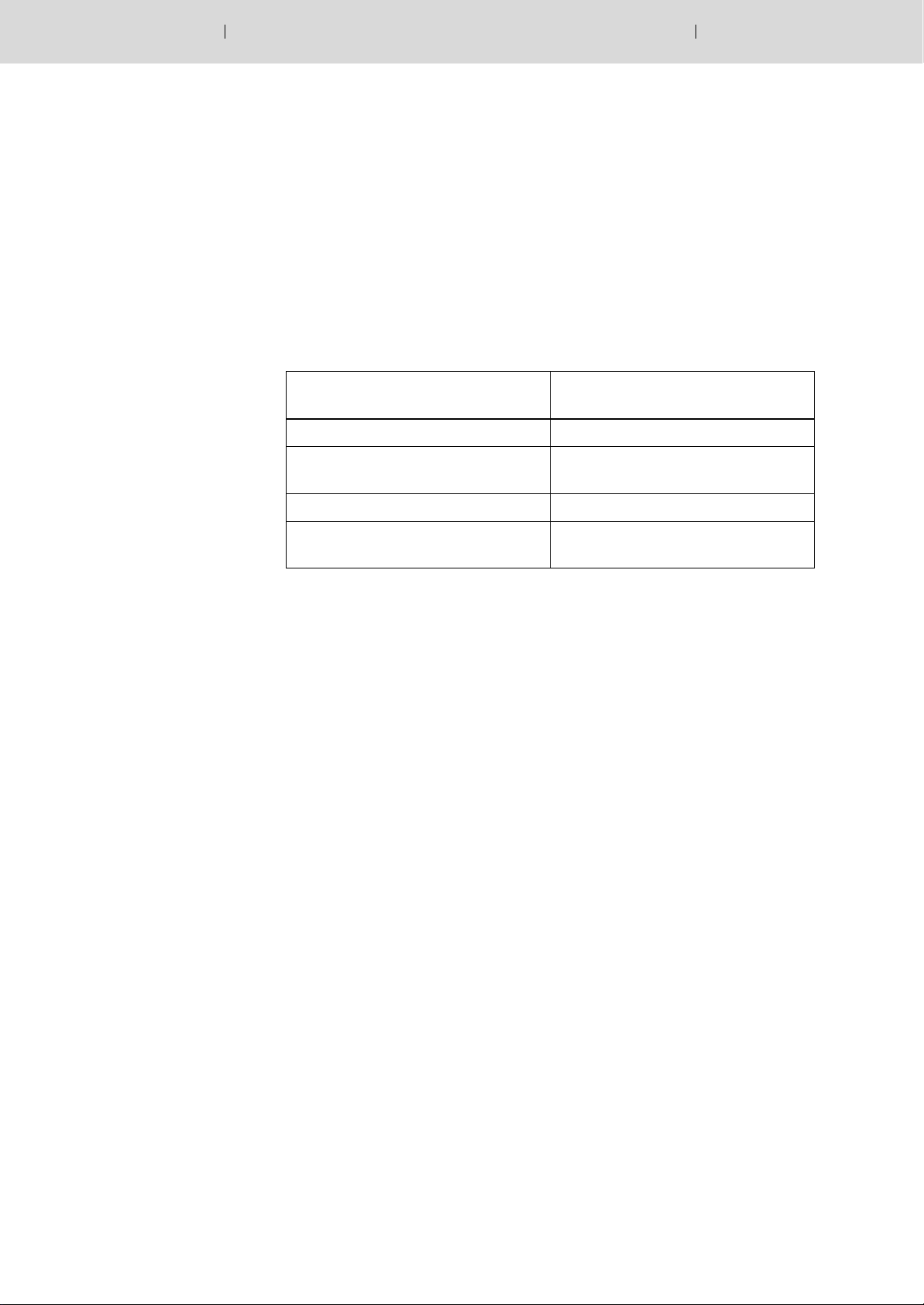

3.2 Digital I/O

On the rho4.0, (without additionally possible coupling of decentral I/O

modules) 16 digital inputs and 8 digital outputs are available.

3.2.1 Digital inputs

The digital inputs of the rho4.0 are multi-function inputs. They can be

used alternatively for several control functions:

Multifunction type can be addressed via channel

High-speed constant start 611 to 618

number

High-speed constant start

High-speed inputs in the BAPS program

High-speed asynchronous inputs 1801 to 1816

Processing of the inputs in the

PCLrho4.0 program

801 to 816

−−−

For certain applications, it is necessary to trigger a movement as Highspeed as possible and always with as constant idle time as possible on a

condition.

By means of the “WAIT UNTIL ...” instruction − by using the input channel

numbers 611 to 618 it is possible to start high-speedly and with constant

delay time (with quantization of an interpolation cycle P5) on a condition.

A movement is triggered as High-speed as possible through a condition

when the BAPS program contains the following instructione sequence:

WAIT UNTIL bedingung_erfuellt MOVE kin1 LINEAR TO P1

kin1: Name of the kinematic that is moved afterward

Condition_met: e.g. SL_INP_1=1

SL_INP_2=0

Any waiting time can be programmed before the next movement is executed:

.

.

1) WAIT UNTIL SL_INP_1=1 MAX_TIME=0.15

2) MOVE DEST_POS

.

.

Loading...

Loading...