Page 1

Marex SB

Manual / Marine

Version 2.10

15.07.2003

Page 2

Short Instructions

Please do also see the general advice in chapter 1.

Step Description

1 Select engine type (chapter 2 "overview")

Assembly

2 Adjust SYSCON switch board in accordance with engine type (chapter 2 "overview")

- Wire components and adjust switches

3

- Power supply (chapter 3.1)

- Control head (chapter 3.2)

Attention: Enter the control head ID and write it down.

- Throttle and gear control ("mechanical" chapter 3.3, "electrical" chapter 3.4)

- Extra functions if necessary (alarm, engine start interlock, idle speed relay, chapter 3.5

ff.)

Commissioning

4 Enter control heads (chapter 4.2)

Enter additional functions of control heads if applicable.

5 For mechanical throttle control: enter nominal value for idle speed (chapter 4.3)

6 For mechanical gear shifting: adjust position ahead / astern

(chapter 4.4)

7 Enter extra functions if necessary (power boost, increased idle speed, see chapter 4.3,

synchronization, buzzer in neutral, change of control station, see chapter 4.2).

Mooring Trial

8 Adjustment of delay times for gear shifting (chapter 4.4)

Adjustment of power boost if applicable (chapter 4.3)

Adjustment of increased idle speed if applicable (chapter 4.3)

Sea Trial

9 Adjustment of reversing delay times (chapter 4.4)

How to operate the system is described in chapter 5.

In case of malfunction, an error analysis as explained in chapter 6 has to be carried out.

Imprint: The copyright of this user manual remains the property of Bosch Rexroth AG.

Included are instructions and technical drawings which may not be reproduced or

copied either in part or whole, nor may they be used for evaluation or distributed for

competition purposes.

The diagrams and drawings used in this manual are for guidelines only and are not be

used for the actual design.

This edition supersedes all previous ones.

Order No.: 883 890 060 3

Bosch Rexroth AG

Department Marine Technique

Bartweg 13

30453 Hannover

P. O. Box 91 07 62

30427 Hannover

Tel.: +49 (0)5 11-2136-2 51

Fax.: +49 (0)5 11-2136-1 62

e-mail: marinesales@boschrexroth.de

Internet: http://www.boschrexroth.de

Page 3

Table of Contents

Page

1 General 1.1 System components 1

1.2 General preconditions for the operation 2

1.3 Mounting advice 2

1.4 Operating advice 2

2 Overview 2.1 Single engine 3

2.2 Twin engine 5

3 Wiring 3.1 Voltage supply 7

3.2 Control head 7

3.3 Mechanical throttle control / gear shifting 10

3.4 Electrical throttle control / gear shifting 11

3.5 Alarm relays 15

3.6 Engine start interlock 16

3.7 Idle gas relay 18

4 Adjustment 4.1 Hardware configuration 19

4.2 Control head 20

4.3 Speed 23

4.4 Gearing 25

4.5 Reset to default 28

5 Operation 5.1 General 29

5.2 Activation and request control station 30

5.3 Station transfer 31

5.4 Warming Up 32

5.5 Increased idle speed 32

5.6 Synchronising 32

6 Error analysis 6.1 Error at control station 33

6.2 Error indication control panel 34

Appendix Control unit 40

Page 4

General

1

1 General

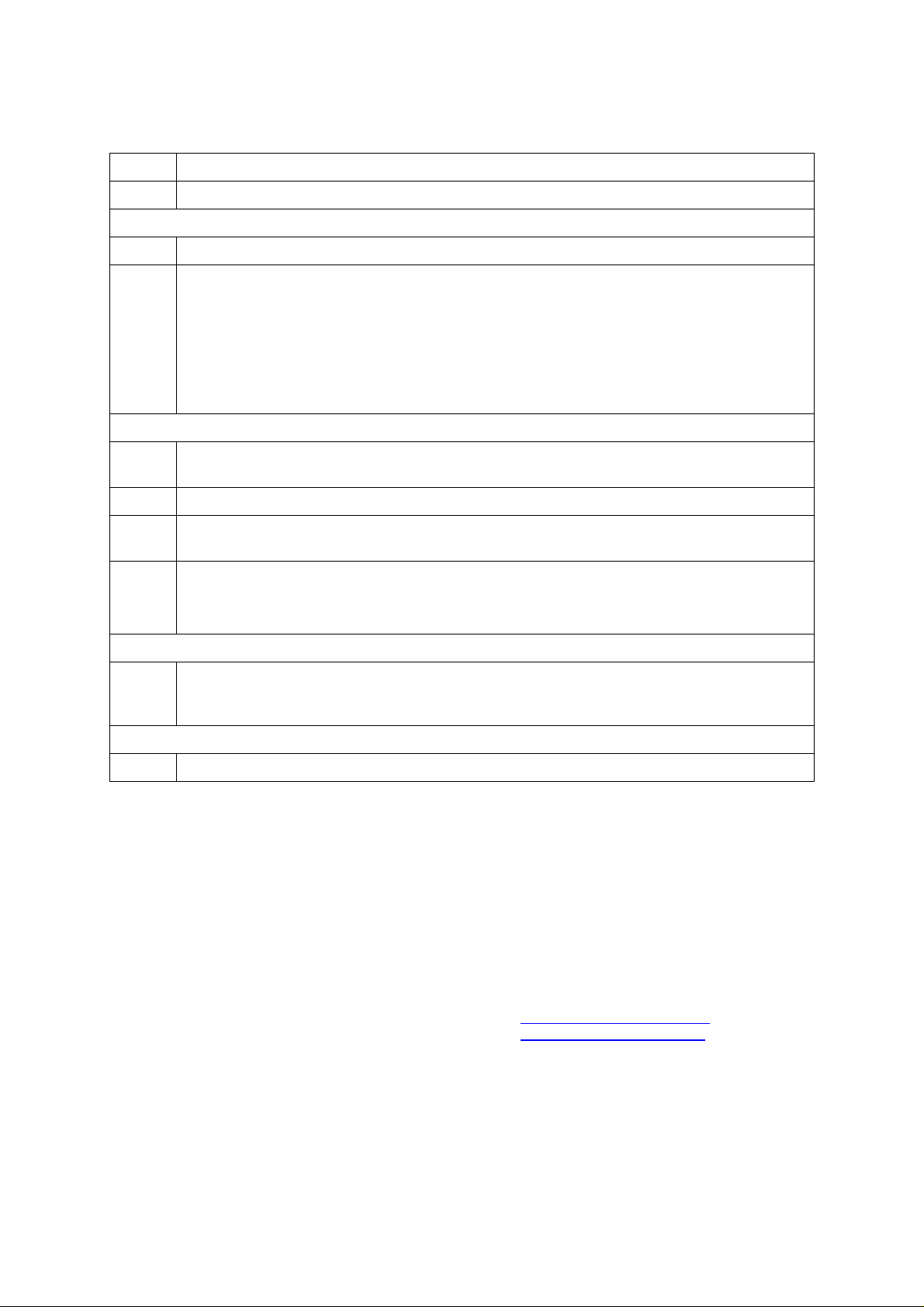

1.1 System components

Designation Code No. Photo

Control head

(single engine)

Overview Wiring Operation Error Analysis

Control head

(twin engine)

Control unit 346 068 000 0

Adjustment

DC actuator 323 698 020 0

Symbol

362 241 100 0

362 241 000 0

I/O-extension board 346 068 721 2

Synchro-board 346 068 730 2

Push-/Pull-cable 2m 323 699 415 2

Mounting kit 323 699 006 2

Additionally required:

Data cable LIYCY 4 x 1mm²

Supply cable Ölflex 100 2 x 2,5mm²

Throttle cable LIYCY 2 x 0,75mm² for electrical throttle control only

Gearing cable LIYCY 7 x 1mm² for electrical gear shifting only

Appendix

Cable alarm LIYCY 2 x 0,75mm² if alarm system is connected

Cable start interlock LIYCY 2 x 0,75mm² if engine start interlock is connected

Cable idle gas LIYCY 2 x 0,75mm² if idle gas is connected

1

2

3

4

Page 5

2

1.2 General preconditions for the operation

(According to classification rules)

Indication of the current cruising command*

The current cruising command (speed, gearing position) must be indicated on every control station.

Indication of active control station*

It must be indicated on every control station which control station is in command.

If, from any control station, any other station is visible, the indication of current cruising command and

active control station is not necessary (e. g. on small yachts).

Capacity of independent actuation*

Besides the remote control, a second possibility of controlling speed and gearing must be provided.

Emergency stop-button*

A separate emergency stop-button for the engine must be installed on every control station

independent from the remote control.

*These components are not included in the MAREX SB delivery.

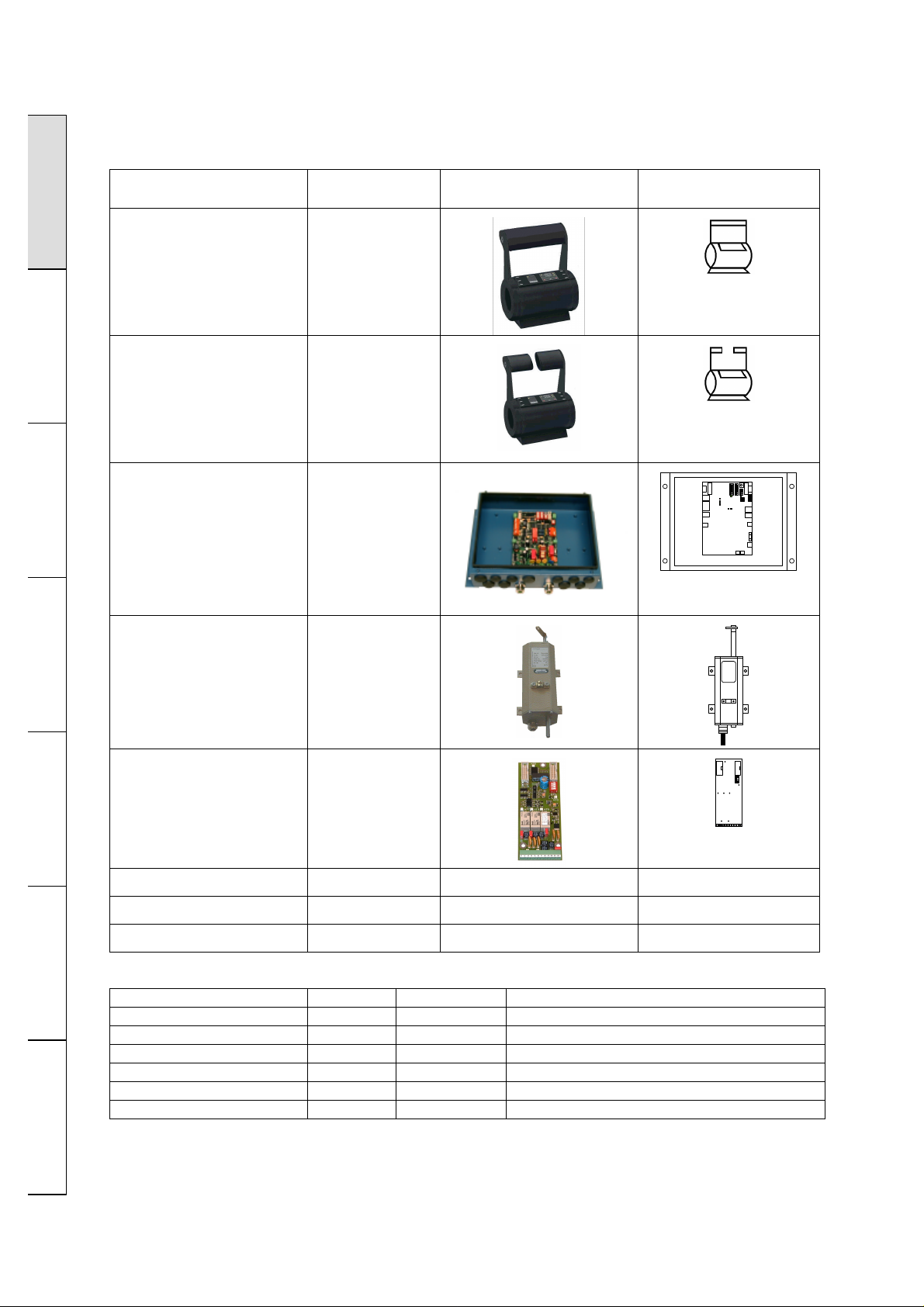

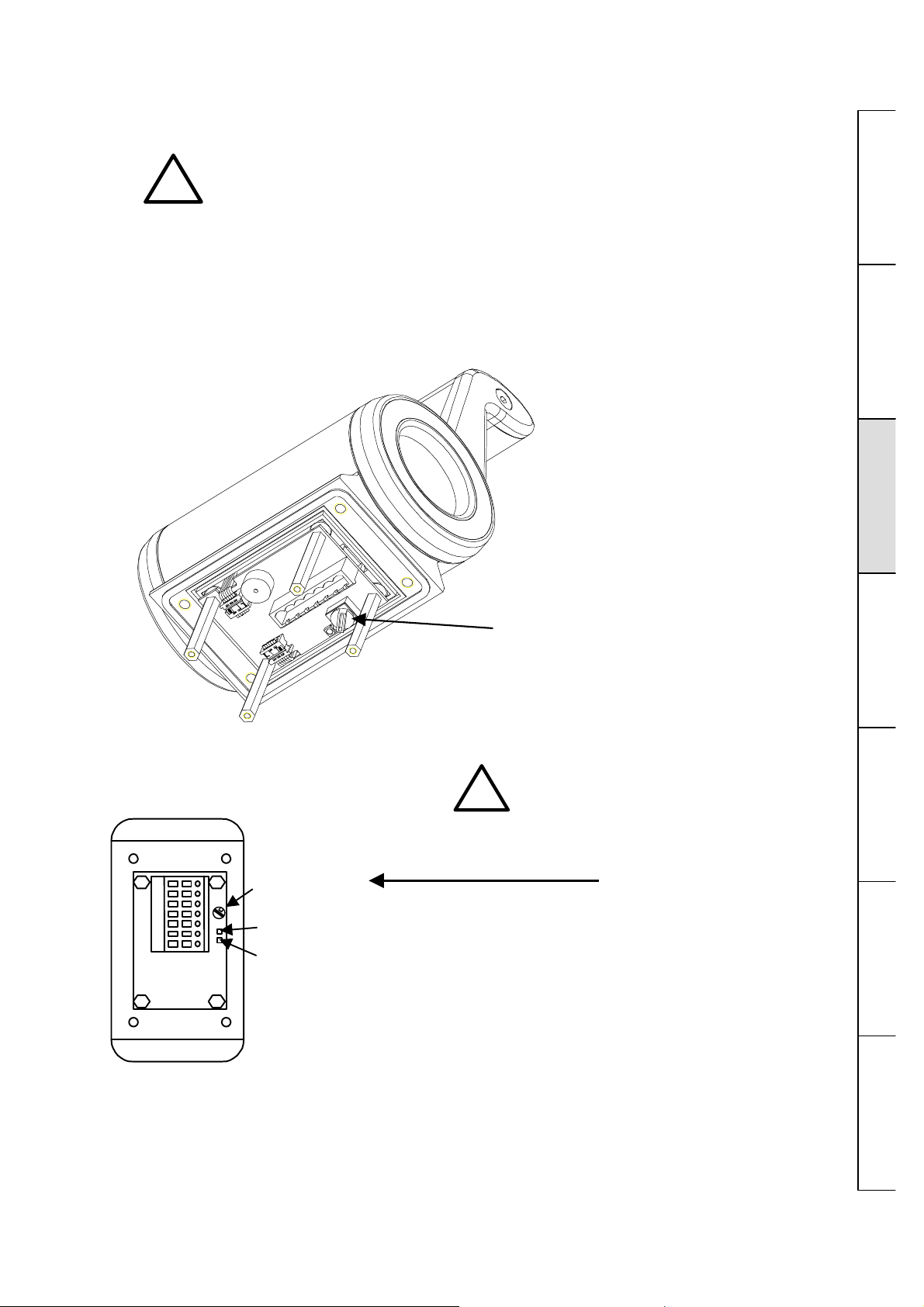

1.3 Mounting advice

Cables to be connected to the control unit must always be provided with the metallic cable joints

supplied. The joints are mounted as shown below:

GeneralOverviewWiringAdjustment

shielded cable

sleeving

conductors

outside cone Inserted sealing

Mounting work must be done only if the system is in voltage-free condition. The power supply must be

secured against activation in this case.

Mounting and commissioning work must be carried out by skilled personnel and in accordance with

the manual only.

pressure screw

cable

1.4 Operating advice

Do not reach into the actuator while it is in operation. You risk injuring.

The remote control MAREX SB has been designed for the control of Diesel engines. If it is applied for

petrol or gas propulsion systems, its components must be installed outside the hazardous area. The

instructions for hazardous areas have to be followed.

Operation

Error AnalysisAppendix

Page 6

2 Overview

2

2

General Overview Wiring Operation Error Analysis

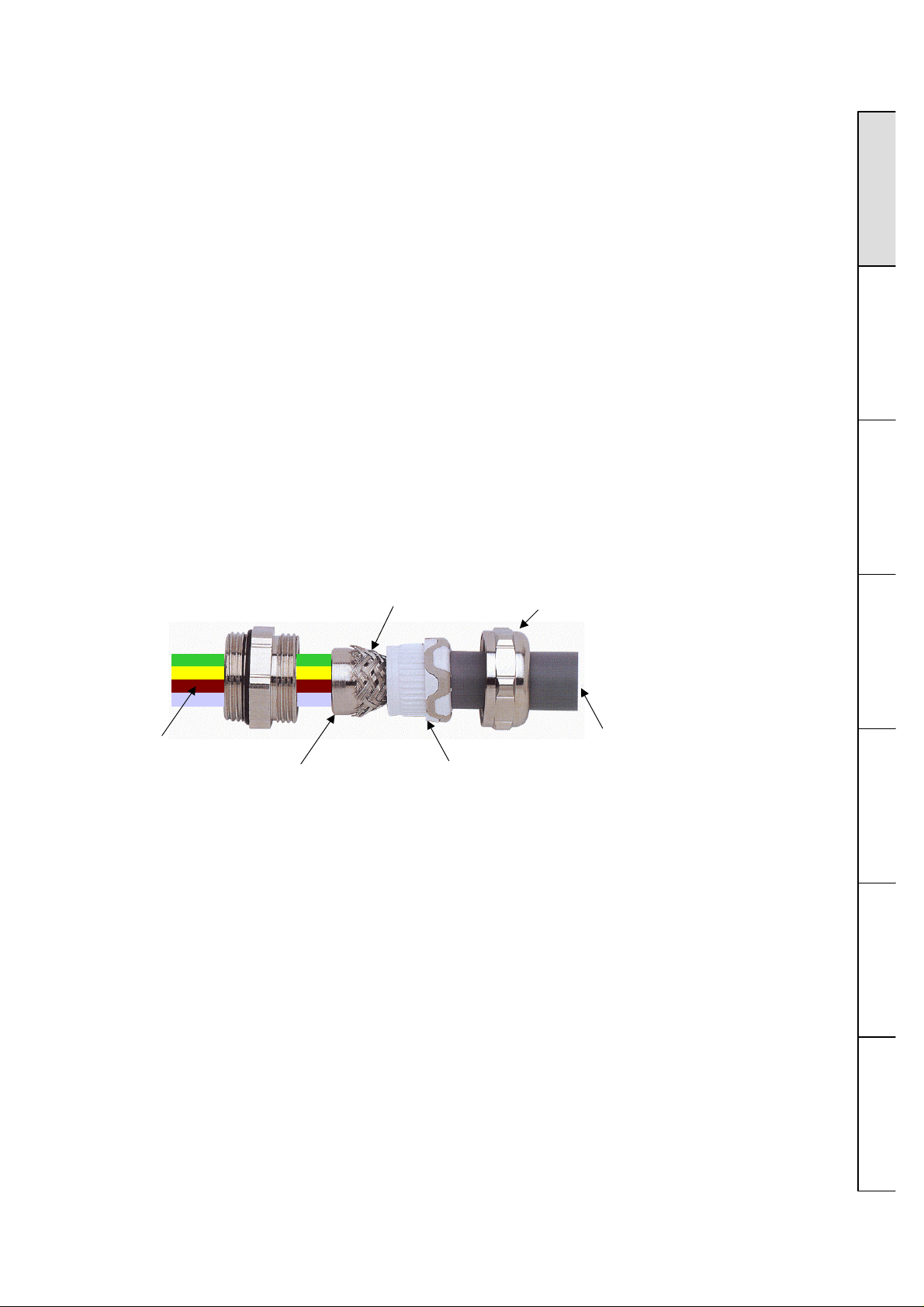

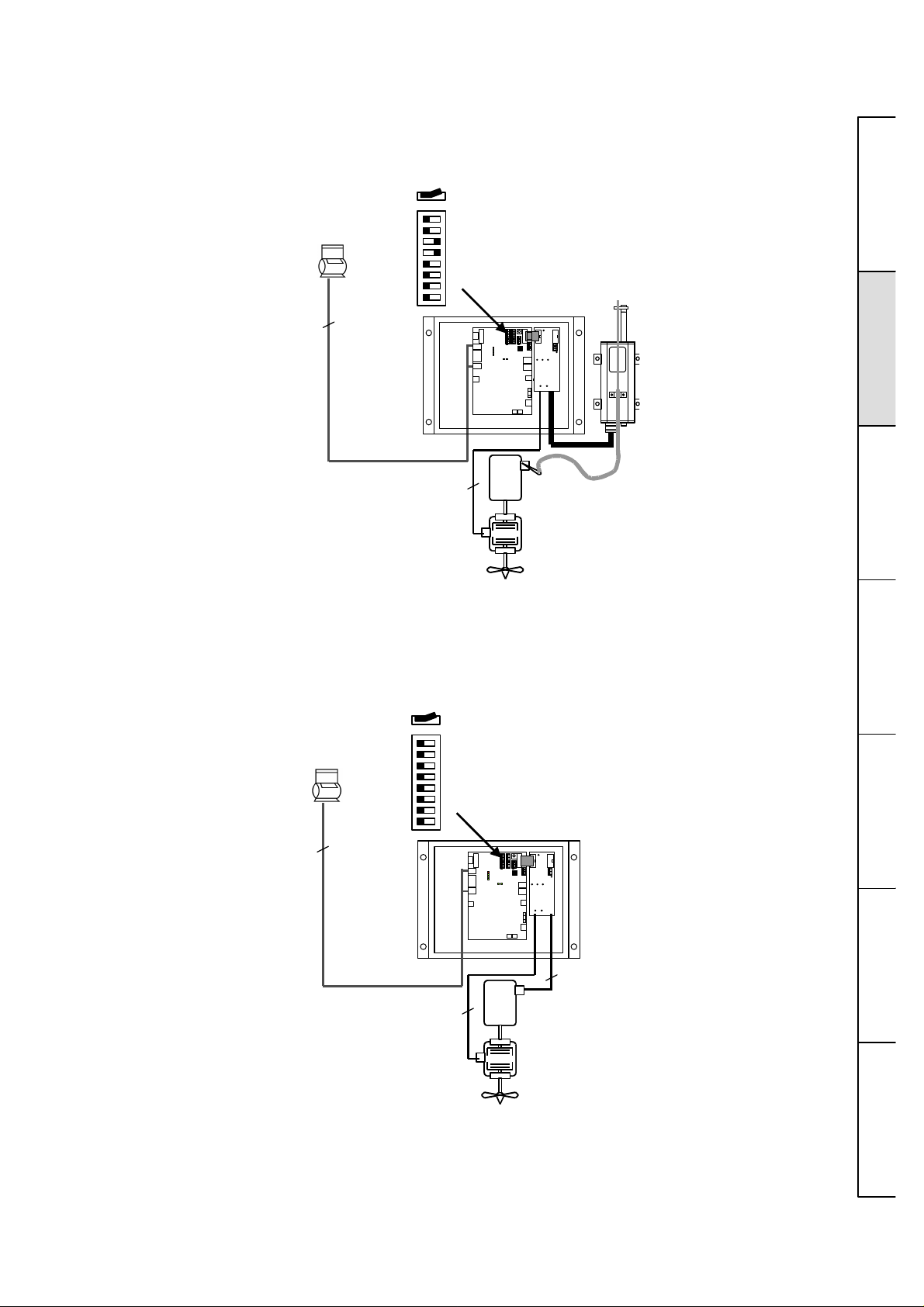

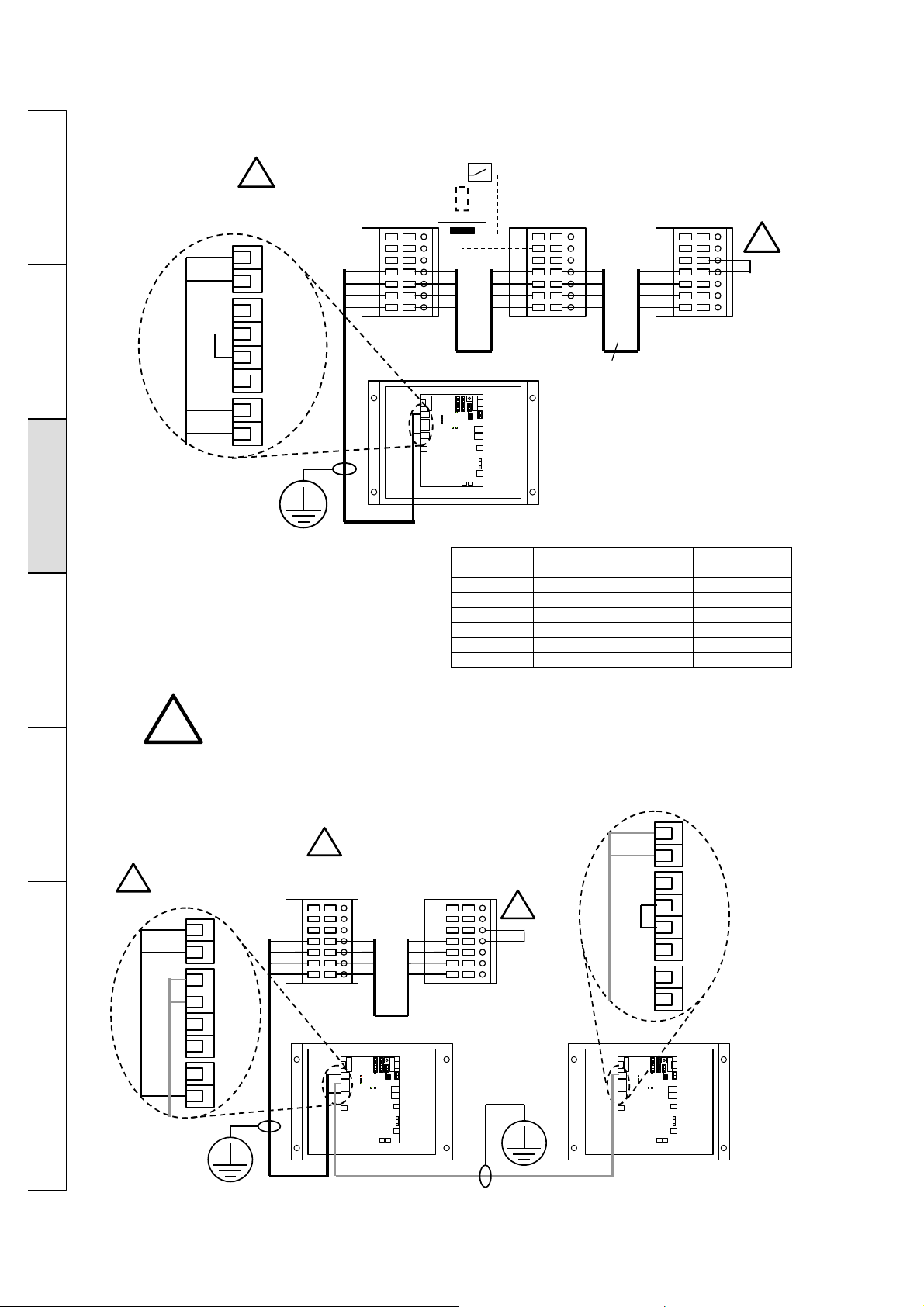

2.1 Single engine

Single engine – mechanical throttle control and gear shifting

Throttle and gear shifting are operated by mechanical rods.

shielded cable

type LIYCY

4 x 1 mm

3

1

1

SYSCON

2

3

4

5

6

7

8

S1 S2

Adjustment

Single engine - electrical throttle control, mechanical gear shifting

The throttle is adjusted electrically (4 ... 20 mA), the gears are shifted by mechanical rods.

shielded cable

type LIYCY

4 x 1 mm

S1

70 mm

100 N

1

1

2

3

4

5

6

7

8

SYSCON

70 mm

100 N

4...20 mA

shielded cable

type LIYCY

2 x 0,75 mm

2

Appendix

70 mm

100 N

Page 7

4

2

Single engine - mechanical throttle control, electrical gear shifting

Throttle is actuated by mechanical rods, gear shifting is controlled by 24 V-signals.

1

1

SYSCON

2

3

4

5

6

7

8

shielded cable

type LIYCY

4 x 1 mm

2

A2

General

OverviewWiringAdjustmentOperationError AnalysisAppendix

shielded cable

type LIYCY

7 x 1 mm

2

70 mm

100 N

24 V

Single engine – electrical throttle control and gear shifting

Throttle is adjusted electrically (4 ... 20 mA), the gears are shifted using 24 V-signals.

1

1

SYSCON

2

3

4

5

6

7

8

shielded cable

type LIYCY

4 x 1 mm

shielded cable

shielded cable

type LIYCY

7 x 1 mm

type LIYCY

2 x 0,75 mm

4...20 mA

2

2

24 V

Page 8

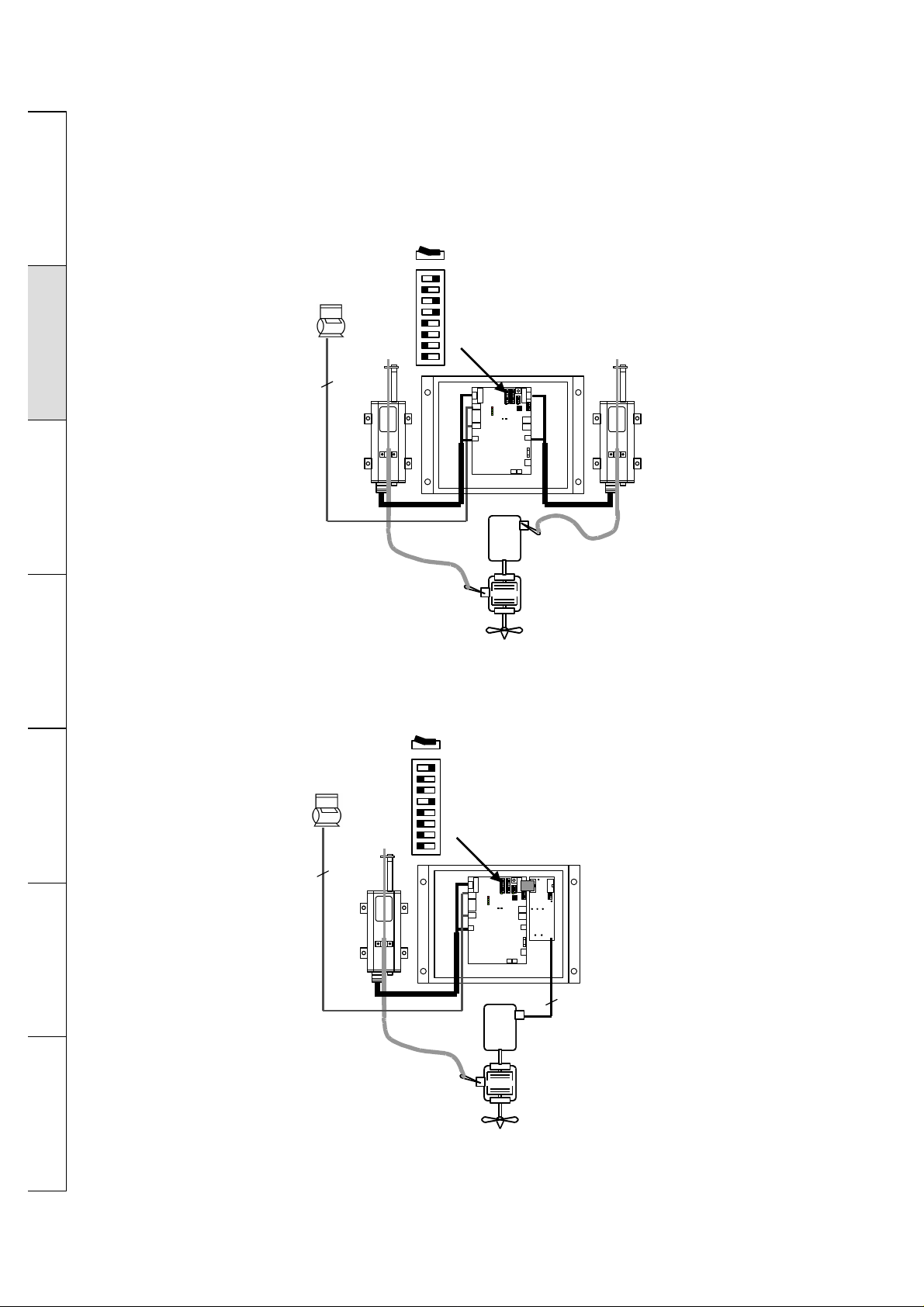

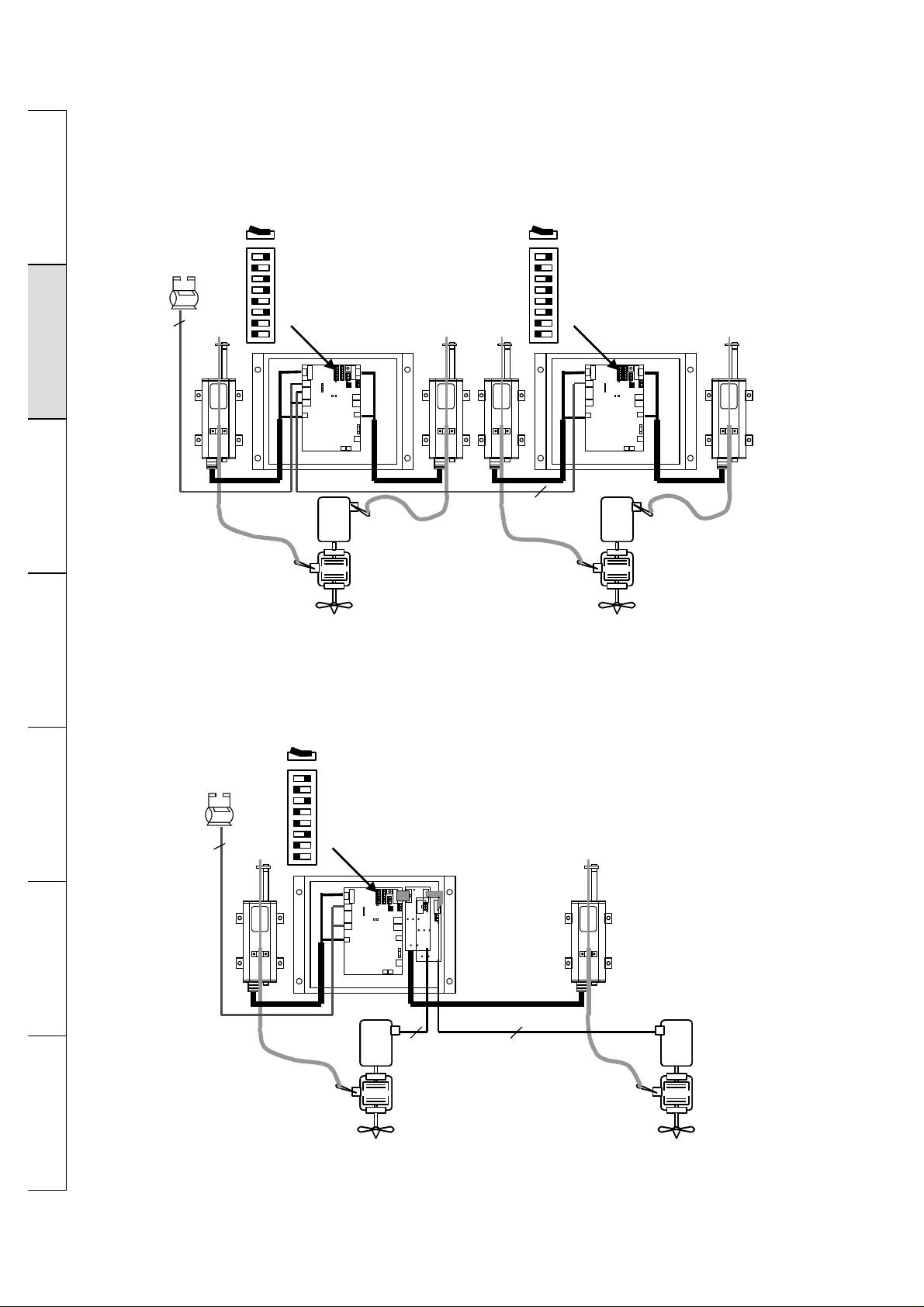

2.2 Twin engine

5

General

Twin engine – mechanical throttle control, mechanical gear shifting

Throttle and gear shifting are controlled by mechanical rods.

Overview

shielded

type LIYCY

4 x 1 mm

Wiring

Adjustment

cable

1

1

SYSCON SYSCON

2

3

4

5

6

7

8

2

A1 A2

70 mm

100 N

port starboard

70 mm

100 N

1

1

2

3

4

5

6

7

8

A1 A2

shielded cable

type LIYCY

2 (4) x 1 mm

70 mm

100 N

2

70 mm

100 N

Twin engine – electrical throttle control, mechanical gear shifting

Throttle is actuated electrically (4 ... 20 mA), the gears are shifted by mechanical rods.

Operation

Error Analysis

Appendix

shielded

cable

type LIYCY

4 x 1 mm

1

1

SYSCON

2

3

4

5

6

7

8

2

A1 A2

70 mm

100 N

I/O-extension board 1:

actuation rpm port

I/O-extension board 2:

actuation rpm starboard

port

1

2

4...20 mA 4...20 mA

2

shielded cable

type LIYCY

2 x 0,75 mm

shielded cable

type LIYCY

2 x 0,75 mm

starboard

2

70 mm

100 N

Page 9

6

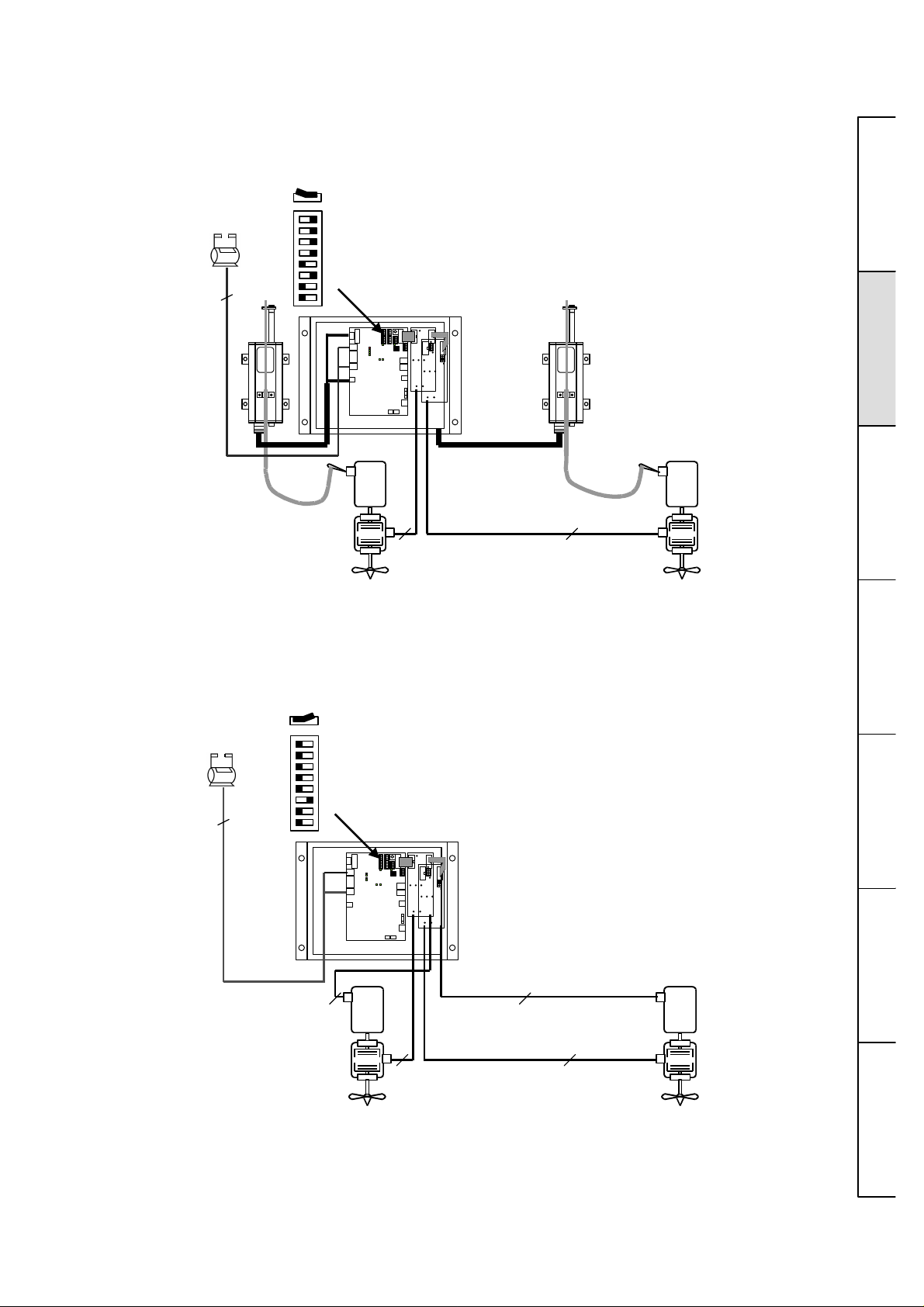

Twin engine – mechanical throttle control, electrical gear shifting

Throttle is adjusted by means of mechanical rods, gear shifting is controlled by 24 V-signals.

1

I/O-extension board 1:

actuation gearing port

I/O-extension board 2:

actuation gearing starboard

shielded

cable

type LIYCY

4 x 1 mm

1

SYSCON

2

3

4

5

6

7

8

2

A1 A2

port starboard

General

1

2

70 mm

100 N

70 mm

100 N

24 V 24 V

shielded cable

type LIYCY

2

7 x 1 mm

shielded cable

type LIYCY

7 x 1 mm

2

Twin engine – electrical throttle control, gear shifting electrical

Throttle is adjusted electrically (4 ... 20 mA), gear shifting is operated by 24V-signals.

shielded

cable

type LIYCY

4 x 1 mm

1

1

SYSCON

2

3

4

5

6

7

8

2

port starboard

I/O-extension board 1:

actuation gearing port

actuation rpm port

I/O-extension board 2:

actuation gearing starboard

actuation rpm starboard

OverviewWiringAdjustmentOperationError AnalysisAppendix

shielded cable

type LIYCY

2 x 0,75 mm

1

2

4...20 mA 4...20 mA

shielded cable

2

type LIYCY

2 x 0,75 mm

2

24 V 24 V

shielded cable

type LIYCY

2

7 x 1 mm

shielded cable

type LIYCY

7 x 1 mm

2

Page 10

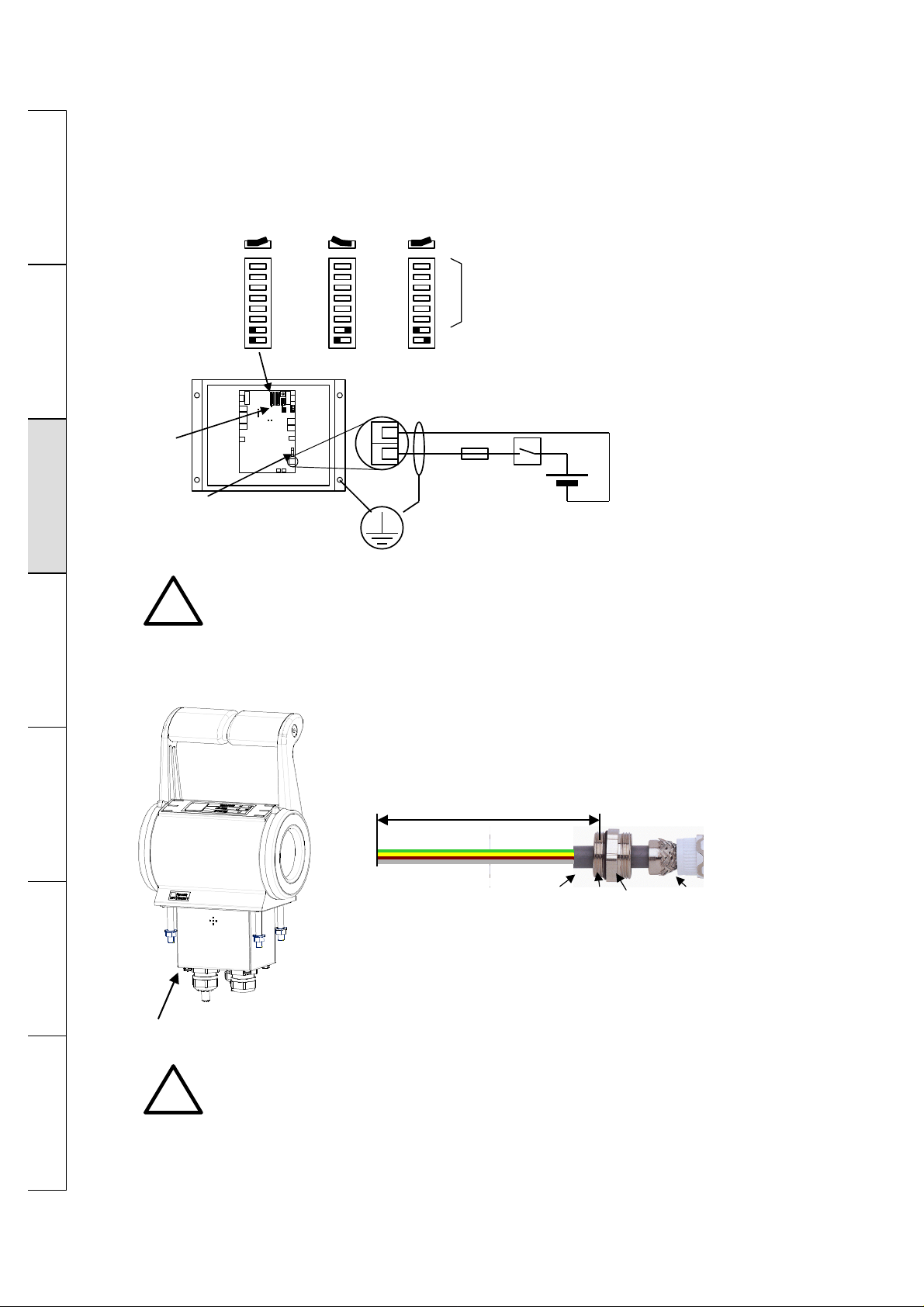

3 Wiring

7

General

3.1 Voltage supply

Overview

LED -

Wiring

readyness

Adjustment

fuse

10A T

voltage

12...24 V DC

7

1

2

3

4

5

6

7

8

voltage

12 V DC

voltage

24 V DC

7

1

2

3

4

5

6

7

8

2

1

7

1

2

switch for configuration

3

of engine type

4

(see chapter 2 overview)

5

6

7

8

supply line 2,5mm2,

length. 10m max

GND

screened

Vcc

fuse

16A T

earthing at one of the 4 mounting screws directly

(connection to ship mass)

main

switch

+

-

12V / 24V DC

10 A nominal current

30 A peak current

(acc. to Lloyds Register)

For systems approved by classification societies, the voltage range 12V or has to

be selected. If the supply voltage exceeds or falls below the range by +30% or -

!

25% respectively, a corresponding error message will be issued.

3.2 Control head

Advice how to mount the connecting cable

Operation

Error Analysis

loosen screws and

lift housing cover

Appendix

preparation

connection cable

100 mm

male

taper

shieldedcable

sleeving

sealing

insert

pressure

screw

The data cable must be prepared as shown above. The cables must not be

squeezed when assembling the components after the wiring.

!

The sealing of the housing must be fitted correctly to guarantee protection type

IP65.

Page 11

8

Adjustment

ID (1...6)

bottom side control head

adjustment

ID (1...6)

LED

power supply

ok

LED

communication

ok

On every control head, an individual

once.

Entering the identification (ID)

To enable the control to identify the control heads, an individual ID must be

!

To enter the ID, the housing cover must be removed.

entered once at every control head (e. g. control head bridge ID 1, control head

port ID 2, control head starboard ID 3)

ID 0 is not admissible.

à This procedure is not necessary, if the automatic ID setting is used. (Chapter

4.2)

General

OverviewWiring

starboard side

X1

7

6

5

4

3

2

1

port side

ID must be entered

ID 0 is not admissible.

Adjustment

!

OperationError AnalysisAppendix

Page 12

Wiring control head

9

General

Overview

Wiring

Terminal assignment control head

Adjustment

!

gb

gr

br

ws

screened line

grounded at both ends

1

2

1

2

3

4

1

2

The IDs of the control heads

must be different.

control head

7

6

5

gr

4

gb

3

br

2

ws

1

ID 1

optional switch: station tranfer interlock

(required for ECR stations according to classification rules)

gr

gb

br

ws

control head

ID 2

7

6

5

4

3

2

1

7

6

5

gr

4

gb

3

br

2

ws

1

screened line

(LIYCY)

2

4 x 1 mm

total length 60m max.

+

7

-

6

5

gr

4

gb

3

br

2

ws

1

gr

gb

br

ws

control head

7

6

5

4

3

2

1

Terminal Designation Colour

1 0 V white (ws)

2 +8 V brown (br)

3 CAN – yellow (gb)

4 CAN + green (gr)

5 CAN end

6 switch 7 switch +

ID 3

7

!

6

5

4

bridge

3

at last

2

head

1

Operation

Special application: twin engine with mechanical throttle control and gear shifting

remove bridge

!

Error Analysis

Appendix

terminal 2/3

gb

gr

br

ws

At the last control head, a bridge must be connected between terminals 4 and 5.

!

Example: 2 control head

The IDs of the control heads

!

must be different.

gr

gb

br

ws

control head

ID 2

7

6

5

4

3

2

1

7

!

6

5

4

3

bridge

2

at last

1

head

shielded cable

2 (4) x 1 mm

earthed at both ends

2

control head

ID 1

7

1

2

gb

1

gr

2

3

4

1

2

6

5

gr

4

gb

3

br

2

ws

1

7

6

5

gr

4

gb

3

br

2

ws

1

port starboard

gb

gr

1

2

1

2

3

4

1

2

shielded cable

2

4 x 1 mm

earthed at both ends

Page 13

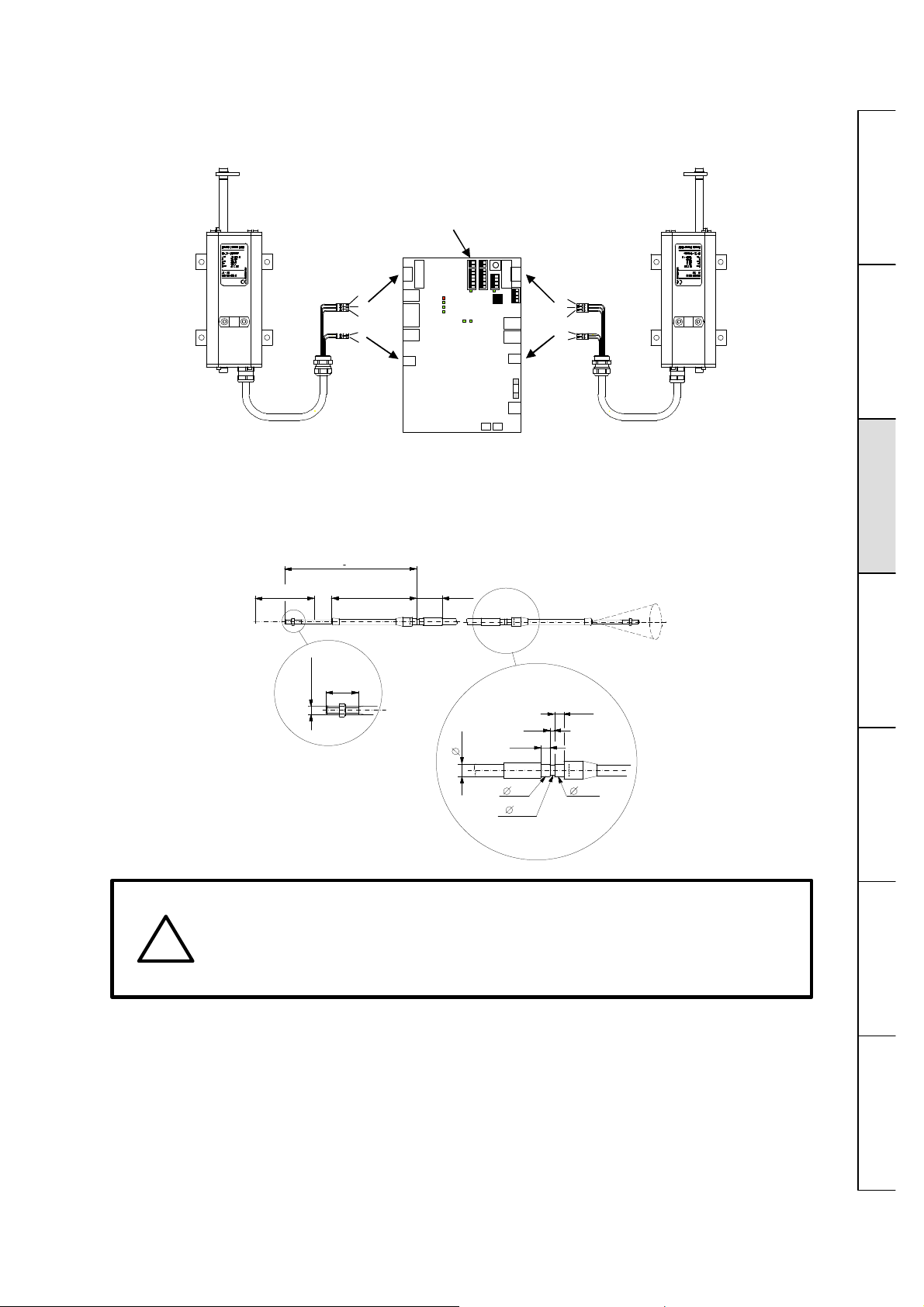

3.3 Mechanical throttle control and gear shifting

10

actuator 1

SYSCON

1

2

3

1

2

3

2

1

2

1

actuator 2

The setting of switchboard SYSCON (switches 1 – 6) assigns the function (speed or gear control) to

the actuators (see chapter 2 overview).

3.3.1 Push-/pull-cable

The mechanical connection between actuator and lever for throttle adjustment or gear control at the

engine is done by push-/pull-cables.

76 stroke

170

+

for half the stroke

3

110

33 max

General

OverviewWiring

**

22,1

10-32 UNF-2A

radial excursion: 8° max. to all sides

**

min 5

3,27

8,5

min 5

9,46

6,35

9,46

Adjustment

OperationError AnalysisAppendix

When laying push-/pull cables as few direction changes as possible should be

made. The efficiency of the cables decreases with every deflection.

!

Deflection angle 90° usable force = 82% of the force applied

Deflection angle 360° usable force = 55% of the force applied

Page 14

3.3.2 Mounting of the actuator

General

Overview

3.3.3. Connection at the throttle and gear adjusting lever

To fix the push-/pull-cable at the adjusting lever, a ball joint may be used.

11

Mounting work may only be carried out if the actuator

is idle.

!

Risk of injury!

Wiring

Adjustment

Operation

counter bearing

!

ball joint

"s"

hexagone nut

When adjusting the traveling range of the actuator (stroke), it must be ensured

that both markings remain visible in the end positions.

The travel may not be blocked by exterior mechanical stops. Misadjustment may

lead to blocking and distruction of the electric actuators.

stroke 70 mm

Error Analysis

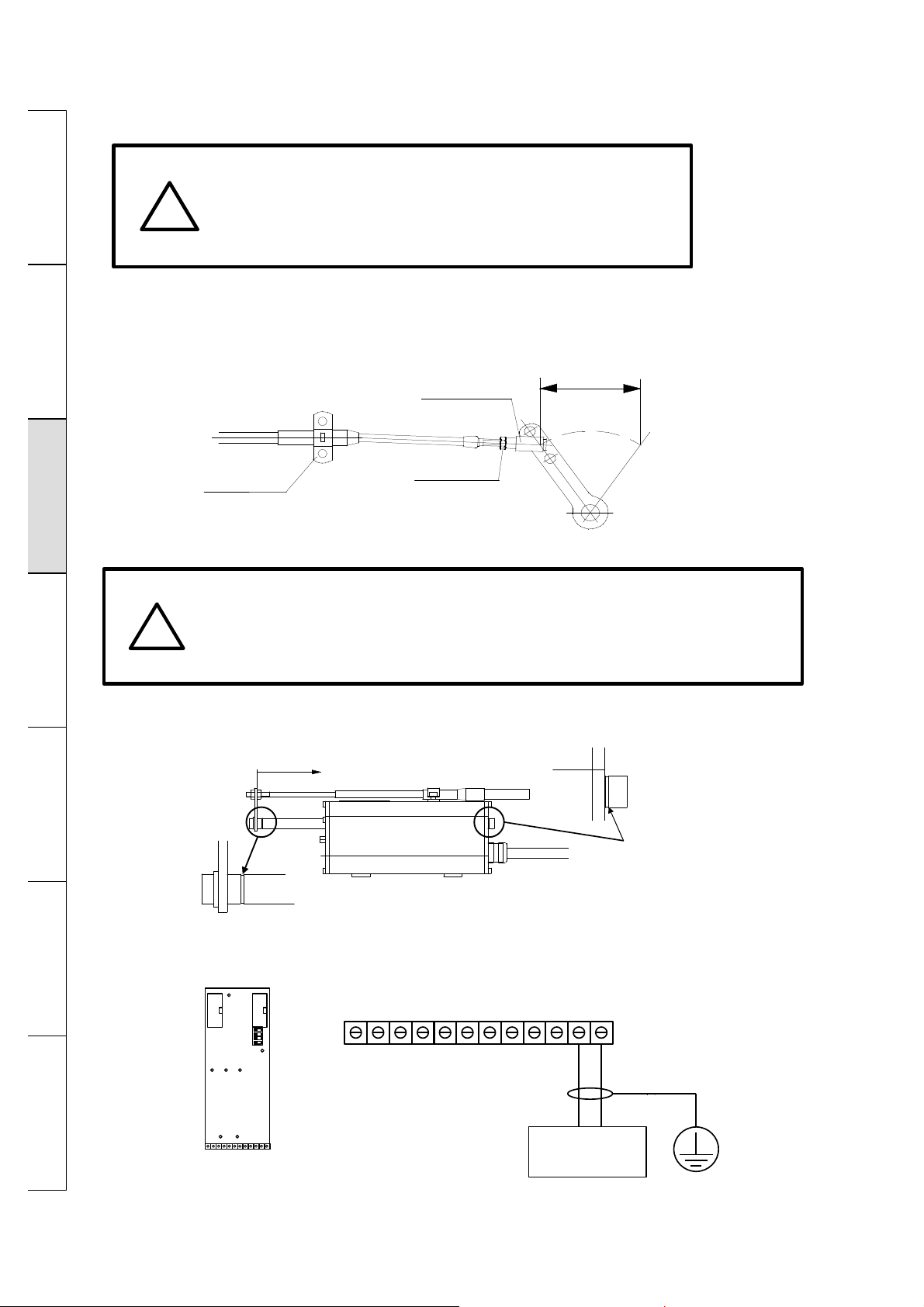

3.4 Electrical throttle control and gear shifting

Electrical throttle control

Appendix

1

2

3

4

71 72 73 74 75 76 77 78 79 80 81 82

+ -

4...20 mA

galvanically separated

(max. 500 Ohm)

ECU, EDC

E

ngineControlUnit

E

ngineDigitalControl

shielded cable

Typ:LIYCY

2 x 0,75 mm

earthed at both ends

2

Page 15

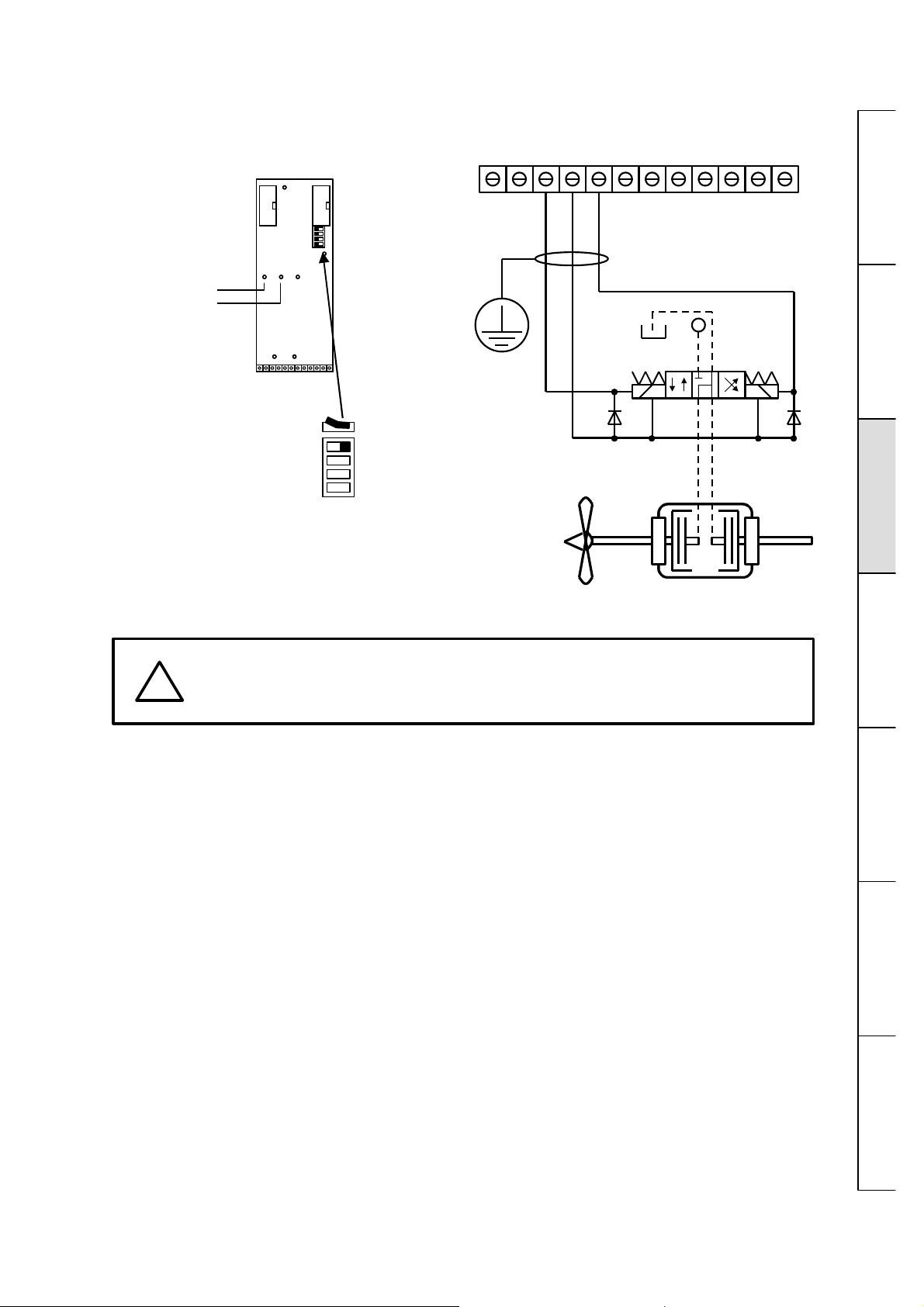

Electrical gear shifting without feedback

12

Indication gear condition

screened cable

1

1

2

2

3

3

4

4

LED set ahead (73)

LED set astern (75)

1

1

gear feedback off

2

3

4

Solenoid valve not included in MAREX SB delivery.

The power supply for the gearbox must be fused separately.

An emergency manual override for gear shifting must be provided.

type LIYCY

7 x 1 mm

grounded at both ends

71 72 73 74 75 76 77 78 79 80 81 82

2

ahead

Vcc, 2A

solenoid valve

relay with

free-wheeling diode

reversing gearbox

astern

Vcc, 2A

General

OverviewWiring

!

If not, the digital output may be destroyed.

Adjustment

OperationError AnalysisAppendix

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

Page 16

General

Indication gear condition

13

Electrical gear shifting with separate feedback

71 72 73 74 75 76 77 78 79 80 81 82

LED set ahead (73)

LED set astern (75)

Overview

LED act. astern (78)

LED act. astern (76)

Wiring

Solenoid valve and pressure switch are not included in the MAREX SB delivery.

The power supply for the gearbox must be fused separately.

An emergency manual override to shift gears must be provided.

Adjustment

screened cable

type LIYCY, 7 x 1 mm

1

1

2

2

3

3

4

4

grounded at both ends

2

Voraus

Vcc, 2A

Zurück

Vcc, 2A

solenoid valve

with free-wheeling diodes

1

1

2

3

gear feedback on

sep. feedback on

pressure switch

4

reversing gearbox

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

!

If not, the digital output may be destroyed.

Electrical gear shifting with collective feedback

Indication condition gearbox

Operation

LED set ahead (73)

LED set astern (75)

LED collective-

feedback (76)

Error Analysis

Solenoid valve and pressure switch are not included in the MAREX SB delivery.

Appendix

The power supply for the gearbox must be fused separately.

An emergency manual override to shift gears must be provided.

71 72 73 74 75 76 77 78 79 80 81 82

screened cable

type LIYCY, 7 x 1 mm

1

1

2

2

3

3

4

4

grounded at both ends

2

Voraus

Vcc, 2A

Zurück

Vcc, 2A

solenoid valve

with free-wheeling diodes

1

1

2

3

gear feedback on

sep. feedback off

pressure switch

4

reversing gearbox

!

If not, the digital output may be destroyed.

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

Page 17

Power supply for electrical gear shifting

fuse

2A T

71 72

14

1

2

3

4

General

OverviewWiring

+

-

Vcc GND

supply line 2 x 1 mm2,

length max. 10m

The power supply shown above is recommended according to the classification rules.

Alternatively, the control unit may supply the voltage for the electrical gear control:

1

2

3

4

1

2

3

4

Adjustment

OperationError AnalysisAppendix

!

1 2

When the control unit supplies the voltage for the electrical gear control, the power

supply is not protected by fuse. In this case, the control unit must be protected

!

separately (see chapter 3.1 "power supply").

71 72

Vcc GNDVcc GND

Page 18

Mounting the I/O-extension boards

General

Overview

Wiring

1

2

viewing direction

15

X101 X102

2

I/O-extension board II (actuation starboard )

Adjustment

3.5 Alarm relays

Operation

Error Analysis

X31

control unit

LED alarm relay

X101 X102

1

I/O-extension board I (actuation port )

potential-free

2

relay contact

1

closed in case

of error

2

1

max. 30 V DC

max. 0,5

shielded cable

type LIYCY

2 x 0,75 mm

earthed at both ends

2

Appendix

!

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

If not, the digital output may be destroyed.

Page 19

3.6 Engine start interlock

16

single engine

supply battery

+

-

engine

+

-

shielded cable

type LIYCY

2 x 0,75 mm

starterbattery

2

twin engine

+

-

engine

port

connection

I/O-extension board 1

to

1

+

engine

connection

I/O-extension board2

+

-

starboard

configuration

start interlock

2

1

2

3

2

4

shielded cable

LIYCY

type

2 x 0,75 mm

+

-

to

2

The relay "start interlock" is closed whenever the active control head is in neutral or warming up (see

5.4 "warming up") is active.

Wiring control unit

engine start interlock via control unit

2

1

max. 30 V DC

max. 0,5

potential-free

relay contact

when

closed ,

lever in neutral or

warming up active

2

1

General

OverviewWiring

LED start interlock

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

!

If not, the digital output may be destroyed.

Wiring I/O-extension board

configuration

start interlock

2

1

2

3

4

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

If not, the digital output may be destroyed.

!

LED start-

interlock

1

2

3

4

shielded cable

type

LIYCY

earthed at both ends

71 72 73 74 75 76 77 78 79 80 81 82

shielded cable

type

2 x 0,75 mm

earthed at both ends

LIYCY

Adjustment

OperationError AnalysisAppendix

potential-free

relay contact

max. 30V DC

max. 2 A

2

closed when,

lever in neutral or

Warming Up active

Page 20

17

2

-

General

Engine start interlock, special application 1:

Twin engine with mechanical throttle control and gear shifting

Overview

Wiring

Adjustment

Two special cases must be considered when wiring the engine start interlock

!

1

1

2

3

4

5

6

7

8

A1 A2

port starboard

+

-

engine

port starboard

shielded cable

type

LIYCY

2 x 0,75 mm

+

-

1

1

2

3

4

5

6

7

8

A1 A2

shielded cable

LIYCY

2

engine

+

-

type

2 x 0,75 mm

+

-

2

Engine start interlock, special application 2:

Operation

Using the function "idle gas relay" on twin engines

Error Analysis

Appendix

configuration

idle gas relay

2

1

engine

2

3

4

+

-

+

Starterbattery

1

+

-

supply battery

+

-

engine

port starboard

+

-

Starterbattery

Engine start interlock will be released if both levers of the control heads (port and

starboard) are in neutral position or warming up is active.

!

Page 21

18

3.7 Idle gas relay

Single Engine Twin Engine

1 1

General

2

idle gas

idle gas port idle gas starboard

The idle gas relay is closed when the lever of the active control head is in neutral or in 1st detent

ahead/astern.

Wiring I/O-extension board

potential-free

relay contact

1

2

3

4

LEDidle gas

2

1

2

3

4

relay function : idle gas

71 72 73 74 75 76 77 78 79 80 81 82

shielded cable

LIYCY

type

2 x 0,75 mm

earthed at both ends

max. 30V DC

max. 2 A

2

If inductive loads shall be switched, these must be provided with a free-wheeling diode.

!

If not, the digital output may be destroyed.

closed when,

lever in neutral or in

1. detent ahead/astern

OverviewWiring

Adjustment

When the function "idle gas" is applied, the relay on the I/O-extension board is not

available for the function "engine start interlock".

!

OperationError AnalysisAppendix

Page 22

4 Adjustment

alignment

0

1

2

3456789ABCD

E

F

General

4.1 Hardware configuration

Possibilities of adjusting the control unit

Overview

Wiring

SYSCON

1

2

configuration of system type

3

see chapter 2 "overview"

4

5

6

set voltage supply

7

see chapter 3 "wiring" -

8

3.1"voltage supply"

19

see chapter 4.4 "gearing"

TIME

1

delay time before clutch

2

3

delay time after clutch

4

5

6

reversing delay time

7

8

PARSEL

CTRHEAD

setting of parameters

see

chapter 4.3 "speed"

chapter 4.4 "gearing"

see chapter 4.2 "control head"

1

buzzer in neutral

2

range / / position comparision

3

synchronisation

4

Adjustment

The function of the switch board SYSCON (system configuration) is described in chapters 2 "overview

", 3 "wiring" and 3.1 "power supply".

The switch board TIME defines the delay times for the gear shifting. The function is described in

Operation

chapter 4.4.

By the switches PARSEL (parameter selection), parameters are adjusted as e. g., for mechanical

throttle control, idle and nominal speed and, for mechanical gear shifting, the gear positions ahead

and astern. In addition, parameters for special functions are preset (see chapter 4.3 "speed", 4.4.

"gearing").

The switchboard CTRHEAD (control head) determines the function of the control head (described in

chapter 4.2 "control head").

Error Analysis

Possibilities of adjusting the I/O-extension board

1

2

3

4

Appendix

The hardware is configurated by means of the switchboard SYSCON. The position

of the switches can be changed only in deactivated condition.

!

IOCONF

1

gears with/without feedback (see chapter 3.4)

2

start interlock/idle gas (see chapter 3.6/3.7)

3

gear feedback double/single (see chapter 3.4)

reserved

4

4

!

The I/O-extension board will only function

correctly, if switch 4 is in the position described.

The switchboard IOCONF (I/Oconfiguration) defines the function of

the electrical in-/outputs. They are

described in chapter 3 "wiring" in the

respective paragraph.

Switch 4 must be in the position as

shown here.

Page 23

20

4.2 Control head

Introducing the control heads

In order to inform the control about the number of control heads connected, these must be introduced.

For twin engine controls with mechanical throttle control and gear shifting, the procedure has to be

carried out at the portside system. The following steps have to be completed:

Step Action Diagram

1 Activation of the control

General

2 CTRHEAD switch 1 to close

(With two control units, only the port unit must be

adjusted.)

CTRHEAD

1

1

2

3

4

3 Wait 3 seconds

4 CTRHEAD switch 1 to open

(With two control units, only the port unit must be

adjusted.)

CTRHEAD

1

1

2

3

4

All control heads connected must be in condition "lamp test" (see chapter 5.2 "activation and request

of control station").

Special case "automatic ID-setting"

If automatic ID-setting shall be applied, the software versions stated below must be provided for

control unit and heads:

Control unit: MSB V2.00 or higher

Control head: MSKG V2.00 or higher

With this feature, it is no longer necessary to define an ID at every control head as the system

assignes IDs automatically to all heads connected.

OverviewWiring

Adjustment

After the automatic setting of control head IDs, it is no longer possible to combine control

!

heads with software below V2.00 with heads providing a higher software version.

Operation

Error Analysis

Appendix

Page 24

Procedure for automatic ID-setting

21

General

Step Action Diagram

Overview Wiring

Adjustment

1 Activate control.

2 Hold down switch S1.

switch S1

3 Shift CTRHEAD switch 1 to close.

1

CTRHEAD

1

2

3

4

4 Do not further operate switch S1.

Operation

5 The control head buzzers sound at short intervals.

Error Analysis

6 Press the keys of the control heads one after another.

7 Signals after one keystroke:

Appendix

In addition, the control head LEDs are active (see step

6) and flash in the same frequency as the buzzer.

The buzzer stops.

The ID which was stored is indicated by the LEDs of

the control head.

The LEDs flash slowly.

switch S1

key

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

Page 25

ID Indication

LED off

LED steadily lighted

LED flashing

22

no ID assigned

no automatic ID set yet

ID 1 ID 2 ID 3 ID 4

ID 5

8 Shift CTRHEAD switch 1 to open.

1

CTRHEAD

1

2

3

4

Buzzer in neutral

When the lever of the active control head is moved to neutral, a short buzzer sound can signal this.

Short sound, when lever in neutral

(With two control units, only the port unit must be adjusted.)

No sound (default condition)

(With two control units, only the port unit must be adjusted.)

CTRHEAD

CTRHEAD

2

1

2

3

4

2

1

2

3

4

General

OverviewWiring

Adjustment

Comparision of positions/ cruising ranges

Compare position

A change of control stations is possible only, if the lever of the

new control station is set in the same cruising range (ahead,

neutral, astern) and in the same position (maximum deviation

30%) as the lever of the active control station. According to the

classification rules, this mode has to be selected.

(With two control units, only the port unit must be adjusted.)

Compare range

A change of control stations is possible only, if the lever of the

new control station is set either in the same cruising range

(ahead, neutral, astern) as the lever of the active control station

or in neutral position.

(With two control units, only the port unit must be adjusted.)

CTRHEAD

CTRHEAD

3

1

2

3

4

3

1

2

3

4

Operation

Error Analysis

Appendix

Page 26

Synchronising

23

General

Synchronising active

If the lever positions of the port and starboard control heads

deviate at 10% maximum, the same nominal value will be

preset automatically.

No synchronizing (default condition)

Overview Wiring

4.3 Speed setting

Generally, the parameters for speed setting can be set when the active control head is in neutral

position. Idle speed, power boost and increased idle speed can also be set when the lever position is

1st detent ahead or astern. The nominal speed parameters may also be set when the lever position is

full ahead or full astern.

For system configurated with 2 control units (mechanical throttle adjustment and gear shifting) each

unit must be set separately.

Step Action Diagram

Adjustment

Initial condition

1

Activation of control, command active, lever in neutral

or 1st detent ahead/astern

LED Setup

off

CTRHEAD

CTRHEAD

4

1

2

3

4

4

1

2

3

4

1

PARSEL

1

2

3

4

2

Operation

Error Analysis

Appendix

Selection of the parameter to be adjusted

Idle speed

PARSEL Turn switch to position 1

or

Nominal speed

PARSEL Turn switch to position 2

or

Power boost

PARSEL Turn switch to position A

Increased idle speed

PARSEL Turn switch to position B

0

1

F

2

E

3

D

C

C

C

C

4

5

B

6

A

789

0

1

F

2

E

3

D

4

5

B

6

A

789

0

1

F

2

E

3

D

4

5

B

6

A

789

0

1

F

2

E

3

D

4

5

B

6

A

789

Page 27

Selection of the system for which speed

3

parameters shall be set

for single engines

or twin engines: port system

for twin engines: starboard system

During step 4, it is possible the engine revolutions adjust automatically.

24

PARSEL

PARSEL

2

1

2

3

4

General

2

1

2

3

4

!

Change to SETUP-mode

4

The selected position will be reached. The LED Setup

will be activated.

Adjustment of speed

5

Direction +

Parameter will be adjusted as long as the key is

pushed.

Direction –

Parameter will be adjusted as long as the key is

pushed.

Storing of parameter

6

Change to RUN-mode.

LED Setup will be deactivated.

LED Setup

on

LED Setup

off

PARSEL

PARSEL

PARSEL

4

1

2

3

4

direction +

1

2

3

44direction -

PARSEL

OverviewWiring

1

1

2

3

4

Adjustment

1

1

2

3

4

Operation

When modifying the parameters "power boost" or "increased idle speed", the

maximum speed for clutch engagement (see instructions of the gearing

!

manufacturer) must be considered.

Error Analysis

Appendix

Page 28

4.4 Gearing

25

General

Positions for actuating the mechanical gear shifting

The push-/pull-cables at the actuators must be mounted in such a way that

the neutral position of the gear system is actuated when the active lever is placed in neutral. For

systems configurated with 2 control units (mechanical throttle control and gear shifting) each control

unit must be set separately.

Overview Wiring

Step Action Diagram

Adjustment

If the gearing is operated mechanically, the positions ahead and astern must be

pre-adjusted. When doing so, the engines should be turned off.

!

The adjustment is possible only with the active control head lever in neutral

position or if the active lever is in the position that corresponds to the gearing

position which shall be adjusted (e. g. lever in ahead if gear position ahead needs

to be adjusted).

Initial condition

1

Activation of control, command active, lever in neutral

or ahead, if gear position "ahead" has to be adjusted

or lever in astern if gear position "astern" needs to be

adjusted.

LED Setup

off

PARSEL

1

1

2

3

4

2

Operation

Error Analysis

3

Appendix

Selection of the parameter to be adjusted

Ahead

Turn PARSEL-switch to position 4

Neutral

Turn PARSEL-switch to position 5

Astern

Turn PARSEL-switch to position 6

Selection of the system for which the parameters

for gear actuation shall be set

for single engines

or twin engines: portside gear system

for twin engines: starboard gear system

E

D

C

B

A

E

D

C

B

A

E

D

C

B

A

PARSEL

PARSEL

0

1

F

2

3

4

5

6

789

0

1

F

2

3

4

5

6

789

0

1

F

2

3

4

5

6

789

2

1

2

3

4

2

1

2

3

4

Page 29

During step 4, it is possible that the gear position adjusts automatically, the driving

engine should therefore be turned off.

!

Change to SETUP-mode

4

The selected position will be reached.

LED Setup will be activated.

Adjusting the gear position

5

Direction +

Position is adjusted as long as the key is pushed.

26

LED Setup

on

PARSEL

4

1

2

3

4

PARSEL

direction +

1

1

2

3

4

General

OverviewWiring

Direction –

Position is adjusted as long as the key is pushed.

Storing of parameter

6

Change to RUN-mode

LED Setup will be deactivated.

LED Setup

off

PARSEL

1

2

3

44direction -

PARSEL

1

1

2

3

4

Delay times for gear shifting

The delay time before clutch engagement must be long enough to ensure that a parameterized speed

acceleration (see chapter 4.3 "speed adjustment") can be completed safely. The delay time after

clutch engagement must be long enough to ensure the gearing has shifted safely. (This is important if

there is no feedback from the gearing.) In case of a feedback signal, the "delay time after clutch

engagement" will begin only after the feedback signal has been received. The setting is evaluated only

by the portside system (for twin engines with mechanical throttle control and gear shifting).

nominal speed

delay time after clutch

power boost

idle speed

1

delay time before clutch

2

3

delay time after clutch

4

5

6

reversing delay time

7

8

TIME

Adjustment

Operation

nominal position gearing

ahead

delay time before clutch

0,0 s 0,5 s 1,0 s 1,5 s

1 1 1 1

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

delay time before clutch

1

2

3

4

5

6

7

8

time

time

delay time after clutch

0 s 1 s 2 s 3 s

3 3 3 3

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Error Analysis

1

2

3

4

5

6

7

8

Appendix

Page 30

General

27

Conditions when reversing from ahead to astern:

When reversing from ahead to astern, the gearing is at first shifted to neutral, the shaft is disengaged

from the engine (1). As the ship continues to move ahead, the propeller is driven like a windmill by the

water streaming against it so that the shaft continues to turn. When the gears are then shifted to

astern, the engine must work against the shaft which is still turning. In an unfavourable case, the

engine might stall.

Overview Wiring

To avoid stalling the engine, the control can wait an adjustable time (reversing delay time) before

reversing. The delay time depends on the given lever position of the control head.

The reversing delay time must be determined experimentally during a sea trial. For this, the ship must

accelerate from 1st detent ahead to full ahead. The time, the ship needs to reach 2/3 of its maximum

speed, has to be preset as reversing delay time. Afterwards, reversing maneuvers need to be carried

Adjustment

out covering the full speed range.

1 gears neutral

ship -

velocity

2 gears astern

ship -

veloccity

shaft speed depends

on ship velocity

against engine speed

neutral

engine

astern

engine

engine speedshaft speed works

During the reversing maneuvers, start with a slow speed first and increase gently.

If necessary, the reversing delay time must be adjusted (lengthened, if the engine

!

revolutions drop too heavily or shortened if no deceleration of the engine speed is

recognisable.

If the reversing delay time is too short, clutch, gearing and engine may be

damaged, if it is too long, the manoeuvrability may be restricted.

Operation

Error Analysis

Appendix

nominal speed

power boost

nominal position gears

TIME reversing delay time

5

1

2

3

4

5

6

7

8

For applications with 2 control units, only the portside system must be adjusted.

idle speed

ahead

astern

0 s 1 s 2 s 3 s

1

delay time before clutch

2

3

delay time after clutch

4

TIME

5

6

7

8

reversing delay time

reversing delay time

time

time

4 s 5 s 6 s 7 s 8 s 9 s 10 s 11 s 12 s 13 s 14 s 15 s

Page 31

28

4.5 Reset to default

Resetting to default will reset the speed and gearing control values to their

!

Step Action Diagram

Initial condition

1

Activation of control, command active, lever in neutral

Selection default set-up

2

PARSEL Turn switch to position E.

Selection of the system to be reset

3

for single engines

or twin engines: portside system

delivery status. This procedure is irreversible.

A reset to default may be done only if the driving engine is turned off. In case of

mechanical controlling, the push-/pull-cables should be disconnected.

LED Setup

off

E

D

C

B

A

PARSEL

General

1

PARSEL

1

2

3

4

OverviewWiring

0

1

F

2

3

4

5

6

789

2

1

2

3

4

for twin engines: starboard system

Change to SET-UP-mode

4

Default position will be reached.

LED set-up will be activated.

Storing the default set-up

5

Change to RUN-mode.

LED set-up will be deactivated.

LED Setup

on

LED Setup

off

PARSEL

2

1

2

3

4

PARSEL

PARSEL

1

1

2

3

4

1

1

2

3

4

Adjustment

Operation

Error Analysis

Appendix

Page 32

General

COMMAND

ALARM

SYNCHRO

key

lamp

Command

lamp

alarm

lamps

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

5 Operation

5.1 General

By means of the lever position both,

speed and gear position, (ahead,

neutral, astern) are pre-set.

29

1. detent

ahead

neutral

disengaged

1. detent

astern

Overview

Wiring

The following elements are available as user interfaces:

Keys

• Command transfer

Adjustment

• Acknowledge alarm-buzzer

• Activate special functions

Command lamps

• Indication, if station is active.

Alarm lamps

• Indication, if an error exists.

Lamp synchronizing

• Indication, if synchronizing is active.

full

ahead

engaged

ahead

engaged

astern

full

astern

Operation

In case of twin control heads, the LED for

command and alarm are assigned to the

respective propulsion side.

In case of several control stations, passive stations must be distinguished from the active one. A

command can always be set only from the active control station. If a passive control station is to set

the command, a change of control station must be carried out before (see chapter 5.3).

Error Analysis

On the active control station, the command lamps are on, on the passive station they are off.

active

station

By means of an external switch (see chapter "wiring" - control

head 3.2), the command transfer can be locked. If this is the case,

Appendix

the alarm lamps at the passive control station will be active.

passive

station

COMMAND

ALARM

SYNCHRO

Page 33

30

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

5.2 Activation and request of control station

After switching on the power supply, all control heads which work correctly are in condition "lamp test"

(all lamps and buzzer on). The command can be requested from every control station by pressing the

key once. After the key has been pressed, the condition "lamp test" will end for all control heads.

On the control head on which the key has been pushed, the command lamps will flash and the buzzer

sound. The lamps flash slowly and the buzzer sounds at slow intervals when the control head lever is

not in neutral position.

By a slow flashing of the command lamp, the control head signals that the lever must be moved in

neutral position first. If the levers are already in neutral, the command lamp will flash quickly and the

buzzer sounds at high repetition. The command can be taken over by pressing the key again.

GeneralOverviewWiringAdjustment

condition:

lamp test

condition:

requesting

station

all lamps on

all lamps on permanently

push key

lever not in neutral lever in neutral

command lamp flashes slowly Command lamp flashes quickly

slow bleeping

Command lamp on permanently

fast bleeping

condition:

active

station

permanent sound

lever in neutral

push key

As soon as a control station has been activated, gear position neutral and idle speed will be selected.

The command can then be set from the active control station (see chapter 5.1).

Note for control heads twin engine:

In this case, both levers must be moved in neutral. The function of the command lamps is assigned to

the respective lever (port, starboard).

Note for possible error:

If, on a control head, the command lamps do not glow after the activation, it failed to contact the

control unit. Wiring and ID (see chapter 3.2.) need to be controlled. If necessary, the procedure of

entering the control heads into the system (see chapter 4.2) must be repeated.

If there is no functioning control head, the alarm relay will be activated.

Operation

Error AnalysisAppendix

Page 34

5.3 Station transfer

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

General

A command transfer is possible in 2 different modes. Which mode is applicable, depends on the

position of switch 3 on the switch board CTRHEAD (see chapter 4.2 control head – comparision of

range / position). Always, the key on the passive control station must be pushed to change the control

station.

Mode "compare direction"

Overview

31

condition:

passive

station

push key

condition:

requesting

station

Wiring

Adjustment

If the lever of the passive control station is placed in a range which is not admissible for command

transfer (the passive lever in astern when the active one is in ahead or neutral or the passive lever in

ahead with the active one in astern or neutral), the buzzer will sound at long intervals and the

command lamps flash at low repetition.

If the lever of the passive control station is in the correct position for a command transfer (the passive

lever in ahead or neutral when the active lever is in ahead or the passive lever in astern or neutral

while the active one is in astern), the buzzer will sound at short intervals and the command lamps

Operation

Error Analysis

flash at high repetition. By pressing the key again, the command will be taken over.

Mode "compare position"

In the mode "compare position", the position of the passive lever may deviate by 30% maximum from

that of the active control head lever. In addition the range (ahead, neutral, astern) must correspond,

before a command transfer can be carried out. It is not necessary to push the key a second time. The

transfer will be executed as soon as the lever positions are correct.

This gives the operator the possibility, after the first actuation of the key, to move the lever until the

correct range is found and the command transfers automatically. If the correct range is not found

within 30 seconds, the command transfer will be stopped.

wrong lever position correct lever position

Command lamp flashes slowly Command lamp flashes quickly

slow bleeping

condition:

active

station

fast bleeping

push key

Commandlamp on permanenly

Note for twin engines:

In case of control heads with two levers, both levers must be placed correctly before the command

Appendix

can be transferred. The function of the command lamp is assigned to the respective lever. The buzzer

will only sound at short intervals if both lever positions are correct.

According to the classification rules, the given cruising command must not change

during a command transfer. For this reason, classified ships must choose the

!

mode "compare position".

Page 35

32

COMMAND

ALARM

SYNCHRO

5.4 Warming up

By means of the special function "warming up" a determined speed can be set without gear shifting.

This function is necessary to warm up the engines.

To activate "warming up", the key must be pushed at the active control station and, at the same time,

the lever moved in ahead or astern. Then the key may be depressed again. To turn the function off,

the lever must be moved in neutral again. When doing so, the key must not be pushed.

GeneralOverviewWiringAdjustment

When the function "warming up" is active, the

Command lamp flashes

command lamp flashes.

Note for twin engines: The function "warming up" can be activated and deactivated of both sides

separately. The command lamp is assigned to the respective lever.

5.5 Increased idle speed

By the special function "increased idle speed" a higher idle speed can be selected. This function will

be necessary if the driving engine shall operate a bow thruster in addition and the normal idle speed

engine performance is not sufficient therefore.

To turn this function on and off, the key on the active control station must be pushed. The function can

be switched on in neutral only and switched off at any time.

The function "increased idle speed" is available only if it has been set up before

(see chapter 4.3. speed). When this function has been entered, "synchronizing"

!

cannot be deactivated again.

5.6 Synchronising

If, for twin engine systems, the positions of the port and starboard levers on the active control head

deviate less than 10% from each other in the range of "ahead", the same nominal value (of the port

lever) will be set.

If "Synchronising" is active, this will be indicated

by the lamp "Synchro".

COMMAND

ALARM

SYNCHRO

To switch off this function, the key on the active control station must be pushed.

The function will activate again as soon as the levers deviate 10% maximum from each other again at

another position.

Note for „increased idle speed“: "Synchronizing" cannot be switched off if the function "increased idle

speed" is active.

The function "Synchronization" is available only if it has been set up before (see

chapter 4.2 "control head", synchronizing).

!

Operation

Error AnalysisAppendix

Page 36

General

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

COMMAND

ALARM

SYNCHRO

33

6 Error analysis

6.1 Errors at the control station

Two errors at the control stations must be distinguished:

Alarm During an alarm, the setting of the cruising

Overview

Wiring

Warning In case of a warning, the setting of the cruising

Adjustment

functions (speed or gearing) is disturbed. On

the active control head, the red alarm lamp will

be on and a buzzer will sound. The buzzer

signal can be acknowledged and thus switched

off by pushing the key.

The command lamps indicate if the control

head is active or passive, i. e. if this station can

set commands or not.

Special case:

If the active control head is defective, the

passive heads will activate their buzzer and will

go over into the condition "request station".

function is not disturbed directly. The red alarm

lamp will be active, but the buzzer will not

sound.

active station

passive station

special case:

passive station

Command lamp flashes

active station

passive station

For twin engines, the alarm and command lamp are assigned to the respective engine side so that

Operation

several lamp reactions as described above may combine. The buzzer will be activated as soon as an

alarm is signaled on one of the engine sides.

Example twin engine

Port

Alarm

Starboard

No Error

Error Analysis

In case of an alarm, the alarm relay is activated. In addition, idle speed is set and the gears are

disengaged if the remaining function of the system permit it.

Appendix

The starboard system is error-free and the

control head is active. The port system is in

alarm condition, no active command exists on

this control station. Cruising commands can no

longer be set from this station.

COMMAND

ALARM

SYNCHRO

Page 37

6.2 Error indication control unit

34

To indicate errors, 4 error LEDs are available

altogether. The top LED is red to facilitate

orientation.

The operation mode of the control is indicated by

2 additional LEDs (RUN, SETUP).

By pressing a key, further error messages can be

displayed.

error LED

1

2

3

4

LED RUN LED SETUP

It must always be distinguished if the red LED1 flashes or stays on permanently.

LED on in mode "permanent on"

LED on in mode "flashing"

LED off

General

key

Overview

WiringAdjustment

Red LED 1 steady light

1

2

3

4

1

2

3

4

Error type: HARDWARE

Error description: The board of the control unit contains a hardware fault.

Error elimination: Replace board.

Error type: PARAMETER

Error description: Faulty parameter storage of the control unit.

Error elimination: The parameters of the control must be re-set to default (see chapter

4.5). If afterwards the error is still occuring, the board of the control unit must be replaced.

1

2

3

4

Error type: SOFTWARE

Error description: The software of the control unit is defective (e. g. EPROM not plugged).

The board of the control unit must be replaced.

Error elimination: Switch the control on and off. If necessary, replace board of the control

unit.

1

2

3

4

Error type: CAN

Error description: The CAN-controller reports an error.

Error elimination: Control the wiring to the control heads (chapter 3.2). Check the bridges

(see chapter 3.2). There may be a short circuit in the wiring between single veins.

Operation

Error Analysis

Appendix

Page 38

35

General

1

2

3

4

Overview

1

2

3

4

Wiring

1

2

Adjustment

3

4

Error type: ACTUATOR 1

Error description: The system is configurated ( see chapter 2) in such a way that actuator

1 (see chapter 3.3) directs mechanical gear shifting or speed setting. However, the control

states an error in the operation of the actuator.

Error elimination: Check the plugs of actuator 1 for correct connection to the board of the

control unit (see chapter 3.3).

If necessary, connect actuator 1 to the terminal of actuator 2 on the control unit. If the

actuator works perfectly then, the board of the control unit is defective and must be

replaced. If not, replace the actuator.

Error type: ACTUATOR 2

Error description: The system is configurated (see chapter 2) in such a way that actuator

2 (see chapter 3.3) directs mechanical gear shifting or speed setting. However, the control

states an error in the operation of the actuator.

Error elimination: Check the plug of actuator 2 for correct connection to the board of the

control unit (see chapter 3.3).

If necessary, connect actuator 2 to the terminal of actuator 2 on the control unit. If the

actuator works perfectly then, the board of the control unit is defective and must be

replaced. If not, replace the actuator.

Error type: I/O-CARD 1

Error description: The system (see chapter 2) is configurated in such a way that the I/O-

extension board directs electrical gear shifting or speed setting (see chapter 3.4). However,

an error is stated in the activation of I/O-extension board 1.

1

2

Operation

3

4

Error Analysis

Appendix

Error elimination: Check cable between I/O-extension board 1 and the control unit (see

chapter 3.4. electrical throttle control / gear shifting, installation of the I/O-extension board).

If necessary replace cable or I/O-extension board.

Error type: I/O-CARD 2

Error description: The system is configurated (see chapter 2) in such a way that I/O-

extension board 2 directs electrical gear shifting or speed setting (see chapter 3.4).

However, an error is stated in the activation of extension board 2.

Error elimination: Check cable between I/O-extension board 2 and 1 or I/O-card 1 and the

control unit (see chapter 3.4 electrical throttle control / gear shifting, installation of the I/Oextension board).

If necessary, replace cable or I/O-board.

Page 39

Red LED 1 flashing

36

1

2

3

4

Error type: SYN-CARD (warning only)

Error description: No extension board for synchronizing found.

Error elimination: Check cable from synchronizing board to board of the control unit (see

General

instructions attached to the synchronizing board).

If necessary, replace synchronizing board.

1

2

3

4

Error type: SYN-SIG (warning only)

Error description: The synchronizing board cannot measure the speed correctly.

Error elimination: Check cable to the speed sensor (see instructions attached to the

synchronizing board).

Overview

If necessary, replace speed sensor or synchronizing board.

1

2

3

4

Error type: ACT-CTR

Error description: The control unit reports a total failure of the active control head.

Error elimination: Check cable to the control head (see chapter 3.2). Control the

necessary bridges (see chapter 3.2). Check LED power supply at the control head (see

WiringAdjustment

chapter 3.2). Check ID (see chapter 3.2).

If necessary, replace control head.

1

2

3

4

Error type: ACT-CTR-HW

Error description: The hardware of the previous active control head reports an error (e. g.

potentiometer defective).

Error elimination: Replace control head.

1

2

3

4

Error type: POWER

Error description: The supply voltage (see chapter 3.1) is beyond the admissible range

(for 24V: 18 ... 31,2V, for 12V: 9 ... 15,6 V, if no voltage range has been selected: 9 ...

31,2V).

Error elimination: Charge battery.

1

2

3

4

Error type: TEMPERATURE

Error description: The temperature is beyond the admissible range

(-25 ... +70 °C).

Operation

Error elimination: The control may only be operated within the admissible temperature

range.

Error Analysis

Appendix

Page 40

37

General

1

2

3

4

Overview

1

2

3

4

Wiring

In addition, warnings can be issued. In case of warnings, the red error LED 1 will not be activated.

Furthermore, in case of a warning, the operation mode must be considered.

Adjustment

Mode Initialising (LED RUN and SETUP on)

Error type: TWIN

Error description: The system was configurated for twin engines – mechanical gear

shifting and speed setting (chapter 2). The communication between the control units port

and starboard does not function.

Error elimination: Check cable between the control units and the necessary bridges (see

chapter 3.2 – special application twin engine with mechanical throttle control / gear

shifting).

Check power supply of the single control units (LED readiness, see chapter 3.1).

If necessary replace synchronizing board.

Error type: SYSCON (warning only)

Error description: The SYSCON switchboard which controls the system configuration (see

chapter 2), was adjusted while the system was active. This is not admissible. It may only be

adjusted in voltage-free condition. Or, the switchboard was turned to a value which was not

admissible.

Error elimination: If the SYSCON switchboard was misadjusted, it must be reset correctly

according to chapter 2. If the change was done on purpose, the control must be switched

on and off before the alteration can become effective.

Operation

1

2

3

4

Error Analysis

1

2

3

4

Appendix

Error type: TWIN-MASTER

Error description: The SYSCON switchboard is misadjusted for twin engines with

mechanical actuation at the starboard system.

Error elimination: Reset the SYSCON switchboard correctly for twin engines with

mechanical actuation at the starboard system (see chapter 2).

Error type: TWIN-SLAVE

Error description: The SYSCON switchboard is misadjusted for twin engines with

mechanical actuation at the port system.

Error elimination: Reset the SYSCON switchboard for twin engines with mechanical

actuation at the port system (see chapter 2).

Page 41

38

Mode RUN or SETUP (LED RUN or LED SETUP on)

or

General

1

2

3

4

Error type: GEAR MASTER

Error description: Gear feedback has been set at the I/O-extension board (see chapter

3.4). The gear feedback is not signalled (for twin engines on the port side). The system

Overview

works without gear feedback.

Error elimination: Check pressure sensor at the gearing. Control LEDs on I/O-extension

board (LED actual ahead or astern or collective feedback). Check wiring.

1

2

3

4

Error type: PAS-CTRL

Error description: The control states a total failure of a passive control head.

Error elimination: Check wiring (see chapter 3.2). Check LED power supply at the

WiringAdjustment

defective passive control head. If necessary replace control head.

1

2

3

4

Error type: PAS-CTRL-HW

Error description: The hardware of a passive control head is defective (e. g. potentiometer

error).

Error elimination: Replace defective control head

1

2

3

4

Error type: GEAR SLAVE

Error description: Gear feedback has been set at the I/O-extension board (see chapter

3.4). The gear feedback on the twin engine at the starboard system is not signaled. The

control works without gear feedback.

Error elimination: Check pressure sensor at the gearing. Control LEDs on the I/O

extension board (LED actual ahead or astern or collective feedback). Check wiring.

Operation

Error Analysis

Appendix

Page 42

39

General

Overview

Wiring

1

2

3

4

1

2

3

4

1

2

3

4

Adjustment

Error type: CTRL-POS

Error description: Before adjusting parameters for speed and gear control, the active

control head must be placed in the correct position (see chapter 4.3 or 4.4). It is not

permitted to adjust the parameter in this lever position.

Error elimination: Change to RUN-mode (step 1 in chapter 4.3 or 4.4). Move lever in

correct position then and repeat the adjustment.

Error type: PROCEDURE

Error description: Parameters were set (chapter 4) in incorrect order (e. g. adjustment of

rotary switch PARSEL in SETUP-mode).

Error elimination: Change to RUN-mode (step 1 in chapter 4.3 or 4.4). Move lever in

correct position then and repeat the adjustment.

Error type: ADJUST

Error description: It has been tried to set a parameter (chapter 4) that does not exist at all

according to the system configuration (chapter 2) (e. g. rpm starboard for a single engine

system). Or, the rotary switch PARASEL was turned to a value which was not admissible.

Error elimination: Correct setting of switches and rotary switch PARSEL.

Operation

Error Analysis

Appendix

Page 43

Control Unit – In- and Outputs

port / starboard

RUN / SETUP

-

direction setup

see chapter 4.3, 4.4, 4.5

123

345

2

6

1

7

0

8

F

9

E

A

D

B

C

PARSEL setting of parameters

4

key setup

40

see chapter 4.2 Control head

RUN / control head alignment

off / buzzer on in neutral

compare position / compare range

off / synchronization on

123

CTRHEAD

4

GeneralOverviewWiringAdjustment

345

2

6

1

7

0

8

F

9

E

A

D

B

C

1 idle speed

2 rated speed

4 ahead

6 astern

A power boost

B increased idle speed

E default

delay time before clutch

(see chapter 4.4 Gearing)

1234567

TIME

1234567

delay time after clutch

reversing delay time

8

configuration of system type

(see chapter 2 Overview)

adjustment power supply

(see chapter 3 Wiring -

3.1 Power supply)

8

LED setup active

LED run active

LED relay start interlock

LED relay alarm

fuse

X21

X31

S4 S2 S6

X30

X11

H7

S1

S5

H5

H1H3H2

X3

X6

S3

H6 H8

H4

X5

X4

X22

X5

X12

X1

X41

X40

Operation

Error AnalysisAppendix

LED error

SYSCON

Page 44

41

General

Control Unit - Terminals

Overview

Wiring

Vcc

2

head 0 V

4

1

CAN GND

head +8 V

2

3

CAN -

CAN +

CAN terminal

1

CAN -

CAN +

2

1

actuator 1

X12

X5

X4

H1

H2

H4

H3

X3

X11

X30

Adjustment

GND

Vcc

GND

Operation

Error Analysis

H6

X40

X41

X1

X5

X22

X6

H5

H8

S5

S1

H7

S3

S4

S2

S6

X31

X21

actuator 2

2

1

Vcc

2

GND

2

1

alarm

1

engine start interlock

Appendix

Page 45

Page 46

Page 47

Page 48

Rexroth Mecman GmbH

Bartweg 13

D-30453 Hannover

Phone: +49 – 5 11 – 21 36 – 0

Fax: +49 – 5 11 – 21 36 – 2 69

www.boschrexroth.com

Subject to alteration.

This edition supersedes

all previous ones.

Printed in Germany.

No part of this edition may

be repro-duced without

our prior permission.

Order no. 883-890-060-3/2003-07/EN

Loading...

Loading...