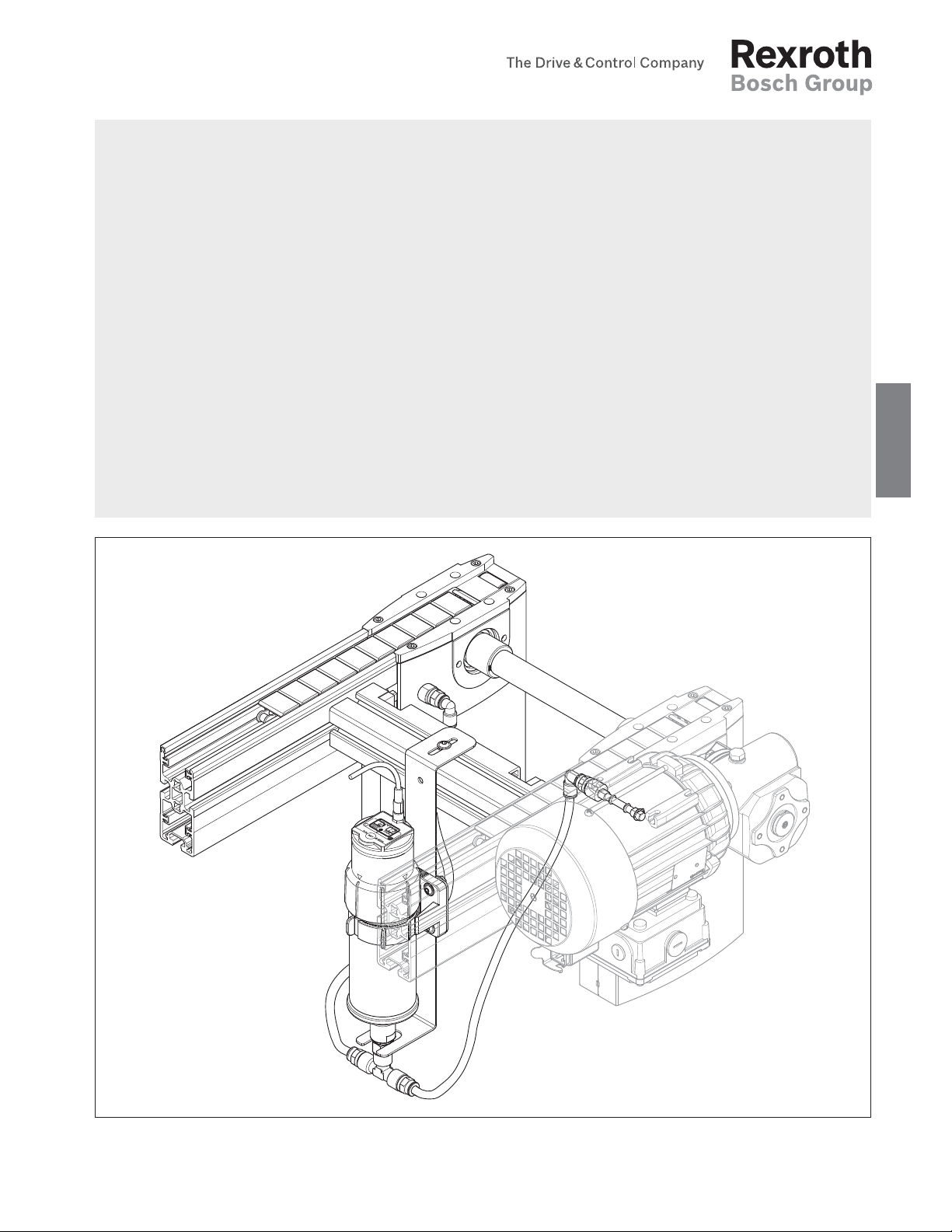

Bosch Rexroth LU 2 Assembly Instructions Manual

LU 2

Automatic lubrication unit

3 842 543 482

3 842 543 483

3 842 543 484

3 842 543 485

3 842 543 486

3 842 543 487

Assembly instructions

3 842 358 814/2017-01

Replaces: 2016-10

ENGLISH

ENGLISH

2/54

The data specifi ed only serve to describe the product. The information provided in the instructions on how to use the supplied product

should only be considered application examples and suggestions. Catalog information is not binding. The information given does not

release the user from the obligation of own judgment and verifi cation. Our products are subject to a natural process of wear and aging.

© This document, as well as the data, specifi cations and other information set forth in it, are the exclusive property of Bosch Rexroth

AG. It may not be reproduced or given to third parties without its consent.

An example confi guration is shown on the title page. The delivered product may thus vary from the illustration.

The original assembly instructions were generated in German.

Die vorliegende Montageanleitung ist in den hier angebenen Sprachen verfügbar. Weitere Sprachen auf Anfrage.

DE

Als gedruckte Version (print) oder als PDF-Datei (media) zum Download aus dem Medienverzeichnis:

www.boschrexroth.com/medienverzeichnis

Geben Sie in die Suchmaske (oben rechts, unter „Suche“) 3 842 358 814 ein, dann klicken Sie auf „fSuche“.

These assembly instructions are available in the languages indicated here. Other languages on request.

EN

They come in a hard copy (print) or a PDF fi le (media) that can be downloaded at:

www.boschrexroth.com/mediadirectory

Enter 3 842 358 814 in the search mask (at the top right, under “Search”), then click “fSearch”.

Les présentes instructions de montage sont disponibles dans les langues spécifi ées ici. Autres langues sur demande.

FR

En version imprimée (print) ou en version PDF (media) téléchargeable sur le répertoire multimédia :

www.boschrexroth.com/mediadirectory

Saisissez 3 842 358 814 (en haut à droite, sous « Search »), puis cliquez sur « fSearch ».

Le presenti istruzioni di montaggio sono disponibili nelle lingue seguenti. Altre lingue su richiesta.

IT

Scaricabile come versione stampata (print) o come fi le PDF (media) dal Media Directory:

www.boschrexroth.com/mediadirectory

Digitare il codice 3 842 358 814 nel campo di ricerca “Search” (in alto a destra), quindi fare clic su “fSearch”.

Las presentes instrucciones de montaje están disponibles en los idiomas indicados. Hay más idiomas a petición.

ES

Las instrucciones están disponibles como versión impresa (print) o como archivo PDF (media) para descargar del archivo de

medios: www.boschrexroth.com/mediadirectory

En el buscador (en la parte superior derecha, donde pone "Search") introduzca 3 842 358 814, a continuación haga clic en

"fSearch".

Este manual de montagem está disponível nos idiomas especifi cados aqui. Outros idiomas mediante pedido.

PTBR

Como versão impressa (impressão) ou como arquivo PDF (mídia) para download do índice de mídias:

www.boschrexroth.com/mediadirectory

Entre na máscara de pesquisa (canto superior direito, em «Search») 3 842 358 814 e clique em «fSearch».

本安装说明书有这里给出的语言版本。有印刷版本 (print) 或者电子版 PDF 文件 (media) 供使用,电子版文件可在下列的公司网站媒体网

ZH

页上下载: www.boschrexroth.com/mediadirectory

1. 在搜索窗口 (右上角,“Search”窗口) 内输入编号 3 842 546 292。2. 点击“fSearch”。

Tento návod k montáži je k dispozici ve zde uvedených jazycích. Jako tištěná verze (print) nebo jako soubor PDF (media) je ke

CS

stažení z adresáře médií: www.boschrexroth.com/mediadirectory

1. Zadejte do vyhledávací obrazovky (nahoře vpravo, pod „Search“) MTCS 358 814. 2. Klikněte na „fSearch“.

Dana instrukcja montażu jest dostpna w podanych tutaj językach. W postaci wydrukowanej lub w wersji pdf (media) do

PL

pobrania ze strony: www.boschrexroth.com/mediadirectory

1. Do wyszukiwarki wpisać (w prawym górnym rogu „Search“) MTPL 358 814 . 2. KKliknać „fSearch“

A jelen szerelési utasítás az itt megadott nyelveken áll rendelkezésre. További nyelvek rendelésre. A nyomtatott (print) változat

HU

vagy a PDF-fájl (media) letölthető a médiakönyvtárból: www.boschrexroth.com/mediadirectory

Írja be a keresőmezőbe (fent jobbra a „Search

“ alatt) MTHU 358 814, majd kattintson a „fSearch“ gombra.

3 842 358 814

3 842 358 814

3 842 358 814

3 842 358 814

3 842 358 814

3 842 358 814

3 842 546 292

MTCS 358 814

MTPL 358 814

MTHU 358 814

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

print media LU 2 Automatische Schmiereinheit DE Deutsch

print media LU 2 Automatic lubrication unit EN English

print media LU 2 Unité de lubrifi cation automatique FR Français

print media LU 2 Unità di lubrifi cazione automatica IT Italiano

print media LU 2 Unidad de lubricación automática ES Español

print media LU 2 Unidade de lubrifi cação automática PT Português

print media LU 2 自动润滑单元 ZH

media LU 2

Automatická mazací jednotka CS Česky

media LU 2 Zespół automatycznego smarowania

media LU 2 Automatikus kenőegység HU Magyar

中文

PL Polski

3/54 Contents

Contents

1 About this document 5

1.1 Scope of document 5

1.2 Required and supplementary documentation 5

1.3 Presentation of information 5

1.3.1 Safety instructions 5

1.3.2 Symbols 6

1.3.3 Designations 7

2 Safety instructions 7

2.1 About this chapter 7

2.2 Intended use 7

2.3 Improper use 8

2.4 Qualifi cation 8

2.5 General safety information 8

2.6 Product-specifi c safety instructions 9

2.7 Personal protective equipment 10

2.8 Owner obligations 10

3 General information regarding damage to property and the product 10

4 Scope of delivery 11

4.1 Delivery state 11

4.2 Accessories 11

5 About this product 11

5.1 Performance description 11

5.1.1 Automatic lubrication unit LU 2 use 11

5.1.2 Automatic lubrication unit LU 2 design 11

5.2 Product description 12

5.3 Identifi cation of the product 13

6 Function 14

6.1 TIME mode 14

6.1.1 Setting the delivery volume in the TIME operating mode 15

6.1.2 Display of the remaining delivery period 16

6.2 PULSE mode 17

6.2.1 Setting the delivery volume in the PULSE operating mode 18

6.3 Required delivery volume 20

6.3.1 Flat top chain: every 1000 h 20

6.3.2 Flat top chain: every 2000 h 20

6.3.3 Accumulation roller chain: every 1000 h 21

6.3.4 Accumulation roller chain: every 2000 h 21

6.3.5 Vplus accumulation roller chain: every 1000 h 22

6.3.6 Vplus accumulation roller chain: every 2000 h 22

6.4 Special delivery PURGE 23

6.5 PIN number 24

6.6 Counter pressure monitoring 24

6.7 Low temperature monitoring 24

6.8 Indicator elements and signal outputs 25

6.8.1 LED indicators and display 25

6.8.2 Signal outputs 25

ENGLISH

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

4/54

6.8.3 Cable break detection 25

7 Transport and storage 26

7.1 Transporting the product 26

7.2 Storing the product 26

8 Installation 27

8.1 Unpacking 27

8.2 Installation requirements 27

8.2.1 Installation position 27

8.2.2 Mounting with T-bolts 27

8.3 Required tools 27

8.4 Symbols used 28

8.5 Installing the product 29

8.5.1 Install the holder for the lubrication unit LU 2 29

8.5.2 Install support bracket and connector set in the holder 30

8.5.3 Install lubrication unit LU 2 31

8.5.4 Install adapter Set AS 2/C-100, -250 33

8.5.5 Install adapter Set AS 2/C-400, AS 2/C-700 34

8.5.6 Install adapter Set AS 2/R-300, AS 2/R-700 35

8.5.7 Install adapter Set AS 2/R-1200, AS 2/R-2200 36

8.5.8 Install adapter Set AS 2/R-1200, AS 2/R-2200 37

8.6 Make the electrical connection to the product 38

8.6.1 PLC programming suggestions for evaluating the signal outputs 39

9 Start-up 41

9.1 First-time operation 41

9.1.1 Short description commissioning 42

9.2 Re-commissioning after a standstill period 42

10 Operation 43

10.1 Notices regarding operation 43

10.1.1 Wear 43

10.1.2 Steps for reducing wear 43

10.1.3 Environmental infl uences 43

11 Maintenance and repair 44

11.1 Cleaning and care 45

11.2 Inspection 45

11.3 Maintenance 45

11.4 Replacement of worn parts 45

11.4.1 Exchange oil container LC 2 46

11.4.2 Exchange battery LU 2 48

11.4.3 Replacement parts 48

12 Shutdown 49

13 Disassembly and replacement 49

13.1 Preparing the product for storage/further use 49

14 Disposal 50

15 Upgrading and modifi cation 50

16 Troubleshooting 51

17 Technical data 52

17.1 Storage period 52

17.2 Ambient conditions 53

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

About this document 5/54

1 About this document

1.1 Scope of document

This documentation applies to the following products:

• Lubrication unit LU 2, 3 842 543 482

• Adapter Set AS 2/C-100, -250, 3 842 543 483

• Adapter Set AS 2/C-400, -700, 3 842 543 484

• Adapter Set AS 2/R-300, -700, 3 842 543 485

• Adapter Set AS 2/R-1200, -2200, 3 842 543 486

• Adapter Set AS 2/R-V, 3 842 543 487

• Oil container LC 2, 3 842 543 469

This manual is intended for engineers, operators, service engineers and

system end users.

This document contains important information to install, transport, commission,

operate, use, maintain, and dismantle the product safely and correctly and

on simple troubleshooting.

f Read this manual completely, especially chapter 2 “Safety” and Chapter 3,

“General notes for property damage and product damage” before working with

the product.

ENGLISH

1.2 Required and supplementary documentation

f Only operate when you are in possession of the documentation marked with the

book symbol

Table 1: Required and supplementary documentation

Title Document number Document type

Safety-related information for staff 3 842 527 147

MTparts 3 842 529 770 Spare part list available on CD

and you have understood and observed this.

1.3 Presentation of information

In order for you to work with your product quickly and safely using this documentation,

safety symbols, terms and abbreviations are used in a uniform manner.

These are explained in the following sections to help you understand them better.

1.3.1 Safety instructions

In this documentation, safety instructions are given in chapter 2.6 “Specifi c product

precautions” and Chapter 3 “General notes on property and product damage”, and

before a course of action or a required action, in which there is a risk of personal

injury or property damage. Be sure to observe all safety precautions.

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

6/54 About this document

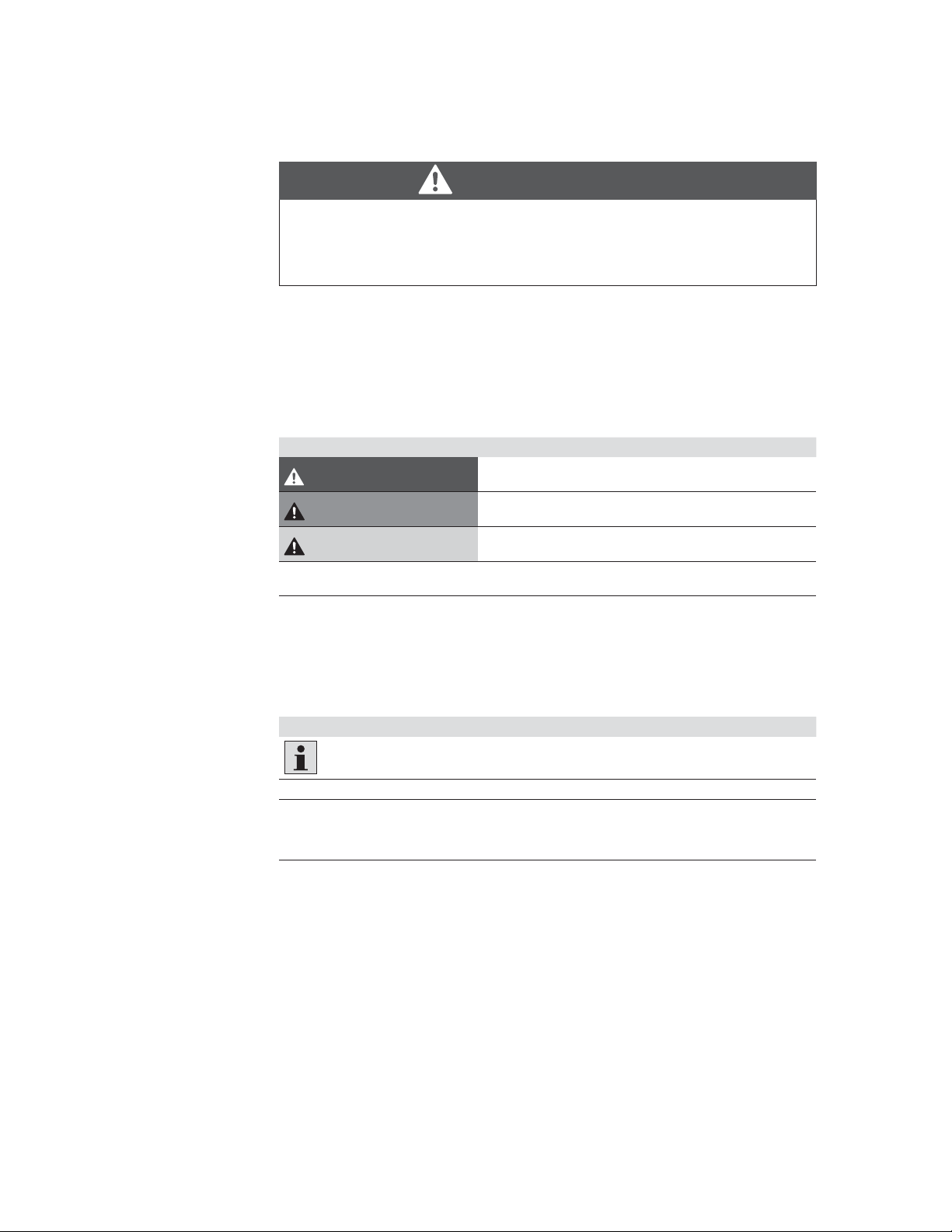

Safety instructions are set out as follows:

SIGNAL WORD

Type and source of danger!

Consequences of non-compliance

f Measures to prevent hazards

f …

• Warning sign: points out the hazard

• Signal word: identifi es the severity of the hazard

• Type and source of danger: indicates the type and source of the danger

• Consequences: describes what occurs when failing to take precautions

• Precaution: states how the hazard can be avoided

Table 2: Hazard classes according to ANSI Z535.6-2006

Warning sign, signal word Meaning

DANGER

WARNING

CAUTION

NOTICE

Indicates a hazardous situation which will result in death or

serious injury if not avoided.

Indicates a hazardous situation which can result in death or

serious injury if not avoided.

Indicates a hazardous situation which can result in minor or

moderate injury if not avoided.

Damage to property: The product or the environment

could be damaged.

1.3.2 Symbols

The following symbols indicate notices which are not safety-relevant but make the layout

of the document more clear.

Table 3: Meaning of the symbols

Symbol Meaning

If this information is not observed, the product cannot be used and/or

operated optimally.

Single, non-related actions

Numbered instructions:

The numbers indicate that the actions must be carried out one after the

other.

1.

2.

3.

f

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

Safety instructions 7/54

1.3.3 Designations

In this documentation, the following designations are used:

Table 4: Designations

Designation Meaning

LU 2 Automatic lubrication unit from the Rexroth transfer system TS 2plus

LC 2 Oil container for the automatic lubrication unit LU 2

AS 2/… Adapter set for the automatic lubrication unit LU 2

2 Safety instructions

2.1 About this chapter

This product has been manufactured using state-of-the-art technology.

Nevertheless, there is a risk of personal injury and property damage if you do not

observe this chapter and the safety instructions in this document.

f Read this manual thoroughly and completely before you start working with

the product.

f Keep these instructions accessible to all users at all times.

f Always include the operating instructions when transferring this product

to third parties.

ENGLISH

2.2 Intended use

The product is an incomplete machine.

This product may be used for the following:

• for installation in a Rexroth transfer system TS 2plus for lubrication of the transport

chain.

• for lubrication of 1 belt section BS 2/… or 1 section unit SE 2/…in the drive station.

• for operation with 2 equal lubrication pins.

• For the environmental conditions see page 53.

The product is strictly intended for professional use and not for private use.

The intended use also implies that you have read and understood this

documentation, especially chapter 2 “Safety”.

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

8/54 Safety instructions

2.3 Improper use

Any use other than that described in Chapter “Intended use” is considered improper

and is not permitted.

Bosch Rexroth AG is not liable for any damages resulting from improper use.

The user is solely responsible for the consequences of improper use.

The following also fall under the category of improper use:

• Using the product for lubrication of more than 1 belt section BS 2/… or

1 section unit SE 2/… .

• Using the product with other than the specifi ed lubricant.

• Using the product with non-specifi ed accessories.

• Using the product with lubrication lines unequal length.

• Using the product with unequal lubrication pins.

• Using the product without ensuring that it is in the correct position.

• Private use.

2.4 Qualifi cation

The activities described in this documentation require basic knowledge of

mechanical, electrical and pneumatic systems, as well as knowledge of the

appropriate technical terms. Additional knowledge in dealing with a hoist and the

associated slings are required for transport and handling of the product.

To ensure safe use, these activities may only be performed by a specialist or

personnel under the direction of a specialist.

“Specialist” refers to a person who can recognize potential hazards and take

appropriate safety measures due to their technical training, knowledge and

experience, and understanding of the relevant regulations pertaining to the work

being performed. Qualifi ed personnel must comply with the relevant technical

regulations and have the necessary expertise.

Bosch Rexroth offers training to support activities in specifi c areas.

You can fi nd an overview of the training content online at

http://www.boschrexroth.de/didactic

2.5 General safety information

• Observe the regulations for accident prevention and environmental protection.

• Observe the safety rules and regulations of the country in which the product is

used/applied.

• Only use Rexroth products that are in good working order.

• Follow all instructions printed on the product.

• Persons who assemble, operate, disassemble, or maintain Rexroth products must

not consume any alcohol, drugs, or pharmaceuticals that may affect their

reaction time.

• Use only original accessories and spare parts from Rexroth to prevent hazards to

persons due to improper spare parts.

• Observe the technical data and ambient conditions listed in the product

documentation.

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

Safety instructions 9/54

• You may operate the product only when it was found that the fi nal product (such as

a machine or system), in which the Rexroth products are installed, is in accordance

with the respective national provisions, safety regulations and the standards for the

application.

2.6 Product-specifi c safety instructions

General

During transport

During assembly

During start-up

During operation

• Do not modify or alter the product.

• Do not expose the product to unacceptable mechanical loads under any

circumstances. Never use the product as a handle or step. Do not place objects on it.

• Always secure the product against tipping.

• Observe the transport information on the packaging.

• Check the product for visible damage during transport.

• Lay the cables and lines so that they cannot be damaged and no one can trip

over them.

• Make sure the relevant system component is not under pressure or voltage before

assembling the product or when connecting and disconnecting plugs.

• Secure the system component from being switched on.

• Before start-up, make sure that all seals and caps for the screwed connections are

correctly installed and undamaged to prevent fl uids and debris from infi ltrating

the product.

• Allow the product to acclimate for a few hours before start-up, otherwise

condensation may form in the housing.

• Make sure that all electrical connections are either used or covered.

• Check the security requirements according to DIN EN 619.

• Start up the product only if it is installed completely.

• Make sure that all safety equipment belonging to the product is present,

has been installed properly, and is fully functional. Do not displace,

bypass, or disable the safety equipment.

• Do not reach into moving parts.

• Check the product for malfunctions.

• Make sure only authorized personnel perform the following within the scope of

intended use:

– Start or operate the system, or intervene in its normal functioning.

– Operate adjustment devices on components.

• Only allow persons who are authorized by the owner to access the product's direct

operating area. This also applies when the product is standing still.

• Make sure that:

– There are no obstacles preventing access to the EMERGENCY STOP control units.

– All delivery points, workstations and passages remain freely accessible.

• Do not use EMERGENCY STOP control units for routine stops.

• Regularly check the proper functioning of the EMERGENCY STOP control units.

• In the event of an error or other irregularities, after an EMERGENCY STOP turn the

product off and secure it against restarting.

• Do not reach into moving parts.

• An idle system is not a safe system, as stored energy can be released

unintentionally or through improper maintenance procedures.

ENGLISH

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

10/54 General information regarding damage to property and the product

EMERGENCY STOP, fault

During maintenance and

repair

During disposal

• After an EMERGENCY STOP or a malfunction, only switch on the system once

the cause of the fault has been determined and the error resolved.

• Make sure that there are no obstacles blocking access to maintenance and

inspection points.

• Perform the prescribed maintenance work at the intervals prescribed in

chapter 10.3 Maintenance.

• Make sure that no lines, connectors, or components are disconnected as long

as the system is under pressure and voltage. Secure the system against being

switched back on.

• Dispose of the product in accordance with the currently applicable national

regulations in your country.

2.7 Personal protective equipment

• Appropriate protective clothing is to be worn when handling the product

(e.g. safety shoes, close-fi tting clothing, a hair net for long, loose hair).

As owner or operator, you are responsible for appropriate protective equipment

when using the product.

All personal protective equipment must be intact.

2.8 Owner obligations

• Before fi rst use or re-commissioning of a conveyor system, run a risk assessment

in accordance with DIN EN ISO 12100.

• Before initial commissioning ensure that there are no protruding or sharp-edged

parts that may endanger personnel working or moving in the area.

• Provide safety-related instructions to the operating personnel before fi rst use or

re-commissioning, and then in regular intervals.

3 General information regarding damage to

property and the product

The warranty only applies to the delivered confi guration.

• The warranty is void in case of faulty installation, commissioning and operation, as

well as improper use and / or improper handling.

During cleaning

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

• Avoid the penetration of detergent into the system.

• Never use solvents or aggressive detergents.

• Do not use a high-pressure cleaner for cleaning.

Scope of delivery 11/54

4 Scope of delivery

The following is included in delivery:

• 1 Automatic lubrication unit LU 2

• Assembly instructions for “Automatic lubrication unit LU 2”

4.1 Delivery state

Unassembled in parts.

4.2 Accessories

(not included in the delivery)

• Oil container LC 2, 3 842 543 469

• Adapter Set AS 2/C-100, -250, 3 842 543 483

• Adapter Set AS 2/C-400, -700, 3 842 543 484

• Adapter Set AS 2/R-300, -700, 3 842 543 485

• Adapter Set AS 2/R-1200, -2200, 3 842 543 486

• Adapter Set AS 2/R-V, 3 842 543 487

ENGLISH

5 About this product

5.1 Performance description

5.1.1 Automatic lubrication unit LU 2 use

• Lubrication of concealed running transport chains in the transfer system TS 2plus.

• for lubrication of 1 belt section BS 2/… or 1 section unit SE 2/…in the drive station.

• Exclusively for operation with 2 equal lubrication pins.

5.1.2 Automatic lubrication unit LU 2 design

• The automatic lubrication unit LU 2 consists of the components

– Lubrication unit LU 2, 3 842 543 482

– Oil container LC 2, 3 842 543 469

– Adapter Set AS 2/C-100, -250, 3 842 543 483

– Adapter Set AS 2/C-400, -700, 3 842 543 484

– Adapter Set AS 2/R-300, -700, 3 842 543 485

– Adapter Set AS 2/R-1200, -2200, 3 842 543 486

– Adapter Set AS 2/R-V, 3 842 543 487

1) Not part of the delivery, please order separately.

1)

1)

1)

1)

1)

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

12/54 About this product

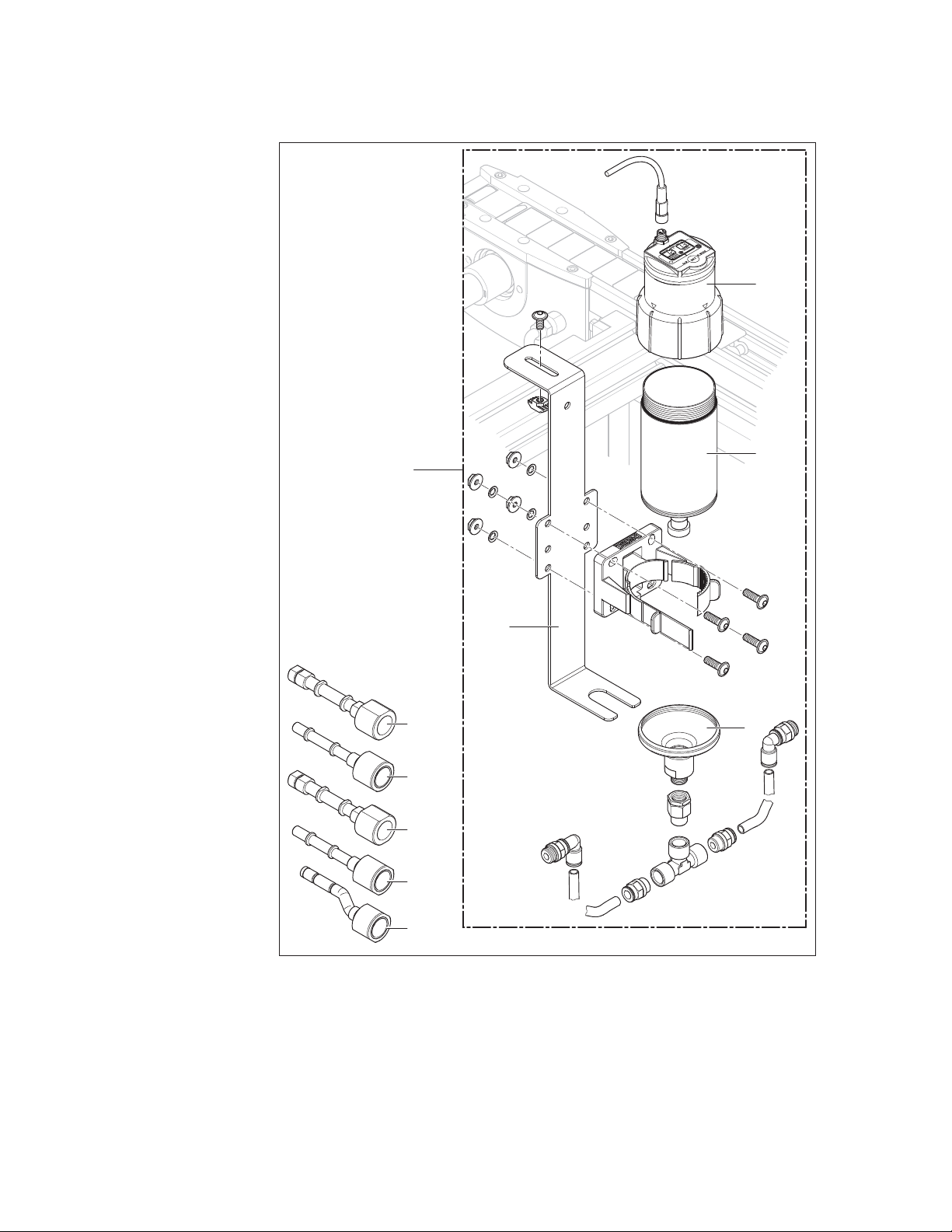

A: Lubrication unit LU 2

B:Drive

C: Oil container LC 2

1)

D: Holder, complete with

assembly accessories

E: Support bracket

F: Connection set

G: Adapter Set

AS 2/C-100, -250

1)

H: Adapter Set

AS 2/C-400, -700

1)

I: Adapter Set

AS 2/R-300, -700

1)

J: Adapter Set

AS 2/R-1200, -2200

1)

K: Adapter Set

AS 2/R-V

1) Not part of the delivery,

please order separately.

1)

5.2 Product description

B

C

A

Fig. 1:

Product description

D

G

2x

2x

H

2x

I

E

F

2x

J

2x

K

358 814-01

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

About this product 13/54

5.3 Identifi cation of the product

A:

Part no.

(Order number)

B:

Designation

C:

Design and

dimensions

A

....... ..........

.........

.................

........

C

Fig. 2: Name plate

B

Typschild

ENGLISH

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

14/54 Function

6 Function

The lubrication unit LU 2 has two operating modes:

• TIME mode

• PULSE mode

A special delivery volume (PURGE) can also be triggered and the operation of

the lubrication unit can also be disabled using a 2-digit PIN number.

The device is equipped with counter pressure and lower temperature monitoring.

Device settings are retained even after a power failure by the use of an integrated

backup battery.

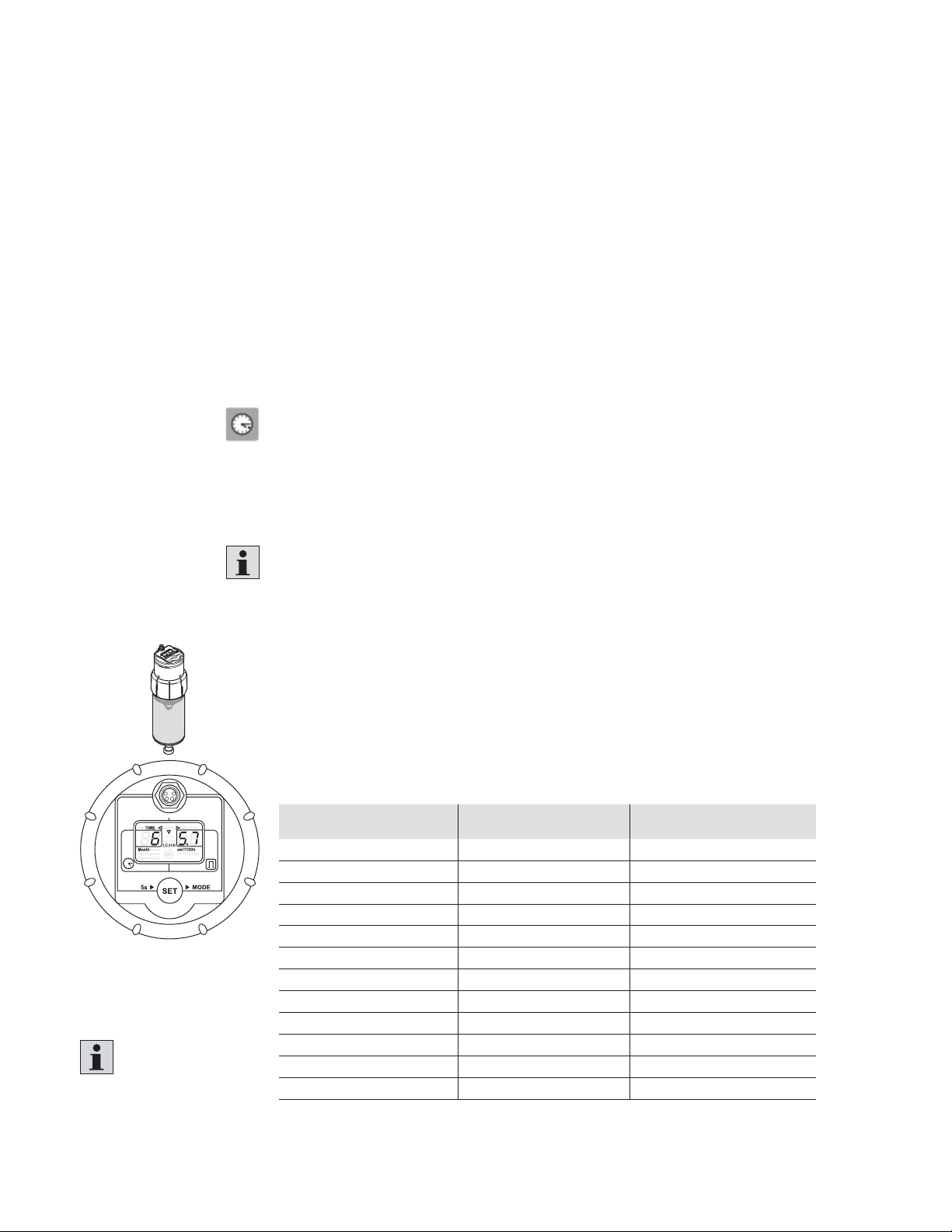

6.1 TIME mode

A metering period (per month, 1 to 12 months) can be entered in the TIME mode.

During this metering period metered volumes of lubricant are delivered at fi xed,

regular intervals (interval period 't [h:mm]). The volume of metered lubricant

delivered is determined by the metering period, the interval period and the entered

oil container LC 2.

Please note:

(1 cm³ | 0.9 g lubricant)

358 814-25

Only in TIME mode: At the initial startup the drive runs for approximately 8 sec

after the supply voltage is connected to prime the lubrication unit.

The operation then starts with the fi rst interval time. When the interval time

has expired the metered volume is delivered.

• The operating mode, the entered delivery period, the entered oil container LC 2

(Ö LC250) and the metered volume to be delivered per 100 hours are shown on

the display.

• Metered lubricant deliveries are only executed when the supply voltage is connected.

• Metered lubricant deliveries not executed because of a fault are automatically

rescheduled at half the interval time.

Table 5: The delivery volume is determined by the delivery duration and interval

Delivery period

Month

1

2

3

4

5

6

7

8

9

10

11

12

Interval time

't [h:mm]

1:30 34

3:00 17

4.36 11

6:06 8.5

7:36 6.8

9:06 5.7

10:36 4.8

12:12 4.2

13:42 3.8

15:12 3.4

16:42 3.1

18:12 2.8

Delivery volume [cm³/100 h]

with oil container LC 2 (= LC250)

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

Function 15/54

6.1.1 Setting the delivery volume in the TIME operating mode

The mode of operation, the oil container used LC 2 (Ö LC250) and the delivery

period is entered via the display using the SET button.

The delivery period must be entered in relation to the required delivery volume,

interval period and the oil tank used LC 2 (Ö LC250) (see Table 5 on page 14).

• The input is executed with the power supply disconnected. The power supply for

the electronics comes from an integrated backup battery.

• The oil container LC 2 must be installed on the drive prior to the setting

(see page 31).

In the as delivered condition the display is on the left.

358 814-27

1. Press and hold the SET button (> 5 s), until the modes TIME and PULSE fl ash

in the display.

2. Press 1x the SET button.

358 814-28

The display switches to the TIME mode (TIME fl ashes).

ENGLISH

358 814-29

After about 3 seconds, the display switches to the selection of the oil container.

3. Press SET button 1x ¨ LC60

358 814-30

Press SET button 2x

Press SET button 3x

¨ LC120

¨ LC250 (= LC 2)

The selected oil container fl ashes in the display (here LC250).

358 814-31

After about 3 seconds, the display switches to the entry of the metered lubricant

delivery period.

358 814-32

4. To enter the delivery period press the SET button repeatedly.

Months

1...12 can be scrolled through.

The delivery period entered fl ashes in the display.

358 814-33

Approximately 3 seconds after the entry (inactive SET button) the setting mode

for the delivery period is terminated.

The operating mode, the entered delivery period, the entered oil container LC 2

(Ö LC250) and the metered volume to be delivered per 100 hours are shown on

358 814-34

the display.

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

16/54 Function

5. Turn on the power to the lubrication unit.

Make the electrical connection to the product see page 38.

The plug icon (cable break detection, see page 25) appears in the display and

358 814-34

the arrow icon

5 s intervals.

d flashes in the display. The drive LEDs flash green at

The initial start of the operation begins about 8 s after the supply voltage with

the interval time.

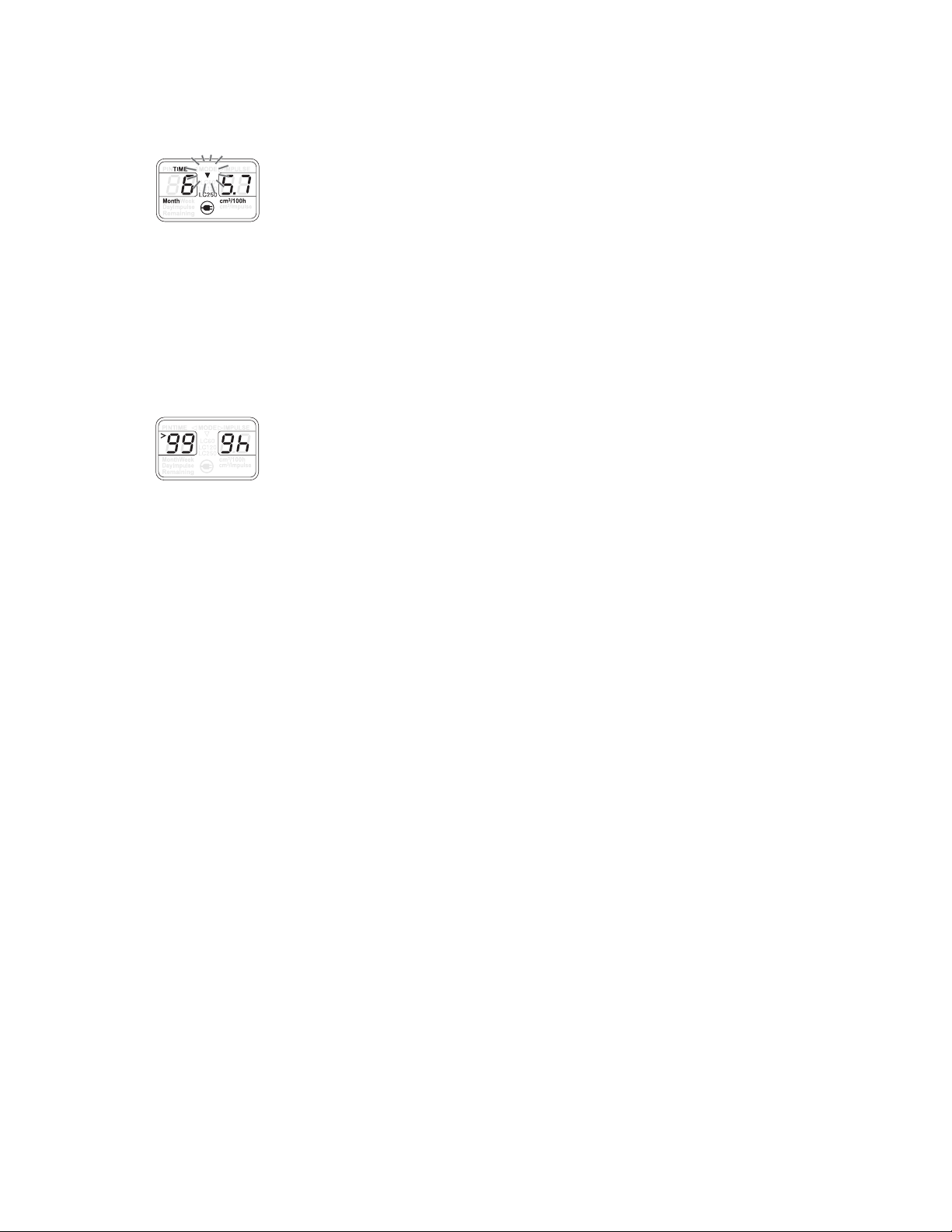

6.1.2 Display of the remaining delivery period

During operation, the remaining delivery period can be shown in the display.

f Press and hold the SET button during operation for > 1 s (fl ashing arrow

icon

din the display).

The display shows the remaining delivery time in hours.

>

999h hours appears in the display where the remaining delivery time is

equal or greater than 1000 hours.

358 814-37

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

Function 17/54

6.2 PULSE mode

In PULSE mode delivery volume can be entered in defi ned steps.

According to the volume of the oil container entered LC 2 (= LC250),

a certain number of lubricant deliveries follow, with the appropriate

delivery volume.

• The operating mode, the oil container used LC 2 (LC250), and the required delivery

volume per pulse (delivery) are entered via the display using the SET button.

• If the number of remaining pulses (deliveries) is 100 or greater, the following

indicator appears in the display

• The delivery is carried out once with supply voltage (rising fl ank).

• The supply voltage must be present at least as long enough for the delivery

process to be completed (min. 2 minutes).

• Before the following delivery the supply voltage must be shut down for > 1 s.

• The signaling/display of system states and errors is only possible when the

supply voltage is present.

>

99 (Field in the table with a gray background).

ENGLISH

358 814-26

3 842 358 814/2017-01, MIT: LU 2, Bosch Rexroth AG

Loading...

Loading...