Bosch Rexroth IndraControl XM21, Rexroth IndraControl XM22 Operating Instructions Manual

IndraControl

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

XM21, XM22

Controls

Operating Instructions

R911340667

Edition 03

Bosch Rexroth AG Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Change Record

Edition Release

Notes

Date

Edition 01 2014-07 First edition

Edition 02 2016-08 Revised edition

Edition 03 2017-03 Notes on the explosion protection (Atex) supplemented for XM22

Copyright

© Bosch Rexroth AG 2017

This document, as well as the data, specifications and other information set

forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

Liability

The specified data is intended for product description purposes only and shall

not be deemed to be a guaranteed characteristic unless expressly stipulated in

the contract. All rights are reserved with respect to the content of this documentation and the availability of the product.

Editorial Department

Development automation systems, control platform HP (MK/MePe)

RS-dd09e598460fdd310a6846a501e7d658-3-en-US-3

Controls Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Table of Contents

Table of Contents

Page

1 About this documentation..................................................................... 1

1.1 Overview on target groups and product phases.................................... 1

1.2 Scope..................................................................................................... 1

1.3 Related documents................................................................................ 2

1.4 Customer feedback................................................................................ 2

2 Product identification and scope of delivery......................................... 2

2.1 Product identification............................................................................ 2

2.2 Scope of delivery................................................................................... 3

3 Use of the safety instructions................................................................ 3

3.1 Structure of the safety instructions....................................................... 3

3.2 Explaining signal words and safety alert symbol................................... 3

3.3 Symbols used......................................................................................... 4

3.4 Signal graphic explanation on the device.............................................. 4

4 Intended Use.......................................................................................... 5

5 Spare parts, accessories and wear parts.............................................. 5

5.1 Power connectors, 24 V......................................................................... 5

5.2 Bus base module for IndraControl XM21/XM22.................................... 6

5.3 Bus base module for IndraControl S20 I/O........................................... 6

5.4 SD card.................................................................................................. 6

5.5 End clamp.............................................................................................. 6

5.6 Wear parts............................................................................................. 6

6 Ambient conditions................................................................................ 6

7 Technical data........................................................................................ 8

7.1 Voltage supply and current consumption.............................................. 9

8 Standards.............................................................................................. 9

8.1 Standards used.................................................................................... 10

8.2 CE marking........................................................................................... 10

8.2.1 Declaration of conformity.................................................................... 10

8.3 UL/CSA certified.................................................................................. 10

8.4 Explosion protection certification (XM2201.01-...).............................. 11

DOK-CONTRL-IC*XM2*****-IT03-EN-P

I

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Controls

Table of Contents

Page

8.4.1 Power matrix........................................................................................ 13

8.4.2 Standards used.................................................................................... 13

8.5 Marine and offshore certification (XM2201...).................................... 13

9 Interfaces............................................................................................. 14

9.1 Connection position............................................................................ 14

9.2 Extension bus...................................................................................... 15

9.3 S20 interface....................................................................................... 15

9.4 Control bus base module .................................................................... 15

10 Mounting, demounting and electric installation.................................. 16

10.1 Installation notes................................................................................. 16

10.2 Housing dimensions............................................................................. 18

10.3 Mounting the control........................................................................... 19

10.4 Mounting S20 I/O modules.................................................................. 20

10.5 Mounting extension modules............................................................... 21

10.6 Demounting the control and the control bus base module................. 22

10.6.1 Demounting steps................................................................................ 22

10.7 Electric installation.............................................................................. 24

10.7.1 External power supply unit ................................................................. 24

10.7.2 Voltage supply for the control.............................................................. 25

10.7.3 24 V voltage supply.............................................................................. 26

10.7.4 Grounding

............................................................................................................. 28

10.7.5 Shielding.............................................................................................. 29

11 Commissioning.................................................................................... 29

11.1 Commissioning steps........................................................................... 29

11.2 Establishing a connection to the engineering PC via the USB device

interface "XF31" .................................................................................. 30

12 Device description............................................................................... 33

12.1 LEDs and operating elements.............................................................. 34

12.1.1 LEDs in the XD1 plug........................................................................... 34

12.1.2 LED block of 10................................................................................... 35

12.1.3 Operation mode switches ................................................................... 36

12.1.4 Reset button........................................................................................ 37

12.2 Initial firmware..................................................................................... 38

12.2.1 License information............................................................................. 39

II

DOK-CONTRL-IC*XM2*****-IT03-EN-P

Controls Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Table of Contents

Page

12.2.2 LED states............................................................................................ 39

12.2.3 Starting and opening the initial firmware............................................ 40

12.2.4 Installing a backup from an external SD card...................................... 41

12.3 Booting................................................................................................ 42

12.4 Fallback and recovery.......................................................................... 42

12.5 IndraControl First Touch...................................................................... 43

12.5.1 Hardware data..................................................................................... 44

12.5.2 Network settings.................................................................................. 44

12.5.3 Firmware management........................................................................ 45

12.5.4 File manager........................................................................................ 50

12.5.5 Core dump........................................................................................... 51

12.6 Backing up remanent data................................................................... 52

12.7 Real-time clock.................................................................................... 52

13 Error causes and troubleshooting........................................................ 53

14 Maintenance........................................................................................ 54

14.1 Regular maintenance tasks.................................................................. 54

15 Ordering information........................................................................... 54

15.1 Type code............................................................................................. 55

15.2 Accessories and spare parts................................................................ 56

16 Disposal............................................................................................... 57

16.1 General Information............................................................................. 57

16.2 Return.................................................................................................. 57

16.3 Packaging............................................................................................. 57

17 Service and support............................................................................ 57

Index.................................................................................................... 59

DOK-CONTRL-IC*XM2*****-IT03-EN-P

III

Bosch Rexroth AG Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

IV

DOK-CONTRL-IC*XM2*****-IT03-EN-P

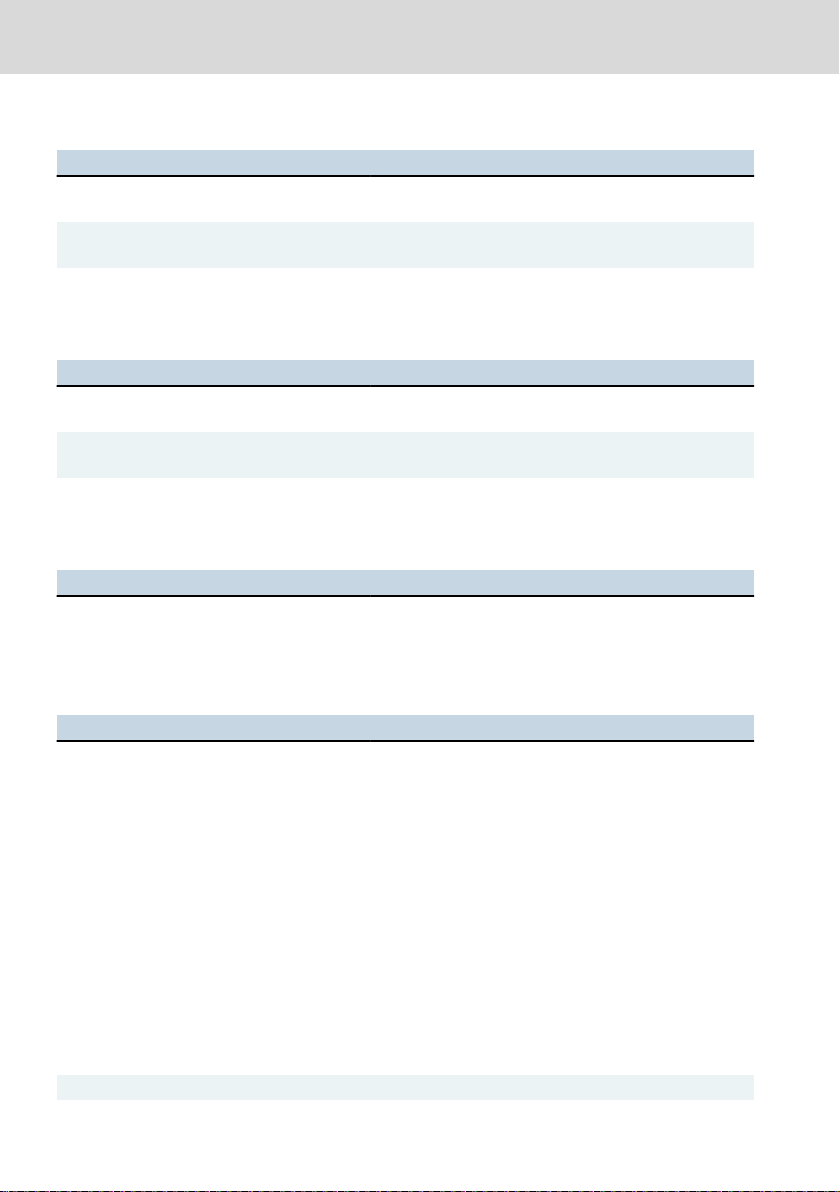

Presales Aftersales

Selection

Mounting

(assembly/installation)

Engineering

Commissioning

Operation

Decommissioning

Product

phases

Target

groups

Activities

Design engineer

Programmer

Technologist

Process

specialist

Select

Prepare

Design

Construct

Mechanic/

electrician

Unpack

Mount

Install

Programmer

Commissioning engineer

Parameterize

Program

Configure

Simulate

Technologist

Process specialist

Optimize

Test

Machine

operator

Maintenance

technician

Service

Operate

Maintain

Remove

faults

Create

the NC program

Mechanic/

electrician

Disposal company

Dismount

Dispose

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Bosch Rexroth AG

About this documentation

1 About this documentation

1.1 Overview on target groups and product phases

In the following illustration, the framed activities, product phases and target

groups refer to the present documentation.

Example: In the product phase "Mounting (assembly/installation)", the target

group "mechanic/electrician" can execute the activity "install" using this documentation.

Fig. 1-1:

tivities of the target group

This document instructs the technical staff of the machine manufacturer on how

to safely perform the mechanical and electrical installation and on how to commission the device.

Required qualification: Individual who is able to assess the tasks assigned and

to identify possible safety risks owing to qualification in the subject, knowledge

and experience. The individual should also be familiar with the standards and

regulations.

1.2

Scope

This operating instructions is valid for all variants of the control, whose type codes start with:

XM21...

DOK-CONTRL-IC*XM2*****-IT03-EN-P

Assigning the present documentation to the target groups, product phases and ac-

1/61

(7261)

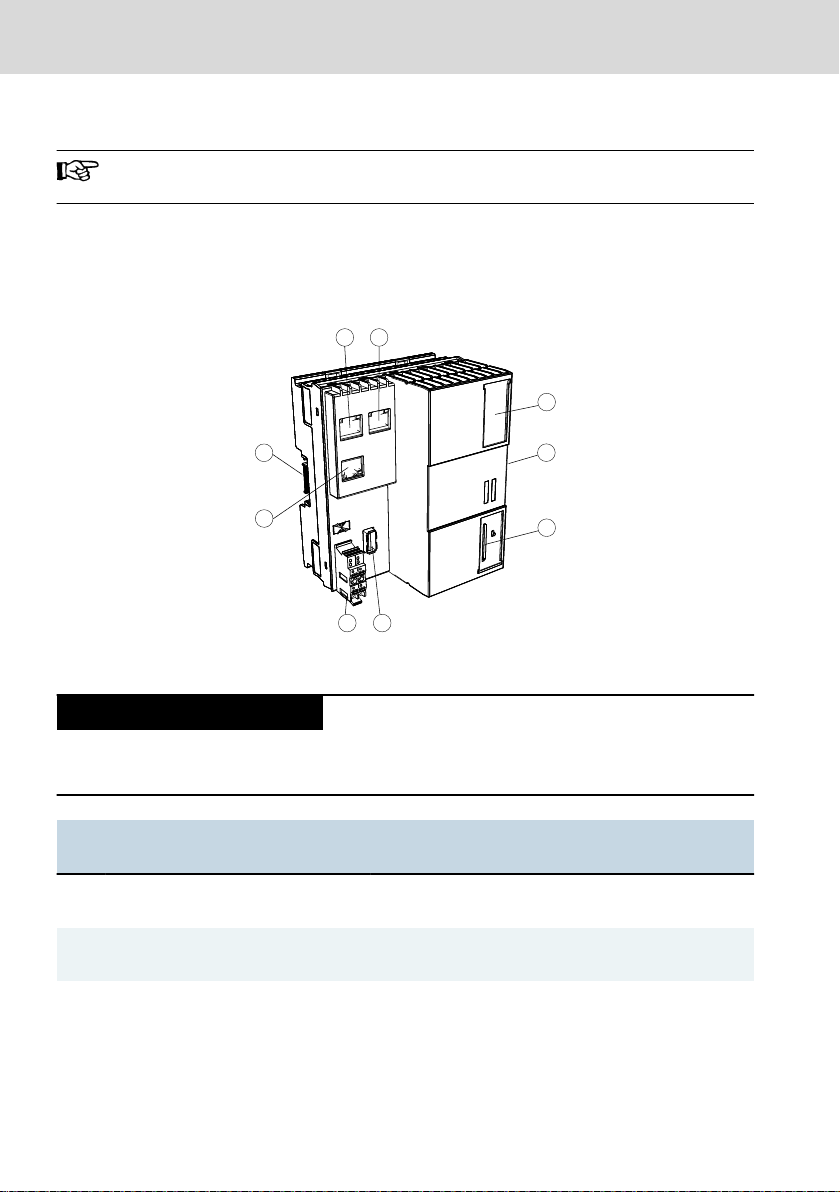

MNR: R911173147

FD: 13W08

AA1

FI:001

SN: 7260007123456789

IND.CONT.EQ

C

U

17YB

US LISTED

I-C-B-H-T-V

Bosch Rexroth AG, 97816 Lohr, Germany

Made in Germany

17

8

3

21 5

11

10

9

13

12

16

15

4 76

14

1 Wortmarke

2 Materialnummer

3 Typenbezeichnung

4 Prüfziffer

5 Fertigungsdatum jjWww

6 Änderungsstand

7 Schutzart des Gehäuses

8 CE-Konformitätskennezeichen

9 Werksnummer

10 Rexroth-Barcode

11 Seriennummer

12 UL-Kennzeichen

13 Bemessungsstrom

14 Bemessungsspannung

15 Firmenanschrift

16 MAC-Adresse, MAC-Adresse al Barcode

UN DC 24 V

IN 0,6 A

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Controls

Product identification and scope of delivery

XM22...

The type code specifications are located on the type plate of the device. Also re-

fer to chapter 2 "Product identification and scope of delivery" on page 2.

1.3 Related documents

Title Part number and document type

Rexroth IndraControl S20:

System and Installation

Rexroth IndraControl S20:

Diagnostic Tabs and Error Messages

Tab. 1-1: Related documents

The XM2x controls are provided as function package with the systems

IndraMotion MLC and IndraMotion MTX. The ordering data (type code, part

number) differ according to the selected function package (system functions).

The hardware characteristics described in this document apply to all available

function packages. For more information on the function packages, refer to the

respective system descriptions.

For related documents, go to the "Rexroth Media Directory" at http://

www.boschrexroth.com.

R911335988

Application Description

R911344826

Application Description

1.4 Customer feedback

Customer requests, comments or suggestions for improvement are of great importance to us. Please email your feedback on the documentations to Feed-

back.Documentation@boschrexroth.de. Directly insert comments in the elec-

tronic PDF document and send the PDF file to Bosch Rexroth.

2

Product identification and scope of delivery

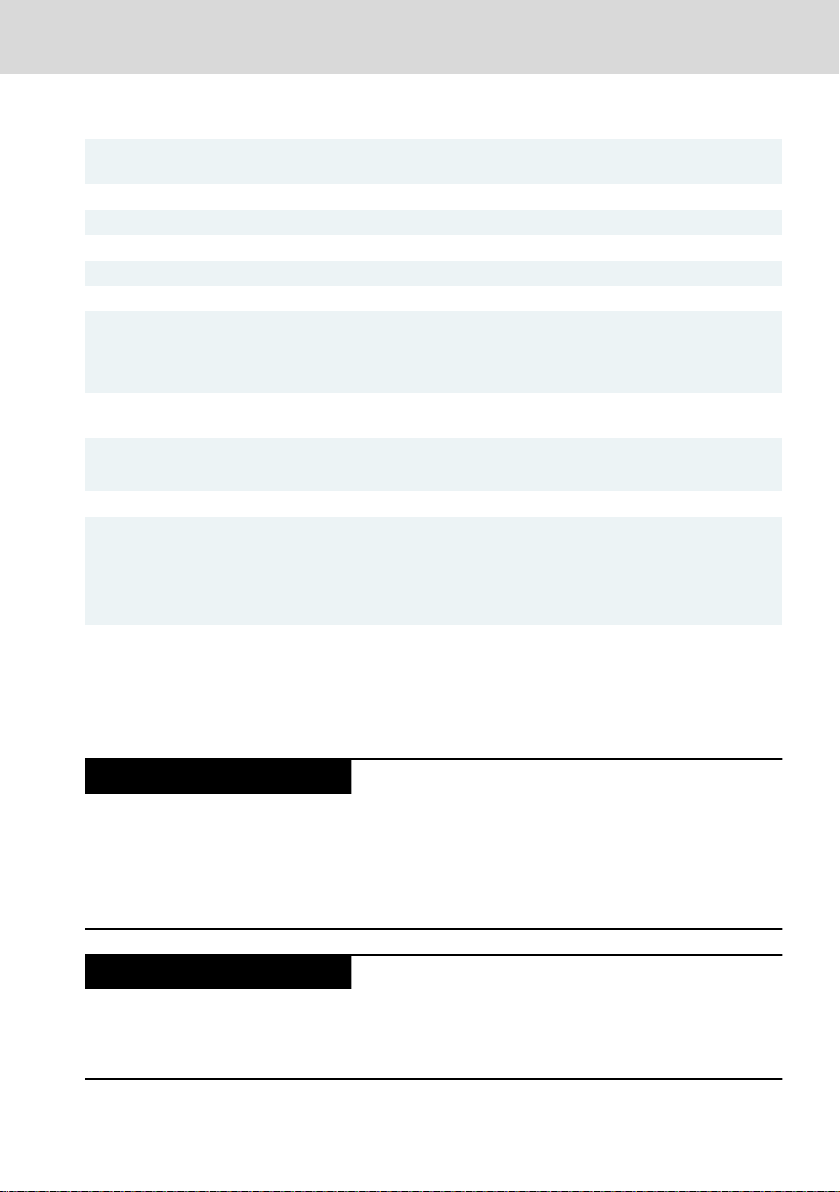

2.1 Product identification

1 Word mark

2 Part number

2/61

3 Type name (type code)

4 Check digit

DOK-CONTRL-IC*XM2*****-IT03-EN-P

Burns and chemical burns due to wrong

battery treatment!

CAUTION

Safety alert symbol

Signal word

Consequences and

source of danger

Avoiding danger

Do not open the batteries and do not heat them over 80 °C.

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Bosch Rexroth AG

Use of the safety instructions

5 Date of manufacture (yyWww)

6 State of revision

7 CE conformity marking

8 Plant number

9 QR code

10 Serial number

11 Underwriters Laboratories Inc. mark

Fig. 2-1: Exemplary type plate

12 Nominal current

13 Nominal voltage

14 Company address

15 MAC address, MAC address as barcode

16 Functional index

17 Manufacturing country

2.2 Scope of delivery

● IndraControl XM21 or IndraControl XM22

● 24 V power connector XA-CN01

● Bus base module:

– XA-BS01 (for S20 connection right)

– XA-BS02 (for S20 connection right and extension modules left)

3

Use of the safety instructions

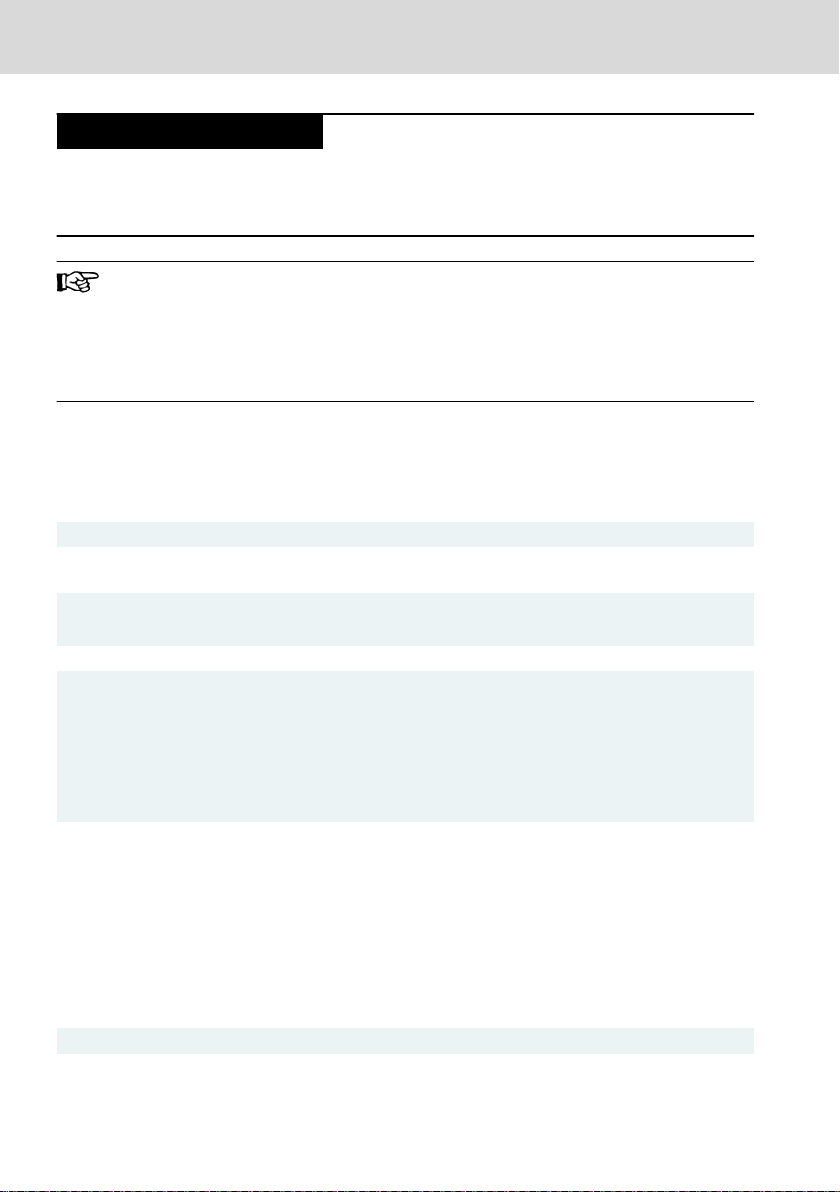

3.1 Structure of the safety instructions

The safety instructions are structured as follows:

Fig. 3-1: Structure of the safety instructions

3.2 Explaining signal words and safety alert symbol

The safety instructions in this documentation contain specific signal words (danger, warning, caution, notice) and, if necessary, a safety alert symbol (according

to ANSI Z535.6-2006).

The signal word is used to draw attention to the safety instruction and also provides information on the severity of the hazard.

The safety alert symbol (a triangle with an exclamation point), which precedes

the signal words danger,warning and caution is used to alert the reader to personal injury hazards.

DOK-CONTRL-IC*XM2*****-IT03-EN-P

3/61

DANGER

WARNING

CAUTION

NOTICE

krax

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Controls

Use of the safety instructions

In case of non-compliance with this safety instruction, death or serious injury

will occur.

In case of non-compliance with this safety instruction, death or serious injury

can occur.

In case of non-compliance with this safety instruction, minor or moderate injury

can occur.

In case of non-compliance with this safety instruction, material damage can occur.

3.3 Symbols used

Hints are represented as follows:

This is an information.

Tips are represented as follows:

This is a tip.

3.4 Signal graphic explanation on the device

Prior to the installation and commissioning of the device, refer to the

device documentation.

4/61

DOK-CONTRL-IC*XM2*****-IT03-EN-P

NOTICE

Controls Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Spare parts, accessories and wear parts

4 Intended Use

Danger of device damage if not the expressly

stated accessories, mounting parts, components, cables, lines, software and firmware are

used.

The IndraControl XM21/XM22 control may only be used with the accessories

and mounting parts listed in this documentation. Components that are not expressly mentioned must neither be attached nor connected. The same applies to

cables and lines.

Only to be operated with the component configurations and combinations expressly defined and with the software and firmware specified in the corresponding functional description.

Typical areas of application of the IndraControl XM21/XM22 are:

● Handling systems and assembly systems

● Packaging and food processing machines

● Printing machines and paper converting machines

● Machine tools

● Wood working machines

The IndraControl XM21/XM22 control may only be operated under the mounting

and installation conditions, the position, and the ambient conditions (temperature, degree of protection, humidity, EMC etc.) specified in the related documentation.

5

Spare parts, accessories and wear parts

5.1 Power connectors, 24 V

Ordering code Part number Description

XA-CN01 R911173741 24 V plug

Tab. 5-1: Power connectors, 24 V

DOK-CONTRL-IC*XM2*****-IT03-EN-P

5/61

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Ambient conditions

Controls

5.2 Bus base module for IndraControl XM21/XM22

Ordering code Part number Description

XA-BS01 R911342346 Bus base module for IndraControl S20 connection

XA-BS02 R911342347 Bus base module for IndraControl S20 connection

Tab. 5-2: Bus base modules IndraControl XM21/XM22

(right)

(right) and extension modules (left)

5.3 Bus base module for IndraControl S20 I/O

Ordering code Part number Description

S20-BS R911172540 Bus base module for wide IndraControl S20 I/O mod-

S20-BS-S R911173203 Bus base module for narrow IndraControl S20 I/O mod-

Tab. 5-3: Bus base modules for S20 I/O

ules

ules

5.4 SD card

Ordering code Part number Description

XA-SD01 R911173844 SD card 1 GB

Tab. 5-4: SD card

5.5 End clamp

Ordering code Part number Description

SUP-M01-ENDHALTER R911170685 2 pieces of snap-on end brackets for 35 mm NS 35/7.5

Tab. 5-5: End clamp

or NS 35/15 carrier plate; width: 9.5 mm

5.6 Wear parts

There are no wear parts in the controls IndraControl XM21 and XM22.

6

Ambient conditions

Ambient temperature in operation Up to 2,000 m: -25 °C to +60 °C

2,000 m to 3,000 m: max. +55 °C

3,000 m to 4,000 m: max. +50 °C

4,000 m to 4,700 m: max. +45 °C

Ambient temperature during storage and transport -30 °C to +85 °C

6/61

DOK-CONTRL-IC*XM2*****-IT03-EN-P

NOTICE

NOTICE

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Bosch Rexroth AG

Ambient conditions

Operating altitude Up to 4,700 m above sea level acc. to DIN 60204

Permitted air humidity 5 % to 95 % acc. to DIN EN 61131-2, no conden-

sation

Degree of protection IP20 acc. to DIN EN 60 529

Protection class III, DIN EN 61010-2-201

Overvoltage category 2

Contamination level 2, no condensation allowed

Mechanical tests

①

Vibration resistance acc. to DIN EN 60068-2-6

Oscillations, sinusoidal in all three axes

5 Hz - 9 Hz with 3.5 mm amplitude

9 Hz -150 Hz with 5 g peak acceleration

Shock test acc. to DIN EN 60068-2-27 Shock stress: Shock resistance in all three axes,

11 ms semi-sinusoidal 30 g

Broadband noise acc. to DIN EN 60068-2-64

5-20-150 Hz with 0.572 g, 5 h per axis

Electrostatic discharge

ESD resistance acc. to DIN EN 61131-2

● Test voltage

Criterion B

8 kV for air discharge

6 kV for contact discharge

① The vibration stress specifications assume the use of industrial-suited RJ45 plug connec-

tions. The "Industrial RJ45 plug" of the company Yamaichi is recommended (Y-ConPlug-41). The cables are available as accessories (RKB0020). To protect against vibration,

secure the cables with a short distance (< 20 cm). The USB interfaces XF30 and XF31

may only be used up to a vibration stress of 1 g.

Tab. 6-1: Ambient conditions

Failure of the product due to contaminated air

● The ambient air must not contain acids, alkaline solutions, corrosive agents,

salts, metal vapors and other electrically conductive contaminants in high

concentrations

● Housing and installation compartments must at least comply with the degree

of protection IP 54 according to DIN EN 60529

Defective product due to gases jeopardizing

functions

Due to the risk of corrosion, avoid sulphurous gases (e.g. sulphur dioxide (SO2)

and hydrogen suphide (H2S)). The product is not resistant against these gases.

DOK-CONTRL-IC*XM2*****-IT03-EN-P

7/61

NOTICE

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Controls

Technical data

Failure of the product due to overheating

To avoid overheating and to ensure a smooth operation of the product according

to the minimum distances specified in chapter 10.1 "Installation notes" on page

16, air has to circulate.

This is a product that corresponds to the limit values of the emitted

interference of class A (industrial environments), but not of class B

(residential area and small enterprises).

When using the product in residential areas or small enterprises, the

operator has to take actions to prevent radio interferences (also refer to DIN EN 55022).

7

Technical data

Processor IndraControl XM21: Intel E620T 600 MHz (CPU frequency)

IndraControl XM22: Intel E660T 1300 MHz (CPU frequency)

RAM 512 MB DRAM

Connection for extension mod-

Via the control bus base module XA-BS02

ules

Extension bus

Number of possible modules 3

Connection for S20 I/O Via control bus base module XA-BS01 or XA-BS02

S20 bus parameters

Transmission rate

Number of connectable mod-

ules

100 MBit/s

Max. 63 (per station)

2 A

Max. current for the S20 bus

(U

)

Bus

Communication interfaces RJ45 connections:

● 1 × Ethernet connection (10 MB, 100 MB, 1 GB)

● 2 × Sercos III master/slave interface

USB ports:

● 1 × USB host, maximum cable length 3 m (for the functionality,

refer to the system description of the respective system)

● 1 × USB device, maximum cable length 3 m (for the functionality,

refer to the system description of the respective system)

SD card Slot for SD card

8/61

DOK-CONTRL-IC*XM2*****-IT03-EN-P

NOTICE

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Bosch Rexroth AG

Standards

Weight 0.38 kg (incl. supply connectors)

Dimensions Refer to chapter 10.2 "Housing dimensions" on page 18

Tab. 7-1: Technical data

7.1 Voltage supply and current consumption

The following values apply to the operating voltage acc. to DIN EN 61131-2:

Nominal voltage at U

LS

Maximum voltage range of the supply voltage allowed U

LS

Current consumption of the control incl. the connected S20 I/O modules from ULS at nominal volt-

age

Current consumption of the control without the

connected S20 I/O modules from ULS at nominal

voltage

Power consumption of the control incl. the connected S20 I/O modules from ULS at nominal volt-

age

Power consumption of the control without the con-

nected S20 I/O modules from ULS at nominal voltage

Reverse voltage protection of the supply voltage Diode

Fuse protection Internal protective fuse, 2.5 A

Transient protection

Pulse load up to 1,500 W

Voltage dips at current supply interfaces PS2 < 10 ms, evaluation criterion A

Electrical isolation

24 V supply ULS to the functional earth

24 V DC SELV/PELV

18 V DC to 31.2 V DC (incl. all tolerances and ripple)

Maximum 1.5 A

Typically 1.0 A

Maximum 36 W

Typically 24 W

Present, suppressor diodes

No separation between 0 V of the ULS and FE

(housing)

Tab. 7-2: Operating voltage and current consumption

Electronic damage due to polarity reversal or

due to a nominal current that is too low

The power supply unit has to be able to deliver the quadruple nominal current of

the protective fuse to ensure that the fuse reliably triggers in case of an error.

8

Standards

The products have been developed according to the German edition of the

standards published at the time of product engineering.

DOK-CONTRL-IC*XM2*****-IT03-EN-P

9/61

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Controls

Standards

8.1 Standards used

Standard Meaning Edition

IEC 60204-1 Electrical equipment of machines 2007

IEC 61131-2 Programmable controllers 2008

IEC 60529 Degrees of protection provided by enclosures (IP Code) 2014

IEC 61010-2-201 Safety requirements for electrical equipment for measure-

2014

ment, control and laboratory use

UL 61010-2-201 Safety requirements for electrical equipment for measure-

2014

ment, control and laboratory use

Tab. 8-1: Standards used

8.2 CE marking

8.2.1 Declaration of conformity

The electronic products described in the present operating instructions comply

with the requirements and the target of the following EU directive and with the

following harmonized European standards:

EMC directive 2014/108/EC

The electronic products described in the present operating instructions are in-

tended for use in industrial environments and comply with the following requirements:

Standard

DIN EN 61000-6-4 Electromagnetic compatibility (EMC)

DIN EN 61000-6-2 Electromagnetic compatibility (EMC)

Title Edition

September

Part 6-4: Generic standards – Emission standard for indus-

2011

trial environments

March 2006

Part 6-2: Generic standards – Immunity for industrial environments

Tab. 8-2: Standards for electromagnetic compatibility (EMC)

Loss of CE conformity due to modifications at the device.

CE marking applies only to the device upon delivery. After modifying

the device, verify the CE conformity.

8.3 UL/CSA certified

10/61

DOK-CONTRL-IC*XM2*****-IT03-EN-P

II 3G

Ex ec IIC T4 Gc

TÜV 16 ATEX 7948 X

IECEx TUR 16.0048 X

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Bosch Rexroth AG

Standards

The devices are certified acc. to

● UL 61010-2-201 (Industrial Control Equipment) and

● CSA22.2 No. 61010-2-201 (CSA)

However, there can be combinations or extension stages with a limited or missing certification. Thus, verify the registration according to the UL marking on the

device.

Loss of UL/CSA conformity due to modifications at the device.

UL and CSA marking applies only to the device upon delivery. After

modifying the device, verify the UL and the CSA conformity.

To guarantee an UL/CSA-compliant operation, the following conditions have to be fulfilled:

● Use only insulated copper wire suitable for at least 60/75°C

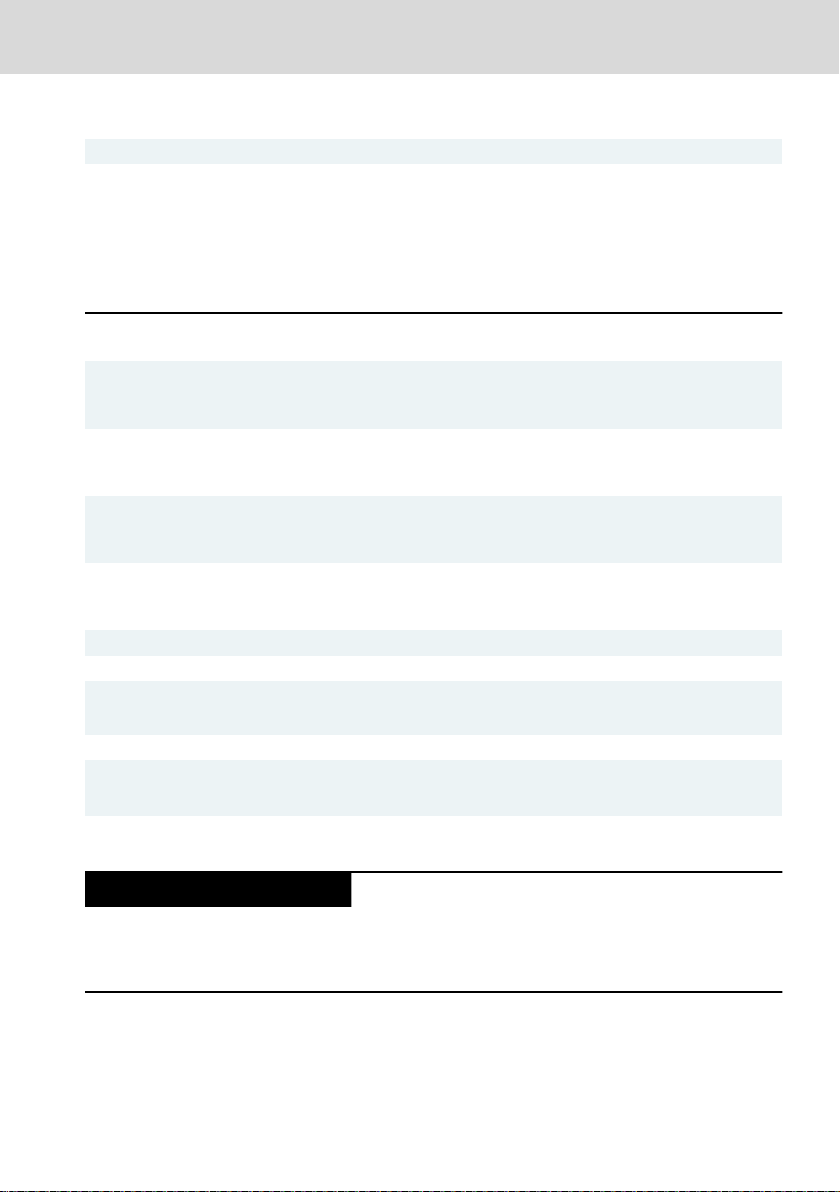

8.4 Explosion protection certification (XM2201.01-...)

Ex Explosion protection label

II Equipment group II: Explosive gas

3G Equipment category 3: Explosive at-

Ex Explosion protection label

ec Type of protection "Increased safety"

IIC Gas group IIC, hydrogen

T4 Maximum surface temperature

Fig. 8-1: Exemplary type plate

atmospheres

mosphere (zone 2)

135 °C

Gc Equipment protection level (EPL),

TÜV... ATEX EU type examination certificate

IECEx... IECEx certificate number

...X Note on special conditions, refer to

rare and momentary explosive atmosphere (zone 2): Flammable

gases, vapors, mists

the following note.

The approval numbers given on the type plate are marked at the end with an "X"

for devices and a "U" for components. "X" indicates special conditions to be observed together with the safety and health regulations given in the standards.

"U" indicates a component (Ex component) that may not be used on its own.

DOK-CONTRL-IC*XM2*****-IT03-EN-P

11/61

DANGER

DANGER

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Standards

Observe the following special conditions for a safe operation of the

devices and components:

● The explosion protection approval applies only to the control

XM2201.01-....

● The explosion protection approval is only valid if the devices and

components approved by Bosch Rexroth are used as intended, refer to chapter 4 "Intended Use" on page 5.

● The XM22 control may only be used together with the additional

components and accessories approved by Bosch Rexroth. Otherwise, the explosion protection approval does not apply.

● In case of unintended modifications at the device or at the com-

ponents, the explosion protection approval does also not apply.

For maintenance and troubleshooting, refer to chapter 14 "Main-

tenance" on page 54 and chapter 13 "Error causes and troubleshooting" on page 53.

● The XM22 control may only be used in an area with the minimum

pollution degree 2 as defined in IEC 60991-1.

● For the permitted ambient temperature range, refer to chapter 6

"Ambient conditions" on page 6.

● The XM22 control may only be installed in a housing (control cabi-

net) providing at least an ingress protection of IP54 in compliance

with IEC 60079-0.

● Take suitable actions to ensure that the supply voltage outside the

device or the component is always within the permitted voltage

range (±10%) acc. to EN 60079-0.

● Maintenance and repair work may only be carried out by the certi-

fied Rexroth service.

● Always store and transport the device or the component in the

original package.

Controls

Explosion hazard

Working at the device is only permitted if there is no explosive atmosphere.

Explosion hazard when exceeding or falling below the ambient temperature

Do not exceed the ambient temperature permitted, refer to chapter 6 "Ambient

conditions" on page 6

12/61

DOK-CONTRL-IC*XM2*****-IT03-EN-P

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

8.4.1 Power matrix

Bosch Rexroth AG

Standards

Devices and com-

Max. internal current consumption Max. internal power consumption

ponents

XM2201.01.-......

1500 mA 36.0 W

R911173148

XFE01.1-FB-03

200 mA 4.8 W

R911173397

XFE01.1-FB-20

200 mA 4.8 W

R911173957

S20-AI6-AO2-

100 mA 2.4 W

SSI2

R911173120

S20-PWM-4-T

400 mA 9.6 W

R911173461

Tab. 8-3: Power matrix of the XM22 control and the approved components

If the housing surface (control cabinet) is 1m2, up to 87 W of internal power consumption of the individual devices and components

are permitted.

8.4.2 Standards used

Standard Title

EN 60079-0:2012 + A11:2013

IEC 60079-0:2011, modified + Corr.:2012

+ Corr.:2013

EN 60079-7:2015

IEC 60079-7:2015

Explosive atmospheres –

Part 0: Equipment –

General requirements

Explosive atmospheres –

Part 7: Equipment protection by increased safety "e"

Tab. 8-4: Standard used for explosion protection

8.5 Marine and offshore certification (XM2201...)

The control XM2201 ... is suitable for the use in marine and offshore applications and was approved by the following certification organizations:

● DNV-GL Det Norske Veritas, Germanischer Lloyd DCTC_30826-001

● ABS American Bureau of Shipping DCTC_30826-002

● RINA Registro Italiano Navale DCTC_30826-003

● LR Lloyd's Register DCTC_30826-004

● BV Bureau Veritas DCTC_30826-005

DOK-CONTRL-IC*XM2*****-IT03-EN-P

13/61

1 2

8

67

5

3

9

4

NOTICE

Bosch Rexroth AG

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Interfaces

● BSH Bundesamt für Seeschifffahrt und Hydrographie DCTC 30826-006

For more information, refer to www.boschrexroth.com/dcc/Vornavi-

gation/VorNavi.cfm?PageID=p650746.

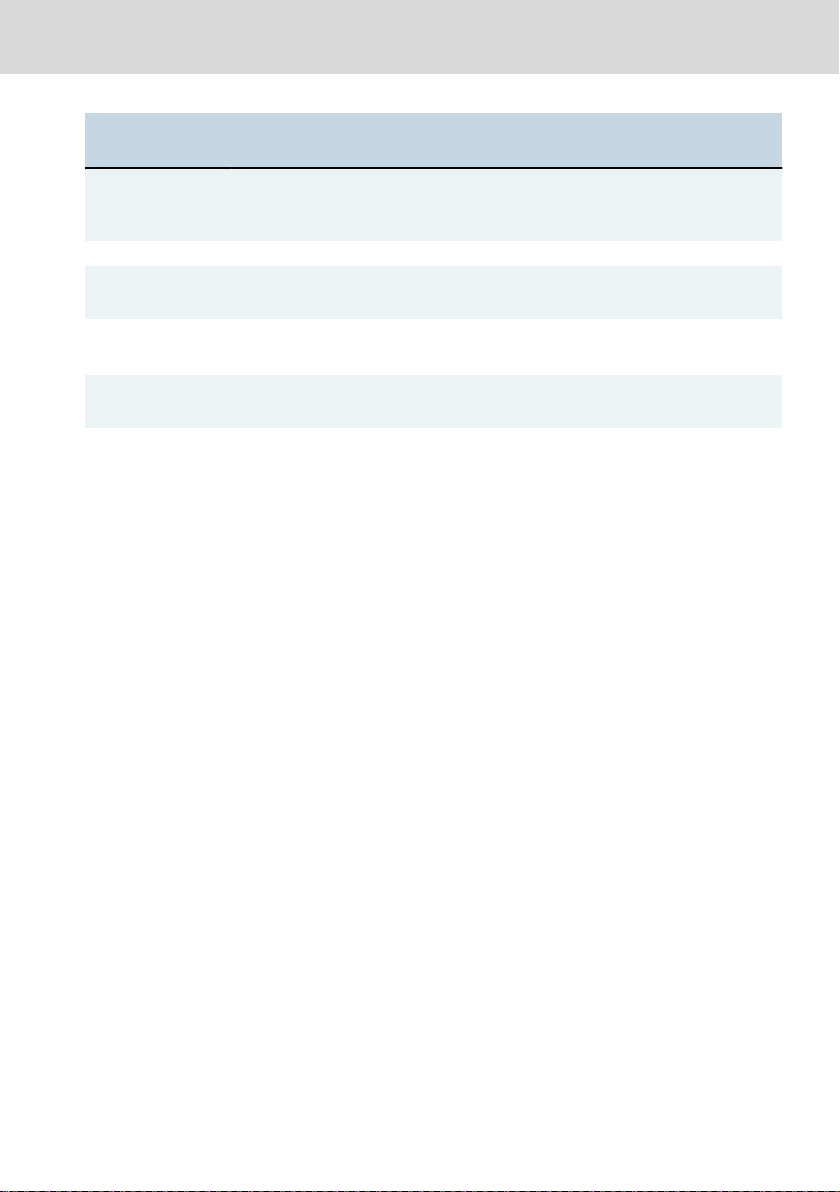

9 Interfaces

9.1 Connection position

Controls

Fig. 9-1: Interfaces

Attaching and detaching connections under

voltage can damage the control!

Switch off the supply voltage before attaching or detaching any connections!

Name Connection type Connector type

No.

(Integrated)

① XF1 Ethernet

(Sercos)

② XF2 Ethernet

(Sercos)

③ XF31 USB device

14/61

USB 2.0

RJ45 socket

8-pin

RJ45 socket

8-pin

Micro USB socket

4-pin

Mating connector and cable

(From outside)

RJ45 plug

(Twisted pair, 8-wire)

RJ45 plug

(Twisted pair, 8-wire)

Micro USB plug

(4-wire)

DOK-CONTRL-IC*XM2*****-IT03-EN-P

Controls

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Bosch Rexroth AG

Interfaces

No. Name Connection type Connector type

(Integrated)

④ S20 bus Bus base module

32-pin

Mating connector and cable

(From outside)

Bus base module for S20 I/O

modules

32-pin

⑤ SD Slot for SD card – SD card

⑥ XF30 USB host

USB 2.0

⑦ XD1 24 V plug

U

LS

⑧ XF5 Ethernet

(TCP/IP, RT Ethernet)

⑨ Extension bus Bus base module

USB TYPE A-socket

4-pin

USB TYPE A-plug

(4-wire)

4-pin (4-wire)

RJ45 socket

8-pin

RJ45 plug

(Twisted pair, 4-/8-wire)

Bus base module for exten-

32-pin

sion modules

32-pin

Tab. 9-1: Control interfaces

9.2 Extension bus

Up to three extension modules can be freely connected at the left of the control.

The extension modules have to be attached without any gaps via the extension

bus base modules on the left side of the IndraControl XM21/XM22 and supplied

with the same 24 V supply voltage. Switch on and off the 24 V supply voltage of

the extension modules synchronously with the IndraControl XM21/XM22.

9.3

S20 interface

Up to 63 S20 modules can be connected to the S20 interface on the right of the

IndraControl XM21/XM22 via S20 bus base modules. The number of connectable modules depends on the total current consumption of the S20 modules. The

IndraControl XM21/XM22 can provide up to 2 A for the power supply of the S20

modules.

9.4

Control bus base module

The control bus base module is connected at the bottom side of the

IndraControl XM21/XM22. The control bus base module is available in two variants:

● BUSMODUL XA-BS01 connects the IndraControl XM21/XM22 with the S20

modules on the right control side

● BUSMODUL XA-BS02 connects the IndraControl XM21/XM22 with the S20

modules on the right control side and the extension modules on the left control side

DOK-CONTRL-IC*XM2*****-IT03-EN-P

15/61

Loading...

Loading...