Bosch Rexroth IndraControl VR 21, Rexroth IndraControl VR 21 Singletouch, Rexroth IndraControl VR2109 Singletouch, Rexroth IndraControl VR2104 Singletouch, Rexroth IndraControl VR2107 Singletouch Operating Instructions Manual

...

Electr ic Drives

and Co ntrols Pneuma tics

Hydrau lics

Linear Motion and

Assemb ly Technolo gies

Servic e

Rexroth IndraControl

VR 21

Operating Panel

Operating Instructions

R911339476

Edition 02

Bosch Rexroth AG VR 21

Record of Revision

Edition

Release Date Notes

First edition 09.2013 -Edition 02 04.2014 Revision

Copyright

© Bosch Rexroth AG 2014

This document, as well as the data, specifications and other information set

forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

Liability

The specified data is intended for product description purposes only and shall

not be deemed to be a guaranteed characteristic unless expressly stipulated in

the contract. All rights are reserved with respect to the content of this documentation and the availability of the product.

Editorial Department

Development Automation Systems Control Hardware CV (KaWa/PiGe)

RS-188e285b0a9b33770a6846a50164e9a6-2-en-US-4

VR 21 Bosch Rexroth AG

Table of Contents

Table of Contents

Page

1 About this Documentation..................................................................... 1

2 Product Identification and Scope of Delivery........................................ 2

2.1 Product Identification............................................................................ 2

2.2 Scope of Delivery................................................................................... 2

3 Using the Safety Instructions................................................................. 3

3.1 Safety Instructions – Structure.............................................................. 3

3.2 Explaining Signal Words and Safety Alert Symbol................................. 3

3.3 Symbols Used........................................................................................ 4

4 Intended Use.......................................................................................... 4

5 Spare Parts, Accessories and Wear Parts.............................................. 5

5.1 External 24 V Power Supply Unit .......................................................... 5

5.2 Wear Parts............................................................................................. 5

6 Ambient Conditions............................................................................... 6

7 Technical Data....................................................................................... 6

7.1 VR 21 Singletouch.................................................................................. 6

7.2 VR 21 Multitouch................................................................................... 7

8 Standards.............................................................................................. 8

8.1 General Information............................................................................... 8

8.2 Used Standards..................................................................................... 8

8.3 CE Marking............................................................................................. 9

8.3.1 Declaration of Conformity .................................................................... 9

8.4 UL/CSA Certified................................................................................... 9

9 Interfaces............................................................................................. 10

9.1 Interface View...................................................................................... 10

9.2 Interface Overview............................................................................... 10

9.3 DC 24 V Voltage Supply....................................................................... 11

9.4 USB Interfaces X9, X10........................................................................ 11

9.5 Ethernet Interface X5........................................................................... 12

9.6 Slot for SD Memory Card..................................................................... 12

DOK-SUPPL*-VR21**.01**-IT02-EN-P

I

Bosch Rexroth AG

VR 21

Table of Contents

Page

10 Assembly, Disassembly and Electrical Installation.............................. 13

10.1 Housing Dimensions............................................................................ 13

10.1.1 Front View............................................................................................ 13

10.1.2 Overview of Housing Dimensions - Side View...................................... 14

10.2 Installation Notes................................................................................. 14

10.3 Mounting Cut-Out................................................................................ 15

10.4 Mounting Dimensions.......................................................................... 16

10.5 Disassembly......................................................................................... 16

10.6 Electrical Wiring................................................................................... 16

10.6.1 Connecting the Supply Voltage............................................................ 16

10.6.2 Connecting the Functional Earth (FE)................................................. 17

11 Commissioning.................................................................................... 18

12 Device Description............................................................................... 18

12.1 General Information............................................................................. 18

12.2 Control and Display Elements.............................................................. 19

12.2.1 Display................................................................................................. 19

12.2.2 Touchscreen........................................................................................ 19

12.2.3 Real-Time Clock .................................................................................. 19

12.3 Variants................................................................................................ 19

13 Error Causes and Elimination.............................................................. 20

14 Maintenance........................................................................................ 20

14.1 General Information............................................................................. 20

14.2 Display................................................................................................. 20

14.3 Cleaning Notes..................................................................................... 21

14.4 Fuse..................................................................................................... 21

14.5 Regular Maintenance Tasks................................................................. 21

15 Ordering Information........................................................................... 21

15.1 Accessories and Spare Parts............................................................... 21

15.2 Type Code VR21xx.01.......................................................................... 22

16 Disposal............................................................................................... 22

16.1 Take-Back............................................................................................. 22

16.2 Packaging............................................................................................. 23

II

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21 Bosch Rexroth AG

Table of Contents

Page

17 Service and Support............................................................................ 23

Index.................................................................................................... 25

DOK-SUPPL*-VR21**.01**-IT02-EN-P

III

Bosch Rexroth AG VR 21

IV

DOK-SUPPL*-VR21**.01**-IT02-EN-P

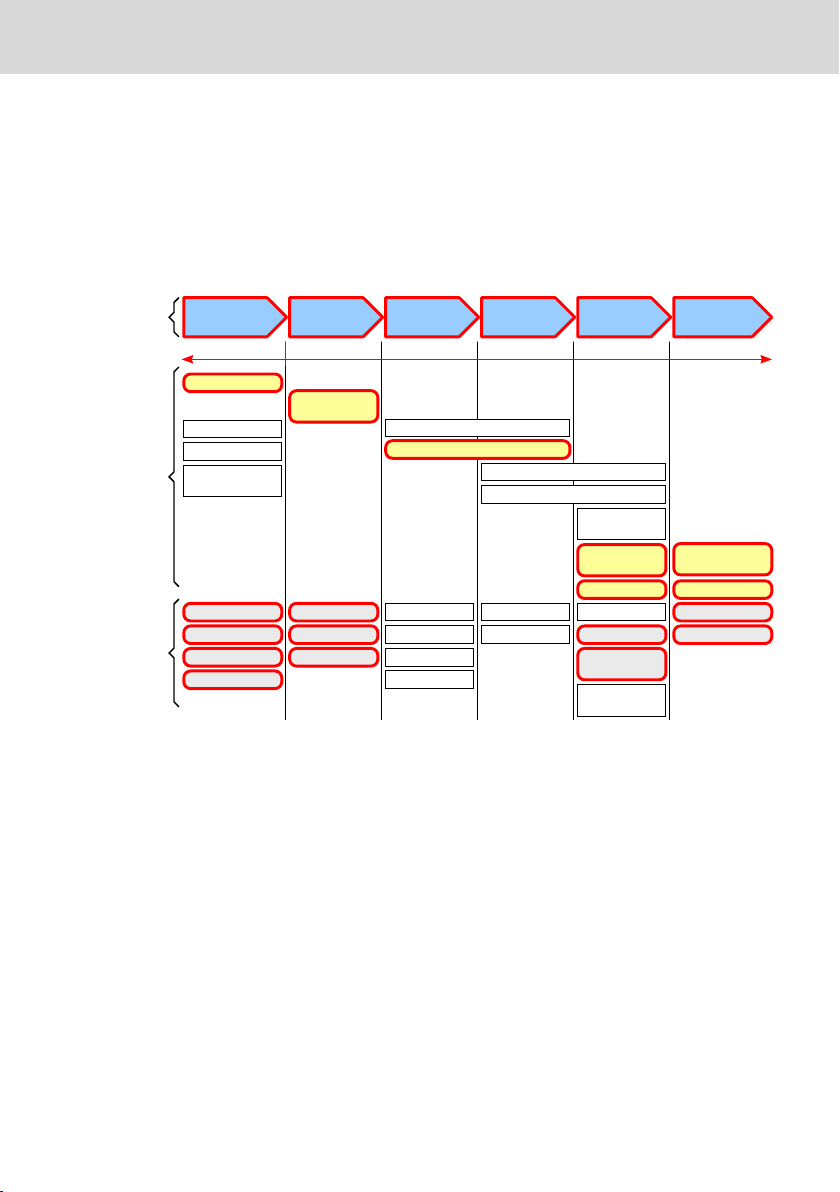

Presales Aftersales

Selection

Mounting

(assembly/installation)

Engineering

Commissioning

Operation

Decommissioning

Product

phases

Target

groups

Activities

Design engineer

Programmer

Technologist

Process

specialist

Select

Prepare

Design

Construct

Mechanic/

electrician

Unpack

Mount

Install

Programmer

Commissioning engineer

Parameterize

Program

Configure

Simulate

Technologist

Process specialist

Optimize

Test

Machine

operator

Maintenance

technician

Service

Operate

Maintain

Remove

faults

Create

the NC program

Mechanic/

electrician

Disposal company

Dismount

Dispose

VR 21

Bosch Rexroth AG

About this Documentation

1 About this Documentation

Overview – target groups and product phases

The activities, product phases and target groups that refer to the present docu-

mentation are marked in red color in the following figure.

Example: In the product phase "Mounting (assembly/installation)", the "mechan-

ic/electrician" can execute the activity "install" using this documentation.

Fig. 1-1: Assigning the present documentation to the target groups, product phases and activities of the target group

Purpose

This document instructs the technical staff of the machine manufacturer on how

to perform the mechanic and electrical installation in a safe way and on how to

commission the device.

Required qualifications: Individual who is able to assess the tasks assigned and

identify possible safety risks owing to qualification in the subject, knowledge

and experience. The individual should also be familiar with the standards and

regulations.

Scope

This document is valid for all variants whose type code starts with "VR21xx.

01…".

The type code specifications are located on the type plate of the device, see al-

so chapter 2.1 "Product Identification" on page 2.

DOK-SUPPL*-VR21**.01**-IT02-EN-P

1/29

1

5

12

9

7

2

3

4

11

8

10

6

Bosch Rexroth AG

VR 21

Product Identification and Scope of Delivery

Further documents

Title Part number and document type

Rexroth IndraControl

VAP 01

R911339613

Operating Instructions

Power Supply Unit

Rexroth IndraControl

V Devices

R911343901

Project Planning Manual

Operating Systems

Tab. 1-1: Required and supplementing documentation

Customer feedback

Customer requests, comments or suggestions for improvement are of great im-

portance to us. Please email your feedback on the documentations to Feed-

back.Documentation@boschrexroth.de. Directly insert comments in the elec-

tronic PDF document and send the PDF file to Bosch Rexroth.

2

Product Identification and Scope of Delivery

2.1 Product Identification

The type plate is located on the rear panel.

1 Logotype

2 Part number

3 State of revision

4 Date of manufacture (yyWww)

5 Division or plant number

6 Designation of origin

Fig. 2-1: Type plate IndraControl VR 21

2.2 Scope of Delivery

● Product insert "Safety and Warning Instructions"

2/29

7 Nominal current

8 Serial number as barcode

9 Company address

10 Serial number

11 Nominal voltage

12 Type code (type designation code)

DOK-SUPPL*-VR21**.01**-IT02-EN-P

Burns and chemical burns due to wrong

battery treatment!

CAUTION

Safety alert symbol

Signal word

Consequences and

source of danger

Avoiding danger

Do not open the batteries and do not heat them over 80 °C.

DANGER

WARNING

VR 21

● Six mounting brackets including tool

● 24 V female connector strip

3 Using the Safety Instructions

3.1 Safety Instructions – Structure

The safety instructions are structured as follows:

Fig. 3-1: Safety instructions – Structure

Bosch Rexroth AG

Using the Safety Instructions

3.2 Explaining Signal Words and Safety Alert Symbol

The safety instructions in this documentation contain specific signal words (danger, warning, caution, notice) and, if necessary, a safety alert symbol (according

to ANSI Z535.6-2006).

The signal word is meant to draw the reader's attention to the safety instruction

and signifies the degree of danger.

The safety alert symbol (a triangle with an exclamation point), which precedes

the signal words danger,warning and caution is used to alert the reader to personal injury hazards.

In case of non-compliance with this safety instruction, death or serious injury

will occur.

In case of non-compliance with this safety instruction, death or serious injury

can occur.

DOK-SUPPL*-VR21**.01**-IT02-EN-P

3/29

CAUTION

NOTICE

NOTICE

Bosch Rexroth AG

Intended Use

In case of non-compliance with this safety instruction, minor or moderate injury

could occur.

In case of non-compliance with this safety instruction, property damage could

occur.

VR 21

3.3 Symbols Used

Notes are displayed as follows:

This is a note.

Tips are displayed as follows:

This is a tip.

4 Intended Use

The IndraControl VR 21 devices by Bosch Rexroth are machine operator panels

that can, depending on the application, visualize control data and trigger functions at the machine.

Danger of destruction of the device if not expressly stated accessories, mounting parts and

other components, cables, lines, software and

firmware are used

The machine operator panels may be used only as intended and with the accessories, mounting parts, and other components specified in this documentation.

Components that are not expressly mentioned must neither be attached nor

connected. The same applies to cables and lines.

Operation must only be carried out with the hardware component configurations and combinations that are expressly specified and with the software and

firmware indicated and specified in the respective documentation and functional descriptions.

Typical areas of application of the machine operator panels are:

● Handling systems and assembly systems

4/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21

Bosch Rexroth AG

Spare Parts, Accessories and Wear Parts

● Packaging and food processing machines

● Printing machines and paper converting machines

● Machine tools

● Wood processing machines

The machine operator panels may only be operated under the mounting and installation conditions, the position, and the ambient conditions (temperature, degree of protection, humidity, EMC etc.) specified in this documentation.

5 Spare Parts, Accessories and Wear Parts

5.1 External 24 V Power Supply Unit

Order code Parts number Description

VAP01.1H-W23-024-010-NN R911171065 External 24 V power supply unit for the

Tab. 5-1: External 24 V power supply unit for the operating panel

5.2 Wear Parts

Wear parts are not subject to any warranty.

Backlight

The service life of the backlight is limited. After this time has been exceeded,

the backlight will produce only 50 % of its original brightness. The service life of

the following table refers to an ambient temperature of 25 °C.

Display size

107.95 mm (4.3") 40,000 hours

177.8 mm (7") 40,000 hours

228.6 mm (9") 70,000 hours

IndraControl V devices

Service life

Tab. 5-2: Half-life period of the TFT displays

Touch screen

After 3 million touches, no damage or malfunction have occured under the fol-

lowing conditions:

Touch element: R8, HS40 silicone rubber

Touch pressure: 150 g

Touch frequency: 3 Hz

DOK-SUPPL*-VR21**.01**-IT02-EN-P

5/29

Bosch Rexroth AG

Technical Data

6 Ambient Conditions

In operation Transport Storage

Max. ambient

temperature

Humidity Min. relative humidity: 20

Air pressure Up to 3000 m above sea level acc. to EN 61131-2

Mechanical

strength

Contamination

level

Overvoltage

category

+0 ℃ to +50 ℃ -25 ℃ to +70 ℃

Min. relative humidity: 20

%

Max. relative humidity:

85 %

Condensation not allowed

Max. vibration:

Frequency range: 10 Hz to

150 Hz

Excursion: 0.075 mm at

10 Hz to 57 Hz

%

Max. relative humidity:

75 %

Condensation not allowed

Max. shock:

15 g 11 ms

acc. to EN 60068-2-27,

no disturbance of the function

Acceleration: 1 g at 57 Hz

to 150 Hz

acc. to EN 600068-2-6

2

3 -

Min. relative humidity:

20 %

Max. relative humidity:

85 %

Condensation not allowed

VR 21

Tab. 6-1: Ambient conditions

7

Technical Data

7.1 VR 21 Singletouch

VR2104 Singletouch VR2107 Singletouch VR2109 Singletouch

Display 107.95 mm TFT (4.3")

480 × 272 pixels

65536 colors

Brightness 450 cd/m

Display

53,8 × 95 (H × B)

Touch technology Analog resistive, 4-wire technology

Touch activation pres-

15 g (standard) with R8 HS60 silicone rubber

sure

Housing Sheet steel, zinc-coated

6/29

177.8 mm TFT (7")

800 × 480 pixels

262144 colors

2

Brightness 350 cd/m

Display

91.4 × 152.4 (H × B)

228.6 mm TFT (9")

800 × 480 pixels

16.77 million colors

2

Brightness 360 cd/m

Display

117 × 195 (H × B)

DOK-SUPPL*-VR21**.01**-IT02-EN-P

2

VR 21 Bosch Rexroth AG

Technical Data

VR2104 Singletouch VR2107 Singletouch VR2109 Singletouch

Front panel material Aluminium, brushed, naturally anodized

Enclosure rating Front panel IP 65 according to DIN EN 60 529, rear side IP 20

Central processing unit ARM Cortex™-A8, 800 MHz with real-time clock

Flash memory 256 MByte

LPDDR memory 512 MByte

Voltage supply DC 24 V (use a 24 V power supply unit according to DIN EN 60742, classifi-

cation VDE 0551, for example the power supply unit VAP01.1HW23-024-010-NN, part number R911171065)

Current consumption 0.2 A (typically at 24 V)

0.3 A (maximum)

0.3 A (typically at 24 V)

0.4 A (maximum)

0.6 A (typically at 24 V)

0.7 A (maximum)

Connection value 4.8 W 7.2 W 14.4 W

Fuse Semiconductor fuse, resettable

Reverse voltage protec-

Integrated

tion

USB Per USB port max. 500 mA, total current at all USB ports is max. 1 A.

Weight Approx. 0.6 kg Approx. 0.8 kg Approx. 1.3 kg

Tab. 7-1: Technical data of the VR 21 Singletouch

7.2 VR 21 Multitouch

VR2107 Multitouch VR2109 Multitouch

Display 177.8 mm TFT (7")

800 × 480 pixels

262144 colors

Brightness 350 cd/m

2

Display 91.4 × 152.4 (H × B)

Touch technology Projected capacitive, can be operated with finger

Touch activation pressure 15 g (standard) with R8 HS60 silicone rubber

Housing Sheet steel, zinc-coated

Front panel material Aluminium, brushed, naturally anodized

Surface of the front panel Glass

Enclosure rating Front panel IP 65 according to DIN EN 60 529

Rear panel IP 20

Central processing unit

ARM CortexTM-A8, 800 MHz with real-time clock

Flash memory 256 MByte

LPDDR memory 512 MByte

DOK-SUPPL*-VR21**.01**-IT02-EN-P

228.6 mm TFT (9")

800 × 480 pixels

16.77 million colors

Brightness 360 cd/m

Display 117 × 195 (H × B)

2

7/29

Bosch Rexroth AG

Standards

VR2107 Multitouch VR2109 Multitouch

Voltage supply DC 24 V (use a 24 V power supply unit according to DIN EN 60742,

Current consumption 0.4 A (typically at 24 V)

Connection value 9.6 W 16.8 W

Fuse Semiconductor fuse, resettable

Reverse voltage protection Integrated

USB Per USB port max. 500 mA, total current at all USB ports is max. 1

Weight Approx. 0.8 kg Approx. 1.3 kg

Tab. 7-2: Technical data of the VR 21 Multitouch

8

Standards

classification VDE 0551, for example the power supply unit

VAP01.1H-W23-024-010-NN, part number R911171065)

0.7 A (typically at 24 V)

0.5 A (maximum)

A.

0.8 A (maximum)

VR 21

8.1 General Information

The products have been developed according to the current German edition of

the standards at the time of product development.

8.2 Used Standards

Standard Meaning

DIN EN 61000-4-2, DIN EN

61000-4-3

DIN EN 61000-4-4, DIN EN

61000-4-5

DIN EN 61000-4-6, DIN EN

61000-6-2

DIN EN 61000-6-3 Interference emission

DIN EN 61131-2 Equipment requirements

DIN EN 61131-2 Storage and transport

DIN EN 61131-2 Power supply

2004/108/EC Electromagnetic compatibility

DIN EN 60529 Degrees of protection

DIN EN 60068-2-27 Impact load, shock

DIN EN 60068-2-6 Sinusoidal vibrations

Tab. 8-1: Used Standards

8/29

Noise immunity

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21

Bosch Rexroth AG

Standards

8.3 CE Marking

8.3.1 Declaration of Conformity

The electronic products that are described in the present instructions, comply

with the requirements and the target of the following EU directive and with the

following harmonized European standards:

EMC Directive 2004/108/EC

The electronic products described in the present instructions are intended for

use in industrial environments and comply with the following requirements:

Standard Title Edition

DIN EN 61131-2 Programmable logic controllers 2008+B1:2010

DIN EN 61000-6-2 Electromagnetic Compatibility (EMC)

Part: 6-2: Generic standards – Immunity for industrial environments

DIN EN 61000-6-3 Electromagnetic Compatibility (EMC)

Part: 6-3: Generic standards - Emission standard for residential environments

Tab. 8-2: Standards for electromagnetic compatibility (EMC)

2006+B1:2011

2007+A1:2011

Non-compliance with CE conformity due to modifications to the device.

The CE marking is only valid for the device in its delivery status. After having modified the device, the CE conformity is to be verified.

8.4 UL/CSA Certified

The devices are certified according to

● UL508 (Industrial Control Equipment) and

● C22.2 No. 142-M1987 (CSA)

UL file no. E210730

However, there can be combinations or extension stages with limited or missing

certification. Thus, verify the registration according to the UL marking on the device.

DOK-SUPPL*-VR21**.01**-IT02-EN-P

9/29

X9

X10X5

X1

1

2

Bosch Rexroth AG

Interfaces

Loss of UL/CSA conformity due to modifications to the device.

The UL and CSA marking is only valid for the device in its delivery

status. After modifying the device, the UL and CSA conformity is to

be verified.

9 Interfaces

9.1 Interface View

VR 21

① SD memory card

② Functional earth ground

Fig. 9-1: IndraControl VR 21 interfaces

9.2 Interface Overview

Designation at

the housing

X1 DC-24-V voltage supply 3-pin, Phoenix MINI

X9, X10 USB

host

X5 Ethernet 10/100 Base-T RJ45 female connector RJ45 connector

Functional

earth ground

SD memory

card

Tab. 9-1: Interfaces

10/29

Connection type Connector type, integra-

2 USB interfaces USB female connector,

Functional earth ground Tab connector Receptacle

SD and SDHC memory card slot -

ted

COMBICON

4-pin, type A

Mating connector or cable (from outside)

3-pin, FK-MCP 1,5/3ST-3,5

USB connector,

4-pin, type A

DOK-SUPPL*-VR21**.01**-IT02-EN-P

NOTICE

X1

1 2

3

VR 21 Bosch Rexroth AG

Interfaces

Malfunctions due to insufficient shielding!

Use only shielded cables and metallic or conductive connector/coupling covers

with large-area shield support.

9.3 DC 24 V Voltage Supply

Cables with a cross section of 0.75 to 2.5 mm2 can be connected to the connection terminal.

Fig. 9-2: Power supply connector X1

Pin Designation Function

1 Low-noise earth, functional earth (FE)

2 0 V Supply voltage 0 V (GND)

3 24 VDC 24 VDC supply voltage

Use a 24 V industrial power supply unit acc. to DIN EN 60742, classification VDE

0551, for example "VAP01.1H-W23-024-010-NN" (parts number R911171065) for

the voltage supply.

9.4 USB Interfaces X9, X10

Two USB host interfaces are available at the operating device.

Operation of the USB ports at the operating device

When using input devices not intended for industrial use (e.g. keyboard, mouse), the operational safety is limited. Input devices intended for home or office use are also part of the devices not intended

for industrial use.

Connect only USB devices that meet the USB2.0 specification.

For the specification of a suitable cable, refer to "Universal Serial

Bus Specification Rev. 2.0".

The max. cable length is 2.5 m.

DOK-SUPPL*-VR21**.01**-IT02-EN-P

11/29

Bosch Rexroth AG

Interfaces

Not all USB devices are recognized.

The operating system does not support all USB devices. Devices that

require a special USB driver, which is not integrated in the system,

cannot be operated at the USB interfaces.

9.5 Ethernet Interface X5

A 10/100Base-T Ethernet interface is provided at the operating device.

Use a twisted-pair cable of category 5 or 6 (CAT 5 or 6). The max.

cable length is 100 m.

Ethernet interface – Status and diagnostic displays

LED ACT/LNK (green)

● On: Connection to network is available

● Off: No connection

● Flashing: Communication is running

LED SPD 10/100 (yellow)

● On: 100 MBit/s mode

● Off: 10 MBit/s mode or connection disconnected

VR 21

9.6 Slot for SD Memory Card

An SD card can be inserted at the bottom of the operating device.

When using hardware not intended for industrial use (e.g. keyboard,

mouse, memory card) in an industrial environment, the operational

safety is limited. Hardware intended for home or office use is also

part of the devices not intended for industrial use.

Inserting the memory card

Insert the memory card with the front facing the top. Insert the card until the

memory card engages.

Fig. 9-3:

12/29

Inserting the memory card

DOK-SUPPL*-VR21**.01**-IT02-EN-P

1

2

VR 21 Bosch Rexroth AG

Assembly, Disassembly and Electrical Installation

Removing the memory card

Insert the memory card in the operating device until it engages. Remove the un-

locked memory card.

10 Assembly, Disassembly and Electrical Installation

10.1 Housing Dimensions

10.1.1 Front View

①, ② See the following table

Fig. 10-1: IndraControl VR 21 front view

Device ①Height ②Width

VR2104 100 mm 140 mm

VR2107 150 mm 211 mm

VR2109 178 mm 263 mm

Tab. 10-1: Front dimensions

DOK-SUPPL*-VR21**.01**-IT02-EN-P

13/29

2

1

3

Bosch Rexroth AG

Assembly, Disassembly and Electrical Installation

10.1.2 Overview of Housing Dimensions - Side View

VR 21

① Front panel

② Mounting surface 1 to 6 mm

Fig. 10-2: Side view (sample illustration)

③ See the following table for mounting

depth

Type code Display ③Mounting depth

VR2104.01-00-01-N2-NNN-AA 4,3" 42 mm

VR2107.01-00-01-N2-NNN-AA

7" 46.3 mm

VR2107.01-00-01-N2-NNN-CA

VR2109.01-00-01-N2-NNN-AA

9" 52.3 mm

VR2109.01-00-01-N2-NNN-CA

Tab. 10-2: Mounting depth

10.2 Installation Notes

A clearance of at least 30 mm has to be complied with during the assembly to ensure sufficient free air conditions.

During the horizontal mounting of the operating device, note that

heat can accumulate below the operating device due to additional

heat sources. Provide sufficient heat dissipation! Comply with the

permissible temperature range specified in the technical data for the

operation of the operating device!

To guarantee the specified degree of protection, ensure that the

seal is positioned flat on the mounting surface and that the threaded

pins of the mounting brackets are uniformly tightened. Comply with

the maximum torque of 1 Nm.

14/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

A

B

1

2

3

VR 21 Bosch Rexroth AG

Assembly, Disassembly and Electrical Installation

Loss of degree of protection IP 65!

The housing in which the operator display is installed, has to fulfil

the following conditions:

● Free from impurities

● Sufficient mechanical strength and flatness

These criteria influence the required degree of protection IP to a

great extent.

Further required measures are to be taken depending on the mounting location, e. g. the stabilization of the mounting frame.

10.3 Mounting Cut-Out

The device facilitates quick and easy mounting of the rear of the device. A wall

thickness of 1 mm to 6 mm is permissible and ensure a correct assembly.

Assemble the operating device as follows:

1. Creating a mounting cut-out, see chapter 10.4 "Mounting Dimensions" on

page 16.

2. Insert the device in the mounting cut-out.

3. Position the mounting brackets in the provided cut-outs (①) and pull the

mounting brackets down until they engage (②).

4. Fix the device using threaded pins (③).

Ⓐ Mounting bracket

Ⓑ Threaded pin

Fig. 10-3: Installing the mounting brackets

DOK-SUPPL*-VR21**.01**-IT02-EN-P

15/29

A

1

2

Bosch Rexroth AG

Assembly, Disassembly and Electrical Installation

10.4 Mounting Dimensions

A Mounting cut-out

Fig. 10-4: Mounting cut-out

Device ① ②

VR2104 92 mm 132 mm

VR2107 142 mm 203 mm

VR2109 170 mm 255 mm

Tab. 10-3: Housing dimensions: IndraControl VR 21 front

VR 21

10.5 Disassembly

1. Disconnect the operating device.

2. Remove all connected cables

3. Loosen the threaded pins of the mounting brackets.

4. Remove the operating device from the mounting frame.

10.6

Electrical Wiring

10.6.1 Connecting the Supply Voltage

The supply voltage is supplied via the X1 male connector strip. A compatible female connector strip is part of the delivered product. The permissible supply

voltage for the operating device is specified in the technical data.

The device is equipped with a reverse voltage protection. The device

is not operated in case of an incorrect polarity.

This device is an item of degree of protection III. To ensure safe operation, use a safety extra-low voltage (SELV) according to DIN EN

61131 for the supply voltage.

16/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

WARNING

30 mm (1.181")

5 mm (0.197")

VR 21

Bosch Rexroth AG

Assembly, Disassembly and Electrical Installation

Use a cable with finely stranded cores with a minimum cross section

of 0.75 mm2 and a maximum cross section of 2.5 mm2 for the supply

voltage. Comply with the following torques at the connectors:

● Screw terminal of the terminals: 0.22 Nm (minimum) up to 0.25

Nm (maximum)

● Bolt flange: 0.3 Nm (maximum)

Danger of electric shock due to electrical voltage.

● Only connect power supply units as power supply with safe isolation accord-

ing to DIN EN 50178 with PELV voltage according to DIN EN 61131-2. Establish permanent protective earth conductor connections.

Connect the supply voltage as described in the following:

1. Strip the oversheath of the cable to a length of 30 mm and the cores to a

length of 5 mm.

Fig. 10-5: Bared cable - Supply voltage

2. Provide the cores with wire end sleeves and connect the cores to the female connector strip.

3. Plug the female connector strip on the X1 connector strip at the operating

device.

4. Protect the female connector strip against disengaging using screw-locking.

10.6.2 Connecting the Functional Earth (FE)

A receptacle is using for the functional earth.

1. Strip the line to a length of 5 mm.

2. Use a receptacle for the bared line.

3. Position the receptacle on the tab connector.

DOK-SUPPL*-VR21**.01**-IT02-EN-P

17/29

Bosch Rexroth AG

Device Description

Fig. 10-6: Functional earth connection

VR 21

11 Commissioning

The product is ready for operation immediately

The IndraControl VR 21 is configured using the cockpit tool. The cockpit tool is

described in the project planning manual "Rexroth IndraControl V Devices Operating Systems" (see tab. 1-1 "Required and supplementing documentation" on

page 2).

12

Device Description

12.1 General Information

Fig. 12-1: IndraControl VR21xx.01 Single and Multitouch

18/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

WARNING

NOTICE

NOTICE

VR 21

Bosch Rexroth AG

Device Description

12.2 Control and Display Elements

12.2.1 Display

Poisoning or chemical burns due to damaged

display

If the display is damaged, avoid direct skin contact, choking, breathing in of

leaking liquid or gas!

Burn-in effects on the display due to missing

image changes

Static image parts displayed on the display for a longer period (> 1 hour) can

result in so-called "image sticking". Image sticking refers to a previously displayed image still being displayed as shadow following an image change. Higher

environment temperatures during the operation can accelerate the burn-in effect. To avoid irreversible damage, regularly actuate the display with a back

screen via the visualization application. The recommended actuation interval is

15 minutes.

The operating device is equipped with different displays, depending on the model (see chapter 12.3 "Variants" on page 19).

12.2.2 Touchscreen

Risk of destroying the touch screen or the front

panel by using inappropriate items.

Operate the touch screen only with your finger or with a special touch pen

(parts number 1070923266).

12.2.3 Real-Time Clock

The real-time clock is buffered by a capacitor. The capacitor reaches maximum

capacity after 48 hours of trickle charge. After the maximum load, the real-time

clock can be buffered for approximately 10 days.

12.3

Variants

The IndraControl VR 21 devices are available in different variants. The devices

differ in display size and touch technology (single and multitouch).

DOK-SUPPL*-VR21**.01**-IT02-EN-P

19/29

NOTICE

Bosch Rexroth AG

Maintenance

Type code Display Resolution Touch technology

VR2104.01-00-01-N2-NNN-AA

Part no. R911340500

VR2107.01-00-01-N2-NNN-AA

Part no. R911340503

VR2107.01-00-01-N2-NNN-CA

Part no. R911340505

VR2109.01-00-01-N2-NNN-AA

Part no. R911340051

VR2109.01-00-01-N2-NNN-CA

Part no. R911340506

Tab. 12-1: IndraControl VR 21 variants

13

Error Causes and Elimination

Error Correction

No image visible ● Connect the voltage supply, check X10 connection

The USB flash drive does not function,

although other USB devices function

Touchscreen functionality is not available

4,3" 480 × 272 pixels Resistive, single touch

7" 800 × 480 pixels Resistive, single touch

7" 800 × 480 pixels Capacitive, multitouch

9" 800 × 480 pixels Resistive, single touch

9" 800 × 480 pixels Capacitive, multitouch

● Check if the USB flash drive is supported by the "Win-

dows Embedded Compact 7" operating system

● Check USB flash drive partitioning. The operating system

only supports FAT16/32

● Recalibrate touchscreen

VR 21

Tab. 13-1: Error causes and error elimination

14 Maintenance

14.1 General Information

Loss of IP degree of protection due to incorrect

maintenance

The IP degree of protection must be ensured during maintenance!

14.2

Display

The backlight is subject to wear (see chapter 5.2 "Wear Parts" on page 5).

A fading backlight causes a progressive deterioration display readability, so that

a replacement is necessary. For further information please contact the Bosch

Rexroth Service.

20/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

NOTICE

VR 21

Bosch Rexroth AG

Ordering Information

14.3 Cleaning Notes

The surface of the foil as well as the display

seal are dissolved by solvents!

● Do not use any solvents (e. g. diluents)!

● No high pressure cleaning devices are to be used!

● To remove dirt from the front panel, only use a moist cloth

14.4 Fuse

The semiconductor fuse is not intended for replacement!

Use a semiconductor fuse to protect the device. After the fuse has

triggered, disconnect the device from the supply voltage so that the

semiconductor fuse can regenerate. The regeneration takes approximately 20 seconds at an ambient temperature of 20 °C. The higher

the ambient temperature, the longer the regeneration phase.

14.5 Regular Maintenance Tasks

● At least once a year, all plug and terminal connections of the components are

to be checked regarding proper tightness and possible damage

● Make sure that cables are not broken or crimped

● Replace damaged parts immediately.

15

Ordering Information

15.1 Accessories and Spare Parts

For ordering information about accessories and spare parts, please refer to

chapter 5 "Spare Parts, Accessories and Wear Parts" on page 5.

DOK-SUPPL*-VR21**.01**-IT02-EN-P

21/29

Short text

column 1 2 3 4 5 6 7 8 910 1 2 3 4 5 6 7 8 920 1 2 3 4 5 6 7 8

Example: V R 2 1 0 4 . 0 1 - 0 0 - 0 1 - N 2 - N N N - A A

Unit type 1

HMI........................ = V

Unit type 2

Box (preconfigured).. = R

Rating class

Rating class S.............. = 2

Processor version

Processor version 1......... = 1

Display size (16:9)

4,3“...................................... = 04

7“......................................... = 07

9“......................................... = 09

Design

HW-Design.................................... = 01

Field bus

None Field bus....................................... = 00

Interface (Ethernet, USB…)

2 x USB Host + 1 x Ethernet 100 Mbit.............. = 01

Remanent Memory

Non-existent............................................................... = N

Mass storage (Harddisk, Flash, SSD)

Onboard Flash min.128 MB........................................... = 2

Hardware configuration

None extension slot........................................................... = NNN

Design & HMI-Display character

Single-Touch in Rexroth-Design...................................................... = AA

Multi-Touch in Rexroth-Design........................................................ = CA

Bosch Rexroth AG

Disposal

15.2 Type Code VR21xx.01

Fig. 15-1: Type code

16

Disposal

16.1 Take-Back

Our products can be returned to our premises free of charge for disposal. However, the products must be free of impurities like oil, grease or other impurities.

Furthermore, the products returned for disposal must not contain any undue

foreign material or foreign components.

Send the products "free domicile" to the following address:

22/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21

VR 21

Bosch Rexroth AG

Electric Drives and Controls

Bürgermeister-Dr.-Nebel-Straße 2

D-97816 Lohr am Main, Germany

Bosch Rexroth AG

Service and Support

16.2 Packaging

The packaging materials consist of cardboard, plastic material, wood or expanded polystyrene (EPS). The packaging materials can be recycled without any

problem.

For ecological reasons, please refrain from returning the empty packages to

Bosch Rexroth.

17 Service and Support

Our worldwide service network provides an optimized and efficient support.

Our experts offer you advice and assistance should you have any queries. You

can contact us 24/7.

Service Germany

Our technology-oriented Competence Center in Lohr, Germany, is responsible

for all your service-related queries for electric drive and controls.

Contact the Service Helpdesk & Hotline under:

Phone: +49 9352 40 5060

Fax: +49 9352 18 4941

E-mail: service.svc@boschrexroth.de

Internet: http://www.boschrexroth.com

Additional information on service, repair (e.g. delivery addresses) and training

can be found on our internet sites.

Service worldwide

Outside Germany, please contact your local service office first. For hotline num-

bers, refer to the sales office addresses on the internet.

Preparing information

To be able to help you more quickly and efficiently, please have the following in-

formation ready:

● Detailed description of malfunction and circumstances resulting in the mal-

function

● Type plate name of the affected products, in particular type codes and serial

numbers

● Your contact data (phone and fax number as well as your email address)

DOK-SUPPL*-VR21**.01**-IT02-EN-P

23/29

Bosch Rexroth AG VR 21

24/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21

Index

Bosch Rexroth AG

Index

A

Accessories..................................... 5

Ambient conditions......................... 6

Assembly....................................... 13

B

Backlight......................................... 5

C

CE marking..................................... 9

Cleaning notes.............................. 21

Clock............................................. 19

Commissioning............................. 18

Complaints..................................... 2

Connector panel........................... 10

Criticism......................................... 2

Customer Feedback........................ 2

D

DC 24V voltage supply.................. 11

Declaration of conformity............... 9

Device description........................ 18

Diagnostic displays....................... 12

Dimensions................................... 13

Disassembly............................ 13, 16

Display.................................... 19, 20

Display elements.......................... 19

Disposal........................................ 22

Documentation overview................ 1

Documents, further......................... 2

E

Electrical wiring............................ 16

Error causes.................................. 20

Ethernet interface......................... 12

External 24 V power supply unit..... 5

F

Feedback........................................ 2

Front view..................................... 13

Functional earth............................ 17

Fuse.............................................. 21

H

Housing dimensions...................... 13

I

Installation notes.......................... 14

Intended use................................... 4

Interfaces...................................... 10

Ethernet interface................... 12

X9, X10 USB interfaces............ 11

M

Maintenance................................. 20

Maintenance notes....................... 21

Memory card................................. 12

Mounting cut-out.......................... 15

Mounting dimensions................... 16

N

24 V power supply unit................... 5

O

Ordering information.................... 21

P

Product identification..................... 2

R

Real-time clock............................. 19

S

Safety alert symbol......................... 3

Safety instructions.......................... 3

Scope of delivery............................ 2

Scope of the documentation.......... 1

SD memory card........................... 12

Service life

Backlight.................................... 5

Side view...................................... 14

Signal words................................... 3

Slot for memory card.................... 12

Spare parts..................................... 5

Standards....................................... 8

Status displays............................. 12

Suggestions.................................... 2

Supply voltage.............................. 16

Support

See service hotline.................. 23

Symbols.......................................... 4

DOK-SUPPL*-VR21**.01**-IT02-EN-P

25/29

Bosch Rexroth AG

Index

T

Target groups................................. 1

Technical data................................ 6

Voltage supply......................... 11

Wear parts................................. 5

Touchscreen................................. 19

Type code..................................... 22

Type plate....................................... 2

U

UL/CSA Certified............................ 9

USB interfaces.............................. 11

Use, intended................................. 4

V

Voltage supply.............................. 11

Voltage supply (DC 24 V).............. 11

VR 21 variants............................... 19

W

Wear parts...................................... 5

X

X1.................................................. 11

X5.................................................. 12

X9.................................................. 11

X10................................................ 11

VR 21

26/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21 Bosch Rexroth AG

DOK-SUPPL*-VR21**.01**-IT02-EN-P

27/29

Bosch Rexroth AG VR 21

28/29

DOK-SUPPL*-VR21**.01**-IT02-EN-P

VR 21 Bosch Rexroth AG

Notes

Bosch Rexroth AG

Electric Drives and Controls

P.O. Box 13 57

97803 Lohr, Germany

Bgm.-Dr.-Nebel-Str. 2

97816 Lohr, Germany

Tel. +49 9352 18 0

Fax +49 9352 18 8400

www.boschrexroth.com/electrics

DOK-SUPPL*-VR21**.01**-IT02-EN-P

Loading...

Loading...