Page 1

PAVIRO Amplifier

PVA-2P500

en Operation manual

Page 2

Page 3

PAVIRO Amplifier Table of contents | en 3

Table of contents

1

2

3

3.1 Front panel 9

3.2 Rear panel 12

4

5

6

6.1 Audio inputs 16

6.2 Audio output 18

6.3 Supply voltage 19

6.4 CAN BUS 20

7

7.1 Setting the CAN address 23

7.2 Displaying the CAN baud rate 24

7.3 Configuring the CAN baud rate 24

8

8.1 Stand-alone mode 25

9

9.1 Firmware update 27

9.2 Resetting to factory default settings 27

10

10.1 Standards 30

10.2 Power consumption 30

10.3 Dimensions 31

10.4 Circuit diagram 32

Safety 4

Short information 8

System overview 9

Parts included 13

Installation 14

Connection 16

Configuration 23

Operation 25

Maintenance 27

Technical data 28

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 4

!

!

4 en | Safety PAVIRO Amplifier

1

Safety

Danger!

High risk: This symbol indicates an imminently hazardous situation such as "Dangerous

Voltage" inside the product.

If not avoided, this will result in an electrical shock, serious bodily injury, or death.

Warning!

Medium risk: Indicates a potentially hazardous situation.

If not avoided, this could result in minor or moderate bodily injury.

Caution!

Low risk: Indicates a potentially hazardous situation.

If not avoided, this could result in property damage or risk of damage to the unit.

1. Read these instructions. – All the safety and operating instructions should be read

before the apparatus or system is operated.

2. Keep these instructions. – The important safety instructions and operating instructions

should be retained for future reference.

3. Heed all warnings. – All warnings on the apparatus and in the operating instructions

should be adhered to.

4. Follow all instructions. – All instructions for installation or use/operating should be

followed.

5. Do no use this apparatus near water. – Do not use this apparatus near water or a moist

environment - for example, near a bath tub, wash bowl, kitchen sink, or laundry tub, in a

wet basement, near a swimming pool, in an unprotected outdoor installation, or any area

which is classified as a wet location.

6. Clean only with dry cloth. – Unplug the apparatus from the outlet before cleaning. Do

not use liquid cleaners or aerosol cleaners.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s

instructions. – Openings in the enclosure, if any, are provided for ventilation and to

ensure reliable operation of the apparatus and to protect it from overheating. These

openings must not be blocked or covered. This apparatus should not be placed in a builtin installation unless proper ventilation is provided or the manufacturer’s instructions

have been adhered to.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat or in direct sunlight.

9. No naked flame sources, such as lighted candles, should be placed on the apparatus.

10. Do not defeat the safety purpose of the polarized or ground-type plug. – A polarized

plug has two blades with one wider than the other. A grounding type plug has two blades

and a third grounding prong. The wider blade or the third prong are provided for your

safety. If the provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

11. Protect the power cord from being walked on or pinched particularly at plug,

convenience receptacles, and the point where they exit from the apparatus.

12. Only use attachments/accessories specified by the manufacturer. – Any mounting of the

apparatus should follow the manufacturer’s instructions, and should use a mounting

accessory recommended by the manufacturer.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 5

!

PAVIRO Amplifier Safety | en 5

13. Use only with the cart, stand, tripod, bracket or table specified by the manufacturer, or

sold with the apparatus. – When a cart is used, use caution when moving the cart/

apparatus combination to avoid injury from tip-over. Quick stops, excessive force, and

uneven surfaces may cause the appliance and cart combination to overturn.

14. Unplug this apparatus during lighting storms or when unused for long periods of time.

– Not applicable when special functions are to be maintained, such as evacuation

systems.

15. Refer all servicing to qualified service personnel. – Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is damaged,

liquid has been spilled or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been dropped.

16. The apparatus shall not be exposed to dripping or splashing and that no objects filled

with liquid, such as vases, shall be placed on the apparatus.

17. Batteries (battery pack or batteries installed) shall not be exposed to excessive heat

such as sunshine, fire or the like.

Caution!

Danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type. Dispose of used batteries according to the environmental law and

procedures.

18. Professional installation only – Do not use this equipment in residential applications.

19. Condensation – In order to avoid condensation; wait a few hours before turning on the

equipment when it is transported from a cold to a warm space.

20. Hearing damage – For apparatus with audio output, to prevent possible hearing damage,

do not listen at high volume levels for long periods.

21. Replacement parts – When replacement parts are required, be sure the service

technician has used replacement parts specified by the manufacturer or having the same

characteristics as the original part. Unauthorized substitutions may result in fire, electric

shock or other hazards.

22. Safety check – Upon completion of any service or repairs to this apparatus, ask the

service technician to perform safety checks to determine that the apparatus is in proper

operating condition.

Danger!

Overloading – Do not overload outlets and extension cords as this can result in a risk of fire or

electric shock.

23. Power sources – This apparatus should be operated only from the type of power source

indicated on the marking label. If you are not sure of the type of power supply you plan to

use, consult your appliance dealer or local power company. For apparatuses intended to

operate from battery power, or other sources, refer to the operating instructions.

24. Power lines – An outdoor system should not be located in the vicinity of overhead power

lines or other electric light or power circuits, or where it can fall into such power lines or

circuits. When installing an outdoor system, extreme care should be taken to keep from

touching such power lines or circuits, as contact with them might be fatal. U.S.A. models

only – refer to the National Electrical Code Article 820 regarding installation of CATV

systems.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 6

!

!

!

!

6 en | Safety PAVIRO Amplifier

Danger!

Object and Liquid entry – Never push objects of any kind into this apparatus through

openings as they may touch dangerous voltage points or short-out parts that could result in a

fire or electric shock. Never spill liquid of any kind on the apparatus.

25. Coax grounding – If an outside cable system is connected to the apparatus, be sure the

cable system is grounded. U.S.A. models only: Section 810 of the National Electrical

Code, ANSI/NFPA No.70-1981, provides information with respect to proper grounding of

the mount and supporting structure, grounding of the coax to a discharge apparatus, size

of grounding conductors, location of discharge unit, connection to grounding electrodes,

and requirements for the grounding electrode.

26. Protective grounding – An apparatus with class I construction shall be connected to a

power outlet socket with a protective grounding connection.

Protective earthing – An apparatus with class I construction shall be connected to a

mains socket outlet with a protective earthing connection.

Note for power connections

– For permanently connected equipment, a readily operable mains plug or all-pole mains

switch shall be external to the equipment and in accordance with all applicable

installation rules.

– For pluggable equipment, the socket-outlet shall be installed near the equipment and

shall be easily accessible.

This label may appear on the bottom of the apparatus due to space limitations.

Caution!

To reduce the risk of electrical shock, DO NOT open covers. Refer servicing to qualified

service personnel only.

Warning!

To prevent fire or shock hazard, do not expose units to rain or moisture.

Warning!

Installation should be performed by qualified service personnel only in accordance with the

National Electrical Code or applicable local codes.

Warning!

Power disconnect: If the apparatus is mains powered and a power supply cord set is

provided, the disconnect device is the mains plug of the power cord set.

If an AC‑DC adapter is provided and the mains plug that is part of the direct plug‑in device,

the AC‑DC adapter is the disconnect device.

The socket outlet shall be near the apparatus and shall be easily accessible.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 7

!

PAVIRO Amplifier Safety | en 7

Warning!

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-

network voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV

circuits. Some LAN and WAN ports both use RJ‑45 connectors. Use caution when connecting

cables.

Old electrical and electronic appliances

Electrical or electronic devices that are no longer serviceable must be collected separately and

sent for environmentally compatible recycling (in accordance with the European Waste

Electrical and Electronic Equipment Directive).

To dispose of old electrical or electronic devices, you should use the return and collection

systems put in place in the country concerned.

Only used at

altitude not

exceeding 2000m.

Only used in non-

tropical climate

regions.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 8

8 en | Short information PAVIRO Amplifier

2

Short information

The PVA-2P500 class-D amplifier is a 2 ✕ 500 W professional audio amplifier for evacuation

purposes. It can be operated from both the mains and a DC supply. The output voltage is

galvanically insulated and is constantly monitored for ground fault. An energy-saving mode and

temperature-controlled fans reduce energy consumption and noise levels. The control and

monitoring functions are performed via CAN bus. This amplifier is designed for operation in an

emergency evacuation system. It can be used as system amplifier or in stand-alone mode. The

amplifiers are usually controlled via a controller and configured using IRIS-Net.

The power amplifier has the following features:

– Floating 100 V or 70 V power outputs

– High efficient amplifier blocks in class-D technology

– Outputs idling and short circuit-protected

– Mains operation 120–240 V (50/60 Hz) and/or 24 V DC emergency backup

– Electronically balanced inputs

– Temperature monitoring function

– Pilot tone and ground fault monitoring function via PVA-4CR12 controller or PVA-4R24

router

– Processor control of all functions

– Monitoring of the processor system via watchdog circuit

– Non-volatile FLASH memory for configuration data

– Internal monitoring function

– Integrated audio relays

– Line monitoring function

The power amplifier is processor-controlled and equipped with extensive monitoring

functions. Line monitoring for the CAN bus and for audio transmission allows line

interruptions and short-circuits to be detected and indicated to the user.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 9

PAVIRO Amplifier System overview | en 9

3

3.1

System overview

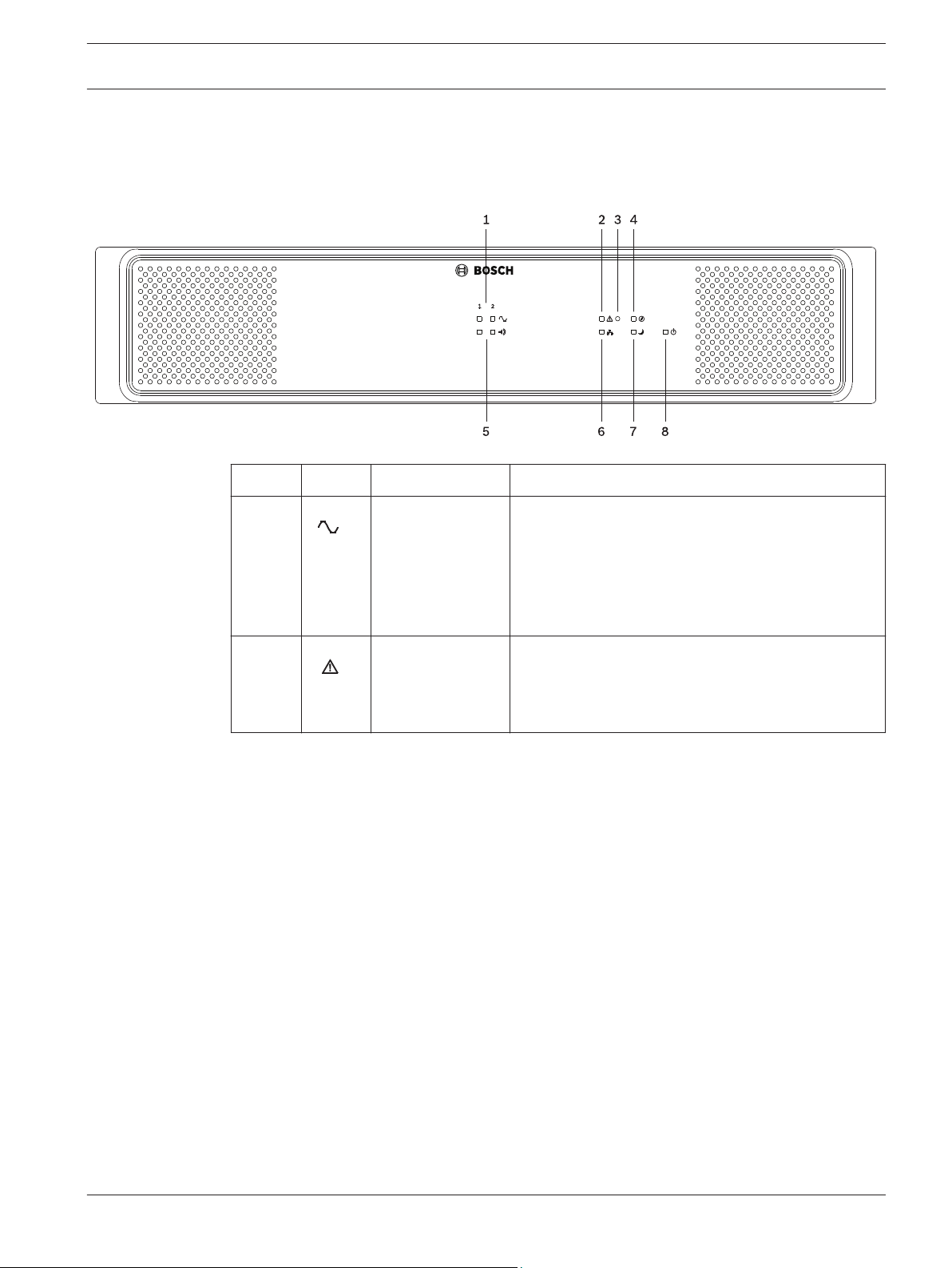

Front panel

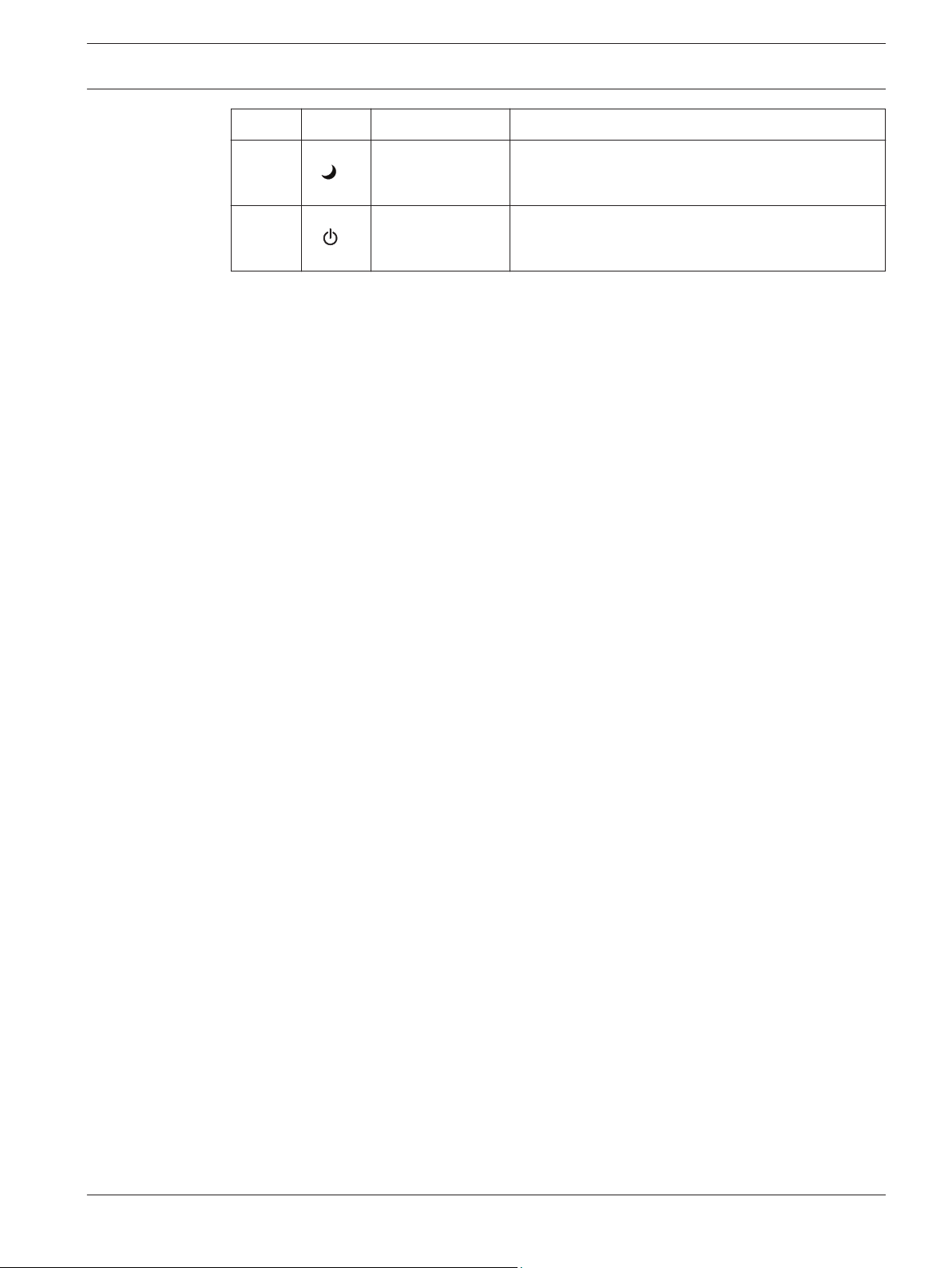

Number Symbol Element Description

1 Signal clip

indicator light

Indicates the signal level of the amplifier channel:

– Green = The output signal is 18 dB below clip

level

– Yellow = The output signal is clipping or the

integrated limiter of the amplifier is limiting the

output signal.

2 General fault

warning indicator

light

This indicator lights up yellow when a fault has

occurred in the device. The types of faults to be

displayed via this indicator are configured in IRISNet. Please refer to section Operation, page 25.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 10

10 en | System overview PAVIRO Amplifier

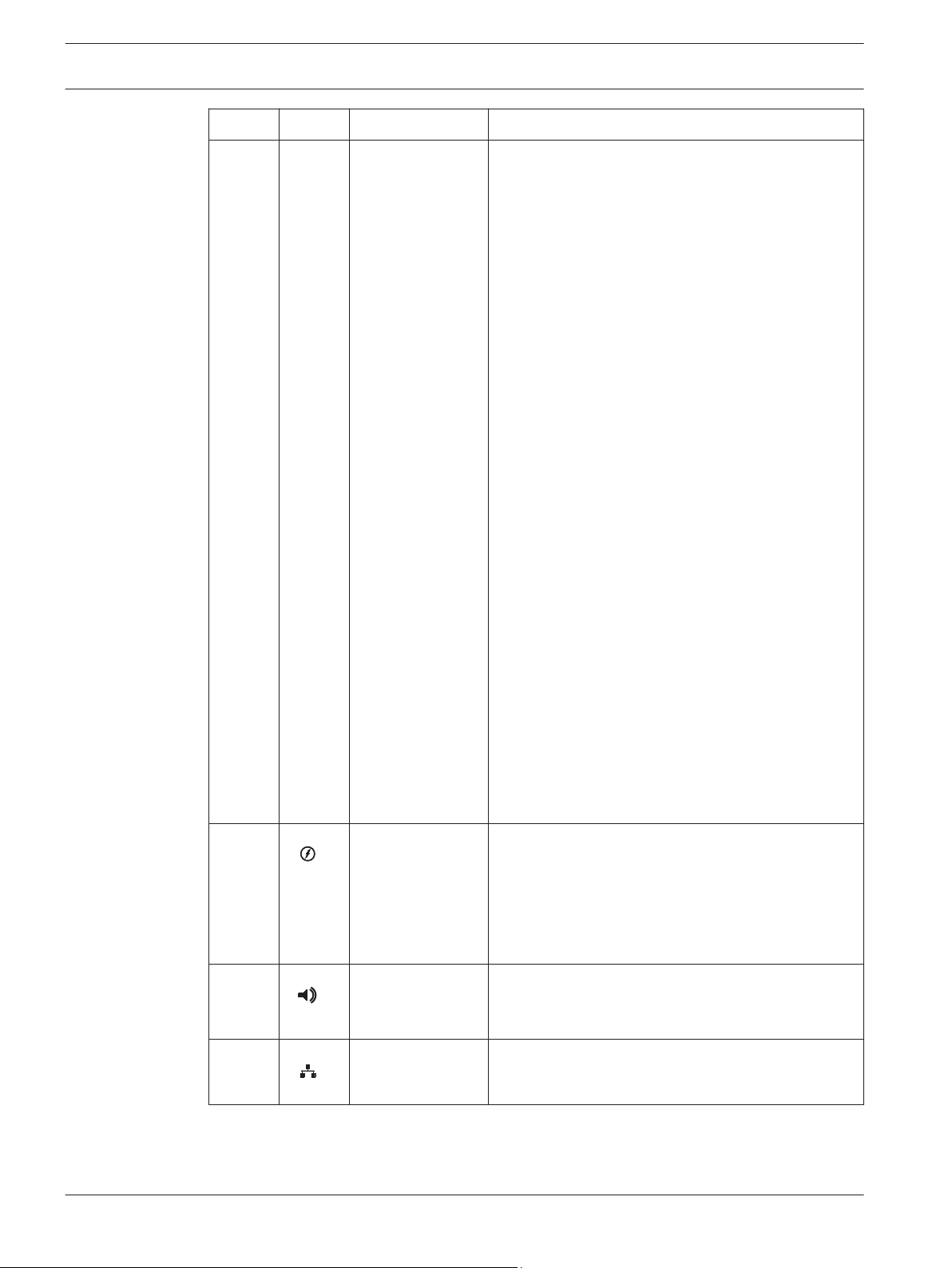

Number Symbol Element Description

3 Recessed button The button is protected to prevent it from being

pressed accidentally. Use a pointed object (such as

a ballpoint pen) to press the button.

This button has the following functions if the CAN

address of the device is not set to 00:

– Find function: If the find function of the device

is activated, press this button to deactivate the

indicators.

– Displaying the CAN baud rate: Press this button

for at least one second. Please refer to section

Displaying the CAN baud rate, page 24.

– LED test: Press this button for at least three

seconds to activate the LED test. All indicators

at the front panel light up as long as the button

is pressed.

This button has the following functions if the CAN

address of the device is set to 00 (stand-alone

mode):

– Resetting a ground fault or watchdog fault:

Press the button briefly to confirm a watchdog

fault or ground fault (stand-alone mode only,

please refer to section Stand-alone mode, page

25)

– Setting/displaying the CAN baud rate: Press this

button for at least one second. Please refer to

section Configuring the CAN baud rate, page

24.

– Resetting to delivery condition: To reset all

settings to their original configuration on

delivery, press this button for at least three

seconds to reset all device settings.

4

Ground fault

indicator light

This indicator lights up yellow when a ground fault

has occurred at least one output. The indicator

remains illuminated even when the ground fault has

been resolved. To deactivate the indicator, press the

Recessed button (3) or use IRIS-Net. Please refer to

section Stand-alone mode, page 25.

5 Audio signal

indicator light

This indicator lights up green if an audio signal

(signal level > -36 dB) is present at the power

amplifier input.

6 Network indicator

light

18-Jun-2015 | 04 | F01U306898 Operation manual

This indicator lights up green in the event of

successful data communication with the controller.

Page 11

PAVIRO Amplifier System overview | en 11

Number Symbol Element Description

7 Standby indicator

light

8 Power indicator

light

This indicator lights up green when the device is in

standby mode.

This indicator lights up green when the power

supply is OK.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 12

12 en | System overview PAVIRO Amplifier

3.2

Rear panel

Number Element Description

1 AC power input and power

switch

2 Grounding screw Ground connection for DC only systems.

3 DC power input

4 CAN BUS port Connection with CAN bus, e.g. controller.

5 CAN ADDRESS selector switch HIGH-byte and LOW-byte for configuring the CAN

address of the device.

6 LINE 1-4 IN / THRU audio

input sockets (RJ-45)

7 LINE IN L1 or L2 audio input

sockets (Euroblock)

8 Amplifier power output

sockets (70 V or 100 V)

Audio input (and through socket) for all

channels. Please refer to section Audio inputs,

page 16.

Balanced audio input for channels 1 or 2. Please

refer to section Audio inputs, page 16.

Power output for speaker zones. Please refer to

section Audio output, page 18.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 13

PAVIRO Amplifier Parts included | en 13

4

Parts included

Quantity Component

1 PVA-2P500

1 Power cord 230 V AC

1 Power cord 120 V AC

1 Euroblock connector 2-pole (Phoenix, PC 5/2-STF-7,62, 1975697, F.01U.

108.398) for 24 V DC

2 Euroblock connector 3-pole (Phoenix, MC 1,5/3-STF-3,81, Nr. 1827716, F.

01U.104.680) for audio input

2 Euroblock connector 6-pole (Phoenix, MC 1,5/6-ST-3,81, 1827745, F.01U.

104.179) for audio outputs

4 Foot stand (self-adhesive)

1 Operation manual

1 Important safety instructions

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 14

!

14 en | Installation PAVIRO Amplifier

5

Installation

This device has been designed to be installed horizontally in a conventional 19” rack cabinet.

In general, an installation location must be selected in which the device is protected from the

following conditions:

– Dripping water or spray

– Direct sunlight

– High ambient temperatures or direct effect of sources of heat

– High level of humidity

– Heavy dust accumulation

– Strong vibrations

Front attachment of the device

Refer to the following illustration to attach the front of the device, using four screws and

washers. Because of painted surfaces the connection of the grounding screw at the rear panel

of the device is recommended.

Figure 5.1: Installation of the device into a 19" rack

Caution!

The use of rack mount rails is recommended when installing the device in a rack shelf or rack

cabinet to prevent the front panel from twisting or warping. If devices should be stacked in

the rack (e.g. using the self-adhesive foot stands supplied) the maximum permissible load of

the mount rails must be considered. Please refer to the technical specifications provided by

the rack rail manufacturer.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 15

PAVIRO Amplifier Installation | en 15

Figure 5.2: Stacking of devices using the supplied foot stands (example with 3 devices, rack mount rails are

used for the bottom device only)

Heat development

The table in chapter Specification can be used to determine the requirements for power

supply and supply lines. The power drawn from the mains is converted into output power to

feed the loudspeaker systems and heat. The difference between power consumption and

power output is called power dissipation (P

). The heat that is generated by losses might

loss

stay in the rack shelf and has to be dissipated by appropriate measures. The table can be used

to calculate the thermal ratio inside of a rack shelf/cabinet or for dimensioning the perhaps

required ventilation measures. The P

column lists the power dissipation for various

loss

operating conditions.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 16

16 en | Connection PAVIRO Amplifier

6

6.1

Connection

Audio inputs

The power amplifier has four audio input channels. With the help of integrated pilot tone

monitoring, a missing or faulty input signal can be detected reliably. Please refer to section

Circuit diagram, page 32 for details about the internal audio routing of the device.

RJ-45

The pin assignment of the LINE 1-4 IN / THRU audio input sockets allows connecting the

power amplifier to the RJ-45 audio output socket of a controller using standard RJ-45 patch

cables. The two RJ-45 sockets are switched in parallel which allows looping through the audio

signal.

Figure 6.1: Pin assignment of LINE IN 1-4 socket

Notice!

Do not use Ethernet crossover cables to connect audio inputs. Only use high quality straight

through Ethernet cables with shielding.

Notice!

Do not plug a CAN terminating resistor into the LINE IN 1-4 socket.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 17

PAVIRO Amplifier Connection | en 17

Euroblock

The L1 or L2 audio inputs allow to connect local audio sources, e.g. in stand-alone mode. The

audio signal L1 is mixed with input signal LINE IN 4 (provided via RJ-45) and amplified by

amplifier output channel 1. Audio signal L2 is mixed with input signal LINE IN 4 and amplified

by amplifier output channel 2.

Notice!

If local audio sources should be used while full system supervision is required, a pilot tone

must be available at LINE IN 4. Please refer to section Circuit diagram, page 32 and the

documentation of IRIS-Net.

The audio inputs are electronically balanced. You must always use a balanced audio signal at

the input of the device where this is possible. The scope of delivery for the device includes a

3-pin connector. Conductor cross-sections of 0.14 mm² (AWG26) to 1.5 mm² (AWG16) can be

used.

Recommended connecting cable: balanced cable with shielded flexible 2 x 0.14 mm².

Balanced cabling

The following illustration shows the balanced cabling of an audio input (or output) on the

device.

Figure 6.2: Balanced cabling

Unbalanced cabling

If the connecting cable(s) is/are very short and no interference signals are to be expected in

the environment of the device, then an unbalanced signal can also be connected. In this case,

it is imperative that a bridge in the connector between the shield and the inverting pin is

switched (see diagram below), otherwise the level can drop by 6 dB. However, for reasons of

immunity to external interference sources such as dimmers, mains supplies, HF control lines

etc., balanced cabling is always preferable.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 18

18 en | Connection PAVIRO Amplifier

Figure 6.3: Unbalanced cabling

6.2

Audio output

The audio outputs on the device are galvanically insulated and are constantly monitored for

ground fault. For each output channel there are 6 pins, two pins for 0V, two pins for 70V and

two pins for 100V speaker lines. The delivery for the device includes 6-pole connectors.

Conductor cross-sections of 0.14 mm² (AWG26) to 1.5 mm² (AWG16) can be used.

Recommended connecting cable: flexible CU strand, LiY, 0.75 mm².

For ease of installation, the connector can be removed. With regard to the maximum number

of speakers that can be connected, speakers can be connected until the point at which the

total power consumption of the speaker network corresponds to the nominal power value of

the output stage, where the rated load resistance of the output stage outputs is not to be

exceeded. The nominal power values and the rated load resistances of the outputs can be

found in the section entitled Technical data.

Notice!

Conductor cross-section

The maximum voltage drop must be less than 10% to avoid alarm signal attenuation and

ensure a sufficient signal level of the pilot tone for (optional) EOL modules.

Notice!

Do not use 70V and 100V outputs simultaneously.

Danger!

It is possible that during operation shock hazard voltages (> 140 V peak value) may be present

at the outputs. Therefore, the connected loudspeaker zones have to be installed in accordance

with applicable safety regulations. When installing and operating 100 V loudspeaker networks,

compliance with the VDE regulation DIN VDE 0800 is mandatory. Especially, when 100 V

loudspeaker networks in alarm system applications are concerned, all safety precautions have

to be in accordance with the safety class 3 standard.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 19

PAVIRO Amplifier Connection | en 19

6.3

Supply voltage

The device is normally operated via the AC mains input (120–240 V). In addition, a battery

input is available for emergency power operation (24 V DC).

Notice!

If the AC and DC power inputs are used, it is recommended to connect AC power first, then

switch on the device, then connect the DC power source.

Notice!

A power-on delay can be programmed for the PVA-2P500 via IRIS-Net. Upon switching on the

power supply the device does not start until the set delay time has elapsed. If several devices

are operated on the same automatic circuit breaker (or battery), cascaded switch-on can be

accomplish by programming individually different power-on delays for the devices. This also

prevents the magnetic trip of an automatic circuit breaker from acting and thus disconnecting

the devices from the mains supply, when various devices are switched on at the same time.

AC input and power switch

The power supply to the device is provided via the mains input using the supplied IEC cable

only. During installation, always disconnect the device from all supply voltages. Connect the

device only to a suitable power supply that meets the requirements specified on the type

plate. The associated fuse is located on the inside of the amplifier and is not accessible from

outside of the device.

The power switch at the rear separates the device from the power supply when the switch is

in the off position (0). The device starts booting up when the switch is in the on position (|). A

soft-start circuit limits in-rush current peaks occurring during this process. The speakers are

switched on via the output relays after a time delay. This effectively suppresses any audible inrush noises.

DC input

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 20

20 en | Connection PAVIRO Amplifier

The device automatically switches to DC input in the event of failure of the mains supply

voltage. For this input, connect a 24-volt DC source to the DC INPUT input. The scope of

delivery for the device includes a 2-pin connector. Conductor cross-sections of 2 mm² to

6 mm² can be used.

Recommended connecting cable: flexible CU strand, LiY, 4 mm².

The DC input is protected against incorrect polarity and overload. The associated fuse is

located on the inside of the device and is not accessible from outside of the device. The

threshold of the internal audio peak limiters are lowered by 3 dB if DC is connected only.

Notice!

The DC input cannot be switched off. The power switch can only be used to switch off the

mains power supply.

6.4

CAN BUS

This section contains information about the connection of the device to the CAN BUS and the

correct setting of the CAN address.

Connection

The device has two RJ-45 jacks for the CAN BUS. The jacks are connected in parallel, and act

as an input and for daisy chaining the network. The CAN bus allows different data rates to be

used, where the data rate is indirectly proportional to the bus length. If the network is small,

data rates of up to 500 kbit/s are possible. In larger networks, the data rate must be

decreased (down to the minimum data rate of 10 kbit/s), please refer to section Configuring

the CAN baud rate.

Notice!

The data rate is preset to 10 kbit/s in the factory.

The following table explains the relationship between data rates and bus lengths/network

size. Bus lengths of over 1,000 m must be implemented only with CAN repeaters.

Data rate (in kbit/s) Bus length (in meters)

500 100

250 250

125 500

62.5 1000

Table 6.1: Data rate and bus length of the CAN BUS

The following diagrams show the assignment of the CAN port/CAN connector.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 21

PAVIRO Amplifier

Connection | en 21

Figure 6.4: Assignment of the CAN port

Figure 6.5: Assignment of the CAN connector

Pin

Designation Cable color

T568A T568B

2 CAN_GND Green Orange

4 CAN_H (+) Blue

5 CAN_L (-) Blue stripes

Table 6.2: Assignment of the CAN BUS interface

Cable specification

In accordance with the ISO 11898-2 standard, shielded twisted-pair cables with an impedance

of 120 ohms must be used as the data transfer cable for the CAN bus. A terminating resistance

of 120 ohms must be provided at both ends as the cable terminator. The maximum bus length

depends on the data transmission rate, the type of data transmission cable, and the number

of bus participants.

Bus length (in

m)

0 to 40 < 70 0.25 to 0.34 mm²

Data transmission cable Termination (inΩ)Maximum data

Resistance per unit

(in mΩ/m)

Cable crosssection

transmission

rate

124 1000 kbit/s at

AWG23, AWG22

40 m

40 to 300 < 60 0.34 to 0.6 mm²

AWG22, AWG20

300 to 600 < 40 0.5 to 0.6 mm²

AWG20

600 to 1000 < 26 0.75 to 0.8 mm²

AWG18

Table 6.3: Relationships for CAN networks with up to 64 participants

127 500 kbit/s at

100 m

150 to 300 100 kbit/s at

500 m

150 to 300 62.5 kbit/s at

1000 m

If there are long cables and several devices on the CAN bus, terminating resistors with ohm

ratings higher than the specified 120 ohms are recommended in order to reduce the resistive

load for the interface drivers, which in turn reduces the voltage loss from one cable end to

another.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 22

en | Connection PAVIRO Amplifier

22

The following table allows initial estimates for the required cable cross-section for different

bus lengths and various numbers of bus participants.

Bus length (in m) Number of devices on the CAN Bus

32 64 100

100 0.25 mm² or AWG24 0.34 mm² or AWG22 0.34 mm² or AWG22

250 0.34 mm² or AWG22 0.5 mm² or AWG20 0.5 mm² or AWG20

500 0.75 mm² or AWG18 0.75 mm² or AWG18 1.0 mm² or AWG17

Table 6.4: CAN BUS cable cross-section

If a participant cannot be directly connected to the CAN bus, a stub line (branch line) must be

used. Since there must always be precisely two terminating resistors on a CAN bus, a stub line

cannot be terminated. This creates reflections, which impair the rest of the bus system. To

minimize these reflections, these stub lines must not exceed a maximum individual length of

2 m at data transmission rates of up to 125 kbit/s, or a maximum length of 0.3 m at higher bit

rates. The overall length of all branch lines must not exceed 30 m.

The following applies:

– In terms of rack wiring, standard RJ-45 patch cables with 100-ohm impedance (AWG 24/

AWG 26) can be used for short distances (up to 10 m).

– The guidelines specified above for the network cabling must be used when wiring the

racks with each other and for the building installation.

See also

– Configuring the CAN baud rate, page 24

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 23

PAVIRO Amplifier Configuration | en 23

7

7.1

Configuration

Setting the CAN address

The CAN address of the device is set using the two address selector switches HIGH and LOW.

Addresses 1 to 250 (01 hex to FA hex) can be used in a CAN network. The address is set using

the hexadecimal numbering system. The LOW selector switch is for the low-order digit and the

HIGH selector switch is for the high-order digit.

Notice!

Each address may only occur once in the system, otherwise network conflicts will occur.

The address 0 (00 hex, set on delivery) ensures that the device is disconnected from the

remote communication. This means that the device does not appear in the system, even if it is

connected to the CAN bus.

HIGH LOW Address

0 0 Stand-alone

0 1 to F 1 to 15

1 0 to F 16 to 31

2 0 to F 32 to 47

3 0 to F 48 to 63

4 0 to F 64 to 79

5 0 to F 80 to 95

6 0 to F 96 to 111

7 0 to F 112 to 127

8 0 to F 128 to 143

9 0 to F 144 to 159

A 0 to F 160 to 175

B 0 to F 176 to 191

C 0 to F 192 to 207

D 0 to F 208 to 223

E 0 to F 224 to 239

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 24

24 en | Configuration PAVIRO Amplifier

HIGH LOW Address

F 0 to A 240 to 250

F B to F Reserved

Table 7.1: CAN addresses

7.2

7.3

Displaying the CAN baud rate

To display the CAN baud rate, press the Recessed button and keep the button pressed down

for at least one second. Three front panel indicator lights then display the set baud rate for

two seconds. Please refer to the following table for details.

Baud rate (in kbit/s) Audio signal

indicator light of

channel 1

10 Off Off On

20 Off On Off

62.5 Off On On

125 On Off Off

250 On Off On

500 On On Off

Table 7.2: Displaying the CAN baud rate via indicator lights on the front panel

Audio signal

indicator light of

channel 2

Network indicator

light

Configuring the CAN baud rate

The CAN baud rate can be configured using a UCC1 USB-CAN CONVERTER or directly on the

front of the device.

Changing the CAN baud rate

Notice!

The CAN baud rate can only be changed if the CAN address is set to 00.

18-Jun-2015 | 04 | F01U306898 Operation manual

To change the CAN baud rate, perform the following steps:

1. Press the Recessed button and keep the button pressed down for at least one second.

The CAN baud rate is indicated for two seconds, please refer to the section entitled

“Displaying the CAN baud rate” for more information.

2. As soon as the CAN baud rate is displayed, release the Recessed button. Please note that

if the button is pressed for more than 3 seconds, the device will be reset to factory

settings.

3. Briefly press the Recessed button to switch to the next-higher CAN baud rate. The LEDs

indicate the new setting.

4. Repeat step 3 until the desired baud rate has been set. (Example: To change the baud

rate from 62.5 kbit/s to 20 kbit/s, press the Recessed button exactly five times, i.e. 62.5 >

125 > 250 > 500 > 10 > 20).

5. The new CAN baud rate is applied two seconds after the last time that the Recessed

button is pressed.

Page 25

PAVIRO Amplifier Operation | en 25

8

Operation

Fault monitoring

The following functions of the power amplifier can be monitored:

– Mains under-voltage

– Battery under-voltage

– Excessive temperature

– Overload

– Output voltage

– Output current

– Ground fault (in stand-alone mode only)

– Pilot tone monitoring when used in combination with PVA-4CR12 and PVA-4R24

– Monitoring of the microprocessor

– CAN BUS connection

Whenever a fault occurs in the power amplifier, this is always indicated by means of the

General fault warning indicator light lighting up. IRIS-Net can be used to configure which

power amplifier fault types are to be displayed. The monitoring of functions that are not being

used (e.g. DC input) must be deactivated, otherwise a permanent fault is displayed.

Standby mode

In standby mode the power consumption of the PVA-2P500 is below 2 W (AC or DC power

supply). Following functions are available in standby mode:

– Remote control via CAN bus

– Supervision of the AC power input

– Supervision of the DC power input

The standby mode is activated or deactivated via CAN bus. The standby mode will be

deactivated automatically if the CAN bus is disconnected or the CAN address is set to 0

(stand-alone mode).

8.1

Stand-alone mode

Audio signals

In stand-alone mode (without CAN connection to a controller, e.g. CAN address set to 0) the

audio input signal L1 (or L2) is mixed with audio input 4, amplified with 36 dB and provided

by audio output 1 (or 2).

Ground fault monitoring

The VDE specification DIN VDE 0800 must be observed when setting up and operating 100-volt

speaker systems. Particularly with 100-volt speaker systems that are used for alarm purposes,

all protective measures must be designed for measuring class 3. The integrated ground fault

monitoring function in the power amplifier allows the insulation of the ungrounded speaker

line network to be monitored in stand-alone mode. Any ground fault (e.g. R ≤ 50kΩ) that

occurs is an indication of either cable damage, which means that a line interruption may occur

in the near future, or a wiring fault, which can result in malfunctions. A ground fault that has

been present for at least five seconds is indicated on the front panel by the Ground fault

indicator light lighting up yellow. The Ground fault indicator light lights up until the power

supply to the output stage is disconnected or the error is reset by pressing the Recessed

button.

To test the ground fault monitoring function, use a 22 kOhm resistor (the power amplifier

must not be in STANDBY mode during the testing process). If the resistance is switched from

a terminal of the power output socket to protective ground for approx. five seconds, the

Ground fault indicator light must light. If the resistance is greater than 100 kOhms and the

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 26

26 en | Operation PAVIRO Amplifier

capacity is less than 5 μF, the Ground fault indicator light must not light up. After the resistor

has been removed, the display and the malfunction message must continue to be shown. To

reset the ground fault monitoring function, press the Recessed button.

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 27

!

PAVIRO Amplifier Maintenance | en 27

9

9.1

9.2

Maintenance

Firmware update

IRIS-Net can be used to update the firmware on the device. Depending on the CAN data rate

used, the update will take one or more minutes to complete. Since development work is

always being performed in relation to all system software, it may be necessary to update the

firmware on the controller. Any software incompatibilities are displayed in IRIS-Net. For more

information on firmware updates, please refer to the IRIS-Net documentation.

Resetting to factory default settings

The device is programmed in the factory with the following functions and properties:

Parameter Setting/description

CAN baud rate 10 kbit/s

Input routing Line input L1 to CH 1

Line input L2 to CH 2

Line input 4 to CH 1 and CH 2 (in stand-alone mode)

Output relays All closed

Table 9.1: Device factory default settings

The device settings can be reset to the default values manually or using IRIS-Net. To perform a

manual reset, perform the following steps with the device switched on:

1. Disconnect the device from the CAN BUS.

2. Set the address to “00” using the CAN ADDRESS selector switch on the rear panel.

3. Press the Recessed button on the front panel and keep the button pressed down for

three seconds.

The device has now been reset to the factory default settings.

Caution!

Before reconnecting the device to the CAN BUS, note the CAN baud rate, which may change

under certain circumstances.

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 28

28 en | Technical data PAVIRO Amplifier

10

Technical data

Specification

Rated load impedance (output power)

– 100 V 20 Ω (500 W)

– 70 V 10 Ω (500 W)

Rated output power, 1 kHz, THD ≤ 1% 2 ✕ 500 W

Rated input voltage +6 dBu

Max. RMS voltage swing, 1 kHz, THD ≤ 1%, without load

– 100 V 110 V

– 70 V 78 V

Voltage gain, ref. 1 kHz, fixed

– 70 V 33.2 dB

– 100 V 36.2 dB

Maximum load capacitance 2 µF

Input level, max. +18 dBu (9.75 V

1

rms

)

Frequency response, ref. 1 kHz, rated load,

50 Hz to 25 kHz

-3 dB

Input impedance, active balanced 20 kΩ

Signal-to-noise ratio (A-weighted) > 104 dB

Output noise (A-weighted) < -62 dBu

Crosstalk , ref. 1 kHz < -85 dB

Output stage topology Class-D, transformer, floating

Power requirements

– AC 115–240 V (-10/+10%)

2

– DC 21‑32 V

Power consumption, AC and DC See section “Power consumption” in

operation manual

Inrush current 2 A

Inrush current, after five-second power cycle 1.3 A

Mains fuse T6.3A (internally)

DC fuse 30A (internally)

Ground fault R < 50 kΩ

CAN BUS port 2 ✕ RJ-45, 10 to 500 kbit/s

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 29

PAVIRO Amplifier Technical data | en 29

Protection Audio input level limiter, RMS output power

limiter, high temperature, DC, short circuit,

mains undervoltage protection, DC supply

undervoltage protection, inrush current

limiter, ground fault

Cooling Front-to-rear, temperature-controlled fans

Operating temperature -5 °C to +45 °C

Safety class Class I

Electromagnetic environment E1, E2, E3

Product dimensions (Width ✕ Height ✕ Depth) 19”, 2 HU, 483 ✕ 88.2 ✕ 391 mm

Net weight 16.5 kg

Shipping weight 19 kg

1

In DC mode and in continuous alarm-signal operation, output signal limited by 3 dB max.

2

Reduced output power at mains voltages below 115 V

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 30

30 en | Technical data PAVIRO Amplifier

10.1

10.2

Standards

– EN 50130-4

– EN 50581

– EN 55103-1/2

– EN 61000-3-2/3

– EN 61000-6-3

– IEC 60065

– EN 60945

Power consumption

230 V/50 Hz operation

I

supply

Standby 0.14 A 33.0 VA 1.9 W 0.0 W 6.5

Idle (no audio) 0.20 A 47.0 VA 19.5 W 0.0 W 66.5

Announcement (-10 dB) 0.88 A 202 VA 175 W 100 W 255.8

Alert (-3 dB) 3.35 A 772 VA 745 W 500 W 835.5

120 V/60 Hz operation

S

supply

P

supply

P

out

BTU/h

I

supply

S

supply

P

supply

P

out

BTU/h

Standby 0.09 A 9.0 VA 1.3 W 0.0 W 4.4

Idle (no audio) 0.27 A 29.0 VA 17.3 W 0.0 W 59.0

Announcement (-10 dB) 1.6 A 189 VA 175 W 100 W 255.8

Alert (-3 dB) 6.9 A 824 VA 800 W 500 W 1023

24 V DC operation

I

supply

S

supply

P

supply

P

out

BTU/h

Standby 0.06 A - 1.4 W 0.0 W 4.8

Idle (no audio) 0.65 A - 15.6 W 0.0 W 53

Announcement (-10 dB) 7.0 A - 168 W 100 W 232

Alert (-3 dB) 32.5 A - 780 W 500 W 938

Description of table columns:

– I

– S

– P

– P

– P

= RMS current drawn from mains (or DC supply)

supply

= apparent power drawn from the mains line

supply

= reactive power drawn from mains (or DC supply)

supply

= NF output power provided to the speaker lines

out

or BTU/h = thermal loss

loss

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 31

PAVIRO Amplifier Technical data | en 31

Dimensions10.3

Operation manual 18-Jun-2015 | 04 | F01U306898

Page 32

IN1+

IN1-

IN2+

IN2-

IN3+

IN4+

OUT1+

IN3-

IN4-

GNDA

OUT2+

OUT3+

OUT4+

OUT1-

OUT2-

OUT3-

OUT4-

All NF-Inputs:

+6dBu input sensitivity

+12dBu input acceptance

2.RJ45

analog audio

input

4 IN 1

Router

250W

250W

250W / 500W

Output

Transformer

Control & Supervision GND-FAULT

+15V

CAN

LED Display

1

2

1

2

1 2

250W / 500W

Output

Transformer

Output Relay

ADCADC

ADCADC

Clipper / Limiter

FAN_PWM

Power

Standby

Remote

General Fault

GND Fault

Signal CH1

Clip CH1

Signal CH2

Clip CH2

Test-Button

Watchdog

4 CH Signal

detection

(>= -50dB)

Display BUS

Phoenix Input

GNDA

GNDA

IN1+

IN1-

IN2+

IN2-

4 IN 1

Router

+

+

Phoenix Input

CH1

CH2

CH3

CH4

Local 1

Local 2

100V

70V

0V

100V

70V

0V

DC Power supply unit

AC Power supply unit

FAN

Powerstage

DC Input

AC Input

Clipper / Limiter

32 en | Technical data PAVIRO Amplifier

10.4

Circuit diagram

18-Jun-2015 | 04 | F01U306898 Operation manual

Page 33

Page 34

Bosch Security Systems B.V.

Torenallee 49

5617 BA Eindhoven

The Netherlands

www.boschsecurity.com

© Bosch Security Systems B.V., 2015

Loading...

Loading...