Page 1

Bosch Installation Manual:

NGT/NGP

Page 2

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Safety Instructiond. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before Calling Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Questions?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

We look forward to hearing from you!

Page 3

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE AFTER INSTALLATION IS COMPLETE.

IMPORTANT: SAVE FOR THE LOCAL INSPECTOR'S USE.

Important Safety

Instructions

• Have the installer show you the location of the circuit breaker or fuse. Mark it

• Be sure your appliance is properly installed and grounded by a qualified tech-

Safety Codes and Specifications • Installation must conform with local codes or, in the absence of local codes

• The appliance must be electrically grounded in accordance with local codes

• This appliance has been tested in accordance with ANS Z21.1, Standard for

• Additional requirements and standards may apply in specific installations.

Equipment and Usage Safety Requirements

• The cooktop must be used in conjunction with a suitable ventilation system.

• Before plugging in an electrical cord, be sure all controls are in OFF position.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to this manual. For assistance or additional information consult a qualified

installer, service agency, manufacturer or the gas supplier.

for easy reference.

nician.

with the National Fuel Gas Code, ANSI Z223.1.

or, in the absence of local codes, with the National Electrical Code ANSI/

NFPA 70, latest edition. (In Canada, installation must be in accordance with

the CAN 1-B149.1 and .2 Installation Codes for Gas Burning Appliances and/

or local codes.)

Household Cooking Appliances (USA) and in accordance with CANl.l-M81

Interim Reqt #58 Domestic Gas Cooktops (CANADA).

Power Requirements and Electrical Grounding Instructions

Gas Requirements • A manual valve must be installed in an accessible location in the gas line

• Power Supply: 120 Volts, 15 Ampere, 60 Hz. This appliance is factory

equipped with a 5-foot power supply cord with a 3-prong grounding plug (with

polarized parallel blades).

• To prevent electrical shock, the third ground prong should not under any circumstances, be cut or removed. It must be plugged into a matching grounding

type receptacle, connected to a correctly polarized 120-volt circuit.

• A separate circuit is recommended which is in compliance with the NEC. If

there is any doubt as to whether the wall receptacle is properly grounded, the

customer should have it checked by a qualified electrician.

external to the appliance for the purpose of turning on and shutting off the gas

to the appliance.

• Leak testing of the appliance shall be conducted according to manufacturer’s

instructions.

English 1

Page 4

Gas Supply Pressure • Natural Gas - 6 inches water column (14.9 Millibars) minimum.

• Propane Gas -11 inches water column (27.4 Millibars) minimum.

The maximum supply pressure to this appliance shall not exceed 14.0 inches

water column (34.9Millibars).

Gas Appliance Safety

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing property damage, personal injury or death.

Do not store or use combustible materials, gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electrical switch.

•Do not use any phone in your building.

•Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer,

authorized service agency or the gas supplier.

Propane Gas Installation (NGT Models only)

High Altitude Installation This cooktop has been CSA certified for safe operation up to a height of 10,000 ft.

For Massachusetts Installations • Installation must be performed by a qualified or licensed contractor, plumber

NOTE: NGP models cannot be converted for propane use.

The propane gas tank must be equipped with its own high pressure regulator in

addition to the pressure regulator supplied with this unit. The cooktop is shipped

from the factory for use with natural gas. For use with LP, a conversion kit is

required and must be purchased separately. Contact BSH or your retailer to

obtain kit # NEZ1065. A qualified technician or installer must do the conversion.

(3,048 m) without any modifications to components for natural gas or after LP

conversion.

or gas fitter qualified or licensed by the state, province or region where this

appliance is being installed.

• Shut-off valve must be a “T” handle gas cock.

• Flexible gas connector must not be longer than 36 inches (91cm).

English 2

Page 5

Installation

Before You Begin

Tools and Parts Needed 1) Phillips Head Screwdriver

2) Drill with 1/4” (6.35mm) bit

3) Tape Measure

Parts Included 1) Foam tape

2) Hold down brackets (4)

3) Screws, #10-32 x 2 1/2” (63.8mm) (4)

4) Sheet Metal Screws, #8 x 3/8” (9.5mm) (4)

5) Washers (4)

6) Rubber Grate Foot (1 extra foot is included for future use if required)

7) Burner Grates

30” models: (2)

36” models (3)

8) Burner Caps

30” models: (4)

36” models: (5)

9) Regulator

If parts are missing or damaged, call the number or write to the address listed

inside the cover.

General Information

Overall Dimensions

Table 1: Overall Dimensions

30” Models 36” Models

Width

(Side to Side)

Depth

(Front to Back)

Height

(Top to Bottom)

31” (787.4 mm) 37” (939.8 mm)

21” (533.4 mm) 21” (533.4 mm)

4” (Below Countertop) 4” (Below Countertop)

Preparation

Electrical Requirements This appliances requires a 60 Hz, 15 Amp, 120 VAC connection. Plan the installa-

tion so that the power connection is accessible from the front of the cabinet.

Gas Requirements Supply Pressure:

English 3

Page 6

• Natural Gas - 6 inches water column (14.9 Millibars) minimum.

• Propane Gas -11 inches water column (27.4 Millibars) minimum.

The propane gas tank must be equipped with its own high pressure regulator in

addition to the pressure regulator supplied with this unit. The cooktop is shipped

from the factory for use with natural gas. For use with LP conversion kit – Model

NEZ1065, must be purchased separately. A qualified technician or installer must

do the conversion.

Note: NGP model cooktops cannot be converted for LP use.

Cabinet Requirements Dimension requirements in Figs. 1 & 2 are for combustible surfaces. When the

surface is protected by a material listed by UL as a Floor Protector and Wall

Shield covered with not less than No. 28 MSG sheet metal 0.015 inch (0.38mm)

stainless steel, 0.024 inch (0.6mm) aluminum or copper, it is considered noncombustible and some dimensions may be reduced. For a noncombustible surface

over the cooktop, the minimum clearance is 24" (61cm) rather than 30" (76cm) .

• Instructions are based on standard American cabinets 36" high (91cm) x 24"

deep (61cm) with a 25" (63cm) countertop.

• Provide approximately a 10 square inch opening (65cm

2

) in the toe kick area

or other cabinet area for adequate air inlet to the cabinet.

Depth from Back Wall

Cabinet 13" (33cm) max.

Hood Depth - 24" (61cm) max.

Above Counter - 30" (76 cm) min. to

Combustible Surface

NGT(P)7x - 30" (76cm) min.

NGT(P)9x - 36" (91cm) min.

18" (46cm) min.

Left Side

6" (15cm) min.

Centered Over Cooktop

Rear Wall - 1-3/4"(4cm)

Right Side

3" (8cm) min.

Figure 1: Installed Dimensions (from cooktop edges)

NOTE: All measurements given have to be precisely followed. If nonstandard

cabinets are used, make sure they are installed with minimum dimensions shown

in fig. 1 and fig. 2.

Plan the installation of the unit so that the power cord, gas shut-off valve and gas

pressure regulator are accessible from the front of cabinet. If a drawer is installed

directly under the cooktop, its depth (front to back) should be no greater than 15"

(38cm).

English 4

Page 7

Countertop Requirements

6” (152.4 mm)

Min. to Left

Side Wall

1/8” (3.5 mm) Min.

Clearance From

Cooktop to Start

of Radius

2-1/4” (57.2 mm) Min. to

Counter Front

1-3/4” (44.5 mm) Min. to

Combustible Wall

7-3/8” (187.8 mm) Min.

to Left Side Wall

3” (76.2 mm) Min.

to

Right Side

Wall

21” (533.4 mm) cooktop depth

4” (101.6 mm) Below Countertop

4-3/8” (111.6 mm) Min.

to Right Side Wall

Figure 2: Cutout Dimensions

Table 2: Cutout Dimensions

# Cooktop 30” Models 36” Models 45” Models

A

Cutout

B

Cutout

C

19-1/8” to 19-7/8”

(486.1 to 505.6 mm)

28-5/8” to 29-3/8”

(727.2 to 746.6 mm)

30” (762 mm) 36” (914.4 mm) 45” (1143 mm)

19-1/8 to 19-7/8”

(486.1 to 505.6 mm)

34-5/8” to 35-3/8”

(879.6 to 899 mm)

19-1/8 to 19-7/8”

(486.1 to 505.6 mm)

43-15/16” to 44-1/2”

(1116.2 to 1130.6

mm)

Corner

D

31” (787.4 mm) 37” (939.8 mm) 46” (1168.4 mm)

Overall

Mounting Requirements Use the mounting brackets supplied. See “Attach Brackets to the Cooktop” on

page 6. and “Install the Cooktop” on page 6 for further details.

Ventilation Recommendations We strongly recommend the installation of a ventilation hood above this appli-

ance. The hood must be installed according to instructions furnished with the

hood.

English 5

Page 8

Installation Procedure

WARNING: To avoid electrical shock hazard, before installing the

cooktop, switch power off at the service panel and lock the panel to

prevent the power from being switched on accidentally.

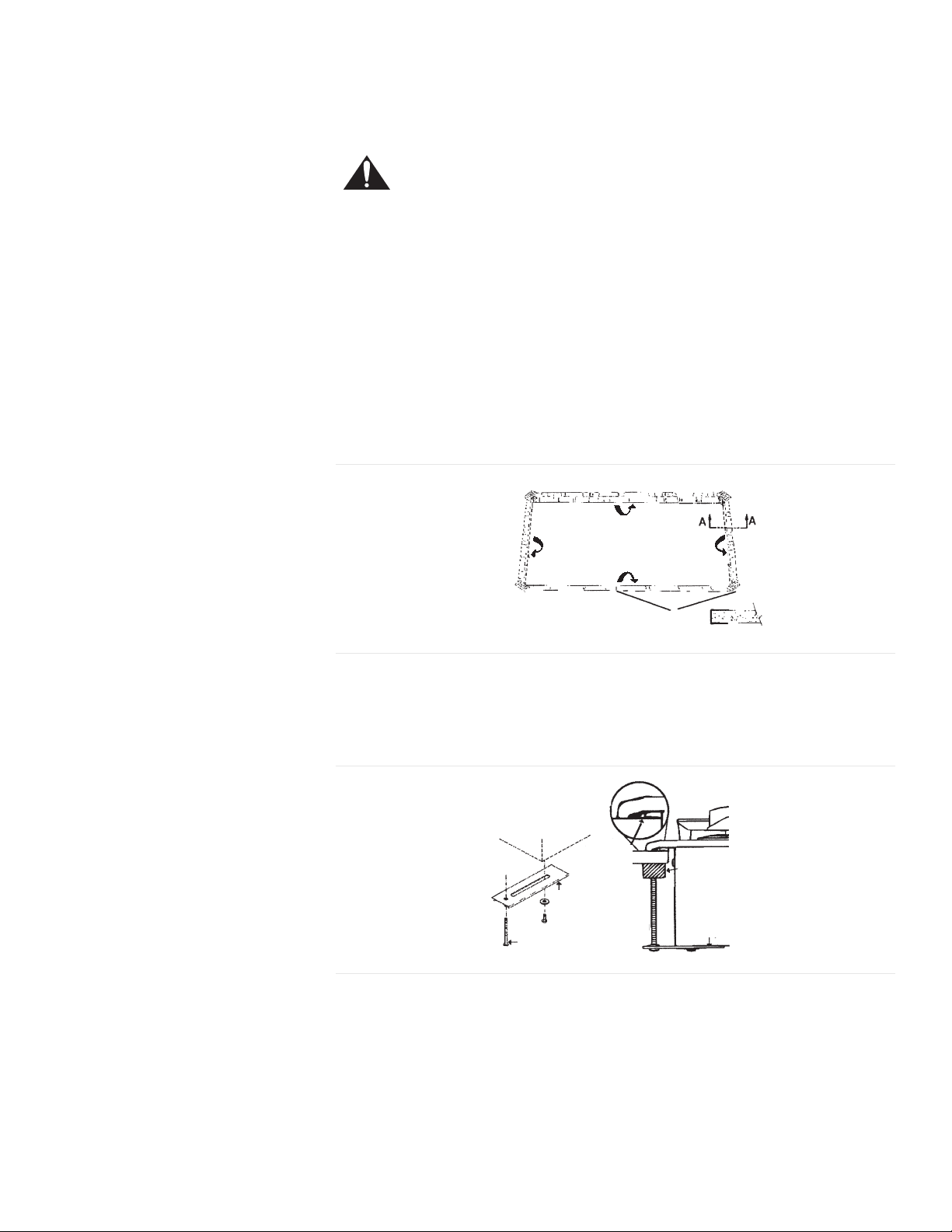

Seal the Cooktop with Foam Tape

Apply the foam tape packaged with the cooktop to underside of the cooktop along

the perimeter before installing.

Prepare the Countertop Cut out the countertop per the dimensions shown in section Countertop Cutout

Dimensions above. For solid surface material installations such as Surell™ and

Corian®, consult with solid surface manufacturer. Apply heat reflective tape such

as Scotch Aluminum Foil Tape #425 or #427 around the cutout so that it folds

over on the top and sides. Do not wrap the tape underneath the cooktop. Be sure

the tape extends beyond the outermost flange of the cooktop. All corners should

be covered with tape.

Cutout shows location

of Aluminum Reflective Tape

Heat Reflective Tape

Section "A - A"

Figure 3: Counter Cutout – Solid Surface Countertops

Attach Brackets to the Cooktop

Attach clamps of the hold-down brackets packaged with the cooktop to the roughin box. Use the washer and screws provided.

Rough-in Box

Adjusting

Screw

Clamp

Foam

Tap e

(Seal)

Adjusting

Screw

Figure 4: Attaching Hold-Down Brackets

Wooden Block

(to be used with

solid surfacing

material, i.e.

Surell™ and

Corian®)

Clamp

Install the Cooktop Insert cooktop into the cutout. Adjust hold-down brackets to desired position and

tighten screws to rough-in box. Insert adjusting screw into clamp and secure cooktop to countertop.

For solid surface material installations: Insert a wooden block between the end of

the screw and the bottom of the countertop. Do not overtighten adjusting screw.

Trim excess aluminum tape around cooktop flange.

English 6

Page 9

Connect Gas Supply The gas inlet to the unit is located at the right rear of rough-in box. After installing

a gas shut-off valve in an easily accessible location under the unit, install the pressure regulator (supplied) to manifold pipe using Teflon tape on threads of manifold

pipe. To prevent possible damage to the gas pressure regulator, install it after the

rough-in box is in its permanent position.

Opening for Gas

Connection and

Electrical Cord

C of Cutout

L

for 30” models - 12-15/16“ (312.8 mm)

for 36” models - 15-15/16“ (389 mm)

for 45” models - 20-3/8” (30 mm)

Figure 5: Rough-in Box Area

CAUTION: Do not attempt any adjustment of the pressure regulator,

except conversion to propane.

Connect the gas supply line to the unit pressure regulator using a 1/2" flex gas line

connector between wall shut-off valve and pressure regulator (see complete pro-

cedure in Figure 6.)

Pressure

Regulator

Shows

Direction of

Gas Flow

Rough-in Box

Flex Gas Line

Gas Shut-Off Valve

Cabinet Floor

Gas Stubout

1/2”

Female Pipe

Threads

Supply Cord

120 V

C of Wall

L

Receptacle

Figure 6: Gas and Electrical Location

Secure regulator to cooktop gas inlet using approved Teflon tape. Turn to hand

tighten plus 1/4 turn, not exceeding 1 turn for alignment.

Check supply line connections for leaks using a soap solution. Do not use a flame

of any sort.

1) Turn on gas.

2. Apply a non-corrosive leak detection fluid to all joints and fittings in the gas

connection between the shut-off valve and the range. Include gas fittings and

joints in the range if connections may have been disturbed during installation.

Bubbles appearing around fittings and connections indicate a leak.

3. If a leak appears, turn off supply line gas shut-off valve and tighten connections.

4. Retest for leaks by turning on the supply line gas shut-off valve. When leak check is complete (no bubbles appear), test is complete.

5. Wipe off all detection fluid residue.

English 7

Page 10

Important Notes for Gas Connection:

e

• The appliance and its individual gas shutoff valve must be disconnected from

the gas supply piping system during any pressure testing of that system at

test pressures in excess of 1/2 psig (3.5kPa).

• The appliance must be isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5kPa).

Connect Electrical Supply

Before connecting 5-foot (1.5 m) supply cord to wall receptacle, make certain that

gas shutoff valve and all burner controls are in OFF position.

Final Check After electrical connection is complete, place each burner cap in correct sized

notched position and check operation of electric igniters. Check flame characteristics. Flame should be blue with no yellow tip.

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow,

verify that the regulator is set for the correct fuel. After adjustment, retest.

Some yellow streaking is normal during the initial start-up. Allow unit to operat

4-5 minutes and re-evaluate before making adjustments.

Service

Before Calling Service

Figure 7: Checking Flame Characteristics

If the elements do not heat or if the indicator “on” light does not glow, check the

power source to see if a fuse has blown or if the circuit breaker has tripped.

Refer to the Warranty in the Use and Care Manual. See Use and Care manual for

troubleshooting information.

English 8

Page 11

Product Data Plate The data plate shows the model and serial number of your cooktop. It is located in

the center front area of the rough-in box, underneath the cooktop.

Data Plate

Figure 8: Data Plate Location

Keep your invoice or escrow papers for warranty validation if service is needed.

English 9

Page 12

Table des matières

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Avant de commencer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Marche à suivre d'installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Avant d’effectuer un appel de service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Questions?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

Nous serons heureux

d’avoir de vos nouvelles!

Page 13

Sécurité

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

LIRE ET CONSERVER CES INSTRUCTIONS

INSTALLATEUR : LAISSER CES INSTRUCTIONS AVEC L’APPAREIL UNE FOIS L’INSTALLATION COMPLÉTÉE. IMPORTANT : CONSERVER POUR L’INSPECTEUR LOCAL.

Instructions de sécurité

importantes

Codes de sécurité et données techniques

Exigences sécuritaires d’équipement et d’utilisation

AVERTISSEMENT : une installation, réglage, modification, service

ou entretien inadéquat peuvent causer des dommages à la propriété ou

des blessures. Consulter ce guide. Pour de l’aide ou de l’information

additionnelle, consulter un installateur qualifié, un centre de service, le

fabricant ou le fournisseur de gaz.

• Demander à l’installateur de montrer l’emplacement du coupe-circuit ou du

fusible. Noter à des fins de références.

• S’assurer que l’appareil est adéquatement installé et mis à la terre par un

technicien qualifié.

• L’installation doit être conforme aux codes locaux ou, en l’absence de ceux-ci,

avec le Code national de gaz combustible, ANSI Z223.1.

• L’appareil doit être mis à la terre électriquement conformément aux codes

locaux ou, en l’absence de ceux-ci, avec le Code national d’électricité ANSI/

NFPA 70, dernière édition. (Au Canada, l’installation doit être conforme aux

codes d’installation CAN 1-B149.1 et .2 pour les appareils à gaz et/ou les

codes locaux.)

• Cet appareil a été testé conformément à la norme ANS Z21.1, pour les appareils de cuisson domestiques (É.-U.) et avec CANl.l-M81 réquisition intérim n°

58, plaques de cuisson à gaz domestique (CANADA).

• Des exigences et normes additionnelles peuvent s’appliquer pour des installations spécifiques.

• La plaque de cuisson doit être utilisée avec un système de ventilation approprié.

• Avant de brancher le cordon électrique, s’assurer que tous les contrôles sont

en position arrêt.

Exigences électriques et instructions de mise à la terre

Exigences de gaz • Une soupape manuelle doit être installée dans un endroit accessible sur la

• Alimentation électrique : 120 volts, 15 Ampère, 60 Hz. Cet appareil est équipé

en usine d’un cordon d’alimentation de 5 pi avec une fiche à 3 broches mise à

la terre (avec lames parallèles polarisées).

• Pour éviter tout choc électrique, la troisième broche de mise à la terre ne doit,

en aucun cas, être coupée ni enlevée. Brancher sur une prise mise à la terre

correspondante, sur un circuit polarisé approprié de 120 volts.

• Un circuit séparé est recommandé conformément au NEC. En cas de doute

concernant si une prise est adéquatement mise à la terre, le consommateur

doit la faire vérifier par un électricien qualifié.

canalisation de gaz externe à l’appareil en vue d’ouvrir ou fermer le gaz à

l’appareil.

• La vérification de fuites de l’appareil doit être effectuée conformément aux

instructions du fabricant.

Français 1

Page 14

Pression de l’alimentation en gaz • Gaz naturel - 6 po, colonne d’eau (14,9 millibars) minimum.

• Gaz propane -11 po, colonne d’eau (27,4 millibars) minimum.

La pression d’alimentation maximale à cet appareil ne doit pas excéder 14,0 po,

colonne d’eau (34,9 millibars).

Sécurité de l’appareil à gaz

Installation du gaz propane (modèle NGT seulement)

AVERTISSEMENT

suivie exactement, il y a un risque d’incendie ou d’explosion causant des dommages à la propriété, des blessures ou la mort.

Ne pas ranger ni utiliser des matériaux combustibles, de l’essence

ou autres vapeurs ou liquides inflammables à proximité de cet

appareil ou de tout autre appareil.

• S’IL Y A UNE ODEUR DE GAZ :

• Ne pas tenter d’allumer tout appareil

• Ne pas toucher aux interrupteurs électriques.

• Ne pas utiliser de téléphone dans l’édifice.

• Téléphoner immédiatement au fournisseur de gaz chez un

voisin et suivre ses instructions.

• S’il est impossible de communiquer avec le fournisseur de

gaz, téléphoner au service des incendies.

L’installation et le service doivent être effectués par un installateur

qualifié, un centre de service autorisé ou le fournisseur de gaz.

REMARQUE : les modèles NGP ne peuvent être convertis pour le propane

Le réservoir de gaz propane doit être doté de son régulateur de haute pression en

plus du régulateur de pression fourni avec l’appareil. La plaque de cuisson est

expédiée de l’usine pour une utilisation avec gaz naturel. Pour utilisation avec le

gaz LP, un nécessaire de conversion est requis et doit être acheté séparément.

Communiquer avec BSH ou le marchand pour obtenir le nécessaire n° NEZ1065.

Un installateur ou technicien qualifié doit effectuer la conversion.

: si l’information de ce guide n’est pas

Installation à haute altitude : Cette plaque de cuisson est certifiée CSA pour un fonctionnement sécuritaire

jusqu’à une hauteur de 10 000 pi (3,048 mètres) sans modification des composants pour le gaz naturel ou après conversion au gaz LP.

Pour installation au Massachusetts • L’installation doit être effectuée par un entrepreneur qualifié ou avec licence,

plombier ou installateur de gaz qualifié ou avec licence émise par l’état, la

province ou la région où l’appareil est installé.

• La soupape d’arrêt doit être un robinet de gaz, poignée en T.

• Le connecteur de gaz flexible ne doit pas dépasser 36 po (91cm).

Français 2

Page 15

Installation

Avant de commencer

Pièces et outils nécessaires

1) Tournevis à lame Phillips

2) Perceuse avec mèche ¼ po (6.35 mm)

3) Ruban à mesurer

Pièces comprises 1) Ruban mousse

2) Fixations (4)

3) Vis, n° 10-32 x 2 ½ po (63.8 mm) (4)

4) Vis à métal, n° 8 x 3/8 po (9.5 mm) (4)

5) Rondelles (4)

6) Pied en caoutchouc de grille (1 pied additionnel compris, si nécessaire)

7) Grilles de brûleur

Modèles 30 po : (2)

Modèles 36 po : (3)

8) Capuchons de brûleurs

Modèles 30 po : (4)

Modèles 36 po : (5)

9) Régulateur

Si des pièces sont manquantes ou endommagées, téléphoner au numéro ou écrire à l’adresse indiqués à la fin de ce guide.

Généralités

Dimensions hors tout

Tableau 1 : Dimensions hors tout

Modèles 30 po Modèles 30 po

Largeur (d'un

côté à l'autre)

Profondeur

(devant à der-

rière)

Hauteur

(haut en bas)

31 po (787,4 mm) 37 po (939,8 mm)

21 po (533,4 mm) 21 po (533,4 mm)

4 po (en dessous du

plan de travail)

4 po (en dessous du

plan de travail)

Préparation

Exigences électriques Cet appareil requiert une connexion de 60 Hz, 15 amp, 120 VAC. Planifier l'instal-

lation afin que la connexion soit accessible depuis le devant de l'armoire.

Exigence de gaz Pression d'alimentation :

Français 3

Page 16

• Gaz naturel - 6 po, colonne d’eau (14,9 millibars) minimum.

• Gaz propane -11 po, colonne d’eau (27,4 millibars) minimum.

Le réservoir de gaz propane doit être doté de son régulateur de haute pression en

plus du régulateur de pression fourni avec l'appareil. La surface de cuisson est

expédiée de l'usine pour utilisation avec gaz naturel. Pour utilisation avec le gaz

LP, un nécessaire de conversion modèle NEZ1065 doit être acheté séparément.

Un technicien ou un installateur qualifié doit faire la conversion.

Remarque : les modèles de surface de cuisson NGP ne peuvent être convertis

pour utilisation au gaz LP.

Exigences pour l’armoire Les exigences de dimensions aux figures 1 et 2 sont pour les surfaces combusti-

bles. Lorsque la surface est protégée par un matériaux marqué U.L. comme protège plancher ou écran mural couvert par pas moins d’une feuille de métal de 28

MSG 0.015 po (0.38 mm) acier inoxydable, 0.024 po (0.6 mm) aluminium ou

cuivre, cela est considéré comme non combustible et certaines dimensions peuvent être réduites. Pour une surface non combustible au-dessus de la plaque de

cuisson, le dégagement minimum est de 24 po (61 cm) plutôt que 30 po (76 cm).

• Les instructions sont fondées sur des armoires standard américaines de 36

po (91 cm) de haut x 24 po (61 cm) de profondeur avec un plan de travail de

25 po (63 cm).

• Fournir une ouverture d’environ 10 po

2

(65 cm2) dans le coup-de-pied ou

autre zone d’armoire pour une entrée d’air à l’armoire.

Profondeur depuis le mur arrière

Armoire 13 po (33 cm) max.

Prof. hotte – 24 po (61 cm) max.

Au-dessus du plan de travail -

30 po (76 cm) min. à

surface combustible

NGT(P)7x - 30 po (76cm) min.

NGT(P) 9x- 36 po (91cm) min.

18 po (46cm) min.

Côté gauche

6 po (15 cm) min.

Centrée au-dessus

de la plaque de cuisson

Mur arrière – 1 3/4 po (4 cm)

Côté droit

3 po (8 cm) min.

Figure 1 : Dimensions d’installation (depuis les bords de la plaque de cuisson)

REMARQUE : toutes les mesures données doivent être suivies. Si des armoires

non standard sont utilisées, s’assurer qu’elles sont installées avec les dimensions

minimales données aux figures 1 et 2.

Planifier l’installation de l’appareil afin que le cordon d’alimentation, la soupape

d’arrêt de gaz et le régulateur de pression de gaz soient accessibles depuis le

devant de l’armoire. Si un tiroir est installé directement sous la plaque de cuisson,

sa profondeur (devant à derrière) ne doit pas dépasser 15 po (38 cm).

Français 4

Page 17

Exigences pour le plan de travail

6 po (152,4 mm)

min. au mur

latéral gauche

1/8 po (3,5 mm) min.

Dégagement de la

plaque de cuisson au

début du rayon

2 1/4 po (57,2 mm) min.

au devant du comptoir

1 3/4 po (44,5 mm) min.

au mur combustible

7 3/8 po (187,8 mm) min.

au mur latéral gauche

3 po (76,2 mm) min.

au mur latéral droit

21 po (533,4 mm), profondeur de la plaque de cuisson

4 po (101,6 mm), dessous

du plan de travail

4 3/8 po (111,6 mm)

min. au mur latéral droit

Figure 2 : Dimensions de découpe

Tableau 2 : Dimensions de découpe

Fig. 2 Modèles 30 po Modèles 36 po

A - Découpe 19-1/8 po á 19-7/8 po

(486,1mm) á (505,6mm)

B - Découpe 28-5/8 po á 29-3/8 po

(727,2mm) á (746,6mm)

19-1/8 po á 19-7/8 po

(486,1mm) á (505,6mm)

34-5/8 po á 35-3/8 po

(879,6mm) á (899mm)

C - Découpe 30 po (762mm) 36 po (914,4mm)

D - Total 31 po (787,4mm) 37 po (939,8mm)

Exigences d'installation Utiliser les fixations fournies. Voir “Installation des fixations à la plaque de cuis-

son” page 6 et “Installation de la plaque de cuisson” page 6, pour plus de détails.

Ventilation recommandées Nous recommandons fortement l'installation d'une hotte au-dessus de cet appar-

eil. La hotte doit être installée selon les instructions fournies avec la hotte.

Marche à suivre d'installation

AVERTISSEMENT : pour éviter tout risque de choc électrique,

avant l’installation de la plaque de cuisson, mettre l’alimentation hors

circuit au panneau de service et le verrouiller pour éviter toute mise en

circuit accidentelle.

Français 5

Page 18

Apposer un ruban mousse à la plaque de cuisson

Apposer le ruban mousse fourni avec l’appareil sous la plaque de cuisson le long

du périmètre avant d’installer.

Préparation du plan de travail

Installation des fixations à la plaque de cuisson

Faire la découpe du plan de travail selon les dimensions données à Dimensions

de découpe pour le plan de travail, ci-dessus. Pour les installation avec surface

solide comme Surell™ et Corian®, consulter le fabricant de la surface. Apposer

du ruban réfléchissant la chaleur comme le ruban aluminium Scotch n° 425 ou n°

427 autour de la découpe afin qu’il soit replié sur le dessus et les côtés. Ne pas

mettre de ruban sous la plaque de cuisson. S’assurer que le ruban dépasse le

rebord extrême de la plaque de cuisson. Tous les coins doivent être couverts de

ruban.

Emplacement du ruban

en aluminium réfléchissant

Ruban réfléchissant

la chaleur

Section A - A

Figure 3 : Découpe du comptoir – plan de travail à surface solide

Attacher les pinces des fixations emballées avec la plaque de cuisson à la boîte

brute. Utiliser la rondelle et les vis fournies.

Installation de la plaque de cuisson

Connexion de l’alimentation en gaz

Boîte brute

Vis de

réglage

Pince

Ruban

mousse

(étanche)

Vis de réglage

Cale en bois

(à utiliser avec

matériau de

surface solide

comme Surrell™

et Corian®)

Pince

Figure 4 : Installation des fixations

Insérer la plaque de cuisson dans la découpe. Régler les fixations en position

désirée et serrer les vis à la boîte brute. Insérer la vis de réglage dans la pince et

fixer de façon sécuritaire la plaque de cuisson au plan de travail.

Pour l’installation avec matériau de surface solide : insérer une cale en bois entre

l’extrémité de la vis et le bas du plan de travail. Ne pas trop serrer la vis de

réglage. Enlever l’excès de ruban aluminium autour du rebord de la plaque de cuisson.

L’entrée de gaz à l’appareil est située à l’arrière droit de la boîte brute. Après avoir

installé la soupape d’arrêt de gaz dans un endroit facile d’accès sous l’appareil,

installer le régulateur de pression (fourni) sur le tuyau collecteur à l’aide de ruban

Téflon sur les filets du tuyau collecteur. Pour prévenir tout dommage possible au

Français 6

Page 19

régulateur de pression de gaz, l’installer une fois que la boîte brute est en position

permanente.

Ouverture pour

la connexion de

gaz et le cordon

électrique

C pour découpe

L

Pour modèle 30 po - 12-5/8 po (320.8 mm)

Pour modèle 36 po - 15-1/2 po (394 mm)

Figure 5 : Zone de la boîte brute

ATTENTION : Ne pas tenter de réglage du régulateur de pression,

sauf pour la conversion au gaz propane.

Brancher la canalisation d’alimentation en gaz sur le régulateur de pression de

l’appareil à l’aide d’un connecteur de canalisation de gaz flexible de ½ po entre la

soupape d’arrêt murale et le régulateur de pression, (voir marche à suivre à la fig-

ure 6)

Régulateur

de pression

montrant le

sens du

débit de gaz

Boîte brute

Canalisation

de gaz flexible

Soupape d’arrêt

Plancher de l’armoire

Connexion de gaz

Filets de tuyau

femelle 1/2 po

Cordon d’alimentation

120 volts

C de prise

L

murale

Figure 6 : Emplacement du gaz et de l’électricité

Fixer le régulateur sur l’entrée de gaz de la plaque de cuisson avec du ruban

Téflon approuvé. Serrer à la main de 1/4 de tour, sans excéder de 1 tour pour

l’alignement.

Vérifier si les connexions de canalisation d’alimentation présentent des fuites

avec une solution savonneuse. Ne pas utiliser de flamme.

1. Ouvrir le gaz.

2. Appliquer un liquide de détection de fuites non corrosif sur tous les joints et

raccords de la connexion de gaz entre la soupape d’arrêt et l’appareil. Inclure

les joints et raccords de gaz de l’appareil si les connexions ont été modifiées

pendant l’installation. Des bulles autour des raccords et connexions indiquent

une fuite.

3. S’il y a une fuite, fermer la soupape d’arrêt de gaz de la canalisation et serrer les connexions.

4. Vérifier de nouveau les fuites en ouvrant la soupape d’arrêt de gaz de la canalisation. Une fois la vérification terminée (il n’y a plus de bulles), le test est complété.

5. Essuyer tout résidu du liquide de détection.

Français 7

Page 20

Remarques importantes sur la connexion de gaz :

• L’appareil et sa soupape d’arrêt de gaz individuelle doivent être débranchés

du système de canalisation d’alimentation en gaz pendant tout test de pres-

sion du système à des tests de pression excédant 1/2 lb/po

• L’appareil doit être isolé du système de canalisation d’alimentation en gaz en

fermant la soupape d’arrêt manuelle individuelle pendant tout test de pression

du système de canalisation d’alimentation en gaz à des tests de pression

égaux ou inférieurs à 1/2 lb/po

2

(3,5 kPa).

2

(3,5 kPa).

Connexion de l’alimentation électrique

Avant de brancher le cordon d’alimentation de 5 pi (1,5 m) sur la prise murale,

s’assurer que la soupape d’arrêt de gaz et tous les contrôles de brûleurs sont en

position arrêt.

Vérification finale Une fois la connexion électrique effectuée, placer chaque capuchon de brûleur

dans la position à encoche appropriée et vérifier le fonctionnement de chaque

allumeur électrique. Vérifier les caractéristiques de la flamme ; elle doit être bleue

avec une pointe jaune.

lamme jaune:

églage additionnel requis.

ointe jaune sur cône extérieur:

ormal pour gaz LP.

lamme bleue, douce:

ormal pour gaz naturel.

Si la flamme est jaune ou presque, vérifier si le régulateur est réglé pour le combustible approprié. Après le réglage, remettre.

Certaines rayures jaunes sont normales pendant la mise en marche initiale.

Laisser l’appareil fonctionner de 4 à 5 minutes et réévaluer avec d’effectuer

d’autres réglages.

Service

Avant d’effectuer un appel de service

Français 8

Figure 7 : Vérification des caractéristiques de flamme

Si l'élément ne chauffe pas ou si le voyant marche ne s'allume pas, vérifier la

source d’alimentation ; un fusible est peut-être grillé ou le coupe-circuit est

déclenché.

Consulter la garantie dans le guide d’utilisation et d’entretien ainsi que le guide de

dépannage.

Page 21

Plaque signalétique La plaque signalétique donne les numéros de modèle et de série de la plaque de

cuisson. Elle est située sur le centre avant de la boîte brute, sous la plaque de cuisson.

plaque signalétique

Figure 8 : Emplacement de la plaque signalétique

Conserver la facture et les documents pertinents pour la validation de la garantie

si un service est requis.

Français 9

Page 22

Contenido

Seguridad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones Importantes de Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Antes de comenzar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Procedimiento de Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Antes de solicitar servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

¿Preguntas?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

¡Estámos a sus órdenes!

Page 23

Seguridad

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL APARATO CUANDO TERMINE LA INSTALACIÓN.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA EL INSPECTOR LOCAL.

Instrucciones

Importantes de

Seguridad

Códigos de seguridad y especificaciones

Requerimientos de seguridad del equipo y su uso

ADVERTENCIA: La instalación, ajuste, alteración, servicio o

mante-nimiento no apropiado puede causar lesiones o dañar la

propiedad. Consulte este manual. Consulte a un instalador calificado,

una agencia de servicio, al fabricante o al proveedor de gas para recibir ayuda o información adicional.

• Pídale al instalador que le muestre el lugar del cortacircuitos o fusible.

Márquelo para encontrarlo fácilmente.

• Asegúrese que su aparato está instalado y puesto a tierra correctamente por

un técnico calificado.

• La instalación debe cumplir con todos los códigos locales o, a falta de códigos locales, con el Código Nacional de Gas Combustible, ANSI Z223.1.

• El aparato debe ser conectado a tierra de acuerdo con los códigos locales, o

a falta de códigos locales, de acuerdo al Código Eléctrico Nacional ANSI/

NFPA 70, última edición. (En Canadá, la instalación debe cumplir con los

códigos de instalación CAN 1-B149.1 y .2 para aparatos que usan gas y/o los

códigos locales)

• Este aparato ha sido probado de acuerdo con la norma ANS Z21.1, para

aparatos de cocina domésticos (eua9 y de acuerdo con el requerimiento

CANl.l-M81 #58 para parrillas domésticas de gas (CANADÁ).

• Requerimientos y normas adicionales pueden aplicar en instalaciones específicas.

• Se debe usar la parrilla en conjunto con un sistema apropiado de ventilación.

• Antes de enchufar un cable eléctrico, asegúrese que todos los controles

están en la posición OFF (apagado).

Requerimientos eléctricos e instrucciones para la puesta a tierra

• Fuente de alimentación: 120 Volts, 15 Amperes, 60 Hz. Este aparato viene de

fábrica con un cable de alimentación eléctrica con un enchufe de 3 clavijas

(con patas paralelas polarizadas).

• Para evitar una descarga eléctrica, no se debe cortar o quitar la tercer clavija

de tierra bajo ninguna circunstancia. Se debe enchufar en una tomacorriente

aterrizada correspondiente, conectada a un circuito de 120 volts que esté

polarizado correctamente.

• Se recomienda un circuito separado que cumpla con NEC. Si existe cualquier

duda con respecto a si la tomacorriente de la pared está correctamente

puesta a tierra, el cliente debe contratar a un eléctrico calificado para checarlo.

Español 1

Page 24

Requerimientos del gas • Se debe instalar una válvula manual en un lugar accesible en el exterior de la

línea de gas al aparato para poder prender y apagar el suministro de gas al

aparato.

• Se deben realizar pruebas de fugas en el aparato de acuerdo a las instrucciones del fabricante.

Presión de suministro de gas • Gas natural - columna de agua 6 pulgadas (14.9 Millibars) mínimo.

• Gas propano -columna de agua 11 pulgadas (27.4 Millibars) mínimo.

La máxima presión de suministro a este aparato no debe exceder una columna

de agua de 14.0 pulgadas (34.9Millibars).

Seguridad del aparato de gas

ADVERTENCIA: El hecho de no observar exactamente

la información contenida en este manual, puede causar

un fuego o explosión, daños a la propiedad, lesiones o la

muerte.

No guarde o use materiales inflamables, gasolina u otros vapores

y líquidos inflamables cerca de este o cualquier otro aparato.

• QUÉ HACER CUANDO HUELE A GAS:

• No trate de encender ningún aparato.

• No toque ningún interruptor eléctrico.

• No use ningún teléfono en su edificio.

• Llame a su proveedor de gas de inmediato desde el teléfono de un vecino. Siga las instrucciones del proveedor.

• Si no puede contactar a su proveedor de gas, llame a los

bomberos.

Un instalador calificado, una agencia de servicio autorizada o el

proveedor de gas debe realizar la instalación y el servicio.

Propane Gas Installation (sólo modelos NGT)

Instalación en grandes altitudes: Esta parrilla ha sido certificada por CSA para una operación segura hasta una

NOTA: No se pueden covertir los modelos NGP para el uso con gas propano.

El tanque del gas propano debe estar equipado con su propio regulador de alta

presión además del regulador de presión que se incluye con esta unidad. La parrilla viene de fábrica para el uso con gas natural. Para el uso con gas LP se

requiere un kit de conversión que se debe comprar por separado. Contacte a

BSH o a su distribuidor para obtener el kit # NEZ1065. Un técnico o instalador

calificado debe realizar la conversión.

altitud de 10,000 pies (3,048 m) sin ninguna modificación a componentes para el

gas natural o tras una conversión a gas LP.

Para instalaciones en Massachusetts • La instalación debe ser realizada por un contratista calificado o autorizado, un

plomero o un instalador de gas calificado o autorizado por el estado, la provincia o región donde se está instalando este aparato.

• La válvula de cierre debe ser una llave de gas con mango en T.

• La manguera flexible de gas no debe medir más de 36 pulgadas (91cm).

Español 2

Page 25

Instalación

Antes de comenzar

Herramientas y partes necesarias

1) Destornillador de cabeza Phillips (de cruz)

2) Taladro con broca de 1/4” (6.35 mm)

3) Cinta de medir

Partes incluidas 1) Cinta de espuma

2) Abrazaderas de retención (4)

3) Tornillos, #10-32 x 2 1/2” (638 mm) (4)

4) Tornillos autorroscantes, #8 x 3/8” (9.5 mm) (4)

5) Arandelas (4

6) Pata de hule para la rejilla (se incluye 1 pata extra para el uso futuro si se requiere)

7) Rejillas de quemador

Modelos de 30”: (2)

Modelos de 36”: (3)

8) Tapas de quemador

Modelos de 30”: (4)

Models de 36”: (5)

9) Regulador

Si falta alguna parte o si está dañada, llame al teléfono o escriba a la dirección listada dentro de la contraportada.

Información general

Dimensiones generales

Tabla 1: Dimensiones generales

Modelos de 30” Modelos de 36”

Ancho

(Lado a Lado)

Profundidad

(Frente al fondo)

Altura

(Parte superior a

la parte inferior)

31” (787.4 mm) 37” (939.8 mm)

21” (533.4 mm) 21” (533.4 mm)

4" (Debajo de la

cubierta)

4" (Debajo de la

cubierta)

Preparación

Requerimientos eléctricos Este aparato requiere una conexión de 60 Hz, 15 Amp, 120 VAC. Planee la insta-

lación de tal modo que se tenga acceso a la conexión de la alimentación eléctrica

desde el frente del gabinete.

Español 3

Page 26

Requerimientos de gas Presión de suministro:

• Gas natural - 6 pulgadas de columna de agua (14.9 milibar) como mínimo.

• Gas propano - 11 pulgadas de columna de agua (27.4 Millibars) mínimo.

El tanque de gas propano debe contar con su propio regulador de alta presión

además del regulador de presión que se incluye con esta unidad. La parrilla viene

de fábrica para el uso con gas natural. Para usarla con gas LP, se tiene que comprar por separado el kit de conversión - Modelo NEZ 1065. Un técnico o instalador calificado debe realizar la instalación.

Nota: No se pueden convertir las parrillas de modelo NGP para el uso con gas

LP.

Requerimientos para los gabinetes Los requerimientos de dimensiones en las Figuras 1 y 2 son para superficies

inflamables. Donde la superficie está protegida por un material listado por UL

como un protector de piso y de pared cubierto con no menos de lámina No. 28

MSG con un espesor de 0.015 pulg. (0.38mm) de acero inoxidable, 0.024 pulg.

(0.6mm) de aluminio o de cobre, se considera una superficie no inflamable y se

pueden reducir algunas dimensiones. Para una superficie no inflamable encima

de la parrilla, la mínima distancia es 24" (61cm) en lugar de 30" (76cm).

• Las instrucciones se basan en gabinetes americanos estándar 36" alto

(91cm) x 24" profundo (61cm) con una cubierta de 25" (63cm).

• Proporcione una abertura aproximada de 10 pulgadas cuadradas (65cm

el área del panel de pie u otra área del gabinete para asegurar una entrada

apropiada de aire al gabinete.

2

) en

Profundidad de pared trasera

Gabinete 13" (33cm) máx.

Profundidad campana - 24" (61cm) máx.

Arriba de la cubierta - 30" (76 cm) mín.

a la superficie inflamable

NGT(P) 7x- 30" (76cm) mín.

NGT(P) 9x - 36" (91cm) mín.

18" (46cm) mín.

Lado izquierdo

6" (15cm) mín.

Centrado sobre la parrilla

Pared trasera - 1-3/4"(4cm)

Lado derecho

3" (8cm) mín.

Figura 1: Dimensiones instaladas (desde los bordes de la parrilla)

NOTA: Se deben observar con precisión todas las medidas indicadas. Si se usan

gabinetes fuera de la norma, asegúrese de instalarlos con las dimensiones mínimas que se indican en las Figuras 1 y 2.

Planee la instalación de la unidad de modo que se tenga acceso al cable de alimentación eléctrica, la válvula de cierre de gas y el regulador de presión del gas

desde el frente del gabinete. Si se instala un cajón directamente abajo de la parrilla, su profundidad (del frente hasta el fondo) no debe ser mayor de 15" (38cm).

Español 4

Page 27

Requerimientos de la cubierta

6” (152.4 mm)

min. a la pared

izquierda

1/8” (3.5 mm) min.

abertura de la

cubierta al inicio

del radio

2-1/4” (57.2 mm) min. al

frente de la cubierta

1-3/4” (44.5 mm) min. a la

pared inflamable

7-3/8” (187.8 mm) min.

a la pared izquierda

3” (76.2 mm) min.

derecha

a la pared

21” (533.4 mm) profundidad de la parrilla

4” (101.6 mm) abajo de la cubierta

4-3/8” (111.6 mm) min.

a la pared derecha

Figura 2: Dimensiones del recorte

Tabla 2: Dimensiones del recorte

Fig. 2 Modelos de 30” Modelos de 36”

A - Recorte 19-1/8” a 19-7/8”

(486.1mm) a (505.6mm)

B - Recorte 28-5/8” a 29-3/8”

(727.2mm) a (746.6mm)

19-1/8 a 19-7/8”

(486.1mm) a (505.6mm)

34-5/8” a 35-3/8”

(879.6mm) a (899mm)

C - Esquina 30” (762mm) 36” (914.4mm)

D - Total 31” (787.4mm) 37” (939.8mm)

Requerimientos de montaje Use los soportes de montaje que se incluyen. Vea “Fijar las abrazaderas a la par-

rilla” en la página 6 e “Instalar la parrilla” en la página 6 para más detalles.

Recomendaciones de ventilación Recomendamos fuertemente instalar una campana de ventilación arriba de este

aparato. Se debe instalar la campana conforme a las instrucciones incluidas con

la campana.

Procedimiento de Instalación

ADVERTENCIA: Para evitar una descarga eléctrica antes de dar

servicio a la parrilla, apague la corriente en el panel de servicio y bloquee este panel para evitar que se prenda accidentalmente.

Español 5

Page 28

Sellar la parrilla con cinta de espuma

Aplique la cinta de espuma que se incluye con la parrilla al lado inferior de ésta a

lo largo del perímetro antes de instalar la unidad. Vea la Figura 3.

Preparar la cubierta Haga sus recortes en la cubierta según las dimensiones indicadas en la sección

Dimensiones del recorte de la cubierta de arriba. Para instalaciones en super-

ficies sólidas de materiales como Surell™ y Corian®, consulte a un fabricante de

superficies sólidas. Aplique cinta termorreflectante como cinta de aluminio Scotch

#425 o #427 alrededor del recorte de modo que se doble encima de la parte

superior y de los costados. No meta la cinta por debajo de la parrilla. Asegúrese

que la cinta se extienda más allá del borde exterior de la parrilla. Todas las

esquinas deben quedar encintadas.

El recorte muestra el lugar de

la cinta reflectante de aluminio

Cinta termorreflectante

Sección "A - A"

Figura 3: Recorte de la cubierta – Cubiertas de superficies sólidas

Fijar las abrazaderas a la parrilla

Fije los sujetadores de las abrazaderas de retención que se incluyen con la parrilla a la caja empotrada. Use las arandelas y los tornillos que se incluyen.

Caja empotrada

Tornillo de

ajuste

Sujetador

Cinta

de

espuma

(sello)

Tornillo de

ajuste

Bloque de madera

(a ser utilizado en

superficies de

materiales sólidos,

i.e., Surell™ y

Corian®)

Sujetador

Figura 4: Fijar las abrazaderas de retención

Instalar la parrilla Inserte la parrilla en el recorte. Ajuste las abrazaderas de retención a la posición

deseada y apriete los tornillos a la caja empotrada. Inserte el tornillo de ajuste al

sujetador y fije la parrilla a la cubierta.

Para instalaciones en superficies con materiales sólidos: Inserte un bloque de

madera entre el fin del tornillo y la parte inferior de la cubierta. No apriete el tornillo de ajuste demasiado. Corte el exceso de la cinta de aluminio alrededor del

borde de la parrilla.

Conectar el suministro de gas

Español 6

La entrada de gas a la unidad se encuentra en la parte trasera derecha de la caja

empotrada. Después de instalar una válvula de cierre de gas en un lugar de fácil

acceso debajo de la unidad, fije el regulador de presión (incluido) al tubo ramificado (manifold) utilizando cinta de teflón en la rosca del tubo. Para evitar posibles

Page 29

daños al regulador de presión del gas, instálelo después de que la caja empotrada esté en su posición permanente.

Abertura para la conexión

de gas y el cable

de alimentación

eléctrica

C del recorte

L

para modelos de 30” - 12-5/8“ (320.8 mm)

para modelos de 36” - 15-1/2“ (394 mm)

Figura 5: Área de la caja empotrada

PRECAUCIÓN: No intente ajustar el regulador de presión, menos

la conversión a gas propano (LP).

Conecte la línea de suministro de gas al regulador de presión de la unidad utilizando una manguera flexible para gas de 1/2" entre la válvula de cierre y el regu-

lador de presión (vea el procedimiento completo en la Figura 6.)

Regulador

de presión

indica la

dirección de

flujo del gas

Caja empotrada

Manguera

para gas

Válvula de cierre

Piso del gabinete

Conexión de gas

Rosca hembra

del tubo de 1/2”

Cable de

alimentación

120 V

C del receptáculo

L

de la pared

Figura 6: Posición del suministro de gas y de la alimentación eléctrica

Fije el regulador a la entrada de gas de la parrilla utilizando cinta de teflón aprobada. Apriete con la mano más 1/4 giro, pero no exceda 1 giro para alinearlo.

Revise las conexiones de la línea de suministro del gas para ver si hay fugas utilizando una solución jabonosa. No use ninguna llama.

1. Prenda el gas.

2. Aplique un líquido de detección de fugas no corrosivo a todas las uniones y

conexiones en la conexión del gas entre la válvula de cierre y la parrilla.

Incluya las conexiones de gas y las uniones en la parrilla si se modificaron o

perturbaron las conexiones durante la instalación. Burbujas que aparecen

alrededor de las conexiones y uniones indican una fuga de gas.

3. Si se presenta una fuga, apague la válvula de cierre del gas y apriete las conexiones.

4. Vuelva a verificar si hay fugas, abriendo la válvula de cierre de gas de la línea de suministro. Al concluir la prueba de fugas (no hay burbujas), termina la prueba.

5. Limpie el exceso del líquido de detección.

Español 7

Page 30

Notas importantes para la conexión del gas:

• Se deben desconectar el aparato y su válvula individual de cierre de gas del

sistema de suministro de gas durante cualquier prueba de presión de ese

sistema a presiones de prueba arriba de 1/2 psig (3.5kPa).

• Se debe aislar el aparato del sistema de suministro de gas cerrando su válvula individual de cierre de gas durante cualquier prueba de presión del

sistema de suministro de gas a presiones de prueba arriba de 1/2 psi

(3.5kPa).

Conectar la alimentación eléctrica

Antes de conectar el cable de alimentación eléctrica de 5 pies (1.5m) a la tomacorriente en la pared, asegúrese que la válvula de cierre de gas y todos los

controles de los quemadores están en la posición OFF (Apagado).

Chequeo final Después de terminar la conexión eléctrica, coloque cada tapa del quemador en

las posiciones ranuradas del tamaño correcto y revise la operación de los

encendedores eléctricos. Revise las características de las llamas. La llama del

quemador debe ser azul y estable sin puntas amarillas.

Llamas amarillas:

Se requiere más ajuste.

Puntas amarillas en conos exteriores:

Normal para gas LP.

Llamas azules suaves:

Normal para gas natural.

Si la llama está completamente o en su mayoría

amarilla, debe verificar que el regulador esté configurado para el gas correcto.

Tras el ajuste, vuelva a probar

Ver algunas puntas de color amarillo es normal durante el arranque. Permita

que la unidad opere 4-5 minutos y vuelva a evaluar antes de hacer ajustes.

.

Servicio

Antes de solicitar servicio

Español 8

Figura 7: Revisar las características de las llamas

Si no calientan los elementos o si no se prende la luz indicadora de "encendido",

revise la fuente de alimentación para ver si se quemó un fusible o si se activó el

cortacircuitos.

Consulte la garantía en el manual de uso y cuidado. Vea el manual de uso y

cuidado para información sobre cómo resolver problemas.

Page 31

Placa con información del producto

La placa con información indica el número de modelo y el número de serie de su

parrilla. Se encuentra en el área delantera central de la caja empotrada, debajo

de la parrilla.

placa con información

Figura 8: Lugar de la placa con información

Guarde su factura o sus papeles para validar la garantía si se necesita servicio.

Español 9

Page 32

5551 McFadden Avenue, Huntington Beach, CA 92649 • 800/944-2904 • www.boschappliances.com

9000065787 (ECO# 5V047G) • 10037 Rev B • 09/05 © BSH Home Appliances Corporation 2005 • Litho in USA

Loading...

Loading...