Bosch NGMP655 Installation Manual

Gas Cooktops

NGM30, NGM50, NGM56

NGM80, NGM86, NGMP65, NGMP055

Table of Contents

Questions?

1-800-944-2904

www.bosch-home.com

We look forward to hearing from you!

This Bosch Appliance is made by

BSH Home Appliances Corporation

1901 Main St, Suite 600

Irvine, CA 92614

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

IMPORTANT SAFETY INSTRUCTIONS . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . 3

Tools and Parts Needed . . . . . . . . . . . . . . . . 3

Parts Included . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information . . . . . . . . . . . . . . . . . . . . 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Procedure . . . . . . . . . . . . . . . . . . 5

Prepare the Countertop . . . . . . . . . . . . . . . . . 5

Seal the Cooktop with Foam Tape . . . . . . . . 5

Install the Cooktop . . . . . . . . . . . . . . . . . . . . . 5

Connect Gas Supply . . . . . . . . . . . . . . . . . . . 6

Connect Electrical Supply . . . . . . . . . . . . . . . 6

Burner Cap Placement . . . . . . . . . . . . . . . . . 7

Install Burner Grates . . . . . . . . . . . . . . . . . . . 8

Final Check . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before Calling Service . . . . . . . . . . . . . . . . . 10

Product Data Plate . . . . . . . . . . . . . . . . . . . . 10

9 IMPORTANT SAFETY INSTRUCTIONS

WARNING:

If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage,

personal injury or death.

-- Do not store or use combustible materials,

gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

-- Installation and service must be performed by a

qualified installer, authorized service agency or

the gas supplier.

READ AND SAVE THESE INSTRUCTIONS

Safety

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE

APPLIANCE AFTER INSTALLATION IS COMPLETE.

IMPORTANT: SAVE FOR THE LOCAL INSPECTOR'S

USE.

Important Safety Instructions

WARNING:

Do not repair or replace any part of the appliance unless

specifically recommended in the manuals. Improper

installation, service or maintenance can cause injury or

property damage. Refer to this manual for guidance. All

other servicing should be done by a qualified technician.

Gas Appliance Safety

any pressure testing at pressures in excess of ½ psi

(3.5 kPa).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than ½

psi (3.5 kPa)

• The minimum supply pressure must be 1" water

column above the manifold pressure printed on the

data plate.

• The maximum supply pressure must not exceed 14.0

inches water column (34.9Millibars).

• For Massachusetts installations:

• Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified

or licensed by the state, province or region where

this appliance is being installed.

• Shut-off valve must be a "T" handle gas cock.

• Flexible gas connector must be new and not longer

than 36 inches.

• Installer - show the owner where the gas shut-off valve

is located.

• Install a gas shutoff valve near the appliance. It must

be easily accessible in an emergency.

• Leak testing must be conducted by the installer

according to the instructions in this manual.

• The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

Propane Gas Installation

• The propane gas tank must be equipped with its own

high pressure regulator. In addition, the regulator

supplied with this unit must also be used.

• The appliance is shipped from the factory for use with

natural gas. It must be converted for use with propane.

A qualified technician or installer must do the

conversion.

Equipment and Usage Safety Requirements

• The cooktop must be used in conjunction with a

suitable ventilation system.

• Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking the

appliance. Never allow children to play with packaging

material.

• Never modify or alter the construction of the appliance.

For example, do not remove panels, wire covers or

screws.

• To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

English 1

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

installing a hood that projects horizontally a minimum of

5 inches beyond the bottom of the cabinet.

• Verify that cabinets above the cooktop are a maximum

of 13" (330 mm) deep.

Appliance Handling Safety

• Unit is heavy and requires at least two people or proper

equipment to move.

• Hidden surfaces may have sharp edges. Use caution

when reaching behind or under appliance.

Safety Codes and Standards

• This appliance complies with one or more of the

following Standards:

• ANSI Z21.1, Household Cooking Gas

Appliances

• It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

• Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

• The appliance must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the National Electrical Code ANSI/ NFPA

70, latest edition. (In Canada, installation must be in

accordance with the CAN 1-B149.1 and .2 Installation

Codes for Gas Burning Appliances and/ or local

codes).

9 WARNING

State of California Proposition 65 Warnings:

This product contains chemicals known to the State

of California to cause cancer, birth defects or other

reproductive harm.

Electric Safety

• Before you plug in an electrical cord, be sure all

controls are in the OFF position.

• For appliances equipped with a cord and plug, do not

cut or remove the ground prong. It must be plugged

into a matching grounding type receptacle to avoid

electrical shock. If there is any doubt as to whether the

wall receptacle is properly grounded, the customer

should have it checked by a qualified electrician.

• This appliance should be installed in accordance with

the National Electric Code or Canadian Electrical

Code. It is required that the cooktop be installed on a

grounded, non-GFCI branch circuit.

• Installer - show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

• Important - Save these instructions for the local

electrical inspector's use.

• Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

• Be sure your appliance is properly installed and

grounded by a qualified technician. Installation,

electrical connections and grounding must comply with

all applicable codes.

English 2

High Altitude Installation

This range is CSA certified for safe operation up to an

altitude of 10,000 ft without any modifications (except LP

conversion, when applicable). Contact service for use at

altitudes above 10,000 feet.

Installation

Before You Begin

Tools and Parts Needed

1. Phillips Head Screwdriver

2. Drill with 1/4” (6.5mm) bit

3. Tape Measure

4. Teflon Tape (Gas Rated)

5. Adjustable wrench or channel lock pliers

Parts Included

1. Foam tape

2. Hold down brackets (4)

3. Screws, #10-32 x 2 1/2” (63.8mm) (4)

4. Sheet Metal Screws, #8 x 3/8” (9.5mm) (4)

5. Washers (4)

6. Burner Grates (3)

7. Burner Caps

36” models: (5)

30” models: (4) or (5)

8. Pressure Regulator

9. LP Gas Conversion Kit

If parts are missing or damaged, call the number or write to

the address listed inside the back cover.

Preparation

Electrical Requirements

9 CAUTION

Do not use an extension cord with the gas cooktop.

This appliances requires a 60 Hz, 15 Amp, 120 VAC

connection. Plan the installation so that the power

connection is accessible from the front of the cabinet.

Gas Requirements

Supply Pressure:

• Natural Gas - 7 inches water column (14.9 Millibars)

minimum.

• Propane Gas -11 inches water column (27.4 Millibars)

minimum.

The propane gas tank must be equipped with its own high

pressure regulator in addition to the pressure regulator

supplied with this unit. The cooktop is shipped from the

factory for use with natural gas. For use with LP conversion

a qualified technician or installer must do the conversion.

Cabinet Requirements

General Information

Overall Dimensions

30” Models 36” Models

Width

(Side to Side)

Depth

(Front to Back)

Height

(Top to Bottom)

NOTE:

These are overall dimensions NOT cutout dimensions.

31” (788 mm) 37” (940 mm)

21 1/4” (540

mm)

3 13/16 (97 mm) 3 13/16 (97 mm)

21 1/4” (540

mm)

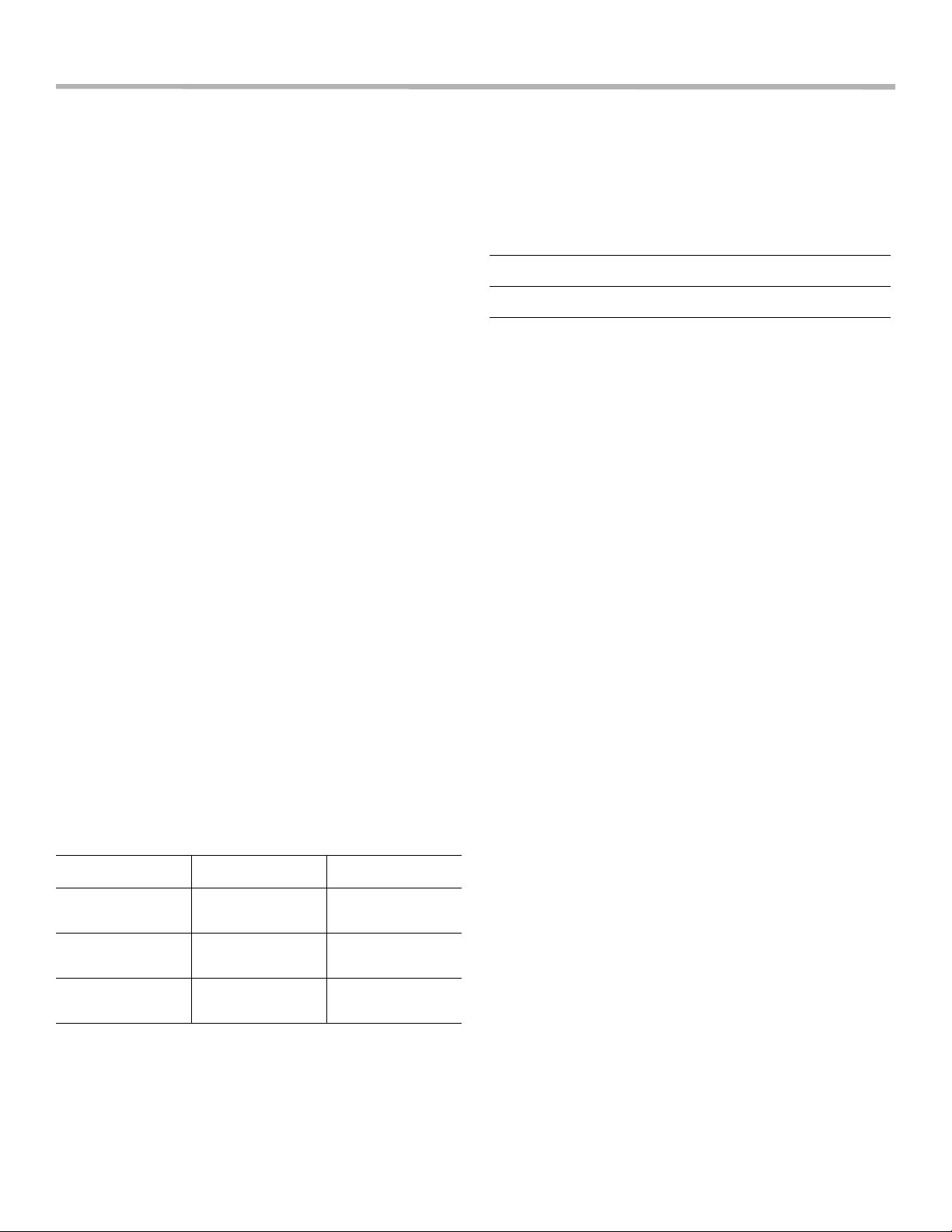

Dimension requirements in Figures 1 and 2 are for

combustible surfaces. When the surface is protected by a

material listed by UL as a Floor Protector and Wall Shield

covered with not less than No. 28 MSG sheet metal 0.015

inch (0.38mm) stainless steel, 0.024 inch (0.6mm)

aluminum or copper, it is considered noncombustible and

some dimensions may be reduced. For a noncombustible

surface over the cooktop, the minimum clearance is 24"

(61cm) rather than 30" (76cm).

• Instructions are based on standard American cabinets

36" high (91cm) x 24" deep (61cm) with a 25" (63cm)

countertop.

• Provide approximately a 10 square inch opening

2

(65cm

adequate air inlet to the cabinet if installed with a

downdraft.

) in the toe kick area or other cabinet area for

English 3

• The maximum depth of cabinet installed above cooktop

Depth from Back Wall

Cabinet 13" (33cm) max.

Hood Depth - 24" (61cm) max.

Centered Over Cooktop

Rear Wall - 2" (5cm)

Right Side

12" (33cm) min.

Left Side

12" (33cm) min.

18" (46cm) min.

Above Counter - 30" (76 cm) min. to

Combustible Surface

NGM30 - 30" (76cm) min.

NGM36 - 36" (91cm) min.

gas

connection

measurement in inches/mm

30” Models

36” Models

2 1/8”

(54)

3”

(76.2)

3”

(76.2)

3 1/8”

(79.4)

measurement in inches/mm

Front

Back

is 13” (33cm).

Figure 1: Installed Dimensions (from cooktop edges)

Countertop Requirements

NOTE:

All measurements given have to be precisely followed. If

nonstandard cabinets are used, make sure they are

installed with minimum dimensions shown in figure 1 and

figure 2.

Plan the installation of the unit so that the power cord, gas

shut-off valve and gas pressure regulator are accessible

from the front of cabinet.

Island Installation Mounting Requirements

English 4

gas

connection

measurement in inches/mm

Figure 2: Cutout Dimensions

Use the mounting brackets supplied. See “Install the

Cooktop” on page 5 for further details.

Ventilation Recommendations

We strongly recommend the installation of a ventilation

hood above this appliance. The hood must be installed

according to instructions furnished with the hood.

Note: The appliance should not be installed with a

Heat Reflective Tape

Cutout shows location

of Aluminum Reflective Tape

Section "A - A"

A

A

Cutout

Foam

Ta pe

Rough-in Box

Foam

Tap e

(Seal)

Adjusting

Screw

Adjusting

Screw

Clamp

Clamp

Wooden Block

(to be used with

solid surfacing

material, i.e.

Surell™ and

Corian®)

ventilation system that blows air downward toward the

burners. This type of ventilation system may cause ignition

and combustion problems with the gas cooking appliance

resulting in personal injury or unintended operation.

Installation Procedure

9 WARNING

To avoid electrical shock hazard, before installing

the cooktop, switch power off at the service panel to

prevent the power from being switched on

accidentally.

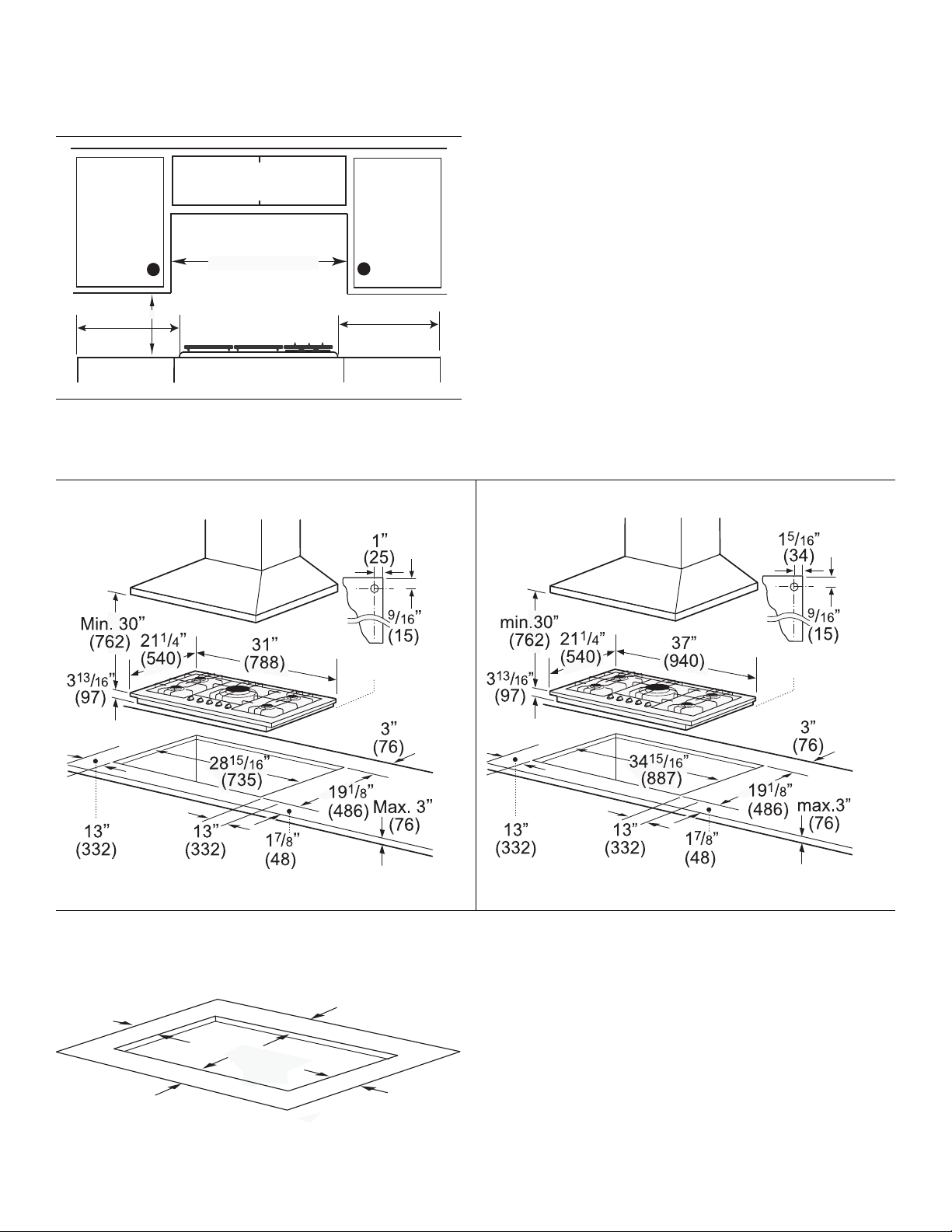

Prepare the Countertop

Cut out the countertop per the dimensions shown in

“Cabinet Requirements” on page 3.

Some solid surface materials, such as Surell™ and

Corian®, require different cutting methods. Consult with the

solid surface manufacturer for the correct cutting method

needed. Apply heat reflective tape such as Scotch

Aluminum Foil Tape #425 or #427 (not included) around the

cutout so that it folds over on the top and sides. Do not

wrap the tape underneath the cooktop. Be sure the tape

extends beyond the outermost flange of the cooktop. All

corners should be covered with tape.

cutout as shown by the dotted line in Figure 4: “Counter

Cutout – Foam Tape Placement”. Leave 1/4” (6.35mm) gap

between the foam tape and the edge of the cutout.

1/4”

(6.35mm)

Figure 4: Counter Cutout – Foam Tape Placement

Install the Cooktop

Insert cooktop into the cutout. Attach clamps of the holddown brackets packaged with the cooktop to the rough-in

box. Use the washer and screws provided.

Figure 3: Counter Cutout – Solid Surface Countertops

Seal the Cooktop with Foam Tape

Apply the self adhesive foam tape in one continuous

rectangle directly to the counter around the perimeter of the

Figure 5: Attaching Hold-Down Brackets

Adjust hold-down brackets to desired position and tighten

screws to rough-in box. Insert adjusting screw into clamp

and secure cooktop to countertop.

NOTE:

For solid surface material installations: Insert a wooden

block between the end of the screw and the bottom of the

countertop. Do not overtighten adjusting screw. Trim

excess aluminum tape around cooktop flange.

English 5

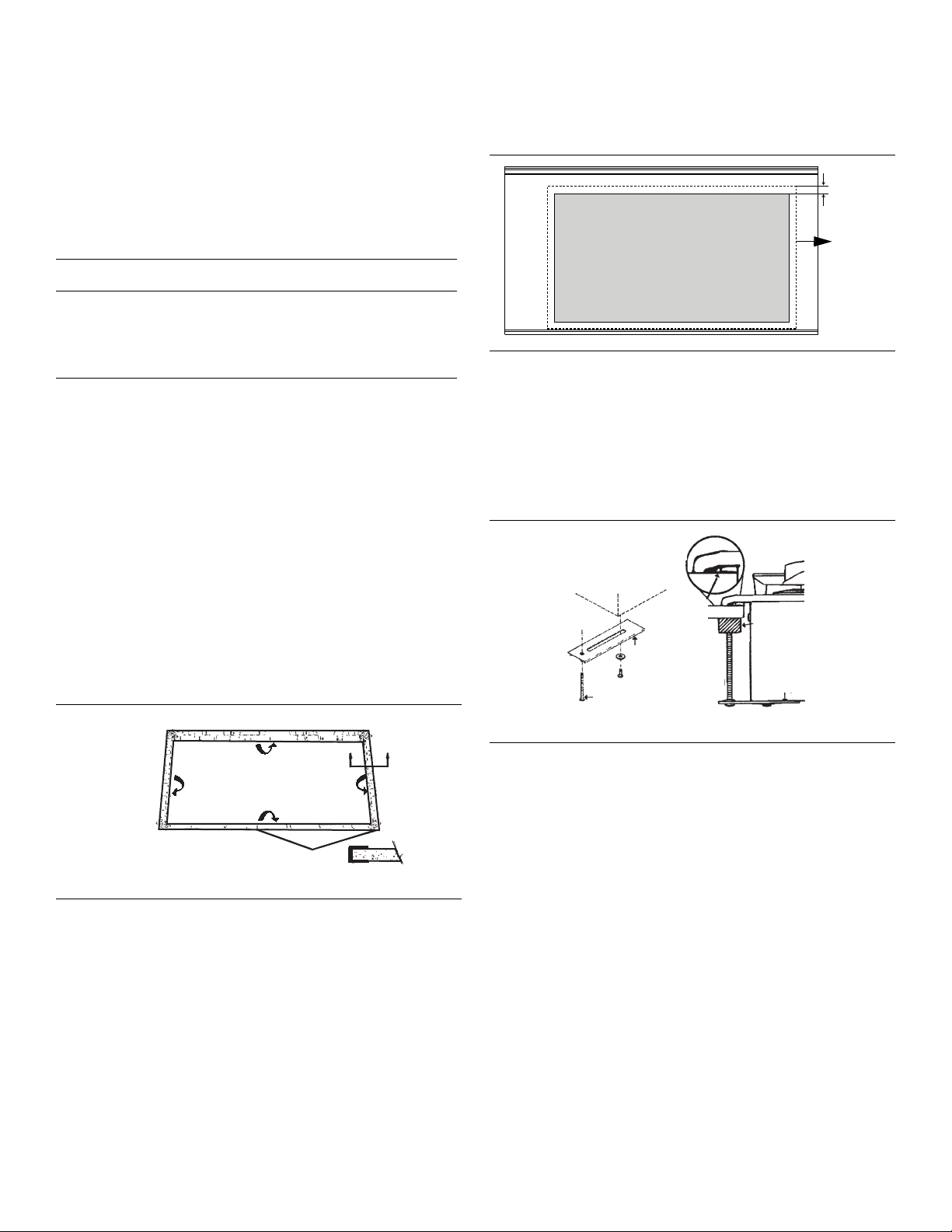

Connect Gas Supply

The gas inlet to the unit is located at the right rear of roughin box.

Opening for Gas

Connection and

Electrical Cord

1”

C of Cutout

L

for 30” models: 12 15/16” (313 mm)

for 36” models: 15 15/16” (389 mm)

Figure 6: Rough-in Box Area

Install the pressure regulator (supplied with unit) to

manifold pipe using Teflon tape on threads of manifold

pipe. Turn to hand tighten plus 1/4 turn, not exceeding 1

turn for alignment. To prevent possible damage to the gas

pressure regulator, install it after the rough-in box is in its

permanent position. When the regulator is securely

installed on the manifold pipe, the conversion nut will be

easily accessible.

Figure 8: Gas and Electrical Location

Check supply line connections for leaks using a soap

solution. Do not use a flame of any sort.

1. Turn on gas.

2. Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the shut-off

valve and the range. Include gas fittings and joints in

the range if connections may have been disturbed

during installation. Bubbles appearing around fittings

and connections indicate a leak.

3. If a leak appears, turn off supply line gas shut-off valve

and tighten connections.

4. Retest for leaks by turning on the supply line gas shutoff valve. When leak check is complete (no bubbles

appear), test is complete.

5. Wipe off all detection fluid residue.

Figure 7: Pressure Regulator

9 WARNING

Do not attempt any adjustment of the pressure

regulator, except conversion to propane..

Connect the gas supply line to the unit pressure regulator

using a 1/2" flex gas line connector between manual shutoff valve and pressure regulator. Always use a new flex

line.

English 6

Important Notes for Gas Connection:

• The appliance and its individual gas shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5kPa).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/

2 psi (3.5kPa).

Connect Electrical Supply

Before connecting 5-foot (1.5 m) supply cord to wall

receptacle, make certain that gas shutoff valve and all

burner controls are in OFF position.

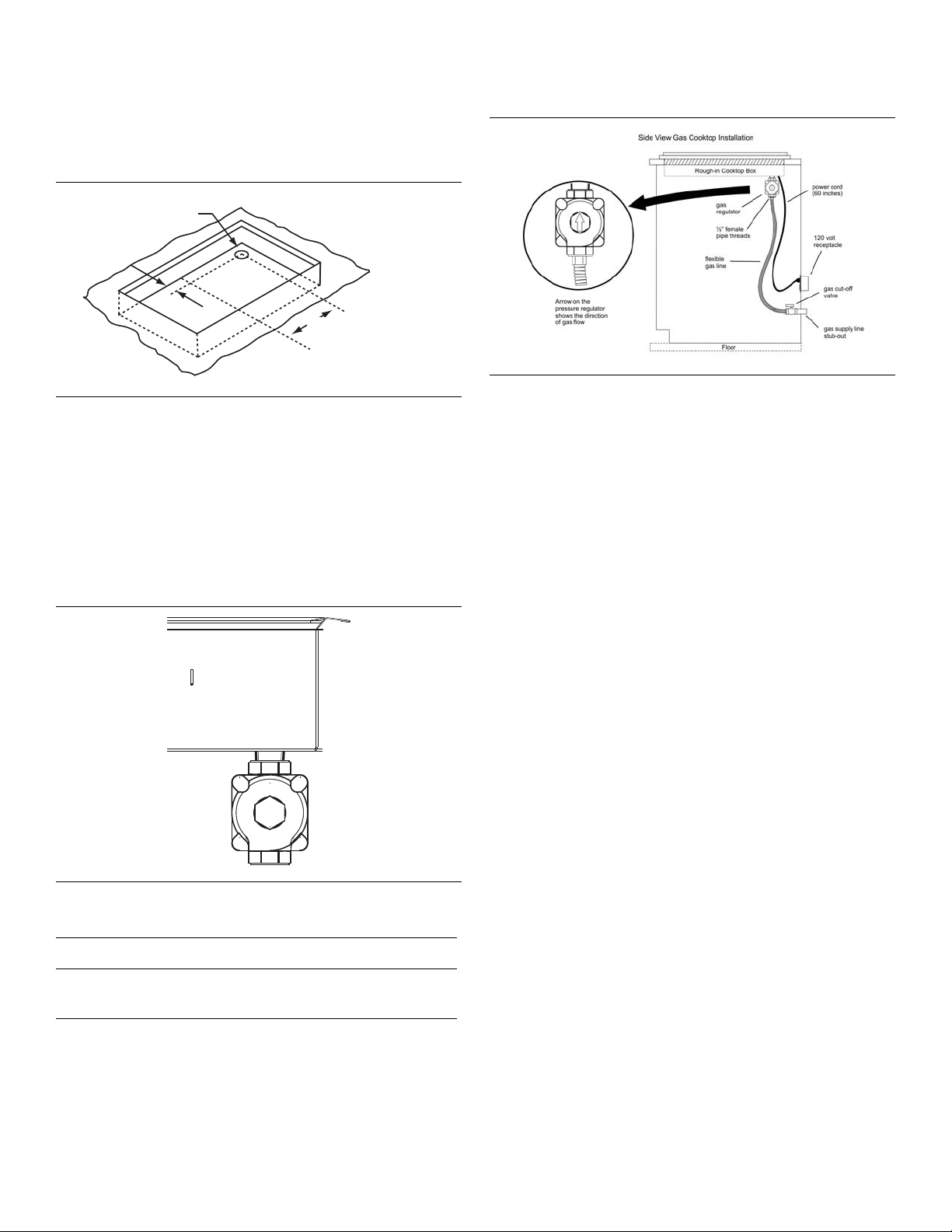

Burner Cap Placement

Burner Base

Burner Cap

Matching letter

designation.

9 WARNING

To prevent flare-ups, do not use the cooktop without

all burner caps and all burner grates properly

positioned.

9 WARNING

• Burner flames are too high.

• Flames shoot out of burners.

• Burners do not ignite.

• Burner flames light unevenly.

• Burner emits gas odor.

Placing Burner Caps

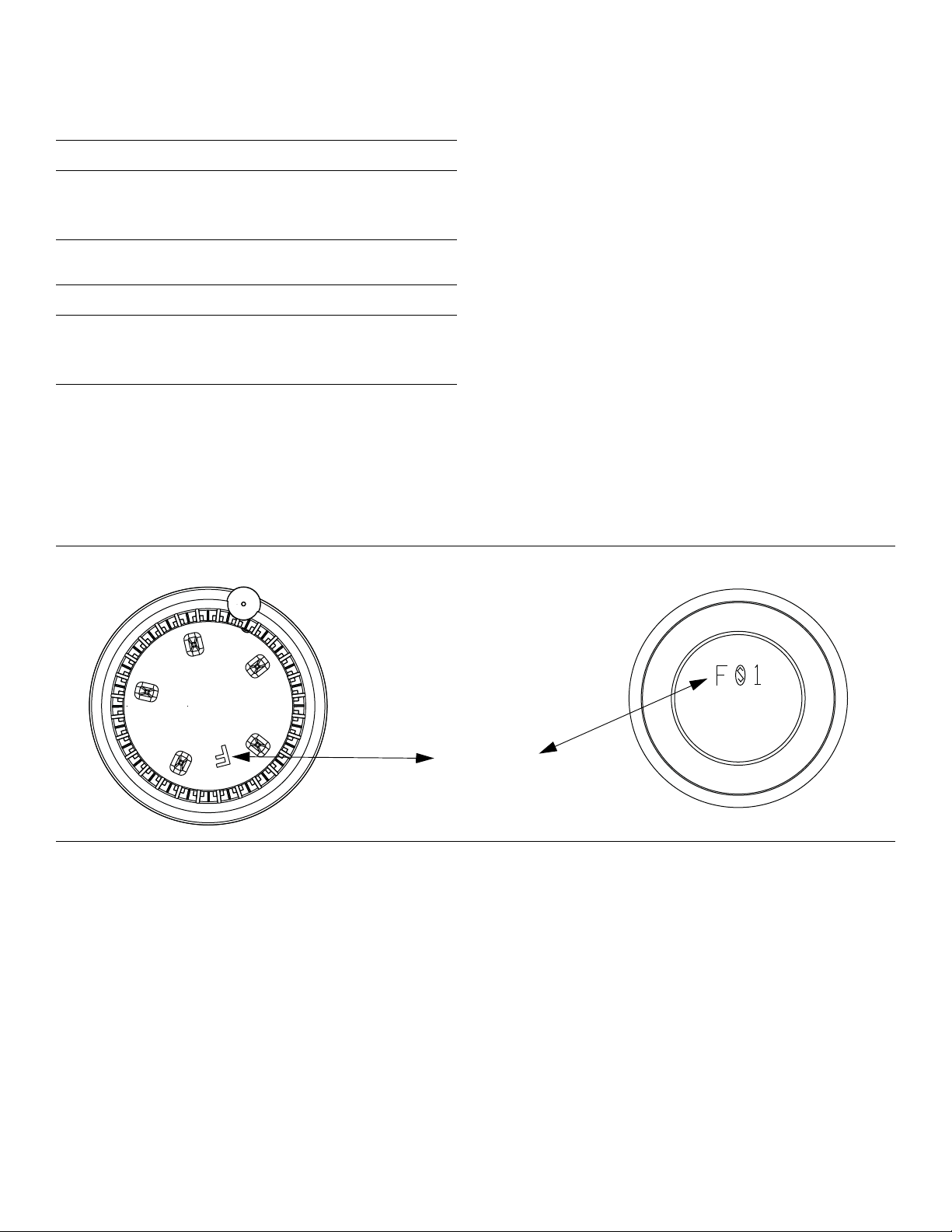

Each cap has a letter (A, D, or F) cast in the underside of

the cap that corresponds to a letter (A, D, or F) cast in the

burner base that is attached to the appliance.

To prevent burns, do not touch burner caps or

grates while hot. Turn the cooktop off and allow the

burners to cool.

Do not attempt any adjustment of the pressure regulator,

except conversion to propane.

The burner caps must be properly placed for the cooktop to

function properly. If the burner cap is not properly placed,

one or more of the following problems may occur:

• After electrical connection is complete, place each

burner cap on its correct burner base per its

corresponding letter designation. See figure “Burners

Caps” on page 7.

• Place burner cap gently on top of base so that the

prongs of the burner base fit snugly into the groove of

the burner cap.

Figure 9: Burners Caps

English 7

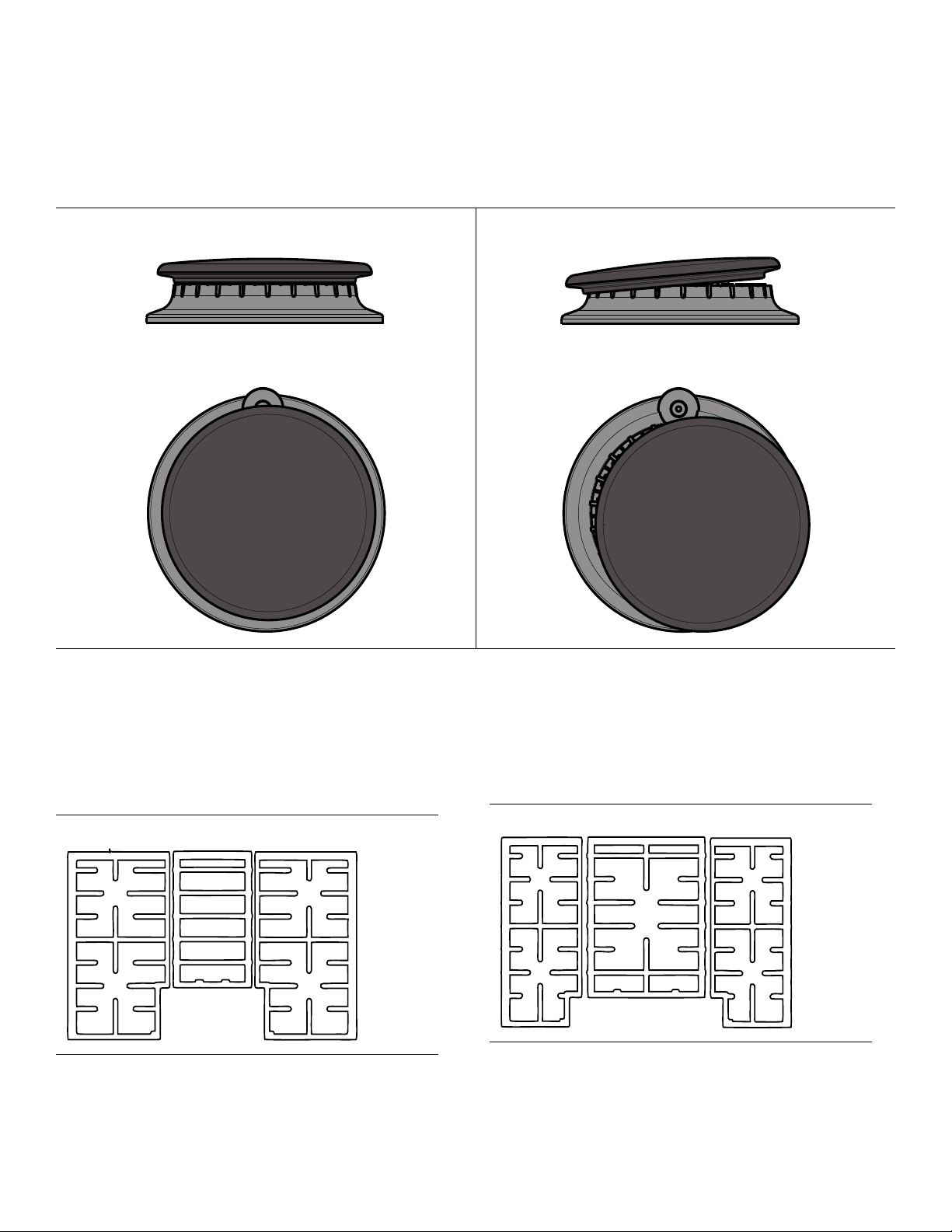

Checking Burner Cap Placement

Correct Burner Cap Placement

Incorrect Burner Cap Placement

30” 4 Burner

30” 5 Burner

• Check to make sure there is not gap between the

burner cap and burner base. See figure “Burner Cap

Placement” on page 8 to see the correct and incorrect

placements of the burner cap.

• You may gently try to move the burner cap from side to

side to check if it is properly placed. If properly placed,

the cap will click from side to side as the prongs hit the

groove ridge.

Install Burner Grates

Properly position and install each burner grate as shown in the following illustrations. The center grate will seat with rubber

feet fitting to indentatations in the cooktop surface. Check to be sure the feet match the indentations.

Figure 10: Burner Cap Placement

English 8

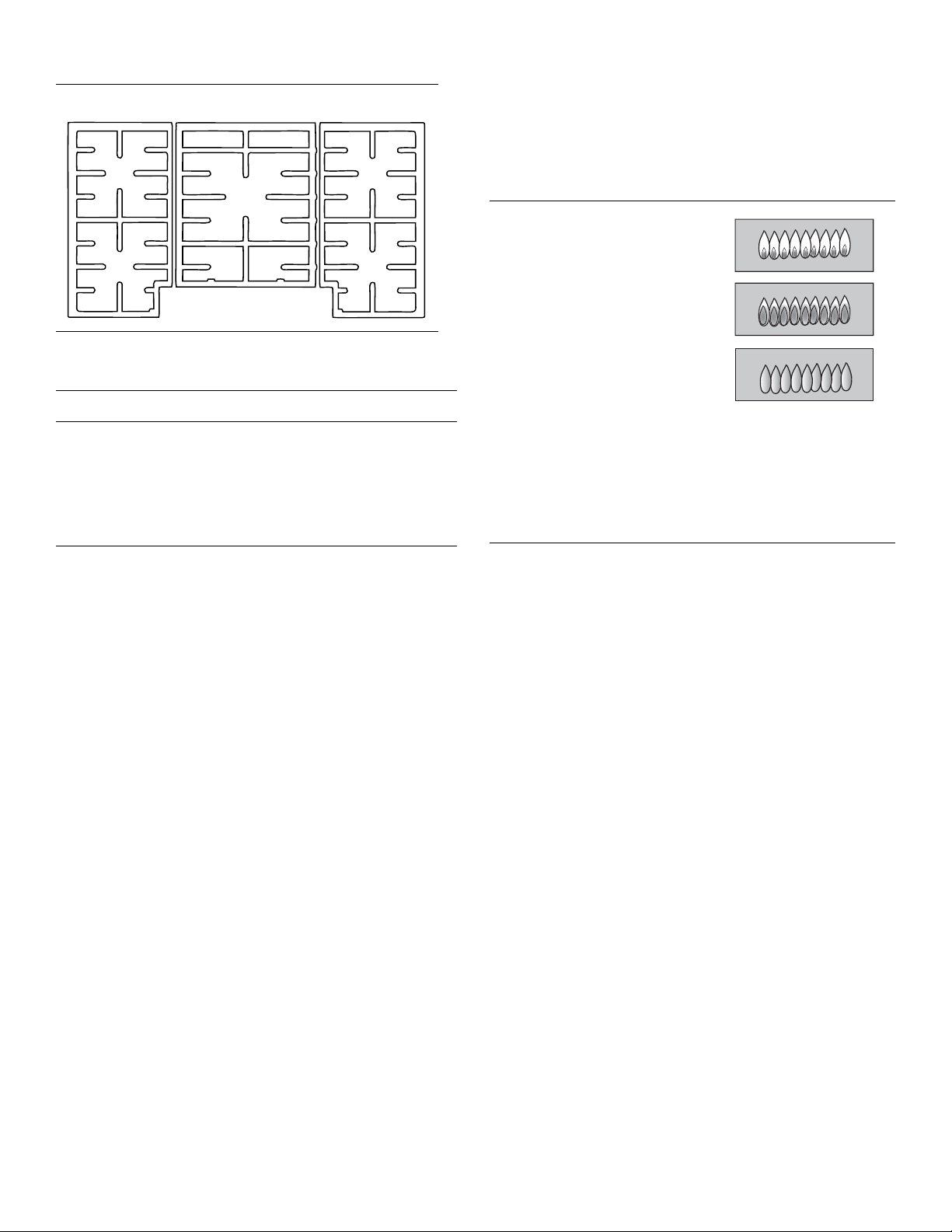

9 WARNING

36” 5 Burner

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or

mostly yellow, verify that the regulator is set for the

correct fuel. After adjustment, retest.

Some yellow streaking is normal during the initial startup. Allow unit to operate 4-5 minutes and re-evaluate

before making adjustments.

To prevent flare-ups, properly support pots, and

avoid spills, all grates must be properly positioned

on the cooktop whenever the cooktop is in use.

Each of the four feet must be placed into the

corresponding dimples in the cooktop. Do not use a

grate if the rubber feet are missing or damaged.

Final Check

Check operation of electric igniters. Check flame

characteristics. Flame should be blue with no yellow tip.

For replacement rubber feet: Part # 416438, contact your

dealer or call the service number listed inside the cover.

Figure 11: Checking Flame Characteristics

English 9

Loading...

Loading...