Bosch NGMP055UC/01, NGM8665UC/01, NGM8655UC/01, NGM8065UC/01, NGM8055UC/01 Installation Guide

...Page 1

LP Gas Conversion Kit

installation Manual

...............................................................................................................................Envented for life ..........

Page 2

NGM Gas Cooktop LP Gas Conversion

Conversion Instructions

BOSCH COOKTOP CONVERSION KIT FOR

TRADITIONAL MODELS NATURAL GAS (NG) TO

PROPANE (LP) GAS

NEZ1054

This kit is used to convert only NGM sealed burner

cooktops from natural gas operation to propane gas

operation. This kit cannot be used to convert other Bosch

model sealed burner cooktops, ranges or any other brand

of cooktops.

A WARNING

This conversion kit shall be installed by a qualified

service agency in accordance with the manufacturer's

instructions and all applicable codes and requirements

of the authority having jurisdiction. If the information in

these instructions is not followed exactly, a fire,

explosion or production of carbon monoxide may result

causing property damage, personal injury or loss of life.

The qualified service agency is responsible for the

proper installation of this kit. The installation is not

proper and complete until the operation of the converted

appliance is checked as specified in the manufacturer's

instructions supplied with the kit.

_1_CAUTION

When connecting the unit to the propane gas, make

certain the propane gas tank is equipped with its own

high pressure regulator. In addition, a pressure

regulator was supplied with the cooktop. This second

regulator must be installed with the cooktop. The

maximum gas pressure to this appliance is not to

exceed 14.0 inches water column from the propane gas

tank regulator.

The following must be met when testing supply piping

system:

a) The appliance and its individual shut-off valve must

be disconnected from the gas supply piping system at

test pressures in excess of 1/2 psig (3.5 kPa).

b) The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

IMPORTANT: Only a qualified service technician or

installer should make this conversion

INSTALLER: Please leave these Installation Instructions

with this unit for the owner.

OWNER: Please retain these instructions for future

reference.

For Massachusetts Installations:

1. Installation must be performed by a qualified or

licensed contractor, plumber, or gas fitter qualified or

licensed by the state, province or region.

2. Shut-off valve must be a "T" handle gas cock.

3. Flexible gas connector must not be longer than 36

inches.

English 1

Page 3

_j[__ _ _ii_11__ ...................................................................................................................................................................................................................................................................................................................................................................................................,_

Preparation

Installation Kit Contents

Component

Quantity

Conversion Kit Instructions

Conversion Sticker

Foam Tape

95 Orifice

66 Orifice

44 Orifice

Note:

Depending on the model, the kit may contain more

components that are necessary to complete your

conversion.

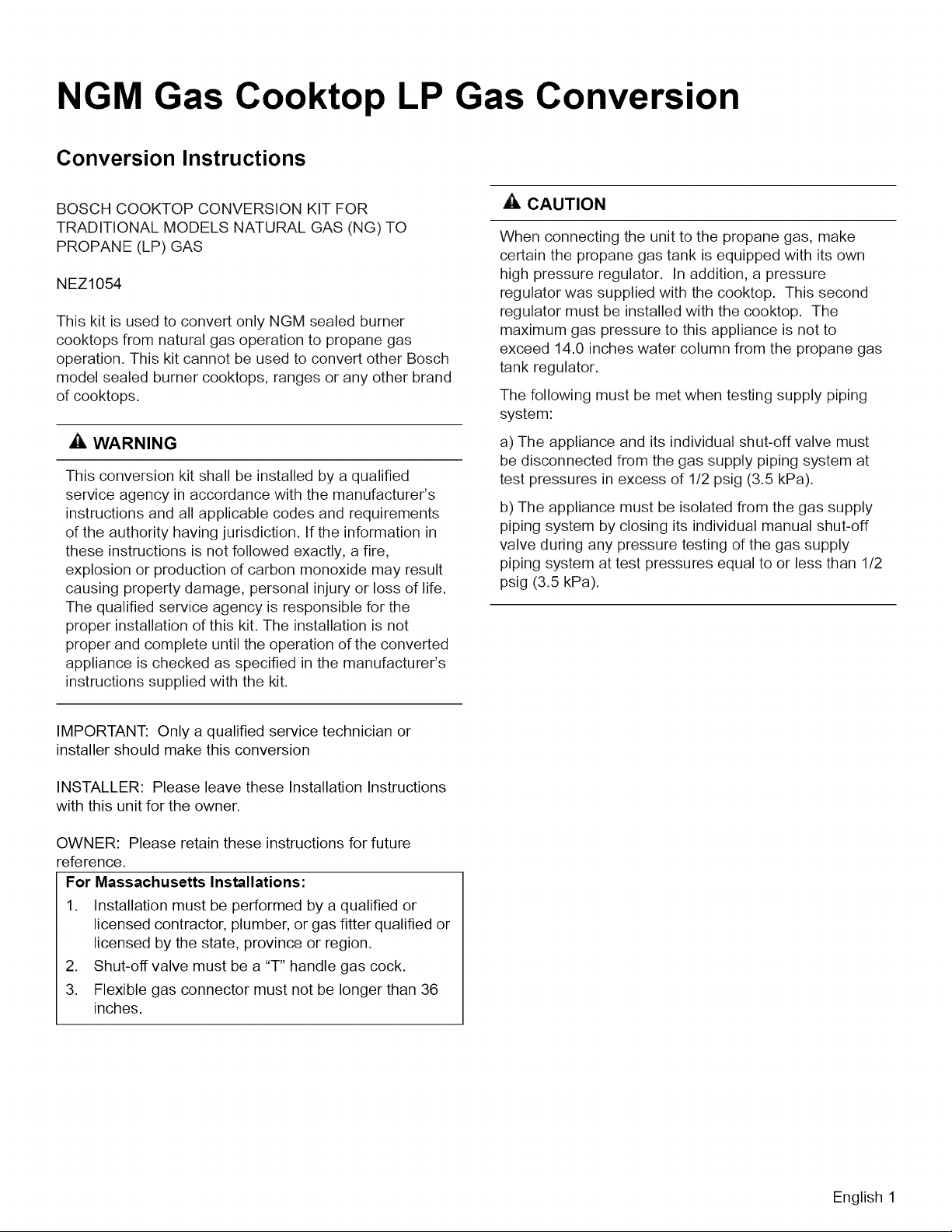

Tools Required

7mm socket

driver (3 inch

minimum

extension

Main Orifices

NGM5055UC

1

1

1

3

2

1

122

95

95

66

Front Right 15,000

Front Left 9,100

Rear Left 9,100

Rear Right 5,000

NGM8055, 8065UC

122 Center 15,000

BTU/hr

66 Front Right 5,000

95 Front Left 9,100

66 Rear Left 5,000

95 Rear Right 9,100

NGMP055UC

109 Large Center 15,000

44 Small Center 5,000

66 Front Right 5,000

95 Front Left 9,100

66 Rear Left 5,000

95 Rear Right 9,100

NGMP655UC

blade

adjustable

wrench and/

or slip joint

pliers

109 Large Center 15,000

44 Small Center 5,000

95 Front Right 9,100

95 Front Left 9,100

95 Rear Left 9,100

66 Rear Right 5,000

NGM5655, 8655, 8665UC

122 Center 15,000

95 Front Right 9,100

95 Front Left 9,100

95 Rear Left 9,100

66 Rear Right 5,000

English 2

Page 4

Installation Procedure

This conversion process adjusts the flow of gas to the

burners to accommodate an LP gas fuel source.

A CAUTION

TURN OFF GAS AND ELECTRICITY.

If the cooktop is installed in the counter,

1) shut off the gas valve for the gas supply line to

the cooktop.

2) remove the cooktop power cord from the

electrical outlet or turn off the breaker at the breaker

box.

3) turn all control knobs to the "Off"position.

Checklist

Each of the following steps must be completed

correctly for the appliance to function properly.

Check off each step as it is finished.

__ Step 1 - Convert the pressure regulator to use LP gas.

__ Step 2 - Remove the grates andburner caps. Remove

the Natural Gas (NG) orifices and replace them with

the LP gas orifices supplied with this kit.

__ Setp 3 - Replace the burner caps and grates

__ Step 4 - Adjust the unit valves to LP settings.

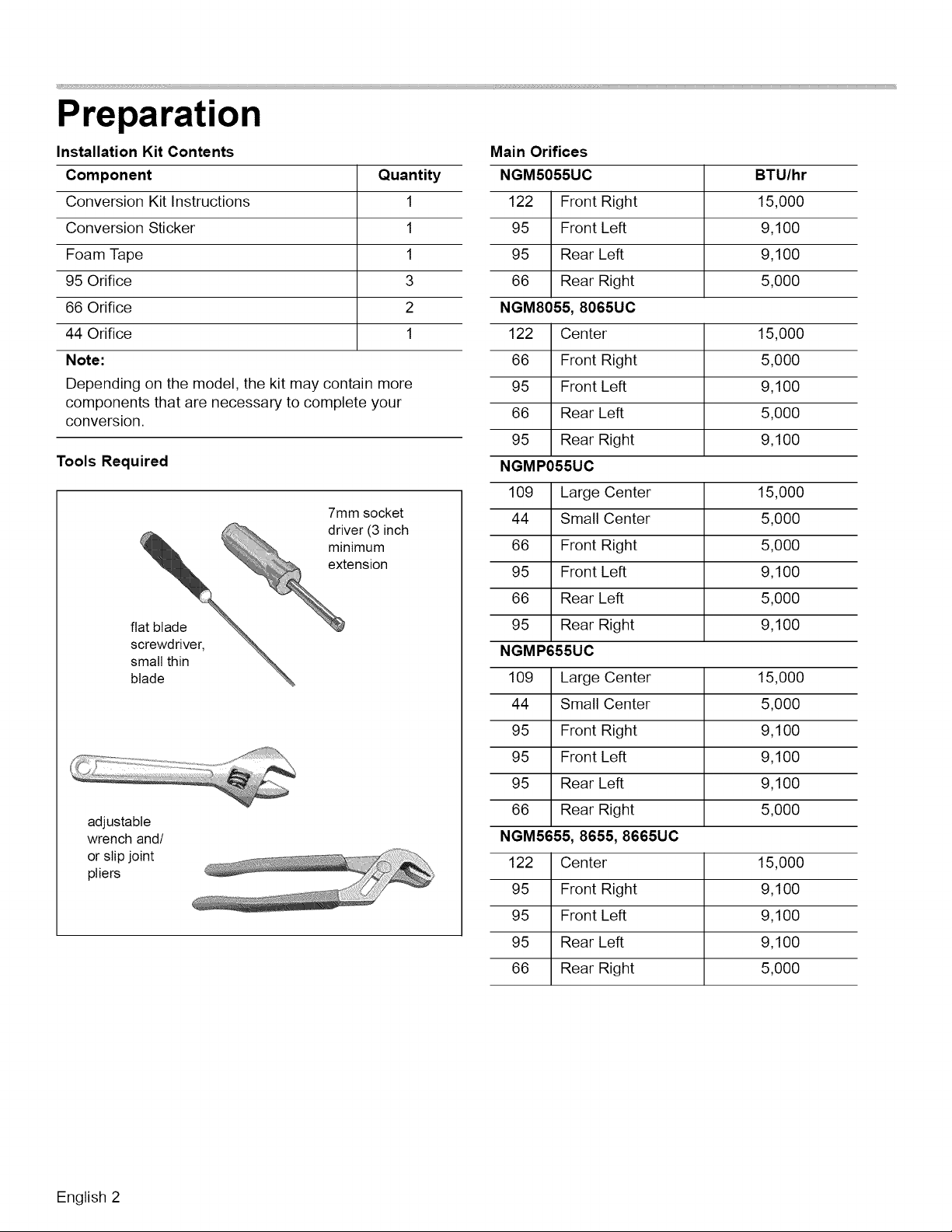

Step 1 - Convert the Pressure Regulator

Locate the pressure regulator on the bottom right end of

the cooktop.

Note: The arrow on the back of the regulator must

point in the direction of the gas flow to the

cooktop.

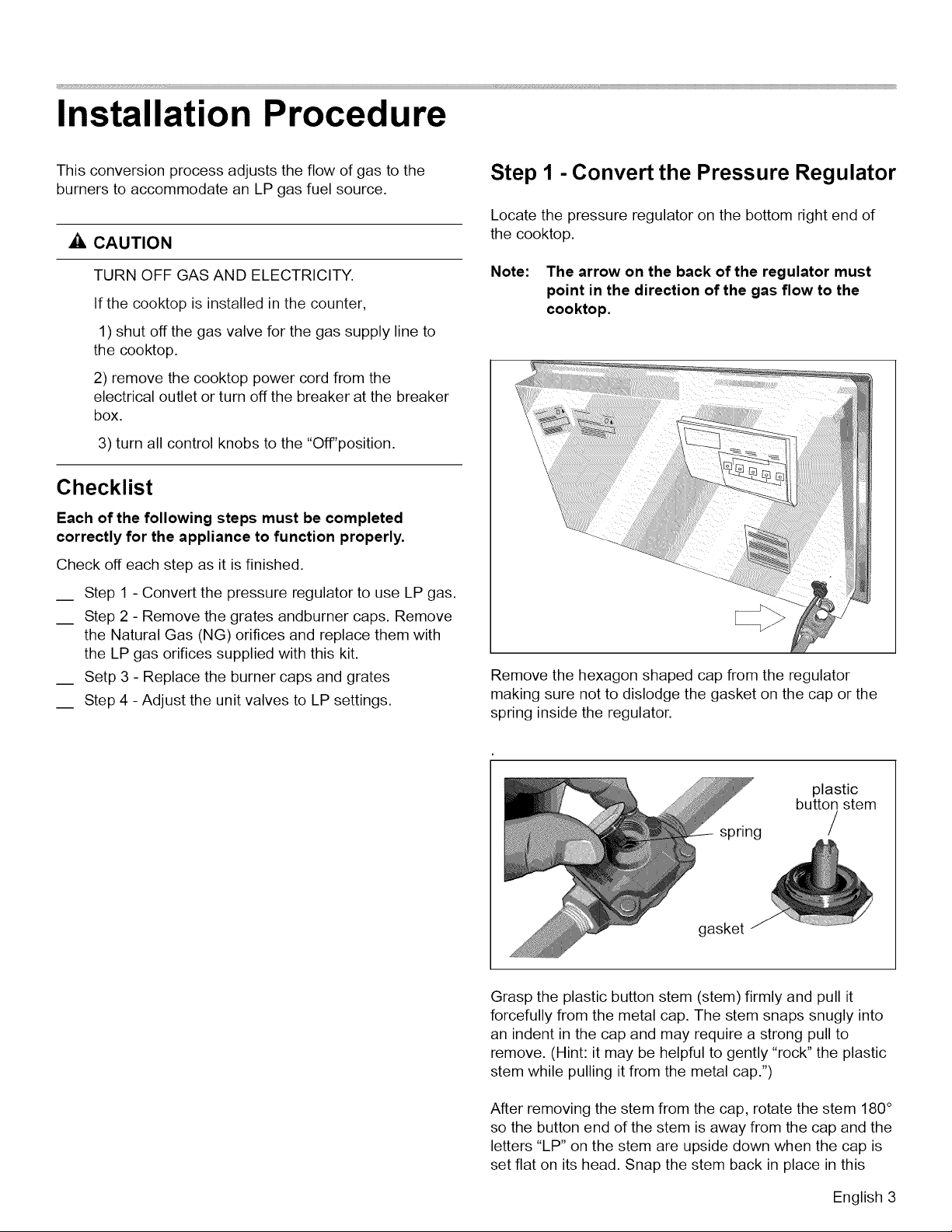

Remove the hexagon shaped cap from the regulator

making sure not to dislodge the gasket on the cap or the

spring inside the regulator.

plastic

button stem

spring

gasket

Grasp the plastic button stem (stem) firmly and pull it

forcefully from the metal cap. The stem snaps snugly into

an indent in the cap and may require a strong pull to

remove. (Hint: it may be helpful to gently "rock" the plastic

stem while pulling it from the metal cap.")

After removing the stem from the cap, rotate the stem 180 °

so the button end of the stem is away from the cap and the

letters "LP" on the stem are upside down when the cap is

set fiat on its head. Snap the stem back in place in this

/

English 3

Page 5

positioninsertingitintotheindentinthemetalcap.The

stemshouldsnapintoplace.

Natural LP

Gas Gas

Important - Attach the metallic sticker (included with this

conversion kit) to the bottom of the appliance as shown,

placing it near the appliance data plate (shows model

number and information about the appliance). This sticker

provides notice that the appliance has been converted for

use with LP gas

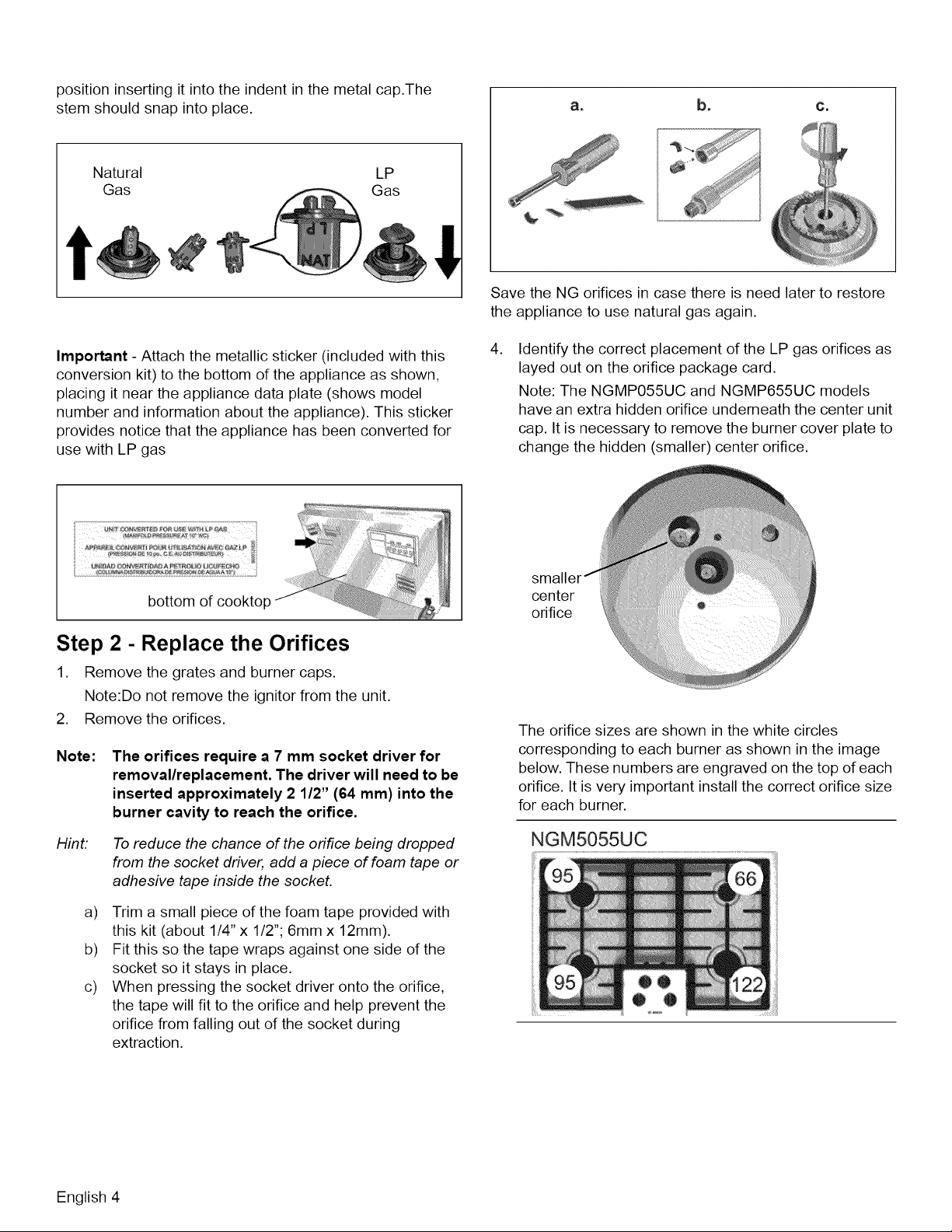

a. b. c,

Save the NG orifices in case there is need later to restore

the appliance to use natural gas again.

,

Identify the correct placement of the LP gas orifices as

layed out on the orifice package card.

Note: The NGMP055UC and NGMP655UC models

have an extra hidden orifice underneath the center unit

cap. It is necessary to remove the burner cover plate to

change the hidden (smaller) center orifice.

bottom of cooktop

Step 2 - Replace the Orifices

1. Remove the grates and burner caps.

Note:Do not remove the ignitor from the unit.

2. Remove the orifices.

Note:

Hint:

The orifices require a 7 mm socket driver for

removal/replacement. The driver will need to be

inserted approximately 2 1/2" (64 mm) into the

burner cavity to reach the orifice.

Toreduce the chance of the orifice being dropped

from the socket driver, add a piece of foam tape or

adhesive tape inside the socket.

a) Trim a small piece of the foam tape provided with

this kit (about 1/4" x 1/2"; 6mm x 12mm).

b) Fit this so the tape wraps against one side of the

socket so it stays in place.

c) When pressing the socket driver onto the orifice,

the tape will fit to the orifice and help prevent the

orifice from falling out of the socket during

extraction.

center

orifice

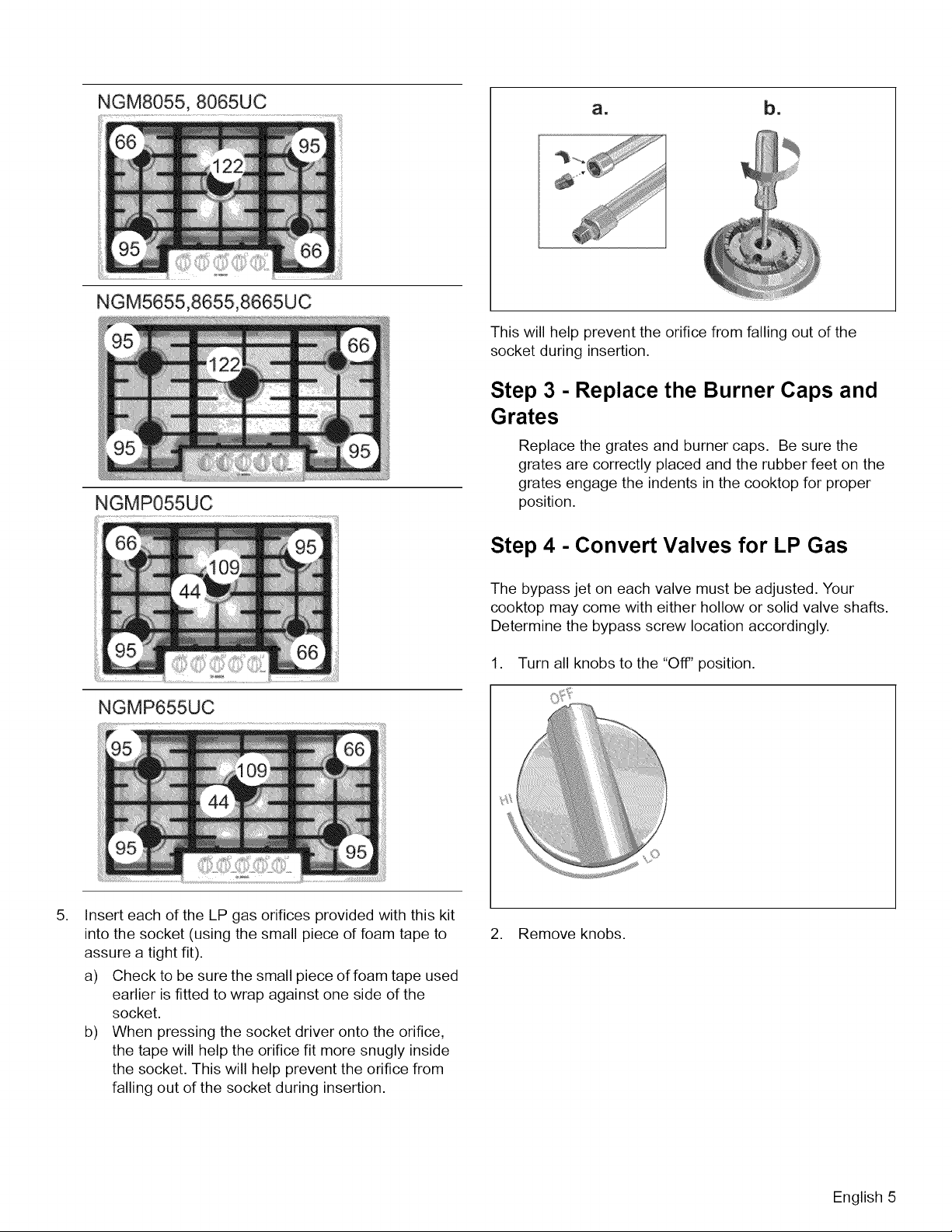

The orifice sizes are shown in the white circles

corresponding to each burner as shown in the image

below. These numbers are engraved on the top of each

orifice. It is very important install the correct orifice size

for each burner.

NGM5055UC

English 4

Page 6

NGM8055, 8065UC

NGMP055UC

am b_

This will help prevent the orifice from falling out of the

socket during insertion.

Step 3 - Replace the Burner Caps and

Grates

Replace the grates and burner caps. Be sure the

grates are correctly placed and the rubber feet on the

grates engage the indents in the cooktop for proper

position.

Step 4 - Convert Valves for LP Gas

NGMP655UC

,

Insert each of the LP gas orifices provided with this kit

into the socket (using the small piece of foam tape to

assure a tight fit).

a) Check to be sure the small piece of foam tape used

earlier is fitted to wrap against one side of the

socket.

b) When pressing the socket driver onto the orifice,

the tape will help the orifice fit more snugly inside

the socket. This will help prevent the orifice from

falling out of the socket during insertion.

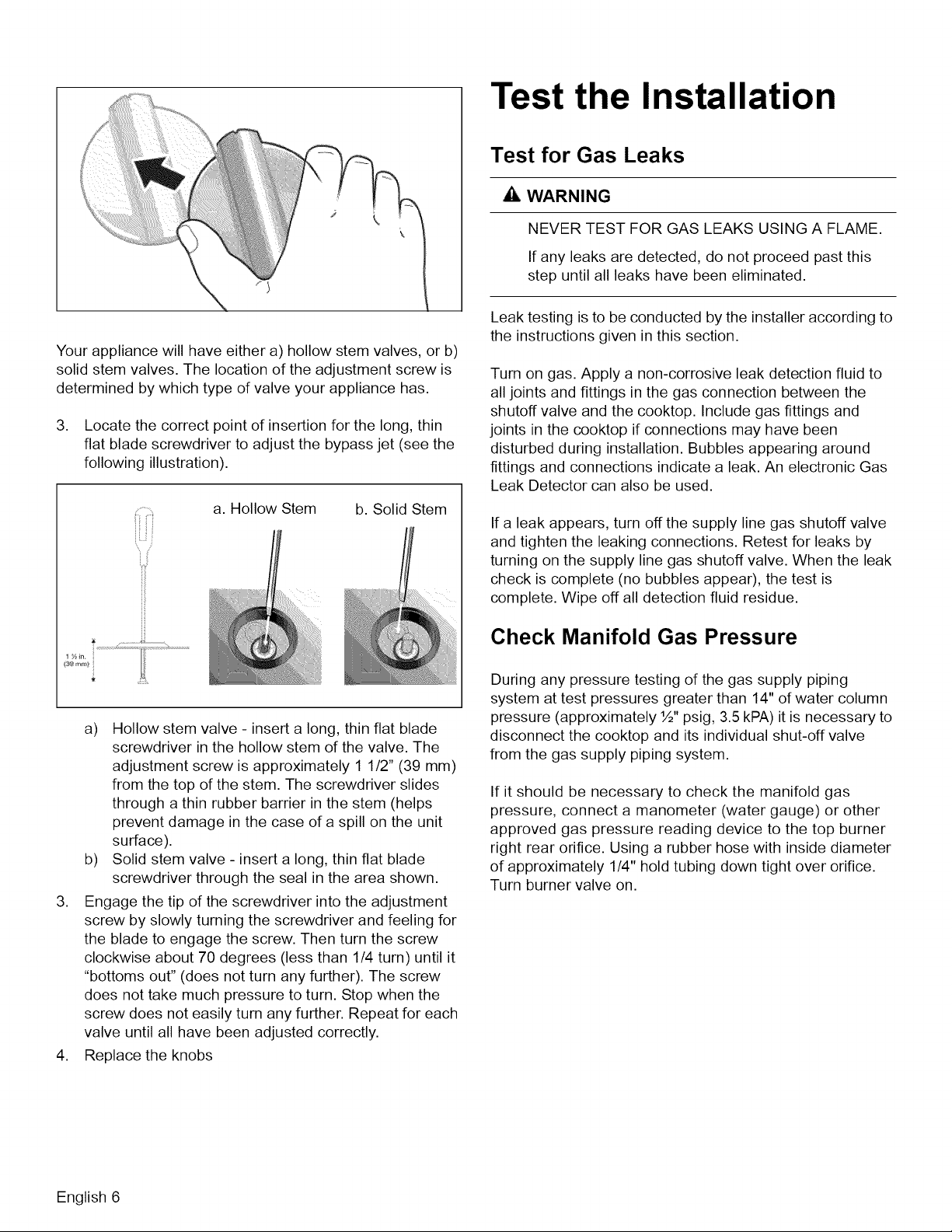

The bypass jet on each valve must be adjusted. Your

cooktop may come with either hollow or solid valve shafts.

Determine the bypass screw location accordingly.

1. Turn all knobs to the "Off" position.

2. Remove knobs.

English 5

Page 7

Test the Installation

Test for Gas Leaks

A WARNING

\

Yourappliancewillhaveeithera)hollowstemvalves,orb)

solidstemvalves.Thelocationoftheadjustmentscrewis

determinedbywhichtypeofvalveyourappliancehas.

3. Locatethecorrectpointofinsertionforthelong,thin

flatbladescrewdrivertoadjustthebypassjet(seethe

followingillustration).

f'x

i _i¸

a. Hollow Stem b. Solid Stem

NEVER TEST FOR GAS LEAKS USING A FLAME.

If any leaks are detected, do not proceed past this

step until all leaks have been eliminated.

Leak testing is to be conducted by the installer according to

the instructions given in this section.

Turn on gas. Apply a non-corrosive leak detection fluid to

all joints and fittings in the gas connection between the

shutoff valve and the cooktop. Include gas fittings and

joints in the cooktop if connections may have been

disturbed during installation. Bubbles appearing around

fittings and connections indicate a leak. An electronic Gas

Leak Detector can also be used.

If a leak appears, turn off the supply line gas shutoff valve

and tighten the leaking connections. Retest for leaks by

turning on the supply line gas shutoff valve. When the leak

check is complete (no bubbles appear), the test is

complete. Wipe off all detection fluid residue.

Check Manifold Gas Pressure

a) Hollow stem valve - insert a long, thin flat blade

screwdriver in the hollow stem of the valve. The

adjustment screw is approximately 1 1/2" (39 mm)

from the top of the stem. The screwdriver slides

through a thin rubber barrier in the stem (helps

prevent damage in the case of a spill on the unit

surface).

b) Solid stem valve - insert a long, thin flat blade

screwdriver through the seal in the area shown.

,

Engage the tip of the screwdriver into the adjustment

screw by slowly turning the screwdriver and feeling for

the blade to engage the screw. Then turn the screw

clockwise about 70 degrees (less than 1/4 turn) until it

"bottoms out" (does not turn any further). The screw

does not take much pressure to turn. Stop when the

screw does not easily turn any further. Repeat for each

valve until all have been adjusted correctly.

,

Replace the knobs

During any pressure testing of the gas supply piping

system at test pressures greater than 14" of water column

pressure (approximately ½" psig, 3.5 kPA) it is necessary to

disconnect the cooktop and its individual shut-off valve

from the gas supply piping system.

If it should be necessary to check the manifold gas

pressure, connect a manometer (water gauge) or other

approved gas pressure reading device to the top burner

right rear orifice. Using a rubber hose with inside diameter

of approximately 1/4" hold tubing down tight over orifice.

Turn burner valve on.

English 6

Page 8

Final Check

After conversion is complete, place each correct sized

burner cap in its seated, notched position and check the

operation of the electric igniters. Check flame

characteristics. Flame should be blue with a minimal yellow

tip on the outer cone of the flames.

Check Flame Characteristics

Service

Before Calling Service

See your appliance Use and Care Manual for

troubleshooting information. Refer to the Warranty section

in the Use and Care Manual for warranty related

information.

Yellow flames:

Further adustment required.

Yellow tips on outer

cones:

Normal for LP Gas.

Soft blue flames:

Normal for Natural Gas.

Note: If the flame is mostly yellow, verify that the reg-

ulator is set for the correct fuel. If adjustment is

necessary, retest the system.

Some yellow streaking in the flame is normal during the

initial start-up. Allow the unit to operate 4 to 5 minutes and

then re-evaluate before making further adjustments.

To reach a service representative, see the contact

information at the front of the manual. Please be prepared

to provide the information printed on your product data

plate when calling (model, serial (FD) number, etc.).

Product Data Plate

The data plate shows the model and serial number. Refer

to the data plate on the appliance when requesting service.

The data plate is located on the bottom of the rough-in box,

underneath the visible part of the installed cooktop.

This data plate information is also provided in a sticker

attached to the product registration card shipped with your

appliance.

Product

Data Plate

Keep your purchase invoice and any other related

documents for warranty validation in the event service is

needed.

English 7

Page 9

Conversion au gaz propane de la table

de cuisson & gaz NGM

Instructions de conversion

KIT DE CONVERSION POUR LES MODC:LES

TRADITIONNELS DE TABLE DE CUISSON BOSCH

POUR LE PASSAGE DU GAZ NATUREL (GN) AU GAZ

PROPANE (LP)

NEZ1054

Ce kit permet de convertir uniquement les tables de

cuisson A brQleurs scell6s NGM d'un fonctionnement au

gaz naturel A un fonctionnement au gaz propane. Ce kit ne

peut pas _tre utilis6 pour convertir d'autres modules de

table de cuisson ou de cuisini_re _ brQleurs scell6s de

Bosch ou une toute autre marque de table de cuisson.

AVERTISSEMENT

Ce kit de conversion doit _tre install6 par une agence

d'entretien qualifi6e conform6ment aux instructions du

fabricant et _ tousles codes et exigences applicables

des autorit6s qui ont juridiction. Si les informations

contenues dans ces instructions ne sont pas suivies Ala

lettre, un incendie, une explosion ou la production de

monoxyde de carbone peuvent se produire, entrafnant

des dommages mat@iels, des 16sions corporelles ou la

mort. L'agence d'entretien qualifi6e est responsable

d'installer ce kit de fagon appropri6e. L'installation n'est

pas appropri6e ou complete tant que I'op6ration de

I'appareil converti n'a pas 6t6 v6rifi6e conform6ment aux

instructions du fabricant fournies avec le kit.

IMPORTANT : Seul un technicien d'entretien ou un

installateur qualifi6 doit effectuer cette conversion.

INSTALLATEUR : Veuillez laisser ces instructions

d'installation avec I'appareil _ I'intention du propri6taire.

PROPRII_TAIRE : Veuillez conserver ces instructions

titre de r6f6rence.

Installations effectuees dans I'etat

du Massachusetts :

1. L'installation doit _tre effectu6e par un entrepreneur

ou plombier qualifi6 ou autoris6, ou par un monteur

d'installations au gaz qualifi6 ou agr66 par 1'6tat, la

province ou la r6gion.

2. Le robinet d'arr6t doit 6tre pourvu d'une poign6e

en <<T >>.

3. La Iongueur du connecteur de gaz flexible ne doit

pas d6passer 36 po (914 mm).

_, MISE EN GARDE

Lors du raccordement de I'unit6 au gaz propane,

s'assurer que le r6servoir de gaz propane est dot6 de

son propre r6gulateur haute pression. En outre, un

r6gulateur de pression a 6t6 fourni avec la table de

cuisson. Ce deuxi_me r6gulateur doit _tre install6 avec

la table de cuisson. La pression de gaz maximale A cet

appareil ne doit pas d6passer 14 po CE (colonne d'eau)

partir du r6gulateur du r6servoir de gaz propane.

Les conditions suivantes doivent _tre remplies lots des

tests effectu6s sur la tuyauterie d'alimentation :

a) L'appareil et son robinet d'arr_t individuel doivent _tre

d6branch6s de la tuyauterie d'alimentation en gaz

Iorsque vous effectuez des tests de pression A une

pression d'6preuve d6passant 3,5 kPa (1/2 psig).

b) L'appareil doit _tre isol6 de la tuyauterie

d'alimentation en gaz en fermant le robinet d'arr_t

manuel individuel Iorsque vous effectuez des essais de

pression sur la tuyauterie d'alimentation en gaz si la

pression d'6preuve est 6gale ou inf@ieure A 3,5 kPa

(1/2 psig).

Francais 1

Page 10

_j[__ _ _ii[11__ ...................................................................................................................................................................................................................................................................................................................................................................................................,_

Preparation

Contenu du kit d'installation

Cornposant Quantite

Instructions du kit de conversion 1

Autocollant de conversion 1

Ruban en mousse 1

Orifice 95 3

Orifice 66 2

Orifice 44 1

Remarque :

Selon le module, le kit peut contenir d'autres

composants, lesquels sont n6cessaires _ la r6alisation

de la conversion.

Outil requis

Tournevis & douitte

de 7 mm (extension

minimum de 3 po ou

76,2 mm)

Orifices principaux

NGM5055UC

122

95

95

66

Avant droit 15 000

Avant gauche 9 100

Arri_re gauche 9 100

Arri_re droit 5 000

NGM8055, 8065U0

122 Milieu 15 000

66 Avant droit 5 000

95 Avant gauche 9 100

66 Arri_re gauche 5 000

95 Arri_re droit 9 100

NGMP055UC

109 Milieu grand 15 000

44 Milieu petit 5 000

66 Avant droit 5 000

95 Avant gauche 9 100

66 Arri_re gauche 5 000

95 Arri_re droit 9 100

NGMP655UC

BTU/h

cle ajustable

et/ou pince

joint

coulissant

109 Milieu grand 15 000

44 Milieu petit 5 000

95 Avant droit 9 100

95 Avant gauche 9 100

95 Arri_re gauche 9 100

66 Arri_re droit 5 000

NGM5655, 8655, 8665U0

122 Milieu 15 000

95 Avant droit 9 100

95 Avant gauche 9 100

95 Arri_re gauche 9 100

66 Arri_re droit 5 000

Francais 2

Page 11

_j[__; _ii[11__ ...................................................................................................................................................................................................................................................................................................................................................................................................,_

Procedure d'installation

Ce processus de conversion ajuste le d6bit du gaz aux

brOleurs pour correspondre _ celui convenant au gaz

propane.

A MISE EN GARDE

ETEIGNEZ LE GAZ ET L'ELECTRICITE.

Si la table de cuisson est install6e dans le plan de

travail •

1) fermez le robinet de gaz reli6 au tuyau

d'alimentation en gaz de la table de cuisson;

2) d6branchez le cordon d'alimentation de la table

de cuisson de la prise 61ectrique ou retirer le fusible

au niveau du boftier de disjoncteurs;

3) placez tous les boutons de commande _ la

position <<d6sactiv6e >>.

Liste de verification

Chacune des etapes suivantes dolt _tre complet6e

correctement pour assurer le bon fonctionnement de

rappareil.

l tape 1 - Convertir le regulateur

de pression

Localisez le r6gulateur de )ression au bas de I'extr6mit6

droite de la table de cuisson.

Remarque : La fleche au dos du regulateur dolt pointer

dans la direction de la circulation du gaz

vers la table de cuisson.

Cochez chaque 6tape en la compl6tant.

__ I_tape 1 - Convertissez le r6gulateur de pression pour

utiliser le gaz propane.

__ I_tape 2 - Retirez les orifices du gaz naturel (GN) et

remplacez-les par les orifices pour le gaz propane (PL)

fournis avec ce kit.

__ I_tape 3 - Remettre les grilles et les capuchons de

brOleur en place

__ I_tape 4 - Ajustez les robinets de I'unit6 conform6ment

aux r6glages pour le gaz propane (PL).

Retirez le capuchon hexagonal du r6gulateur en vous

assurant de ne pas d61oger le joint du capuchon ou le

ressort _ I'int6rieur du r6gulateur.

tige de bouton

ressort en pla//stique

joint

Saisissez fermement la tige de bouton en plastique (la tige)

et retirez-la du capuchon m6tallique. La tige est ins6r6e

solidement dans un retrait du capuchon et peut n6cessiter

un bon effort pour _tre retir6e. Conseil : II peut _tre utile de

<<secouer >>d61icatement la tige en plastique tout en la

tirant du capuchon m6tallique.

Francais 3

Page 12

Apr_savoirretir6latigeducapuchon,faites-lapivoterde

180°pourqueI'extr6mit6enboutondelatigesoit

I'oppos6ducapuchonetqueleslettres<<PL>>ou<<LP>>

surlatigesoient_I'enversIorsquelecapuchonestplac6

platsursonextr6mit6.Remettezlatigeenplacedanscette

positionenI'ins@antdansleretraitducapuchon

m6tallique.Latigedevraitseverrouillerenplace.

Gaz Gaz

naturel propane

Important - Fixez I'autocollant m6tallique (compris avec ce

kit de conversion) au-dessous de I'appareil tel qu'illustr6,

pros de la plaque signal6tique de I'appareil (qui indique le

num6ro de s@ie et des informations sur I'appareil). Cet

autocollant indique que I'appareil a 6t6 converti pour utiliser

le gaz propane (PL).

c) En enfongant la cl6 _ douille dans I'orifice, le ruban

se moulera _ I'orifice pour I'emp_cher de tomber de

la douille au cours de I'extraction.

a, b. C,

Conservez les orifices pour le GN au cas oQvous devriez

reconvertir I'appareil pour utiliser de nouveau du gaz

naturel.

,

Identifiez le positionnement appropri6 des orifices pour

le gaz propane (PL) tel qu'indiqu6 sur le carton

d'emballage des orifices.

Remarque : Les modules NGMP055UC et

NGMP655UC sont 6quip6s d'un orifice suppl6mentaire

dissimul6 sous le capuchon central de I'unit6. II est

n6cessaire de retirer le cache pour modifier I'orifice

central (le plus petit) cach6.

dessous de la table de cuisson

l tape 2 - Remplacer les orifices

1. Retirez les grilles et les capuchons des brOleurs.

Remarque :N'enlevez pas I'allumeur de I'unit6.

2. Retirez les orifices.

Remarque : Les orifices necessitent une cle a douille

de 7 rnrn pour _tre retires ou rernplaces. La

cle doit 6tre inseree a environ 64 mrn (2 1/2

po) dans la cavite du brQleur pour attein-

dre I'orifice.

Conseil : Pour r6duire le risque que I'orifice tombe de la d6

b douille, vous pouvez ajouter un morceau de

ruban en mousse ou de ruban adh6sif a I'int6rieur

de la douille.

1

Orifice

central

plus petit

Les tailles des orifices sont indiqu6es _ I'int6rieur des

cercles blancs correspondant _ chaque brQleur comme

indiqu6 dans I'illustration ci-dessous Ces nombres sont

grav6s sur le dessus de chaque orifice. II est important

d'installer la bonne taille d'orifice pour chaque brQleur.

NGM5055UC

a) D6coupez un petit morceau du ruban en mousse

fourni avec le kit (environ 6 mm x 12 mm ou 1/4 po

x 1/2 po).

b) Placez le morceau de fagon _ entourer un c6t6 de

la douille pour qu'il tienne en place.

Francais 4

Page 13

NGM8055, 8065UC

NGMP055UC

am b_

Vous pourrez ainsi 6viter que I'orifice tombe de la douille au

cours de I'insertion.

l_tape 3 - Remettre les grilles et les

capuchons de br01eur en place

Remettre les grilles et les capuchons de brQleur en

place. S'assurer que les grilles sont correctement

mises en place et que les pieds en caoutchouc des

grilles sont plac6s en position correcte dans les

indentations de la table de cuisson.

NGMP655UC

,

Ins@ez chaque orifice pour gaz propane (PL) fourni

avec ce kit dans la douille (en utilisant un petit morceau

de ruban en mousse pour assurer un ajustement

serr6).

a) Assurez-vous que le petit morceau de ruban en

mousse utilis6 pr6c6demment entoure toujours un

c6t6 de la douille.

b) En enfongant la cl6 _ douille dans I'orifice, le ruban

aidera _ maintenir un ajustement serr6 de I'orifice

dans la douille. Vous pourrez ainsi 6viter que

I'orifice tombe de la douille au cours de I'insertion.

l_tape 4 - Convertir les robinets pour le

gaz propane (PL)

Le jet de contournement sur chaque robinet doit 6tre

ajust6. Votre table de cuisson peut 6tre munie de tiges de

robinet vides ou solides. D6terminez la position de la vis de

contournement en fonction de la configuration de votre

appareil.

1. Placez tousles boutons _ la position <<d6sactiv6e >>.

2. Enlevez les boutons.

Francais 5

Page 14

V rifier I'installation

Verifier la presence de fuites de gaz

A AVERTISSEMENT

NE VI_RIFIEZ JAMAIS LA PRI_SENCE DE FUITES

DE GAZ AVEC UNE FLAMME.

Si des fuites sont d6tect6es, ne passez pas _ la

prochaine 6tape avant d'avoir 61imin6 toutes les

fuites.

Votre appareil sera muni soit de a) robinets _ tige vide ou

de b) robinets _ tige solide. La position de la vis

d'ajustement sera d6termin6e par le type de robinet dont

dispose votre appareil.

3. Trouvez le point d'insertion appropri6 pour le long

tournevis _ lame plate et fine afin d'ajuster le jet de

contournement (consultez I'illustration suivante).

......... a. Tige vide b. Tige solide

_d

_ _m_

a) Robinet _ tige vide - ins@ez un long tournevis

lame plate et fine dans la tige vide du robinet. La

vis d'ajustement se trouve _ environ 39 mm (1 1/2

po) de I'extr6mit6 de la tige. Le tournevis glissera

dans une mince barri@e en caoutchouc dans la

tige (congue pour 6viter des dommages en cas de

d6g_ts sur la surface de I'appareil).

b) Robinet _ tige solide - ins@ez un long tournevis

lame plate et fine _ travers le sceau dans la zone

indiqu6e.

3. Placez le bout du tournevis dans la vis d'ajustement et

tournez lentement le tournevis tout en tentant de

v@ifier que la t_te est bien engag6e dans la vis. Faites

tourner la vis dans le sens des aiguilles d'une montre

sur environ 70 degr6s (moins d'un quart de tour)

jusqu'_ ce qu'elle se bloque (vous ne pourrez plus

tourner davantage). La vis n6cessite tr_s peu de force

pour _tre tourn6e. Arr_tez Iorsque vous sentez de la

r6sistance. R6p6tez I'op@ation pour chaque robinet

jusqu'_ ce que tousles robinets soient bien ajust6s.

4. Replacez les boutons.

La v@ification doit _tre effectu6e par I'installateur

conform6ment aux instructions de cette section.

Ouvrez le gaz. Appliquez un liquide de d6tection des fuites

non corrosif sur tousles joints et raccords de la connexion

de gaz entre le robinet d'arr6t et la table de cuisson. Vous

devez inclure les joints et raccords de gaz de la table de

cuisson si les connexions ont 6t6 perturb6es pendant

I'installation. Des buries autour des raccords et connexions

indiquent la pr6sence d'une fuite. Un d6tecteur

61ectronique de fuites de gaz peut 6galement 6tre utilis6.

S'il y a une fuite, fermez le robinet d'arr_t de gaz du tuyau

d'alimentation et serrez les connexions qui fuient. V@ifiez

de nouveau les fuites en ouvrant le robinet d'arr6t de gaz

du tuyau d'alimentation. Une fois la v@ification termin6e

(il n'y a plus de bulles), le test est termin6. Essuyez tout

r6sidu provenant du liquide de d6tection.

Verifier la pression d'admission du gaz

Au cours de tout test de pression de la tuyauterie

d'alimentation _ des pressions d'6preuve d6passant 3,5

kPA (environ 14 po de la colonne d'eau ou ½" psig), ilest

n6cessaire de d_brancher la table de cuisson et son

robinet d'arr_t individuel de la tuyauterie d'alimentation en

gaz.

Si la pression d'admission doit _tre v_rifi_e, branchez un

manom_tre (colonne d'eau) ou un autre appareil de

mesure de la pression de gaz approuv_ _ I'orifice du

brQleur sup@ieur droit. Utilisez un tuyau de caoutchouc

d'un diam_tre int@ieur de 0,6 cm (1/4 po) et maintenez-le

fermement sur I'orifice. Allumez le robinet du brQleur.

Verification finale

Une fois la conversion termin_e, placez chaque capuchon

de brQleur de la taille appropri_e dans leur position

install_e et engag_e et v@ifiez le fonctionnement des

allumeurs _lectriques. V@ifiez les caract@istiques de la

flamme. La flamme devrait _tre bleue avec une petite

pointe jaune sur les c6nes ext@ieurs des flammes.

Francais 6

Page 15

Verifier les caracteristiques de la flamme

R paration

Flammes jaunes :

Un ajustement est

n6cessaire.

Pointes jaunes au niveau

des c6nes exterieurs :

Normal pour du gaz propane

(PL).

Douces flammes bleues :

Normal pour du gaz naturel.

Remarque :Si la flamme est entierement jaune ou pres-

que, verifiez que le regulateur est regle

pour le combustible appropri& Si un ajus-

tement est necessaire, verifiez de nouveau

le systeme.

II est normal que la flamme pr6sente des raies jaunes

pendant la mise en marche initiale. Laissez I'appareil

fonctionner pendant 4 _ 5 minutes et v@ifiez de nouveau

avant d'effectuer d'autres ajustements.

Avant d'appeler le service de

depannage

Pour des informations sur le d6pannage, consultez le

Manuel d'utilisation et d'entretien de votre appareil.

Consulter la section Garantie dans le Manuel d'utilisation et

d'entretien pour des informations concernant la garantie.

Pour contacter un technicien de d6pannage, consultez les

coordonn6es sur la couverture avant du manuel. Lors de

I'appel, soyez pr6par6 _ fournir les informations imprim6es

sur la plaque signal6tique du produit (modUle, num6ro de

s@ie (FD), etc.).

Plaque signaletique du produit

La plaque signal6tique comporte le num6ro de module et le

num6ro de s@ie. Reportez-vous _ la plaque signal6tique

de I'appareil 61ectrom6nager pour faire une demande de

d6pannage. La plaque signal6tique se trouve sur la face

arri@e du boftier, sous la partie visible de la table de

cuisson install6e.

Les informations de la plaque signal6tique se retrouvent

6galement sur un autocollant fix6 _ la carte

d'enregistrement du produit comprise avec votre appareil.

Plaque

signal6tique

du produit

Conservez la facture et les documents pertinents pour la

validation de la garantie si une r6paration s'av6rait

n6cessaire.

Francais 7

Page 16

Conversibn a gas LP de placa a gas NGM

Instrucciones de conversion

KIT DE CONVERSION DE PLACA DE BOSCH PARA

MODELOS TRADICIONALES DE GAS NATURAL (NG) A

GAS PROPANO LJQUIDO (LP)

_1_PRECAUCION

NEZ1054

Este kit se utiliza para convertir solo placas NGM con

hornillas selladas de la operaci6n con gas natural a la

operaci6n con gas propano. Este kit no puede utilizarse

para convertir otros modelos de Bosch de placas con

hornillas selladas, estufas ni ninguna otra marca de placas.

A ADVERTENCIA

Este kit de conversi6n ser_ instalado por una agencia de

servicio t6cnico califlcada, de acuerdo con las

instrucciones del fabricante y con todos los c6digos y

requisitos aplicables de la autoridad que tenga

jurisdicci6n. Si la informaci6n que se encuentra en estas

instrucciones no se cumple con exactitud, es posible

que se produzca un incendio, una explosi6n o emisi6n

de mon6xido de carbono, Io que provocarJa dados

materiales, lesiones personales o la muerte. La agencia

de servicio t6cnico calificada es responsable de la

instalaci6n adecuada de este kit. La instalaci6n no es

adecuada y no est_ completa hasta tanto se verifique el

funcionamiento del electrodom6stico convertido, segQn

Io especificado en las instrucciones del fabricante

suministradas con el kit.

AI conectar la unidad al gas propano, asegQrese de que

el tanque de gas propano venga equipado con su propio

regulador de presi6n alta. Adem_s, se suministr6 un

regulador de presi6n con la placa. Este segundo

regulador debe instalarse con la placa. La m_xima

presi6n de gas a este electrodom6stico no debe exceder

las 14.0 pulgadas de columna de agua del regulador del

tanque de gas propano.

Se deben cumplir los siguientes requisitos al probar el

sistema de tuberias de suministro:

a) El electrodom6stico y su v_lvula de paso individual

deben estar desconectados del sistema de tuberias de

suministro de gas en pruebas de presi6n superiores a

1/2 psig (3.5 kPa).

b) El electrodom6stico se debe aislar del sistema de

tuberias de suministro de gas cerrando la v_lvula de

paso manual individual durante cualquier prueba de

presi6n del sistema de tuberias de suministro de gas

con presiones de prueba iguales o menores que

1/2 psig (3.5 kPa).

IMPORTANTE: 0nicamente un t6cnico de servicio o

instalador calificados deben hacer esta conversi6n.

INSTALADOR: Deje estas instrucciones de instalaci6n con

esta unidad para el propietario.

PROPIETARIO: Conserve estas instrucciones para

consultarlas en el futuro.

Para instalaciones en Massachusetts:

1. La instalaci6n debe ser realizada por un contratista

calificado o con licencia, un plomero o gasista

calificado o con licencia otorgada por el estado, la

provincia o la regi6n.

2. La vSIvula de paso debe tener una Ilave de gas con

mango en "T".

3. El conector de gas flexible no debe medir m_s de 36

pulgadas.

Espanoll

Page 17

Preparacibn

Contenido del kit de instalacion

Componente

Instrucciones del kit de conversi6n

Adhesivo de conversi6n

Cinta de espuma

Orificio 95

Orificio 66

Orificio 44

Nota:

En funci6n de_mode_o, es posib_e que e_kit contenga

m_s componentes de los que sean necesarios para

completar su conversi6n.

Herramientas requeridas

Destorniiiador ttave

de 7 mm (3 pulgadas

de extensi6n minima)

delgada y peque_a

llave y / o

deslizamient

o ajustable

alicates

Cantidad

Orificios principales

NGMS055UC BTU/h

1

1

1

3

2

1

122 Delantero derecho 15,000

95 Delantero izquierdo 9,100

95 Trasero izquierdo 9,100

66 Trasero derecho 5,000

NGM8055, 8065UC

122 Central

66 Delantero derecho

95 Delantero izquierdo

66 Trasero izquierdo

95 Trasero derecho

NGMP055UC

109 Central grande

44 Central pequeRo

66 Delantero derecho

95 Delantero izquierdo

66 Trasero izquierdo

95 Trasero derecho

NGMP655UC

109 Central grande

44 Central peque_o

95 Delantero derecho

95 Delantero izquierdo

95 Trasero izquierdo

66 Trasero derecho

NGM5655, 8655, 8665UC

66

Central

Delantero derecho

Delantero izquierdo

Trasero izquierdo

Trasero derecho

122

95

95

95

15,000

5,000

9,100

5,000

9,100

15,000

5,000

5,000

9,100

5,000

9,100

15,000

5,000

9,100

9,100

9,100

5,000

15,000

9,100

9,100

9,100

5,000

Espanol2

Page 18

Esteprocesodeconversi6najustaelflujodegasqueIlega

alashornillasparaajustarseaunafuentedecombustible

degasLP.

_1_PRECAUCION

Paso 1" Convierta el regulador de

presion

Ubique el regulador de presi6n en el extremo inferior

derecho de la placa.

APAGUE EL GAS Y LA ELECTRICIDAD.

Si la placa se instala en la superficie de trabajo:

1) Cierre la vSIvula de gas de la linea de suministro

de gas a la placa.

2) Retire el cable de alimentaci6n de la placa de la

toma de corriente el6ctrica o apague el disyuntor en

la caja de disyuntores.

3) Lleve todas las perillas de control a la posici6n

"Off" (Apagado).

Lista de verificacion

Cada uno de los siguientes pasos se debe completar

correctarnente para que el electrodornestico funcione

en forma adecuada.

Marque cada paso a medida que se termine.

__ Paso 1: Convierta el regulador de presi6n para utilizar

gas LP.

__ Paso 2: Retire los orificios de gas natural (natural gas,

NG) y reempl_celos con los orificios de gas propano

liquido (liquid propane, LP) suministrados con este kit.

__ Paso 3: Vuelva a colocar las tapas de los quemadores

y las parrillas.

__ Paso 4: Ajuste las vSIvulas de la unidad a las

programaciones de LP.

Nota: La flecha en la parte trasera del regulador debe

apuntar en la direccion del flujo de gas a la

placa.

Retire la tapa de forma hexagonal del regulador

asegurSndose de no remover el empaque de la tapa ni el

resorte dentro del regulador.

vastago de bot6n

resorte de pl/_stico

empaque

Tome el vSstago de bot6n de pl_stico (v_stago) firmemente

y j_lelo con fuerza de la tapa de metal. El vSstago calza

bien a presi6n en una hendidura en la tapa y es posible

que se requiera jalar fuerte para retirarlo. Sugerencia:

puede ser Qtil suavemente "roca" del vSstago de pl_stico

mientras tira de la tapa de metal.

Espanol3

Page 19

Despu6sderetirarelvSstagodelatapa,r6telo180°de

modoqueelextremodelbot6ndelvSstagoest6lejosdela

tapaylasletras"LP"enelvSstagoseencuentrenalrev6s

cuandolatapasecoloqueenformaplanaensucabeza.

Calceapresi6nelvAstagodenuevoensulugarenesta

posici6ninsert_ndoloenlahendiduradelatapademetal.

ElvSstagodeberiacalzarapresi6nensulugar.

Gas Gas

Natural LP

Importante: Pegue eladhesivo met_lico (que se incluye en

este kit de conversi6n) en la parte inferior del

electrodom6stico, segQn se muestra, coloc_ndolo cerca de

la placa de datos del electrodom6stico (muestra el nQmero

del modelo e informaci6n sobre el electrodom6stico). Este

adhesivo notifica que el electrodom6stico ha sido

convertido para el uso con gas LP.

c) AI presionar el destornillador Ilave en el orificio, la

cinta se ajustar8 al orificio y ayudar8 a evitar que el

orificio se caiga de la Ilave durante la extracci6n.

a, b. C,

Conserve los orificios de NG en caso de que, en el futuro,

haya necesidad de restablecer nuevamente el

electrodom6stico al uso de gas natural.

,

Identifique la colocaci6n correcta de los orificios de gas

LP, segQn se detalla en la tarjeta del paquete de

orificios.

Nota: Los modelos NGMP055UC y NGMP655UC

tienen un orificio oculto adicional debajo de la tapa de

la unidad central. Es necesario retirar la placa de la

cubierta para cambiar el orificio central (m_s peque_o)

oculto.

Parte inferior de la placa

Paso 2: Reemplace los orificios

1. Retire las tapas de las rejillas y de las hornillas.

Nota:No retire el encendedor de la unidad.

2. Retire los orificios.

Nota:

Consejo:Para reducir la probabilidad de caida de los orifi-

Los orificios requieren un destornillador Ilave

de 7 mm para ser retirados/reemplazados. El

destornillador debera insertarse aproximada-

mente 2 1/2 pulg. (64 mm) en la cavidad de la

hornilla para Ilegar al orificio.

cios del destornillador Ilave, agregue un pedazo de

cinta de espuma o cinta adhesiva dentro de la

Ilave.

a) Corte un peque_o pedazo de la cinta de espuma

que se proporciona en este kit (alrededor de 1/4

pulg. x 1/2 pulg.; 6 mm x 12 mm).

b) Ajuste esto de modo que la cinta se envuelva en

un lado de la Ilave, a fin de que permanezca en su

lugar.

Orificio

central

m_s

pequ_o

Los tama_os de los oriflcios se muestran en los

circulos blancos que corresponden a cada hornilla,

segQn se muestra en la imagen que se encuentra a

continuaci6n. Estos nQmeros se graban en la parte

superior de cada orificio. Es muy importante instalar el

tama_o de orificio correcto para cada hornilla.

NGM5055UC

Espanol4

Page 20

NGM8055, 8065UC

NGMP055UC

am b_

Esto ayudar_ a evitar que el orificio se salga de la Ilave

durante la inserci6n.

Paso 3 -Vuelva a colocar las tapas de

los quemadores y las parrillas.

Vuelva a colocar las parrillas y las tapas de los

quemadores. AsegQrese de las rejillas se colocan

correctamente y que las patas de goma en las rejillas

se acoplan con las muescas en la superficie de

cocci6n para la posici6n correcta.

NGMP655UC

,

Inserte cada uno de los orificios de gas LP que se

proporcionan en este kit en la Ilave (utilizando el

peque_o pedazo de cinta de espuma para garantizar

un ajuste apretado).

a) AsegQrese de que el peque_o pedazo de cinta de

espuma utilizado anteriormente est6 ajustado para

que se envuelva en un lado de la Ilave.

b) AI presionar el destornillador Ilave en el orificio, la

cinta ayudar8 a que el orificio se ajuste mejor

dentro de la Ilave. Esto ayudar_ a evitar que el

orificio se salga de la Ilave durante la inserci6n.

Paso 4: Convierta las valvulas para la

utilizacion de gas LP

Se debe ajustar la salida del regulador de cada v_lvula. Es

posible que su placa venga con ejes de las vSIvulas

huecos o s61idos. En forma acorde, determine la ubicaci6n

del tornillo regulador.

1. Coloque todas las perillas en la posici6n "Off"

(Apagado).

2. Retire las perillas.

Espanol5

Page 21

\

Suelectrodom6sticotendrS:a)vSIvulasdevSstagohueco

ob)vSIvulasdev_stagos61ido.Laubicaci6ndeltornillode

ajustesedeterminaporeltipodevSIvulaquetengasu

electrodom6stico.

4. Reemplace las perillas.

Pruebe la instalacibn

Realice pruebas para detectar fugas

de gas

ADVERTENCIA

NUNCA REALICE PRUEBAS PARA DETECTAR

FUGAS DE GAS UTILIZANDO UNA LLAMA.

Si se detecta alguna fuga, no continue con los

siguientes pasos hasta tanto se hayan eliminado

todas las fugas.

,

Ubique la punta de inserci6n correcta para el

destornillador de hoja plana largo y delgado, a fin de

ajustar la salida del regulador (consulte la siguiente

ilustraci6n).

......... a. V_stago hueco b. V_stago s61ido

a) V_lvula de vSstago hueco: inserte un destornillador

de hoja plana largo y delgado en el vSstago hueco

de la v_lvula. El tornillo de ajuste se encuentra

aproximadamente a 1 1/2 pulg. (39 mm) de la

parte superior del vSstago. El destornillador se

desliza a trav6s de una barrera de hule delgada en

el vSstago (ayuda a evitar da_os en caso de un

derrame en la superficie de la unidad).

b) V_lvula de vSstago s61ido: inserte un destornillador

de hoja plana largo y delgado a trav6s del sello en

el 8rea mostrada.

,

Enganche la punta del destornillador en el tornillo de

ajuste girando lentamente el destornillador y

percibiendo que la hoja enganche el tomillo. Luego,

gire el tornillo hacia la derecha alrededor de 70 grados

(menos de 1/4 de giro) hasta que "llegue a su tope" (no

se pueda girar m&s). No se necesita mucha presi6n

para que el tornillo gire. Det6ngase cuando el tornillo

deje de girar con facilidad. Repita el procedimiento

para cada vSIvula hasta que todas se hayan ajustado

correctamente.

Las pruebas para detectar fugas deben ser Ilevadas a cabo

por el instalador, de acuerdo con las instrucciones que se

proporcionan en esta secci6n.

Encienda el gas. Coloque un liquido de detecci6n de fugas

no corrosivo en todas las juntas y los accesorios de la

conexi6n de gas entre la vSIvula de paso y la placa. Incluya

los accesorios y las juntas de gas en la placa si existe la

posibilidad de que se hayan movido las conexiones

durante la instalaci6n. La presencia de burbujas alrededor

de los accesorios y las conexiones indican una fuga.

Tambi6n se puede utilizar un detector de fugas de gas

electr6nico.

Si aparece una fuga, apague la vSIvula de paso de gas de

la linea de suministro y ajuste las conexiones que tienen

fugas. Vuelva a realizar pruebas para detectar fugas

abriendo la vSIvula de paso de gas de la linea de

suministro. Cuando haya finalizado de verificar que no

haya fugas (no aparecen burbujas), la prueba est_

completa. Limpie todos los restos de liquido de detecci6n.

Verifique la presion de admision de gas

Durante cualquier prueba de presi6n del sistema de

tuberias de suministro de gas realizada con presiones de

prueba superiores a 14 pulg. de presi6n de columna de

agua (aproximadamente ½ pulg. psig, 3.5 kPA), es

necesario desconectar la placa y su vSIvula de paso

individual del sistema de tuberias de suministro de gas.

Si es necesario verificar la presi6n de admisi6n de gas,

conecte un man6metro (indicador del nivel del agua) u

otro dispositivo aprobado para la lectura de la presi6n de

gas al orificio trasero derecho de la hornilla de la parte

superior. Utilizando una manguera de hule con un di_metro

interior de aproximadamente 1/4 pulg., mantenga la tuberia

en forma ajustada sobre el orificio. Encienda la vSIvula de

la hornilla.

Espanol6

Page 22

Verificacion final

Despu6s de completar la conversi6n, coloque todas las

tapas de tama_o correcto de las hornillas en su posici6n

sentada y muescada, y verifique el funcionamiento de los

encendedores el6ctricos. Verifique las caracteristicas de la

llama. La llama debe ser azul y tener una minima punta

amarilla en el cono exterior de las llamas.

Verifique las caracteristicas de la llama

Servicio tdcnico

Antes de Ilamar al servicio tecnico

Para obtener informaci6n sobre resoluci6n de problemas,

consulte el Manual de uso y cuidado de su

electrodom6stico. Consulte la secci6n Garantia en el

Manual de uso y cuidado para obtener informaci6n

relacionada con la garantia.

Llamas amarillas:

Se requiere ajuste adicional.

Puntas amarillas en conos

externos:

Normal para gas LP.

Llamas azul claro:

Normal para gas natural.

Nota:

La presencia de algunas vetas amarillas en la llama es

normal durante el encendido inicial. Permita que la unidad

opere de 4 a 5 minutos y, luego, vuelva a realizar una

evaluaci6n antes de Ilevar a cabo m_s ajustes.

Si la llama es amarilla en su mayor parte, verifi-

que que el regulador este programado para el

combustible correcto. 8i se necesita un ajuste,

vuelva a realizar pruebas en el sistema.

Para consultar a un representante de servicio t6cnico,

remitase a la informaci6n de contacto que aparece en el

frente del manual. AI Ilamar, est6 preparado para

proporcionar la informaci6n impresa en la placa de datos

de su producto (modelo, nQmero de serie [FD], etc.).

Placa de datos del producto

La placa de datos muestra el modelo y el nQmero de serie.

AI solicitar servicio t6cnico, consulte la placa de datos del

electrodom6stico. La placa de datos est_ ubicada en la

parte inferior de la caja empotrada, debajo de la parte

visible de la placa instalada.

Esta informaci6n de la placa de datos tambi6n se

proporciona en un adhesivo pegado en la tarjeta de

registro del producto que se envia con su

electrodom6stico.

Placa de

datos del

producto

Conserve su factura de compra y cualquier otro documento

relacionado para la validaci6n de la garantia, en caso de

que se necesite servicio t6cnico.

Espanol 7

Page 23

Invented for life

1901 Main Street,, Suite 600, Irvine, CA 92614 • 800-944-2904 • www.bosch-home.com

9000947165 • Rev. A • 5VORSS • 01/14 © BSH Home Appliances Corporation, 2014 • All rights reserved

Loading...

Loading...