Page 1

Communications Systems | LH2-UC15E Horn loudspeaker, 15W, marine

LH2-UC15E Horn loudspeaker, 15W,

marine

www.boschsecurity.com

u Suitable for marine and industrial applications in

humidity-, chlorine- and salty environments

The Horn Loudspeaker LH2‑UC15E is specifically

designed for excellent sound reproduction in marine

applications and other industrial environments.

The housing is rugged, water- and dust-protected, and

resistant to the corrosive effects of seawater and most

industrial atmospheres.

The horn loudspeaker is made from an UV‑stable, glass

reinforced polyester (GRP). This strong, fire-retardant

and corrosion resistant material is chemical resistant

and thermally stable, making it ideal for even the

harshest environments. The horn is standard supplied

with a stainless steel mounting bracket.

Functions

The horn loudspeaker is standard supplied with a

sturdy mounting bracket allowing the sound beam to

be accurately directed.

The mounting bracket has a ratchet facility to ensure it

stays correctly positioned.

The connection cable is fed out through an ABS cable

gland (PG13.5 standard supplied) in the rear cover,

which can be removed for entering the inside

u Glass reinforced polyester housing with

fire‑retardant properties

u Water– and dust-protected to class IP67

u Provisions for internal mounting of the optional

supervision boards

u Type approval certified EN 60945 and EN54‑24

certified

connection terminal. For loop‑through connection, the

rear cover is fitted with a second hole (covered with a

blanking plug as standard supplied).

The horn loudspeaker includes a transformer for both

70 V and 100 V input voltage, with taps on the primary

winding for different power settings.

Nominal full‑power, half‑power, quarter‑power or

eight‑power radiation (i.e. in 3 dB steps) can easily be

selected by connecting to the appropriate terminal of

the 6‑way screw terminal block.

The horn loudspeaker has built‑in protection to ensure

that, in the event of a fire, damage to the loudspeaker

does not result in failure of the circuit to which it is

connected. In this way, system integrity is maintained;

ensuring loudspeakers in other areas can still be used

to inform people of the situation.

The horn loudspeaker has ceramic screw‑terminal

connection blocks, thermal fuse, heat‑resistant high

temperature wiring and has a provision for internal

mounting of the optional line/loudspeaker supervision

boards.

Page 2

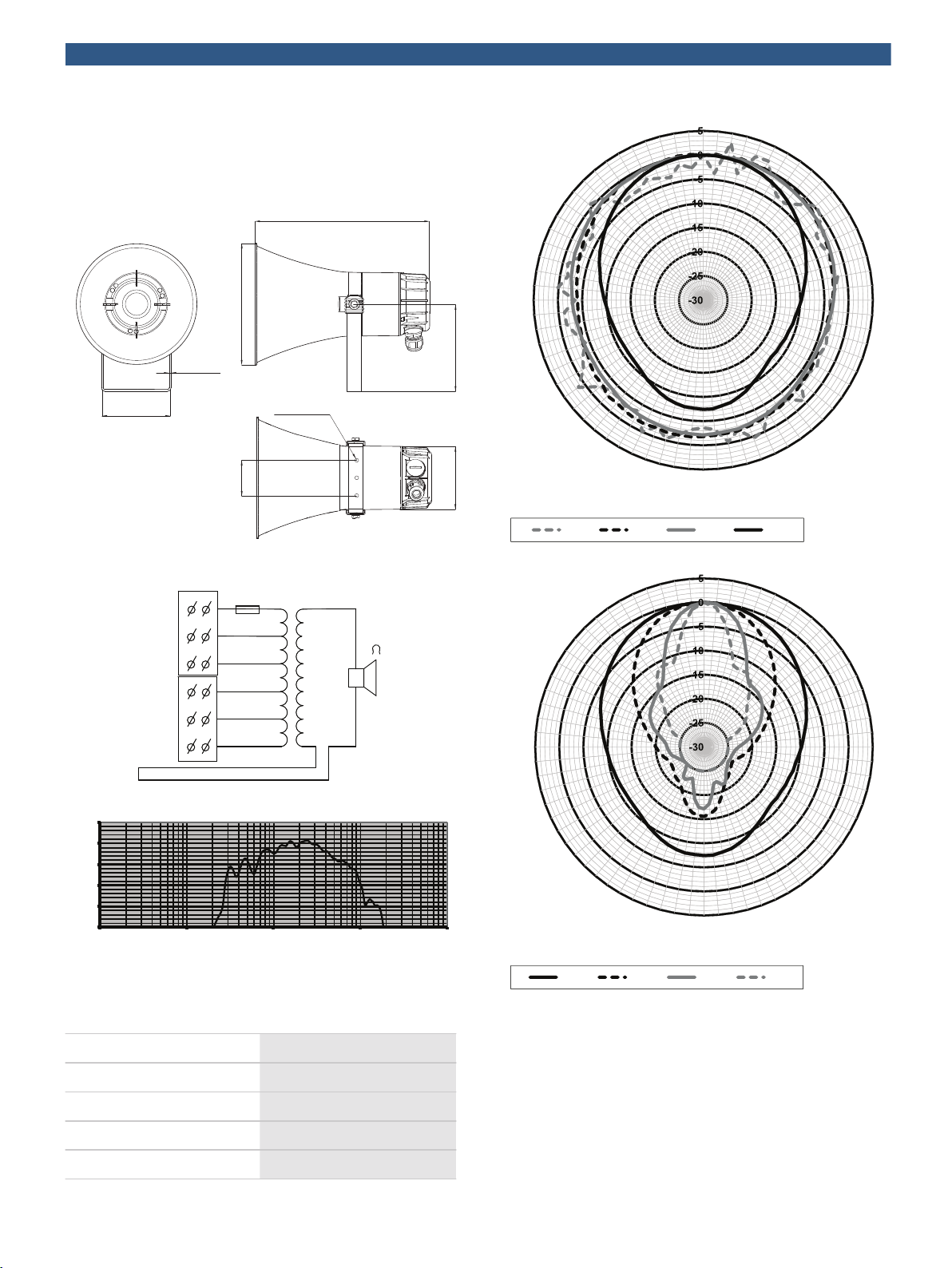

302 mm (11.89”)

121 mm (4.76”)

3 mm (0.12”)

212 mm (8.35”)

60 mm (2.36”)

152 mm (5.98”)

111 mm (4.37”)

7 mm (0.28”)

7.5 W

1.87 W

1.87 W 3.75 W

3.75 W

15 W7.5 W

NC

15 W

0 0

100 V70 V

8

NC

70

80

90

100

110

120

10 100 1000 10000 100000

dB SPL

Frequency

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

125 250 500 1000

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

1000 2000 4000 8000

2 | LH2-UC15E Horn loudspeaker, 15W, marine

For enabling loudspeaker supervision, a wire loop from

the secondary side of the horn loudspeaker is available

in the connection area. This wire loop is normally

closed, but when used with the supervision board, it is

cut and connected.

Dimensions in mm (inch)

Circuit diagram

EQ setting

Frequency response

To meet EN54‑24 requirements, below stated 1/3

octave band equalization is required:

1/3 octave band (Hz)

1250 Hz -2 dB

1600 Hz -3 dB

2000 Hz -1 dB

6300 Hz +3 dB

Polar diagrams (measured with pink noise)

Page 3

| LH2-UC15E Horn loudspeaker, 15W, marine

3

Octave band sensitivity *

Octave SPL

1W/1m

125 Hz 55.2 - -

250 Hz 93.4 - -

500 Hz 99.8 - -

1000 Hz 107.8 - -

2000 Hz 110.8

4000 Hz 107.6 - -

8000 Hz 99.3 - -

A‑weighted - 104.9 115.2

Lin‑weighted - 104.1 114.9

Octave band opening angles

Horizontal Vertical

125 Hz 360 360

250 Hz 360 360

500 Hz 360 360

1000 Hz 119 119

2000 Hz 68 68

4000 Hz 38 38

8000 Hz 23 23

Total octave

SPL

1W/1m

Total octave

SPL

Pmax/1m

Acoustical performance specified per octave

* (all measurements are done with a pink noise signal;

the values are in dB SPL).

Certifications and approvals

Quality assurance

All Bosch loudspeakers are designed to withstand

operating at their rated power for 100 hours in

accordance with IEC 60268-5 Power Handling Capacity

(PHC) standards. Bosch has also developed the

Simulated Acoustical Feedback Exposure (SAFE) test

to demonstrate that they can withstand two times

their rated power for short durations. This ensures

improved reliability under extreme conditions, leading

to higher customer satisfaction, longer operating life,

and lessons the chance of failure or performance

deterioration.

Safety

Emergency According to EN 54‑24 / compliant to

According to EN 60065

BS 5839‑8

Water and dust protection According to EN 60529, IP 67

Salt mist According to IEC 60068‑2‑11

Chlorine resistant According to IEC 60068‑2‑60

Wind force According to Bft 11

Region Regulatory compliance/quality marks

Europe CE DECL EC LH2-UC15E

CE DOC (IP)

Parts included

Quantity Component

1 LH2‑UC15E Horn Loudspeaker

1 Installation instruction

Technical specifications

Electrical*

Maximum power 22.5 W

Rated power (PHC) 15 W

Power tapping 15 / 7.5 / 3.75 / 1.87 W

Sound pressure level

at rated power / 1 W

(1 kHz, 1 m)

Sound pressure level

at rated power / 1 W

(1 kHz, 4 m)

(reference axis 0 degrees,

free field)

Effective frequency range

(- 10 dB)

Opening angle at

1 kHz / 4 kHz

(‑6 dB)

Rated input voltage 70 / 100 V

Rated impedance 334 ohm (15 W at 70 V)

Electrical connection 6‑pole screw terminal

Acceptable wire gauge 1.0 – 2.3 mm

120 / 108 dB (SPL)

102 / 90 dB

300 Hz to 9 kHz

119° / 38°

667 ohm (7,5 W at 70 V / 15 W at

100 V)

1333 ohm (3,75 W at 70 V / 7,5 W at

100 V)

2667 ohm (1,87 W at 70 V / 3,75 W at

100 V)

5347 ohm (1,87 W at 100 V)

* Technical performance data acc. to IEC 60268‑5

Type approval certified According to EN 60945

Page 4

0560

Bosch Security Systems BV

Torenallee 49, 5617BA Eindhoven, The Netherlands

0560-CPR-142190008

EN 54-24:2008

Loudspeaker for voice alarm systems

for fire detection and fire alarm systems for buildings

Horn Loudspeaker 15W

LH2-UC15E

Type B

4 | LH2-UC15E Horn loudspeaker, 15W, marine

Represented by:

Europe, Middle East, Africa: Germany: North America: Asia-Pacific:

Bosch Security Systems B.V.

P.O. Box 80002

5600 JB Eindhoven, The Netherlands

Phone: + 31 40 2577 284

emea.securitysystems@bosch.com

emea.boschsecurity.com

Bosch Sicherheitssysteme GmbH

Robert-Bosch-Ring 5

85630 Grasbrunn

Germany

www.boschsecurity.com

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, New York, 14450, USA

Phone: +1 800 289 0096

Fax: +1 585 223 9180

onlinehelp@us.bosch.com

www.boschsecurity.us

Robert Bosch (SEA) Pte Ltd, Security Systems

11 Bishan Street 21

Singapore 573943

Phone: +65 6571 2808

Fax: +65 6571 2699

apr.securitysystems@bosch.com

www.boschsecurity.asia

© Bosch Security Systems 2017 | Data subject to change without notice

17958502155 | en, V8, 07. Nov 2017

Mechanical

Dimensions (L x D max) 302 x 212 mm

(11.89 x 8.35 in)

Weight 2.25 kg (4.96 lb)

Color Light grey (RAL 7035)

Material horn Glass Reinforced Polyester (GRP)

Material mounting bracket Stainless steel (grade 316)

Cable diameter 6 mm to 12 mm (0.24 in to 0.47 in)

Environmental

Operating temperature -55 ºC to +70 ºC (-67 ºF to +158 ºF)

Storage and transport

-40 ºC to +70 ºC (-40 ºF to +158 ºF)

temperature

Relative humidity <95%

Ordering information

LH2-UC15E Horn loudspeaker, 15W, marine

Horn Loudspeaker 22.5 W, Glass Reinforced Polyester

(GRP) IP 67 housing, high‑quality speech and music

reproduction, IP67 water and dust protected, salt mist

and chlorine resistant, EN 60945 and EN54‑24

certified, light grey RAL7035.

Order number LH2-UC15E

Loading...

Loading...