Page 1

KTS 200

d e

Betriebsanleitung

Systemtester für die Steuergeräte-Di-

a gn o se

e n

Instruc tio n m anual

System tester fo r c o n tro l un it dia gn o -

sis

f r

Instruc tio ns d ‘em p lo i

T esteur systè me p o ur dia gn o stic des

c en tra les de c o mma n de

e s

Instruc c io nes d e m anejo

C o mp ro b a do r del sistema p a ra dia gn ó -

stic o de un ida des de c o n tro l

it

M anuale d ‘istruz io ni

T ester di sistema p er la dia gn o si delle

c en tra lin e di c o ma n do

s v

Bruk sanvisning

Systemtester fö r styrdo n sdia gn o s

p t

M anual d e serviç o

A p a relh o de teste do sistema p a ra a

dia gn o se de un ida des de c o ma n do

p l

Instruk c ja o bstugi

tester systemu do dia gn o styk i stero w -

n ik ó w

c s

N á v o d k o bsluz e

Systé mo v ý tester p ro dia gn o stik u

rídic íc h jedn o tek

t r

K ullanm a talim ati

K o n tro l ün iteleri a riz a tesh is islemi iç in

sistem test c ih a z i

Page 2

Bosch Diagnostics 1 689 989 001 2007-05-30|

Contents | KTS 200 | 15 | 15

1. Symbols Used 16

2. User instructions 16

2.1 Important notes 16

2.2 Safety instructions 16

2.3 Disposal 16

2.4 Electromagnetic compatibility (EMC) 16

2.5 Open Source software 16

3. Product description 17

3.1 Application 17

3.2 Requirements 17

3.2.1 Hardware 17

3.2.2 Software 17

3.3 Delivery specification 17

3.4 Special accessories 17

3.5 Device description 18

3.6 Selection and function keys 18

3.7 Wall bracket 19

4. Initial startup 19

4.1 Connection 19

4.2 Licensing with ESI[tronic] Startcenter 19

4.2.1 Installing ESI[tronic]

Startcenter from DVD 19

4.2.2 Starting the KTS 200 20

4.2.3 Licensing the KTS 200 by fax 21

4.2.4 Performing KTS 200 fax licensing 21

4.2.5 Online KTS 200 licensing 21

5. Operation 23

5.1 Connection to the vehicle 23

5.2 Turning on 23

5.3 Turning off 23

5.4 Program description 23

5.5 Software update 24

5.5.1 Software update using

the ESI[tronic] Startcenter DVD 24

5.5.2 Online software update 24

5.6 Faults 24

6. Maintenance 25

6.1 Cleaning 25

6.2 Spare and wearing parts 25

7. Technical data 25

7.1 General data 25

7.2 Interface protocols 25

7.3 Power pack 25

en

Contents

Page 3

Bosch Diagnostics1 689 989 001 2007-05-30|

16 | KTS 200 | Symbols Used

1. Symbols Used

Pictograms linked with the key words Danger, Warning

and Caution are warnings and always indicate an immediate or potential hazard to the user.

Danger

Immediate danger that could cause serious

personal injury or death.

Warning

Potentially dangerous situation that could

cause serious personal injury or death.

Caution

Potentially dangerous situation that could

cause personal injury or damage to property.

Important – warns of a potentially hazardous situation in which the product, the test sample or other

object in the vicinity could be damaged.

In addition to these warnings, the following symbols are

also used:

Info – In addition to these warnings, the following

symbols are also used.

Single-step procedure – instructions for a procedure

that can be completed in just one step.

Intermediate result – an intermediate r esult is

displayed during a procedure.

Final result – the final result is displayed at the end

of the procedure.

0

¶

?

G

2. User instructions

2.1 Important notes

Important notes on the agreement pertaining to copyright, liability and warranty, about the user group and

obligation on the part of the contractor, are available

in the separate instructions entitled "Important notes"Important notesImportant notes

and safety instructions on Bosch Test Equipment".Bosch Test Equipment"..

These are to be read thoroughly before using, connecting and operating the product and they must be

observed.

2.2 Safety instructions

All safety instructions are available in the separate instructions "Important notes and safety instructions“ on"Important notes and safety instructions“ onImportant notes and safety instructions“ on

Bosch Test Equipment". These are to be read thorough-. These are to be read thoroughly before using, connecting and operating the product

and they must be observed.

2.3 Disposal

This product is subject to European guidelines 2002/96/EG (WEEE).

Old electrical and electronic devices, including

cables and accessories or batteries must be

disposed of separate to household waste.

Please use the return and collection systems in place for disposal in your area.

Damage to the environment and hazards to

personal health are prevented by properly

disposing of old equipment.

¶

¶

2.4 Electromagnetic compatibility (EMC)

This product is a product of Class A as under

EN 61 326.

This product can cause radio interference in the

home; in this case the operator may be asked to

implement appropriate measures.

0

2.5 Open Source software

An overview of the Open Source software licenses for

the KTS 200 is available on the "ESI[tronic] Startcenter"

DVD as an Adobe PDF document.

en

Page 4

Bosch Diagnostics

1 689 989 001 2007-05-30|

Product description | KTS 200 | 17 | 17

3. Product description

3.1 Application

The KTS 200 is a system tester for control unit diagnosis

in vehicle workshops. The KTS 200 features licensed

control unit diagnosis software and has the following

functions:

Error memory reading

Actual value display

Actuator initiation

Use of control unit specific functions

The KTS 200 is a precision device and must not be

exposed to the effects of heat (e.g. direct sunlight),

impacts or vibration, magnetic fields or excessive

levels of dirt.

3.2 Requirements

3.2.1 Hardware

To license the KTS 200 ESI[tronic] software and perform the software update for KTS 200 control unit

diagnostics, a PC/laptop with the operating system

WIN 2000, WIN XP (SP2) or WIN Vista and at least one

free USB port is required. The USB port must support

the USB 2.0 protocol – USB 1.x protocols are not supported.

To license the KTS 200 ESI[tronic] software and update

the KTS 200 control unit diagnosis software, a PC/laptop

with the WIN XP or Windows Vista operating system and

at least one free USB port is required.

The KTS 200 may not be opened. Opening the

KTS 200 erases its licensing data. It is then no longer

possible to perform control unit diagnosis.

3.2.2 Software

The control unit diagnosis software on the KTS 200 must

be activated using the ESI[tronic] software license key.

R

R

R

R

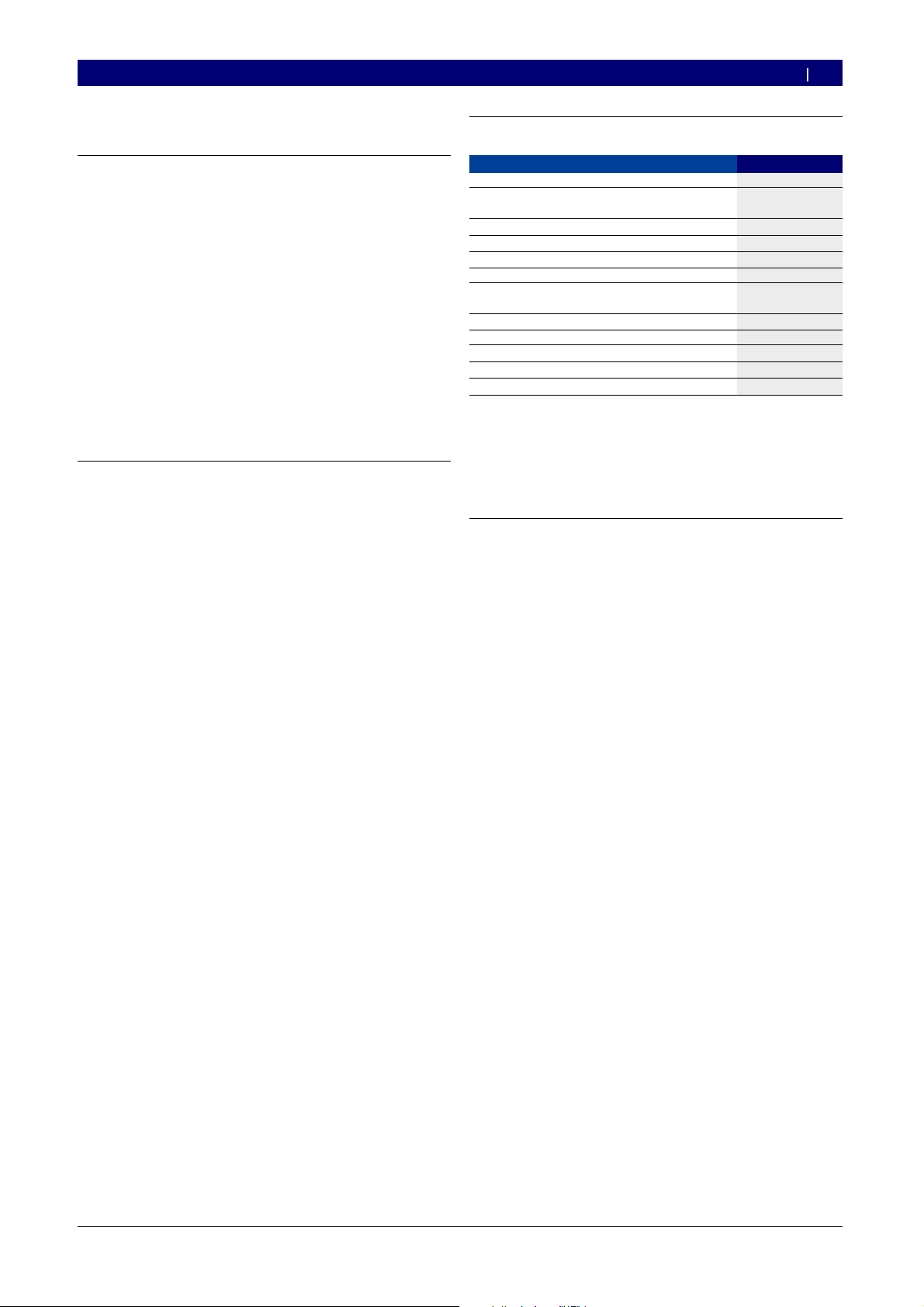

3.3 Delivery specification

Description Order number

KTS 200

Power pack

Power supply lead

1 687 022 889

1 684 461 106

USB connecting lead, 1 m 1 684 465 491

OBD diagnostic lead, 1.5 m 1 684 465 555

DVD ESI[tronic] Startcenter 1 987 P12 005

Case 1 685 438 019

Connecting lead for

cigarette lighter socket (12 V)

1 684 465 584

Important information and safety instructions 1 689 979 922

KTS 200 operating instructions 1 689 989 001

Set of leads

<)

1 687 001 855

Set of leads

<)

1 687 001 875

Wall bracket

<)

1 681 320 082

<)

In some cases, special accessory only

Always store the KTS 200 and accessories in the

case when not in use.

3.4 Special accessories

Information on special accessories, such as vehiclespecific connecting leads, can be obtained from your

authorized Bosch dealer.

en

Page 5

Bosch Diagnostics1 689 989 001 2007-05-30|

18 | KTS 200 | Product description

3.5 Device description

The KTS 200 is a modular, portable diagnostic system

for control unit diagnosis that can be used anywhere.

The KTS 200 contains a computer unit with memory

card and a 3.5 inch LCD display. The KTS 200 control

unit diagnosis software is pre-installed on the memory

card in the factory.

The selection and function keys located next to the LCD

display are used to operate the unit.

The KTS 200 and the accessories are housed in a

protective case.

US

B

15V

D

C

KTS

200

Pow

ered by

ESI

[tronic]

B

O

S

C

H

459804/5K

o

1

4

6

5

4

3

2

3

Fig. 1: KTS 200

1 OBD diagnostic lead connection

2 LCD display

3 Selection keys

4 Function keys

5 Power pack connection

6 USB connection

3.6 Selection and function keys

The selection and function keys are assigned various

functions in the control unit diagnosis software. The

functions of the keys are specified in the soft key bar in

the control unit diagnosis software at each step in the

program.

The selection keys with the left and right arrow symbols

allow you to open and close selection lists.

The selection keys with the up and down arrow symbols

allow you to select one of the options in an open selection list (holding down a selection key automatically

scrolls through the options).

The selection keys located to the right and left of the

LCD display perform the same functions.

0

en

Page 6

Bosch Diagnostics 1 689 989 001 2007-05-30|

Product description | KTS 200 | 19 | 19

4. Initial startup

4.1 Connection

Before starting up for the first time, make sure that

the mains voltage matches the voltage specified on the

power pack (use power supply lead supplied).

The German power supply lead is included with

the unit.

4.2 Licensing with ESI[tronic]

Startcenter

Before you can use the KTS 200 to perform control unit

diagnosis, you must install the “ESI[tronic] Startcenter”

software on a PC/laptop and then license the KTS 200.

Do not connect the KTS 200 to the PC/laptop until

prompted to do so during the installation routine.

4.2.1 Installing ESI[tronic] Startcenter from DVD

Procedure:

Insert the “ESI[tronic] Startcenter” DVD in the DVD

drive (e.g. “D:\”) on the PC/laptop.

Open the “Run” input window (select “Start >>

Run...” in the taskbar).

Enter D:\setup.exe and confirm by

clicking <OK>.

The Setup routine is started.

4. Select the installation language and confirm

with <OK>.

The installation language selected will also be the

language used in ESI[tronic] Startcenter.

5. Follow the installation instructions on the screen.

In the “Country selection” installation menu, you

must select the country in which the KTS 200 will

be operated.

0

1.

2.

3.

?

0

0

3.7 Wall bracket

The KTS 200 can be hooked onto the wall bracket

(special accessory in some cases) for storage.

Attach the wall bracket at the desired location using

the 2 screw anchors and 2 wood screws supplied.

4598044

K

TS

2

00

P

o

w

er

edb

y

ESI

[

troni

c]

B

O

S

C

H

33 mm

Fig. 2: Wall bracket assembly

¶

en

Page 7

Bosch Diagnostics1 689 989 001 2007-05-30|

20 | KTS 200 | Initial startup

The first time you connect the KTS 200 to the

PC/laptop, the USB driver installation in the Windows operating system must not be carried out. The

ESI[tronic] Startcenter installation routine automatically installs the USB driver that enables the KTS 200

to communicate with the PC/laptop.

If the Adobe Reader software is not yet installed on

the PC/laptop, it will be installed at the end of the

ESI[tronic] Startcenter installation routine. Adobe

Reader is required to display the logs from KTS 200

control unit diagnosis on the PC/laptop.

6. When installation is complete, restart the computer.

Windows is shut down and ESI[tronic]

Startcenter is restarted.

7. License the KTS 200 either by fax or online.

The “Help >> Help” menu opens up the online help.

Here, you will find all of the important information

about ESI[tronic] Startcenter.

0

?

0

4.2.2 Starting the KTS 200

Connect the KTS 200 to the mains using the power

pack supplied.

The KTS 200 starts up.

When turned on for the first time, the KTS 200

always starts in English.

If you want to use an alternative language on the

KTS 200, select it under “Menu >> Settings >>

Language”.

Connect the KTS 200 to the PC using the USB

connecting lead.

The KTS 200 waits for licensing to be completed.

1.

?

0

2.

3.

?

en

Page 8

Bosch Diagnostics 1 689 989 001 2007-05-30|

Initial startup | KTS 200 | 21 | 21

4.2.3 Licensing the KTS 200 by fax

In Startcenter, select “Licensing >> Fax” in the

menu.

The “License request” input window is opened.

Step 1: Enter your company data.

Step 2: Select the country for the license request.

Step 3: Enter the ID number and print out the

licensing form.

Sign the licensing form and return it by fax.

4.2.4 Performing KTS 200 fax licensing

Once you have received the license key by fax, you need

to perform the actual licensing.

Connect the KTS 200 to the mains using the power

pack supplied.

The KTS 200 starts up.

Connect the KTS 200 to the PC using the USB

connecting lead.

In Startcenter, click on “Licensing >> Perform

licensing” in the menu.

The “Perform license request” input window

is opened.

Enter the customer number, ID number and

license key.

Perform licensing.

The license key is transferred.

If licensing is successful, the KTS 200 is

restarted.

The KTS 200 is now licensed and you can perform

control unit diagnosis.

1.

?

2.

3.

4.

5.

1.

?

2.

3.

?

4.

5.

?

?

G

4.2.5 Online KTS 200 licensing

Online licensing can only be performed on a PC with

Internet access.

Connect the KTS 200 to the mains using the power

pack supplied.

The KTS 200 starts up.

Connect the KTS 200 to the PC using the USB

connecting lead.

In Startcenter, select “Licensing >> Online” in the

menu.

The “Online” input window is opened.

Step 1: Enter the customer number / password and

select <Login>.

The Internet connection for online licensing is

established.

If “Login” is not possible, check your proxy

settings under “Settings >> User settings”.

1.

?

2.

3.

?

4.

?

0

en

Page 9

Bosch Diagnostics1 689 989 001 2007-05-30|

22 | KTS 200 | Initial startup

Step 2: Select the contract ID and then select

<Generate>.

The license key is requested.

The request for the license key can take several

seconds.

While the license key is being transferred, the

USB connection and the power supply to the

KTS 200 may not be broken.

<Select <Execute>.

The license key is transferred to the KTS 200.

If licensing is successful, the KTS 200 is

restarted.

5.

?

0

6.

?

?

The KTS 200 is now licensed and you can perform

control unit diagnosis.

G

en

Page 10

Bosch Diagnostics 1 689 989 001 2007-05-30|

Operation | KTS 200 | 23 | 23

5. Operation

5.1 Connection to the vehicle

The KTS 200 is designed for operation on a vehicle

with a battery voltage of 12 Volts and 24 Volts.

Make sure that the OBD diagnostic lead is correctly

plugged into the KTS 200 and securely screwed

in. If incorrectly plugged in, the pins on the male

connector may bend or be broken off. Only use the

OBD diagnostic lead supplied.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

3

5

2

U

SB

15VD

C

KTS 20

0

Pow

e

red by ESI[

tronic]

B

O

S

C

H

459804/3Ko

4

6

7

Fig. 3: KTS 200 connection schematic

1 OBD diagnostic socket in vehicle

2 OBD diagnostic lead

3 UNI connecting lead (special accessory)

4 KTS 200

5 Power pack

6 Connecting lead for cigarette lighter socket

7 USB connecting lead

When placing the KTS 200 on the steering

wheel, there is a risk of injury due to

triggering of the airbag.

The connection to the diagnostic interface in the

vehicle is made via

the OBD diagnostic lead (Fig. 3, item 2) or

the OBD diagnostic lead and also the UNI connecting

lead (Fig. 3, item 3; special accessory) or

the OBD diagnostic lead and a vehicle-specific

adapter lead (special accessory) or

a vehicle-specific adapter lead (special accessory).

5.2 Turning on

The KTS 200 is normally supplied with power by the

OBD diagnostic socket in the vehicle. If the position of

the OBD diagnostic socket in the vehicle is not known,

we recommend connecting the KTS 200 to the cigarette

lighter socket using the connecting lead and searching

for the OBD diagnostic socket using the KTS 200

control unit diagnosis software.

On some vehicles, the cigarette lighter socket only

supplies power when the ignition is turned on.

In test steps that require the engine to be started,

the battery voltage may drop to a point at which the

supply from the vehicle is no longer guaranteed. In

these cases, it may be necessary to use the power

pack to supply the KTS 200 with power.

On some vehicles, the power supply may only be

present on the OBD interface when the ignition has

been turned on.

If the KTS 200 is connected to a PC/laptop using the

USB connecting lead, the KTS 200 power supply must

come from the power pack supplied.

5.3 Turning off

The KTS 200 is always turned off when the OBD

diagnostic lead, the power pack or the connecting lead

for the cigarette lighter socket are not connected.

5.4 Program description

The online help for the KTS 200 control unit diagnosis software is opened under “Menu >> Help” in the soft key bar.

Basic information about the KTS 200 and ESI[tronic]

Startcenter can be found under “ESI[tronic] trainer” in

the ESI[tronic] Startcenter software.

R

R

R

R

0

0

0

en

Page 11

Bosch Diagnostics1 689 989 001 2007-05-30|

24 | KTS 200 | Operation

5.5 Software update

The software update is either performed using the

“ESI[tronic] Startcenter” DVD or “online”.

The online software update (section 5.5.2) can only

be performed with ESI[tronic] Startcenter version

2007/3 or later.

5.5.1 Software update using the ESI[tronic]

Startcenter DVD

Insert the “ESI[tronic] Startcenter” DVD in the DVD

drive (e.g. “D:\”) on the PC/laptop.

Open the “Run” input field (select “Start >> Run...”

in the taskbar).

Enter D:\setup.exe and confirm by

clicking <OK>.

The Setup routine is started.

Follow the installation instructions on the screen.

When installation is complete, restart the computer.

Windows is shut down and ESI[tronic]

Startcenter is restarted.

Connect the KTS 200 to the PC using the USB connecting lead.

Connect the KTS 200 to the mains using the power

pack supplied.

The KTS 200 starts up.

During the software update, the USB connection

and the power supply to the KTS 200 may not be

broken.

ESI[tronic] Startcenter: Open “KTS 200 >> Device

information”.

Select an available update.

Select <Update>.

The system software is installed on the KTS 200.

0

1.

2.

3.

?

?

4.

?

5.

6.

?

7.

8.

9.

G

5.5.2 Online software update

Start “ESI[tronic] Startcenter”.

Open the “Settings >>Online updates” input

window.

Enter the customer number and password and

select <Next>.

If “Login” is not possible, check your proxy

settings under “Settings >> User settings”.

Select an available update and start the software

update.

Follow the installation instructions on the screen.

When installation is complete, restart the computer.

Windows is shut down and ESI[tronic]

Startcenter is restarted.

Connect the KTS 200 to the PC using the USB

connecting lead.

Connect the KTS 200 to the mains using the power

pack supplied.

The KTS 200 starts up.

During the software update, the USB connection

and the power supply to the KTS 200 may not

be broken.

ESI[tronic] Startcenter: “KTS 200 >> Device

information”.

Select an available update

Select <Update>.

The system software is installed on the KTS 200.

5.6 Faults

The KTS 200 may not be opened. Opening the

KTS 200 erases its licensing data. It is then no

longer possible to perform control unit diagnosis.

No communication with the control unit

The fault message “No system found” appears during

control unit diagnosis.

Possible causes What can you do?

Incorrect lead

connected.

Check whether the correct

lead has been used.

Incorrect pin selected

in pin selection menu

Under “Start >> Diagnostic socket”,

check which pin has to be used.

If problems of a different nature occur, please

contact the ESI[tronic] service hotline directly.

1.

2.

3.

0

4.

5.

6.

?

7.

8.

?

9.

10.

11.

G

0

en

Page 12

Bosch Diagnostics 1 689 989 001 2007-05-30|

Maintenance | KTS 200 | 25 | 25

6. Maintenance

6.1 Cleaning

The housing and the display on the KTS 200 may only

be cleaned with soft cloths and with neutral cleaning

agents. Do not use any abrasive cleaning agent or rough

cleaning cloths.

6.2 Spare and wearing parts

Description Order number

System tester KTS 200 (green) 1 687 023 279

System tester KTS 200 (blue) 1 687 023 428

System tester KTS 200 (gray) 1 687 023 429

Power pack

Power supply lead

(<)

1 687 023 889

1 684 461 106

USB connecting lead, 1 m

(<)

1 684 465 491

OBD diagnostic lead, 1.5 m

(<)

1 684 465 555

Wall bracket 1 681 320 082

(<)

Wearing parts

7. Technical data

7.1 General data

Property Value/Range

Operating voltage 7 VDC — 34 VDC

Power consumption approx. 7 Watt

LCD display 3,5"

320 * 240 Pixel

Dimensions (L x W x H) 140 x 220 x 40 mm

Weight (without connecting leads) 600 g

Operating temperature 5 °C – 40 °C

Relative humidity 90 % (at 25 °C)

Protection class IP 30

7.2 Interface protocols

The following interfaces and their associated protocols

are supported for control unit diagnosis in compliance

with ISO 15031:

ISO 9141-2 (communication lines K and L)

SAE J1850VPW und SAE J1850PWM

(communication lines BUS+ and BUS-)

CAN ISO 11898 ISO 15765-4 (OBD)

(communication lines CAN-H and CAN-L)

CAN Single Wire

CAN Low Speed

7.3 Power pack

Property Value/Range

Input voltage 90 VAC — 264 VAC

Input frequency 47 Hz — 63 Hz

Output voltage 15 V

Operating temperature 0 °C — 40 °C

R

R

R

R

R

en

Loading...

Loading...