Bosch HDI7132U, HGS232UC, HDS7062U, HDS256C, HDS255U User Manual

...

LP Conversion Manual

Bosch Range

Guide de conversion LP

Cuisinière Bosch

Manual de Conversión a Gas LP

Estufas Bosch

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Test the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Before Calling Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Questions?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

We look forward to hearing from you!

Safety

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

• Please read Installation Instructions before beginning the conversion

• Please read all instructions before proceeding. Save the natural gas parts for

possible conversion from LP back to natural gas in the future

• This kit is used to convert dual fuel ranges and gas ranges from natural gas

operation to propane (LP) gas operation. Only ranges manufactured by BSH

Home Appliances can be converted using this kit.

• CAUTION: When connecting the unit to the propane gas,make certain the

propane gas tank is equipped with its own high pressure regulator. In addition, the range has its own pressure regulator. Verfiy that it is installed for the

appropriate gas supply.

• The maximum gas pressure to this appliance is not to exceed 14.0 inches

water column from the propane gas tank regulator.

• The following must be met when testing supply piping system:

a) The appliance and its individual shut-off valve must be disconnected from

the gas supply piping system at test pressures in excess of 1/2 psig (3.5

kPa).

b) The appliance must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

• WARNING: This conversion kit shall be installed by a qualified service

agency in accordance with the manufacturer's instructions and all applicable

codes and requirements of the authority having jurisdiction. If the information

in these instructions is not followed exactly, a fire, explosion or production of

carbon monoxide may result causing property damage, personal injury or loss

of life. The qualified service agency is responsible for the proper installation of

this kit. The installation is not proper and complete until the operation of the

converted appliance is checked as specified in the manufacturer's instructions

supplied with the kit.

• For Massachusetts Installations:

1) Installation must be performed by a qualified or licensed contractor,

plumber or gas fitter qualified or licensed by the state, province or region

where this appliance is being installed.

2) Shut-off valve must be a "T" handle gas cock.

3) Flexible gas connector must not be longer than 36 inches.

• High Altitude Installation Note: This range is CSA certified for safe operation

up to an altitude of 10,000 ft. without any modifications (except LP conversion, when applicable).

English 1

Conversion

Before You Begin

Tools and Parts Needed • 7 mm Socket Driver w/ 3" extension

• Torx (T20)-head screwdriver

• Adjustable Wrench

• Flathead Screwdriver (1/8" or smaller)

• Phillips Head Screwdriver

Parts Included • Conversion Kit Instructions

• Conversion Sticker

• 4 LP Orifices

General Information

Always Provide Adequate Gas Supply

This appliance is shipped from the factory for use with natural gas. Use this kit to

convert the appliance for LP gas use if necessary. Observe the following:

Be sure the range is converted for use with the appropriate gas before using it.

This appliance is designed to operate at a pressure of 10" of water column when

used with LP gas.

When checking for proper operation of the regulator, the inlet pressure must be at

least 1" greater than the operating (manifold) pressure above. When converting

for LP gas use, the pressure supplied to the regulator must be between 11" and

14" of water column. See step 2 "Convert Pressure Regulator from 5" to 10"

W.C.", next page.

The pressure regulator located in the inlet of the range manifold must remain in

the supply line.

Use a flexible metal appliance connector or rigid pipe to connect the Range to the

gas supply. The connector should have an I.D. of 1/2" and be 5' in length (Exception: Maximum connector length in Massachusetts installations is 3'). In Canada,

the connector must be single wall metal and not longer than 6'.

Preparation CAUTION: Turn off Gas and Electricity

Procedure

English 2

Before proceeding with the conversion; shut off the gas supply to the appliance

prior to disconnecting the electrical power.

1. Turn all control knobs to the "OFF" position.

2. Shut off the outside propane tank gas valve to the range.

3. Remove range power cord from electrical outlet or turn breaker off at breaker box

Conversion

r

Convert Pressure Regulator from 5" W.C. to 10"

W.C.

1. Remove Warming Drawer; Pull drawer out until stop is reached. Facing the range, push clip on left side up and clip on right side down. Pull drawer the rest of the way out.

2. Remove cover plate from interior back wall by removing single screw on left side of panel. Use a torx T-20 head screwdriver.

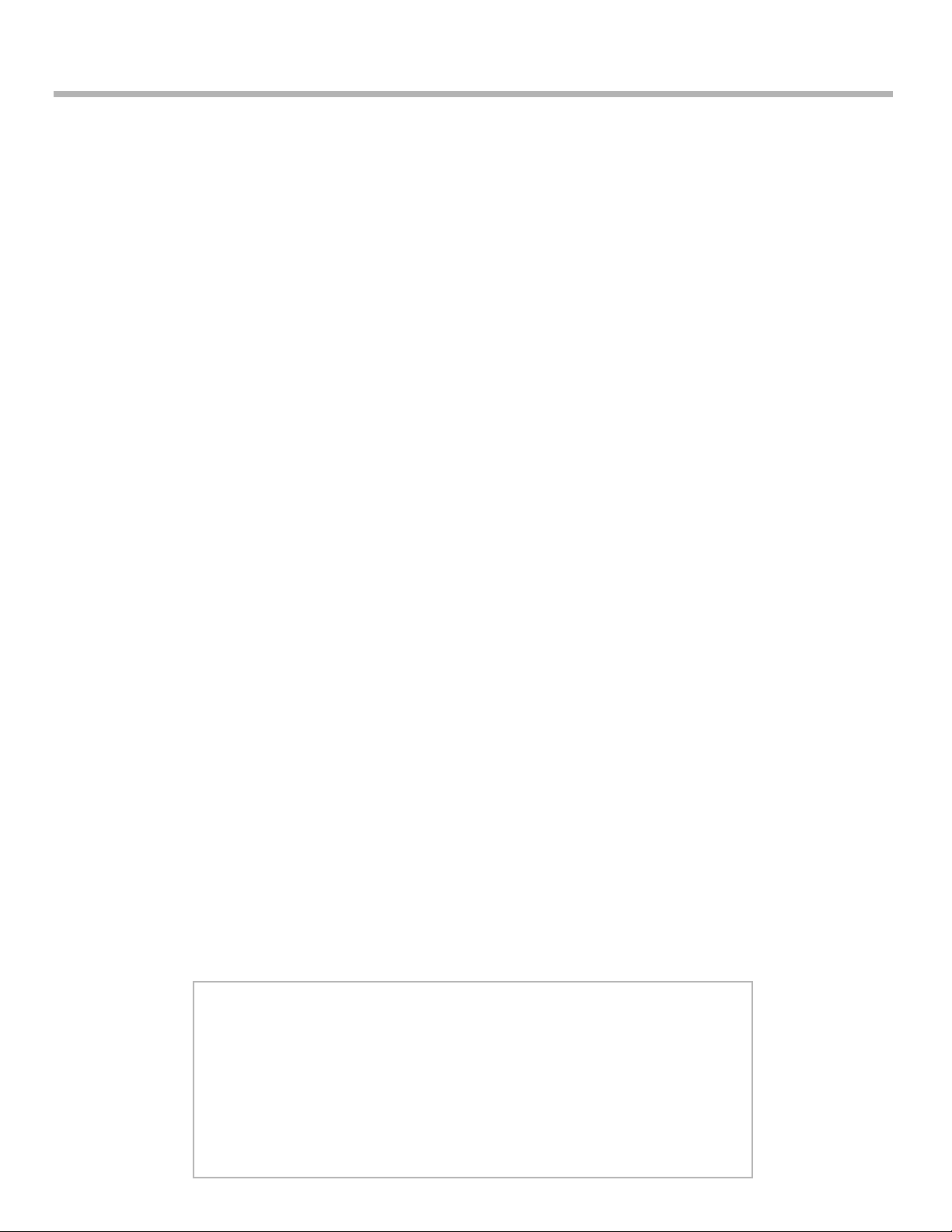

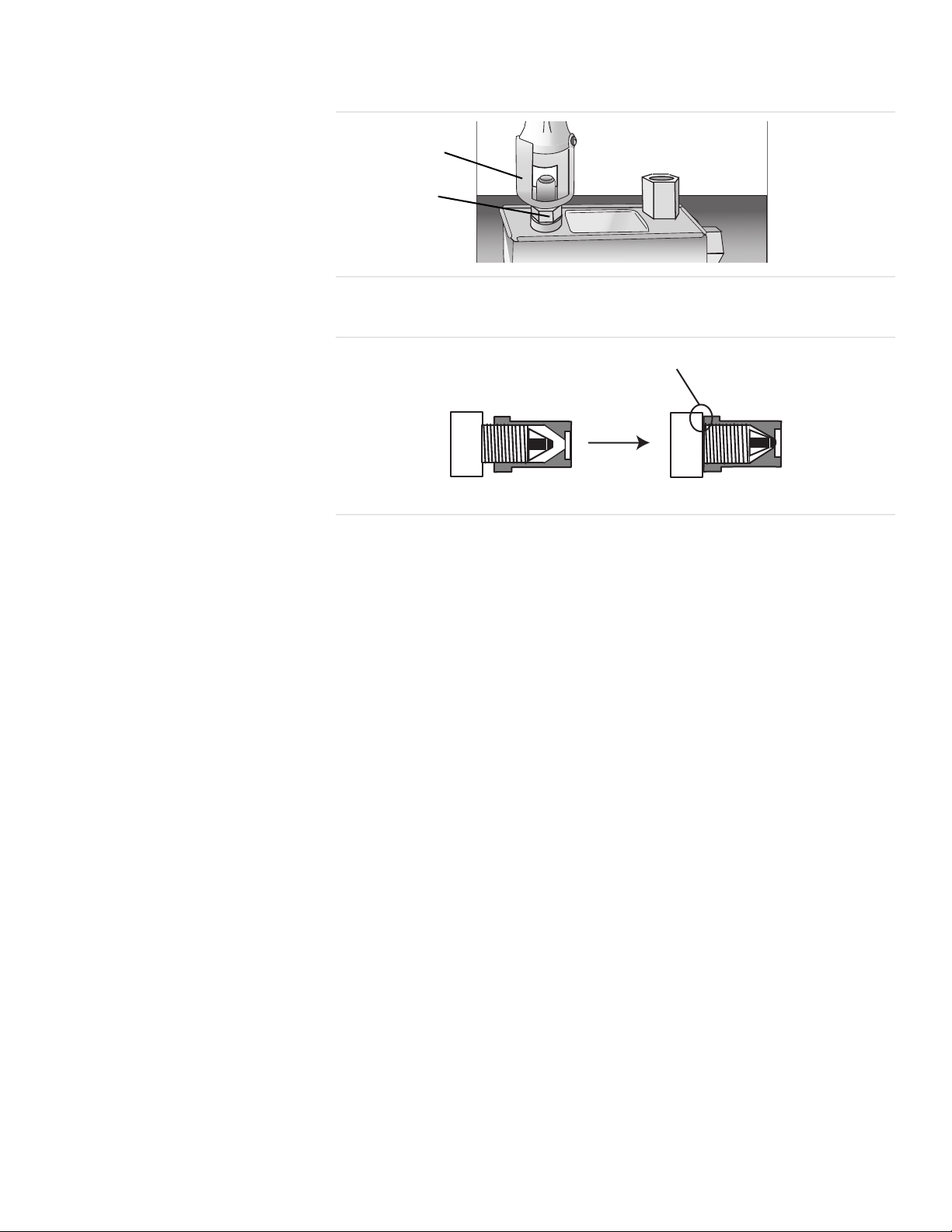

3. Remove the hexagon cap from the top of the regulator with an adjustable wrench.

4. Pop out the plastic stem in the cap and turn it over pressing it firmly in place so that the letters "LP" (rather than "NAT") are seen upright in the stem.

5. Replace the cap and button assembly into the top of the regulator sealing it

firmly. Make certain spring is still in place (See Fig. 1). DO NOT OVER

TIGHTEN.

Pin Position

for Propane

Hex

Cap

Pin

LP

LP

Spring

Hex

Cap

NAT

Pin

Position

for Nat.

Gas

NA

T

Pin

7. Fill out and affix the CONVERSION STICKER on the back side of the cover plate so that it appears on the back side of range next to the regulator.

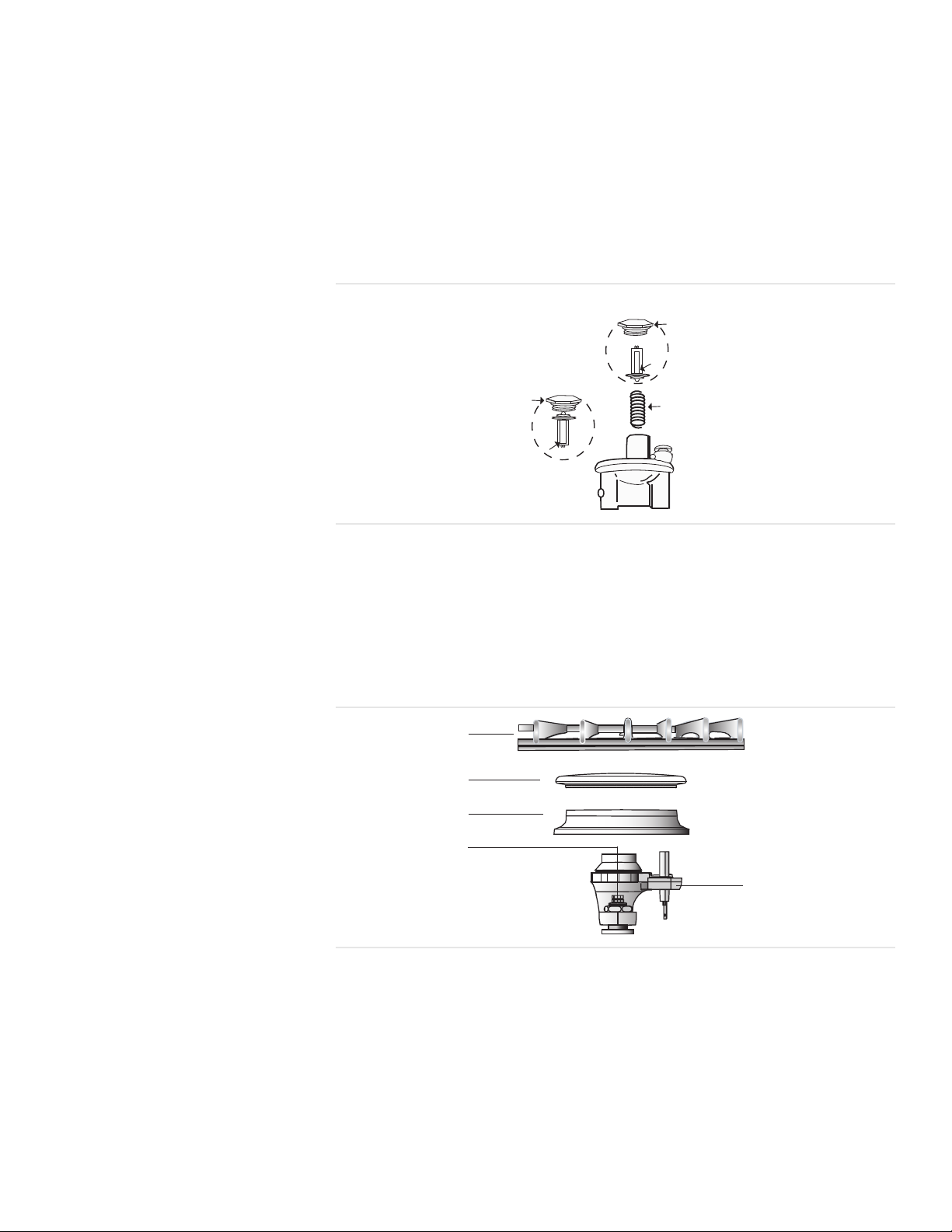

Replace Cooktop Orifices 1. Remove Grates, Burner Caps and Burner Bases.

Unscrew two (2) T20 screws inside each base and remove burner bases.

Reinsert screws in jet holder to hold tubing assembly in place.

Burner Grate

Burner Cap

Burner Base

Orifice

Figure 6: Pressure Regulator

Ignito

Figure 2: Cooktop Orifice

3. Remove Natural Gas Cooktop Orifices. Insert the socket driver with 3" minimum extension into the jet holders to remove existing orifices. Set natural gas orficies aside.

4. Assemble LP Cooktop Orifices.

Place in cooktop exactly as laid out in the orifice card. If the orifices become

separated from the card, placement can be determined by matching the number and/or color on the orifice with the placement specifications displayed in

the chart on the card

English 3

Conversion

5. Place the new orifice into the socket then insert each orifice into its respective threaded hole in the jet holder. Tighten until the orifice stops turning. DO NOT OVER TIGHTEN.

6. Remove screws to replace burner base, burner cap and burner grate. Replace screws. Note: Burner cap must be properly positioned on burner base for burner to light.

7. Place natural gas orifices in back of card for future conversion back to natural gas.

Convert Cooktop Valves for Propane Use

1. Verify that all knobs are in the OFF position

2. Remove knobs (pull straight out)

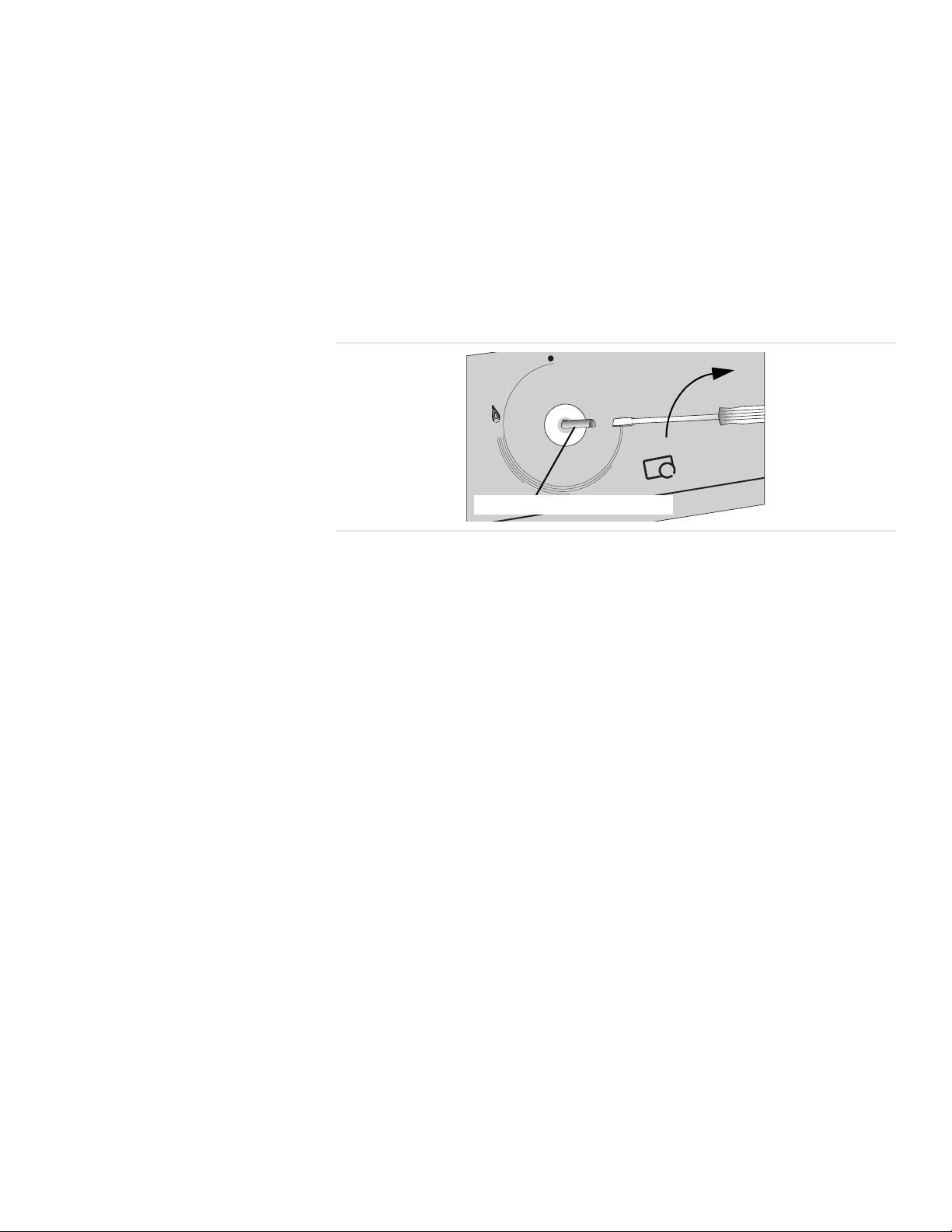

3. Insert 1/8” (or smaller) flat head screwdriver into shaft and turn bypass screw

clockwise until it stops (bypass screw is inside shaft). DO NOT OVER-

TIGHTEN.

OFF

SIM

HI

LO

Bypass Screw Inside Shaft

Figure 4: Cooktop Valve Conversion

5. Replace knobs.

If your range is dual fuel your conversion is complete. Replace the cover

plate and warming drawer and proceed to “Test the Installation” on page 6.

For gas range conversions, continue to next step.

Adjust Broil Burner Orifice

1. Remove oven door (see section "Removing Oven Door" in Use and Care manual).

2. Remove Broil Burner Assembly. The broil burner assembly is attached to the

top of the oven cavity with 7 screws. Remove screws and gently pull broil

burner assembly straight out being careful not to detach electrical wires.

Place broil burner against back wall of oven cavity.

3. Adjust Broil Orifice. The orifice is located behind the broil burner in the back

oven wall (See Figure 5). Use a 1/2" deep socket driver with 3" minimum

English 4

Conversion

extension to turn orifice clockwise until it stops (2- 2 1/2 turns). DO NOT

OVERTIGHTEN.

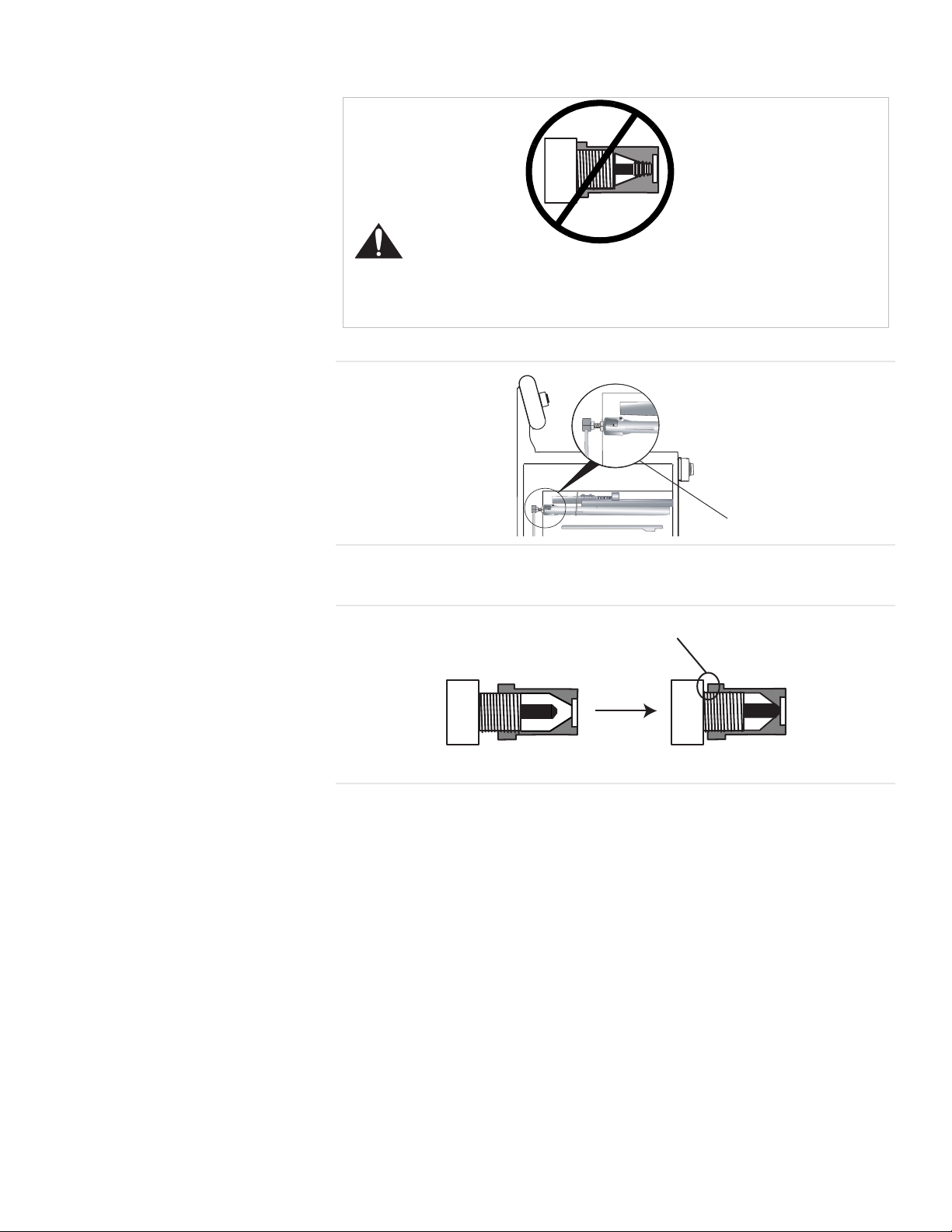

CAUTION: DO NOT overtighten the broil burner orifice. Overtighten-

ing may result in damage to the pin inside the orifice. This affects cooking

performance. It could cause inconsistent flames and unintentional release of

carbon monoxide.

Adjust Bake Burner Orifice

Broil Orifice

Figure 4: Broil Orifice

Tightened, but not fully seated

Natural Gas Setting LP Gas Setting

Figure 5: Broil Orifice Conversion

6. Replace Broil Assembly. Replace broil assembly being careful to feed all wires through back wall of oven. Reinsert all 7 screws. Note: The air shutter on the broil burner fits over the orifice when installed correctly.

The bake burner orifice is located below the air shutter (See Figure 6). Reach it

through the access hole in the interior back panel of the warming drawer cavity.

English 5

Conversion

1. Use a 1/2" wrench to turn orifice clockwise until it stops (2 1/2 - 3 turns).

Unlike the broil burner orifice, the bake burner orifice should be tightened as

far as it will go in order to ensure that complete conversion has occurred.

Air Shutter

Bake Orifice

Figure 2: Bake Orifice

Fully seated

Natural Gas Setting LP Gas Setting

Figure 3: Bake Orifice Conversion

Test the Installation

Test for Gas Leaks Leak testing is to be conducted by the installer according to the instructions given

in this section.

Apply Leak Detection Fluid Turn on Gas. Apply a non-corrosive leak detection fluid to all joints and fittings in

the gas connection between the shutoff valve and the range. Include gas fittings

and joints in the range if connections may have been disturbed during installation.

Bubbles appearing around fittings and connections indicate a leak.

If a leak appears, turn off supply line gas shutoff valve and tighten connections.

Retest for leaks by turning on the supply line gas shutoff valve. When leak check

is complete (no bubbles appear), test is complete. Wipe off all detection fluid residue.

CAUTION: Never check for leaks with a flame.

Do not continue to the next step until all leaks are eliminated.

Test Electric Ignition Turn on power at breaker

Caution: If the display flashes and beeps, the polarity of the wiring may be

reversed. Reversed polarity can damage the range and can result in electrical

shock hazard. Immediately switch off power at the breaker and return to installation instructions.

Test Cooktop Burners: Each burner must be tested for proper lighting, proper flame characteristics on the

low setting and proper flame characteristics on the high setting.

Test for proper ignition:

English 6

Conversion

e

e

1. Push down and turn the knob to ignition symbol.

2. Verify that the ignitor/spark module clicks.

3. Once the air has been purged from the supply lines, verify that the burner lights within four (4) seconds. After burner lights, turn knob to the off position.

4. Test each rangetop burner in this fashion. Call Service if any of the burners do not light.

Test flame characteristics on the low setting:

1. Push in and turn the knob to the ignition symbol until the burner ignites.

2. Turn knob to the low setting.

3. Verify that the burner maintains a minimum, steady, flame without going out.

The flame should not lift or blow off of the burner. It should carry over, or surround, the entire burner.

4. Verify that the flame is the right color. It should be blue with an inner and outer cone. “Checking Flame Characteristics” on page 7 for more information.

5. Test each rangetop burner in this fashion. If any flame goes out, does not carry over properly or is too large, contact service.

Test flame characteristics on the high setting:

1. Push in and turn the knob to the ignitor symbol until the burner ignites.

2. Turn knob to the high setting.

3. Verify that the burner maintains a steady flame. The flame should not lift or blow off of the burner. It should carry over, or surround, the entire burner.

4. Verify that the flame is the right color. It should be blue with an inner and outer cone. See Figure 6: Checking Flame Characteristics for more information.

5. Test each rangetop burner in this fashion.

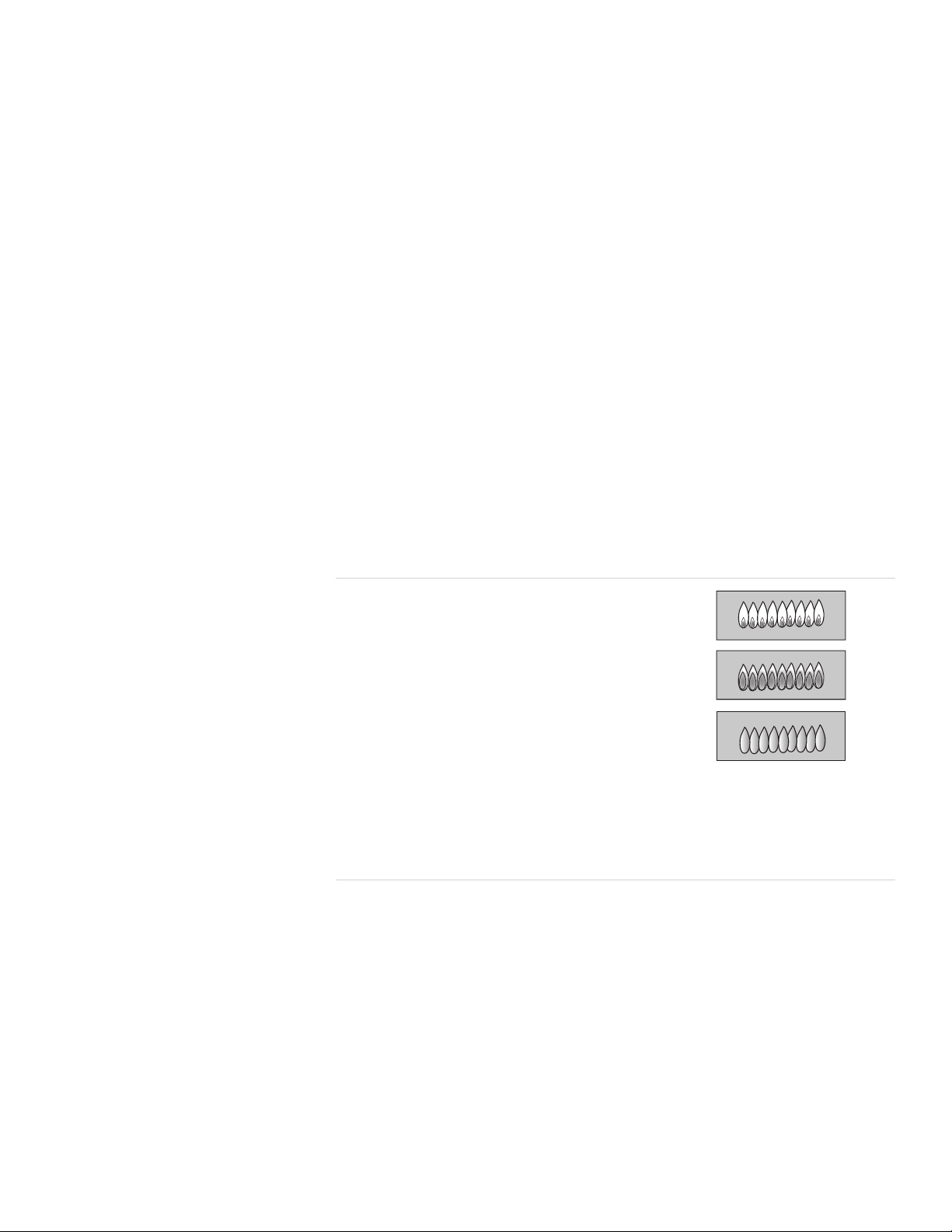

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow, verify that the regulator is set for th

correct fuel. After adjustment, retest.

Some yellow streaking is normal during the initial start-up. Allow unit to operat

4-5 minutes and re-evaluate.

Figure 6: Checking Flame Characteristics

If any flame does not carry over properly, adjust the bypass jet. Return to “Convert Cooktop Valves for Propane Use” on page 4. If any flame burns yellow, contact Service.

Dual Fuel appliance installation is complete when correct color, carryover

and size are verified on each cooktop burner.

For gas appliances, continue to “Test Broil Burner” on page 8

English 7

Conversion

Test Broil Burner

Test Ignition Set cooking mode to Hi Broil. The burner will ignite after 30-75 seconds.

Test Flame Verify that flame characteristics are as shown in “Checking Flame Characteristics”

on page 7. If flame characteristics are not consistent with those in the graphic

above, adjust the flame as describerd below. Otherwise, continue to “Test Bake

Burner” .

Adjust Broil Flame (if necessary)

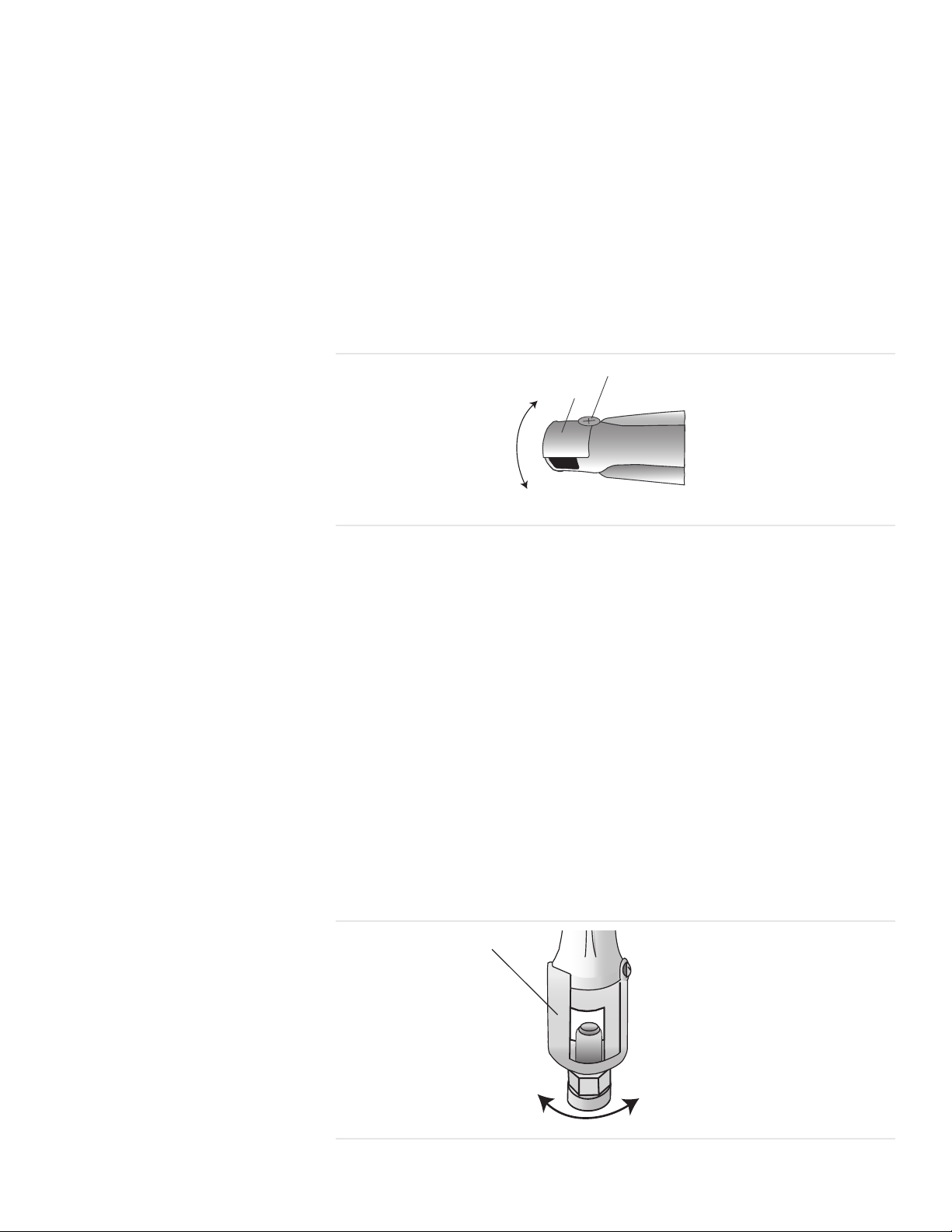

Adjust the air shutter to alter the flame characteristice. The air shutter is located

on the back end of the broil burner.

1. Loosen screw and turn shutter. Close the shutter if the flame is lifting or blowing or not carrying over; Open the shutter if it is too yellow. (See Figure 8).

Tighten screw.

Screw

More Open:

Less Yellow Flame

More Closed:

Less Blue Flame

More Carryover

Less Lifting or Blowing

Air

Shutter

Figure 2: Broil Burner Air Shutter

Test Bake Burner

Test Ignition Set the oven to bake at 350° F. After 30-75 seconds, the burner will ignite. The

burner will stay lit until the 350° F is reached and then shut off. From this point

forward, the burner will cycle on and off to maintain the temperature.

Test Flame Verify that flame characteristics are as shown in “Checking Flame Characteristics”

on page 7. If flame characteristics are not consistent with those in the graphic

above, adjust flame as described below.

Adjust Bake Flame (if necessary)

Adjust the air shutter to alter the flame characteristice. The oven burner air shutter

is located to the left of the oven regulator. Reach it through the access hole in the

interior back panel of the warming drawer

1. Loosen screw and turn shutter. Close the shutter if the flame is lifting or blowing or not carrying over; Open the shutter if it is too yellow. (See Figure 8).

Tighten screw.

Shutter

More Open:

Less Yellow Flame

Less Open:

Less Blue Flame

More Carryover

Less Lifting or Blowing

Figure 2: Broil Burner Air Shutter

English 8

Loading...

Loading...