Page 1

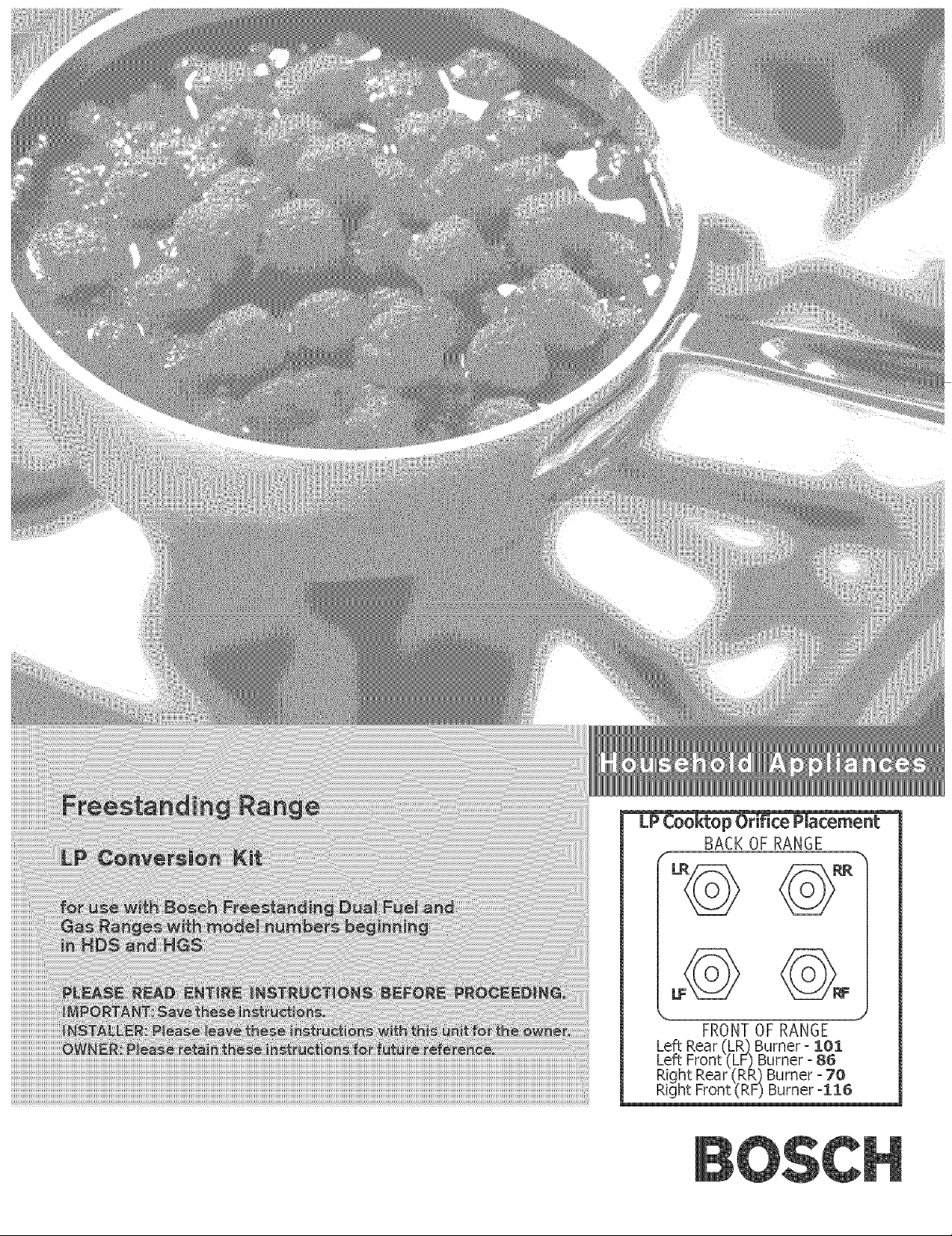

BACK OF RANGE

X

k_, j

FRONT OF RANGE

Left Rear (LR) Burner- IQI

Left Front (LF) Burner - 86

Right Rear (RR) Burner ° 70

Right Front (RF) Burner -116

Page 2

Page 3

Thiskitisusedto convertonlydualfuelranges(model# HDS252U,HDS255UandHDS256U)andgasranges(model#

HGS232UC,HGS236UC,HGS242UC,HGS245UC,HGS246UC,HGS247UC,HGS252UC,HGS255UC,HGS256UC),fromnaturalgas

operationtopropanegasoperation.ThiskitcannotbeusedtoconvertotherBoschmodelrangesorotherbrandranges.The

modelnumberonyourrangeisstampedontheplatebehindthewarmingorstoragedrawer.

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING. Savethe natural gas partsfor possibleconversion from LP

back to natural gas in the future.

PLFJ_E READ INSTALLA_ON INSII_UCT%ON$ BEFORE BE431NNINGTHE CONV£RSION.

This conversion kit shall be installed by a quali o

fled service agency in accordance with the

manufacturer's instructions and all applicable

codes and requirements of the authority having

jurisdiction, If the information in these instruc o

tions is not followed exactly, a fire, explosion

or production of carbon monoxide may result

causing property damage, personal injury or

loss of life, The qualified service agency is reo

sponsible for the proper installation of this kit,

The installation is not proper and complete uno

til the operation of the converted appliance is

checked as specified in the manufacturer's ino

structions supplied with the kit,

_J

High Altitude Installation:

For conversion in areas above 2,000 feet, contact Bosch

service for instructions: 800=944=2904.

f

_ CAUT][ON:

(!) When connecting theunit to the propane gas, make

certain the propane gas tank is equipped with its own

high pressure regulator. In addition, a pressure regulator

was supplied with the range. This second regulator must

be installed with the range. The maximum gas pressure

to this appliance is not to exceed :[4.0 inches water col=

umn from the propane gas tank regulator,

The following must be met when testing supply piping

system:

a) The appliance and its individual shut-off valve must

be disconnected from the gas supply piping system

at test pressures in excess of :[/2 psig (3.5 kPa).

b) The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-

off valve during any pressure testing of the gas sup-

ply piping system at test pressures equal to or less

than :[/2 psig (3.5 kPa).

F For Massachusetts Installations: "

:[.Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified

or licensed by the state, province or region where

this appliance is being installed.

2.Shut=off valve must be a "T" handle gas cock.

3.Flexible gas connector must not be longer than 36

inches.

Kit Contents,

Conversion Kit Instructions

Conversion Sticker

4 LPOrifices (:[=70/:[=86/:[=:[0:[/:[=:[:[6)

Tools Required:

7 mm Socket Driver wi 3" extension

Torx (T20)=head screwdriver

Adjustable Wrench

Flat:head Screwdriver (:[/8" or smaller)

Phillips Head Screwdriver

Always Provide Adequate Gas Supply

The Bosch Freestanding Dual Fuel and GasRanges are shipped

from the factory for use with natural gas. Use this kit to con=

vert the appliance for LPgas use if necessary.

, Be sure the range is converted for use with the appropri=

ate gas before using it.

, Your range is designed to operate at a pressure of :[0" of

water column when used with LPgas.

, When checking for proper operation of the regulator, the

inlet pressure must be at least :["greater than the operat=

ing (manifold) pressure above. When converting for LP

gas use, the pressure supplied to the regulator must be

between :[:[" and :[4" of water column. See step 2

"Convert Pressure to Regulator from 5" to :[0" W,C.",next

page.

, The pressure regulator located in the inlet of the range

manifold must remain in the supply line.

o Use a flexible metal appliance connector to connect the

range to the gas supply. The connector should have an

[.D. of :[/2" and be 5' in length. In Canada, the connector

must be single wall metal and no longer than 6:

Page 4

i, CAUTION: TurnoffGasand Emectridty

Before Proceedingwith the conversion;shut off

the{)assuppmytotheappliancepriortodiscono

nectingthe electricam power,

Shutofftheoutsidepropanetankgas valvetotherange,Re=

move range power cord from electrical outlet or turn breaker

off at breaker box, and turn all control knobs to the "OFF" posi=

tion.

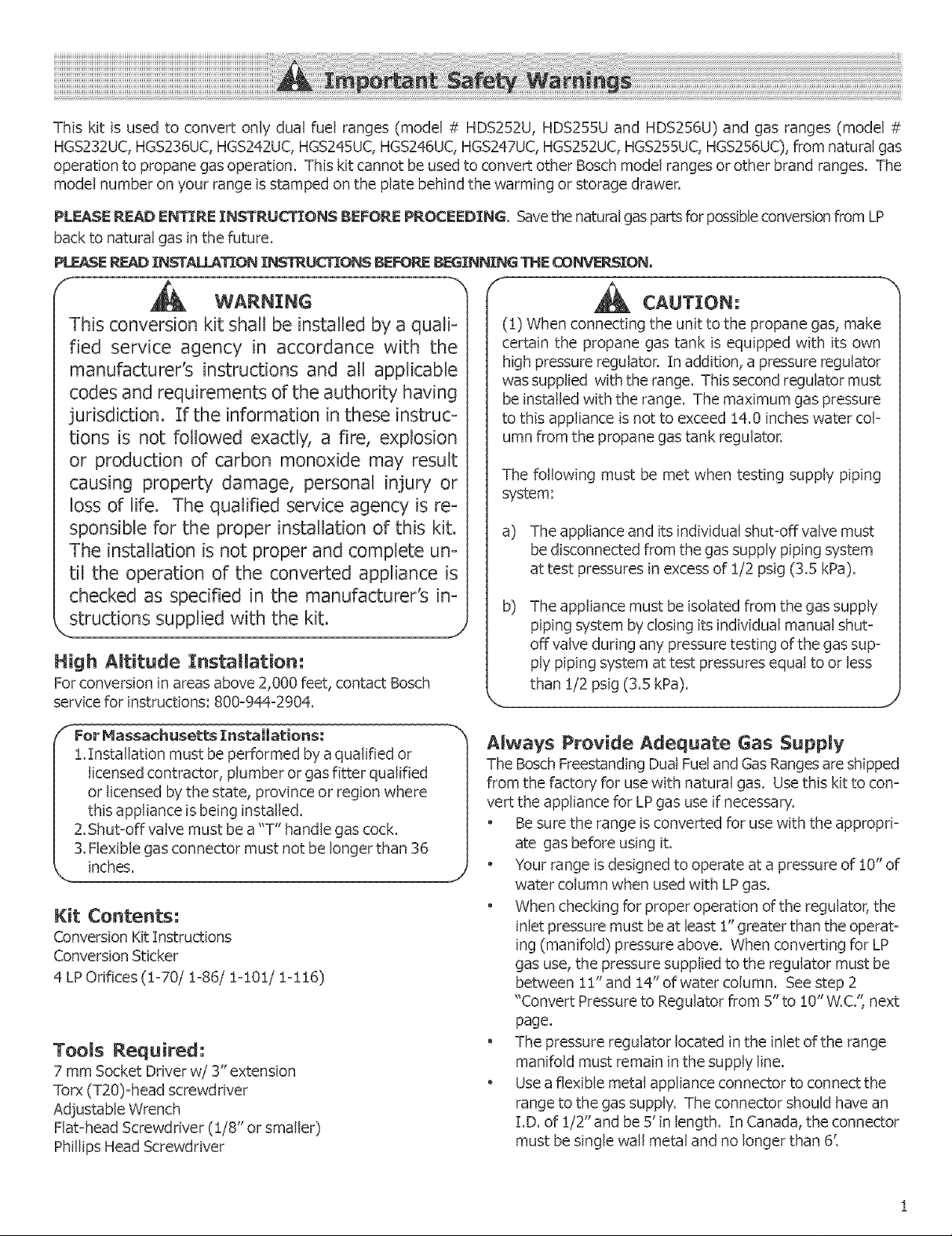

2° Convert Pressure Regulator from 5"

W°C° to 10" W°C°

!. Remove Warming Drawer; Pull drawer out until stop is

reached. Push clip on right side up and clip on left side

down. Pull drawer the rest of the way out.

Figure 1

Convert Pressure Regulator

Pin Position

for Propane

I

Pin \

Position

Gas

2, Remove cover plate from interior back wall by removing

single screw on left side of panel

3. Remove the hexagon cap from the top of the regulator

with an adjustable wrench.

4. Pop out the plastic stem in the cap and turn it over pressing

it firmly in place so that the letters"LP" can now be seen

upright in the stem, rather than "NAT".

5. Replace the cap and button assembly into the top of the

regulator sealing it firmly. Make certain spring is still in place

(See Fig. !). DO NOT OVERTORQUE.

6. Install the FOIL CONVERSIONSTICKERon the back side of

the cover plate so that it appears on the back side of range

next to the regulator,

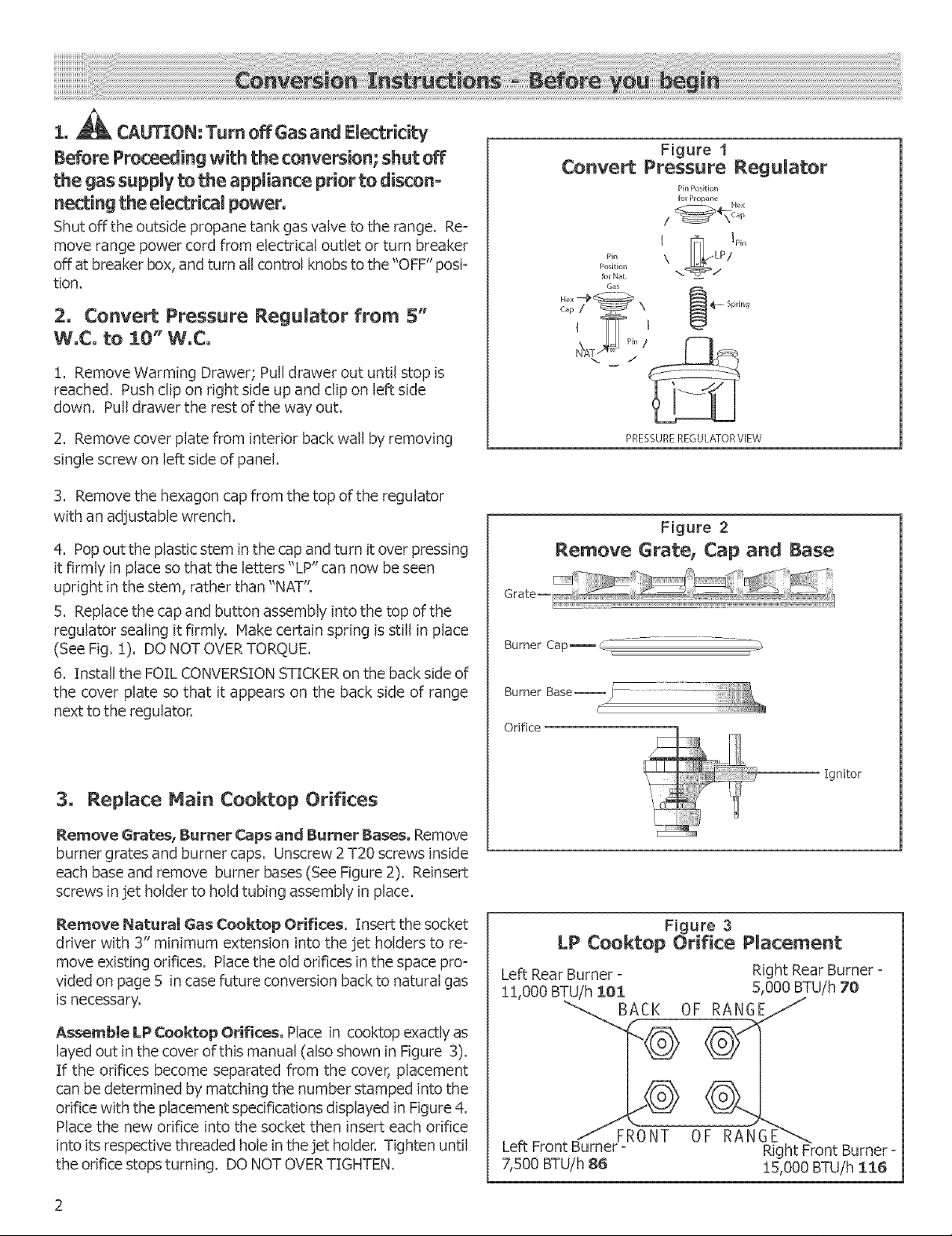

3, Repmace Main Cooktop Orifices

Remove Grates_ Burner Caps and Burner Bases, Remove

burnergratesand burnercaps,Unscrew 2 T20 screwsinside

each base and remove burner bases (See Figure 2). Reinsert

screws in jet holder to hold tubing assembly" in place.

PRESSUREREGULATORVIEW

Figure 2

Remove Grate, Cap and Base

Burner Cap_ d:

Burner Base--_)

Orifice

Remove NaturalGas Cooktop Orifices.Insertthesocket

driver with 3" minimum extension into the jet holders to re-

move existing orifices. Placethe old orifices in the space pro-

vided on page 5 in case future conversion back to natural gas

is necessary.

AssemMe LP Cooktop Orifices, Place in cooktop exactly as

layed out in the cover ofthB manual (also shown in Figure 3).

If the orifices become separated from the cover, placement

can be determined by matching the number stamped into the

orifice with the placement specifications displayed in Figure 4.

Place the new orifice into the socket then insert each orifice

into its respective threaded hole in the jet holder. Tighten until

the orifice stops turning. DO NOT OVERTIGHTEN.

Figure 3

LP Cooktop Orifice Placement

Left Rear Burner : Right Rear Burner :

! 1,000 BTUIh 101 5,000 BTU/h 70

Left Front B_N T 6_

Right Front Burner -

7,500 BTU/h 86 !5,000 BTUih I:_B

Page 5

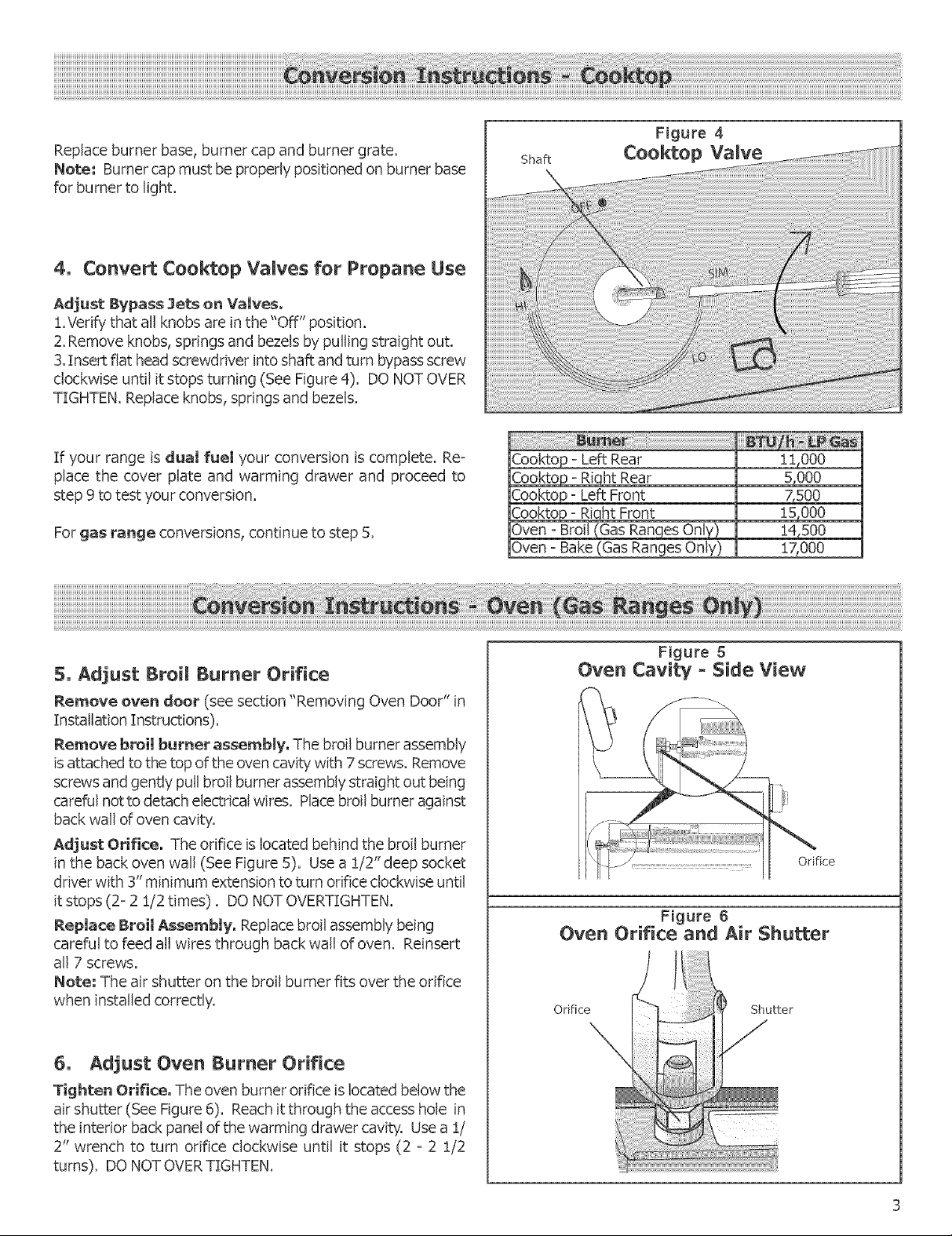

Replace burner base, burner cap and burner grate.

Note: Burner cap must be properly positioned on burner base

for burner to light.

4o Convert Cooktop Valves for Propane Use

Adjust Bypass Jets on Valves,

1.Verify that all knobs are in the "Off" position.

2.Remove knobs, springs and bezels by pulling straight out.

3.Insert flat head screwdriver into shaft and turn bypass screw

clockwise until it stops turning (See Figure 4). DO NOT OVER

TIGHTEN. Replace knobs, springs and bezels.

Shaft

Figure 4

Cooktop Valve

If your range is dual fuel your conversion is complete. Re-

place the cover plate and warming drawer and proceed to

step 9 to test your conversion.

For gas range conversions, continue to step5.

5° Adjust Broil Burner Orifice

Remove oven door (see section "Removing Oven Door" in

InstalJation Instructions).

Remove broil burner assembly. The broil burner assembly

isattached to the top of the oven cavity,with 7 screws. Remove

screws and gently pull broil burner assembly straight out being

careful notre detach electrical wires. Placebroil burner against

back wall of oven cavity.

Adjust Orifice, The orifice is located behind the broil burner

in the back oven wall (See Figure 5). Use a 1/2"deep socket

driver with 3" minimum extension to turn orifice clockwise until

it stops (2=2 1/2 times). DO NOT OVERTIGHTEN.

Replace Broil Assembly. Replace broil assembly being

careful to feed all wires through back wall of oven. Reinsert

all 7 screws.

Note; The air shutter on the broil burner fits over the orifice

when installed correctly.

Cooktop - Left Rear

Cooktop - Riqht Rear

Cooktop ° Left Front

Cooktop - Riqht Front

Oven - Broil (Gas Ranges Only')

Oven oBake (Gas Ranges Only)

Figure 5

Oven Cavity _ Side View

Figure 6

Oven Orifice and Air Shutter

Orifice Shutter

11,000

5,,000

7_500

15,000

14,500

17,000

Orifice

6. Adjust Oven Burner Orifice

Tighten Orifice, The oven burner orifice is located below the

air shutter (See Figure 6). Reach it through the access hole in

the interior back panel of the warming drawer cavity. Use a 1/

2" wrench to turn orifice clockwise until it stops (2 - 2 1/2

turns). DO NOT OVER TIGHTEN.

Page 6

7. Test for Gas Leaks.

Leak testing is to be conducted by the installer according to

the instructions given in this section,

Turn on supply line gas shut off valve, Apply a non-corrosive

leak detection fluid to all joints and fittings in the gas connec-

tion between the supply line shut-off valve and the range,

Include gas fittings and joints in the range if connections

were disturbed during installation. Bubbles appearing

around fittings and connections indicate a leak.

If a leak appears, turn off supply line gas shut-off valve and

tighten connections. Retest for leaks by turning on the

supply line gas shut-off valve. When leak check is complete

(no bubbles appear), test is complete. Wipe off all detection

fluid residue.

NEVERCHECKFOR LEAKSWITH A FLAHE. |

O NOT CONTINUE TO THE NEXTSTEPUNTIL ALL LEAKS I

AREELIHINATED. j/

8. Test Electric Ignition°

Test Cooktop Burner Ignition, Select a rangetop burner

knob. Push down and turn to the flame symbol. If the

ignitor/spark module is operating correctly, it will click. Once

the air has been purged from the supply lines, the burner

should light within four (4) seconds. After burner lights, turn

knob to the off position.

Test each rangetop burner in this fashion.

Test Broil Burner Ignition, Set cooking mode to Hi Broil.

The burner will ignite after 30-75 seconds.

Test Bake Burner Ignition, Set the oven to bake at 350°

R After 30-75 seconds, the burner will ignite. The burner

will stay lit until the 350° F is reached and then shut off.

From this point forward, the burner will cycle on and off to

maintain the temperature.

Call Bosch Service ([8OOo944o2gO4} if:

1, Any of the burners do not tight,

2. The broil burner or bake burner does not stay lit,

3. The bake burner does not cyde,

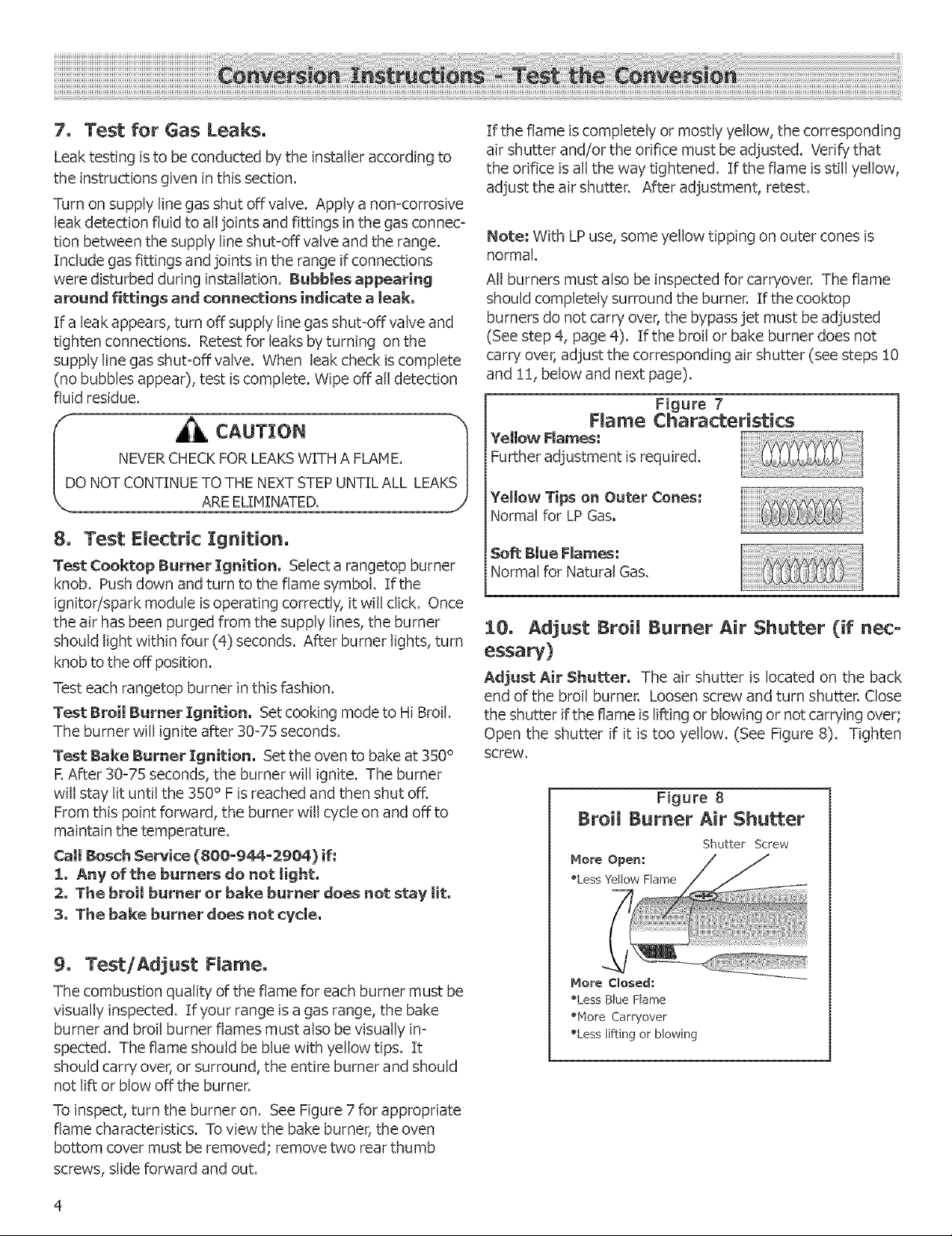

If the flame iscompletely or mostly yellow, the corresponding

air shutter and/or the orifice must be adjusted. Verify that

the orifice is all the way tightened. If the flame is still yellow,

adjust the air shutter. After adjustment, retest.

Note; With LP use, some yellow tipping on outer cones is

normal.

All burners must also be inspected for carryover. The flame

should completely surround the burner. If the cooktop

burners do not carry over, the bypass jet must be adjusted

(See step 4, page 4). If the broil or bake burner does not

carry"over, adjust the corresponding air shutter (see steps 10

and 11, below and next page).

Figure 7

Flame Characteristics

Yellow Haines:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft II}[ue Flames:

Normal for Natural Gas.

11}, Adjust l}roi[ Burner Air Shutter (if nec-

essary)

Adjust Air Shutter, The air shutter is located on the back

end of the broil burner. Loosen screw and turn shutter. Close

the shutter if the flame is lifting or blowing or not carrying over;

Open the shutter if it is too yellow. (See Figure 8). Tighten

SCreW.

Figure 8

Broil Burner Air Shutter

Shutter Screw

More Open:

%ess Yellow Flame

9. Test/Adjust Fmameo

The combustion quality of the flame for each burner must be

visually inspected. If your range is a gas range, the bake

burner and broil burner flames must also be visually in-

spected. The flame should be blue with yellow tips. It

should carry over, or surround, the entire burner and should

not lift or blow offthe burner.

To inspect, turn the burner on. See Figure 7 for appropriate

flame characteristics. To view the bake burner, the oven

bottom cover must be removed; remove two rear thumb

screws, slide forward and out.

More Closed:

%ess Blue Flame

_Hore Carryover

%ess [i_ing or blowing

Page 7

11. Adjust Oven Burner Air $hu_er (if nec-

essary)

Adjust Air Shutter. The oven burner air shutter is located to

the left of the oven regulator. Reachit through the access hole

in the interior back panel of the warming drawer. Loosen screw

on shutter. Closethe shutter if the flame is lifting or bJowing or

not carrying over; Open the shutter if it is too yellow, Tighten

screw,(See Figure 9), Tighten screw.

Reattach cover plate and replace warming drawer,

Figure 9

Oven Orifice and Air Shutter

Shutter

More Cmosed:

_Less BJue Hame

_lqore Carryover

%ess lifting or blowing

Save natural gas orifices for future conversion by placing

them in the appropriate space below.

NaturaJ Gas

Cooktop Orifice PJacement

Left Rear Burner - Right Rear Burner -

12,500 BTU! h 16S 5,500 BTU/h 109

_OF RANGE

Left Front Burner -

9,!00 BTU/h 139

_ront Burner =

!5,000 BTUih 180

Page 8

Page 9

Cen_cessaireestutilis_porulaconversiondescuisini_res5conbustionjumel_e(n°moduleHDS252U,HDS255UetHDS256U)

et5gaz(n°moduleHGS232UC,HGS236UC,HGS242UC,HGS245UC,HGS246UC,HGS247UC,HGS252UC,HGS255UC,HGS256UC),

dugaznaturelaugazpropane,Cen_cessairenepeut&treutilis_pourconvertird'autresmodulesdecuisini_resBoschou

d'autresmarques,Lenum_rodemoduledelacuisini_reestestamp6surlaplaquederri_ereletiroirderangementour_chaud,

LIRE ENTIEREMENT AVANT DE PROCEDER : conserver lespi_ces pour gaz naturel pour une conversion possible ult_rieure

de LPau gaz natureL

LI_ LES INSTRUCTIONS D_NSTALLA_ON AVANT DE COHNIENCER LA CONVERSION,

_ AVFRT][$SEMENT

Ce n6cessaire de conversion doit 6tre install_ par

une agence de service qualifi6e confor=m6ment aux

instructions du fabricant et _ tousles codes et

exigences applicables ayant juridiction. Si ces in=

structions ne sont pas suivies, il peut en r_sulter un

incendie, une explosion ou une production de

monoxyde de carbone causant des dommages

la propri6t_, des blessures ou la mort. L'agence de

service qualifi6e est responsable de I'installation

appropri6e de ce n_cessaire. L'installation n'est pas

appropri_e ni compl_t6e tant que le fonctionnement

de Vappareil converti n'est pas v_rifi_ comme indiqu6

dans les instructions du fabricant, fournies avec le

n6cessaire.

]Installation en haute altitude :

Pour la conversion dans des r_gions auodessus de 2 000 pi,

communiquer avec [e service Bosch au 800,944,2904,

Installation au Massachusetts :

1.L'installation doit _tre effectu6e par un entrepreneur

qualifi_ ou avec licence, un plombier ou un ajusteur

de gaz qualifi6 ou avec licence par I'_tat, province

ou r_gion ou]I'appareil est installS.

2, La soupape de s_curit_ doit _tre un robinet _ gaz

poign_e en T.

3,Un connecteur de gaz flexible ne doit pas d_passer

36 po,

Contenu du n cessaire :

Tnstructions du n_cessaire de conversion

Adh_sif de conversion

4 orifices LP (1-70/1-86/1-101/1-116)

Outils requis :

Tourne-_crou 7 mm avec rallonge 3 po

Toumevis _ t_te torx (T20)

CI_ r_glable

Tournevis _ lame plate (1/8 po ou plus petit)

Toumevis _ t_te Phillips

ATTENTION o°

(1) En branchant Fappareil sur le gaz propane, s'assurer

que le r_servoir _ gaz propane est dot_ de son r_gulateur

de haute pression. De plus, un r_gulateur de pression est

fourni avec la cuisini&re. Ce second r6gulateur doit 8tre

install_ avec la cuisini&re. La pression de gaz maximale

de cet appareil ne doit pas d_passer 14,0 po, colonne

d'eau, depuis le r_gulateur du r_servoir _gaz propane.

Ce qui suit est exig_ au moment de tester le syst_me de

canalisation :

a) L'appareil et sa soupape de s_curit_ doivent &tre

d_branch_s du syst_me de canalisation d'alimentation

destests de pression exc_dant 1/2 Ibipo _ (3,5 kPa).

b) L'appareil doit _tre isol_ du syst&me de canalisation

d'alimentation en fermant sa soupape de s_curit_

individuelle pendant le test de pression du syst_me

de canalisation d'alimentation _ des tests de pression

_gaux ou inf_rieurs 8 !/2 Ibipo _ (3,5 kPa).

To,jolts avoir _ne aHmentation en gaz

adequate

Les cuisini_res 8 gaz et combustion jumel_e amovibles Bosch

sont expedites de Fusine pour une utilisation au gaz naturel.

Utiliser ce n_cessaire pour convertir Fappareil au gaz LP,au

besoin.

. S'assurer que la cuisini_re est convertie pour I'utilisation

avec le gaz appropd_ avant d'utiliser.

o La cuisini_re est tongue pour fonctionner 8une pression

de 10 po, colonne d'eau, Iorsqu'utilis_e avec le gaz LR

o Au moment de v_rifier lefonctionnement appropd_ du

r_gulateur, la pression d'entr_e doit _tre 8 au moins :[ po

plus grande que la pression de fonctionnement (distrF

buteur) cFdessus. En convertissant au gaz LP,la pression

foumie au r_gulateur doit _tre entre :[:[ et 14 po, colonne

d'eau. Voir _tape 2 <<Conversionde pression au r_gulateur

de 5 _ 10 po, C.E.>bpage suivante.

o Le r_gulateur de pression situ_ dans I'entr_e du distributeur

de la cuisini_re dolt demeurer darts la canalisation

d'alimentation.

o Utiliser un connecteur en m_tal flexible pour _lectom_nager

pour brancher la cuisini_re sur Falimentation en gaz. Le

connecteur doit avoir un D.I. (L D.) de :[/2 poet avoir 5 po

de Iongueur. Au Canada, le connecteur dolt _tre en m_tal

parois simples de pas plus de 6 po.

:[

Page 10

1o ATTENTION :fermer le gaz et I'_lectricit_

avant de proc_der_la conversion, Fermer

I'alimen_tion en gaz avant de d_brancher

m'amimen_tion _lectrique,

Fermer la soupape de gaz du r_servoir de propane ext@ieur

la cuisini@e, Retirer le cordon d'alimentation de la cuisini&re

de la prise _lectrique ou mettre le coupe=circuit hors circuit _ la

boTtede jonction. R_gler tousles boutons de contr61e _ OFF.

2o Conversion du r_guRateur de pression

de 5 _ 10 po, C°E°

1. Retirer le tiroir=r_chaud; le tirer jusqu'5 ce qull arr_te.

Pousser la pince, c6t_ droit, vers le haut et celle de gauche

vers le bas. Tirer compl@ement le tiroir.

2. Retirer la plaque de la parol arri@e int_deure en enlevant

la vis sur le c6t_ du panneau.

3. Retirer le capuchon hexagonal au haut du r_gulateur

I'aide d'une cl_ r_glable.

4. Enlever la tige en plastique dans le capuchon et la tourner

en la pressant fermement en place afin que les lettres LP

puissent @re vues _ I'endroit plut6t que NAT.

5. Remettre le capuchon et le bouton sur le dessus du

r_gulateur, le posant fermement.

6. Apposer FADHF!SIFDE CONVERSION ENALUMINIUM sur

Fard@e de la plaque pour qull soit visible _ Farri@e de la

cuisini@e _ c6t_ du r_gulateur.

Figure !

Conversion r_gulateur de pressien

Position tige

pour propane

/ _ Capuchonhexagonal

E

Position \

tige pour _j-

gaz naturel

VUE REGULATEUR DE PRESSION

Figure 2

Retirer grille, capuchon et base

....... [i

Capuchon _ x

br@leur

Base brOleur---_) _ :::Z

Orifice

3, Replacer _es orifices principau×

Retirer grille, capuchon et base de br_leu_. Enlever les

grilles et les capuchons. D@isser 2 vis T20 8 I1nt@ieur de

chaque baseet retirer les bases de brOleur (figure 2). R_ins@er

lesvis dans le porte=jets pour maintenir en place I'assemblage

de tube.

P.etirer tes orifices de ta surface de cuisson_ gaz natureL

Ins6rer le tourne=_crou avec rallonge 3 po dans le porte=jets

pour retirer les orifices existants. Placer les andens orifices

dans FespacepSrvu 6 la page 5 en cas de conversion ult@ieure

au gaz naturel, au besoin.

Assembler les orifices de surface de cuisson. Placerdarts

la surface de cuisson exactement comme indiqu_ sur la

couverture de ce guide (aussi 8 la figure 3). Si les orifices se

s@arent du couverde, Femplacement peut @re d@ermin_ en

faisant correspondre le num@o estamp6 dans Fodfice avec

lesdonnSes techniques d'emplacement indiqu_es 8 la page 4.

Placer le nouvel orifice dans la douille, puis ins6rer chaque

Allumeur

Figure 3

Emplacement orifice plaque de cuisson LP

BrOleur arri@e gauche BrOleur arri&re droit

- :[_ 000 BTu!h 101 =5 000 BTuih 70

DEVANT CU_

BrOleur avant gauche BrOleur avant droit =

7 500 BTu/h 86 15000 BTu/h _6

Page 11

orificedanssontroufilet_respectifduporte=jet,Setterjusqu'5

cequeI'odficearr_te.NEPASTROPSERRER.

Replacerlabasedubr(]leur,lecapuchonetlagrille.

Remarque: le capuchon du br_leur doit _tre positionn_

ad_quatement sur la base du br(]leur afin que ce dernier

s'allume.

4, Conversion des soupapes pour utilisation

avec propaBe

R_glage des jets d_viateurs sur tes seupapes.

!.V_rifier siles boutons sent en position OFF.

2.Enlever los boutons, ressorts et plaque indicatrice en tirant

droit.

3.InsUrer un tournevis 6 t6te plate dans la tige et toumer la vis

d_viatdce darts le sens horaire jusqu'_ ce qu'elle s'arr_te (fi=

gure 4). NE PASTROP SERRER.Remettre bouton, ressort et

plaque indicatrice,

Si la cuisini_re est de type combustion jumel_e_ la conver-

sion est termin_e, Replacer la plaque et le tiroir=r6chaud et

passer 5 I'_tape 9 pour tester la conversion,

Pour conversion de cuisini&re _ gaz, passer _ 1'6tape 5.

Figure 4

TigeSoupape surface de cuL,

Surface cuisson= art. gauche :[:[ 000

Surface cuisson - art. droit 5 000

Surface cuisson - av. qauche 7 500

Surface cuisson - av. droit :[5000

Four -gall (_ gaz seulement) :[4 500

Four =cuisson (&gaz seulement) :[7 000

5. R_gLage de Forifice du br6leur gri_

Enlever Japorte du four (voir <<Retraitde la porte du four>>

dans les instructions d'installation).

Rotifer Yassembiage br_teur griL Cotassemblage est fix_

au haut de la cavit_ du four 8 I'aide de 7 vis, Enlever lesvis et

tirer droit d_licatement sur Fassemblage en faisant attention

pour ne pas d_tacher les ills _lectriques. Placer le br(]leur gril

centre la paroi arri_re de la cavit_ du four.

R_glage de Yerifice, L'odfice est situ_ derriere le brOleur

gril sur la paroi arri_re (figure 5), Utiliser un tourne=_crou de

:[/2 po de profondeur avec rallonge 3 po pour tourner Fodfice

dans le sens horaire jusqu'_ ce qu'il s'arrSte (2 _ 2 :[/2 fois),

NE PASTROP SERRER,

Replacer Yassemblage gril. Replacer I'assemblage en

faisant attention pour alimenter les ills par la paroi arriSre

du four. Remettre les 7 vis,

Remarque : I'obturateur d'air sur le br01eur gall s'ajuste sur

I'orifice Iorsqu'install_ ad_quatement,

6. R@glage orifice br_eur four

Sorter Yorifice. L'orifice du br01eurfour est situ_ en dessous

de I'obturateur d'air (figure 6), Y acceder par le trou d'acc_s

darts le panneau artiste int_rieur de la cavit_ du tiroir=r_chaud,

Utilise une cl_ :[/2 po pour toumer I'odfice dans le sens horaire

jusqu'_ cequ'il s'arrSte (2 _ 2 :[/2 fois). NE PASTROPSERRER.

Figure 5

Capacit_ du four - Vue lat_rale

Orifice

Figure 6

Orifice du four et obturateur d'air

Orifice Obturateur

Page 12

7. V rification des fuites de gaz

Le test de fuite doit _tre effectue par I'installateur

conformement aux instructions donnees dans cette section.

Ouvrir la soupape d'arr_t de gaz de la canalisation d'alimen-

tation. Appliquer un liquide de detection de fuite non corrosif

sur tousles joints et raccords de la connexion de gaz entre

la soupape d'arr_t de la canalisation et la cuinisi_re. Les

bulles indiquent qu'il y a une fuite.

S'il y a une fuite, fermer la soupape d'arrCt de gaz de

canalisation d'alimentation et setter les connexions. Verifier

de nouveau en ouvrant la soupape d'arrCt de gaz. Une fois la

verification terminee (aucune bulle), le test est complete.

Essuyer les residus de Iiquide de detection.

NE]ANAIS VERIFIER LESFUITESAVEC UNE FLANNE. |

PASPASSERA L'ETAPESUIVANTE TANT QUE LES FUITESI

NESeNT PASTOUTES ELIHINEES_ ._

8, V_rifier i'allumage _lectrique

V_rifier I'allumage du br_leur de surface de cuisson.

Choisir un bouton. Pousser et tourner au symbole de

fiamme. Si le module aliumeurietincelle fonctionne correcte-

merit, il fera un dic. Une fois Fairpruge des canalisations

d'alimentation, le br01eur devrait s'allumer dans un delai de

4 secondes. Une fois le br01eur allume, touner le bouton en

positon OFR

Verifier chaque br01eur de cette faqon.

V_rifier t'ailumage du br@ieur grii. Regler le mode

cuisson _ gril eleve. Le brOleur s'allume apr@s30 _ 75

secondes.

V_rifier I'allumage du br_leur cuisson. Regler le four

350 °F.Apr_s 30 8 75 secondes, le br01eur devrait s'allumer.

Le br01eur demeure allume jusqu'_ ce que la temperature de

350 °F soit atteinte, puis s'eteint. Par la suite, le br(]leur fait

un cycle marche-arrCt pour maintenir latemperature, is

reached and then shut off.

Appeier te service Bosch (800.944.2904) si :

1. Un br_leur ne s'allume pas.

2, Le br_teur gril ou cuisson ne demeure pas ailum_.

3. Le br_leur cuisson ne fait de cycle.

9, V_rifier et r_gler la flamme

La qualite de combustion de la fiamme pour chaque br_leur

doit 8tre visuellement v_rifiee. Si I'appareil est une cuisini_re

gaz, les fiammes des br(]leurs gril et cuisson doivent aussi

8tre verifiees visuellement. La fiamme dolt _tre bleue avec un

bout jaune et doit se propager sur ou envelopper tout le

br(_leur et ne doit pas etre soulevee du br01eur.

Pour verifier, mettre le br(]leur en circuit. Voir figure 7 pour

les caracteristiques de flamme appropriees. Pour voir le

l

brOleur de cuisson, le couvercle inferieur du four doit _tre

enleve; enlever les deux vis arri_res, faire glisser devant et

enlever.

Si la fiamme est compl_tement ou presque toute jaune, Fob-

turateur d'air correspondant etiou I'orifice dolt _tre ajuste.

S'assurer que I'orifice est bien serre. Si la fiamme est encore

jaune, regler I'obturateur d'air. Apr_s le reglage, faire une

remise.

P,emarque : Avec le gaz LP,un bout jaune sur les cenes

exterieur est normal.

Tousles br01eurs doivent aussi 8tre verifies pour un ben eta-

lement. La flamme doit envelopper compl_tement le br01eur.

Si les br(]leurs ne sent pas bien etales, lejet deviateur doit

8tre regle (_tape 4 8 la page 4). Si le br01eur grii ou cuisson

n'est pas etale, regler I'obturateur d'air correspondant

(etapes !0 et !!, ci-dessous et page suivante).

. Figure 7

Caracteristiques de flamme

Reglage necessaire.

Bout jaune sur cene e×t_reiur :

Normal gaz LP.

Deuce fiamme bieue :

Normal pour gaz naturel.

10, R_glage de l'obturateur d'air du br_leur

gril (si n cessaire)

R_giage obturateur d'air° L'obturateur d'air est situe

I'extremite arri_re du br01eur gril. Desserrer la vis et tourner

I'obturateur. Fermer I'obturateur si la flamme est soulevee ou

ne s'etale pas; ouvrir si elle est trop jaune. (Voir figure 8).

Serrer la vis.

Figure 8

Obturateur d'air br_leur gril

Obturateur Vis

P_us o_vert :

"Hoins de flamme

jaune

P_s ferm_ :

"Hoins de flamme bleue

"Plus d'&talement

*Hoins soulev_e ou

vacillante

Page 13

11. R_gler obturateur d'air du br_leur four

(si n_cessaire)

R_glage obturateur d'air, L'obturateur d'air du brOrleur four

est situ_ _ la gauche du r_gulateur du four. Passer par le trou

d'acc_s dans le panneau artiste int_rieur du tiroir=r_chaud,

Desserrer la vis sur I'obturateur, Fermer I'obturateur si la

flamme est soulev_e ou vaciile ou ne s'_tale pas; ouvrir si elle

est trop jaune. Setter la vis, (Voir figure 9).

Remettre la plaque et le tiroir-r_chaud.

Figure 9

Oven Orifice and Air Shutter

Conserver les orifices de gaz naturei 5 des fins de conversion

ult_rieure en les plagant dans I'espace appropri_ ci-dessous,

Gaz naturem

Empmacement orifice surface de cuissom

BrQleur arri&re gauche BrQleur arri_re droit

- 12 500 BTui h ::[65 - 5 500 BTu/h :[09

Obturateur

DEVAN? CU_

BrQieur avant gauche - BrQieur avant droit -

9 100 BTuih :[39 15 000 BTuih :[80

Page 14

Page 15

Este kit se usa para convertir estufas de dos combustibles (modelo # HDS252U, HDS255U y HDS256U) y estufas de gas

(modelo # HGS232UC, HGS236UC, HGS242UC, HGS245UC, HGS246UC, HGS247UC, HGS252UC, HGS255UC, HGS256UC), de

una operaci6n con gas natural a propano. No se puede usar este kit para convertir otras estufas de Bosch o las estufas de

otras marcas. La placa detr_is del caj6n calentador en su estufa muestra el n0mero del modelo.

FAVOR DE LEER TODAS LAS INSTRUCCIONES ANTES DE PROCEDER, Guarde laspaFtespara gas naturalpara

una posible conversi6n futura del gas LP a gas natural.

FAVOR DE LLER LAS INSTRUCCIONES DE INSTALACI6N ANTES DE INICIAR LA CONVERSI6N.

ADVERTENCIA %

Una agenda calificada de servido debe instalar este

kit de conversi6n de acuerdo con las instrucciones del

fabdcante y los c6digos y requedmientos aplicables

de la autoddad juridica competente. El hecho de no

observar la informad6n propordonada en estas

instrucdones puede causar un fuego, explosi6n o la

producd6n de mon6xido de carbono, resultando en

da_os a la propiedad, heridas personales hasta la

muerte. La agenda calificada de servido es responsable

de la instalad6n correcta de este kit. La instatad6n no

terminada y aprobada hasta que se verifique la

operad6n del aparato convertido de acuerdo con las

instrucciones del fabricante que se incluyen con el kit.

Instalad6n en gran altitud:

Parainstaladonesen _reasarribade 2,000pies(610 m),

flamea Bosch pararecibirinstrucciones:800=944=2904.

Para instalaciones en Massachusetts:

!.Un contratista, fontanero o instalador de gas

calificado o autorizado pot el estado, provincia o

regi6n, donde se instala este aparato, debe

realizar la instalaci6n.

2.La v_lvula de cierre debe set una Ilave de gas, tipo

grifo en "T'.

3.El conectador flexible de gas no debe medir m_s

de 36 pulgadas (9:[.4 cm) de Iongitud.

Contenido del Kit:

Tnstrucdones del kit de conversi6n

Etiqueta de conversi6n

4 orificios LP (1=70/ 1=86/ 1=101/ 1=116)

Herramientas que se necesitan:

[qatraca de 7 mm con extensi6n de 3"

Desarmador de cabeza Torx (T20)

Llave ajustable

Desarmador de cabeza plana (1/8" o m_s peque_o)

Desarmador de cruz

CUIDADO:

(!) AI conectar la unidad al gas de propano, asegurese

que el tanque de gas tenga su propio regulador de alta

presi6n. AdemSs, se induye un regulador de presi6n

con la estufa. Se debe instalar este segundo regulador

con la estufa. Lam_xima presi6n de gas a este aparato

no debe exceder :[4.0 pulgadas de la columna de agua

del regulador en el tanque de gas de propano.

Se debe cumplir Io siguiente al probar la tubeda del

suministro de gas:

a) Se debe desconectar el aparato y su wilvula de derre

individual del sistema de suministro de gas a

presiones de prueba arriba de :[/2 psig (3.5 kPa).

J

b) Se debe aislar el aparato del sistema de suministro

de gas cerrando su vSIvula individual de cierre du=

rante cualquier prueba de presi6n del sistema de

suministro de gas a presiones de prueba iguales o

inferiores que :[/2 psig (3.5 kPa).

$iempre proporcione un suministro adecuado de gas

Las estufas autoestables Bosch de gas y de dos combus=

tibles vienen de f_ibrica para el uso con gas natural. Use

este kit para convertir el aparato para el uso con gas LP si

se neces[ta.

Aseg0rese de convertir la estufa para el uso con el gas

apropiado antes de usarla.

Su estufa est_ dise_ada para operar a una presi6n de

10" de columna de agua cuando se usa con gas LP.

AI checar la operaci6n correcta del regulador, la presi6n

de entrada debe set al menos :[" m_s grande que la

presi6n de operaci6n de arriba (manifold). Cuando se

convierte para el uso con gas LP,la presi6n aplicada al

regulador debe estar entre :[:[" y :[4" de la columna de

agua. Vea el paso 2 "Convertir la presi6n al regulador de

5" a 10" W.C.', siguiente p_gina.

o El regulador de presi6n ubicado en la entrada del mani

fold de la estufa debe permanencer en la linea de

suministro.

o Use un conector met_lico flexible para conectar la estufa

al suminstro de gas. El conector debe tener un D.I. de

:[i2"y una Iongitud de 5' (:[.5 m). En Canad_i, el conector

debe set met_ilico de una sola pared y no m_s largo de 6'

J

Page 16

i_iiiiiiiii

1o CUIDADO: Apague el gas y mamuzantes de

proceder con la conversi6n; derre el suministro

de gas al aparato antes de desconectar ma

corriente,

Cierre la v61vulade gas del tanque extemo de propano. Saque

el cable de alimentaci6n de la estufa o apague el interrupter

en la caja de interruptores y cambie todas las perillas de

control a la posid6n "OFF" (Apagado).

2o Convertir el Regu[ador de Presi6n de 5"

W°C° a 10" W°C°

!. Saque el caj6n calentador; saque el caj6n hasta Ilegar

al ret6n. Empuje el sujetador en el lade derecho hacia

arriba yen el lade izquierdo hacia aba]o. Saque el caj6n

completamente.

2. Quite la cubierta de la pared trasera interior abriendo el

tornillo sencillo en el lade izquierdo del panel.

3. Saque la tapa hexagonal de la parte superior del

regulador con una liave ajustable.

4. Saque la espiga de pl_stico en la tapa y volt6ela,

presion_ndola firmente en su lugar hasta poder vet las letras

"LP" en la espiga, en lugar de "NAT"

5. Reemplace el conjunto de la tapa y bot6n en la parte

superior de[ regulador sell_ndo[o bien. Asegt_rese que el

resorte est@ en su lugar (Yea la Figura 1). NO APR[ETE

DEMAS[ADO.

6. Instale la ETIQUETA DE CONVERSION en el lade trasero

de la cubierta de tal mode que aparezca en el lade trasero

de la estufa, en seguida del regulador.

Figura 1

Cenvertir el Regulador de Presi6n

posici6n de espiga

para propane

tapa

[

posici6n de \

espiga para _._J

gas natural

Vista del Regulador de Presi6n

Figura 2

Quitar la rejilla, tapa y base

Tapa del _ F

quemador

Base del

quemador

Orificio

3, Reemplazar los or[tides de [a estufa

Quitar las rejillas, tapas y bases del quemadero Quite las

rejillas y las tapas de los quemadores, Desatornille 2 torni=llos

T20 dentro de cada base y quite las bases de los quemadores

(Vea la Figura 2), Vuelva a insertar los tomillos en el portador

del inyector para mantener el conjunto de tuber[a en su lugar,

Quitar los orificios de [a estufa para gas natural, Inserte

[a matraca con una extensiSn minima de 3" en los portadores

de inyector para quitar los odficios existentes. Co[oque los

odfidos viejos en el espado propordonado en [a p_gina 5 en

case de una futura conversi6n de vue[ta a gas natural.

Ensamblar los orificios de [a estufa para gas LP, Coloque

[a estufa exactamente come se muestra en [a portada de este

manual (se muestra tambi6n en[a Figura 3). Cuandose separan

los entities de [a cubierta, se puede determinar [a co[ocad6n

al emparejar el n0mero estampado en el odfido con [as

especificadones indicadas en [a Figura 4. Coloque el orifido

Flgura 3

Colocaci6n de Orificies de Estufa LP

Quemador trasero izq. Quemador trasero def.

=11,000 BTUih 101 =5,000 BTUih 70

FRENTE D_

Quemador delantero Quemador delantero

izq. ° 7,500 BTUih 86 def. ° :[5,000 BTUih :_:_6

Page 17

nuevo en el recept_culo y luego inserte cada orificio en su

respectivo agujero roscado en el portador, Apriete hasta que

el orificio deje de girar, NO APRIETE DEIASIADO,

Reemplace la base, tapa y rejilla de los quemadores.

Nora; Se debe posicionar la tapa del quemador correctamente

sobre la base del quemador para que _ste se encienda.

4, Conveffdr [as v_lvulas de [a estufa para

el uso con gas de propano

Ajustar los inyeetores en tas v_lvutas,

l.Vedfique que todas las pedllas est_n en la posici6n "Off'.

2.quite las perillas, resortes y anillos biselados.

3.Inserte el desarmador de cabeza plana en el eje y gire el

tornil[o de derivaci6n en sentido del reloj hasta que deje de

girar (Vea la Figura 4). NOAPRIETE DEHASIADO.

Reemplace las perillas, resortes y anillos biselados.

Si su estufa es de doble combustible, su conversi6n ya

terrain6. Reemplace la cubierta y el caj6n calentador y siga

con el paso 9 para probar su conversi6n.

Para conversiones con estufas de gas, siga con el paso 5.

Estufa =Trasero Izquirdo

Estufa =Trasero Derecho

Estufa = Delantero Izquierdo

Estufa =DeJantero Derecho

Homo =Asado (Estufas de qas)

Homo = Horn. (Estufas de gas)

11,000

5,000

7_5oo

15,,000

!4_500

!7,000

5. Ajustar el orificio dei quemador de

asado

Qu[tar [a puer_a det homo (vea la secci6n "Quitar la puerta

del homo" en las instrucciones de instalaci6n).

Quitar el co,junto del quemador de asadoo El conjunto

del quemador de asado est_ fijado a la parte superior de la

cavidad del homo con 7 tomillos, Quite los tornillos y jale el

conjunto del quemador suavemente, teniendo cuidado de no

desconectar cables el_ctricos, Ponga el quemador de asado

contra la pared trasera de la cavidad del homo,

Ajustar el orificioo El orificio se encuentra detr_s del

quemador de asado en la pared trasera del homo (Vea la Figura

5). Useuna matraca con dado de 1/2" con una extensi6n minima

de 3" para girar el orificio en sentido del reloj hasta que se

detenga (2= 2Y2 veces), NO APRIETE DEMAS][ADO,

Reemplazar el conjunto det asador, Reemplace el

conjunto del asador teniendo cuidado de poner todos los

cables a trav_s de la pared trasera del homo, Vuelva a poner

los 7 tornillos,

_ota; El obturador de aire en el quemador cabe encima del

orificio cuando se instala de modo correcto,

6, Ajustar el orifi¢io de! q_emador de! homo

Apretar el orificioo El orificio del quemador del homo se

encuentra abajo del obturador de aire (Vea Figura 6), Lo puede

alcanzar a trav_s del agujero de acceso en el panel trasero de

la cavidad del caj6n calentadon Use una matraca con dado de

1/2" para girar el orificio en sentido del reloj hasta que se

detenga (2=2Y_veces), NO APRIETE DEHASIADO

Figura S

Cavidad del homo - vista lateral

Orificio

Flgura 6

Orificio dei homo y obturador de aire

Orificio Obturador

Page 18

7. Verificar fugas de gas.

El instaladordebe verificar si hay fugas de gas de acuerdo a

las instrucdonesproporcionadas en esta secd6n,

Abra la v_lvula de cierre de la I[nea de suministro del gas,

Aplique un I[quido no corrosivo de detecci6n de fugas a todas

las uniones y conexiones entre la v_lvula de cierre de la I[nea

de suministro y la estufa. [nduya las conexiones y uniones de

gas en la estufa si _stas fueron manipuladas durante la

instalaci6n. Burbujas que eperecen alrededor de

conexiones indican una fugao

Cuando aparece una fuga, cierre la v_lvula de la linea de

suministro de gas y apriete las conexione& Vuelva a prober si

hay fugas abriendo la v_lvula de cierre, Cuando termina el

chequeo de fugas (no aparecen burbujas), termina la prueba.

Limpie todos los residuos del liquido de detecd6n,

Cuando la llama est_ totalmente o en su mayoria amarilla, se

debe ajustar el obturador de aire y,/u orificio correspondiente,

Verifique que el orificio quede totalmente apretado. Si la

llama ann est_ amarilla, ajuste el obturador de aire, Despu_s

del ajuste, vuelva a realizer la prueba,

Note: Con gas LP,puntas amarillas en los conos exteriores es

algo normal,

Tambi_n se debe verificar el arrastre de los quemadores, La

llama debe envolver el quemador completamente, Cuando los

quemadores de la estufa no envuelven, se debe ajustar el

inyector de derivaci6n (Vea el paso 4, p_gina 4), Cuando los

quemadores del homo o asador no envuelven, ajuste el

obturador de aire correspondiente (vea los pasos 10 y 11, a

continuaci6n yen la p_gina siguiente),

UNCA USE UNA LLAMA PARAVERIFICAR SI HAY FUGAS, I

INOSIGA CON EL SIGUIENTE PASOHASTAHABERELIMINADO_

L TODAS LAS FUGAS,

8. Prober la icjnici6n el@ctricao

Prober la ignici6n del quemador de estufeo Seleccione

una perilla de un quemador de la estufa, EmpQjela y girela

hasta el simbolo de la llama, Si el ignitor/'m6dulo de chispas

funciona bien, se escucha un clic, Una vez que se haya

purgado el aire de ]as ][neasde suministro, el quemador debe

encenderse dentro de cuatro (4) segundos, Despu@sde

encender el quemador, gire la perilla a la posici6n de "Off"

Verifique cada perilla de ]a estufa de este modo.

Prober la ignici6n del quemedor de esadoo Cambie el

modo de cocinar a Hi Broil (Asado Alto), El quemador se va a

encender despu_s de 30°75 segundos,

Prober at igmici6m del quemador de hormeado. Ajuste

el homo a una temperatura de 350°R Despu_s de 30=75

segundos se enceder_ el quemador, El quemador se

mantendr_ encendido hasta alcanzar los 350°F y luego se

apaga, A partir de este punto, el quemador de prende y

apaga para mantener la temperatura,

Llarae at servicio Bosch (800-944-2904) cuando:

1. Alg_n queraador no so enciende.

2. ELqueraador do asado o homeado no se mantiene

encendido.

3. No so cida el queraader do homeade.

Caractensticas de las llamas

. Figure 7

Llama amarilla,

Se requieren m_s ajustes.

Pumtas amarillas en comes:

Normal pare gas LP,

Mamas azules suaves:

Normal para gas natural.

10o Ajustar el obturador de aire del quemador

de asado (si es necesario)

Ajustar el obturedor de aireo El obturador de aire se

encuentra en el extremo trasero del quemador de asado, Afloje

el tornillo y gire el obturador, Cierre el obturador cuando la

llama no envuelve el quemador completamente o cuando la

llama se levanta o seapaga, Abra el obturador si la llama es

demasiado amarilla, (Vea la Figura 8), Apriete el tornillo,

Figura 8

Obturador de aire del quemador

Obturador Tornillo

M_s abierto:

"Menor llama amarill_

9. Probar/Ajustar la llama.

Se debe inspeccionar visualmente la calidad de combusti6n

de la llama, Si su estufa es de gas, se deben verificar adem_s

las llamas de los quemadores de horneado y asado, La llama

debe ser azul con puntas amarillas, Debe envolver todo el

quemador y no levantar o apagar el quemador.

Para inspeccionar, prenda el quemador. Vea la Figura 7 pare

las caracteristicas apropiadas de las llamas. Para ver el

quemador del homo, se tiene que quitar la cubierta inferior

del horno; quite dos tornillos traseros de mariposa, deslice

hacia adelante y s_quelo,

M_s cerrado:

"Menor llama azul

"M_s arrastre

"Menos elevaci6n y soplado

Page 19

11. Ajustar el obturador de aire del

quemador dei homo (si es necesario)

Ajustar eJ obturador de aire, El obturador de aire se

encuentra a la izquierda de] regu]ador de] homo, Lo puede

a]canzar a trav_s del agujero de acceso en e] pane] trasero

interior de] caj6n ca]entador, Afioje e] tornil]o en e] obturador,

C]erre e] obturador cuando la llama no envue]ve e] quemador

comp]etamente o cuando la llama se levanta o se apaga, Abra

e] obturador si la Hama es demasiado amariHa, (Vea la Figura

9), Apriete el tornillo,

Vuelva a poner la cubierta y reemplace el caj6n calentador,

Figura 9

Orificio del homo y obturador de aire

Obturador

MRs cerrade:

°lVlenor llama azul

_lVi&sarrastre

"lVlenos elevaci6n o

soplado

Guarde los orificios para gas natural en el espacio apropiado

abajo para una futura conversi6n.

Gas Natural

Co_ocaci6n de Orificios de Estufa

Quemador Trasero Izq. Quemador Trasero Def.

- :[2,500 BTUi h 165 - 5,500 BTUi h 109

FONDO DE ESTUF

QQ"

Quemador Delantero Izq. Quemador Delantero Def.

= 9,:[00 BTUih ::[39 = :[5,000 BTUih 180

Page 20

5551 McFadden Avenue, Huntington Beach, CA 92649 800-944-2904

P/N 5060010009 RevA, BSH Home Appliances Corp,, 2003, Litho in U,S,A, 08/03

Loading...

Loading...