Bosch HGEW 36 FS User Manual

MODEL: HGEW 36 FS

VENTILATION

INSTALLATION MANUAL

DOWNDRAFT

DOWNDRAFT

USE AND CARE MANUAL

USE AND CARE

MODELS: CVS2

MODELS: UCV2

MANUAL

2

en

page 03–11

fr

page 12 – 20

es

página 21 – 29

3

WARNING

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE

FOLLOWING:

A. Installation work and electrical wiring

must be done by qualified person(s) in

accordance with all applicable codes

and standards, including fire-related

construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s guideline and

safety standards such as those

published by the National Fired

Protection Association (NFPA), and

the American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local

code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical

wiring and other hidden utilities.

D. Ducted fans must always be vented

to the outdoors.

E. Always unplug or disconnect the

appliance from the power supply

before servicing.

F. This unit is designed for indoor use

only. Use this unit only in the manner

intended by the manufacturer.

WARNING

For general ventilating use only. Do not

use to exhaust hazardous or explosive

materials and vapors.

To r educe risk of fire and to properly

exhaust air, be sure to duct air outside.

Do not vent exhaust air into spaces

within walls, ceilings, attics, crawl spaces

or garages.

TO REDUCE THE RISK OF FIRE, USE

ONLY METAL DUCT WORK.

To r educe the risk of fire or electric

shock, do not use the fan with any solidstate speed control device.

This appliance has been found to be in

compliance with UL 507 Standard for

Electric Fans and CAN/CSA-22.2 No.

113 Canadian Standard for Fans and

Ventilators. It is the responsibility of the

owner and the installer to determine if

additional requirements or standard

apply in specific installation.

SAFETY INSTRUCTIONS

Read All Instructions Before Using the Appliance.

READ AND SAVE THESE INSTRUCTIONS

Parts Needed

❑ Tape Measure

❑ Phillips Head Screwdriver

❑ Duct Tape

❑ Ductwork (configuration varies

depending on location; see ”Prior to

installation”).

❑ Additional Sheetmetal screws

(as necessary for ductwork installation)

Parts Supplied

❑ Appliance assembly (1)

❑ Sheetmetal Screws (6)

❑ Wood Screws (4)

❑ Counter Sink Screws (2)

❑ Hardware for brackets on vent (2)

❑ Plugs UX6 (6)

4

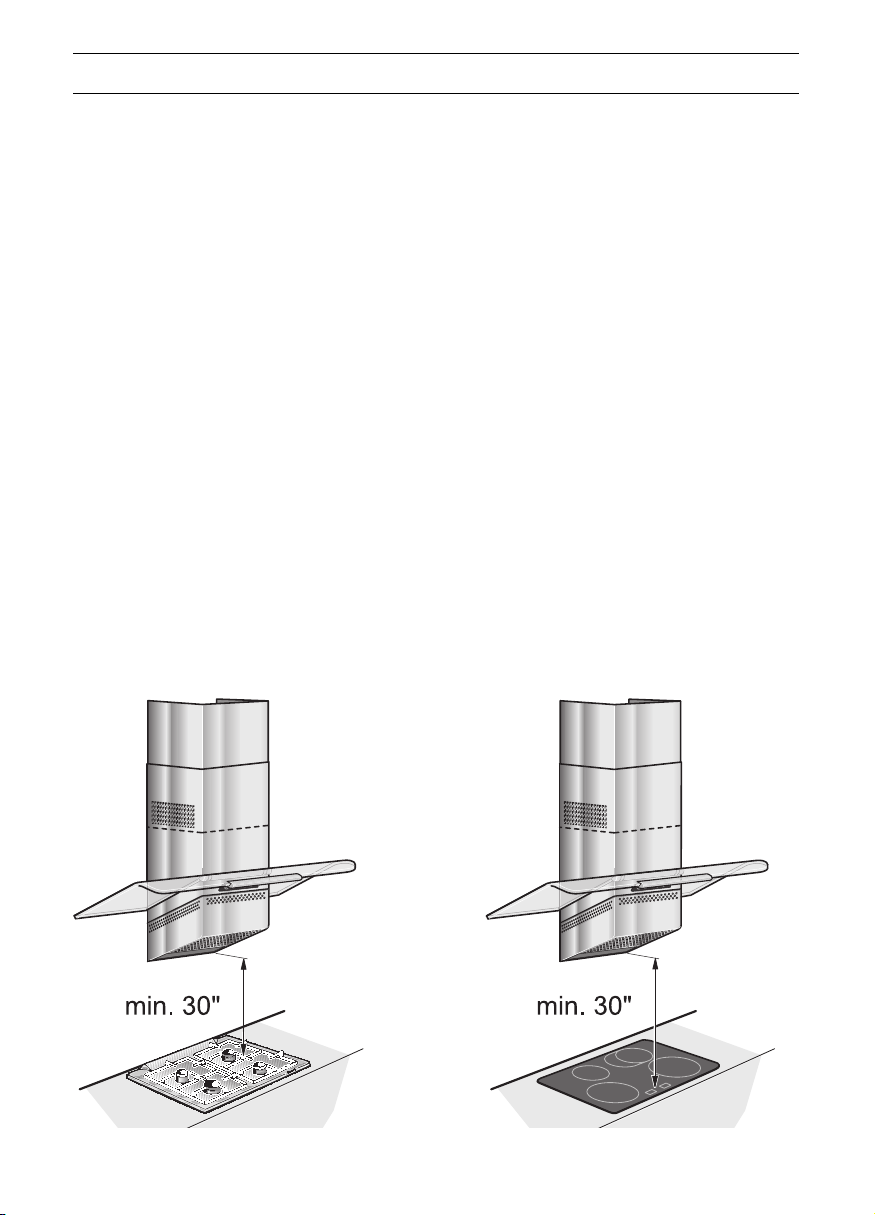

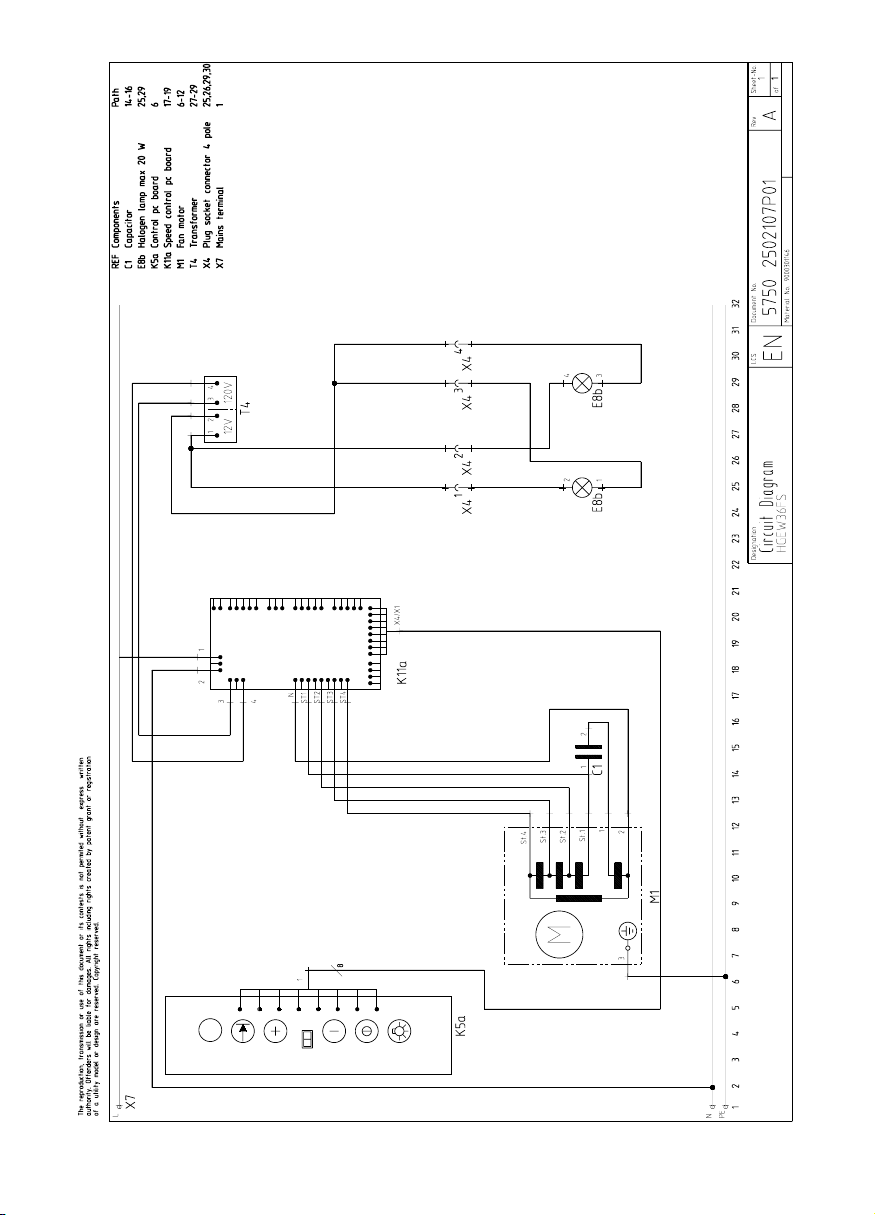

Fig. 1

GAS

ELECTRIC

IMPORTANT INFORMATION

Old appliances are not worthless rubbish.

Valuable raw materials can be reclaimed by

recycling old appliances. Before disposing

of your old appliance, render it unusable.

You received your new appliance in a

protective shipping carton. All packaging

materials are environmentally friendly and

recyclable. Please contribute to a better

environment by disposing of packaging

materials in an environmentally-friendly

manner.

The hood can only be used in exhaust air

mode.

Always mount the hood over the center of

the cooking surface.

Minimum distance between electric

cooktop and bottom edge of hood: 30”,

Fig. 1.

The hood must not be installed over a

wood or coal burning stove – a potential fire

hazard (e.g. flying sparks) – unless the stove

features a closed, non-removable cover

and all national regulations are observed.

The smaller the gap between the hood and

cooktops, the greater the likelihood that

droplets will form on the underside of the

hood.

Additional information

concerning gas cookers:

When installing gas cooktops, comply with

the relevant national statutory regulations.

Always comply with the currently valid

regulations and installation instructions

supplied by the gas appliance

manufacturer.

Only one side of the hood may be

installed next to a high-sided unit or high

wall. Gap at least 2”.

Minimum distance on gas cooktops

between the upper edge of the grate and

lower edge of the hood: 30”, Fig. 1.

5

The exhaust air is discharged upwards

through a duct or directly through the

outside wall into the open.

D

Exhaust air should neither be directed

into a smoke or exhaust flue that is currently

used for other purposes, nor into a duct

that is used for ventilating rooms in which

stoves or fireplaces are also located.

Exhaust air may be discharged in

accordance with official and statutory

regulations only (e.g. national building

regulations).

Local authority regulations must be

observed when discharging air into smoke

or exhaust flues that are not otherwise in

use.

D

When the hood is operated in

exhaust-air mode simultaneously with a

different burner which also makes use of

the same chimney (such as gas, oil or

coal-fired heaters, continuous-flow heaters,

hot-water boilers) care must be taken to

ensure that there is an adequate supply

of fresh air which will be needed by the

burner for combustion.

Safe operation is possible provided that the

underpressure in the room where the burner

is installed does not exceed 4 Pa (0.04

mbar).

This can be achieved if combustion air can

flow through non-lockable openings, e.g. in

doors, windows and via the air-intake/

exhaust-air wall box.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

WARNING – Avoid risk of poisoning – If

the air intake to the room is inadequate,

there is a risk of poisoning from combustion

gases which can be drawn back into the

room.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

If the exhaust air is going to be

discharged into the open, a telescopic

wall box should be fitted into the

outside wall.

PRIOR TO INSTALLATION

Step 1: EXHAUST-AIR MODE

6

For optimum hood efficiency:

❑ Short, smooth duct pipe.

❑

As few bends in the ducting as possible.

❑

Diameter of ducting to be as large as

possible and no tight bends in ducting.

If long, rough exhaust-air ducting,

many ducting bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

IMPORTANT: The manufacturer of the

hood accepts no liability for com-

plaints which can be attributed to the

design and layout of the ductwork.

❑

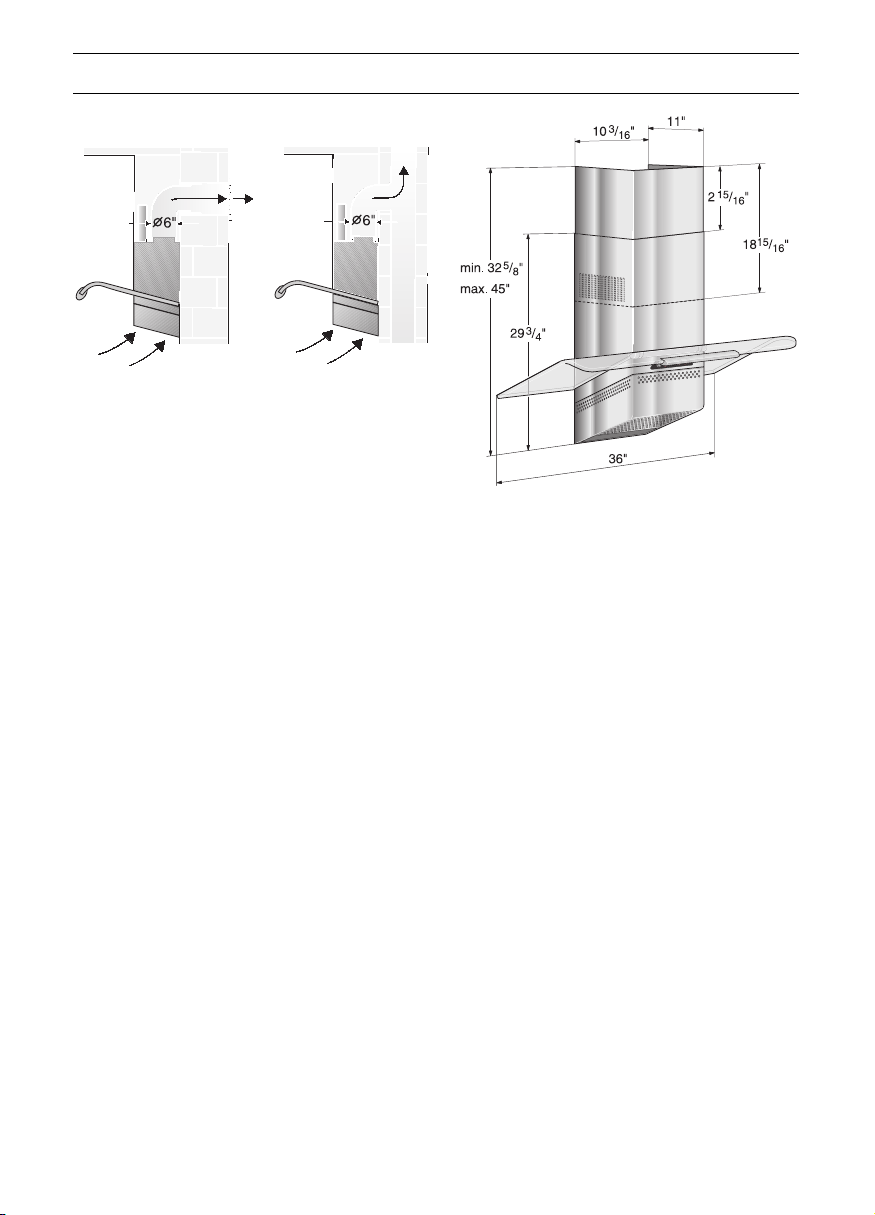

Round pipes:

We recommend

Internal diameter: 6”.

❑

Flat ducts must have an internal cross-

section that equates to that of round

pipes.

There should be no sharp bends.

l 6” approx. 28.3 inches

2

❑

If pipes have different diameters:

Insert sealing strip.

❑

For exhaust-air mode, ensure that

there is an adequate supply of fresh air.

CONNECTING A l 6” EXHAUST-AIR

DUCT:

❑ Mount the duct directly onto the air out-

let on the hood.

Step 2: PREPARING THE WALL

❑ The wall must be flat and perpendicular.

❑

Ensure that the wall is capable of providing a firm hold for mounting screws and

plugs.

Weight in kg: 23.5

PRIOR TO INSTALLATION

7

Step 3: ELECTRICAL CONNECTION

WARNING: THIS APPLIANCE MUST

BE GROUNDED

The hood should only be connected to a

grounded socket that has been installed

according to relevant regulations.

If possible, site the earthed socket directly

behind the chimney paneling.

❑ The grounded socket should be

connected via its own circuit.

❑ If the grounded socket is no longer

accessible following installation of the

hood, ensure that there is a permanently

installed disconnector.

Step 4: INSTALL ELECTRICAL

SERVICE

Check your local building codes for proper

method of installation. In the U.S., if there

are no applicable local codes, this unit

should be installed in accordance with the

National Electric Code ANSI/NFPA No. 70,

Current Issue. (In Canada, installation must

be in accordance with the CAN 1- B149.1

and .2 - Installation Codes for Gas Burning

Appliances and/ or local codes).

The appliance must be grounded. In the

event of an electrical short circuit, grounding

reduces the risk of electric shock by

providing an escape wire for the electric

current. This appliance is equipped with a

cord having a grounding wire with a

grounding plug. The plug must be plugged

into an outlet that is properly installed and

grounded.

WARNING – Improper grounding can

result in a risk of electric shock.

Consult a qualified electrician if the

grounding instructions are not completely

understood, or if doubt exists as to whether

the appliance is properly grounded.

Do not use an extension cord. If the power

supply cord is too short, have a qualified

electrician install an outlet near the

appliance.

If it is necessary to wire the hood directly

into the mains:

WARNING – Avoid risk of electrical

shock – If the connecting cable for this

appliance is damaged, the cable must be

replaced by the manufacturer or his

customer service or a similarly qualified

person in order to prevent serious injury to

the user.

ELECTRICAL DATA:

Are to be found on the name plate inside

the appliance after removal of the filter

frame.

WARNING – Avoid risk of electrical

shock – Before undertaking any repairs,

always disconnect the hood from the

electricity supply.

Length of the connecting cable: 511/8”.

This hood corresponds to EC regulations

concerning RF interference suppression.

PRIOR TO INSTALLATION

8

9

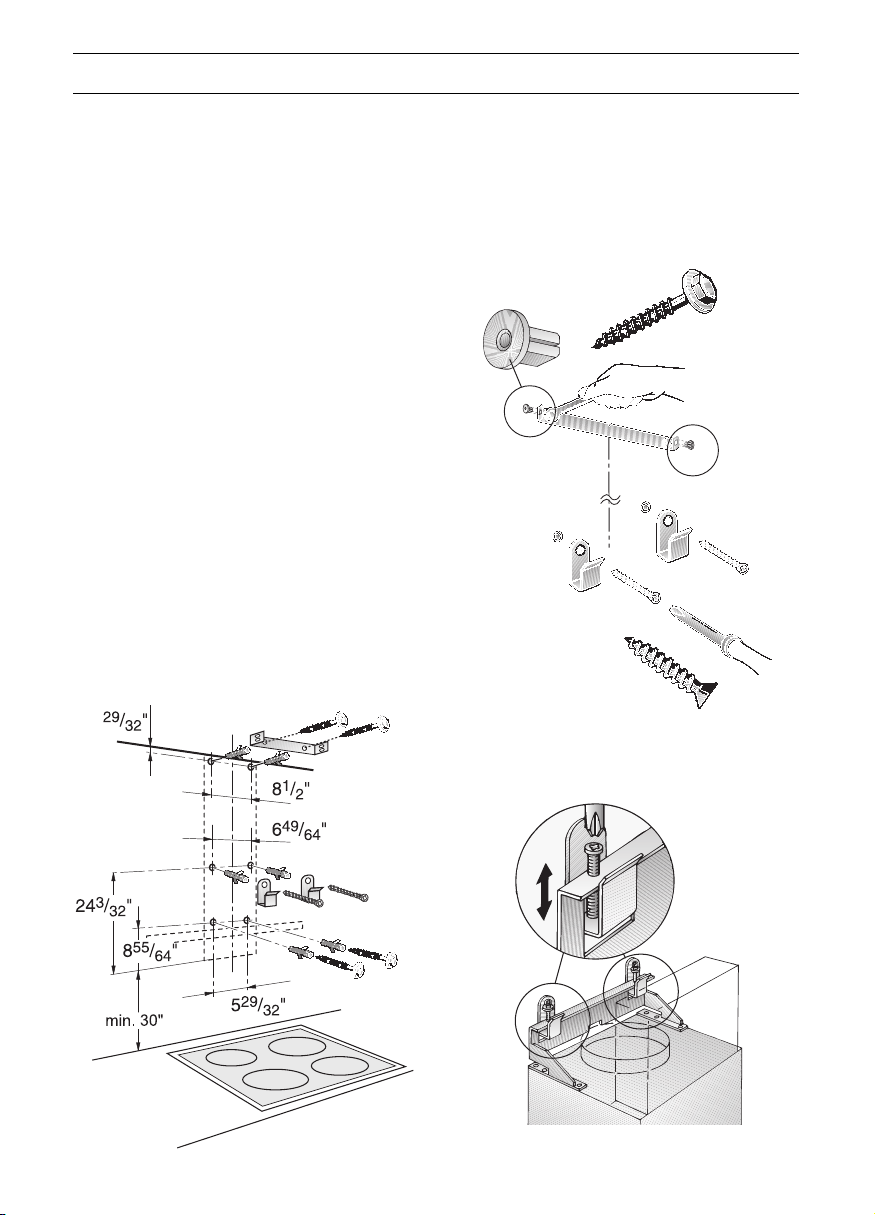

Step 5: INSTALLATION

This hood is intended to be mounted onto

the kitchen wall.

1. Remove the grease filter (refer to Opera-

ting Instructions).

2. Draw a line on the wall from the ceiling to

the lower edge of the hood at the center

of the location where the hood is going

to be mounted.

3. Use the template to mark the points on

the wall where the screws will be moun-

ted. In order to make it easier to hook

the hood onto the screws, draw the out-

line of the area where the hood will be

attached.

CAUTION – Ensure that the minimum

distance between the cooktop and the

hood is maintained – 30”. The bottom edge

of the template equates to the lower edge

of the hood.

4. Drill 2x

1

/4” ø holes for the upper fixing

bracket and

2x

1

/4” ø holes for the lower fixing bracket

and press in wall plugs flush with the

wall.

Note: At least one screw for the mounting

must be installed through a stud.

INSTALLATION

6. Attach the hood.

Adjust the height and align horizontally

with the adjusting screws.

Note: Take into account any special

accessories that are going to be fitted.

5. Attach the 2 enclosed spacers to the

fixing bracket for the flue duct panelling.

Attach the fixing bracket for the

chimney panelling using two hexagon

head cap screws.

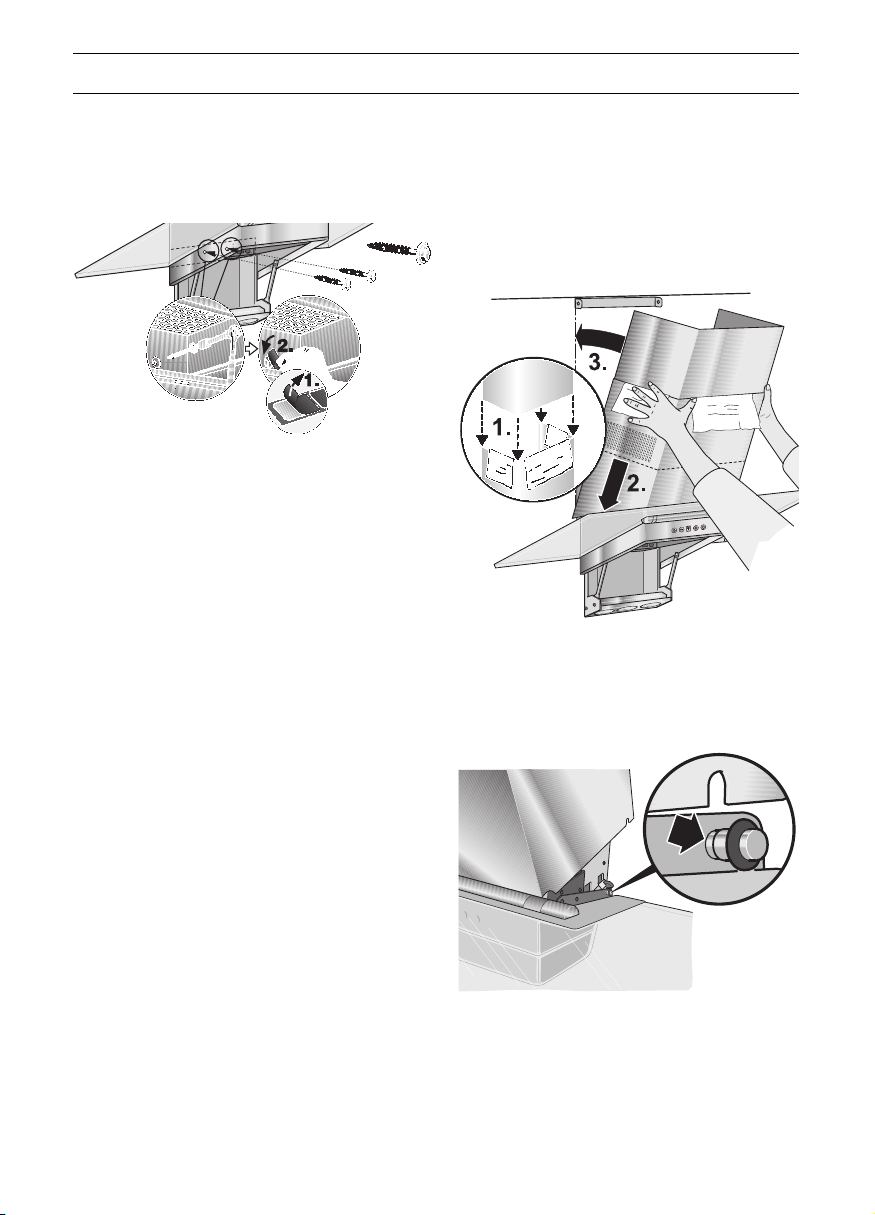

10

13. Insert the cover panels at an angle and

tilt them back.

The bottom panel must snap in the

bolts at the back.

07. Screw in lower screws (hex screws).

08. Stick protective film over the holes of

the 2 lower mounting bolts in the

protective grid.

09. Connect up the air outlet pipe.

10. Connect the hood to the electricity

supply.

11. Remove the protective film from the

two flue ducts.

Take care not to damage the

surfaces which are susceptible to

scratches etc.

Warning: The interior walls of the flue

panelling can have sharp edges – Risk of

injury –.

We recommend that you wear gloves when

installing.

INSTALLATION

12. Push both sections of the flue panelling

together (slots in the upper section

must be pointing downwards) and

insert into the opening in the hood.

Protect the cover panels from

scratches, for example by laying the

template used for marking the wall over

the top edge of the lower section.

Loading...

Loading...