Bosch HES7252U/01, HES7152U/01, HEI7282U/01, HEI7152U/01, HEI7132U/06 Installation Guide

...Page 1

Slide-in Electric Ranges with European Convection

_) BOSCH

Invented for life

!iiiiiiiii¸ i!ii_!ii_iOpigiiiii{i

!!!P

Page 2

Table of Contents

Safety ..................................................... 1

Installation ................................................. 2

Before You Begin ............................................................. 2

Installation Procedure .......................................................... 7

Service ................................................... 15

Before Calling Service ......................................................... 15

Questions?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

We look forward to hearing from you!

Page 3

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Important Safety

Instructions

Appliance Handling Safety

Safety Codes and Standards

Electric Safety

Warning: If the information in this manual is not followed exactly, fire or shock

may result causing property damage or personal injury.

WARNING: Do not repair or replace any part of the appliance unless specifi-

cally recommended in the manuals. Improper installation, service or mainte-

nance can cause injury or property damage. Refer to this manual for

guidance. All other servicing should be done by a qualified technician.

• Do not lift appliance by door handle. Remove the door for easier handling and

installation. See instructions in Use and Care Manual.

• Unit is heavy and requires at least two people or proper equipment to move.

• Hidden surfaces may have sharp edges. Use caution when reaching behind

or under appliance.

This appliance complies with one or more of the following Standards:

UL 858, The Standard for the Safety of Household Electric Ranges

UL 923, The Standard for the Safety of Microwave Cooking Appliances

UL 507, The Standard for the Safety of Electric Fans

ANSI Z21.1-2000, The American National Standard for Household Cook-

ing Gas Appliances

CAN/CSA-C22.2 No. 113-M1984 Fans and Ventilators

CAN/CSA-C22.2 No. 61-M89 Household Cooking Ranges

It is the responsibility of the owner and the installer to determine if addi-

tional requirements and/or standards apply to specific installations.

Before you plug in an electrical cord, be sure all controls are in the OFF posi-

tion.

For appliances equipped with a cord and plug, do not cut or remove the

ground prong. It must be plugged into a matching grounding type receptacle

to avoid electrical shock. If there is any doubt as to whether the wall recepta-

cle is properly grounded, the customer should have it checked by a qualified

electrician.

If required by the National Electrical Code (or Canadian Electrical Code), this

appliance must be installed on a separate branch circuit.

Only a power-supply cord kit rated for this appliance and marked "for use with

ranges" shall be used.

Installer - show the owner the location of the circuit breaker or fuse. Mark it for

easy reference.

Important - Save these instructions for the local electrical inspector's use.

Before installing, turn power OFF at the service panel. Lock service panel to

prevent power from being turned ON accidentally.

Be sure your appliance is properly installed and grounded by a qualified tech-

nician. Installation, electrical connections and grounding must comply with all

applicable codes.

Related Equipment Safety

Warning: All ranges can tip. Injury to persons could result. Install anti-tip

device packaged with range. Verify that the anti-tip devices are engaged. See

installation instructions.

English 1

Page 4

Installation

Before You Begin

Removealltapeandpackagingbeforeusingtheappliance.Destroythepack-

agingafterunpackingtheappliance.Neverallowchildrentoplaywithpackag-

ingmaterial.

Nevermodifyoraltertheconstructionoftheappliance.Forexample,donot

removelevelinglegs,panels,wirecoversoranti-tipbrackets/screws.

Toeliminatetheriskofburnsorfirebyreachingoverheatedsurfaceunits,

cabinetstoragespacelocatedabovethesurfaceunitsshouldbeavoided.If

cabinetstorageistobeprovided,theriskcanbereducedbyinstallingahood

thatprojectshorizontallyaminimumof5inchesbeyondthebottomofthe

cabinet.

Verifythatcabinetsabovethecooktopareamaximumof13"(330mm)deep.

Tools and Parts Needed

Additional Parts Needed For

Hard Wire Installations

Parts Included

40 or 50 Amp Power Supply Cord Kit (depending on local code)

Note: Not necessary for Canadian installations

Measuring Tape

Phillips Head Screwdriver

1-1/4" (31.8 mm) Wrench

Pencil

T-20 Torx Screwdriver

Screws (2) and Anchors (2) for Anti-Tip Bracket (Style will vary depending on

mounting surface)

Level

Drill and Drill Bit

Soapy Water

Safety Gloves and Goggles

Tape (Optional)

Cloth or Cardboard (Optional - to Protect Floor)

• Flexible Conduit

• Torque Wrench

• Note: Power Supply Cord Kit Not Necessary For Hard Wire Installations

• Anti-Tip Bracket

• Foam Tape

• Terminal Lugs (For Use With Hard Wire Installations) (not necessary for

Canadian installations)

English 2

Page 5

General Information

Overall Dimensions

Table 1: Overall Dimensions

Dimension Inches centimeters

Height 36 91.44 cm

Width 29 5/16" 74.55 cm

Depth 25 5/8" 65.09 cm

Level

Tips

Preparation

Electrical Requirements

For best results, cabinets, countertops walls and floors in the installation location

should be as level and plumb as possible. Variance may cause damage to coun-

tertops and floors during installation, could jeopardize the seal around the cooktop

and may adversely affect cooking and baking performance.

Tape warming drawer shut to keep it from opening while installing the range.

During installation, place a portion of the box or a piece of cloth under the range to

protect floors.

To make range lighter and easier to handle remove door (see instructions in Use

and Care manual).

Refer to data plate for more information. See "Product Data Plate" on page 17 for

data plate location.

We recommend that the range be installed with a power cord set (not supplied). 1

The electrical rating of the power cord set must be 120/240 volt, 40 or 50 amperes

minimum (depending on local code). The power cord set shall be marked "For

Use with Ranges." Always use a new power cord.

Note: In Canada, the range is shipped from the factory with the range cord

already installed.

Ranges are dual rated for use on either 120/240 VAC or 120/208 VAC. Check the

data plate for the kW rating. Reference the kW rating in the table below to deter-

mine amperage requirements.

Table 2: Electrical Specifications

kW Rating Hz Amps Req'd

120/240V 120/208V

13 9.8 60 40 or 50a

13.8 10.4 60 40 or 50 a

[ ..........................................................................................................................

a. Varies by location. Check local codes.

1.Not needed for Canadian installations

English 3

Page 6

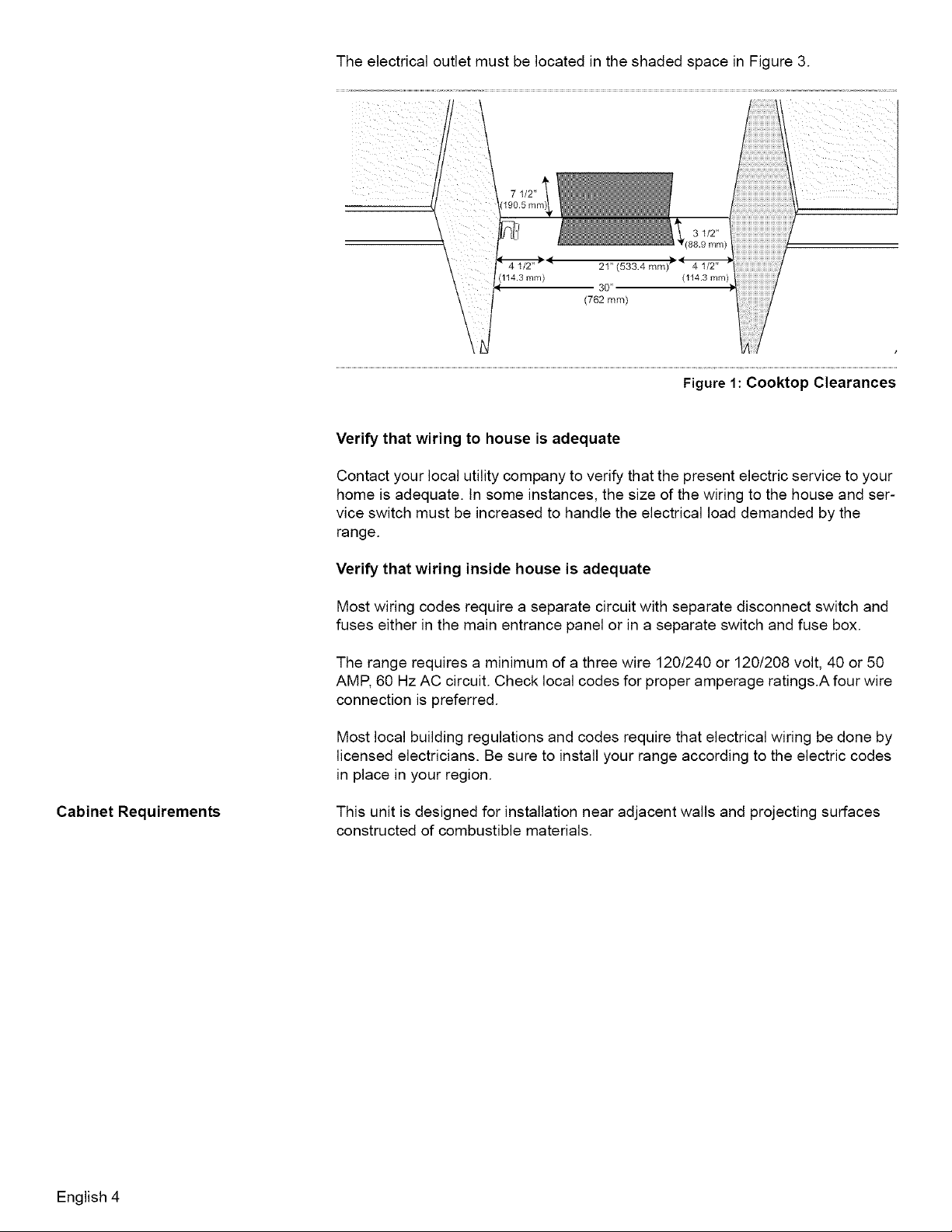

TheelectricaloutletmustbelocatedintheshadedspaceinFigure3.

30

(762 ram)

Figure 1: Cooktop Clearances

Verify that wiring to house is adequate

Contact your local utility company to verify that the present electric service to your

home is adequate. In some instances, the size of the wiring to the house and ser-

vice switch must be increased to handle the electrical load demanded by the

range.

Cabinet Requirements

Verify that wiring inside house is adequate

Most wiring codes require a separate circuit with separate disconnect switch and

fuses either in the main entrance panel or in a separate switch and fuse box.

The range requires a minimum of a three wire 120/240 or 120/208 volt, 40 or 50

AMP, 60 Hz AC circuit. Check local codes for proper amperage ratings.A four wire

connection is preferred.

Most local building regulations and codes require that electrical wiring be done by

licensed electricians. Be sure to install your range according to the electric codes

in place in your region.

This unit is designed for installation near adjacent walls and projecting surfaces

constructed of combustible materials.

English 4

Page 7

Allowaminimumof30inchesbetweencabinetswhererangeistobeinstalled1.

See Figure2:CutoutRequirementsformoreinformation..

23 1/16"

(585.4 mm)

Figure 2: Cutout Requirements

Note: The slide-in range can also replace a freestanding range. In this case, ver-

ify that the opening is at least 30 inches. 1

Figure 3: Cutout Requirements - Replacing a Free-Standing Model

1.In Canada, a clearance of 12 mm from range sidewall to cabinet is required.

English 5

Page 8

®

30" (76.2 cm)

min. centered "_

k

®

4"(10,2cm)

rain.

(12 mm clearance required in Canada)

30" (76.2 cm) min. 4" (10.2 cm)

min.

no clearance required

Figure 4: Cabinet Preparation

Required Clearance I

From cooktop to materials above: There must be a minimum clearance of 30

inches between the top of the cooking surface and the bottom of an unprotected

wood or metal cabinet. See Figure 4: Cabinet Preparation.

24 inches is acceptable when the bottom of the wood or metal cabinet is protected

by (a) not less than 1/4" of flame retardant material which must be covered with

(b) not less than No. 28 MSG sheet metal, 0.015 inch stainless steel' or 0.024 inch

aluminum or copper.

From range walls to adjacent materials: See Figure 4: Cabinet Preparation. No

clearance is required from unit walls to adjacent vertical combustible walls on

rear, right or left.2

Countertop Requirements

Mounting Requirements

English 6

Clearance from range top to adjacent vertical walls must be at least 4".

Note: Some cabinet finishes cannot survive the temperatures allowed by U.L.,

particularly self-cleaning ovens; the cabinets may discolor or stain. This is most

noticeable with laminated cabinets.

Prepare Walls and Floor

Seal any holes in the walls or floor. Remove any obstructions (extra electrical or

gas connections, etc.) so that range will rest against wall properly.

Countertops must be smooth and level.

Install Anti-Tip Bracket

1.instructions were determined using standard American cabinets. Standard base cabinets mea-

sure 36" high x 24" deep. Cabinets over the cooking surface and cabinets adjacent to those over

the cooking surface measure 13 inches deep from backwail. If nonstandard cabinets are used,

care should be taken to alter dimensions accordingly.

2.In Canada, a clearance of 12 mm from range sidewall to cabinet is required.

Page 9

1. Adjust height of range and level by rotating the adjustable leg supports on the

bottom of the range, using 1-1/4" wrench.

2. Measure to locate bracket position as shown in See Figure 5: Anti-Tip

Bracket.

3. Secure bracket with 2 screws adequate for mounting surface (i.e., for wood

...............................floo us woodscr ew fo concr e! f!oo us €°ncret anch° and screws): ..........

rearwali

cabinet wall

o__L f_o9m/lr6e"a_39a71_om_n ter of screw ho,e

Ventilation Recommendations

We strongly recommend the installation of a ventilation hood above this appli-

ance. For most kitchens a certified hood rating of not less than 300 CFM is recom-

mended. The range hood must be installed according to instructions furnished

with the hood.

Installation Procedure

Apply Foam Tape

Apply foam tape to underside of cooktop trim in one continuous piece.

Note: DO NOT use caulk or glue/adhesive of any kind.

flush against

cabinet wail

anti-tippin g

device

floor

Figure 5: Anti-Tip Bracket

Install Backwall Trim

Note: This step is only required if the countertop does not connect behind the

range (i.e.; when replacing a free-standing range). See "Cabinet Requirements"

on page 6 for more information

English 7

Page 10

Install2screwsthroughholesintrimandinrangebackwall.SeeFigure6:Back-

wallTrimStripandFigure7:InstallBackwallTrimStrip

Backwall

Trim Strip

Figure 6: Backwall Trim Strip

J

Connect Electric - Range

Cord

Install Strain Relief

\

Back of Range

\

Figure7: Install Backwall Trim Strip

Note: tn Canada, the range is shipped from the factory with the range cord

already installed. Continue to "Complete the installation" on page 15.

For installations other than those in Canada, connect the range cord at the termi-

nal block (See next page for detailed instructions). Access the terminal block by

removing the cover in the lower right hand corner of the range back panel.

_Warning: The strain relief provided with your range cord must be properly

installed.

Place strain relief in knockout below terminal block. See Figure 8: Strain Relief

Knockout. Feed range cord through hole and strain relief up to terminal block.

Allow for slack in the cord between the strain relief and terminal block. Once cord

English 8

Page 11

length/slackhasbeenadjusted,attachstrainreliefperinstructionsincludedwith

strainrelief.

Tip:Theknockoutpanelbelowtheterminalblockcanberemovedfrom

therangetoinstallthestrainrelief:Removeknockoutpanelfromrange,

installstrainreliefinpanelandreattach.DONOTremoveentirerange

backpane.

!!l

Figure8: Strain Relief Knockout

,_Warning: Risk of Electric Shock or Fire. Frame grounded to neutral

through a ground strap. Grounding through the neutral conductor is prohibited

for new branch-circuit installations (1996 NEC), mobile homes, and recreational

vehicles, or in an area where local codes prohibit grounding through the neutral

conductor.

For installations where grounding through the neutral conductor is prohibited,

(a) disconnect the link from the neutral, (b) use grounding terminal or lead to

ground unit, (c) connect neutral terminal to lead branch circuit neutral in usual

manner (when the appliance is to be connected by means of a cord kit, use 4-

conductor cord for this purpose).

Use only cord kits rated 125/250 volts (minimum), 40 or 50 amperes (depend-

ing on local code) and labeled "For Use with Ranges". Strain relief provided

with cord must be installed per instructions

3=WIRE HOOK UP 4=WIRE HOOK UP

Figure 9: Grounding Requirements

,_Warning: To prevent electrical shock, the grounding prong on the range

cord should not be cut or removed under any circumstances. It must be plugged

into a matching grounding type receptacle and connected to a correctly polarized

240- Volt circuit. If there is any doubt as to whether the wall receptacle is properly

grounded, have it checked by a qualified electrician.

English 9

Page 12

FourWireRangeCordConnection 1. Disconnectelectrical power at breaker box.

(Recommended Method) 2: Remove the termina! b!ock cover to expose the termina! b!ock.........................................................................................................................

Figure 10:4 Wire Connection

3. Remove top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wiring leads.

4. Remove screw from bottom end of ground strap.

5. Remove ground strap from center post, rotate so that wide end is at top and

attach wide end to range through hole below junction box. Attach green wire

................................°n toP of ground strap: Tighten Screw:...................................................................................................................................................................................................

green ground screw

ground strap

Figure 11: Four Wire Range cord Connection - Ground Strap and Wire

ground wire

6. Attach red wire, round washer, star washer and nut IN THIS ORDER to left

post.

7. Attach white wire, round washer, star washer and nut IN THIS ORDER to cen-

ter post.

English 10

Page 13

black

red

iii;

white

Figure 12: Four Wire Range Cord Connection (continued)

9. Tighten all connections securely and replace terminal block cover.

10. Properly secure strain relief (see previous section).

Note: DO NOT plug in range at this time.

Three Wire Range Cord Connection

The Four Wire Connection (above) is preferred, but where local codes and ordi-

nances permit grounding through neutral and where conversion to four wire is

impractical, the unit may be connected to the power supply via a three wire con-

nection.

1. Disconnect electrical power at breaker box.

2: Rem°v th termina b!oc cove t ex13os th termina b!ock:.....................................................................................................................

Figure 13: Terminal Block

3. Remove top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wiring leads.

4. Attach white wire, round washer, star washer and nut IN THIS ORDER on top

of ground strap on center post.

5. Attach red wire, round washer, star washer and nut IN THIS ORDER to left

post.

English 11

Page 14

6. Attachblackwire,roundwasher,starwasherandnutINTHISORDERtoright

................................p°st ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................

/

groundstrap

red

7: Tighten a!! connecti on sec ure!y and re13!ace term!na b!ock cove r.........................................................................................

white

Figure 14: Three Wire Connection

biack

/

green ground screw

Figure 15: Completed Three Wire Range Cord Connection

8. Properly secure strain relief. See "Install Strain Relief' on page 8 for detailed

instructions.

Connect Electric - Flexible

Conduit Connection

Four Wire Flexible Conduit Connec-

tion

English 12

The range can also be connected via flexible conduit. If using this method, always

use the lugs supplied.

Note: tn Canada, the range is shipped from the factory with the range cord

already installed. Continue to "Complete the installation" on page 15.

1. Disconnect electrical power at the breaker box.

2. Remove the terminal block cover to expose the terminal block.

3. Remove the top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wire leads.

4. Remove screw from bottom end of ground strap.

5. Remove ground strap from center post. Discard.

6. Attach one terminal lug (packaged with this manual) through hole below termi-

nal block with ground screw.

7. Place one terminal lug (packaged with this manual) on each post. Replace the

star washer and round washer and secure with 20 inch pounds of torque.

Page 15

8. Strip3/8(9.53mm)inchesofinsulationfromtheendofthewire.

Figure 16: Wire Stripping

9. Insert the insulated grounding wire into the lug below the terminal block.

10. Insert stripped end of white wire into the center lug. Secure the clamping-

screw.

3/8

wire

clamping screw

Figure 17: Attaching Wire to Lug

11. Insert stripped end of red wire into the left lug. Secure clamping screw.

12. Insert black wire into the right lug. Secure clamping screw. Tighten each

clamping screw with the appropriate torque (see table).

Table 3: Appropriate Torque Levels for Aluminum or Copper Wire

Gauge Torque (in./Ibs.) Torque (Nm)

6 35 3.95

8 25 2.82

13. Properly secure flexible conduit at knockout on angle and at supply side junc-

...............................t!° bo Th wirin ! no £omp!ete ...............................................................

black wire

red wire

white wire

green ground wire

Figure18: Completed Four Wire Flexible Conduit Connection

English 13

Page 16

Note:DONOTpluginrangeatthistime.

ThreeWireFlexibleConduitConnec-TheFourWireConnectionispreferred,butwherelocalcodesandordinances

tion permitgroundingthroughneutraland/orconversiontofourwireisimpractical,unit

maybeconnectedtothepowersupplyviaa threewireconnection.

1. Disconnectelectricalpoweratthebreakerbox.

2: Removethetermina!b!ockcovertoexp0setheterminalblock.

Figure 19: Terminal Block

3. Remove the top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wire leads.

4. Place one terminal lug (packaged with this manual) on each post. Replace the

star washer and round washer and secure with 20 inch pounds of torque.

5. Strip 3/8 (9.53 mm) inches of insulation from the end of each wire.

H

3/8 "

Figure20: Wire Stripping

6. Insert stripped end of white wire into the center lug on top of the ground strap.

Secure the clamping screw.

lug • - •_/

wire

7. Insert stripped end of red wire into the left lug. Secure clamping screw.

8. Insert stripped end of black wire into the right lug. Secure clamping screw.

clamping screw

Figure 21: Attaching Wire to Lug

English 14

Page 17

9. Tighteneachclampingscrewwiththeappropriatetorque(Seetablebelow).

Table 4: Appropriate Torque Levels for Aluminum or Copper Wire

Gauge Torque (in./Ibs.) Torque (Nm)

6 35 3.95

8 25 2.82

10. Properly secure flexible conduit at knockout panel on range and at supply

................................sidejunc!!o bo Th wr!ng! no €°m£!ete: .................................................................................................................................................................................................................................................

green g_ound screw

Figure 22: Completed Three Wire Flexible Conduit Connection

Note: DO NOT plug in range at this time.

Complete the installation

Adjust Levelling Legs 1. Line up range in front of opening.

2. Measure back left corner of opening from floor to top of countertop.

3. Measure back left corner of range to bottom of cooktop trim. Use a wrench to

adjust leveling leg until this height is the same as the corner dimension.

drawer

adjustable leg

Figure23: Adjust the Front Leveling Leg

Slide Range into Opening

4. Repeat in right back corner.

5. Adjust front leveling legs so that the bottom of the cooktop trim is ½" higher

than the corresponding countertop surface.

1. Plug in power cord.

2. Dampen countertop and foam tape with soapy water.

English 15

Page 18

3. Slide range into opening, being careful not to damage countertops, floors, or

the range drawer front. Do not apply pressure to cooktop when sliding into

position.

Tip: Remove the drawer to prevent damage.

Check Back of Range for Proper

Installation

Adjust Front of Range for Proper

Installation

Test the Installation

Turn on Power at Breaker

.

When properly installed, the cooktop trim around the back of the range will

rest lightly on the countertop.

2.

There should not be any gap between the countertop and the trim; however,

the weight of the range must not rest on the countertop. Look under the range

to verify that both back legs are resting solidly on the floor. Also verify that the

left range leg is under the anti-tip bracket.

Caution: Verify that the weight of the range is not resting on the counterrop. This

could result in damage to the countertop and the appliance.

3. If the back legs are not resting solidly on the floor or the left leg is not under

the anti-tip bracket, slide range out, adjust legs and slide back in.

1. Adjust front leveling legs so that the cooktop trim rests snugly against the

countertop all the way around.

2. Verify that both front legs are resting solidly on the floor.

3. Use a level to verify that the range is level and plumb.

Caution: If the display flashes and beeps, the polarity of the wiring may be

reversed. Reversed polarity can damage the range and can result in electrical

shock hazard. Immediately switch off power at the breaker and return to "Connect

Electric - Range Cord" on page 8.

Service

Before Calling

Service

English 16

See Use and Care Manual for troubleshooting information. Refer to the Warranty

in the Use and Care Manual.

To reach a service representative, see the contact information at the front of the

manual. Please be prepared with the information printed on your product data

plate when calling.

Page 19

Product Data Plate

The data plate shows the model and serial number. Refer to the data plate on the

appliance when requesting service. It is located on the frame near the drawer.

Open the drawer to view it.

Data Plate_

Figure24: Data Plate

English 17

Page 20

BOSCH

5551 McFadden Avenue, Huntington Beach, CA 92649 • 800-944-2904 • www.boschappliances.com

9000135012 (No ECO) ° 10086 Rev B° 03/06 • © BSH Home Appliances Corporation • Litho U.S. A.

Loading...

Loading...