Page 1

IMPORTANT

Read Before Using

IMPORTANT

Lire avant usage

IMPORTANTE

Leer antes de usar

Operating / Safety Instructions

Consignes d’utilisation / de sécurité

Instrucciones de funcionamiento y seguridad

GWX13-50

GWX13-50VSP

Call Toll Free for Consumer Information & Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente, appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version

See page 2

Version française

Voir page 30

Versión en español

Ver la página 59

1600A019ZE 05-19 GWX13.indd 1 5/28/19 3:15 PM

Page 2

page headingContents

Safety Symbols ............................................ 3

General Power Tool Safety Warnings ...........3

Work Area Safety .......................................3

Electrical Safety ......................................... 3

Personal Safety ..........................................3

Power Tool Use and Care ........................... 4

Service ....................................................... 4

Power Tool-Specific Safety Warnings ...........5

Safety Warnings Common

for Grinding, Sanding, Wire

Brushing, and Abrasive

Cutting-Off Operations ..............................5

Kickback and Related Warnings .................6

Safety Warnings Specific

for Grinding and Abrasive

Cutting-Off Operations ..............................6

Additional Safety Warnings

Specific for Abrasive

Cutting-Off Operations ..............................7

Safety Warnings Specific for

Sanding Operations ................................... 7

Safety Warnings Specific for Wire Brushing

Operations ................................................. 7

Additional Safety Warnings ..........................8

Symbols ....................................................... 9

Functional Description and Specifications 11

Basic X-Lock Operation ..............................14

Assembly ....................................................15

Installing Side Handle .............................. 15

Hand Shield .............................................15

Installing Wheel Guards

(Type 27 and Type 41/1A

Wheel Guards) ......................................... 16

Mounting and Removing

X-Lock Accessories ..................................17

Abrasive Type 27 Grinding

Wheel & Sanding Flap Disk

Assembly .................................................. 19

Abrasive Type 41/1A

Cutting Wheel Assembly .......................... 19

Sanding Assembly ................................... 20

Wire Cup Brush Assembly ........................21

Wire Wheel Assembly ...............................21

Masonry Cutting Guard

Assembly .................................................. 22

Installing Masonry Type 41/1A

Cutting Guard .......................................... 23

Installing Dry Diamond Wheel.................. 23

Operating Instructions ...............................24

Paddle Switch (Fig. 21) ...........................24

Slide Switch (Fig. 23) .............................. 24

Metal Grinding ......................................... 25

Metal Cutting ........................................... 25

Masonry / Concrete Cutting ....................26

Sanding .................................................... 27

Wire Brush (Wheels and Cups) ................28

Maintenance ..............................................28

Service ..................................................... 28

Tool Lubrication ....................................... 28

Carbon Brushes ....................................... 29

Cleaning ................................................... 29

Accessory Storage &

Maintenance ............................................29

Extension Cords.........................................29

Accessories ................................................ 29

-2-

1600A019ZE 05-19 GWX13.indd 2 5/28/19 3:15 PM

Page 3

page heading

The definitions below describe the level of severity for each signal word.

Please read the manual and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Safety Symbols

General Power Tool Safety Warnings

Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or seri-

ous injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

▶ Work Area Safety

Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

▶ Electrical Safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your

body is earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor use. Use of a cord suitable for out-

door use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a Ground Fault

Circuit Interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of

electric shock.

▶ Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment

of inattention while operating power tools

may result in serious personal injury.

-3-

1600A019ZE 05-19 GWX13.indd 3 5/28/19 3:15 PM

Page 4

General Power Tool Safety Warnings

Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and / or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on

the switch or energizing power tools that

have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of

the power tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. This enables bet-

ter control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts.

Loose clothes, jewelry or long hair can be

caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and

properly used. Use of dust collection can

reduce dust-related hazards.

▶ Power Tool Use and Care

Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better

and safer at the rate for which it was designed.

Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be repaired.

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety mea-

sures reduce the risk of starting the power

tool accidentally.

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If

damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp

cutting edges are less likely to bind and

are easier to control.

Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for op-

erations different from those intended

could result in a hazardous situation.

▶ Service

Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that

the safety of the power tool is maintained.

-4-

1600A019ZE 05-19 GWX13.indd 4 5/28/19 3:15 PM

Page 5

Power Tool-Specific Safety Warnings

▶ Safety Warnings Common

for Grinding, Sanding, Wire

Brushing, and Abrasive

Cutting-Off Operations

This power tool is intended to function

as a grinder, sander, wire brush or cut-off

tool. Read all safety warnings, instructions, illustrations and specifications

provided with this power tool. Failure to

follow all instructions listed below may result in electric shock, fire and/or serious

injury.

Operations such as polishing are not recommended to be performed with this

power tool. Operations for which the

power tool was not designed may create a

hazard and cause personal injury.

Do not use accessories which are not specifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power

tool, it does not assure safe operation.

The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool. Accessories

running faster than their rated speed can

break and fly apart.

The outside diameter and the thickness

of your accessory must be within the

capacity rating of your power tool. In-

correctly sized accessories cannot be adequately guarded or controlled.

Threaded mounting of accessories must

match the grinder spindle thread. For accessories mounted by flanges, the arbour

hole of the accessory must fit the locating diameter of the flange. Accessories

that do not match the mounting hardware

of the power tool will run out of balance,

vibrate excessively and may cause loss of

control.

Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess

wear, wire brush for loose or cracked

wires. If power tool or accessory is

dropped, inspect for damage or install

an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders away from

the plane of the rotating accessory and

run the power tool at maximum no-load

speed for one minute. Damaged accesso-

ries will normally break apart during this

test time.

Wear personal protective equipment. Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection

must be capable of stopping flying debris

generated by various operations. The dust

mask or respirator must be capable of filtrating particles generated by your operation. Prolonged exposure to high intensity

noise may cause hearing loss.

Keep bystanders a safe distance away

from work area. Anyone entering the

work area must wear personal protective equipment. Fragments of workpiece

or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

Hold the power tool by insulated gripping surfaces only, when performing an

operation where the cutting accessory

may contact hidden wiring or its own

cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the

power tool “live” and could give the operator an electric shock.

Position the cord clear of the spinning accessory. If you lose control, the cord may

be cut or snagged and your hand or arm

may be pulled into the spinning accessory.

Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the surface and pull the power tool out of your

control.

Do not run the power tool while carrying

it at your side. Accidental contact with the

spinning accessory could snag your clothing, pulling the accessory into your body.

-5-

1600A019ZE 05-19 GWX13.indd 5 5/28/19 3:15 PM

Page 6

Power Tool-Specific Safety Warnings

Regularly clean the power tool’s air

vents. The motor’s fan will draw the dust

inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

Do not operate the power tool near flammable materials. Sparks could ignite

these materials.

Do not use accessories that require liquid

coolants. Using water or other liquid cool-

ants may result in electrocution or shock.

Only use Bosch or Bosch licensed X-Lock

accessories. Incompatible accessories

may not clamp properly resulting in personal injury and/or property damage.

Confirm proper clamping by ensuring

that top of the accessory flange surface

is not above the top of the accessory

height gage. Accessories that are above

the accessory height gage may not be

clamped properly and separate from the

tool causing personal injury and/or property damage.

Always inspect accessory mount and accessory clamping flange before use. Do

not use the tool or accessory if the accessory mount or accessory is damaged

or deformed. Accessories that are not

clamped properly may cause personal injury and/or property damage.

Check for presence or buildup of foreign

material on tool and accessory clamping

surfaces and remove before use. Unwant-

ed material can cause incomplete clamping and may cause personal injury and/or

property damage.

Never actuate X-Lock Release Lever while

accessory is moving. Make sure that the

accessory has come to a complete stop

before removing the accessory. Releasing

accessory while still spinning could cause

personal injury and/or property damage.

direction opposite of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is

snagged or pinched by the workpiece, the

edge of the wheel that is entering into the

pinch point can dig into the surface of the

material causing the wheel to climb out

or kickout. The wheel may either jump toward or away from the operator, depending on direction of the wheel’s movement

at the point of pinching. Abrasive wheels

may also break under these conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

Maintain a firm grip on the power tool

and position your body and arm to allow

you to resist kickback forces. Always use

auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper precautions are taken.

Never place your hand near the rotating

accessory. Accessory may kickback over

your hand.

Do not position your body in the area

where power tool will move if kickback

occurs. Kickback will propel the tool in di-

rection opposite to the wheel’s movement

at the point of snagging.

Use special care when working corners,

sharp edges etc. Avoid bouncing and snag-

ging the accessory. Corners, sharp edges

or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

▶ Kickback and Related Warnings

Kickback is a sudden reaction to a pinched

or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating accessory which in turn causes the uncontrolled power tool to be forced in the

▶ Safety Warnings Specific

for Grinding and Abrasive

Cutting-Off Operations

Use only wheel types that are recommended for your power tool and the

specific guard designed for the selected

wheel. Wheels for which the power tool

-6-

1600A019ZE 05-19 GWX13.indd 6 5/28/19 3:15 PM

Page 7

Power Tool-Specific Safety Warnings

was not designed cannot be adequately

guarded and are unsafe.

The grinding surface of centre depressed

wheels must be mounted below the plane

of the guard lip. An improperly mounted

wheel that projects through the plane of

the guard lip cannot be adequately protected.

The guard must be securely attached to

the power tool and positioned for maximum safety, so the least amount of wheel

is exposed towards the operator. The

guard helps to protect operator from broken wheel fragments and accidental contact with wheel.

Wheels must be used only for recommended applications. For example: do

not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for

peripheral grinding, side forces applied to

these wheels may cause them to shatter.

Always use undamaged wheel flanges

that are of correct size and shape for

your selected wheel. Proper wheel flang-

es support the wheel thus reducing the

possibility of wheel breakage. Flanges for

cut-off wheels may be different from grinding wheel flanges.

Do not use worn down wheels from larger power tools. Wheel intended for larger

power tool is not suitable for the higher

speed of a smaller tool and may burst.

When wheel is binding or when interrupting a cut for any reason, switch off

the power tool and hold the power tool

motionless until the wheel comes to a

complete stop. Never attempt to remove

the cut-off wheel from the cut while the

wheel is in motion otherwise kickback

may occur. Investigate and take correc-

tive action to eliminate the cause of wheel

binding.

Do not restart the cutting operation in

the workpiece. Let the wheel reach full

speed and carefully reenter the cut. The

wheel may bind, walk up or kickback if the

power tool is restarted in the workpiece.

Support panels or any oversized workpiece to minimize the risk of wheel pinching and kickback. Large workpieces tend

to sag under their own weight. Supports

must be placed under the workpiece near

the line of cut and near the edge of the

workpiece on both sides of the wheel.

Use extra caution when making a “pocket

cut” into existing walls or other blind areas. The protruding wheel may cut gas or

water pipes, electrical wiring or objects

that can cause kickback.

Do not use type 1 abrasive wheels designed for straight grinding.

Do not attempt to cut large stock or

sheets of metal as this machine is not designed to be a dedicated cut-off machine.

▶ Additional Safety Warnings

Specific for Abrasive

Cutting-Off Operations

Do not “jam” the cut-off wheel or apply

excessive pressure. Do not attempt to

make an excessive depth of cut. Over-

stressing the wheel increases the loading

and susceptibility to twisting or binding of

the wheel in the cut and the possibility of

kickback or wheel breakage.

Do not position your body in line with

and behind the rotating wheel. When the

wheel, at the point of operation, is moving

away from your body, the possible kickback may propel the spinning wheel and

the power tool directly at you.

▶ Safety Warnings Specific for

Sanding Operations

Do not use excessively oversized sanding disc paper. Follow manufacturer’s

recommendations, when selecting sanding paper. Larger sanding paper extending

beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the disc or kickback.

▶ Safety Warnings Specific for

Wire Brushing Operations

Be aware that wire bristles are thrown

by the brush even during ordinary operation. Do not overstress the wires by applying excessive load to the brush. The

-7-

1600A019ZE 05-19 GWX13.indd 7 5/28/19 3:15 PM

Page 8

Power Tool-Specific Safety Warnings

wire bristles can easily penetrate light

clothing and/or skin.

If the use of a guard is recommended for

wire brushing, do not allow any interfer-

Additional Safety Warnings

Do not use AC only rated tools with a DC

power supply. While the tool may appear

to work, the electrical components of the

AC rated tool are likely to fail and create a

hazard to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead

to loss of control.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be

careful not to disassemble any portion

of the tool since internal wires may be

misplaced or pinched or safety guard return springs may be improperly mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

Do not use vacuum or other dust collection system when cutting metal. Sparks

from metal cutting can cause fire in the

collector.

ence of the wire wheel or brush with the

guard. Wire wheel or brush may expand in

diameter due to work load and centrifugal

forces.

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and ce-

ment and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially designed to filter out microscopic particles.

-8-

1600A019ZE 05-19 GWX13.indd 8 5/28/19 3:15 PM

Page 9

page heading

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and safer.

Symbol Designation/Explanation

V Volts (voltage)

A Amperes (current)

Hz Hertz (frequency, cycles per second)

W Watt (power)

kg Kilograms (weight)

min Minutes (time)

s Seconds (time)

⌀

n

n Rated speed (Maximum attainable speed)

.../min

0 Off position (zero speed, zero torque...)

1, 2, 3, ...

I, II, III,

Diameter (size of drill bits, grinding wheels, etc.)

No load speed (rotational speed, at no load)

0

Revolutions or reciprocation per minute (revolutions, strokes, surface

speed, orbits etc. per minute)

Selector settings (speed, torque or position settings. Higher number

means greater speed)

Infinitely variable selector with off (speed is increasing from 0 setting)

Arrow (action in the direction of arrow)

Type or a characteristic of current

Type or a characteristic of current

Type or a characteristic of current

Designates Double Insulated Construction tools

Grounding terminal

Alerts user to warning messages

-9-

1600A019ZE 05-19 GWX13.indd 9 5/28/19 3:15 PM

Page 10

page heading

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and safer.

Symbol Designation/Explanation

Designates Li-ion battery recycling program.

Designates Ni-Cad battery recycling program.

Alerts user to read manual.

Alerts user to wear eye protection.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

-10-

1600A019ZE 05-19 GWX13.indd 10 5/28/19 3:15 PM

Page 11

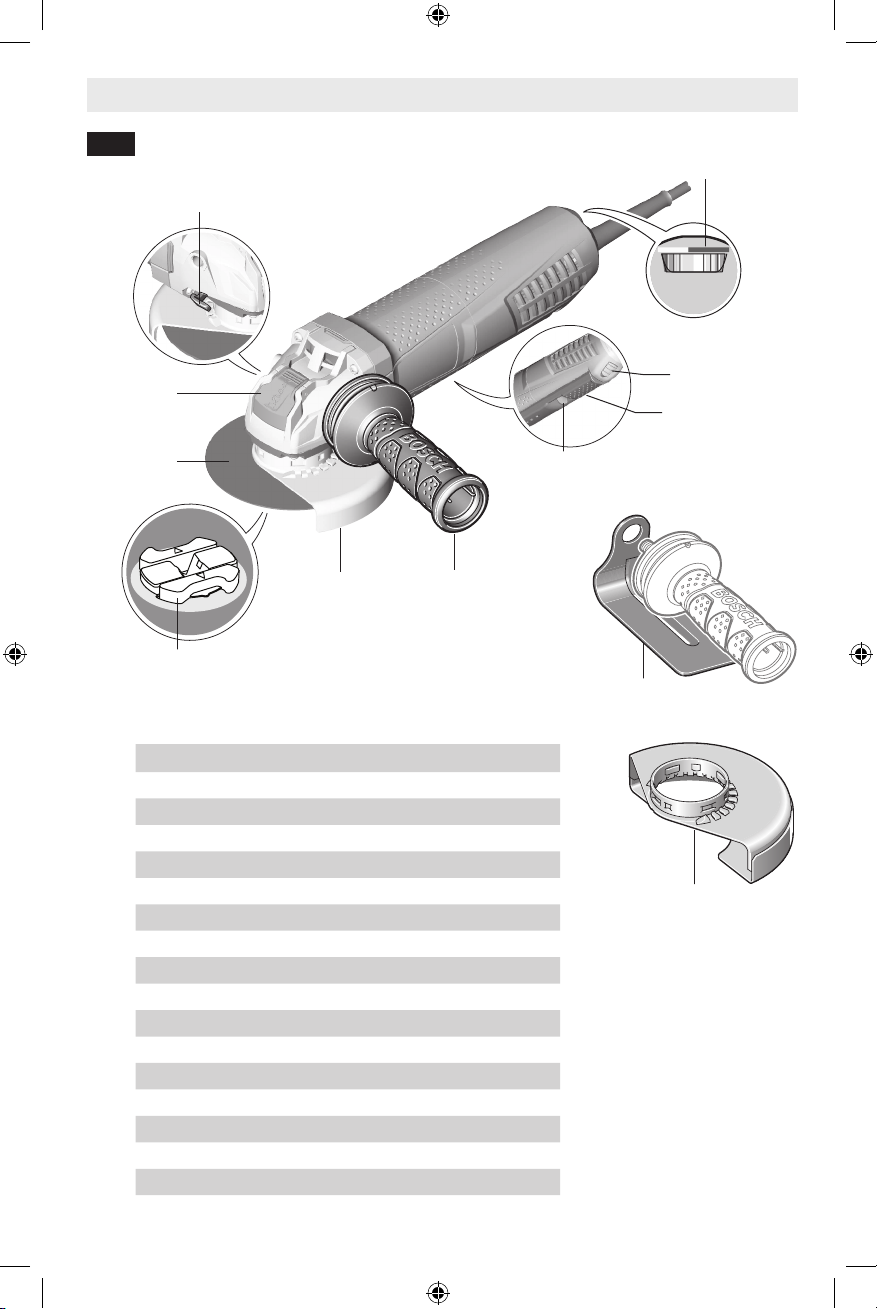

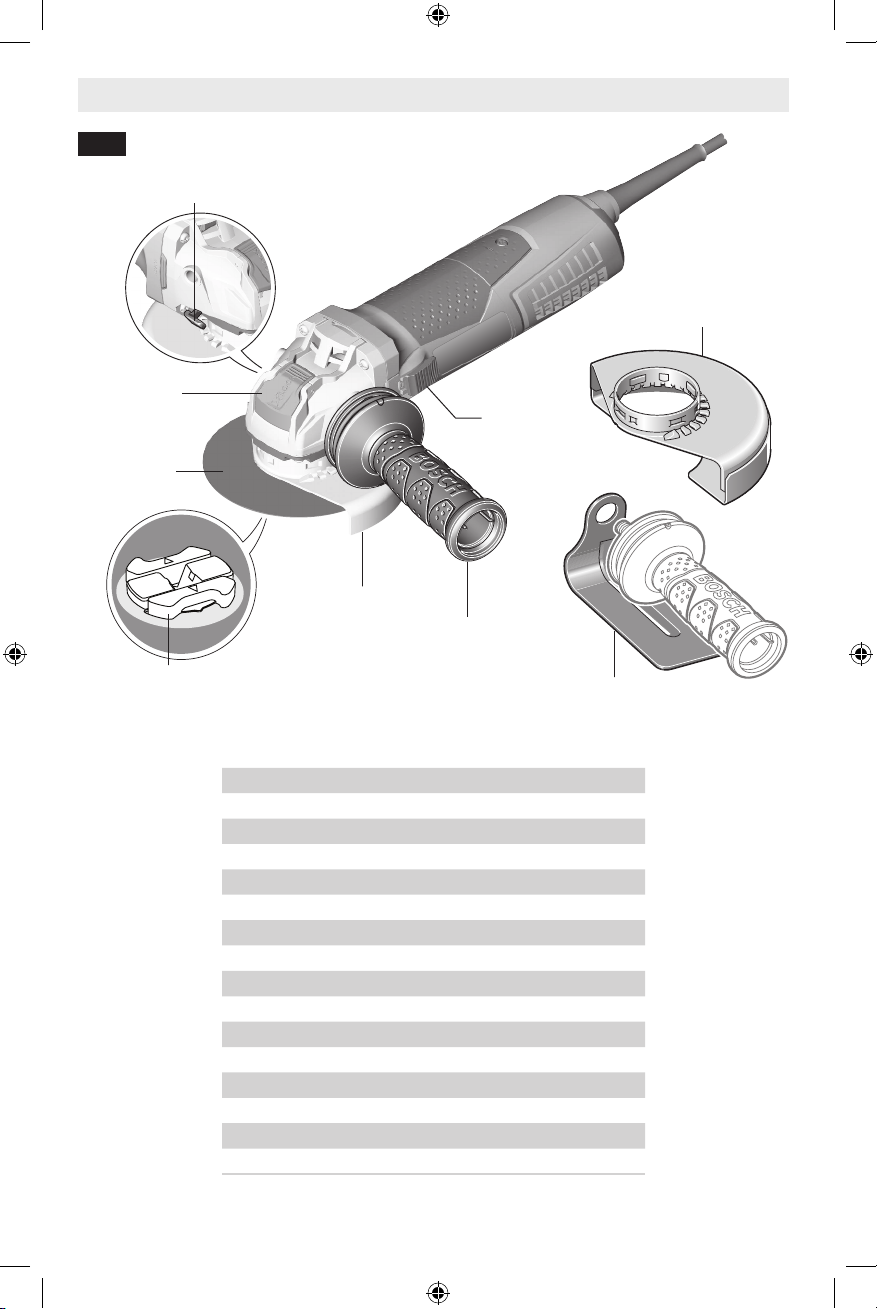

page headingFunctional Description and Specifications

6

Fig. 1

Adjustment Button

X-Lock

Release

Lever

Grinding

Wheel

Accessory

Guard Release /

X-Lock

Mount

Type 27

Grinding

Guard

Variable Speed

(GWX13-50VSP)

Lock-ON Button

Paddle Switch

“Lock-OFF” Switch

Release Lever

Vibration

Control Side

Handle

Hand Shield

(Optional Accessory)

Model Number GWX13-50VSP

Amps 13

Volts AC 120

Rated Speed (RPM), /min 2800 - 11500

Max. grinding wheel ⌀ 5” (125mm)

Grinding wheel thickness 1/4” (6 mm)

Max. cutting wheel ⌀ 5” (125mm)

Max. sanding disc ⌀ 5” (125mm)

Max. flap disc ⌀ 5” (125mm)

Max. wire wheel ⌀ 4” (102mm)

Max. wire cup ⌀ 3” (76mm)

Variable speed ●

Electronic clutch ●

Constant response circuitry ●

Restart protection ●

Overload protection ●

Soft start ●

Type 41/1A

Cutting Guard

(Optional Accessory)

-11-

1600A019ZE 05-19 GWX13.indd 11 5/28/19 3:15 PM

Page 12

Fig. 2

X-Lock

Release Lever

Grinding

Wheel

Guard Release /

Adjustment Button

X-Lock

Accessory

Mount

page headingFunctional Description and Specifications

Side

Switch

Type 27

Grinding

Guard

Vibration

Control Side

Handle

Hand Shield

(Optional Accessory)

Type 41/1A

Cutting Guard

(Optional Accessory)

Model Number GWX13-50

Amps 13

Volts AC 120

Rated Speed (RPM), /min 11500

Max. grinding wheel ⌀ 5” (125mm)

Grinding wheel thickness 1/4” (6 mm)

Max. cutting wheel ⌀ 5” (125mm)

Max. sanding disc ⌀ 5” (125mm)

Max. flap disc ⌀ 5” (125mm)

Max. wire wheel ⌀ 4” (102mm)

Max. wire cup ⌀ 3” (76mm)

Electronic clutch ●

Constant response circuitry ●

Restart protection ●

Overload protection ●

Soft start ●

-12-

1600A019ZE 05-19 GWX13.indd 12 5/28/19 3:15 PM

Page 13

page headingFunctional Description and Specifications

Do not use Type 11 abrasive (cup) wheels with this tool. This tool is

not designed for use with type 11 (cup) abrasive grinding wheels.

Model Number GWX13-50 GWX13-50VSP

Metal Grinding (Type 27) X X

Metal Grinding (Type 11) N N

Metal Grinding (Type 1) N N

Metal Cutting (Type 41/1A) O O

Flap Disc Type 29 X X

Concrete Cutting O O

Sanding O O

Wire Brushing (Wheel) X X

Wire Brushing (Cup)

X = Tool is provided with attachments to perform this application.

O = Tool can use optional attachments to perform this application.

N = Tool is not capable of this application.

Accessory speed rating must be equal to or greater than the tool’s speed rating. Do not

exceed the recommended wheel diameter.

O O

-13-

1600A019ZE 05-19 GWX13.indd 13 5/28/19 3:15 PM

Page 14

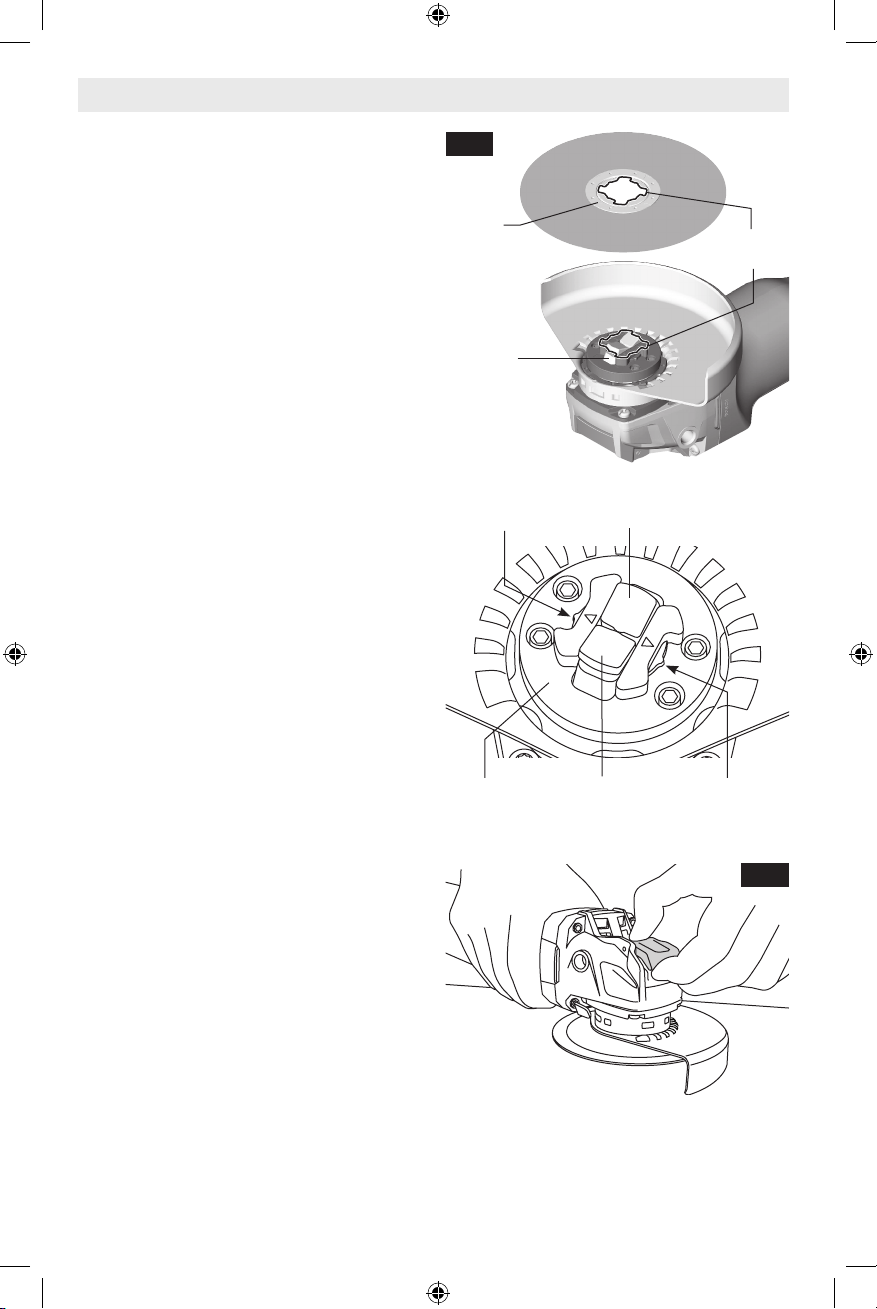

Basic X-Lock Operation

The X-Lock system is a combination of

patented tool mount and accessory designs that provide the operator with fast

accessory changes. Available on select

Bosch angle grinders, X-Lock allows tool

free installation and removal of grinder accessories (grinding, cut-off wheels, wire

brushes, sanding discs, etc.). The X-Lock

system is a replacement for the traditional

method of attaching grinder accessories.

Traditional grinders have 5/ 8”-11 threaded spindles that require a nut and backing

flange to hold the accessory in place. To

replace an accessory, a wrench is used to

loosen or tighten the nut. X-Lock equipped

grinders have a tool free interface system,

eliminating the spindle, backing flange and

lock nut.

The X-Lock interface has a tool component

– X-Lock Accessory Mount, and an accessory component – typically an Accessory

X-Lock Mounting Hub. The two components have keyed alignment contours,

which help to ensure correct assembly of

accessory to tool.

The X-Lock Accessory Mount consists of

a round base, clamping height gages and

locking mechanism, which activates the

clamping tabs. X-Lock equipped grinders can only use X-Lock accessories since

the specially designed X-Lock Mounting

Hub matches the contours of the X-Lock

Accessory Mount on the tool (See figure

3). However, select X-Lock accessories are

backward compatible with the traditional

threaded spindle design.

Attachment of the X-Lock accessory to the

X-Lock Accessory Mount on the grinder

requires alignment of the mounting hub

with the accessory mounting mechanism.

Once the Accessory X-Lock Mounting Hub

is aligned, and pressed against the base of

the X-Lock Accessory Mount, the locking

mechanism is activated. This causes the

two opposing clamping tabs to lock the accessory to the grinder. An audible ‘click’ in

combination with the alignment of the flat

surface of the Accessory X-Lock Mounting hub with the Clamping Height Gages

means the accessory is firmly attached to

the tool. To remove the accessory, a lever

Fig. 3

Accessory

X-Lock

Mounting Hub

X-Lock

Accessory

Mount

Clamping

Height Gage

Base Clamping

Clamping Tab

Clamping Tab

Alignment

contours

Height Gage

Fig. 4

on the grinder gearhead is actuated which

will release the locking tabs, allowing the

accessory to be detached from the tool.

(Fig. 4)

-14-

1600A019ZE 05-19 GWX13.indd 14 5/28/19 3:15 PM

Page 15

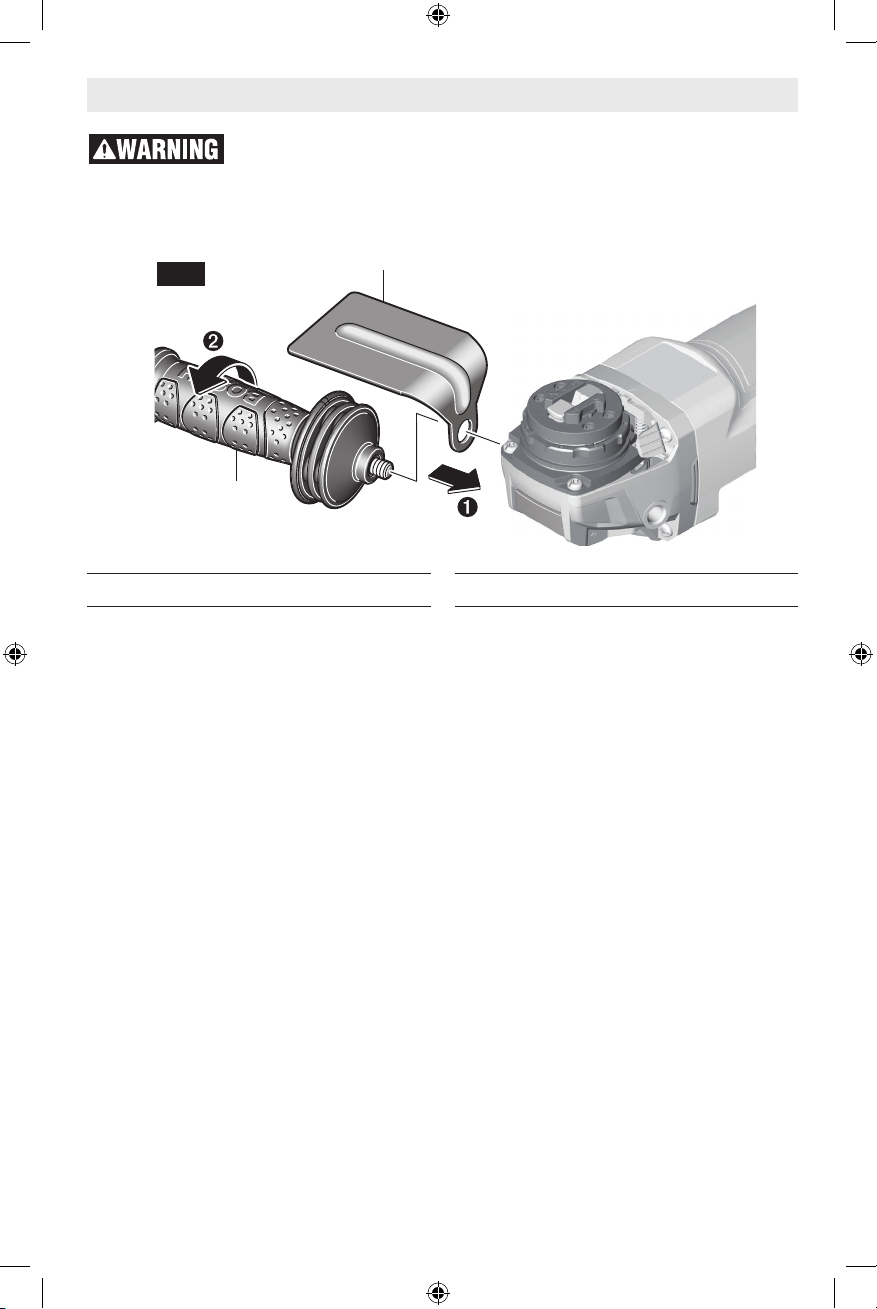

Assembly

Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any

adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

Hand Shield

Fig. 5

Side

Handle

(Optional Accessory)

▶ Installing Side Handle

The side handle is used to control and balance the tool.

Securely thread handle into either side of

gear housing, depending on personal preference, comfort, and operation being performed (Fig. 5).

The handle should always be installed

onto the guard protected side of the tool,

see figure 7. Use the side handle for safe

control and ease of operation.

▶ Hand Shield

The hand shield is to be used with backing pads, sanding discs, and wire brushes

to keep fingers and hand away from work

surface, sharp edges, burrs and debris.

When using the hand shield, insert side

handle through hole in shield and then

thread into housing (Fig. 5). Ensure that

hand shield is positioned between hand

and backing pad, sanding disc or wire

brush.

-15-

1600A019ZE 05-19 GWX13.indd 15 5/28/19 3:15 PM

Page 16

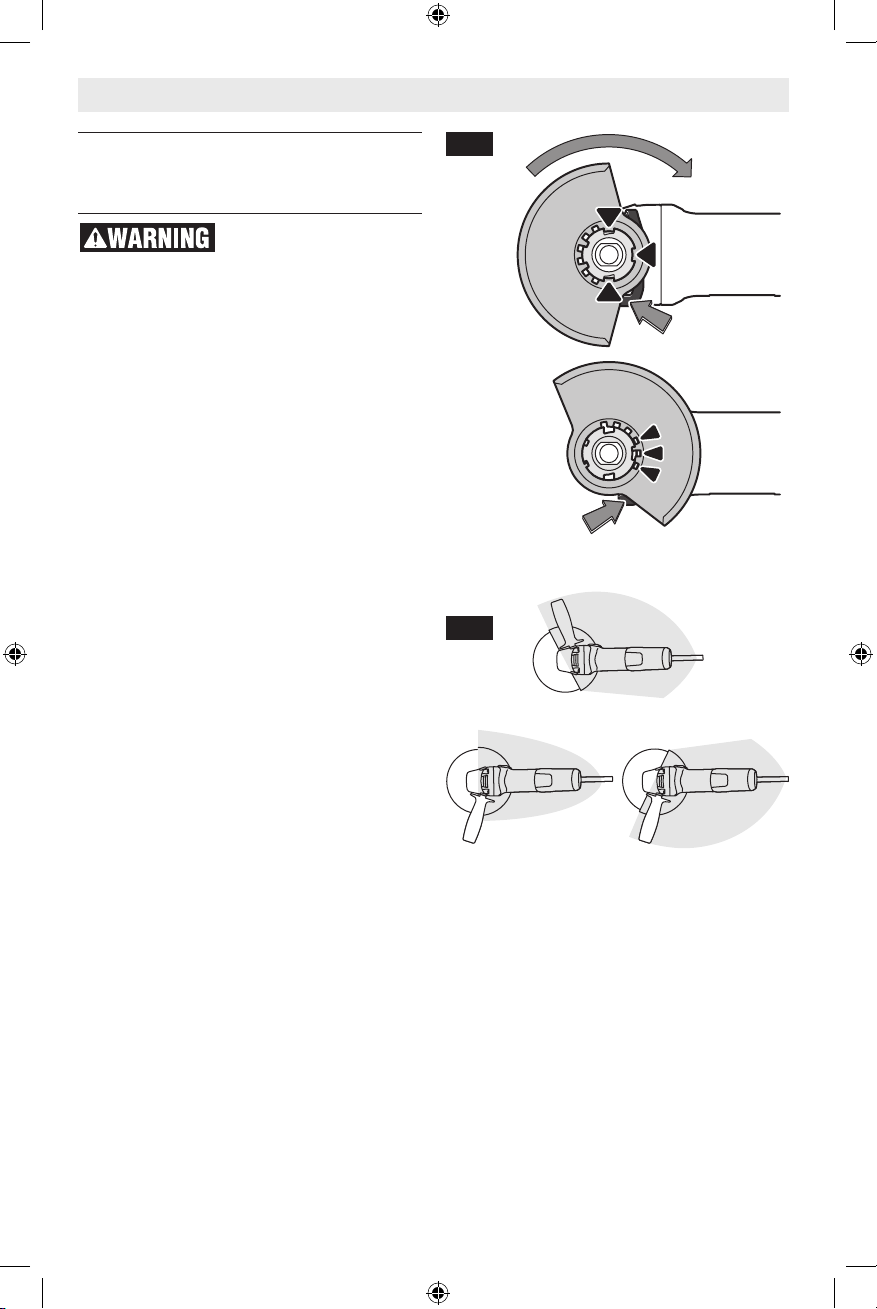

Assembly

▶ Installing Wheel Guards

(Type 27 and Type 41/1A

Wheel Guards)

A Type 27 guard must

be used with all grind-

ing wheels, bonded body sanding flap

discs, wire brushes and wheels. The tool

may be used without a guard only when

sanding with conventional sanding discs.

▼ To attach guard

1. Unplug tool from power source.

2. Position appropriate guard on collar

mount so arrows on guard and collar

mount align (Fig. 6).

3. Rotate wheel guard clockwise 90º until

guard clicks in place.

4. Adjust guard by depressing guard release button and rotate to desired

position. Always position wheel guard

between operator and work piece

and direct sparks away from operator

(Fig. 7).

5. Allow guard release button to click in

place.

▼ To remove wheel guard

1. Depress guard release button and rotate guard until arrows on guard and

collar mount align (Fig. 6).

2. Remove guard from collar mount.

Fig. 6

Fig. 7

OPERATING ZONE

-16-

1600A019ZE 05-19 GWX13.indd 16 5/28/19 3:15 PM

Page 17

page headingAssembly

▶ Mounting and Removing

X-Lock Accessories

Only use Bosch or

Bosch licensed X-LOCK

accessories. Incompatible accessories

may not clamp properly resulting in personal injury and/or property damage.

Confirm proper clamp-

ing by ensuring that top

of the accessory X-Lock mounting hub

surface is not above the top of the clamping height gage. Accessories that are

above the clamping height gage may not

be fixed properly and separate from the

the tool causing personal injury and/or

property damage.

Always inspect acces-

sory mount and accessory clamping flange before use. Do not

use the tool or accessory if the accessory

mount or accessory is damaged or deformed. Accessories that are not clamped

properly may cause personal injury and/or

property damage.

Check for presence or

buildup of foreign material on clamping surfaces and remove before use. Unwanted material can cause in-

complete clamping and may cause

personal injury and/or property damage.

Never actuate X-Lock

Release Lever while accessory is moving. Make sure that the accessory has come to a complete stop before removing the accessory. Releasing

accessory while still spinning could cause

personal injury and/or property damage.

Verify that the accessory and the X-Lock

Accessory Mount are not deformed and

are free from dirt. If necessary, clean the

area around the two X-Lock Clamping

Tabs.

Verify that both X-Lock Clamping Tabs are

open (see Fig. 8) before fitting the X-Lock

accessory.

Fig. 8

Accessory

X-Lock

Mounting Hub

X-Lock

Accessory

Mount

Fig. 9

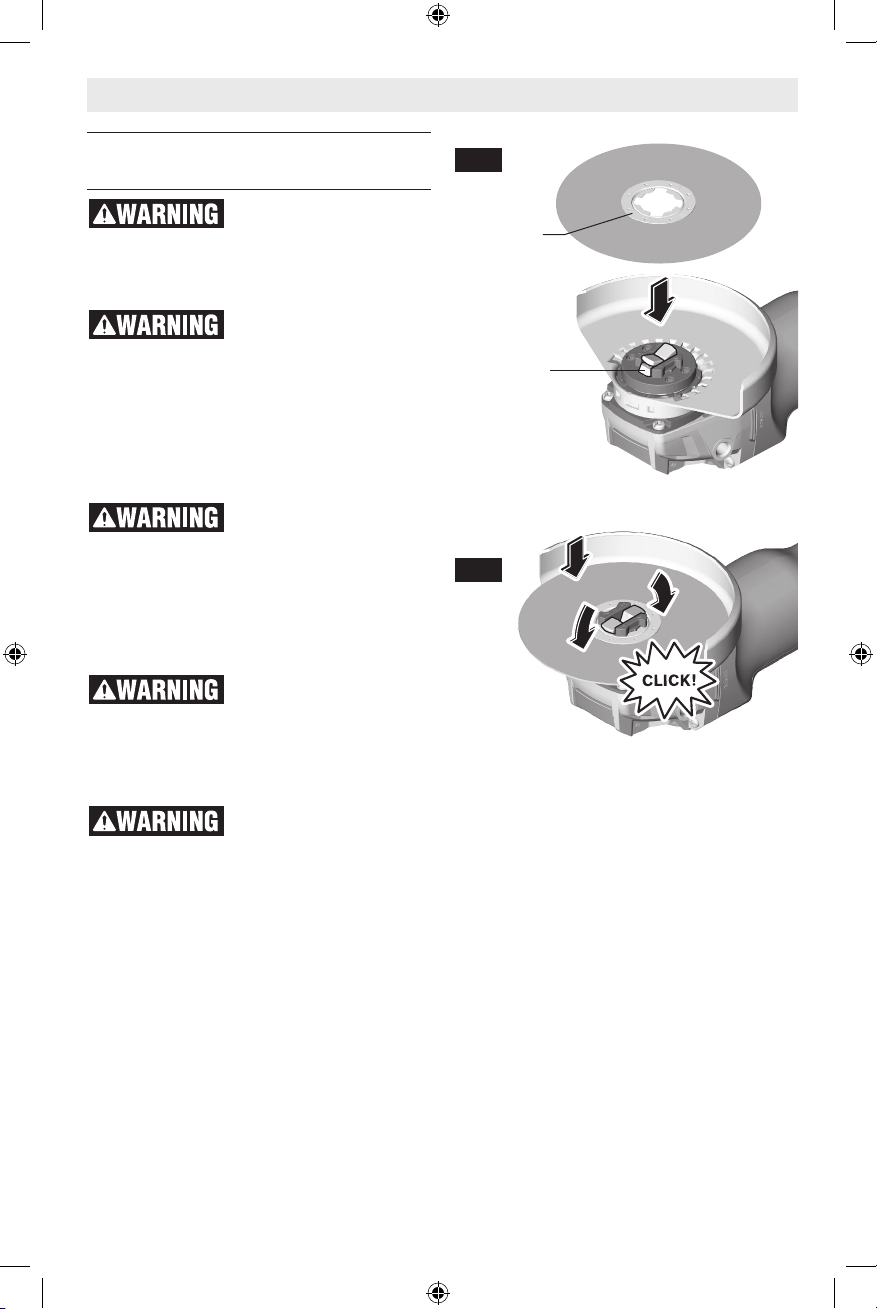

▼ Mounting accessory to the tool

1. Place the accessory on the X-Lock Accessory Mount, by aligning the alignment contours of the Accessory X-Lock

Mounting Hub with the X-Lock Accessory Mount on the grinder (Fig. 8).

2. Push the accessory into the X-Lock Accessory Mount. The accessory audibly

clicks as the Clamping Tabs lock into

place (Fig. 9).

3. Check that the edge of the Accessory

X-Lock Mounting Hub is correctly engaged in the slots of the X-Lock Clamping Tabs (Fig. 10). If the top surface of

the Accessory X-Lock Mounting Hub is

higher than the Clamping Height Gage

(located on each side of the X-Lock Accessory Mount), the X-Lock accessory

-17-

1600A019ZE 05-19 GWX13.indd 17 5/28/19 3:15 PM

Page 18

Assembly

must not be used until this condition

is eliminated by cleaning the X-Lock

Accessory Mount or replacing the accessory.

▼ Removing accessories

Never actuate X-Lock

Release Lever while accessory is moving. Make sure that the accessory has come to a complete stop before removing the accessory. Releasing

accessory while still spinning could cause

personal injury and/or property damage.

Do not touch grinding

and cutting discs until

they have cooled down. The discs can be-

come very hot while working.

Do not allow accesso-

ries to fall uncontrollably after release. Falling accessories can

become damaged and may cause personal

injury and/or property damage.

Do not use a damaged

accessory. Before each

use inspect the accessory such as abrasive wheels for chips and cracks, backing

pad for cracks, tear or excess wear, wire

brush for loose or cracked wires. If power

tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders

away from the plane of the rotating accessory and run the power tool at maximum

no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

Before removing the accessory: Make sure

that the power tool has come to a complete stop and is disconnected from power.

1. Orient the tool to prevent the accesso-

ry from being dropped during release.

2. Open the X-Lock Release Lever (Fig. 11):

(A) Press on the backside of the lever.

(B) Lift the front-side of the lever.

3. Remove the accessory from the tool

with care, preventing it from being

dropped.

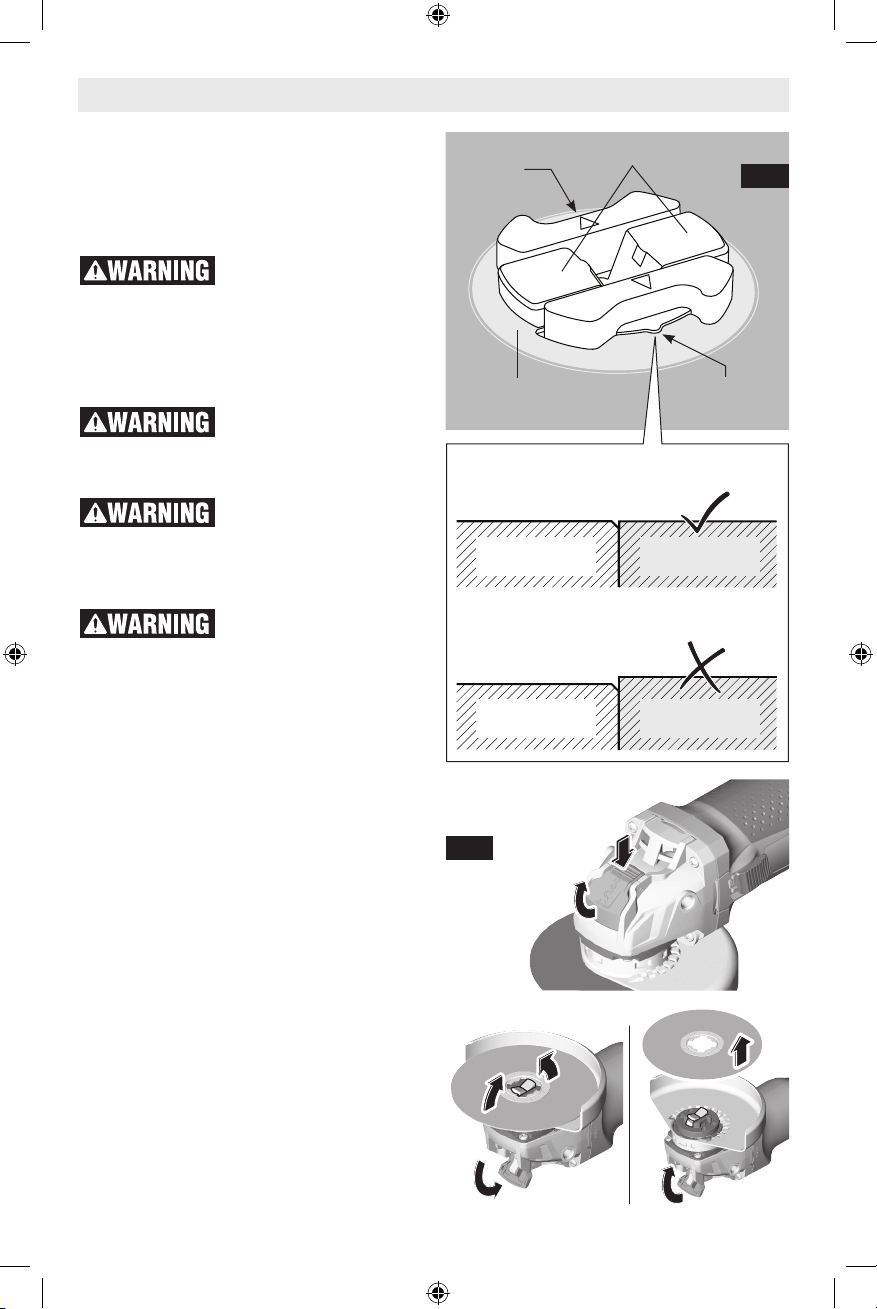

Clamping

Height Gage

Accessory X-Lock

Mounting Hub

CORRECT: Height of Accessory

X-Lock Mounting Hub is equal or less

than X-Lock Accessory Mount

X-Lock Accessory

Mount

INCORRECT: Height of Accessory

X-Lock Mounting Hub is greater

than X-Lock Accessory Mount

X-Lock Accessory

Mount

Clamping Tabs

Accessory X-Lock

Accessory X-Lock

(A)

Fig. 11

(B)

Fig. 10

Clamping

Height Gage

Mounting Hub

Mounting Hub

-18-

1600A019ZE 05-19 GWX13.indd 18 5/28/19 3:15 PM

Page 19

Assembly

▶ Abrasive Type 27 Grinding

Wheel & Sanding Flap Disk

Assembly

Do not use accessories

that run eccentrically.

The tool will vibrate excessively and may

cause loss of control and the accessory

may burst.

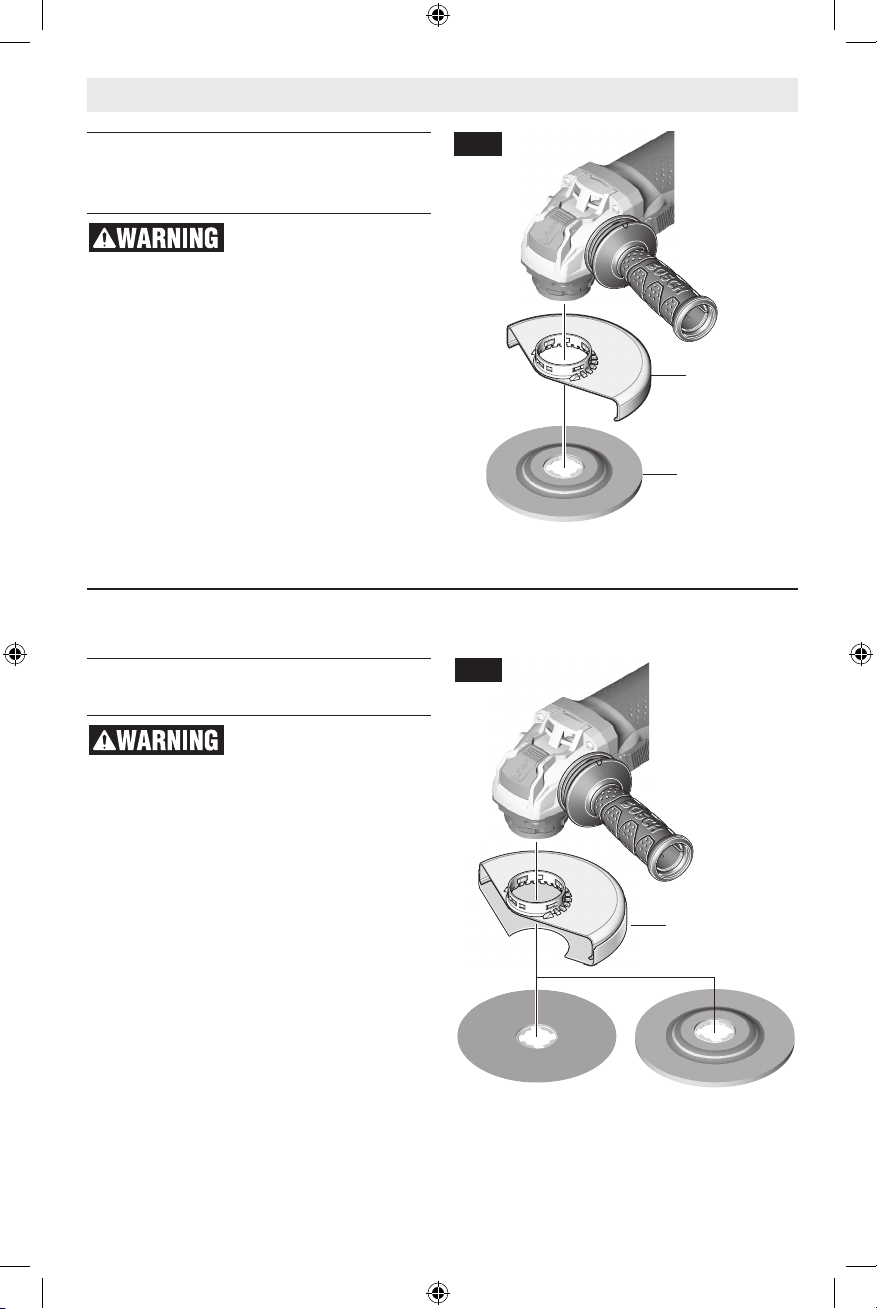

To install grinding wheel or flap disk (Fig.

12) see instructions on page 17.

▶ Abrasive Type 41/1A

Cutting Wheel Assembly

Always use type 41/1A

cutting guard for cut-

ting operations. Other guards or attach-

ments may not protect operator in the

event of a wheel burst.

To install cutting wheel (Fig. 13) see instructions on page 17.

Fig. 12

Type 27

Wheel Guard

Type 27

Grinding

Wheel

Fig. 13

Type 41/1A

Wheel Guard

Type 41/1A

Cutting Wheel

Type 27

Cutting Wheel

-19-

1600A019ZE 05-19 GWX13.indd 19 5/28/19 3:15 PM

Page 20

Assembly

▶ Sanding Assembly

A type 27 wheel guard

may not be used for all

tool operations. Do not discard guard

when not in use. Always reinstall wheel

guard when converting back to grinding

operations.

The Hand Shield is to be used with backing pads, sanding discs and wire brushes

to keep fingers and hand away from work

surface, sharp edges, burs and debris.

When using the Hand Shield accessory, insert side handle through hole in shield and

then thread into housing (Fig. 5). Ensure

that hand shield is positioned between

hand and backing pad, sanding disc or

wire brush.

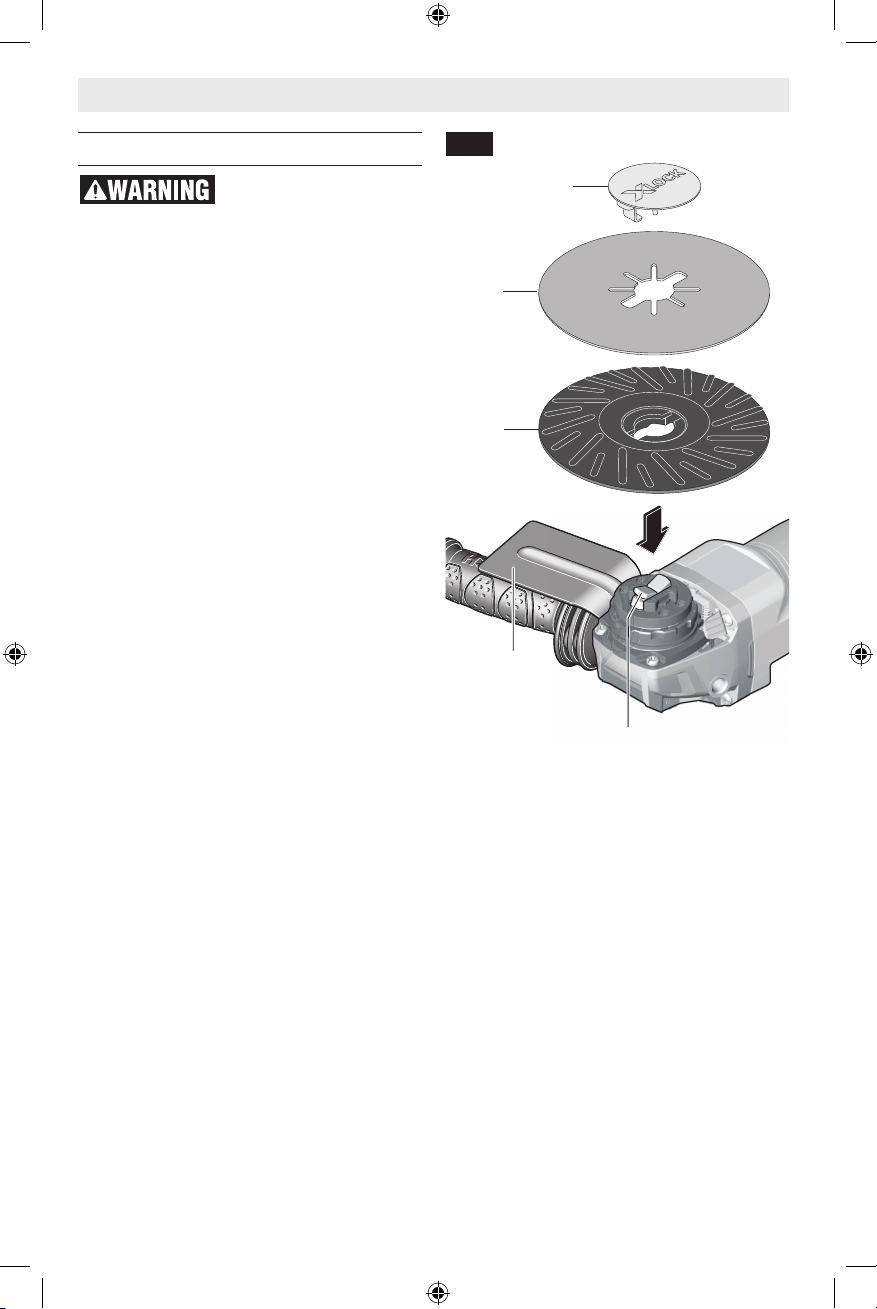

▼ To install backing pad and sanding

disc (Fig. 14)

1. Inspect Hand Shield to ensure that it is

properly attached to the grinder.

2. Place the Backing Pad onto the X-Lock

Accessory Mount with the rectangular

openings positioned around the X-Lock

Clamping Tabs.

3. Center the Sanding Disc on top of the

Backing Pad and align the rectangular

cut-outs with the Clamping Tabs on the

X-Lock Accessory Mount.

4. Align the X-Lock Clip with the slots in

the Sanding Disc. Insert the X-Lock

Clip through the Sanding Disc and apply pressure to it, until it is fully engaged by the Clamping Tabs, which will

be indicated by an audible “click”.

5. To remove the sanding assembly from

the grinder, follow instructions for

Mounting and Removing X-Lock Accessories starting on page 17.

Fig. 14

X-Lock

Clip

Sanding

Disc

Backing

Pad

Hand

Shield

Clamping

Tabs

-20-

1600A019ZE 05-19 GWX13.indd 20 5/28/19 3:15 PM

Page 21

page headingAssembly

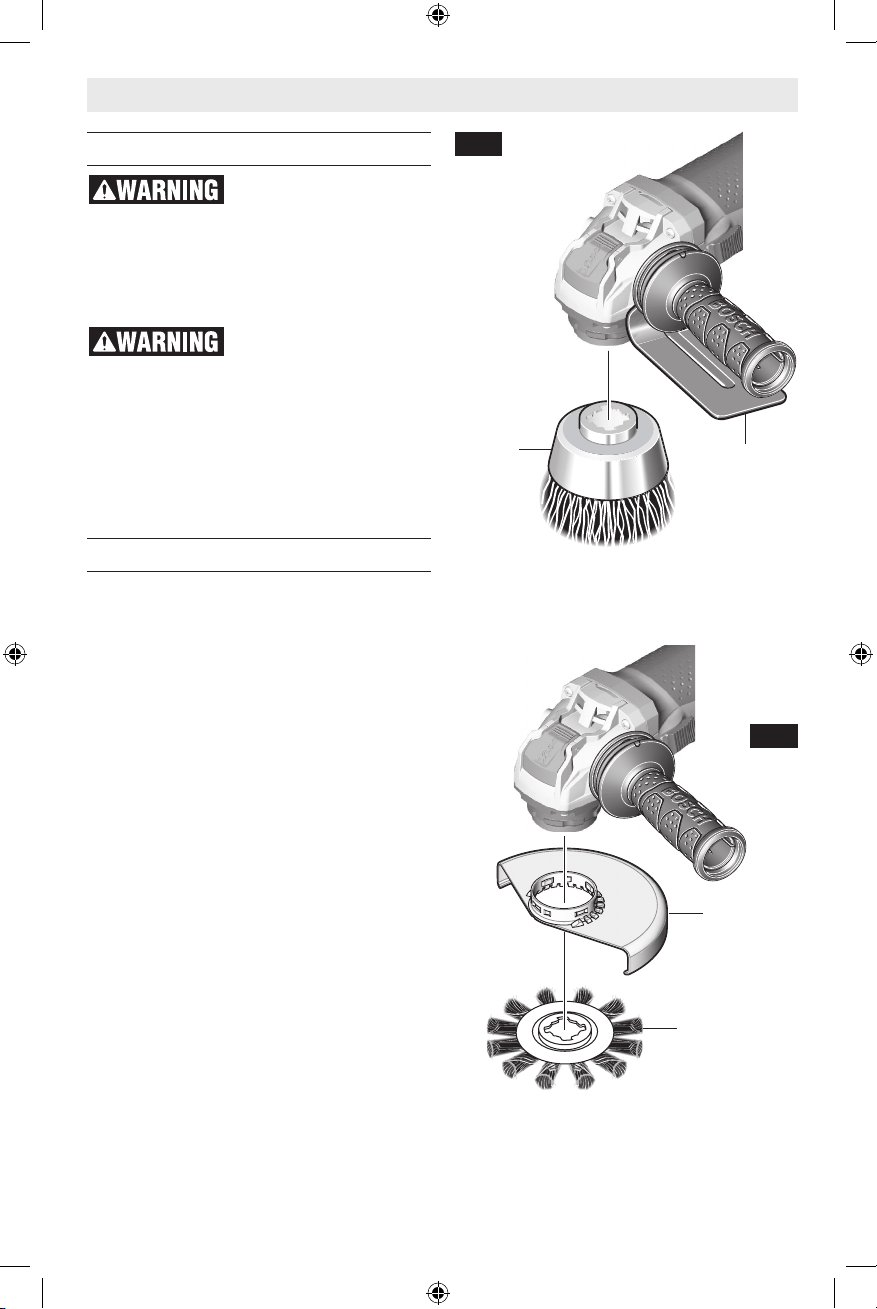

▶ Wire Cup Brush Assembly

A type 27 wheel guard

may not be used for all

tool operations. Do not discard guard

when not in use. Always reinstall wheel

guard when converting back to grinding

operations. When using Wire Cup Wheels,

tool may be used without a guard.

Wear protective gloves

when handling wire

brush accessories. Handling of wire brush

accessories without gloves may result in

personal injury.

▼ To install wire cup brush (Fig. 15)

Follow instructions for Mounting and Removing X-Lock Accessories starting on

page 15.

▶ Wire Wheel Assembly

▼ To install wire wheel (Fig. 16)

1. Inspect and adjust Type 27 Grinding

Guard to the proper position, as shown

in figure 7 on page 16.

2. Follow instructions for “Mounting accessory to the tool” and “Removing the

accessories on page 17.

Fig. 15

Wire Cup

Brush

Hand

Shield

Fig. 16

Type 27

Wheel Guard

Wire Wheel

-21-

1600A019ZE 05-19 GWX13.indd 21 5/28/19 3:15 PM

Page 22

page heading

Assembly

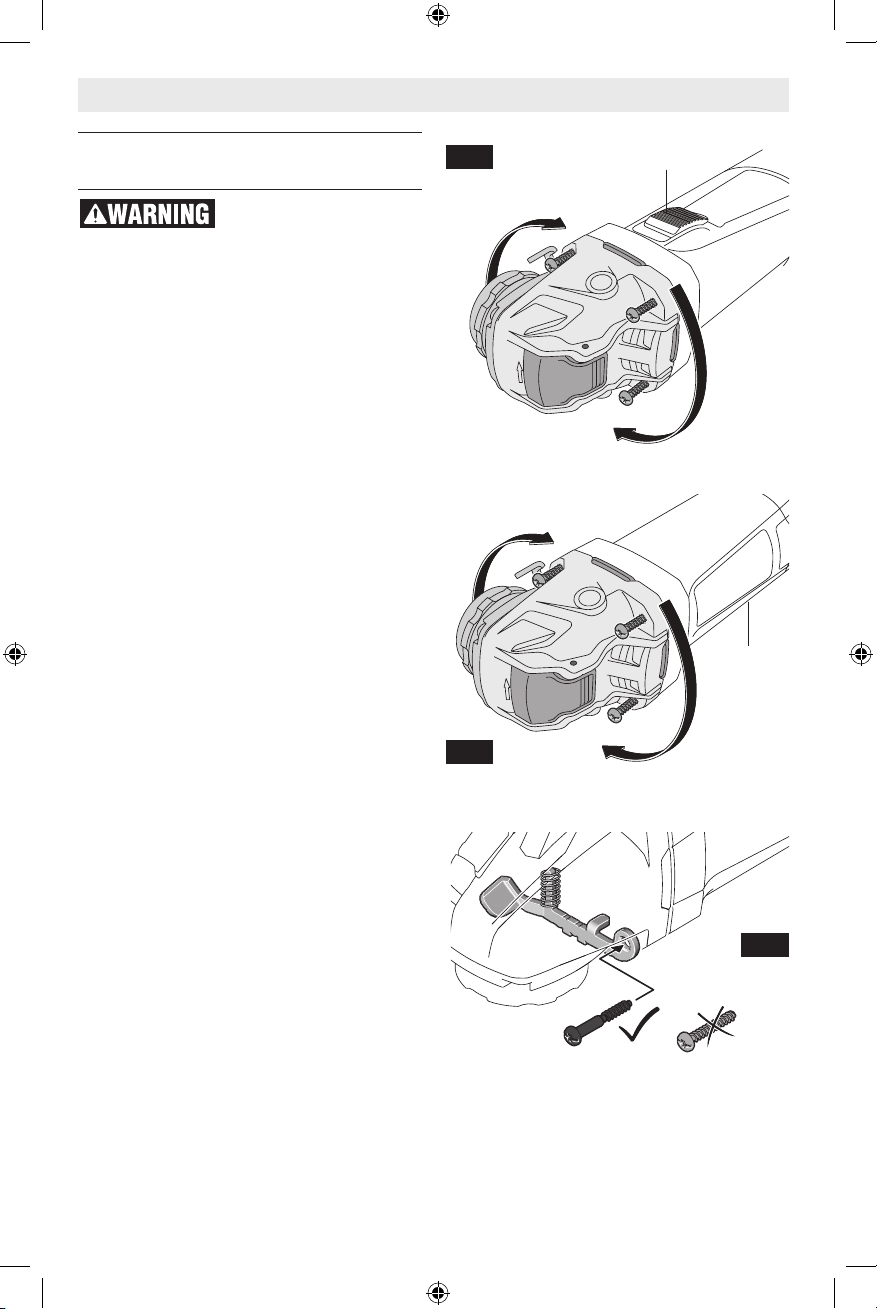

▶ Masonry Cutting Guard

Assembly

A type 27 grinding

wheel guard may not be

used for all tool operations. Do not dis-

card guard when not in use. Always reinstall wheel guard when converting back to

grinding operations.

For cutting masonry, gearbox must be rotated relative to the position of the switch

as the tool was assembled at the factory.

▼ Rotate Gearbox

1. Completely unscrew the four screws

between the gear housing and motor

body.

2. Rotate gear housing to the proper orientation without removing motor from

the housing.

a. For the slide switch models (Fig.

17), rotate gear housing 180 degrees, so the switch is 90 degrees

from the X-Lock Accessory Mount.

b. For the paddle switch models (Fig.

18), rotate gear housing 90 degrees, so the switch is facing the

work piece.

3. After adjusting the position of the gear

housing, screw in and tighten the four

screws.

4. The screw holding the guard release lever is longer than the other screws (Fig.

19), this long screw must stay with the

guard release lever when re-attaching

gear housing for the guard release button to operate properly.

5. To install proper guard follow instructions in the next section.

Fig. 17

90

DEGREES

Fig. 18

Slide

Switch

180

DEGREES

180

DEGREES

Paddle

Switch

Under Tool

90

DEGREES

Fig. 19

-22-

1600A019ZE 05-19 GWX13.indd 22 5/28/19 3:15 PM

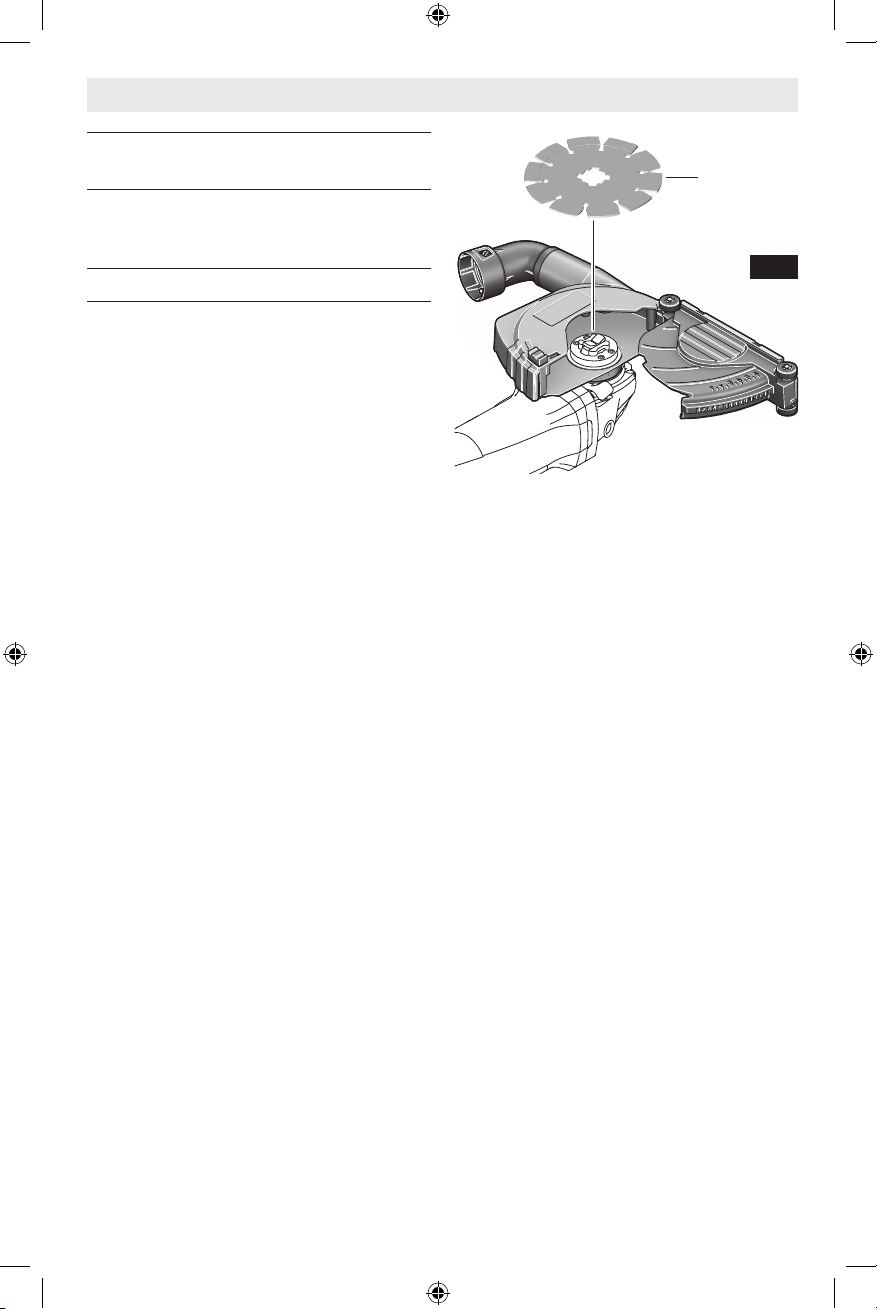

Page 23

page heading

Assembly

▶ Installing Masonry Type 41/1A

Cutting Guard

Follow all instructions provided with the

masonry Type 41/1A cutting guard to install and use it with this grinder.

▶ Installing Dry Diamond Wheel

Follow all instructions provided with the

masonry Type 41/1A cutting guard to prepare it for installation of compatible accessories and operation.

To install Dry Diamond Wheel (Fig. 20) see

instructions on page 17.

Dry Diamond

Wheel

Fig. 20

-23-

1600A019ZE 05-19 GWX13.indd 23 5/28/19 3:15 PM

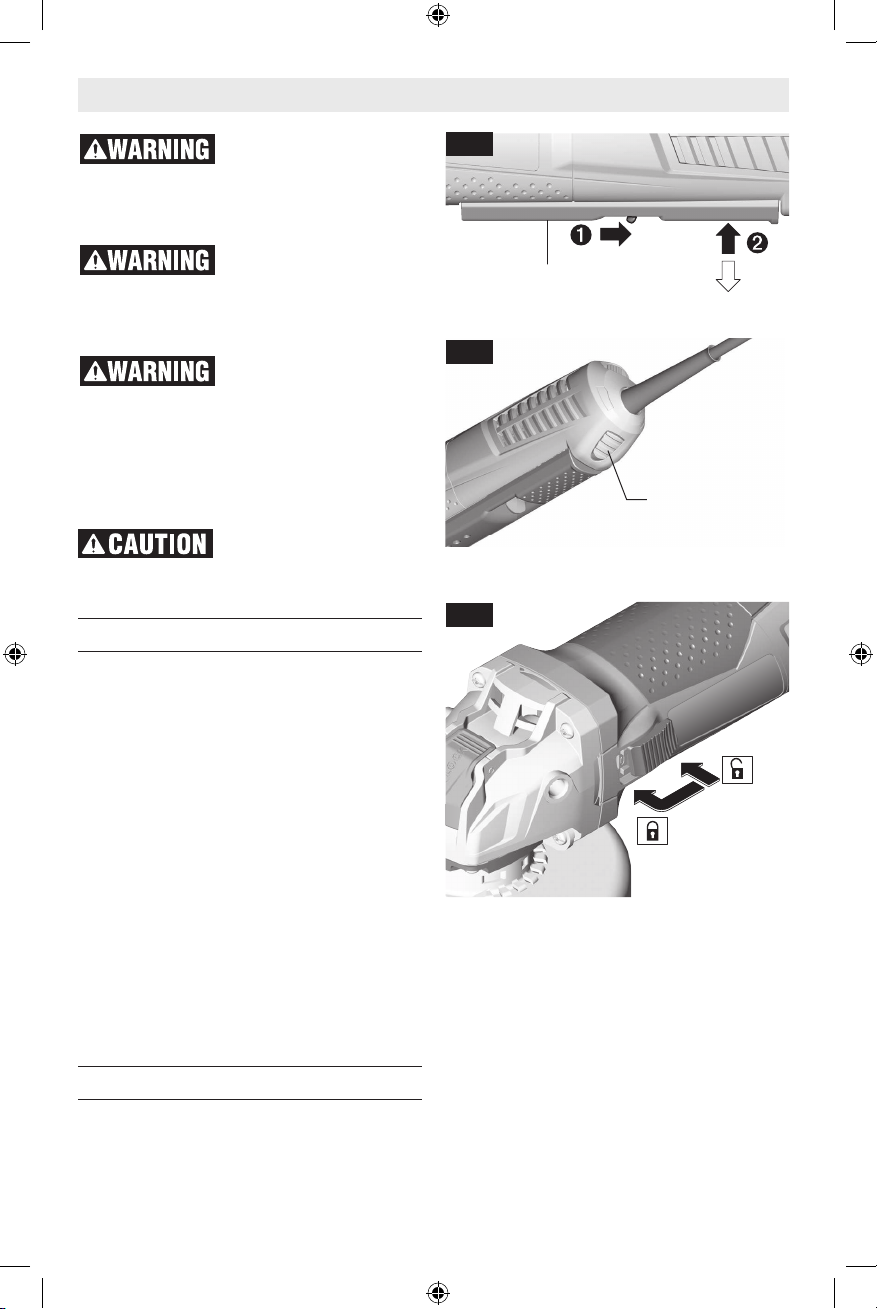

Page 24

Operating Instructions

Never leave the trigger

locked “ON”. Before

plugging the tool in, check that the trigger

lock is “OFF”. Accidental start-ups could

cause injury.

Be aware of the location and setting of the

switch “Lock-ON” button. If the switch is

locked “ON” during the use, be ready for

emergency situations to switch it “OFF”.

Do not use the switch

“Lock-ON” feature in

situations where kickback is likely, such

as when working into a corner. When the

wheel binds, the tool will kick-back in opposite direction of wheel rotation and the

release of the trigger “Lock-ON” may be

difficult.

If the “Lock-ON” button

is continuously being

depressed, the trigger cannot be released.

▶ Paddle Switch (Fig. 21)

The paddle switch has a Lock-OFF feature

to help prevent accidental startups. TO

TURN TOOL “ON”, push Lock-Off switch

backward to unlock the paddle switch,

then squeeze paddle switch. TO TURN

TOOL “OFF”, release pressure on paddle

switch. The switch is spring loaded and

will return to the “OFF” position automatically.

If your tool has the Lock-ON feature incorporated into the paddle switch for extended operation, there will be a red button on

the bottom of the tool directly behind the

paddle switch, Fig. 22. TO LOCK SWITCH

“ON” after paddle switch has been activated, push “Lock-ON” button while simultaneously releasing pressure from the paddle switch. TO TURN TOOL “OFF”, squeeze

and release paddle switch.

▶ Slide Switch (Fig. 23)

TO TURN TOOL ON, press the back of the

switch and slide it forward towards the

gear housing until it comes to a stop and

Fig. 21

ON

Paddle Switch

Fig. 22

Fig. 23

the motor starts running. For Lock-ON,

when the switch is in the ON position,

press the front of the switch and release

it. the switch should remain in the LockON position and the tool will continue to

run.

TO TURN TOOL “OFF”, press the rear portion of the switch. The switch is spring

loaded and will return to the “OFF” position automatically.

OFF

Lock-ON Button

Side

Switch

-24-

1600A019ZE 05-19 GWX13.indd 24 5/28/19 3:15 PM

Page 25

Operating Instructions

▶ Metal Grinding

Grinding wheels should be carefully selected in order to use the grinder most efficiently. Wheels vary in type of abrasive,

bond, hardness, grit size and structure.

The correct wheel to use is determined by

the job. Use disc grinding wheels for fast

grinding of structural steel, heavy weld

beads, steel casting, stainless steel and

other ferrous metals.

1. Allow the tool to reach full speed before touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate

at high speed. Grinding rate is greatest

when the tool operates at high speed.

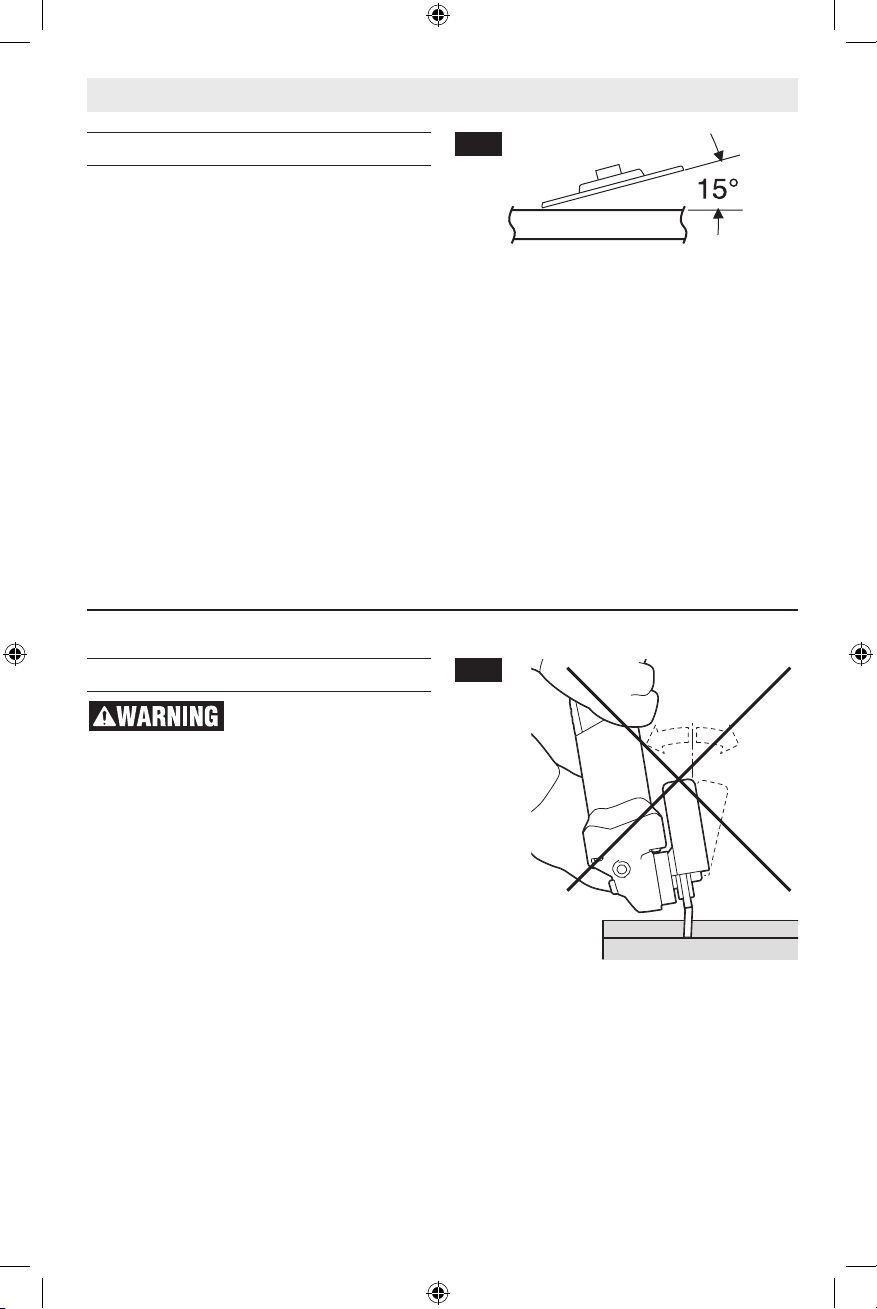

3. Maintain a 10° to 15° angle between

the tool and work surface, (Fig. 24).

▶ Metal Cutting

A Type 1 wheel guard

may not be included

with this tool but is required when using

a cutting wheel. Cutting with a type 27

wheel guard may not provide the operator

sufficient protection in the event of a wheel

burst.

With this grinder it is possible to perform

cutting of limited small stock such as metal tubes, piping or rebar. When cutting,

work with moderate feed, adapted to the

material being cut. When cutting profiles

and square bar, it is best to start at the

smallest cross section.

Always follow precautions for kickback.

1. Allow the tool to reach full speed before touching the tool to the work surface.

2. The tool should always be used in such

way that the sparks are directed away

from user.

3. Apply minimum pressure to the work

surface, allowing the tool to operate

Fig. 24

4. Continuously move the tool at a moderate speed to avoid creating gouges in

the work surface.

5. Remove the tool from work surface before turning tool off. Allow the tool to

stop rotating before laying it down.

Tip: When grinding with a new wheel be

certain to grind while pulling tool backwards until the wheel becomes rounded

on its edge. New wheels have sharp edges

which tend to “bite” or cut into the work

piece when pushed forward.

Fig. 25

at high speed. Cutting rate is greatest

when the tool operates at high speed.

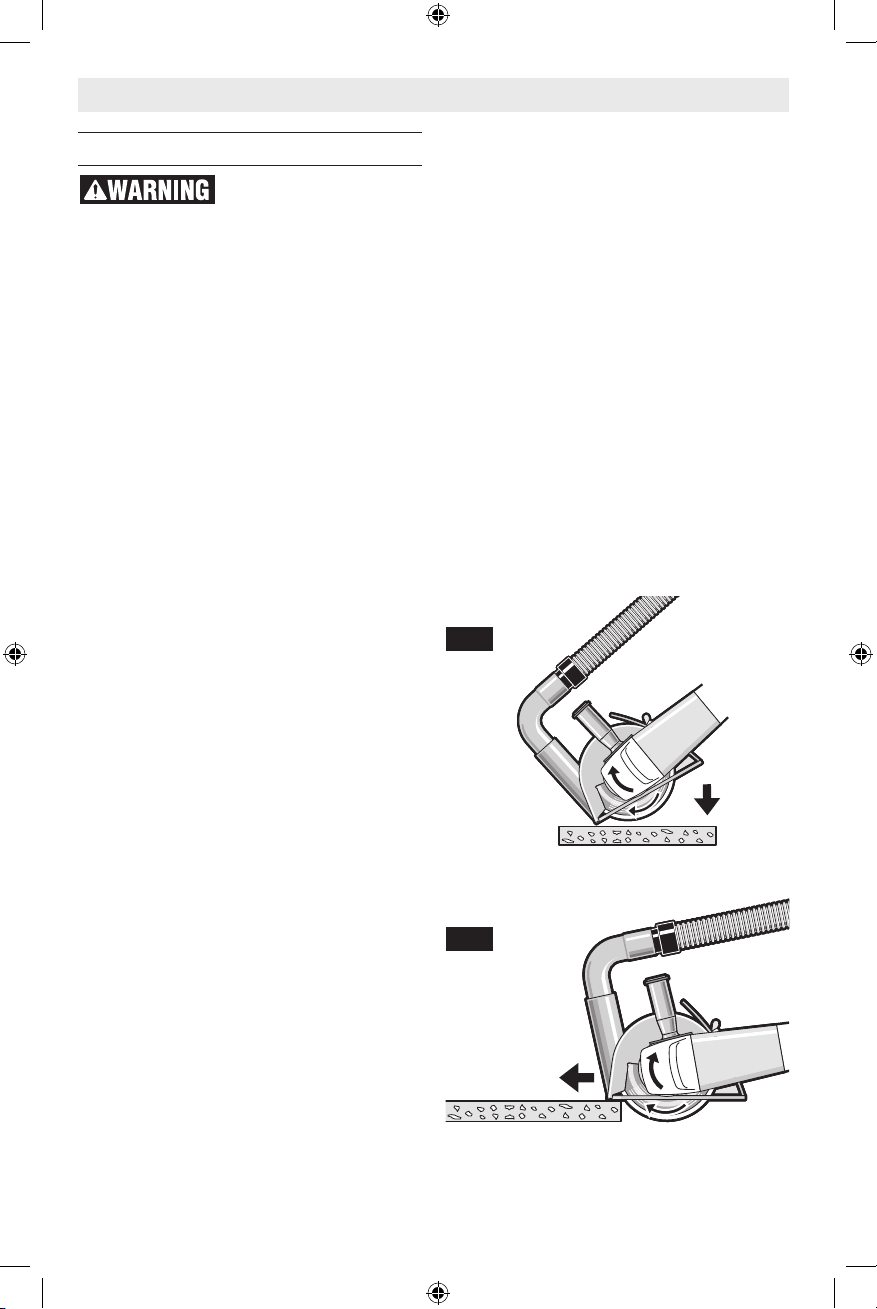

4. Do not exert side pressure onto the

cutting disc. Do not tilt or oscillate the

tool as wheel may burst, (Fig. 25).

5. Remove the tool from the work surface before turning the tool off. Allow

the tool to stop rotating before laying

it down.

-25-

1600A019ZE 05-19 GWX13.indd 25 5/28/19 3:15 PM

Page 26

page headingOperating Instructions

▶ Masonry / Concrete Cutting

Never pull the tool

backward since blade

will climb out of the material and KICKBACK will occur.

With this grinder it is possible to perform

cutting of concrete and masonry materials. When cutting, work with moderate

feed, adapted to the material being cut.

Always follow precautions for kickback.

Operate the tool with a dust extraction

system and personal dust protection, e.g.

respirator, dust mask, etc. The vacuum

used for this application must be approved for the extraction of masonry and

concrete dust. Bosch sells suitable vacuum cleaners.

1. Allow the tool to reach full speed be-

fore touching the tool to the work surface.

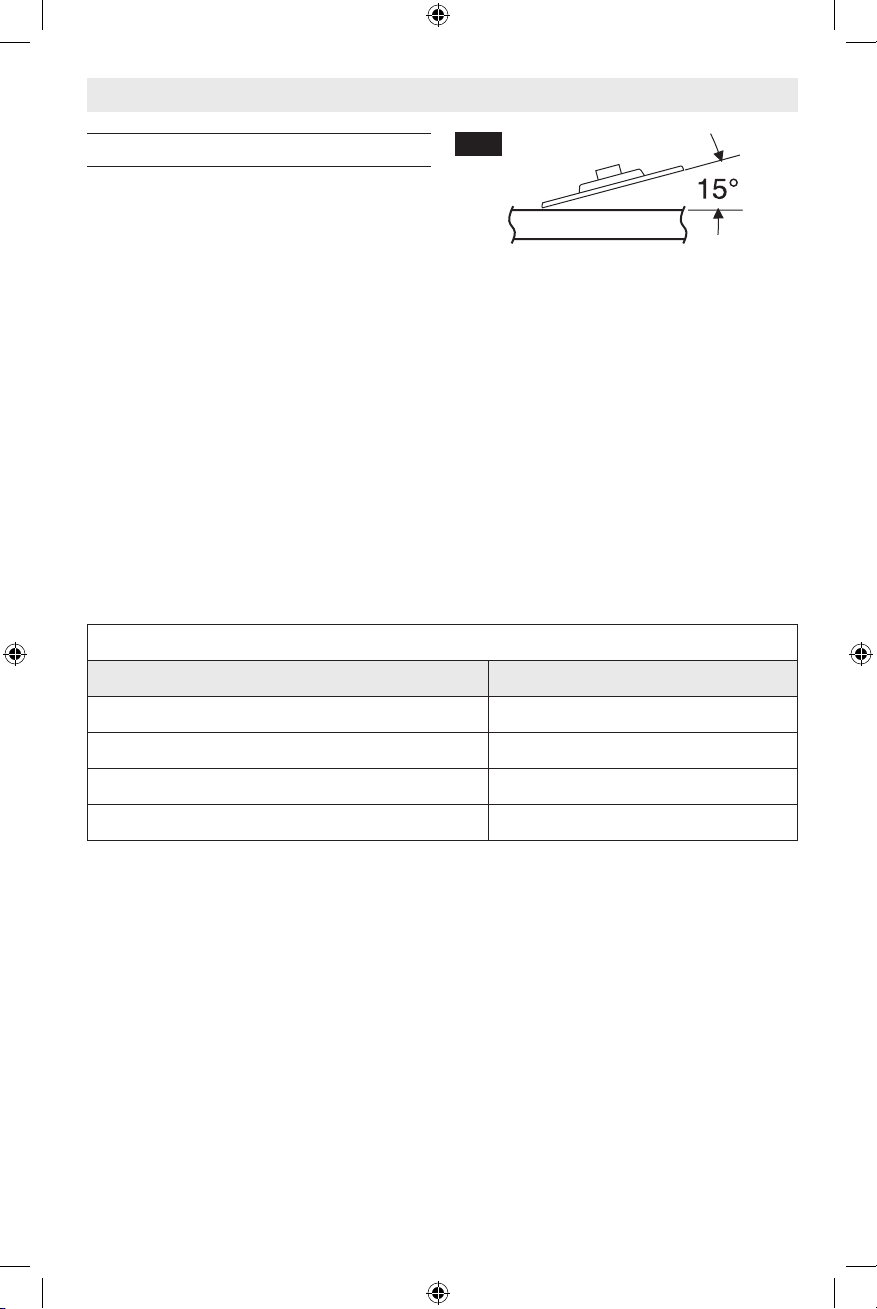

2. If plunge cutting:

a. Tilt tool forward with wheel lined

up with the cut line and hold the

tool by the grinder body and the

auxiliary handle (Fig. 26).

b. Gradually lower the rear of tool us-

ing the front end of the foot as the

hinge point.

c. When the foot rests flat on the sur-

face being cut, proceed cutting in

forward direction to end of cut.

3. Always maintain contact between the

guard foot and work piece.

4. Slide the tool forward at a moderate

speed adapted to the material being

cut. Always cut towards the dust extraction port to maximize dust extraction and reduce likelihood of kickback

(Fig. 27).

5. Apply minimum pressure to the work

surface, allowing the tool to operate

at high speed. Cutting rate is greatest

when the tool operates at high speed.

6. When the cut is completed, remove

tool from work piece before turning off.

Allow wheel to stop rotating before setting tool down.

Tip: When performing deep cuts, it is best

to cut in several shallow passes. Each pass

should be only to the segment depth of

the wheel. Masonry dust is abrasive and

may wear and weaken the segment bond.

When cutting especially hard material, e.

g., concrete with high pebble content, the

dry diamond wheel can overheat and become damaged. This is clearly indicated

by circular sparking of the rotating dry

diamond wheel. In this case, interrupt

the cutting process and allow the dry diamond wheel to cool by running the tool

for a short period of time at the maximum

speed with no-load.

Noticeable decreasing work progress and

circular sparking are indications of a dry

diamond wheel that has become dull.

Briefly cutting into abrasive materials (e.

g. brick) can resharpen the wheel.

Fig. 26

Fig. 27

-26-

1600A019ZE 05-19 GWX13.indd 26 5/28/19 3:15 PM

Page 27

page headingOperating Instructions

▶ Sanding

Sanding discs range in grit from 16 (very

course) to 180 (very fine). They also vary

in size and spacing of grit.

OPEN COAT (type H) is used for soft materials and on paint and varnish, CLOSED

COAT (type K) is used for metal, hardwood, stone, marble and other materials. To obtain best results, select sanding

discs carefully. Many jobs require the use

of several grit sizes and at times both open

coat and closed coat discs are required to

complete the job. See chart for application examples.

1. Allow the tool to reach full speed before touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate

at high speed. Sanding rate is greatest

when the tool operates at high speed.

Operation: Refinishing painted wood or metal surfaces.

REMARKS GRIT

To remove paint and to smooth surface irregularities. Coarse 16-24-30

Fig. 28

3. Maintain a 10° to 15° angle between

the tool and work surface, (Fig. 28).

4. Continuously move the tool at a moderate speed to avoid creating gouges in

the work surface.

5. Remove the tool from work surface before turning tool off. Allow the tool to

stop rotating before laying it down.

Tip: Guide the disc with crisscross strokes.

Do not use a circular motion as this makes

swirl marks.

To smooth the rough sanding. Medium 36-50-80

To remove scratches left by previous discs. Fine 100-120

To smooth surfaces for painting, polishing or waxing. Very Fine 150-180

-27-

1600A019ZE 05-19 GWX13.indd 27 5/28/19 3:15 PM

Page 28

page headingOperating Instructions

▶ Wire Brush (Wheels and Cups)

Wire brushes are intended to “clean”

structural steel, castings, sheet metal,

stone, and concrete. They are used to remove rust, scale, and paint.

1. Allow the tool to reach full speed before touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate at

high speed.

3. Continuously move the tool at a moderate speed to avoid creating gouges in

the work surface.

4. Remove the tool from work surface before turning tool off. Allow the tool to

stop rotating before laying it down.

Tip: The tips of the brush do the work.

Operate wire brushes with the lightest

pressure so only the tips of the wire come

in contact with the work piece. If heavier

pressures are used, the wires will be overstressed, resulting in a wiping action and

a shortened brush life due to wire fatigue.

Applying the side or edge of the brush to

the work piece will result in wire breakage

and shortened brush life.

WIRE WHEEL BRUSH

CORRECT:

Wire tips

doing

the work.

INCORRECT:

Excessive

pressure can

cause wire

breakage.

WIRE CUP BRUSH

CORRECT:

Wire tips

doing

the work.

INCORRECT:

Excessive

pressure can

cause wire

breakage.

Maintenance

Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any

adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

▶ Service

Preventive mainte-

nance performed by unauthorized per so n nel may result in misplacing of internal wires and components

which could cause serious hazard. We

recommend that all tool service be performed by a Bosch Factory Service Center

or Autho rized Bosch Service Station.

1600A019ZE 05-19 GWX13.indd 28 5/28/19 3:15 PM

GFCI and personal protection devices like

electrician’s rubber gloves and footwear

will further enhance your personal safety.

▶ Tool Lubrication

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with

a special gear lubricant at every brush

change.

-28-

Page 29

Maintenance

▶ Carbon Brushes

The brushes and commutator in your tool

have been engineered for many hours of

dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brush es be examined. Only genuine Bosch replace ment

brushes specially designed for your tool

should be used.

▶ Cleaning

Certain cleaning agents

and solvents damage

plastic parts. Some of these are: gasoline,

Extension Cords

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for

your tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use

3-wire extension cords that have 3-prong

plugs and receptacles.

NOTE: The smaller the gauge number, the

heav i er the cord.

carbon tetrachloride, chlorinated cleaning

solvents, ammonia and household detergents that contain ammonia.

Ventilation openings and switch levers

must be kept clean and free of foreign

matter. Do not attempt to clean by inserting pointed objects through opening.

▶ Accessory Storage &

Maintenance

Store accessories in a cool dry place and

avoid freezing. Before use check accessory

for cracks and fractures, do not use if damage is suspected.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6 18 16 16 14 0.75 0.75 1.5 2.5

6-8 18 16 14 12 0.75 1.0 2.5 4.0

8-10 18 16 14 12 0.75 1.0 2.5 4.0

10-12 16 16 14 12 1.0 2.5 4.0 —

12-16 14 12 — — — — — —

Cord Size in A.W.G. Wire Sizes in mm

Cord length in feet Cord length in Meters

25 50 100 150 15 30 60 120

2

Accessories

The use of accessories not specified for use with the tool described

in this manual may create a hazard.

Do not use Type 11 abrasive (cup) wheels with this tool. This tool is

not designed for use with type 11 (cup) abrasive grinding wheels.

Standard Equipment Optional Accessories

Type 27 Wheel Guard

Side Handle

1600A019ZE 05-19 GWX13.indd 29 5/28/19 3:15 PM

Type 41/1A Wheel Guard

Type 41/1A Masonry Cutting Guard

Concrete Dust Extraction Attachment

Grinding Wheel

Backing Pad

Hand Shield

-29-

Page 30

Table des matières

Symboles relatifs à la sécurité ................... 31

Avertissements généraux concernant la

sécurité des outils électroportatifs............31

Sécurité du lieu de travail ........................ 31

Sécurité électrique ..................................31

Sécurité personnelle ................................ 31

Utilisation et entretien des outils

électroportatifs ........................................ 32

Entretien .................................................. 32

Avertissements spécifiques à la sécurité

des outils électroportatifs ......................... 33

Avertissements habituels concernant la

sécurité des opérations de rectification,

de ponçage, de brossage métallique et

de tronçonnage à la meule abrasive : ......33

Avertissements sur les rebonds

et effets associés ..................................... 34

Avertissements spécifiques à la

sécurité des opérations de rectification

et de tronçonnage à la meule : ................34

Avertissements supplémentaires

spécifiques à la sécurité des opérations

de tronçonnage à la meule abrasive : ......35

Avertissements spécifiques à la sécurité

des opérations de ponçage : ...................35

Avertissements spécifiques à la sécurité

des opérations de brossage métallique : . 35

Avertissements supplémentaires

concernant la sécurité ............................... 36

Symboles ................................................... 37

Description fonctionnelle et

spécifications .............................................39

Fonctionnement basique du

système X-Lock ..........................................42

Assemblage ................................................43

Installation de la poignée latérale ............ 43

Écran de protection de la main ................43

Installation des dispositifs de

protection des meules (Protège-

meule de type 27 et de type 41/1A) ........ 44

Montage et retrait des

accessoires X-Lock ...................................45

Montage de la meule abrasive de

type 27 et du disque de ponçage ............47

Montage de molettes abrasives

de Types 41/1A ........................................47

Montage d’un disque de support

et d’un disque de ponçage .....................48

Montage de la brosse métallique

en forme de coupelle ............................... 49

Montage de la brosse métallique ............. 49

Montage du dispositif de protection pour

un outil de coupe de maçonnerie ............ 50

Installation du dispositif de

protection pour la coupe de

maçonnerie de type 41/1A .......................51

Installation de la meule diamantée

pour coupe à sec .....................................51

Consignes de fonctionnement ................... 52

Interrupteur à palette (Fig. 21) ................52

Interrupteur coulissant (Fig. 23) .............. 52

Meulage de métaux .................................. 53

Coupe de métaux .....................................53

Coupe de maçonnerie/béton ................... 54

Ponçage ................................................... 55

Brosse métallique

(meules et coupelles) .............................. 56

Entretien .................................................... 57

Réparations ..............................................57

Lubrification des outils ............................ 57

Balais de charbon .................................... 57

Nettoyage .................................................57

Rangement & maintenance

des accessoires........................................57

Cordons de rallonge .................................. 57

Accessoires ................................................ 58

-30-

1600A019ZE 05-19 GWX13.indd 30 5/28/19 3:15 PM

Page 31

Symboles relatifs à la sécurité

Les définitions ci-dessous décrivent le niveau de gravité pour chaque terme signalant un danger.

Veuillez lire le mode d’emploi et lire la signification de ces symboles.

C’est le symbole d’alerte relatif à la sécurité. Il est utilisé pour vous avertir

de l’existence possible d’un danger de lésion corporelle. Obéissez à tous les

messages relatifs à la sécurité qui suivent ce symbole pour éviter tout risque de

blessure ou même de mort.

DANGER indique une situation dangereuse qui, si elle n’est pas évitée,

causera la mort d’une personne ou une blessure grave.

AVERTISSEMENT indique une situation dangereuse qui, si elle n’est pas

évitée, pourrait causer la mort d’une personne ou une blessure grave.

MISE EN GARDE indique une situation dangereuse qui, si elle n’est pas

évitée, pourrait causer une blessure légère ou modérée.

Avertissements généraux concernant la sécurité des outils électroportatifs

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si

risque de choc électrique, d’incendie et/ou de blessures corporelles graves.

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES DE

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil branché sur le secteur (avec fil) ou à

votre outil alimenté par piles (sans fil).

▶ Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé. Les

risques d’accident sont plus élevés quand on travaille

dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des atmosphères explosives, comme par exemple en présence

de gaz, de poussières ou de liquides inflammables. Les

outils électroportatifs produisent des étincelles qui risquent d’enflammer les poussières ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une perte

de contrôle si on vous distrait.

▶ Sécurité électrique

Les fiches des outils électroportatifs doivent correspondre à la prise. Il ne faut absolument jamais modifier la fiche. N’utilisez pas d’adaptateur de prise avec

des outils électroportatifs munis d’une fiche de terre.

Le risque de choc électrique est moindre si on utilise une

fiche non modifiée sur une prise qui lui correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente si

votre corps est relié à la terre.

l’on n’observe pas ces avertissements et ces consignes de sécurité, il existe un

SÉCURITÉ POUR RÉFÉRENCE FUTURE.

N’exposez pas les outils électroportatifs à la pluie ou à

l’humidité. Si de l’eau pénètre dans un outil électroporta-

tif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez jamais

pour transporter l’outil électroportatif, pour le tirer ou

pour le débrancher. Éloignez le cordon de la chaleur,

des huiles, des arêtes coupantes ou des pièces mobiles. Les cordons abîmés ou emmêlés augmentent les

risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces ral-

longes sont faites pour l’extérieur et réduisent le risque de

choc électrique.

S’il est absolument nécessaire d’utiliser l’outil électroportatif dans un endroit humide, utilisez une alimentation protégée par un disjoncteur de fuite de terre

(GFCI). L’utilisation d’un disjoncteur GFCI réduit les ris-

ques de choc électrique.

▶ Sécurité personnelle

Restez concentré, faites attention à ce que vous faites,

et servez-vous de votre bon sens lorsque vous utilisez

un outil électroportatif. N’employez pas d’outils électroportatifs quand vous êtes fatigué ou sous l’emprise

de drogues, d’alcool ou de médicaments. Quand on

-31-

1600A019ZE 05-19 GWX13.indd 31 5/28/19 3:15 PM

Page 32

Avertissements généraux concernant la sécurité des outils électroportatifs

page heading

utilise des outils électroportatifs, il suffit d’un moment

d’inattention pour causer des blessures corporelles

graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d’équipements de sécurité tels que des masques antipoussières, des chaussures de sécurité antidérapantes,

des casques de chantier et des protecteurs d’oreilles dans

des conditions appropriées réduira le risque de blessure

corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l’interrupteur est dans la position arrêt (Off) avant de

brancher l’outil dans une prise de courant et/ou un

blocpiles, de le ramasser ou de le transporter. Le trans-

port d’un outil électroportatif avec le doigt sur la gâchette

ou le branchement de cet outil quand l’interrupteur est en

position de marche (ON) est une invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé sur

une pièce tournante de l’outil électroportatif, il y a risque

de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de mieux

maîtriser l’outil électroportatif dans des situations inattendues.

Habillez-vous de manière appropriée. Ne portez pas de

vêtements amples ou de bijoux. Attachez les cheveux

longs. N’approchez pas les cheveux, les vêtements

ou les gants des pièces en mouvement. Les vêtements

amples, les bijoux ou les cheveux longs risquent d’être

happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le raccordement d’un système d’aspiration et de collecte

des poussières, assurez-vous que ces dispositifs

sont raccordés et utilisés correctement. L’utilisation

d’un dépoussiéreur peut réduire les dangers associés à

l’accumulation de poussière.

▶ Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et est

plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas être

commandé par son interrupteur est dangereux et doit être

réparé.

Débranchez la fiche de la prise secteur et/ou retirez

le bloc-piles de l’outil électrique avant d’y apporter de

quelconques modifications, de changer d’accessoire

ou de ranger l’outil électrique. De telles mesures de

sécurité préventive réduisent le risque de démarrage intempestif de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans les

mains d’utilisateurs inexpérimentés.

Entretenez de façon appropriée les outils électriques.

Assurez-vous que les pièces en mouvement sont bien

alignées et qu’elles ne se coincent pas, qu’il n’y a pas

de pièces cassées ou qu’il n’existe aucune situation

pouvant affecter le fonctionnement de l’outil électrique. Si l’outil électrique est endommagé, faites-le

réparer avant de vous en servir à nouveau. Les outils

coupants entretenus correctement et dotés de bords tranchants affûtés sont moins susceptibles de coincer et sont

plus faciles à maîtriser.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de coincer et sont plus faciles à maîtriser.

Utilisez l’outil électroportatif, les accessoires et les

embouts d’outil, etc. conformément à ces instructions, en tenant compte des conditions de travail et

des travaux à réaliser. L’emploi d’outils électroportatifs

pour des tâches différentes de celles pour lesquelles ils

ont été prévus peut résulter en une situation dangereuse.

▶ Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de rechange identiques. Ceci assure que la sécurité de l’outil

électroportatif est préservée.

-32-

1600A019ZE 05-19 GWX13.indd 32 5/28/19 3:15 PM

Page 33

Avertissements spécifiques à la sécurité des outils électroportatifs

▶ Avertissements habituels concernant la

sécurité des opérations de rectification,

de ponçage, de brossage métallique et

de tronçonnage à la meule abrasive :

Cet outil électroportatif a été conçu pour fonctionner comme un outil de rectification, de ponçage, de

brossage métallique ou de tronçonnage. Veuillez lire

toute la documentation relative à la sécurité qui a été

fournie avec cet outil électroportatif, notamment, les

avertissements, les consignes, les illustrations et les

spécifications. Si l’on n’observe pas toutes les consignes

indiquées ci-dessous, il existe un risque de choc électrique, d’incendie et/ou de blessures corporelles graves.

Il n’est pas recommandé de réaliser des opérations

telles que le polissage avec cet outil électrique. L’usage

de l’outil au cours de travaux pour lesquels il n’a pas été

conçu risque de présenter un danger et de causer des

blessures corporelles.

N’utilisez pas d’accessoires qui n’ont pas été spécifiquement conçus et recommandés par le fabricant

de l’outil. Le simple fait qu’un accessoire puisse être at-

taché à votre outil électroportatif ne garantit pas un fonctionnement sans danger.

La vitesse nominale de l’accessoire doit être au moins

égale à la vitesse maximum indiquée sur l’outil électroportatif. Les accessoires que l’on fait tourner à une

vitesse supérieure à leur VITESSE NOMINALE peuvent se

casser et voler en éclats.

Le diamètre externe et l’épaisseur de votre accessoire

doivent être dans les limites de capacité de votre outil

électroportatif. Des accessoires de la mauvaise taille ne

peuvent pas être adéquatement protégés ou contrôlés.

Le montage fileté des accessoires doit correspondre

au filet de la broche de la meuleuse. Pour les accessoires montés à l’aide de brides de fixation, le trou de

l’arbre de l’accessoire doit correspondre au diamètre

de la bride de fixation qui doit être introduite dans celui-ci. Les accessoires qui ne correspondent pas au petit

matériel de montage de l’outil électrique fonctionneront

de manière déséquilibrée, vibreront de façon excessive et

risquent de causer une perte de contrôle de l’outil.

N’utilisez pas d’accessoires endommagés. Inspectez

vos accessoires avant chaque utilisation : vérifiez

par exemple que votre meule abrasive n’est ni fêlée,

ni ébréchée, que votre disque d’appui n’est ni fêlé, ni

déchiré, ni trop usé et que votre brosse métallique ne

contient pas de fils cassés ou détachés. Si vous laissez

tomber l’outil ou l’accessoire, vérifiez que ce dernier

n’est pas endommagé ou remplacez-le par un accessoire en bon état. Après l’inspection et l’installation

d’un accessoire, tenez-vous à distance du plan de

l’accessoire en mouvement et demandez à toute per-

sonne présente de faire de même, et faites fonctionner l’outil à sa vitesse à vide maximale pendant une