IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

For English Version Version française Versión en español

See page 2 Voir page 22 Ver la página 43

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

GWS18V-45C

GWS18V-45PC

GWS18V-45PSC

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 1

-2-

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapt e r plugs wi t h e arthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e c o mmon sen se w hen ope r atin g a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

General Power Tool Safety Warnings

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the manual

and pay attention to these symbols.

!

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 2

-3-

Use personal protective equipment. Always

w

ear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in the off- posi tion be fore

connecting to power source and / or battery

pa ck, pic king up or carryi ng the too l.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the power

tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co n trol of the powe r too l in unex p ected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not for ce th e pow er to o l. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca n n o t be control l e d with the switc h is

dangerous and must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

o

r binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma n y a c c i dents are caused by po o r l y

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Battery tool use and care

Recharge only with the charger specified

by th e ma nufactu rer. A cha rger that i s

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

Use power too ls only with specific ally

designated battery packs. Use of any other

battery packs may create a risk of injury and

fire.

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small m e t a l objects that c a n make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery, avoid contact. If

contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

Service

Have your power tool serviced by a qualified

re p a i r pe r son us ing o n l y id e n tical

replacement parts. This will ensure that the

safety of the power tool is maintained.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 3

-4-

Power Tool-Specific Safety Warnings

Safety Warnings Common for

Grinding, Sanding, Wire Brushing,

and Abrasive Cutting-Off

Operations:

This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool.

Read all safety warnings, instructions,

illustrations and specifications provided

with this power tool. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious injury.

Op e ratio n s su c h as poli s hing is no t

recommended to be performed with this

power tool. Operations for which the power

tool was not designed may create a hazard

and cause personal injury.

Do not us e accessori es which are not

specifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power tool,

it does not assure safe operation.

The rated speed of the accessory must be

at leas t eq u al to the maxi m um sp eed

marked o n the power tool. Accessories

running faster than their RATED SPEED can

break and fly apart.

The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

Threaded mounting of accessories must

match the GRINDER spindle thread. For

accessories mounted by FLANGES, the

arbour hole of the accessory must fit the

lo c ating di a meter of th e FLANGE.

Accessories that do not match the mounting

hardware of the power tool will run out of

balance, vibrate excessively and may cause

loss of control.

Do not use a damaged accessory. Before

each use inspect the accessory such as

abra siv e whe els for ch ips a nd cr ack s,

backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If

power tool or accessory is dropped, inspect

fo r damage or ins tall an unda maged

accessory. After inspecting and installing

an access ory, po siti on y ours elf and

bystanders away from the plane of the

rotating accessory and run the power tool

at maximum no-load speed for one minute.

Damaged accessories will normally break apart

during this test time.

We ar per s onal protec tive eq uipm ent.

Depending on application, use face shield,

sa fety goggl es or sa fety glasse s. As

ap prop riat e, w ear dus t ma sk, hea ring

protectors, gloves and workshop apron

capable of s top pin g small abr asi ve or

workpiece fragments. The eye protection

must be capable of stopping flying debris

generated by various operations. The dust

mask or respirator must be capable of filtrating

pa rtic les gen e rate d b y yo ur o pera tion .

Prolonged exposure to high intensity noise may

cause hearing loss.

Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fr agme nts of wor kpiec e or of a broken

accessory may fly away and cause injury

beyond immediate area of operation.

Hold the power tool by insulated gripping

su rfac es onl y, whe n perfo rmin g an

operation where the cutting accessory may

contact hidden wiring. Cutting accessory

contacting a “live” wire may make exposed

metal parts of the power tool “live” and could

give the operator an electric shock.

Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the surface

and pull the power tool out of your control.

Do not run the power tool while carrying it

at your side. Accidental contact with the

spinning accessory could snag your clothing,

pulling the accessory into your body.

Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the

ho usin g and exce ssiv e accu mula tion of

powdered metal may cause electrical hazards.

Do not o pera te the powe r t ool nea r

flammable materials. Sparks could ignite

these materials.

Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 4

-5-

which in turn causes the uncontrolled power

t

ool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged

or pinched by the workpiece, the edge of the

wheel that is entering into the pinch point can

dig into the surface of the material causing the

wheel to climb out or kickout. The wheel may

either jump toward or away from the operator,

de pend ing on d irec t ion of t he w heel ’s

movement at the point of pinching. Abrasive

wheels may also break under these conditions.

Kickback is the result of power tool misuse

and/ or in cor rect ope rating p rocedures or

conditions and can be avoided by taking proper

precautions as given below.

Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control

over kickback or torque reaction during

start-up. The operator can control torque

re acti ons or k ickba ck forc es, if p roper

precautions are taken.

Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

Do not position your body in the area where

power tool will move if kickback occurs.

Kickb ack wi ll propel the t ool in direc tion

opposite to the wheel’s movement at the point

of snagging.

Use special care when working corners,

sh arp ed ges etc . A void bo unci ng and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or

kickback.

Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

Safety Warnings Specific for

Grinding and Abrasive

Cutting-Off Operations:

Us e on ly wheel typ es that are

recommended for your power tool and the

specific guard designed for the selected

wheel. Wheels for which the power tool was

not designed cannot be adequately guarded

and are unsafe.

The grinding surface of centre depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted wheel

that projects through the plane of the guard lip

c

annot be adequately protected.

The guard must be securely attached to the

power tool and positioned for maximum

safety, so the least amount of wheel is

exposed towards the operator. The guard

helps to protect operator from broken wheel

fragments and accidental contact with wheel.

Wh eels mu st be used on ly for

recommended applications. For example:

do not grind with the side of cut-off wheel.

Abras ive cut-o ff wheels are int ende d for

peripheral grinding, side forces applied to these

wheels may cause them to shatter.

Always use undamaged wheel flanges that

are of c orrec t size and shape for your

selected wheel. Proper wheel flanges support

the wheel thus reducing the possibility of wheel

breakage. Flanges for cut-off wheels may be

different from grinding wheel flanges.

Do not use worn down wheels from larger

power tools. Wheel intended for larger power

tool is not suitable for the higher speed of a

smaller tool and may burst.

Additional Safety Warnings Specific

for Abrasive Cutting-Off Operations:

Do not “jam” the cut-off wheel or apply

excessive pressure. Do not attempt to make

an excessive depth of cut. Overstressing the

wheel increases the loading and susceptibility

to twisting or binding of the wheel in the cut and

the possibility of kickback or wheel breakage.

Do not position your body in line with and

behind the rotating wheel. When the wheel,

at the point of operation, is moving away from

your body, the possible kickback may propel

the spinning wheel and the power tool directly

at you.

When wheel is binding or when interrupting

a cut for any reason, switch off the power

tool and hold the power tool motionless

until the wheel comes to a complete stop.

Never attempt to remove the cut-off wheel

from the cut while the wheel is in motion

otherwise kickback may occur. Investigate

and take corrective action to eliminate the

cause of wheel binding.

Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed

and carefully reenter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 5

-6-

Additional Safety Warnings

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Use clamps or other practical way to secure

and support t he workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Develop a periodic maintenance schedule

for your t ool. When cleaning a tool b e

careful not to disassemble any portion of

th e tool sin c e inter nal wire s may be

misplaced or pinched or safety guard return

sp ring s may be improp erly mount ed.

Certain cleaning agents such as gasoline,

carbon tetrachloride, am mon ia, etc. may

damage plastic parts.

Do not use vacuum or other dust collection

system when cutting metal. Sparks from

metal cutting can cause fire in the collector.

Some dust creat ed by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

ca use ca ncer , b i r t h de f ects or ot her

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic an d chromium from chemically-

treated lumber.

Yo u r risk f r o m these expo s u r es var i e s ,

depending on how often you do this type of

work. To reduce your expos ure to th ese

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

kickback. Large workpieces tend to sag under

t

heir own weight. Supports must be placed

under the workpiece near the line of cut and

near the edge of the workpiece on both sides of

the wheel.

Use extra caution when making a “pocket

cut” into existing walls or other blind areas.

The protruding wheel may cut gas or water

pipes, electrical wiring or objects that can cause

kickback.

Do not use type 1 abrasive wheels designed

for straight grinding.

Do not attempt to cut large stock or sheets

of metal as this machine is not designed to

be a dedicated cut-off machine.

Safety Warnings Specific for

Sanding Operations:

Do not use excessively oversized sanding

di sc paper . Fo llow man ufac ture r’s

recommendations, when selecting sanding

paper. Larger sanding paper extending beyond

the sanding pad presents a laceration hazard

and may cause snagging, tearing of the disc or

kickback.

Safety Warnings Specific for Wire

Brushing Operations:

Be aware that wire bristles are thrown by

the brush even during ordinary operation.

D

o not overstress the wires by applying

ex cess ive load to the br ush. Th e wi re

bristles can easily penetrate light clothing

and/or skin.

If the use of a guard is recommended for

wi r e b r ushin g , do not allo w any

interference of the wire wheel or brush with

the guard. Wire wheel or brush may expand in

diameter due to work load and centrifugal

forces.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 6

-7-

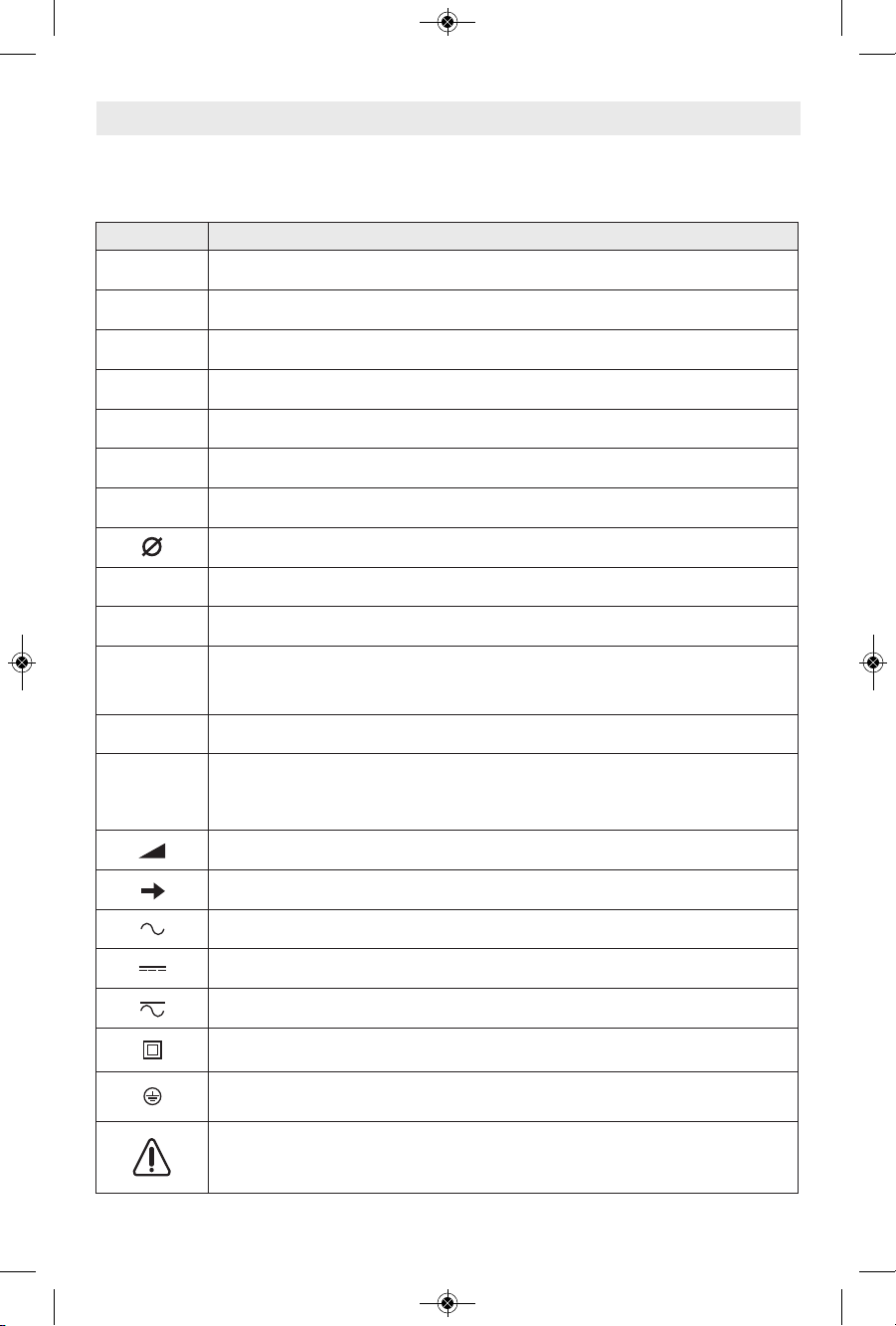

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Designation / Explanation

V Volts (voltage)

A Amperes (current)

Hz Hertz (frequency, cycles per second)

W Watt (power)

kg Kilograms (weight)

min Minutes (time)

s Seconds (time)

Diameter (size of drill bits, grinding wheels, etc.)

n

0

No load speed (rotational speed at no load)

n Rated speed (maximum attainable speed)

.../min

Revolutions or reciprocation per minute (revolutions, strokes, surface speed,

orbits etc. per minute)

0 Off position (zero speed, zero torque...)

1, 2, 3, ...

I, II, III,

Selector settings (speed, torque or position settings. Higher number means

greater speed)

0

Infinitely variable selector with off (speed is increasing from 0 setting)

Arrow (action in the direction of arrow)

Alternating current (type or a characteristic of current)

Direct current (type or a characteristic of current)

Alternating or direct current (type or a characteristic of current)

Class II construction (designates double insulated construction tools)

Earthing terminal (grounding terminal)

Warning symbol (alerts user to warning messages)

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 7

-8-

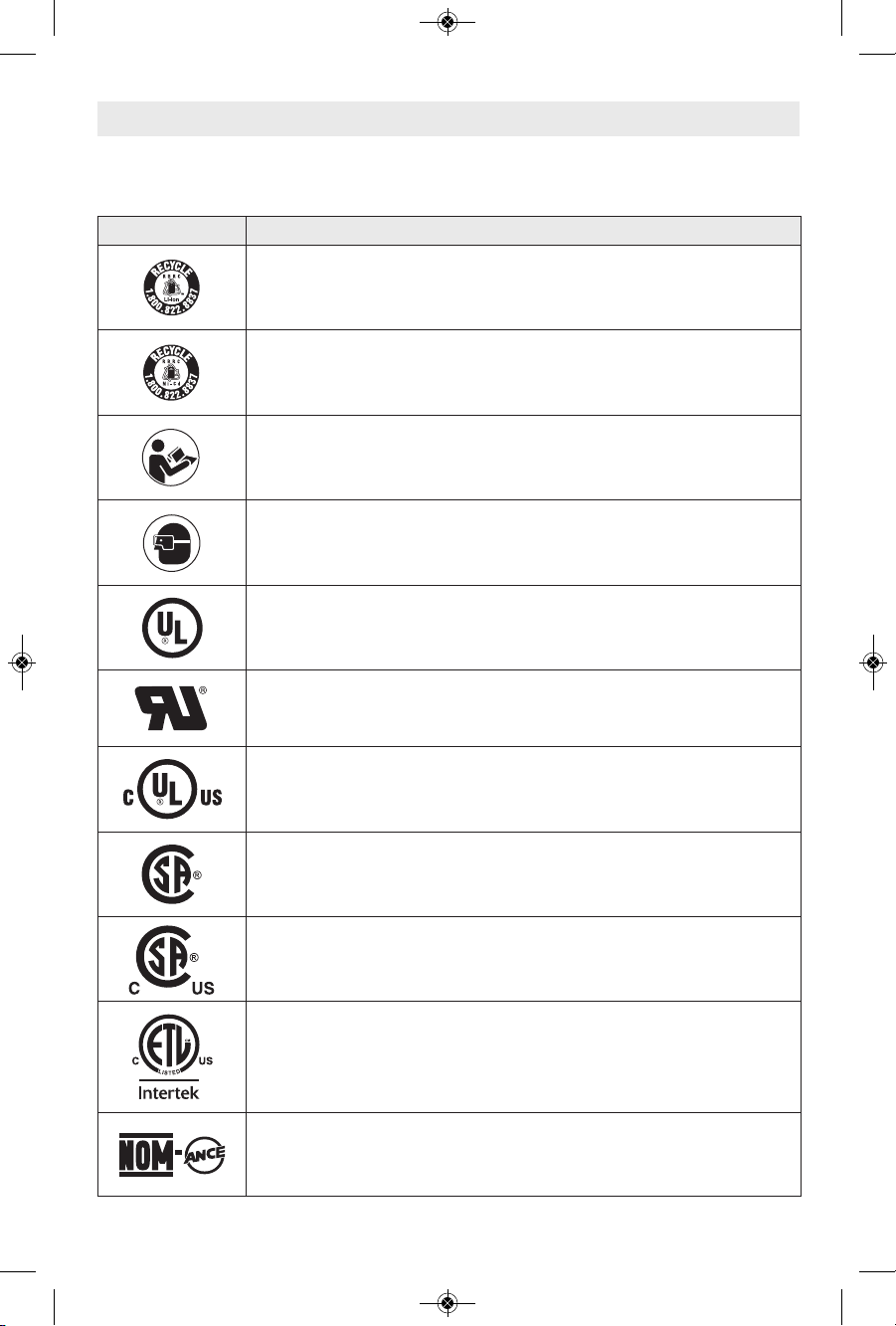

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Designation / Explanation

Designates Li-ion battery recycling program

Designates Ni-Cad battery recycling program

Alerts user to read manual

Alerts user to wear eye protection

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 8

-9-

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

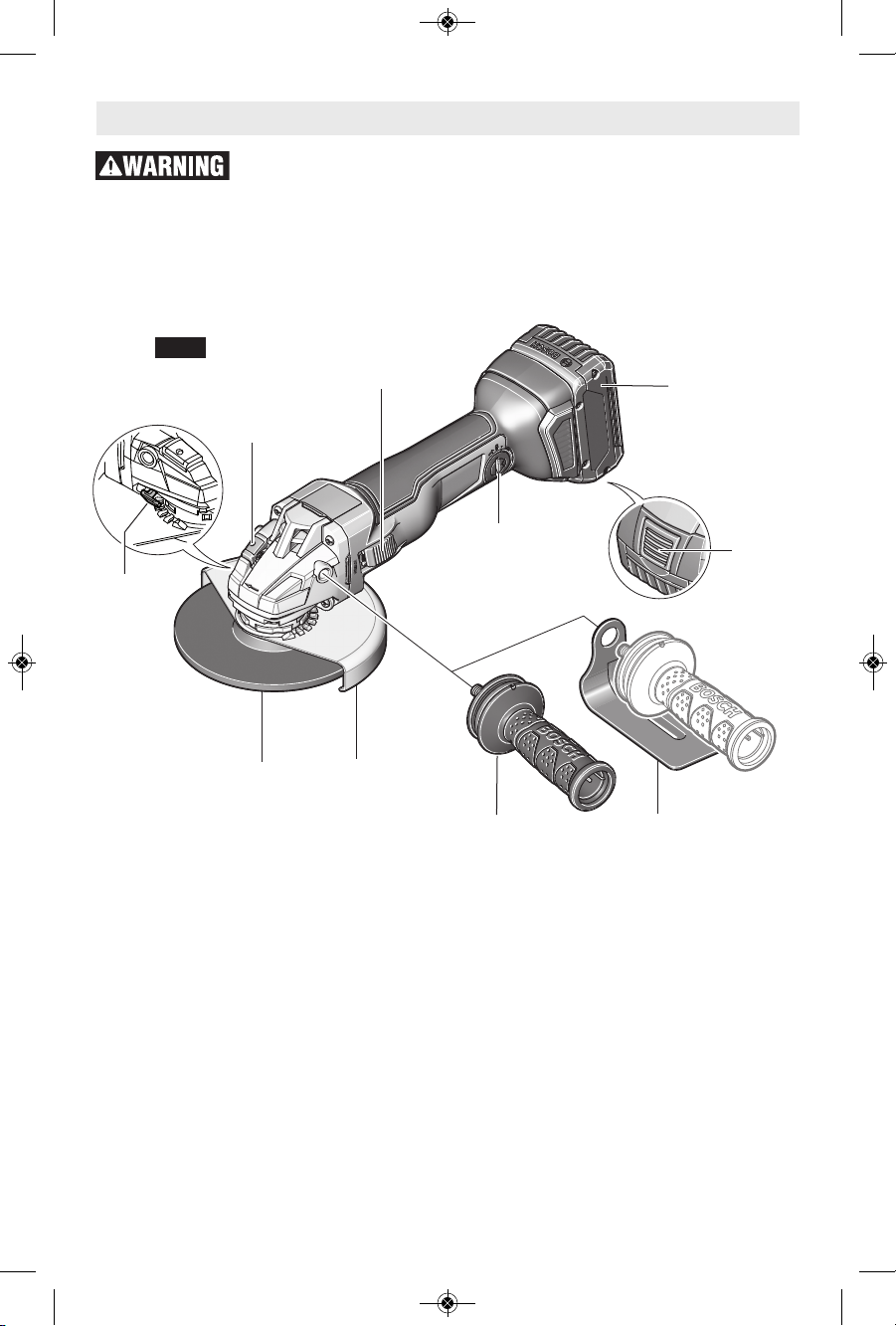

GWS18V-45C

Cordless Angle Grinder with Side Switch

GRINDING

WHEEL

WHEEL

GUARD

HAND GUARD

(Optional Accessory)

VIBRATION CONTROL

SIDE HANDLE

SPINDLE

LOCK

FIG. 1

SIDE

SWITCH

BATTERY

PACK

RELEASE

BUTTON

LOCATION FOR

BLUETOOTH

CONNECTIVITY

MODULE

(OPTIONAL)

BATTERY PACK

GUARD

RELEASE

LEVER

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 9

-10-

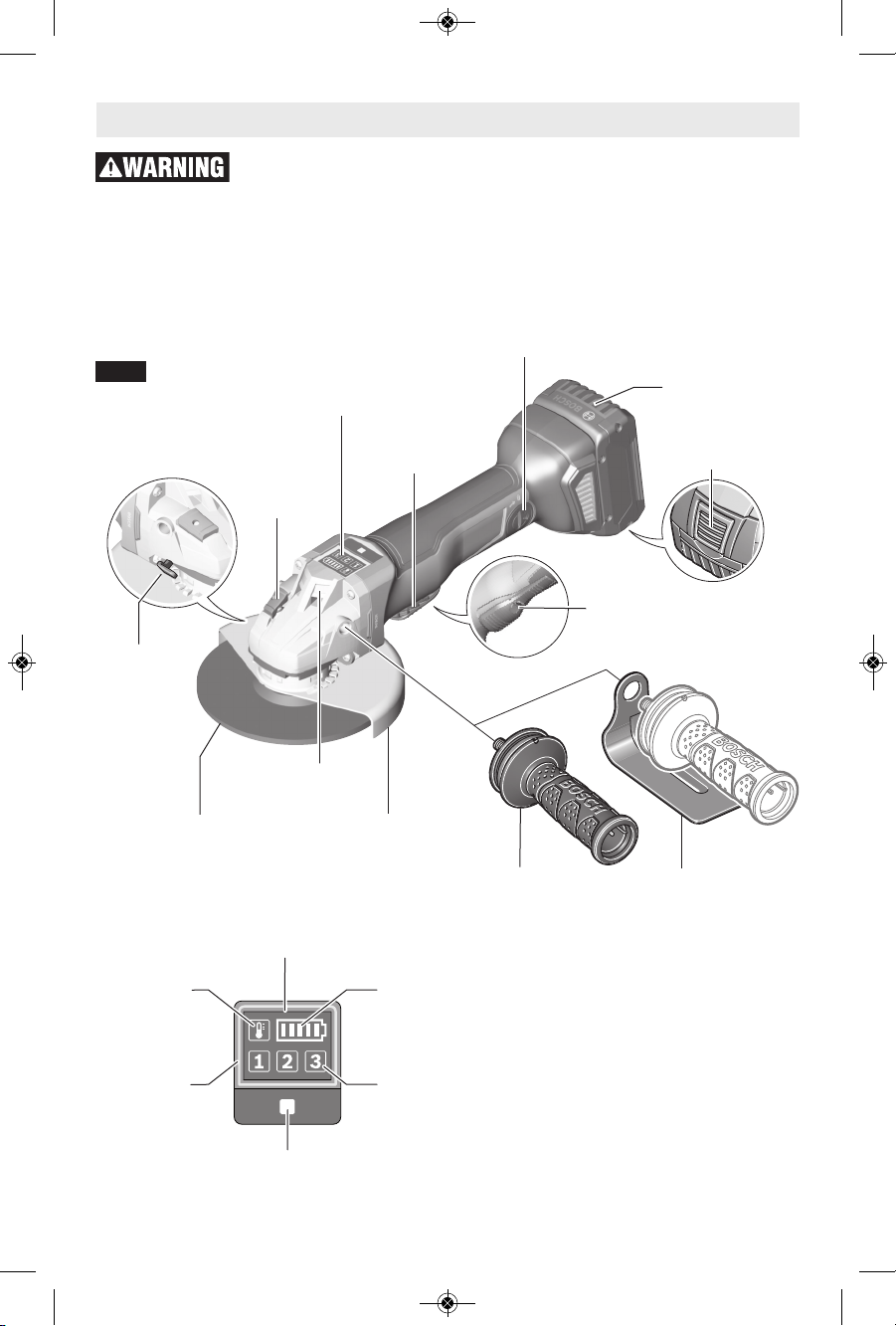

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

GWS18V-45PC/PSC

Cordless Angle Grinder with Paddle Switch

GRINDING

WHEEL

WHEEL

GUARD

HAND GUARD

(Optional Accessory)

VIBRATION CONTROL

SIDE HANDLE

SPINDLE

LOCK

FIG. 2

PADDLE

SWITCH

"LOCK-OFF" SWITCH

RELEASE LEVER

BATTERY PACK

RELEASE BUTTON

LOCATION FOR BLUETOOTH

CONNECTIVITY MODULE

(GWS18V-45PC OPTIONAL)

BATTERY PACK

GUARD

RELEASE

LEVER

USER INTERFACE

(GWS18V-45PSC)

USER INTERFACE

(GWS18V-45PSC)

BATTERY STATUS

INDICATOR

SPEED

PRESELECTION

LEVEL

SPEED

PRESELECTION

BUTTON

POWER TOOL

STATUS

INDICATOR

OVERLOAD

PROTECTION

INDICATOR

WORK LIGHT

(GWS18V-45PSC)

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 10

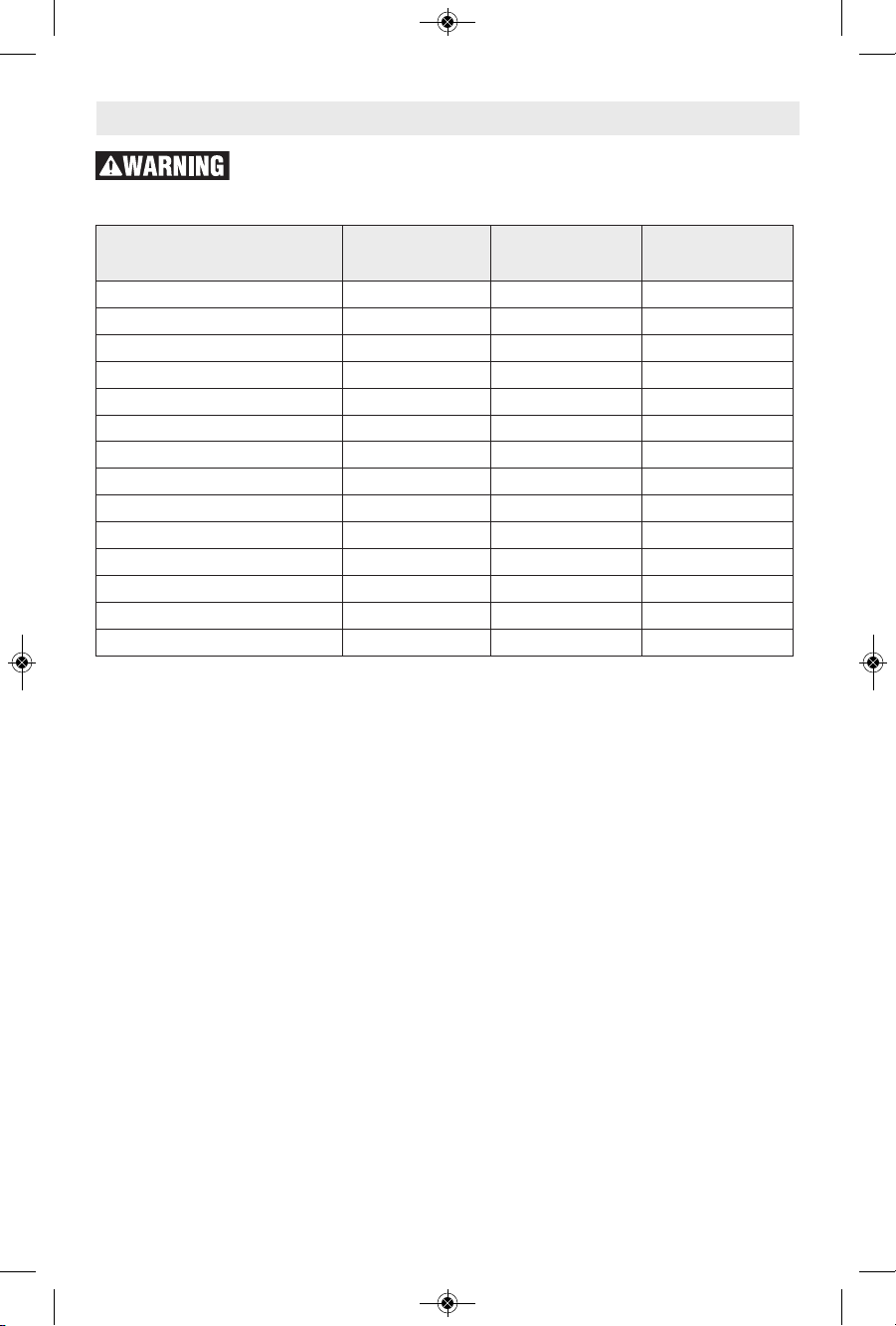

-11-

Model number GWS18V-45C GWS18V-45PC GWS18V-45PSC

Battery 18V (Bosch Series) 18V (Bosch Series) 18V (Bosch Series)

Rated speed n 9,000/min n 9,000/min n 9,000/min

Switch Type Side Paddle Paddle

Run-Out Brake Included Included Included

Bluetooth Connectivity Tool Module Optional Optional Included

Spindle thread 5/8"-11 UNC 5/8"-11 UNC 5/8"-11 UNC

Max. spindle length 9/16" (14,3 mm) 9/16" (14,3 mm) 9/16" (14,3 mm)

Max.Type 27 grinding wheel ⌀ 4 1/2" (115 mm) 4 1/2" (115 mm) 4 1/2" (115 mm)

Type 27 grinding wheel thickness 0.25" (6mm) 0.25" (6mm) 0.25" (6mm)

Max.Type 41/1A, 27A cutting wheel

⌀ 4 1/2" (115 mm) 4 1/2" (115 mm) 4 1/2" (115 mm)

Max. flap disc ⌀ 4 1/2" (115 mm) 4 1/2" (115 mm) 4 1/2" (115 mm)

Max. sanding disc ⌀ 4 1/2" (115 mm) 4 1/2" (115 mm) 4 1/2" (115 mm)

Max. wire wheel ⌀ 4" (102 mm) 4" (102 mm) 4" (102 mm)

Max. wire cup brush ⌀ 3" (76 mm) 3" (76 mm) 3" (76 mm)

Battery Packs/Chargers

Please refer to the Charger Manual included with your tool.

NOTE: For tool specifications refer to the nameplate on your tool.

Accessory speed rating must be equal to or greater than the tool’s speed rating. Do not

exceed the recommended wheel diameter.

NOTE: Not recommended for use with type 11 cup wheels.

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 11

INSERTING THE BLUETOOTH

CONNECTIVITY TOOL MODULE

Read the corr e s p o n d i n g operating

instruction s f o r information a b o u t the

Bluetooth® Connectivity Tool Module.

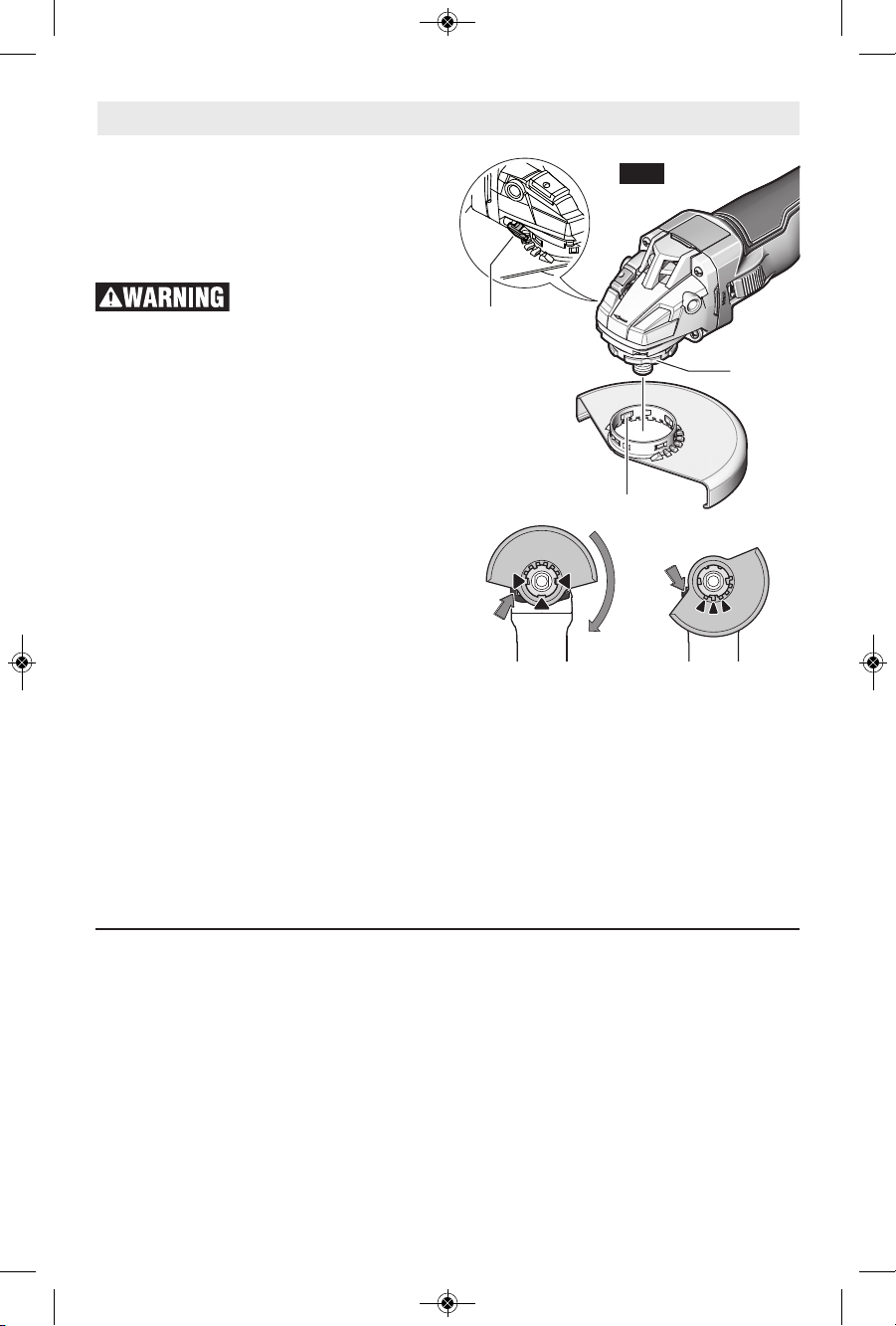

WHEEL GUARD INSTALLATION

Wh e el guar d must be

at t ached w h en usin g

disc grinding or cutting wheels. Always

keep wheel guard be tween you and your work

while grinding or cutting.

TO ATTACH WHEEL GUARD: Disconnect

battery pack from tool.

Press and hold the release lever (Fig. 3), and

pl a c e th e guard on the guard mount i n g

flange until the guard’s keys line up with the

notches in the spindle collar (Fig. 3A).

Press the guard onto the guard mounting

flang e until the sh ould er of t he g uard is

seated against the flange of the tool, and turn

the gu ard u ntil it can clearly be hea rd to

engage.

Adjust th e positio n of the g u a rd t o the

requirements of the work process. For this,

press the release lever upward and turn the

guard until it clicks into place then adjust as

needed.

• Always adjust the guard in such a manner

that all 3 red cams of release lever engage

in to th e co r respo nding notc h es o f the

guard (Fig. 3B).

• Adjust the guard in such a manner that

sparking is prevented in the direction of the

operator.

• The guard should turn only upon actuation

of the release lever! Otherwise the tool

may not continue to be used under any

circumstances and must be taken to an

after-sales service agent.

Note: T h e encoding k e y s on t h e guard

ensure that only a guard that fits the tool type

can be mounted.

TO REMOVE GUARD: Press release lever,

rotate guard until the keys on guard line up

with the notches on the guard mounting flange,

and lift guard off the guard mounting flange

(Fig. 3).

FIG. 3

Assembly

-12-

GUARD

MOUNTING

FLANGE

KEYS

GUARD

RELEASE

LEVER

AB

LOCK NUT AND BACKING FLANGE

Your tool is equipped with a threaded spindle

for mounting ac ces sories. Always use the

supplied lock nut (and backing flange) that

has same thread size as spindle.

VIBRATION CONTROL SIDE HANDLE

The side handle is used to control and balance

the tool. The handle must be thread ed into the

fr o nt h ousing on eith e r si d e o f the too l ,

de p endin g on per sonal pr e feren c e and

comfort. Use the side handle for safe control

and ease of operation (Fig. 1).

OPTIONAL HAND GUARD

(Optional Accessory)

The hand guard is to be used with backing

pads, sanding discs and wire brushes to keep

fingers and hand away from work surface,

sharp edges, burrs and debris. When using the

optional hand guard accessory insert side

handle through hole in guard and then thread

into housing (Fig. 1).

Ensure that hand guard is positioned between

hand and backing pad, sanding disc or wire

brush.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 12

-13-

ABRASIVE TYPE 41/1A AND 27A

WHEEL ASSEMBLY

Using the optional Type 41/1A wheel guard,

it is possible to perform limited cutting on

small stock such as metal tubes, piping or

rebar.

Do not attempt to cut large stock or sheets of

metal as this tool is not designed to be a

dedicated cutting tool.

Always use Type 41/1A

pr otec tion guard for

cutting.

Disconnect battery pack from tool. Be sure

that wheel guard is in place for cutting.

When u s i n g mo unting w h e e l s , thread

BACKING FLANGE onto spindle, then place

WHEEL on the spindle. Thread on the lock

nut and tighten nut using a lock nut wrench

provided with adapter kit, while holding the

spindle lock in (Fig. 5).

TO REMOVE: Reverse procedure.

TYPE 41/1A ABRASIVE

STRAIGHT GRINDING WHEELS

Do not use Type 41/1A

ab r asive w heels

designed for straight/die grinding. This tool

is not designed for use with Type 41/1A

abrasive straight/die grinding wheels.

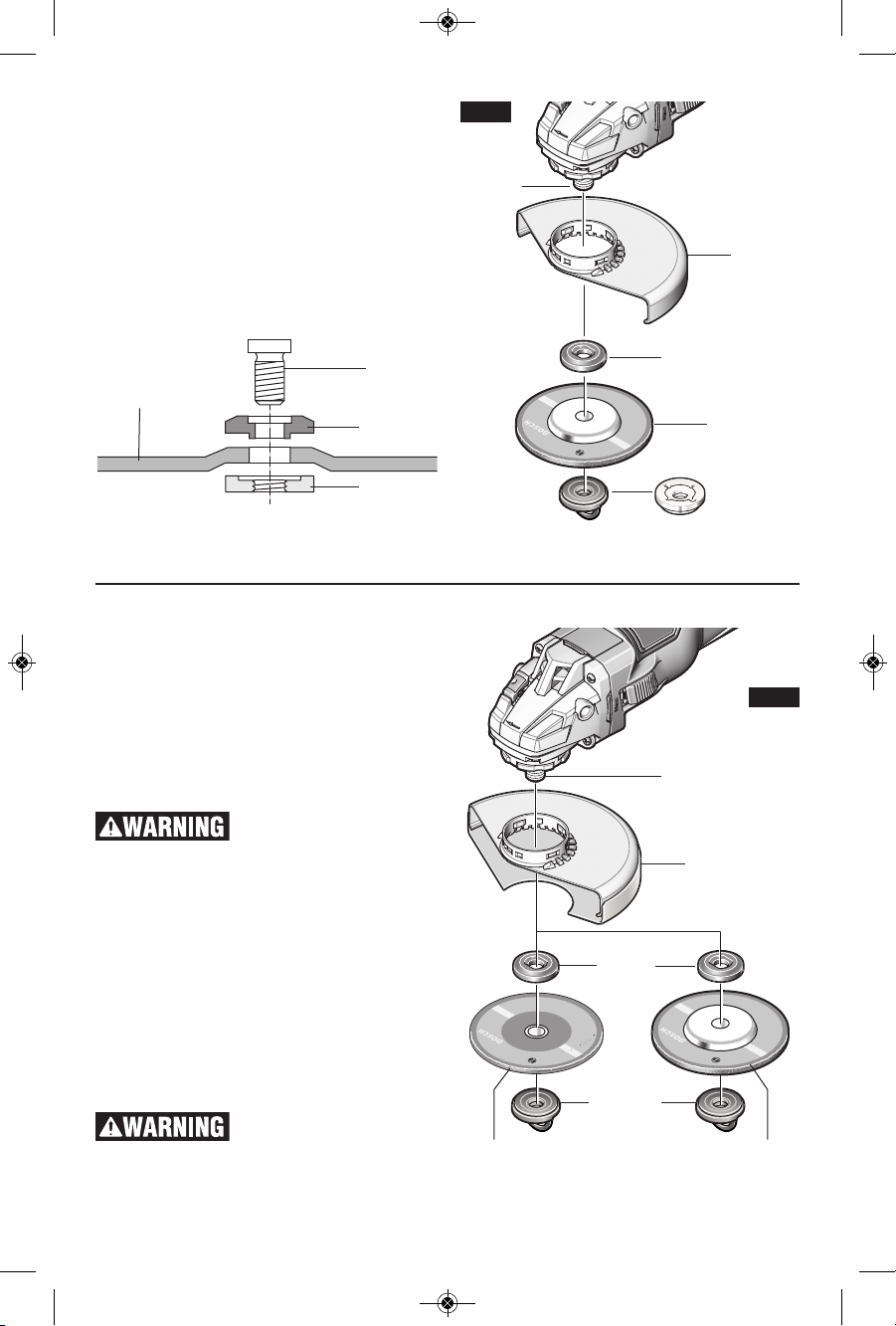

DISC GRINDING WHEEL ASSEMBLY

D

isconnect battery pack from tool. Be sure

that wheel guard is in place for grinding. Place

BACKING FLANGE and GRINDING WHEEL

on the spindle. Thread on the lock nut and

tighten nut using the supplied lock nut wrench,

while holding the spindle lock in (Fig. 4).

TO REMOVE: Reverse procedure.

No t rec o m m e nded fo r use w i t h spin- o n

wheels.

LOCK NUT

(OPTIONAL)

TYPE 27

GRINDING

WHEEL

BACKING

FLANGE

SPINDLE

TYPE 27

GRINDING

WHEEL

LOCK NUT

(OPTIONAL)

SPINDLE

TYPE 27

WHEEL

GUARD

BACKING

FLANGE

FIG. 4

TYPE 41/1A

WHEEL GUARD

(OPTIONAL)

SPINDLE

BACKING

FLANGE

TYPE 41/1A

CUTTING WHEEL

FIG. 5

QUICK-

CLAMPING NUT

TYPE 27A

CUTOFF

WHEEL

QUICK-

CLAMPING NUT

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 13

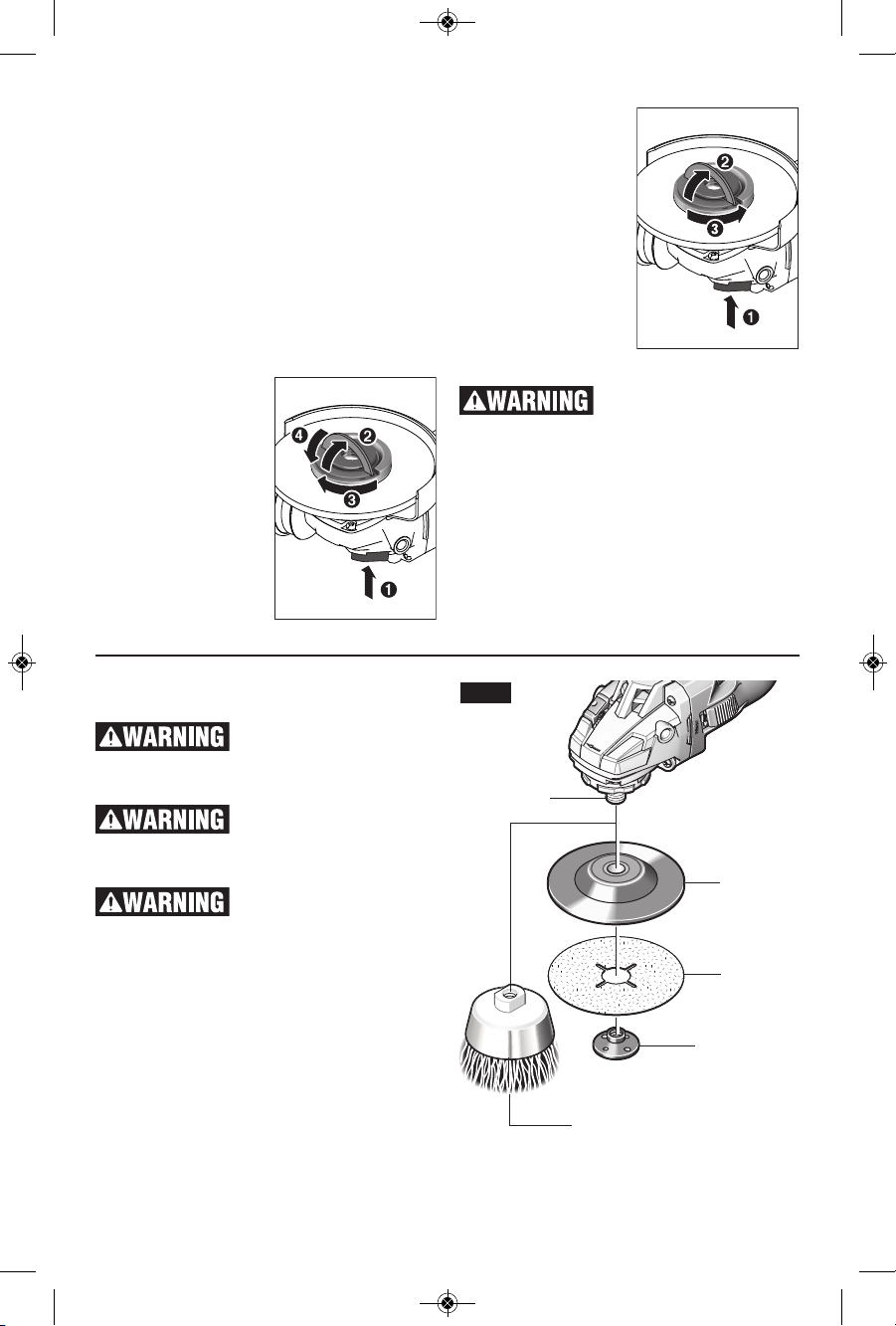

QUICK-CLAMPING NUT

Use the quick-clamping nut to secure the

grinding/cutting disc without th e need for

additional tools. Only use the quick-clamping

nut for grinding/cutting discs up to a maximum

d

iameter of 4 1/2”.

• The quick-clamping nut may be used

only for grinding or cutting discs.

• Only use quick-clamping nuts that are in

good working order and not damaged.

• When screwing on, make sure that the

printed side of the quick-clamping nut is

not facing the grinding disc.

Press the spindle lock

bu t t o n to lock the

grinding spin dle. To

ti g h t en the qu i c kclamping nut, fold up

the bar a nd turn the

qu i c k -clampi n g nut

firmly clockwise. Then

fold d own the bar to

se c u r e t h e q u i c k clamping nut. It is not

sufficient to tighten the

disc along the edge.

A pro p erly sec u red,

un d a m aged q u i c kclamping nut can be

removed by hand. To

do this, fold up the bar

a

nd tu rn the qui c k cl a m p ing nut fi rmly

anticlockwise, Fig 8. If

the quick-clamping nut

is st u c k , do not

at t e mpt t o lo o s en i t

with a to ol – alw ays

use a two pin spanner.

On l y us e acc e s sories

wi t h Maximu m S afe

Operating Speed rated at least equal to the

maximum speed marked on th e power

tool. This speed is based on the strength of

the wheel. It is not meant to imply a best or

most efficient operating speed. Do not exceed

the Maximum Safe Operating Speed.

-14-

SANDING ACCESSORIES ASSEMBLY

BACKING PAD

Before attaching a backing

pad be sure its maximum

safe operating speed is not exceeded by the

nameplate speed of the tool.

Wheel guard may not be

us e d fo r mos t san d ing

operations. Always reinstall wheel guard when

converting back to grinding operations.

Do no t us e th e Qu ick-

Clamping Nut with backing

pad for sanding accessories.

TO INSTALL BACKING PAD AND

SANDING DISC (Not Included)

Disconnect battery pack from tool.

Attach hand guard (Fig. 1). Set the tool on its

to p sid e (sp i n d l e up). Place the rubbe r

backing pad onto the spindle shaft. Center

the sanding disc on top of the backing pad.

Insert th e lo ck n ut t hrou gh t he d isc and

thread onto the spindle as far as you can

with your fingers. Press in the spindle lock,

then tighten the backing pad securely with

lock nut wrench (Fig. 6).

TO REMOVE: Reverse procedure.

SANDING

DISC

BACKING

PAD

LOCK NUT

(OPTIONAL)

WIRE BRUSH

SPINDLE

FIG. 6

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 14

-15-

Operating Instructions

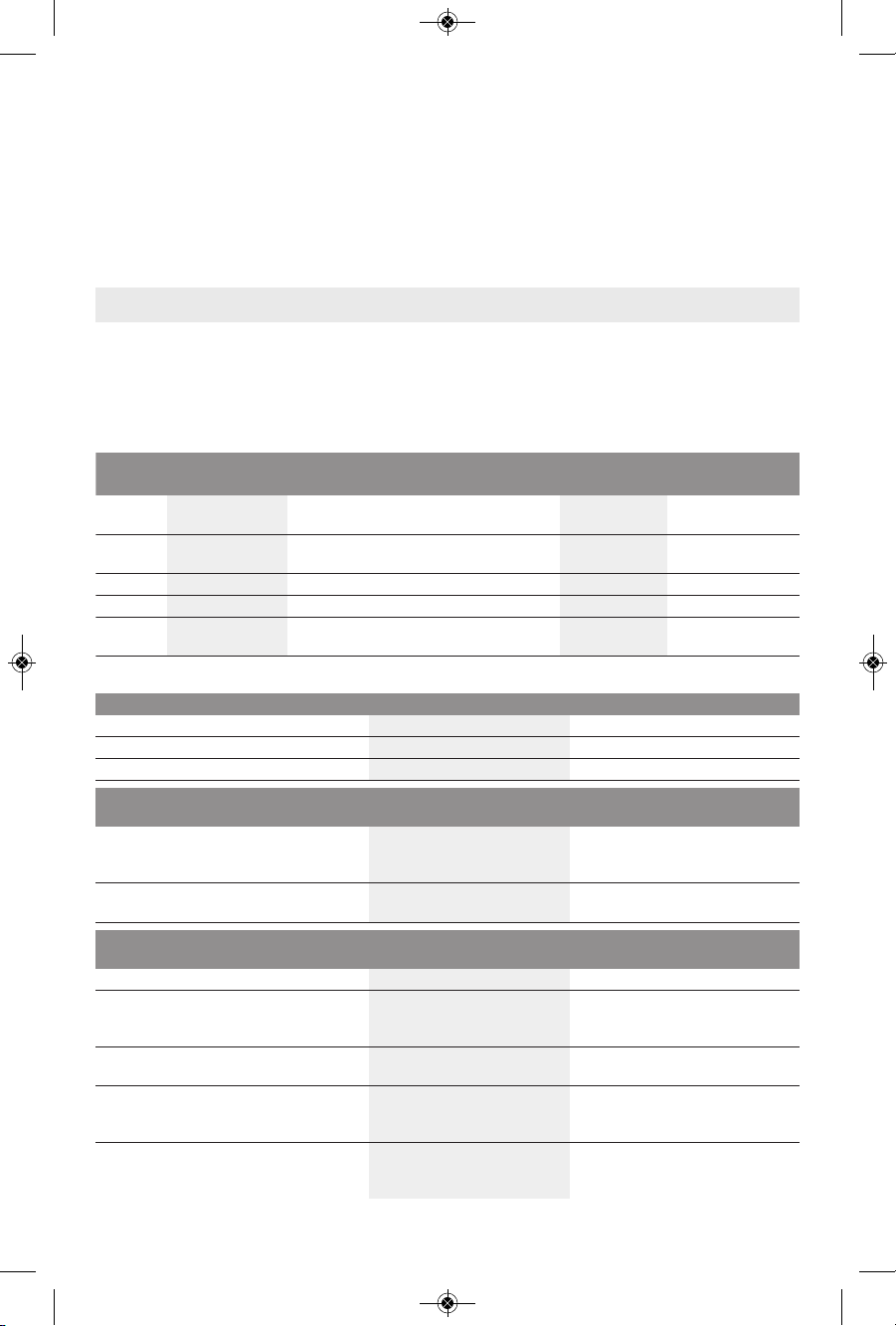

User Interface (GWS18V-45PSC) (see figure 2)

The user interface is used to preselect the speed and to indicate the status of the power tool.

SPEED PRESELECTION

You can use the button for speed preselection to preselect the required speed, even during

operation. The data in the following table are recommended values.

Material Application Accessory Speed preselec-

tion level

GWS18V-45PSC

[min

-1

]

Metal

Brushing, rust removal

Cup brush 14500

Stainless

steel

Grinding Fibre disc 26000

Metal

Rough grinding Grinding disc 39000

Metal

Cutting Cutting disc 39000

Masonry,

stone

Cutting Diamond cutting disc and cutting guide (cutting

stone is permitted only with a cutting guide)

39000

STATUS INDICATIONS

Battery status indicator (User interface) Meaning/Cause Solution

green

Battery charged

yellow

Battery almost empty Replace or charge battery soon

red

Battery pack empty Replace or charge battery

Overload protection indicator

(User interface)

Meaning/Cause Solution

yellow

Critical temperature has been

reached (motor, electronics,

battery)

Ru n th e po wer too l at no loa d an d al low it

to cool down

red

Power tool is overheated and

switches off

Allow the power tool to cool down

Power tool status indicator

(User interface)

Meaning/Cause Solution

green

Status OK –

yellow

Critical temperature has been

reached or battery is almost empty

Ru n th e po wer too l at no loa d an d al low it

to cool down, or replace or charge the

battery soon

Illuminated red

Pow er t ool i s ov erhe ate d or b att ery

is empty

Allow the po wer tool to cool down, or replace or charge the battery

Flashing red

Kickb ack shu tdown, r estart

protection has been triggered

Switch the power tool off and on again

Flashing blue

Po we r to ol is con ne ct ed to a mo bi le

terminal device or settings are

being transferred

–

WIRE BRUSH ASSEMBLY

Before assembling wire brush to this tool,

disconnect from the power source. Attach

hand guard (Fig. 1). Wire br u s h e s are

equipped with their own threaded hub, simply

thread on to spindle. Be sure to seat against

shoulder before turning tool “ON”.

TO REMOVE: Reverse procedure.

WIRE WHEEL ASSEMBLY

Before assembling wire wheel to this tool,

disconnect from the power source. Attach type

27 guard (Fig. 3). Wire wheels are equipped

with their own threaded hub, simply thread on

to spindle. Be sure to seat against shoulder

before turning tool “ON”.

TO REMOVE: Reverse procedure.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 15

-16-

Ho l d th e too l with both

hands while starting the

tool, since torque from the motor can cause the

tool to twist.

Start the tool before applying to work and let

the tool come to full speed before contacting

the workpiece. Lift the tool from the work

before releasing the switch. DO NOT turn the

switch “ON” and “OFF” while the tool is under

load; this will greatly decrease the switch life.

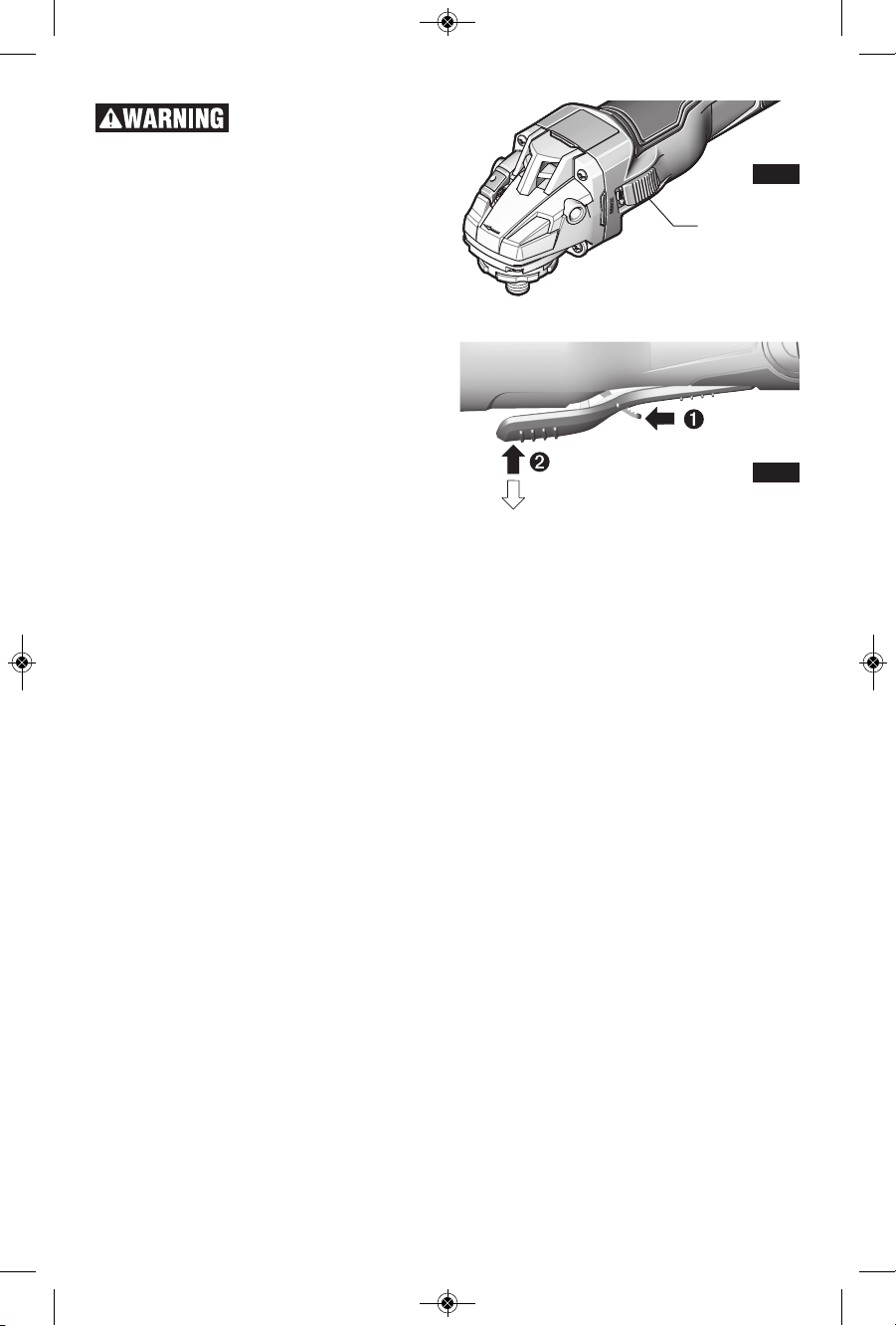

SIDE ON-OFF SWITCH

WITH LOCK (FIG. 8)

The tool is switched “ON” by the side switch

located at the side of the motor housing. The

switch can be locked in the “ON” position, a

convenience for long grinding operations.

TO TURN THE TOOL “ON” without locking it,

move t h e switch f o r wa rd b y ap plying

pressure ONLY at the REAR portion of the

switch. When pressure is released the switch

will return to “OFF” position.

TO L OCK THE SWITCH “ON”, move the

switch forward and press the FRONT portion.

TO UNLOCK THE SWITCH, simply press

and release the REAR portion of the slider.

Switch is spring loaded and will snap back

automatically.

PADDLE SWITCH (FIG. 9)

The paddle switch has a lock-off feature to

help prevent accidental startups.

TO TURN TOOL “ON”, push lock-off switch

forward to unlock the paddle switch, then

squeeze paddle switch.

TO TURN TOOL “OFF”, release pressure on

paddle switch. The switch is spring loaded

and w i l l retu r n to t h e “OFF” p os ition

automatically.

ON

OFF

FIG. 9

SIDE

SWITCH

FIG. 8

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 16

-17-

SELECTING GRINDING WHEELS

Before usi ng a gri nding

wheel, be certain that its

ma ximu m sa fe o perat ing spee d is not

exceeded by the name plate speed of the

grinder. Do not exceed the recom mended

wheel diameter.

DISC GRINDING WHEELS

Grinding wheels should be carefully selected in

order to use the grinder most efficiently. Wheels

vary in type of abrasive, bond, hardness, grit

size and structure. The correct type of wheel to

use is determined by the job. Use disc grinding

wheels for fast grinding of structural steel,

heavy weld beads, steel casting, stainless steel

and other ferrous metals.

GRINDING TIPS

Efficient grinding is achieved by controlling the

pressure and keep ing the angle between wheel

and workpiece at 10° to 15°. If the wheel is flat,

the tool is difficult to control. If the angle is too

steep, the pressure is concentrated on a small

area causing burning to the work surface.

Ex c essiv e o r su d den

pressure on the wheel will

sl ow g rindi n g a c tion and put dan g erous

stresses on the wheel.

When grinding with a new wheel be certain to

grind while pulling tool backwards until wheel

becomes rounded on its edge. New wheels

have sharp corners which tend to “bite” or cut

into work piece when pushing forward.

Grinding Operations

Cutting Operations

Do not use this grinder for

cutting masonry.

CUTTING METAL

Using the optional Type 41/1A wheel guard,

it is possible to perform limited cutting on

small stock such as metal tubes, piping or

rebar. When cutting, work w ith m oderate

feed, adapted to the material being cut. Do

not exert side pressure onto the cutting disc,

tilt or oscillate the tool. When cutting profiles

and s quare b ar, it is best to st art at th e

smallest cross section.

• Always follow precautions for kickback.

• Do not apply side pressure to cutting wheel

to reduce wheel speed.

• The tool should always be used so that

sparks are directed away from user.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 17

-18-

Sanding Operations

SELECTING SANDING DISC

Sanding discs are made of extremely hard

and sharp aluminum oxide grits, phenol-resin

b

onded to a sturd y fiber back ing for fast

heavy-duty service and long life. The discs

vary as to size and spacing of the abrasive

grits. OPEN COAT (type H) — used for soft

materials and on paint or varnish. CLOSED

COAT (type K) —used for metal, hardwood,

stone, marble and other materials.

Sanding discs range in grit from 16 (very

coarse) to 180 (very fine). To obtain best

results, select sanding discs carefully. Many

jobs require the use of several grit sizes and

at times both “open coat and closed coat”

discs are required to get the job done faster.

See chart for application examples.

Operation: Refinishing painted wood or metal surfaces.

REMARKS GRIT

To remove paint and to smooth Coarse

surface irregularities. 16-24-30

To smooth Medium

the rough sanding. 36-50-80

To remove scratches left by Fine

previous discs. 100-120

To smooth surfaces for painting, Very Fine

polishing or waxing. 150-180

SANDING TIPS

For best results, tilt the Disc Sander at a 10° to

15° angle while sanding so that only about 1"

of the surface around the edge of the disc

contacts the work.

If the disc (accessory) is

held flat or the back edge

of the disc comes in contact with the work, a

violent thrust to the side may result.

If sander is tilted too much, sanding action will

be to o g reat an d a ro u gh cut sur face or

gouging and snagging will result.

Guide the Disc Sander with crosswise strokes.

Be careful not to hold the sander in one spot

too long. Do not use a circular motion, as this

makes swirl marks. Test before use on scrap stock.

Do not force or apply pressure when sanding.

Use only the weight of the tool for pressure.

Excess pressure actually slows the tool down.

If faster stock removal is desired, change to a

coarser grit disc.

Remove gummy paint from metal with an

“open coat” disc. Sand until sparks start to

appear, then stop and change to a “closed

coat” disc to remove any remaining paint.

SANDING WOOD

When sanding wood the direction of the disc

motion at the contact point should parallel the

grain as much as possible. The rapid cut of

discs and the swirl type scratch pattern they

occasionally create generally prohibit their use

for producing the final finish.

Scratches and circular marks are usually the

re s ult of usin g too coars e a gr i t. When

changing to a finer grit, move across the sand ing lines that were made by a previous coarser

disc.

SANDING METAL

When sanding automobiles or appliances,

wipe the metal clean with a non-flammable

solvent or commercial cleaner to remove all

wa x an d g r ease. By doi ng t his first , th e

sanding discs will sand better and last longer.

For heavy duty work, use a coarse grit disc

first. Follow-up with a medium grit to remove

scratches. To produce smooth finish, use fine

grit disc.

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 18

-19-

This tool is equipped with Automatic Restart

Pr o tecti o n. T his featu r e h e lps preve n t

accidental s tartups after power has been

interrupted, e.g. the battery was removed with

the switch locked in the on position. To resume

oper ati on, turn the sid e switch to the off

position, and back to on position to restart the

tool.

Make sure that the side switch is in the off

position before inserting or removing battery

pack. (Fig. 8). To insert the battery pack slide it

into the housing until the battery pack locks

into position.

Your tool is equipped with a secondary locking

la t ch to pre v ent the ba ttery pack from

completely falling out of the handle, should it

become loose due to vibration.

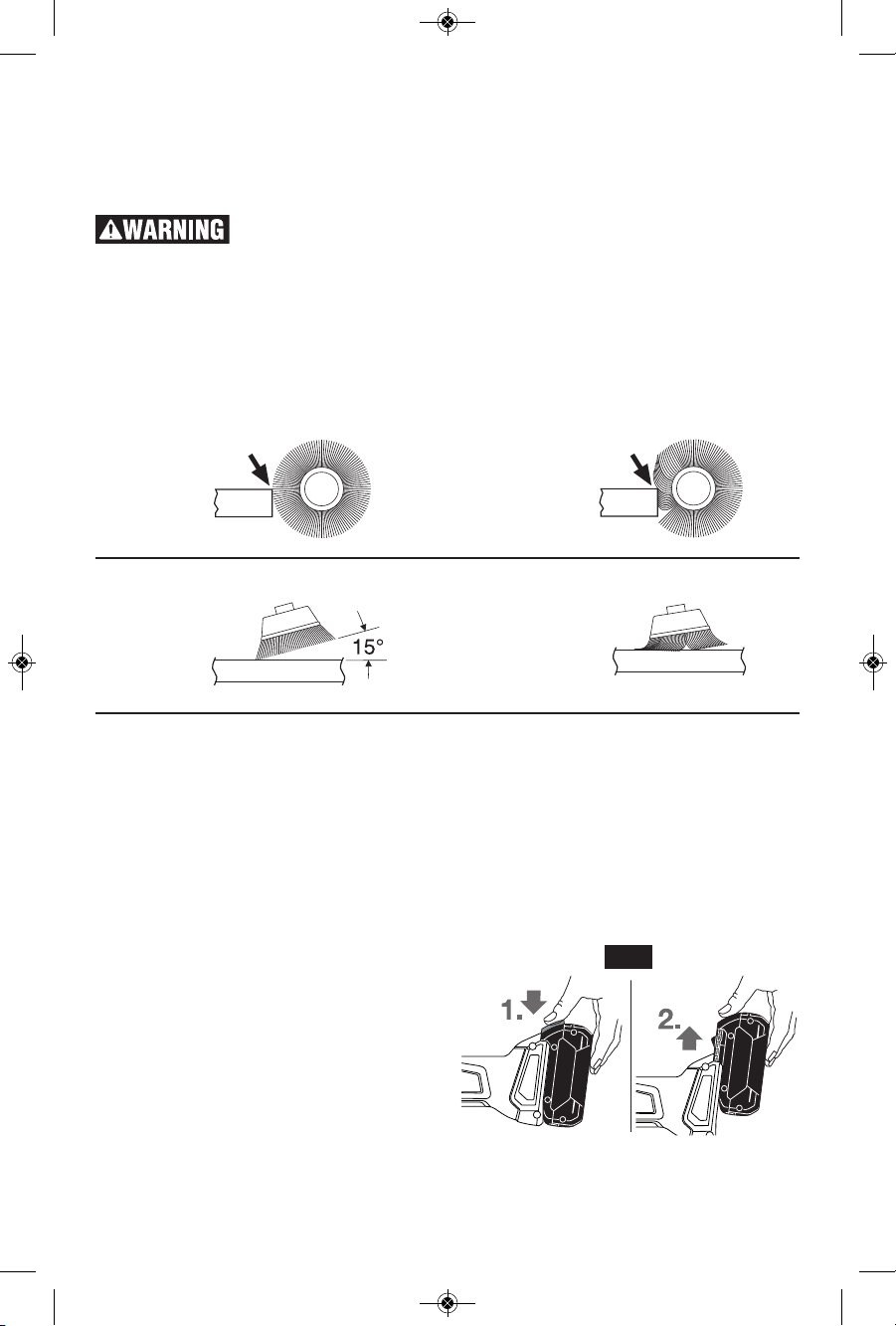

To remove the battery pack, press the battery

pack release button and slide the battery pack

forward.

Press the battery pack release button again

and slide the battery pack completely out of

tool housing (Fig. 10).

FIG. 10

INSERTING AND RELEASING BATTERY PACK

Wire brushes are intended to “clean” structural

st e el, cas t ings, sheet metal , sto n e and

c

oncrete. They are used to remove rust, scale

and paint.

Av o i d b o u n cing and

snagging the wire brush,

especially when working corners, sharp edges

etc. This can cause loss of control and kickback.

BRUSHING PRESSURE

1.Remember, the tips of a wire brush do the

work. Operate the brush with the lightest

pressure so only the tips of the wire come

in contact with the work.

2.If heavier pressures are used, the wires will

be ove rstre ssed, res ultin g in a w iping

action; and if this is continued, the life of

the brush will be shortened due to wire

fatigue.

3. Apply the brush to the work in such a way

that as much of the brush face as possible is

in full contact with the work. Applying the side

or edge of the brush to the work will result in

wire breakage and shortened brush life.

Wire Brush Operations

CORRECT:

Wire tips doing

the work.

INCORRECT:

Excessive

pressure can

cause wire

breakage.

CORRECT:

Wire tips doing

the work.

INCORRECT:

Excessive pressure

can cause wire

breakage.

WIRE WHEEL BRUSH

WIRE CUP BRUSH

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 19

-20-

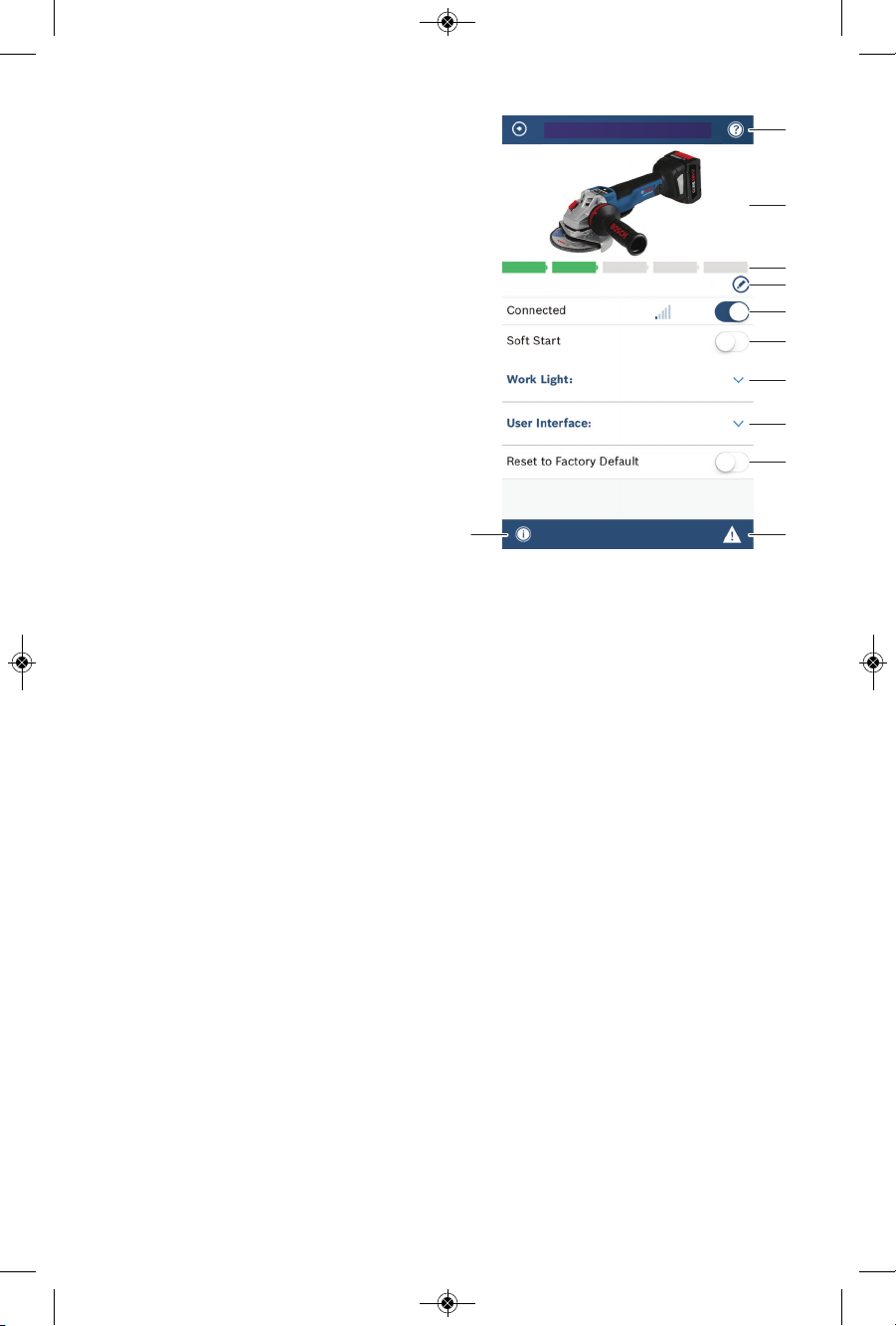

USING ‘BOSCH TOOLBOX’ APP

After pairing your tool with a mobile device

you can adjust certain functions or check the

status of the power tool using Bosch Toolbox

app.

Every time you change any setting the tool

will confirm the changes by flashing the white

LED work light on GWS18V-45PSC.

A. Help button – tappi ng this butt on will

bring up help screen.

B. Tool photo – tapping on the photo will let

you customize the photograph of the tool.

C. Power tool battery charge status – the

number of green ‘batteries’ indicates the

estimated charge level for the battery

pack.

D. Power tool nickname – tapping on the

‘pencil’ icon will let you customize the tool

nickname. Yo u ca n al so do it wh e n

changing the tool photo.

E. Connection status bar – Here you can

see the c o n n e c t i o n (signal) s t r e n g t h

indicated by vertical bars. You can use

toggle switch to disconnect the tool from

you mobile device.

F. So ft Start - Allo ws spee d r amp-up of

grinder.

G. Work Light - Modify settings to LED (PSC

only).

H. User Interface - Customize tool interface

and usage settings.

I. Factory Reset toggle switch – you can

reset tool settings back to factory default

settings. When you do so the LED after

gl o w wi l l re s et t o ‘10s ’ and Kick B ack

Control will be reset to ‘Later’ setting.

J. Tool alerts – tapping the ‘alerts triangle’

will display any alerts received from the

tool.

K. Info button – displays tool information

and specifications.

A

B

C

D

E

F

G

H

I

JK

GWS18V-45PSC

GWS18V-45P SC

160992A3WF 08-18 GWS18V-45C.qxp_GWS 8/28/18 1:07 PM Page 20

Loading...

Loading...