Bosch ES 100 5, ES 120 5, ES 150 5, ES 035 5, ES 050 5 Installation And Operating Instructions Manual

...

Installation and operating instructions

DHW cylinder

Tronic 4000 T | Tronic 6000 T

6720818520-00.1V

ES 035/050/080/100/120/150 5 ...

6 720 818 731 (2016/07) EN

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

2 | Table of Contents

Table of Contents

1 Explanation of symbols and safety instructions . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . 3

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . 3

2 Technical properties and dimension's . . . . . . . . . . . 4

2.1 Determined use . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Description of the DHW cylinder . . . . . . . . . 4

2.4 Corrosion protection . . . . . . . . . . . . . . . . . . . 4

2.5 accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.8 Appliance layout . . . . . . . . . . . . . . . . . . . . . . 7

2.9 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . 7

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Transportation, storage and recycling . . . . . 7

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1 Important information . . . . . . . . . . . . . . . . . . 7

5.2 Selecting the installation location . . . . . . . . 8

5.3 Wall mounting bracket . . . . . . . . . . . . . . . . . 8

5.4 Water connection . . . . . . . . . . . . . . . . . . . . . 9

5.5 Electrical connection . . . . . . . . . . . . . . . . . . 10

5.6 Commissioning . . . . . . . . . . . . . . . . . . . . . . 10

6 Operating the appliance . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Turn the appliance on/off . . . . . . . . . . . . . . 10

6.2 Adjust the domestic hot water

temperature . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Draining the DHW cylinder . . . . . . . . . . . . . 11

7 Environmental protection/Recycling . . . . . . . . . . . 12

8 Maintenance/inspection . . . . . . . . . . . . . . . . . . . . . 12

8.1 User information . . . . . . . . . . . . . . . . . . . . . 12

8.1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.1.2 Checking the pressure relief valve . . . . . . . 12

8.1.3 Pressure relief valve . . . . . . . . . . . . . . . . . . 12

8.1.4 Maintenance and repair . . . . . . . . . . . . . . . 12

8.2 Regular maintenance . . . . . . . . . . . . . . . . . 12

8.2.1 Function check . . . . . . . . . . . . . . . . . . . . . . 13

8.2.2 Magnesium anode . . . . . . . . . . . . . . . . . . . . 13

8.2.3 Regular thermal disinfection . . . . . . . . . . . 13

8.2.4 Extended nonuse (longer than 3 months) . 13

8.3 Safety Thermostat . . . . . . . . . . . . . . . . . . . . 14

8.4 After maintenance . . . . . . . . . . . . . . . . . . . . 14

9 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.1 Fault/cause/remedy . . . . . . . . . . . . . . . . . . 15

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Explanation of symbols and safety instructions | 3

1 Explanation of symbols and safety

instructions

1.1 Explanation of symbols

Warnings

The following signal words are defined and can be used in this

document:

• NOTICE indicates that material damage may occur.

• CAUTION indicates that minor to medium personal injury

may occur.

• WARNING indicates that severe or life-threatening

personal injury may occur.

• DANGER indicates that severe to life-threatening personal

injury will occur.

Important information

Additional symbols

1.2 Safety instructions

Installation

▶ Installation must only be carried out by an authorised

contractor.

▶ If applicable, the installation of the DHW cylinder and/or

the electrical accessories must satisfy IEC 60364-7-701.

▶ Install the DHW cylinder in a room free from the risk of frost.

▶ Before making the electoral connections, make the

hydraulic connections first and check for tightness.

▶ Before installation, disconnect the DHW cylinder from the

power supply.

Installation and conversion

▶ Only permit an authorised contractor to install or convert

this DHW cylinder.

▶ Never plug the drain of the pressure relief valve.

▶ Water may escape from the pressure relief valve drain

when it is being heated.

Maintenance

▶ Only authorised contractors are permitted to maintain this

appliance.

▶ Isolate the appliance from its power supply before

commencing any maintenance work on the DHW cylinder.

▶ The user is responsible for safety and environmental

compatibility during installation and service work.

▶ Use only original spare parts.

▶ If the power cable is damaged, it may only be replaced by

the manufacturer, the manufacturer's customer service, or

individuals who are comparably qualified in order to

prevent danger.

Handover to the user

When handing over the heating system, instruct the user in its

operation and operating conditions.

▶ Explain the operation - with particular emphasis on all

safety-related actions.

▶ Explain that conversions and repairs must only be carried

out by an approved contractor.

▶ Point out the need for inspections and maintenance for

safe and environmentally-compatible operation.

▶ The installation and operating instructions must be given to

the user for safekeeping.

Safety of electrical devices for domestic

use and similar purposes

The following requirements apply in

accordance with EN 60335-1 in order to

prevent hazards from occurring when using

electrical appliances:

“This appliance can be used by children of 8

years and older, as well as by people with

reduced physical, sensory or mental

capabilities or lacking in experience and

knowledge, if they are supervised and have

been given instruction in the safe use of the

appliance and understand the resulting

dangers. Children shall not play with the

Warnings in the text are indicated by a warning

triangle.

In addition, signal words are used to indicate

the type and seriousness of the ensuing risk if

measures for minimising the danger are not

taken.

Important information where there is no danger

to people or property is indicated with the

adjacent symbol.

Symbol Meaning

▶Action step

Cross-reference to another part of the document

• List/list entry

– List/list entry (second level)

Table 1

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

4 | Technical properties and dimension's

appliance. Cleaning and user maintenance

shall not be made by children without

supervision.”

“If the power cable is damaged, it must be

replaced by the manufacturer, its customer

service department or a similarly qualified

person, so that risks are avoided.”

2 Technical properties and dimension's

2.1 Determined use

DHW cylinders are designed for heating and storing potable

water. Please observe national, regional, and local codes,

regulations, guidelines and standards for potable water.

Any other use is considered inappropriate. We take no

responsibility for damage caused through incorrect use.

The service life of the device strongly depends on using water

with appropriate properties.

2.2 Type overview

[ES] Electrical domestic hot water cylinder

[035] Cylinder capacity (liters)

[5] Version

[1200 W] Performance

[BO] Make

[H1, M1] Design

[X] Standard diameter

[C] Capillary temperature controller

[T] Thermometers

[W] Wall-mounted installation

[V] Vertical installation

[R] Reversible installation

[B] Connections to the bottom side

2.3 Description of the DHW cylinder

• Enamel-coated steel storage cylinder according to

European standards

• High pressure stability

• Outer wall jacket: Sheet-metal and/or plastic

• Easy operation

• CFC-free PU insulation

• Magnesium anode

2.4 Corrosion protection

The internal wall of the DHW cylinder is enamel-coated. This

provides fully neutral and water-compatible contact with

possible water. As an additional corrosion protection measure,

a magnesium anode is installed.

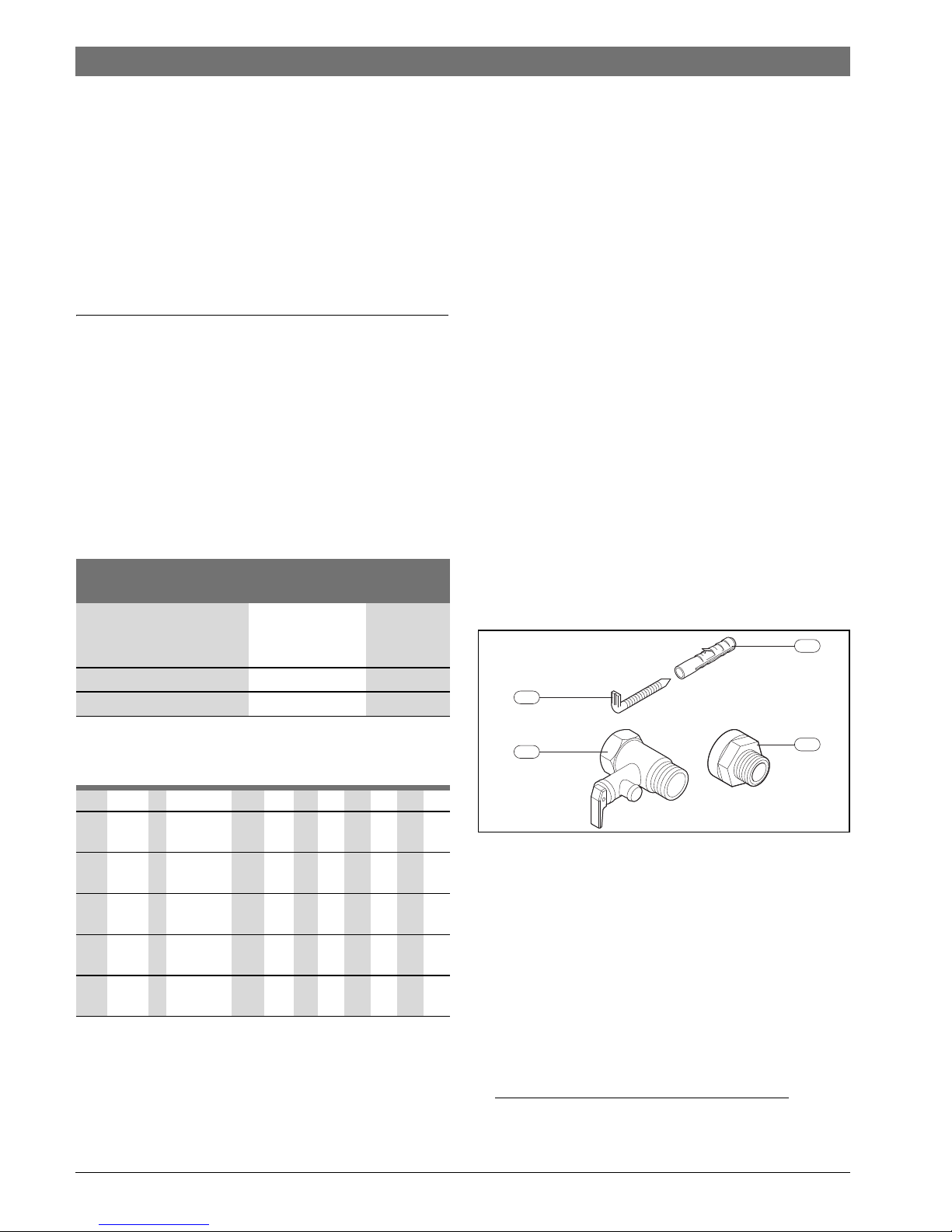

2.5 accessories

Fig. 1

[1] Screws (2x)

1)

[2] Rawl plug (2x)

1)

[3] Pressure relief valve (8 bar)

1)

[4] Isolation fitting (2x)

1)

Requirements for

potable water

Units

Water hardness, min. ppm

grain/US gallon

°dH

120

7.2

6.7

pH, min. – max. 6.5 – 9.5

Conductivity, min. – max. μS/cm 130 – 1500

Table 2 Requirements for potable water

ES 035 5 1200 W BO H1 XCTWVB

ES 050 5 1600 W

1500 W

BO H1M1XCTWRVB

ES 080 5 2000 W BO H1M1XCTWRVB

ES 100 5 2000 W BO H1M1XCTWRVB

ES 120 5 2000 W BO H1M1XCTWRVB

ES 150 5 2400 W

2000 W

BO H1M1XCTWRVB

Table 3

1) Only some models

6720801526-01.2V

3

1

2

4

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Technical properties and dimension's | 5

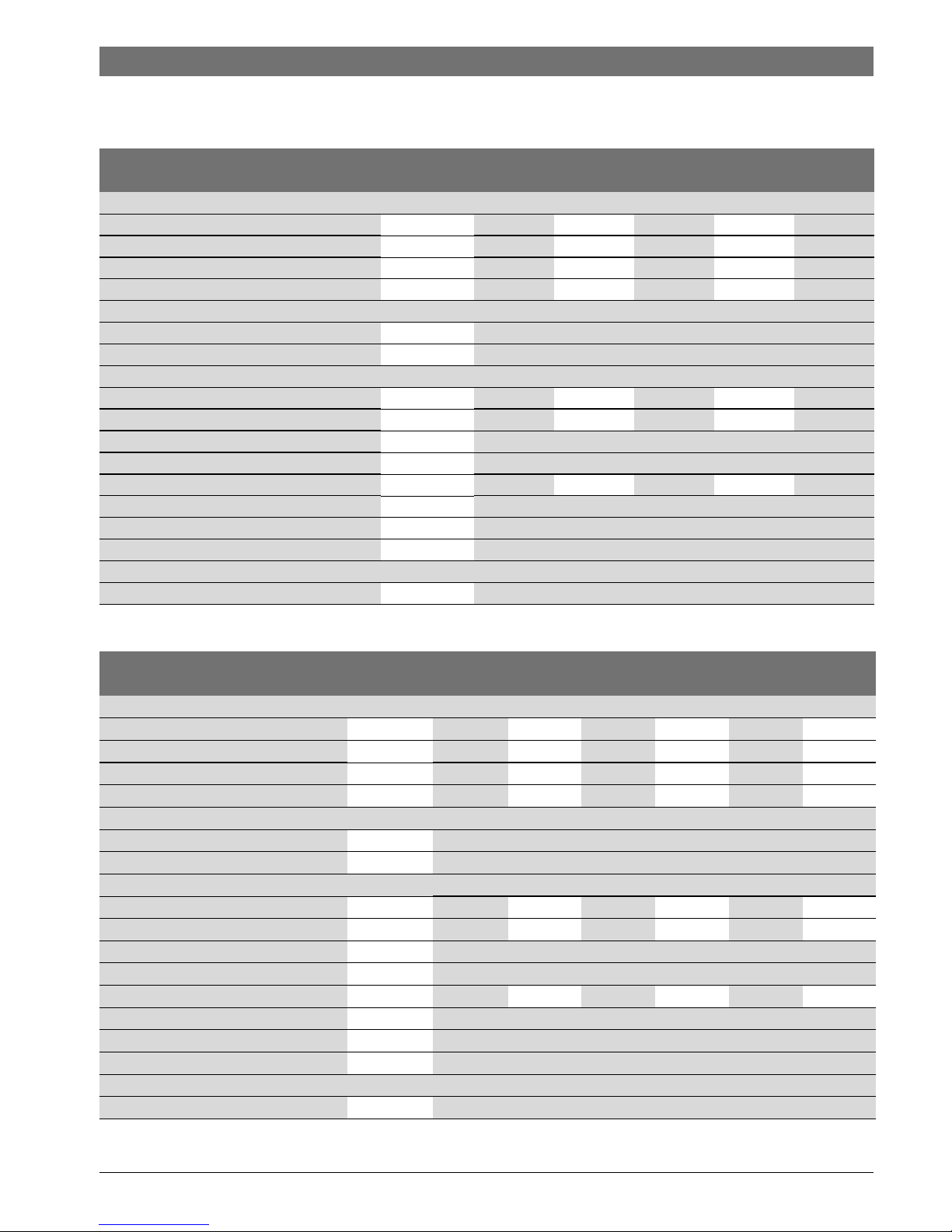

2.6 Technical data

This appliance meets the requirements specified by the European Directives 2014/35/EC and 2014/30/EC.

Tronic 4000 T

Technical data Units ES 050 ES 080 ES 100 ES 120 ES 150

General Information

Capacity l 48 77 95 115 143

Dry weight kg 18,8 22,5 25,8 29,3 35

Weight when full kg 66,8 99,5 120,8 144,3 178

Standing loss kW/24h 0,73 0,91 1,03 1,28 1,43

Water data

Max. permissible operating pressure bar 8

Water connections inch 1/2

Electrical data

Rated output W 1500 2000 2000 2000 2000

Heat-up time (T- 50 °C) 1 h 52 min 2 h 14 min 2 h 47 min 3 h 22 min 4 h 09 min

Supply voltage VAC 230

Frequency Hz 50

Electrical current (single phase) A 6,5 8,7 8,7 8,7 8,7

Power cable with plug (type) HO5VV - F 3 x 1,5 mm2 or HO5VV - F 3 x 1,0 mm

2

Protection class I

IP-Rating IP24

DHW temperature

Temperature range °C up to 70 °C

Table 4 Technical data

Tronic 6000 T

Technical data Units ES 035 ES 050 ES 080 ES 100 ES 120 ES 150

General Information

Capacity l 34 47 76 95 115 142

Dry weight kg 15,7 19,2 22,5 25,8 29,3 35

Weight when full kg 49,7 66,2 98,5 120,8 144,3 177

Standing loss kW/24h 0,78 0,73 0,91 1,03 1,28 1,43

Water data

Max. permissible operating pressure bar 8

Water connections inch 1/2

Electrical data

Rated output W 1200 1600 2000 2000 2000 2400

Heat-up time (T- 50 °C) 1 h 40 min 1 h 44 min 2 h 14 min 2 h 46 min 3 h 21 min 3 h 27 min

Supply voltage VAC 230

Frequency Hz 50

Electrical current (single phase) A 5,2 6,9 8,7 8,7 8,7 10,4

Power cable with plug (type) HO5VV - F 3 x 1,5 mm2 or HO5VV - F 3 x 1,0 mm

2

Protection class I

IP-Rating IP24

DHW temperature

Temperature range °C up to 70 °C

Table 5 Technical data

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

6 | Technical properties and dimension's

2.7 Dimensions

Fig. 2 Dimensions in mm (vertical installation)

Fig. 3 Dimensions in mm (horizontal installation)

A

185

ØG1/2''

27.5

C

Ø470

486

100

B

6720818520-01.1V

min. 220

max. 300

D

>250

>500

6720818520-02.1V

Device A B C D

ES035... 485 300 405 ----ES050... 585 400 505 180

ES080... 810 625 730 407

ES100... 960 775 880 552

ES120... 1110 925 1030 702

ES150... 1329 1144 1250 927

Table 6

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Regulations | 7

2.8 Appliance layout

Fig. 4 Design of the storage take

(Tronic 6000 T as an example)

[1] Storage cylinder

[2] CFC-free PU insulation

[3] Heating insert

[4] DHW outlet ½ "

[5] Cold water inlet ½ "

[6] Magnesium anode

[7] Temperature control

[8] Isolation fitting

2.9 Wiring diagram

Fig. 5 Connection diagram Tronic 4000 T

Fig. 6 Connection diagram Tronic 6000 T

3Regulations

The applicable local standards regarding the installation and

handling of electrical DHW cylinders must be observed.

4Transport

▶ Do not let the DHW cylinder fall.

▶ Transport the storage tank in the original packaging, and

use suitable means of transportation.

4.1 Transportation, storage and recycling

• The product must be stored in a dry, frost-free location.

• If applicable, observe Directive EU 2012/19/EC for

disposal of electrical and electronic old appliances.

5 Installation

5.1 Important information

1

6720818520-07.2V

2

8

4

5

7

3

6

A1/L

A2/L

B1/N

B2/N

T2

R1

6720818585-01.1V

A1/L

A2/L

B1/N

B2/N

T2

R1

6720818585-02.1V

R2

Installation, electrical connection and

commissioning may only be carried out by a

contractor approved for such work by the gas or

energy supplier.

CAUTION:

▶ Do not let the DHW cylinder fall.

▶ Only remove the DHW tank from the

packaging at the installation location.

▶ If applicable, the installation of the DHW

cylinder and/or the electrical accessories

must satisfy IEC 60364-7-701.

▶ Select a wall for mounting the cylinder that

has sufficient load bearing capacity to

support the full DHW cylinder. Page 5.

CAUTION: Damage to the heating inserts!

▶ First make the water connections, and then

fill the DHW cylinder.

▶ Then connect the DHW cylinder to the

power supply via a connection socket with a

ground.

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

8 | Installation

5.2 Selecting the installation location

Regulations for the installation location

▶ Observe country-specific requirements.

▶ Installing the DHW cylinder at a safe clearance from heat

sources.

▶ Install the DHW cylinder in rooms where the temperature

does not below 0 °C.

▶ Install the DHW cylinder close to the most frequently used

hot water tap in order to reduce heat loss and wait time.

▶ Install the DHW cylinder in a room that allows the

magnesium anode to be replaced and the necessary

maintenance to be performed.

Protection zones 1 and 2

▶ Do not install in protection zones 1 and 2.

▶ Install the DHW cylinder outside of the protection zones

and maintain a clearance of 60 cm to the bathtub.

Fig. 7 Protection zones

5.3 Wall mounting bracket

Vertical installation

Fig. 8 Vertical installation

Horizontal installation (only Tronic 6000 T)

Fig. 9 Horizontal installation

CAUTION:

▶ Select a wall for mounting the cylinder that

has sufficient load bearing capacity to

support the full DHW cylinder. Page 5.

CAUTION:

▶ Make sure that the DHW cylinder is

connected by a ground conductor to the

system (fuse box).

225 cm

6 720 612 659-13.3TT

22 11

60 cm

60 cm

CAUTION: Danger from falling device!

▶ Use screws and wall mounting brackets

suitable for the type of wall, with

specifications which permit suspension of

the full cylinder.

NOTICE:

▶ Make sure that the hot water outlet is in the

top part of the appliance.

>220 mm

<300 mm

6720812247-07.1V

D

6720812247-08.2V

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Installation | 9

5.4 Water connection

▶ Mark the cold water lines and the DHW lines accordingly to

avoid confusion (Fig. 10).

Fig. 10

[1] Cold water inlet (right)

[2] Hot water outlet (left)

▶ Use suitable accessories for the hydraulic connection of

the DHW cylinder.

Fig. 11 Water connection

[1] Isolation fitting

[2] Hot water outlet

[3] Pressure relief valve

[4] Siphon connection

[5] Gate valve

[6] Pressure reducing valve

[7] Check valve

[8] Connection to the water line

Risk of frost:

▶ Switch off the DHW cylinder.

▶ Drain the DHW cylinder ( sec. 6.3).

Pressure relief valve

Device D

ES050... 180

ES080... 407

ES100... 552

ES120... 702

ES150... 927

Table 7

NOTICE: Corrosion damage to the DHW

cylinder's connections!

▶ Provide the water connections with

insulating dielectric unions. This prevents

current (DC current) from flowing between

the metal hydraulic connections and the

resulting corrosion.

NOTICE: Material damage!

▶ Use a filter at the water inlet if the water has

suspended matter.

Recommendation:

▶ Flush the system beforehand as the water

flow could be reduced by contaminants and,

in case of severe contamination, be stopped

completely.

6720812247-02.1V

2

1

We recommend the installation of a non-return

valve upstream of the cylinder to prevent faults

resulting from sudden pressure fluctuations in

the water supply (Fig. 11, [7]).

DANGER:

▶ Fit a pressure relief to the cold water

connection on the DHW cylinder (Fig. 11).

6720818520-06.1V

1

5678

3 421

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

10 | Operating the appliance

5.5 Electrical connection

All control, monitoring and safety equipment for this appliance

has been subjected to intense scrutiny and is ready for

operation.

▶ Then connect the DHW cylinder to the power supply via a

connection socket with a ground.

5.6 Commissioning

▶ Check for correct installation of the DHW cylinder.

▶ Open the water valves.

▶ Open all of the hot water taps and completely vent the

water lines.

▶ Check the tightness of all connections, and fill up the

storage tank.

▶ Connect the DHW cylinder to the power supply.

▶ Instruct the customer in the function and operation of this

DHW cylinder.

6 Operating the appliance

Fig. 12 User interface

[1] ON indicator

[3] Temperature control

6.1 Turn the appliance on/off

Switching on

▶ Connect the DHW cylinder to the power supply via a

connection socket with a ground.

Switching off

▶ Isolate the storage tank from the power supply.

NOTICE:

NEVER CLOSE OFF THE PRESSURE RELIEF

VALVE DRAIN.

Never install accessories between the pressure

relief valve and the cold water connection (on

the right) of the electrical DHW cylinder.

If the water pressure is 80 % above the

maximum pressure of the DHW cylinder

(6.4 bar), install a pressure reducing valve

(Fig. 11).

If the water pressure in the DHW cylinder rises

above 6.4 bar, the pressure relief valve triggers.

The discharged water must be drained.

DANGER:

Risk of electrocution!

▶ Prior to working on the appliance, isolate it

from the power supply (fuse or similar).

CAUTION:

Current protection!

▶ The wiring diagram for this DHW cylinder

must have a separate connection and must

be protected by a 30 mA RCD and earth.

The electrical connection must meet the current

standards for electrical installations in the

country of use.

CAUTION: The DHW cylinder must be

commissioned by an authorised contractor.

This contractor must give the customer all

information required to ensure correct

operation of the appliance.

6720818520-03.1V

2

1

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Operating the appliance | 11

6.2 Adjust the domestic hot water temperature

The water discharge temperature can be controlled up to 70 °C

by the temperature controller.

Raise the temperature

▶ Turn the temperature controller to the right.

Fig. 13 Raise the temperature

Lower the temperature

▶ Turn the temperature controller to the left.

Fig. 14 Lower the temperature

6.3 Draining the DHW cylinder

▶ Isolate the DHW cylinder from the power supply.

▶ Close the water tap and open a hot water tap.

▶ Open pressure relief valve (Fig. 15).

▶ Wait until the DHW cylinder has drained fully.

Fig. 15 Manually opening the pressure relief valve

The DHW cylinder stops heating once the water

reaches the required temperature, and the ON

indicator goes dark (Fig. 12, [1]). The DHW

cylinder starts heating again once the water

temperature falls below the required

temperature (ON indicator shines) until the set

temperature has been reached.

6720818520-05.1V

+

6720818520-04.1V

-

DANGER: Risk of scalding!

Before opening the pressure relief valve, open

the hot water tap and check the appliance's

water temperature.

▶ Wait until the water temperature has

dropped enough to prevent scalding and

other damage.

6720643873-06.1V

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

12 | Environmental protection/Recycling

7 Environmental protection/Recycling

Environmental protection is a fundamental corporate strategy

of the Bosch Group.

Product quality, efficiency and environmental protection are

equally important objectives for us. We comply with all

environmental protection laws and regulations.

In order to protect the environment, we use the latest

technologies and the best materials whilst bearing in mind the

economic implications.

Packaging

Where packaging is concerned, we participate in countryspecific recycling processes that ensure optimum recycling.

All of our packaging materials are environmentally compatible

and can be recycled.

Old electrical and electronic appliances

Electrical or electronic devices that are no

longer serviceable must be collected

separately and sent for environmentally

compatible recycling (in accordance with the

European Waste Electrical and Electronic

Equipment Directive).

To dispose of old electrical or electronic

devices, you should use the return and

collection systems put in place in the country

concerned.

8Maintenance/inspection

8.1 User information

8.1.1 Cleaning

▶ Do not use abrasive, caustic or solvent containing

cleansers.

▶ If required, clean the casing of the DHW cylinder with a soft

cloth.

8.1.2 Checking the pressure relief valve

▶ Check whether water leaks from the pressure relief valve

drain during heating.

▶ Never plug the drain of the pressure relief valve.

8.1.3 Pressure relief valve

▶ Open the pressure relief valve manually at least once a

month (Fig. 15).

8.1.4 Maintenance and repair

▶ The customer is responsible for ensuring regular

maintenance and testing by customer service or an

approved contractor.

8.2 Regular maintenance

▶ Use only original spare parts.

▶ Order spare parts from the DHW cylinder spare parts

catalogue.

▶ During maintenance, replace removed gaskets with new

ones.

Only authorised contractors are permitted to

maintain this appliance.

WARNING:

Make sure that the draining water does not

cause personal injury or material damage.

WARNING:

Prior to commencing maintenance work:

▶ Isolate the appliance from the mains

power supply.

▶ Close the water tap ( Fig. 11).

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Maintenance/inspection | 13

8.2.1 Function check

▶ Check that all components are functioning correctly.

8.2.2 Magnesium anode

▶ Disconnect the safety switch of the DHW cylinder.

▶ Before starting work, make sure that the DHW cylinder is

disconnected from the power supply.

▶ Completely drain the DHW cylinder ( sec. 6.3).

▶ Remove the screws in the cylinder cover, and remove the

cover.

▶ Disconnect the connecting lead of the temperature limiter.

▶ Remove the fixing screws in the flange [2].

▶ Remove the flange [1].

▶ Check the magnesium anode [3] and replace if necessary.

Fig. 16 Access to the interior and component identification

(example: Tronic 6000 T)

[1] Fixing screws

[2] Flange

[3] Magnesium anode

8.2.3 Regular thermal disinfection

▶ Turn off all hot water taps.

▶ Warn all residents of risk of scalding.

▶ Select the maximum temperature.

▶ Wait until the ON indicator lamp goes out.

▶ Open all hot water taps. Start with the water tap closest to

the DHW cylinder. Let all of the hot water drain for at least

3 minutes from the DHW cylinder.

▶ Close the hot water taps, and set the temperature limiter to

the normal operating temperature.

8.2.4 Extended nonuse (longer than 3 months)

▶ Isolate the DHW cylinder from the power supply.

▶ Completely drain the DHW cylinder.

▶ Fill the DHW cylinder until water drains from all of the hot

water taps.

▶ Connect the DHW cylinder to the power supply.

CAUTION: Damage to the enamel coating!

Never clean the enamel-coated inner walls of

the DHW cylinder using a descaling agent. No

additional products are necessary to protect

the enamel coating.

The DHW cylinder is protected against corrosion

by a magnesium anode inside the cylinder.

WARNING:

Only commission the DHW cylinder with fitted

magnesium anode.

WARNING:

Check the magnesium anode annually and

replace if required. DHW cylinders operated

without this protection are excluded from our

warranty.

DANGER: Risk of scalding!

Hot water can lead to severe scalding during

regular cleaning.

▶ Perform cleaning outside of the normal

operating times.

Replace the water in the DHW cylinder if it has

not been used for a long period (longer than

3months).

2

3

1

6720812247-04.2V

6 720 818 731 (2016/07) Tronic 4000 T | Tronic 6000 T

14 | Maintenance/inspection

8.3 Safety Thermostat

The DHW cylinder is equipped with an automatic safety device.

This safety device isolates the DHW cylinder from the power

supply to prevent the risk of injury if the DHW cylinder water

temperature rises above a certain limit.

Fig. 17 Reset button

[1] Screw

[2] Reset button

8.4 After maintenance

▶ Retighten all water connections and check for tightness.

▶ Connect the DHW cylinder.

DANGER: Only authorised contractors are

permitted to troubleshoot the temperature

limiter.

The high limit safety cut-out must be reset

manually, but only once the cause of the fault

has been eliminated. To troubleshoot the high

limit safety cut-out:

▶ Remove the screws in the cylinder cover,

and remove the cover [1].

▶ Push down the reset key [2].

6720812247-05.2V

2

1

6 720 818 731 (2016/07)Tronic 4000 T | Tronic 6000 T

Faults | 15

9Faults

9.1 Fault/cause/remedy

The following table describes troubleshooting procedures for

possible faults (these must only be carried out by authorised

contractors).

DANGER:

Installation, maintenance and repair work may

only be carried out by an authorised contractor.

Problem Reason Remedy

Domestic Cold Water

Very hot water

Insufficient capacity

Continuous drain from the

pressure relief valve

Rust-colored water

Water with a bad odour

Noises in the DHW cylinder

X Overvoltage or the safety switch was triggered

(performance too high).

▶ Check whether the cable of the device is

designed to supply the required power.

XX Incorrect temperature set by the temperature

regulator.

▶ Adjust the temperature regulator.

X High limit safety cut-out triggered. ▶ Replace the temperature limiter or install a

new one.

X Defective heating element. ▶ Exchange the heating element.

X Incorrect operation of the temperature limiter. ▶ Replace the temperature limiter or install a

new one.

X XX Scale on the DHW cylinder and/or the safety

group.

▶ Remove scale.

▶ If necessary replace the safety group.

XX X Water pressure in the system. ▶ Check the system water pressure.

▶ If necessary, install a pressure reducer.

X X Capacity of the water supply network. ▶ Check piping.

X Corrosion of DHW cylinder. ▶ Drain the DHW cylinder and check the

inner wall for corrosipon.

▶ Replace the magnesium anode.

X Bacterial contamination. ▶ Drain the DHW cylinder and clean it.

▶ Disinfect the DHW cylinder.

X The device capacity does not meet the need. ▶ Replace the product with one that has

sufficient capacity.

Table 8

Bosch Thermotechnik GmbH

Junkersstrasse 20-24

D-73249 Wernau

www.bosch-thermotechnology.com

Loading...

Loading...