Page 1

Control Air M and M+

For Commercial Water to Water DDC Applications

Installation & Operation Manual

BTC 469503103 A (2019/02) US

Page 2

|

2

Control Air M/M+ Water to Water Applications Installation & Operation Manual

02.2019 | BTC 469503103 AData subject to change

Page 3

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 3

Table of Contents

1 Key to Symbols and Safety Instructions 4

1.1 Key to Symbols 4

1.2 Safety Warnings 4

2 Introduction 5

2.1 The Control Air M/M+ Interfaces 5

2.2 The Control Air M/M+ Module 5

2.3 Virtual Control Air M/M+ (Equipment Touch (OEM) APP) 5

3 Specifi cations 6

4 Physical Dimensions 7

5 Wiring 8

5.1 Recommended Wiring Scheme 8

5.2 Rnet Wiring Specifi cations 8

6 Connection 8

6.1 Communicate Using a Tablet Through Virtual Control Air M and M+ 8

6.2 To Wire and Mount the Control Air M/M+ 8

6.3 Additional Information on Connecting Control Air

M/M+ to a Controller 9

9 The Control Air M and M+ Screens 14

9.1 Units Status Screen/Home Page 14

9.2 Settings Screen 14

9.2.1 Unit Settings Screen 14

9.2.2 Device Settings Screen 16

9.2.2.1 Controller Screen 16

9.2.2.1.1 Set Time and Date 16

9.2.2.1.2 Communication 16

9.2.2.1.3 Router 17

9.2.2.1.4 IP 17

9.2.2.1.5 Time Master 17

9.2.2.2 Touchscreen Screen 18

9.2.3 Alarms Settings Screen 18

9.2.4 Pumps 19

9.2.5 Temperature 19

9.2.6 Setpoints 19

9.2.7 Schedule Screen 20

9.2.8 Lead/Lag Screen 22

9.3 Service Screen 22

9.3.1 Heat/Cool Screen 23

9.3.2 UPM Status Screen 23

9.3.3 Help Screen 24

7 How to Navigate Screens in Control Air M/M+ 11

7.1 Login 11

7.2 Alarms 11

7.3 Trends 11

8 To Update the Control Air M/M+’s Firmware 12

8.1 Prerequisite 12

8.2 To Update the Firmware 12

8.3 Resetting the Control Air M/M+ 12

8.4 Compliance 13

BTC 469503103 A | 02.2019

Data subject to change

Page 4

|

4

Control Air M/M+ Water to Water Applications Installation & Operation Manual

1 Key to Symbols and Safety Instructions

1.1 Key to Symbols

Warnings

Warnings in this document are identifi ed by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent the

risk are not taken.

The following keywords are defi ned and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor to moderate injury.

NOTICE is used to address practices not related to personal

injury.

Important information

This symbol indicates important information where

there is no risk to people or property.

1.2 Safety Warnings

WARNING: ELECTRIC SHOCK HAZARD

Installation and servicing of this equipment can be

hazardous due to the electrical components. Only

trained and qualified personnel should install, repair,

or service the equipment.

WARNING: ELECTRIC SHOCK HAZARD

Before performing service or maintenance

operations on the system, turn off main power to the

unit. Electrical shock could cause personal injury or

death.

WARNING: FIRE, INJURY HAZARD

When working on equipment, always observe

precautions described in the literature, tags,

and labels attached to the unit. Follow all safety

codes. Wear safety glasses and work gloves. Use

a quenching cloth for brazing, and place a fire

extinguisher close to the work area.

WARNING: ELECTRIC SHOCK HAZARD

To Reduce the risk of Fire or Electric Shock, Do

not interconnect the outputs of different class 2

circuits.

WARNING:

This product can expose you to chemicals including

Lead and Lead components, which are known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to

www.P65Warnings.ca.gov.

02.2019 | BTC 469503103 AData subject to change

Page 5

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 5

2 Introduction

2.1 The Control Air M/M+ Interfaces

The Control Air M and M+ (M=Manager) is a Human-Machine Interface

(HMI) that interfaces with the BOSCH DDC Control Air 5600, enabling the

user to view and change property values, and/or control parameters, to

match a corresponding application whether it is a Water to Air or Water to

Water Heat Pump. It also provides a means of accessing and modifying the

controller’s schedule and real time clock in applications where a system

server or Building Automation System (BAS) is not available. The Control

Air M is designed for applications where there is one (1) WSHP. The

Control Air M+ is designed for applications where there is up to fi fty (50)

WSHP's (existing networks only).

The software is normally confi gured at the factory to match the unit

confi guration, however, there are cases where additional on-site changes

need to be made and this screen will allow the qualifi ed technical or

commissioning agent to incorporate such changes (without having to

download a diff erent software application) via the commissioning tool.

The interface is off ered in two forms: as a wall mount or unit mounted

Control Air M/M+module or in the form of an APP called the Equipment

Touch (OEM), which can be found in the Google Play Store (Android Only).

2.2 The Control Air M/M+ Module

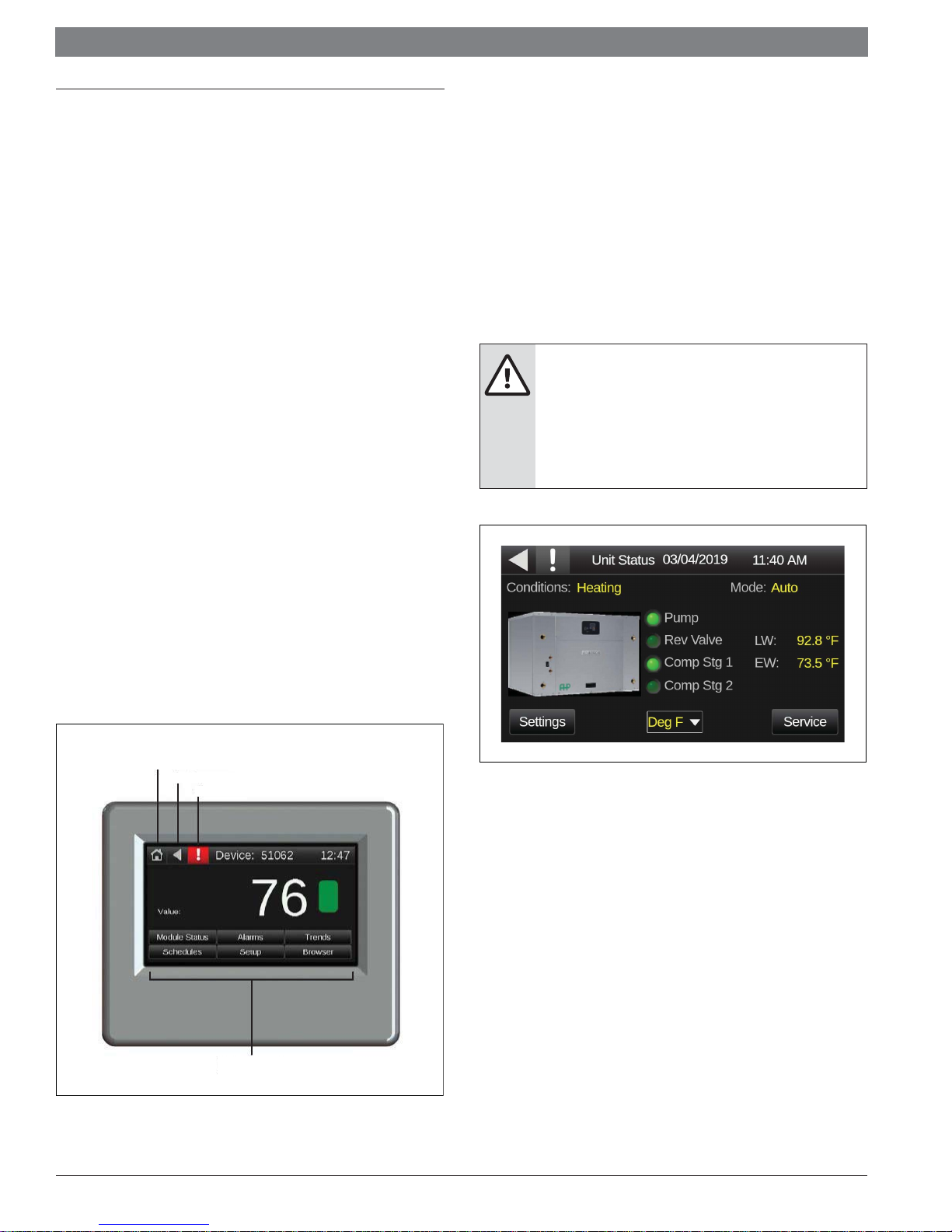

The Control Air M/M+ module (Figure 1) is a touchscreen device with a

4.3" color LCD display that you connect to a Control Air 5600 to view or

change its property values, schedule units, view trends and alarms, and

more. The unit connects to the controller via the onboard serial port. The

module can be purchased by the following part numbers:

2.3 Virtual Control Air M/M+ (Equipment Touch (OEM) APP)

Virtual Control Air M/M+ (see Figure #2) provides the end-user an

interface to a controller by way of a Android Tablet and a purchased USB-L

cable (8733-927-403). The adapter; USB to micro USB (not provided by

BOSCH) may be needed if USB port is not available on Android device.

This adapter, not provided by Bosch, needs to be a female USB to male

micro USB. Once the cables are purchased, the corresponding driver will

need to be downloaded and installed before using the application. The

USB or micro USB end of the cable is connected to the Android device,

and the serial end is connected to the DDC controller. The Control Air M/

M+ cable driver, and instruction manual are all available for free download

at the Bosch Thermotechnology website.

WARNING: FIRE, INJURY HAZARD

When working on equipment, always observe

precautions described in the literature, tags,

and labels attached to the unit. Follow all safety

codes. Wear safety glasses and work gloves. Use

a quenching cloth for brazing, and place a fire

extinguisher close to the work area.

Control Air M (8733951042)

Control Air M+ (8733951043)

Connecting Cable (Virtual Control Air M/M+ only) (8733908163)

The module is only compatible with the Control Air 5600 controller.

Touch to display:

Home screen

Previous screen

Alarms screen

Touch a button to

display that screen

Figure 2

Figure 1

BTC 469503103 A | 02.2019

Data subject to change

Page 6

|

6

Control Air M/M+ Water to Water Applications Installation & Operation Manual

3 Specifi cations

Description Value

Power 24 Vac (+/-15%), 5 VA, 50-60 Hz, Class 2

Backlit LCD display 4.3" resistive touchscreen color LCD discplay with backlighting WQVGA 480x272 px

Cable 6 ft. (1.8 m) cable to connect to controller's Local Access port.

Communication Rnet: 2-wire EIA-485 port for connection to the Rnet sensor network (115 kbps)

— 16 MB Flash memory to store screen file.

Memory

Operating Range -4° to 140°F (-20°C to 60°C), 10%-90% RH noncondensing

Overall dimensions

— 1.5 MB RAM to store variable data and LCD data.

— 4 KB Serial EEPROM to store non-volatile configuration data.

— Width: 5-7/16 in. (138mm)

— Height: 4-1/16 in. (116mm)

— Depth: 1-3/8 in. (30mm)

Weight 0.54 lbs (0.24 kg)

Listed by UL-916 (PAZX), CE, FCC Part 15-Subpart B-Class A

— Range @ 95% RH: -4°F to 140°F (-20°C to 60°C)

— Range @ 20% RH: -4°F to 194°F (-20°C to 90°C)

— Accuracy @ 25°C: ±0.4°C

Temperature Sensor

Humidity Sensor

Table 1 Specifi cations

— Accuracy over 20°C to 30°C: ±0.5°C

— Accuracy over 10°C to 45°C: ±1.0°C

— Accuracy over full range: ±2.5°C

— Resolution: 0.01°C

— Range: 0 to 100% RH

— Accuracy over 20 to 80% RH: ±3.0% RH

— Accuracy over full range: ±5.0% RH

— Resolution: 0.05 RH

02.2019 | BTC 469503103 AData subject to change

Page 7

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 7

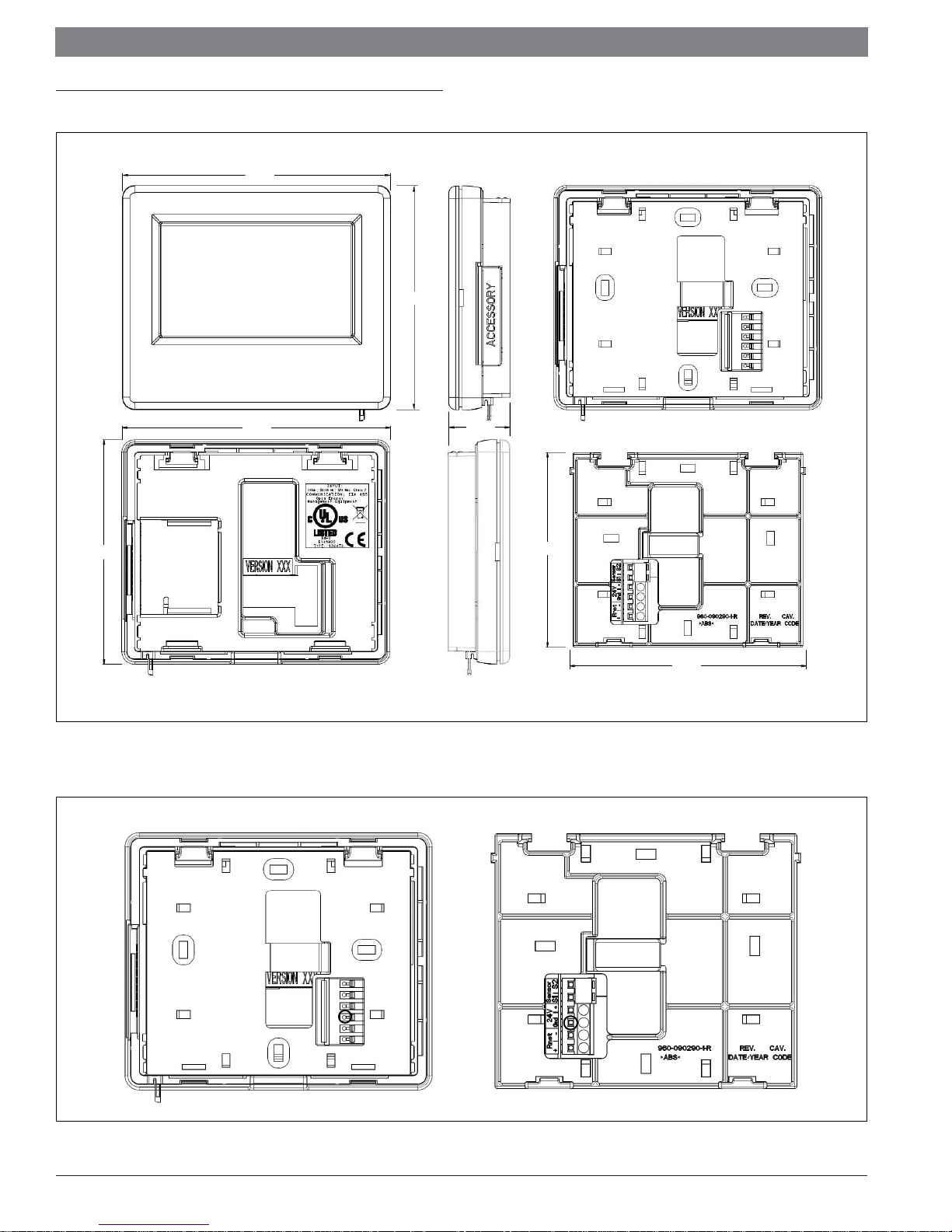

4 Physical Dimensions

4.550

5.440

5.440

Side View - Right Back View with Mounting Plate

4.550

1.242

Mounting Plate

3.938

Figure 3

Control Air M/M+ Module Termination Details

Back View with Mounting Plate

4.799

Side View - LeftBack View without Mounting Plate

Mounting Plate

Figure 4

BTC 469503103 A | 02.2019

Data subject to change

Page 8

|

8

Control Air M/M+ Water to Water Applications Installation & Operation Manual

5 Wiring

The Control Air M communicates through a Rnet connection. The Control

Air M is intended for use with a single WSHP. It can be wired using the

instructions in section 6. The Control Air M+ communicates through a

BACnet MS/TP connection. The Control Air M+ is intended for use with up

to 50 WSHP's on an exisiting network.

5.1 Recommended Wiring Scheme

Connect this wire: To this terminal on the Control Air M:

Red 24 VAC (R)

Black 24 VAC (C)

White Rnet+

Blue Rnet-

Table 2 Power Wiring

2-conductor wire 18 AWG for distances up to 100 feet. All transformer

secondaries must be grounded. Wiring connections must be in

accordance with NEC and local codes. All wiring and mounting screws

must be fi eld supplied.

5.2 Rnet Wiring Specifi cations

NOTICE:

Use the specified type of wire and cable for maximum

signal integrity.

Description Value

Cable

Conductor 22 AWG (7x0096) bare copper

Maximum length 500 feet (152 meters)

Recommended coloring Jacket: White

4 conductor, unshielded, or unshielded

CMP, plenum rated cable

6 Connection

6.1 Communicate Using a Tablet Through Virtual Control Air M and M+

In lieu of using the module to interface with the controller, a connection

may be established at the local access port of the controller to perform

test and balance operations or to make changes to any device on the networ k.

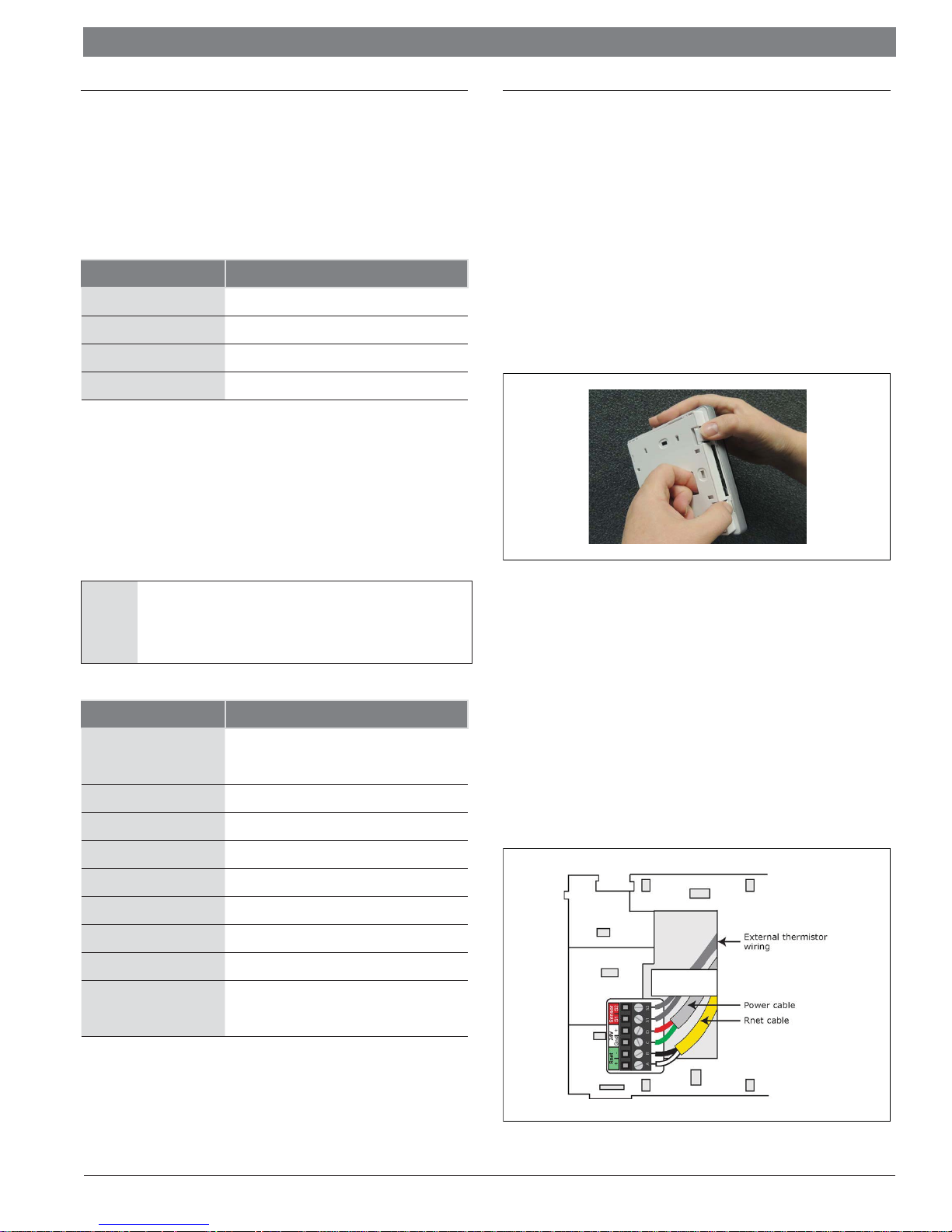

6.2 To Wire and Mount the Control Air M/M+

1. Remove the backplate from the Control Air M/M+

a. Hold the Control Air M/M+ as shown in the picture below.

b. While fi rmly pressing the 2 tabs on top of the Control Air M/

M+, pull on the backplate with your index fi nger until the

backplate releases from the Control Air M/M+.

Figure 5

2. Pull the communication cable, power cable, and external

thermistor wiring (if applicable) through the large hole in the center

of the backplate.

3. Partially cut, then bend and pull off the outer jacket of the Rnet

cable(s). Do not nick the individual wire insulation.

4. If wiring 1 cable to the Control Air M/M+, cut the shield wire off at

the outer jacket, then wrap the cable with tape at the outer jacket

to cover the end of the shield wire. If wiring 2 cables in a daisychain confi guration, twist together the shield wires, then wrap the

shield wires with tape.

5. Strip about 0.25 inch (0.6 cm) insulation from the end of each

wire.

6. Connect wiring to the Control Air M/M+ as shown in Figure 6.

UL temperature 32–167°F (0–75°C)

Voltage Limited Listing 300 VAC, power UL: NEC CL2P, or better

Insulation Low-smoke PVC (or equivalent)

Color Code Black, white, green, red

Shielding

Table 3

If shielded, Aluminum/Mylar shield

(100% coverage) with TC drain wire

Figure 6

02.2019 | BTC 469503103 AData subject to change

Page 9

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 9

6.3 Additional Information on Connecting Control Air

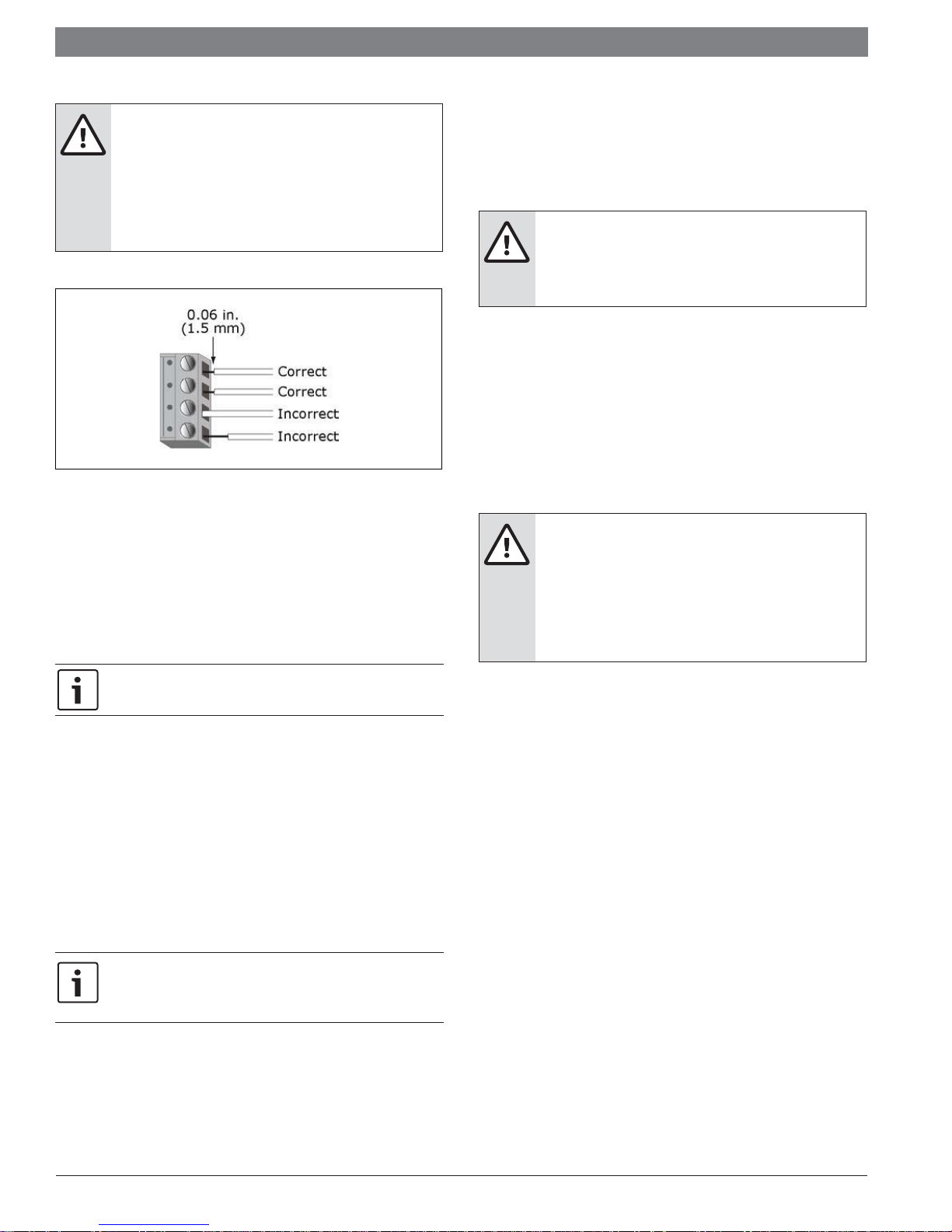

CAUTION: ELECTRIC SHOCK HAZARD

Allow no more than 0.06 inch (1.5 mm) bare

communication wire to protrude. If bare

communication wire contacts the cable's foil shield,

shield wire, or a metal surface other than the

terminal block, the device may not communicate

correctly.

Figure 7

M/M+ to a Controller

Connect the Control Air M/M+ module (or Android tablet if using Virtual

Control Air M/M+) to the serial port on the DDC controller as indicated

below.

CAUTION: ELECTRIC SHOCK, INJURY HAZARD

If the equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

Mounting

The Control Air M/M+ must be mounted within the building interior. You

can mount the Control Air M/M+:

In a panel with the controller or on the panel door

On a wall up to 500 feet from the controller

Wiring

The Control Air M/M+ requires a 24 Vac power supply. It is not powered by

the Rnet.

7. Attach the backplate to the wall or panel. If mounting in or on a

panel:

a. Drill two 3/16 inch (4.8 mm) pilot holes in the panel.

b. Attach backplate using pan head 6-32 x 3/8" to l/2" long

machine screws. Do not overtighten screws to prevent

damage to plastic housing.

It is recommended to use Loctite 220 on screw threads if the

Control Air M/M+ will be subject to vibration.

8. Attach the Control Air M/M+ to the backplate:

a. Place the bottom of the Control Air M/M+ onto the backplate

by aligning the 2 slots on the Control Air M/M+ with the tabs

on the backplate.

b. Push the Control Air M/M+ onto the backplate until the tabs

at the top of the Control Air M/M+ snap onto the backplate.

9. Turn off the controller's power.

10. Connect the other end of the Rnet wiring to the controller's Rnet

port or to a zone sensor.

- Insert the shield wire with the ground wire into the controller's

GND terminal.

- Use the same polarity throughout the Rnet or MS/TP.

CAUTION: ELECTRIC SHOCK HAZARD

The Control Air M/M+ can share a power supply

with the DDC controller as long as you:

1. Maintain the same polarity.

2. User the power supply only for DDC

controllers.

You can also wire an external 10 kOhm, Type II thermistor to the Control

Air M/M+. See External sensor resistance requirements (Table 6, page

13).

11. Connect power wiring to a 24 Vac power supply.

12. Turn on the controller's power.

BTC 469503103 A | 02.2019

Data subject to change

Page 10

|

10

Control Air M/M+ Water to Water Applications Installation & Operation Manual

Establishing Communication

Plug the USB-L cable to the USB (Bosch part number 8733-927-403)

to USB micro adapter (fi eld supplied) and then to the Android tablet and

controller before launching Virtual Control Air M/M+ (Equipment Touch

(OEM) app). The DDC controller must be connected to a 24 VAC source

and powered on.

Not provided

by Bosch

Control Air

M/M+

connector

8733-927-403

Figure 8

Figure 9

02.2019 | BTC 469503103 AData subject to change

Page 11

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 11

7 How to Navigate Screens in Control Air M/M+

7.1 Login

The following displays if the screen you selected requires a password.

Enter your password, then touch Done.

Figure 10

Each screen is programmed with one of the following password levels:

A screen having this

password level…

User

A user logged in with the User, Admin, or

Can be accessed by…

Factory password

7.2 Alarms

The Alarm screen allows the user to view up to 100 events starting with

the most recent. It also allows user to see which points have gone into

alarm and retuned to normal as well as the ones that have been manually

cleared.

Figure 11

7.3 Trends

Admin

A user logged in with the Admin or Factory

password

Factory A user logged in with the Factory password

No password Anyone

Table 4

The default password for a new Control Air M/M+ is 0000.

You can change passwords on the Control Air M/M+ by going to

Touchscreen Setup > Passwords screen.

You log out on the Setup screen.

Figure 12

This screen can be accessed from the Help Screen on the Service page

(Home -> Service -> Help -> Trends). It allows the end user to view trends

for points that have trending enabled.

Figure 13

BTC 469503103 A | 02.2019

Data subject to change

Page 12

|

12

Control Air M/M+ Water to Water Applications Installation & Operation Manual

8 To Update the Control Air M/M+’s Firmware

The Control Air M/M+ has a USB port at the bottom that allows you to

update the device's fi rmware from a USB fl ash drive.

8.1 Prerequisite

The USB fl ash drive must be formatted as FAT, FAT16, or FAT32. To verify,

right-click the fl ash drive in Windows Explorer, then select Properties.

File system should show FATxx. If File system shows NTFS or anything

else, you must reformat the drive. Right-click the fl ash drive, then select

Format. In the File system fi eld, select FAT (Default), then click Start.

NOTICE:

Follow the steps below in order. If you select Reload

Firmware (step 3) on the display before you insert

the USB drive (step 2), the touchscreen will become

inoperable.

8.2 To Update the Firmware

1. Create a folder on the fl ash drive called Touch, then put the

ETxxxxxx.hex fi le in the folder.

2. Plug the fl ash drive into the Control Air M/M+'s USB port.

3. From the System screen, touch Setup > Touchscreen Setup >

Reload Firmware.

4. A warning message appears. Touch Yes to continue.

5. The following series of messages appear:

Verifying Firmware Image

Reading Firmware Image from USB

Installing Application

Verifying Firmware Image.

6. When the Home screen displays, remove the fl ash drive.

7. Insert the fl ash drive into the USB port at the bottom of the Control

Air M/M+.

8. Cycle power to the Control Air M/M+.

If… Then you should…

You cannot get to

the Touchscreen

You need to

quickly update

the fi rmware on

several Control Air

M/M+ devices

You want to carry

your Control Air

M/M+ from site

to site.

Your Control

Air M/M+ has a

unrecoverable

error from site

to site

The Control

Air M/M+ does

not respond

correctly to the

location where

you touched the

screen

Table 5

Reload the fi rmware 01

Reload the fi rmware - Put the

new fi rmware in the Touch

folder with the reset.dat fi le

Reset factory defaults 04

Calibrate the touchscreen 08

Function

number

01

8.3 Resetting the Control Air M/M+

You can create a reset.dat fi le and put it on a USB fl ash drive to reset some

of the Control Air M/M+’s functionality.

Prerequisite

The USB fl ash drive must be formatted as FAT, FAT16, or FAT32. To verify,

right-click the fl ash drive in Windows Explorer, then select Properties.

File system should show FATxx. If File system shows NTFS or anything

else, you must reformat the drive. Right-click the fl ash drive, then select

Format. In the File system fi eld, select FAT (Default), then click Start.

1. Insert the USB fl ash drive into your computer.

2. Create a folder on the fl ash drive named Touch.

3. In a text editor such as Notepad, start a new fi le.

4. In the fi le, type a function number from the table below.

5. Save the fi le to the fl ash drive's Touch folder with the name reset.

dat.

6. For function 01 or 02, copy any updated fi rmware .hex fi le or .stv

fi le in the Touch folder.

02.2019 | BTC 469503103 AData subject to change

Page 13

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 13

8.4 Compliance

FCC Compliance

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

NOTICE: HARMFUL INTERFERENCE HAZARD

Changes or modifications not expressly approved

by the responsible party for compliance could void

the user’s authority to operate the equipment.

CE Compliance

NOTICE: HARMFUL INTERFERENCE HAZARD

This is a Class A product. In a domestic

environment, this product may cause radio

interference in which case the user may be

required to take adequate measures.

External sensor resistance requirements

Temp (°C) Temp (°F) Resistance (Ohms)

-40 -40 335,651

-35 -31 242,195

-30 -22 176,683

-25 -13 130,243

-20 -4 96,974

-15 5 72,895

-10 14 55,298

-5 23 42,315

0 32 32,651

5 41 25,395

10 50 19,903

15 59 15,714

20 68 12,494

25 77 10,000

30 86 8,056

35 95 6,530

Table 6

40 104 5,325

45 113 4,367

50 122 3,601

55 131 2,985

60 140 2,487

65 149 2,082

70 158 1,752

BTC 469503103 A | 02.2019

Data subject to change

Page 14

|

14

Control Air M/M+ Water to Water Applications Installation & Operation Manual

9 The Control Air M and M+ Screens

9.1 Units Status Screen/Home Page

The Unit Status screen (Figure 14) is the home page for the Control Air

M, and shows the main menus/categories of the software the user can

interface with on the devices.

Settings – For an installer, these settings allow for changes to

the device, as well as unit configuration at start-up.

Service – For a service technician, this menu allows a user to

diagnose or troubleshoot the unit.

The screen provides valuable unit diagnostic data - entering and leaving

water temperatures, states of the compressors, Reversing valve, Pump.

It gives the user the ability to change the temperature units between

Fahrenheit and Celsius. The header of the screen is common to most

screens.

Figure 14

9.2 Settings Screen

The Settings page allows the user to access one of the following pages:

Unit Settings

Device Settings

Alarm Settings

*Pumps

Temperature

Schedule

Setpoints

*Lead/Lag

9.2.1 Unit Settings Screen

This screen can be accessed from the Settings menu. This menu allows

the commissioning agent to setup or modify operational parameters of the

unit.

Once all operational parameters are confi gured, these settings may be

saved and archived to fl ash memory by selecting the Save Settings checkbox.

Figure 16

Occupancy Command

Under the Unit Settings screen, this parameter is used to select the

control source that will provide the occupancy command to the unit. The

options for this variable are the following:

Digital Input

Local Schedule

BAS Command

Manual Override

Throughout the setup process, by selecting diff erent boxes, this

is how you advance to the next setup screen if available, while

the back arrow is used to backtrack to previous screens.

Digital Input: The Digital Input option may be selected if the unit

occupancy is required to be controlled remotely via a switch (dry

contact) or other binary input. The connection (typically from a room

occupancy sensor) should be made in IN-1 of the controller. Choosing

this setting allows the unit to be placed in occupied mode once the

input is shorted to ground, and in unoccupied mode once the input is

opened.

*

If confi gured in Unit Settings.

Figure 15

Local Schedule: Schedule runs the unit on a local, modifi able

schedule, which cannot be accessed over a network. The occupancy

schedule for heating or cooling can be set according to the morning,

daytime, and night time settings for each day of the week. The option

will allow the unit to run on an 8:00 AM to 5:00 PM default schedule

everyday if the unit is to be started up during the construction phase of

the project. See the Schedule Screen for more information.

02.2019 | BTC 469503103 AData subject to change

Page 15

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 15

BAS Command:

The unit factory default for the Occupancy Command

parameter is set to BAS Command. A qualifi ed technical agent may change

the parameter to be BAS Command, if diff erent from the default setting. This

option will enable the unit to be commanded from the BAS Server. The unit

is ready for BAS integration once this parameter is set up, and it can then

be commanded to occupied or unoccupied via the BAS by writing to the

Occupancy Status integration point (refer to Integration Points List document).

Manual Override: If the unit is intended to run all the time it can be set

to Manual Override, which will override the schedule and set the unit

into occupied mode indefi nitely, until the Manual Override option is

deselected.

Compressor Stages

This parameter allows the user to choose the number of compressors and stages

for the application. This parameter is typically set up from the factory to match the

unit confi guration and should only be changed by a qualifi ed technician.

Ensure the compressor confi guration is set accurately as this

selection will determine the code structure for reporting

compressor safety alarms from the Unit Protection Module

(UPM) to the controller. The fault codes for a 1 compressor 1

stage unit are diff erent from that for a 2 compressor 2 stage unit.

Mode Selection Method

This setting is similar to a thermostat mode select feature, which gives the user the

option of setting the unit mode. The options are: Heat, Cool, Off , Auto and Digital

input. When operating on Digital Input mode the unit will change from heat to cool

by using the state of the digital input (IN6) on controller as follows:

Off = Heat

On = Cool

This feature is typically used when the unit is not confi gured into a BAS network.

However, if there is a BAS network, it is recommended to operate the unit using

the integration points.

Figure 17

2 Compressor 2 Stages: This value is selected when unit has 2 compressors

and each compressor will operate as an independent stage.

1 Compressor 2 Stages: This value is selected when unit has 1 compressor

that has two independent stages. This is the default setting from the factory.

1 Compressor 1 Stage: This value is selected when unit has 1 compressor with

only 1 stage of operation.

Night Setback Enable:

This parameter allows users to enable or disable night setback feature.

Enabling Night setback will operate the unit under the following setpoints

when it enters the unoccupied state.

74°F (adj.) Cooling setpoint.

85°F (adj.) Heating setpoint.

Disabling it puts the unit in an OFF state and the unit will not try to meet

any setpoints.

Aux Output Enable

This parameter can be used to energize the Auxiliary output (DO-5). This

is a manual setting and DO-5 is not confi gured to support any device in

particular. Its a simple On/Off function for D0-5 and is Off by default.

Use Optional Pump Output

When this parameter is set to Yes, BO-1 can be used for pump output.

Selecting Yes also enables the "Pump" confi guration page on the Settings

screen.

BTC 469503103 A | 02.2019

Data subject to change

Page 16

|

16

Control Air M/M+ Water to Water Applications Installation & Operation Manual

9.2.2 Device Settings Screen

Figure 18

The Device Settings menu allows the user to adjust or reset any settings

on the actual Control Air M/M+ module.

On this screen the BACnet® ID will be displayed. This value can be

changed, however, it is not recommend to change this parameter

arbitrarily as it may cause network problems.

Always consult with Network Administrator (Front End company) before

changing the controllers BACnet® ID as it may interfere with other devices

in the network.

Two main sub menus are available on this screen:

Controller

Touchscreen

9.2.2.1 Controller Screen

9.2.2.1.2 Communication

This screen lets you edit the information below for the controller.

Figure 21

Touch a fi eld to tap in new information.

— BACnet Device Instance – number

— Auto Generate Device ID – Enter No or Yes

You can edit the following fi elds that pertain to the controller's MS/

TP network:

— Max Masters - Set this to the highest MAC

address (up to 127) on the MS/TP network. If

you later add a device with a higher address, you

must change this field to that new address.

— Max Info Frames - Specifi es the maximum

number of information messages a controller

may transmit before it must pass the token to the

next controller. CAUTION Increasing this number

allows the controller to transmit more messages

while it has the token, but it also increases the

overall time it takes for the token to pass through

the network.

Figure 19

This screen provides access to the device Module Setup menu, that

provides the end-user the ability to set the time/date, update device

communication information, and access to the Time Master page.

9.2.2.1.1 Set Time and Date

Touch the time or date fi eld to edit it.

Figure 20

For a router, set this value to a high number such as 200

In non-router controllers, use the following formula to

calculate this value: [2 - (devices * (.002 + (80/baud))] /

[(600/baud) * devices] = Max Info Frames

For example, if the network has 15 devices at 19200 baud,

Max Info Frames would be 4.

You may need to increase the result of the formula for controllers

that need to communicate many values to other devices.

02.2019 | BTC 469503103 AData subject to change

Page 17

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 17

9.2.2.1.3 Router

Lets you view or edit the router's ARC156, MS/TP, or Ethernet

network number.

Figure 22

Touch a fi eld to tap in the new number on the keypad.

9.2.2.1.4 IP

Lets you view or edit network addresses and the UDP Port.

9.2.2.1.5 Time Master

If the controller can be a BACnet Time Master, this screen lets you

confi gure how it sends time synchronization broadcasts.

Figure 24

Time Sync Mode - Tap in the number below that represents your

selection:

— 0 = No Broadcast - The controller will not act as Time

Master.

— 1 = Local Broadcast - If it doesn't already exist, a

BACnet address with network number and MAC address

length both set to zero is added to the controller's Time

Synchronization Recipients list found on the driver's

Device page in WebCTRL®. The controller will then send

time broadcasts only to controllers on its ARCnet or MS/

TP network.

Figure 23

Touch a fi eld to tap in the new number on the keypad.

— 2 = Global Broadcast - If it doesn't already exist, a global

address with network number set to 65535 and MAC

address length set to zero is added to the controller's

Time Synchronization Recipients list found on the driver's

Device page in WebCTRL®. The controller will then send

time broadcasts to all its connected networks.

Time Sync Interval - Enter how often local or global time

broadcast should be sent (1-9999 minutes). If Time Sync Interval

is set to zero, no time sync messages are sent.

If the controller looks through its Time Synchronization Recipient

List and fi nds an entry with MAC address length set to zero and

network number set to 65535, the controller's BACnet Time

Master mode is set for Global Broadcast. If there is no global

broadcast entry in the recipient list, the controller then looks for

a local broadcast address (MAC address length set to zero and

network number set to zero or to the same network number as

the module's). If such an entry is found, the BACnet Time Master

mode is set for Local Broadcast. Otherwise, the mode defaults to

Disabled/None.

BTC 469503103 A | 02.2019

Data subject to change

Page 18

|

18

Control Air M/M+ Water to Water Applications Installation & Operation Manual

9.2.2.2 Touchscreen Screen

Figure 25

This screen provides the end-user the ability to edit and modify the

touchscreen settings.

Touch a button to go to one of these screens:

Screen Description

About Displays information about the touchscreen fi rmware

Inactivity

Timeout

Lets you defi ne how long the Control Air M can have

no activity before returning to the Standby screen and

logging out the user. Set to 0 to deactivate this feature

9.2.3 Alarms Settings Screen

The Alarm Settings screen can be accessed from the home page

through the Settings menu. This screen allows the user to adjust heat

pump unit alarm settings, including:

Set values for alarm trip limits on leaving water temperature.

Set values for entering water temperature differentials

Set Pump and compressor(s) runtime trip values.

Figure 26

Lets you set up the Control Air M temperature

Sensor

Setup

and humidity sensors. See Using Control Air M’s

temperature and humidity sensors to control

equipment

Displays a one-minute count-down timer so that you

Clean

Screen

can clean fi ngerprints from the display window without

touching something that would aff ect equipment

operation.

Key Click

Off /On

Alarm

Sound

Off /On

Reload

Firmware

Touch Key Click Off to turn off the sound when you

touch a fi eld or button. Touch Key Click On to turn on

the sound

Touch Alarm Sound Off to turn off the alarm notifi cation

sound or touch Alarm Sound On to turn on the sound.

An alarm will generate a sound only if it is set up by

Bosch

Erases the current fi rmware so that you can load new

fi rmware through the USB port. See To update the

Control Air M/M+'s fi rmware

Passwords Let you change the User or Admin password, if allowed.

Figure 27

Lets you recalibrate the Control Air M/M+ by touching

Calibrate

Touch

Panel

targets. The device is calibrated in the factory, but

time, temperature, or handling could aff ect the

calibration. Recalibrate the screen if you touch it in one

location and it responds as if you touched it in another.

Table 7

02.2019 | BTC 469503103 AData subject to change

Page 19

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 19

9.2.4 Pumps

This screen can be accessed from the Home page through the Setting

Menu. This screen Allows the user to view and/or adjust the following

parameters:

Run Continuously in Occupied mode:This parameter when

set to "Yes" runs the pump continuously in the occupied mode

and if set to "No", cycles with the compressor

Pump Output: This parameter does not indicate is the pump

output is actually energised, instead indicates if there is a

pump call.

Pump Start Counter (total): This value indicates how many

times in total the pump was started after its corresponding

reset.

Pump Start Counter (Last hr): This value indicates how many

times in the last hour the pump was started.

9.2.6 Setpoints

This screen can be accessed from the Settings screen. It allows the user to

adjust the following setpoints and diff erentials

Occupied heating and cooling setpoints

Unoccupied heating and cooling setpoints

Heat/Cool Setpoint differential

Heat/Cool Stage 2 setpoint differential

Auto Changeover setpoint and deadband

Figure 30

Figure 28

9.2.5 Temperature

The Temperature Screen can be accessed from the home page through

the Settings menu. This screen allows the user to view the following

temperatures and temperature setpoints.

Entering water temperature

Leaving water temperature

Auto changeover temperature

Effective cooling setpoint

Effective heating setpoint.

Figure 31

Figure 29

BTC 469503103 A | 02.2019

Data subject to change

Page 20

|

20

Control Air M/M+ Water to Water Applications Installation & Operation Manual

9.2.7 Schedule Screen

The Schedule menu can be accessed from the home page through the

Settings menu. This screen allows the user to view, add, edit, or delete

BACnet schedules in the controller.

Figure 32

The controller comes with the following default schedule:

Day of Week Time Mode

MON-FRI 8:00AM - 5:00PM Occupied Mode

SAT 7:00AM - 3:00PM Occupied Mode

SUN 10:00AM - 1:00PM Occupied Mode

Week View

Figure 34

Which days of the week shown have schedules (indicated by

green bars).

If you see Schedule editing disabled at the bottom of the screen

instead of Add Schedule, scheduling is being done through

another application and is disabled for the Control Air M+.

Touch a day to see the schedule(s) for that day. In the screen

below, touch a schedule’s name or green bar (not the Eff ective

Schedule bar) to edit or delete the schedule.

Table 8

Viewing Schedules

Month View (default)

Figure 33

The schedule screen is confi gured to display the monthly view by default.

To change to weekly view, click drop down option and change accordingly.

Figure 35

The Eff ective Schedule is the combined result of the day's

schedule(s).

You cannot edit a schedule's Type (Dated, Weekly, Continuous),

its Priority (Normal or Override), or whether the schedule is an

ON Schedule or Off Schedule. If you need to change any of these

settings, delete the schedule, and then make a new one.

02.2019 | BTC 469503103 AData subject to change

Page 21

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 21

Creating Schedule

Figure 36

In the above image there is no schedule for the weekend (Sat/Sun). To

create a schedule for every Saturday (Occupied from 7 AM to 3 PM),

click Add schedule.

Figure 37

Touch the Schedule Name fi eld, and enter a unique name (for Example:

Saturdays). Select one (ON for this example) of the following:

ON Schedule for an occupied period

ON Schedule only–Select one (normal for this example) of the

following:

Normal for a typical occupied period

Override for a occupied period that is to override an OFF

schedule.

Touch Next to defi ne the criteria for the type of schedule you selected

earlier in the scheduling process.

Figure 38

If you have a date range confi gure accordingly. Touch Save when

fi nished.

Editing/Deleting Schedules

Open the schedules screen from the Settings page. To delete or edit the

Saturdays schedule (for example), click on View schedule drop down

and select week view. Now Click on the green bar for a Saturday.

OFF Schedule for an unoccupied period that is to override

an ON schedule. For example, a holiday schedule that is to

override a weekly schedule.

Touch the Type fi eld, then select one (weekly for this example) of the

following:

Select… To use the schedule…

For a specifi ed period of time between a start and

Dated

end date. For example, 7:00 am to 7:00 pm every day

between July 1st and July 22.

Weekly

Every week on the specifi ed days. For example, every

Monday through Friday, 8:00 am to 5:00 pm.

Continuously between 2 specifi ed dates/times, For

Continuous

example, a non-stop schedule that starts June 1st at

12:00 am and ends August 31st at 11:50 pm.

Table 9

Figure 39

Click Delete to Delete this schedule,or modify as needed. To add

another schedule (period) to the current schedule, click add period. A

weekly schedule can have multiple periods.

For example, the fi rst period could be every Saturday 7:00AM to

3:00PM. The second period could be every Saturday, 6:00PM to

8:00PM.

BTC 469503103 A | 02.2019

Data subject to change

Page 22

|

22

Control Air M/M+ Water to Water Applications Installation & Operation Manual

9.2.8 Lead/Lag Screen

This screen is accessed from the Setting screen and allows the user to

confi gure the compressor rotation. This screen can only be accessed if the

unit has 2 separate compressors and i confi gured accordingly in the unit

settings screen. Under this menu, one can view and adjust the following:

Demand: This parameter displays how many compressors/

compressor stages are being called.

Compressor rotation frequency: This parameter gives the user

the option to set the frequency at which the compressors are

switched from lead to lag or vice-versa. Based on this selection the

user can set the next parameter value accordingly

Figure 40

9.3 Service Screen

The Service menu allows the qualifi ed technician to adjust or reset any

settings on the WSHP, and effi ciently troubleshoot and correct issues on

the unit. Under this menu, one can scroll up/down to view and adjust the

following:

Analog Inputs

Binary Inputs/Outputs

Figure 42

Figure 41

Figure 43

Figure 44

Figure 45

02.2019 | BTC 469503103 AData subject to change

Page 23

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 23

9.3.2 UPM Status Screen

The UPM Status screen can be accessed from the home

Screen via the Service Menu. Once an alarm is received via pulse

feedback from the UPM board, it is displayed in the screen as shown

below. From this screen the user may reset the UPM board after it has

enter the lockout mode by navigating to “Reset UPM now?” selecting yes.

Figure 46

9.3.1 Heat/Cool Screen

The Heating/Cooling screen can be accessed from the Home screen

through the Service menu. From the Heating/ Cooling screen the user can

see the actual state of the diff erent points that are involved and needed

Figure 49

for the cooling and heating operation respectively.

The runtime hours and counters for the compressors are displayed and

can be reset by navigating selecting and changing the particular value.

Figure 47

Figure 48

BTC 469503103 A | 02.2019

Data subject to change

Page 24

|

24

Control Air M/M+ Water to Water Applications Installation & Operation Manual

9.3.3 Help Screen

Figure 50

The Help screen can be accessed from the home Screen via the Service

Menu. From this screen the user is able to access the software version of

the controller to which they are connected.

Other information on this screen include the controller part number and

unit serial number. This information will be useful whenever technical

support is contacted, or may be required to download the correct manuals

or integration point list fi les from our website. The technical support

phone numbers can also be found in this screen.

In addition, troubleshooting tips as well as confi guration help tips may

also be accessed from this screen.

Figure 51

Figure 52

02.2019 | BTC 469503103 AData subject to change

Page 25

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 25

BTC 469503103 A | 02.2019

Data subject to change

Page 26

|

26

Control Air M/M+ Water to Water Applications Installation & Operation Manual

02.2019 | BTC 469503103 AData subject to change

Page 27

Installation & Operation Manual Control Air M/M+ Water to Water Applications | 27

BTC 469503103 A | 02.2019

Data subject to change

Page 28

United States

Bosch Thermotechnology Corp.

65 Grove Street

Watertown, MA 02472

Tel: 866-642-3198

Fax: 603-965-7581

www.boschheatingandcooling.com

BTC 469503103 A | 02.2019

Loading...

Loading...