Page 1

Service instructions for contractors

Control unit

Control 8313

0010004580-001

6720859567 (2017/03) GB/AU

Page 2

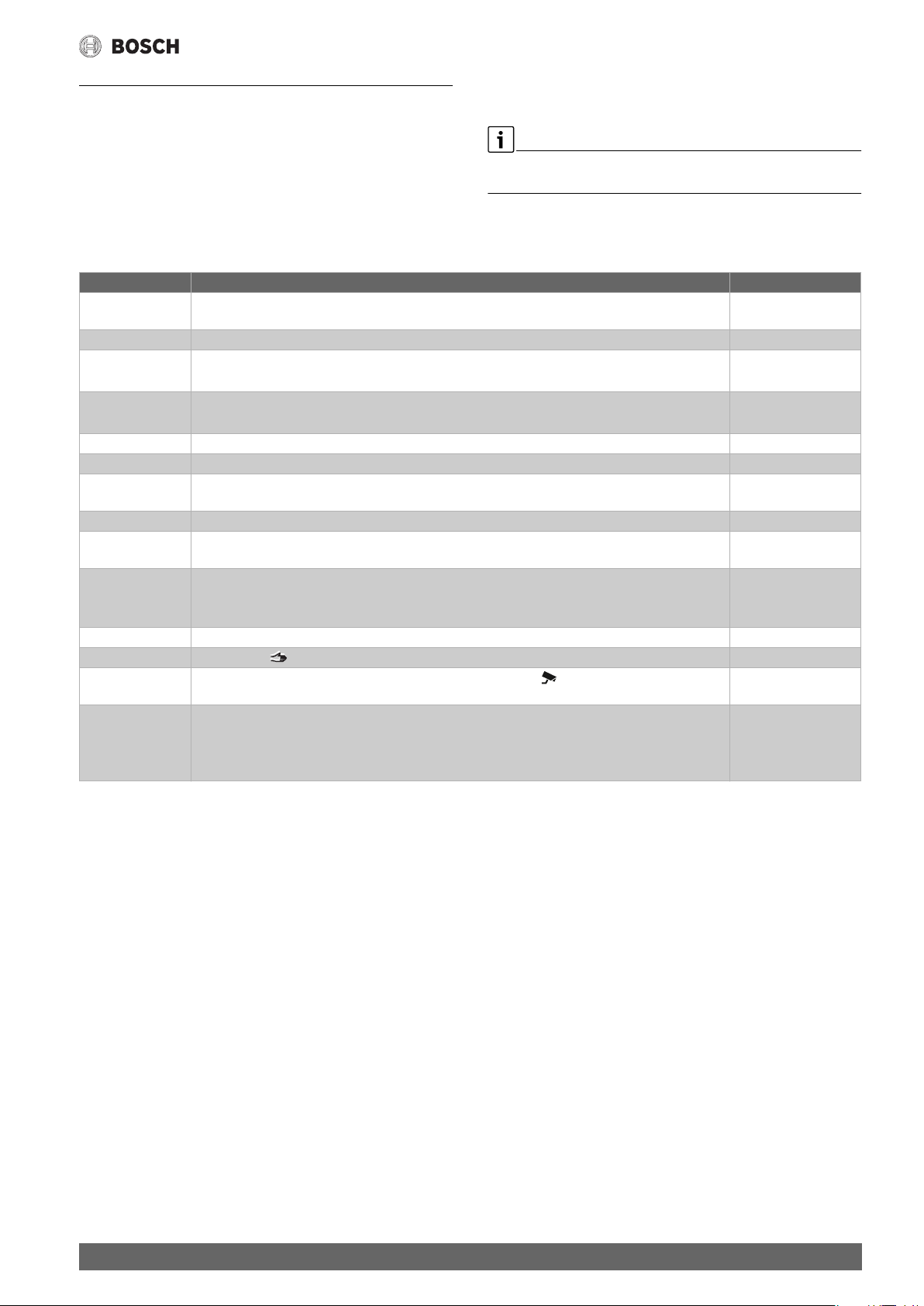

Table of contents

Table of contents

1 Explanation of symbols and safety instructions . . . . . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Open Source Software. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Product data for energy consumption. . . . . . . . . . . . . . . 5

2.4 Tools, materials and miscellaneous parts . . . . . . . . . . . . 5

2.5 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.8 Determined use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Modules and their function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Fitted modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.1 Notice regarding fitted modules . . . . . . . . . . . . . . . . . . . 6

3.2 BCT531 (HMI) user interface . . . . . . . . . . . . . . . . . . . . . 6

3.3 Central module ZM5313 . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 NM582 power supply module. . . . . . . . . . . . . . . . . . . . . 7

3.5 Base module BM592 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 FM-MM function module (accessory) . . . . . . . . . . . . . . . 7

3.7 FM-MW function module (accessory). . . . . . . . . . . . . . . 7

3.8 FM-SI function module (accessory) . . . . . . . . . . . . . . . . 7

3.9 FM-RM function module (accessory) . . . . . . . . . . . . . . . 7

4 Standards, regulations and directives . . . . . . . . . . . . . . . . . . . 7

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Overview of controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.4 User interface connections (HMI) . . . . . . . . . . . . . . . . . . 9

5.5 Connecting the heat source to the control unit . . . . . . . 9

5.5.1 Connection to the SAFe. . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.5.2 Connection to a EMS heat source . . . . . . . . . . . . . . . . .10

5.5.3 Connection via the Modbus interface . . . . . . . . . . . . . . 10

5.6 Connection to other control units in the 8000

series or to a network. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.7 Connection of modules . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.8 Connection of safety equipment and the FM-SI

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.9 Remote control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.10 Other connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Operation of the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1 Control elements of the control unit and the user

interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Function buttons and system status . . . . . . . . . . . . . . . 12

6.3 Operating and display elements of the touch

screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Operating the appliance . . . . . . . . . . . . . . . . . . . . . . . . 13

6.5 Modifying settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.6 Labelling a text field . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.7 Labelling the text field of the FM-SI module

(accessory). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.8 Calling up the service menu. . . . . . . . . . . . . . . . . . . . . . 14

7 Function keys of the user interface. . . . . . . . . . . . . . . . . . . . . 14

7.1 Reset key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.2 Chimney sweep button (flue gas test) . . . . . . . . . . . . . 14

7.3 Key for manual operation, emergency operation . . . . . 15

8 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1 Notes on commissioning . . . . . . . . . . . . . . . . . . . . . . . . 16

8.2 Control unit settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.2.1 Setting the control unit address . . . . . . . . . . . . . . . . . . 16

8.2.2 Terminating resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.1 General characteristic data . . . . . . . . . . . . . . . . . . . . . . 18

9.2 Module selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9.3 Boiler parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.3.1 Basic boiler settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.3.2 Settings of the safety equipment . . . . . . . . . . . . . . . . . 20

9.4 Heating circuit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.4.1 Basic setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.4.2 Heating curve, operating mode. . . . . . . . . . . . . . . . . . . 23

9.4.3 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.4.4 Screed drying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.5 Domestic hot water . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.5.1 Thermal disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.6 Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.7 Lock screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 Information on the general data main menu . . . . . . . . . . . . . 30

10.1 Submenu Minimum outdoor temperature . . . . . . . . . . 30

10.2 Building type, insulation standard submenu . . . . . . . . 30

10.2.1 Building. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.2.2 Insulation standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.3 External heat requirement. . . . . . . . . . . . . . . . . . . . . . . 31

10.3.1 Temperature 0...10 V . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.3.2 Output 0...10 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11 Information on the boiler parameters main menu . . . . . . . . 32

11.1 General settings regarding boiler parameters . . . . . . . 32

11.1.1 Setting up the pump function . . . . . . . . . . . . . . . . . . . . 32

11.2 Maximum shutdown temperature. . . . . . . . . . . . . . . . . 32

11.3 Information on the FM-SI module . . . . . . . . . . . . . . . . . 32

12 Information on the heating circuit data main menu . . . . . . . 33

12.1 Default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12.1.1 Submenu Remote Control . . . . . . . . . . . . . . . . . . . . . . . 33

12.1.2 Submenu Third party WF control settings . . . . . . . . . . 33

12.1.3 Submenu Room temperature offset . . . . . . . . . . . . . . . 33

12.2 Temperature settings. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12.2.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12.2.2 Setback types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

12.3 Information on the Heating curve main menu . . . . . . . 35

12.4 Submenu Screed drying . . . . . . . . . . . . . . . . . . . . . . . . 36

13 Information on the DHW data main menu . . . . . . . . . . . . . . . 36

13.1 Circulation systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

13.2 Submenu Thermal disinfection . . . . . . . . . . . . . . . . . . . 36

2

Control 8313 – 6720859567 (2017/03)

Page 3

Explanation of symbols and safety instructions

14 Information on the reset main menu . . . . . . . . . . . . . . . . . . . .37

15 Information on the Version main menu. . . . . . . . . . . . . . . . . .37

16 Information on the Connectivity main menu . . . . . . . . . . . . .37

16.1 Establishing a network with other Control 8000

control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

16.1.1 Establishing a network . . . . . . . . . . . . . . . . . . . . . . . . . .37

16.1.2 Control unit coupling . . . . . . . . . . . . . . . . . . . . . . . . . . .38

16.2 Network connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

16.3 Set up access to MEC Remote Portal. . . . . . . . . . . . . . .40

16.3.1 Registration of control unit. . . . . . . . . . . . . . . . . . . . . . .40

16.3.2 Accessing the MEC Remote Portal. . . . . . . . . . . . . . . . .41

16.3.3 Changing the system data . . . . . . . . . . . . . . . . . . . . . . .41

16.3.4 User settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

17 Information on the function check main menu . . . . . . . . . . .43

18 Information on the lock screen main menu . . . . . . . . . . . . . . 43

19 Information on the monitor data main menu . . . . . . . . . . . . .44

19.1 SI monitor data submenu. . . . . . . . . . . . . . . . . . . . . . . .44

20 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

20.1 Information on the control unit main menu. . . . . . . . . . 44

20.2 Service adapter (accessory) . . . . . . . . . . . . . . . . . . . . .44

20.3 Control unit update. . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

20.4 Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

20.4.1 Fault display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

20.5 Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

20.6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

21 Cleaning the control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

22 Environmental protection/disposal. . . . . . . . . . . . . . . . . . . . .48

23 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

23.1 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

23.1.1 Control unit specifications . . . . . . . . . . . . . . . . . . . . . . .49

23.1.2 FM-MM function module specifications . . . . . . . . . . . .49

23.1.3 FM-MW function module specifications . . . . . . . . . . . .49

23.1.4 FM-SI function module specifications . . . . . . . . . . . . . .49

23.2 Sensor curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

23.2.1 Pressure drop values for outside, room, flow and

hot water temperature sensors . . . . . . . . . . . . . . . . . . .50

23.2.2 Pressure drop values for boiler water temperature

sensor and flue gas temperature sensor with EMS

floor standing boiler with SAFe burner control unit . . . .50

23.3 Explanation of symbols and keys. . . . . . . . . . . . . . . . . .51

23.3.1 Explanation of keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

23.3.2 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . .51

23.3.3 Explanation of symbols, portal settings . . . . . . . . . . . .53

1 Explanation of symbols and safety instructions

1.1 Explanation of symbols

Warnings

In warnings, signal words at the beginning of a warning are used to

indicate the type and seriousness of the ensuing risk if measures for

minimising danger are not taken.

The following signal words are defined and can be used in this document:

DANGER:

DANGER indicates that severe or life-threatening personal injury will

occur.

WARNING:

WARNING indicates that severe to life-threatening personal injury may

occur.

CAUTION:

CAUTION indicates that minor to medium personal injury may occur.

NOTICE:

NOTICE indicates that material damage may occur.

Important information

The info symbol indicates important information where there is no risk to

people or property.

Additional symbols

Symbol Meaning

▶ a step in an action sequence

a reference to a related part in the document

• a list entry

– a list entry (second level)

Table 1

1.2 Safety precautions

H General safety instructions

Failure to observe the safety instructions can result in

serious personal injury and a risk to life as well as

material losses and damage to the environment.

▶ Carry out service work at least once a year. As part

of this, check that the entire system is working

correctly. Defects must be remedied immediately.

▶ Before commissioning the heating system, read

these instructions carefully.

Control 8313 – 6720859567 (2017/03)

3

Page 4

Explanation of symbols and safety instructions

H Original spare parts

The manufacturer assumes no liability for damage

caused by spare parts not supplied by the

manufacturer.

▶ Use only original spare parts and accessories from

the manufacturer.

H Risk of scalding

Risk of scalding from DHW temperatures over 60 °C.

▶ Do not draw off DHW unmixed.

H Safety of electrical devices for domestic use

and similar purposes

The following requirements apply in accordance with

EN 60335-1 in order to prevent hazards from

occurring when using electrical appliances:

“This appliance can be used by children of 8 years and

older, as well as by people with reduced physical,

sensory or mental capabilities or lacking in experience

and knowledge, if they are supervised and have been

given instruction in the safe use of the appliance and

understand the resulting dangers. Children shall not

play with the appliance. Cleaning and user

maintenance must not be performed by children

without supervision.”

“If the power cable is damaged, it must be replaced by

the manufacturer, its customer service department or

a similarly qualified person, so that risks are avoided.”

H Risk of fatal injury from electric current

▶ Observe the relevant requirements when working

on electrical installations.

▶ Installation and commissioning as well as service

and maintenance must only be carried out by an

approved and qualified contractor.

▶ Before unpacking the appliance, touch a radiator or

an earthed metal water line to discharge any

electrostatic charge in your body.

▶ Ensure that a country-specific emergency isolation

switch (emergency-off button) is present.

In the case of systems with three-phase consumers,

incorporate the emergency isolation switch into the

safety chain.

▶ Ensure that a standards-compliant disconnection

device in accordance with EN 60335-1 is available

for all-pole disconnection from the power grid. If

there is no circuit breaker present, you must install

one.

▶ Before opening the controller, disconnect all poles

of the heating system via the circuit breaker. Secure

against unintentional reconnection.

▶ Size cables according to how they are to be laid and

environmental conditions. The cable cross-section

for power outputs (e.g. pumps, mixers) must be at

2

least 1.0 mm

.

H Heating system damage due to frost

When the heating system is not in operation

(e.g. controller switched off, fault shutdown), there is

a risk of it freezing when there is frost.

▶ When shutting down or switching off for extended

periods, drain the heating and drinking water pipes

to the lowest point in order to protect the heating

system from freezing.

H Handover to the user

When handing over, instruct the user how to operate

the heating system and inform the user about its

operating conditions.

▶ Explain how to operate the heating system and draw

the user's attention to any safety relevant action

▶ Explain that conversions and repairs must only be

carried out by a competent person.

▶ Point out the need for inspections and maintenance

for safe and environmentally-compatible operation.

▶ Leave the installation instructions and the

operating instructions with the user for

safekeeping.

4

Control 8313 – 6720859567 (2017/03)

Page 5

Product Information

2 Product Information

This installation and maintenance instructions contain important

information for the safe and correct installation, initial commissioning,

and maintenance of this control unit.

Depending on the software version, the display and menu items shown

in the instructions may differ from those in the control unit.

The operating instructions contain information on operation of the

control unit.

▶ Observe operating instructions of the control unit and the heat

source.

2.1 Declaration of Conformity

The design and operation of this product conform to European Directives

and the supplementary national requirements. Its conformity is

demonstrated by the CE designation.

You can view the Declaration of Conformity on the internet

( back cover).

2.2 Open Source Software

This product contains proprietary software by Bosch (licensed

according to the Bosch standard licensing conditions) and Open Source

Software (licensed according to the Open Source licensing conditions).

The special provisions stated in the license texts apply for LGPL, reverse

engineering is permitted for these components in particular.

You can find Open Source information on the DVD supplied with the

device.

2.6 Accessories

• Sensor for DHW heating functions

• Function modules

2.7 Product Description

The modular control system provides the perfect means of adjustment

for boilers and wall mounted boilers equipped with a SAFe burner

control unit to ensure the operating conditions for the specific product

are satisfied.

The control unit controls an EMS oil boiler or EMS gas boiler. As an

option, a modulating boiler circulation pump can be activated via a PWM

signal or a 0...10-V interface.

The standard equipment of the control unit comprises the boiler circuit

or heating circuit with mixer and DHW heating functions. So it can be

perfectly matched with the heating system, the control unit can be

extended by up to four function modules.

No parameter settings are lost in the event of a power failure. When the

power supply is restored, the user interface resumes operation.

Notice regarding systems with several heat sources

The CC 8313 control unit can control systems containing several heat

sources (cascades) in combination with the FM-CM cascade module.

For a description of this function, refer to the technical documentation

for the module.

2.8 Determined use

The control unit controls and monitors heating systems in apartment

buildings, residential complexes and other buildings.

▶ Observe country-specific standards and regulations concerning

installation and operation!

2.3 Product data for energy consumption

The product data on energy consumption can be found in the operating

instructions for the user.

2.4 Tools, materials and miscellaneous parts

You will require the following to carry out installation, assembly and

maintenance:

• Electrical engineering tools and measuring devices

The following may also prove useful:

• A PC for commissioning and service

2.5 Scope of delivery

Upon delivery:

▶ Check that the packaging is in perfect condition.

▶ Check the scope of delivery for completeness.

The scope of delivery includes:

• Digital control unit CC 8313

• User interface (HMI)

• FA outside temperature sensor

• FZ auxiliary temperature sensor for flow or return temperature

• SAFe connecting lead extensions

• SAFe BUS cable extension

• Fixing materials

• Technical documents

Control 8313 – 6720859567 (2017/03)

5

Page 6

Modules and their function

t

3 Modules and their function

3.1 Fitted modules

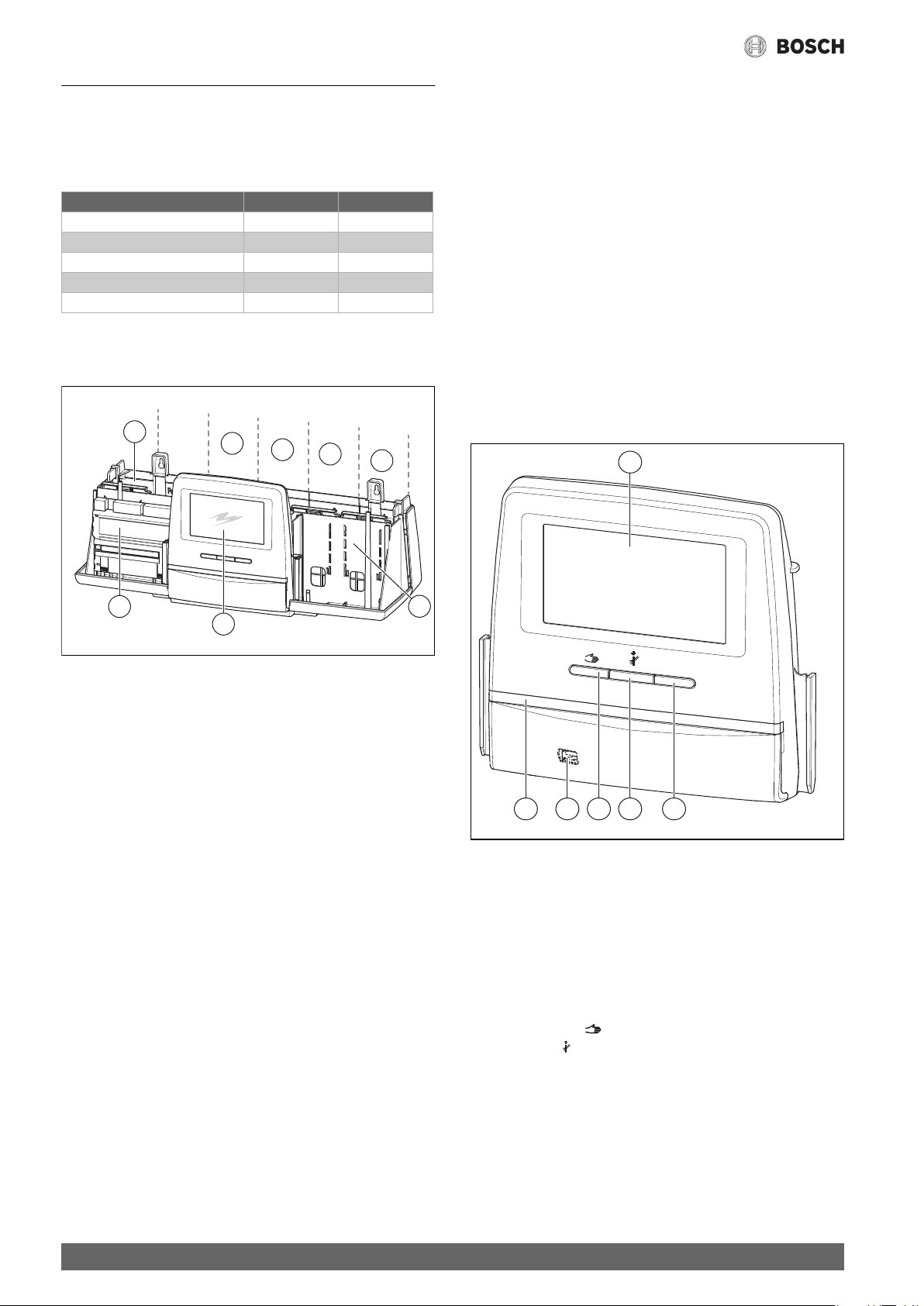

All modules fitted in the control unit are listed in the following table. The

description also includes the FM-MM, FM-MW and FM-SI modules.

Module Slot CC 8313

BCT531 (HMI) user interface HMI X

Central module ZM5313 A X

NM582 power supply module B X

Function module (e.g. FM-MM) 1...4 O

FM-RM function module C O

Table 2 Modules and their functions

[X] Standard equipment

[O] Optional equipment

2

3

4

5

6

FM-CM (cascade module)

To avoid interrupting the heating circuit numbering and as the FM-CM

has no supply voltage output, it should be mounted at slot 4 (on the far

right). If several cascade modules are used, assembly should start from

the right. With several control units, the FM-CM in the master control unit

must be installed with the address 0.

FM-RM

The module can only be installed at slot C.

FM-MW

Each control unit can only support 2 DHW heating systems, e.g. DHW

heating via the central module (ZM) and via the FM-MW.

3.2 BCT531 (HMI) user interface

The user interface is equipped with a touch screen. Information is

displayed and commands entered at the touch screen.

The user interface is equipped with a USB interface for service

purposes.

The control unit address is set on reverse side.

1

1

7

8

0010005505-001

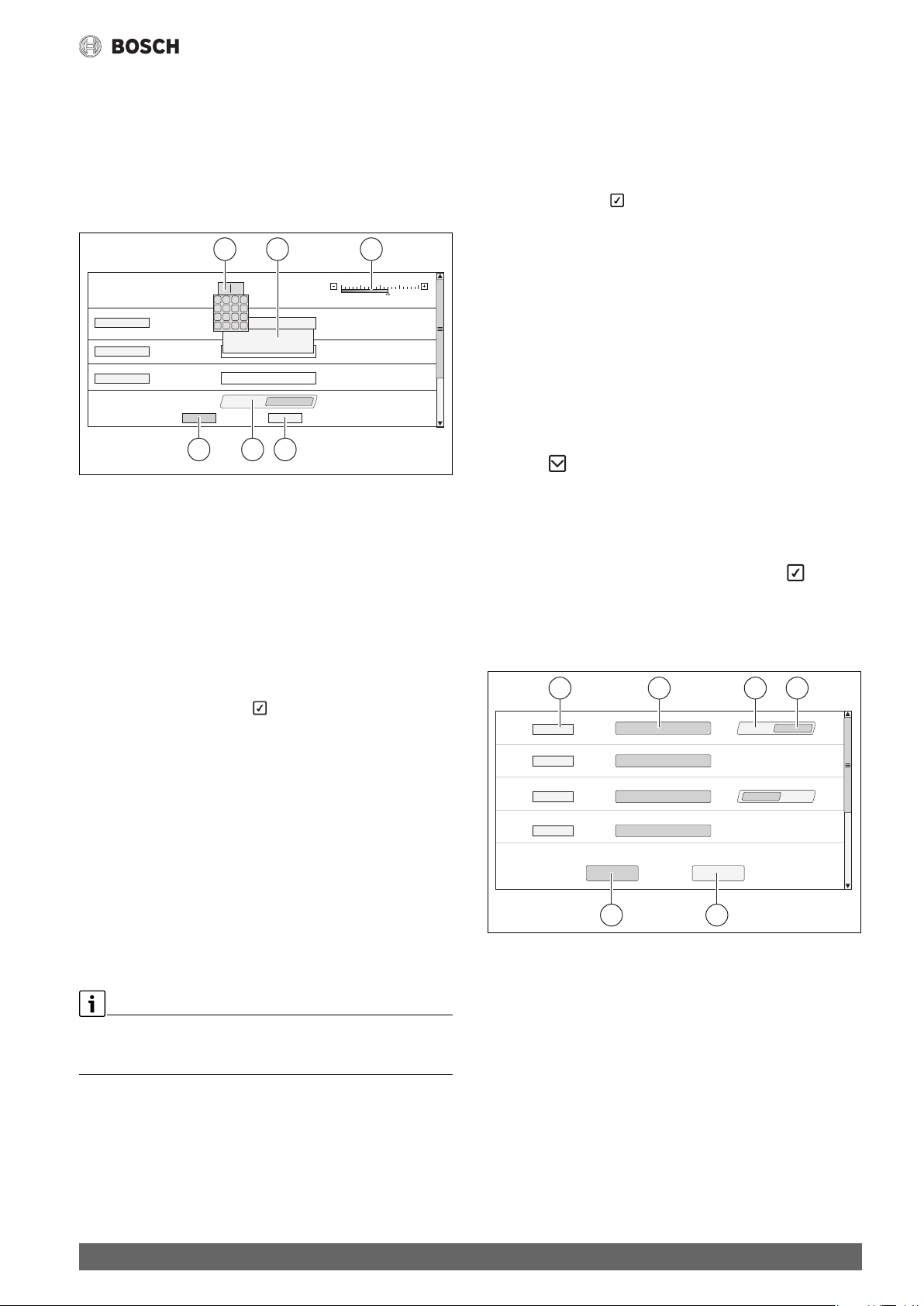

Fig. 1 Overview of slots

[1] Slot A (central module)

[2] Slot B (power supply module)

[3] Slot 1

[4] Slot 2

[5] Slot 3

[6] Slot 4

[7] Slot C

[8] User interface

3.1.1 Notice regarding fitted modules

The additional modules can be installed in any free slot 1...4. In doing so,

make sure that the power supply leads from module to module. We

recommend that you insert the modules in order from left to right to

ensure the heating circuits are logically numbered.

When using the following modules, it is advisable to mount them at

specific slots.

FM-AM

The module only affects the control unit in which it is fitted. If the module

is installed in the master control unit with address 0, it is effective for the

connected boiler(s). If the module is fitted in a substation, it will respond

to the heat requirement issued by that substation.

FM-SI

Due to the length of the SI connecting lead, the safety module should be

mounted at slot 1.

reset

23456

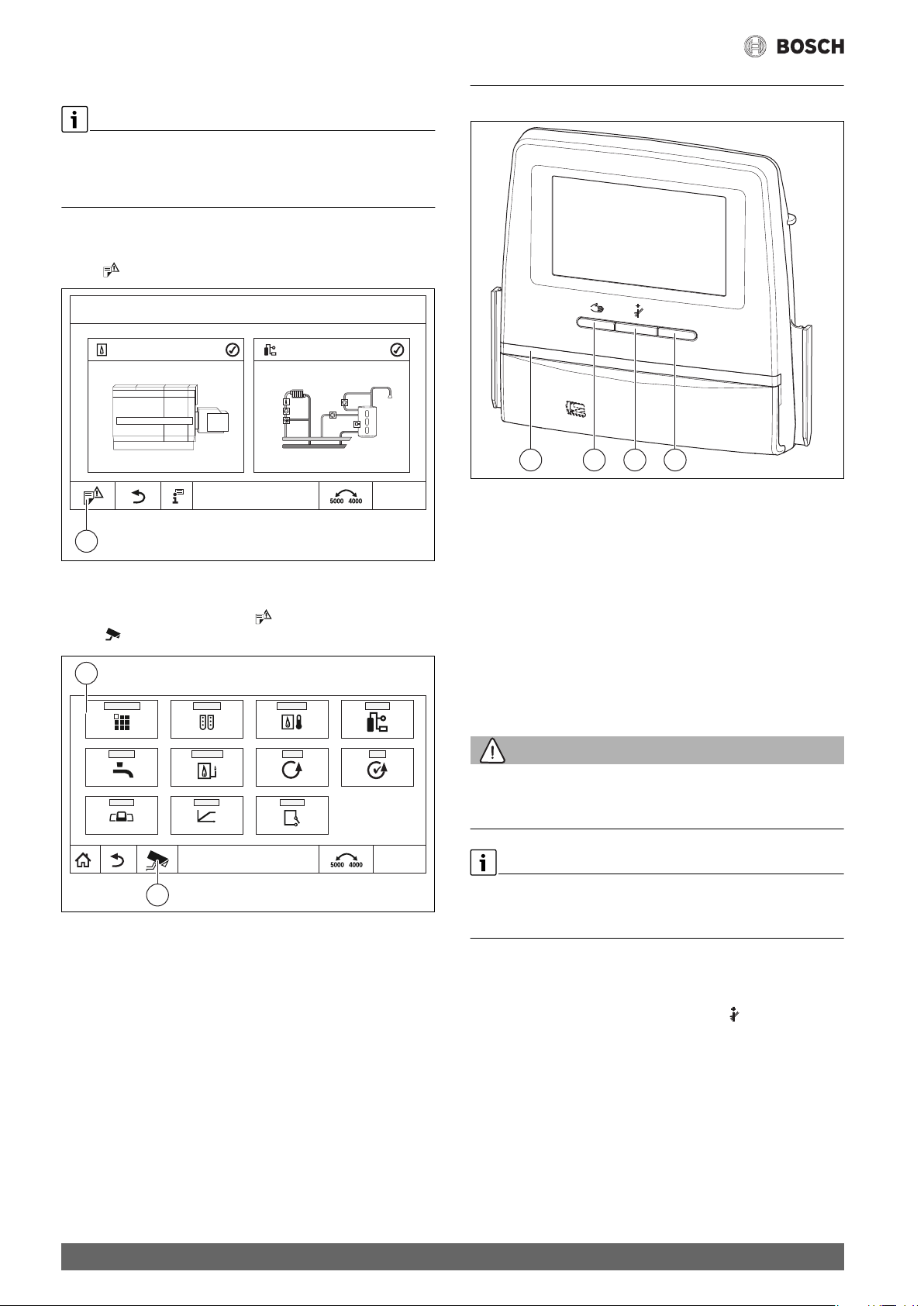

Fig. 2 User interface

[1] Touch screen

[2] Reset button (e.g. high limit safety cut-out, SAFe)

[3] Chimney sweep button (Flue gas test)

[4] Key for manual operation

[5] USB interface for service purposes (behind cover)

[6] LED status display

Function buttons

The function buttons enable

• Manual operation

• Flue gas test

• Reset (e.g. high limit safety cut-out, SAFe)

rese

0010005507-001

6

Control 8313 – 6720859567 (2017/03)

Page 7

Standards, regulations and directives

System status, function status, component status

The status of the system, the functions and system components is

displayed via the Function status display ( Fig. 6, [1], page 12), the

System components status display ( Fig. 6, [15], page 12) and the

LED status display ( Fig. 2, [6]):

• Green = system in automatic mode

• Yellow = system in manual operation, Flue gas test, Service display or

Blocking fault SAFe

• Yellow flashing = Control unit coupling

• Red = Fault

Battery CR2032

The battery ensures that the time and date are not lost when the

control unit is switched off or in the event of a voltage failure

( Fig. 4, [8], page 9).

3.3 Central module ZM5313

The central module controls the following functions:

• Functions of a boiler circuit or a heating circuit with mixer

• Functions of the DHW supply

• BUS communication with the SAFe burner control unit

• Function of the safety chain (SI chain)

• Function of flue gas damper

• Modulating control of boiler circulation pump (possible via 0...10 V)

3.4 NM582 power supply module

The power supply module ( Fig. 1, [2], page 6) supplies voltage to the

following components:

• Control unit

• Load outputs (e.g. pumps, burners, actuators)

• Boiler controller

• Modules used and corresponding connected system components

(e.g. sensor)

It is equipped with:

• 2 safety switches (10 A) as fuse protection of the power sources for

– the central module and user interface

– the modules at slots 1...4

• ON/OFF switch, that switches the phase (L) and neutral conductor (N)

If a safety switch has tripped due to overload, the pin projects noticeably

out of it.

To switch on the safety switch:

▶ Push in the pin.

If the safety switch triggers frequently:

▶ Check the current consumption.

3.5 Base module BM592

A power supply for 24 V components is available at slot C on the base

module.

• Connection: 24 V =, max. 250 mA

▶ Do not exceed the total current.

3.6 FM-MM function module (accessory)

The FM-MM module regulates 2 independent heating circuits with mixer.

The module can be used more than once in the control unit. The

functions of the module are selected and adjusted via the display.

The adjustable functions and parameters are described in the menu

structure of the control unit ( Chapter 9, page 17).

3.7 FM-MW function module (accessory)

The FM-MW module regulates 1 heating circuit with mixer and 1 DHW

supply system. The module can be used more than once in the control

unit. The functions of the module are selected and adjusted via the

display.

The adjustable functions and parameters are described in the menu

structure of the control unit ( Chapter 9, page 17).

3.8 FM-SI function module (accessory)

The purpose of the FM-SI function module is to integrate external

safety equipment into the system or system control. When integrated

into the system control, faults are evaluated via the control unit

(observe Chapter 5.8, page 10).

Examples of external safety equipment:

• Low water indicator

• Pressure limiter

• Additional high limit safety cut-out (STB)

3.9 FM-RM function module (accessory)

The module allows components (e.g. coupling relay, modem) to be

installed on a mounting rail. It can only be installed at slot C.

The maximum overall height of the components is 60 mm. The maximum

supply voltage is 230 V.

4 Standards, regulations and directives

The following are some of the regulations and standards that must be

observed during installation and operation:

• Regulations for electrical installation and connection to the

electrical grid

• Pressure Equipment Directive – systems with boiler temperatures

> 110 °C

• EN 12953-6 – Shell boilers. Requirements for equipment

for the boiler

• EN 12828 – Heating systems in buildings

• ICOM Water treatment guide for commercial heating systems.

• Country-specific regulations to protect potable water

(e.g. DVGW Code of practice W551– Drinking water protection)

• Manufacturer's technical Codes of Practice (e.g. in the catalogue)

• National standards and regulations

Control 8313 – 6720859567 (2017/03)

7

Page 8

Installation

5 Installation

5.1 Assembly

Descriptions of how the control unit is positioned at the heat source are

provided in the installation instructions for the control unit and

documentation for the heat source.

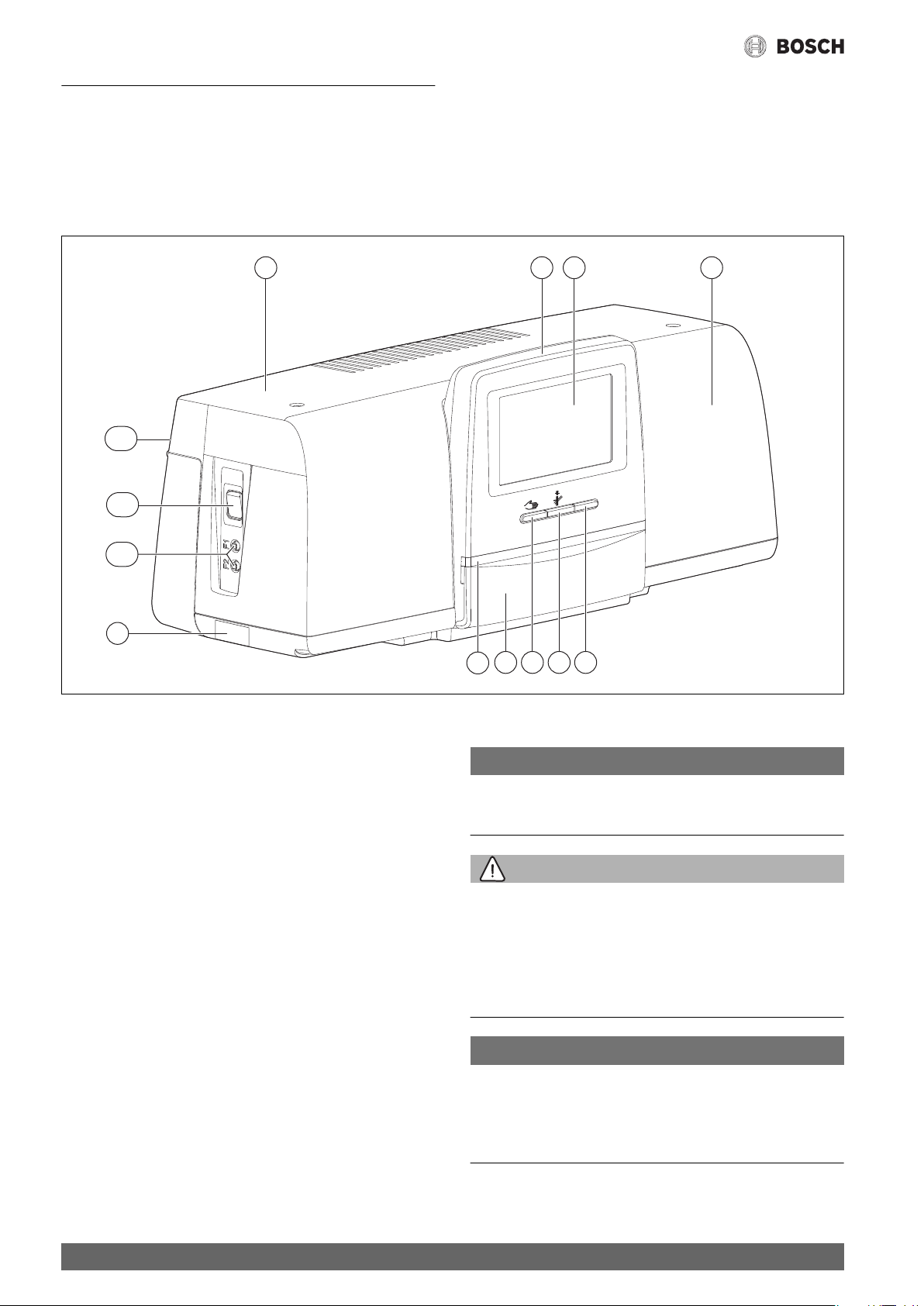

5.2 Overview of controller

1 2 3 1

12

11

10

9

Fig. 3 Overview of controller

[1] Housing lid/cover

[2] User interface

[3] Touch screen

[4] Reset button (e.g. high limit safety cut-out, SAFe)

[5] Chimney sweep button (Flue gas test)

[6] Key for manual operation

[7] Cover (USB interface for service purposes, behind cover)

[8] LED status display

[9] Type plate

[10] F1-, F2 circuit breaker

[11] ON/OFF switch

[12] Back panel

reset

47

8

56

0010003622-001

5.3 Electrical connection

NOTICE:

Faults/material damage due to inductive interference!

▶ Make sure all low-voltage cables are routed separately to mains

voltage cables (min. clearance 100 mm).

WARNING:

Risk to life and of system damage due to high temperatures.

All parts directly or indirectly exposed to high temperatures must be

designed to withstand these temperatures.

▶ Keep cables and electrical wiring at a safe distance from hot

components.

▶ Route cables and electrical wiring in the cable routings provided,

or above the insulation.

NOTICE:

Material damage as a result of disregarding other instructions!

If other instructions for components are disregarded, the heating system

may develop faults or be damaged due to incorrect connections/settings.

▶ Follow the directions in all instructions for the components that are to

be installed.

8

Control 8313 – 6720859567 (2017/03)

Page 9

Installation

Note the following when making electrical connections:

• All electrical connections, safety measures and safety devices must

be implemented by an approved contractor, taking into account the

standards and guidelines that are applicable in each case as well as

the local regulations.

• Establish electrical connection as a fixed connection in accordance

with local/national regulations.

• Electrical connections are established as specified in the connection

diagram for the control unit and the module.

To prevent inductive influences:

▶ Make sure all low-voltage cables are routed separately to mains

voltage cables (min. clearance 100 mm).

• When installing the devices, ensure an earth connection is present.

• Do not exceed the total current stated on the data plate, and the

partial currents for each safety switch and connection.

• Before opening the control unit, disconnect all poles of the control

unit and secure against unintentional reconnection.

• Incorrect attempts to make connections under voltage may damage

the control unit beyond repair and lead to dangerous electric shocks.

▶ Establish electrical connections as specified in the connection

diagram of the control unit and the local conditions.

5.4 User interface connections (HMI)

5.5 Connecting the heat source to the control unit

5.5.1 Connection to the SAFe

WARNING:

Danger to life due to flue gas at the installation location!

With older SAFe software versions (not permitted here), the heat source

may start automatically in unfavourable circumstances!

Unfavourable scenario: connection between heat source (with old SAFe)

and ZM5313 is interrupted.

▶ Only use heat sources with SAFe with software version ≥ Table 3.

If a boiler with SAFe burner control unit is being connected, the EMS

connection has no function!

SAFe heat sources are heat sources that are equipped with a SAFe

(burner control unit) for burner control. The SAFe is directly connected

to the higher level plant control system (e.g. Control CC 8313).

As the software version of the connected heat source determines

whether or not the control functions correctly, the software version of

the SAFe must be checked directly following connection.

Connections:

• On the ZM5313 central module at the BUS SAFe and mains

SAFe terminals

• On the SAFe at the BUS and mains SAFe terminals.

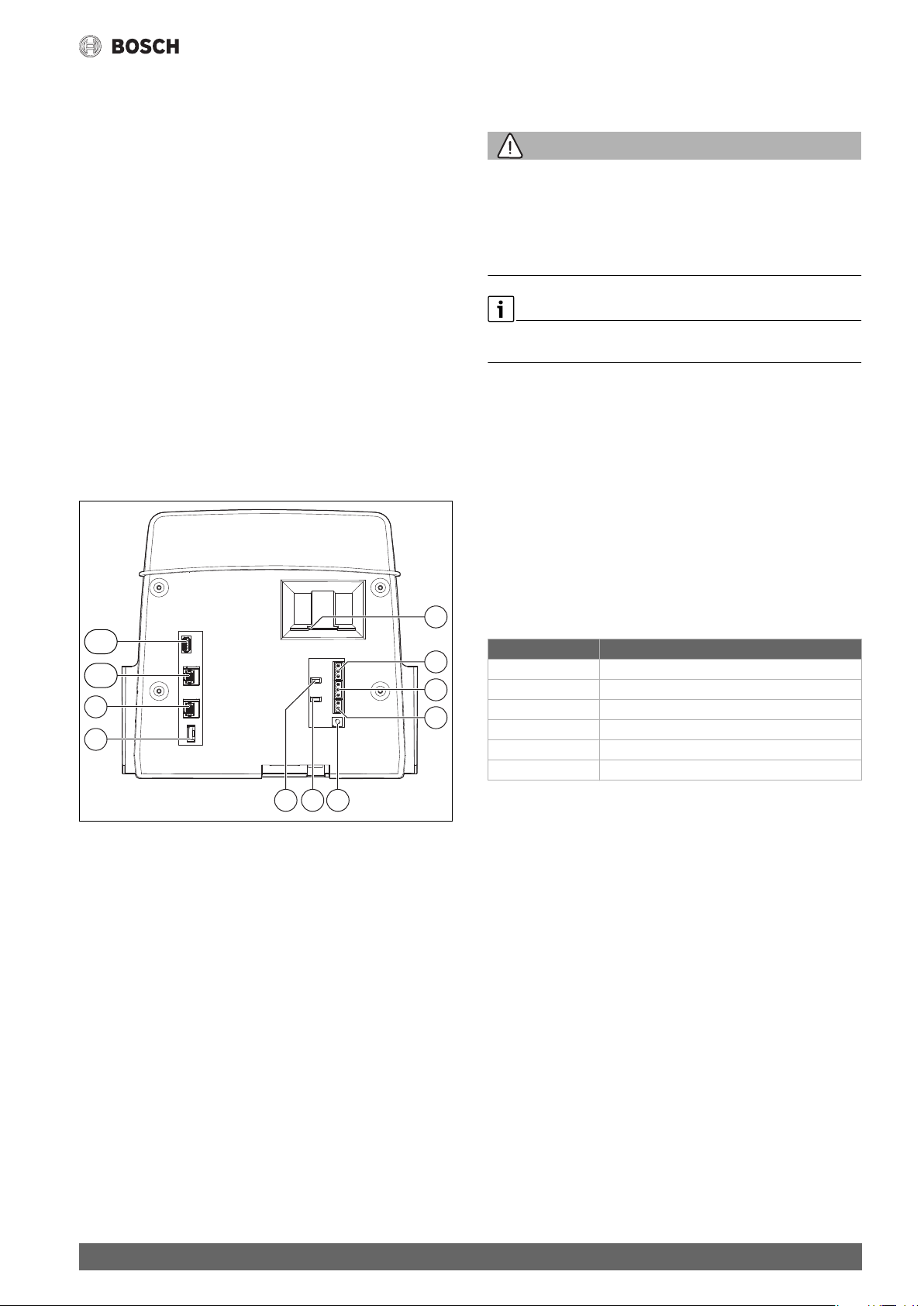

1

11

10

9

8

Fig. 4 User interface connections

[1] Slide type insert for SD card

[2] CAN-BUS connection (no function, provided for

subsequent functions)

[3] Modbus-RTU connection for Bosch/Bosch CHP module

[4] EMS connection (connection for EMS heat source with its own

basic control (control panel))

[5] Address setting of control unit

[6] Jumper (J2) for activating the Modbus-RTU terminating resistance

[7] Jumper (J1) for activating the terminating resistance CAN-BUS

[8] Battery CR2032

[9] Network connection 2 (CBC-BUS)

[10] Network connection 1 (Internet, Modbus TCP/IP, CBC-BUS)

[11] USB connection

Depending on the use and configuration, the plug-in connections on the

rear of the user interface must be occupied.

Configuration of CAN-BUS/Modbus-RTU/EMS plug:

• Jumper for activating the Modbus-RTU terminating resistance

• Jumper for activating the CAN-BUS terminating resistance

LAN1

LAN2

USB1

+-

J1

3 2 13 2 1

J2

2 1

2

3

4

567

0010005508-001

Check SAFe version

▶ Check at the heat source whether the SAFe has at least one of the

software versions listed in table 3.

SAFe Software version

10 V4.27

20 V4.23

30 V4.27

40 V4.23

42 V4.28

50 –

1) No function with SAFe 50

1)

Table 3 SAFe version

Control 8313 – 6720859567 (2017/03)

9

Page 10

Installation

5.5.2 Connection to a EMS heat source

NOTICE:

Material damage due to incorrect connection!

When connecting EMS heat sources:

▶ Remove jumper at the external interlock terminal.

▶ Only connect safety equipment directly at the EMS boiler.

EMS heat sources have their own basic control (control panel,

e.g. BC10). The SAFe is connected to the control of the heat source.

If a plant control system is installed, it is superordinate to the control of

the heat source.

The user interface of the control unit and the basic control

(control panel) of the heat source are directly connected.

Connections:

• On the back of the user interface at the EMS terminals

( Fig. 4, [4], page 9) with

• Basic control of the heat source at the (EMS)-BUS terminals

When connecting a boiler via the EMS terminals:

▶ Remove jumper at the external interlock terminal.

The external interlock connection has no function in conjunction

with EMS boilers!

▶ External safety equipment that lead to blocking must be connected

to the EMS boiler directly.

5.5.3 Connection via the Modbus interface

For heat sources (e.g. CHP module) that are connected via the

Modbus-RTU ( Fig. 4, [3], page 9):

▶ Connect communications cable to the Modbus-RTU connection.

▶ Consider connection to the heat source.

5.8 Connection of safety equipment and the FM-SI

module

SAFe heat source

If a boiler with SAFe burner control unit is being connected, the EMS

connection has no function!

▶ Connect safety equipment or a condensates neutraliser at the FM-SI

module.

▶ Close unused SI inputs with a jumper.

When using a condensate neutraliser:

▶ Connect condensate neutraliser to SI1 input.

EMS heat source

Use of the FM-SI with EMS heat sources is not permitted if the heat

source is connected via the EMS terminal ( Fig. 4, [4], page 9).

▶ Connect external safety equipment directly to the control of the heat

source (terminal SI 17, 18).

▶ Always connect safety equipment that shuts down the heat source to

the basic control of the heat source (EMS control).

If EMS heat source was selected in the setting:

▶ Open the safety chain (terminal SI 17, 18) at the ZM5313

without fail.

▶ Do not install a jumper!

If safety equipment is connected, a jumper is installed or a Sl module is

inserted at the ZM5313, a fault display is generated.

To avoid vagabond voltages:

▶ Only connect cable shield to one control unit!

5.6 Connection to other control units in the 8000 series

or to a network

The connection options are presented in Chapter 16.1, page 37.

5.7 Connection of modules

Mains voltage

The 230 V power supply must be ensured for modules fitted at slots

1…4 via a plug-in connector on the power supply module. The modules

supply voltage to one another via additional plug-in connections.

If voltage is not supplied to the module or its 230 V components

(e.g. because the plug-in connector has not been inserted), the

components assigned to this module are not switched on (e.g. pumps).

This malfunction cannot be detected at the user interface itself as the

display and control functions are independent of the 230 V voltage.

5.9 Remote control

If a remote control is provided for the heating circuit, this must be

connected to the BF terminals. The remote control is assigned to the

corresponding heating circuit via the coding switch in the remote

control.

5.10 Other connections

Other connections may need to be established, depending on the

function of the modules.

▶ Observe documents and connection diagrams of the installed

modules!

UM10 function module

A UM10 must not be installed in a heating system if the heat source is

activated via the ZM5313. The ZM5313 takes over the UM10

functionality.

10

Control 8313 – 6720859567 (2017/03)

Page 11

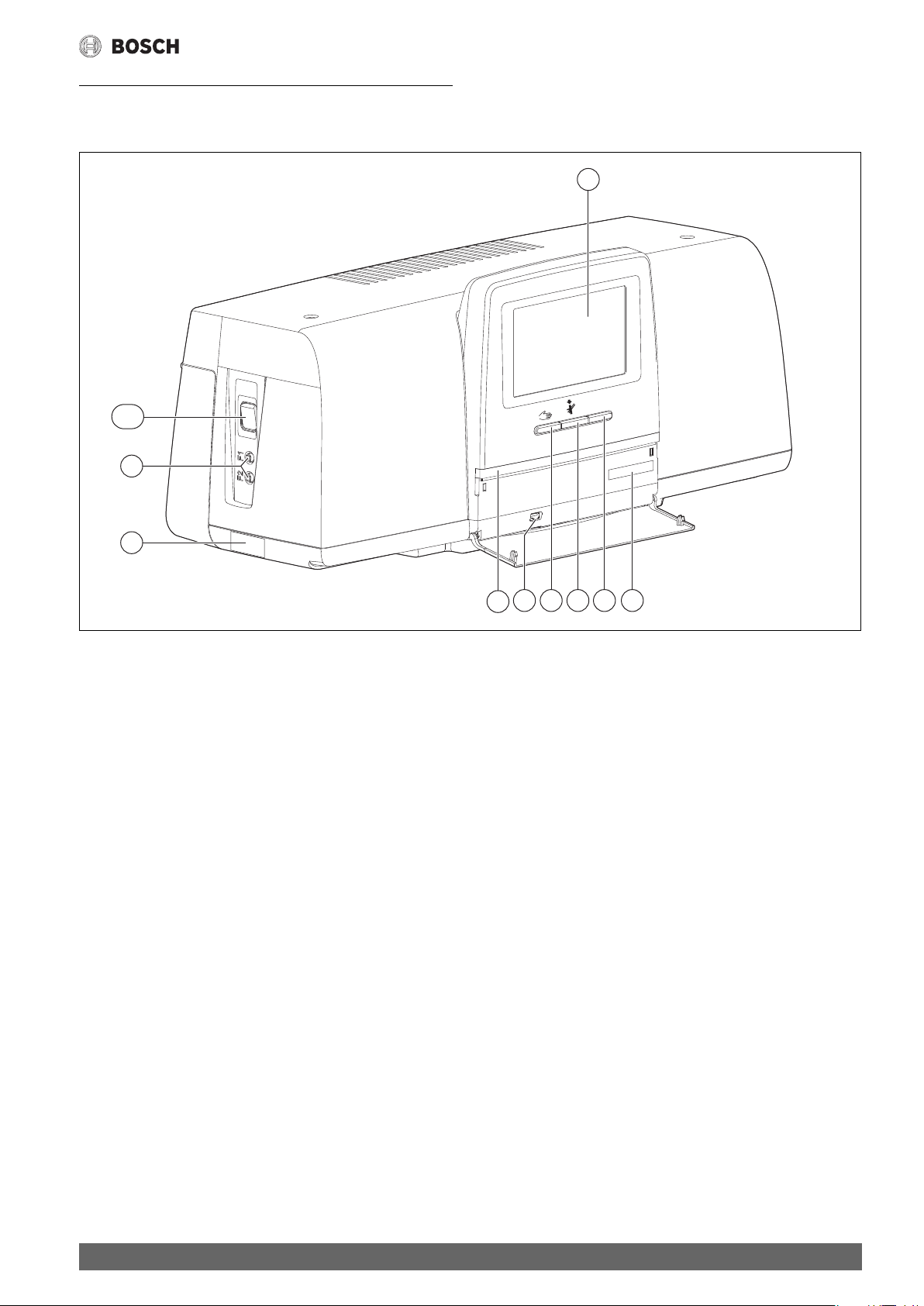

6 Operation of the control unit

6.1 Control elements of the control unit and the user interface

Operation of the control unit

1

10

9

8

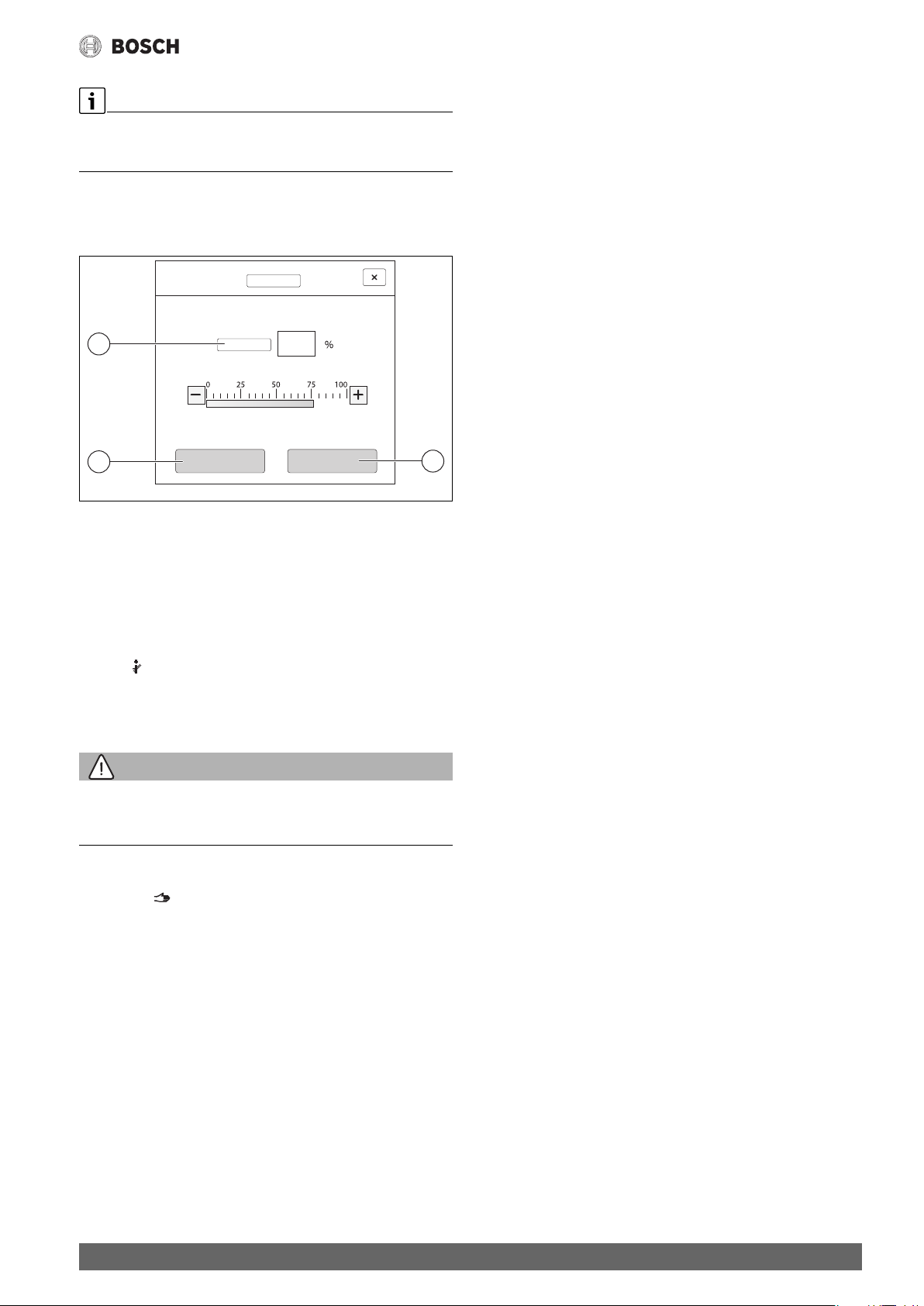

Fig. 5 Control elements

[1] Touch screen

[2] Activation code (registration code)

[3] Reset button (e.g. high limit safety cut-out, SAFe)

[4] Chimney sweep button (for Flue gas test)

[5] Manual operation key

[6] USB connection (e.g. for service purposes)

[7] LED status display

[8] Data plate

[9] F1-, F2 circuit breaker

[10] ON/OFF switch

reset

7

3 26 45

0010005509-001

Control 8313 – 6720859567 (2017/03)

11

Page 12

Operation of the control unit

t

6.2 Function buttons and system status

Function buttons

The function buttons enable

• Manual operation

• Flue gas test

• Reset (e.g. high limit safety cut-out, SAFe)

System status, function status, component status

The status of the system, the functions and system components is

displayed via the Function status display ( Fig. 6, [1], page 12), the

System components status display ( Fig. 6, [15], page 12) and the

LED status display ( Fig. 5, [7]):

• Green = system in automatic mode

• Yellow = system in manual mode, Flue gas test, Service display or

Blocking fault SAFe

• Yellow flashing = Control unit coupling

• Red = Fault

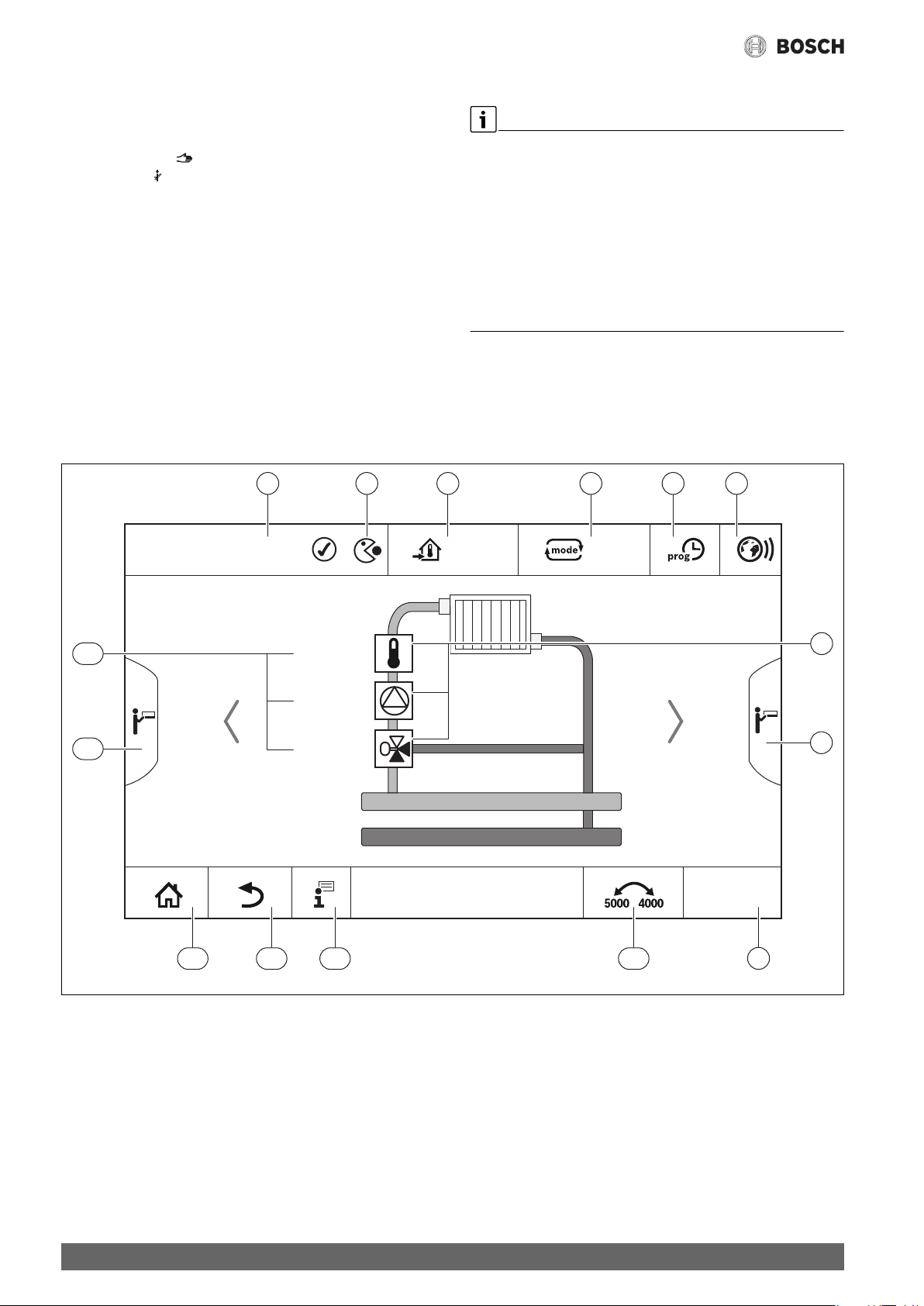

rese

1 2 3 4 5 6

6.3 Operating and display elements of the touch screen

Whether menu items can be displayed or selected depends on which

modules are inserted and which settings have been made.

The displays shown are examples. The display of the symbols depends

which software is installed, which modules are inserted and which

settings have been made.

The operating instructions contain information on operation of the

control unit.

▶ Observe operating instructions of the control unit and the heat

source.

The following displays can be called up via the touch screen:

• Heat source in the system

• Heat consumers and heat distributors in the system

• Monitor data

• Setting parameters for commissioning and system optimisation.

These parameters are protected by a code.

15

50 °C

on/o

14

Fig. 6 Operating and display elements

[1] Display of system, subsystem or function

[2] Status display of active menu level

[3] Display of temperature set (set temperature)

[4] Display of operating mode set

[5] Display of time program set

[6] Display of Internet connection

[7] Display of system components

[8] Advanced functions for heating circuit, DHW

[9] Display of time

[10] Press field to switch between display types on the display

[11] Information menu

30 %

12:00

10111213

[12] Press field to go back to the previous level/screen

[13] Press field to return to the system overview

[14] Advanced functions of the heat source

[15] Status display of system components

The symbols used are listed in Chapter 23.3 on page 51,

accompanied by an explanation.

9

0010005510-001

7

8

12

Control 8313 – 6720859567 (2017/03)

Page 13

Operation of the control unit

6.4 Operating the appliance

The operating instructions contain information on operation of the

control unit.

▶ Observe the operating instructions of the control unit.

A description of operation of the control unit from the contractor's

standpoint is provided below.

6.5 Modifying settings

1 2 3

°C

C

7

9

8

+

4

6

5

1

3

2

-

.

OK

x

0

O On

6 45

Fig. 7 Modifying settings

[1] Numerical values

[2] Selection box

[3] Scale

[4] Cancel

[5] Off/On

[6] Save

Changes to parameters can be made in a number of different ways,

depending on the menu item.

• Changing numerical value

Numerical values can be changed by entering the number directly.

A keyboard opens when you tap the numerical field.

▶ Type in numerical values and .

If the values you entered are invalid, the previous value will be

displayed.

• Scale

You can change the value by tapping the Plus and Minus keys.

• Selection box

Tap this field to open a selection box. Tap on the required parameter/

function to select it.

• Label text field ( Chapter 6.6, page 13)

• Off/On

Tap on the required parameter/function to select it.

To save the changes:

▶ Tap Save field.

To cancel the operation:

▶ Tap Cancel field.

If parameters are linked to settings, a temperature, for example, can only

be selected/modified if the function is set to On.

Fields that are not active are highlighted in grey.

-30 -22 -15 -7 0

0010007715-001

6.6 Labelling a text field

In some cases, the selection box contains an empty field/User-defined

which can be labelled by entering text.

▶ Tap on the empty field.

A keyboard opens.

▶ Enter a suitable text for the length of the field.

▶ Confirm entry with

To save the changes:

▶ Tap Save field.

To cancel the operation:

▶ Tap Cancel field.

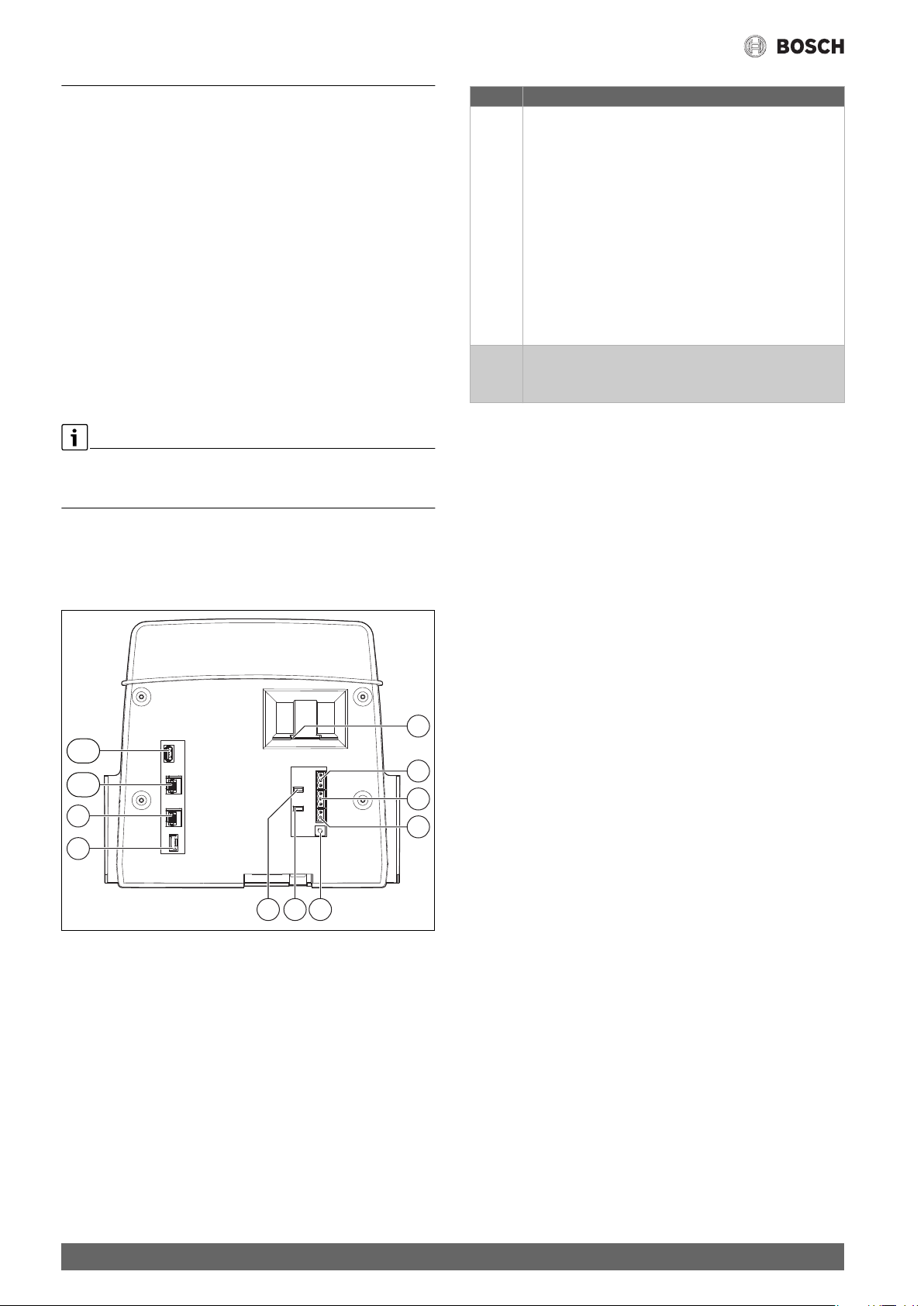

6.7 Labelling the text field of the FM-SI module

(accessory)

You can name the inputs of the FM-SI safety module according to the

connected safety equipment.

If other devices are connected, you can assign your own names to these

by entering text in an empty field. If fields have been selected but not

saved, the selection is reset.

To label a field:

▶ Tap the field.

The pre-selection opens.

▶ Select name.

-or-

▶ Tap FM-SI field.

A keyboard opens.

▶ Enter a suitable text for the length of the field and tap to apply.

To save the change:

▶ Tap Save field.

To cancel the operation:

▶ Tap Cancel field.

31 2 4

6 5

Fig. 8 Labelling a text field

[1] FM-SI1

[2] Name of safety equipment

[3] Free

[4] Allocated

[5] Cancel

[6] Save

0010009240-001

Control 8313 – 6720859567 (2017/03)

13

Page 14

Function keys of the user interface

t

t

6.8 Calling up the service menu

The Service menu is protected against unauthorised use. The Service

menu is intended exclusively for approved heating contractors.

Unauthorised access will invalidate the warranty!

The Service menu can only be accessed from the system overview.

To call up the Service menu:

▶ Tap and hold for roughly 5 seconds.

12:00

1

Fig. 9 Call up Service menu

[1] Fault history, Service display

In the Service menu tap the symbol to select the Settings or the

symbol to select the Monitor data.

0010009028-001

1

7 Function keys of the user interface

reset

1234

Fig. 11 Function buttons

[1] Reset button

[2] Chimney sweep button

[3] Manual operation key

[4] LED status display

7.1 Reset key

When the key is pressed the locking fault is unlocked and the

functions are reset (e.g. following triggering of the high limit safety cutout or resetting of the SAFe).

To unlock a function:

▶ Key Hold down for 2 seconds.

rese

rese

0010007084-001

2

Fig. 10 Service menu

[1] Symbols for available functions

[2] Monitor data

12:00

0010008706-001

7.2 Chimney sweep button (flue gas test)

WARNING:

Risk of scalding from hot water!

Setting the set temperature > 60 °C creates a risk of scalding.

▶ Do not draw off DHW unmixed.

To perform the flue gas test:

▶ Observe the relevant national requirements for limiting flue losses

from the heating system.

The flue gas test is switched on if required at the heat source

( Technical documentation of heat source) or at the control unit.

▶ Ensure heat consumption within the heating system.

▶ Starting from the initial position, hold the key down for several

seconds.

The flue gas test starts immediately.

The parameters for defining the conditions under which the flue gas

test is carried out are shown in the display.

▶ Setting parameters (e.g. modulation).

▶ Tap Save.

The heat source is operated at the set output.

14

Control 8313 – 6720859567 (2017/03)

Page 15

If a preset parameter (e.g. minimum boiler output) is exceeded or

undercut when making the adjustment, a warning message appears that

must be confirmed. The parameter remains at the previous value.

To exit the view:

▶ Tap Cancel.

The flue gas test continues.

3

77

Function keys of the user interface

Emergency operation

The “emergency operation” operating mode is activated automatically if

the user interface is faulty or if communication with the control unit via

the internal BUS is interrupted.

In the “emergency operation” operating mode, the heat source heats

continuously without setback at a boiler temperature of 60 °C. All pumps

connected to the central module (boiler circulation pump, pump of

heating circuit 00, DHW pump and DHW circulation pump) are switched

on.

The SR mixing valve is de-energised and must be adjusted manually if

necessary. The installed function modules cannot be triggered by the

BCT531 user interface and do not work.

The LED status display lights up red in the “emergency operation

”operating mode.

2

Fig. 12 Flue gas test

[1] Save

[2] Cancel

[3] Modulation

The LED status display ( Fig. 11, [4], page 14) lights up yellow during

the flue gas test and is accompanied by a constantly recurring pop-up

window.

To conclude the flue gas test:

▶ Press key again.

If the flue gas test is not ended manually, it ends automatically after

30 minutes.

1

0010009474-001

7.3 Key for manual operation, emergency operation

WARNING:

Risk of scalding from hot water!

Setting the set temperature > 60 °C creates a risk of scalding.

▶ Do not draw off DHW unmixed.

Key for manual operation

Press the key to ensure the “Manual operation” operating mode is

available if e.g. the user interface has failed or the internal control unit

communication has been disrupted. The heat source heats continuously

without setback at a boiler temperature of 60 °C. The pumps and mixers

of the heating circuits, the DHW heating of the central module and the

function modules continue running normally. The LED status display

lights up yellow.

Manual operation

The “manual operation” operating mode can be set and adjusted for

every function separately.

▶ Observe the operating instructions of the control unit.

Control 8313 – 6720859567 (2017/03)

15

Page 16

Commissioning

8 Commissioning

8.1 Notes on commissioning

▶ Ensure there is sufficient heat load available

(e.g. by the DHW heating).

Otherwise the heat source will switch off.

Different messages are displayed according to the application.

8.2 Control unit settings

With this control unit, a number of temperatures are specified by the

SAFe of the heat source.

The temperature values are set or modified via the touch screen.

Long burner run times can be ensured by optimising the settings at the

control. Rapid temperature fluctuations in the heat source are avoided.

Gentle temperature transitions extend the service life of the heating

system.

8.2.1 Setting the control unit address

Each connected control unit must be given a different address if several

control units are networked. A fault is indicated on the display of the user

interface if the same address is allocated more than once.

The address is set [5] at the control unit on the back of the user

interface.

▶ Remove the user interface.

▶ Set the control unit address (e.g. using a screwdriver).

Address Description

0 Stand-alone control unit (default setting):

• The controller operates alone.

Master (lead control unit):

• The master activates the heat source.

• Always connect the outside temperature sensor to the

master.

• The master recognises if an address has been allocated

more than once. A fault is indicated on the display of the

user interface.

• All networked controllers transfer their set values to the

master. The master uses them to generate the overall set

value.

• Only 1 master is permitted in each network!

1...15 Slave (control units subordinate to the master):

• The address 0 must never be assigned to a slave.

• Each address is only allocated once.

Table 4 Control unit addresses

8.2.2 Terminating resistors

The terminating resistors J1 and J2 ( Fig. 13, [6], [7], page 16) are

closed in the delivered condition (activated = inserted). If a network is

established via the BUS connections ( Fig. 13, [2], [3], page 16), the

jumpers must be opened here and closed at the last BUS node.

11

10

9

8

LAN1

LAN2

USB1

+-

J1

3 2 13 2 1

J2

2 1

567

0010005508-001

Fig. 13 Back of the user interface

[1] Slide type insert for SD card

[2] CAN-BUS connection

(no function, provided for subsequent functions)

[3] Modbus-RTU connection for CHP module

[4] EMS connection (connection for EMS heat source

with its own basic control (control panel))

[5] Address setting of control unit

[6] Jumper for activating the Modbus-RTU terminating resistance

[7] Jumper for activating the CAN-BUS terminating resistance

[8] Battery CR2032

[9] Network connection 2 (CBC-BUS)

[10] Network connection 1 (Internet, Modbus TCP/IP, CBC-BUS)

[11] USB connection

1

2

3

4

16

Control 8313 – 6720859567 (2017/03)

Page 17

Menu structure

Chapter 6 from page 11 describes how to operate and call the menus

9 Menu structure

The control unit electronics have 2 levels, in which system-dependent

settings are made. The levels and parameters displayed depend on the

installed modules and the factory defaults. The parameters that are not

required for the selected function are not displayed.

Parameters that are not active are highlighted in grey.

The functions of the most frequently used modules FM-MM, FM-MW and

FM-SI are described in these instructions, in addition to the basic

functions of the control unit.

Main menu Explanation/Function Further information

General

characteristic data

Module selection For selecting whether modules are detected and installed automatically or manually chapter 9.2, page 18

Boiler

characteristics

Heating circuit data Setting of different heating circuit data (e.g. heating circuit system, maximum flow temperature)

Domestic hot water Water treatment settings chapter 18, page 27

Reset Reset values in the main menu and service menu to the default settings. chapter 14, page 37

Version Shows the software versions of the user interface, the control unit and the Open Source information Chapter 2.2, page 5,

Control unit Save or load configurations chapter 20.1, page 44

Connectivity Activation and setting of network connection Chapter 9.6, page 28

Function test Check whether system components (e.g. pumps) are correctly connected.

Lock screen Option for locking the screen. chapter 9.7, page 29

Manual operation When the key is pressed, the heat source operates using stored values. chapter 7.3, page 15

Monitor data Shows set values and actual values of the system. Tap the symbol to display the values in the

Fault Shows the faults in the heating system. The user interface can only display the faults for the

Table 5 Main menu

Settings of the control unit, of heating system parameters and the house properties chapter 9.1, page 18

Setting of different boiler data, depending on heat source

If a FM-SI is installed: settings for the safety equipment.

and display of current heating curves of the relevant heating circuit

The displays depend on which modules are installed. Depending on the operating conditions, there may

be a time delay between the demand and display.

bottom bar.

control unit it is connected to.

with the user interface.

In the following tables, the default settings are highlighted in bold in the

"Settings/Adjustment range" column.

chapter 9.3.1, page 19

chapter 9.4.1, page 21

chapter 9.5, page 27

chapter 15, page 37

Chapter 9.6, page 28

chapter 17, page 43

chapter 19, page 44

chapter 11.3, page 32

Chapter 20.5, page 45

and chapter 20.6,

page 45

Control 8313 – 6720859567 (2017/03)

17

Page 18

Menu structure

9.1 General characteristic data

Submenu Settings/

adjustment

range

Language Selection of language of texts displayed.

Date format Selection of date format

Calendar Entry of date

Time Entry of time

Time Zone Europe/Berlin Regional zone where the same time applies

Europe/London

Europe/Paris

Europe/Moscow

Universal time/

Greenwich Mean

Time

Minimum outdoor

temperature

Building Light Poor heat storage capability, e.g. pre-fabricated

Insulation standard Small No or minimum insulation effect, e.g. house

Outside temperature source ZM The outside temperature sensor is connected to

External heat demand None

Table 6 General characteristic data menu

–30...–10...0 °C The minimum outside temperature is the average

Medium medium heat storage capability,

Heavy High thermal storage capacity,

Medium Medium insulating effect, e.g. house with 10 cm

Good Large insulating effect, e.g. new build or

Control unit 00 The outside temperature sensor is connected to a

Off/On WA1/3 closed = external heat demand on

Temperature Specifies the effect the 0...10 V input (WA1/2) is

Output Specifies the effect the 0...10 V input (WA1/2) is

Explanation Note

▶ For regional average minimum outside

of coldest outside temperature recorded in each

previous year.

▶ Adapt heating system to the construction

houses, wooden-framed constructions

e.g. house built with hollow blocks

e.g. house made of bricks

▶ Adapt heating system to the insulation

without insulation

mineral wool

renovated house with 20 cm mineral wool

The parameter is only displayed with control

this control unit.

different control unit. The sensor values are

transmitted via the BUS.

to have on the system.

to have on the system.

units with address > 0 (e.g. substations).

Chapter 10.3.1, page 31

Chapter 10.3.2, page 31

temperature values, refer to tab. 23

( Chapter 10.1, page 30).

( Chapter 10.2.1, page 30).

situation ( Chapter 10.2.2, page 30).

9.2 Module selection

When the control unit is switched on or after a reset, the modules are

automatically recognised and their information downloaded.

If the modules are not recognised automatically:

▶ Set the modules manually.

Submenu Settings/adjustment range Explanation Note

Slot A ZM5313 Automatic recognition and

installation of the modules for slot A

Slot 1...4 None Slots for function modules and

Module selection The installed modules can be

selected from a list.

Table 7 Module selection menu

18

Slot for boiler module

auxiliary modules

Control 8313 – 6720859567 (2017/03)

Page 19

9.3 Boiler parameters

9.3.1 Basic boiler settings

Depending on which boiler type and burner type have been chosen,

special setting options will be displayed.

Menu structure

Submenu Settings/adjustment

Explanation Note

range

Boiler type None No boiler available. Control is used as standalone

master control unit with address 0 or as

substation.

SAFe The parameters of the SAFe are adopted by the

heat source. A boiler control is not installed in the

heat source.

EMS The parameters of the boiler control the SAFe are

adopted by the heat source in the control unit.

Hydraulic Boiler The heating circuit on the central module is used

as boiler circuit.

Heating circuit The heating circuit on the central module is used

as boiler circuit (00).

Sensor Heat source

(low loss header)

Heating circuit (Flow)

Boiler circulation pump No/Yes Setting that specifies whether a boiler circulation

pump is installed.

Modulating pump No/Yes Setting that specifies the conditions according to

which the pump is controlled

Pump control mode In accordance with

boiler operating

conditions

Off/On Setting that determines whether the modulating

pump is to be switched on and off via a 0....10 V

signal.

According to output ▶ Observe pump manufacturer's

Temperature difference

between boiler and low

loss header

Pump overrun time for

lead boiler

According to

temperature difference

1...4...10 K Setting of the temperature differential between

0...60...120 Min To utilise the heat stored in the heat source to the

Setting that specifies the conditions according to

which the pump is controlled

temperature sensor in the system flow (FZ) and

boiler water temperature sensor.

maximum possible extent, a time must be

specified for which the pump should continue to

operate after the burner has been shut down.

Pump overrun time for

slave boiler

0...60...120 min To utilise the heat stored in the heat source to the

maximum possible extent, a time must be

specified for which the pump should continue to

operate after the burner has been shut down.

Voltage for min. flow

temp

Voltage for max. flow

temp

Boiler temperature

increase at low loss

header

0...10 V Specifies the voltage at which the minimum flow

rate occurs.

0...10 V Specifies the voltage at which the maximum flow

rate occurs.

No/Yes 5 K is added to the desired set value for the boiler

temperature, so that the set value can be reached

quickly and safely.

Standalone as master control unit with address

0. Substation as control unit with address >0

Note selection at menu item Hydraulic.

( Chapter 5, page 8 and chapter 11.2,

page 32)

Note selection at menu item Sensor.

Attention: the SI and external interlock terminal

must be opened!

( Chapter 5, page 8 and chapter 11.2,

page 32)

Boiler/heating circuit 00 with the terminals PK,

SR, FZ ( Chapter 9.4, page 21)

Chapter 11.1.1, page 32

The control operates within the limits specified

by the SAFe, e.g. maximum boiler temperature.

Digital activation of modulating pump.

Activation: On = 10 V, Off = 0 V

Prerequisite: continuous external power supply

to pump.

specifications.

Change the factory setting only in exceptional

cases.

Change the factory setting only in exceptional

cases.

Observe pump manufacturer's specifications.

Observe pump manufacturer's specifications.

Control 8313 – 6720859567 (2017/03)

19

Page 20

Menu structure

Submenu Settings/adjustment

Explanation Note

range

External Heat Detection No/Yes Once sufficient heat to supply the system has

built up at sensor FZ, the heat source is

The temperature sensor FZ is in the low loss

header or buffer cylinder.

prevented from starting. If the system set value is

undercut by 4 K, the heat source is started.

Maximum shutdown

temperature

30...85...99 °C The burner is switched off once the heating flow

temperature reaches the maximum cut-off

temperature at the latest.

The maximum possible cut-off temperature is

specified by the SAFe of the connected heat

source.

Change the factory setting only in exceptional

cases. The value can only be reduced.

Chapter 11.2, page 32

Maximum boiler output 0...100 % Limiting the performance of the heat source This function is active in heating and DHW

mode.

Cycle deactivation 0...10...60 min Setting the blocking time between switching off

the heat source and switching it back on

This function is active in heating and DHW

mode.

Negative hysteresis -30...-4...0 K Setting that specifies when the set value is

undercut what the difference in temperature

should be before heat production starts

Positive hysteresis 0...2...15 K Setting that specifies when the set value is

exceeded what the difference in temperature

should be before heat production ends

Max. Air Correction -9...0...9 Matching the fan speed The function depends on the heat source.

Min. Air Correction -9...0...9 Matching the fan speed The function depends on the heat source.

Service display None

After hours Maintenance according to hours run

(only in control units with direct activation of

heat source)

Next maintenance Setting the number of hours until maintenance is

next due

Burner run time since

last maintenance

Number of hours that have elapsed since

maintenance was last carried out.

• The service display is recorded in the fault

history can be displayed via the building

services management system.

• The status of the service display can be

requested in the fault history.

• The service display can be reset in the Reset

menu.

Date Service display set according to date: entry of

next maintenance deadline

Table 8 Boiler characteristics menu

9.3.2 Settings of the safety equipment

Submenu Settings/adjustment

Explanation Note

range

FM-SI1...FM-SI5 Free/Allocated Inputs for fault displays Only if a FM-SI is installed. Inputs must be

activated ( Chapter 6.7, page 13 and

chapter 11.3, page 32).

Max. pressure 1 Selection of a name for the connected safety

Max. pressure 2

equipment or entry of an individual name

Min-PressWMS

Neutralisation

STB 2 safe.

Max-pressure1/2 = maximum pressure

limiter 1 or 2

This must be connected to input SI1 when using

a condensate neutraliser.

Unallocated inputs of the safety chain module

must be jumpered.

Min-pr.WMS = minimum pressure limiter

or low water indicator

STB2 Safety = 2nd safety temperature limiter

Table 9 Safety equipment settings

20

Control 8313 – 6720859567 (2017/03)

Page 21

Menu structure

9.4 Heating circuit data

The heating circuit on the central module (PK, SR, FZ) can be used either

as a heating circuit with mixer or as a boiler circuit. If a system

component is used in a function, the other system components can no

longer be used for the other function.

Example: if SR is used as the mixing valve for the boiler circuit, PK cannot

be used for a heating circuit without mixer.

When used as a heating circuit, this is displayed as heating circuit 00.

Display of heating circuits

The designation assigned to the heating circuits depends on the slot of

the heating circuit module. The heating circuits are numbered according

to the sequence of slots. This means that the heating circuits at slot 1 are

displayed as heating circuit 01 and 02. The heating circuits at slot 2 are

displayed as 03 and 04. If a different module is inserted at a slot, these

heating circuit numbers are omitted.

If a name has been assigned to the heating circuit, this is displayed.

Only the heating circuits that are available via modules are displayed.

The heating circuit symbols turn grey if heating circuits are available but

not active. If heating circuits are available and active, the heating circuit

symbols are displayed normally in white.

9.4.1 Basic setting

Submenu Settings/

Explanation Note

adjustment range

Heating circuit Off/On

Heating circuit name Heating circuit

name

You can choose the name of the heating circuit

from a list or give it your own name.

• Basement

• Apartment

• Swimming pool

• Building

• Underfloor

Heating

• Floor

Heating system Radiator/

Underfloor

The type of heating system determines the

gradient or curvature of the heating curve.

Heating

Constant

Base Point

Room

Damping influence of outdoor

temperature

0...100 % Setting that determines the extent to which the

adjusted outside temperature affects the

control parameter.

Remote Control No/Yes Determines whether a remote control is

installed for the heating circuit that influences

the heating circuit.

Underfloor Heating Off/On

Maximum underfloor flow

temperature

20...45...60 °C This value specifies the temperature above

which the flow temperature must not rise.

Maximum flow temperature 30...75...120 °C This value specifies the temperature above

which the flow temperature must not rise.

Minimum flow temperature 5...70 °C Limiting the heating curve to a minimum set

value

This value sets the temperature below which

the flow temperature must not drop.

Actuator No/Yes Information as to whether or not the system is

equipped with a heating circuit mixing valve

Chapter, 12, page 33

Chapter, 12, page 33

Chapter 12.1.1, page 33

The value set influences the heating curve.

The maximum flow temperature depends on the

heat source and is therefore limited by the heat

source.

This parameter cannot be adjusted with the

Constant heating system.

▶ Only change value if necessary.

If the heating circuit is equipped with a heating

circuit mixing valve, this is activated by the

control unit.

The heating circuit is regulated via the flow

temperature of the heat source if no heating

circuit mixing valve is installed. No heating circuit

mixing valve is entered for heating circuit 00.

Control 8313 – 6720859567 (2017/03)

21

Page 22

Menu structure

Submenu Settings/

Explanation Note

adjustment range

Actuator runtime 5...120...600 s Setting the runtime of the available mixing

valves

Generally, servomotors have a runtime of

120 s.

Boiler temperature increase 0...5...20 K The flow temperature for the heating circuit is

obtained by adding the increase in boiler

temperature to the calculated/required flow

temperature.

DHW priority No/Yes The pumps of all heating circuits are switched

off during the water heating phase.

Pump blocking protection Off/On Setting that determines whether or not a pump/

mixer is to be regularly switched on for short

periods to prevent it from seizing up during

extended downtimes.

Overrun time 0...2...60 min Setting that determines how many minutes a

pump should remain switched on once the

switch-on condition no longer exists.

Third party WF control

settings

None Switching the operating mode of the heating

Heating mode/

Setback mode

circuit via an external contact (connecting

terminal WF) at the FM-MM and FM-MW module

WF1/2

Heating mode/

Setback mode/

Automatic

WF1/2/3

External fault

Display of faults for a pump Not available with the connections of the

display for pump

WF1/2

External fault

display for pump

Display of faults for a pump via 1/2 and external

changeover via 1/3.

WF1/2 and

External fault

display for pump

WF1/2 and

external heating/

setback mode

WF1/3 WF1/3

Table 10 Basic settings of heating circuits

If the mixing valve constantly oscillates, the

control characteristics can be slowed down by

reducing the operating time of the mixing valve.

If a heating circuit is controlled with a mixing

valve, a higher set value should be set for the heat

source than the normal set value for the heating

circuit.

In heating circuits with mixer, the mixing valve is

moved in the “close” direction (colder).

Not available with the connections of the

boiler circuit.

Chapter 12.1.2, page 33

boiler circuit.

22

Control 8313 – 6720859567 (2017/03)

Page 23

Menu structure

9.4.2 Heating curve, operating mode

Individual settings can be made for each operating mode separately in

every heating curve.

Heating curve

The heating curve set refers to the Heating system selected under the

menu item Heating circuit data > Basic setting. The settings can be

made in a table or a graphic representation ( Chapter 12.3, page 35).

The following heating curves can be set:

• Constant

• Base Point

• Radiator/Underfloor Heating

• Room

Operating modes

You can set the following operating modes for each heating curve

separately:

• Automatic heating mode

• Automatic setback mode

• Manual heating mode

• Manual setback mode

• Holiday

Temperature settings for the operating modes of the Constant heating curve in the Automatic heating mode operating mode:

Submenu Settings/

Explanation Note

adjustment range

Set flow temperature 10...75...120 °C Constant:

Controlling of a swimming pool heating system

or pre-controlling of ventilation circuits if the

With the Constant heating system, a remote

control cannot be connected for this heating

circuit.

heating must always provide the same set flow

temperature, independent of the outside

temperature.

Standby mode No/Yes The heating circuit or this function is switched

off.

Heating Limit (Summer from /

Outdoor Setback)

No/Yes Selection that determines whether the heating

circuit or a function is to be switched off once a

The heating circuit is switched off

(summer mode) when the setting is Yes.

The heating circuit is switched off from a set

outside temperature.

set outside temperature has been reached.

-50...17...50 °C The heating circuit is switched off when the set

outside temperature is exceeded and switched

back on when it is undercut.

Manual setback mode Shortcut keys If you tap a shortcut key, the display jumps to

Automatic heating mode

Automatic setback mode

the settings area of the selected operating

mode.

You can make separate settings for each

operating mode. For the settings of the setback

types, refer to Chapter 12.1.2, page 33.

Holiday

Table 11 Settings for the operating modes of the Constant heating curve

Temperature settings for the operating modes of the Base Point heating curve in the Automatic heating mode operating mode:

Submenu Settings/

Explanation Note

adjustment range

Outdoor Temperature 1 -50...20...50 °C Initial temperature of the heating curve.

Outdoor Temperature 2 -50...-10...50 °C

Reference temperature for the design of the

heating curve.

Flow temperature setpoint 1 0...45...80 °C Flow temperature for operation with Outdoor

Temperature 1.

Flow temperature setpoint 2 0...80 °C Flow temperature for operation with Outdoor

Temperature 2.

Room temperature setpoint 5...21...50 °C Setting of the required room temperature:

Room influence /

maintenance

None Limits the influence of the room temperature

According to offset

Maximum / room

maintenance

mode

(room temperature hook-up) on the flow

temperature set value. The value specifies the

highest possible room temperature setback.

This also applies for rooms which are also

supplied by the heating circuit and where no

remote control units are installed.

Room temperature offset –5...0...5 °C Adjustment of the temperature differentials

between the actual and set temperature

This adjustment effects a parallel displacement

of the heating curve.

The set Flow temperature setpoint 1 is not

undercut. This temperature ensures that the

minimum boiler temperature is maintained.

Setting under: Heating curve > Outdoor

temperature

Requirements for the setting:

• A Remote Control is selected.

• Room heating system is not selected.

Ensure that the remote control is not exposed to

heat (e.g. lamps, TV sets or other heat sources).

This setting is only recommended if no remote

control has been installed inside the living space.

Chapter 12.1.3, page 33

Control 8313 – 6720859567 (2017/03)

23

Page 24

Menu structure

Submenu Settings/

Explanation Note

adjustment range

Standby mode No/Yes The heating circuit or this function is

switched off.

Heating Limit (Summer from /

Outdoor Setback)

No/Yes Selection that determines whether the heating

circuit or a function is to be switched off once a

The heating circuit is switched off

(summer mode) when the setting is Yes.

The heating circuit is switched off from a set

outside temperature.

set outside temperature has been reached.

-50...17...50 °C The heating circuit is switched off when the set

outside temperature is exceeded and switched

back on when it is undercut.