Page 1

6720871579 (2018/07) IE/UK

Operating instructions for users

Gas condensing boiler

Condens 7000 F

GC7000F 75...300

Page 2

Table of contents

Condens 7000 F – 6720871579 (2018/07)

2

Table of contents

1 Explanation of symbols and safety instructions . . . . . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 3

2 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Product data for energy consumption. . . . . . . . . . . . . . . 5

2.3 Water quality (fill and top-up water) . . . . . . . . . . . . . . . . 5

2.4 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.2 The heating system is operated and monitored via

App or Web Portal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Product description of optional control units . . . . . . . . . . . . . 7

3.1 Product description of optional control units. . . . . . . . . 7

3.2 Switching on the boiler at the control unit . . . . . . . . . . . 7

4 MX25 control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 MX25 control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Overview of control elements . . . . . . . . . . . . . . . . . . . . . 9

4.3 Switching on the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 Switching the heating on or off . . . . . . . . . . . . . . . . . . . . 9

5 CC8313 control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.1 Control elements of the control unit and the user

interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Function buttons and system status . . . . . . . . . . . . . . .10

5.2.1 ResetReset key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2.2 Flue gas inspector key (flue gas test) . . . . . . . . . . . . . . 11

5.2.3 Key for manual operation, emergency operation . . . . . 11

5.3 Operating and display elements of the touch

screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.4 Operating the appliance . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4.1 Control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4.2 Switch on and enable control unit. . . . . . . . . . . . . . . . . 13

5.4.3 Lock screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4.4 Calling up menu levels or functions. . . . . . . . . . . . . . . . 13

5.4.5 Calling up submenus . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4.6 Information menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Checking the operating pressure, topping up the

heating water and venting the system. . . . . . . . . . . . . . 15

6.1.1 Checking the operating pressure . . . . . . . . . . . . . . . . .15

6.1.2 Topping up the heating water and venting the

system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.2 Switching on the heating system. . . . . . . . . . . . . . . . . .15

7 Shutting down the heating system . . . . . . . . . . . . . . . . . . . . . 15

7.1 Shutting down the heating system via the control

unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.2 Shutting down the heating system in an

emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Environmental protection/disposal. . . . . . . . . . . . . . . . . . . . . 16

9 Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.1 What makes regular service important? . . . . . . . . . . . .16

9.2 Cleaning and care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.1 Recognising the operating condition and clearing

faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page 3

Explanation of symbols and safety instructions

3

Condens 7000 F – 6720871579 (2018/07)

1 Explanation of symbols and safety instructions

1.1 Explanation of symbols

Warnings

In warnings, signal words at the beginning of a warning are used to

indicate the type and seriousness of the ensuing risk if measures for

minimising danger are not taken.

The following signal words are defined and can be used in this document:

DANGER:

DANGER indicates that severe or life-threatening personal injury will

occur.

WARNING:

WARNING indicates that severe to life-threatening personal injury may

occur.

CAUTION:

CAUTION indicates that minor to medium personal injury may occur.

NOTICE:

NOTICE indicates that material damage may occur.

Important information

The info symbol indicates important information where there is no risk to

people or property.

Additional symbols

Table 1

1.2 General safety instructions

H Instructions for the target group

These operating instructions are intended for the

heating system user.

All instructions must be observed. Failure to comply

with instructions may result in material damage and

personal injury, including possible loss of life.

▶ Read and retain the operating instructions (heat

source, heating controller, etc.) prior to operation.

▶ Observe the safety instructions and warnings.

H Safety of electrical devices for domestic use

and similar purposes

The following requirements apply in accordance with

EN 60335-1 in order to prevent hazards from

occurring when using electrical appliances:

“This appliance can be used by children of 8 years and

older, as well as by people with reduced physical,

sensory or mental capabilities or lacking in experience

and knowledge, if they are supervised and have been

given instruction in the safe use of the appliance and

understand the resulting dangers. Children shall not

play with the appliance. Cleaning and user

maintenance must not be performed by children

without supervision.”

“If the power cable is damaged, it must be replaced by

the manufacturer, its customer service department or

a similarly qualified person, so that risks are avoided.”

H Danger through failure to consider your own

safety in an emergency such as a fire

▶ Never put yourself at risk of fatal injury. Your own

safety is paramount.

H If you smell gas

▶ Close gas isolator.

▶ Open windows and doors

▶ Never operate electrical switches, including

telephones, plugs or doorbells.

▶ Extinguish any naked flames. Do not smoke! Never

use any lighters or sources of ignition of any kind!

▶ Warn all occupants in the building, but do not ring

doorbells.

▶ If you can actually hear gas escaping, leave the

building immediately. Prevent third parties from

entering and notify police and fire brigade from

outside the building.

▶ From outside the building, call your gas supplier

and licensed contractor.

H Danger if you smell flue gas

▶ Switch off the boiler.

▶ Open windows and doors.

▶ Notify an approved contractor.

H Installation and conversion

▶ Correct and proper installation and adjustment of

the burner and the control unit are the fundamental

requirements for safe and economical operation of

the floor standing boiler.

▶ Only permit an authorised contractor to install the

boiler.

▶ Never modify any parts for flue gas routing.

Symbol Meaning

▶ a step in an action sequence

a reference to a related part in the document

• a list entry

– a list entry (second level)

Page 4

Explanation of symbols and safety instructions

Condens 7000 F – 6720871579 (2018/07)

4

▶ Electrical work must only be carried out by qualified

electricians.

▶ With open-flue mode: do not cover or reduce the

size of ventilation apertures in doors, windows or

walls. If draught-proof windows are fitted, ensure

there is an adequate supply of combustion air.

▶ Use the DHW cylinder exclusively for heating hot

water.

▶ Never shut off pressure relief valves!

Water may be expelled at the pressure relief valve of

the heating circuit and DHW pipework during heatup.

H Inspection/maintenance

Heating systems must be regularly maintained.

In that way, you will obtain a high level of efficiency and

low fuel consumption.

You will achieve a high level of operational safety and

reliability.

And you will obtain the cleanest possible combustion.

▶ Recommendation for customers: arrange a

maintenance and inspection contract with an

authorised contractor, covering an annual

inspection and demand-dependent maintenance.

▶ Maintenance and repairs may only be carried out by

an authorised contractor.

▶ Have any faults immediately rectified to prevent

damage to the system.

▶ The user is responsible for ensuring the heating

system is safe and environmentally compatible.

▶ Only use genuine spare parts! Damage caused by

the use of spare parts not supplied by Bosch is not

covered by the warranty.

H Danger posed by explosive and easily

flammable materials

▶ Any work on components that carry gas may only be

carried out by an approved contractor.

▶ Never use or store easily flammable materials

(paper, thinners, paints etc.) near the boiler.

H Danger of poisoning

Insufficient ventilation can lead to dangerous flue gas

leaks.

▶ Ensure that ventilation or extract air apertures are

not reduced or closed.

▶ Faults should be rectified without delay, otherwise

the boiler must not be operated.

▶ If flue gas enters the installation location, ventilate

and vacate the area and if necessary call the fire

brigade.

▶ Inform the system user in writing of the problem and

associated danger.

H Danger of water damage

▶ In the event of severe risk of flooding, shut down the

power and fuel supply to the device before water

enters the installation location.

▶ Never use the device if any part of it has been under

water.

▶ Immediately get in touch with a qualified service

technician to have the device inspected and have

any part of the control system and any air/gas ratio

control valves that have been under water replaced.

H Combustion air/ambient air

The air in the installation location must be free of

flammable or chemically aggressive substances.

▶ Do not store or use any corrosive substances

(solvents, adhesives, chlorinated cleaning agents,

etc.) within the vicinity of the heat source.

▶ Avoid very dusty atmospheres.

H Risk of damage from operating errors

Operator errors can result in personal injury and/or

material damage.

▶ Ensure that children never operate this appliance

unsupervised or play with it.

▶ Ensure that only personnel who can operate this

appliance correctly have access to it.

H Additional important notes

▶ Never switch off or interrupt the power supply to

the pump in case of overheating or if the gas supply

does not shut down. Instead, interrupt the gas

supply at another point outside the heating system.

▶ The flue system must be checked annually. During

this inspection, have a contractor replace any parts

that show signs of damage through corrosion or

other causes.

▶ The boiler must be serviced annually by a qualified

service provider. The inspection must include the

main burner, the entire flue gas and air supply

system and the ventilation apertures or air inlet

openings. During this inspection, have a contractor

replace any parts that show signs of damage

through corrosion or other causes.

Page 5

Product Information

5

Condens 7000 F – 6720871579 (2018/07)

2 Product Information

To ensure safe, economical and environmentally responsible use of the

heating system, we recommend that you read the safety instructions and

operating instructions carefully.

These instructions provide the operator of the heating system with an

overview of the use and operation of the boiler.

2.1 Declaration of Conformity

The design and operation of this product conform to European Directives

and the supplementary national requirements. Its conformity is

demonstrated by the CE designation.

You can view the Declaration of Conformity on the internet

( back cover).

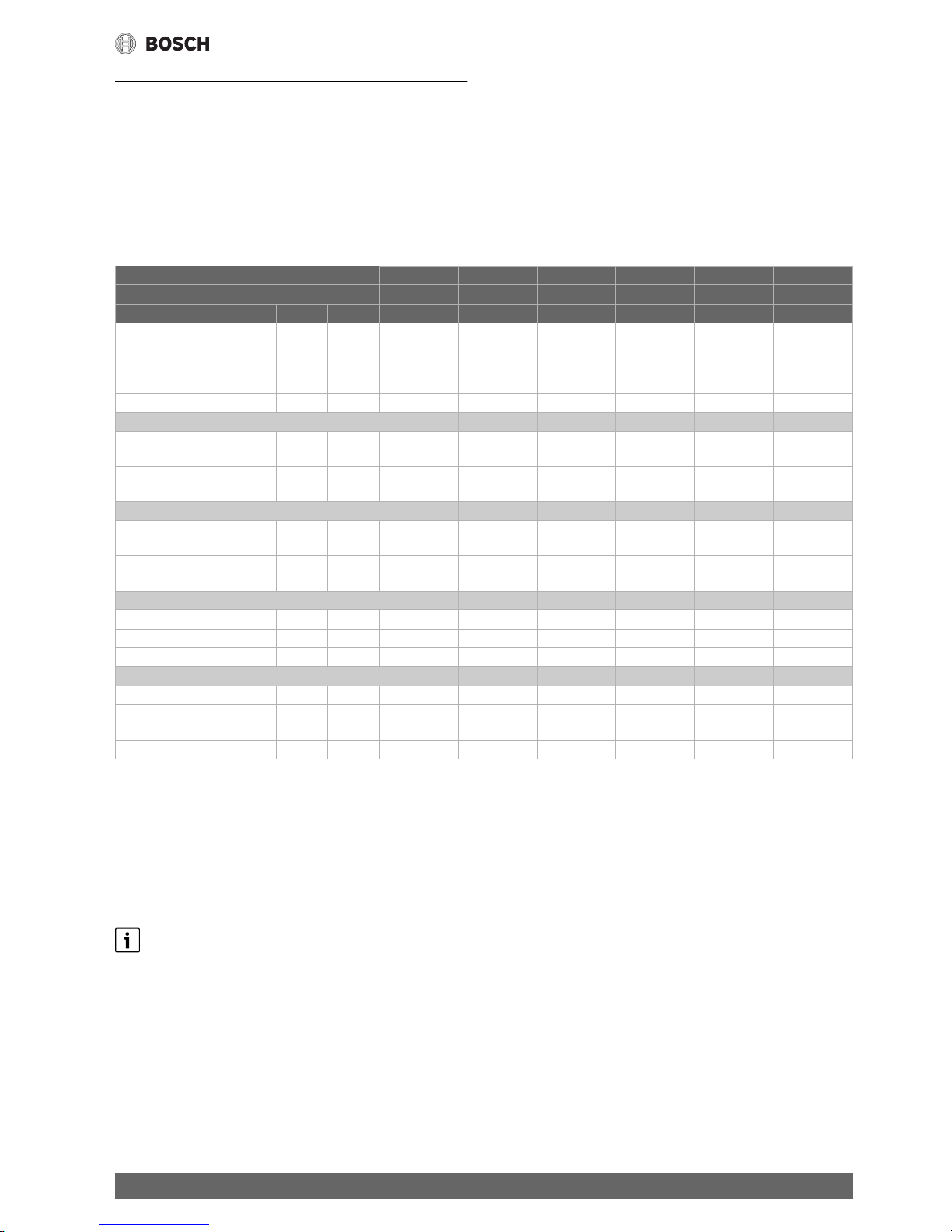

2.2 Product data for energy consumption

The following product data satisfy the requirements of the EU Regulations No. 811/2013, No. 812/2013, No. 813/2013 and No. 814/2013

supplementing Directive 2010/30/EU.

Table 2 Product data for energy consumption

2.3 Water quality (fill and top-up water)

▶ For information regarding the water quality, see the enclosed

operator's log "Water quality requirements for heat sources made

from aluminium".

Do not use softened water as fill and top-up water.

2.4 Product overview

The Condens 7000 F is a floor standing condensing boiler with an

aluminium heat exchanger.

Right-hand version 8732909990 8732909991 8732909992 8732909993 8732909994 8732909995

Left-hand version 8732909996 8732909997 8732909998 8732909999 8732910000 8732910001

Product data Symbol Unit

Product type – – Condens

7000 F-75

Condens

7000 F-100

Condens

7000 F-150

Condens

7000 F-200

Condens

7000 F-250

Condens

7000 F-300

Floor standing condensing

boiler

– – Yes Yes Yes Yes Yes Yes

Nominal heat output P

rated

kW 69 93 140 186 233 280

Available heat output

At rated output and hightemperature operation

1)

1) High temperature operation means a return temperature of 60 °C at the boiler inlet, and a flow temperature of 80 °C at the boiler outlet.

P

4

kW 69.4 93.0 139.8 186.2 233.1 280.0

At 30 % of rated output and

low-temperature operation

2)

2) Low temperature operation means a return temperature (at the boiler inlet) of 30 °C for floor standing condensing boilers, of 37 °C for floor standing boilers,

and 50 °C for other boilers

P

1

kW 23.1 31.0 46.5 62.1 77.7 93.0

Useful efficiency

At rated output and hightemperature operation

1)

4

% 88.3 88.1 88.1 88.3 88.2 88.3

At 30 % of rated output and

low-temperature operation

2)

1

% 97.8 98.0 97.7 98.1 98.0 97.7

Auxiliary power consumption

At full load el

max

kW 0.083 0.156 0.250 0.234 0.298 0.336

At part load el

min

kW 0.028 0.032 0.046 0.048 0.049 0.057

In standby mode P

SB

kW 0.009 0.009 0.009 0.009 0.009 0.009

Other data

Standby heat loss P

stby

kW 0.161 0.161 0.183 0.247 0.261 0.298

Energy consumption of the

ignition flame

P

ign

kW – – – – – –

NOx emissions NOx mg/kWh 41 49 34 36 32 36

Page 6

Product Information

Condens 7000 F – 6720871579 (2018/07)

6

2.4.1 Product Description

The main Condens 7000 F components are:

• Control unit

• Boiler block

• Appliance frame and casing

• Gas burner

The control unit monitors and controls all electrical boiler components.

The boiler block transfers the heat generated by the burner to the

heating water. The thermal insulation reduces the radiation and standby

losses.

The control unit enables the standard operation of the heating system.

For this, it makes the following functions available, including:

• Switching the heating system on/off

• Setting the DHW temperature and the maximum boiler temperature

in heating mode

• Status display

This floor standing boiler can be operating via the CC 8313 or MX25

control unit.

Many additional functions that enhance control and operating

convenience as well as information on the heating system settings are

described in the corresponding Technical documentation of the

installed control unit.

Fig. 1 Condens 7000 F, 75...100 kW main components (shown: right-hand version; cleaning cover and flow and return are located on the right)

[1] Boiler front panel (2-part)

[2] Gas valve

[3] Gas burner with burner rod

[4] Control unit CC 8313 (optional)

[5] MX25 control unit (optional)

[6] Boiler block with thermal insulation

[7] Boiler casing

[8] Condensation catch pan and siphon

[9] Bottom panel

[10] Burner control unit

0010014182-001

6

7

4

5

3

2

1

810 9

Page 7

Product description of optional control units

7

Condens 7000 F – 6720871579 (2018/07)

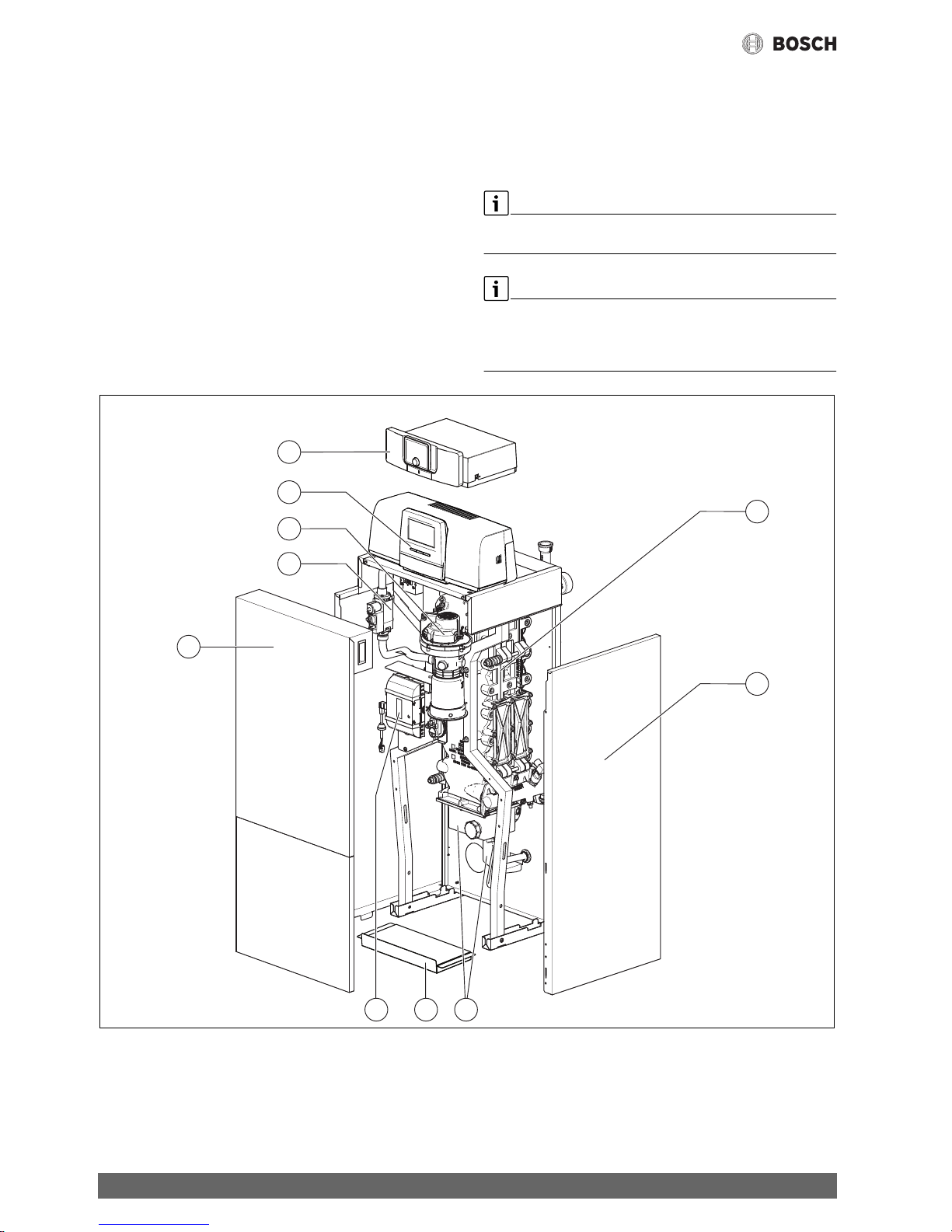

Fig. 2 Condens 7000 F, 150...300 kW main components (shown: right-hand version; cleaning cover and flow and return are located on the right)

[1] Boiler front panel (2-part)

[2] Gas valve

[3] Gas burner with burner rod

[4] Control unit CC 8313 (optional)

[5] MX25 control unit (optional)

[6] Boiler block with thermal insulation

[7] Boiler casing

[8] Condensation catch pan and siphon

[9] Bottom panel

[10] Burner control unit

The right-hand versions of the boiler are shown. In this case the cleaning

cover and the flow and return are located on the right.

In the left-hand version, the cleaning cover and flow and return are

located on the left.

2.4.2 The heating system is operated and monitored via App

or Web Portal

We offer, in combination with the relevant control unit, a comprehensive

range of products for monitoring, diagnosis and control of the floor

standing boiler via mobile terminal devices, PC or tablet.

3 Product description of optional control units

3.1 Product description of optional control units

The Condens 7000 F is equipped with a control unit that was assigned

when ordering.

A brief description of the optional control units follows. Additional

functions that enhance control and operating convenience as well as

information on the heating system settings are described in the

corresponding Technical documentation of the installed control unit.

3.2 Switching on the boiler at the control unit

▶ To commission the control unit, observe the technical

documentation for the specific control unit.

To avoid frequent cycling of the burner and to ensure efficient operation,

the heating curve should generally be set as low as possible.

0010014184-001

9

6

7

4

5

3

2

1

810

Page 8

MX25 control unit

Condens 7000 F – 6720871579 (2018/07)

8

4 MX25 control unit

4.1 MX25 control unit

Fig. 3 Control unit MX25 with user interface – control elements

[1] Main power switch

[2] Appliance fuse 6.3 A

[3] fav key (favourites functions)

[4] man key (manual operation)

[5] auto key (automatic mode)

[6] menu key (to call up menus)

[7] info key (info menu and help)

[8] Back key

[9] Network connection

(RJ45, only available with IP inside control units)

[10] Selector

[11] Flue gas inspector, reset and emergency operation key

[12] Status-LED

[13] Service key connection

The MX25 control unit enables the standard operation of the

heating system.

The following functions are available for this:

• Activation of chimney sweep mode

• Status displays for boiler and burner operation

• Reset of locking faults

• Activation of emergency operation (manual operation)

The user interface offers many additional functions for conveniently

controlling the heating system via the CW 400/CW 800 user interface or

the CR 100 and CR 10 (available separately).

0010004473-002

1 543 8

11 10

9

13 12

762

Page 9

MX25 control unit

9

Condens 7000 F – 6720871579 (2018/07)

4.2 Overview of control elements

If the display lighting is off, pressing any control element for the first time

activates the lighting only. The descriptions of the steps to be carried out

by the operator in these instructions always assume that the lighting is

activated. If no control element is actuated, the lighting turns off

automatically.

Fig. 4 Control elements

[1] fav key – Press briefly to call up and hold pressed to configure

favourites functions

[2] man key – Press briefly to activate manual operation

and hold pressed to set duration for manual operation

[3] auto key – Activate automatic mode

[4] menu key – Press briefly to open the main menu

and hold pressed to open the service menu

[5] info key – Displays the info menu for information

about the current selection

[6] Back key – Returns to previous menu or discards a value

(press briefly); returns to the standard display (hold down)

[7] Control knob – Selects (turn) and Confirms (press)

4.3 Switching on the boiler

▶ Switching on the boiler at the ON/OFF switch [1].

The display lights up and shows the appliance temperature after a

short time.

Fig. 5 Main power switch

[1] Main power switch

4.4 Switching the heating on or off

NOTICE:

Risk of damage to the system from frost!

When heating mode is switched off and in summer mode, only device

frost protection exists.

▶ Observe the need for frost protection if there is a risk of frost.

▶ Open Main menu.

▶ Select and confirm the Heat source menu.

▶ Select and confirm Heating.

▶ Select and confirm On or Off.

Fig. 6 Switching heating on

▶ To select manual summer mode, go to the menu Main menu >

Heating > Sum./wint. changeover and select the setting Sum./

wint. changeover under the menu item Permanently summer.

The heating is off and DHW heating is active in summer mode.

For more information on summer mode see the technical

documentation of the user interface.

0010005432-001

auto

man

fav

menu

info

5

6

7

4

2

3

1

0010004475-001

1

0010005615-001

Page 10

CC8313 control unit

Condens 7000 F – 6720871579 (2018/07)

10

5 CC8313 control unit

5.1 Control elements of the control unit and the user interface

Fig. 7 Control elements

[1] Touch screen

[2] Activation Code (registration code)

[3] Reset button (e.g. high limit safety cut-out, SAFe)

[4] Flue gas inspector key (for flue gas test)

[5] Manual operation key

[6] USB interface (e.g. for service purposes)

[7] LED status display

[8] Type plate

[9] F1-, F2 circuit breaker

[10] Appliance on/off switch

5.2 Function buttons and system status

Function buttons

The function buttons enable

• Manual operation

• Flue gas test

• Reset (e.g. high limit safety cut-out, SAFe)

System status, function status, component status

The status of the system, the functions and system components is

displayed via the Function status display ( Fig. 9, [1], page 12), the

System components status display ( Fig. 9, [15], page 12) and the

LED status display ( Fig. 7, [7], page 10):

• Green = system in automatic mode

• Yellow = system in manual mode, Flue gas testFlue gas test,

Service displayService display or Blocking faultBlocking fault

SAFe

• Yellow flashing = Control unit couplingControl unit coupling

• Red = FaultFault

5.2.1 ResetReset key

When the key is pressed the locking fault is unlocked and the

functions are reset (e.g. following triggering of the high limit safety

cut-out or resetting of the SAFe).

To unlock a function:

▶ Key Hold down for 2 seconds.

0010005509-001

1

3 26 45

7

9

10

8

reset

rese

t

rese

t

rese

t

Page 11

CC8313 control unit

11

Condens 7000 F – 6720871579 (2018/07)

5.2.2 Flue gas inspector key (flue gas test)

WARNING:

Risk of scalding from hot water!

Setting the set temperature > 60 °C creates a risk of scalding.

▶ Do not draw off DHW unmixed.

To perform the flue gas test:

▶ Observe the relevant national requirements for limiting flue losses

from the heating system.

The flue gas test is switched on if required at the heat source

( Technical documentation of heat source) or at the control unit.

▶ Ensure heat consumption within the heating system.

▶ Starting from the initial position, hold the key down for several

seconds.

The flue gas test starts immediately.

The parameters for defining the conditions under which the flue gas

test is carried out are shown in the display.

▶ Setting parameters (e.g. modulation).

▶ Tap Save.

The heat source is operated at the set output.

If a preset parameter (e.g. minimum boiler output) is exceeded or

undercut when making the adjustment, a warning message appears that

must be confirmed. The parameter remains at the previous value.

To exit the view:

▶ Tap cancel.

The flue gas test continues.

Fig. 8 Flue gas test

[1] Save

[2] Cancel

[3] Modulation

The LED status display ( Fig. 7, [7], page 10) lights up yellow during

the flue gas test and is accompanied by a constantly recurring pop-up

window.

To conclude the flue gas test:

▶ Press key again.

If the flue gas test is not ended manually, it ends automatically after 30

minutes.

5.2.3 Key for manual operation, emergency operation

WARNING:

Risk of scalding from hot water!

Setting the set temperature > 60 °C creates a risk of scalding.

▶ Do not draw off DHW unmixed.

Key for manual operation

Press the key to ensure a manual operation if, for example, the user

interface has dropped out or the internal controller communication is

disrupted. The heat source heats continuously without setback at a

boiler temperature of 60 °C. The pumps and mixers of the heating

circuits, the DHW heating of the central module and the function

modules continue running normally. The LED status display lights up

yellow.

Manual operation

The manual operation operating mode can be set and adjusted for every

function separately.

▶ Observe the operating instructions of the control unit.

Emergency mode

The emergency operation is activated automatically if the user

interface is faulty or if communication with the control unit via the

internal BUS is interrupted.

During emergency operation, the heat source heats continuously

without setback at a boiler temperature of 60 °C. All pumps connected to

the central module (boiler circulation pump, pump of heating circuit 00,

DHW pump and DHW circulation pump) are switched on.

The SR mixing valve is de-energised and must be adjusted manually if

necessary. The installed function modules cannot be triggered by the

user interface BCT531 and do not work.

In emergency operation the LED status display lights up red.

5.3 Operating and display elements of the touch screen

The display and selectability of the menu items depends on which

modules are inserted and which settings have been made.

The following displays can be called up via the touch screen:

• Heat source in the system

• Heat consumers and heat distributors in the system

• Monitor data

• Setting parameters for commissioning and system optimisation.

These parameters are protected by a key code.

0010009474-001

77

3

2

1

Page 12

CC8313 control unit

Condens 7000 F – 6720871579 (2018/07)

12

Fig. 9 Operating and display elements

[1] Display of system, subsystem or function

[2] Status display of active menu level

[3] Display of temperature set (set temperature)

[4] Display of operating mode set

[5] Display of time program set

[6] Display of Internet connection

[7] Display of system components

[8] Advanced functions for heating circuit, DHW

[9] Display of time

[10] Press field to switch between display types on the display

[11] Information menu

[12] Press field to go back to the previous level/screen

[13] Press field to return to the system overview

[14] Advanced functions of the heat source

[15] Status display of system components

The symbols used are listed in Fig. 7 on page 10, accompanied by an

explanation.

5.4 Operating the appliance

5.4.1 Control system

The display and operation is organised in several menu levels. These can

be accessed by tapping the corresponding symbol. Several menu levels

can only be accessed by contractors. If an arrow is displayed on the right

or left of the selected menu ( Fig. 9, page 12) additional menu items

are available. The corresponding status of the system, part of the

system, function or system components can be identified from the

individual images displayed.

Further information:

• Menu structure Chapter 3.1, from page 7

• Functions Chapter 3.1, from page 7

• Explanation of symbols and keys Chapter 3.1, from page 7

Tap and swipe the touch screen to navigate through the menu levels and

operate the functions.

To go back to the previous level/screen:

▶ Tap symbol.

12:00

50 °C

on/o

30 %

1 2 3 4 5 6

9

7

8

10111213

14

15

0010005510-001

Page 13

CC8313 control unit

13

Condens 7000 F – 6720871579 (2018/07)

5.4.2 Switch on and enable control unit

▶ Switch on control unit at ON/OFF switch ( Fig. 7, [10], page 10).

The standard display appears following initialisation of the control

unit, or if there has been no user activity at the display for some time.

Fig. 10 Standard display

[1] Boiler Temperature

[2] Continue to overview

The boiler temperature is displayed and the display is disabled in the

standard display. To reduce the current consumption of the

control unit, the display changes to sleep mode after several minutes.

When this happens the display becomes darker.

To activate the display:

▶ Tap the display.

To enable the display:

▶ Tap Continue to overview.

The system name of the control unit series appears briefly after the

display is enabled. The start page is then displayed with the system

overview.

To display the system overview:

▶ Tap the display.

Fig. 11 System Overview

5.4.3 Lock screen

The main menu can be protected from unauthorised access using a

4-digit password. The block can only be set up and removed by

customer service.

If the display remains untouched for a longer period, the main menu is

disabled. The password is requested the next time the display is

touched.

If the password is lost the block can only be removed by customer

service.

5.4.4 Calling up menu levels or functions

To call up individual menu levels or select functions:

▶ Tap the corresponding position on the display with your finger.

Fig. 12 Calling up a menu level or function

[1] Heat production

[2] Status display

[3] System

[4] Fault history

The next menu level or function is displayed.

Kesseltemp. 75°

1

2

0010007852-001

0010009266-001

12:00

0010006521-001

12:00

321

4

Page 14

CC8313 control unit

Condens 7000 F – 6720871579 (2018/07)

14

Menu levels

If several menus or functions are available at one level:

▶ Tap the corresponding position (function) on the display with your

finger.

Fig. 13 Heating circuit overview (example)

[1] System > Control unit 01

[2] Domestic hot water

[3] Heating circuit 03

[4] Heating circuit 01

[5] Heating circuit 04

[6] Heating circuit 02

[7] Heating circuit 05

[8] Heating circuit 07

[9] Heating circuit 06

To select a different function within a menu level:

▶ Tap the right or left arrow on the display with your finger.

-or-

▶ Swipe to the left or right across the display with your finger.

Fig. 14 Scrolling

-or-

▶ Swipe your finger across the display.

Fig. 15 Wipe

Display of heating circuits

Designations are allocated to the heating circuits depending on the slot

of the heating circuit module. The heating circuits are numbered

according to the sequence of slots. This means that the heating circuits

at slot 1 are displayed as heating circuit 01 and 02. The heating circuits

at slot 2 are displayed as 03 and 04. If a different module is inserted at a

slot, these heating circuit numbers are omitted. If the heating circuit has

been given a name, this is displayed.

5.4.5 Calling up submenus

Observe technical documentation of the installed control unit.

5.4.6 Information menu

To display information about the installation or the system:

▶ Tap symbol.

▶ Tap the required area in the Info menu.

Fig. 16 Overview of Info menu

Depending on the area, the following information is e.g. displayed:

• Statuses of safety equipment

• Temperatures

• Operating modes

• Hours run

0010006525-001

12:00

1 2 3 4

89

5 6 7

0010006536-001

12:00

50 °C

on/o

30 %

0010006537-001

12:00

50 °C

on/o

30 %

0010009883-001

12:00

i

Page 15

Commissioning

15

Condens 7000 F – 6720871579 (2018/07)

6 Commissioning

6.1 Checking the operating pressure, topping up the

heating water and venting the system

6.1.1 Checking the operating pressure

Your heating contractor will have set the red needle of the pressure

gauge [1] to the required operating pressure (at least 1 bar) and will

have recorded this value in table 8, page 14.

▶ Check that the pressure gauge needle [2] is within the green

band [3}.

▶ If the pressure gauge needle drops below the green band, top up the

heating water.

Fig. 17 Pressure gauge for sealed systems

[1] Red needle

[2] Pressure gauge needle

[3] Green marking

Table 3 Operating pressure (entered by the heating contractor)

6.1.2 Topping up the heating water and venting the system

CAUTION:

Health risk through contaminated drinking water!

▶ Obser ve all country-specific regulations and standards regarding the

prevention of drinking water contamination.

▶ In Europe, observe standard EN 1717.

NOTICE:

Material damage due to thermal stresses!

When topping up a hot boiler with cold heating water, thermal

stresses can lead to cracking due to internal stress.

▶ Only fill the heating system when cold. Maximum flow

temperature 40 °C.

NOTICE:

System damage due to frequent topping up!

If you have to top up the heating water frequently, the heating system

may suffer damage through corrosion or scaling, depending on the water

quality.

▶ Ask a certified heating contractor if the local water can be used

untreated or whether it needs to be treated.

▶ Notify your heating contractor if you frequently need to top up your

heating system.

Topping up heating water is different for individual heating systems.

Therefore, ask your approved contractor to advise you accordingly.

The refill quantities must be documented in the operator's log.

6.2 Switching on the heating system

Observe technical documentation of the installed control unit.

Before switching on (Chapter 3.1), ensure that:

• the operating pressure is high enough,

• the fuel supply has been turned on at the main shut-off valve, and

• the heating system emergency stop switch is switched on.

7 Shutting down the heating system

7.1 Shutting down the heating system via the control unit

NOTICE:

Frost damage!

If the heating system is not standing in a frost-proof room and is not in

operation, it may freeze up when exposed to frost. In summer mode or if

heating mode is blocked, only the device frost protection remains active.

▶ Leave the heating system switched on at all times whenever possible,

and set the flow temperature to at least 30 °C,

-or-

▶ Protect the heating system against frost by having the heating and

DHW pipes drained by a contractor from the lowest point.

▶ Shutting down the heating system via the ON/OFF switch at the

control unit (Chapter 3.1).

7.2 Shutting down the heating system in an emergency

Only use the boiler room circuit breaker or heating system emergency

stop switch to switch off the heating system in an emergency.

▶ Never risk your own life. Your own safety is paramount.

▶ Close off the fuel supply installed on site.

▶ Isolate the heating system from the mains power supply via the

heating system emergency stop switch or the main circuit breaker.

Operating pressure

Set operating pressure (optimum

value) _____________ bar

6 720 615 876-59.2T

3

2

1

Page 16

Environmental protection/disposal

Condens 7000 F – 6720871579 (2018/07)

16

8 Environmental protection/disposal

Environmental protection is a fundamental corporate strategy of the

Bosch Group.

The quality of our products, their economy and environmental safety are

all of equal importance to us and all environmental protection legislation

and regulations are strictly observed.

We use the best possible technology and materials for protecting the

environment taking account of economic considerations.

Packaging

Where packaging is concerned, we participate in country-specific

recycling processes that ensure optimum recycling.

All of our packaging materials are environmentally compatible and can be

recycled.

Used appliances

Used appliances contain valuable materials that can be recycled.

The various assemblies can be easily dismantled. Synthetic materials are

marked accordingly. Assemblies can therefore be sorted by composition

and passed on for recycling or disposal.

Used electrical and electronic appliances

Electrical or electronic devices that are no longer

serviceable must be collected separately and sent for

environmentally compatible recycling (in accordance with

the European Waste Electrical and Electronic Equipment

Directive).

To dispose of old electrical or electronic devices, you

should use the return and collection systems put in place in the country

concerned.

Batteries must not be disposed together with your household waste.

Used batteries must be disposed of in local collection systems.

9 Inspection and maintenance

9.1 What makes regular service important?

Heating systems should be regularly serviced for the following reasons:

• To maintain a high level of efficiency and to operate the heating

system economically (low fuel consumption)

• To achieve a high level of operational reliability

• To maintain the cleanest possible combustion

NOTICE:

Material damage due to a lack of or incorrect cleaning and service.

▶ Have the heating system inspected, maintained and cleaned once a

year by a certified heating contractor.

▶ We recommend you enter a contract covering an annual inspection

and demand-based maintenance.

9.2 Cleaning and care

To clean the boiler:

▶ Do not use abrasive or aggressive cleaning agents.

▶ Clean the casing with a damp cloth (soapy solution).

10 Troubleshooting

10.1 Recognising the operating condition and clearing

faults

NOTICE:

Frost damage!

If the heating system is not standing in a frost-proof room and is not in

operation, it may freeze up when exposed to frost. In summer mode or if

heating mode is blocked, only the device frost protection remains active.

▶ Leave the heating system switched on at all times whenever possible,

and set the flow temperature to at least 30 °C,

-or-

▶ Protect the heating system against frost by having the heating and

DHW pipes drained by a contractor from the lowest point.

If a fault has developed, the fault code flashes on the control unit display.

For more information on rectifying the problem or on possible faults,

refer to the corresponding technical documentation of the installed

control unit.

If the fault cannot be cleared:

▶ Note down the fault message and notify a heating contractor.

Page 17

Page 18

Page 19

Page 20

Bosch Thermotechnik GmbH

Sophienstrasse 30-32

D-35576 Wetzlar

www.bosch-industrial.com

Loading...

Loading...