Bosch Condens 2000F30 Regular, Condens 2000F16 Regular, Condens 3000F30 System, Condens 2000F42 Regular, Condens 3000F16 System Installation, Commissioning And Servicing Instruction Manual

Page 1

Installation, Commissioning and Servicing Instruction manual

Floor-standing gas-fired condensing appliance

Condens

6720809859-00.1Wo

2000F16, 30, 42 Regular boiler/3000F 16, 30 System boiler

6 720 816 930 (2015/04)

Page 2

Contents

Condens – 6720816930 (2015/04)

2

Contents

1 Key to symbols and safety precautions . . . . . . . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Legislation and regulations . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Appliance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5.1 Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5.2 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 Dimensions and description . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Regular boiler layout and components . . . . . . . . . . . . . . . 6

2.8 Regular boiler wiring diagram . . . . . . . . . . . . . . . . . . . . . . 7

2.9 Regular boiler Technical data . . . . . . . . . . . . . . . . . . . . . . 8

2.10 Gas type and installation type . . . . . . . . . . . . . . . . . . . . . 9

2.11 Output power reduction due to altitude . . . . . . . . . . . . . . 9

2.12 System boiler layout and components . . . . . . . . . . . . . 11

2.13 System boiler wiring diagram . . . . . . . . . . . . . . . . . . . . 12

2.14 System boiler Technical data . . . . . . . . . . . . . . . . . . . . 13

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Country specific regulations . . . . . . . . . . . . . . . . . . . . . 15

3.2 Approvals and notifications . . . . . . . . . . . . . . . . . . . . . 15

3.3 Quality of the heating water . . . . . . . . . . . . . . . . . . . . . 15

3.4 Connection to combustion air and flue gas systems . . 15

3.5 Room air dependent operation . . . . . . . . . . . . . . . . . . . 15

3.6 Flue gas systems type Bxx . . . . . . . . . . . . . . . . . . . . . . 15

3.7 Flue gas systems type Cxx . . . . . . . . . . . . . . . . . . . . . . 15

3.8 Combustion air quality . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.9 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.10 Inspection, service and maintenance . . . . . . . . . . . . . 16

4 Pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Cleaning primary systems . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Connecting flow and return . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Expansion vessel and drain valve . . . . . . . . . . . . . . . . . 17

4.3 Water systems and pipework . . . . . . . . . . . . . . . . . . . . 17

4.4 Condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.1 To remove the condensate trap . . . . . . . . . . . . . . . . . . 17

4.5 Boiler location and clearances . . . . . . . . . . . . . . . . . . . 17

4.5.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5.2 Installations and servicing clearances: . . . . . . . . . . . . 17

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

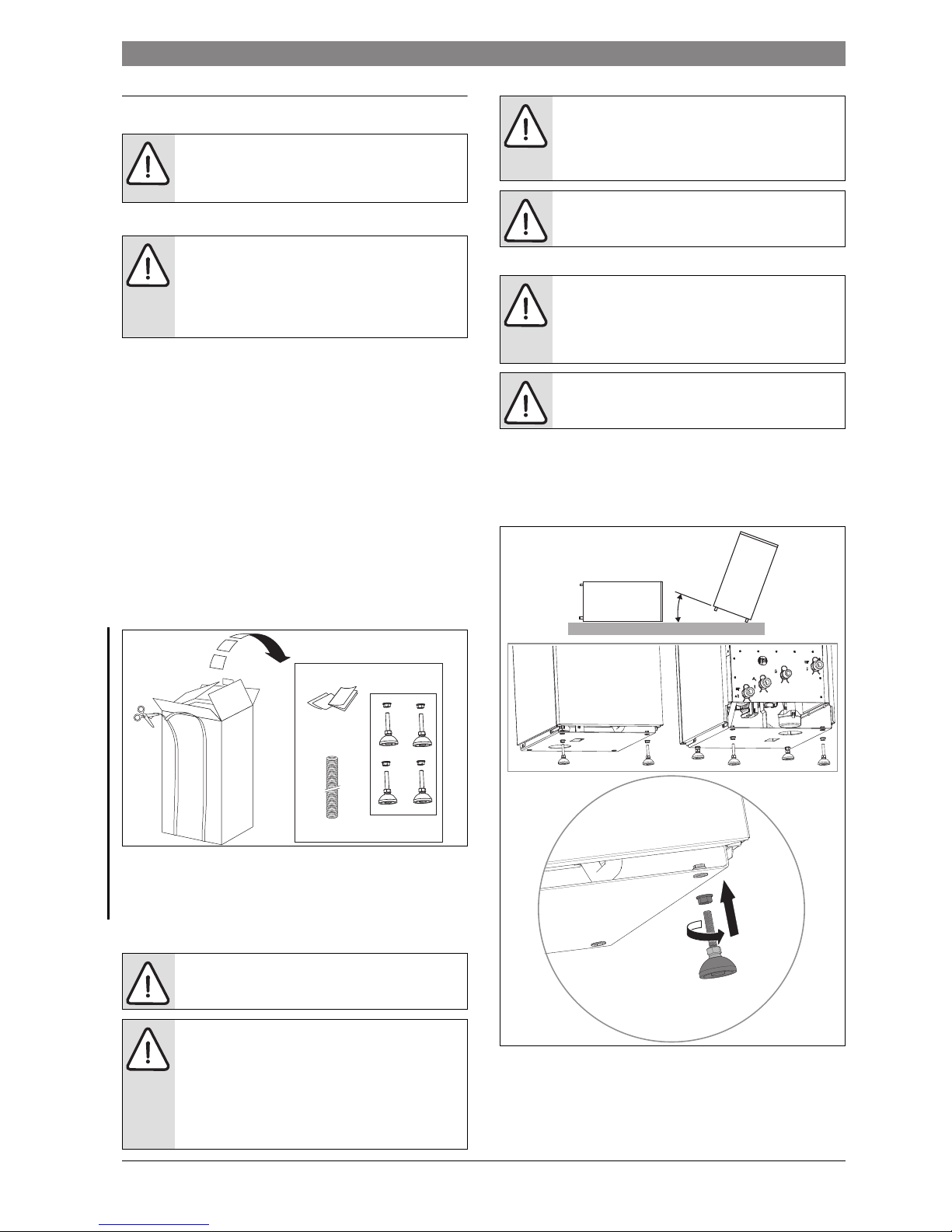

5.1 Unpacking the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Boiler room requirements . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Installing the levelling feet . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 Positioning the appliance . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Mounting the boiler and flue opening . . . . . . . . . . . . . . 19

5.4 Flue options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Vertical flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Pre-Commissioning checks . . . . . . . . . . . . . . . . . . . . . 24

7.2 Filling the system and checking for leaks . . . . . . . . . . . 24

7.3 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 Starting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.5 Checking gas inlet pressure . . . . . . . . . . . . . . . . . . . . . 26

7.5.1 Measuring the inlet pressure . . . . . . . . . . . . . . . . . . . . 26

7.5.2 Checking the gas rate . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.6 Finishing commissioning . . . . . . . . . . . . . . . . . . . . . . . 26

7.7 Commissioning checklist . . . . . . . . . . . . . . . . . . . . . . . 27

8 Thermal disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.1 Perform thermal disinfection . . . . . . . . . . . . . . . . . . . . 28

8.2 Thermal disinfection for system with a hot water tank 28

9 Operating the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.1 Controls overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2 Screen display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.3 Appliance on/off switch . . . . . . . . . . . . . . . . . . . . . . . . 29

9.4 Heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.4.1 Heating mode on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.4.2 Set the maximum flow temperature . . . . . . . . . . . . . . . 30

9.5 Setting the DHW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.5.1 DHW on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.5.2 Setting the DHW temperature . . . . . . . . . . . . . . . . . . . 31

9.6 Control unit setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.7 Summer mode ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . 32

9.8 Setting frost protection . . . . . . . . . . . . . . . . . . . . . . . . 32

10 Servicing and spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 Inspection and service . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.2 Service function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.2.1 Selecting service menus . . . . . . . . . . . . . . . . . . . . . . . . 33

10.2.2 Selecting the Information menu . . . . . . . . . . . . . . . . . . 34

10.2.3 Selecting menu 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2.4 Selecting menu 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2.5 Selecting menu 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.2.6 Selecting the Test menu . . . . . . . . . . . . . . . . . . . . . . . . 36

10.2.7 Setting the boiler to maximum output . . . . . . . . . . . . . 37

10.3 Flue integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.4 Service inspection - Component access . . . . . . . . . . . 37

10.4.1 Control panel - Service position . . . . . . . . . . . . . . . . . . 38

10.5 Checking the gas inlet pressure . . . . . . . . . . . . . . . . . . 38

10.6 Fan pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.7 Flue gas analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.8 Setting the air/gas ratio . . . . . . . . . . . . . . . . . . . . . . . . 40

10.9 Cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . 40

10.10 Inspection and servicing checklist . . . . . . . . . . . . . . . . 42

10.11 Demand dependant maintenance . . . . . . . . . . . . . . . . 44

11 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.1 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.1.1 Access to components . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.1.2 Fan assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.1.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.1.4 To remove the condensate trap . . . . . . . . . . . . . . . . . . 47

11.1.5 Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.1.6 Primary Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . 48

12 Fault finding and dianostics . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12.1 Status codes and faults . . . . . . . . . . . . . . . . . . . . . . . . . 49

12.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12.3 Information and service menus . . . . . . . . . . . . . . . . . . 49

12.3.1 Selecting the information menu . . . . . . . . . . . . . . . . . . 51

12.3.2 Selecting service menus . . . . . . . . . . . . . . . . . . . . . . . . 52

12.3.3 Menu 1 - System parameters . . . . . . . . . . . . . . . . . . . . 52

12.3.4 Menu 2 - Boiler parameters . . . . . . . . . . . . . . . . . . . . . 52

12.3.5 Reset to factory settings . . . . . . . . . . . . . . . . . . . . . . . . 53

12.3.6 Menu 3 - Boiler maximum & minimum limits . . . . . . . . 53

12.3.7 Using the test menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

12.4 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Page 3

Key to symbols and safety precautions

Condens – 6720816930 (2015/04)

3

1 KEY TO SYMBOLS AND SAFETY PRECAUTIONS

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or

death.

Appliance operation:

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without

supervision.

Important information

Additional symbols

Symbols used in the manual

Please read these instructions carefully before starting installation.

If you smell gas

A gas leak could potentially cause an explosion. If you smell gas, observe

the following rules.

▶ Prevent flames or sparks:

– Do not smoke, use a lighter or strike matches.

– Do not operate any electrical switches or unplug any equipment.

– Do not use the telephone or ring doorbells.

▶ Turn off the gas at the meter or regulator.

▶ Open windows and doors.

▶ Warn your neighbours and leave the building.

▶ Prevent anyone from entering the building.

▶ Well away from the building, call the Emergency Services.

▶ L.P.G. boilers: Call the supplier’s number on the side of the gas tank.

Combustion and corrosive materials

Do not store or use any combustible materials (paper, thinners, paints

etc.) inside or within the vicinity of the appliance.

Chemically aggressive substances can corrode the appliance and

invalidate any warranty.

Fitting and modification

Flue systems must not be modified in any way other than as described in

the fitting instructions. any misuse or unauthorised modifications to the

appliance, flue or associated components and systems could invalidate

the warranty. The manufacturer accepts no liability arising from any

such actions, excluding statutory rights.

Servicing

Advise the user to have the system serviced annually by a competent

registered engineer. Approved spares must be used to help maintain the

economy, safety, and reliability.

Central heating water

Artificially softened water must not be used to fill the central heating

system.

1.2 Legislation and regulations

Installation regulations

The appliance must be installed by a competent person in accordance

with all the legislation and regulations that are in force at the time of

installation, paying particular attention to any provisions or regulations

made by the local authorities.

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

This symbol indicates important information where

there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Domestic Hot Water

Central Heating

Hot Water Storage Cylinder

Domestic Cold Water Supply

Gas Supply

Ø Diameter

Equal to or less than

Equal to or greater than

< Less than

> Greater than

NG Natural Gas

LPG Liquid Petroleum Gas

CH Central Heating

DHW Domestic Hot Water

DCW Domestic Cold Water

PRV Pressure Relief Valve

NTC Negative Temperature Coefficient (sensor)

IP Ingress Protection

RCD Residual Current Device

TRV Thermostatic Radiator Valve

Table 1 Abbreviations use in this manual

Page 4

4 | Appliance information

Product Name6 720 ... ... (YYYY/MM)

2 Appliance information

2.1 General information

Boiler features and checklist

• Pre-wired and pre-plumbed

• Galvanised steel inner frame

• Bosch EMS control system

• Automatic ignition

• Direct burner ignition electrodes

• Built-in frost protection

• Built-in fault finding diagnostics

• Modulating automatic gas valve

• Combustion air fan with speed regulator

• CH temperature sensor and control

• Flue gas overheat sensor

Fig. 1 Standard package

2.2 Intended use

These appliances may only be used in a closed loop hot water central

heating system.

Any other purpose is considered improper use. Any damage resulting

from misuse is excluded from the manufacturer’s guarantee.

The commercial or industrial use of the appliance to produce process

heat is not permitted.

Only use genuine gas from official gas suppliers.

Ensure the appliance is operated within the limits on the data label and

parameters in this manual.

2.3 Declaration of conformity

This product, in design and operation, conforms to the European

Directives and supplementary national requirements.

Compliance is demonstrated by the CE marking.

You can request the declaration of conformity of the product. To do so,

send your request to the address on the back of the manual.

The appliances meet the requirements for gas-fired condensing boilers

in terms of energy saving regulations.

The appliances are tested according to EN 677.

2.4 Type plate

The type label contains information on device performance, the

registration data and the serial number.

2.5 Type overview

KSBR units, heat only gas-fired condensing boilers with an integrated

circulating pump and optional 3-way valve for the connection of the hot

water tank.

KBR units, heat only, gas-fired condensing boilers without a circulating

pump or optional three way valve, for use in systems where this is

provided externally.

2.5.1 Electrical supply

• Supply: 230V - 50 Hz

• External “Quick blow” 3A fuse

• The appliance must be earthed

• IPX4D

• The wiring between the appliance and the electrical supply must

comply with the latest IEE wiring regulations that apply to wiring a to

a fixed appliance

• Any system connected to the appliance must not have a separate

electrical supply

2.5.2 Gas supply

• Boilers using Natural Gas (NG) must be connected to a governed

meter.

• Liquid Petroleum Gas (LPG) must be connected to a regulator.

• Installation and connection of the gas supply to the boiler must be in

accordance with country and local regulations.

• Under no circumstance should be size of the gas supply pipe be less

than DN20.

• The meter or regulator and pipe work to the meter must be checked,

by the gas supplier. This is to ensure that the equipment is in good

working order and can meet the gas flow and pressure requirements,

in addition to the demand from any other appliance being served.

CHECK LIST - LITERATURE PACK: Qty.

1 Installation, Commissioning and Servicing Instructions 1

Users Instructions

1

Table 2 Literature pack - checklist

CHECK LIST - INSTALLATION PACK: Qty.

2 PRV discharge pipe 1

3 Levelling feet 4

Table 3 Installation pack - checklist

6720809859-47.1Wo

1

2

3

K Floor standing appliance

S Built-in circulation pump & optional 3 way diverter valve

B Condensing technology

R Modulating burner

16 output up to 16 kiloWatts

30 output up to 30 kiloWatts

42 output up to 42 kilowatts

Table 4 Appliance designation

Page 5

Appliance information | 5

6 720 ... ... (YYYY/MM)Product Name

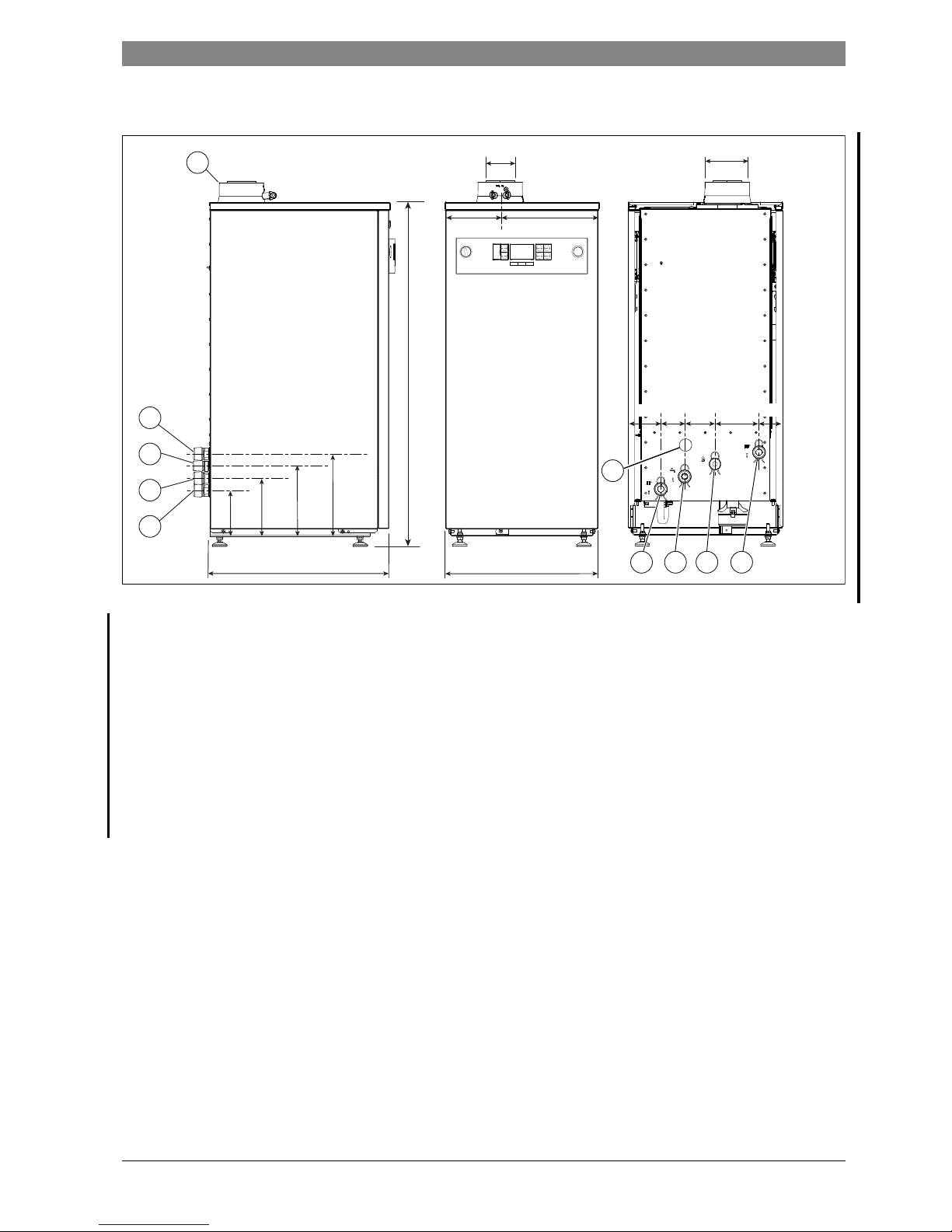

2.6 Dimensions and description

Fig. 2 Pipe work connector location

Regular boiler:

[1] Hot water flow (1”)

[2] Gas (3/4”)

[3*] Not used on the regular boiler

[4] Hot water return (1”)

[5] Condensate outlet

[6] 80/125 Flue outlet

System boiler:

[1] Heating and DHW flow (1”)

[2] Gas (3/4”)

[3*] DHW return (1”) (only if optional diverter valve kit is fitted)

[4] Heating return (1”)

[5] Condensate outlet

[6] 80/125 Flue outlet

1

6

2

3*

4

6720809859-10.1Wo

123*4

466

394

61

78 111

141 253

Ø80

Ø125

98

130

162

193

5

83

59

900 - 930

Page 6

6 | Appliance information

Product Name6 720 ... ... (YYYY/MM)

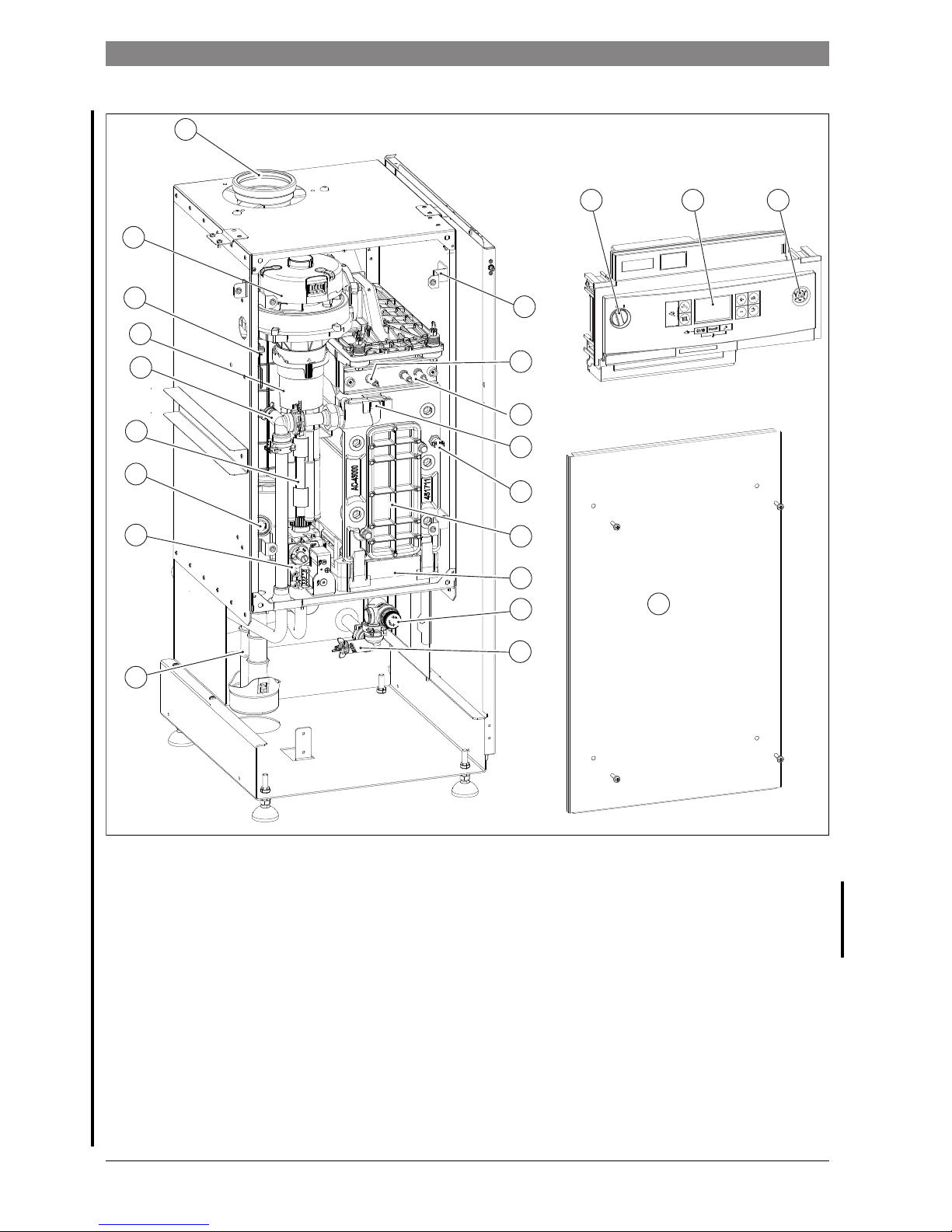

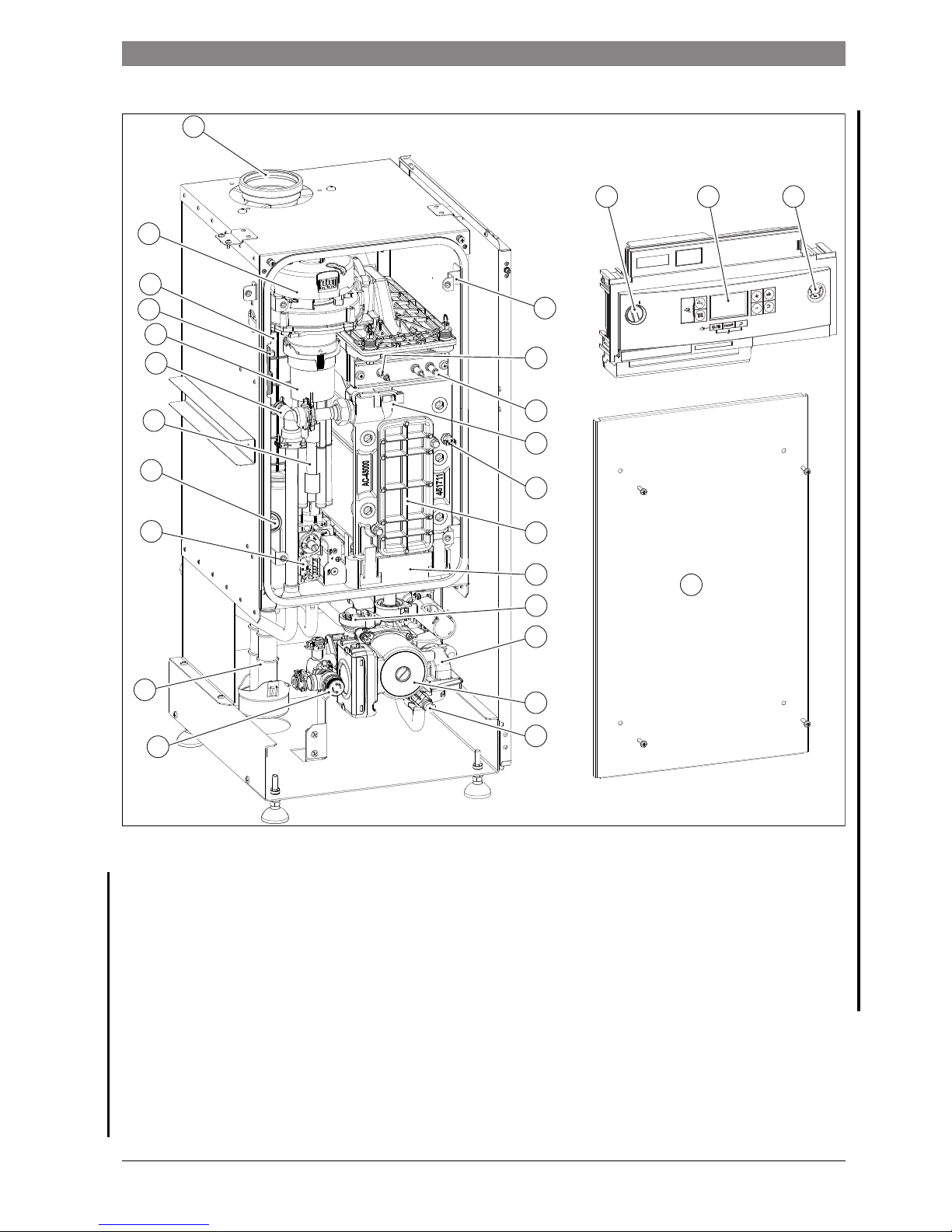

2.7 Regular boiler layout and components

Fig. 3 Component layout KBR

Legend to figure 3:

[1] Flue connector

[2] ON/OFF switch

[3] Display

[4] Pressure gauge

[5] Combustion chamber cover mounting bracket x 4

[6] Flame sense electrode

[7] Electrode assembly

[8] Flow temperature sensor

[9] High limit thermostat

[10] Heat exchanger inspection cover

[11] Condensate pan

[12] Pressure relief valve

[13] Drain cock

[14] Condensate trap

[15] Gas valve

[16] Flue overheat thermostat

[17] Air Intake pipes (30 and 42kW boilers only)

[18] Manual vent

[19] Pre-mix chamber

[20] Spark generator

[21] Fan

[22] Combustion chamber cover

2

14

16

12

10

11

15

9

8

7

6

21

5

18

20

19

43

6720809859-12.1Wo

13

17

1

22

Page 7

Appliance information | 7

6 720 ... ... (YYYY/MM)Product Name

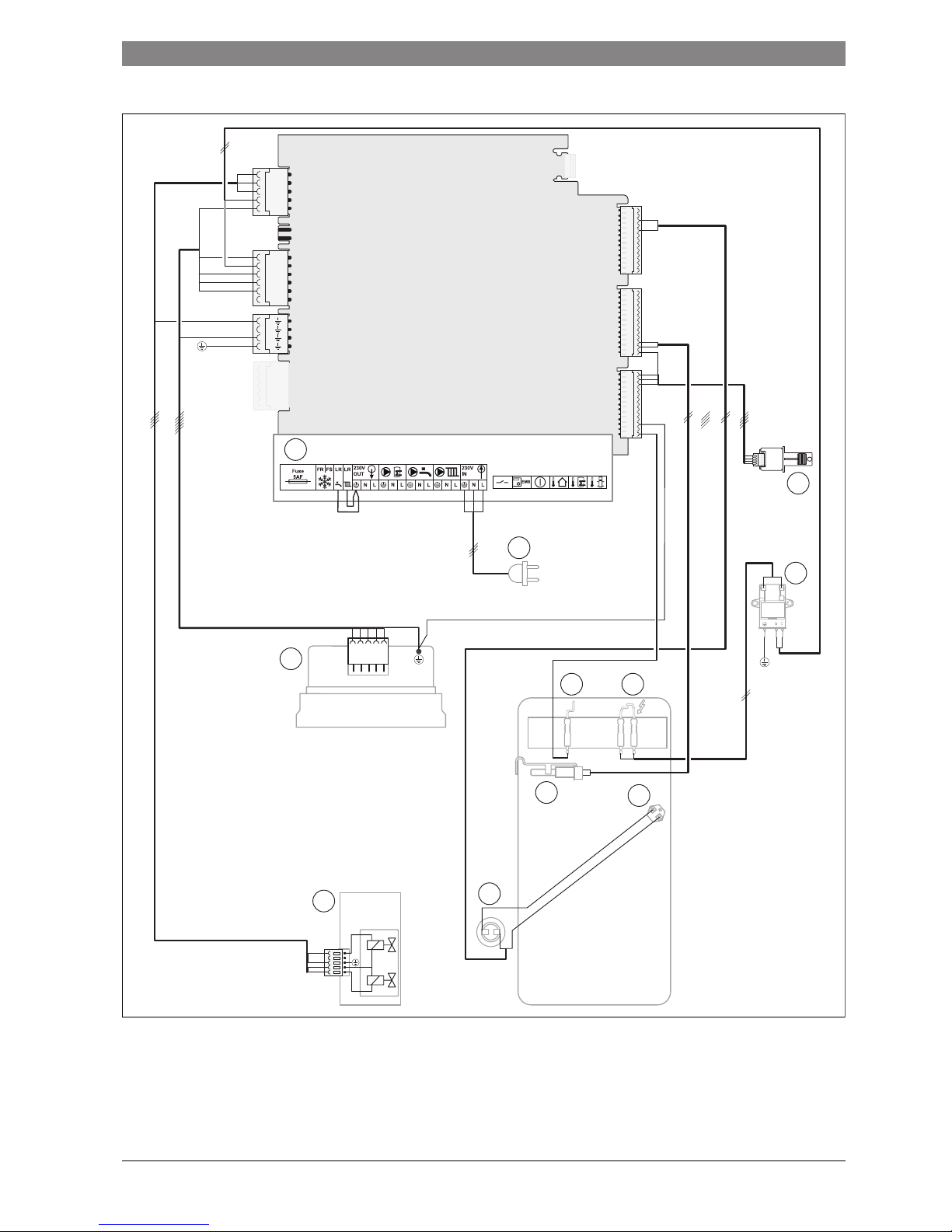

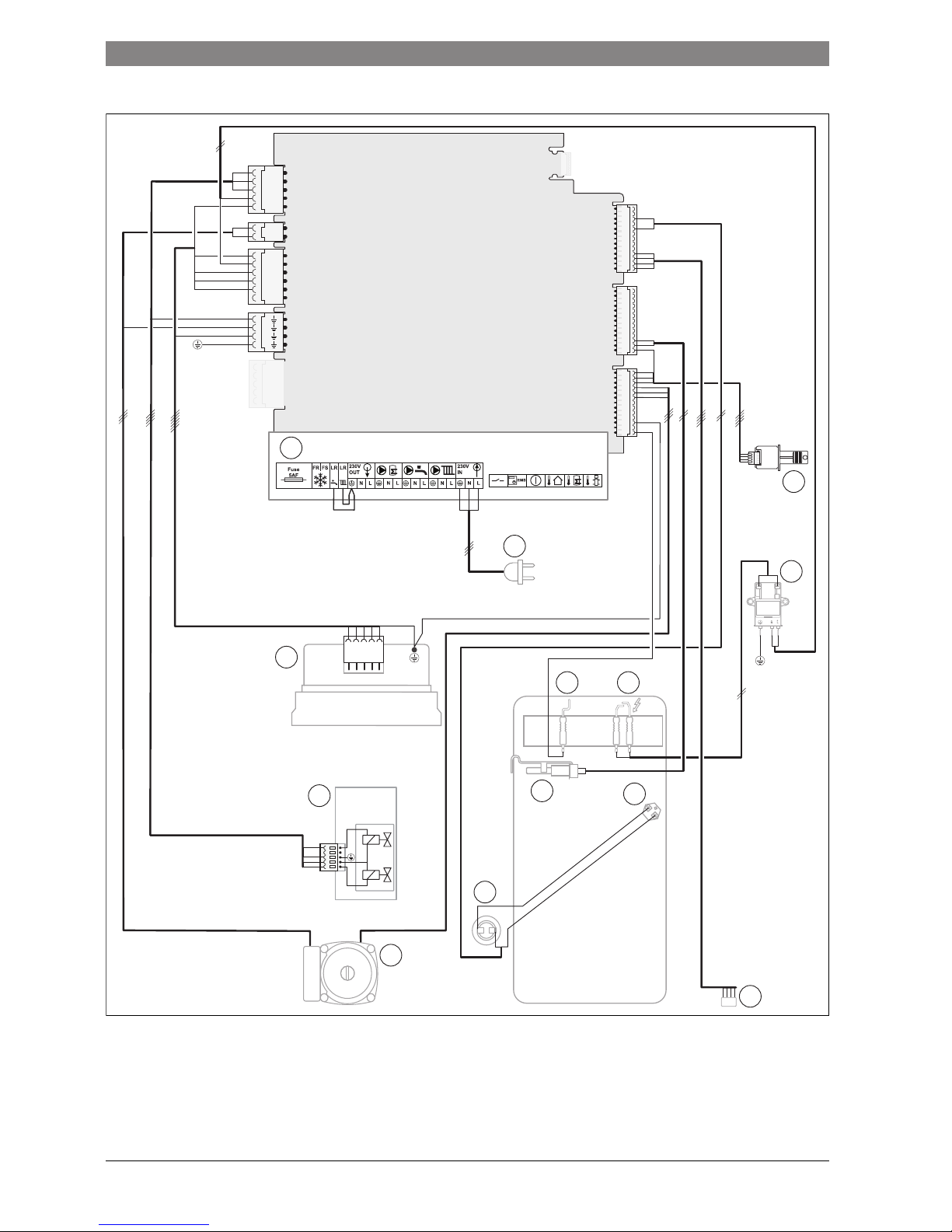

2.8 Regular boiler wiring diagram

Fig. 4

[1] Appliance terminal connector block

[2] Mains supply

[3] Heat control module (HCM)

[4] Spark generator

[5] Spark electrodes

[6] Flame sense electrode

[7] High limit thermostat

[8] Flow temperature sensor

[9] Flue overheat thermostat

[10] Gas valve

[11] Fan

L1

N

L2

N

N

1

11

3

4

2

9

7

56

8

10

6720809859-08.1Wo

Page 8

8 | Appliance information

Product Name6 720 ... ... (YYYY/MM)

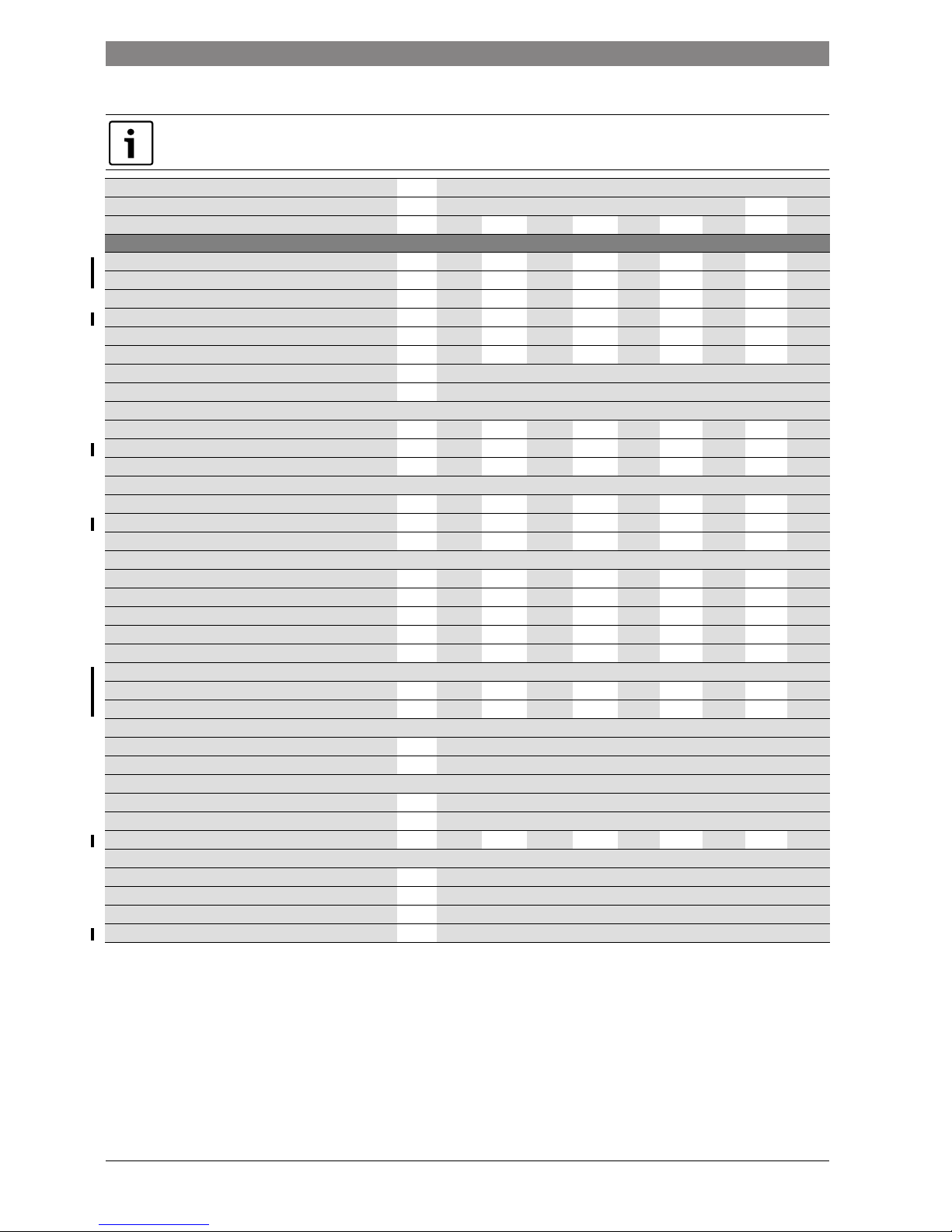

2.9 Regular boiler Technical data

All the technical data quoted in the table below refer to an appliance tested at sea level.

Power outputs are reduced due to altitude, refer to figures 5 and 6 for the percentage reduction power output due to altitude

DESCRIPTION Units Natural Gas Propane

16kW 30kW 42kW 16kW 30kW 42kW

Central Heating G20 G25 G20 G25 G20 G25 G31 G31 G31

Input/Output

Max. rated heat output net 50/30°C kW 17.00 13.90 31.70 26.00 39.80 32.60 15.80 31.70 41.00

Max. rated heat output net 80/60°C kW 15.30 12.60 30.10 24.67 38.10 31.20 14.60 30.10 38.40

Max. rated heat input net kW 16.00 13.10 30.90 25.30 39.00 32.00 16.00 30.90 39.00

Min. rated heat output net 50/30°C kW 3.80 3.10 8.00 6.60 10.10 8.30 6.40 11.52 13.50

Min. rated heat output net 80/60°C kW 3.50 2.90 7.00 5.60 9.40 7.70 5.70 10.20 12.50

Min. rated heat input net kW 3.70 3.10 8.00 6.60 10.30 8.40 6.30 10.80 13.50

Max. flow temperature °C 82

Max. permissible operating pressure bar 3.00

Gas flow rate - Max. 10 minutes from lighting

Natural Gas G20 m3/h 1.66 3.28 4.05

Natural Gas G25 m3h 1.54 3.17 3.92

Propane Gas G31 kg/h 0.61 1.27 1.65

Gas supply pressure

Natural Gas G20 mbar 20 20 20

Natural Gas G25 mbar 25 25 25

Propane Gas G31 mbar 37 37 37

Flue

Flue Gas Temp. 80/60°C, max/min °C 67/55 67/55 67/55 67/55 77/55 77/55 67/55 67/55 77/55

Flue Gas Temp. 40/30°C, max/min °C 43/25 43/25 43/25 43/25 43/25 43/25 43/25 43/22 43/25

CO2 level at max. rated heat output % 9.4 7.4 9.4 7.4 9.4 7.5 10.8 10.8 10.9

CO2 level at min. rated heat output % 8.6 6.9 8.6 6.9 9.4 7.4 10.4 10.4 10.8

NOx - classification class 555555555

Exhaust gas flow rate

Maximum g/s 6.8 6.8 13.3 13.3 17.2 17.2 6.7 12.8 16.2

Minimum g/s 1.7 1.7 3.4 3.4 4.1 4.1 2.6 6.2 7.9

Condensate

Max. condensation rate l/h 3.7

pH value, approx. 4.8

Electrical

Electrical power supply voltage AC...V 230

Frequency Hz 50

Max. power consumption (excluding external pumps) W 28 28 48 48 68 68 27 48 66

General Data

Appliance protection rating IP X4D

Permissible ambient temperatures °C -20 to +50

Nominal water capacity of appliance Itr 3.75

Weight (excluding packaging) kg 52

Table 5 Appliance technical data KBR

Page 9

Appliance information | 9

6 720 ... ... (YYYY/MM)Product Name

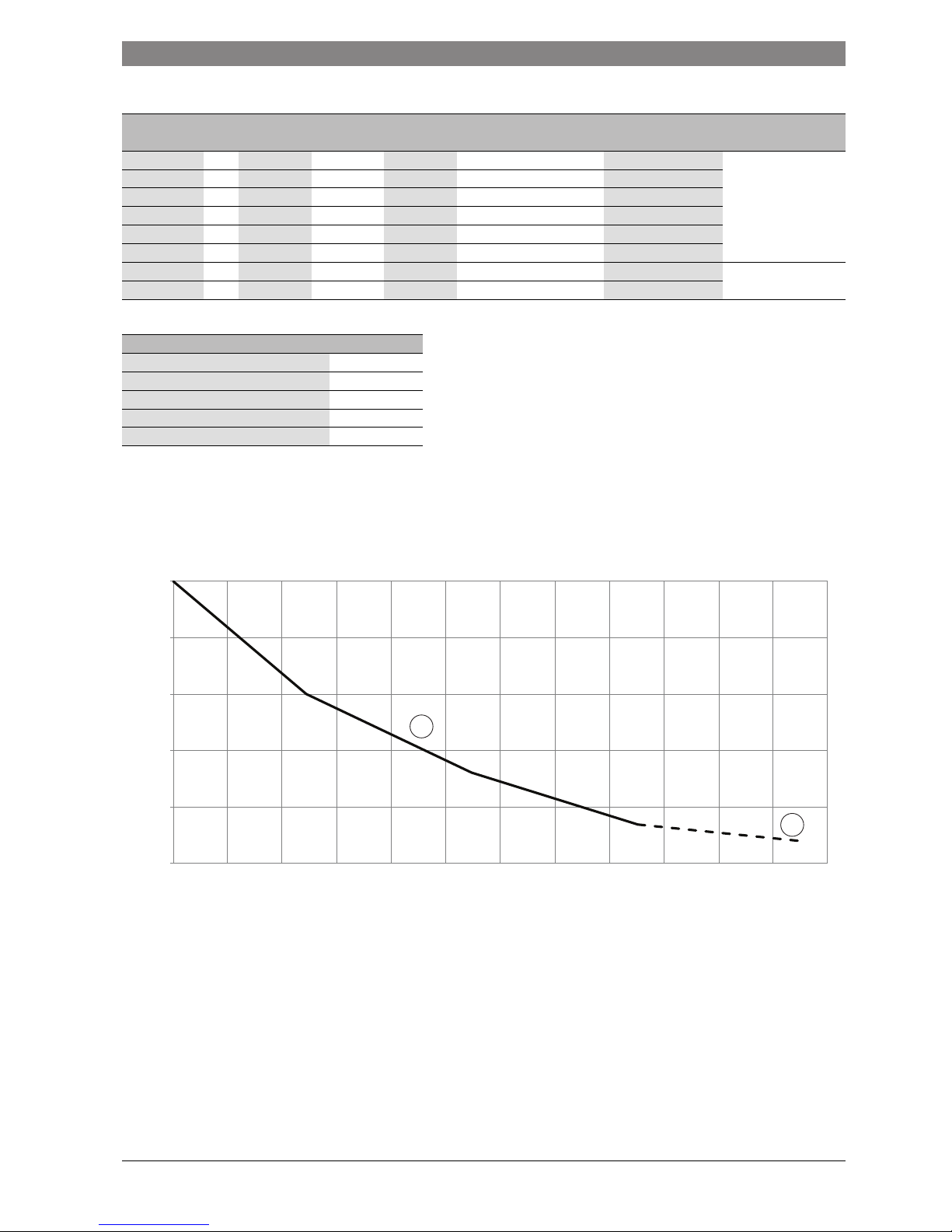

2.10 Gas type and installation type

2.11 Output power reduction due to altitude

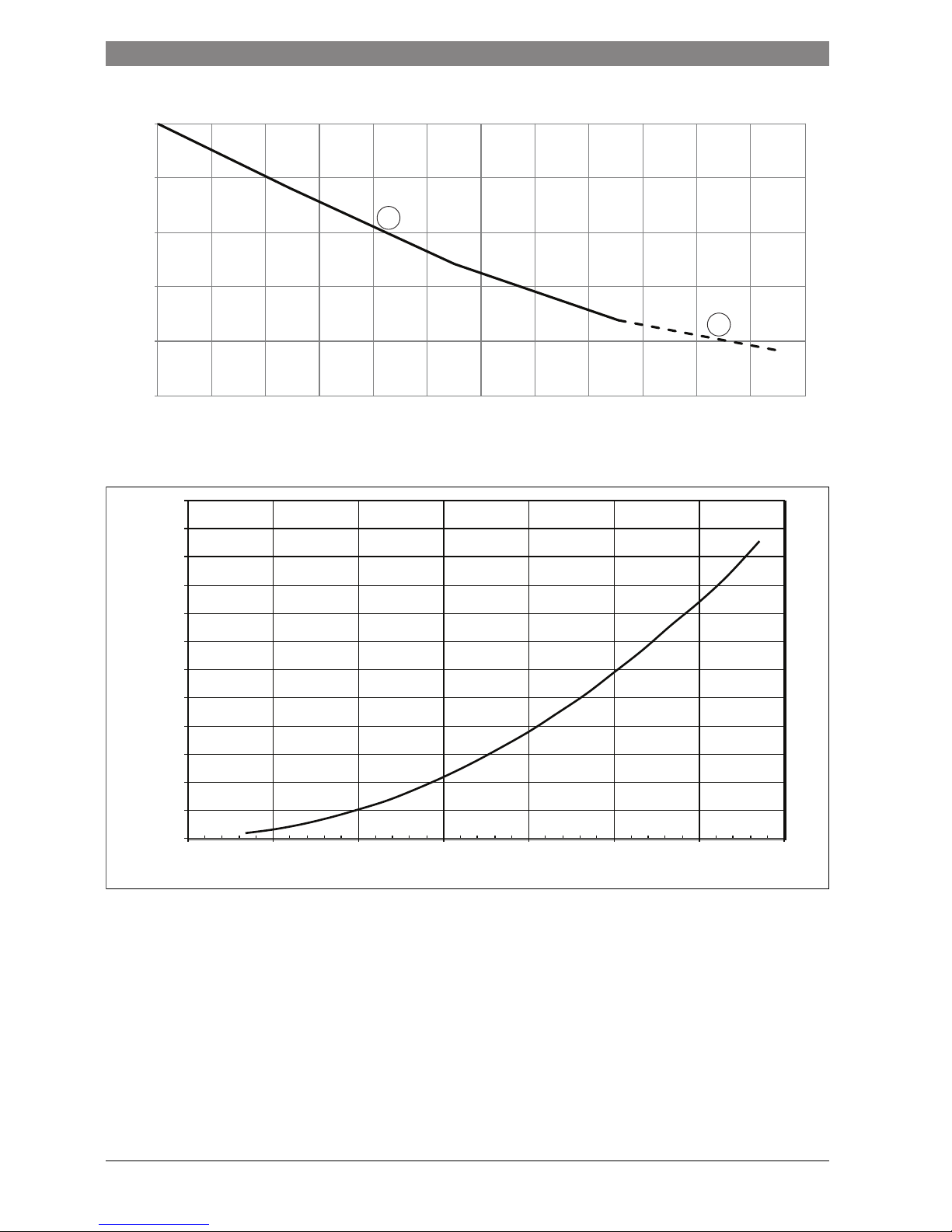

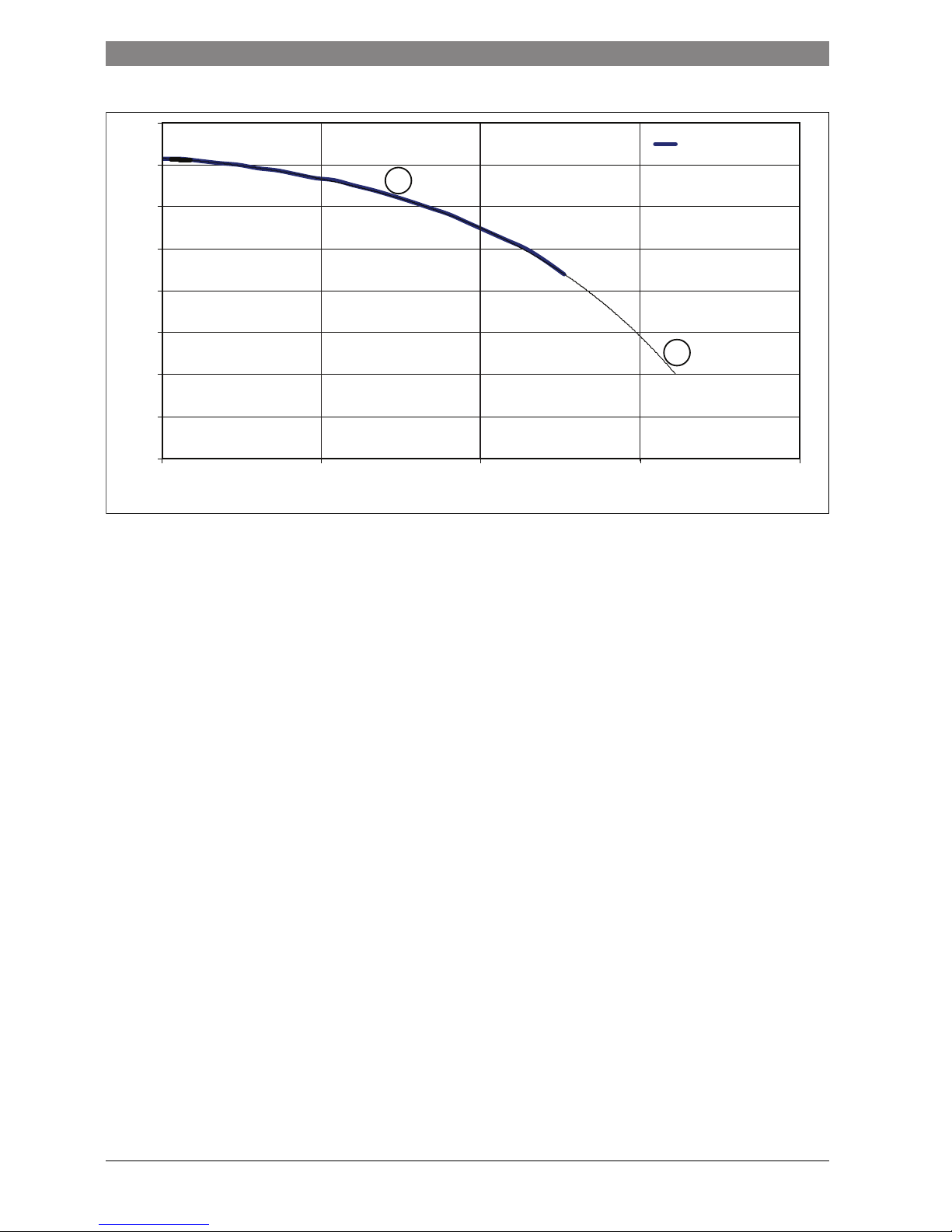

The graph in figure 5 below applies to all boiler sizes using natural gas, and the graph in figure 6 below applies to all boiler sizes using LPG.

The power output of the boilers quoted in tables 5 and 8 are reduced due to the altitude of the installation, refer to the graphs below for the percentage

output reduction.

Output power reduce on natural gas boilers due to altitude

Fig. 5 Output reduction due to altitude for natural gas

[1] Percentage output at elevation

[2] Percentage estimated output at elevation

[A] Altitude in metres

[kW(%)] Percentage kiloWatt output

Country

Rated gas pressure (mbar)

Gas

category

Factory setting (gas family,

gas group and test gas)

Factory setting rated

gas pressure (mbar)

Installation typeNatural gas LPG

Austria AT 20 50 Cat II

2H 3P

G20 20 B

23, B23P, B33, C13X,

C

33X, C43X, C53X, C63X,

C

83X, C93X

France FR 20 37 Cat II

2E SI 3P

G20 20

Italy IT 20 37 Cat II

2H 3B/P

G20 20

Czech Republic CZ 20 37 Cat II

2H 3B/P

G20 20

Russia RU 13 37 Cat II

2H 3B/P

G20 20

Poland PO 20 37 Cat II

2H 3P

G20 20

Belgium BE 20/25 Cat II

2E

G20/25 20 B

23, B33, C13X, C33X,

C

43X, C53X, C83X, C93X

Belgium BE 37 Cat II

3P

G31 37

Table 6 Gas type and installations per country

Wobbe index (WS) (15C) gas group Gas group

12.5 to 15.2 kWh/m

3

Natural gas 2H

11.4 to 15.2 kWh/m

3

Natural gas 2E

9.5 to 12.5 kWh/m

3

Natural gas 2LL

20.2 to 24.3 kWh/m

3

LPG 3B/P

20.2 to 21.4 kWh/m

3

LPG 3P

Table 7 Test gas disclosures with code and gas group (EN437)

75%

80%

85%

90%

95%

100%

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000

kW (%)

A (Metres)

1

2

6720809859-75.1Wo

Page 10

10 | Appliance information

Product Name6 720 ... ... (YYYY/MM)

Output power reduce on LPG boilers due to altitude

Fig. 6 Output reduction due to altitude for LPG

Pressure loss in the system versus system flow

Fig. 7

[p( mbar)]Pressure loss in millibars

[F (litres/h)]Re-circulated quantity of water in litres per hour

75%

80%

85%

90%

95%

100%

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000

kW (%)

A (Metres)

1

2

6720809859-76.1Wo

0

50

100

150

200

250

300

350

400

450

500

550

600

0 300 600 900 1200 1500 1800 2100

P (mbar)

F (litres/h)

6720809859-88.1Wo

Page 11

Appliance information | 11

6 720 ... ... (YYYY/MM)Product Name

2.12 System boiler layout and components

Fig. 8 Component layout KSBR

Legend to figure 5:

[1] Flue connector

[2] ON/OFF switch

[3] Display

[4] Pressure gauge

[5] Combustion chamber cover mounting bracket x 4

[6] Flame sense electrode

[7] Electrode assembly

[8] Flow temperature sensor

[9] High limit thermostat

[10] Heat exchanger inspection cover

[11] Condensate pan

[12] Auto air vent

[13] Diverter valve assembly (only with option accessory kit)

[14] Pump

[15] Drain cock

[16] Pressure relief valve

[17] Condensate trap

[18] Gas valve

[19] Flue overheat thermostat

[20] Air Intake pipes (30 and 42kW boilers only)

[21] Manual vent

[22] Mixing device

[23] Spark generator

[24] Flue exhaust

[25] Fan

[26] Combustion chamber cover

20

1

2

19

15

14

13

12

10

11

18

17

16

9

8

7

6

25

5

24

22

23

21

43

6720809859-11.1Wo

26

Page 12

12 | Appliance information

Product Name6 720 ... ... (YYYY/MM)

2.13 System boiler wiring diagram

Fig. 9

[1] Appliance terminal connector block

[2] Mains electrical supply connector

[3] Heat control module (HCM)

[4] Spark generator

[5] Spark electrodes

[6] Flame sense electrode

[7] High limit thermostat

[8] Flow temperature sensor

[9] Diverter valve connection

[10] Pump

[11] Flue overheat thermostat

[12] Gas valve

[13] Fan

L1

N

L2

N

N

1

13

9

3

4

2

11

7

56

8

6720809859-07.1Wo

12

10

Page 13

Appliance information | 13

6 720 ... ... (YYYY/MM)Product Name

2.14 System boiler Technical data

All the technical data quoted in the table below refer to an appliance tested at sea level.

Power outputs are reduced due to altitude, refer to figures 5 and 6 for the percentage reduction in power output due to altitude

DESCRIPTION Units Natural Gas Propane

16kW 30kW 16kW 30kW

Central Heating G20 G25 G20 G25 G31 G31

Input/Output

Max. rated heat output net 50/30°C kW 17.00 13.90 31.70 26.00 15.80 31.70

Max. rated heat output net 80/60°C kW 15.30 12.60 30.10 24.67 14.60 30.10

Max. rated heat input net kW 16.00 13.10 30.90 25.30 16.00 30.90

Min. rated heat output net 50/30°C kW 3.80 3.10 8.00 6.60 6.40 11.52

Min. rated heat output net 80/60°C kW 3.50 2.90 7.00 5.60 5.70 10.20

Min. rated heat input net kW 3.70 3.10 8.00 6.60 6.30 10.80

Max. flow temperature °C 82

Max. permissible operating pressure bar 3.00

Gas flow rate - Max. 10 minutes from lighting

Natural Gas G20 m3/h 1.66 3.28

Natural Gas G25 m3/h 1.54 3.17

Propane Gas G31 kg/h 0.61 1.27

Gas supply pressure

Natural Gas G20 mbar 20 20

Natural Gas G25 mbar 25 25

Propane Gas G31 mbar 37 37

Flue

Flue Gas Temp. 80/60°C, max/min °C 67/55 67/55 67/55 67/55 67/55 67/55

Flue Gas Temp. 40/30°C, max/min °C 43/25 43/25 43/25 43/25 43/25 43/25

CO2 level at max. rated heat output % 9.4 7.4 9.4 7.4 10.8 10.8

CO2 level at min. rated heat output % 8.6 6.9 8.6 6.9 10.4 10.4

NOx - classification class 5

Exhaust gas flow rate

Maximum g/s 6.8 6.8 13.3 13.3 6.7 12.8

Minimum g/s 1.7 1.7 3.4 3.4 2.6 6.2

Condensate

Max. condensation rate l/h 3.7

pH value, approx. 4.8

Electrical

Electrical power supply voltage AC...V 230

Frequency Hz 50

Max. power consumption (including pump) W 97 97 116 116 95 116

General Data

Appliance protection rating IP X4D

Permissible ambient temperatures °C -20 to +50

Nominal water capacity of appliance Itr 3.75

Weight (excluding packaging) kg 54

Table 8 Appliance technical data KSBR

Page 14

14 | Appliance information

Product Name6 720 ... ... (YYYY/MM)

Pumphead versus Flow rate

Fig. 10

[APH] Available pump head

[FR] Flow rate

[1] Actual data

[2] Extrapolated data

0

1

2

3

4

5

6

7

8

0 500 1000 1500 2000

6720809859-87.1Wo

1

2

APH ( m wg)

FR (l/hr)

Pump (m wg)

Page 15

Appliance information | 15

6 720 ... ... (YYYY/MM)Product Name

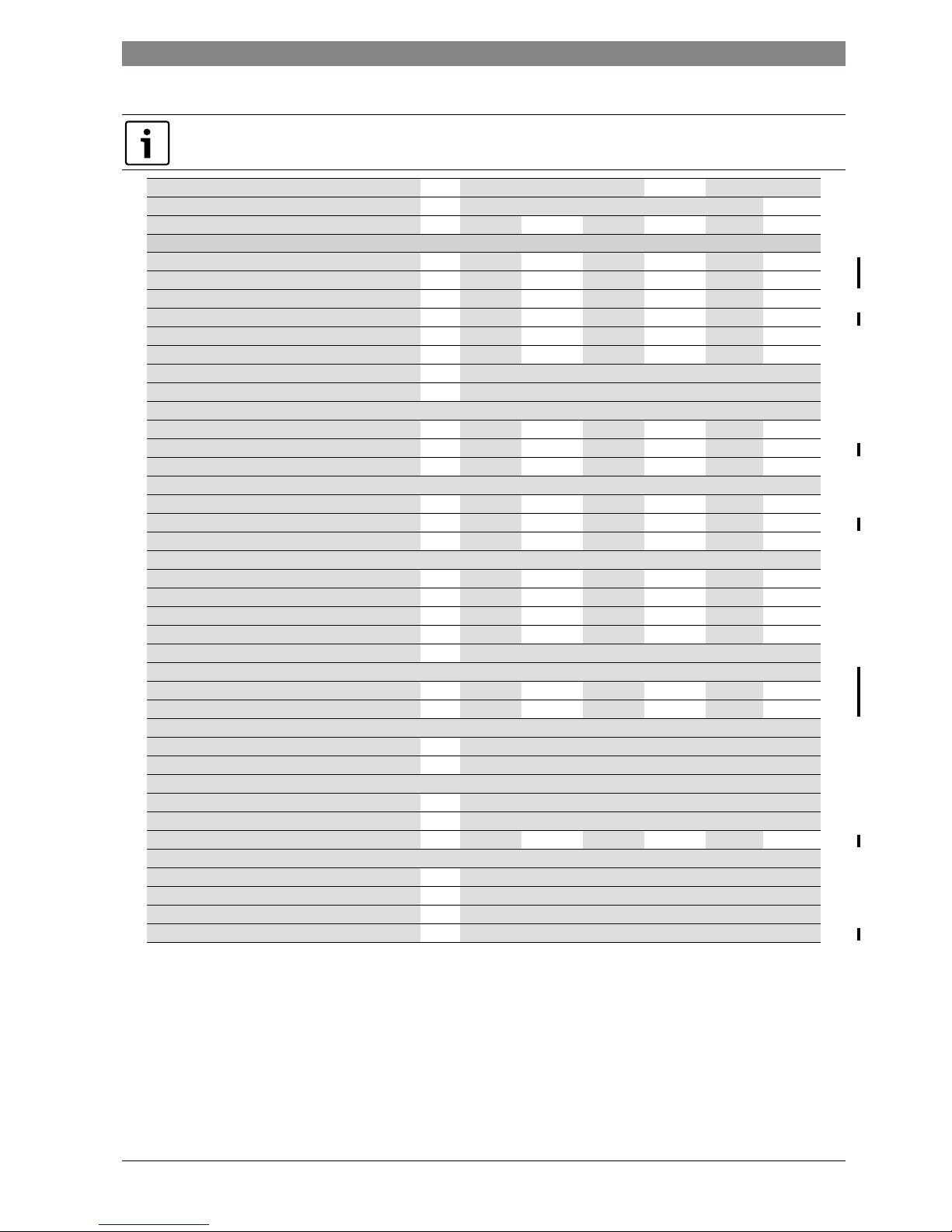

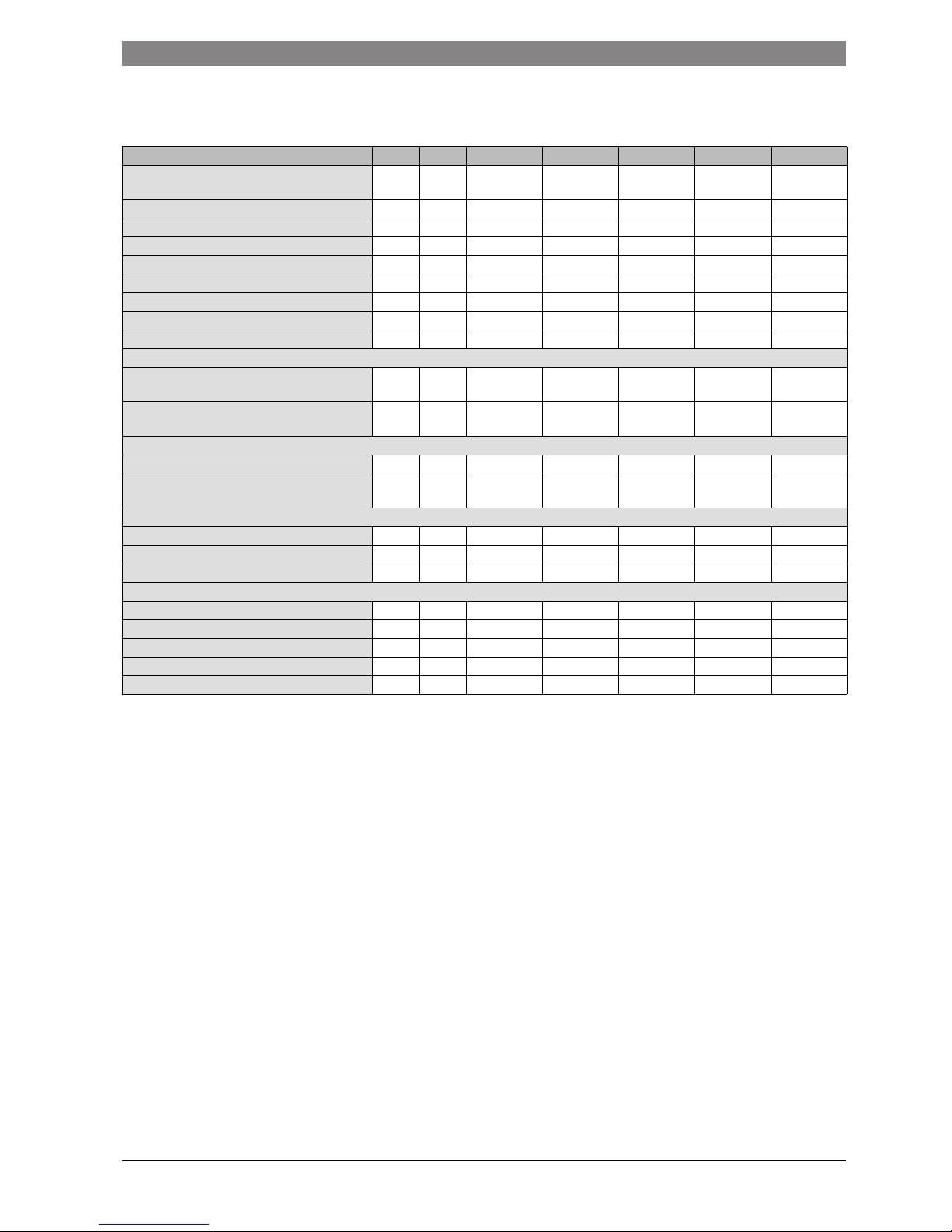

2.15 Energy efficiency

The following product data satisfy the requirements of the EU Regulations No. 811/2013, No. 812/2013, No. 813/2013 and No. 814/2013

supplementing Directive 2010/30/EU.

Product data Symbol Unit 7731600026 7731600027 7731600028 7731600029 7713600030

Product type – – Condens

2000F 16 NG

Condens

2000F 30 NG

Condens

2000F 42 NG

Condens

3000F16 NG

Condens

3000F 30 NG

Condensing boiler – – Yes Yes Yes Yes Yes

Low temperature boiler – – No No No No No

B1 boiler – – No No No No No

Cogeneration space heater (CHP) – – No No No No No

Combination heater – – No No No No No

Rated heat output P

rated

kW 16 30.9 39 16 30.9

Seasonal space heating energy efficiency

s

% 9393929393

Energy efficiency class – – A A A A A

Useful heat output

At rated heat output and high temperature regime

1)

1) High temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

P

4

kW 15.3 30.1 38.1 15.3 30.1

At 30 % of rated heat output and low temperature

regime

2)

2) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return temperature (at heater inlet).

P

1

kW 3.5 7 9.4 3.5 7

Useful efficiency

At rated heat output & high temperature regime 1)

4

% 88.2 88.2 88.2 88.2 88.2

At 30 % of rated heat output & low temperature

regime

2)

1

% 98.9 97.6 97 98.7 97.6

Auxiliary electricity consumption

At full load el

max

kW 0.028 0.048 0.068 0.097 0.116

At part load el

min

kW 0.015 0.015 0.016 0.049 0.054

In standby mode P

SB

kW 0.0016 0.0016 0.0016 0.0016 0.0016

Other items

Standby heat loss P

stby

kW 0.059 0.059 0.059 0.076 0.076

Ignition burner power consumption P

ign

kW00000

Emissions of nitrogen oxides NOx mg/kWh 32 29 27 32 29

Annual energy consumption Q

HE

kWh - - - - Sound power level, indoors L

WA

dB(A) 47.9 54.9 52.6 47.9 52.6

Table 9 Product data for energy consumption according to the EU regulations no. 813/2013 and no. 813/2013

Page 16

16 | Regulations

Product Name6 720 ... ... (YYYY/MM)

3 Regulations

The boiler is designed to operated in conformity with the following

requirements:

• EN 677, EN 483, EN 15502

• EN 437

• Gas appliance directive 2009/142/EG

• Efficiency directive 92/42/EWG

• EMV directive 2004/108/EG

• Low voltage directive 2006/95/EG

3.1 Country specific regulations

For installation and operation, please refer to country specific standards

and regulations. Critical are:

• Local standards and regulations for siting the appliance

• Local standards and regulations for combustion air supply,

ventilation and connection to a flue gas system

• Regulations for connection to an electrical mains supply

• Regulations of the gas supplier for connecting a gas appliance onto

the local distribution network

• Standards and regulations for safety equipment on wet heating

systems

3.2 Approvals and notifications

• The installation of a gas boiler must be declared to, and approved by

the gas supplier.

• Please note, local regulations may require third party approval when

connecting to a flue gas system or drain condensate into the local

sewage system

• Where required, inform local representative (i.e. chimney sweeper)

before installing the boiler

3.3 Quality of the heating water

Use water to drinking water quality when filling and toping up the heating

system.

Unsuitable or contaminated water can lead to problems or damage of the

heat exchanger and water supply caused by i.e. sludge, corrosion and

scale build up.

Apply the following steps:

▶ Thoroughly flush the system before filling

▶ Water from wells and springs are not suitable as fill water

▶ Consider the total volume of scale introduced into the heating system

over its lifetime, by fill and top up water, and protect it against

damage with that in mind

▶ For systems with a volume 50litres/kW (i.e. when using buffer

vessels) the water must be treated. An approved solution is the full

removal of salts from the fill and top up water, achieving a

conductivity of 10

μsiemens/cm (= 10μS/cm).

Instead of a the water treatment solution you could install a means of

system separation (i.e. plate heat exchanger) directly after the

boiler.

▶ Please contact the manufacturer of the appliance for additional

inhibitors and anti freezes. Always refer to the manufacturer's advice

for filling and continuous maintenance when using these solutions.

3.4 Connection to combustion air and flue gas systems

• Always refer to the latest version of the applicable local standards

and regulations

• Further information about combustion air supply and connection to

flue gas systems can be found in chapter 5 in this manual.

• Also refer to the documentation supplied with the flue gas system.

3.5 Room air dependent operation

The boiler primarily operates as a “room air sealed” unit, however the

boiler can be operated as a “room air dependant” unit, if required.

Provide sufficient boiler room ventilation when operating the appliance

room air dependent

▶ Do not obstruct or block any ventilation openings

▶ Ventilation openings must always be kept clear

3.6 Flue gas systems type B

xx

Type B flue gas systems take combustion air from the boiler room. Flue

gas exits the appliance via the flue gas system. Special regulations apply

for installations of this type - comply with these requirements. Sufficient

combustion air must be available.

3.7 Flue gas systems type C

xx

Type C flue gas systems take combustion air from outside the building.

Flue gas exits the appliance via the flue gas system to the outside. To

ensure this, the combustion chamber door is air tight. Therefore always

ensure the combustion chamber door is closed when operating the

appliance room air sealed.

• Refer to the installation instructions of the flue gas system when

installing the appliance

3.8 Combustion air quality

To avoid corrosion, combustion air must be free from aggressive

substances (hydrogen halide, chlorines and fluorine).

3.9 Disposal

• Dispose any part of the heating system via an authorised facility

3.10 Inspection, service and maintenance

The heating system should be service regularly for the following reasons:

• To achieve and maintain a high efficiency and low fuel consumption

• To ensure operational safety

• To keep combustion clean and emissions low

Water quality is an important factor to increase the

efficiency, safety, reliability and availability of your

heating system.

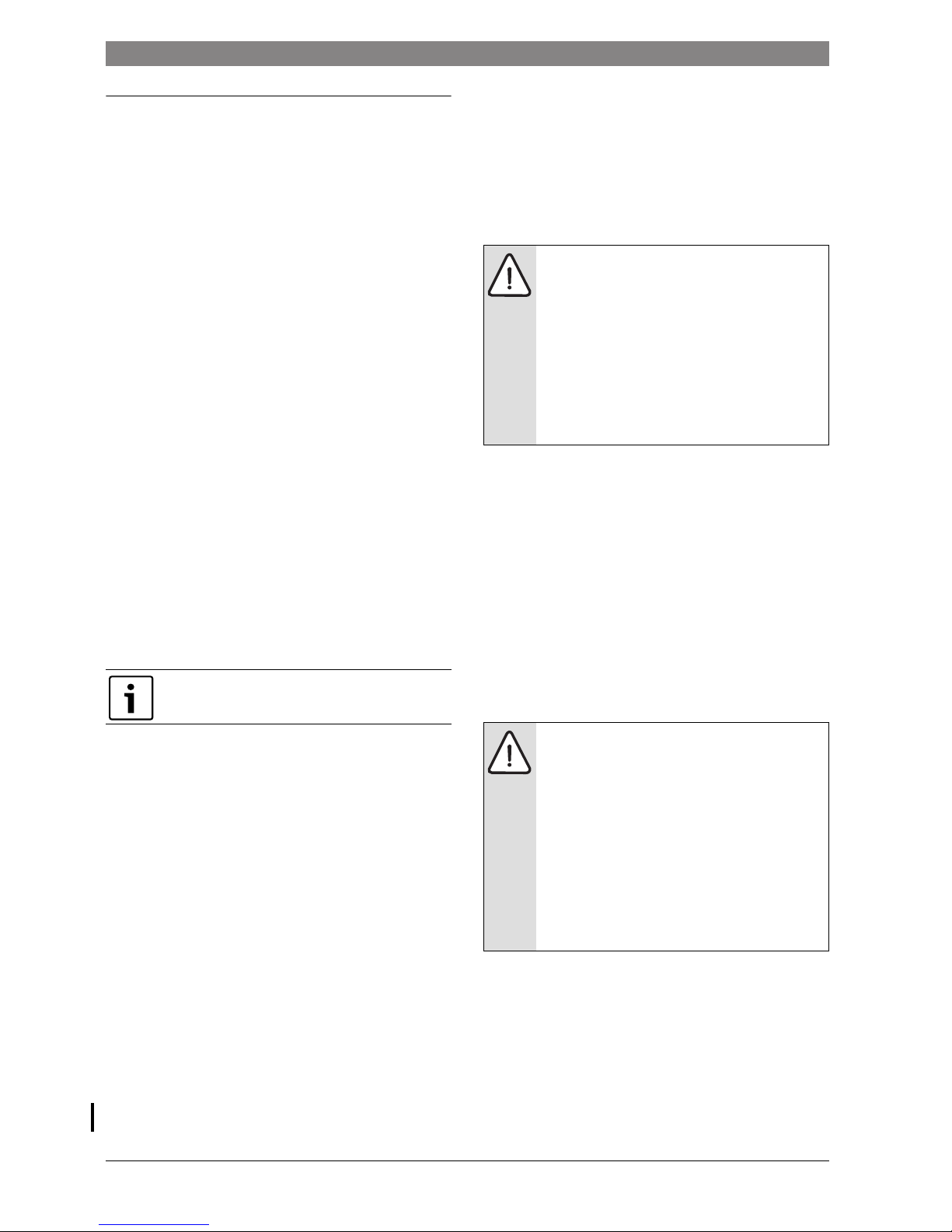

DANGER: Risk to life from flue gas poisoning.

Insufficient combustion air supply can lead to flue gas

escaping.

▶ Ensure combustion air supply

▶ Supply and extract vents in doors, windows and

walls must not be closed off or reduced in size.

▶ Ensure a sufficient combustion air supply, also with

equipment installed afterwards: i.e. kitchen extract

fans and air conditioning units extracting air to the

outside

▶ Do not operate the appliance if combustion air

supply is insufficient.

NOTICE: Damage to boiler from contaminated

combustion air and contaminated air in the vicinity of

the appliance!

▶ Never operate the boiler in an dusty and chemically

aggressive environment i.e. spray painting, hair

dressing and farming facilities

▶ Never operate the boiler in places where using or

storing trichlorethane, hydrogen halide and other

aggressive chemical substances. These substances

can be contained in spray cans, various glues,

primers, paints and cleaning substances. In this case

always install the appliance room air sealed in a

hermetically sealed plant room with ventilation

directly to the outside.

Page 17

Pre-installation | 17

6 720 ... ... (YYYY/MM)Product Name

Service interval

4 Pre-installation

4.1 Cleaning primary systems

4.2 Hydraulic connections

4.2.1 Connecting flow and return

Fig. 11 Pipe work connector location

Regular boiler:

[1] Hot water flow (1”)

[2] Gas (3/4”)

[3*] Not use on the Regular boiler

[4] Hot water return (1”)

[5] Condensate outlet

System boiler:

[1] Heating and DHW flow (1”)

[2] Gas (3/4”)

[3*] DHW return (1”) (only if optional diverter valve kit is fitted)

[4] Heating return (1”)

[5] Condensate outlet

NOTICE: Damage to the system caused by a lack of or

insufficient cleaning and servicing.

▶ Get the heating system inspected at least annually by

an authorised heating engineer

▶ Carry out a service as required. Carry out any repairs

immediately to avoid any damage to the system

NOTICE: Before installation

▶ All the following Pre-Installation sections must be

read and requirements met before starting boiler or

flue installations.

CAUTION: MAINS POWER

▶ ISOLATE THE MAINS SUPPLIES BEFORE STARTING

ANY WORK AND OBSERVE ALL RELEVANT SAFETY

PRECAUTIONS.

NOTICE: Protect the boiler

▶ Debris from the system can damage the boiler and

reduce efficiency.Failure to comply with guidelines

for the use of water treatment with the appliance will

invalidate the appliance warranty.

WARNING: Sealing agents

▶ The addition of sealing agents to the system water is

not permitted, this can cause problems with deposits

left in the heat exchanger.

NOTICE: Damage to property caused by leaking

connections:

▶ Ensure the pipes are installed without mechanical

strain onto the appliance connections

▶ Refurbish seals when loosening or removing

connection joints

▶ Check gaskets and connections for signs of damage

▶ We recommend the installation of a line strainer in

the system return to protect the heating system

▶ Fit isolating valves before and after the line strainer

to allow for servicing

Fit isolation valves in the flow and return to allow

servicing of the appliance

6720809859-10.1Wo

123*4

61

78 111

Ø125

5

83

59

Page 18

18 | Pre-installation

Product Name6 720 ... ... (YYYY/MM)

4.2.2 Expansion vessel and drain valve

Connect an expansion vessel

EN12828 requires and expansion vessel to be installed with the boiler.

▶ Install an expansion vessel in the return to the pump

Fill and drain connections

EN1717 requires a filling of the heating system with drinking water only

via a fixed connection between water supply and heating circuit.

▶ Fit an external filling link between the DCW and CH Flow on the

appliance

4.3 Water systems and pipework

Primary system plastic pipework

• Any plastic pipe work must have a polymeric barrier with 600mm

(minimum) length of copper connected to the boiler.

• Plastic pipe work used for under floor heating must be correctly

controlled with a thermostatic blending valve limiting the

temperature of the circuits to approximately 50°C. The pipe work

from the boiler to the blending valve must be in copper.

Primary system/connections/valves:

• Do not use galvanised pipes or radiators.

• All system connections, taps and mixing valves must be capable of

sustaining a pressure of 3 bar.

• Drain cocks are required at all the lowest points on the system.

• Air vents are required at all high points on the system.

4.4 Condensate drain

Ensure that the condensate trap has at least 250ml of clean water in it

before the boiler is run.

If the flue has not been fitted yet, the water can be poured down the inner

flue pipe. If the flue has already been fitted, the condensate trap will

have to be removed and filled.

4.4.1 To remove the condensate trap

▶ Release the hose clamp [1]

▶ Remove the screw retaining the trap [2]

▶ Pull the trap down to remove the trap from boiler

▶ Pour 250ml of clean water into the top of the trap

▶ Re-fit the trap to the boiler

Fig. 12 Condensate trap

▶ Install condensate neutralisation systems (optional accessory) in line

with the installation instructions

▶ Ensure that the condensate pipework leading away from the

appliance falls away towards the drainage point

▶ Connect into the sewage system based on national and local

standards and regulations

4.5 Boiler location and clearances

4.5.1 Installation

• This boiler is only suitable for installing internally within a property at

a suitable location onto a fixed rigid non-combustible surface at least

the same size as the boiler and capable of supporting the boiler

weight.

• The boiler is not suitable for external installation unless a suitable

enclosure is provided.

4.5.2 Installations and servicing clearances:

The dimensions below are the minimum space required to install,

service and perform maintenance on the boiler only.

Fig. 13 Installation clearances

[1] 1900mm

[2] 2500mm

[3] 2000mm

[4] 70mm

DANGER: Danger to life by poisoning from escaping flue

gas. Flue gas can escape if condensate trap is not filled

with water or connections are not sealing properly.

▶ Fill the siphon with water

NOTICE: Additional advice on draining condensate

▶ Any condensate in the appliance and the flue gas

system must be drained in an appropriate manner

(flue gas system must have sufficient fall towards the

appliance)

▶ Comply with country specific standards and

regulations when connecting the condensate into the

sewage system

▶ Comply with local regulations

Condensate neutralisation systems are available as an

accessory.

6720809859-77.1Wo

2

1

6720809859-09.1Wo

1

2

3

4

Page 19

INSTALLATION | 19

6 720 ... ... (YYYY/MM)Product Name

5 INSTALLATION

5.1 Unpacking the boiler

Unpacking:

1. Undo the ties securing the carton

If a sharp implement is used, care must be taken not to pierce the

carton or cause injury.

2. Before removing the carton it is advised that the top flaps are opened

and the ancillary items (A, B, & C) are removed and set to one side.

3. The carton can now be lifted off the boiler.

▶ Remove the plastic bag protecting the boiler surfaces and place

safely away from the working area.

General handling guidelines:

▶ Lift only a manageable weight, or ask for help.

▶ When lifting, bend the knees, and keep the back straight and feet

apart.

▶ Do not lift and twist at the same time. Lift and carry items close to the

body

▶ Wear protective clothing and gloves to protect from any sharp edges

Fig. 14 Unpacking

[A] Literature pack

[B] PRV disposal pipe

[C] Levelling feet x4

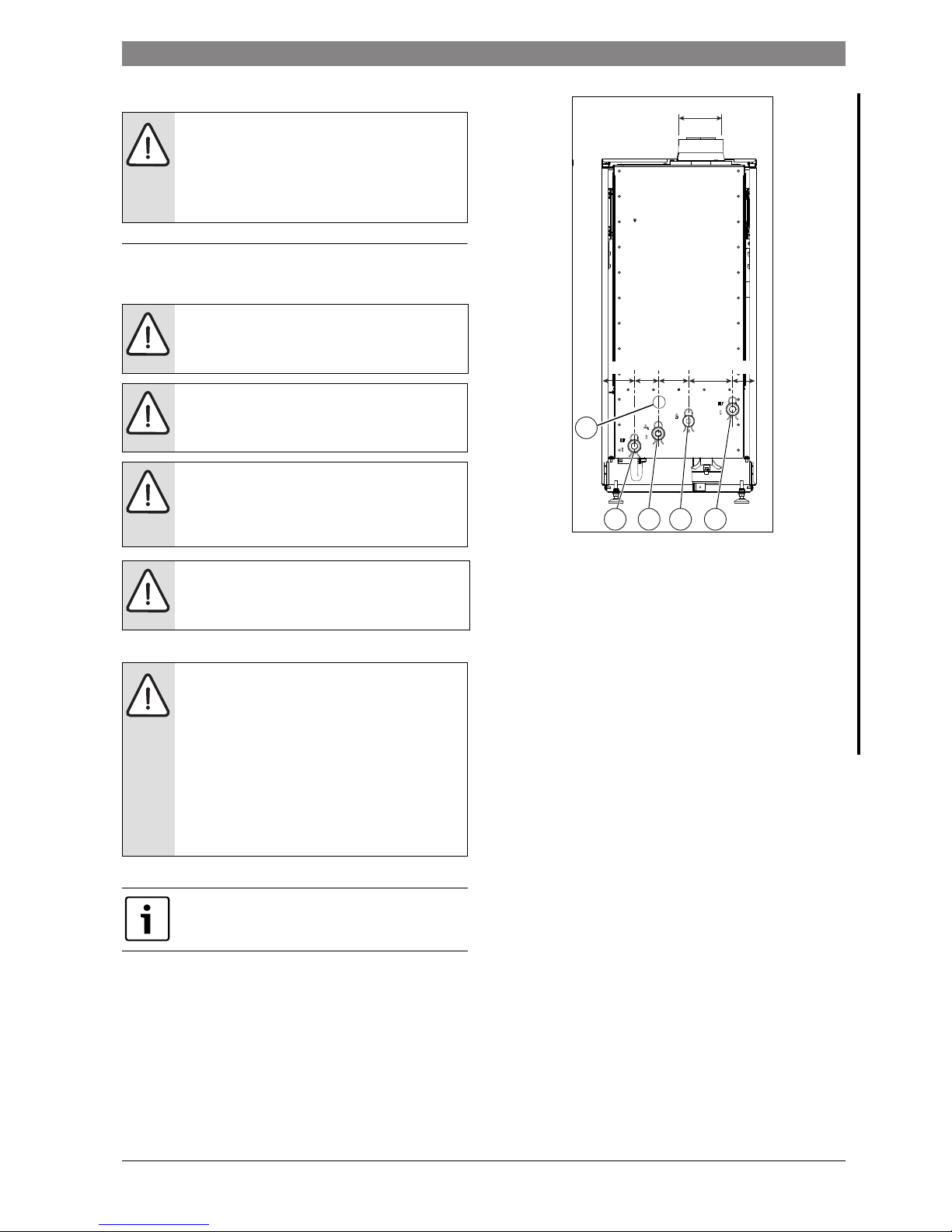

5.2 Boiler room requirements

5.2.1 Installing the levelling feet

▶ Screw a levelling nut onto the threaded shaft of each of the feet

▶ Screw the threaded shaft into the base of the boiler at each corner as

indicated in figure 15

▶ Adjust the feet to be approximately the same length

▶ Level the boiler as described in section 5.2.2

Fig. 15 Fitting the feet

NOTICE: Boiler start up

▶ All the previous Pre-Installation sections must be

read and requirements met before starting boiler or

flue installation.

NOTICE: Boiler handling

▶ At all times the correct method for handling heavy

objects should be strictly observed.

▶ Take care not to damage the boiler panels or floor.

▶ The boiler may contain water due to factory testing

▶ Store the boiler in a dry area prior to installation

DANGER: Explosive and flammable materials

▶ Do not store flammable materials (paper, curtains,

clothing, primer, paint, …) in proximity to the boiler

NOTICE: Damage to the appliance from contaminated

combustion air

▶ Do not use any cleaners containing chlorine or

hydrogen halide (i.e. spray cans, primers, cleaners,

paint and glue)

▶ Don’t store or use these substances in the boiler

room

▶ Avoid the build up of dust

1

2

6720809859-94.1Wo

A

B

C

NOTICE: Damage from overheating.

Excessive ambient temperatures may cause damage to

the heating system.

▶ Ensure the ambient temperature is above 0 °C and

below 35 °C

NOTICE: Frost damage to the appliance

▶ Fit the boiler in a frost free room

CAUTION: Toppling hazard

Boiler will topple over if tilted passed 45 °

▶ Tilt the boiler to no more than 40 °

▶ Take care when tilting the boiler to fit levelling feet,

ideally two people are required to safely fit the feet.

NOTICE: Damage to boiler

▶ Do not lie the boiler down to fit the levelling feet

x4

6720809850-95.1Wo

<40

o

Page 20

20 | INSTALLATION

Product Name6 720 ... ... (YYYY/MM)

5.2.2 Positioning the appliance

The boiler must be adjusted to be level. This ensures air can escape from

the heat exchanger and condensate drains freely.

▶ Place boiler in its final location

▶ Release the locknuts on the boiler feet

▶ Adjust the boiler feet until the boiler is level vertically and

horizontally, check using a spirit level

▶ Secure in position with the locknuts

Fig. 16 Levelling the boiler

5.3 Mounting the boiler and flue opening

Safety

All relevant safety precautions must be undertaken. Protective clothing,

footwear, gloves and safety goggles must be worn as appropriate.

Running pipes behind the boiler

• The boiler should sit at least 70mm from the rear wall to allow enough

room for access to the pipe work.

• Do not cross a pipe over another.

Fig. 17 Pipe Connections

System boiler:

[1] Heating and DHW flow (1”)

[2] Gas (3/4”)

[3*] System boiler - DHW return (1”)

(only if optional diverter valve kit is fitted)

Regular boiler - Not used

[4] Heating return (1”)

[5] Condensate outlet

NOTICE: Damage caused by insufficient load bearing or

unsuitability of the boiler room floor

▶ Ensure the floor area is suitable for installing a boiler

and can take the “wet weight” of the appliance.

NOTICE: Damaged caused by mechanical strain on the

hydraulic and flue gas connections when adjusting the

position of the appliance.

▶ Do not apply any strain the connections when

adjusting the boiler position

CAUTION: Isolate the mains gas supply before starting

any work and follow all relevant safety precautions.

6720809859-79.1Wo

6720809859-48.1Wo

394

Ø80

Ø125

1

2

3*

4

466

98

130

162

193

900 - 930

C

82

C

L

1

2

3*

4

5

61

78 111

83

59

141253

L

Page 21

INSTALLATION | 21

6 720 ... ... (YYYY/MM)Product Name

Gas connections

Flue opening

5.4 Flue options

Fig. 18 Flue options

DANGER: Risk to life from explosion of flammable gases

▶ Work on components in contact with gas must only

be carried out by a competent and authorised

person.

▶ Comply with national and local standards and

regulations

▶ Only use approved methods of making gas tight

connections

Surplus water may be present due to factory testing.

Any horizontal flue sections must rise away from the

boiler by 52mm per metre to ensure that condensate

flows back into the boiler for safe discharge via the

condensate waste pipe.

CAUTION: Non accessible flue systems:

▶ Where a flue system is not going to be accessible,

provision must be made for service and inspection.

▶ Voids containing concealed flues must have at least

one inspection hatch no less than 300mm square.

▶ Flue joints within the void must not be more than 1.5

metres from the edge of the inspection hatch.

▶ Inspection hatches should be located at changes of

direction.

▶ If this is not possible, bends should be viewable from

both directions.

NOTICE: Effective flue lengths:

▶ each 90 ° bend used is equivalent to 2.0 metres of

straight flue

▶ each 45 ° bend used is equivalent to 1.0 metre of

straight flue

Maximum total

flue length L (mm)

Flue type

1 High level horizontal flue 11 000

2 High level horizontal flue with 2 x 90 ° bends 9 000

3 High level horizontal flue with 3 x 90 ° bends 7 000

4 Vertical balanced flue assembly 15 000

5 Vertical balanced flue with 2 x 90 ° bends 11 000

6 Vertical balanced flue with 2 x 45 ° bends 13 000

Table 10 Flue options

3

L

120 mm

120 mm

1

L

120 mm

2

L

6720809859-82.1Wo

Flat roof

300 mm

500 mm

Pitched

roof

4

L

5

L

6

L

120 mm

120 mm

Page 22

22 | INSTALLATION

Product Name6 720 ... ... (YYYY/MM)

5.5 Vertical flues

Room sealed flues C33 and C93

Fig. 19 C33 RSF flue

Fig. 20 C93 RSF flue

L

1

Ø110

Ø 80

Ø 80/125

6720809859-83.1Wo

A

C33

> 1m

L

Boiler

output

(kW)

L max

(metres)

L1 max

(metres)

Equivalent

length 93 ° flue

elbow (metres)

Equivalent length

15 ° and 45 ° flue

elbow (metres)

16 13 3 2 1

30 13 3 2 1

42 13 3 2 1

Table 11

L

1

Ø 80

L

Ø 80/125

A

6720809859-84.1Wo

> 1m

C93

L

Page 23

INSTALLATION | 23

6 720 ... ... (YYYY/MM)Product Name

Open flues B33

Fig. 21 Rigid B33 flue Fig. 22 Flexible B33 flue

L

1

Ø 80

A

Ø 80/125

> 1m

6720809859-85.1Wo

L

B33

Boiler

output

(kW)

L max

(metres)

L1 max

(metres)

Equivalent

length 93 ° flue

elbow (metres)

Equivalent length

15 ° and 45 ° flue

elbow (metres)

16 13 3 2 1

30 13 3 2 1

42 13 3 2 1

Table 12

Ø 80/125

A

Ø 80

6720809859-86.1Wo

L

1

L

> 1m

B33

Page 24

24 | ELECTRICAL

Product Name6 720 ... ... (YYYY/MM)

6 ELECTRICAL

6.1 Electrical

Access to the electrical connections:

Remove the boiler front panel to gain access to electrical connections.

▶ Pull the top corners of the front panel away from the case until the

ball catches are released.

▶ Lift the panel off the lower brackets and set the panel safely aside.

Fig. 23 Electrical connections access

Access to electrical connections:

▶ Access to all wiring connections are via the Installer access cover at

the bottom front of the control panel. No access is required to other

parts of the control board.

▶ Release the three screws in the connections cover and remove the

cover.

Fig. 24

[1] Mains voltage connections

[2] Low voltage connections

[3] Cable retainers

Fig. 25 Mains voltage connections

Fig. 26 Low voltage connections

DANGER: Risk of fire from hot boiler components.

Hot boiler components can damage electrical cables.

▶ Ensure all electrical cables are in the correct cable

guides and away from hot boiler components

Run power cables separately from signal cables.

Interference from power cables can induce spurious

faults on signal cables, ensure that there is at least

300mm separation from each other.

CAUTION: ISOLATE THE MAINS ELECTRICITY SUPPLY

BEFORE STARTING ANY WORK AND OBSERVE ALL

RELEVANT SAFETY PRECAUTIONS

▶ All electrical work must be carried out by a competent

and authorised person.

▶ All work must be in line with country specific and local

standard and regulations.

▶ The isolator must have contact separation of 3mm

minimum between poles. Any system connected to

the boiler must not have a separate electrical supply.

▶ External fuse 3 Amps.

▶ When stripping the wires ensure copper strands do

not fall into the control box.

6720809859-18.1Wo

Mains voltage terminal strip

1 External frost thermostat

2 230 V A.C. switched live inputs

3 230 V A.C. mains output

4 DHW charge pump

5 DHW circulation pump

6 CH circulation pump

7 Boiler 230 V A.C. mains supply

Table 13 Key to figure 25

Low voltage terminal strip

8 Input for external demand

9 EMS bus connections

10 External cut off switch (supplied with factory fitted link)

11 Outside sensor

12 DHW cylinder sensor

13 Low Loss Header sensor

Table 14 Key to figure 26

6720809859-16.1Wo

1

3

2

6720809859-15.1Wo

230V

IN

230V

OUT

FRFSLR

LR

LN

L

N

LN

LN

LN

1

2

3 4

5

6

7

6720809859-14.1Wo

EMS

8

9

10

11

12

13

Page 25

COMMISSIONING | 25

6 720 ... ... (YYYY/MM)Product Name

Cable retainer clamps

▶ Unclip the cable clamp [1}.

▶ Cut off the tapered cable entry [2] to suit the cable diameter.

Fig. 27 Cable entry

▶ Unscrew the cable retaining screw [3}.

Run the cable [4] through the cable clamp ensuring there is ample

cable to reach the connectors.

▶ Tighten the cable retaining screw [3] to secure the cable and replace

clamp into the control panel.

Fig. 28 Cable retainers

7 COMMISSIONING

7.1 Pre-Commissioning checks

1. Check that the service and water pipes are connected to the correct

points on the back of the boiler;

1 - CH flow (1”)

2 - Gas inlet (3/4”)

3* - DHW return (1”) System boiler with optional diverter valve kit only

4 - CH return (1”)

5 - Condensate out

Fig. 29 Pre-commissioning checks

2. Check all system and boiler drain points are closed.

3. Check the gas type specified on the identification plate matches that

of the gas supply.

▶ Turn on the main gas supply and purge the gas supply to the boiler

ensuring that the room is well ventilated.

▶ Test the gas supply for tightness.

4. Check the flue is correctly fitted and the connections are secure.

5. Check the condensate pipe work is correctly fitted and connected.

6. Refit cover onto the bottom clips and secure with the ball catches.

7.2 Filling the system and checking for leaks

Check the heating system for leaks to avoid problems during

commissioning and operation.

• Ensure good ventilation, ensure all isolating valves in the heating

circuits and radiation temperature regulating valves are fully open

• Open all automatic air vents

4

3

3

1

2

≥ 5mm

6720809529-92.1Wo

36-40mm

26-30mm

6-8mm

6-8mm

N

L

6720809529-92.1Wo

CAUTION: ISOLATE THE MAINS SUPPLIES BEFORE

STARTING ANY WORK AND OBSERVE ALL RELEVANT

SAFETY PRECAUTIONS.

NOTICE: If the boiler is not commissioned immediately

then, after successfully completing all of the checks and

any rectification work, shut off the gas supply and

electrically isolate the boiler.

NOTICE: Damage due to the ingress of air into the

system

▶ The appliance is only suitable for installation and

operation on pumped, sealed and pressurised

heating systems in line with EN12828.

▶ Do not connect onto gravity and/or open vented

systems

CAUTION: Risk to health from contaminated drinking

water:

▶ Comply with country specific standards and

regulations for avoiding contamination of drinking

water

▶ In Europe, also comply with EN 1717

6720809859-67.1Wo

1

2

3*

4

5

Page 26

26 | COMMISSIONING

Product Name6 720 ... ... (YYYY/MM)

▶ Open all the system and radiator valves.

▶ Turn on the water main stop cock.

Sealed System

1. Monitor the pressure gauge on the control panel of the appliance

2. Slowly fill the system via the external filling link

3. Set the pressure between 1 and 1.5 bar pressure.

Fig. 30 Setting the system pressure

▶ Close the external filling valve

▶ Check the pipe work and connections for leaks and rectify as

necessary

▶ Vent all radiators, retighten when completed.

If the test pressure drops off as a result of the air bleeding:

▶ Top up with domestic cold mains water

▶ Complete pressure test based on the local requirements

Once the pressure test is completed and no leaks are present:

▶ Set correct working pressure

7.3 Water treatment

7.4 Starting the appliance

Fig. 31

[1] Main on/off switch

[2] Diagnostic port (Service engineers only)

[3] DHW button

[4] Heating button

[5] Display

[6] Minus button

[7] Plus button

[8] ok button

[9] Back button

[10] Pressure gauge

[11] Service button

[12] Reset button

[13] Summer/Winter mode button

Switching the appliance on/off:

1. Turn on the mains power supply.

▶ Turn on any external controls.

▶ Set the TRV controls to maximum.

▶ Set the clock or programmer, if fitted, to continuously ON and the

room thermostat to maximum temperature.

2. Switch on the appliance with the ON/OFF switch on the control

panel.

The display lights up and initially shows the appliance temperature.

Fig. 32 Main power switch

NOTICE: Damage to property from overpressure during

pressure tests!

Pressure, control and safety devices may be damaged

by excessive pressure.

▶ After filling the system pressure test to the release

pressure of the safety valve

NOTICE: Damage caused by cracks from thermal shock!

Cracks can occur when toping up a warm heating system

with cold mains water. The boiler could start leaking.

▶ Only fill and top up the heating system when cold

(maximum flow temperature 40 °C)

▶ Comply with the requirements for water quality

Have a fixed connection between mains water supply

and filling point in line with EN 1717. Fit the appropriate

safety device.

NOTICE: Debris from the system can damage the boiler

and reduce efficiency. Failure to comply with the

guidelines for the use of water treatment with the

appliance will invalidate the appliance warranty.

NOTICE:

▶ The quality of the system water must be checked

regularly. Please contact the appliance manufacturer

for further guidance.

▶ The addition of sealing agents to the system water is

not recommended as this can cause problems with

deposits left in the heat exchanger.

20809859-78.1Wo

1.

2.

3.

Min

1 bar

1.5 bar

Max

NOTICE: Never run the appliance when the appliance or

system is empty or unpressurised.

The condensate trap fill program starts each time the

appliance is turned on. The appliance runs at minimum

output for about 15 minutes to fill the condensate trap.

The symbol . flashes until 15 minutes of burner

operation has been completed.

10

6 94 732 8

1113 12

reset

5

1

6720809978-01.1Wo

6 720 646 606-27.1O

Page 27

COMMISSIONING | 27

6 720 ... ... (YYYY/MM)Product Name

Setting the boiler to maximum output

3. Press the / button together with the button to enter the

“Chimney sweep mode” , the display shows the current flow

temperature and flashes the percentage heat output in the

alphanumeric display. The burner symbol will be shown in the

display.

Press the + or - buttons until the required percentage output is

displayed. Set the output to 100% initially.

Fig. 33 Operating the boiler

4. If the boiler fails to light, press the reset button until the reset line of

text displays. The device goes back into operation and the flow

temperature is displayed.

5. Press the button at any time to return to normal operation.

7.5 Checking gas inlet pressure

7.5.1 Measuring the inlet pressure

▶ Remove the front panel figure 23

▶ Remove the combustion chamber cover.

The inlet pressure to the appliance must be checked using the following

procedure:

Fig. 34 Inlet test point

▶ Close gas isolation valve.

▶ Slacken the screw in the inlet pressure test point and connect a

manometer.

▶ Open gas isolation valve.

▶ Measure the pressure with the boiler running at maximum output.

▶ Check the gas supply working pressure at the gas valve conforms to

values shown in table 15.

Gas pressure within the system

If the gas pressure, for your gas type, is below the minimum shown in

table 15, then this would indicate a problem with the pipe work or

connections within the system.

▶ If pressure is satisfactory press the button and the boiler will

return to normal operation.

▶ If left in the central heating boost mode the control will return to

normal operation after 30 minutes.

▶ Re-seal the screw in the gas inlet pressure test point.

7.5.2 Checking the gas rate

▶ The gas rate should be measured at the gas meter after 10 minutes

operation at maximum.

See technical data section at the front of this manual.

▶ Where a gas meter is not available (e.g. L.P.G.) the CO/CO

2

must be

checked to the units shown in section “Setting the air/gas ratio”.

▶ If pressure and gas rate are satisfactory press the button and the

boiler will return to normal operation.

– If left in the “Chimney sweep” mode the control will return to

normal operation after 30 minutes.

▶ Close the gas isolation valve.

▶ Remove the manometer.

▶ Re-seal the screw in the gas inlet pressure test point.

▶ Open the gas isolation valve.

▶ Ensure that there are no gas leaks.

▶ Replace the outer case.

7.6 Finishing commissioning

1. Refit and secure the inner combustion chamber cover with the four

screws removed earlier.

2. Locate the lower edge of the front panel onto the brackets and

engage ball catches into the receptors in each side panel.

HANDOVER:

▶ Complete the Commissioning checklist supplied.

▶ Set up the controls and show the user how to operate all the controls

shown in the User Guide.

▶ If appropriate instruct the customer how to repressurise the system.

▶ If the appliance is unused and exposed to freezing conditions, advise

the customer of the precautions necessary to prevent damage to the

boiler, system and building.

In the event of the appliance being inoperative, isolate the boiler and

drain the system and boiler.

7.7 Commissioning checklist

▶ After commissioning, confirm work carried out, enter values, sign

and date to complete.

The boiler will run at maximum output for 30 minutes

before switching back to normal operation.

Ensure inlet pressure is satisfactory with all other gas

appliances working.

6 720 619 605-16.1O

6720809859-89.1Wo

A

Gas type min.pressure (mbar) max. pressure (mbar)

G20 17 25

G25 22 30

G31 25 45

Table 15 Gas pressure range

NOTICE:

Do not continue commissioning until the correct gas

pressure is achieved.

At the time of commissioning, complete all relevant

sections of the Commissioning Checklist supplied.

Page 28

28 | COMMISSIONING

Product Name6 720 ... ... (YYYY/MM)

Commissioning Page Unit Values Comment

1 Fill the heating system and check for leaks

2 Record gas values

Wobbe index

Calorific value

kWh/m

3

3 Check gas supply for leaks

Bleed gas supply

4 Pressurise the heating system and record the value bar

5 Check the flue inlet and exhaust, and connections

6

7 Set the gas type, if required

8 Commission burner and controls

9 Measure and record gas supply pressure mbar

10 Measure flue gas values and record Full load Partial load

- Flue gas pressure Pa

- Flue gas temperature (gross) t

A

°C

- Air temperature t

L

°C

- Flue gas temperature (net) tA - t

L

°C

- CO2 or O2 content Vol. %

- Flue gas losses q

A

%

- CO content (air free) ppm

- Supply air CO2 or O2 content when operating room sealed Vol. %

11 Check for leaks during operation

12 Functional tests

Measure ionisation current

13 Refit casing panels

14 Inform homeowner and hand over documentation

15 Correct installation by approved installer Signature

16 Homeowner Signature

Table 16 Commissioning checklist

Page 29

THERMAL DISINFECTION | 29

6 720 ... ... (YYYY/MM)Product Name

8 THERMAL DISINFECTION

8.1 Perform thermal disinfection

General

To prevent Legionella bacterial contamination of the hot water system,

we recommend that a thermal disinfection is performed after a long

period of inactivity.

Some control systems have a preset programmed time interval for

thermal disinfection to be performed, see the operating instructions for

your control system.

Thermal disinfection treats the entire hot water system including the

extraction points.

8.2 Thermal disinfection for system with a hot water tank

Thermal disinfection via external controller

The thermal disinfection is in this case is performed via the external

controller, refer to the controller operating instructions

▶ Turn off all the hot water taps.

▶ Warn the occupants about the potential for scalding.

▶ Set any other pumps for continuous operation.

▶ Activate the Thermal disinfection at the maximum temperature via

the controller.

▶ Wait until the maximum temperature is reached.

▶ Run each hot water taps for at least 3 minutes at 70 °C, starting at the

one nearest to the boiler and working your way to the furthest outlet

▶ Set the circulation pump and control system back to normal

operation.

Thermal disinfection via built in controller

The Thermal disinfection is perform via the built-in controller and is

automatically started and ended.

▶ Turn off all hot water taps

▶ Warn the occupants about the potential for scalding

▶ Set any other pumps for continuous operation

▶ Activate the thermal disinfection via the service function 2.9L see

table 20 on page 35

▶ Wait until the maximum temperature is reached

▶ Run each hot water tap for at least 3 minutes at 70 °C, starting at the

tap nearest to the boiler and working your way to the furthest tap

▶ Set the other circulation pump back to normal operation

▶ Thermal disinfection is completed after the water was maintained at

70 °C for 35 minutes

To interrupt thermal disinfection

▶ Turn the device off and on again.

The appliance returns to normal into operation and the flow temperature

is displayed.

WARNING: Risk of scalding

Hot water can cause serious burns

▶ Perform thermal disinfection outside normal hot

water use times.

Drawing off hot water at too high a rate may mean that

the required temperature can not be achieved.

▶ Draw off only as much water as the appliance can

supply constantly at the disinfection temperature of

70 ° C.

Page 30

30 | Operating the appliance

Product Name6 720 ... ... (YYYY/MM)

9 OPERATING THE APPLIANCE

This manual only applies to the appliances listed on the front cover.

Depending on the control system fitted some function may be different.

The following option control systems can be used:

• EMS externally mounted programmer

9.1 Controls overview

Fig. 35

[1] Main on/off switch

[2] Diagnostic port (Service engineers only)

[3] DHW button

[4] Heating button

[5] Display

[6] Minus button

[7] Plus button

[8] ok button

[9] Back button

[10] Pressure gauge

[11] Service button

[12] Reset button

[13] Summer/Winter mode button

9.2 Screen display

Fig. 36 Display symbols

[1] DHW mode off

[2] DHW mode on

[3] Solar mode (not used on this appliance)

[4] Weather compensation (External sensor required)

[5] Chimney sweep mode

[6] Fault alert

[7] Service mode

[6 + 7] Maintenance mode

[8] Burner on

[9] Temperature units °C

[10] Confirmation

[11] Scroll up or down through the sub menus

[12] Alphanumeric display (e.g. Temperature)

[13] Text display

[14] Heating mode off

[15] Heating mode on

9.3 Appliance on/off switch

Initial switch on

▶ To switch on, use the main appliance on/off switch on the control

panel.

The display lights up and initially shows the appliance temperature.

Fig. 37 Main power switch

For more information refer to the manual of that

controller or programmer.

10

6 94 732 8

1113 12

reset

5

1

6720809978-01.1Wo

The condensate trap fill program starts each time the

appliance is turn on. The appliance runs at minimum

output for about 15 minutes to fill the condensate trap.

The symbol . flashes until 15 minutes of burner

operation have been completed.

13 121415

2 3 4 876 95

11

6 720 619 605-12.1O

10

1

6 720 646 606-27.1O

Page 31

Operating the appliance | 31

6 720 ... ... (YYYY/MM)Product Name

Switching the appliance off

▶ To switch off: use the main appliance on/off switch on the control

panel. The display goes blank.

▶ If the appliance is to be taken out of service for a while: Check the

anti-freeze ( Section 9.8).

9.4 Heating mode

9.4.1 Heating mode on/off

▶ Press the Heating mode button repeatedly until the display

shows the Heating mode on symbol or the Heating mode off

symbol flashing.

Fig. 38 Heating display

▶ Press the + or – button to select Heating mode on or off:

– =Heating mode on

– = Heating mode off

▶ Press the ok button to save the setting.

The tick symbol will be displayed briefly.

Fig. 39 Heating mode display

The burner symbol is displayed when the there is a heating

demand.

9.4.2 Set the maximum flow temperature

The maximum flow temperature can be set between 30 °C and 82 °C

1)

.

The current flow temperature appears on the display.

When in the Heating mode:

▶ Press the button.

The display shows the flashing maximum flow temperature and the

Heating mode symbol is displayed.

Fig. 40 Maximum flow temperature

▶ Press the + or – button to set the desired maximum flow

temperature.

▶ Press ok to save the setting.

The tick symbol is displayed briefly to confirm that the setting

has been saved.

Fig. 41 Setting the maximum flow temperature

The controller has a pump anti-seize function for when

the pump is inactive for a long period of time, the pump

is run periodically to prevent it seizing. If the controller is

turned off, then this function is inactive.

NOTICE: Risk of the system freezing

When the heating is turned off, only the appliance is

protected from frost.

▶ Check the anti-freeze if there is at risk of freezing

( Page 33).

No heating will occur if the Heating mode has been set to

off.

6 720 619 605-15.1O

6 720 619 605-14.1O

1) The maximum value can be reduced by the service technician.

For under-floor heating be aware of the maximum flow

temperature.

Flow temperature

(approx.)

Example

50 °C Under-floor

75 °C Radiators

82 °C Convection

Table 17 Maximum flow temperatures

6 720 619 605-13.1O

6 720 619 605-14.1O

Page 32

32 | Operating the appliance

Product Name6 720 ... ... (YYYY/MM)

9.5 Setting the DHW

9.5.1 DHW on/off

▶ Press the button repeatedly until the symbol or the

flashing is displayed.

Fig. 42 DHW display

▶ Press + or – button to set the desired hot water use:

– = DHW mode

– + Eco = Eco mode

– = DHW mode off

▶ Press ok to save the setting.