Bosch Compress 3000 DW FO, Compress 3000 DW FO HP 270-1E 0 FOV/S Installation Instructions Manual

Installation instructions

Electric Heat Pump Water Heater

Compress 3000 DW FO

6720801244-00.1V

HP 270-1E 0 FOV/S...

6 720 801 244 (2013/08) AU

6 720 801 244 (2013/08) Compress 3000 DW FO

2 | Index

Index

1 Key to symbols and safety instructions . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . 3

2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Appliance details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Features and safety devices . . . . . . . . . . . . . . . 7

3.3 Specification tables . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Storing and transportation . . . . . . . . . . . . . . 10

3.4.1 Transport using a forklift . . . . . . . . . . . . . . . . 10

3.4.2 Manual transport . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Operational principle (brief overview

of modes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Tools required . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Location requirements . . . . . . . . . . . . . . . . . 15

4.3 Secure the appliance . . . . . . . . . . . . . . . . . . . 16

4.4 Water piping . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.1 Inlet - Outlet connections . . . . . . . . . . . . . . . 16

4.4.2 Dielectric joint (not supplied with

the appliance) . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.3 Condensate Drain Tubes (not supplied with

the appliance) . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.4 TPR Valve (supplied with the appliance) . . . 17

4.4.5 Thermal expansion tank (not supplied with

the appliance) . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4.6 Temperature mixing device (not supplied

with the appliance) . . . . . . . . . . . . . . . . . . . . . 18

4.4.7 Pressure limiting valve (not supplied with

the appliance) . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4.8 Expansion control valve (not supplied with

the appliance) . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.5 Electric requirements . . . . . . . . . . . . . . . . . . 18

4.6 Installation configurations . . . . . . . . . . . . . . . 19

4.6.1 Ecological ambient heat recovery . . . . . . . . . 19

4.7 Insulation blanket . . . . . . . . . . . . . . . . . . . . . 20

4.8 Fill the water storage tank . . . . . . . . . . . . . . . 20

4.8.1 Water characteristics . . . . . . . . . . . . . . . . . . 21

4.9 Installation checklist . . . . . . . . . . . . . . . . . . . 21

4.10 What to expect for “normal startup” . . . . . . . 23

4.11 Off-peak compatibility . . . . . . . . . . . . . . . . . . 23

5 Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Safety warnings . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Working display . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Working modes . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 „Operating“ menu . . . . . . . . . . . . . . . . . . . . . . 25

5.4.1 „manual“ mode . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.2 „P1“, „P2“ and „P3“ modes . . . . . . . . . . . . . . 25

5.4.3 „Off“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Temperature set point . . . . . . . . . . . . . . . . . . 26

5.6 „Main“ menu . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6.1 „Mode“ function - heating modes . . . . . . . . . . 26

5.6.2 „Prog“ function - Timetable operation

programming . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.6.3 Silent Mode programming - „Sil“ function . . . 29

5.6.4 „Leg“ function - automatic thermal

disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.6.5 „Set“ function - adjustments . . . . . . . . . . . . . 31

5.6.6 „Purg“ function - purge . . . . . . . . . . . . . . . . . . 31

5.6.7 „Info“ function - information . . . . . . . . . . . . . . 31

5.7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 32

5.8 Factory configurations . . . . . . . . . . . . . . . . . . 32

5.9 Selecting the temperature units - „°C“ or „ °F“ 32

5.10 Setting the time and day of the week . . . . . . . 33

5.11 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Periodic Inspection . . . . . . . . . . . . . . . . . . . . . 35

6.2 Temperature and pressure relief valve

(PTR Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3 Flushing tank . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Draining the Water Heater . . . . . . . . . . . . . . . 35

6.5 Vacation and Extended Shutdown . . . . . . . . . 36

6.6 Clearing the Condensation Drain Tubes . . . . 36

6.7 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . 36

6.8 Anode Rod servicing . . . . . . . . . . . . . . . . . . . . 36

6.9 Checking/replacing the magnesium anode . . 36

6.10 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.1 Fault display . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 Environmental protection . . . . . . . . . . . . . . . . . . . . . . . 43

10 Warranty details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 720 801 244 (2013/08)Compress 3000 DW FO

Key to symbols and safety instructions | 3

1 Key to symbols and safety

instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

1.2 Safety information

„Water“ safety warnings

Warnings in this document are identified by a

warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

•List entry

– List entry (second level)

Table 1

WARNING:

This water heater is not suitable for pool

heating.

WARNING:

The appliance should be located in an area

where leakage of the heater or connections

will not result in damage to the area adjacent

to the appliance or to lower floors of the

structure. When such locations cannot be

avoided, it is recommended that a suitable

drain pan, adequately drained, be installed

under the appliance.

WARNING:

If a water heater is installed in a closed water

supply system, such as one having a

backflow preventer in the cold water supply

line, means shall be provided to control

thermal expansion. Contact the water

supplier or local plumber on how to control

this situation.

WARNING:

Precautions must be taken prior to manually

operating the relief valve to avoid contact

with hot water coming out of the relief valve

and to prevent water damage.

WARNING:

If a relief valve discharges periodically, this

may be due to thermal expansion in a closed

water supply system. Contact the water

supplier or local plumber on how to correct

this situation. Do not plug the relief valve.

WARNING:

The temperature pressure relief valve

should be checked for performance every

six months or replaced at intervals not

exceeding 3 years, or more frequently in

areas where there is a high incidence of

water deposits.

6 720 801 244 (2013/08) Compress 3000 DW FO

4 | Key to symbols and safety instructions

Refrigerant

▶ Please observe the relevant environmental regulations

when using and reusing refrigerant. Do not allow

refrigerant to be discharged into the environment. Use the

refrigerant R134a. It is non-flammable and does not have a

destructive impact on the ozone layer.

▶ Before working on parts of the refrigerant circuit, remove

the refrigerant to ensure work safety.

Use HFC-134a and PAG-OIL for maintenance purposes. It

contains fluorinated greenhouse gas and is rated with a

greenhouse potential of 1300 in the Kyoto Protocol.

„Electric“ safety warnings

„General“ safety warnings

Do not store or use gasoline or other flammable, combustible

or corrosive vapors and liquids in the vicinity of this or any

other appliance.

For your safety

WARNING:

This water heater contains electronic

equipment and 500V insulation tests must

only be conducted between active and earth

and between neutral and earth. An active to

neutral test WILL damage the electronics.

WARNING:

All electrical work and fixed wiring must be

carried out by a qualified person and in

accordance with the Wiring Rules AS/NZS

3000 and local authority requirements.

DANGER:

Shock hazard: line voltage is present. Before

servicing the water heater, please cut the

power supply. Failure to do so could result in

severe personal injury or death.

CAUTION:

Label all wires prior to disconnection when

servicing controls. Wiring errors can result in

improper and dangerous operation.

Verify proper operation after servicing.

WARNING:

Do not turn power off to the appliance if cold

weather is expected as components may be

damaged by freezing. If power needs to be

turned off or power failure occurs and

freezing conditions are expected, water

should be drained from the appliance.

WARNING:

Do not operate this system before reading

the manual.

WARNING:

This appliance must be installed,

commissioned and serviced by an

authorised person in accordance with all

applicable local rules and regulations.

WARNING:

Keep appliance area clear and free from

combustible materials, gasoline and other

flammable vapors and liquids.

WARNING:

The power supply to the appliance must not

be activated until the system is filled with

water.

WARNING:

To meet the requirements of the National

Plumbing Standard, the temperature of the

stored water must not be below 60 °C.

6 720 801 244 (2013/08)Compress 3000 DW FO

Key to symbols and safety instructions | 5

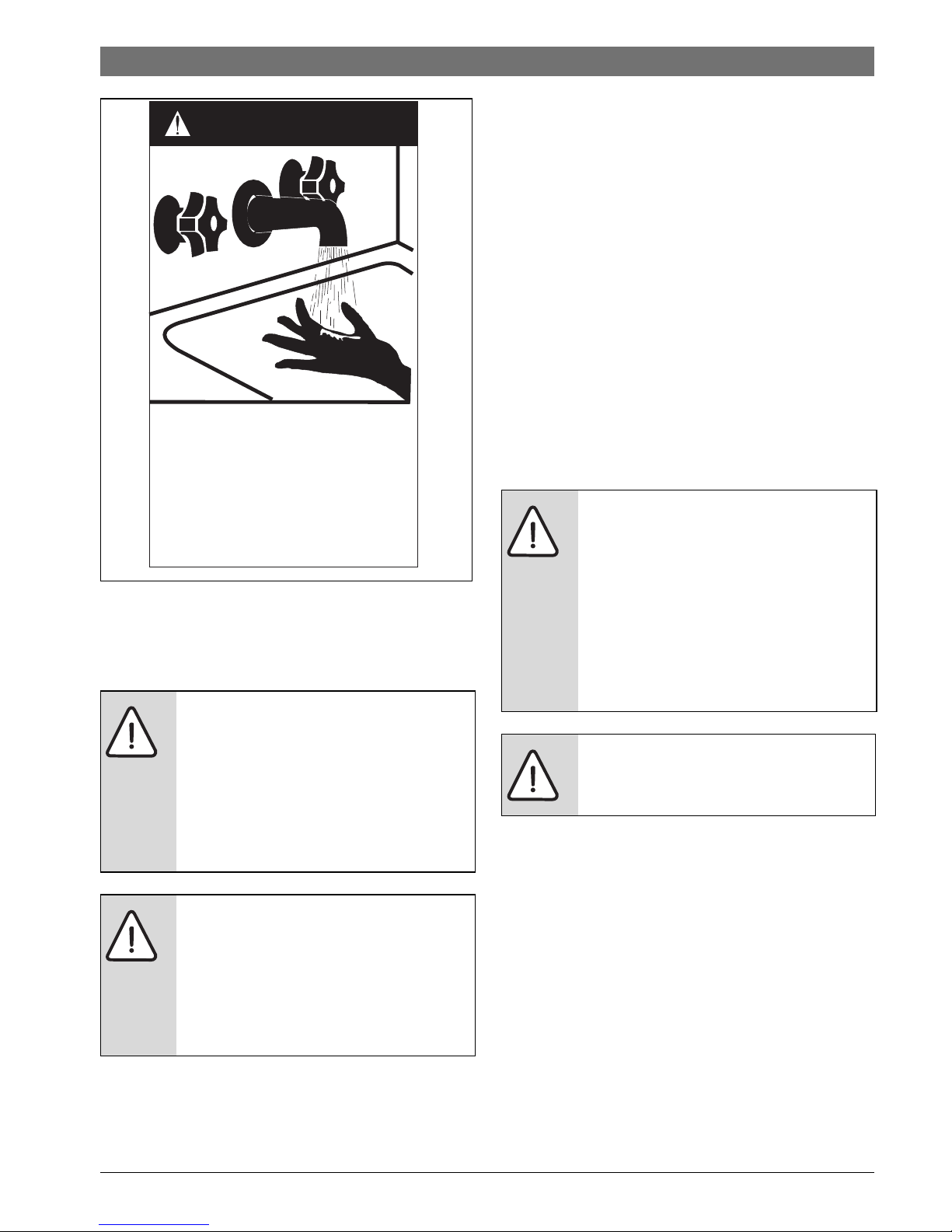

Fig. 1

To prevent serious injury, unit damage or damage to other

property, please use the unit properly. Read this manual

carefully and understand the following information correctly.

High temperature water increases the risk of scald injury

This water heater can heat up water to temperatures which can

cause scalding. Always feel the water temperature before use,

either before having a shower or when filling a bath tub to

ensure it will not cause scald injuries.

We rec om men d, a nd i t m ay a lso be r eq uir ed b y re gu lat ion s th at

an approved temperature limiting device is fitted into the hot

water pipe connected to sanitary outlets (i.e. bathroom and

ensuite). This will keep the water temperature below 50 °C at

these outlets. The risk of scald injury will be reduced and still

allow hotter water to the kitchen and laundry.

Notice to Victorian Customers from the Victorian Plumbing

Industry Commission.

This water heater must be installed by a licensed person as

required by the Victorian Building Act 1993. Only a licensed

professional will give you a Compliance Certificate, showing

that the work complies with all the relevant standards. Only a

licensed person will have insurance protecting their

workmanship.

Make sure you use a licensed person to install this water heater

and ask for your Compliance Certificate.

Every care has been taken to ensure accuracy in preparing this

document.

No liability can be accepted for any consequences, which may

arise as a result of its application.

WARNING:

This appliance is not intended for use by

persons, including children, with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety.

WARNING:

Water temperatures over 50 °C can cause

severe scalds. Local regulations and/or the

requirements of AS/NZS 3500.4 must be

considered regarding the temperature

limitations of hot water used primarily for

personal hygiene.

HOT

BURN

DANGER

Water temperature over 50°C can

cause severe burns instantly or

death from scalds.

Children, disabled and elderly are

at highest risk of being scalded.

Feel water before bathing or

showering.

6720801244-15.1V

WARNING:

Installation requirements are described in

section 4. The water heat er must be installed

by an authorised person and the installation

must comply with Standards AS/NZS

3500.4, AS/NZS 3000 and all local codes

and regulatory authority requirements. In

New Zealand, the installation must conform

with Clause G12 of the New Zealand Building

Code.

WARNING:

A wrong operation may lead to death or

serious injury to people.

6 720 801 244 (2013/08) Compress 3000 DW FO

6 | Standard delivery

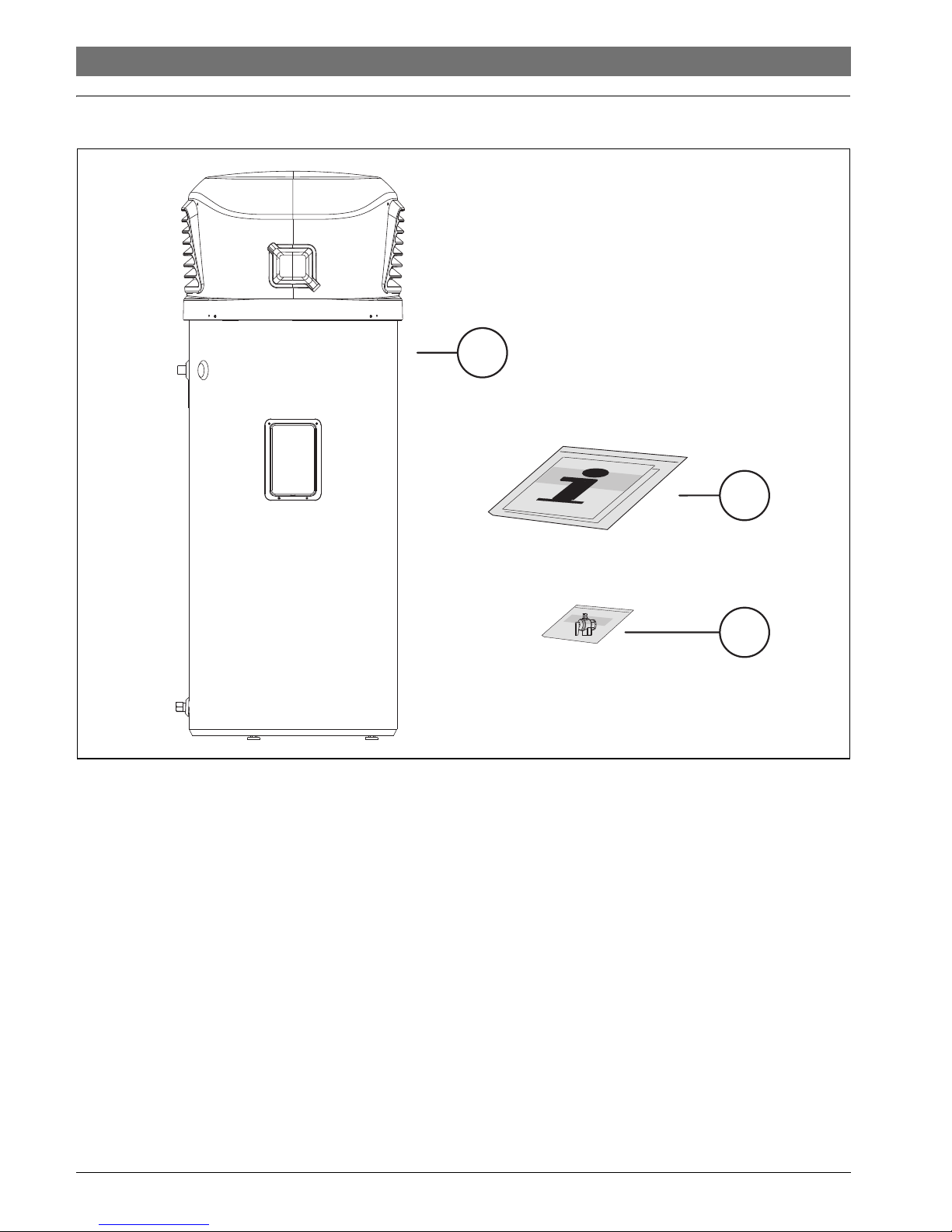

2 Standard delivery

Fig. 2

[1] Heat pump

[2] Set of printed documents for the appliance

[3] PTR valve

1

2

6720801244-02.1V

3

6 720 801 244 (2013/08)Compress 3000 DW FO

Appliance details | 7

3 Appliance details

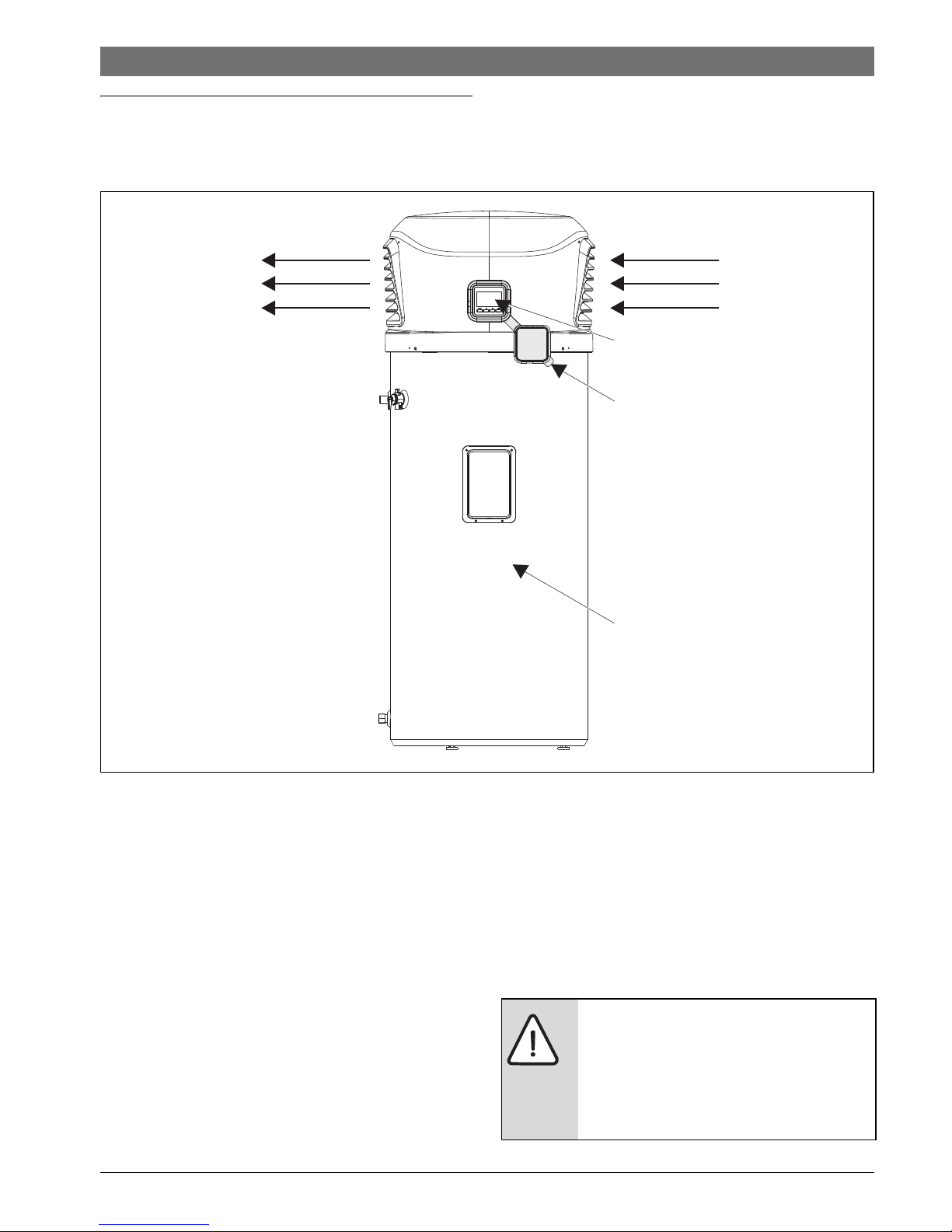

3.1 Overview

Fig. 3 Appliance overview

3.2 Features and safety devices

Easy to operate and environmentally friendly

The heat pump has user interface with easy use menu keys for

ease of programming. The heat pump is also environmental

friendly as it transfers heat from the surrounding area into the

water.

Heating capacity

The unit absorbs ambient energy and releases the heat into the

water stored in the tank. If the ambient temperature is low, the

heating capacity of the heat pump will be reduced, but you can

still rely on the electric element for backup.

Thermal Cut Out (TCOs)

The water heater is equipped with one thermal cut out (TCO)

located above the heating element, in contact with the tank

surface. If for any reason the water temperature becomes

excessively high, the thermal cut-out (TCO) cuts the power

circuit to the heatin g element. Once activated, the TCO must be

reset manually. Resetting of the temperature limiting control

should be done by a qualified service technician.

Air inletAir outlet

User

interface

User

interface

cap

Tank

6720801244-03.1V

CAUTION:

The cause of the high temperature condition

must be investigated by a qualified service

technician and corrective action must be

taken before placing the water heater in

service again.

6 720 801 244 (2013/08) Compress 3000 DW FO

8 | Appliance details

Defrosting

During heating, when the air temperature is between 3 °C and

10 °C, the unit will defrost automatically to make sure the

heating efficiency is retained (it will last 15 minutes).

The fan motor will continue running when the unit is being

defrosted.

Working condition

The appliance is designed to operate with best efficiency when

the air temperature is between +3 °C and +40 °C. For the best

results please install the unit in an area with an environment

temperature of +3 °C to +40 °C.

Care should be taken to feed the unit only with potable water

( section 4.8.1). Do not use untreated water from lakes,

rivers or groundwater!

Overheating protection

When the water temperature reaches 84 °C ± 4 °C the power to

the heating element will be cut off and will require a manual

reset.

Water temperature or pressure protection

The unit is supplied with a PTR valve for your safety (supplied

accessory). If the tank pressure reaches 1000kPa or the

temperature reaches 99 °C, the PTR valve will open

automatically to allow the pressure or temperature to decrease

to safe values.

The warranty can become void if relief valves or other safety

devices are tampered with or if the installation is not in

accordance with the instructions in this manual.

Mains Pressure

This water heater is designed for direct connection to mains

water supply. In case the mains supply pressure exceeds

800kPa, a pressure limiting valve must be installed

(section 4.4.6). A minimum water supply pressure of

200kPa is required to assure the effective operation of this

water heater.

6 720 801 244 (2013/08)Compress 3000 DW FO

Appliance details | 9

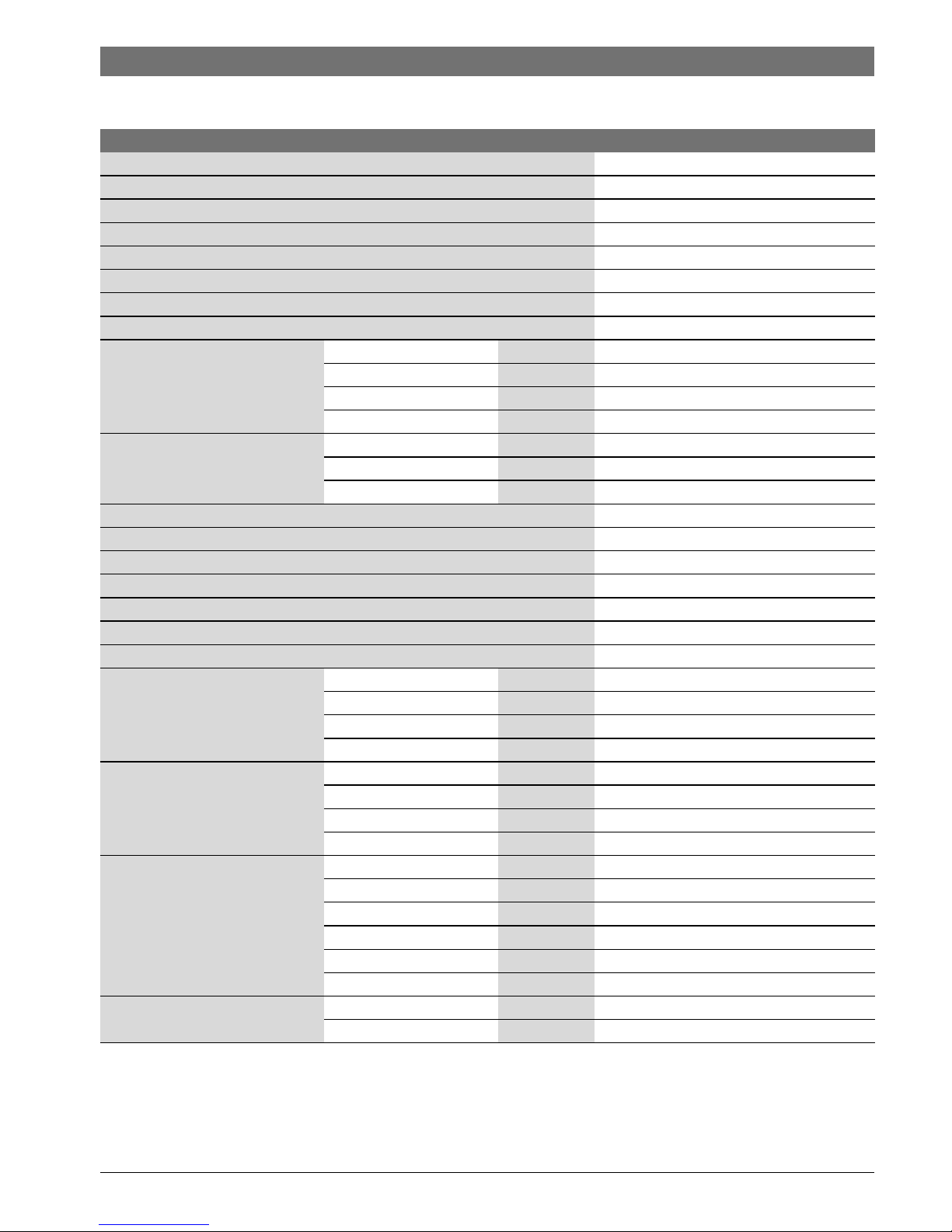

3.3 Specification tables

Model HP 270-1E 0 FOV/S...

Running modes Heat Pump Only Mode

Running ambient air temp. °C +3 °C/+40 °C

Outlet Water Temp. °C 60 °C - 65 °C

Minimum Inlet Water Temp. °C 3 °C

Maximum Inlet Water Temp. °C 70 °C

Power supply Ph-V-Hz 1ph / 230V-240V / 50 Hz

IP rating IP X4

Storage size ltr 270

Water heating Heating capacity

1)

kW 1.5

Max. input

1)

kW 0.6

COP

1)

-3.3

Max. current

1)

A2.5

Unit Dimension (D×H) mm 670 x 1840

Packing (W×H×D)

mm 770 x 770 x 2050

Net/gross weight

kg 130

Sound pressure level at 2 m dB (A) 43

Refrigerant type/Mass kg R134a / 0.375

Max. refrigerant circuit pressure kPa 2700

PTR valve setting

2)

kPa 1000

Throttling type Thermal expansion valves

System protection High pressure switch, Temperature limiter

Air flow m3/h 350

Compressor Model WHP01900

Type

Rotary

Brand

Highly

Input

W700

Fan motor Model W1G230EB

Brand

EBM Papst

Input

W28

Speed

r/min 1500

Water connections Water inlet ¾ BSP inch

Water outlet

¾ BSP inch

Max. water working

kPa 1000

PTR valve joint

½ BSP inch

Max inlet pressure

kPa 800

Heat exchanger

Double wall plate heat exchanger

E-heater Rated power input at 240 V kW 1.8

Rated current at 240 V

A7.8

Table 2

1) EN255-3, water inlet 15 °C, air at 15 °C

2) PTR valve power capacity: 10 kW

6 720 801 244 (2013/08) Compress 3000 DW FO

10 | Appliance details

Operating ambient air temperature range:

Operating ambient temperature range (Heat pump only): 3 40 °C

Range of warehouse storage temperature: -20~60 °C

Set point for the hot water temperature: fixed at 60 °C

3.4 Storing and transportation

As a rule, the unit is to be stored and/or transported in its

shipping package in upright position and with an empty tank.

For transport over short distances, and provided due care is

taken, an inclination angle of up to 20° is permitted. Both

during transport and storage, ambient temperatures of - 20 to

+60 °C are permissible.

3.4.1 Transport using a forklift

When transported by a forklift, the unit must remain mounted

on the pallet. The lifting rate should be kept to a minimum. Due

to its top-heaviness, the unit must be secured against tipping

over. To prevent any damage, the unit must be placed on a level

surface!

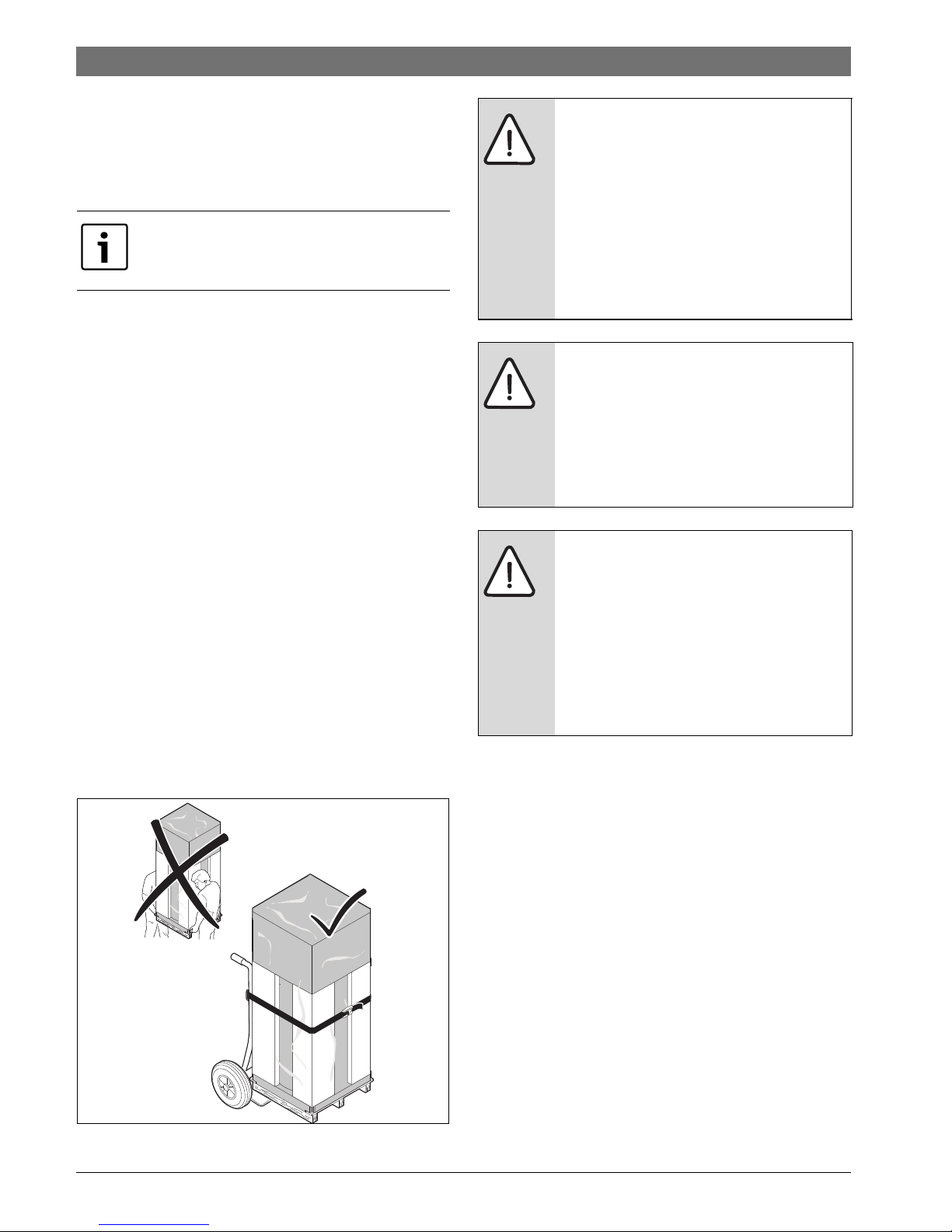

3.4.2 Manual transport

For the manual transport, the wooden pallet can be used for

bottom part as long as the carrying straps are secure. Care

must be taken that the maximum permissible inclination angle

of 20° from vertical is not exceeded. If transport in an inclined

position cannot be avoided, the unit should only be taken into

operation one hour after it has been moved into it's final vertical

position.

Fig. 4

In Combi Mode the appliance can operate

beyond the normal temperature range by the

use of the electrical heater only.

6720801244-18.1V

WARNING:

Heat pumps are heavy and bulky. Australian

States and Territories have a Principal

Occupational Health and Safety (OH&S) Act

which contains requirements relating to the

handling of large, bulky or awkward items.

Persons installing this heat pump system

must be aware of their responsibilities and

be adequately trained and qualified in

accordance with local OH&S requirements.

WARNING: Transport damage!

▶ Avoid tilting the appliance at an angle of

more than 20°.

▶ Take care when handling the appliance.

▶ To avoid dropping the appliance and

damaging internal components, do not

pivot the appliance.

WARNING: Transport damage!

▶ To avoid transport damage, wait until the

appliance is at the installation location to

remove the protective packaging.

▶ U se straps to prevent the appliance from

becoming scratched.

▶ Use suitable means of transport to bring

the appliance to the installation location

(special car, pallet truck, etc).

6 720 801 244 (2013/08)Compress 3000 DW FO

Appliance details | 11

3.5 Operational principle (brief overview of modes)

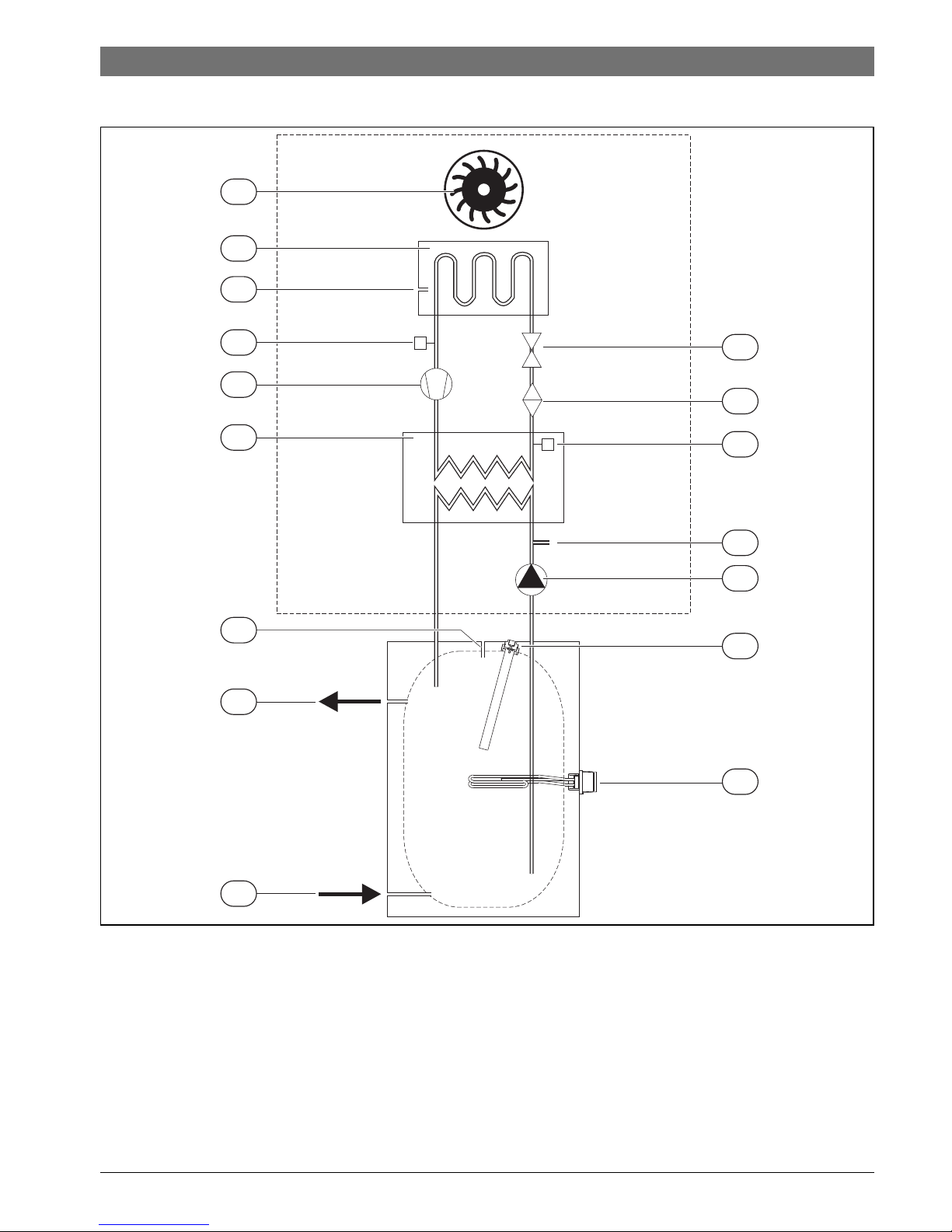

Fig. 5

[1] Air fan

[2] Evaporator

[3] Compressor

[4] Condenser (gas/water heat exchanger)

[5] NTC temperature sensor (air inlet)

[6] DHW connection

[7] Cold water inlet

[8] Electric heating element

[9] NTC temperature sensor (top of storage tank)

[10] DHW circulation pump

[11] NTC temperature sensor (bottom of storage tank)

[12] High-pressure pressure switch

[13] Expansion valve

[14] Dry filter

[15] Low-pressure pressure switch

[16] Magnesium anode

1

2

3

4

6

7

16

10

11

14

13

6720801244-05.1V

8

5

12

15

9

6 720 801 244 (2013/08) Compress 3000 DW FO

12 | Appliance details

System theory

The refrigerant circuit is a closed system in which the

refrigerant R134a circulates as a heat transfer medium.

The evaporator transfers the heat from the air to the refrigerant

circuit, and the refrigerant evaporates into a gas.

The compressor compresses the refrigerant R134a, thus

increasing its temperature.

Then the heat is transferred via a heat exchanger, also referred

to as a condenser, to the storage water tank. The refrigerant

R134a condenses in the process.

R134a flows through the expansion valve in a liquid state with

decreasing pressure. Then it is routed back to the evaporator.

Brief overview of modes

• Heat pump mode: only the economical heat pump cycle

is used; if the air temperature goes beyond the nominal

range (3 °C - 40 °C) the appliance automatically turns

off.

• Combi mode: the heat pump cycle is used under the

nominal range for the air temperature (3 °C - 40 °C); if

the air temperature goes out of this interval, the

appliance automatically switches to the electrical

heating element; this is the factory pre-selected mode.

6 720 801 244 (2013/08)Compress 3000 DW FO

Appliance details | 13

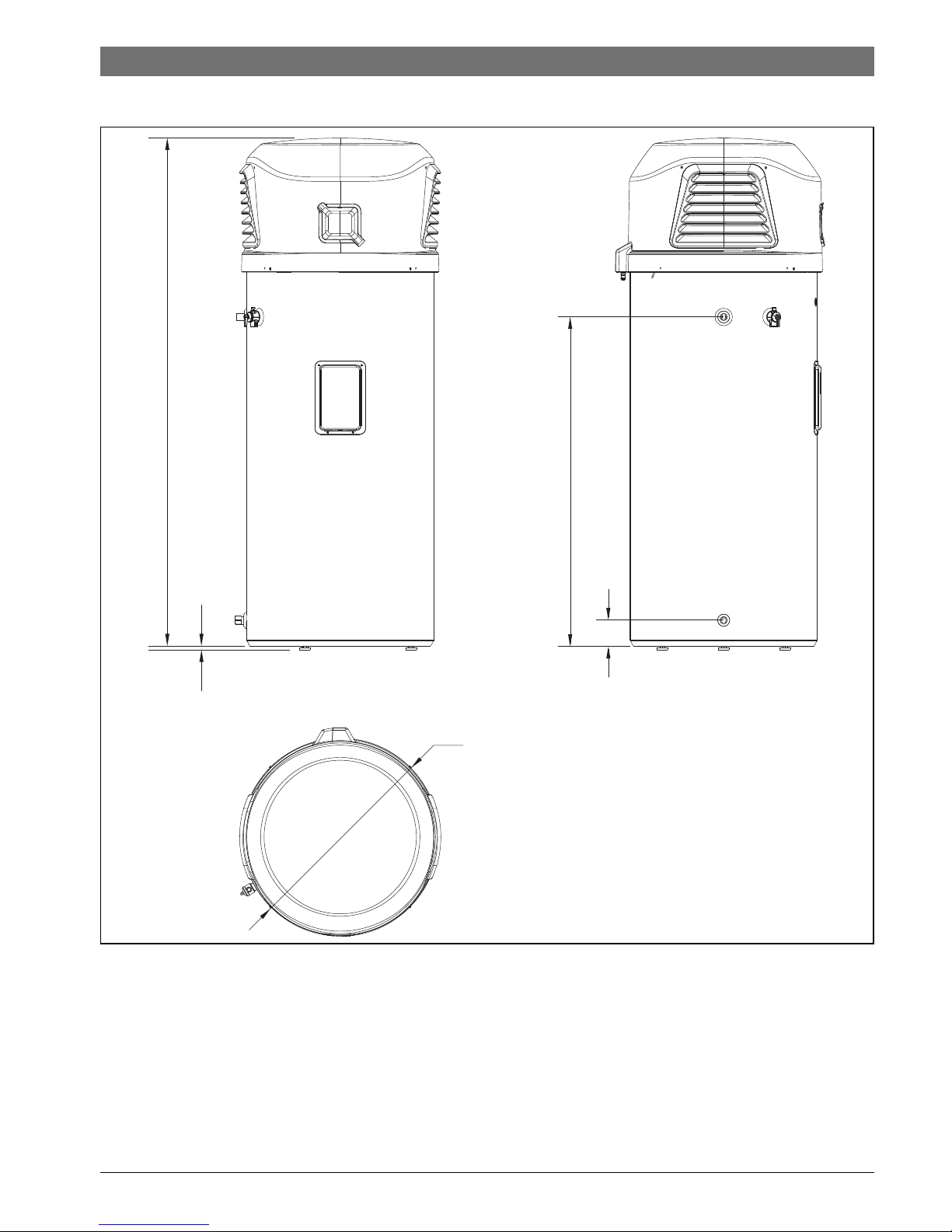

3.6 Dimensions

Fig. 6 Dimensions (in mm)

1840

16,5

1180

64

Ø 670

6720801244-06.1V

6 720 801 244 (2013/08) Compress 3000 DW FO

14 | Installation instructions

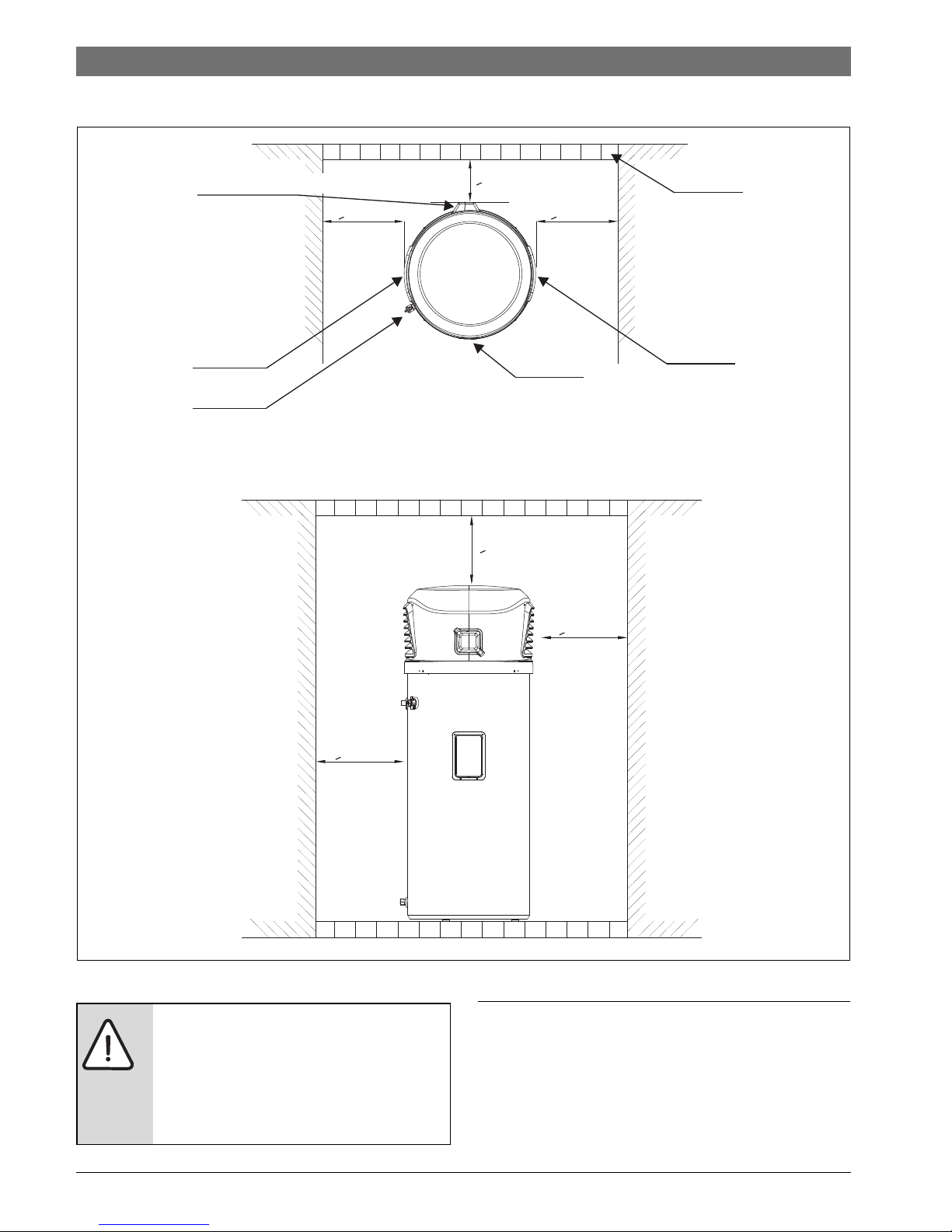

3.7 Clearances

Fig. 7

4 Installation instructions

The manufacturer’s warranty does not cover any damage or

defect caused by improper installation, attachment or use of

any type of accessories (other than those listed in this user

manual) with this water heater. The use of unauthorized

>1000mm

>200mm

>1000mm

>1000mm

>1000mm

>600mm

Air outlet

Display

Barrier

Air inlet

6720801244-07.1V

Condensate drain

PTR valve

DANGER:

The Temperature and Pressure relief valve

delivered with the unit must be installed and

must not be sealed or blocked. Failing to do

so will result in a dangerous situation

(section 4.4.4).

6 720 801 244 (2013/08)Compress 3000 DW FO

Installation instructions | 15

energy-saving devices may shorten the life of the water heater

and may endanger life and cause property damage.

The manufacturer disclaims any responsibility for such loss or

injury resulting from the use of such unauthorized devices.

4.1 Tools required

•Wrench ¾"

• Philips screwdriver

• Flat screwdriver

4.2 Location requirements

Locate the water heater in a clean area as near as possible to

the area of biggest hot water demand. Long uninsulated hot

water lines can waste energy and water.

Note: Because this unit draws in ambient air to heat the water,

wh en us ing the u nit indoo rs, t he roo m must be at lea st 3m x 3m

x 2,5m (22,5 m

3

) or larger, and preferably vented. If the room

is smaller, there must be a louvered door with minimum

500cm

2

venting area.

Place the water heater in such a way that clearance for proper

servicing is considered (section 3.7), namely for top cover

removal, PTR valve access and anode rod removal and

installation.

Remember you may need to remove the entire unit later for

servicing.

The water heater and water lines should be protected from

freezing temperatures and highly corrosive atmospheres.

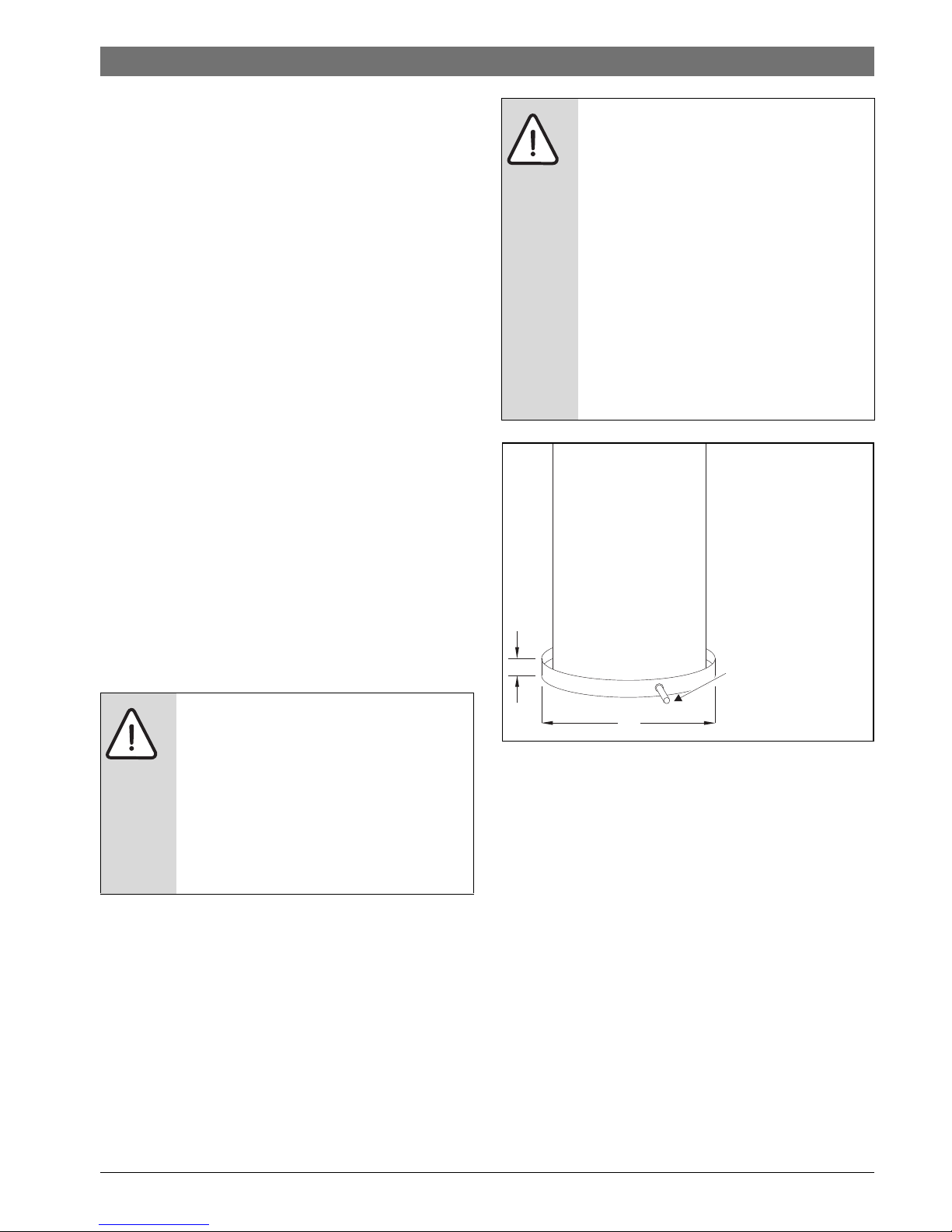

Fig. 8 Water heater support as specified in AS3500.4

NOTE: Auxiliary catch pan MUST conform to local codes. Catch

Pan Kits are available from the store where the water heater

was purchased, a builder store or any water heater distributor.

Recommendation

Even if this unit runs at very low noise levels, it is advisable to

install it away from any living area windows.

▶ Check council laws for specific localized rules in relation to

location requirements for this appliance.

Outdoor installation

This unit was designed both for outdoor and indoor installation.

Proper clearances must be observed.

Local installation regulations

The installation must comply with the requirements of AS/NZS

3500.4 and AS/NZS 3000 standards and all additional local

codes and regulatory authority requirements.

CAUTION:

The water heater should not be located in an

area where leakage of the tank or connection

will result in damage to the area adjacent to

it or to lower floors of the structure. In places

where installation in such areas cannot be

avoided, it is recommended that a suitable

catch pan, adequately drained, be installed

under the water heater (Fig. 8).

WARNING:

This water heater SHOULD NOT be installed

in an area with a corrosive atmosphere

where chemicals or flammable liquids are

stored or where aerosol propellants are

released. When using outdoors, because of

natural air movement in a room or other

enclosed space, these corrosive/flammable

vapours can be carried from where they are

being used or stored. Any electric arc drawn

within the water heater's electronic controls

can ignite these vapours causing an

explosion or fire, which may result in severe

burns or death to those in range, as well as

property damage.

6720801244-11.1V

B

A

Route to open drain.

Line should be at least

DN50 and pitched for

proper drainage.

A= Ø of appliance

plus 50 mm min

B= Maximum 50 mm

Loading...

Loading...