Page 1

Heat pump

6720804054-00.1V

Compress 3000 DW FI

HP 270-2...

Installation and operating instructions

Please read the installation instructions before installing the appliance!

Please read the operating instructions before commissioning the appliance!

Please observe the safety instructions in the operating instructions!

The installation location must meet the requirements for sufficient ventilation!

Installation must only be carried out by an authorised contractor!

6 720 809 134 (2013/09) EN

Page 2

2 | Contents

Contents

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . 3

2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 About the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Description of appliance . . . . . . . . . . . . . . . . 5

3.5 Dimensions and minimum clearances . . . . . 6

3.6 Appliance layout . . . . . . . . . . . . . . . . . . . . . . 7

3.7 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . 8

3.8 Safety, control and protection devices . . . . 8

3.8.1 High Pressure Switch . . . . . . . . . . . . . . . . . . 8

3.8.2 High limit safety cut-out . . . . . . . . . . . . . . . . 8

3.8.3 Temperature sensor for air inlet . . . . . . . . . . 8

3.9 Corrosion protection . . . . . . . . . . . . . . . . . . . 8

3.10 Technical properties . . . . . . . . . . . . . . . . . . . 9

4 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 Installation location . . . . . . . . . . . . . . . . . . . 10

5.2 Installing the appliance . . . . . . . . . . . . . . . . 11

5.3 Connecting the ducts . . . . . . . . . . . . . . . . . 12

5.3.1 Open flue operation . . . . . . . . . . . . . . . . . . 12

5.3.2 Outdoor air operation . . . . . . . . . . . . . . . . . 12

5.4 Connecting the water pipes . . . . . . . . . . . . 12

5.5 Internal indirect coil connection . . . . . . . . . 13

5.6 Connecting the DHW circulation line . . . . . 14

5.7 Condensate hose connection . . . . . . . . . . . 14

5.8 DHW expansion vessel . . . . . . . . . . . . . . . . 14

5.9 Filling the cylinder . . . . . . . . . . . . . . . . . . . . 15

5.9.1 Water quality . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1 Operation modes . . . . . . . . . . . . . . . . . . . . 18

8.2 Setting the domestic hot water

temperature . . . . . . . . . . . . . . . . . . . . . . . . .18

8.3 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.4 "Prog" submenu - Operating modes . . . . . . 19

8.4.1 "Manual" operating mode . . . . . . . . . . . . . . 19

8.4.2 "P1", "P2" and "P3" operating modes . . . . 19

8.4.3 "Full" operating mode . . . . . . . . . . . . . . . . . 19

8.4.4 "OFF" operating mode . . . . . . . . . . . . . . . . 19

8.5 "Mode" submenu - Heating mode . . . . . . . . 20

8.5.1 Electrical heating mode . . . . . . . . . . . . . . . 20

8.5.2 "Heat pump" operating mode . . . . . . . . . . . 20

8.5.3 "Combi" operating mode . . . . . . . . . . . . . . 20

8.6 "Set" submenu - Settings . . . . . . . . . . . . . . 21

8.6.1 Date - Setting the temperature unit, date,

time and day of the week . . . . . . . . . . . . . . .21

8.6.2 Prog - Programming of the operating times 21

8.6.3 "Leg" - Automatic thermal disinfection . . . 23

8.6.4 « Duct » - use of ducts . . . . . . . . . . . . . . . . . 24

8.6.5 "Purg" - Drain . . . . . . . . . . . . . . . . . . . . . . . . 24

8.6.6 "Fset" - Default settings . . . . . . . . . . . . . . . 24

8.7 "Info" submenu - Information . . . . . . . . . . . 24

8.8 Fault diagnosis . . . . . . . . . . . . . . . . . . . . . . 25

8.9 Default settings . . . . . . . . . . . . . . . . . . . . . . 25

9 Environmental protection/Recycling . . . . . . . . . . . 25

10 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.1 General inspections . . . . . . . . . . . . . . . . . . 26

10.2 Checking/replacing the magnesium anode 26

10.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.4 Condensate pipe . . . . . . . . . . . . . . . . . . . . . 26

10.5 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.6 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . 27

10.7 High limit safety cut-out . . . . . . . . . . . . . . . 27

10.8 Draining the cylinder . . . . . . . . . . . . . . . . . . 27

10.9 "Service" menu . . . . . . . . . . . . . . . . . . . . . . 27

6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Appliance's electrical connection . . . . . . . . 16

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1 Before commissioning . . . . . . . . . . . . . . . . 17

7.2 Switching the appliance on/off . . . . . . . . . . 17

6 720 809 134 (2013/09) Compress 3000 DW FII

11 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.1 Faults that are displayed . . . . . . . . . . . . . . 28

11.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 3

1

Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identified by

a warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe injury

or death.

Important information

This symbol indicates important information

where there is no risk to people or property.

Additional symbols

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

1.2 Safety instructions

Installation

▶ The appliance may only be installed by an authorised

contractor.

▶ Do not install the appliance in the following locations:

–outside

– in locations which promote corrosion

– in locations with a risk of frost

– in locations where there is a risk of explosion.

Key to symbols and safety instructions | 3

▶ Wait until the appliance is at the installation location to

remove it from its packaging.

▶ All water connections must be checked for tightness before

the appliance is connected to the power.

▶ Observe minimum clearances ( Fig. 6, page 11).

▶ The electrical connection must comply with the local

applicable regulations.

▶ Connect the appliance to an independent, earthed power

source.

▶ Install a safety valve at the appliance's cold water inlet.

▶ The drain line from the safety valve must be laid in a frost-

free location. It must remain open to the atmosphere and

always be kept in a sloped position.

Minimum and maximum water temperatures: 3 °C/80 °C

Minimum/maximum water pressure: 0.2 bar/2 bar below the

value of the installed safety valve

Risk of scalding at the hot water draw-off points

▶ When the appliance is in operation, temperatures in excess

of 70 °C can occur. To limit the temperature at the tap,

install a thermal DHW tempering valve.

Service

▶ The end customer is responsible for safety and

environmental compatibility during installation and service

work.

▶ The appliance may only be serviced by an authorised

contractor.

▶ Isolate the appliance from the power supply before

performing any service work.

Service and maintenance

▶ Maintenance may only be carried out by an authorised

contractor. Faulty maintenance may pose a danger to the

user and cause malfunctions in the appliance.

▶ Use only original spare parts.

▶ Have an authorised contractor perform an annual inspection

and service the appliance as needed.

▶ Any work involving cooling gas may only be carried out by

qualified contractors.

▶ Empty cylinders as described on page 27, chapter 10.8 if

necessary.

▶ Open the safety valve manually at least once a month to

ensure that it is functional.

▶ We recommend that you arrange a maintenance and

inspection contract with the manufacturer.

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 4

4 | Key to symbols and safety instructions

Room/inlet air

Keep the inlet air free of contaminants. It must no t contain any

of the following substances:

• corrosive substances (ammonia, sulphur, halogen

products, chlorine, solvents)

• fatty or explosive substances

• aerosol concentrations

No other air inlet systems may be connected to the fan.

Refrigerant

▶ Please observe the applicable environmental regulations

when using and reusing refrigerant. Do not release it into the

environment! Use the refrigerant R134a. It is non flammable and does not damage the ozone layer.

▶ Before working on parts of the refrigerant circuit, remove

the refrigerant for safety reasons.

Please note that HFC-134a and PAG-ÖL are used during

service work. This is a chlorofluorocarbon and is rated with a

greenhouse potential of 1300 in the Kyoto Protocol.

Instructions to the customer

▶ Explain to the customer how the appliance works and how to

operate it.

▶ Advise the customer that he/she must not make any

modifications to the appliance or carry out any repairs on it.

Safety of electrical appliances for domestic use and similar

purposes

The following requirements apply in accordance with EN

60335-1 in order to prevent hazards from occurring when

using electrical appliances:

“This appliance may be operated by children aged 8 or over and

by people with full physical, sensory and mental capabilities

who have the necessary training and experience to use this

type of appliance. They must be supervised or instructed on

how to use the appliance safely and on the associated risks.

Children must not play with the appliance. Children must not

clean or service the appliance without supervision.”

“Damaged power cables must be replaced by the

manufacturer, the service department or a qualified contractor

in order to prevent hazards.”

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 5

Standard delivery | 5

1

6720804054-13.1V

2

3

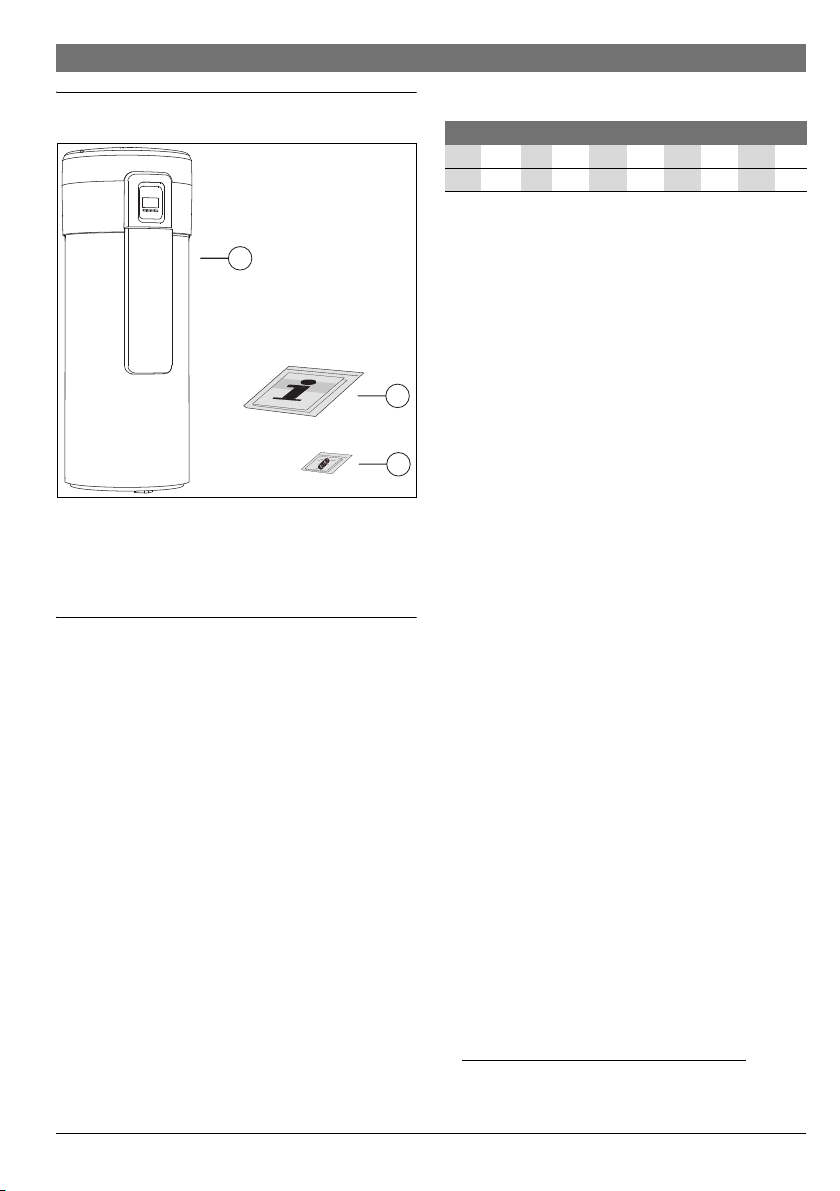

2 Standard delivery

Fig. 1

[1] Heat pump

[2] Set of printed documents for the appliance

[3] Condensate drain pipe

3 About the appliance

Appliances in the HP270... series are heat pumps which use

the energy in the ambient air for DHW heating.

3.1 Intended use

The appliance may only be used for DHW heating.

Using the boiler for any other purpose will be considered

incorrect use. Buderus accepts no liability for any damage

resulting from such use.

The appliance is not suitable for commercial or industrial

applications. It is approved for household use only.

3.2 Type overview

HP 270 -2 E 1FIIVs

HP 270 -2 E 0FIIVs

Table 2

[HP] Heat pump

[270] Cylinder capacity (in litres)

[-2] Version

[E] Electronic control

[1] Number of internal indirect coils in the cylinder

[F] Floor installation

[I] Indoor installation

[I] Air supply from inside

[V] Vertical installation

[S] Side connections

3.3 Data plate

The data plate is located on the rear side of the appliance.

There you will find details on the appliance performance, part

numbers, approval data, the coded date of manufacture (FD),

serial numbers and other specifications.

3.4 Description of appliance

Appliance for DHW heating with the following properties:

• Glass-lined steel cylinder with thermal insulation using CFCfree rigid polyurethane foam.

• Cylinder is corrosion-protected using internal magnesium

anode.

• The refrigerant and DHW circuits are completely separate.

• "Heat pump" operating mode stops automatically

inlet temperatures below -10 °C or over 35 °C.

• Upper limit pressure switch protects the refrigerant circuit.

• R134a used as the refrigerant.

• DHW temperatures between 30 °C and 70 °C (the default

setting for the DHW temperature is 50 °C).

1)

at air

1) chapter 8.5.2

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 6

6 | About the appliance

6720804054-03.1V

670

25

94

331

630

735

1266

916

1835

350

700

735

445

160

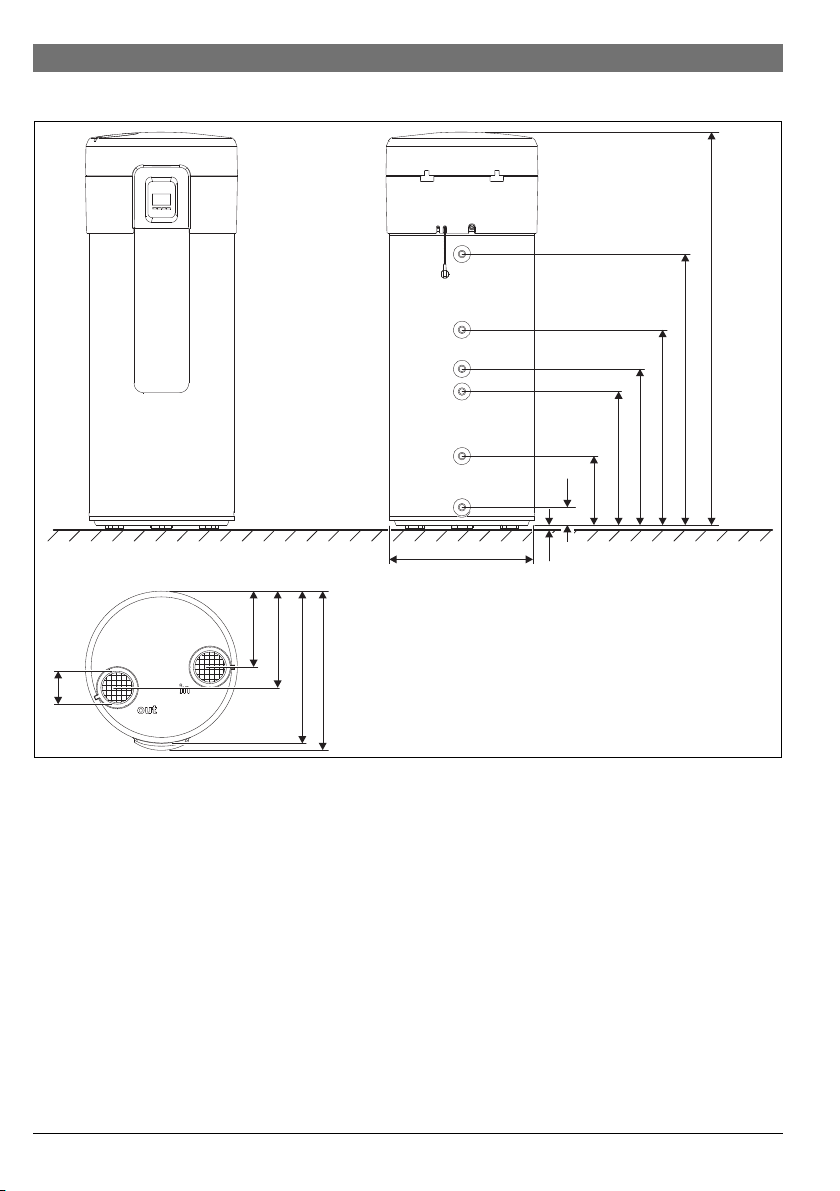

3.5 Dimensions and minimum clearances

Fig. 2 Appliance dimensions (in mm)

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 7

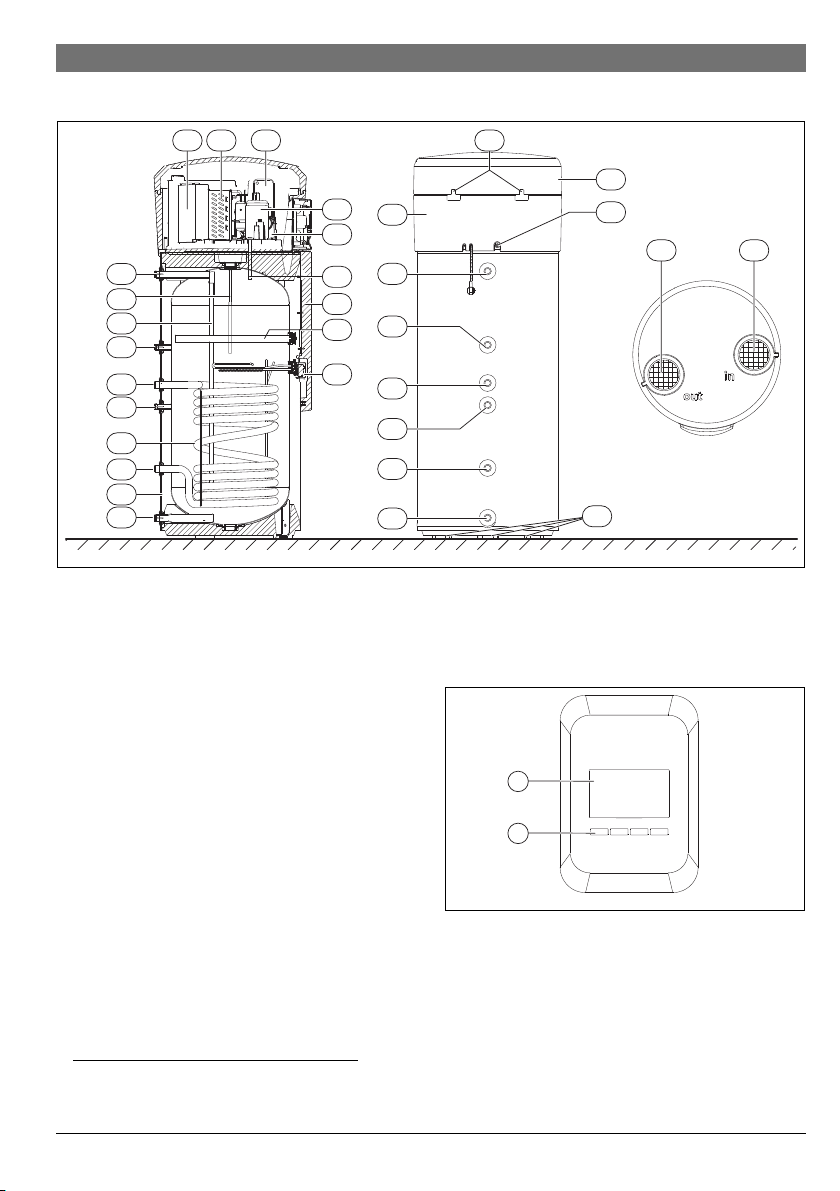

3.6 Appliance layout

1

2

4

3

6

11 12 13

18

24

25

16

17

3

1

5

23

21

15

22

14

19 20

6

10

9

5

4

7

2

8

6720804054-04.1V

26

6720804054-16.1V

1

2

Fig. 3 Heat pump

[1] Water inlet - G1"

[2] Internal indirect coil outlet - G1"

[3] Internal indirect coil inlet - G1"

[4] Sensor pocket for temperature sensor (data for solar

system or electric booster heater)

[5] DHW circulation line inlet - G3/4"

[6] Water outlet - G1"

[7] Internal indirect coil

[8] Thermal insulation

[9] Water inlet to condenser

[10] Water outlet from condenser

[11] Fan

[12] Evaporator

[13] Condenser (gas/water heat exchanger)

[14] Compressor

[15] Sensor pocket for DHW temperature sensor

[16] Magnesium anode

[17] Central heating resistor

[18] Adjustable feet (3x)

[19] Air outlet aperture

[20] Air inlet aperture

[21] Condensate outlet

[22] Circulation pump

1) model HP270-2E1... only

1)

1)

1)

About the appliance | 7

[23] Front protective covering

[24] Housing ring

[25] Housing lid

[26] Fastening for housing lid

Fig. 4 User interface

[1] Display

[2] Setting buttons

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 8

8 | About the appliance

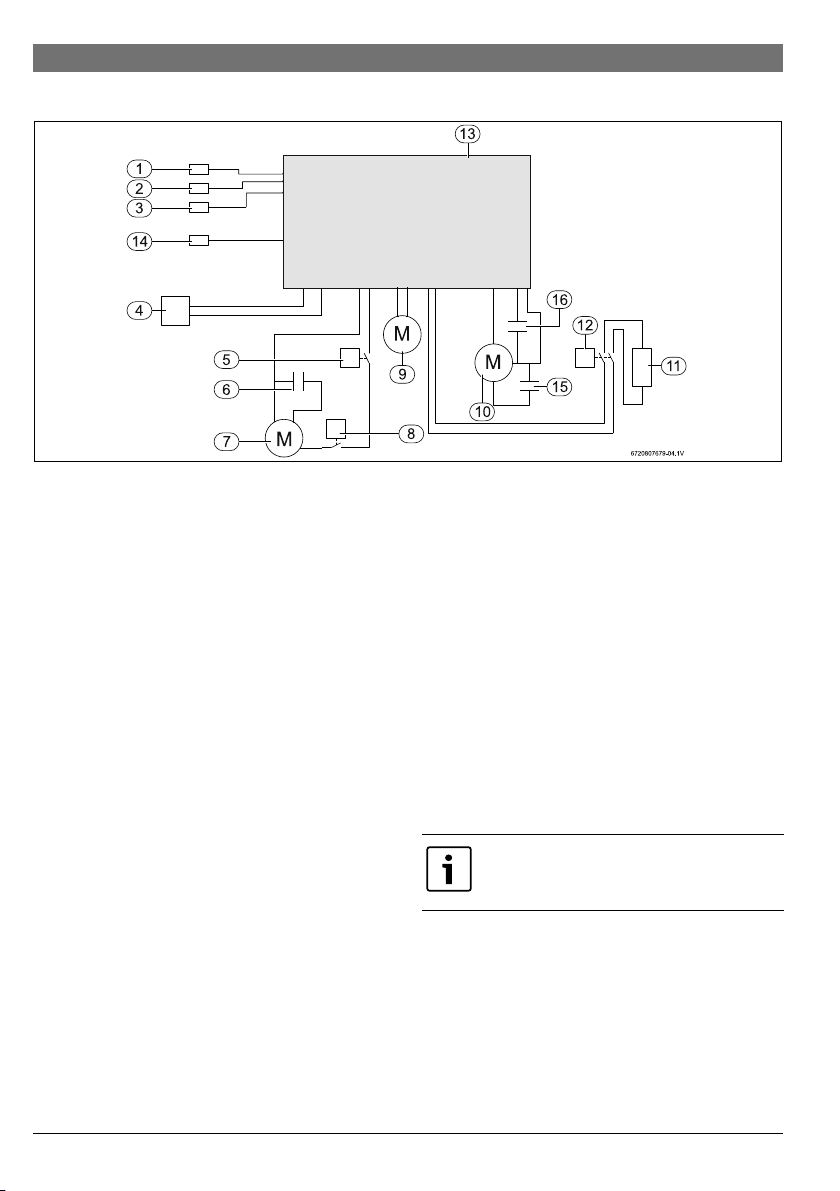

3.7 Wiring diagram

Fig. 5

[1] NTC temperature sensor for air inlet

[2] Flow NTC temperature sensor

[3] NTC temperature sensor in water inlet

[4] Power cable

[5] High Pressure Switch

[6] Electrical capacitor for compressor

[7] Compressor

[8] High limit safety cut-out for compressor

[9] Circulation pump

[10] Fan

[11] Resistor

[12] Resistor for high-limit safety cut-out

[13] Electronics box

[14] NTC temperature sensor (evaporator plates)

[15] Electrical capacitor for fan start

[16] Electrical capacitor for fan speed

3.8 Safety, control and protection devices

3.8.1 High Pressure Switch

If the operating pressure is outside of the recommended range,

the pressure switch switches off the appliance and displays a

fault ( chapter 11, page 28).

3.8.2 High limit safety cut-out

The high limit safety cut-out ensures that the water

temperature in the cylinder does not exceed the prescribed

limit. If the temperature limit is exceeded, the DHW heating

shuts down. The reset is performed manually by a certified

contractor.

3.8.3 Temperature sensor for air inlet

The temperature sensor measures the temperature of the inlet

air in the evaporator. If the measured value is outside the

operating temperature range, DHW heating automatically

switches from the "Combi" operating mode to "Electric booster

heater". If the appliance is in the "Heat pump" operating mode,

DHW heating is interrupted until the temperature returns to

within the permissible range.

3.9 Corrosion protection

The internal wall of the DHW cylinder is glass-lined (double

coating), making it neutral when in contact with water and

therefore suitable for potable water.

As an additional corrosion protection measure, the cylinder is

equipped with a magnesium anode. This must be inspected at

regular intervals and replaced if necessary.

The first inspection must take place 6

months after installation.

In regions with more corrosive water, safety measures (filter,

etc.) must be taken, and the magnesium anode must be

serviced more frequently.

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 9

About the appliance | 9

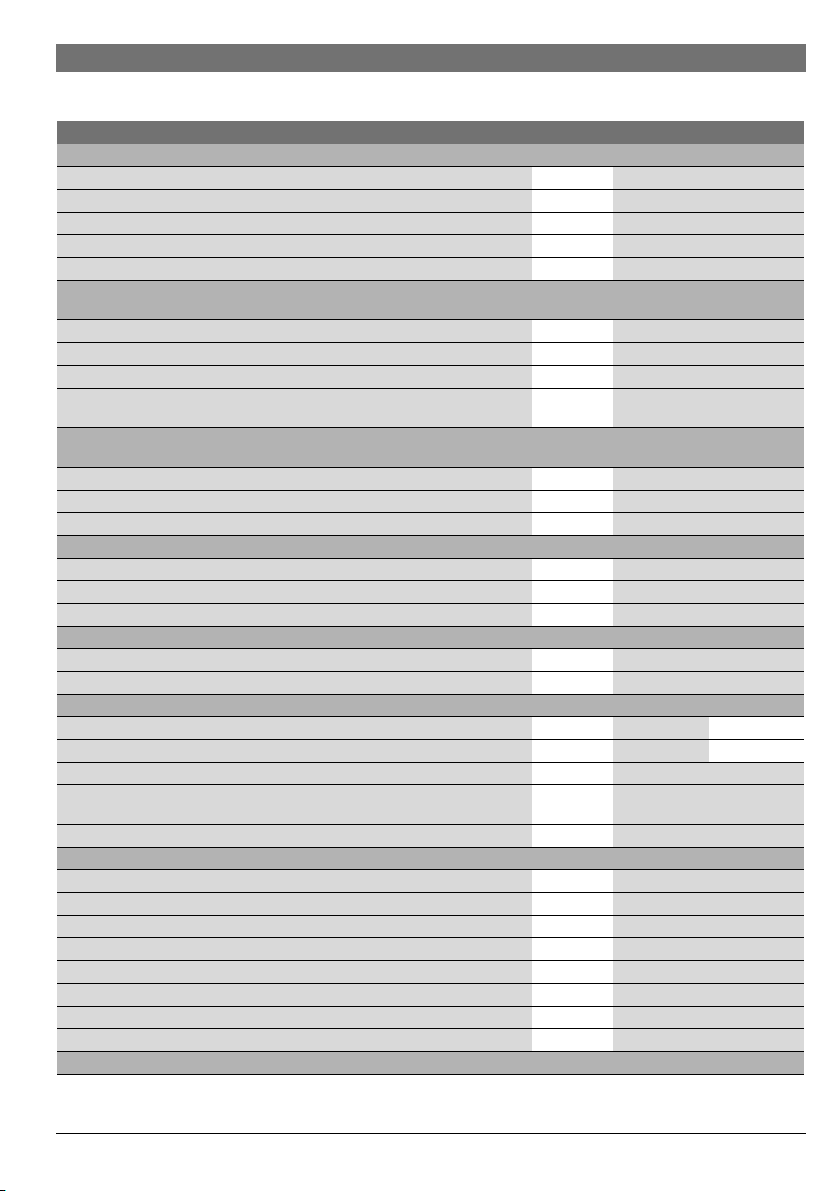

3.10 Technical properties

Unit HP270-2E0... HP270-2E1...

Heating output - in accordance with EN255-3, air temperature 20 °C, heating water from 15 °C to 45 °C

Output kW 1,7

Total heating output (including electric booster heater) kW 3,7

Performance coefficient (COP) – 4,3

Heat-up time h 5:00

Heat loss in 24h kWh/day 0,74

Heating output - in accordance with EN16147, XL cycle, air temperature 15 °C, heating water from 10 °C to 54 °C,

Tref > 52.5 °C

Performance coefficient (COP) – 3,20

Heat-up time h 8:48

Heat loss in 24h kWh/day 1,08

DHW volume, corresponds to water at a temperature of 40 °C, available after

heating

Heating output - in accordance with EN16147, XL cycle, air temperature 7 °C, heating water from 10 °C to 54 °C,

Tref > 52.5 °C

Performance coefficient (COP) – 2,79

Heat-up time h 10:38

Heat loss 24h kWh/day 0,97

Air inlet

Air flow rate (without/with pipework) - fan speed "SP1" m3/h 380/300

Air flow rate (without/with pipework) - fan speed "SP2" m3/h 490/300

Operating temperature °C -10 ... +35

Refrigerant circuit

Refrigerant R134a g 400

Maximum pressure bar 27

DHW

Cylinder capacity l 270 260

Area of heat exchanger (internal indirect coil) m

Maximum outlet temperature without/with electric booster heater °C 60/70

DHW volume per day, corresponds to a water temperature of 40 °C, air

temperature 20 °C, heating water from 15 °C to 60 °C

Maximum operating pressure bar/MPa 10/1

Electrical details

Mains power supply V ~230 (+10%/-10%)

Frequency Hz 50

Current rating (without/with electric booster heater) O 2.6/11.3

Max. rated consumption kW 0.6

Total heating output of the electric booster heater kW 2.0

Total max. rated consumption (including electric booster heater) kW 2.6

IP rating I

IP rating (without/with pipework) IP 21/24

General data

Table 3

l

2

l

372

-1.3

1200

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 10

10 | Transport and storage

Unit HP270-2E0... HP270-2E1...

Sound pressure level with pipework (at a distance of 2 m) dB(A) 40

Dimensions, W x H x D mm 700 × 1835 × 735

Net weight (without packaging) kg 108 125

Table 3

Manual transport

4 Transport and storage

NOTICE: Damage caused by straps!

WARNING: Transport damage!

▶ Take care when handling the appliance.

▶ To avoid dropping and damaging the

appliance, do not pivot it.

NOTICE: Transport damage!

▶ To avoid transport damage, do not

remove the protective packaging. Wait

until the appliance is at the installation

location to remove the protective

packaging.

▶ Transport and set down the appliance

carefully. Jerky movements can damage

the internal glass-lined coating, the

components and their connections or the

external casing.

▶ Use suitable means of transport to bring

the appliance to the installation location

(special car, pallet truck, etc).

Straps can be placed around the cylinder in order to position

the appliance in its final location.

5 Installation

▶ The appliance may only be installed by an authorised

contractor.

▶ The heat pump installation must follow the applicable

regulations.

▶ Check that all pipe connections are intact and have not

shaken loose during transportation.

▶ Remove the front protective covering

( Fig. 3, [23]).

▶ Make sure that the straps do not scratch

or make indentations on the surface of the

appliance.

▶ Do not attach straps to the appliance

connections.

General information

The appliance is delivered on a single pallet and is protected

against transport damage by special packaging.

The appliance must be stored and transported vertically in its

original packaging

temperatures of -20 °C to +60 °C are permissible for storage

and transport.

1) Horizontal transportation is permitted over short distances,

provided that the conditions described above are fulfilled.

6 720 809 134 (2013/09) Compress 3000 DW FII

1)

and the cylinder must be empty. Ambient

5.1 Installation location

Please note the following when choosing the installation

location:

• The appliance must be installed in a dry, frost-free room.

The supply air temperature must be betw een -10 °C and

35 °C in order to optimise the appliance performance.

• The appliance must be installed on a sufficiently strong and

level surface.

• The air outlet and air inlet must not be in locations where

there is a risk of explosion cause by gas, steam or dust.

• Ensure that condensate drains correctly.

• The surf ace below the appliance must be strong enough (the

appliance weighs about 400 kg when the cylinder is filled,

NOTICE: Refrigerant leak!

▶ Only authorised contractors are

permitted to maintain and repair the

refrigerant circuit.

Page 11

Installation | 11

500

400

2200

430

6720804054-17.1V

with the weight distributed equally over its 3 adjustable

feet).

If the appliance only has one duct (inlet or

outlet duct), its operation may create

negative or positive pressure in the

installation room. If other burners are

already installed in the same place, please

bear in mind that the appliance requires a

clearance of at least 220 cm

and outlet in order to operate correctly.

Note: The clearance of 220 cm

2

for the air inlet

2

is required

for the correct functioning of the heat pump

only. In addition, you must ensure that the

burner has the necessary clearance.

To ensure faultless operation and easy access to all

components and connections for service and maintenance,

maintain the minimum clearances specified in Fig. 6.

▶ Assure correct positioning of all temperature sensors.

Fig. 7 Temperature sensor at the top of the cylinder

Fig. 6 Recommended minimum clearances (mm)

5.2 Installing the appliance

▶ Remove the foil and external protective packaging.

▶ Lift the appliance from its pallet and position it on its final

plinth.

▶ To correctly align the appliance at the installation location,

adjust the height of the adjustable feet.

Fig. 8 Temperature sensors (evaporator plates + air inlet)

To ensure that the system operates

faultlessly and the condensate drains

correctly, the appliance must be aligned

vertically. The appliance must not tilt more

than 1°, preferably in the direction of the

condensate drain.

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 12

12 | Installation

L

2T

L

T1

L1

C1 C2

L2

L4

L3

L = L1+C1+L2

T1

L = L3+C2+L4

L=L +L

SP1: L 30m

T2

T1 T2

≤

2

1

NOTICE: Possible damage to external

casing!

▶ Do not tilt the appliance on his feet more

than 20°.

5.3 Connecting the ducts

The air inlet can be located in the installation room, in a

different room or outside. In the latter two cases, air inlet ducts

must be installed.

To ensure maximum appliance performance

and to prevent condensation forming on the

external duct walls, use thermally and

acoustically insulated ducts.

When choosing a room for the air inlet, observe the average air

temperature and required air flow rate ( Tab. 3). In order to

minimise air resistance, lay the air inlet and outlet ducts

(Ø 160 mm) as straight as possible.

The length (L

exceed the following values:

• 30 m at fan speed SP1

0.5 m duct 0.5 m

1m duct 1.0m

2 m duct 2.0 m

10 m hose 19.0 m

45° elbow 0.9 m

90° elbow 2.0 m

90° flexible curve 2.3 m

Weather grille 8 m 4m

Roof output 7 m 4m

Table 4

To ensure that condensate forming in the air inlet and air outlet

ducts drains from the appliance:

▶ Install air ducts horizontally or at a slight angle to the air inlet

and air outlet apertures on the top side of the appliance.

Installation with ducts

▶Activate “Duct” function ( page 24, chapter 8.6.4).

) of the air inlet and outlet ducts must not

eq

Air inlet

(IN)

Air outlet

(OUT)

L

eq

5.3.1 Open flue operation

If the heat pump is operated with air from the installation

location, the volume of the room must be at least 20 m

3

.

5.3.2 Outdoor air operation

If the pump is operated with outdoor air, the ducts must be

protected against the weather using the correct end pieces.

Fig. 9 Equivalent duct length (L)

[1] Air inlet

[2] Air outlet

L Fan speed

1)

Up to 30 m SP1

Table 5

1) chapter 8.6.4

5.4 Connecting the water pipes

Never close the water shut-off valve during

operation (Fig. 6, [4]).

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 13

To prevent faults occurring due to sudden

pressure fluctuations in the supply:

▶ Fit a non-return valve and a pressure

control valve to the appliance supply.

NOTICE: Pipes can be damaged if treated

incorrectly.

▶ Do not allow pipes to become

contaminated during installation.

▶ If necessary, flush the pipes with water

prior to commissioning.

Prior to installation, thoroughly flush water

pipes as the water flow could be reduced by

contaminants and, in case of severe

contamination, be stopped completely.

▶ Fit a water filter to the water inlet.

NOTICE: Corrosion damage to the cylinder's

connections!

If the connections are made from copper:

▶ Use an isolation fitting for the hydraulic

connection

1)

. This extends the service

life of the magnesium anode.

1) Accessory not included in standard delivery

▶ Determine the nominal diameter of the room's water

installation. Please note the current water pressure and the

expected pressure loss.

▶ Carry out the water connection in accordance with the

applicable regulations. P lease observe the local regulations

on DHW installations.

▶ The water pipes can be rigid or flexible. To avoid corrosion,

take into account the behaviour of the materials used in the

pipe system and the connections.

To prevent heat loss and to ensure maximum appliance

performance:

▶ Thermally isolate the water connections.

Installation | 13

Safety valve

1)

▶ Fit the safety valve to the water inlet of the appliance.

If the water inlet pressure is higher than

8 bar - 80% of the allowable maximum value

(10 bar) -, install a reducing valve. The safety

valve is activated when the water pressure

exceeds the upper limit (

allowing water to drain off. A tundish

Tab.6, page15),

should

be provided for this purpose.

NEVER CLOSE OFF THE SAFETY VALVE

DRAIN.

Never install accessories between the safety

valve and the appliance water connection.

NOTICE:

The drain line from the safety valve must be

laid in a frost-free location. It must remain

open to the atmosphere and always be kept

in a sloped position.

5.5 Internal indirect coil connection

2)

The appliance is equipped with an additional internal indirect

coil which enables the solar system or boiler to provide

support.

When the water temperature in the cylinder re aches 80 °C, the

control switches off the support system. This prevents damage

to the refrigerant circuit in the heat pump and stops the high

limit safety cut-out from being activated.

WARNING: Risk of scalding!

Hot water can lead to severe scalding.

▶ Inform users of the danger of scalding and

always monitor the thermal disinfection

process. Install a thermostatic DHW

mixer.

If the internal indirect coil is not used:

▶ Seal off the internal indirect coil's inlet and outlet apertures

with plugs.

1) Accessory not included in standard delivery

2) HP270-2E1...model only

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 14

14 | Installation

1.

2.

6720804054-11.1V

2

1

Water temperature sensor in cylinder

▶ Install DHW temperature sensor in the correct pipe

( Fig. 3, [4]).

▶ Insulate the pipe to prevent heat loss.

5.6 Connecting the DHW circulation line

Using circulation systems always reduces

efficiency.

With regard to the output, DHW circulation should only be used

when it is really needed. To reduce heat loss, circulation

systems which are connected to the DHW distribution system

must be controlled via a valve, time control or similar device.

5.7 Condensate hose connection

The condensate drain pipe is supplied

separately.

NOTICE: Damage to the appliance!

▶ Connect the condensate hose to the

condensate drain before installing the

part.

▶ Do not bend the condensate hose.

The condensate is drained on the rear side of the appliance.

▶ Connect the condensate hose to the

(Fig. 10, [1]).

▶ Connect the condensate hose to the collection area.

▶ Drain off condensate via a siphon drain (Fig. 10, [2]).

1)

condensate drain

Fig. 10 Condensate collection

[1] Condensate drain pipe

[2] Outlet siphon

5.8 DHW expansion vessel

1)

To prevent water loss from the safety valve, a

DHW expansion vessel can be installed.

▶ Install an expansion vessel at the water connection between

the cylinder and the safety assembly.

Tab. 6 serves as a reference for the selection of an expansion

vessel at a reference temperature of 60 °C. The capacity of the

expansion vessel must be selected subject to the water

pressure in the system.

1) Accessory not included in standard delivery

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 15

Installation | 15

6720804054-12.1V

2

1

Capacity of the

expansion vessel

corresponding to the

switch-on pressure of

the safety valve

Cylinder

type

Safety

valve

(maximum

pressure)

Water

pressure

in the

system

212l

6bar

318l

425l

HP

270...

8bar

212l

312l

418l

212l

10 bar

312l

418l

Table 6

5.9 Filling the cylinder

NOTICE: Damage to the appliance!

▶ Prior to commissioning the appliance, fill

the cylinder with water and bleed the

system if necessary.

Automatic filling - systems with water pressure above 3 bar

▶ Open the water outlet valve and at least one hot water tap.

▶ Open the water inlet valve on the cylinder (Fig. 5, [4]).

The cylinder is filled.

▶ Do not close the hot water taps until the water f lows steadily

and is free from air bubbles.

The process of filling the cylinder is complete.

▶ Connect the appliance to the power supply via a separate

socket with an earth connection.

If the fault code "E09" appears on the display after a few

minutes, proceed as follows:

▶Fill manually.

Manual filling - systems with water pressure below 3 bar

▶ Open the water outlet valve and at least one hot water tap.

▶ Open the water inlet valve on the cylinder (Fig. 5, [4]).

The cylinder is filled.

▶ Do not close the hot water taps until the water f lows steadily

and is free from air bubbles.

▶ Connect the appliance to the power supply via a separate

socket with an earth connection.

▶ Set the selector switch on the heating pump (Fig. 11, [1]) to

"III".

Fig. 11 Heating pump

[1] Selector switch

[2] Air vent screw

▶ Select "Purg" operating mode ( page 24, chapter 8.6.5).

CAUTION: Risk of scalding!

▶ Ensure that draining water from the air

vent screw presents no risk to people or

property.

▶ Open the drain screw on the heating pump (Fig. 11, [2])

until the water flows steadily and without air bubbles.

▶ Close the drain screw on the heating pump.

▶ Wait around 5 minutes until the "Purg" operating mode has

finished.

▶ Set the selector switch on the heating pump to "I ".

The process of draining and filling the cylinder is complete.

If the fault code "E09" appears on the display after a few

minutes, proceed as follows:

▶ Clear the fault ( page 25, section "Resetting the fault

display").

▶ Refill manually.

5.9.1 Water quality

Inadequate water quality or contaminated water can damage

the appliance.

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 16

16 | Electrical connection

Fig. 12 Water quality

Water treatment not required

(-0.5 < LSI < 1.5)

Water treatment required against scaling

(LSI > 1.5)

Water treatment required against corrosion

(LSI < -1.5)

Water treatment may be needed against corrosion

(-0.5 < LSI < -1.5)

LSI Langelier Saturation Index

Table 7

Please note that the Langelier saturation Index depends on the

water temperature and the above information considers two

extremes: 10 °C et 70 °C.

While corrosion is higher at low water temperature, scaling is

more important at higher water temperature.

In case of water hardness above 600 mg/l, the Langelier

saturation index must be determined to evaluate the necessity

for water treatment.

Notify certified contractor.

Water conductivity for sacrificial anodes

130 S/cm - 1500 S/cm

Table 8 Water conductivity

Do not use fully desalinated, distilled or

deionised water for this appliance type.

DANGER: Risk of electric shock!

▶ Isolate the appliance from the power

supply using the fuse or another electrical

protection device before carrying out any

work on electrical parts.

DANGER: Electric shock!

The electrical capacitor must discharge after

the appliance has been switched off.

▶ Wait at least 5 minutes.

DANGER:

To ensure compliance with all safety

requirements, defective power cables may

only be replaced by an authorised contractor.

All control, monitoring and safety equipment for this appliance

has been subjected to intense scrutiny and is ready for

operation.

The appliance is set at the factory to a power

supply of 230 V (single phase).

CAUTION:

Current protection!

▶T

The appliance is equipped with a cable for the mains

connection (1.5 m long) and is ready to be connected to a

socket (230 V AC/50 Hz).

For safety and maintenance purposes,

ensure that the socket is accessible after

installation.

Electric shock!

he control unit must have a separate

connection for the appliance with a 30 mA

safety switch and earth connection.

6 Electrical connection

The appliance may only be installed by an

authorised contractor.

6 720 809 134 (2013/09) Compress 3000 DW FII

6.1 Appliance's electrical connection

The electrical connection must meet the

current standards for electrical installations

in the country of use.

Page 17

Commissioning | 17

6720804054-16.1V

1

2

▶ The power connections must be as short as possible in order

to protect the system against overloading; for example,

during a storm.

▶ Connect the appliance to the power supply via a separate

socket with an earth connection.

7Commissioning

7.1 Before commissioning

NOTICE: Damage to the appliance!

After installing the appliance in its final

position, wait at least 30 minutes before

switching it on.

NOTICE: Do not start the appliance without

water!

▶ Only operate the appliance once it has

been filled with potable water.

▶ Check whether the cylinder is filled with water.

▶ Check all connections for tightness.

▶ Check the electrical connection.

7.2 Switching the appliance on/off

Switching ON

▶ The appliance must be connected to the power supply via a

separate socket with an earth connection.

For the first few seconds after switching on, the display will

not be activated.

Normal start

Time Activity

0 - 1 minutes Water temperature check (circulation pump in

operation)

1 - 2 minutes Wait mode

2 - 4 minutes Air temperature check (fan in operation)

> 4 minutes Compressor in operation

Table 9

Switching off

▶ Switch off the appliance at the power connection.

NOTICE: Damage to the appliance!

Minus temperatures can cause the water to

freeze.

▶ Do not interrupt the power supply. This

will ensure that the "frost protection"

function keeps working.

▶ Set the appliance to the "Off" operating

mode ( cha pter 8.4.4, page 19).

-or-

▶ Drain the appliance fully.

8Operation

Once the compressor has been started, the

appliance must run for at least 5 minutes

before it can be switched off again.

Fig. 13 User interface

[1] Display

[2] Selector keys

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 18

18 | Operation

2 3

4

5

6

8

9

12

11

16

14

13

6720645393-10.1V

1 7

15

10

6720646160-13.1V

6720646160-14.1V

menu

-

ok

+

<3s

Fig. 14 Display

[1] Electrical heating mode

[2] DHW heating by heat pump

[3] External heating (solar or boiler)

[4] Information

[5] Input of adjustable parameters

[6] Error display

[7] Service menu selection

[8] Days of the week

[9] "Auto/Man" operation

[10] ON/OFF indicator

[11] "Prog" menu selection

[12] Setting the hour

[13] Runtime

[14] Power consumption

[15] Code for cylinder temperature sensors

[16] Frost protection

▶ Press the "+" or "-" button to set the desired value.

Fig. 15 Setting the temperature

▶ Press the "OK" button to confirm the setting.

The set value flashes until the setting is

confirmed.

If the setting is not confirmed within

10 seconds, the previously set value is

retained.

Once the temperature has been set, the

display indicates the water temperature in

the cylinder.

8.3 Main menu

Calling up the main m enu

▶ Press and hold the "Menu" button for max. 3 seconds.

8.1 Operation modes

" " symbol is displayed

Operating times as set (P1, P2 or P3).

" " symbol is displayed

Continuous operation (24 h/7 days) without time setting or in

"Full" operating mode.

8.2 Setting the domestic hot water temperature

The water temperature is set to 50 °C at the

factory.

6 720 809 134 (2013/09) Compress 3000 DW FII

Fig. 16 Calling up the main menu

Once you have called up the main menu, you can select the

following menus/submenus:

• Prog - Operating modes

–Manual

–P1

–P2

–P3

–Full

–Off

• Mode - H eat types

– "Electrical" operating mode

– "Heat pump" mode

– "Combi" operating mode

• Set - Settings

Page 19

Operation | 19

6720646160-37.1V

6720646160-08.1V

–Date

– Prog - Programming of the operating times

– Leg - Legionella program

–Duct - use of ducts

–Purg - Drain

– Fset - Default settings

• Info - Information

▶ Use the "+" or "-" button to select the required menu.

▶Confirm by pressing "ok".

To switch to the previous menu:

▶ Press the "Menu" button.

-or-

▶ Do not press any buttons for 15 seconds.

8.4 "Prog" submenu - Operating modes

You can set 7 different operating times in the "Prog" submenu.

•Manual

•P1

•P2

•P3

•Full

•Off

8.4.1 "Manual" operating mode

Selecting this operating mod e puts the appliance into

continuous operation in order to keep the temperature at the

set value for a longer period of time. The heat appliance can be

set in the main menu using the "Mode" function

( chapter 8.5).

"P2" and "P3" operating modes

Selecting this menu causes the appliance to run according to

the user-set operating times ( "P2" and "P3" operating times,

page 22).

8.4.3 "Full" operating mode

In this operating mode, two heat appliances are used at the

same time: the heat pump and the electric booster heater.

The appliance performance decreases in

"Full" operating mode. For this reason, it

must only be used when the water

temperature needs to be increased rapidly.

Fig. 18 "Full" operating mode

The water temperature can be set to between 30 °C and 70 °C.

Both heat appliances are used at the same

time until the desired temperature is

reached.

Only the electric booster heater is used at

temperatures above 60 °C.

The display shows "Full" until the desired

temperature is reached.

Fig. 17 "Manual" operating mode

8.4.2 "P1", "P2" and "P3" operating modes

"P1" operating mode

Selecting this menu causes the appliance to run according to

the factory-set operating times ( "P1" operating time,

page 22).

As soon as the set DHW temperature is reached, the appliance

switches from the "Full" operatin g mode back to the previously

set operating mode.

"Quick" activation of the "Full" operating mode

▶ Press and hold the "+" and "-" buttons for more than

3seconds.

8.4.4 "OFF" operating mode

In this operating mode, the appliance is switched off. If

necessary, the electric booster heater is switched on by itself

for the frost protection function.

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 20

20 | Operation

6720646160-10.1V

6720646160-19.1V

6720646160-07.1V

6720646160-06.1V

6720646160-09.1V

Fig. 19 "OFF" operating mode

Frost protection

The electric booster heater starts up when the water

temperature in the cylinder falls to 5 °C and switches off again

when the temperature reaches 8 °C.

8.5 "Mode" submenu - Heating mode

3 different types of heating mode can be selected in the "Mode"

submenu.

• Electrical heating mode

• "Heat pump" operating mode

• "Combi" operating mode

8.5.2 "Heat pump" operating mode

Water heating is only guaranteed when the

inlet air temperature is between -10 °C and

35 °C.

Selecting this operating mode means that the heat pump is the

only heat appliance used.

Fig. 22 "Heat pump" operating mode

The water temperature can be set to between 30 °C and 60 °C.

At very low temperatures, the frost

protection function ( page 20) is

activated.

8.5.3 "Combi" operating mode

In this operating mode, two heat appliances are used

depending on the situation: the heat pump or the electric

booster heater.

Fig. 20 "Mode" function

8.5.1 Electrical heating mode

In this operating mode, the electric booster heater is the only

heat appliance used.

Fig. 23 "Combi" operating mode

The water temperature can be set to between 30 °C and 70 °C.

If the water temperature in the cylinder is

below 60 °C and the inlet air temperature is

between -10 °C and 35 °C, the heat pump is

the only heat appliance used. Otherwise, the

Fig. 21 Electrical heating mode

electric booster heater is switched on.

The water temperature can be set to between 30 °C and 70 °C.

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 21

Operation | 21

6720646160-18.1V

6720646160-11.1V

6720646160-12.1V

6720646160-15.1V

8.6 "Set" submenu - Settings

You can set various parameters in the "Set" submenu:

•Date

• Prog - Operating times

•Leg - Legionella

•Duct - use of ducts

•Purg - Drain

• Fset - Default settings

Fig. 24 "Set" function

8.6.1 Date - Setting the temperature unit, date, time and day of the week

▶ Set the day of the week using the "+" or "-" button.

Fig. 26 Setting the weekday

▶ Confirm by pressing "OK".

The hour flashes on the display.

▶ Set the hour using the "+" or "-" button.

▶ Confirm by pressing "OK".

The minutes flash on the display.

▶ Set the minutes using the "+" or "-" button.

▶ Confirm by pressing "OK".

The process of setting the clock is complete.

8.6.2 Prog - Programming of the operating times

In the "Prog" submenu, you can set the operation period for the

heat pump.

Fig. 25 Setting the date

▶ Select the temperature unit using the "+" or "-" button.

▶Confirm by pressing "OK".

The year flashes on the display.

▶ Set the year using the "+" or "-" button.

▶Confirm by pressing "OK".

The month flashes on the display.

▶ Set the month using the "+" or "-" button.

▶Confirm by pressing "OK".

The day flashes on the display.

▶ Set the day using the "+" or "-" button.

▶Confirm by pressing "OK".

The day flashes on the display.

Monday is set as the first day of the week by

default. Depending on individual

requirements, the user can choose to set a

different day as the first day of the week.

Fig. 27 "Prog" function

The following menus can be called up in the "Prog" submenu:

• "P1" operating time (days 1 to 5)

• "P1" operating time (days 6 and 7)

• "P2" operating time (days 1 to 5)

• "P2" operating time (days 6 and 7)

• "P3" operating time (days 1 to 5)

• "P3" operating time (days 6 and 7)

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 22

22 | Operation

6720646160-16.1V

6720646160-35.1V

6720646160-39.2V

6720646160-40.2V

6720646160-41.1V

"P1" operating time

The heat pump only goes into operation during the operating

times set at the factory. These cannot be changed:

Days 1 - 5: [00:00 06:00] and [16:00 19:00]

Days 6 - 7: [02:00 08:00]

Fig. 28 "P1" operating time

"P2" and "P3" operating times

The heat pump runs according to the operating times set by the

user.

Fig. 29 "P2" and "P3" operating times

Setting the operating times for "P2" and "P3"

4 operating times are set for each function:

•2 operating times for days 1 to 5

• 2 operating times for days 6 and 7

Setting the operating times

▶ Call up function "P2" or "P3" ( chapter 8.4).

▶Press "OK".

The start of the first operating time flashes.

▶ Set the start of the operating time using the "+" and "-"

buttons.

▶Press "OK".

The end of the first operating time flashes.

▶ Set the run time using the "+" and "-" buttons.

▶Press "OK".

The start of the second operating time flashes.

Fig. 31 Start of the second operating time

If the start of the second operating time is set

so that it is within the fi rst operating time, the

first operating time ends automatically when

the second operating time starts.

▶ Set the start of the second operating time using the "+" and

"-" buttons.

▶Press "OK".

The end of the second operating time flashes.

▶ Set the run time using the "+" and "-" buttons.

▶Press "OK".

The operating time for days 1 to 5 is saved.

Fig. 32 Start of the first operating time for days 6 and 7

▶ Repeat the steps above for the operating times for days 6

and 7.

Once you have set the second operating time f or days 6 and 7,

the process of setting the operating times is complete.

Fig. 30 Start of the first operating time

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 23

Fig. 35 "Leg" function

6720646160-38.1V

1 2 3 4

6720804054-14.1V

6720646160-17.1V

Operation | 23

Fig. 33 Setting operating times

[1] Start of the first operating time

[2] End of the first operating time

[3] Start of the second operating time

[4] End of the second operating time

Deleting the operating time

▶ Set the start and end of the operating time to the same time.

The operating time is deleted.

If you do not wish to set a second operating time:

▶ Set the start and end of the second operating time to the

same time.

The display will show "--:--".

Fig. 34

" " symbol is displayed

During appliance operating time.

" " symbol is di splayed

Outside of appliance operating time.

8.6.3 "Leg" - Automatic thermal disinfection

The "Leg" function allows you to activate/deactivate thermal

disinfection. This process is used to kill bacteria and must be

performed by the user at least once a week.

This function is deactivated on the appliance

at the factory.

When the disinfection is activated, all other

settings are temporarily suspended.

WARNING: Risk of scalding!

Hot water can lead to severe scalding.

▶ Only schedule thermal disinfection for

periods outside normal usage times.

▶ Inform occupants of the building of the

danger of scalding and always monitor

the thermal disinfection process. Install a

thermostatic DHW mixer.

The disinfection takes max. 48 h. During the

first 24 hours, the appliance is in the "Combi"

operating mode. If it does not reach 70 °C,

the appliance switches to the "Full" operating

mode for the next 24 hours.

Activating the automatic "Leg" function

The DHW temperature is automatically set to

70 °C.

▶ Call up the "Leg" function and press "OK".

" " flashes on the display.

▶Press "+".

" " flashes on the display.

▶Press "OK".

The "Leg" function is activated and the first day of the week

flashes.

Set the day of the week for disinfection.

▶ Select the day using the "+" and "-" buttons.

▶Press "OK".

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 24

24 | Operation

6720807839-01.1V

6720801967-02.1V

6720804054-10.1V

Set the time for disinfection.

▶ Select the time using the "+" and "-" buttons.

▶Press "OK".

As soon as the temperature reaches 70 °C, the appliance

switches back to the previously set operating mode.

Activating the manual "Leg" function

▶ Call up the "Leg" function and press "OK".

" " flashes on the display.

▶Press "OK".

The "Leg" function is active.

The DHW temperature is automatically set to

70 °C.

As soon as the temperature reaches 70 °C, the appliance

switches back to the previously set operating mode.

To repeat the disinfection process, you must

reactivate it.

Cancelling the "Leg" function.

▶ Call up the "Leg" function and press "OK".

" " flashes on the display.

▶ Press "+" until the display shows "LstP".

▶Press "OK".

The current Legionella program is cancelled.

▶ Press « + » or « - » to define the use of ducts:

– « dOFF » : installation without ducts

– « dON » : installation with ducts

▶Press «OK».

8.6.5 "Purg" - Drain

The "Purg" function can be used to drain water from the system.

Fig. 37 "Purg" function

Switching on the "Purg" function.

▶ Call up the "Purg" function and press "OK".

The pump is switched on.

The display indicates the time remaining until the draining

procedure is complete (in minutes).

After 5 minutes, the appliance reverts to the previously

selected operating mode.

8.6.6 "Fset" - Default settings

The "Fset" function can be used to restore the default settings.

This only ends the current program; the

weekly repetition is still active.

8.6.4 « Duct » - use of ducts

Fig. 38 "Fset" function

Switching on the "Fset" function

▶ Call up the "Fset" function and press "OK".

The display shows "Fset".

▶Press "OK".

After 10 seconds, the default settings are restored

( chapter 8.9).

Fig. 36 « Duct » function

Switching on the « Duct » function

▶ Select « Duct » function and press « OK ».

The display shows “dOFF”.

6 720 809 134 (2013/09) Compress 3000 DW FII

8.7 "Info" submenu - Information

With the "Info" function, it is possible to display the total

consumption for the last 30 days.

Page 25

Fig. 39 "Info" function

6720646160-36.1V

6720646160-42.1V

6720800765-04.1V

menu

-

ok

+

6720646160-21.1V

menu

-

ok

+

>3s

6720646160-37.1V

Displaying the consumption

▶ Call up the "Info" function and press "OK".

The display shows the total consumption (in kWh).

Resetting the consumption

The display shows the total consumption.

▶ Press "-".

"Del" flashes on the display.

Environmental protection/Recycling | 25

Resetting the fault display

▶ Press and hold the "OK" button for at least 3 seconds.

Fig. 42 Resetting the system

8.9 Default settings

After setting the temperature units and the time, the appliance

adopts the default settings.

• Heating mode: "Combi" ( chapter 8.5)

• Operating mode: "Manual" (chapter 8.4.1)

• Selected temperature: 50 °C

Fig. 40 "Del" function

▶Press "OK".

The counter is reset.

8.8 Fault diagnosis

The appliance is equipped with a system for fault diagnosis.

Malfunctions are displayed on the digital display by means of a

fault code ( Tab. 10, page 28) and a fault symbol ( Fig. 14,

[6]). The fault must be eliminate and the appliance

recommissioned before it is ready for use again. Chapter 11

gives an overview of the faults.

Fig. 41 Fault display with associate fault code

Fig. 43 Initial menu

9 Environmental protection/Recycling

Environmental protection is one of the fundamental company

policies of the Bosch Group.

Product quality, efficiency and environmental protection are

equally important objectives for us. We comply with all

environmental protection laws and regulations.

In order to protect the environment, we use the latest

technologies and the best materials whilst bearing in mind the

economic implications.

Packaging

Where packaging is concerned, we participate in the relevant

local recycling systems in order to ensure optimum recycling.

All of our packaging materials are environmentally friendly and

can be reused.

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 26

26 | Service

6720800765-05.1V

Obsolete equipment

Used appliances contain materials that can be reused.

The assemblies are easy to separate and the types of plastic are

identified. In this manner the individual components are easily

sorted and added into the recycling and disposal systems.

10 Service

DANGER: Risk of electric shock!

▶ Isolate the appliance from the powe r

supply using the fuse or another

protection device before carrying out any

work on electrical parts.

NOTICE: Damage to the appliance!

▶ Do not shut off the water supply while the

appliance is in operation.

10.1 General inspections

Check the appliance regularly for faults.

▶ Keep the appliance and the installation location clean.

▶ Dust the system regularly using a damp cloth.

In this way, leaks can be identified and repaired at an early

stage.

▶ Check all connections regularly for tightness.

10.2 Checking/replacing the magnesium anode

The appliance is protected against corrosion

by a magnesium anode in the cylinder.

NOTICE: Damage to the appliance!

The magnesium anode must be installed

before commissioning the appliance.

NOTICE: Damage to the appliance!

Check the magnesium anode annually and

replace if required. Appliances operated

without this protection are excluded from

our warranty.

The internal wall of the DHW cylinder is coated with a double

glass lining. The coating is designed for normal quality water.

When using more corrosive water, the warranty only applies if

additional safety measures have been taken (e.g. the use of an

isolation fitting) and the magnesium anode is checked more

frequently.

To check the protective anode:

▶ Isolate the appliance from the power supply.

▶ Remove protective coverings.

WARNING: Risk of scalding!

▶ Before removing the magnesium anode,

drain about 75 litres of water from the

cylinder.

▶ Remove the magnesium anode.

Fig. 44 Checking the state of the magnesium anode

▶ Check the state of the magnesium anode and replace if

necessary.

10.3 Cleaning

▶ Check and clean the evaporator regularly.

▶ The air inlet and air outlet apertures must be unobstructed

and accessible.

▶ Check the air grille, air filter and air ducts regularly and clean

them if necessary.

10.4 Condensate pipe

▶ Disconnect the condensate hose from the condensate

drain.

▶ Check the drain and/or hose for contamination and clean if

necessary.

▶ Reconnect the condensate hose to the condensate drain.

10.5 Safety valve

▶ Open the safety valve at least once a month ( Fig. 45) to

ensure that it is functional.

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 27

Service | 27

1

6720608467-18.2AL

2

6720646160-27.1V

2

1

▶ Push the reset button until it stops ( Fig. 46, [1]).

Fig. 45 Safety valve

[1] Safety valve

[2] Sequence

CAUTION: Risk of scalding!

▶ Ensure that draining water from the

safety valve presents no risk to people or

property.

10.6 Refrigerant circuit

NOTICE: Refrigerant leak!

▶ Maintenance work may only be carried

out on the refrigerant circuit (e.g. on the

compressor, condenser, evaporator,

expansion vessel, etc.) by a certified

contractor.

10.7 High limit safety cut-out

The appliance is equipped with an automatic safety facility.

This safety facility switches off the DHW cylinder in order to

prevent the risk of injury if the DHW cylinder water temperature

rises above a certain limit.

NOTICE: The high limit safety cut-out may

only be reset by a qualified contractor!

The high limit safety cut-out must be reset

manually, but only once the cause of the fault

has been eliminated.

Resetting the high limit safety cut-out

▶ Remove the front protective covering ( Fig. 3, [24]).

▶ Remove the protective cap from the resistor.

Fig. 46 Temperature control unit

[1] Reset button

[2] Temperature setting of the high limit safety cut-out.

After resetting, ensure that the temperature

controller is in the position shown in Fig. 46.

Do not damage the sealing.

10.8 Draining the cylinder

CAUTION: Risk of scalding!

Check the appliance's DHW temperature

before opening the safety valve.

▶ Wait until the water temperature has

dropped enough to prevent scalding and

other damage.

▶ Isolate the appliance from the power supply.

▶ Close the water shut-off valve at the cold water inlet and

open one DHW tap.

▶ Open the drain tap.

-or-

▶Open safety valve.

▶ Wait until the water stops flowing out of the safety valve

drain tap and the appliance has been completely drained.

10.9 "Service" menu

This menu is meant to assist the contractor

and may be used by the contractor only.

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 28

28 | Display

11 Display

11.1 Faults that are displayed

Installation, service and maintenance may only be carried out by an certified contractor. The following table lists the fault codes and

their remedies.

Display Description Remedy

E01 Fault in the temperature sensor at the top of the cylinder Notify certified contractor

E02 Fault in the temperature sensor at the bottom of the cylinder Notify certified contractor

E03 Temperature sensor for air inlet not working Notify certified contractor

E04 Temperature in cylinder 80 °C If the problem persists after pressing "OK", notify a

E05 NTC temperature sensor (evaporator plates) not working Notify certified contractor

E06 Setting buttons hold down for longer than 30 seconds. Release buttons

E07 Accessory 7 736 501 8391) not (correctly) installed

E08 Accessory 7 736 501 8391) not (correctly) installed Notify certified contractor

E09 System emptied incorrectly

Water shortage (> 12h)

Fault in the pump

E10 Resistor not working

High limit safety cut-out not working

Temperature of high limit safety cut-out set to a lower value

than the appliance

E11 Fault in the fan

Pressure loss in the pipes

Leaks in refrigerant circuit

Fault in the compressor

Expansion valve not working

Drying filter not working

Table 10 Fault codes

1) Not available

certified contractor.

Notify certified contractor

Notify certified contractor

Clear the fault

Notify certified contractor

Notify certified contractor

Notify certified contractor

11.2 Display

Display Description Note

HOT Supply air temperature 35 °C System stops automatically in the "Heat pump" operating

COLD Supply air temperature -10 °C

Table 11 Display

6 720 809 134 (2013/09) Compress 3000 DW FII

mode if the air inlet temperature is below -10 °C or above

35 °C. General operating conditions are checked on an

hourly basis.

Page 29

Notes

| 29

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 30

30 |

Notes

6 720 809 134 (2013/09) Compress 3000 DW FII

Page 31

Notes

| 31

6 720 809 134 (2013/09)Compress 3000 DW FII

Page 32

Bosch Thermotechnik GmbH

Junkersstrasse 20-24

D-73249 Wernau

www.bosch-thermotechnology.com

Loading...

Loading...