Page 1

Air-Water Split Heat Pump

6 720 814 470-00.2I

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

Compress 3000 AW

230V 1N~ / 400V 3N~

Operating instructions

6 720 818 009(2015/07)

Page 2

2 | Table of Contents

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

Table of Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 3

2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Overview of system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Description of the functions . . . . . . . . . . . . . . . . . . . . . . . 4

4 Overview of the most frequently used functions . . . . . . . . . . . 6

4.1 Changing the room temperature . . . . . . . . . . . . . . . . . . . 7

4.2 DHW settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Setting the operating mode . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 Selecting a heating circuit for the standard display . . . . 8

4.5 Favourite functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Remove dirt and leaves . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Protective covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.4 Snow and ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.5 Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.6 Leakage tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.7 Checking the safety valves . . . . . . . . . . . . . . . . . . . . . . . . 9

5.8 Particle filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.9 Pressure switch and overheating protection . . . . . . . . 10

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or

death.

Important information

This symbol indicates important information where

there is no risk to people or property.

Additional symbols

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

6 Internet connection via integrated IP module . . . . . . . . . . . 12

7 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compress 3000 AW6 720 818 009 (2015/07)

Page 3

General | 3

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

1.2 General safety instructions

These operating instructions are intended for the user of the heating

system.

▶ Read any operating instructions (heat pump, heating controls, etc.)

carefully before operation and keep them.

▶ Observe the safety instructions and warnings.

Intended use

This heat pump must only be used as a heat appliance in a sealed hot

water heating system for domestic purposes.

Any other use is considered inappropriate. Any damage that results from

such use is excluded from liability.

Safety of electrical appliances for domestic use and similar

purposes

The following requirements apply in accordance with EN 60335-1 in

order to prevent hazards from occurring when using electrical

appliances:

“This appliance can be used by children of 8 years and older, as well as

by people with reduced physical, sensory or mental capabilities or

lacking in experience and knowledge, if they are supervised and have

been given instruction in the safe use of the appliance and understand

the resulting dangers. Children must not play with the appliance.

Cleaning and user maintenance must not be performed by children

without supervision.”

“If the power cable is damaged, it must be replaced by the manufacturer,

its customer service department or a similarly qualified person, so that

risks are avoided.”

Inspection and maintenance

If there is a lack of cleaning, inspection or maintenance, or if these are

carried out incorrectly, this may result in material damage and/or

personal injury, including possible loss of life.

▶ Have work carried out only by an approved contractor.

▶ Have any defects rectified immediately.

▶ Have the heating system inspected once a year by an approved

contractor, and have any required maintenance or cleaning work

carried out.

▶ Have the heat source cleaned at least every two years.

▶ We recommend that you enter into a contract covering an annual

inspection and needs-based maintenance with an approved

contractor.

Modifications and repairs

Unprofessional modifications to the heat pump or other parts of the

heating system can result in injury and/or damage to property or

equipment.

▶ Have any work carried out only by an authorised contractor.

▶ Do not remove the casing of the heat pump.

▶ Do not modify the heat pump or other parts of the heating system in

any way.

2General

Compress 3000 heat pumps belong to a series of heating systems that

recover energy from the outdoor air for heating and DHW heating.

By reversing this process and removing heat from the heating water and

releasing it to the outdoor air, the heat pump can also be used for cooling

if necessary. To do this however, the heating system must be configured

for cooling mode.

In order to obtain a complete heating system, the heat pump which is set

up outdoors must be connected to an indoor unit in the building and in

some cases also to an existing external heat source, a boiler for example.

The indoor unit with integrated electric booster heater or external heat

source serve as auxiliary heating when the heat energy demand is

particularly high, e.g. if the outside temperature is too low for the heat

pump to operate effectively.

The heating system is controlled by a user interface which is located in

the indoor unit. The user interface controls the system using a range of

different settings for the heating, cooling, DHW and other operations.

The monitoring function switches the heat pump off in the event that

faults occur for example, as this prevents the main components being

damaged.

2.1 Control unit

The user interface in the indoor unit controls the heat production based

on the outdoor sensor values, possibly in combination with the room

controller (accessory). The temperature in the building is adapted

automatically, based on the outside temperature.

The user specifies the temperature of the heating system by setting the

required room temperature at the user interface or room controller.

Various accessories (e.g. swimming pool, solar and room controller) can

be connected to the indoor unit. Additional functions and setting options

therefore become available and can also be controlled via the user

interface. For more information on accessories, refer to the relevant

instructions.

2.2 Use

Following the installation and commissioning of the heat pump and

indoor unit, specific tasks must be performed at regular intervals. These

include checking whether alarms have been triggered and simple

maintenance tasks. These actions can normally be performed by the

user unassisted. However, if problems persist it may be necessary to

contact the system installer.

Room air

The air in the installation room must be free of combustible or chemically

aggressive substances.

▶ Do not use or store combustible or explosive materials (paper,

propellants, thinners, paints, etc.) within the vicinity of the

appliance.

▶ Do not use or store corrosive substances (solvents, adhesives,

chlorinated cleaning agents, etc.) within the vicinity of the appliance.

6 720 818 009 (2015/07)Compress 3000 AW

Page 4

4 | Overview of system

6 720 814 470-03.1l

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

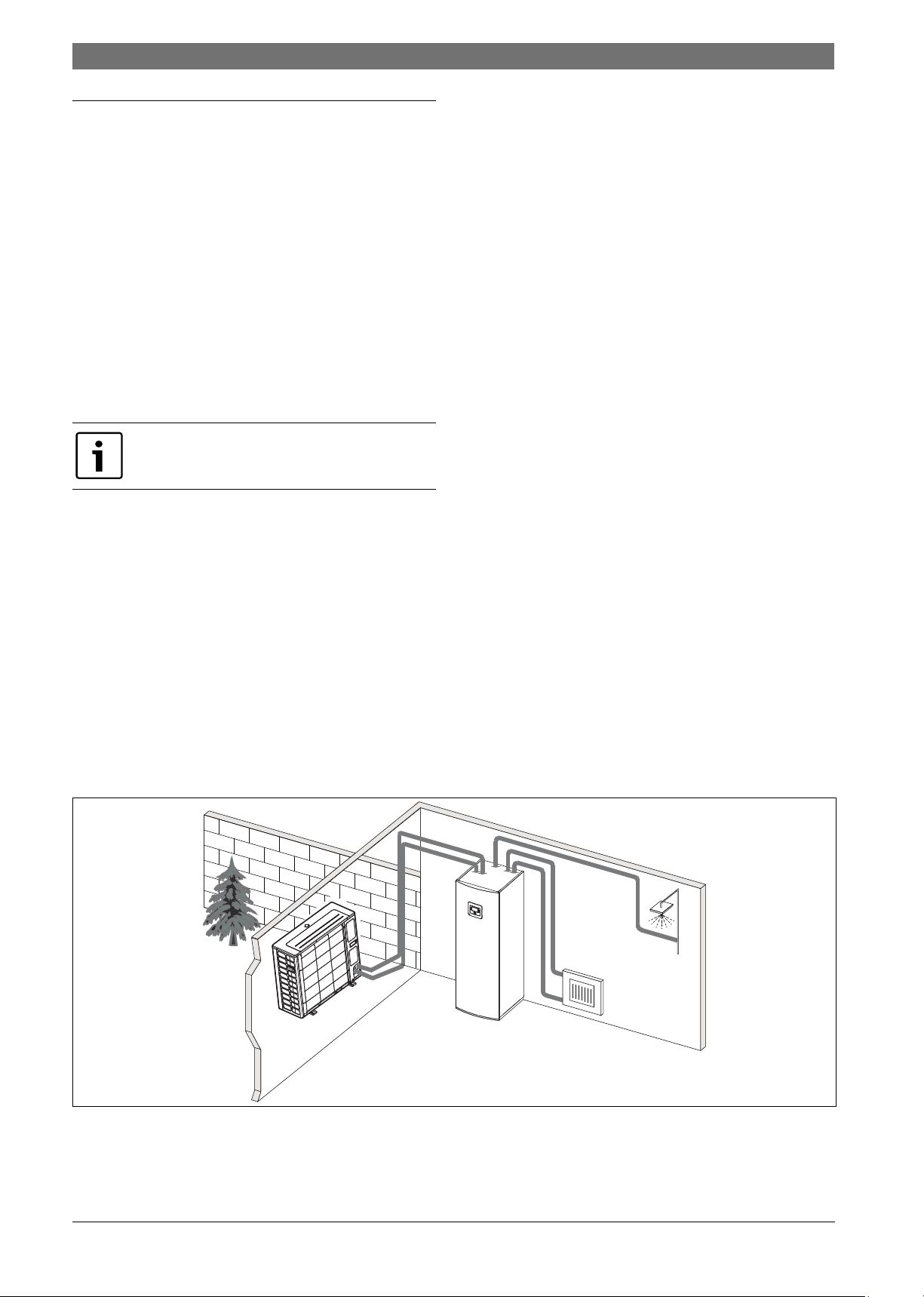

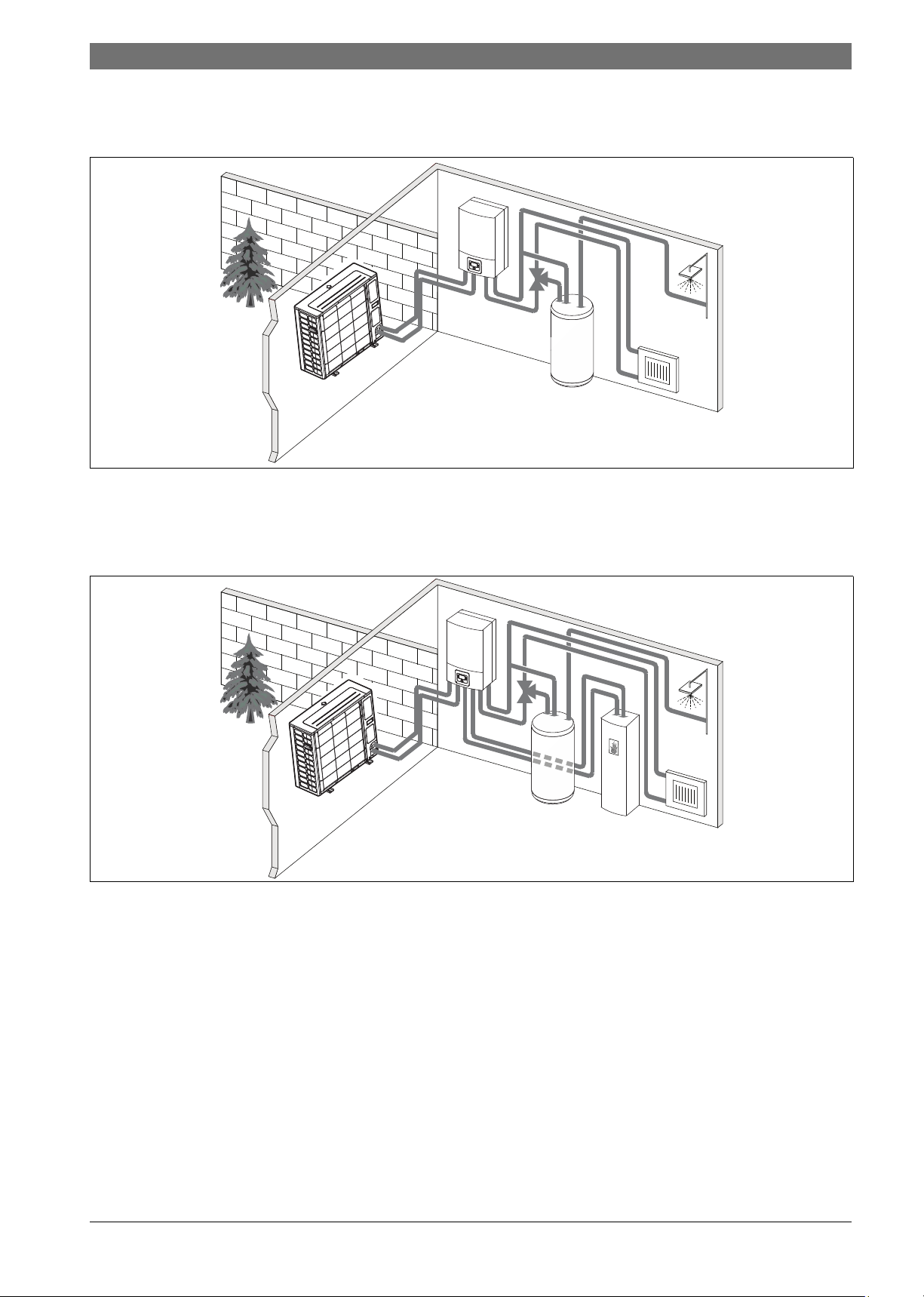

3 Overview of system

The heating system consists of two parts: the heat pump outdoors and

the indoor unit with or without integrated electric booster heater in the

building (AWES/AWMS/AWMSS).

An external heat source can also be connected, in which case an existing

electric, gas-fired or oil-fired boiler (AWBS) can be used as the auxiliary

heater.

The heating systems are normally designed with one of these

alternatives in mind. However, as the system is highly flexible, countless

other configurations are possible.

3.1 Description of the functions

In a house with water based heating a difference is made between

heating water and domestic hot water (DHW). The heating water is for

radiators and floor coils and hot water is for showers and taps.

If the system contains a DHW cylinder, the user interface ensures that

DHW heating has priority over heating mode.

The heat pump switches off at an outside temperature of

approx. – 20 °C. The indoor unit or an external heat

source then take over the heating and DHW heating.

3.1.1 Heat pump (outdoor unit)

The heat pump has the task of recovering energy from the outdoor air

and transferring it to the indoor unit.

The heat pump is equipped with an inverter control, i.e. it varies the

speed of the compressor automatically so that precisely the required

amount of energy is supplied in each instance. The speed of the fan can

also be controlled and it regulates its speed according to the

requirements. This keeps the energy consumption as low as possible.

defrosting

Ice can form on the evaporator at low outside temperatures. If the layer

of ice becomes so thick that it impedes the flow of air through the

evaporator, an automatic de-icing process is initiated. As soon as all the

ice has melted, the heat pump reverts to normal mode.

At outside temperatures greater than +5 °C, defrosting takes place when

heating mode is active with an increased output rate of air via the fan. At

low outside temperatures, defrosting is achieved by reversing the flow

direction of the refrigerant in a circuit via a 4-way valve; this type of

defrosting is referred to as 'reverse circulation'.

Working principle

The principle of operation in heating mode is as follows:

• The fan draws air through the evaporator.

• The energy in the air causes the refrigerant to boil. The gas which

forms is routed to the compressor.

• The pressure of the refrigerant in the compressor increases and its

temperature rises. The heated gas is routed under pressure to the

condenser.

• In the condenser, the water in the heat transfer medium circuit

absorbs the energy in the gas. The gas cools down and reverts to

liquid.

• The pressure in the refrigerant falls as it is controlled via expansion

valves and it is then routed back to the evaporator. It changes back to

gas when it enters the evaporator.

• The hot water arriving in the indoor unit from the heat transfer

medium circuit is then routed to the building heating and DHW

heating.

3.1.2 Indoor unit

The purpose of the indoor unit is to distribute the heat from the heat

pump to the heating system and DHW cylinder. The speed of the pump

in the indoor unit is controlled so that it automatically reduces when

demand is low. The energy consumption falls as a result.

If the heat energy demand is higher at low outside temperatures, an

auxiliary heater may be required. Auxiliary heaters can be integrated or

external and are switched in or disconnected via the user interface in the

indoor unit. If the heat pump is in operation, the electric booster heater

only produces enough heat to make up the shortfall between the heat

pump output and the required heat. As soon as the heat pump is once

again producing the required output on its own, the auxiliary heater is

switched off automatically.

Internal unit AWMS/AWMSS

If the external heat pump is combined with the AWM indoor unit,

together they constitute a complete heating and DHW system as the

indoor unit contains a DHW cylinder. The changeover between heating

and DHW is effected by an internal 3-way valve. The integrated electric

booster heater in the indoor unit is started if required.

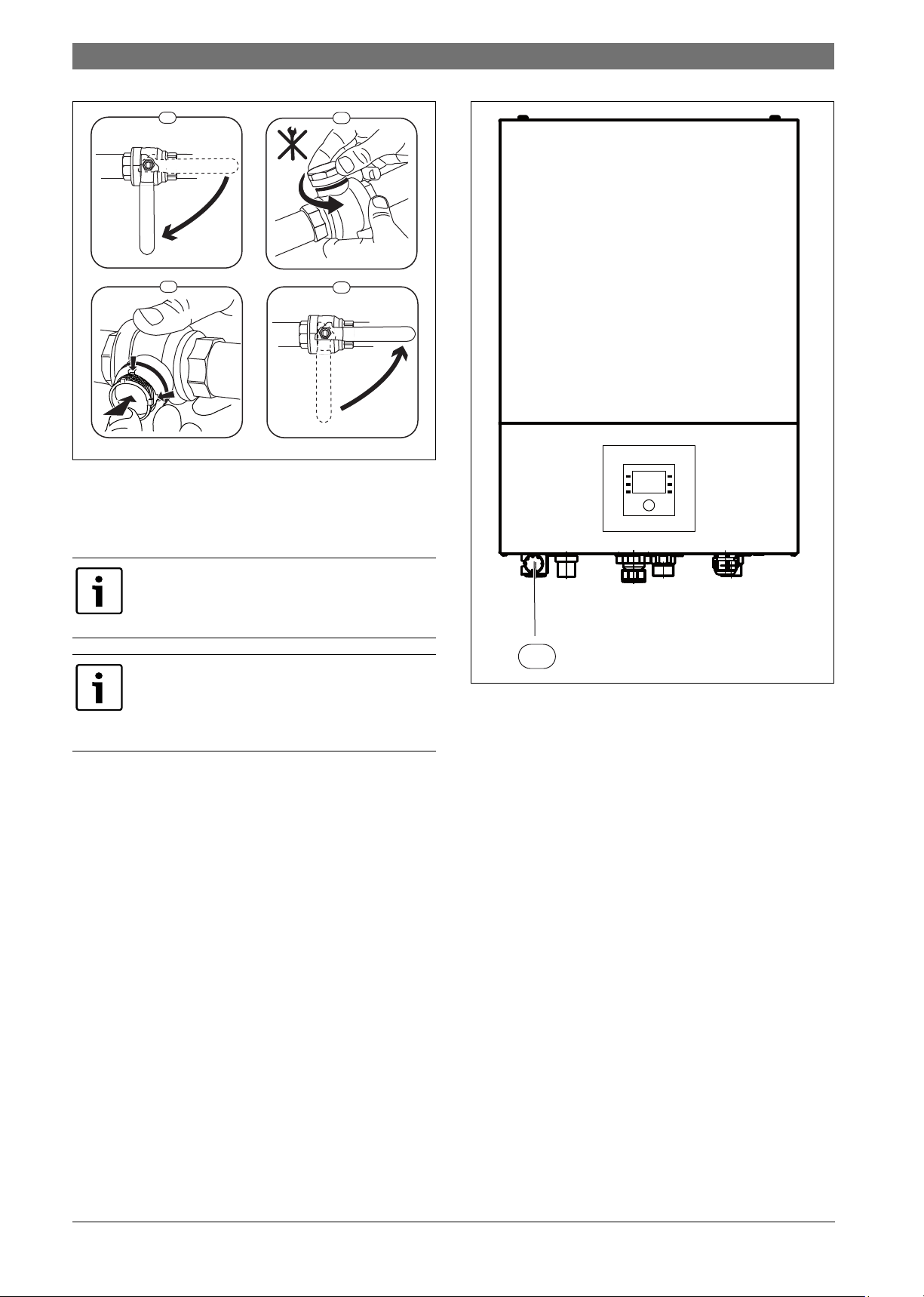

Fig. 1 Heat pump for outdoor unit, indoor unit AWMS/AWMSS with integrated DHW cylinder and electric booster heater

Compress 3000 AW6 720 818 009 (2015/07)

Page 5

Overview of system | 5

6 720 814 470-05.1l

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

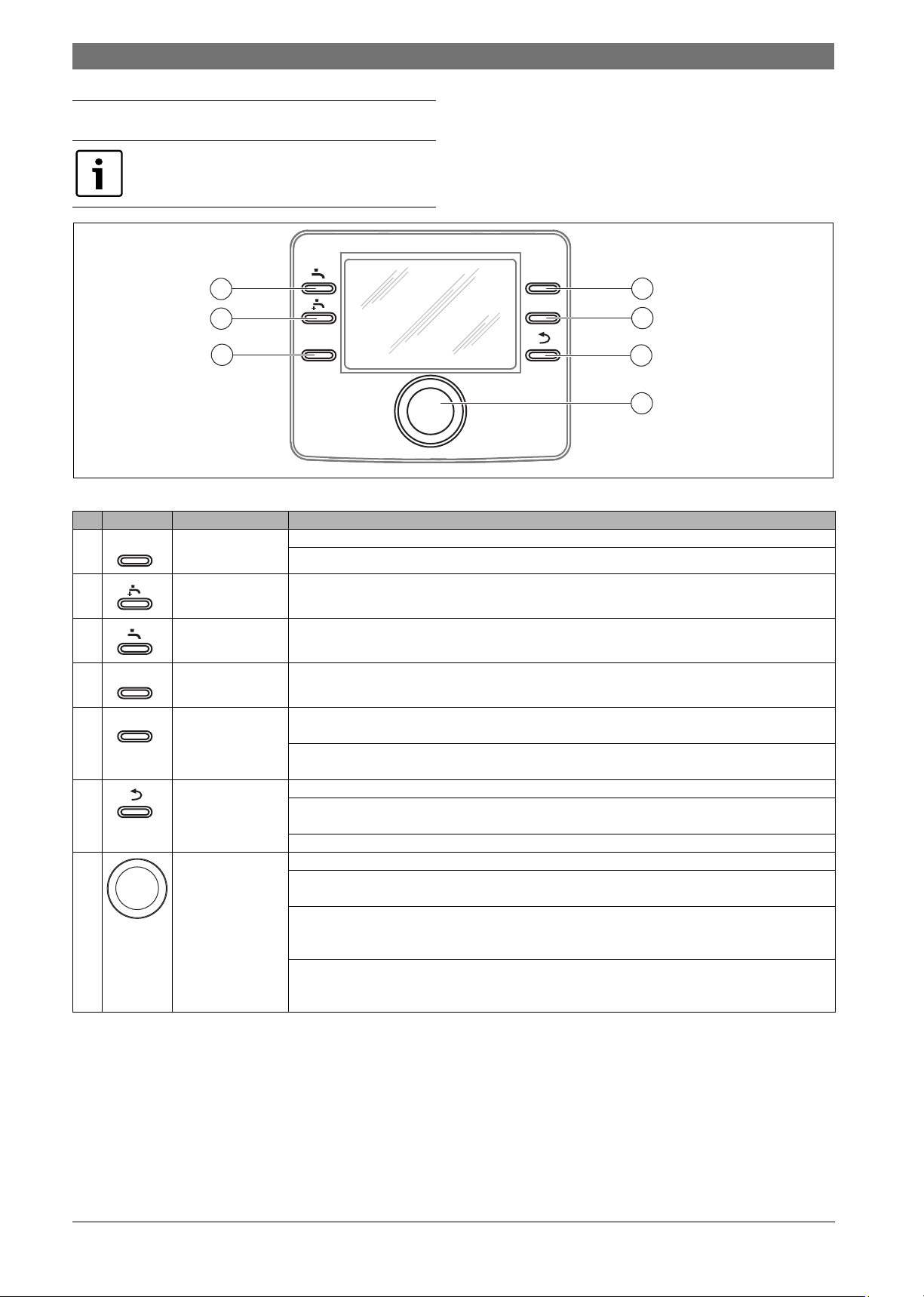

Indoor unit AWES

If the outdoor unit is combined with the indoor unit AWE and DHW is also

to be produced via the heat pump, an external DHW cylinder must be

connected. The changeover between heating and DHW is then effected

by an external 3-way valve. The integrated electric booster heater in the

indoor unit is started if required.

Fig. 2 Heat pump for outdoor unit, indoor unit AWE with electric booster heater and external DHW cylinder

AWBS

If the outdoor unit is combined with the indoor unit AWB and DHW is also

to be produced via the heat pump, an external DHW cylinder must be

by an external 3-way valve. The indoor unit is equipped with a mixe r. This

controls the heat from the external auxiliary heater which can be started

from the indoor unit if required.

connected. The changeover between heating and DHW is then effected

6 720 814 470-04.1l

Fig. 3 Heat pump for outdoor unit, indoor unit AWB without electric booster heater, external DHW cylinder and external auxiliary heater

6 720 818 009 (2015/07)Compress 3000 AW

Page 6

6 | Overview of the most frequently used functions

fav

menu

info

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

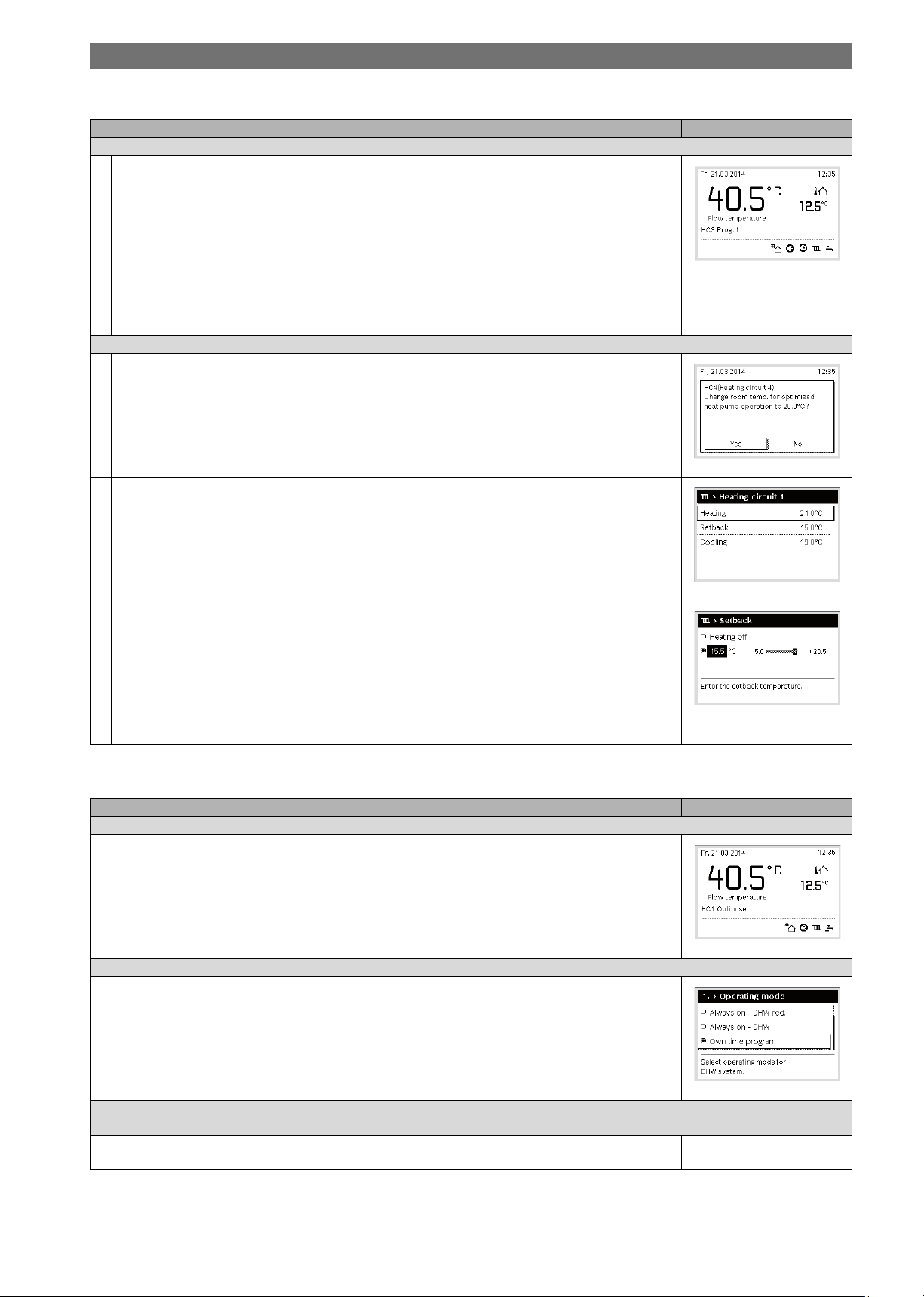

4 Overview of the most frequently used functions

The user manual for the user interface contains a

comprehensive description of all functions and settings.

3

2

fav

1

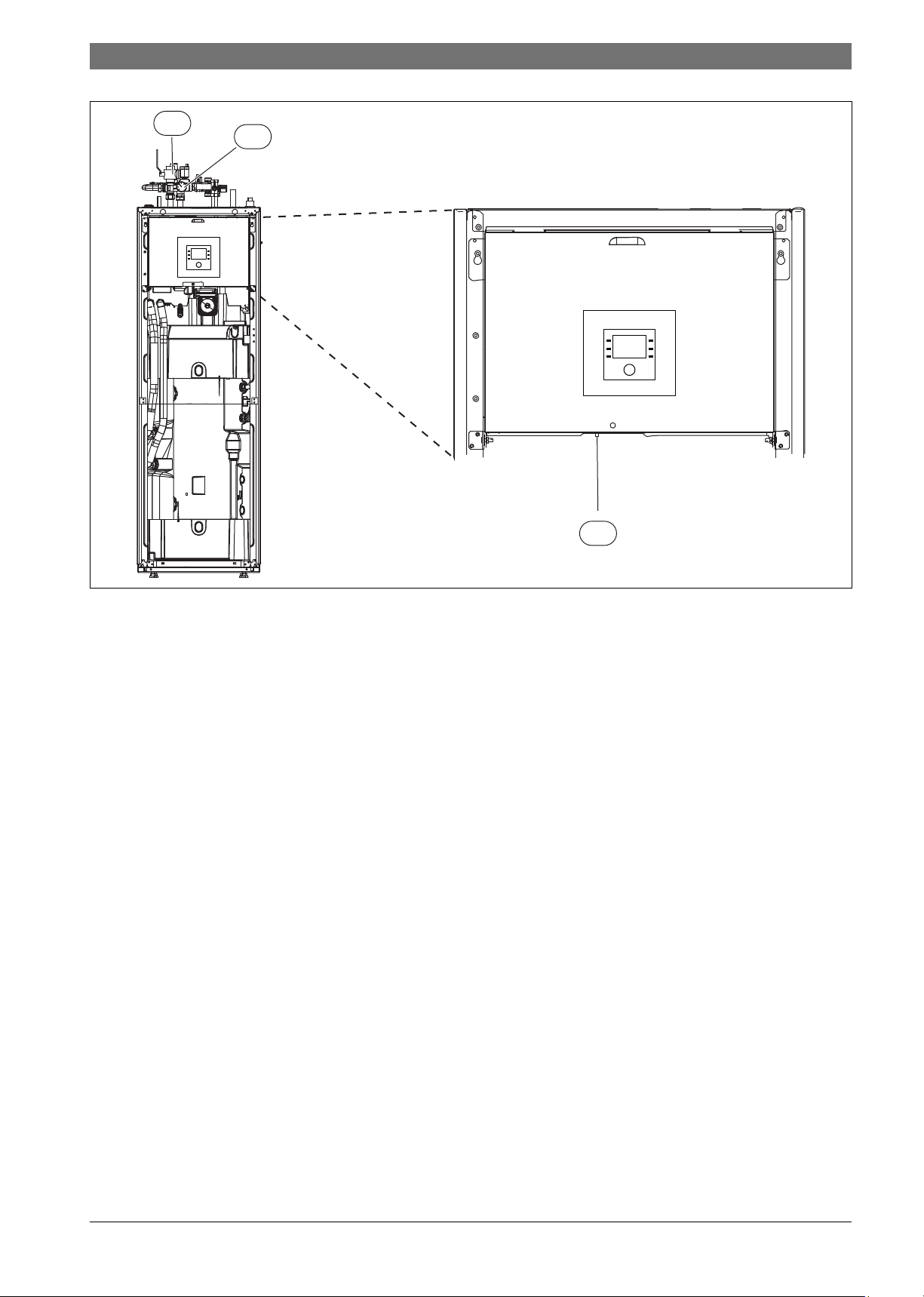

Fig. 4 Control elements

menu

4

info

5

6

7

6 720 810 300-01.1O

Item Element Designation Explanation

1 fav key ▶ Press to call up the favourite functions for heating circuit 1.

▶ Hold down to adjust the favourites menu to individual requirements.

2 extra DHW key ▶ Press to activate the extra-hot DHW function.

3 DHW key ▶ Press to select the DHW operating mode.

4 menu button ▶ Press to open the main menu.

5 Info key If a menu is open:

▶ Press to call up more information about the current selection.

If the standard display is active:

▶ Press to open the info menu.

6 Back key ▶ Press to return to the higher menu level or discard a changed value.

If the need for a service or a fault is displayed:

▶ Press to switch between standard display and fault display.

▶ Hold to switch from a menu to the standard display.

7 Control knob ▶ Turn to change a setting value (e. g. temperature) or select from among the menus or menu items.

If the lighting is switched off:

▶ Press to switch the lighting on.

If the lighting is switched on:

▶ Press to open a selected menu or menu item, confirm a set value (e.g. temperature) or a message or to close a pop-

up window.

If the standard display is active:

▶ Press to activate the input field for selecting the heating circuit in the standard display (only systems with at least

two heating circuits).

Table 2 Control elements

Compress 3000 AW6 720 818 009 (2015/07)

Page 7

Overview of the most frequently used functions | 7

6 720 812 775-05.1O

6 720 811 136-08.1O

6 720 811 136-10.1O

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

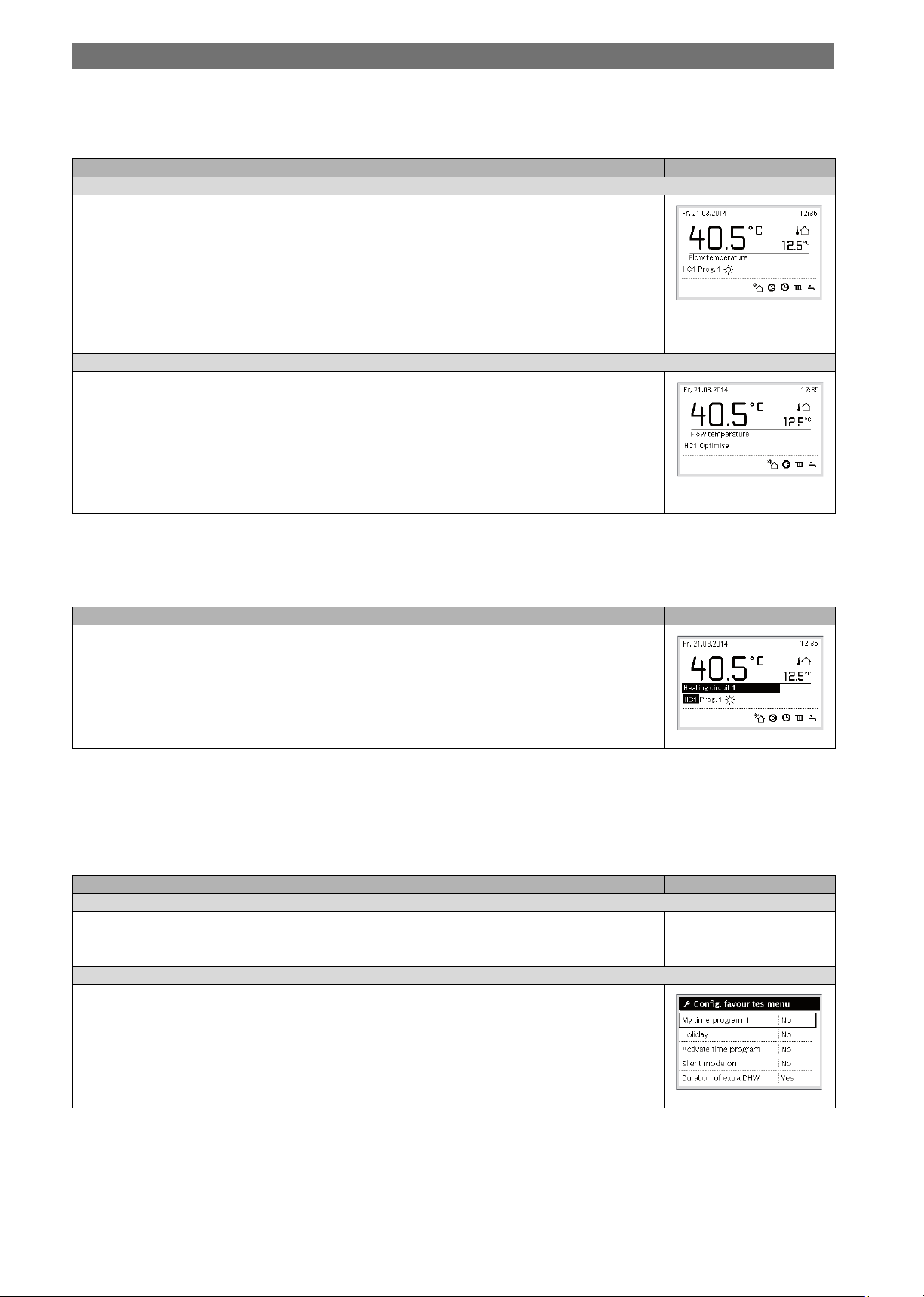

4.1 Changing the room temperature

Operating the appliance Result

If it is too cold or too warm for you today: Change the room temperature temporarily

Changing the room temperature until the next switching time

▶ Turn the selector to set the required room temperature.

The corresponding time slot is displayed in grey in the time program bar chart.

▶ Wait a few seconds or press the selector.

The user interface operates with the modified setting. The change applies until the next switching time in your heating

system time program is reached. After this, the time program settings are restored.

Undoing a temperature change

▶ Turn the selector until the corresponding time slot turns back to black in the time program bar chart and press the

selector.

The change is undone.

Automatic mode

If it is permanently too cold or too hot for you: set the required room temperature (e.g. for heating and setback mode)

▶ Activate optimised operation ( Chapter 4.3).

▶ Wait a few seconds or press the selector to close the pop-up window.

▶ Turn the selector to set the required room temperature.

▶ Wait a few seconds or press the selector. Press the selector to confirm the change in the pop-up window (or press the

back key to discard the change).

The room temperature that is currently valid is shown in a pop-up window in the lower part of the display.

The user interface operates with the modified settings.

Optimised operation

▶ Press the menu key to open the main menu.

▶ Press the selector to open the Heating/Cooling menu.

▶ Turn the selector to highlight the Temperature settings menu.

▶ Press the selector to open the menu.

▶ If two or more heating circuits are installed, turn the selector to highlight Heating circuit 1, 2, 3 or 4 and press the

selector.

▶ Turn the selector to mark Heating, Setback, Elevate or Cooling.

▶ Press the control knob.

▶ Turn the selector and press it to activate the required setting, e.g. for setback mode.

If the temperature control is activated:

▶ Turn and press the selector to set the temperature. The limits of the setting values for the temperatures are determined by

the settings for the other operating mode in each case.

The user interface operates with the modified settings. The settings are applied to all time programs for the heating

system (if two or more heating circuits are installed, it is only applied in the selected heating circuit).

Automatic mode

Table 3 Room temperature

6 720 812 775-06.1O

6 720 811 136-07.1O

4.2 DHW settings

Operating the appliance Result

If you need hot water outside of the times set in the time program: Activate extra DHW (= immediate DHW function).

▶ Press the extra DHW key.

DHW heating is active immediately with the set temperature and for the set duration. After a few seconds, the symbol for extra

DHW will be displayed in the information graphic.

To deactivate the extra DHW function before the end of the set duration:

▶ Press the extra DHW key again.

If the DHW is too cold or too hot for you: Change the DHW heating operating mode

▶ Press the DHW key.

The user interface displays the pick list for DHW heating.

▶ Turn the selector to highlight the required operating mode.

▶ Press the control knob.

The user interface operates with the modified settings. Your contractor can set the temperatures for the DHW and DHW

reduced operating modes.

To prevent the settings for the programming unit from being modified inadvertently:

Activate or deactivate button lock

▶ Press and hold down the DHW key and the selector for a few seconds to activate or deactivate the key block.

When the key lock is enabled, the key symbol appears in the display ( Fig. 4 [5], page 6).

Table 4 More settings

6 720 812 775-09.1O

6 720 818 009 (2015/07)Compress 3000 AW

Page 8

8 | Overview of the most frequently used functions

6 720 811 136-15.1O

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

4.3 Setting the operating mode

Optimised operation is enabled by default, as this operating mode

ensures maximum efficiency of the heat pump.

Operating the appliance Result

To activate automatic mode (by taking account of the time program),

▶ Press the menu key to open the main menu.

▶ Press the selector to open the Heating/Cooling menu.

▶ Press the selector to open the Operating mode menu.

▶ If two or more heating circuits are installed, turn the selector to highlight Heating circuit 1, 2, 3 or 4 and press the selector.

▶ Turn the selector to highlight Auto and press the selector.

▶ Press and hold the Back key to return to the standard display.

All temperatures set in the currently valid time program for the heating system are show n in a pop-up window in the lower part

of the display. The currently valid temperature flashes.

The user interface controls the room temperature according to the active time program for the heating system.

To activate optimised operation (without time program)

▶ Press the menu key to open the main menu.

▶ Press the selector to open the Heating/Cooling menu.

▶ Press the selector to open the Operating mode menu.

▶ If two or more heating circuits are installed, turn the selector to highlight Heating circuit 1, 2, 3 or 4 and press the selector.

▶ Turn the selector to highlight Optimise and press the selector.

▶ Press and hold the Back key to return to the standard display.

The required room temperature is shown in a pop-up window in the lower part of the display. The user interface will now

constantly maintain the required room temperature.

Table 5 Getting started – Activating operating modes

6 720 812 775-03.1O

6 720 812 775-04.1O

4.4 Selecting a heating circuit for the standard display

The standard display only ever shows data for a single heating circuit. If

two or more heating circuits are installed, a setting can be made to

Operating the appliance Result

▶ When the lighting is turned on, press the selector.

The number, operating mode and if applicable the name of the heating circuit that is currently selected are shown in the lower

part of the display.

▶ Turn the selector to select a heating circuit.

Only heating circuits that exist in the system are displayed for selection.

▶ Wait a few seconds or press the selector.

The standard display refers to the heating circuit selected.

Table 6 Overview – Standard display of heating circuit

determine which heating circuit the data in the standard display relates

to.

4.5 Favourite functions

Via the fav key you have direct access to often used functions for heating

circuit 1. The first pressing of the fav key opens the menu for configuring

the favourites menu. There you can add your personal favourites and if

necessary later adapt the favourites menu to your requirements.

Operating the appliance Result

To access a favourite function: Open the favourites menu

▶ Press the fav key to open the Favourites menu.

▶ Turn the selector and press to select a favourite function.

▶ Change the settings (procedure is the same as when making a setting in the main menu).

To adapt the list of favourites to meet your requirements: Select favourite functions

▶ Press and hold down the fav key until the menu for configuring the favourites menu is displayed.

▶ Turn and press the selector to select a function (Yes) or to cancel your selection (No).

The changes are effective immediately.

▶ Press the Back key to close the menu.

The function of the fav key is independent of the heating circuit

displayed in the standard display. Settings changes via the favourites

menu always apply only to heating circuit 1.

6 720 812 775-02.2O

Table 7 Favourite functions

Compress 3000 AW6 720 818 009 (2015/07)

Page 9

Maintenance | 9

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

5 Maintenance

The heat pump requires a minimum of maintenance, however, some

servicing is still required to get optimal performance from your heat

pump. Check the following items a few times per year:

• Remove soiling and foliage at the evaporator and casing

DANGER: The heat pump is connected to high current.

▶ Break the power supply before rectifying.

Damage to system due to use of unsuitable cleaning

agents!

▶ Do not use acidic or alkaline cleaning agents or

cleaning agents containing chlorine or abrasive

products.

5.1 Remove dirt and leaves

▶ Use a brush to remove the dirt and leaves from the heat pump.

5.2 Protective covers

Over time dust and other dirt will collect on the heat pump.

▶ If required, clean the outside with a damp cloth.

▶ Repair cracks and damage at the casing with anti-corrosion paint.

▶ Car wax can be applied to protect the paint.

5.6 Leakage tests

In accordance with current EU legislation (the F-gas regulation, EC

Regulation No 817/2014 which came into effect on 1 January 2015),

Operators of equipment that contains fluorinated greenhouse gases in

quantities of 5 tonnes of CO

foams shall ensure that the equipment is checked for leaks.

In contrast, devices that contain less than 3 kg fluorinated greenhouse

gases are not subject to tightness testing until 31 December 2016.

▶ Contact your installer.

2

equivalent or more and not contained in

5.7 Checking the safety valves

The safety valve should be checked by a qualified

engineer - usually as part of an annual service visit.

Water can drip out of the opening of the pressure relief

valve. The opening of the pressure relief valve (outlet)

must not be sealed under any circumstances.

▶ The pressure relief valve should only drip once the maximum

permissible pressure in the heating system has been exceeded. If the

pressure relief valve still drips at pressures below 2 bar, please

consult the principal contractor of the system.

▶ Make sure that the liquid emerging from the pressure relief valve is

visibly discharged into the drain.

5.3 Evaporator

Wash off any layers of e.g. dust or dirt deposited on the surface of the

evaporator.

WARNING: The thin aluminium fins are fragile and can

be damaged if careless. Never wipe the delicate fins with

a cloth.

▶ Use protective gloves to protect your hands from

cuts.

▶ Do not use a too powerful water jet.

Cleaning the evaporator:

▶ Spray cleaning agent on the evaporator fins on the back of the heat

pump.

▶ Rinse off coatings and cleaning agent with water.

5.4 Snow and ice

In certain geographical regions or during periods of heavy snow, snow

can get stuck on the back and the roof of the heat pump. To prevent

subsequent formation of ice, remove the snow.

▶ Clear the snow off the roof.

▶ Warm water can be used to rinse off the ice.

5.5 Moisture

NOTICE: If moisture frequently forms near the indoor

unit or the fan convectors in cooling mode, this could

mean that the condensation insulation is defective.

▶ If moisture forms in the vicinity of components of the

heating system, switch the heat pump off and consult

the system installer.

5.8 Particle filter

Check particle filter

The filter prevents contamination from the heating system from entering

the heat pump. Clogged filters can lead to faults.

The system does not have to be drained in order to clean

the filter. The filter is normally integrated into the shutoff valve and should be installed in the heating return.

Cleaning the strainer

▶ Close valve (1).

▶ Unscrew the cap (by hand) (2).

▶ Remove the strainer and clean under running water.

▶ Reinstall the strainer. To ensure the installation is performed

correctly, make sure the guide lugs fit into the recesses in the valve

(3).

Moisture can form under the heat pump (outside) due to condensate not

falling into the condensation catch pan. This is normal and no special

action is required.

6 720 818 009 (2015/07)Compress 3000 AW

Page 10

10 | Maintenance

1.

2.

2.

1.

1

2

3

4

6 720 805 915-01.1I

1

6 720 810 353-11.1I

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

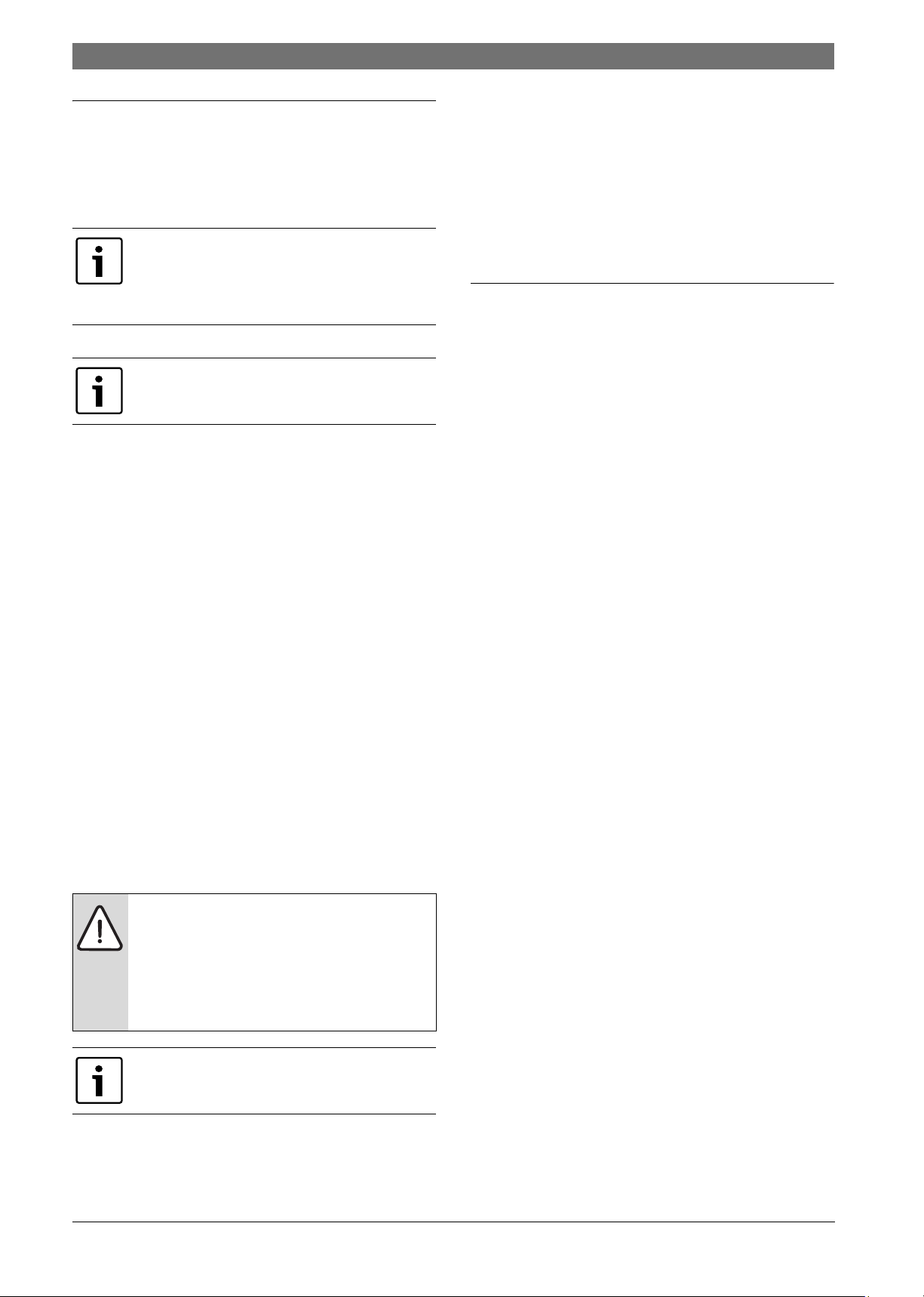

Fig. 5 Filter version without circlip

▶ Screw cap back on (by hand).

▶ Open valve (4).

5.9 Pressure switch and overheating protection

The pressure regulator and overheating protection are

only installed in the indoor unit with integrated electric

booster heater. If the overheating protection has been

triggered, it must be reset manually.

The pressure switch and overheating protection are

connected in series. Alarms or mes sages triggered at the

user interface indicate either that the system pressure is

too low, or that the temperature at the electric booster

heater is too high.

If the pressure switch has been triggered, it is automatically reset as

soon as the system pressure reaches the correct value.

▶ Check the pressure at the pressure gauge.

▶ If the pressure is less than 0.5 bar, increase the pressure slowly to

max. 2 bar by filling with water via the fill valve.

▶ If you have any questions about the procedure, consult the installer

of the system.

Resetting the overheating protection at the indoor unit AWMS/AWMS

solar:

▶ Pull out the front panel at the bottom and pull up and off.

▶ Firmly push the button at the overheating protection.

▶ Reinsert the front panel

Resetting the overheating protection at the indoor unit AWES:

▶ Consult the system installer.

Fig. 6 Indoor unit AWES

[1] Pressure gauge

Compress 3000 AW6 720 818 009 (2015/07)

Page 11

Maintenance | 11

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

2

3

1

Fig. 7 Indoor unit AWMS/AWM solar

[1] Resetting the overheating protection

[2] Particle filter

[3] Pressure gauge

6 720 810 353-10.1I

6 720 818 009 (2015/07)Compress 3000 AW

Page 12

12 | Internet connection via integrated IP module

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

6 Internet connection via integrated IP module

The indoor unit is equipped with an integrated IP module . The indoor unit

and heat pump can be controlled and monitored via a mobile unit using

this IP module. The module is used as an interface between the heating

system and a network (LAN) and also makes the SmartGrid function

possible.

Login data for the IP module

Manuf. no.:__ __ __ __ - __ __ __ __ __ __ __ __ __ - __ __ __ __ __ __ __ __ __ __

Login name: ___ ___ ___ ___ ___ ___ ___ ___ ___

Password: __ __ __ __ - __ __ __ __ - __ __ __ __ - __ __ __ __

To be able to use the full scope of functions, Internet

access and a router with unassigned RJ45 output are

required. This can lead to additional costs. The Bosch

connect app is required to control the system using a

mobile phone and is available free of charge.

Commissioning

Observe the documentation for the router when

commissioning.

The router must be configured as follows:

• DHCP active

• Ports 5222 and 5223 must not be blocked for outgoing

communication.

• Unassigned IP address is available

• Address filtering (MAC filter) adapted to the module.

The following options for commissioning the IP module are available:

• Internet

The IP module automatically obtains an IP address from the router.

The name and address of the target server are stored in the standard

settings of the module. If an internet connection is established, the

module logs onto the server automatically.

• Local network

The module does not have to have Internet access. It can also be used

in a local network. In this case however, the heating system cannot be

accessed through the Internet, and the module software is not

automatically updated.

• App Bosch connect

When starting the app for the first time, you will be asked to enter the

login name and password set at the factory. The login details are

printed on the data plate of the IP module.

•SmartGrid

The indoor unit can communicate with the energy exchange and

modify the operation of the heat pump so that it is at the maximum

output when the price for the power is the most affordable. For more

information see the Bosch website.

Mac: ___ ___ - ___ ___ - ___ ___ - ___ ___ - ___ ___ - ___ ___

7 Environment / disposal

Environmental protection is a fundamental corporate strategy of the

Bosch Group.

The quality of our products, their efficiency and environmental safety

are all of equal importance to us and all environmental protection

legislation and regulations are strictly observed.

We use the best possible technology and materials for protecting the

environment taking into account of economic considerations.

Packaging

We participate in the recycling programmes of the countries in which our

products are sold to ensure optimum recycling.

All of our packaging materials are environmentally friendly and can be

recycled.

Used appliances

Used appliances contain valuable materials that should be recycled.

The various assemblies can be easily dismantled and synthetic materials

are marked accordingly. Assemblies can therefore be sorted by

composition and passed on for recycling or disposal.

NOTICE: If the IP module is replaced, the login details

will be lost!

Individual login details are required for each IP module.

▶ After commissioning, enter the login data in the

▶ Following a replacement, replace with the details of

Alternately, the password can be changed at the user

interface.

corresponding field.

the new IP module.

Compress 3000 AW6 720 818 009 (2015/07)

Page 13

Technical terms

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

Technical terms | 13

Heat pump

The central heat source. Installed in the open air. Alternative

designation: outdoor unit. Contains the cooling circuit. Heated or cooled

water is routed from the heat pump to the indoor unit.

Indoor unit

Installed in the building and distributes the heat from the heat pump to

the heating system and DHW cylinder. Contains the user interface and

primary pump to the outside to the heat pump.

Heating system

Designation for entire installation, comprising the heat pump, indoor

unit, DHW cylinder, heating system and accessories.

Heating system

Comprises heat source, container, radiators, underfloor heating system

or fan radiators or a combination of these elements if the heating system

is made up of several heating circuits.

Heating circuit

The part of the heating system that distributes the heat throughout the

various rooms. Consists of pipework, pump and radiators, heating hoses

of the underfloor heating system or fan convectors. Only one of the

specified alternatives is possible within a circuit. However, if for

example the heating system is equipped with two circuits, radiators can

be installed in one and an underfloor heating system installed in the

other. Heating circuits can be configured with and without mixers.

Heating circuit without mixer

In a heating circuit without a mixer the temperature in the circuit is

controlled purely by the energy from the heat source.

Heating circuit with mixer

In a heating circuit with mixer, the mixer mixes return water from the

circuit with hot water from the heat source. This allows heating circuits

with mixers to be operated at lower temperatures than the other heating

system, e.g. so that underfloor heating systems that operate at lower

temperatures can be separated from radiators that require higher

temperatures.

Mixing device

The mixer is a valve that mixes colder return water with hot water from

the heat source in order to achieve a specific temperature. The mixer can

be in a heating circuit or in the indoor unit for the external auxiliary

heater.

3-way valve

The 3-way valve distributes thermal energy to the heating circuits or the

DHW cylinder. It has two defined settings so that heating and DHW

heating cannot take place at the same time. This is also the most

effective operating mode as the DHW is always heated to a specific

temperature whereas the heating water temperature is continuously

adapted to the outside temperature in each case.

External auxiliary heater in dual-fuel mode

The external auxiliary heater is a separate heat source which is

connected via pipework to the indoor unit. The heat produced in the

auxiliary heater is controlled via a mixer. It is therefore also referred to as

an auxiliary heater with mixer or boiler. The user interface controls the

connection and shutdown of the auxiliary heater according to the

existing heat energy demand. Heat sources are electric, oil-fired or gasfired boilers.

Primary circuit

The part of the heating system that transports the heat from the heat

pump to the indoor unit.

Cooling circuit

The main part of the heat pump that recovers energy from the outdoor

air and transfers this as heat to the primary circuit. Consists of

evaporator, compressor, condenser and expansion valve. The

refrigerant circulates in the cooling circuit.

Evaporator

Heat exchanger between air and refrigerant. The energy from the air that

is drawn in through the evaporator causes the refrigerant to boil and turn

to gas.

Comp

Moves the refrigerant through the cooling circuit from the evaporator to

the condenser. Increases the pressure of the gaseous refrigerant. The

temperature also increases as the pressure increases.

Condenser

Heat exchanger between refrigerant in cooling circuit and water in the

heat transfer medium circuit. During the heat transfer, the temperature

of the refrigerant falls as it transfers to the liquid aggregation state.

Expansion Valve

Reduces the pressure of the refrigerant after it is discharged from the

condenser. The refrigerant is then routed back to the evaporator where

the process starts again.

Transformer

Located in the heat pump and allows the speed of the compressor to be

controlled based on the heat energy demand.

Setback phase

A time slot during automatic mode, with Setback operating mode.

Automatic mode

The heating system is heating in accordance with the time program and

an automatic changeover takes place between operating modes.

Mode

The operating modes for heating are: Heating and Setback. They are

depicted by the symbols and .

Operating modes for DHW heating are:DHW, DHW reduced and Off.

An adjustable temperature is assigned to each operating mode (except

for Off).

Frost protection

Depending on the selected frost protection, the heat pump will turn on

when the outside and/or room temperature reaches below a certain set

threshold. Frost protection prevents the heating system from freezing

up.

Required room temperature (also desired or set temperature/set

room temp.)

The room temperature to be achieved by the heating system. It can be

set individually.

Default setting

Values permanently saved in the programming unit (e.g. complete time

programs) that are available at any time and that can be reinstated

according to demand.

Heating phase

A time slot during automatic mode, with Heating operating mode.

Child lock

Settings in the standard display and in the menu can only be changed if

the child lock (key lock) is switched off ( page 7).

6 720 818 009 (2015/07)Compress 3000 AW

Page 14

14 | Technical terms

VOGEL&NOOT

CLIMATE CONTROL SYSTEMS

Mixer

Assembly that automatically ensures that hot water can be drawn from

the taps at a temperature no higher than the temperature set on the

mixer.

Optimised operation

In optimised operation, automatic mode (the heating system time

program) is not active and the home is heated constantly to the

temperature set for optimised operation.

Reference room

The reference room is the room in the home where a room unit has been

installed. The room temperature in this room acts as the control variable

for the assigned heating circuit.

Switching time

A certain time at which the heating system starts to heat or hot water is

produced, for example. A switching time is a component of a time

program.

Temperature of an operating mode

A temperature that is assigned to an operating mode. The temperature is

adjustable. See the explanations on operating mode.

Flow temperature

Temperature at which the heated water flows in the central heating

system from the heat source to the heating surfaces in the rooms.

Water heater

A water heater stores large volumes of heated tap DHW. Thereby,

sufficient DHW is available at the draw-off points (e.g. taps). This is a

prerequisite for longer hot shower.

Time program for the heating system

This time program ensures automatic changeover between operating

modes at defined switching times.

Compress 3000 AW6 720 818 009 (2015/07)

Page 15

Notes

| 15

6 720 818 009 (2015/07)Compress 3000 AW

Page 16

CLIMATE CONTROL SYSTEMS

KE KELIT NZ Ltd

0800 4 KEKELIT (0800 4 5353548)

climatecontrol@kekelit.co.nz

www.kekelit.co.nz

Loading...

Loading...