Bosch BOVA, BOVA-36, BOVA-60 Installation Instructions Manual

Bosch BOVA 2.0 Split System Heat Pump

Condensing Units Up to 20.5 SEER

2-3-4-5 Ton Capacity

R410A

Installation Instructions

|

2

Bosch IDS 2.0 BOVA Installation Instructions

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BOVA | 3

Table of Contents

1 Key to Symbols and Safety Instructions 4

1.1 Key to Symbols 4

1.2 Safety 4

2 Unit Location Considerations 6

2.1 Unit Dimensions 6

2.2 Refrigerant Piping Limits 6

2.3 Location Restrictions 7

3 Unit Preparation 8

3.1 Prepare the Unit for Installation 8

4 Setting the Unit 8

4.1 Pad Installation 8

5 Refrigerant Line Considerations 9

5.1 Refrigerant Line and Service Valve Connection Sizes 9

5.2 Required Refrigerant Line Length 9

5.3 Refrigerant Line Insulation 9

5.4 Reuse Existing Refrigerant Lines 9

6 Refrigerant Line Routing 10

6.1 Precautions 10

7 Refrigerant Line Brazing 11

7.1 Braze The Refrigerant Lines 11

8 Refrigerant Line Leak Check 13

8.1 Check For Leaks 13

9 Evacuation 13

9.1 Evacuate the Refrigerant Lines and Indoor Coil 13

13 Start Up 20

13.1 System Start Up 20

14 System Charge Adjustment 21

14.1 Charging: Weigh-In Method 21

14.2 Subcooling Charging And Refrigerant Adjustment In Cooling

(Above 55°F Outdoor Temp.) 21

15 System Operation and Troubleshooting 24

15.1 Control Logic Description 24

15.2 Sensors (Thermistors/Pressure Transducer) 24

15.3 Pressure Equalizer Valve (PEV) 24

15.4 Defrost Description 24

15.5 Compressor Crankcase Heater Description 25

15.6 Reversing Valve Operation 25

15.7 Protection Functions 25

15.8 Fault Code Table 26

15.9 Parameter Point Check Table 27

15.10 Control Board Overviews 28

15.11 Error Code Troubleshooting 30

15.12 Temperature and Resistance Relationship Tables (for Sensors) 36

15.13 Temperature and Resistance Relationship Tables (for T5 & Tf Sensors) 37

16 Wiring Diagram 39

17 Care and Maintenance 40

17.1 Cleaning Precautions 40

17.2 Maintenance – Pre-Season Inspection 40

10 Service Valves 14

10.1 Open the Service Valves 14

11 Electrical - Low Voltage 15

11.1 Low Voltage Maximum Wire Length 15

11.2 Low Voltage Hook-Up Diagrams 15

11.3 Thermostat Wiring Diagrams 15

12 Electrical - High Voltage 19

12.1 High Voltage Power Supply 19

12.2 High Voltage Disconnect Switch 19

12.3 High Voltage Ground 19

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

4

Bosch IDS 2.0 BOVA Installation Instructions

1 Key to Symbols and Safety Instructions

1.1 Key to Symbols

Warnings

Warnings in this document are identifi ed by a

warning triangle printed against a grey background.

Keywords at the start of a warning indicate the type and seriousness

of the ensuing risk if measures to prevent the risk are not taken.

The following keywords are defi ned and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor to moderate injury.

NOTICE is used to address practices not related to personal injury.

Important information

1.2 Safety

Please read before proceeding

WARNING: ELECTRICAL HAZARD 380 VOLTS DC

Failure to follow this warning could result in property

damage, severe personal injury, or death.

WAIT THREE (3) MINUTES after disconnecting power

prior to touching electrical components as they may hold a

dangerous charge of 380 VDC,then verify DC Voltage is less

than 42VDC at inverter TEST POINTS P-N.

NOTICE:

This document is customer property and is to remain with

this unit. Please return to service information pack upon

completion of work.

These instructions do not cover all variations in systems

or provide for every possible contingency to be met in

connection with the installation.

Should further information be desired or should particular

problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to your

installing dealer or local distributor.

This symbol indicates important information where

there is no risk to people or property.

The manufacturer recommends installing only approved

matched indoor and outdoor systems. All of the manufacturer’s split

systems are AHRI rated only with TXV indoor systems. Some of the

benefi ts of installing approved matched indoor and outdoor split

systems are maximum effi ciency, optimum performance and the best

overall system reliability.

This document contains a wiring diagram and service information.

This is customer property and is to remain with this unit. Please return to

service information pack upon completion of work.

WARNING:

This information is intended for use by individuals

possessing adequate backgrounds of electrical and

mechanical experience. Any attempt to repair a central air

conditioning product may result in personal injury and/or

property damage.

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BOVA | 5

WARNING: HAZARDOUS VOLTAGE

Failure to follow this warning could result in property

damage, severe personal injury, or death.

Disconnect all electric power, Including remote disconnects

before servicing. Follow proper lockout/tagout procedures

to ensure the power cannot be inadvertently energized.

WARNING: REFRIGERANT OIL

Any attempt to repair a central air conditioning product may

result in property damage, severe personal injury, or death.

These units use R-410A refrigerant which operates at

50 to 70% higher pressures than R-22. Use only R-410A

approved service equipment. Refrigerant cylinders are

painted a “Rose” color to indicate the type of refrigerant

and may contain a “dip” tube to allow for charging of liquid

refrigerant into the system. All R-410A systems with variable

speed compressors use a POE oil (VG74 or equivalent )

that readily absorbs moisture from the atmosphere. To

limit this ‘hygroscopic“ action, the system should remain

sealed whenever possible. If a system has been open to

the atmosphere for more than 4 hours, the compressor oil

must be replaced. Never break a vacuum with air and always

change the driers when opening the system for component

replacement.

CAUTION: GROUNDING REQUIRED

Failure to inspect or use proper service tools may result

in equipment damage or personal injury. Reconnect all

grounding devices. All parts of this product that are capable

of conducting electrical current are grounded. If grounding

wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they

must be returned to their original position and properly

fastened.

WARNING: SERVICE VALVES

Failure to follow this warning will result in abrupt release

of system charge and may result in personal injury and/

or property damage. Extreme caution should be exercised

when opening the Liquid Line Service valve. Turn valve stem

counterclockwise only until the stem contacts the rolled

edge.

WARNING: BRAZING REQUIRED

Failure to inspect lines or use proper service tools may result

in equipment damage or personal injury. If using existing

refrigerant lines make certain that all joints are brazed, not

soldered.

WARNING: HOT SURFACE

May cause minor to severe burning. Failure to follow this

Caution could result in property damage or personal injury.

Do not touch top of compressor.

CAUTION: CONTAINS REFRIGERANT

Failure to follow proper procedures can result in personal

illness or injury or severe equipment damage.System

contains oil and refrigerant under high pressure. Recover

refrigerant to relieve pressure before opening system.

CAUTION: INDOOR UNIT REQUIRED

The indoor units must be matched with TXV. The model of

TXV can be changed according to the system capacity.

WARNING: HIGH CURRENT LEAKAGE

Failure to follow this warning could result in property

damage, severe personal injury, or death.

Grounding is essential before connecting electrical supply.

WARNING:

This product can expose you to chemicals including Lead

and Lead components, which are known to the State

of California to cause cancer and birth defects or other

reproductive harm. For more information go to www.

P65Warnings.ca.gov.

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

6

Bosch IDS 2.0 BOVA Installation Instructions

2 Unit Location Considerations

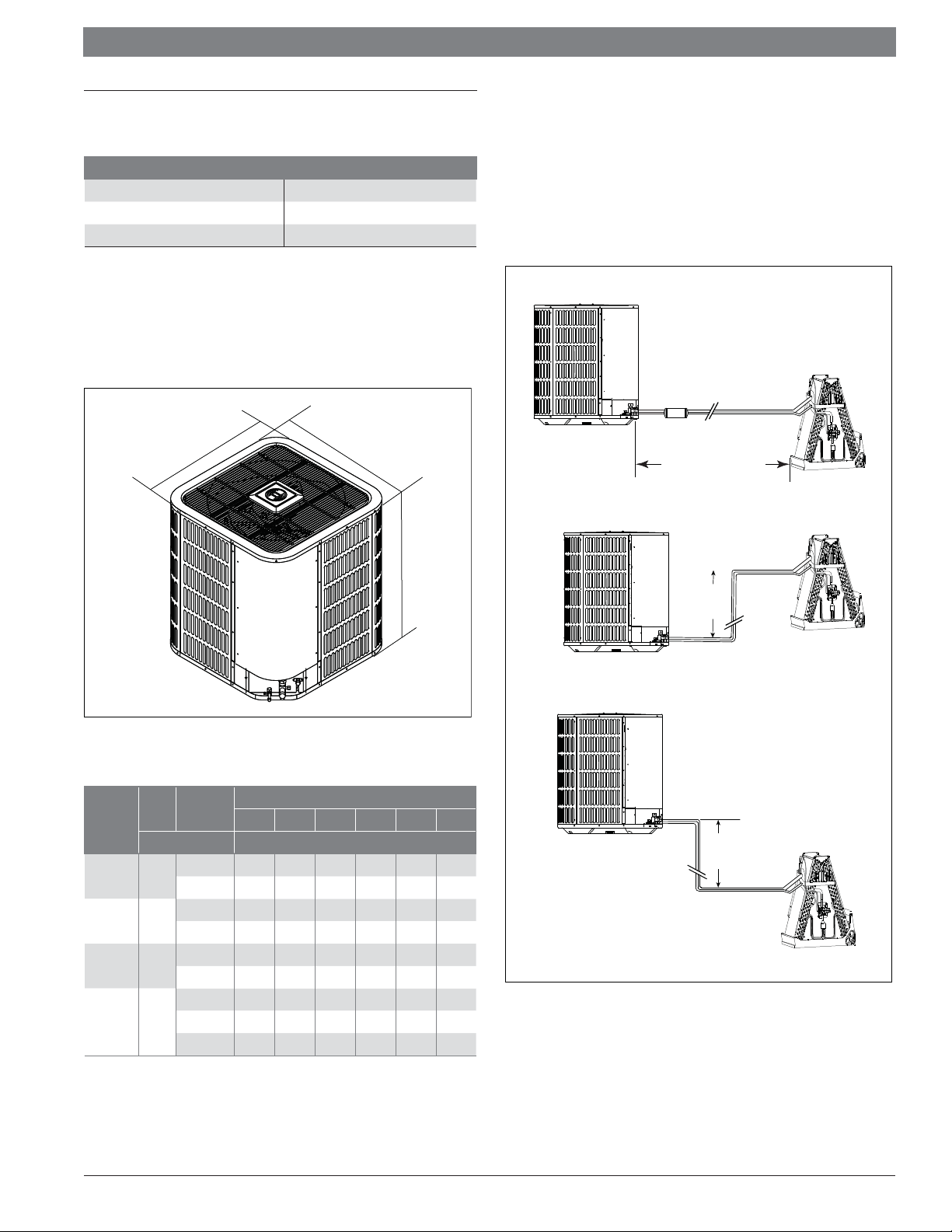

2.1 Unit Dimensions

Unit Dimensions

Models H x W x L (Inches)

BOVA-36 24-15/16 x 29-1/8 x 29-1/8

BOVA-60 33-3/16 x 29-1/8 x 29-1/8

Table 1

The unit’s weight values are on the carton box.

When mounting the outdoor unit on a roof, be sure the roof will support the unit’s

weight. Properly selected isolation is recommended to prevent sound or vibration

transmission to the building structure.

L

L

W

W

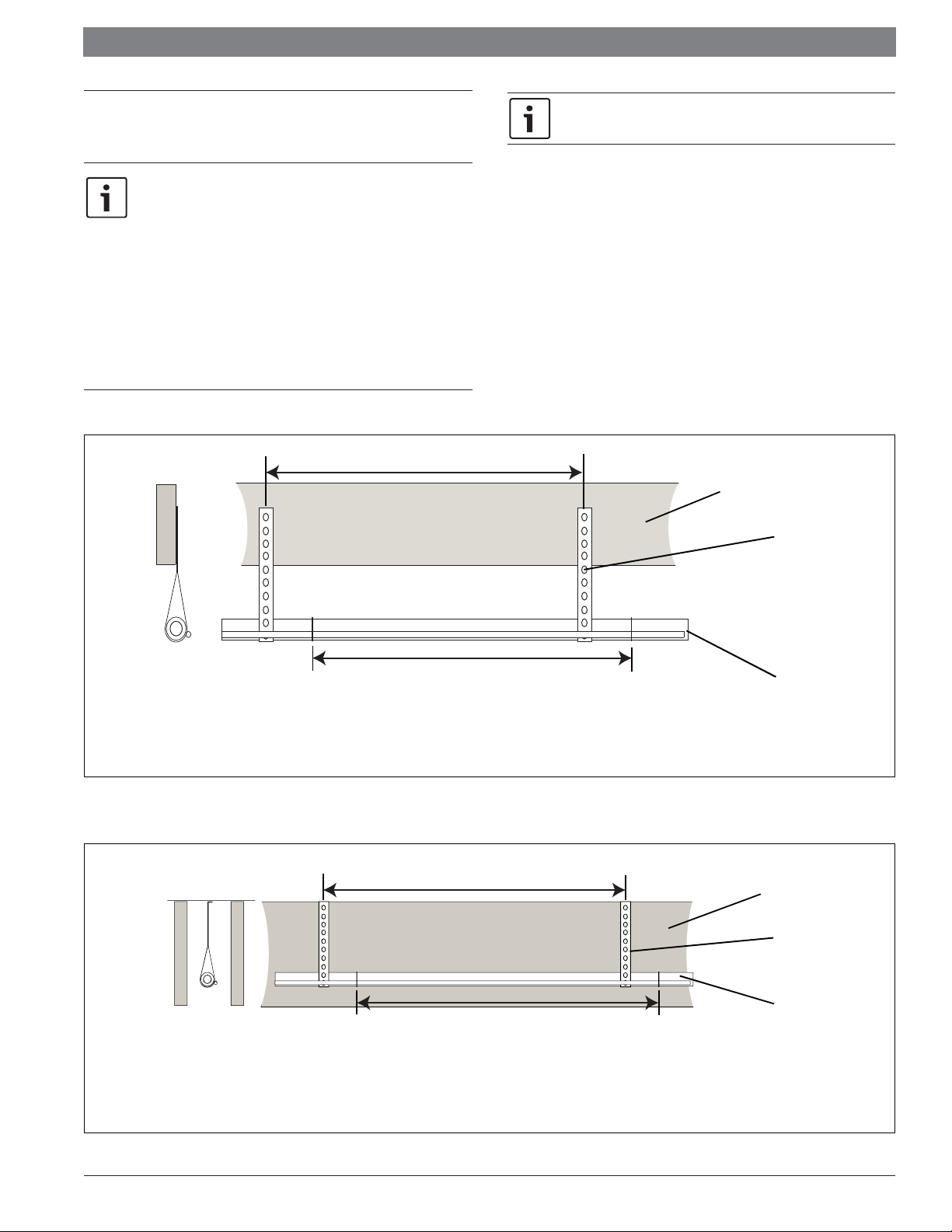

Maximum line equivalent length = 150 feet.

Maximum vertical equivalent length = 50 feet.

Use only the line diameters indicated in Table 2.

If the suction linesets are greater than 50 feet, do not use a larger suction

line than recommended.

Standard Lineset

Lineset 150' Max

Line Length

Figure 1

2.2 Refrigerant Piping Limits

Liquid

System

Capacity

Model

2 Ton 3/8 *

3 Ton 3/8 *

4 Ton 3/8 *

5 Ton 3/8 *

Table 2

* Standard line size is recommended;

N/A: Application not recommended;

Refrigerant charge: refer to Sec. 14

Suction

Line

Line

Inch O.D. Maximum Vertical Separation - Feet

3/4 Std. 25 50 45 40 30 25

5/8 Opt. 25 50 45 40 30 25

3/4 Std. 25 50 50 50 35 25

5/8 Opt. 25 50 50 50 35 25

7/8 Std. 25 50 50 40 30 25

3/4 Opt. 25 50 50 40 30 25

7/8 Std. 25 50 50 40 30 25

3/4 Opt. 25 50 50 40 30 25

1 1/8 Opt. 25 40 N/A N/A N/A N/A

H

H

Total Equivalent Length - Feet

25 50 75 100 125 150

50' Max

Line Lift

50' Max

Line Lift

Figure 2

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BOVA | 7

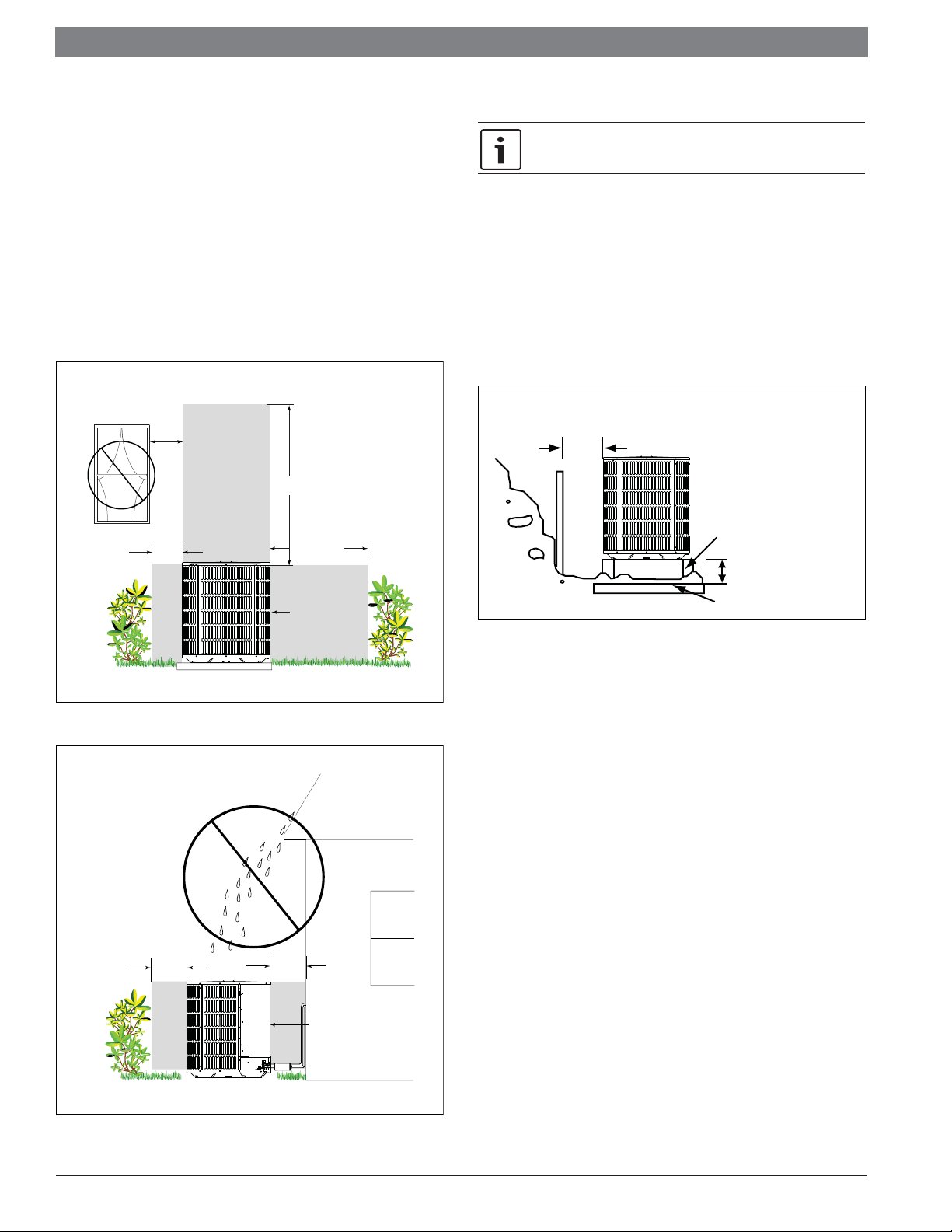

2.3 Location Restrictions

Ensure the top discharge area is unrestricted for at least 60 inches above the unit.

Do not locate outdoor unit near bedrooms since normal operational sounds may be

objectionable.

Position unit to allow adequate space for unobstructed airfl ow, wiring, refrigerant

lines, and serviceability.

Allow a minimum of 12 in. clearance on one side of control board access panel to a

wall and a minimum of 24 in. on the adjacent side of control board access panel.

Maintain a distance of 24 in. between units.

Position unit where water, snow, or ice from roof or overhang cannot fall directly

on unit.

See Fig. 3 and Fig. 4.

Avoid Installations

Near Bedrooms

Min. 60" Unrestricted

Min. 12" to

Shrubbery

Min. 24"

Unrestricted

Cold climate considerations (heat pump only)

Precautions must be taken for units being installed in areas where

snow accumulation and prolonged below-freezing temperatures occur.

Units should be elevated 3-12 inches above the pad or rooftop,

depending on local weather. This additional height will allow drainage of

snow and ice melted during defrost cycle prior to its refreezing. Ensure

that drain holes in unit base pan are not obstructed, which could prevent

the drainage of defrost water (Fig. 5).

If possible, avoid locations that are prone to snow drifts. If not possible,

a snow drift barrier should be installed around the unit to prevent a

build-up of snow on the sides of the unit.

Min. 12"

Snow

barrier

Snow legs

3-12" Elevation

Figure 3

Min. 12" to

Shrubbery

Access Panel

Min. 24" to

Shrubbery

Access Panel

Pad

Figure 5

Corrosive Environment

Exposure to a corrosive environment may shorten the life of the equipment,

corrode metal parts, and/or negatively aff ect unit per formance. Corrosive elements

include, but are not limited to: sodium chloride, sodium hydroxide, sodium sulfate,

and other compounds commonly found in ocean water, sulfur, chlorine, fl uorine,

fertilizers, and various chemical contaminants from industry/manufacturing

plants. If installed in areas which may exposed to corrosive environments, special

attention should be given to the equipment placement and maintenance.

Lawn sprinklers/hoses/waste water should not spray directly on the unit

cabinet for prolonged periods of time.

In coastal areas: locate the unit on the side of the building away from the

waterfront.

Fencing or shrubbery may provide some shielding protection to the unit,

however minimum unit clearances must still be maintained.

Approximately every three months, wash the outdoor coil and any

exposed cabinet surfaces.

Figure 4

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

8

Bosch IDS 2.0 BOVA Installation Instructions

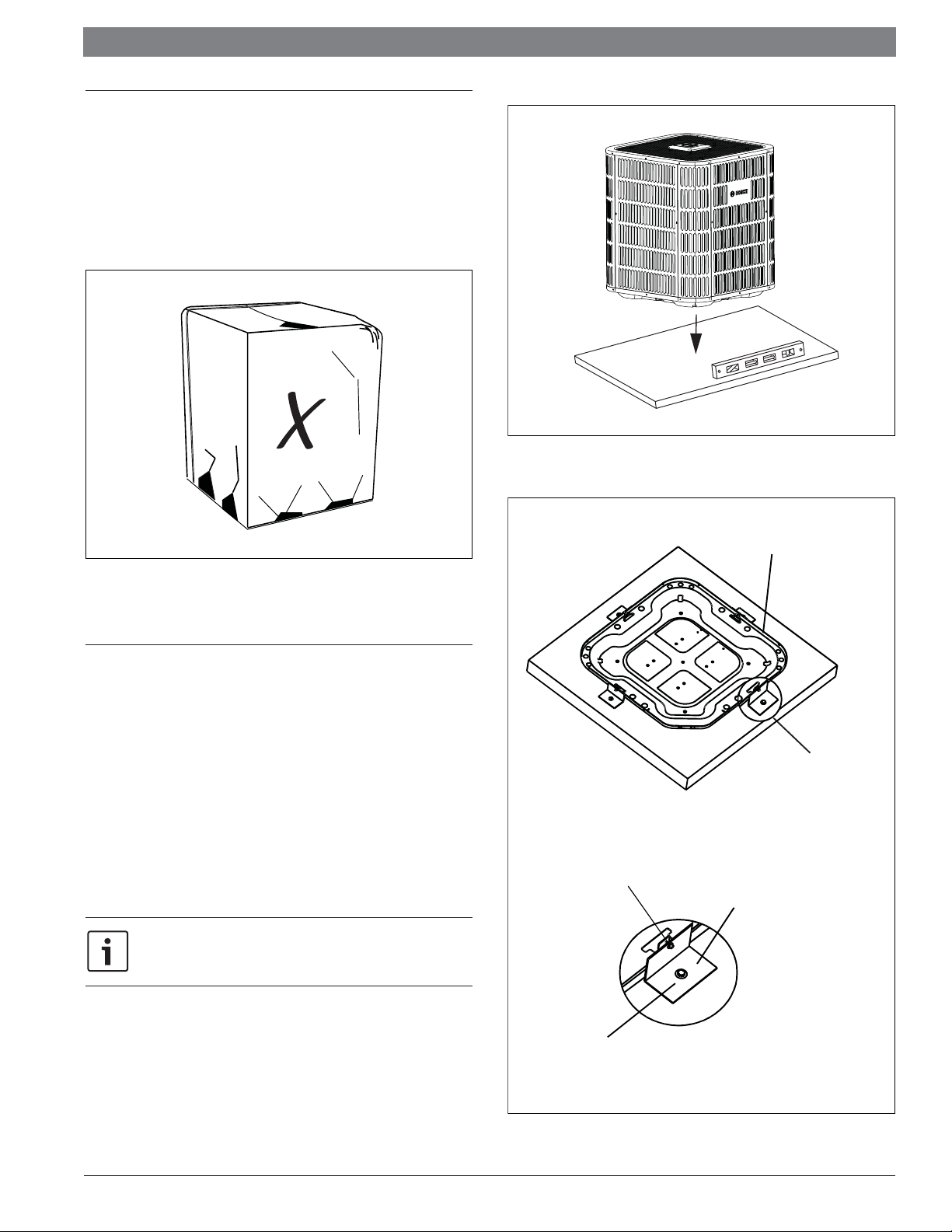

3 Unit Preparation

3.1 Prepare the Unit for Installation

Check for damage and report promptly to the carrier any damage found to

the unit (Fig. 6).

The charge port can be used to ensure the refrigerant charge has been

retained during shipment.

Figure 7

Figure 6

4 Setting the Unit

4.1 Pad Installation

When installing the unit on a support pad, such as a concrete slab, consider the

following:

The pad must be at least 1-2” larger than the unit on all sides.

The pad must be separated from any structure.

The pad must be level.

The pad must be high enough above grade to allow for drainage.

The pad location must comply with National, State, and local codes.

These instructions are intended to provide a method to tie-down system

to cement slab as a securing procedure for high wind areas. Check local

codes for tie-down methods and protocols.

#7 X 3/8" Self-tapping screws

(Do not exceed 3/8" length screws!)

Detail A

See Section 2.1

for unit dimensions

See Detail A

Field-supplied brackets:

2" width, 1/16" thickness,

height as required.

Data subject to change

1/4” Χ 1-1/2” Hex washer head concrete screws

(3/16” pilot hole needed. Pilot hole should be 1/4” deeper

than the fastener embedment)

Figure 8

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BOVA | 9

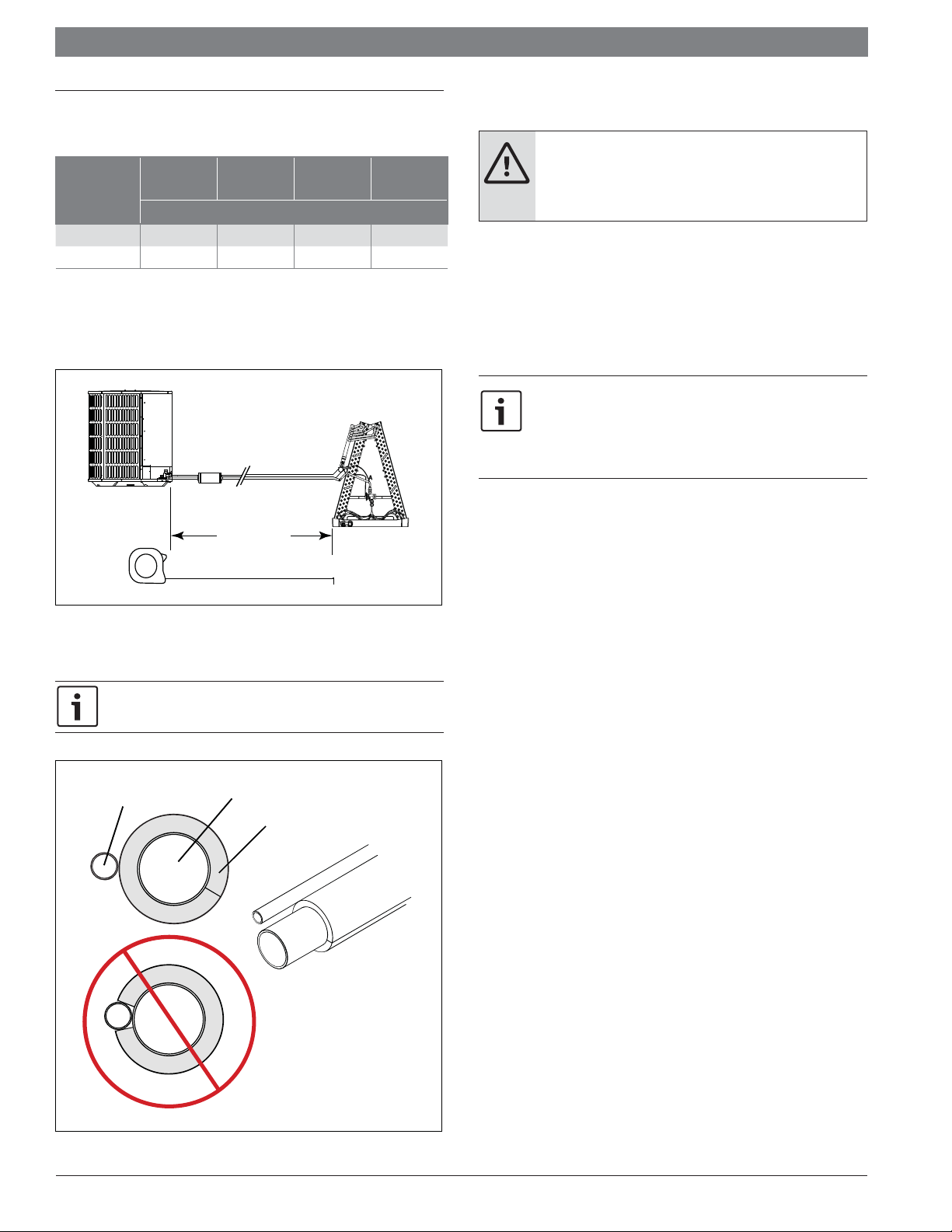

5 Refrigerant Line Considerations

5.1 Refrigerant Line and Service Valve Connection Sizes

Models

BOVA-36 3/4 3/8 3/4 3/8

BOVA-60 7/8 3/8 7/8 3/8

Table 3

Suction Line Liquid Line

Dimensions in inches

5.2 Required Refrigerant Line Length

Determine required line length (Fig. 9). Refer to Section 2.2.

Line Length

Suction Line

Connection

Liquid Line

Connection

5.4 Reuse Existing Refrigerant Lines

CAUTION: MINOR TO MODERATE BURNS

If using existing refrigerant lines, make certain that all joints

are brazed, not soldered.

For retrofi t applications, where the existing refrigerant lines will be used, the

following precautions should be taken:

Ensure that the refrigerant lines are the correct size. Refer to Section 2.2

and Table 2.

Ensure that the refrigerant lines are free of leaks, acid, and oil.

The manufacturer recommends installing only approved matched indoor

and outdoor systems. All of the manufacturer’s split systems are AHRI

rated only with TXV indoor systems. The benefi ts of installing approved

matched indoor and outdoor split systems are maximum effi ciency,

optimum performance and the best overall system reliability.

Figure 9

5.3 Refrigerant Line Insulation

The Suction Line must always be insulated. DO NOT allow the Liquid Line

and Suction Line to come in direct (metal to metal) contact.

Liquid Line

Suction Line

Insulation

Figure 10

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

10

Bosch IDS 2.0 BOVA Installation Instructions

6 Refrigerant Line Routing

6.1 Precautions

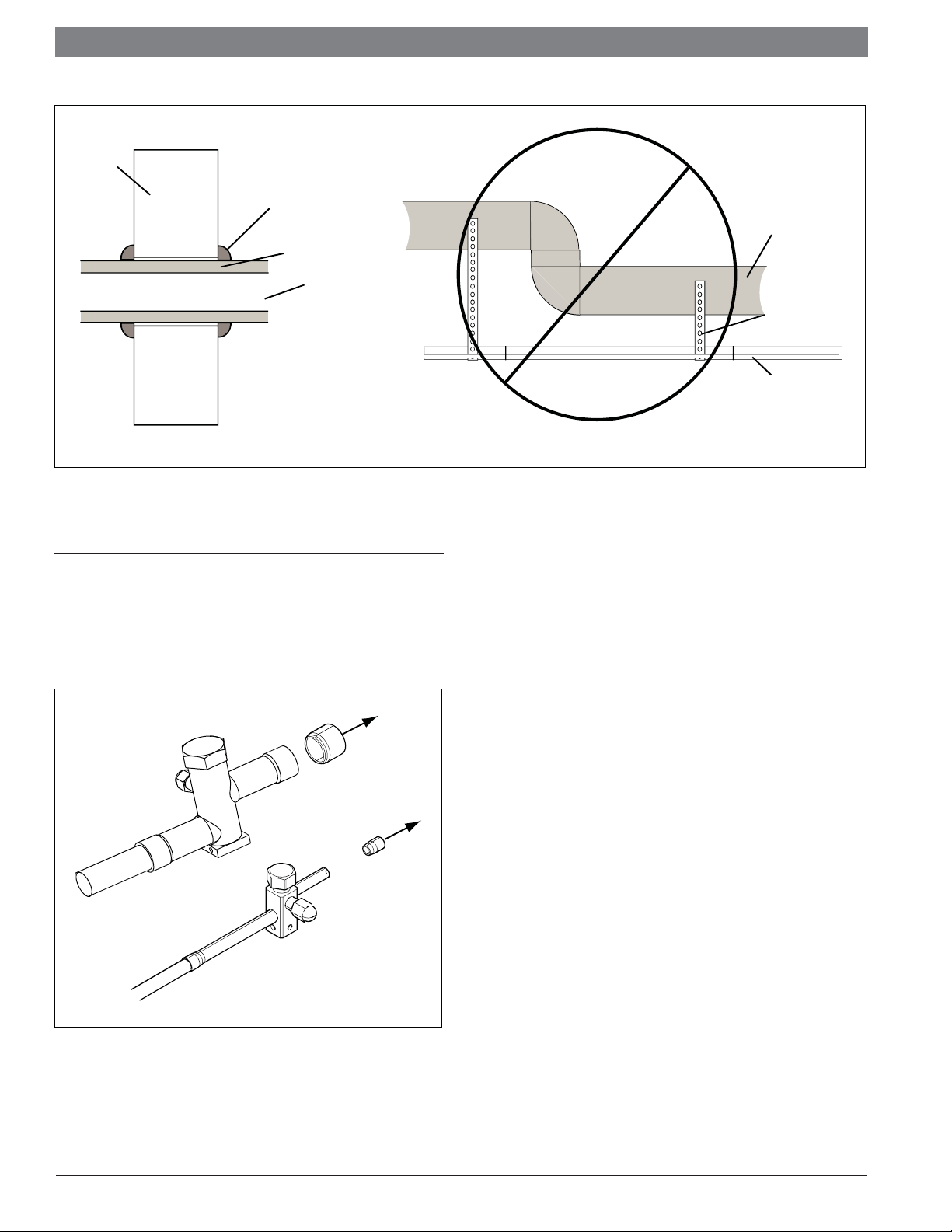

Take precautions to prevent noise within the building structure due to

vibration transmission from the refrigerant lines. For example:

When the refrigerant lines have to be fastened to floor joists or

other framing in a structure, use isolation type hangers.

Isolation hangers should also be used when refrigerant lines are

run in stud spaces or enclosed ceilings.

Where the refrigerant lines run through a wall or sill, they should

be insulated and isolated.

Isolate the lines from all ductwork.

Minimize the number of 90º turns.

8 Feet Maximum

Comply with National, State, and local codes when isolating linesets

from joists, rafters, walls, or other structural elements.

Joist/Rafter

Isolator

Figure 11

Side View

Side View

8 Feet Maximum

Secure Suction Line from joists using isolators every 8 ft. Secure Liquid Line

directly to Suction Line using tape, wire, or other appropriate method every 8 ft.

Isolation From Joist/Rafter

8 Feet Maximum

8 Feet Maximum

Secure Suction Line using isolators every 8 ft. Secure Liquid Line directly to

Suction Line using tape, wire, or other appropriate method every 8 ft.

Isolation On Walls

Lineset

Wall

Isolator

Linesets

Figure 12

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BOVA | 11

Wall

Sealant

Ductwork

Insulation

Suction Line

Isolator

Lineset

Isolation Through Wall

Figure 13

7 Refrigerant Line Brazing

7.1 Braze The Refrigerant Lines

1. Remove caps or plugs. Use a deburring tool to deburr the pipe ends. Clean

both internal and external surfaces of the tubing using an emery cloth.

DO NOT hang linesets from ductwork

Figure 14

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

12

Bosch IDS 2.0 BOVA Installation Instructions

2. Remove the pressure tap cap from both service valves.

Shipped in package

field installed

3-4" from valve

Figure 15

3. Purge the refrigerant lines and indoor coil with dry nitrogen.

This pipe

must have

a thimble

Figure 16

4. Wrap a wet rag around the valve body to avoid heat damage and continue the

dry nitrogen purge (Fig. 17).

Braze the refrigerant lines to the service valves.

Braze the fi lter drier to the Liquid Line.

Figure 17

5. Replace the pressure tap caps after the service valves have cooled.

Figure 18

All units come standard with a bi-fl ow fi lter drier. Braze the fi lter drier to

the liquid line, using caution not to push the refrigerant line too hard past

the stop within the fi lter drier (this could damage the drier).

Continue the dry nitrogen purge. Do not remove the wet rag until all brazing

is completed.

Remove the wet rag before stopping the dry nitrogen purge.

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BOVA | 13

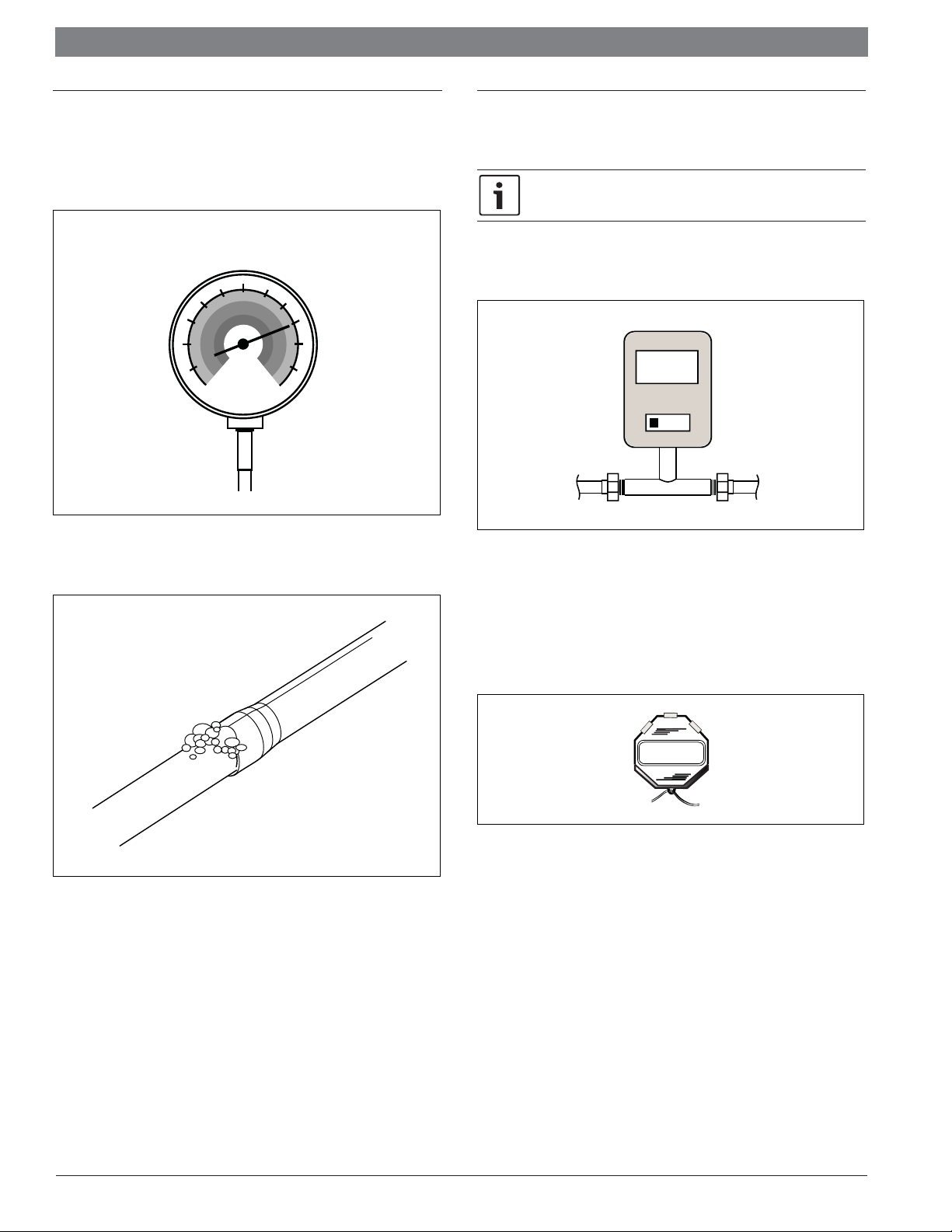

150 PSI

G

8 Refrigerant Line Leak Check

8.1 Check For Leaks

1. Pressurize the refrigerant lines and evaporator coil to 150 PSIG using dry

nitrogen.

Figure 19

9 Evacuation

9.1 Evacuate the Refrigerant Lines and Indoor Coil

Do not open the service valves until the refrigerant lines and indoor coil

leak check and evacuation are complete.

1. Evacuate until the micron gauge reads no higher than 350 microns, then

close the valve to the vacuum pump.

0350

Microns

ON

OFF

Figure 21

2. Check for leaks by using a soapy solution or bubbles at each brazed location.

Figure 20

2. Observe the micron gauge. Evacuation is complete if the micron gauge does

not rise above 500 microns in one (1) minute.

Once evacuation is complete, turn off the vacuum pump and micron gauge,

and close the valves on the manifold gauge set.

1MIN.

Figure 22

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

14

Bosch IDS 2.0 BOVA Installation Instructions

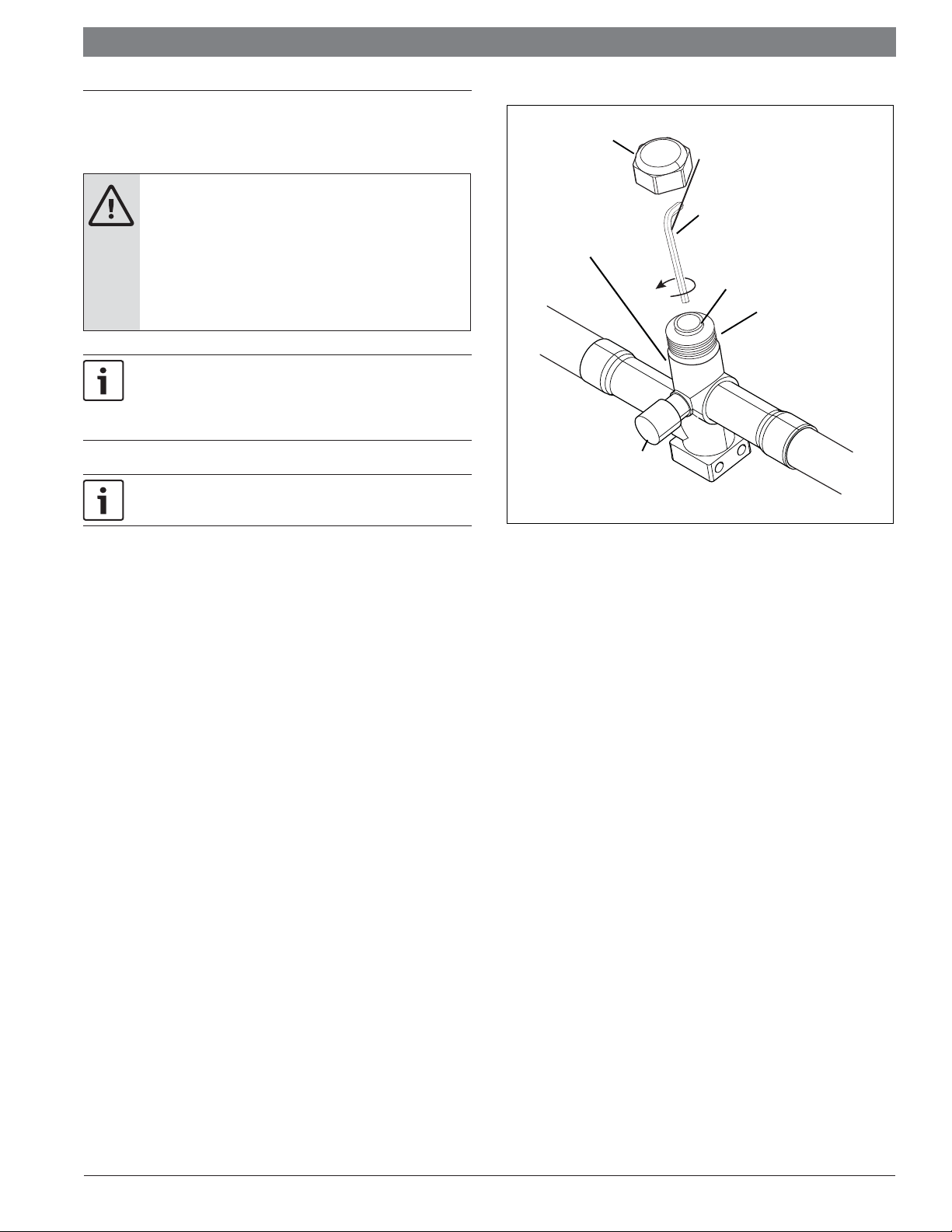

10 Service Valves

10.1 Open the Service Valves

WARNING: MODERATE TO SEVERE BURNS

Extreme caution should be exercised when opening the

Liquid Line Service Valve. Turn counterclockwise until

the valve stem just touches the rolled edge. No torque is

required. Failure to follow this warning will result in abrupt

release of system charge and may result in personal injury

and /or property damage.

Leak check and evacuation must be completed before opening the

service valves. The brazed lineset valves should be used for leak

checking and vacuuming. Using the separate suction port for this

process will result in loss of charge.

The Suction Service Valve must be opened fi rst BEFORE opening the

Liquid Service Valve.

1. Remove Service Valve Cap (Fig. 23).

Figure 23

Cap

Unit Side

of Service

Val ve

Service Port

5/16" Hex Wrench

for Suction Service Valve

3/16" Hex Wrench

for Liquid Service Valve

Rolled Edge to

Captivate Stem

Hex Headed

Valve System

2. Fully insert hex wrench into the stem and back out counterclockwise until

valve stem just touches the rolled edge (approximately five (5) turns.)

3. Replace the Valve Stem Cap to prevent leaks. Tighten finger tight plus an

additional 1/6 turn.

4. Repeat STEPS 1 - 3 for Liquid Service Valve.

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Loading...

Loading...