Bosch 660 EF, 660 EFO User Manual

Installation must conform with local codes, or in the absence of local codes, the National Fuel Gas Code,

ANSI Z223.1/NFPA 54.

When applicable, installation must conform with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part

3280 or the Canadian Standard CAN/CSA-Z240 MH Mobile Homes, Series M86. (660 EFO only)

SBA8517

660 EF/EFO

INDOOR MODEL/OUTDOOR MODEL

INDOOR MODEL 660 EF- Natural Gas/Liquefied Petroleum (LP) Gas

OUTDOOR MODEL

660 EFO- Natural Gas/Liquefied Petroleum (LP) Gas

6 720 644 063 (2010/03) US/CA

Warning: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency or the gas

supplier.

In the Commonwealth of Massachusetts this

product must be installed by a licensed plumber or

gas fitter.

Upon completion of the installation, these

instructions should be handed to the user of the

appliance for future reference.

What to do if you smell gas

• Close gas valve. Open windows.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

6 720 644 063

2

Index

Index

1 Important Safety Information 3

2 Appliance details 7

2.1 Features 7

2.2 Specifications (Technical data) 8

2.3 Before Installation 9

2.4 Dimensions (660 EF) 10

2.5 Dimensions (660 EFO) 10

3 Installation instructions 11

3.1 Specialized tools 11

3.2 Introduction 11

3.3 Venting (660 EF only) 11

3.4 Combustion air requirements 15

3.5 Choosing Installation Site 17

3.6 Installation Clearances 18

3.7 Installation 19

3.8 Gas piping 21

3.9 Water piping 24

3.10 Water Treatment 25

3.11 Plumbing Applications 27

4 Electrical Wiring 28

4.1 Electrical wiring 28

4.2 Remote Controller 29

4.3 Remote Controller Installation Guide 30

5 Operation instructions 33

5.1 Trial Operation 33

5.2 Initial Operation 33

5.3 How to Use

(Not using the remote controller) 34

5.4 How to Use (Using the remote controller) 35

6 Maintenance and service 37

6.1 Regular Maintenance 37

6.2 Preventing Damage from Freezing 38

7 Troubleshooting 40

7.1 Initial Operation 40

7.2 Temperature 40

7.3 Amount of Hot Water 41

7.4 Remote Controller 42

7.5 Sounds 42

7.6 Others 43

7.7 Check for an Error Code

(Using the remote controller) 44

8 Follow- up Service 45

8.1 Requesting Service 45

8.2 Gas conversion 45

9 Interior components diagram 46

9.1 660 EF Interior components 46

9.2 660 EFO Interior components 47

10 Protecting the environment 48

11 Limited Warranty 49

6 720 644 063

Important Safety Information

3

1 Important Safety Information

To prevent damage to property and injury to the user,

the icons shown below will be used to warn of varying

levels of danger. Every indication is critical to the safe

operation of the water heater and must be understood

and observed. Potential dangers from accidents during

installation and use are divided into the following four

categories. Closely observe these warnings; they are

critical to your safety.

Icons warning of risk level

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

Attention Installers

• In order to use the water heater safely, read this

installation manual carefully, and follow the installation instructions.

• Failures and damage caused by erroneous work or

work not as instructed in this manual are not covered

by the warranty.

• Check that the installation was done properly in

accordance with this Installation Manual upon

completion.

• After completing installation, please either place this

Installation Manual in a plastic pouch and attach it to

the side of the water heater (or the inside of the pipe

cover or recess box if applicable), or hand it to the

customer to retain for future reference.

Fig. 1

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

Danger: DANGER indicates an

imminently hazardous situation which, if

not avoided, will result in death or

serious injury.

Warning: WARNING indicates a

potentially hazardous situation which, if

not avoided, could result in death or

serious injury.

Caution: CAUTION indicates a

potentially hazardous situation which, if

not avoided, may result in minor or

moderate injury.

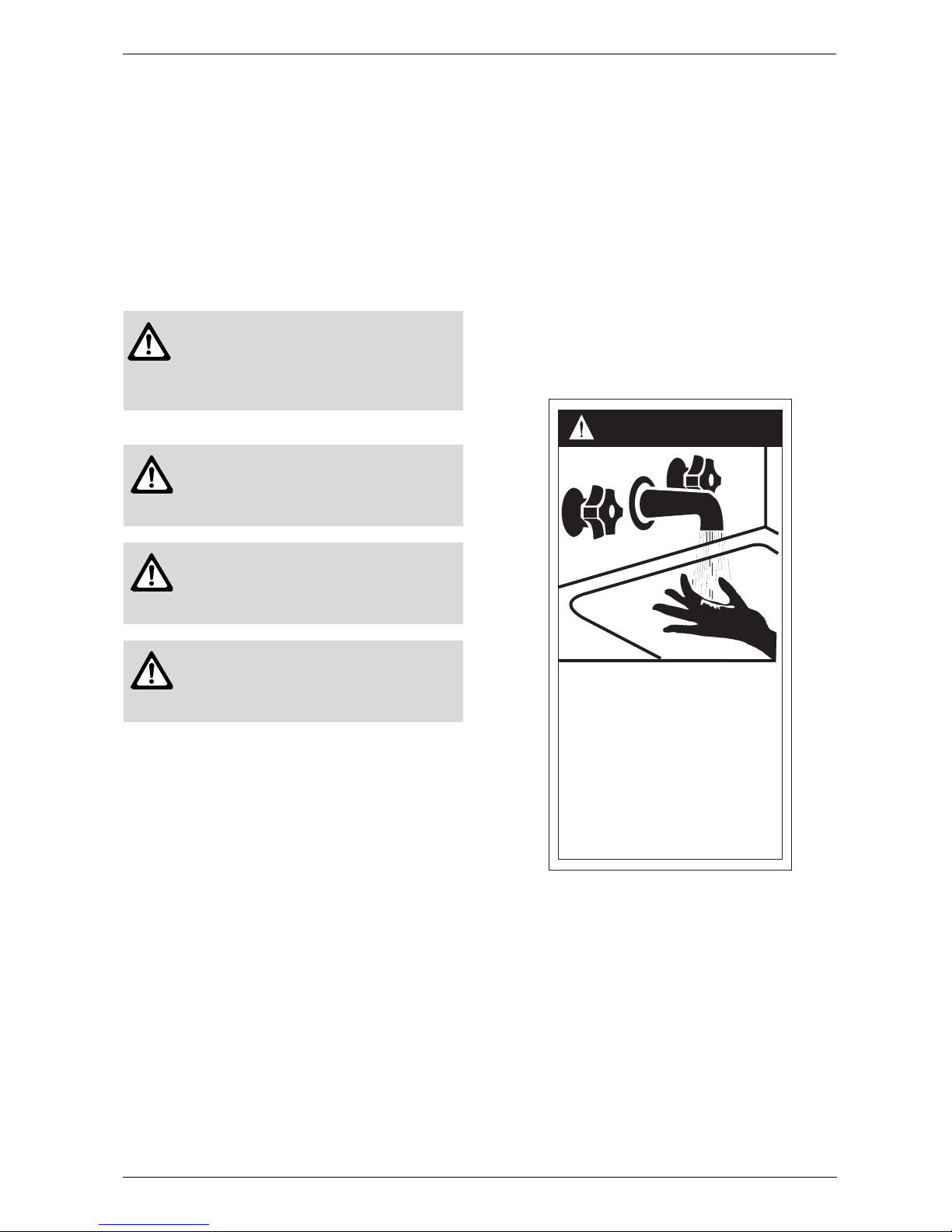

HOT

BURN

DANGER

Water temperature over 125°F can

cause severe burns instantly or

death from scalds.

Children, disabled and elderly are

at highest risk of being scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or

showering.

6 720 644 063

4

Important Safety Information

Fig. 2

Danger: [660 EF] - do not install

outdoors!

Do not use the water heater if the exhaust pipe is displaced, has holes, is

clogged or is corroded.

Danger: [660 EFO] - do not install

indoors!

This will cause carbon monoxide poisoning and a potential fire hazard.

Danger: Do not allow anyone to

change the water temperature while hot

water is being used!

To prevent scalding, do not change the

water temperature to a higher setting.

Warning: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

Warning: This water heater does not

have a pilot. It is equipped with an ignition device that automatically lights the

burner. Do not try to light the burner by

hand.

Warning: BEFORE OPERATING

smell all around the water heater area

for evidence of leaking gas. Be sure to

smell next to the floor because some

gas is heavier than air and will settle on

the floor.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electrical switch; do

not use any phone inyour building.

- Immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier,

call the fire department.

Warning:

Use only your hand to turn the gas valve

knob. Never use tools. If the knob will

not turn by hand, don’t try to repair it.

Call a qualified service technician.

Force or attempted repair may result in

a fire or explosion.

Warning:

Do not use this water heater if any part

has been under water. lmmediately call

a qualified service technician to inspect

the water heater and to replace an damaged parts.

Warning:

When a gas leak is noticed:

1. Stop use immediately

2. Close the gas valve

3. [When installing indoors] Open windows and doors.

Warning:

If you detect abnormal combustion or

abnormal odors, or during an earthquake, tornado or fire:

1. Turn off the hot water supply

2. Turn off the power to the water heater

3. Turn off gas and water supply valve.

4. Call the nearest Bosch agent.

6 720 644 063

Important Safety Information

5

Warning: Explosion Hazard!

If the temperature and pressure relief

valve is dripping or leaking, have a qualified service technician replace it. Do

not plug or remove the valve. Failure to

follow these instructions can result in

fire or explosion, and personal injury or

death.

Warning:

Check the temperature of the running

hot water before entering the shower.

Check the temperature before stepping

into the bath tub.

Warning:

Do not place the exhaust vent terminal

in an indoor environment by means of

adding walls and ceiling (do not enclose using corrugated sheets, etc.).

Carbon monoxide poisoning or fire may

occur as a result.

Warning:

Leave the proper clearance between

the water heater and nearby objects

(trees, timber, boxes with flammable

materials etc.).

Warning:

Do not use combustible chemicals

such as oil, gasoline, benzene etc. in

the near the heater or the exhaust vent

terminal.

Warning:

Do not place combustibles such as

laundry, newspapers, oils etc. near the

heater or the exhaust vent terminal.

Warning: [660 EF only]

Carbon Monoxide Poisoning Hazard.

Do not install this water heater in a mobile home, recreation vehicle or on a

boat.

Warning: [660 EFO only]

Carbon Monoxide Poisoning Hazard.

Do not install this water heater in a recreation vehicle or on a boat.

Warning:

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any other appliance.

Warning:

Do not place or use a spray can near

the heater or the exhaust vent terminal.

Warning:

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

Warning: [When installing indoors

660 EF]

Check the air supply vent for dust or obstructions.

Warning:

If this unit will be installed in a beauty

salon or other location where hair spray

or aerosols will be used, locate the unit

in a separate area that is supplied with

fresh air from outdoors.

Warning:

Do not use hair spray or spray detergent in the vicinity of the heater.

Warning:

Do not allow small children to play unsupervised in the bathroom. Do not allow small children to bathe

unsupervised.

Warning:

Do not touch the powercord with wet

hands.

Warning:

Consult the nearest Bosch agent if the

water heater location needs to be

changed.

Warning:

Contact a qualified service technician

for any necessary repairs, service or

maintenance.

6 720 644 063

6

Important Safety Information

Warning:

Contact Bosch before using with a solar pre-heater.

Warning:

California Proposition 65 lists chemicalsubstances known to the state to cause

cancer, birth defects, death, serious illness or other reproductive harm. This

product may contain such substances,

be their origin from fuel combustion

(gas, oil) or components of the product

itself.

Warning:

The gas conversion kit shall be installed

by a qualified service agency in accordance with the manufacturer’s instructions and all applicable codes and

requirements of the authority having jurisdiction. The information in the instructions must be followed to minimize the

risk of fire or explosion or to prevent

property damage, personal injury, or

death. The qualified service agency is

responsible for the proper installation of

this kit. The installation is not proper

and complete until the operation of the

converted appliance is checked as

specified in the manufacturer’s instructions supplied with the kit.

Caution:

Be sure to electrically ground the unit.

Caution:

Keep power cord free of dust.

Caution:

Do not use the water heater for other

than hot water supply, shower and bath.

Caution:

Do not use a broken or modified power

cord. Do not bind, bend or stretch power cords. Do not scratch, modify, or

subject them to impact or force.

Caution:

To prevent burns or scalding, turn off

the power button or power supply and

wait until the equipment cools before

performing maintenance.

Caution:

Do not turn off the water heater while

someone is bathing.

Caution:

Do not cover the water heater and the

exhaust vent terminal, store trash or debris near it, or in any way block the flow

of fresh air to the unit.

Caution:

Do not install in locations where excessive dust or debris will be in the air.

Caution:

Do not touch the exhaust vent (pipe, terminal) during or immediately after operation of the water heater.

Caution:

Do not drink water that has been inside

the unit for an extended period of time.

Do not drink the first use of hot water

from the unit in the morning.

Caution:

Clean the filter on the water inlet as frequently as required by the quality of

your local water.

Caution:

Keep the area around the unit clean. If

boxes, weeds, cobwebs, cockroaches

etc. are in the vicinity of the unit,

damage or fire can result.

Caution:

Do not install the equipment where the

exhaust will blow on walls or windows.

Caution:

Treat hard, acidic or otherwise impure

supply water with approved methods to

ensure full warranty coverage.

Caution:

Problems resulting from scale formation

are not covered by the warranty.

Caution:

Check ignition during use and extinction after use.

6 720 644 063

Appliance details

7

2 Appliance details

2.1 Features

Parts included with the unit

• Tapping Screw

• Installation Manual/user manual with warranty inside

(this document)

• Cross Recess Head Screw (660 EFO NG, 660 EFO

LP)

• Power Cord (660 EF NG, 660 EF LP).

Accessories (Bosch part #)

• Optional Remote Control to operate with the appliance BRC01US for USA, BRC01CA for Canada

• Isolation Valves (includes pressure relief valve)

• Remote Controller Outdoor Junction Box (BOJB)

• Remote Controller cord 3m (10ft) BRC10CORD

• Remote Controller cord 8m (26ft) BRC26CORD

• Recess Box BRBKIT (for 660 EFO only)

• Pipe Cover (BPCKIT).

Caution:

Do not run water through the unit

when unit is not on. When discharg-

ing hot water, make sure the unit is ON.

If water is run through the unit with the

unit OFF, water may condense inside

the unit and cause incomplete combustion or damage to the internal electrical

components. For single-handle fixtures

or valves, discharge water setting the

handle completely to the water side.

Caution:

This unit is only approved for installation

up to 1350m (4500 ft.) above sea level.

For installations at higher elevations,

contact Bosch Thermotechnology

Corp. for Instructions.

Caution:

Do not disassemble the remote controller. Do not use benzene, oil or fat detergents to clean the remote controller.

This may cause deformation. Do not get

the remote controller wet. Although it is

water resistant, too much water can

cause damage. Do not splash water on

the remote controller. Do not expose

the remote controller to steam. Do not

locate the remote controller near stoves

or ovens, this may cause damage or failure.

Caution:

Preventing damage from freezing (see

section 6.2). Damage can occur from

frozen water within the device and

pipes even in warm environments. Be

sure to read below for appropriate

measures. Repairs for damage caused

by freezing are not covered by the warranty.

Caution:

Take necessary measures to prevent

freezing of water and leakage of gas

when leaving the unit unused for long

periods of time (see section 6.2).

Caution:

If it is snowing, check the air inlet, exhaust gas vent and exhaust vent terminal for blockage.

Caution:

Do not use parts other than those

specified for this equipment.

i

BOSCH is constantly improving its products, therefore specifications are subject

to change without prior notice.

6 720 644 063

8

Appliance details

2.2 Specifications (Technical data)

Approved in US/Canada

Capacity

Maximum flow rate: 5.3 GPM (20 l/min) at a 45°F

(25°C) rise.

Maximum Input

140,000 Btu/h (41,03 kW)

Minimum Input

20,000 Btu/h (5.67 kW)

Temperature Control

Selection range: 100°F (37°C) - 160°F (70°C)

Default temperature: 120°F (50°C)

Temperature Settings using the remote controller:

USA

100- 150 °F (5°F intervals), 160 °F

Canada

37-48°C (In 1°C intervals), 50-70°C (In 5°C intervals)

Gas Requirement

Gas connection (inches) - ¾”

Inlet gas pressure under operation (with a high hot

water flow rate)

• Propane: 8” - 14” water column

• Natural Gas: 4” - 10.5” water column.

Power Supply Consumption

• Freeze Prevention 141W.

Water

• Hot water connection (inches) - ¾”

• Cold water connection (inches) - ¾”

• Minimum water flow: 0.5 gallon/minute (2 l/m)

Note: The capacity may differ slightly, depending on

the water pressure, water supply, piping conditions,

and water temperature

• Water pressure recommend: 29 to 70 psi

• Connections:

– Bottom of heater

Dimensions

• Depth (in): 6.7” (170 mm)

• Width (in): 13.8” (350 mm)

• Height (in): 20.5” (520 mm)

• Weight: 36 pounds (16.3 kg).

Gas types

Natural Gas.

LP Gas.

Voltage

120 V AC (60 Hz) nominal

Safety devices

• Flame Rod

•Thermal Fuse

• Lightning Protection Device (ZNR)

• Overheat Prevention Device

• Freezing Prevention Device

• Fan Rotation Detector.

i

If this water heater is being installed at an

elevation of 2,000' (610m) or higher,

disconnect the connector labeled "High

Elevation Disconnect". This connector is

located inside the unit.

6 720 644 063

Appliance details

9

2.3 Before Installation

Fig. 3 Ex. For LP Gas 660 EFO

Danger: Checkup!

Check the fixing brackets and vent pipe

yearly for damage or wear. Replace if

necessary.

Danger: Check the gas!

- Check that the rating plate indicates

the correct type of gas.

- Check that the gas supply line is sized

for 140,000 BTU for 660 EF, 660 EFO.)

Warning: Check the power!

The power supply required is 120VAC,

at 60Hz. May result in fire or electric

shock.

Warning: Use Extreme Caution if Using With a Solar Pre-Heater!

Using this unit with a solar pre-heater

can lead to unpredictable output temperatures and possibly scalding. If absolutely necessary, use mixing valves to

ensure output temperatures do not get

to scalding levels.

Caution: Do Not Use Equipment for

Purposes Other Than Those Specified!

Do not use for other than increasing the

temperature of the water supply, as unexpected accidents may occur as a result.

Caution: Check Water Supply Quality!

If the water supply is in excess of 6

grains per gallon (100 mg/L) of hardness, acidic or otherwise impure, treat

the water with approved methods in order to ensure full warranty coverage.

6 720 644 063

10

Appliance details

2.4 Dimensions (660 EF)

Fig. 4 Dimensions

2.5 Dimensions (660 EFO)

Fig. 5 Dimensions

6 720 644 063

Installation instructions

11

3 Installation instructions

3.1 Specialized tools

The following specialized tools may be required for

installation:

• Manometer

• Multimeter

• Combustion Gas Analyzer.

3.2 Introduction

Please follow these instructions. Failure to follow

instructions may result in:

B Damage or injury.

B Improper operation.

B Loss of warranty.

3.3 Venting (660 EF only)

3.3.1 Vent piping

• Bosch Vent System is suggested for the vent system.

If Bosch Vent is not used, a UL listed category III

ventsystem must be used

• Follow the vent pipe manufacturer's installation

instructions.

• Make the vertical section of the exhaust ventas short

as possible

• Maintain the same vent pipe diameter from the heater

flue to the vent termination.

Clearances

Clearances vary by manufacturer, refer to the UL

approved clearances when using materials other than

Bosch Vent System.

• The first vertical run from the top of the heater should

be no longer than 0.9m (3')

• Make sure vent pipe is gas tight and will not leak. Use

silicon sealant wherever necessary

• Do not common vent or connect more than one appliance to this venting system

• The total vent length including horizontal & verticalvent runs should be no less than 3' (0.9m).

• Do not store hazardous or flammable substances

near the vent termination and check that the termination is not blocked in any way

• Steam or condensed water may come out from the

vent termination. Select the location for the termination so as to prevent injury or property damage

• If snow is expected to accumulate, take care the end

of the pipe is not covered with snow or hit by falling

lumps of snow

• Consult the vent pipe manufacturer's installation

instructions for chimney connections.

Appliance Adapters

When using a vent system other than Bosch Vent, an

appliance adapter will be required to properly connect

the vent to this appliance. Consult the manufacturer's

instructions for the proper appliance adapter.

Warning: The water heater must be

installed by a qualified installer in

accordance with these instructions. If

improperly installed, a hazardous condition

such as explosion or carbon monoxide

poisoning could result. Bosch

Thermotechnology Corp. is not

responsible for improperly installed

appliances.

Warning:

CARBON MONOXIDE POISONING!

Follow all vent system requirements in accordance with relevant local or state regulation,or, in the absence of local or state

code, in the U.S. to the National Fuel Gas

Code ANSIZ233.1/NFPA 54 – latest edition, and in Canada, in accordance with

NSCNGPI.

660 EF

Pipe diameter 3’’ (75mm)

Table 1

No. of elbows Max. Straight Vent Length

1)

1) Not including the termination.

3 15' (4.5m)

2 25' (7.5m)

1 35' (10.6m)

Table 2

Manufacturer

and Product

Enclosed Unenclosed

Hort. Vert. Hort. Vert.

Bosch Vent

System

10" (250mm) (sides)

15" (375mm) (top)

6" (150mm) (bottom)

4"

(100mm)

1"

(25mm)1"(25mm)

Table 3

6 720 644 063

12

Installation instructions

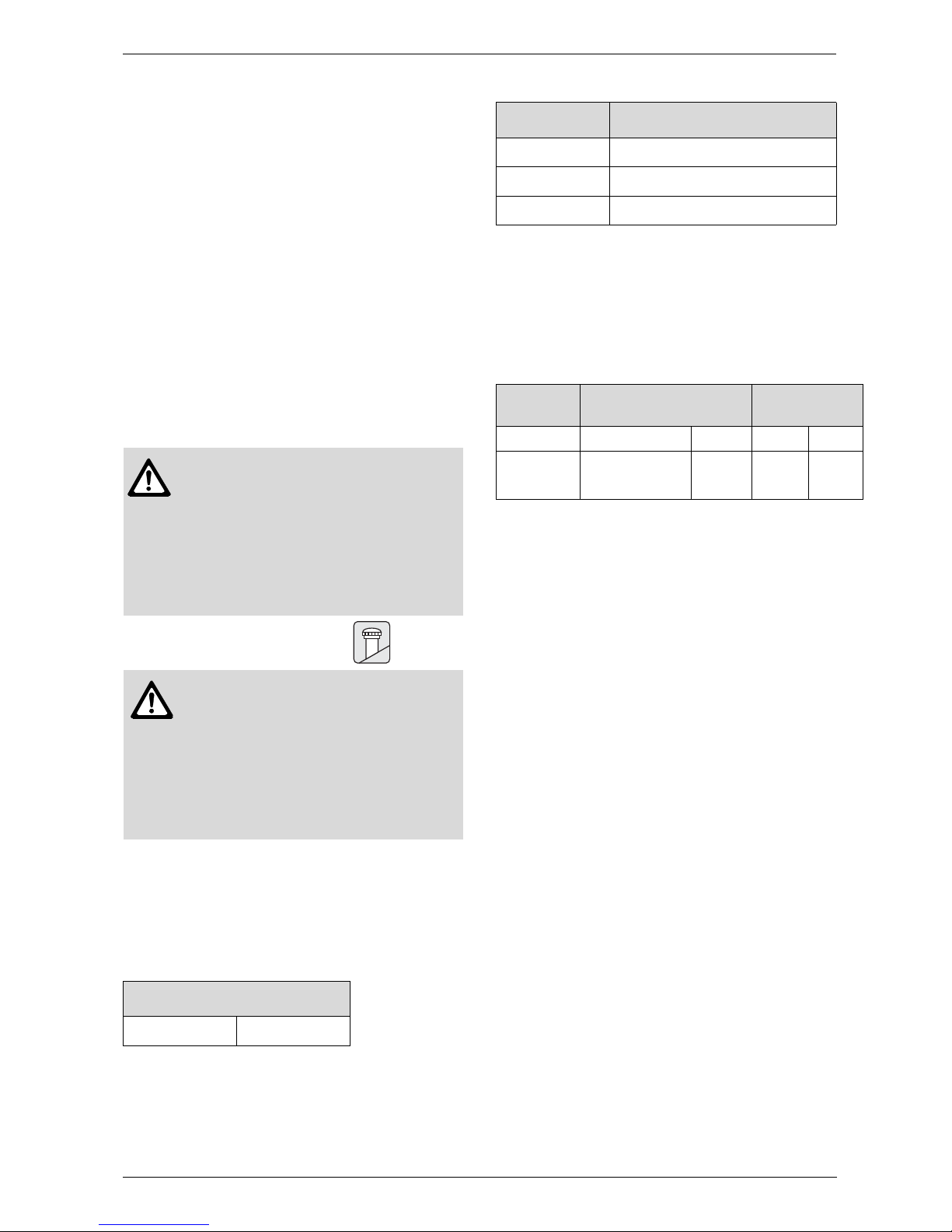

Horizontal Vent Termination

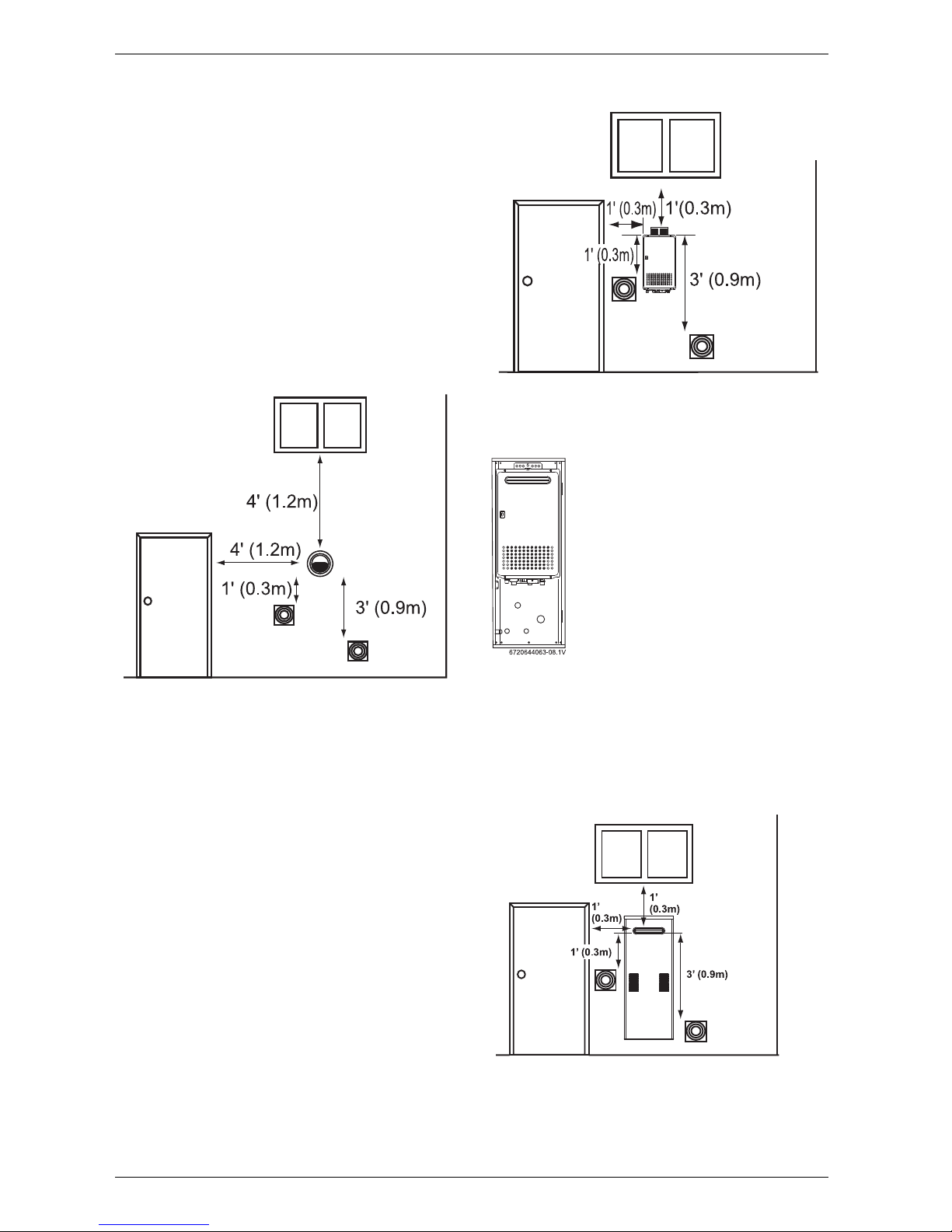

Fig. 6

• Terminate at least 12" (300mm) above grade or

above snow line.

• Terminate at least 7' (2.1m) above a public walkway,

6' (1.8m) from the combustion air intake of any appliance, and 3' (0.9m) from any other building opening,

gas utility meter, service regulator etc.

• Terminate at least 3' (0.9m) above any forced air inlet

within 10' (3m), 4' (1.2m) below, 4' (1.2m) horizontally from or 1' (0.3m) above any door, window, or

gravity air inlet into any building per National Fuel

Gas Code ANSI Z223.1/NFPA 54.

• Slope the horizontal vent 1/4" downwards for every

12" (300mm) toward the termination.

• In the Commonwealth of Massachusetts a carbon

monoxide detector is required for all side wall horizontally vented gas fuel equipment.

Vertical Vent Termination

Fig. 7

• Terminate at least 6' (1.8m) from the combustion air

intake of any appliance, and 3' (0.9m) from any other

building opening, gas utility meter, service regulator

etc.

• Enclose exterior vent systems below the roofline to

limit condensation and protect against mechanical

failure.

• When the vent penetrates a floor or ceiling and is not

running in a fire rated shaft, a firestop and support is

required.

• When the vent termination is located not less than 8'

(2.4m) from a vertical wall or similar obstruction, terminate above the roof at least 2' (0.6m), but not more

than 6' (1.8m), in accordance with the National Fuel

Gas Code ANSI Z223.1/NFPA 54.

• Provide vertical support every 12' (3.6m) or as

required by the vent pipe manufacturer's instructions.

• Slope the horizontal vent 1/4" for every 12" (300mm)

towards the drain tee.

• A short horizontal section is recommended to prevent debris from falling into the water heater.

• Install a condensation drain in the horizontal section

of the venting. For installations in tight spaces where

there is not enough room to install two elbows and a

horizontal drain tee, a vertical drain tee may be substituted.

6 720 644 063

Installation instructions

13

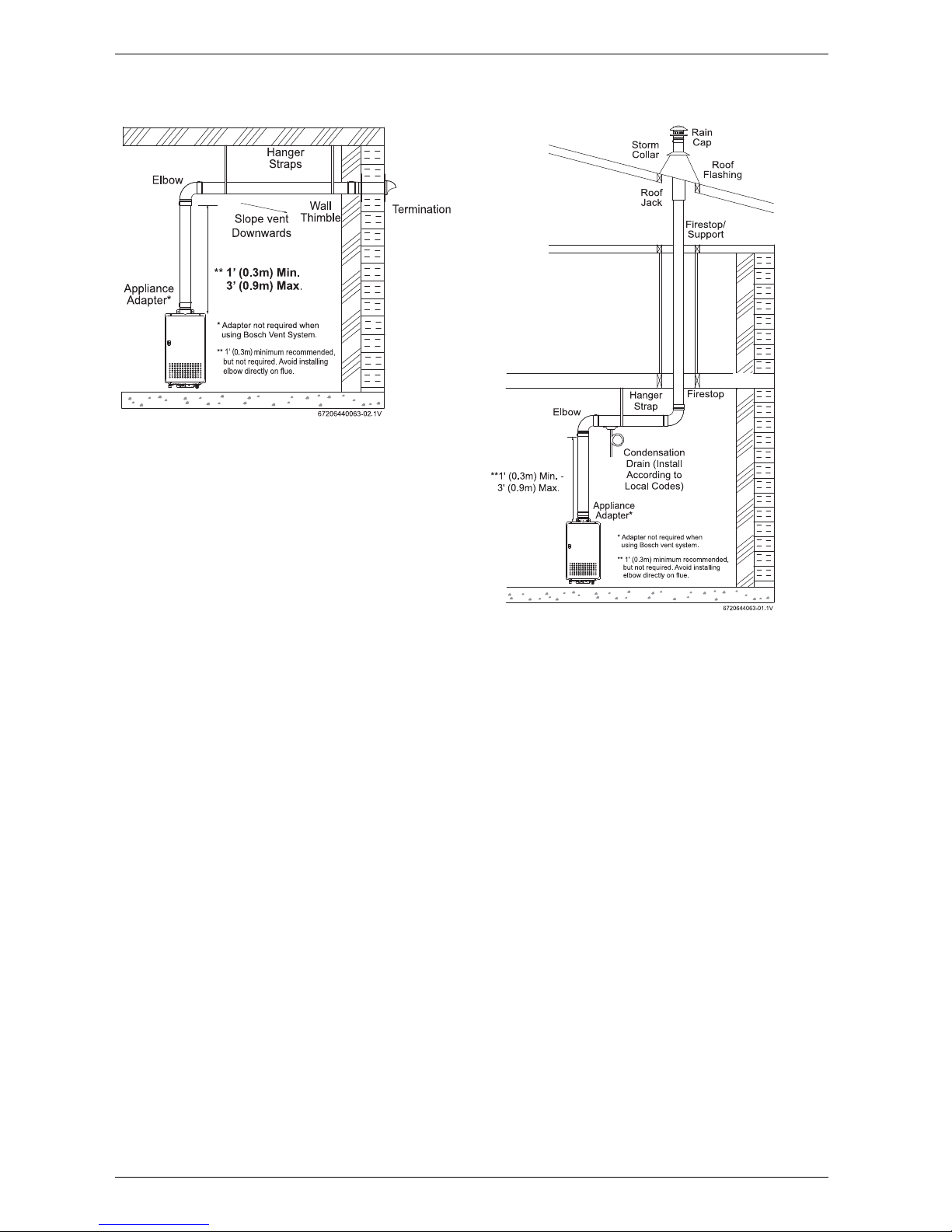

Clearance Requirements from Vent Terminations to Building Openings

*All clearance requirements are in accordance with ANSI Z21.10.3 and the National Fuel Gas Code, ANSI Z223.1

and in Canada, in accordance with NSCNGPIC.

Fig. 8

6 720 644 063

14

Installation instructions

3.3.2 Clearance Requirements from Vent Terminations to Building Openings

All clearance requirements are in accordance with ANSI

Z21.10.3 and the National Fuel Gas Code, ANSI

Z223.1 and in Canada, in accordance with

NSCNGPIC.

Vent Clearances When Heater is Installed

Indoors (For 660 EF appliance)

Maintain the following clearances to any opening in any

building:

• 4' (1.2m) below, 4' (1.2m) horizontally from, or 1'

(0.3m) above any door, operable window, or gravity

air inlet into any building. 3' (0.9m) above any forced

air inlet within 10' (3m).

Fig. 9

For Installations in Canada, clearances are as follows:

To windows, doors, & gravity air inlets: 36" (900mm). To

forced air inlets: 6' (1.8m). These clearance requirements hold true for all of the above situations: Indoor.

Outdoor Clearances to Opening into any Building

(For 660 EFO appliance)

Maintain the following clearances to any opening in any

building:

• 1' (0.3m) below, 1' (0.3m) horizontally from, or 1'

(0.3m) above any door, operable window, or gravity

air inlet into any building. 3' (0.9m) above any forced

air inlet within 10' (3m).

Fig. 10

Vent Clearances When Heater is Installed in a

Recess Box (For 660 EFO appliance)

Fig. 11 Recess box installation with cover removed

Maintain the following clearances to any opening in any

building:

• 1' (0.3m) below, 1' (0.3m) horizontally from, or

1' (0.3m) above any door, operable window, or gravity air inlet into any building. 3' (0.9m) above any

forced air inlet within 10' (3m).

Fig. 12

For Installations in Canada, clearances are as follows:

To windows, doors, & gravity air inlets: 36" (900mm).

To forced air inlets: 6' (1.8m).

6 720 644 063

Installation instructions

15

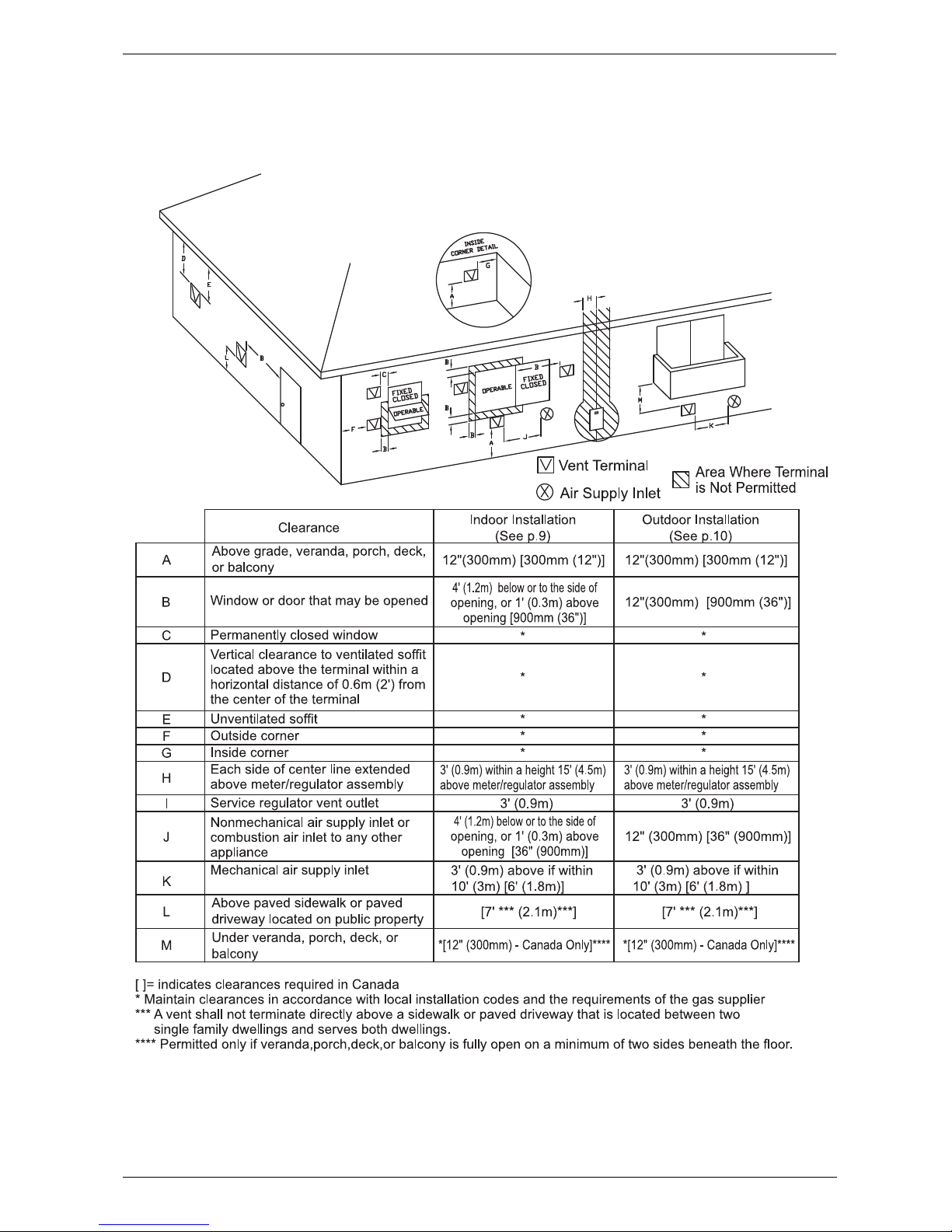

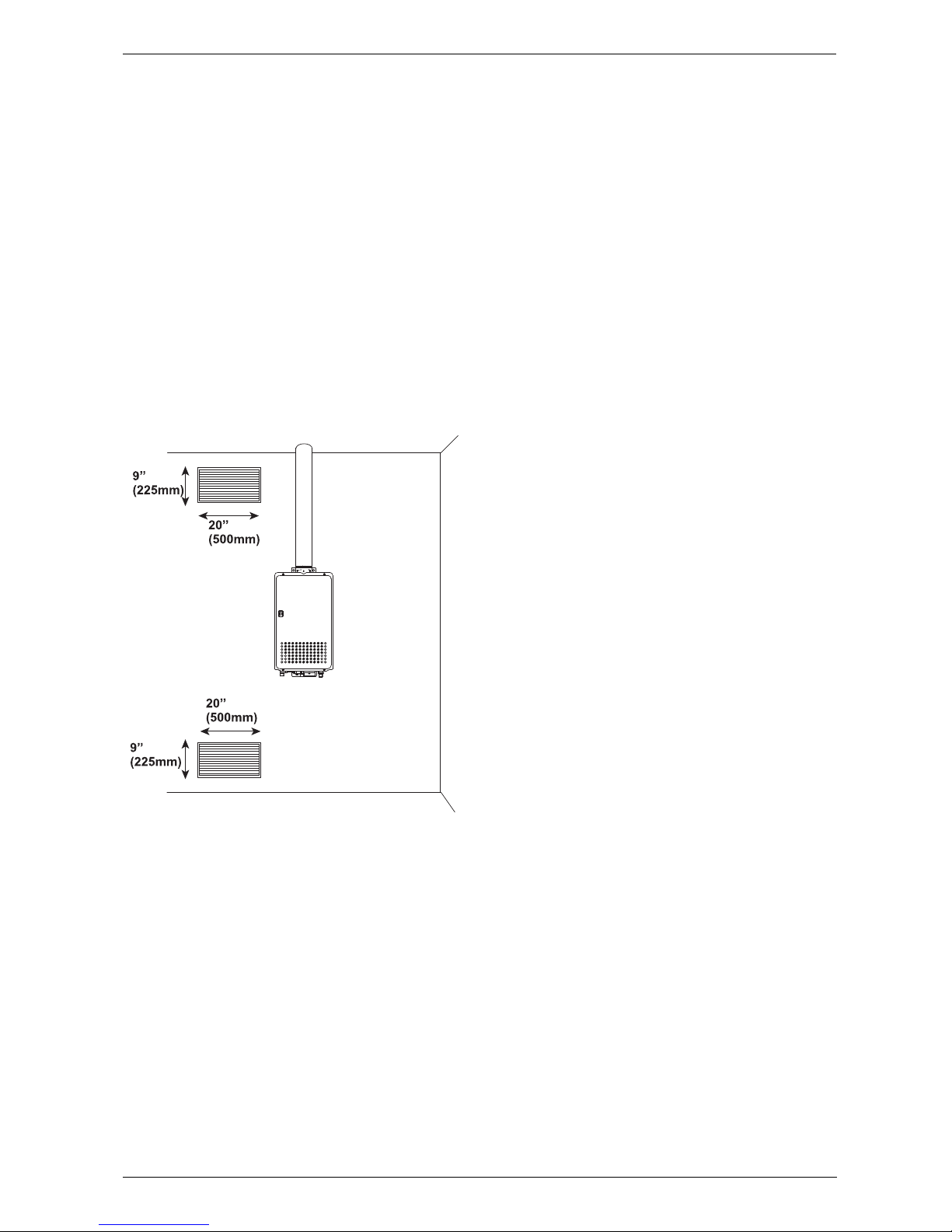

3.4 Combustion air requirements

Combustion Air

Supply combustion air to the units as per the National

Fuel Gas Code, ANSI Z223.1 and in Canada, in

accordance with NSCNGPIC.

• Provide two permanent openings to allow circulation

of combustion air.

• Make each opening 180 square inches if they provide indoor air, and 100 square inches for outdoor

air.

• If the unit is installed in a mechanical closet, provide

a 24" (600mm) clearance in front of the unit to the

door.

• If combustion air will be provided through a duct, size

the duct to provide 60 cubic feet of fresh air per

minute.

Fig. 13

6 720 644 063

16

Installation instructions

Attention residents of the Commonwealth of Massachusetts:

In the Commonwealth of Massachusetts the following

regulation went into effect on 12/30/2005:

(a)For all side wall horizontally vented gas fueled

equipment installed in every dwelling, building or

structure used in whole or in part for residential

purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent

termination is less than seven (7) feet above finished

grade in the area of the venting, including but not limited

to decks and porches, the following requirements shall

be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing

plumber or gasfitter shall observe that a hard wired

carbon monoxide detector with an alarm and battery

back-up is installed on the floor level where the gas

equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery

operated or hard wired carbon monoxide detector with

an alarm is installed on each additional level of the

dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the

services of qualified licensed professionals for the

installation of hard wired carbon monoxide detectors.

a.In the event that the side wall horizontally vented gas

fueled equipment is installed in a crawl space or an at

tic, the hard wired carbon monoxide detector with alarm

and battery back-up may be installed on the next

adjacent floor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation,

the owner shall have a period of thirty (30) days to

comply with the above requirements; provided,

however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an

alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in

accordance with the above provisions shall comply with

NFPA 720 and be ANSI/UL 2034 listed and IAS

certified.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade

directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print size no less than

one half (1/2) inch in size, "GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment shall

not approve the installation unless, upon inspection, the

inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of

248 CMR 5.08(2)(a)1 through 4.

(b)EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

"Equipment Not Required To Be Vented" in the most

current edition of NFPA 54 as adopted by the Board;

and

2. Product approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure used in

whole or in part for residential purposes.

(c) MANUFACTURERS REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM REQUIRED. When

the manufacturer of Product Approved side wall

horizontally mounted gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the

manufacturer for the installation of the equipment and

the venting shall include:

1. Detailed instructions for the installation of the venting

system or the venting system components: and

2. A complete parts list for the venting system design or

venting system.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a product approved side wall

horizontally vented gas fueled equipment does not

provide the parts for the venting of flue gases, but

identifies "special venting systems," the following

requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions

shall be included with the appliance or equipment

installation instructions; and

2. The "special venting systems" shall be product

approved by the Board, and the instructions for that

system shall include a parts list and detailed installation

instructions.

(e) A copy of all installation instructions for all products

approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for

venting instructions, and/or all venting design

instructions shall remain with the appliance or

equipment at the completion of the installation.

Loading...

Loading...