Page 1

CATALOG U E 2 004/200 5

HIGH-FREQUENCY POWER TOOLS

FOR INDUSTRY

www.boschproductiontools.com

TOP

P ERFO RMAN C E WITH THE

LOWEST P OSS IBL E

ENERGY CONSUM PTION.

PRODUCTION TOOLS

Ideas that work.

Page 2

45-58

2 3

63-75

5-12

13-44

Selection Guide for Drills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Drills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Selection Guide for Sanders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Straight Grinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Angle Grinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Disc Sanders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

CONT ENTS.

DR ILLS

GRINDERS

Selection Guide for Screwdrivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Shut-off Screwdriver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 8

Impact Wrenches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Tappers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

SC REWD RIVE R S AND TAPP ER S

High-frequency technology correctly applied . . . . . . . . . . . . . . . . . . . .64

59-62

ACCESSORIES

Balancers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Plug-in Connections and Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

HIGH-FREQUENCY TECHNOLOGY

All of the air tools listed in this

catalogue meet the following

standards or norm documents

EN 792, EN 50144, in accordance

with the regulations of Directives

89/392/EEC.

Conformity

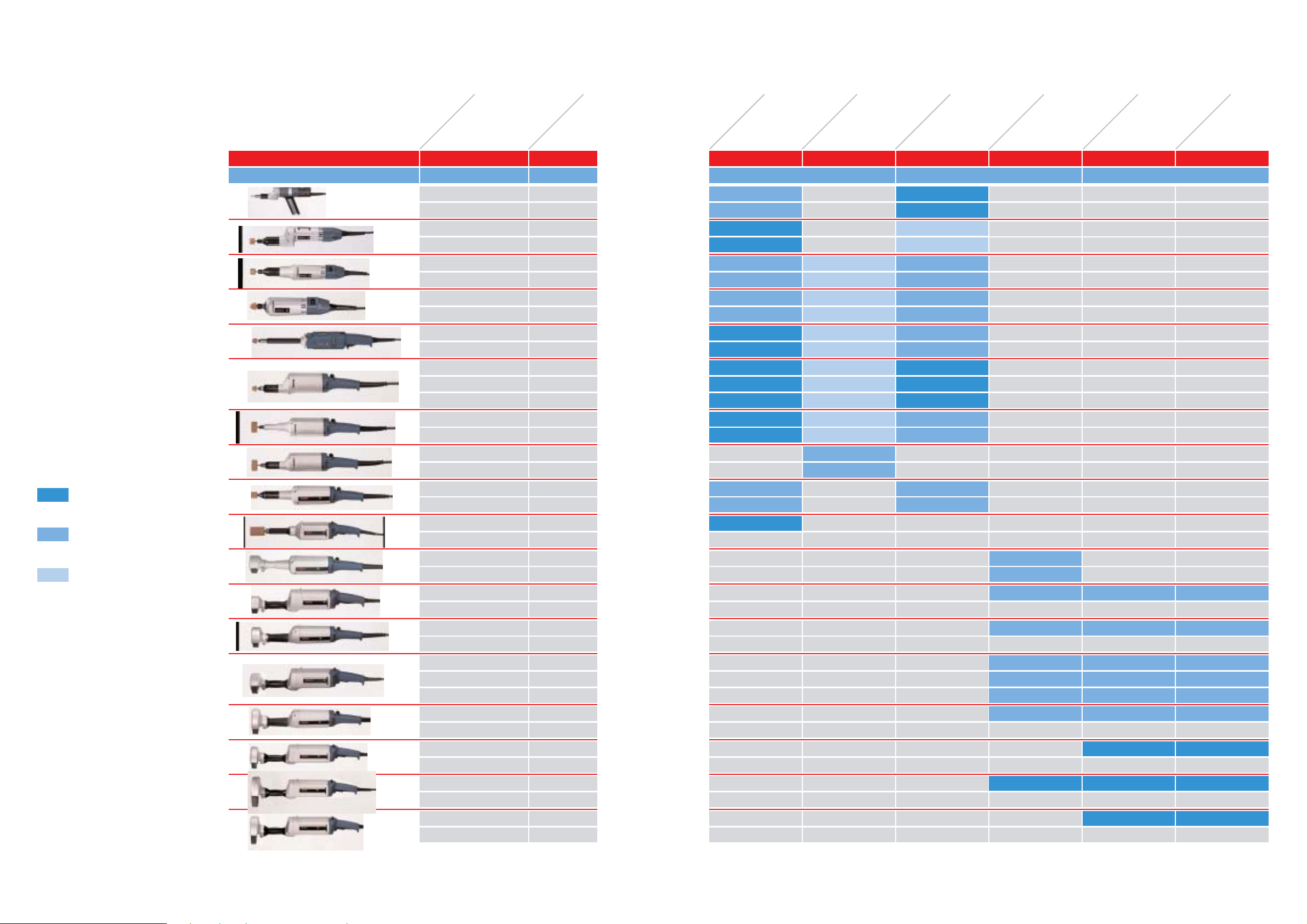

Better performance through

higher frequency

Because their carbon brushes are

subject to wear, universal motors of

conventional power tools are unable

to satisfy these requirements.On the

other hand, the brushless asynchronous motor is ideally suited.

The current frequency it is supplied

with determines its rotational speed,

which, in turn, determines the output that can be achieved.A higher

frequency therefore means a higher

speed and a higher output.

High power at a constant

speed

In continuous operation at 300 Hz,

Bosch high-frequency tools have a

power output of up to 400 Watts

per kg machine weight. In the short

term, peak perfor mances of up to

2.5 times this value are possible.

The speed remains almost constant

– irrespective of whether the tool is

being operated at idle or full load.

Unique

economy

A further argument in favour of

high-frequency tools: their economy. Their efficiency and thus their

power consumption means that

they have unrivalled economy.

Their long service life and low

maintenance requirementsand

power consumption offer an economic solution for every type of

application.

Distinct environmental

consciousness

Environmental thinking plays a central role in all Bosch products:

from the initial development of the

idea and energy saving products, to

environmentally friendly packaging

and disposal.

If a Bosch high-frequency tool is

irreparably damaged, B osch will

take back the old tool.They are collected centrally in the service centre

and passed on for careful recycling.

Special power saving

measures

Bosch is also innovative in the

area of power saving and places an

emphasis on future-oriented technology: The heat recovery system

in the Murrhard plant,for example,

produces savings of over half a million litres of heating oil a year.

Information

from the Internet

Bosch now offers users and others

interested in industrial tools all current product information on the

Internet.Here you will find a free

online catalogue illustrating in text

and pictures all the common cordless, air and hig h-frequency tools for

industrial use. More information on

Pag e 4.

H IG H-F R EQU E N CY POWE R TOO LS:

I N EXP E NS IVE POWE R APP LI CATI ON.

In spite of increasing automation in industrial production, the use of hand-held tools has

advantages in many work operations. These tools must fulfil several requirements: robustness,

powerful and a long service life, but they must also be easy to manage with high operating

comfort.

Certified in

accordance

with ISO 900 1

Certificate no. FM 3 0078

All weight data in this catalogue corresponds to the EPTA Procedure 01/2003.

Page 3

4

DRILLS

AN OVE RVI EW WITH A S I NG LE C LI CK:

ALL I N D USTR IAL TO OLS O N LI N E.

Everything the user needs to know

can now be found on the Internet:

under

www.boschproductiontools.com

the user has an extensive online

catalogue to find which products

are available and how they can be

applied. The selection of tools is

made easier by the possibilities to

run comparisons between tools.

Users,for example, can display all

high-frequency sanders and compare their respective data such as

output or rotational speed.Furthermore, they find out the latest news

about measurement data, innovations and new developments from

the area of Bosch Industrial Tools.

Within a short time,this provides

users with all the relevant information they need to select the

correct production tools.

Operating instructions, pictures and exploded drawings can be downloaded directly

from the Internet.

A spare parts service informs users about which spare parts they need – and where they can

order them.

Service

Product

Picture

Product

Comparison

Dimensioned

drawing

Instruction

manual

Page 4

Order number

Brass, copper,

bronze

Aluminium

Silumin

Cast iron up tp

300 N/mm2plastic

Cast iron up to

180 N/mm

2

Seel over

600 N/mm

2

Frequency

Speed [rpm]

Seel up to

600 N/mm

2

0 602 135 001 / ...004

0 602 135 101 /...104

0 602 135 104

0 602 117 001/ ...004 / ...008

0 602 117 004

Cutting speed [m/min]:

200

300

200

300

2450

3700

1350

2000

0 602 120 101/ ...10 4 /...107

0 602 120 104

0 602 121 101/...104 /...107

0 602 121 104

20 to 25 15 to 20 20 to 30 10 to 20 50 to 60 30 to 40 80 to 120

2 4 6 8 10 12 1416 18202224

200

300

200

200

300

200

1350

2050

690

1000

1030

3300

200

200

200

200

300

300

1600

2400

900

1500

1500

2200

1. gear

2. gear

1. gear

2. gear

1. gear

2. gear

0 602 131 101/...104/...107

0 602 131 104

0 602 133 101 / ...104

0 602 133 107

0 602 133 104

0 602 134 101

200

300

510

760

0 602 119 001 / ...004 / ...008

0 602 119 004

200

200

300

300

216

512

328

775

1. gear

2. gear

1. gear

2. gear

Drill diameter (mm)

2 4 6 8 10 12 1416 18202224 2 4 6 8 10 12141618202224 2 4 6 8 10 1214 1618 20 2224 2 4 6 8 10 1214 1618 20 2224 2 4 6 8 1012 14 161820 2224 2 4 6 8 10 1214 161820 22 24

2 4 6 8 10 12 1416 18202224 2 4 6 8 10 121416 18202224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1 214161820 2224 2 4 6 8 101 214 161820 2224 2 4 6 8 10 12141618202224

2 4 6 8 10 12 1416 18202224 2 4 6 8 10 121416 18202224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1 214161820 2224 2 4 6 8 101 214 161820 2224 2 4 6 8 10 12141618202224

2 4 6 8 10 12 1416 18202224 2 4 6 8 10 121416 18202224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1 214161820 2224 2 4 6 8 101 214 161820 2224 2 4 6 8 10 12141618202224

2 4 6 8 10 12 1416 18202224 2 4 6 8 10 121416 18202224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1214 161820 2224 2 4 6 8 10 1 214161820 2224 2 4 6 8 101 214 161820 2224 2 4 6 8 10 12141618202224

Selection of the rig ht drill depends

mainly on the following two points:

drill bit diameter and

the recommended cutting speed

of the material to be processed.

In the table, the preferred bit sizes

are assigned to the individual drill

types for some common materials.

The table shows the drill bit sizes

with which the individual types are

able to reach the recommended

cutting speeds. However, the feed

of hand-held tools cannot be increased arbitrarily with increasing bit

diameter, since the necessary feed

force can no longer be applied. For

this reason, the maximum bit diameters for steel and aluminium

are allocated to the individual types

on page 6. These maximum diameters were determined by tests,unlike the information in the table. In

order to achieve a sufficient cutting

speed with normal hand pressure,

some materials should be predrilled

for the following bit diameters:

steel upto 600 N/mm

2

as of 8 mm

steel upto 600 N/mm

2

as of 6 mm

cast iron up to 180 N/mm

2

as of

10 mm

cast iron up to 300 N/mm

2

as of

8 mm

Note: If only one bit diameter is

specified in the table, it refers to

the lower limit of the recommended cutting speed. If nothing is

specified, the recommended bit

diameter is outside the clamping

range of the standard chuck.

SE LECTION GU I DE FOR DR I LLS.

6 7

Page 5

8 9

Accessory

order number

Accessories supplied

Remarks

Speed settings

Motor size (mm)

Output drive tool-

holding fixture

Weight withouth calbe (kg)

Nominal current (A)

Nominal power

output (W)

Nominal power

consumption (W)

Idling

speed (min

-1

)

Max. bit-

l

in aluminium (mm)

Max. bit-

l

in steel (mm)

Frequecy (Hz)

Voltage (V)

Order number

DR I LLS.

The suitable drills for a very wide

variety of materials

Drill at constant speed for optimised operational life

Motors with extremely long service

lives for economical work

HB M 55/1

0 602 120 101 265 200 3

0 602 120 104 135 200 3

0 602 120 107 72 200 3

0 602 120 104 200 300 2

0 602 121 101 265 200 6

0 602 121 104 135 200 6

0 602 121 107 72 200 6

0 602 121 104 200 300 4

3 608 571 0017 2450 260 150 0.9 1.7 1/2

HH-20 UNF 55 1

7 2450 260 150 1.7 1.7 1/2

HH-20 UNF 55 1

7 2450 260 150 3.2 1.7 1/2

HH-20 UNF 55 1

7 3700 400 230 1.7 1.7 1/2

HH-20 UNF 55 1

9 1350 260 140 0.9 1.7 1/2

HH-20 UNF 55 1

9 1350 260 140 1.7 1.7 1/2

HH-20 UNF 55 1

9 1350 260 140 3.2 1.7 1/2

HH-20 UNF 55 1

9 2000 400 230 1.7 1.7 1/2

HH-20 UNF 55 1

1-speed drill

with three-jaw chuck

Chuck with key

Clamping range 1–10 mm

HBM 57/1

0 602 131 101 265 200 6

0 602 131 104 135 200 6

0 602 131 107 72 200 6

0 602 131 104 200 300 4

0 602 133 101 265 200 9

0 602 133 104 135 200 9

0 602 133 107 72 200 8

0 602 133 104 200 300 8

0 602 134 101 265 200 2

3 608 571 001

3 608 571 004

10 1350 470 310 1.6 2.0 1/2HH-20 UNF 57 1

10 1350 470 310 3.3 2.0 1/2

HH-20 UNF 57 1

10 1350 470 310 6.1 2.0 1/2HH-20 UNF 57 1

10 2050 600 400 3.3 2.0 1/2

HH-20 UNF 57 1

10 690 470 310 1.6 2.0 1/2

HH-20 UNF 57 1

10 690 470 310 3.3 2.0 1/2

HH-20 UNF 57 1

10 1000 400 310 6.1 2.0 1/2

HH-20 UNF 57 1

10 1030 700 460 3.3 2.0 1/2

HH-20 UNF 57 1

6 3300 400 270 1.6 2.0 M 13 x 1 57 1

1-speed drill

with three-jaw chuck

1-speed drill with keyless

chuck

Chuck with key

Clamping range 1–10 mm

HBM 57/2

0 602 135 001 265 200 5/3

0 602 135 004 135 200 5/3

0 602 135 101 265 200 8/5

0 602 135 104 135 200 8/5

0 602 135 104 200 300 5/4

3 608 571 00110/8 1600/2400 400 270 1.6 2.0 1/2

HH-20 UNF 57 2

10/8 1600/2400 400 270 3.3 2.0 1/2

HH-20 UNF 57 2

10/8 900/1500 400 270 1.6 2.0 1/2

HH-20 UNF 57 2

10/8 900/1500 400 270 3.3 2.0 1/2

HH-20 UNF 57 2

10/8 1500/2200 600 400 3.3 2.0 1/2

HH-20 UNF 57 2

2-speed drill

with three-jaw chuck

Chuck with key

Clamping range 1–10 mm

HB M 65/1

0 602 117 001 265 200 13

0 602 117 004 135 200 13

0 602 117 008 72 200 13

0 602 117 004 200 300 10

1 608 571 027

1 602 025 022

13 510 600 440 1.6 2.8 Taper B 16 65 1

13 510 600 440 3.3 2.8 Taper B 16 65 1

13 510 600 440 5.9 2.8 Taper B 16 65 1

13 760 900 630 3.3 2.8 Taper B 16 65 1

1-speed drill with

speed handle.

Three-jaw chuck can be

ordered as a special

accessory.

Chuck

Clamping range 1.5 –13 mm

Additional handle

HBM 77/2

0 602 119 001 265 200 16/12

0 602 119 004 135 200 16/12

0 602 119 008 72 200 16/12

0 602 119 004 200 300 16/18

1 600 763 010

3 601 030 002

23 216/512 950 700 2.8 5.6 Morse Taper2 77 2

23 216/512 950 700 5.5 5.6 Morse Taper2 77 2

23 216/512 950 700 10.0 5.6 Morse Taper2 77 2

23 328/775 1450 1050 5.5 5.6 Morse Taper 2 77 2

2-speed drill with

cross handle.

Without chuck.

Suitable for bits with.

morse taper 2.

Three-jaw chuck can be

ordered as a special

accessory.

Tubular handlef (M 27 x 2)

Drill drift

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 6

Up to drill-ø

(mm)

Steel uo tp

600 N/mm

2

Seel over

600 N/mm

2

Cast iron up to

180 N/mm

2

Cast iron uo tp

300 N/mm2Brass,

copper,

bronze

Silumin

Aluminium

Cutting

speed (m/min):

20 to 25 15 to 20 20 to 35 10 to 20 5 0 to 60 3 0 to 40 80 to 120

4 2380 1600 2200 1200 4400 2800 8000

5 1900 1270 1800 950 3500 2200 6400

6 1600 1060 1500 800 2900 1850 5300

7 1360 910 1300 680 2500 1600 4550

8 1200 800 1100 600 2200 1400 4000

9 1060 700 1000 530 1900 1200 3540

10 950 640 890 480 1700 1100 3200

11 860 580 810 430 1600 1000 2900

12 800 530 740 400 1500 930 2660

13 730 490 680 370 1350 860 2450

14 680 450 640 340 1250 800 2270

15 630 420 600 320 1150 740 2120

16 600 400 560 300 1100 700 2000

17 560 380 520 280 1050 660 1870

18 530 350 500 260 1000 620 1770

19 500 330 470 250 950 590 1680

20 480 320 450 240 900 560 1600

23 410 280 390 210 760 480 1380

30 310 210 300 160 580 370 1060

DI ME NS IO NAL DRAWI N GS: D R I LLS.

Order number

Size in mm

0 602 120 101

0 602 120 104

0 602 120 107

0 602 121 101

0 602 121 104

0 602 121 107

0 602 131 101

0 602 131 104

0 602 131 107

0 602 133 101

0 602 133 104

0 602 133 107

0 602 134 101

0 602 135 001

0 602 135 004

0 602 135 101

0 602 135 104

0 602 119 001

0 602 119 004

0 602 119 008

0 602 117 001

0 602 117 004

0 602 117 008

l 6;8 deep

Inner Tapper M K2

l 6;8 deep

Tapper B16

DIN 238

Please consult your stockist for information on the complete range of quality accessories.

ACCESSORI ES FOR DRI LLS.

Morse taper MK2 on B 16 for using drill chucks with clamping diameters up to

16 mm, B16.

Order number

Packing unit

1 603 115 002 1

10 11

RECOMMENDED SPEEDS FOR HSS TWIST DRILL

BITS.

Page 7

12

GRINDERS

Page 8

With grinding points

With tapered

grinding wheels

With straight

grinding wheels

14

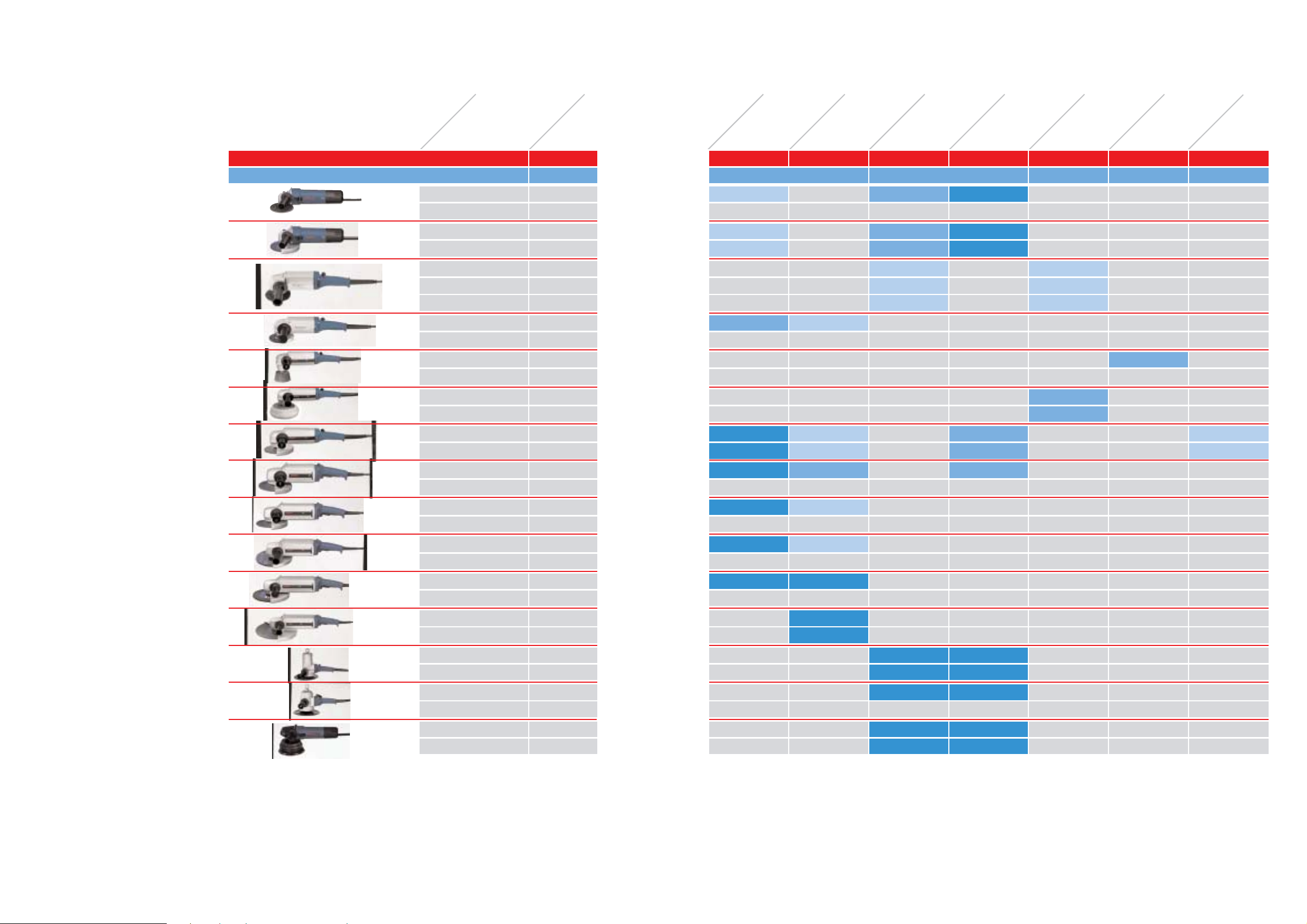

SELECTION GUIDE FOR GRINDERS.

Order number

Idle speed

(rpm)

optimally suited

for this application

well suited

for this application

suited for this

for this application

Please observe manufacturer’s

information regarding grinding

material.

In order to select the correct grinding machine, you must take the

area of application and specific

circumstances into consideration.

That is to say, selection of a gr inding point predetermines selection

of the suitable g rinder. In both

tables – one for straight grinders

and one for angle grinders – the

machines have been ordered to the

grinding tasks or grinding points

for which they are appropriate.

The more powerful the machine,

the larger the amount of material

that is removed.Because of the

great variety in individual working

conditions and spatial considerations, these recommendations can,

however, only serve as guidelines.

In any case,when selecting a grinder,you should take other product

features into consideration in addition to performance.

With fan-shaped

abrasives

With grinding points

With tapered

grinding wheels

0 602 226 2...

0 602 227 2...

0 602 228 2... / 3...

0 602 228 2... / 3...

0 602 229 1...

0 602 229 1...

0 602 238 1...

0 602 238 1...

0 602 207 0...

0 602 208 0...

0 602 208 0...

0 602 209 1...

0 602 209 1...

0 602 210 0...

0 602 210 0...

0 602 211 0...

0 602 211 0...

50 000

50 000

30 500

29 000

12 000

18 000

12 000

18 000

23 400

18 300

27 400

12 000

18 000

3 100

4 700

12 000

18 000

0 602 245 0... 18 000

0 602 211 1...

0 602 211 1...

12 000

18 000

0 602 243 1... 10 700

9 000

0 602 242 1...

0 602 242 1...

0 602 242 4...

0 602 213 1...

8 600

6 800

6 800

6 800

0 602 240 1... 5 700

0 602 240 0...

0 602 239 1...

10 200

4 800

12 000

18 000

Form grinding and deburring Interior processing Coarse grinding

0 602 225 1... / 2...

0 602 233 2... / 3...

0 602 212 1...

15

Page 9

With cup brushes

SELECTION GUIDE FOR GRINDERS,

DI SC AN D RAN D OM O R B IT SAND E RS.

1716

With grinding wheels

With fan-shaped

wheels

With lamb skin

covers

With cutting wheels

With fibre wheels

With grinding stone

Order number

Idle speed (rpm)

0 602 234 3...

0 602 234 3...

0 602 234 3...

4800

5 800

7 300

0 602 326 2...

0 602 305 0...

0 602 228 3...

0 602 228 3...

0 602 305 0...

0 602 306 0...

0 602 304 0...

0 602 304 0...

0 602 331 0...

0 602 332 0...

0 602 331 0...

0 602 334 1...

0 602 335 0...

0 602 335 0...

9 000

0 602 329 0...

1 750

1 750

1 650

5 700

8 600

8 500

6 600

6 600

6 600

4 700

5 100

0 602 373 0...

0 602 373 0...

3 600

5 400

0 602 370 1... 6 000

0 602 370 3...

0 602 370 3...

5 800

7 300

8 500

0 602 301 2...

0 602 301 2...

0 602 327 0...

4 100

6 150

2 550

Coarse grinding Coarse polishing (sanding) Polishing Wet grinding Brushing

Page 10

19

Accessory

Part number

Comes complete

with

Remarks

Switch

type

Toolholding

fixture

Collet chuck (mm)

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible

grinding point-

l

(mm)

Frequency (Hz)

Voltage (V)

Order number

STRAIGHT GRINDERS.

The optimised straight grinders in

all power classes for the widest possible variety of applications

The ideal structural shape for ergonomic work

Constant speed, even at extremely

high loads

Efficient work with longest possible

service life

Robust motors with long service

lives and low maintenance costs

Extremely favourable weight-performance ratio

2 608 570 019

1 907 950 503

1 907 950 505

3 602 025 002

0 602 225 101 265 200 8

0 602 225 104 135 200 8

0 602 225 107 72 200 8

0 602 225 204 200 300 8

0 602 225 211 72 300 8

0 602 233 201 265 200 8

0 602 233 204 135 200 8

0 602 233 207 72 200 8

0 602 233 304 200 300 8

0 602 226 201 265 200 25

0 602 226 204 135 200 25

0 602 226 207 72 200 25

0 602 227 204 200 300 25

0 602 227 211 72 300 25

0 602 228 201 265 200 50

0 602 228 204 135 200 50

0 602 228 207 72 200 50

0 602 228 204 200 300 50

0 602 228 211 72 300 50

0 602 229 101 265 200 50

0 602 229 104 135 200 50

0 602 229 104 200 300 50

50 000 80 40 0.2 0.7 3

50 000 80 40 0.5 0.7 3

50 000 80 40 0.9 0.7 3

50 000 125 65 0.5 0.7 3

50 000 125 65 1.4 0.7 3

Collet chuck 3 mm

Open-ended spanner SW 9

Open-ended spanner SW 11

Auxiliary handle

Bar handle,

offset output drive

Slide switch

HGS 44/8

2 608 570 019

1 907 950 503

1 907 950 505

3 602 025 002

50 000 26 0 150 0.9 1.7 3

50 000 26 0 150 1.7 1.7 3

50 000 26 0 150 3.2 1.7 3

50 000 4 00 230 1.7 1.7 3

Collet chuck 3 mm

Open-ended spanner SW 9

Open-ended spanner SW 11

Auxiliary handle

Bar handle,

offset output drive

Slide switch

2 608 570 079

2 607 950 511

30 500 26 0 150 0.9 1.6 6

30 500 26 0 150 1.7 1.6 6

30 500 26 0 150 3.2 1.6 6

29 000 400 230 1.7 1.6 6

29 000 400 230 4.6 1.6 6

Collet chuck 6 mm

2 open-ended spanner

SW 17

Bar handle,

offset output drive

Slide switch

2 608 570 079

2 607 950 511

12 000 260 150 0.9 1.6 6

12 000 260 150 1.7 1.6 6

12 000 260 150 3.2 1.6 6

18 000 400 230 1.7 1.6 6

18 000 400 230 4.6 1.6 6

Collet chuck 6 mm

open-ended spanner SW 17

Bar handle,

central output drive

Slide switch

2 608 570 079

2 607 950 511

12 000 260 150 0.9 1.3 6

12 000 260 150 1.7 1.3 6

18 000 400 230 1.7 1.3 6

Collet chuck 6 mm

with nut

open-ended spanner SW 17

Bar handle,

central output drive,

short spindle

for tight spaces

Slide switch

for grinding points

8 to 50 mm in diameter

Your specialist dealer can provide you with information on the complete set of quality accessories.The machines come equipped with a special 4-m-long cable without plug.

HGS 55/8

HGS 55/25

HGS 55/5 0

HGS 55/5 0

18

Page 11

2120

Order number

Voltage (V)

Frequency (Hz)

Admissible

grinding point-

l

(mm)

No load speed

(rpm)

Nominal power

consumption (W)

Nominal power

Output (W)

Nominal current (A)

Weight without

cabel (kg)

Toolholding

fixture

Collet chuck (mm)

Switch

type

Remarks

Comes complete

with

Accessory

Part number

STRAIGHT GRINDERS.

The optimised straight grinders in

all power classes for the widest possible variety of applications

The ideal structural shape for ergonomic work

Constant speed, even at extremely

high loads

Efficient work with longest possible

service life

Robust motors with long service

lives and low maintenance costs

Extremely favourable weight-performance ratio

1 608 570 025

1 607 950 001

0 602 228 361 265 200 50

0 602 228 364 135 200 50

0 602 228 364 200 300 50

0 602 228 371 265 200 50

0 602 228 374 135 200 50

0 602 228 377 72 200 5 0

0 602 228 374 200 300 40

0 602 238 101 265 200 50

0 602 238 104 135 200 50

0 602 238 107 72 200 50

0 602 238 134 200 300 50

0 602 238 111 72 300 50

0 602 207 001 265 200 32

0 602 207 004 135 200 32

0 602 207 008 72 200 32

0 602 208 001 135 200 50

0 602 208 001 200 300 27

0 602 209 101 265 200 50

0 602 209 104 135 200 50

0 602 209 107 72 200 50

0 602 209 134 200 300 50

0 602 209 111 72 300 50

12 000 260 150 0.9 1.6 6

12 000 260 150 1.7 1.6 6

18 000 400 230 1.7 1.6 6

Collet chuck

l 6 mm

Offset screwdriver

Bar handle,

central output drive

with eccentric

clamping

ON/OF F switch

HGS 55/5 0

1 608 570 025

1 607 950 001

12 000 260 150 0.9 1.6 6

12 000 260 150 1.7 1.6 6

12 000 260 150 3.2 1.6 6

18 000 400 230 1.7 1.6 6

Collet chuck

l 6 mm

Offset screwdriver

Pistol handle,

with eccentric

clamping

Pressure switch

with lock

1 608 570 025

1 907 950 506

1 907 950 509

12 000 400 270 1.6 2.1 6

12 000 400 270 3.3 2.1 6

12 000 400 270 6.1 2.1 6

18 000 600 400 3.3 2.1 6

18 000 600 400 9.2 2.1 6

Collet chuck

l 6 mm

Open-ended spanner SW 12

Open-ended spanner SW 15

Post handle,

central output drive

Spindle length up to

480 mm optional.

Pressure switch

with lock

1 608 570 025

1 907 950 506

1 907 950 509

23 400 6 00 440 1.6 2.4 6

23 400 6 00 440 3.3 2.4 6

23 400 6 00 440 5.9 2.4 6

18 300 6 00 440 3.3 2.4 6

27 400 900 630 3.3 2.4 6

Collet chuck

l 6 mm

Open-ended spanner SW 12

Open-ended spanner SW 15

Post handle,

central output drive

Toggle

1 608 570 025

1 907 950 506

1 907 950 509

12 000 600 44 0 1.6 2.5 6

12 000 600 44 0 3.3 2.5 6

12 000 600 44 0 5.9 2.5 6

18 000 900 630 3.3 2.5 6

18 000 900 630 8.8 2.5 6

Collet chuck

l 6 mm

Open-ended spanner SW 12

Open-ended spanner SW 15

Post handle,

central output drive

Toggle

for grinding points

27 to 50 mm in diameter

The machines come equipped with a special 4-m-long cable without plug.

HGS 55/5 0

HGS 57/50 Ls

HGS 65/32

HGS 65/5 0

Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 12

2322

Accessory

Part number

Comes complete

with

Remarks

Switch

type

Toolholding

fixture

Collet chuck (mm)

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible

grinding point-

l

(mm)

STRAIGHT GRINDERS.

The optimised straight grinders in

all power classes for the widest possible variety of applications

The ideal structural shape for ergonomic work

Constant speed, even at extremely

high loads

Efficient work with longest possible

service life

Robust motors with long service

lives and low maintenance costs

Extremely favourable weight-performance ratio

Order number

Voltage (V)

Frequency (Hz)

1 608 570 025

1 907 950 506

1 907 950 509

0 602 210 001 265 200 50

0 602 210 004 135 200 50

0 602 210 004 200 300 50

0 602 211 004 265 200 50

0 602 211 010 135 200 50

0 602 211 017 72 200 50

0 602 211 010 200 300 50

0 602 211 018 72 300 50

0 602 245 034 200 300 40

0 602 245 011 72 300 40

3100 600 440 1.6 2.5 6

3100 600 440 3.3 2.5 6

4700 900 630 3.3 2.5 6

Collet chuck

l 6 mm

Open-ended spanner SW 12

Open-ended spanner SW 15

Post handle,

offsett drive for

polishing heads with

low circumference

velocity

Toggle

HGS 65/5 0

2 608 570 009

1 607 950 511

1 607 950 505

12 000 950 700 2.8 4.3 8

12 000 950 700 5.5 4.3 8

12 000 950 700 10.0 4.3 8

18 000 1450 1050 5.5 4.3 8

18 000 1450 1050 15.2 4.3 8

Collet chuck

l 8 mm

Open-ended spanner SW 14

Open-ended spanner SW 22

Post handle,

central output dirve

Toggle

3 607 950 004

18 000 1800 1500 6.4 4.7 Spindle M 14

18 000 1800 1500 17.7 4.7 Spindle M 14

Open-ended spanner SW 27Post handle,

central output dirve

for grinding wheels

with internal thread

Toggle

Lever switch with

lock

for grinding points

40 to 50 mm in diameter

The machines come equipped with a special 4-m-long cable without plug.

HGS 77/50

HGS 85/40

Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 13

24 25

No load speed

(rpm)

Nominal power

consumption (W)

Nominal power

Output (W)

Nominal current (A)

Weight without

cabel (kg)

Toolholding

fixture

Collet chuck (mm)

Switch

type

Remarks

Comes complete

with

Accessory

Part number

Admissible

grinding point-

l

(mm)

STRAIGHT GRINDERS.

The optimised straight grinders in

all power classes for the widest possible variety of applications

The ideal structural shape for ergonomic work

Constant speed, even at extremely

high loads

Efficient work with longest possible

service life

Robust motors with long service

lives and low maintenance costs

Extremely favourable weight-performance ratio

for grinding wheels

50 to 80 mm in diameter

The machines come equipped with a special 4-m-long cable without plug.

Order number

Voltage (V)

Frequency (Hz)

3 607 950 005

3 607 950 006

3 605 510 025

3 605 703 028

3 605 703 074

3 607 950 005

3 607 950 006

3 605 510 025

3 605 703 028

3 605 703 074

0 602 211 101 265 200 75 mm

l

0 602 211 107 135 200 45 m/s

0 602 211 116 72 200 circumference

velocity

0 602 211 134 200 300 50 mm

l

45 m/s

circumference

velocity

0 602 243 134 200 300 80 mm

l

45 m/s

circumference

velocity

12 000 950 700 2.8 4.7

12 000 950 700 5.5 4.7

12 000 950 700 10.0 4.7

18 000 1450 1050 5.5 4.7

Open-ended spanner SW 32

Pin sparrer

Protective guard

Mounting flange

Collet flange

Open-ended spannerSW 32

Pin sparrer

Protective guard

Mounting flange

Collet flange

The machine must

not be operated

without a protective

guard.

The machine must

not be operated

without a protective

guard.

Toggle

Lever with lock

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 77/75

3 607 950 005

3 607 950 006

3 605 510 025

3 605 703 028

3 605 703 074

10 700 1800 1500 6.4 5.4 Open-ended spanner SW 32

Pin sparrer

Protective guard

Mounting flange

Collet flange

The machine must

not be operated

without a protective

guard.

Lever with lockMounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 85/8 0

Your specialist dealer can provide you with information on the complete set of quality accessories.

3 607 950 005

3 607 950 006

3 605 510 019

3 605 703 028

3 605 703 074

0 602 212 101 265 200 100 mm

l

0 602 212 104 135 200 45 m/s

0 602 212 107 72 200 circumference

velocity

9000 950 700 2.8 5.1

9000 950 700 5.5 5.1

9000 950 700 10.1 5.1

Open-ended spanner SW 32

Pin sparrer

Protective guard

Mounting flange

Collet flange

The machine must

not be operated

without a protective

guard.

ToggleMounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 77/100

3 607 950 005

3 607 950 006

3 605 510 019

3 605 703 028

3 605 703 074

3 607 950 005

3 607 950 006

3 605 510 019

3 605 703 028

3 605 703 074

3 607 950 010

1 607 950 061

0 602 242 101 265 200 100 mm

l

0 602 242 104 265 200 45 m/s

0 602 242 107 72 200 circumference

velocity

0 602 242 134 200 300 100 mm

l

45 m/s

circumference

velocity

0 602 242 436 200 300 125 mm

l

45 m/s

circumference

velocity

8600 1200 1000 3.3 5.5

8600 1200 1000 3.3 5.5

8600 1200 1000 11.8 5.5

8600 1800 1500 6.4 5.5

6800 1800 1500 6.4 5.5

Open-ended spanner SW 32

Pin sparrer

Protective guard

Mounting flange

Collet flange

Open-ended spanner SW 32

Pin sparrer

Protective guard

Mounting flange

Collet flange

Open-ended spanner SW 32

Pin sparrer

The machine must

not be operated

without a protective

guard.

The machine must

not be operated

without a protective

guard.

The machine must

not be operated

without a protective

guard.

Lever with lock

Lever with lock

Toggle

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 85/1 00

Page 14

26 27

Toolholding

fixture

Collet chuck (mm)

Switch

type

Remarks

Comes complete

with

Accessory

Part number

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible

grinding

wheels-

l

(mm)

Frequency (Hz)

Voltage (V)

Order number

STRAIGHT GRINDERS.

The optimised straight grinders in

all power classes for the widest possible variety of applications

The ideal structural shape for ergonomic work

Constant speed, even at extremely

high loads

Efficient work with longest possible

service life

Robust motors with long service

lives and low maintenance costs

Extremely favourable weight-performance ratio

for grinding wheels

125 to 180 mm in diameter

3 607 950 010

1 607 950 061

3 605 510 014

3 605 703 068

3 605 703 077

0 602 213 104 200 300 125 mm

l

45 m/s

circumference

velocity

6800 145 0 1050 5.5 5.2 Open-ended spanner SW 32

Pin spanner

Protective guard

Mounting flange

Collet flange

The machine must not

be operated without a

protective guard.

ToggleMounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 77/125

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

3 607 950 010

1 607 950 061

3 605 510 018

3 605 703 068

3 605 703 077

3 607 950 010

1 607 950 061

3 605 510 018

3 605 703 068

3 605 703 077

0 602 240 104 135 200 150 mm

l

0 602 240 107 72 200 45 m/s

circumference

velocity

0 602 240 134 200 300 150 mm

l

45 m/s

circumference

velocity

5700 1950 1500 10.0 7.7

5700 1950 1500 18.0 7.7

5700 2900 2200 10.0 7.7

Open-ended spanner SW 32

Pin spanner

Protective guard

Mounting flange

Collet flange

Open-ended spanner SW 32

Pin spanner

Protective guard

Mounting flange

Collet flange

The machine must not

be operated without a

protective guard.

The machine must not

be operated without a

protective guard.

Lever with lock

Lever with lock

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 88/1 50

3 607 950 010

1 607 950 061

3 605 510 031

3 605 703 068

3 605 703 077

0 602 240 034 200 300 150 mm

l

0 602 240 035 200 300 80 m/s

circumference

velocity

10 200 2900 2200 10.0 7.7

10 200 2900 2200 10.0 7.7

Open-ended spanner SW 32

Pin spanner

Protective guard

Mounting flange

Collet flange

The machine must not

be operated without a

protective guard.

Lever with lock

Lever

without lock

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 88/1 50

3 607 950 010

1 607 950 061

3 605 510 035

3 605 703 068

3 605 703 077

3 607 950 010

1 607 950 061

3 605 510 035

3 605 703 068

3 605 703 077

0 602 239 104 135 200 180 mm

l

0 602 239 107 72 200 45 m/s

circumference

velocity

0 602 239 134 200 300 180 mm

l

45 m/s

circumference

velocity

4800 1950 1500 10.0 7.9

4800 1950 1500 18.0 7.9

4800 2900 2200 10.0 7.9

Open-ended spanner SW 32

Pin spanner

Protective guard

Mounting flange

Collet flange

Open-ended spanner SW 32

Pin spanner

Protective guard

Mounting flange

Collet flange

The machine must not

be operated without a

protective guard.

The machine must not

be operated without a

protective guard.

Lever with lock

Lever with lock

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

Mounting flanges M 14

for grinding wheels

with bore-

l 20 mm

HGS 88/1 80

Page 15

28 29

Accessory

Part number

Switch

type

Toolholding

fixture

chuck (mm)

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible grinding

wheels-

l (mm)

Frequency (Hz)

Voltage (V)

Order number

ANGLE GRINDERS.

The correct grinder/sander for

every application

Extremely robust and maintenancefriendly motors

Constant speeds throughout the

whole power range for top economy

and longest possible service lives

Robust angular gear with high

operational performance

1 607 950 052

1 602 025 031

1 603 345 043

2 605 703 014

0 602 324 301 265 200 125

0 602 324 304 135 200 125

0 602 324 307 72 200 125

4800 520 360 1.6 2.0

4800 520 360 3.2 2.0

4800 520 360 6.1 2.0

Pin-type wrench

Auxiliary handle

Pin-type wrench

Mounting flange

For fibre-sanding discs

with spindle locking.

SDS-clic available as

special accessory

Slide-

switch

Mounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 5265/125

Remarks

Comes complete

with

for grinding wheels

100 to 18 0 mm in diameter

1 605 510 155

1 607 950 052

2 607 950 511

1 602 025 022

1 603 345 043

0 602 326 104 200 300 125 9000 900 63 0 3.3 3.2 Protective guard

l 125 mm

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

Pin-type wrench

For light grinding workToggleMounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 65/125

1 605 510 155

1 607 950 052

1 602 025 031

1 603 345 043

2 605 703 014

0 602 324 341 265 200 125

0 602 324 344 135 200 125

0 602 324 347 72 200 125

0 602 324 324 200 300 125

0 602 324 331 72 300 125

5800 520 360 1.6 2.2

5800 520 360 3.2 2.2

5800 520 360 6.1 2.2

7300 800 550 3.2 2.2

7300 800 550 8.7 2.2

Protective guard

l 125 mm

Pin-type wrench

Auxiliary handle

Pin-type wrench

Mounting flange

For light grinding work

For fan-type discs

Slideswitch

Mounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 5265/125

2 607 950 511

1 602 025 022

0 602 305 001 265 200 175

0 602 305 004 135 200 175

0 602 305 008 72 200 175

0 602 306 034 200 300 175

1750 950 700 2.8 4.4

1750 950 700 5.5 4.4

1750 950 700 10.0 4.4

1650 1450 1050 5.5 4.4

Open-ended spanner SW 17

Auxiliary handle

For polishing workToggleMounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 77/175

2 607 950 511

1 602 025 022

1 607 950 052

0 602 301 201 265 200 125

0 602 301 204 135 200 125

0 602 301 207 72 200 125

0 602 301 204 200 300 125

0 602 327 001 265 200 100

4100 600 440 1.6 3.0

4100 600 440 3.3 3.0

4100 600 440 5.9 3.0

6150 900 630 3.3 3.0

2550 600 410 1.6 3.0

Open-ended spanner SW 17

Auxiliary handle

Pin-type wrench

For fibre-sandingToggleMounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 65/125

2 607 950 511

1 602 025 022

1 607 950 061

2 605 703 014

1 603 345 043

0 602 305 010 42 200 125 1750 950 700 17.5 4.5 Open-ended spanner SW 17

Auxiliary handle

Pin-type wrench

Mounting flange

Pin-type wrench

For wet grindingToggleMounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 77/100 for wet grinding

1 605 510 176

2 605 703 014

1 603 345 043

1 607 950 061

2 607 950 511

1 602 025 022

0 602 304 001 265 200 180

0 602 304 004 135 200 180

0 602 304 009 72 200 180

0 602 304 034 200 300 180

0 602 304 010 72 300 180

5700 950 700 2.8 4.6

5700 950 700 5.5 4.6

5700 950 700 10.0 4.6

8600 1450 1050 5.5 4.6

8600 1450 1050 15.2 4.6

Protective guard

l 180 mm

Mounting flange

Pin-type wrench

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

For medium-heavy

grinding work

ToggleMounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 77/180

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 16

30 31

Accessory

Part number

Comes complete

with

Switch

type

Toolholding

fixture

chuck (mm)

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible grinding

wheels-

l (mm)

Frequency (Hz)

Voltage (V)

Order number

ANGLE GRINDERS.

1 605 510 176

2 605 703 014

1 603 345 043

1 607 950 061

2 607 950 511

1 602 025 022

0 602 329 001 265 200 180

0 602 329 004 135 200 180

0 602 329 007 72 200 180

0 602 329 034 200 300 180

0 602 329 011 72 300 180

0 602 329 036 200 300 180

8500 1200 1000 3.3 5.6

8500 1200 1000 6.4 5.6

8500 1200 1000 11.8 5.6

8500 1800 1500 6.4 5.6

8500 1800 1500 17.7 5.6

8500 1800 1500 6.4 5.6

Protective guard

l 180 mm

Mounting flange

Round nut

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

For medium-heavy

grinding work. SDS-clic

available as special

accessory.

Lever with lock

Toggle

Mounting flanges M 14

for grinding wheels

with bore-

l

2,3 mm

HWS 85/18 0

Remarks

for grinding wheels

180 to 23 0 mm in diameter

1 605 510 176

2 605 703 014

1 603 345 043

1 607 950 061

2 607 950 511

1 602 025 022

0 602 331 001 265 200 180

0 602 331 004 135 200 180

0 602 331 007 72 200 180

0 602 331 003 265 200 180

0 602 331 034 200 300 180

0 602 331 036 200 300 180

8500 1950 1500 5.0 6.5

8500 1950 1500 10.0 6.5

8500 1950 1500 18.0 6.5

8500 1950 1500 5.0 6.5

8500 2900 2200 10.0 6.5

8500 2900 2200 10.0 6.5

Protective guard

l 180 mm

Mounting flange

Round nut

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

For medium-heavy

grinding work. SDS-clic

available as special

accessory.

Lever with lock

Toggle

Lever with lock

Toggle

Mounting flanges M 14

for grinding wheels

with bore-

l

2,3 mm

HWS 88/18 0

1 605 510 173

2 605 703 014

1 603 345 043

1 607 950 061

2 607 950 511

1 602 025 022

0 602 332 001 265 200 230

0 602 332 011 200 300 230

0 602 332 034 200 300 230

0 602 332 003 265 200 230

0 602 332 036 200 300 230

0 602 332 005 135 200 230

6600 1950 1500 5.0 7.0

6600 2900 2200 10.0 7.0

6600 2900 2200 10.0 7.0

6600 1950 1500 5.0 7.0

6600 2900 2200 10.0 7.0

6600 1950 1500 10.0 7.0

Protective guard

l 180 mm

Mounting flange

Round nut

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

For medium-heavy

grinding work. SDS-clic

available as special

accessory.

Lever with lock

Toggle

Lever with lock

Mounting flanges M 14

for grinding wheels

with bore-

l

2,3 mm

HWS 88/230

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

The correct grinder/sander for

every application

Extremely robust and maintenancefriendly motors

Constant speeds throughout the

whole power range for top economy

and longest possible service lives

Robust angular gear with high

operational performance

Page 17

32 33

Accessory

Part number

Comes complete

with

Remarks

Switch

type

Toolholding

fixture

chuck (mm)

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible grinding

wheels-

l (mm)

Frequency (Hz)

Voltage (V)

Order number

ANGLE GRINDERS

1 605 510 173

2 605 703 014

1 603 345 043

1 607 950 061

2 607 950 511

1 602 025 022

0 602 334 101 265 200 230

0 602 334 107 72 200 230

0 602 334 134 200 300 230

0 602 334 136 200 300 230

6600 2500 2000 6.7 8.5

6600 2500 2000 24.7 8.5

6600 3800 3100 13.2 8.5

6600 3800 3100 13.2 8.5

Protective guard

l 230 mm

Mounting flange

Round nut

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

For heavy grinding work.

SDS-click available as

special accessory.

Lever with lock

Lever with lock

Toggle

Mounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 810/23 0

for grinding wheels

230 to 300 mm in diameter

1 605 510 212

2 605 703 011

1 603 345 043

2 605 703 022

1 907 950 007

1 607 950 061

2 607 950 511

1 602 025 022

0 602 335 001 265 200 300

0 602 335 004 135 200 300

0 602 335 007 72 200 300

0 602 335 034 200 300 300

0 602 335 036 200 300 300

4700 2500 2000 6.7 10.0

4700 2500 2000 13.2 10.0

4700 2500 2000 24.7 10.0

5100 3800 3100 13.2 10.0

5100 3800 3100 13.2 10.0

Protective guard

l 300 mm

Mounting flange

Round nut

Mounting flange

Internal hexagon key

Pin-type wrench

Open-ended spanner SW 17

Auxiliary handle

For cutting work.

Lever with lock

Lever with lock

Toggle

Mounting flanges M 14

for grinding wheels

with bore-

l

22,3 mm

HWS 810/3 00

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

The correct grinder/sander for

every application

Extremely robust and maintenancefriendly motors

Constant speeds throughout the

whole power range for top economy

and longest possible service lives

Robust angular gear with high

operational performance

Page 18

35

Accessory

Part number

Comes complete

with

Remarks

Switch

type

Toolholding

fixture

Collet chuck (mm)

Weight without

cabel (kg)

Nominal current (A)

Nominal power

Output (W)

Nominal power

consumption (W)

No load speed

(rpm)

Admissible grinding

wheels-

l (mm)

Frequency (Hz)

Order number

Voltage (V)

DI SC SAN DE R S AN D RAN DO M OR B IT SAN DE R S.

disc sanders and random orbit

sanders for sanding discs with

180 mm diameter

2 607 950 511

1 602 025 022

2 912 521 237

2 916 680 011

2 601 329 036

0 602 373 004 135 200 180

0 602 373 004 200 300 180

3600 850 580 2.2 3.7

5400 1300 900 4.5 3.7

For fibre-sanding discsToggleThreaded mounting

M 14

HTS 75/180

Open-ended spanner SW 17

Auxiliary handle

Ringscrew

Spring

Gloves

1 907 950 513

1 907 950 511

1 602 025 022

2 601 329 036

0 602 370 101 265 200 180

0 602 370 104 135 200 180

0 602 370 107 72 200 180

6000 1000 800 3.4 4.7

6000 1000 800 6.0 4.7

6000 1000 800 12.8 4.7

For fibre-sanding discsToggleThreaded mounting

M 14

HTS 86/180

Open-ended spanner SW 24

Open-ended spanner SW 19

Auxiliary handle

Gloves

2 602 025 067

2 605 411 046

2 605 702 009

1 907 950 007

0 602 370 301 265 200 150

0 602 370 304 135 200 150

0 602 370 307 72 200 150

0 602 370 311 72 300 150

0 602 370 334 200 300 150

5800 520 360 1.6 2.7

5800 520 360 3.2 2.7

5800 520 360 6.1 2.7

7300 800 550 6.1 2.7

7300 800 550 3.2 2.7

Slide switchFastener

HEX 526 5/15 0

Auxiliary Handle

Dust bag

Screw-on connector

Allen key

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

34

The correct sander for all surfaces

Best sanding results, even on large

surfaces

Robust motors with an extremely

long service life

Small random orbit sander with

very high performance

Page 19

1 603 345 004

1 603 340 031

1 600 501 006

0 602

226 ...

...201/ ...204/ ...207

3736

SELECTION GUIDE FOR GRINDERS.

ACCESSORIES FOR ANGLE GRINDERS.

ACCESSORIES FOR STRAIGHT GRINDERS.

The table shows the relationship between the permissible diameter of the grinding wheel

and the speed.

speed 60000

rpm

50000

40000

30000

20000

15 000

12000

10000

8000

5000

4000

3000

2000

1500

1000

disc-ø mm

10 15 20 30 40 50 60 80 100 120 150 178 230 300

100 m/s

60 m/s

20 m/s

15 m/s

10 m/s

5 m/s

80 m/s

45 m/s

25 m/s

Admissible working speed

Observe the following with grinding stones: Permissible speeds

(rpm) depend on abrasive wheel

diameter and length, as well as

shank diameter and clamping

length as per DIN 69170.

0 602 225 ...

...101/ ...104/ ...107/

... 204/ ...211

0 602

236 ...

...001/ ...007

0 602

237

004

0 602

233 ...

...201/ ...204/ ...207/

...304

0 602

227

...

...204/ ...211

0 602

228

...

...201/ ...204/ ...207/

...211

0 602

229

...

...101/ ...104

0 602

228

...

...361/ ...361/ ...371/

...374/ ...377

0 602

238 ...

...101/ ...104/ ...107/

...134/ ...111

0 602

207

...

...001/ ...008

0 602

208

001

0 602

209 ...

...101/ ...104/ ...107/

...134/ ...111

0 602

210 ...

...001/ ...004

0 602

211 ...

...004/ ...010/ ...017/

...018

3 mm1 608 570 0312 608 570 077 – –

1/8’’ –2 6 0 8 570 078 – –

4 mm1 608 570 033 – – –

6 mm1 608 570 0372 608 570 079 2 608 570 118 –

1/4’’ –2 6 0 8 570 080 – 2 608 570 014

8 mm –2 6 0 8 570 081 2 608 570 0162 608 570 009

10 mm – – – 2 608 570 017

Collets-ø

0 602 221...

and 243 ...

0 602 212 ...

and 242 ...

0 602 213 ...

0 602 240 ...

0 602 240 ...

0 602 239...

45 and 80 m/s 45 and 80 m/s 45 m/s 45 m/s 80 m/s 45 m/s

up to 80 mm ø up to 1 00 mm ø up to 125 mm ø up to 150 mm ø up to 150 mm ø up to 1 8 0 mm ø

Wheel guards 3 605 510 025 3 6 05 510 03 0 3 6 05 510 031 3 605 510 018 3 6 05 510 017 3 605 510 016

Mounting flange 3 605 703 028 3 605 703 028 3 605 703 068 3 605 703 068 3 605 703 068 3 605 703 068

Collet flange 3 605 703 074 3 605 703 074 3 605 703 077 3 605 703 077 3 605 703 070 3 605 703 077

admissible

grinding point

width (mm)

20/25 20/25 20/25 20/25 20/25 20

Accessories for conical grinding wheels

Spindle extension

Auxiliary handle

Order number

Product type for model

0 602 ...

Length in mm

3 606 120 031 ... 238 101 – 234 15 0

3 606 120 032 ... 238 101 – 234 3 00

3 602 025 008 ... 225 ... 4 6

Protective guard

Order number

Working-ø (mm)

1 605 510 110 180

Flange for straight grinding wheels

1 605 703 028

Flange for tappered grinding wheels

Locking nut

SDS quick clamping flange

Page 20

3938

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: STRAI G HT G R I N DE R S.

0 602 225 101

0 602 225 104

0 602 225 107

0 602 225 204

0 602 225 211

0 602 233 201

0 602 233 204

0 602 233 207

0 602 233 304

0 602 226 201

0 602 226 204

0 602 226 207

0 602 227 204

0 602 227 211

0 602 228 201

0 602 228 204

0 602 228 207

0 602 228 211

0 602 229 101

0 602 229 104

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: STRAI G HT G R I N DE R S.

0 602 228 361

0 602 228 364

0 602 228 371

0 602 228 374

0 602 228 377

0 602 238 101

0 602 238 104

0 602 238 107

0 602 238 111

0 602 238 134

0 602 207 001

0 602 207 004

0 602 207 008

0 602 208 001

0 602 209 101

0 602 209 104

0 602 209 107

0 602 209 111

0 602 209 134

Page 21

4140

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: STRAI G HT G R I N DE R S.

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: STRAI G HT G R I N DE R S.

0 602 212 101

0 602 212 104

0 602 212 107

0 602 242 101

0 602 242 104

0 602 242 107

0 602 242 134

0 602 242 436

0 602 213 104

0 602 240 034

0 602 240 035

0 602 240 104

0 602 240 107

0 602 240 134

0 602 239 104

0 602 239 107

0 602 239 134

0 602 210 001

0 602 210 004

0 602 211 004

0 602 211 010

0 602 211 017

0 602 211 018

0 602 245 011

0 602 245 034

0 602 211 101

0 602 211 107

0 602 211 116

0 602 211 134

0 602 243 134

Page 22

4342

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: AN G LE G R I N D E RS.

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: AN G LE G R I N D E RS.

0 602 329 001

0 602 329 004

0 602 329 007

0 602 329 011

0 602 329 034

0 602 329 036

0 602 331 001

0 602 331 003

0 602 331 004

0 602 331 007

0 602 331 034

0 602 331 036

0 602 332 001

0 602 332 003

0 602 332 004

0 602 332 005

0 602 332 007

0 602 332 011

0 602 332 034

0 602 332 036

0 602 334 101

0 602 334 107

0 602 334 134

0 602 334 136

0 602 335 001

0 602 335 004

0 602 335 007

0 602 335 034

0 602 335 036

0 602 324 301

0 602 324 304

0 602 324 307

0 602 324 341

0 602 324 344

0 602 324 347

0 602 324 324

0 602 324 331

0 602 301 201

0 602 301 204

0 602 301 207

0 602 301 104

0 602 327 001

0 602 305 010

0 602 304 001

0 602 304 004

0 602 304 009

0 602 304 010

0 602 304 034

0 602 305 001

0 602 305 004

0 602 305 008

0 602 306 034

M14:11mm deep

for water hose with 10 mm

l

M14:11mm deep

M14:

11mm deep

Page 23

44

SCR EWDR IVE RS

TAPPERS

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS: D IS C SAN D E RS

AN D RAN DO M OR B IT SAN DE R S.

0 602 370 101

0 602 370 104

0 602 370 107

0 602 373 004

0 602 370 301

0 602 370 304

0 602 370 307

0 602 370 311

0 602 370 334

Page 24

4746

0,1 0,5 1 5 10 50 100 500 1000

Torque for hard screwdriving application as per ISO 5393 (Nm)

Hardness

class per

DIN 267

8.8 10.9

M 2.5 0.7 1.0

M 3 1.2 1.7

M 4 2.9 4

M 5 5.5 8

M 6 9.7 13.6

M 8 23 33

M 10 47 65

M 12 80 113

M 14 130 180

M 16 196 275

M 18 270 3 8 0

M 20 385 540

M 22 510 715

M 24 650 910

M 27 960 1345

M 30 1300 1830

Tightening

torque

Guideline values for maximum

bolt/screw tightening torques in

Nm. Assumed friction below head

m

ges.

= 0.12, calculated from the

stressed cross sections: yield point

usage 90 %. Valid for shaft screws

with standard metric thread as per

DIN 13, BL 13; heads as per

DIN 931, 933.

When you select a screwdriver,you

must consider not only the required torque – as a function of

the pretensioning force required

from the bolted connection – but

also the torque accuracy as a function of the bolting event. This

information has been compiled in

tables 1 and 2 in order to facilitate

the selection from among the

various bolting systems. The fixed

torque values provided apply to

“hard”bolted connections. The

maximum values are lower for

“soft”bolted connections (e.g.

spring washers, rubber washers,

etc.)

Order number

0 602 485 1..

0 602 488 1..

0 602 486 2..

0 602 489 0..

0 602 487 0..

0 602 442 0..

0 602 443 0..

0 602 440 0..

0 602 433 1..

0 602 438 0..

0 602 435 0..

0 602 439 0..

Screwdrivers with adjustable cut-off clutch

For screw connections with high torque accuracy

Torque upper range limited by reaction torques

Further advantages: low noise,low wear, long service life,

the user has no influence on the torque

Impact Wrenches

For large screw / bolt diameters with high torque

Virtually free of reaction torque,therefore no upward limitation

Torque is a decisive parameter for

controlling the pretension force

applied. The table provides an overview of the recommended torques

for common bolt and nut sizes.The

recommended maximum torques

apply to untreated,oil-lubricated

screws (coefficient of friction =

0.125). The torques correspond to

approx.62% of the yield point.

Torque accuracy

with automatic

shut-off

Torque accuracy

with overload

disengaging clutch

Torque accuracy

with percussion

mechanism

Torque Torque Torque Torque Torque

Rotation

Rotation

Rotation

Rotation

Rotation

Rotation

up to

approx.

30°

up to

approx.

60°

over 60°

angle of

rotation

not

definable

very good good to very good satisfactory –

depending upon

the degree of

accuracy required

somewhat

unsatisfactory

satisfactory –provided only a low

level of accuracy

is required

satisfactory

satisfactory

good to very good good to

satisfactory

satisfactory

satisfactory

good

good – provided

cut-out function

is still operative

good – provided

cut-out function

is still operative

good – provided

cut-out function

is still operative

good – provided

cut-out function

is still operative

goodgood – provided

that the function

is still operative

Bolting event Angle of

rotation

to M

d

max.

Torque accuracy depending

on screwdriver system and

screwdriving type

The torque that can be achieved for

a screw connection depends on the

type of screwdriving / bolting situation. To achieve a balanced basis for

assessment, all data on screwdrivers

is based on unbending,or “hard”

screw connections (30° angle of

rotation).In the case of flexible or

“soft”screw connections,achievable

values are,in part, considerably

belowthe nominal values. Furthermore , torq ue v a r i a n ce increases. Due

to the wide varie ty of possibilities,

specifications with absolute values

are not possible. If in doubt, use a

trial and error system. The table

offers an overview of the advantages

and achievable torque accuracy of

the individual screwdriver s ystems

with various characteristic screwdriving applications.

Torque

SEL EC TI ON GUI D E FO R SC REWD R IVER S.

Page 25

Accessory part

number

Comes complete

with

Toolholding fixture

Hex. = hexagon

Remarks

Weight without

cabel (kg)

Nominal current (A)

Nominal power

output (W)

Nominal capacity

Output (W)

No load speed

(rpm)

Torque (Nm) for hard

screwdriving application

as per ISO 5393

Max.

thread size

Frequency (Hz)

Voltage (V)

Order number

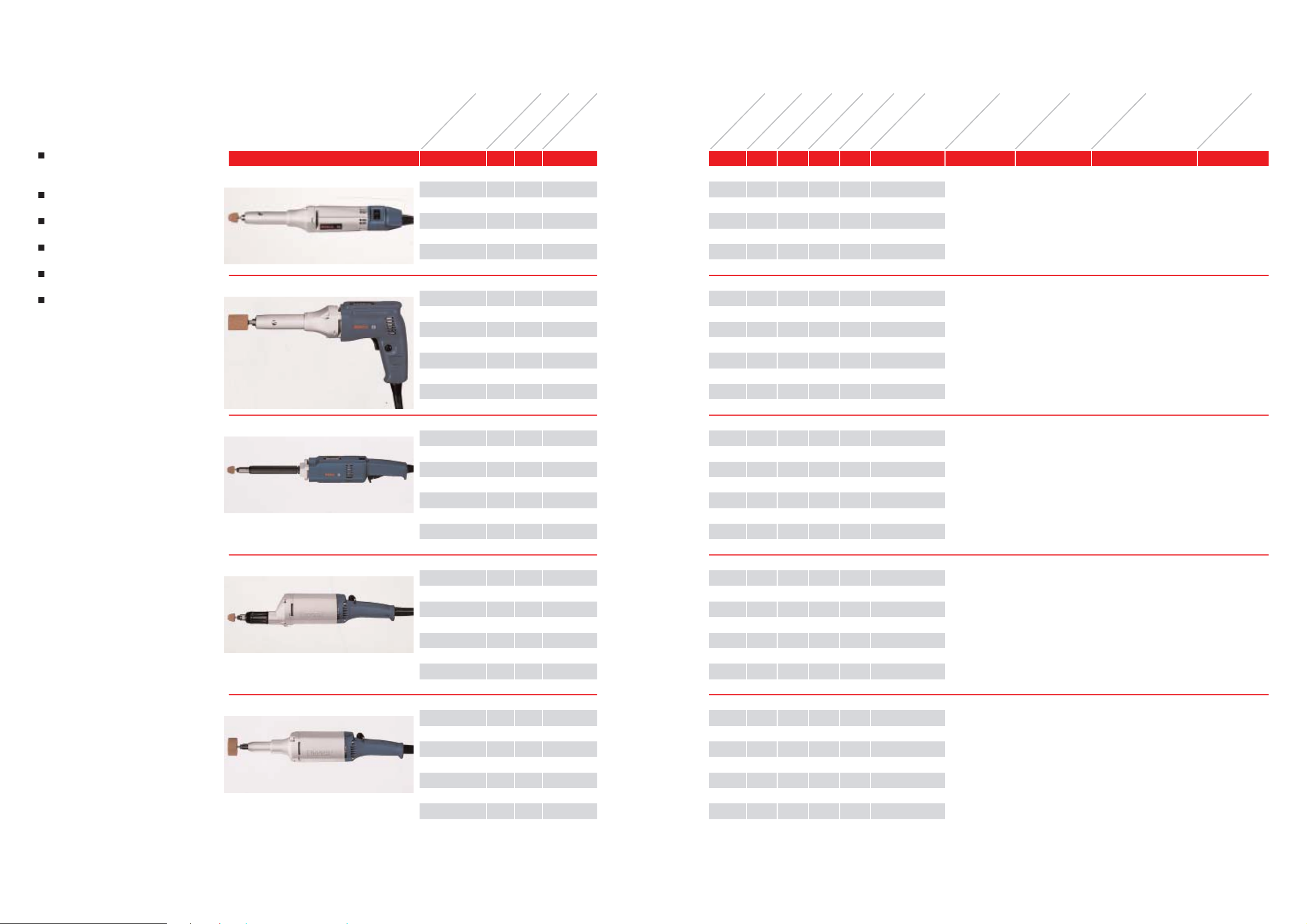

CUT-O UT SC R EWD RIVER S.

1 607 950 0370 602 485 101 265 200 M 4

0 602 485 104 135 200 M 4

0 602 485 118 42 300 M 4

0.8–2.5 840 80 40 0.2 0.8 1/4

HH Hex.

0.8–2.5 840 80 40 0.5 0.8 1/4

HH Hex.

0.9–3.0 1260 125 65 2.4 0.8 1/4

HH Hex.

Gib-head key

for torque adjustment

Handle grip

with ON/OF F and

reverse switch

HS R 44-A

with adjustable cut-out

clutch for screws from

M4 to M10

The machines come equipped with a special 4-m-long cable without plug.

1 607 950 037

0 602 488 101 265 200 M 6

0 602 488 104 135 200 M 6

0 602 488 107 72 200 M 6

0 602 488 104 200 300 M 6

0 602 488 118 42 300 M 6

3–6 840 170 85 0.5 1.1 1/4

HH Hex.

3–6 840 170 85 1.0 1.0 1/4

HH Hex.

3–6 840 170 85 1.8 1.0 1/4

HH Hex.

3.2–6.5 1260 265 135 1.0 1.0 1/4

HH Hex.

3.2–6.5 1260 265 135 5.0 1.0 1/4

HH Hex.

Gib-head key

for torque adjustment

Handle grip

with ON/OF F and

reverse switch

HS R 48-A

1 607 950 037

0 602 486 201 265 200 M 6

0 602 486 204 135 200 M 6

0 602 486 204 200 300 M 8

3.5–12 590 260 140 0.9 2.1 1/4

HH Hex.

3.5–12 590 260 140 1.7 1.7 1/4

HH Hex.

4–13 900 400 220 1.7 1.7 1/4

HH Hex.

Gib-head key

for torque adjustment

Middle grip

with ON/OF F and

reverse switch

HS R 55-A

1 607 950 037

0 602 489 001 265 200 M 8

0 602 489 004 135 200 M 8

0 602 489 007 72 200 M 8

0 602 489 004 200 300 M 8

5–17 690 400 270 1.6 2.3 1/4

HH Hex.

5–17 690 400 270 3.3 2.3 1/4

HH Hex.

5–17 690 400 270 6.1 2.3 1/4

HH Hex.

6–20 1040 600 400 3.3 2.3 1/4

HH Hex.

Gib-head key

for torque adjustment

Pistol grip

with ON/OF F and

reverse switch

HS R 57-A

1 607 950 037

0 602 487 001 265 200 M 10

0 602 487 004 135 200 M 10

0 602 487 007 72 200 M 10

9–24 780 350 200 1.0 2.8 1/4

HH Hex.

9–24 780 350 200 2.0 2.8 1/4

HH Hex.

9–24 780 350 200 3.0 2.8 1/4

HH Hex.

Gib-head key

for torque adjustment

Middle grip

with ON/OF F and

reverse switch

HS R 64-A

48 49

Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 26

5150

Comes complete

with

Accessory part

number

Toolholder Drive

Hex. = hexagon

Sq. = external square

Weight without

cabel (kg)

Nominal current (A)

Nominal power

output (W)

Nominal capacity

Output (W)

No load speed

(rpm)

Torque (Nm) for hard

screwdriving application

as per ISO 5393

Max.

thread size

Frequency (Hz)

Voltage (V)

Order number

IMPACT WRENCHES.

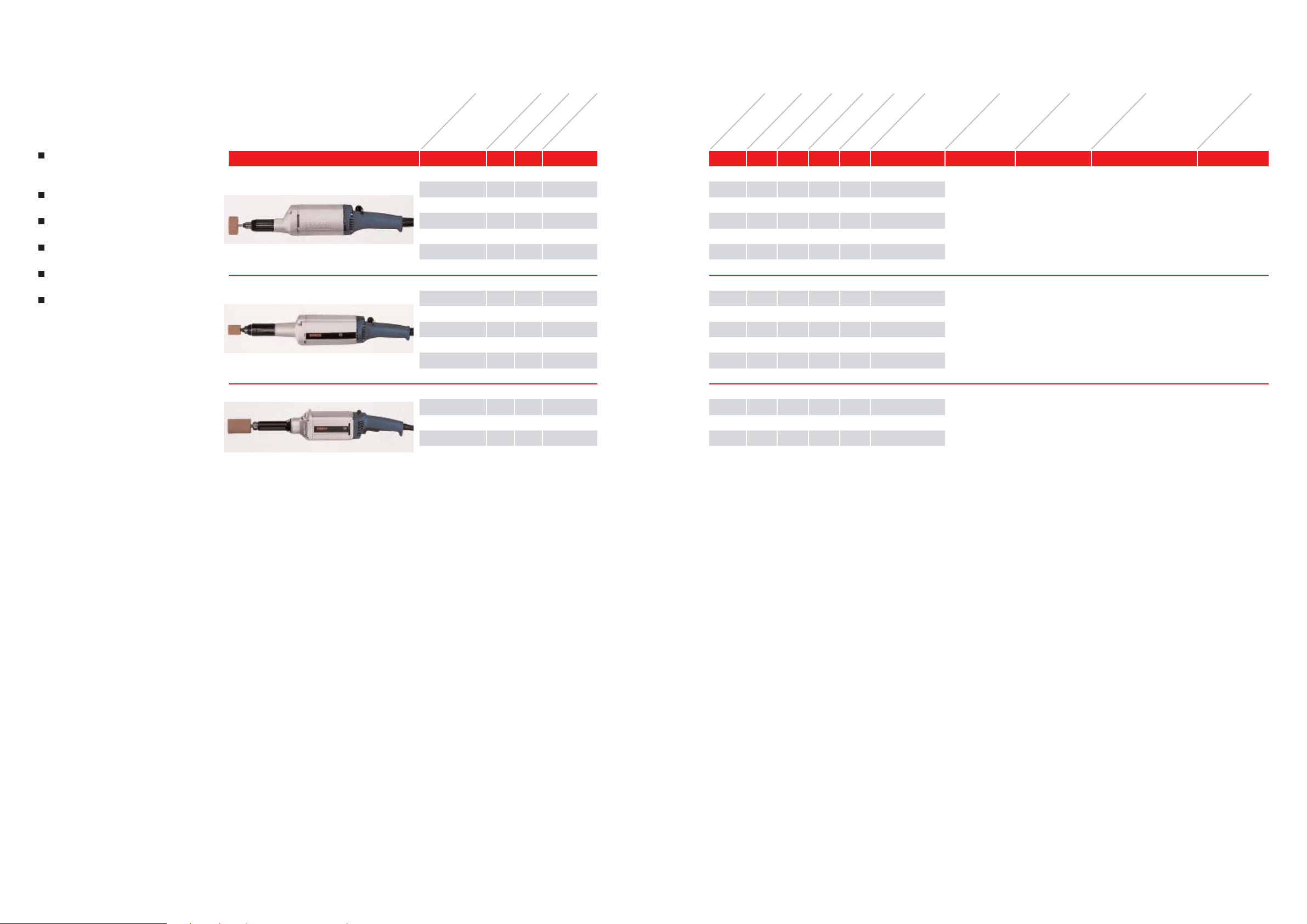

0 602 442 001 265 200 M 10

0 602 442 004 135 200 M 10

0 602 442 007 72 200 M 10

0 602 443 004 200 300 M 10

30 1650 170 85 0.5 1.1 1/4

HH Hex.

30 1650 170 85 1.0 1.1 1/4

HH Hex.

30 1650 170 85 1.8 1.1 1/4

HH Hex.

30 1780 265 135 1.0 1.1 1/4

HH Hex.

Handle grip with

ON/OF F and

reverse switch

HSS 48

Remarks

impact wrenches for

screws from M6 to M30

0 602 440 001 265 200 M 12

0 602 440 004 135 200 M 12

80 1410 260 140 0.9 2.4 1/2HH Sq. with spring pin

80 1410 260 140 1.7 2.4 1/2

HH Sq. with spring pin

Handle grip with

ON/OF F and

reverse switch

HSS 55

0 602 435 001 265 200 M 22

0 602 435 004 135 200 M 22

0 602 435 008 72 200 M 22

350 800 850 580 2.2 5.6 3/4HH Sq.

350 800 850 580 4.5 5.6 3/4

HH Sq.

350 800 850 580 8.5 5.6 3/4

HH Sq.

Palm grip with

ON/OF F and

reverse switch

Auxiliary handle 1 602 025 03 0

HSS 75

0 602 433 101 265 200 M 16

0 602 433 104 135 200 M 16

0 602 433 107 72 200 M 16

0 602 438 004 200 300 M 16

190 1100 360 220 1.0 3.0 1/2

HH Sq. without spring pin

190 1100 360 220 2.0 3.0 1/2

HH Sq. without spring pin

190 1100 360 220 3.7 3.0 1/2

HH Sq. without spring pin

190 1100 550 340 2.0 3.0 1/2

HH Sq. without spring pin

Centre grip with

ON/OF F and

reverse switch

HSS 64

0 602 439 001 265 200 M 30

0 602 439 004 135 200 M 3 0

0 602 439 007 72 200 M 30

1000 600 950 700 2.8 8.6 1HH Sq.

1000 600 950 700 5.5 8.6 1

HH Sq.

1000 600 950 700 10.0 8.6 1

HH Sq.

Two handled grip

with ON/OF F and

reverse switch

HSS 77

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 27

Accessory part

number

Comes

complete with

Remarks

Toolholding

fixture

Weight without

cabel (kg)

Nominal current (A)

Nominal power

output (W)

Nominal power

consumption (W)

Reverse

No load speed

(rpm) forward

Nominal power

consumption [W]

Spacebolt

l (mm)

Working range

thread

l

(mm)

Frequency (Hz)

Voltage (V)

Order number

TAPPERS.

0 602 463 101 265 200 8 6

0 602 463 104 135 200 8 6

0 602 463 107 72 200 8 6

3–10 380 750 260 150 0.9 2.3 Cone B 12 DIN 238

3–10 380 750 260 150 1.7 2.3 Cone B 12 DIN 238

3–10 380 750 260 150 3.2 2.3 Cone B 12 DIN 238

HGR 55/1 0

tappers for threads up

to 8 mm in diameter

3 608 573 000

3 603 111 004

3 603 111 005

3 603 111 003

2 607 950 012

Two-jaw drill chuck

Fastening key

for 3.0 mm high

for 3.3 mm high

for 3.6 mm high

Spare key

52 53

The machines come equipped with a special 4-m-long cable without plug. Your specialist dealer can provide you with information on the complete set of quality accessories.

Page 28

0 602 433 ...

0 602 442 ...

0 602 489 ...

0 602 486 ...

0 602 488 ...

0 602 485 ...

55

Order number

Dimensions mm

DI ME NS IO NAL DRAWI N GS:

CUT-OUT SCR EWDRIVERS.

0 602 485 101

0 602 485 104

0 602 485 118

0 602 488 101

0 602 488 104

0 602 488 107

0 602 488 118

0 602 486 201

0 602 486 204

0 602 489 001

0 602 489 004

0 602 489 007

0 602 487 001

0 602 487 004

0 602 487 007

ACCESSORI ES FOR SHUT-OFF SCREWDRIVER.

SP EC IAL ACCESS OR IES FO R S CR EWD R IVER S.

Order number

Packing unit

3 604 682 001

••

1

3 604 682 000

••

1

Hanging hook

Order number

Packing unit

3 604 682 001 1

2 910 021 118

•••

1

1 606 455 012

•

1

0 602 440 ...

0 602 443 ...

Loop hanger

Cylinder screws for fastening

Quick-change collet chuck 7/16

HH

Your specialist dealer can provide you with information on the complete set of quality accessories.

54

Page 29

Order number

M14; 11 deep

M24x2 13 deep

Order number

Dimensions mm

DI ME NS IO NAL DRAWIN GS: I M PACT WRE NCH ES.

0 602 433 101

0 602 433 104

0 602 433 107

0 602 438 004

0 602 435 001

0 602 435 004

0 602 435 008

0 602 439 001

0 602 439 004

0 602 439 007

56

Order number

Dimensions mm

Dimensions mm

DI ME NS IO NAL DRAWIN GS: I M PACT WRE NCH ES.

DI ME NS IO NAL DRAWI N GS: AN G LE WR E N CH ES.

0 602 442 001

0 602 442 004

0 602 442 007

0 602 443 004

0 602 440 001

0 602 440 004

0 602 463 101

0 602 463 104

0 602 463 107

57

Cone B12 DIN 238

with transverse key

Two-jaw drill chuck

Page 30

5958

ACCESSORIES

Page 31

6160

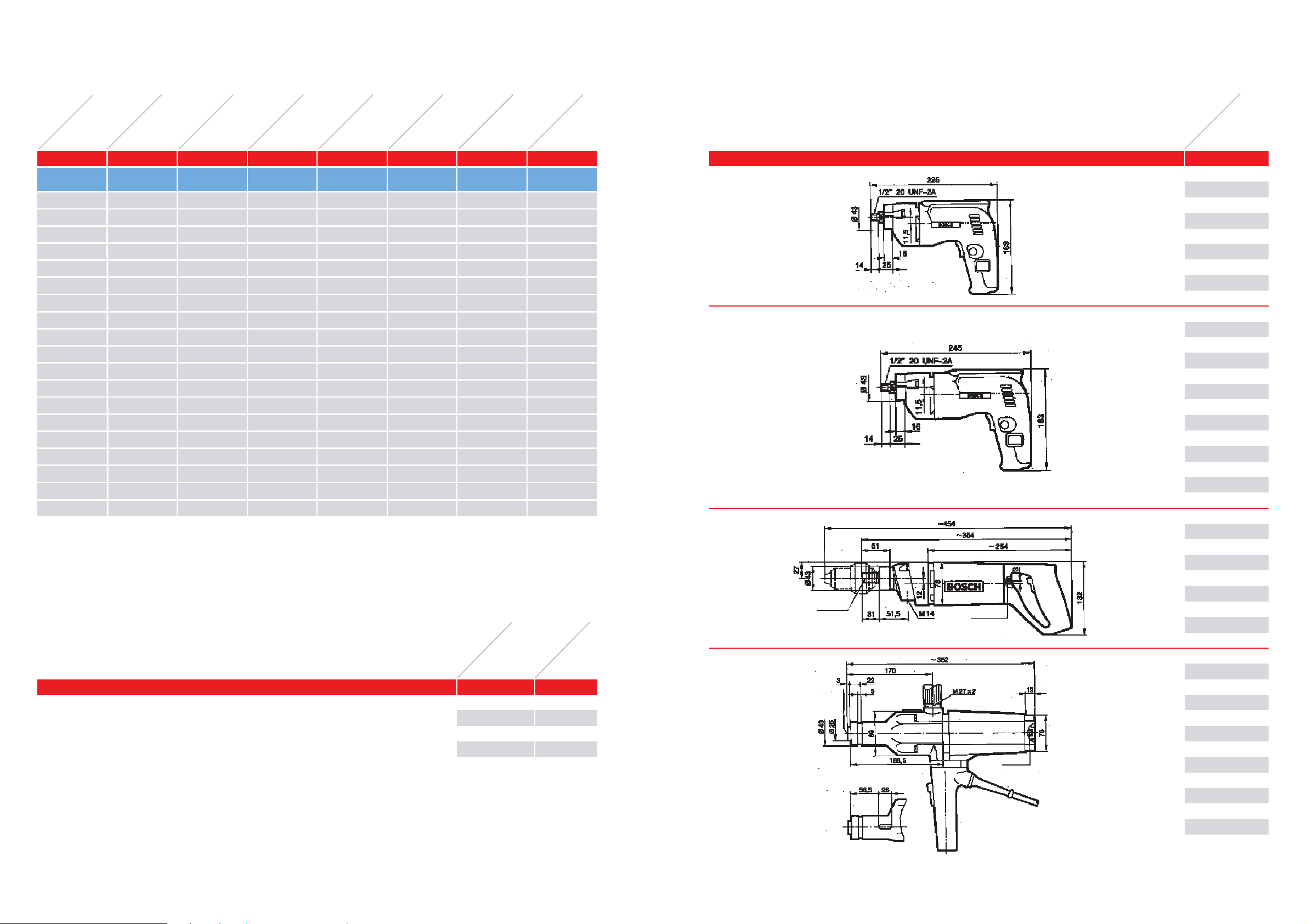

Order number

BAL ANC ER .

Robust metal safety hanger including spring hook

Bowden cable with high-quality

distributor valve and safety coupling for uniform pulling out behaviour

Spring fracture safety device

balancers with a load burden

greater than 3 kg

Cable change possible without

disassembly of the spring drum

Simple change of the weight class

through modular structure

Balancer

0 607 950 920

Balancer

for loads

from 0.3 to 17 kg

0 607 950 921

0 607 950 922

0 607 950 923

0 607 950 931

0 607 950 937

Balancer

0 607 950 924

0 607 950 925

0 607 950 926

Balancer

0 607 950 927

0 607 950 928

Balancer

Remarks

Weight

(kg)

Max. lift

(mm)

Load

max. (kg)

Load

min. (kg)

0.3 1.2 1200 0.5 Spring balancer with adjustable load range

Your specialist dealer can provide you with information on the complete set of quality accessories.

0.6 1 2000 0.7

1 2 2000 0.7

2 3 2000 0.8

0.5 2 2000 0.7

1.5 3 2000 0.8

Spring balancer with adjustable load range

Balancer with adjustable load range with lock

3 5 2000 3

6 8 2000 3.2

8 10 2000 3.4

Spring balancer with adjustable load range

9 14 2000 3.4

13 17 2000 3.6

Spring balancer with adjustable load range

Page 32

6362

HIGH-FREQUENCY

TECH NOLOGY

PLU G CO N N E CTI O N S, LEADS.

Connector plug

Coupling socket

Wall socket

Order number

Voltage (V)

Load capacity (A)

Packing unit

1 614 482 048 50 – 300 16 1

1 614 482 049 50 – 300 32 1

1 614 482 050 to 50 32 1

1 614 484 010 50 – 300 16 1

1 614 484 011 50 – 300 32 1

1 614 484 012 to 50 32 1

1 614 485 024 5 0 – 3 00 16 1

1 614 485 025 5 0 – 3 00 32 1

1 614 485 026 to 50 32 1

CEE plugged connections DI N 49 4 62/63 and DI N 49

465 for frequencies from 100 to 300 Hz (green housing)

4-core cable

(length 50 m)

3-core cable

(length 50 m) for 42 V operating voltage

working lenght 4 m (spiral line)

working lenght 6 m (spiral line)

Order number

Material number

Lead cross-

section (mm

2

)

Outer-Ø (mm)

3 604 422 003* 6 254 812 403 0.75 18

3 604 422 077* 3 6 0 4 422 023 1.50 11

3 604 422 050* 3 604 422 024 2.50 13

3 604 462 002 0.75 8

3 604 462 003 0.75 8

3 604 422 004 6 254 811 303 0.75 17

*unpacked

Electrical leads

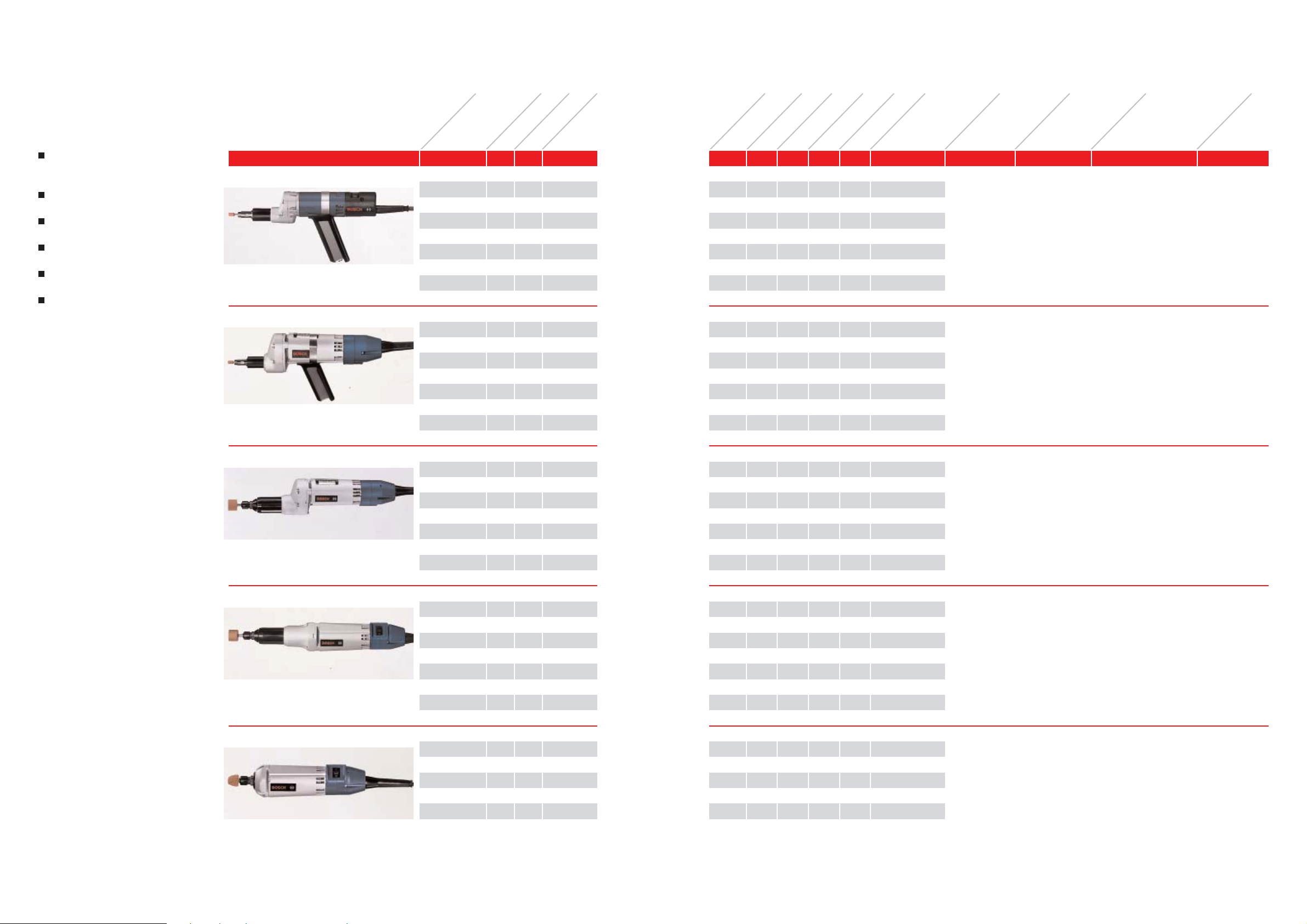

Frequency converters can be obtained from: EM E GmbH · Postfach 0306 · D-78257 Ettlingen · Telephone 0 7243/32 0 6 0 6 · Fax 072 43/32 0 6 11 or 32 0612