Page 1

MODEL 125BO LP and 125BO NG - OUTDOOR MODEL

For exterior use only

Piezo Ignition

Suitable for heating potable water only

Not approved for space heating purposes

AQ 125 BO NG - Natural Gas

AQ 125 BO LP - Liquefied Petroleum (LP) Gas

Warning: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Do not store or use gasoline or other flammable

vapor and liquids in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration, service

or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer,

service agency or the gas supplier.

In the Commonwealth of Massachusetts this

product is approved only for seasonal use.

Installation must be performed by a licensed

plumber or gas fitter.

Upon completion of the installation, these

instructions should be handed to the user of the

appliance for future reference.

8 716 473 147 US (05.12) AL

What to do if you smell gas

• Close gas valve.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• If you cannot reach your gas supplier, call the fire

department.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions

•

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Page 2

Index

Index

1 Warning 2

2 Appliance details 4

2.1 Features 4

2.2 AQ125 BO specifications (Technical data) 4

2.3 Unpacking the AQ-125-BO heater 5

2.4 General rules to follow for safe operation 5

2.5 Dimensions and installation clearances 6

3 Installation instructions 7

3.1 Introduction 7

3.2 Proper location for installing your heater 7

3.3 Heater placement and clearances 8

3.4 Mounting installation 8

3.5 Gas piping & connections 10

3.6 Measuring gas pressure 12

3.7 Water connections 12

3.8 Electrical connections 13

4 Operation instructions 14

4.1 For your safety read before operating your water

heater 14

4.2 Lighting instructions 14

4.3 To turn off appliance 14

4.4 Setting the water temperature 14

5 Maintenance and service 16

5.1 Maintenance intervals 16

5.2 Water valve 16

5.3 Pilot 16

5.4 Main burners 16

5.5 Vent assembly 16

5.6 Mineral scale build-up 16

1 Warning

Warning: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

Warning: Improper installation,

adjustment, alteration, service or

maintenance can cause injury or

property damage. Refer to this manual.

For assistance or additional information

consult a qualified installer, service

agency or the gas supplier.

Upon completion of the installation,

these instructions should be handed to

the user of the appliance for future

reference.

Featuring

Piezo Ignition

For your safety

Do not store or use gasoline or other flammable,

combustible or corrosive vapors and liquids in the

vicinity of this or any other appliance.

Warning: Carefully plan where you

install the heater. If a gas appliance is

not installed correctly, fatal accidents

can result from lack of air, carbon

monoxide poisoning or fire.

6 Troubleshooting 17

6.1 Introduction 17

6.2 Pilot will not light 17

6.3

Pilot will light but not stay on when button released

6.4 Burner do not ignite with water flow 17

6.5 Hot water temp fluctuates from hot to cold 17

6.6 Water is too hot 18

6.7 Water is not hot enough 18

7 Interior components and diagram parts list 19

7.1 Interior components 19

7.2 Components diagram 20

7.3 Parts list 21

8 Protecting the environment 22

9 Twelve Year Limited Warranty 23

17

2

Warning: Place the heater in a location

where water leaks will do NO DAMAGE

to adjacent areas.

8 716 473 147

Page 3

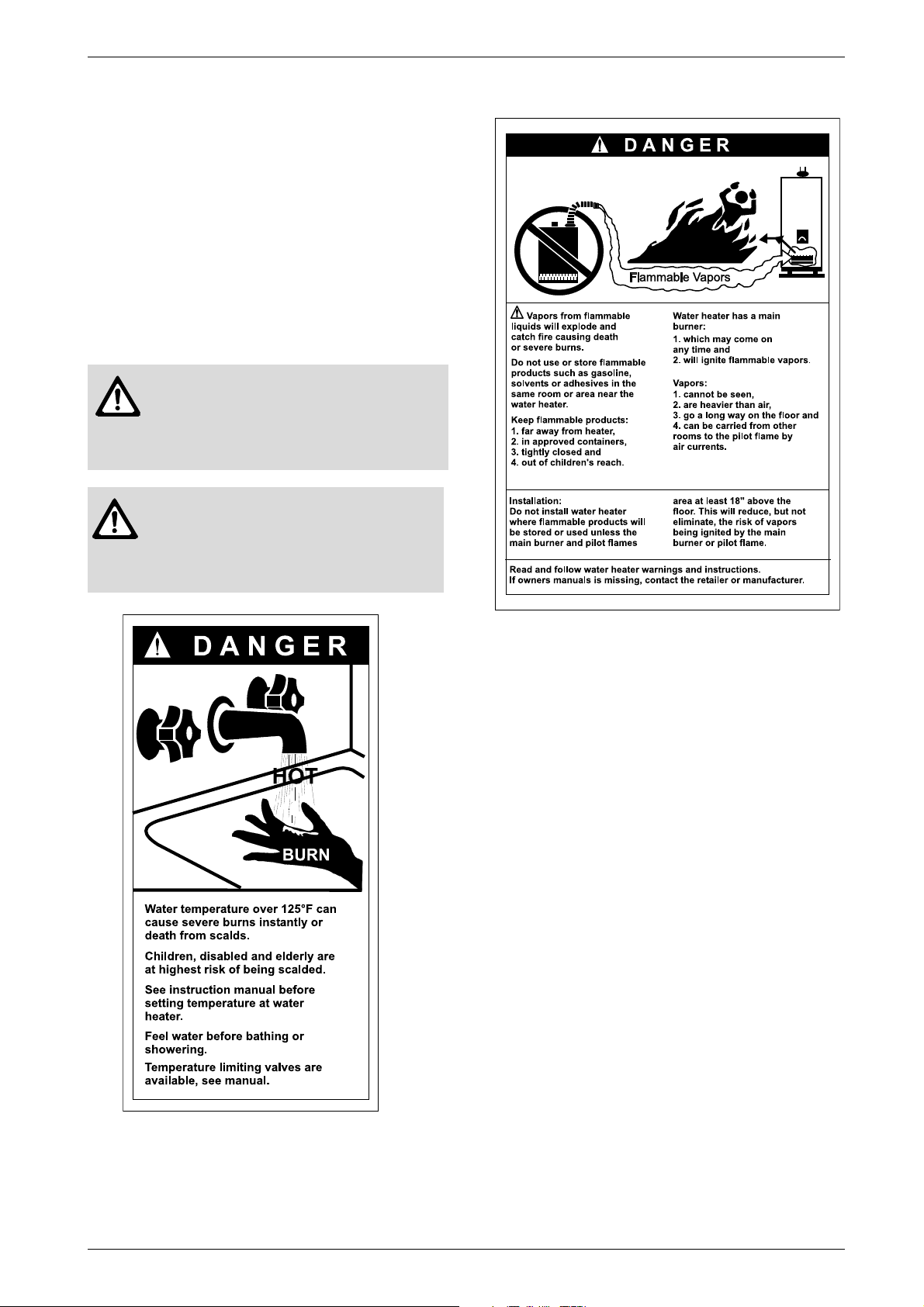

What to do if you smell gas

• Close gas valve.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Warning: The heater must be isolated

from the gas supply piping system

during any pressure testing of that

system at test pressures equal to or

more than 0.5 psig.

Warning

Caution: Any changes or

modifications not expressly approved

by the party responsible for compliance

could void the user’s authority to

operate the equipment.

Fig. 2

Fig. 1

8 716 473 147

3

Page 4

Appliance details

i

2 Appliance details

2.1 Features

• Burner output proportional to hot water flow demand

for maximum energy efficiency

• Stainless steel burners with stabilized blue flame

• Built-in corrosion resistant draft diverter

• Adjustable water flow restrictor to ensure that water

flow demand will not exceed the heating capacity of

the heater

• Safety thermocouple at pilot burner

• Automatic overheating protection shut-off sensor

• Copper heating coils for endless supply of hot water

• Easily removable one-piece cover

• Easy one person installation

• Easy Pilot Flame Ignition with push button piezo

ignition.

BOSCH is constantly improving its

products, therefore specifications are

subject to change without prior notice.

2.2 AQ125 BO specifications

(Technical data)

Approved in US/Canada

Capacity

Maximum flow rate: 3.7 GPM (14 l/min) at a 45°F

(25°C) rise.

• Cold water connection (inches) - ½”

• Water valve material: Polymer (PPS) (Polypropylene

Sulfid)

• Minimum water flow: 0.5 gallon/minute (1.9 l/m)

• Minimum recommended water pressure: 30 PSI

(2.07 bar)

• Connections:

– Bottom of heater

Dimensions

• Depth (in): 10.5” (265 mm)

• Width (in): 18.25” (460 mm)

• Height (in): 36.75” (936 mm)

• Weight: 64 pounds (29 kg).

Gas types

Natural Gas.

LP Gas

Safety devices

• Flame failure device (ionization flame rod sensor)

• Pressure relief valve (supplied with heater)

• Over heat prevention (temperature limiter).

Water resistant

IP X5 (protection against water drops).

Maximum output

101,772 Btu/h (29.8 kW)

Maximum input

117,000 Btu/h (34.3 kW)

Efficiency in %

Recovery efficiency 80%

Min. Output

28,000 Btu/h (8.2 kW)

Gas Requirement

Gas connection (inches) - ¾”

Inlet gas pressure under maximum operation*

• Propane: 10.5” - 14” water column

• Natural Gas: 5.7” - 14” water column.

* To measure Gas Pressure, see Measuring Gas

Pressure, chapter 3.6.

Water

• Hot water connection (inches) - ½”

4

8 716 473 147

Page 5

Appliance details

2.3 Unpacking the AQ-125-BO heater

This heater is packed securely.

Before installing the unit, be certain you have the

correct heater for your type of Gas - Propane or

Natural Gas. Identification labels are found on the

shipping box, and on the rating plate which is located on

the right side panel of the cover.

The box includes:

• Pressure relief valve

• Heat shield

• Mounting screws

• Product registration card

• Installation manual.

Do not lose this manual, there is a charge for a

replacement.

Please complete and return the enclosed product

registration card.

The AQ125 BO is not approved or designed for:

• Manufactured (mobile) homes, RV's or boats

• Heating or other recirculating/pumping applications*

• Solar/preheat backup or high temperature booster

use

* This includes domestic hot water circulator pump loop

systems that may previously exist in a home hot water

system. The use of a small electric mini-tank (4-6 gallon

size) should be used for this application; when

designed so the pump will circulate the hot water in the

mini-tank only and through the building's hot water

return loop (timed or thermostatic controlled operation

of the pump is commonly done). The AQ125 BO should

be plumbed in line before the mini-tank water heater,

contact BBTNA if further instruction is needed.

2.4 General rules to follow for safe

operation

B 1. You should follow these instructions when you

install your heater. In the United States: The

installation must conform with local codes or, in the

absence of local codes, the National Fuel Gas Code

ANSI Z223.1/NFPA 54.

In Canada: The Installation should conform with

CGA B149.(1,2) INSTALLATION CODES and /or

local installation codes.

B 2. Carefully plan where you install the heater. Proper

clearances must be followed.

B 3. The appliance must be isolated from the gas

supply piping system by closing its individual manual

gas shutoff valve (not supplied with heater) during

any pressure testing at pressures in excess of ½ Psig

(3.5 kPa).

The appliance and its gas connection must be leak

tested before placing the appliance in operation.

B 4. Keep water heater area clear and free from

combustibles and flammable liquids. Do not locate

the heater over any material which might burn.

B 5. Correct gas pressure is critical for the optimum

operation of this heater. Gas piping must be sized to

provide the required pressure at the maximum output

of the heater, while all the other gas appliances are in

operation. Check with your local gas supplier, and

see the section on connecting the gas supply.

B 6. Should overheating occur or the gas supply fail to

shut off, turn off the gas supply at the manual gas

shut off valve, on the gas line. Note: manual gas

shutoff valve is not supplied with the heater.

B 7. Do not use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been underwater.

8 716 473 147

5

Page 6

Appliance details

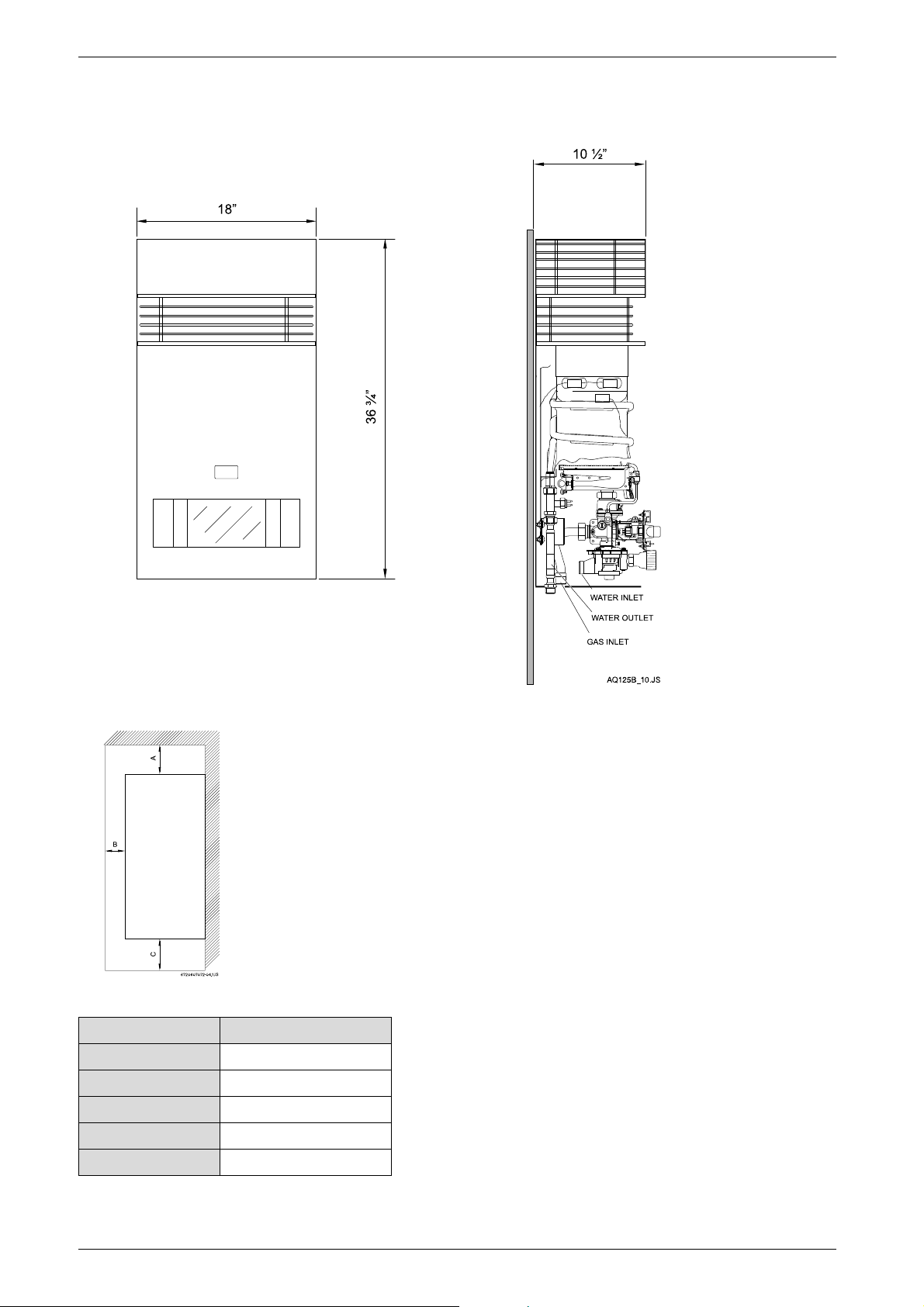

2.5 Dimensions and installation clearances

Fig. 3 Dimensions

Fig. 4 Minimum clearances

Model AQ125 BO

TOP (A) 3 ft.

FRONT (B) 4 ft.

BACK 0”

SIDES 4 ft.

BOTTOM (C) 1 ft.

Table 1 Minimum clearances

6

8 716 473 147

Page 7

3 Installation instructions

Installation instructions

3.1 Introduction

Please follow these instructions. Failure to follow

instructions may result in:

B Damage or injury.

B Improper operation.

B Loss of warranty.

Please contact BBT North America with any questions.

3.2 Proper location for installing your

heater

Carefully select the location of the water heater.

Follow the guidelines below:

B 1. Locate the heater where an adequate gas line size

and plumbing connections are feasible and

convenient.

B 2. The hot water lines should be kept short to save

energy. Centrally locating the water heater is best. It

is always best to have hot water lines insulated to

prevent the possibility of any freeze damage.

B 3. The water in this heater is cold and always remains

cold except for the times that hot water is being used.

The heater is equipped with freeze prevention

equipment that will operate and prevent freezing of

the water in the heater to 5°F with no wind chill.

Electrical power must be maintained to the heater to

allow this to function.

Danger: Flue gases will be released

through the vent cap. Flue gas is very

hot and contains carbon monoxide. The

heater cannot be installed indoors. To

prevent risk of fire and poisoning by

carbon monoxide, assure all clearances

indicated in manual.

Danger: Surface temperature around

vent cap is less than 140°F, except

highest top surface of vent cap may

reach 300°F.

Danger: Do not place or store any

combustible material within 5 feet of the

appliance. Risk of fire could be caused

by hot flue gas.

Warning: Flammable materials,

gasoline, pressurized containers, or any

other items or articles that are potential

fire hazards must NOT be placed on or

adjacent to the heater. The appliance

area must be kept free of all

combustible materials, gasoline and

other flammable vapors and liquids.

WARNING: Proper insulation of the

water lines below the heater is required

if below freezing temperatures, below

32°F, are ever anticipated!

Danger: If the temperature drops

below 32°F, freeze damage to the water

heater itself must be prevented by

turning off the power to the heater, then

disconnecting the plumbing connections, as well as removing the drain

plug and introducing short bursts of

compressed air (20-40 psi) through the

heater's connections. This will remove

the residual water in the horizontal

pipes and water valve.

Danger: Keep children away as the top

of the water heater vent cap will get very

hot during operation. Install in a place

that prevents the top of the heater being

reached by small children.

8 716 473 147

7

Page 8

Installation instructions

i

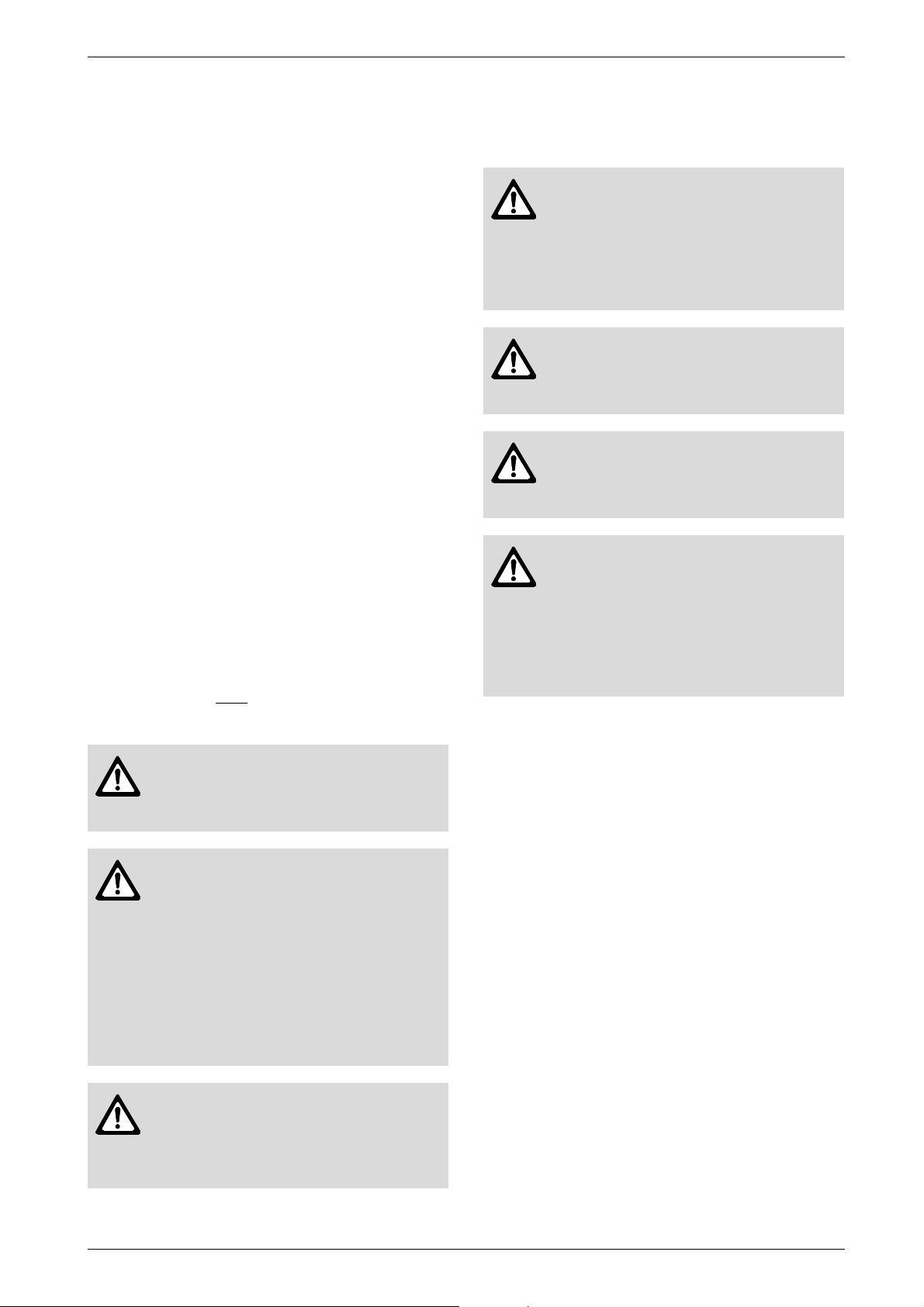

3.3 Heater placement and clearances

The AQ125 BO is design certified for installation

directly on a combustible wall. (see 3.4 Mounting

installation). For installation on vinyl siding see Fig. 7.

Keep the area below the heater free of combustible

material.

Minimum clearances

If the appliance is installed under an overhang, there

must be a 36” clearance from the top of the appliance

and the mounting area must be open in front and on the

sides of the appliance.

3.4 Mounting installation

Warning: before starting installation:

B check that there are no loose parts

inside the appliance

B ensure that gas pipe, gas valve, and

burner have no damage and are

properly fitted.

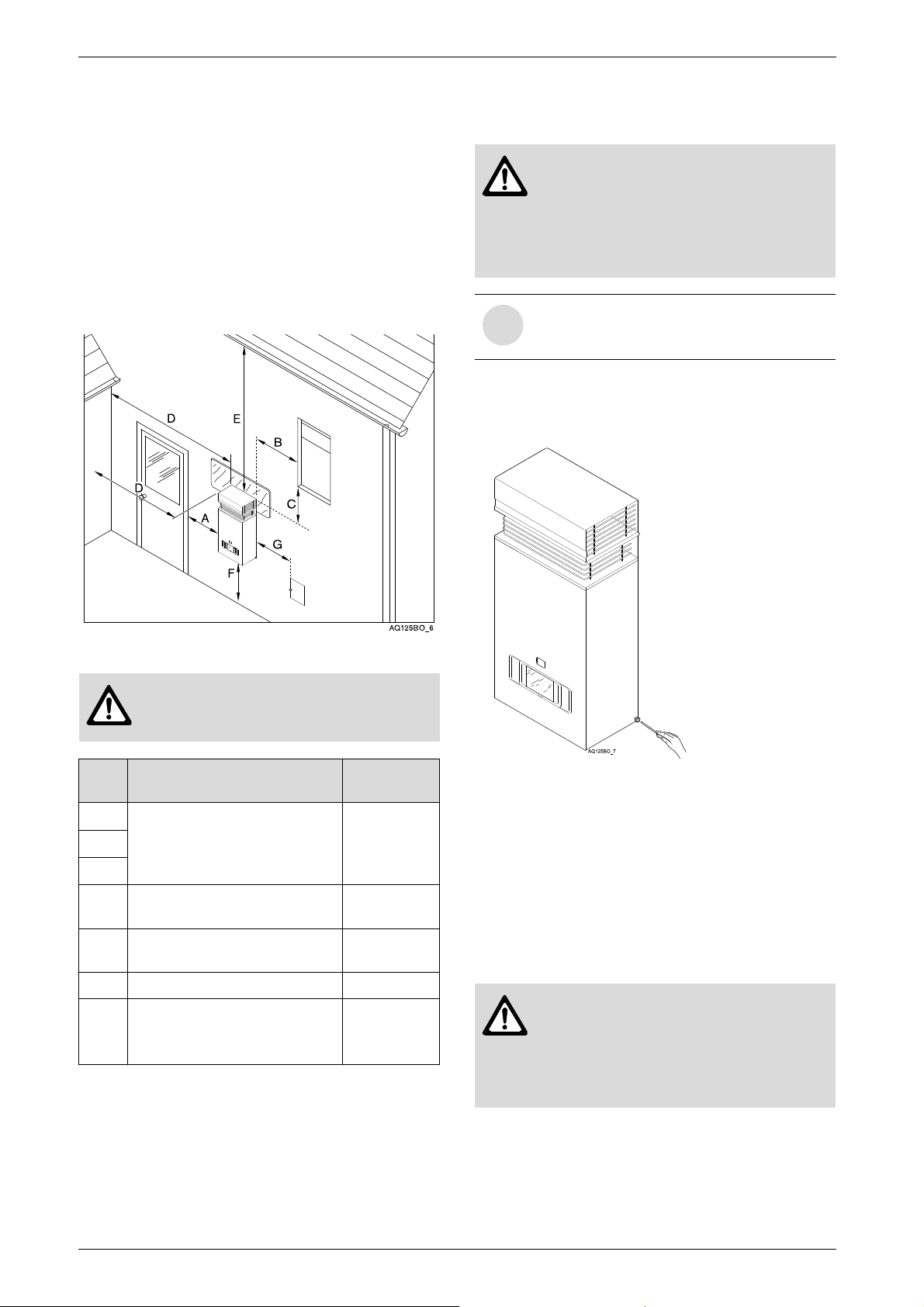

Front cover should be removed in order to

inspect components visually (see

instructions below).

To remove front cover.

B Loosen the two screws located on the sides of the

front panel, see Fig. 6.

Fig. 5

Danger: The top of the kit will get hot

due to the flue gases. Install away from

children.

Ref. Description

A Directly below or from an

B

C

D

E

F Above ground ≥ 1 ft

G

Table 2 Clearances

opening; operable windows,

doors and any fresh air

openings

From any adjacent wall or tall

shruberry

Below a gutter, sanitary

pipework, eaves or overhang

From a gas meter, gas

regulator, electrical box or

another 125 BO heater.

Min.

distances

≥ 4 ft

≥ 4 ft

≥ 3 ft

≥ 3 ft

Fig. 6 Remove front cover

B Ensure that the flue terminal is clear of any

combustible material.

B After inspection, replace front cover and tighten

screws.

B Install only on an external wall, as close as possible

to the most frequently used hot tap (note clearances

in chapter 3.3).

B If the unit is to be installed on a combustible surface

use the enclosed heat shield (see Fig. 5).

Warning: Do not mount heater directly

to vinyl siding. With vinyl siding

surfacing, a 6' x 4' area of the siding

must first be covered or replaced with

wood or other non-plastic made

material. See Fig. 7.

8

8 716 473 147

Page 9

Fig. 7

B Secure heater to wall using enclosed mounting

screws. Use mounting template for proper screw

location.

B Locate head of screw in the key hole of the top

mounting bracket.

Installation instructions

Vent Safety System

The AQ125 BO will shut down if the intake or exhaust

louvers on the vent cap are blocked for any reason; see

troubleshooting section on page 17.

8 716 473 147

9

Page 10

Installation instructions

3.5 Gas piping & connections

Before connecting the gas supply, check the rating

plate on the right side of the heater to be sure that the

heater is rated for the same gas to which it will be

connected.

In the United States: The installation must conform with

local codes or, in the absence of local codes, the

National Fuel Gas Code ANSI Z223.1/NFPA 54.

In Canada: The Installation should conform to CGA

B149 INSTALLATION CODES and/or local installation

codes.

Note: The 125 BO comes with a gas pressure

regulator installed. Disconnecting or altering the gas

pressure regulator will be a violation of CSA

certification of the unit. The regulator supplied with the

heater is preset for the gas shown on the rating plate to

the correct pressure. It is an appliance level regulator

designed for (low inlet) pressure (less than 1/2 Psig or

14" W.C.).

Warning: DO NOT connect to an

unregulated or high pressure propane

line or to a high pressure commercial

natural gas line.

Danger: If you have a leak, shut off the

gas. Tighten appropriate fittings to stop

leak. Turn the gas on and check again

with a gas leak detection solution.

Never test for gas leaks using a match

or flame.

HIGH ALTITUDE INSTALLATION

The pressure regulator provided with the heater is

adjusted to deliver the proper gas pressure (as

indicated on the rating plate and in the manual for

altitude up to 2000 feet (660 meters) above sea level.

On appliances being installed above 2000 ft (660

meters) elevation, the inlet gas pressure should be set

at installation to the value shown below.

Note: The gas pressures specified below refer to

pressures taken at the pressure tap on the gas inlet pipe

just above the regulator. See chapter 3.6 for measuring

gas pressure.

MAXIMUM INLET GAS FLOW PRESSURE SETTING

Altitude

0’ - 2 000 ft 5.7” 10.5”

Nat. Gas

inches W.C.

Liquid Propane

inches W.C.

Warning: The heater must be isolated

from the gas supply piping system

during any pressure testing of that

system at test pressures equal to or

more than 0.5 psig. If overpressure has

occurred, such as through improper

testing of the gas lines or malfunction of

the supply system, the gas valve must

be checked for safe operation.

GAS CONNECTIONS

B Install a manual gas shut off valve, on the gas supply

line.

B Install a union when connecting gas supply.

B The minimum diameter required for any appliance

connector used is ¾”.

B National Fuel Gas Code requires that a sediment

trap (drip leg) be installed on gas appliances not so

equipped. The drip leg must be accessible and not

subject to freezing conditions. Install in accordance

with the recommendations of the serving gas

supplier.

2 000 ft - 4 500 ft 4.6” 8.4”

Table 3 Above 4.500 ft consult your local gas provider

GAS LINE SIZING

The gas supply piping should be sized according to the

applicable code for a maximum draw of 117,000 BTUH.

Measure the length of gas supply line and use the tables

in Fig. 9 or the gas line manufacturer’s sizing tables to

determine the pipe diameter necessary to

accommodate the BTU demand of the unit. If there are

more gas drawing appliances on the line, size the gas

line according to the total maximum amount of BTU

draw for all appliances.

Note: Under sizing the gas line may result in diminished

output and improper operation. See chapter 3.6 for the

procedure to confirm gas pressure.

When connections are made, check for gas leaks at all

joints. Apply some gas leak detection solution to all gas

fittings. Bubbles are a sign of a leak. A combustible gas

detector may also be used to detect for leaks.

10

8 716 473 147

Page 11

Installation instructions

Follow boxed numbers for piping just one AQ125 BO (example: ¾” B.I. Natural Gas pipe for 20 ft (6.1m). will

handle 190,000 btu’s (55.7 kWh). For multiple appliances combine the total btu input load and then refer to

applicable chart below.

* EHD = Equivalent Hydraulic Diameter. The greater the

value of EHD, the greater the gas capacity of the tubing

.

Maximum Capacity of Semi-Rigid copper Tubing in

Thousands of BTU per Hour of Undiluted Liquefied

Petroleum Gases (at 11 inches Water Column Inlet

Pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

* Source National Fuel Gas Code NFPA 54, ANSI Z223.1

- No Additional Allowance is necessary for an ordinary

number of fittings

FOR LP GAS

Maximum Capacity of Pipe in Thousands of BTU per Hour of Undiluted Petroleum Gases (at 11 inches Water Column Inlet

Pressure) (Based on a Pressure Drop of 0.5 Inch Water Column).

* EHD = Equivalent Hydraulic Diameter. The greater the

value of EHD, the greater the gas capacity of the tubing.

Nominal

Iron

Length of Black Iron Pipe, Feet

Pipe Internal

Size Diameter

inches inches 10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/4 0.364 32 22 18 15 14 12 11 11 10 9 8 8 7 6

3/8 0.493 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2 0.622 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4 0.824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1 1/4 1.380 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1 1/2 1.610 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

Tube

size,

inches EHD*

10 20 30 40 50 60

1/2

18 EHD

82 58 47 41 37 34

3/4

23 EHD

161 116 96 83 75 68

1

30 EHD

330 231 188 162 144 131

1 1/4

37 EHD

639 456 374 325 292 267

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Nominal

Iron pipe

Black Iron Pipe

size

Length of pipe, Feet

inches

10 20 30 40 50 60 70 80 90 100 125 150

1/2 275 189 152 129 114 103 96 89 83 78 69 63

3/4 567 693 315 267 237 217 196 185 173 162 146 132

1 107 732 590 504 448 409 378 346 322 307 275 252

1 1/4 220 149 121 103 913 834 771 724 677 630 567 511

1 1/2 330 229 185 155 141 127 118 108 102 976 866 787

2 622 433 346 299 264 239 220 204 192 1811 1606 1496

Tube

size

inches EHD*

10 20 30 40 50 60

1/2

18 EHD

129 91 74 64 58 53

3/4

23 EHD

254 183 151 131 118 107

1

30 EHD

521 365 297 256 227 207

1 1/4

37 EHD

971 661 528 449 397 359

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Copper (LP gas only)

Outside Length of Tubing, Feet

diameter

Inch 10 20 30 40 50 60 70 80 90 100

3/8 39 26 21 19

_ _ _ _ _ _

1/2 92 62 50 41 37 35 31 29 27 26

5/8 199 131 107 90 79 72 67 62 59 55

3/4 329 216 181 145 131 121 112 104 95 90

FOR NATURAL GAS

Maximum Capacity of pipe in Cubic Feet of Gas per Hour for Gas Pressure of 0.5 Psig or less and a Pressure drop

of 0.3 in Water Column (0.75mbar).(Based on a 0.60 Specific Gravity Gas) Btu numbers given in thousands.

Copper tubing is prohibited for use with Natural Gas in the Commonwealth of Massachusetts and not recommended

elsewhere.

Fig. 8

8 716 473 147

11

Page 12

Installation instructions

3.6 Measuring gas pressure

Connecting manometer

B Shut off gas.

B Remove front cover and locate inlet gas pressure

measuring point on the right side of the gas valve.

B Loosen screw from test point on the left side of gas

valve and connect manometer tube on test point.

Static pressure test

B Turn gas supply back on.

B Operate all other gas appliances on same gas piping

system at maximum output.

B Record static gas pressure reading on back page of

manual.

Operating pressure test

B Run high hot water flow rate.

B Set flow control knob fully clockwise.

B Set slide control to the right.

B Record operating gas pressure reading on back

page of manual.

Gas pressures lower than 5.7" W.C. for Natural Gas or

10.5" W.C. for LP Gas will result in insufficient degree

rise to the hot water being used, and must be corrected.

See Gas Line Sizing under chapter 3.5.

are no loose particles or dirt in the piping. Blow out or

flush the lines before connecting to the water heater.

Full port valves should be installed on both the cold

water supply and hot water outlet lines to facilitate

servicing the heater (see Fig. 9). For installation on a

private well system with the use of a pressure tank, the

lowest pressure range setting recommended is 30-50

psi (2.07 and 3.45bar).

Connecting the pressure relief valve (PRV)

A listed pressure relief valve supplied with the heater

must be installed at the time of installation. No valve is

to be placed between the PRV and the heater. No

reducing coupling or other restriction may be installed

in the discharge line. The discharge line must be a

minimum of 4” above a drain and installed such that it

allows complete drainage of both the PRV and the line.

The location of the PRV must be readily accessible for

servicing or replacement, and be mounted as close to

the water heater as possible. See Fig. 9. To install the

PRV, a suitable fitting connected to an extension on a

“T” fitting can be sweated to the hot water line.

Support all piping.

3.7 Water connections

When facing the heater, the ½” cold water inlet is on the

bottom right and the hot water outlet is on the bottom

left.

B INSTALL A UNION WHEN CONNECTING

WATER PIPE TO FACILITATE ANY

NECESSARY CLEANING AND SERVICING.

Although water piping throughout your structure may be

other than copper, we recommend that copper piping

or suitably rated stainless steel flex line piping be used

for at least three feet before and after the heater (follow

local codes if more stringent). Never sweat any rigid

piping directly to or beneath the water connections,

damage can occur to the internal water valve from

heating of the pipe. Plastics or other PEX type plumbing

line materials are not recommended for connecting

directly to the water heater. Keep water inlet and outlet

pipes to no less than ½" (12.7mm) diameter to allow the

full flow capacity.

It is recommended that all water piping below the

heater be properly insulated to avoid heat loss. If

below freezing temperatures are ever anticipated where

the heater is located, insulation material is required and

must be capable of protecting the piping from freezing.

The freeze protection provided with the heater will not

prevent any freeze damage to the exterior water piping.

If the cold and hot connections to the heater are

reversed, the heater will not function. Be certain there

Fig. 9 Plumbing Connections and Pressure Relief

Valve

12

8 716 473 147

Page 13

3.8 Electrical connections

Warning: Confirm that the water

heater is appropriately grounded and

that the installation meets all electrical

codes. Outdoor electrical outlets have

special requirements.

Warning: For safety reasons,

disconnect the power supply to the

heater before any service or testing is

performed.

Warning: This heater must be

electrically grounded in accordance

with the most recent edition of the

National Electrical Code. NFPA 70. In

Canada, all electrical wiring to the

heater should be in accordance with

local codes and the Canadian Electrical

Code, CSA C22.1 Part 1. Do not rely

on the gas or water piping to ground the

metal parts of the heater.

Installation instructions

The 125 BO requires an electrical power supply from a

120VAC 60Hz circuit and must be properly grounded.

A means for switching off the 120VAC power supply

must be provided.

Warning: The heater is equipped with

freeze prevention equipment that will

operate and prevent freezing of the

water in the heater to 5°F with no wind

chill. Electrical power must be

maintained to the heater to allow this to

function. WARNING: Proper

insulation of the water lines below

the heater is required if below

freezing temperatures, below 32°F,

are ever anticipated.

8 716 473 147

13

Page 14

Operation instructions

i

4 Operation instructions

4.1 For your safety read before

operating your water heater

Warning: If you do not follow these

instructions exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

A. This appliance employs a piezo-igniter to light the

pilot burner. When lighting the pilot, follow these

instructions exactly.

B. What to do if you smell gas.

WHAT TO DO IF YOU SMELL GAS

B Do not try to light any appliance.

B Do not touch any electric switch; do not use any

phone in your building.

B Immediately call your gas supplier from a neighbors

phone. Follow the gas supplier’s instructions.

B If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in the gas control

buttons. Never use tools. If a button will not push in,

check to make sure the buttons are being pushed in the

proper sequence. Follow these instructions exactly. If

control button(s) are jammed, close the heater’s

individual manual shutoff valve and call a qualified

service technician. Forced or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

B 8. Observe the pilot flame through the peephole. The

gas valve button should be held down for at least 15

seconds with pilot burning. When the gas valve

button is released, the pilot should continue to burn.

- If the gas valve button does not pop up when

released, stop and immediately call your service

technician or gas supplier.

- If pilot does not stay lit, repeat steps 1 through 8.

- If pilot will not stay lit after several tries, slide the gas

valve button all the way to the left and call service

technician or gas supplier.

B 9. Once pilot remains lit, release the gas valve button.

The heater will now fire at minimum power when

water is drawn at a rate greater than the threshold

flow rate.

Note: If main burner should fail to ignite, make sure pilot

is burning. If not, repeat lighting steps 1 through 8.

Note: The 125BO operates in two modes. See

SETTING THE WATER TEMPERATURE.

Note: On first time initial

installation, existence of air in the

gas supply line and in the water

line may cause some ignition

delay. In that case, repeat the

ignition process until all the air

has been purged.

4.3 To turn off appliance

B Slide the gas valve button all the way to the left and

turn off the manual gas valve on the supply line to the

heater.

4.4 Setting the water temperature

4.2 Lighting instructions

B 1. STOP! Read the previous safety information.

B 2. The gas valve must be turned off by sliding the gas

valve button to all the way to the left.

B 3. Wait five (5) minutes to clear out any gas. If you

smell gas, STOP! Follow “B” in the safety information

above on this plate. If you don’t smell gas, go to next

step.

B 4. The pilot burner is located behind the peephole in

the front center of the cover directly below this

instruction plate.

B 5. Open the sliding viewer window.

• 6. Slide the gas valve button to the right, under the

mark .

• 7. Fully depress gas valve button and light pilot by

pushing the button marked . This step may have

to be repeated.

14

The 125 BO has a gas control that modulates burner

input in response to flow. Its purpose is to ensure that

the hot water temperature will remain steady, although

the water flow demand might vary. The output

temperature can be adjusted with either the

temperature adjustment knob or the gas control slide.

8 716 473 147

Page 15

Fig. 10 Temperature Adjustment Controls

GAS CONTROL

SLIDE

TEMPERATURE

ADJUSTMENT KNOB

Temperature adjustment knob

The temperature adjustment knob on the front bottom of

the heater (see Fig. 10) adjusts temperature by

adjusting flow capacity. See table 4 for details.

Operation instructions

Knob

position

clockwise

counter-

clockwise

Degree rise 90°F 45°F

Activation rate 0.5 GPM 1.1 GPM

Max flow rate 2.0 GPM 3.7 GPM

Table 4 Clearances

As the temperature adjustment knob is turned counterclockwise, the output temperature will lower and the

activation rate will be raised. Turning the knob

clockwise will raise the temperature and lower the

activation rate.

Fig. 11

Gas control slide button

The gas control slide button adjusts temperature by

adjusting how much gas is allowed to flow to the

burners.

As the slide is adjusted to the left, the output

temperature will lower, with the lowest setting being the

one flame position . The hottest position is the three

flame position all the way to the right .

8 716 473 147

15

Page 16

Maintenance and service

5 Maintenance and service

5.1 Maintenance intervals

The 125 BO requires periodic maintenance. The below

time maintenance intervals should kept the unit

operating for many years.

Every year

B Inspect inlet water filter screen ( 5.2)

B Inspect pilot assembly and flame ( 5.3)

B Inspect burner assembly ( 5.4)

Every 2 years

B Lubricate and clean water valve ( 5.2)

Every 3 to 5 years

B Rebuild water valve ( 5.2)

B Clean pilot assembly and clean or replace orifice

( 5.3)

5.2 Water valve

The water valve is the main control that tells the heater

to fire. If the periodic maintenance is neglected, more

costly damage may occur over time.

Inspecting inlet water filter screen

Shut off the installer supplied cold water supply valve.

Disconnect water pipe going to the back of the water

valve. Remove filter from back of water valve. Clean the

filter and inspect for damage. Replace if the filter is at all

damaged. Inspect the top of the water valve for signs of

a water leak or corrosion. If present, rebuild the water

valve. (See below).

Lubricating the water valve

A more detailed instruction is available on our website

at www.boschhotwater.com. Shut off all water to the

unit and disconnect water pipe going to the back of the

water valve. Disconnect water pipe going to heat

exchanger by removing pin and pulling pipe out.

Loosen two set screws at the base of the gas valve and

drop the water valve down. Separate the two halves by

removing 5 screws on the top of the water valve. Apply

lithium or faucet and valve grease to the pushrod (see

Fig 13, pos. 23). Inspect and clean the venturi (see Fig

13, pos. 29).

Rebuilding the water valve

Several parts within the water valve should be replaced

every 3-5 years. The parts list and instruction can be

found on our website at www.boschhotwater.com.

5.3 Pilot

Inspecting pilot

The pilot should burn with a clean sharp blue flame. The

flame should fully envelope the bend of the flame sensor

rod. If it does not, clean the pilot assembly per

procedure below.

Cleaning pilot assembly

Disconnect the flame sensor rod cable and the igniter

cable by pulling gently down. Remove two screws holding pilot assembly in place. Loosen compression fitting

and remove pilot assembly. Note: The orifice sits on top

of the compression fitting DO NOT LOSE. Polish flame

sensor rod and igniter tip with emery cloth. Clean out

pilot assembly and orifice with carburetor cleaner. If

heater is an LP unit, replace orifice. Caution: Do not

enlarge orifice.

5.4 Main burners

The main burner flames should be blue, with a more

intense blue cone in the center core. Yellow flames

could be a sign of wrong size gas orifices or dirty

burners, or a blockage on the heat exchangers fins. If

some burners have yellow flames while others have

good flames, it is likely that dust, lint or spider webs

have partially clogged the burner venturis. To clean the

burners, contact a gas service person.

5.5 Vent assembly

Inspect the draft hood and heat exchanger fins for signs

of soot build-up or any other foreign material such as

spider webs. Clean out any debris found in the vent

hood. Signs of soot indicate insufficient combustion air

or exhaust draft. Check for vent assembly blockage or

combustion air blockage on the underside of the unit.

5.6 Mineral scale build-up

The 125 BO, when operated at lower temperatures

settings, does not accumulate mineral build-up. If

however, the heater is used at the higher temperature

settings and the water has a high mineral content,

periodic descaling may be necessary. The heating coils

should be flushed with a descaling solution. Consult

your dealer or BBT North America for instructions.

Consult your service person.

16

8 716 473 147

Page 17

6 Troubleshooting

Troubleshooting

6.1 Introduction

Many of the questions customers ask regarding

operation of this unit can be answered by following the

troubleshooting steps as outlined below. Visit our web

site at www.boschhotwater.com for more detailed

troubleshooting. For best results, perform each step

before proceeding to the next. The suggested solutions

may require that the cover be taken off. (See chapter

3.4).

6.2 Pilot will not light

• 1. If the unit was just installed or the gas lines have

been worked on, there may be air in the gas line. To

bleed air out of the gas line, hold down the gas valve

button while hitting the piezo ignitor button every

second.

• 2. Check to make sure the manual gas shut off valve

is in the open position. Have licensed gas technician

or service person check the presence of gas at the

gas pressure measuring tap on the left side of the

gas control valve. If gas is not present, the regulator

may be locked up and need replacing. See

chapter 3.5 for required gas pressures.

• 3. Clean or replace the pilot orifice. See chapter 5.3

for instructions.

6.3 Pilot will light but not stay on when

button released

millivoltage from the thermocouple lead to ground.

The expected reading is 24mVDC or greater.

6.4 Burners do not ignite with water

flow

• 1. Verify the pilot is lit.

• 2. Turn temperature adjustment knob all the way

clockwise. Turn hot water faucet to full on position

and fill a quart container. If the container fills in 30

seconds or less your flow rate (1/2 gallon per minute)

is sufficient to activate the heater. If the knob is full

counter clockwise, the container will need to fill in 14

seconds (1.1 gallons per minute) to activate the

heater. Check for restrictions in the water line such

as clogged aerators or a clogged inlet water filter

screen if flow rate is not sufficient.

• 3. Clean water inlet filter screen. See chapter 5.2.

• 4. Shut off installer supplied cold water supply valve

(if none installed, install before proceeding). Open all

hot water taps supplied by the 125 BO. Wait 5

minutes and check all taps. Water running is a sign

of a plumbing cross-over. Consult a local plumber or

service person for help in correcting plumbing crossover.

• 5. Verify the cold water supply is connected to the

right side of the heater.

• 6. Service the water valve. See chapter 5.2 for

intervals and instructions.

• 1. When lighting pilot ensure the gas valve button is

fully depressed and held down for at least 15 sec

after pilot is lit.

• 2. Pilot flame should be blue in color and hitting the

thermocouple tip. See chapter 5.3 for instructions.

• 3. Check the electromagnet connections. Electromagnet is located on the right side of the gas valve

behind the piezo push-button assembly. The

Electromagnet connection is a large aluminum 17mm

hex head nut. The thermocouple end is a 5 mm brass

nut which screws into the 17 mm nut. Tighten both

nuts snugly but do not over tighten.

• 4. Check if connections at the ECO are loose or

corroded. Clean any corrosion with very fine sand

paper or an eraser and reconnect leads.

• 5. If cleaning the terminals attached to the ECO did

not fix the problem, connect a jumper wire between

the two wires attached to the ECO and try to relight

the pilot. If the pilot flame now remains on, the ECO

may be defective and need to be replaced. Do not

leave jumper connected.

• 6. Have a licensed gas technician verify the proper

operation of the thermocouple by measuring the

6.5 Hot water temp fluctuates from hot

to cold

• 1. Shut off installer supplied cold water supply valve

(if none installed, install before proceeding). Open all

hot water taps supplied by the 125 BO. Wait 5

minutes and check all taps. Water running is a sign

of a plumbing cross-over. Consult a local plumber or

service person for help in correcting plumbing crossover.

• 2. Check for restrictions in the water line such as

clogged aerators, clogged shower head or a clogged

inlet water filter screen.

• 3. If hot water is so hot that a large amount of cold

water must be introduced to lower temperature to

comfortable level, lower output temperature. See

chapter 4.4 for instructions.

• 4. Check the inlet water pressure. For installation on

a private well system with the use of a pressure tank,

the lowest pressure range setting recommended is

30-50 psi (2.07 - 3.45 bar). Confirm that the

pressure tank is not water logged.

8 716 473 147

17

Page 18

Troubleshooting

• 5. Service water valve See chapter 5.2 for intervals

and instructions.

• 6. ECO (overheat sensor) tripped due to overheating

re-ignite the appliance 10 minutes later. If it happens

again, contact your service person.

6.6 Water is too hot

• 1. Check gas type on right side panel rating plate.

NG is a natural gas unit and LP is for liquid propane.

• 2. Since the unit does not measure incoming water

temperature, the output water may be warmer in the

summer than in the winter. Use the slide control to

lower output temperature as outlined in chapter 4.4.

• 3. Contact your service person if water temperature

does not lower per procedure outlined in

chapter 4.4.

• 4. Check the inlet water pressure. For installation on

a private well system with the use of a pressure tank,

the lowest pressure range setting recommended is

30-50 psi (2.07 - 3.45 bar). Confirm that the

pressure tank is not water logged.

• 5. Service water valve See chapter 5.2 for intervals

and instructions.

• 6. ECO (overheat sensor) tripped due to overheating

period Re-ignite the appliance 10 minutes later. If it

happens again, contact your service person.

6.7 Water is not hot enough

• 1. Adjust the temperature per chapter 4.4.

• 2. Shut off installer supplied cold water supply valve

(if none installed, install before proceeding). Open all

hot water taps supplied by the 125 BO. Wait 5

minutes and check all taps. Water running is a sign

of a plumbing cross-over. Consult a local plumber or

service person for help in correcting plumbing crossover.

• 3. While the heater is running with full hot water flow,

the flames should be 3-4" tall off the burner bed. If

the flames are not this tall, have the gas pressure

measured per chapter 3.6 by a license gas

technician or your service person.

• 4. Service water valve See chapter 5.2 for intervals

and instructions.

18

8 716 473 147

Page 19

Interior components and diagram parts list

1

2

5

11

10

8

7

3

4

9

6

7 Interior components and diagram parts list

7.1 Interior components

Fig. 12 Functional scheme

1 Heat exchanger

2 Pilot assembly

3 Burner manifold gas pressure test nipple

4 Main gas burner

5 Pilot gas tubing

6 on/off switch

8 716 473 147

7 Water valve

8 Gas control slide

9 Electronic control box

10 Temperature adjustment selector

19

Page 20

Interior components and diagram parts list

7.2 Components diagram

Fig. 13 Components Diagram

20

8 716 473 147

Page 21

Interior components and diagram parts list

7.3 Parts list

Item Description Reference

1 Screw 8 716 461 314

2 Heat exchanger 8 705 406 235 0

3 Temperature limit 8 707 206 017 0

4 Hot water pipe 8 716 416 714

5 Thermocouple 8 707 202 087 0

6 Burner 8 708 120 298 0 (NG)

6 Burner 8 708 120 296 0 (LP)

7 Nozzle (120) 8 708 202 124 0 (NG)

7 Nozzle (79) (10x) 8 708 202 149 0 (LP)

8 Washer 8 701 003 010 0

90 Washer 1" (10x) 8 710 103 060 0

10 Throttle disc (7,0) 8 700 100 174 0

11 Pilot burner (41.1) 8 718 105 051 0

12 Pilot injector (5) 8 708 200 005 0 (NG)

12 Pilot injector (49) 8 748 200 173 0 (LP)

13 Sparking plug 8 708 107 002 0

14 Strainer 8 700 507 055 0

15 Pipe - Pilot gas 8 700 707 320 0

16 Gas valve 8 707 021 090 0 (NG)

16 Gas valve 8 707 021 091 0 (LP)

17 Magnetic unit 8 707 201 012 0

18 Piezo igniter 8 708 108 040 0

19 Nut 8 743 301 025 0

20 Cable 8 704 401 023 0

21 Water valve 8 707 002 708 0

22 Cover 8 705 500 101 0

23 Sleeve 8 700 306 114 0

24 Diaphragm (C) 8 700 503 053 0

25 Wire form spring 8 704 705 024 0

26 Water strainer 8 700 507 001 0

27 Selector Screw 8 708 500 289 0

28 Volumetric water governor 8 705 705 027 0

29 Venturi (23s) 8 708 205 279 0

30 Gas regulator 8 716 487 043 (LP)

30 Gas regulator 8 716 487 044 (NG)

31 Anti frost device 8 716 459 336

32 Thermostat 8 716 459 273

33 Screw 8 703 401 051 0

34 Cold water pipe 8 716 416 715

Table 5

8 716 473 147

21

Page 22

Protecting the environment

8 Protecting the environment

Packing

The packing box may be fully recycled as confirmed by

the recycling symbol .

Components

Many parts in the heater can be fully recycled in the end

of the product life. Contact your city authorities for

information about the disposal of recyclable products.

Saving water resources:

B Make sure you close all the taps after any use. Avoid

leaving the taps dripping. Repair any leaking tap.

B Define the temperature you want. This way you have

the precise water flow needed (mixing cold water to

regulate temperature will increase the water flow with

consequent waste of water).

For increased safety shut off the appliance from

the main water supply if your are staying away

from home for a considerable time.

At below freezing temperatures, disconnect the

plumbing connections to the heater and allow

the heater to drain.

To prevent any freeze damage, introduce short

bursts of compressed air (20-40 psi) through

these connections to remove the residual water

in the horizontal pipes and water valve.

22

8 716 473 147

Page 23

9 Twelve Year Limited Warranty

i

Twelve Year Limited Warranty

General

Aquastar water heaters are warranted by the

Manufacturer (BOSCH) through BBT North America.

BBT North America (BBTNA) will furnish a replacement

heat exchanger and will furnish a replacement of any

other part which fails in normal use and service within

the applicable periods specified below, in accordance

with the terms of this warranty. The BBTNA

replacement will be warranted for the unexpired portion

of the original warranty. This warranty will be valid only

for water heaters in possession of the original purchaser

as recorded on the warranty card.

The Heat Exchanger

If the heat exchanger fails within twelve (12) years after

the original installation and operation BBTNA will

furnish a replacement heat exchanger. However, if the

water heater is installed in other than a single family

dwelling this heat exchanger warranty is limited to two

(2) years from date of original installation and operation.

Exceptions

This warranty will not apply:

• 1. to defects or malfunctions resulting from failure to

properly install, operate or maintain the unit in

accordance with the printed instructions provided;

• 2. to damage or abuse, accident, neglect or freezing

and other acts of nature;

• 3. to damage resulting from operation with either the

flame sensor rod or overheat sensor removed;

• 4. to failure of the heat exchanger resulting from the

operation of the water heater in a corrosive

atmosphere or at water temperatures exceeding the

maximum rating, or if the water heater is not supplied

with potable water;

• 5. to defects or damage cause by any attachment

or modification, including any energy-saving device.

All Other Parts

If any other part fails within two (2) years after original

installation and operation, BBTNA will furnish a

replacement part free of charge.

Shipping costs

In addition to supplying the replacement part(s),

BBTNA will provide ground service delivery for these

parts. Expedited or upgraded shipping will be charged

to the customer.

costs associated with service, removal or re-installation

of the original water heater or a replaced water heater.

Note: the water heater must be free of

damaging scale deposits and not subject

to gas pressures greater than those

shown on the rating plate, which must not

be altered, defaced or removed.

How to Make a Claim

Any claim for warranty parts should be made to your

local dealer, distributor or to BBTNA. If BBTNA, please

contact the Technical Support Department:

BBT NORTH AMERICA

Bosch Group

340 Mad River Park

Waitsfield, VT 05673

Phone: 800-642-3111

www.boschhotwater.com

In most cases, the dealer or distributor will be able to

promptly honor your claim and subsequently notify

BBTNA. However, all replacements are made subject to

validation by BBTNA of in-warranty coverage. The

damaged or defective item must be made available in

exchange for the replacement.

Miscellaneous

No one is authorized to make any other warranties on

behalf of BBTNA. It is expressly understood that the

replacement warranty of BBTNA shall be in lieu of any

and all other warranties, express or implied, including

warranties of merchantability or fitness for a particular

use or purpose, and further that BBTNA shall not be

liable for any loss or damage directly or indirectly arising

from the use of the hot water heater, or for any

consequential damages arising from such use

(including damages from water leakage). BBTNA sole

liability with respect to any defect shall be for the

replacement of the defective part(s). Some states do

not allow such limitations and exclusions, so the above

may not apply to you.

This warranty gives specific legal rights. You may also

have other rights which vary from state to state.

Service Labor Costs

This warranty does not cover any labor costs

associated with service, removal or re-installation of

part(s). All such costs must be borne by the Purchaser.

Additionally, this warranty does not cover any labor

8 716 473 147

23

Page 24

Installer Checklist, to be performed by installer upon installation

Serial Number ___ ___ ___ ___ ___ ___ ___ ___

(8 digit serial number is located on rating plate on right side panel)

Gas Pressure Reading* Static__________ Operating__________

Building Water Pressure __________ Range if on Well system __________

Average Winter Temperature __________

Average Summer Temperature __________

Installing Company _____________________________________________

Installer name _____________________________________________

Address _____________________________________________

Phone _____________________________________________

* See Chapter 3.6 and gas pressure table (to be filled out by installer)

Installation manual should be left with the owner after the installation is tested and completed

Replacement Parts available from:

BBT NORTH AMERICA

Bosch Group

Bosch Water Heating

340 Mad River Park

Waitsfield, VT 05673

VULCANO Termodomésticos S.A.

Estrada de Cacia

3801 - 856 Aveiro - PORTUGAL

Phone 800-642-3111

Fax (802) 496-6924

www.boschhotwater.com

techsupport@boschhotwater.com

Recycled paper © 2005 BBT NORTH AMERICA,

Waitsfield, VT all rights reserved

Loading...

Loading...