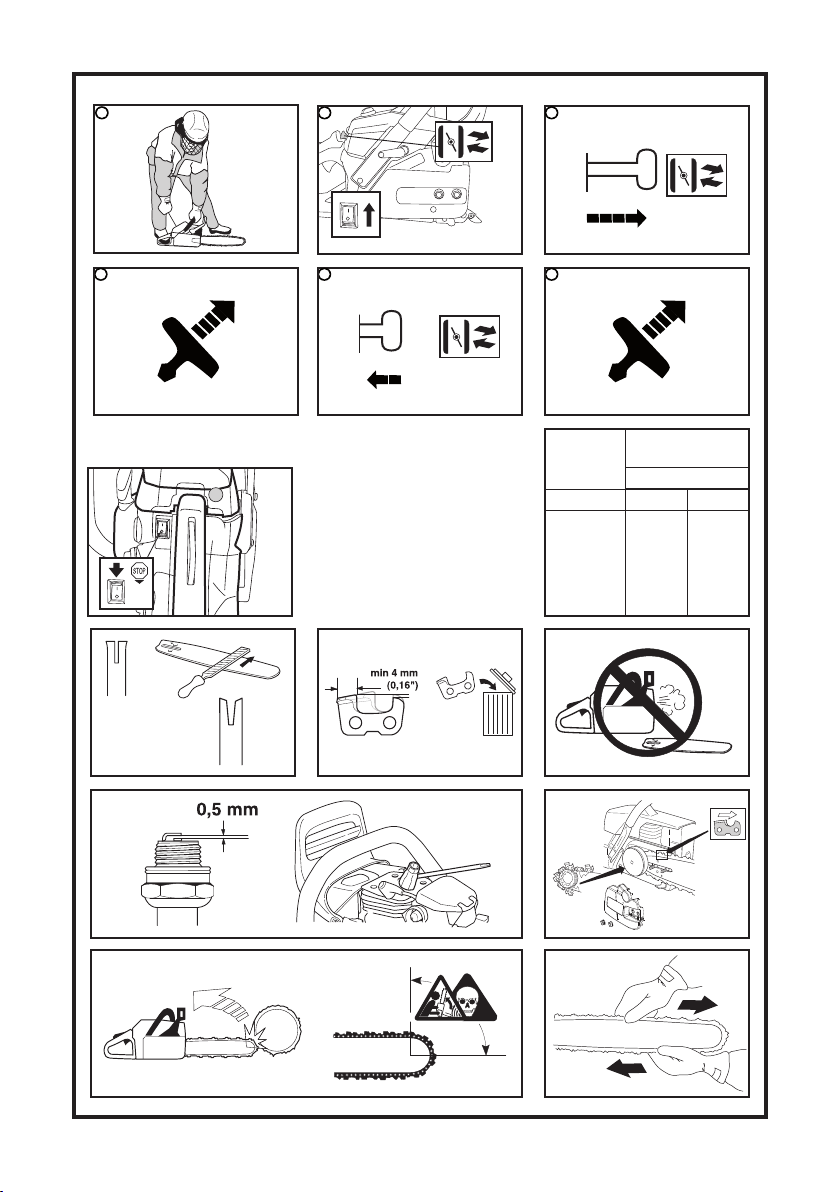

Page 1

BBK-2220

98296198

User’s Manual ....................................4

Инструкция по эксплуатации .........12

Page 2

2200W2-stroke 2800

min

50.0

-1

cm

0.55

3

L

0.26

L

1,5mm

0.33"

7

kg

72pcs

SUMMER WINTER

Page 3

Starting

31 2

FULL

Stopping

5

64

OFF

Petrol

Benzin

Бензин

10

15

20

25

1

1

5

Oil - Öl - Масло

4%-25 : 1

(cm

0,04

0,20

0,40

0,60

0,80

1,00

(40)

(200)

(400)

(600)

(800)

(1000)

3

)1

Page 4

Petrol chainsaw

GENERAL SAFETY PRECAUTIONS

Before using a new chain saw please read this manual

carefully.

WARNING! Under no circumstances may the

design of the machine be modifi ed without

the permission of the manufacturer. Always

use genuine accessories. Non-authorized modifi ca-

tions and/or accessories can result in serious personal

injury or the death of the operator or others.

WARNING! A chain saw is a dangerous tool if

used carelessly or incorrectly and can cause

serious, even fatal injuries. It is very important that you read and understand the contents of this

operator’s manual.

WARNING! Running an engine in a confi ned

or badly ventilated area can result in death

due to asphyxiation or carbon monoxide poisoning.

PERSONAL PROTECTIVE EQUIPMENT

● Approved protective helmet

● Hearing protection

● Protective goggles or a visor

● Gloves with saw protection

● Trousers with saw protection

● Boots with saw protection, steel toe-cap and non-

slip sole

Generally clothes should be close-fi tting without re-

stricting your freedom of movement.

MACHINE'S SAFETY EQUIPMENT

The life span of the machine can be reduced and the

risk of accidents can increase if machine maintenance

is not carried out correctly and if service and/or repairs

are not carried out professionally. If you need further

information please contact your nearest service workshop.

WARNING! Never use a machine with defec-

tive safety components. Safety equipment

must be inspected and

maintained. See instructions under the heading Checking, maintaining and servicing chain saw safety equipment. If your machine does not pass all the checks,

take the saw to a servicing dealer for repair.

CHAIN BRAKE AND FRONT HAND GUARD

Your chain saw is equipped with a chain brake that is

designed to stop the chain if you get a kickback. The

chain brake reduces the risk of accidents, but only you

can prevent them.

Take care when using your saw and make sure the

kickback zone of the bar never touches any object.

● The chain brake can either be activated manually

(by your left hand) or automatically by the inertia release mechanism.

● The brake is applied when the front hand guard is

pushed forwards.

● This movement activates a spring-loaded mecha-

nism that tightens the brake band around the engine

drive system (clutch drum).

● The front hand guard is not designed solely to ac-

tivate the chain brake. Another important feature is

that it reduces the risk of your left hand hitting the

chain if you lose grip of the front handle.

● The chain brake must be engaged when the chain

saw is started to prevent the saw chain from rotating.

● Use the chain brake as a ”parking brake” when

starting and when moving over short distances, to

reduce the risk of moving chain accidentally hitting

your leg or anyone or anything close by.

● To release the chain brake pull the front hand guard

backwards, towards the front handle.

● Kickback can be very sudden and violent. Most

kickbacks are minor and do not always activate the

chain brake. If this happens you should hold the

chain saw fi rmly and not let go.

● The way the chain brake is activated, either manu-

ally or automatically by the inertia release mechanism, depends on the force of the kickback and the

position of the chain saw in relation to the object that

the kickback zone of the bar strikes.

If you get a violent kickback while the kickback zone

of the bar is farthest away from you the chain brake is

designed to be activated by the inertia in the kickback

direction.

VIBRATION DAMPING SYSTEM

Your machine is equipped with a vibration damping

system that is designed to minimize vibration and make

operation easier.

The machine′s vibration damping system reduces the

transfer of vibration between the engine unit/cutting

equipment and the machine′s handle unit. The body of

the chain saw, including the cutting equipment, is insulated from the handles by vibration damping units.

Cutting hardwoods (most broadleaf trees) creates

more vibration than cutting softwoods (most conifers).

Cutting with cutting equipment that is blunt or faulty

(wrong type or badly sharpened) will increase the vibration level.

4

Page 5

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve damage

in people who have impaired circulation.

Contact your doctor if you experience symptoms of

overexposure to vibration. Such symptoms include

numbness, loss of feeling, tingling, pricking, pain, loss

of strength, changes in skin colour or condition. These

symptoms normally appear in the fi ngers, hands or

wrists. These symptoms may be increased in cold temperatures.

Stop switch

Use the stop switch to switch off the engine.

Muffl er

The muffl er is designed to reduce noise levels and to

direct exhaust fumes away from the user.

WARNING! The exhaust fumes from the en-

gine are hot and may contain sparks which

can start a fi re. Never start the machine in-

doors or near combustible material!

CAUTION! The muffl er gets very hot during

and after use. This also applies during idling.

Be aware of the fi re hazard, especially when

working near fl ammable substances and/or vapours.

WARNING! Never use a saw without a muf-

fl er, or with a damaged muffl er. A damaged

muffl er may substantially increase the noise

level and the fi re hazard. Keep fi re fi ghting equipment

handy. If a spark arrestor screen is required in your area, never use the saw without or with a broken spark

arrestor screen.

CUTTING EQUIPMENT GENERAL RULES

● Only use cutting equipment recommended by us!

● Keep the chain’s cutting teeth properly sharpened!

● Maintain the correct depth gauge setting! Follow our

instructions and use the recommended depth gauge

clearance. Too large a clearance increases the risk

of kickback.

● Keep the chain properly tensioned! If the chain is

slack it is more likely to jump off and lead to increased wear on the bar, chain and drive sprocket.

● Keep cutting equipment well lubricated and properly

maintained! A poorly lubricated chain is more likely

to break and lead to increased wear on the bar,

chain and drive sprocket.

CUTTING EQUIPMENT DESIGNED

TO REDUCE KICKBACK

The only way to avoid kickback is to make sure that the

kickback zone of the bar never touches anything.

By using cutting equipment with ”built-in” kickback

reduction and keeping the chain sharp and wellmaintained you can reduce the effects of kickback.

Bar

The smaller the tip radius the lower the chance of kickback.

Chain

A chain is made up of a number of links, which are

available in standard and low-kickback versions.

IMPORTANT! No saw chain design eliminates the danger of kickback.

WARNING! Any contact with a rotating saw

chain can cause extremely serious injuries.

SHARPENING YOUR CHAIN AND ADJUSTING DEPTH GAUGE SETTING

WARNING! Always wear gloves, when working with the chain, in order to protect your

hands from injury.

General information on sharpening cutting teeth

● Never use a blunt chain. When the chain is blunt

you have to exert more pressure to force the bar

through the wood and the chips will be very small. If

the chain is very blunt it will produce wood powder

and no chips or shavings.

● A sharp chain eats its way through the wood and

produces long, thick chips or shavings.

● The cutting part of the chain is called the cutter and

consists of a cutting tooth and the depth gauge.

The cutters cutting depth is determined by the dif-

ference in height between the two (depth gauge setting).

When you sharpen a cutting tooth there are four important factors to remember.

1 Filing angle

2 Cutting angle

3 File position

4 Round fi le diameter

It is very diffi cult to sharpen a chain correctly without the

right equipment. We recommend that you use our fi le

gauge. This will help you obtain the maximum kickback

reduction and cutting performance from your chain.

WARNING! Departure from the sharpening

instructions considerably increases the risk

of kickback.

● Check that the chain is correctly tensioned. A slack

chain will move sideways, making it more diffi cult to

sharpen correctly.

● Always fi le cutting teeth from the inside face. Re-

duce the pressure on the return stroke. File all the

teeth on one side fi rst, then turn the chain saw over

and fi le the teeth on the other side.

● File all the teeth to the same length. When the length

of the cutting teeth is reduced to 4 mm (0.16") the

chain is worn out and should be replaced.

WARNING! The risk of kickback is increased

if the depth gauge setting is too large!

5

Page 6

ADJUSTMENT OF DEPTH GAUGE SETTING

● The cutting teeth should be newly sharpened before

adjusting the depth gauge setting. We recommend

that you adjust the depth gauge setting every third

time you sharpen the cutting teeth.

NOTE! This recommendation assumes that

the length of the cutting teeth is not reduced

excessively.

● You will need a fl at fi le and a depth gauge tool. We

recommend that you use our depth gauge tool to

acheive the correct depth gauge setting and bevel

for the depth gauge.

● Place the depth gauge tool over the chain. Detailed

information regarding the use of the depth gauge

tool, will be found on the package for the depth

gauge tool. Use the fl at fi le to fi le off the tip of the

depth gauge that protrudes through the depth gauge

tool. The depth gauge setting is correct when you no

longer feel resistance as you draw the fi le along the

depth gauge tool.

TENSIONING THE CHAIN

WARNING! A slack chain may jump off and

cause serious or even fatal injury.

WARNING! Always wear approved protective

gloves. Even a non-moving chain can cause

serious cuts to yourself or persons you bump

into with an exposed chain.

The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take

up the slack.

Check the chain tension every time you refuel.

NOTE! A new chain has a running-in period

during which you should check the tension

more frequently.

LUBRICATING CUTTING EQUIPMENT

WARNING! Poor lubrication of cutting equip-

ment may cause the chain to snap, which

could lead to serious, even fatal injuries.

Chain oil

Chain oil must demonstrate good adhesion to the chain

and also maintain its fl ow characteristics regardless of

whether it is warm summer or cold winter weather.

Filling with chain oil

● All our chain saws have an automatic chain lubri-

cation system. On some models the oil fl ow is also

adjustable.

● The saw chain oil tank and the fuel tank are de-

signed so that the fuel runs out before the saw chain

oil.

However, this safety feature requires that you use the

right sort of chain oil (if the oil is too thin it will run out

before the fuel), and that you adjust the carburetor as

recommended (a lean mixture may mean that the fuel

lasts longer than the oil) and that you also use the recommended cutting equipment (a bar that is too long will

use more chain oil).

Checking chain lubrication

● Check the chain lubrication each time you refuel.

See instructions under the heading Lubricating the

bar tip sprocket.

Aim the tip of the bar at a light coloured surface about

20 cm (8 inches) away. After 1 minute running at 3/4

throttle you should see a distinct line of oil on the light

surface.

If the chain lubrication is not working:

● Check that the oil channel in the bar is not obstruct-

ed.

Clean if necessary.

● Check that the groove in the edge of the bar is clean.

Clean if necessary.

● Check that the bar tip sprocket turns freely and that

the lubricating hole in the tip sprocket is not blocked.

Clean and lubricate if necessary.

If the chain lubrication system is still not working after

carrying out the above checks and associated measures you should contact your service agent.

Chain drive sprocket

The clutch drum is fi tted with a Spur sprocket (the chain

sprocket is welded on the drum).

Regularly check the degree of wear on the drive

sprocket.

Replace if wear is excessive. Replace the drive sprocket whenever you replace the chain.

Checking wear on cutting equipment

Check the chain daily for:

● Visible cracks in rivets and links.

● Whether the chain is stiff.

● Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points

above.

We recommend you compare the existing chain with

a new chain to decide how badly the existing chain is

worn.

When the length of the cutting teeth has worn down to

only 4 mm the chain must be replaced.

Bar

Check regularly:

● Whether there are burrs on the edges of the bar.

Remove these with a fi le if necessary.

● Whether the groove in the bar has become badly

worn.

Replace the bar if necessary.

6

Page 7

ASSEMBLY

FITTING THE BAR AND CHAIN

WARNING! Switch off the engine before carrying out any checks or maintenance. The

stop switch automatically returns to the start

position. In order to prevent unintentional starting, the

spark plug cap must be removed from the spark plug

when assembling, checking and/or performing maintenance.

Always wear gloves, when working with the chain, in

order to protect your hands from injury.

Check that the chain brake is in disengaged position by

moving the front hand guard towards the front handle.

Remove the bar nuts and remove the clutch cover

(chain brake). Take off the transportation ring.

Fit the bar over the bar bolts. Place the bar in its rearmost position. Place the chain over the drive sprocket

locate it in the groove on the bar. Begin on the top edge

of the bar.

Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

Fit the clutch cover (the chain brake) and locate the

chain adjuster pin in the hole in the bar. Check that

the drive links of the chain fi t correctly over the drive

sprocket and that the chain is correctly located in the

groove in the bar. Tighten the bar nuts fi nger tight.

Tension the chain by turning the chain tensioning screw

clockwise using the combination spanner. The chain

should be tensioned until it does not sag from the underside of the bar.

The chain is correctly tensioned when it does not sag

from the underside of the bar, but can still be turned

easily by hand. Hold up the bar tip and tighten the bar

nuts with the combination spanner.

When fi tting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain ensures good cutting performance and long life.

FUEL

Note! The machine is equipped with a two-stroke engine and must always be run using a mixture of petrol

and twostroke oil. It is important to accurately measure

the amount of oil to be mixed to ensure that the correct mixture is obtained. When mixing small amounts

of fuel, even small inaccuracies can drastically affect

the ratio of the mixture.

WARNING! Always ensure there is adequate

ventilation when handling fuel.

Petrol

● Use good quality unleaded or leaded petrol.

● The lowest recommended octane grade is 92.

● When working with continuous high revs (e.g. limb-

ing) a higher octane is recommended.

Running-in

Avoid running at a too high speed for extended periods

during the fi rst 10 hours.

TWO-STROKE OIL

● Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated TCW).

● Never use oil intended for four-stroke engines.

MIXING RATIO

Petrol, litre Two-stroke oil, litre

2% (1:50) 3% (1:33)

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

MIXING

● Always mix the petrol and oil in a clean container

intended for fuel.

● Always start by fi lling half the amount of the petrol

to be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount

of petrol.

● Mix (shake) the fuel mixture thoroughly before fi lling

the machine’s fuel tank.

● Do not mix more than one month’s supply of fuel at

a time.

● If the machine is not used for some time the fuel tank

should be emptied and cleaned.

Chain oil

● We recommend the use of special oil (chain oil) with

good adhesion characteristics.

● Never use waste oil. This results in damage to the oil

pump, the bar and the chain.

● It is important to use oil of the right grade (suitable

viscosity range) to suit the air temperature.

● In temperatures below 0°C (32°F) some oils become

too viscous. This can overload the oil pump and result in damage to the oil pump components.

● Contact your service agent when choosing chain oil.

FUELLING

WARNING! Taking the following precautions,

will lessen the risk of fi re: Do not smoke and

do not place any hot objects in the vicinity of

fuel. Always stop the engine and let it cool for a few

minutes before refuelling. When refuelling, open the

fuel cap slowly so that any excess pressure is released

gently. Tighten the fuel cap carefully after refuelling.

Always move the machine away from the refuelling

area before starting.

7

Page 8

Clean the area around the fuel cap. Clean the fuel

and chain oil tanks regularly. The fuel fi lter must be re-

placed at least once a year. Contamination in the tanks

causes malfunction.

Make sure the fuel is well mixed by shaking the container before refuelling. The capacities of the chain oil

tank and fuel tank are carefully matched. You should

therefore always fi ll the chain oil tank and fuel tank at

the same time.

WARNING! Fuel and fuel vapour are highly

fl ammable. Take care when handling fuel and

chain oil. Be aware of the risks of fi re, explo-

sion and those associated with inhalation.

FUEL SAFETY

● Never refuel the machine while the engine is run-

ning.

● Make sure there is plenty of ventilation when refuel-

ling or mixing fuel (petrol and 2-stroke oil).

● Move the machine at least 3 m from the refuelling

point before starting it.

● Never start the machine:

1 If you have spilt fuel or chain oil on the machine.

Wipe off the spillage and allow remaining fuel to

evaporate.

2 If you have spilt fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines.

WARNING! Never use a machine with visible

damage to the spark plug guard and ignition

cable. A risk of sparking arises, which can

cause a fi re.

TRANSPORT AND STORAGE

● Always store the chain saw and fuel so that there

is no risk of leakages or fumes coming into contact

with sparks or naked fl ames from electrical equip-

ment, electric motors, relays/switches, boilers and

the like.

● Always store fuel in an approved container designed

for that purpose.

● For longer periods of storage or for transport of the

chain saw, the fuel and chain oil tanks should be

emptied. Ask where you can dispose of waste fuel

and chain oil at your local petrol station.

● Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

● The bar guard must always be fi tted to the cutting

attachment when the machine is being transported

or in storage, in order to prevent accident contact

with the sharp chain. Even a non-moving chain can

cause serious cuts to yourself or persons you bump

into with an exposed chain.

● Secure the machine during transport.

LONG-TERM STORAGE

Empty the fuel/oil tanks in a well ventilated area. Store

the fuel in approved cans in a safe place. Fit the bar

guard. Clean the machine.

STARTING AND STOPPING

WARNING! Note the following before start-

ing: The chain brake must be engaged when

the chain saw is started to reduce the chance

of contact with the moving chain during starting.

Never start a chain saw unless the bar, chain and all

covers are fi tted correctly. Otherwise the clutch can

come loose and cause personal injuries. Place the machine on fi rm ground. Make sure you have a secure

footing and that the chain cannot touch anything.

Keep people and animals well away from the working

area.

COLD ENGINE

Starting: The chain brake must be engaged when the

chain saw is started. Activate the brake by moving the

front hand guard forwards.

1. Air purge: Press the air purge repeatedly until fuel

begins to fi ll the bulb. The bulb need not be com-

pletely fi lled.

2. Choke: Pull the blue choke/fast idle lever out to the

full extent (to the FULL CHOKE position). When the

choke/ fast idle lever is pulled out to the full extent,

the correct throttle setting is set automatically.

Start throttle: The correct choke/start throttle setting

is obtained by moving the control to the choke position.

Starting

Grip the front handle with your left hand. Hold the chain

saw on the ground by placing your right foot through

the rear handle.

3. Pull the starter handle with your right hand and pull

out the starter cord slowly until you feel a resistance

(as the starter pawls engage) then pull fi rmly and

rapidly. Never twist the starter cord around your

hand.

CAUTION! Do not pull the starter cord all the

way out and do not let go of the starter handle

when the cord is fully extended. This can

damage the machine.

4. Push in the choke control to the ”1/2 choke” set-

ting as soon as the engine fi res which can be heard

through a "puff" sound.

5. Keep on pulling the cord powerfully until the engine

starts. Allow engine to warm for thirty seconds, then

squeeze throttle trigger to set normal idle.

As the chain brake is still engaged the speed of the

engine must be set to idling as soon as possible, this

is achieved by quickly pressing the throttle trigger

once. This prevents unnecessary wear to the clutch,

clutch drum and brake band.

8

Page 9

Warm engine

Use the same procedure as for starting a cold engine

but without setting the choke control in the choke position. Set the throttle to the start position by pulling out

the blue choke control to the choke position and then

pushing it in again.

WARNING! Long term inhalation of the engine’s exhaust fumes, chain oil mist and dust

from sawdust can represent a health risk.

● Never start a chain saw unless the bar, chain and

all covers are fi tted correctly. See instructions under

the heading Assembly. Without a bar and chain attached to the chain saw the clutch can come loose

and cause serious injury.

● The chain brake should be activated when starting.

See instructions under the heading Start and stop.

Do not drop start. This method is very dangerous

because you may lose control of the saw.

● Never start the machine indoors. Exhaust fumes can

be dangerous if inhaled.

● Observe your surroundings and make sure that

there is no risk of people or animals coming into

contact with the cutting equipment.

● Always hold the saw with both hands. The right hand

should be on the rear handle, and the left hand on

the front handle. All people, whether right or left

handed, should use this grip. Use a fi rm grip with

thumbs and fi ngers encircling the chain saw han-

dles.

Stopping

Stop the engine by pressing down the stop button.

WORKING TECHNIQUES

BEFORE USE:

1 Check that the chain brake works correctly and is

not damaged.

2 Check that the rear right hand guard is not dam-

aged.

3 Check that the throttle lockout works correctly and

is not damaged.

4 Check that the stop switch works correctly and is

not damaged.

5 Check that all handles are free from oil.

6 Check that the anti vibration system works and is

not damaged.

7 Check that the muffl er is securely attached and not

damaged.

8 Check that all parts of the chain saw are tightened

correctly and that they are not damaged or miss-

ing.

9 Check that the chain catcher is in place and not

damaged.

10 Check the chain tension.

Basic safety rules

Look around you:

● To ensure that people, animals or other things can-

not affect your control of the machine.

● To make sure that none of the above might come

within reach of your saw or be injured by falling

trees.

CAUTION! Follow the instructions above, but

do not use a chain saw in a situation where you

cannot call for help in case of an accident.

Do not use the machine in bad weather, such as dense

fog, heavy rain, strong wind, intense cold, etc.

Working

in bad weather is tiring and often brings added risks,

such as icy ground, unpredictable felling direction, etc.

3 Take great care when removing small branches and

avoid cutting bushes (i.e. cutting many small branches

at the same time). Small branches can be grabbed by

the chain and thrown back at you, causing serious injury.

4 Take great care when cutting a tree that is in tension. A tree that is in tension may spring back to its

normal position before or after being cut. If you position yourself incorrectly or make the cut in the wrong

place the tree may hit you or the machine and cause

you to lose control. Both situations can cause serious

personal injury.

5 Before moving your chain saw switch off the engine

and lock the chain using the chain brake. Carry the

chain saw with the bar and chain pointing backwards.

Fit a guard to the bar before transporting the chain saw

or carrying it for any distance.

6 When you put the chain saw on the ground, lock the

saw chain using the chain brake and ensure you have

a constant view of the machine. Switch the engine off

before leaving your chain saw for any length of time.

WARNING! Sometimes chips get stuck in the

clutch cover causing the chain to jam. Always

stop the engine before cleaning.

GENERAL RULES

1 If you understand what kickback is and how it happens then you can reduce or eliminate the element of

surprise. By being prepared you reduce the risk.

Kickback is usually quite mild, but it can sometimes be

very sudden and violent.

2 Always hold the chain saw fi rmly with your right hand

on the rear handle and your left hand on the front handle. Wrap your fi ngers and thumbs around the handles.

You should use this grip whether you are right-handed

or left-handed. This grip minimises the effect of kickback and lets you keep the chain saw under control. Do

not let go of the handles!

3 Most kickback accidents happen during limbing.

Make sure you are standing fi rmly and that there is

nothing in the way that might make you trip or lose your

balance.

9

Page 10

Lack of concentration can lead to kickback if the kickback zone of the bar accidentally touches a branch,

nearby tree or some other object.

Have control over the workpiece. If the pieces you

intend to cut are small and light, they can jam in the

saw chain and be thrown towards you. This is not necessarily dangerous in itself, but you may be surprised

and lose control of the saw. Never saw stacked logs or

branches without fi rst separating them. Only saw one

log or one piece at a time. Remove the cut pieces to

keep your working area safe.

4 Never use the chain saw above shoulder height and

try not to cut with the tip of the bar. Never use the chain

saw one-handed!

5 You must have a steady stance in order to have full

control over the chain saw. Never work standing on a

ladder, in a tree or where you do not have fi rm ground

to stand on.

6 Always use a fast cutting speed, i.e. full throttle.

7 Take great care when you cut with the top edge of the

bar, i.e. when cutting from the underside of the object.

This is known as cutting on the push stroke. The chain

tries to push the chain saw back towards the user. If the

saw chain is jamming, the saw may be pushed back

at you.

8 Unless the user resists this pushing force there is a

risk that the chain saw will move so far backwards that

only the kickback zone of the bar is in contact with the

tree, which will lead to a kickback.

Cutting with the bottom edge of the bar, i.e. from the

top of the object downwards, is known as cutting on

the pull stroke. In this case the chain saw pulls itself

towards the tree and the front edge of the chain saw

body rests naturally on the trunk when cutting. Cutting

on the pull stroke gives the operator better control over

the chain saw and the position of the kickback zone.

9 Follow the instructions on sharpening and maintaining your bar and chain. When you replace the bar and

chain use only combinations that are recommended by

us.

GENERAL

The user must only carry out the maintenance and

service work described in this Operator’s Manual. More

extensive work must be carried out by an authorised

service workshop.

CARBURETTOR ADJUSTMENT

Your BORT product has been designed and manufactured to specifi cations that reduce harmful emissions.

FUNCTION

● The carburettor governs the engine’s speed via the

throttle control. Air and fuel are mixed in the carburettor. The air/fuel mixture is adjustable. Correct

adjustment is essential to get the best performance

from the machine.

● The T-screw regulates the throttle setting at idle

speed. If the T-screw is turned clockwise this gives

a higher idle speed; turning it anti-clockwise gives a

lower idle speed.

Basic settings and running in

The basic carburettor settings are adjusted during testing at the factory. Fine adjustment should be carried

out by a skilled technician.

Rec. idle speed: See the Technical data section.

Fine adjustment of the idle speed T

Adjust the idle speed with the T-screw. If it is necessary to re-adjust, turn the T-screw clockwise while

the engine is running, until the chain starts to rotate.

Then turn anticlockwise until the chain stops. When

the idle speed is correctly adjusted the engine should

run smoothly in every position and the engine speed

should be safely below the speed at which the chain

starts to rotate.

WARNING! Contact your servicing dealer, if

the idle speed setting cannot be adjusted so

that the chain stops. Do not use the chain

saw until it has been properly adjusted or repaired.

MAINTENANCE SCHEDULE

The following is a list of the maintenance that must be

performed on the machine. Most of the items are described in the Maintenance section.

10

Page 11

Daily maintenance (Every 5-10 h) Weekly malntenance (Every 10-25 h) Monthly maintenance (Every 25-40 h)

Check the brake band on the chain brake

Clean the outside of the machine.

Check that the components of the

throttle control work safely. (Throttle

lockout and throttle control.)

Clean the chain brake and check that

it operates safely. Make sure that the

chain catcher is undamaged, and

replace it if necessary.

The bar should be turned daily for more

even wear. Check the lubrication hole

in the bar, to be sure it is not clogged.

Clean the bar groove. If the bar has a

sprocket tip, this should be lubricated.

Check that the bar and chain are getting

suffi cient oil.

Check the saw chain with regard to

visible cracks in the rivets and links,

whether the saw chain is stiff or whether

the rivets and links are abnormally worn.

Replace if necessary.

Sharpen the chain and check its tension

and condition. Check the drive sprocket

for excessive wear and replace if

necessary.

Clean the starter units air intake. Check all cables and connections.

Check that nuts and screws are tight.

Check that the stop switch works

correctly.

Check that there are no fuel leaks from

the engine, tank or fuel lines.

Check the starter, the starter cord and

the recoil spring.

Check that the vibration damping

elements are not damaged.

File off any burrs from the edges of

the bar.

Clean the carburettor compartment. Clean the outside of the carburettor.

Clean the air fi lter. Replace if necessary. Check the fuel fi lter and the fuel hose.

for wear. Replace when less than 0.6

mm (0,024 inch) remains at the most

worn point.

Check the clutch centre, clutch drum and

clutch spring for wear.

Clean the spark plug. Check that the

electrode gap is 0.5 mm.

Replace if necessary.

Empty the fuel tank and clean the inside.

Empty the oil tank and clean the inside.

11

Page 12

Пила цепная бензиновая

Уважаемый покупатель!

Благодарим за покупку инструмента торговой марки

"BORT". В данном руководстве приведены правила

эксплуатации пилы бензиновой цепной (далее по

тексту – пила). Перед началом работ внимательно

прочтите руководство. Эксплуатируйте пилу в соответствии с правилами и с учетом требований безопасности, а также руководствуясь здравым смыслом. Сохраните инструкцию. При необходимости

Вы всегда можете обратиться к ней.

Производитель оставляет за собой право вносить

изменения в конструкцию отдельных деталей без

предварительного уведомления. Имейте это в виду,

читая руководство по эксплуатации.

Назначение пилы

Пилы цепные бензиновые торговой марки BORT

(далее – пилы), предназначенные для распиловки

древесины и готовых пиломатериалов в домашнем

или приусадебном хозяйстве (расчистка зарослей

кустарника, обрезка ветвей, распиливание дров).

Данные пилы не предназначены для профессионального или интенсивного использования в течение длительного времени.

Любой другой вид использования пилы считается

использованием не по назначению. Изготовитель

пилы не несет ответственность за вред, причиненный вследствие такого использования. Ответственность за подобное использование несет только

пользователь.

Поскольку пила является инструментом для пиления древесины с высокой скоростью вращения

пильной цепи, должны быть предприняты специальные меры предосторожности для того, чтобы

снизить вероятность возникновения несчастных

случаев. Беспечность или неправильное использование бензопилы может стать причиной серьезных

травм. Прочтите эту инструкцию перед использованием и неукоснительно соблюдайте ее положения

Предостерегающие наклейки:

Перед началом работы обязательно прочтите инструкцию по эксплуатации

Остерегайтесь отскока! При работе держите пилу двумя руками!

Внимание! Опасность!

!

При работе с пилой используйте

средства индивидуальной защиты

для рук: перчатки для защиты рук

от механических повреждений

При работе с пилой используйте

средства индивидуальной защиты:

для защиты глаз - защитные очки,

для защиты от шума - наушники

или беруши, для защиты от ушиба

головы при падении предметов защитную каску

При работе с пилой используйте

средства индивидуальной защиты:

защитную обувь

Характеристики и параметры прибора:

Пила бензиновая цепная

торговой марки "BORT"

Тип двигателя

BBK-2220

1-цилиндровый,

2-х тактный

Топливо АИ-92 и выше

Масло

Объем цилиндра, см

3

Для 2-х тактных

двигателей

50

Мощность, кВт/л.с. 2,2 / 2,99

Скорость на холостом ходу,

об/мин

Свеча зажигания

2800

Champion

RCJ7Y

Зазор между электродами, мм 0,5

Объем топливного бака, л 0,55

Объем масляного бака, л 0,26

Состав смеси

(топливо / масло двутактное)

1:25

Запуск двигателя Ручной

Тормоз цепи Ручной

Шаг цепи, дюйм 0,325

Длина шины, см 50,8

Автоматическая смазка цепи +

Предохранитель включения +

Индикатор уровня масла +

Масса, кг 7

Изготовитель

технических изменений!

оставляет за собой право внесения

Изготовитель: BORT GLOBAL LIMITED

12

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

Page 13

Комплект поставки

1. Напильник для заточки цепи

Емкость для смешивания топлива

2.

3. Набор инструмента для сборки

Срок службы изделия

Срок службы изделия составляет 5 лет.

Дата изготовления

Указана на упаковке товара

Срок хранения

При соблюдении условий хранений срок хранения

не ограничен.

Условия хранения

Продукция хранится в сухих, проветриваемых

складских помещениях при температуре от 0°С до

+40°С при относительной влажности не более 80%.

Транспортировка

Категорически

механические воздействия на упаковку при транс-

не допускается падение и любые

портировке

При разгрузке/погрузке не допускается использование любого вида техники, работающей по принципу

зажима упаковки

Общие правила безопасности

1. Не работайте пилой одной рукой! Последстви-

ями работы одной рукой могут стать серьезные

травмы оператора, помощников и окружающих.

Пила предназначена для работы

2. Не работайте цепной пилой, если Вы устали, на-

двумя руками.

ходитесь под воздействием наркотиков, алкого-

ля или лекарственных препаратов.

3. При эксплуатации пилы используйте средства

индивидуальной защиты: очки, обувь, перчатки,

шлем, противошумные наушники или беруши.

Надевайте подходящую одежду. Не надевайте

свободную одежду или ювелирные украшения.

Оберегайте ваши волосы, одежду и

попадания в движущиеся части пилы. Свобод-

перчатки от

ная одежда, ювелирные украшения или длин-

ные волосы могут попасть в движущиеся части

пилы.

4. Будьте осторожны при обращении с топливом.

Прежде чем запустить двигатель, во избежание

пожара, отойдите с пилой на расстояние мини-

мум 3 м от места заправки топливом.

5. Не позволяйте никому

мя запуска двигателя и при эксплуатации пилы.

подходить к Вам во вре-

Не допускайте в рабочую зону посторонних лиц,

детей и животных. Пила не предназначена для

использования лицами (включая детей) с осла-

бленными физическими, сенсорными или ум-

ственными способностями, у которых нет опыта

и знаний по обращению с инструментом.

начинайте пилить, не очистив рабочую зону,

6. Не

не заняв устойчивое положение и не определив

беспрепятственный путь на случай эвакуации.

7. При работающем двигателе пила является ис-

точником высокой опасности – соблюдайте пре-

дельную осторожность.

8. Перед запуском двигателя убедитесь, что пильная цепь не соприкасается с посторонними

предметами.

9. Переносите пилу с выключенным двигателем,

крышкой шины к ноге, шиной назад, предварительно надев на шину защитный чехол.

10. Не используйте пилу, которая неисправна, ненадлежащим образом отрегулирована, собрана

не полностью или ненадежно. Убедитесь, что

пильная цепь

вации тормоза.

прекращает вращаться при акти-

11. Прежде чем поставить пилу на землю, выключайте двигатель.

12. При спиливании тонких деревьев и веток соблюдайте особенную осторожность, т.к. может

произойти зажатие пильной цепи, отскок пилы,

потеря равновесия.

13. При обрезке зажатых и напряженных веток и

сучьев будьте готовы к тому, что

скочить после ослабления натяжения.

они могут от-

14. Рукояти пилы должны быть сухими, чистыми и

без следов масла и топлива.

15. Работайте с цепной пилой только на открытом

воздухе или в хорошо проветриваемом помещении.

16. При работах на высоте всегда используйте

подъемную платформу. Запрещается работать

на лестнице, на дереве, в неустойчивом

жении, на высоте выше уровня плеча, одной

поло-

рукой.

17. Техническое обслуживание пилы должен производить только квалифицированный специалист

в авторизированном сервисном центре, кроме

работ, которые описаны в разделе «Техническое

обслуживание» настоящего руководства.

18. При транспортировке используйте соответствующий защитный чехол на шину.

19. Не работайте пилой возле огнеопасных жидкостей или

находитесь: в помещении или на улице. Резул ь-

газов, вне зависимости от того, гд е вы

татом может быть взрыв и/или пожар.

20. Не заправляйте топливный и масляный бак при

работающем двигателе.

21. Используйте пилу по назначению – только для

резки древесины. Не используйте пилу для того,

чтобы резать пластмассу, пенобетон и любые

не деревянные материалы.

другие

22. Работайте в перчатках и следите, чтобы руки

были теплыми. При длительной работе с цепной пилой под воздействием вибрации может

развиться синдром белых пальцев. Работа в

перчатках и контроль за теплотой рук снижают

риск развития синдрома белых пальцев. При появлении симптомов этого заболевания сразу же

обратитесь

к врачу.

ВНИМАНИЕ! Данная модель пилы пред-

назначена для нечастого использования

в домашнем и приусадебном хозяйстве в

таких областях применения, как расчистка зарослей кустарника, обрезка ветвей,

распиливание дров и т.д. Данная пила не

предназначена для профессионального

либо интенсивного использования в течение длительного времени.

Изготовитель: BORT GLOBAL LIMITED

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

13

Page 14

Требования безопасности при отскоке пилы

Отскок или отдача пилы происходит, когда движущаяся цепь касается какого-либо объекта верхней

четвертью концевой части направляющей шины

или, когда дерево смыкается и защемляет пилу в

пропиле.

Прикосновение верхней четверти концевой части

направляющей шины к какому-либо объекту может

заставить цепь вонзиться в объект,

ние остановит ее. В результате происходит внезап-

что на мгнове-

ная и быстрая реверсивная реакция, которая отбрасывает пилу вверх и назад на оператора. Такие

реакции пилы могут привести к потере контроля

над ней и серьезным травмам.

Как пользователь пилы, Вы должны предпринять

все меры, чтобы исключить возможность возникновения несчастных

1. Постарайтесь понять, что такое отскок. Это по-

случаев и ранений.

может уменьшить эффект внезапности его возникновения, что, в свою очередь, уменьшит вероятность несчастного случая.

2. Крепко и жестко держите пилу обеими руками

при работе. Пальцы левой руки должны сверху

обхватывать переднюю рукоятку, большой палец находится снизу рукоятки.

3. Ваша правая рука должна полностью обхватить

заднюю рукоятку, независимо от того правша вы

или левша. Жесткий хват поможет вам уменьшить отскок и не потерять контроль над пилой.

4. Очистите свое рабочее место от мусора. Уберите также все предметы, на которые ваша цепная

пила может наткнуться в процессе пиления кон

кретного бревна.

5. Запрещается пиление выше высоты плеча.

6. Следуйте рекомендациям изготовителя и ин-

струкциям по техническому обслуживанию для

пильной цепи.

7. Используйте направляющие шины и цепи, разрешенные заводом-изготовителем.

Конструктивные особенности, снижающие

опасность отскока:

ВНИМАНИЕ! Цепная пила имеет ряд

конструктивных особенностей, которые,

хотя и снижают опасность отдачи, тем не

менее, полностью не устраняют ее.

1. Конструкцией пилы предусмотрена направляющая шина с уменьшенной отдачей, что достигается минимальным радиусом закругления. Это

уменьшает размер зоны на конце шины, в которой существует опасность отдачи.

2. Конструкцией

ограничитель глубины реза и предохранитель-

цепи предусмотрен контурный

ный шарнир, что обеспечивает плавное врезание цепи в дерево и изменение направления

силы отдачи пилы при работе.

3. Конструкцией пилы предусмотрено низкое расположение передних и задних рукояток

4. Конструкцией пилы с низко расположенными

рукоятками предусмотрено защитное устройство, расположенное перед передней рукояткой

(рычаг тормоза цепи), снижающее риск опасно-

сти контакта руки оператора с пильной цепью в

случае соскальзывания руки во время работы

пилы.

Совокупное действие этих факторов обеспечивает

баланс и противодействие при контроле за точкой поворота полотна к оператору, когда происходит отдача.

Цепная пила снабжена тормозом цепи, который

сконструирован таким образом, чтобы мгновенно

остановить цепь, как только произойдет отскок.

Цепной тормоз уменьшает риск несчастных случаев, но не предотвращает их полностью.

ВНИМАНИЕ! Пользовать пилы не должен

полностью полагаться на конструктивные

особенности. Следует соблюдать все меры предосторожности и правила техники

безопасности, изложенные в настоящем

руководстве, чтобы избежать отскока и

других ситуаций, способных привести к

серьезным травмам. Не рассчитывайте

на то, что цепной тормоз полностью защитит Вас в случае отскока.

Требования

в эксплуатацию

безопасности при вводе

Расположение основных узлов

и органов управления

-

рисунок 1

Изготовитель: BORT GLOBAL LIMITED

14

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

Page 15

1 - направляющая шина

2- пильная цепь

3 - ручка тормоза

4 - передняя рукоятка

5 - крышка воздушного фильтра

6 - выключатель

7 - рычаг воздушной заслонки

8 - пробка топливного бака

9 - пробка масляного бака

10 - задняя рукоятка

11 - стопорный рычаг курка газа

12 - курок газа

13 - кнопка подкачки топлива

14 - винт натяжения цепи

15 - гайки крепления крышки тормоза

16 - улавливатель цепи

17 - зубчатый упор

Номера перед описаниями соответствуют номерам

на рисунке 1 — это поможет Вам найти то или иное

предохранительное устройство .

2. Цепь с низкой отдачей — помогает значительно

снизить силу и интенсивность отскока благодаря

особой конструкции ограничителя глубины реза и

соединительных звеньев

3. Ручка тормоза цепи/защита руки - защищает

левую руку оператора при соскальзывании ее с

передней

скоке

рукоятки во время работы пилы. При от-

пилы за счет силы инерции приводит в действие

механизм тормоза, который мгновенно останавливает цепь.

6. Выключатель - служит для выключения

двигателя. При запуске и работе двигателя должен

находится в положении «1».

11. Стопорный рычаг курка газа - предотвращает

случайное нажатие на курок газа при работающем

двигателе. Курок

конца не нажат стопорный рычаг.

газа невозможно нажать, если до

16. Улавливатель цепи — уменьшает опасность

травм в случае обрыва или соскакивания цепи с направляющей шины

Установка шины и цепи

1. Убедиться, что тормоз цепи находится в расторможенном положении. Потянуть ручку тормоза 3

(рисунок 1) на себя в сторону передней рукоятки

до щелчка.

2. Ослабить гайки 15 (рисунок 1) и с помощь отвертки открутить винт натяжения цепи 14 (рисунок 1).

3. Удалить гайки 15 крепления крышки шины и

снять крышку.

ВНИМАНИЕ! удалить из-под крышки

пластмассовый фиксатор (если предусмотрено конструкцией). Фиксатор предназначен только для транспортировки

пилы

4. Установить шину на шпильки (рисунок 2).

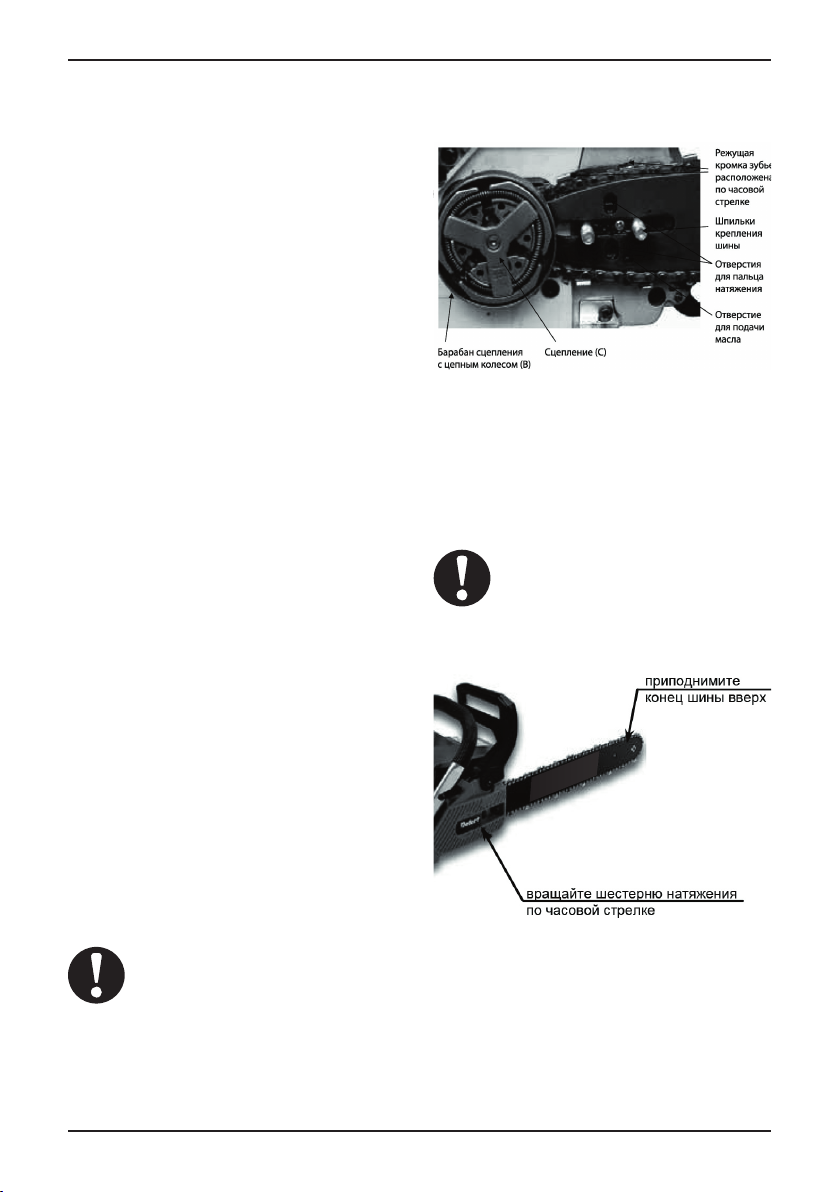

5. Поместить цепь на зубья цепного колеса (В),

расположенного позади сцепления (С). Удостовериться в правильном расположении цепи на

звездочке. Цепь на шине должна быть установ-

Изготовитель: BORT GLOBAL LIMITED

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

лена таким образом, чтобы зубья цепи своими

режущими кромками были расположены вперед

по ходу движения цепи (по часовой стрелке).

6. Установить на место крышку тормоза цепи и затянуть гайки крепления крышки.

ВНИМАНИЕ! При установке крышки

следите за тем, чтобы палец натяжения

цепи точно вошел в отверстие для натя-

жения цепи на шине.

7. Прокрутить вручную цепь на шине и убедится,

что цепь плотно легла на зубья звездочки и в

направляющий паз на шине.

8. Отрегулировать натяжение цепи (см. раздел на-

тяжение цепи).

9. Затянуть гайки крепления крышки шины.

Рисунок 2

Регулировка натяжения цепи:

Правильное натяжение цепи очень важно и должно

проверяться перед началом работы, а также при

каждой заправке топливом. Потраченное время на

проверку натяжения цепи, позволит сделать работу

более эффективной и продлит срок службы цепи,

шины и звездочки.

ВНИМАНИЕ! Всегда надевайте защит-

ные перчатки при установке и регулировке натяжения цепи.

1. Приподнимите передний конец шины вверх, и

удерживая его, вращайте винт натяжения цепи

по часовой стрелке (рисунок 3).

Рисунок 3

2. Вращайте винт до тех пор, пока цепь не будет

плотно прилегать к нижней части шины, на середине шины цепь должна выходить из направляющего паза на высоту зуба (рисунок 4).

3. После натяжения цепи, придерживая шину за

передний конец, затяните ключом гайки крепления шины, не прилагая при этом усилий

точно подтянуть гайку на 1/3 полного оборота.

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

. Доста-

15

Page 16

ВНИМАНИЕ! Чрезмерная затяжка гаек

приведет к повреждению резьбы шпильки

крепления шины или вытягиванию ее из

посадочного места в картере двигателя.

ВНИМАНИЕ! После начала работы, при-

мерно через 5 резов цепь необходимо

подтянуть, так как при нагреве цепи произойдет ее удлинение.

ВНИМАНИЕ! После окончания работы

цепь обязательно надо ослабить, чтобы

снять статическую нагрузку с шины и

шпилек крепления шины, так при охлаждении металл сжимается и цепь укорачивается

Рисунок 4

Механический тормоз цепи:

Ваша пила оборудована механическим инерционным тормозом цепи, который уменьшает вероятность травмы из-за отскока.

В случае возникновения отскока, при резком поступательном движении пилы верх/назад, под действием сил инерции рукоятка тормоза движется

вперед и, преодолевая усилие пружины, активирует

тормозной механизм.

Барабан сцепления (В

ся и цепь останавливается.

рис.2) мгновенно блокирует-

ВНИМАНИЕ! Для нормальной работы

всего механизма ручка тормоза должна

быть в исправном состоянии, не иметь

трещин, сколов. В экстренных случаях

тормозной механизм можно включить

вручную, нажав при этом на ручку тормоза вперед.

ВНИМАНИЕ! Задача тормоза цепи со-

стоит в том, чтобы уменьшить вероятность травмы из-за отскока, однако, это

не гарантирует полную безопасность,

если пилой управляют небрежно. Всегда

проверяйте тормоз цепи перед началом

работы вашей пилы и, периодически, во

время работы.

Проверка тормоза цепи:

1. Тормоз цепи заторможен (цепь остановлена),

когда тормозной

ном положении. В этом положении Вы не в со-

рычаг находится во включен-

стоянии провернуть цепь (рис. 5а).

Изготовитель: BORT GLOBAL LIMITED

16

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

2. Тормоз цепи расторможен (цепь может вращаться), когда ручка тормоза взведена (рис. 5б).

а) Тормоз цепи заторможен б) Тормоз цепи расторможен

Рисунок 5

ВНИМАНИЕ! Тормозной рычаг должен

фиксироваться в обоих крайних положениях. Если чувствуется сильное сопротивление при нажатии на рычаг, рычаг не

фиксируется в крайних положениях, либо

не перемещается ни в одно из положений,

не используйте вашу пилу. Обратитесь в

сервисный центр для проведения ремонта.

ВНИМАНИЕ! Работа при заторможенном

тормозе цепи приводит к повреждению

деталей бензопилы и не подлежит гарантийному ремонту.

Смазка направляющей шины и пильной цепи:

Ваша пила оборудована автоматической системой

подачи масла.

• Система автоматически подает необходимое

количество масла к шине и цепи.

• Увеличение оборотов двигателя, увеличивает

подачу масла к шине. Поток

• Объем масляного и топливного бака рассчитан

не регулируется.

таким образом, чтобы масло и топливная смесь

заканчивались приблизительно одновременно.

• Пильная цепь должна постоянно смазываться

во время работы.

ВНИМАНИЕ! Запрещено работать без

смазки пильной цепи.

• При работе пильной цепи без смазки режущая

гарнитура разрушается непоправимо в течении

короткого времени.

Проверку подачи масла на цепь проводить перед

началом работы и каждый раз после заправки баков топливом и маслом.

1. Расположить пилу над чистой светлой поверхностью на расстоянии 15-20

2. Нажать на курок газа и дать двигателю порабо-

см.

тать 10-15 сек. на максимальных оборотах. Под

шиной должен остаться масляный след.

Рисунок 5

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

Page 17

В случае отсутствия подачи масла:

• проверить наличие и уровень масла в масляном

баке. При необходимости долить.

• проверить чистоту отверстия смазочного канала

на шине. При необходимости почистить.

• проверить чистоту

не. При необходимости почистить.

направляющего паза на ши-

Если после выполнения этих мер работоспособность системы подачи масла не восстановилась, то

следует обратиться в специализированный сервисный центр для выяснения причины неисправности.

ВНИМАНИЕ! Работа, даже незначитель-

ное время, без подачи масла или при

недостаточной подаче масла приводит к

выходу из строя пильной гарнитуры (шины, цепи, звездочки)

Для смазки цепи и шины необходимо использовать

специальное адгезионное масло. Это масло имеет

специальные добавки и вязкие присадки, которые

обеспечиваю хорошую смазку, уменьшают окис-

и истирание металла. С течением времени

ление

масло полностью разлагается в почве.

В качестве замены, для кратковременных

работ, допускается использование для смазки цепи

и шины чистого автомобильного моторного масла.

В моторных маслах содержатся моющие присадки,

которые разрушают резиновые уплотнения и шланги системы маслоподачи.

ВНИМАНИЕ! Не допускать использова-

ния для смазки цепи отработанного масла, а также любые жидкие масла (веретенное, трансформаторное и т.д.).

Рекомендации по приготовлению

топливной смеси:

Для приготовления топливной смеси используйте

неэтилированный бензин с октановым числом 92,

смешанный с моторным маслом для двухтактных

двигателей с воздушным охлаждением, в пропорции 50:1.

Используйте двухтактное моторное масло для

•

высокооборотистых двухтактных двигателей с

воздушным охлаждением.

• Никогда не используйте масло, предназначенное

для двигателей с водяным охлаждением, масло

для низкооборотистых двухтактных двигателей

или масло для четырехтактных двигателей.

Для определения пропорций смешивания используйте таблицу пропорций топливной смеси

Бензин Масло Соотношение

1 литр 20 мл 50:1

5 литров 100 мл 50:1

10 литров 200 мл 50:1

• Смешать бензин и масло в специальной ем-

кости из металла или непищевого пластика.

Смесь приготовить в хорошо проветриваемом

помещении.

• Вылить в емкость половину приготовленного

для работы бензина.

• Добавить необходимое количество двухтактного моторного масла.

• Плотно закрыть крышку емкости.

• Взболтать топливную смесь в емкости.

• Медленно открыть крышку емкости и долить

оставшийся бензин.

• Закрыть емкость и взболтать.

• Перед каждой заправкой топливного бака тща-

тельно взболтайте топливную смесь в

емкости.

Заполнение топливного бака:

1. Перед заполнением топливного бака остановите двигатель и дайте ему полностью остыть.

2. Заполняйте топливный бак на открытом воздухе, или в хорошо проветриваемом помещении,

вдали от источников возможного воспламенения.

3. Очистите от мусора поверхность рядом с крышкой топливного бака.

4. Медленно отвинтите крышку топливного бака

после чего положите ее на чистую, сухую поверхность.

5. Аккуратно влейте топливную смесь.

6. Не заполняйте топливный бак полностью, долж-

но оставаться пространство для расширения

топлива.

7. Закрутите крышку топливного бака плотно руками. Перед запуском насухо протрите топливный

бак от остатков пролитого топлива.

ВНИМАНИЕ! Гото вую к работе топливную

смесь рекомендуется использовать в течение 90 дней. При длительном хранении

топливная смесь окисляется, становится

неоднородной и непригодной к применению. Никогда не используйте топливную

смесь, которая была приготовлена более

чем 90 дней назад

ВНИМАНИЕ! При приготовлении топлив-

ной смеси тщательно выдерживайте соотношение бензин/масло. Никогда не

заливайте чистый бензин для заправки

двигателя вашей пилы. Факт поломки

двигателя в результате эксплуатации на

чистом бензине, с неправильно приготовленной или старой топливной смесью, не

подлежит гарантийному ремонту

ВНИМАНИЕ! Не храните двигатель с то-

пливом в баке в закрытом помещении.

Топливо и его пары крайне взрывоопасны. Не смешивайте бензин с маслом непосредственно в топливном баке двигателя

ВНИМАНИЕ! Используйте только сер-

тифицированные канистры из металла

или непищевого пластика. Обращаться

с топливом и заполнять топливный бак

должны только взрослые

,

Изготовитель: BORT GLOBAL LIMITED

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

17

Page 18

ВНИМАНИЕ! Проводите все работы с то-

пливом только на открытом воздухе, или

в хорошо проветриваемом помещении,

вдали от источников возможного воспламенения. Не запускайте двигатель, если

топливо пролито. Протрите остатки пролитой смеси и дождитесь их полного высыхания

Эксплуатация:

ВНИМАНИЕ! Не обкатывать и не остав-

лять работать двигатель длительное

время на холостых оборотах. Новую пилу

вплоть до третьей заправки топливного

бака не эксплуатировать без нагрузки на

высоких оборотах. Двигатель достигает

максимальной мощности только после

выработки 8-10 полных заправок топливного бака

1. Заполнить топливный бак смесью.

2. Заполнить масляный бак чистым маслом

смазки цепи.

для

3. Проверить натяжение цепи.

4. Убедиться, что тормоз цепи заторможен.

Запуск холодного двигателя (рисунок 6):

1. Нажать на кнопку подкачки топлива 7-10 раз до

появления в ней топлива.

2. Установить выключатель в положение "1".

3. Закрыть воздушную заслонку (вытянуть назад

до упора рычаг воздушной заслонки).

4. Потянуть за ручку стартера до сопротивления.

Произвести

действия 5-6 раз до первого "хлопка" в глуши-

резкий рывок за ручку. Повторить

тель.

5. Открыть воздушную заслонку, задвинув рычаг

управления воздушной заслонкой.

6. Нажать и отпустить курок газа. Двигатель перейдет в режим холостого хода.

Рисунок 6

ВНИМАНИЕ! После запуска двигателя

немедленно установить тормоз цепи в

позицию расторможен (рисунок 5б).

В случае, если двигатель не заводится, то, возмож-

Изготовитель: BORT GLOBAL LIMITED

18

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

но, Вы пропустили первую вспышку и свечу залило

бензином. В этом случае необходимо выполнить

следующие действия:

•

вывернуть и просушить свечу зажигания;

•

установить выключатель в положение "0";

•

перевернуть пилу свечным отверстием вниз,

нажать на курок газа, протянуть несколько раз

пусковое устройство для удаления ли топлива

из цилиндра;

•

установить свечу на место;

•

не закрывая воздушную заслонку, повторить

процедуру запуска.

Запуск прогретого двигателя:

1. Установить выключатель в положение "1".

2. Резко дернуть за ручку стартера 1-2 раза. Двигатель должен завестись.

3. Если двигатель не завелся, повторить проце-

дуры "перед началом работы" и далее "запуск

двигателя".

ВНИМАНИЕ! Для запуска прогретого дви-

гателя воздушную заслонку не закрывать.

Для облегчения запуска можно вытянуть

назад до упора и задвинуть обратно рычаг воздушной заслонки. В этом случае

курок газа зафиксируется в положении

повышенных оборотов. Для перевода

двигателя в режим холостого хода после

запуска нажмите и отпустите курок газа

Остановка двигателя

:

Для остановки двигателя отпустите курок газа, дайте поработать двигателю на холостых оборотах 1015 с. Установите выключатель в положение "0" для

остановки двигателя.

ВНИМАНИЕ! При запуске двигателя

обязательно выбирайте свободный ход

шнура стартера до плотного зацепления.

Шнур стартера никогда не вытягивайте

до конца, есть опасность разрыва шнура

или повреждения деталей стартерной

группы. Никогда не отпускайте при запуске ручку стартера в верхнем положении

опасность поломки стартера

Общие приемы пиления и валки

Распиловка древесины:

ВНИМАНИЕ! Чтобы распилить дерево,

неукоснительно соблюдайте правила

безопасного производства работ.

• Убедитесь, что дерево, предназначенное для

распила, находится в устойчивом положении и

не может соскользнуть. При необходимости закрепите концы дерева перед распилом.

• Пилить можно только дерево или деревянные

предметы. Во время работы убедитесь, что на

рабочем месте нет камней

могут отскочить и повредить цепь пилы.

или гвоздей, которые

• Избегайте контакта работающей пилы с прово-

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

Page 19

лочной оградой или землей. Когда производите

очистку от веток, не пилите кончиком шины.

• Будьте внимательны во время работы,

пеньки деревьев, корни, ямы или кочки могут

так как

быть причиной вашего падения.

Бревно, лежащее на земле, испытывает на себе

действие сил растяжения и сжатия, которые распределены в теле древесины в зависимости от того,

куда приходится основной вес, каковы точки опоры.

• Если вы неправильно оценили, как распределены растяжение

с неправильной стороны, произойдет защемле-

и сжатие, и сделали пропил

ние пильной шины и пильной цепи в древесине,

и вы не сможете вытащить бензопилу.

ВНИМАНИЕ! Не нажимайте на курок га-

за для того, чтобы увеличить обороты

двигателя, в то время как пильная цепь

защемлена в пропиле, муфта сцепления

сгорит

• Если все-таки произошло защемление шины в

пропиле, и вы не можете ее вытащить, не дергайте и не вырывайте ее.

• Остановите бензопилу. Вбейте клин

чтобы он приоткрылся, затем вытащите пилу из

в пропил,

пропила.

• Производите пиление только острой цепью, пиление тупой цепью небезопасно и может быть

причиной чрезмерного износа пильной гарнитуры и деталей двигателя.

• При пилении острой цепью опилки вылетают

крупными хлопьями, если опилки из-под цепи

вылетают мелкие или в

пыли, то цепь следует заточить.

виде мелкодисперсной

ВНИМАНИЕ! Запрещается использовать

пилу для профессиональной валки дере-

вьев.

При необходимости спилить дерево следует выполнить следующие правила безопасности:

1. Прежде чем приступать к валке, расчистите место вокруг дерева от посторонних предметов и

мусора.

2. Примите устойчивую позу для начала пиления,

расположившись таким образом, чтобы пила во

время работы не

пятствие. Затем выберите путь к отходу.

3. Когда дерево начнет падать, путь отхода должен

наткнулась на какое-либо пре-

быть направлен по диагонали в сторону, противоположную направлению падения, под углом

45 градусов, и вы должны отойти минимум на 3

метра от ствола, на тот случай, если во время падения комель дерева отскочит в сторону (Рис.7).

Рисунок 7

4. Выберите направления падения дерева, для

этого следует учесть силу и направление ветра,

естественный наклон дерева, равномерность

распределения веток в кроне дерева. Начните

пилить с той стороны дерева, куда оно должно

упасть(Рис. 8)

Рисунок 8

5. Сделайте запил (1) с той стороны, куда должно

упасть дерево глубиной примерно 1/3 диаметра

ствола.

6. Сделайте основной валочный пропил (2) с противоположной стороны, выше основания запила

на 2,5-5 см.

7. Между основным пропилом и запилом должно

оставаться недопил (3) примерно 1/10 диаметра

ствола. Вставьте своевременно клин в пропил.

Недопил(3) действует как шарнир и позволяет

контролировать падение дерева.

ВНИМАНИЕ! Ни в коем случае не допи-

ливать до конца недопил (3), так как вы

не сможете контролировать направление

падения дерева.

При спиливании дерева зубчатый упор используется в качестве точки вращения - пила по возможности должна подтягиваться незначительно.

Когда дерево начинает падать, выключите двигатель пилы, положите ее на землю

те в намеченную сторону.

и быстро отойди-

Рекомендации по обслуживанию

1. При обслуживании пилы необходимо использовать только рекомендованные изготовителем

сменные расходные материалы. Использование

не рекомендованных расходных материалов

приводит к поломке пилы или травмам.

2. Ремонт пилы необходимо осуществлять только

квалифицированным специалистам с использованием деталей, изготовленных производителем машины.

3. Сроки проведения

относятся только к нормальным условиям экс-

технического обслуживания

плуатации. При экстремальных условиях эксплуатации (сильная запыленность, пиление

сухой древесины и т.п.) или более длительной

ежедневной работе, указанные интервалы следует сократить

Изготовитель: BORT GLOBAL LIMITED

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

19

Page 20

Сроки проведения технического обслуживания относятся

только к нормальным условиям эксплуатации. При экстремальных условиях эксплуатации (сильная запыленность,

пиление сухой древесины и т.д.) или более длительной

ежедневной работе, указанные интервалы необходимо сократить

Перед началом работы

После окончания работы

После каждой заправки

топливного бака

Ежемесячно

Ежегодно

При неисправности

При повреждении

При необходимости

Комплектное

устройство

Визуальный контроль ++

Очистка +

Рычаги управления Контроль функционирования ++

Тормоз пильной цепи

Топливный фильтр

Контроль функционирования ++

Осмотр в сервисном центре +++

Контроль +

Замена +++

Топливный бак Очистка +

Масляный бак Очистка +

Система смазки цепи Контроль +

Контроль состояния заточки ++

Пильная цепь

Контроль натяжения цепи ++

Заточка +

Замена +++

Контроль (износ, повреждения)+

Направляющая шина

Очистки и поворот на другу сторону +

Замена ++

Ведущая звездочка

Воздушный фильтр

Антивибрационные

элементы

Охлаждающие ребра

цилиндра

Отверстия для всасывания воздуха на

крышке стартера

Карбюратор

Контроль (износ, повреждения)+

Замена ++

Очистка ++

Замена ++

Контроль +++

Замена +

Очистка ++

Очистка ++

Контроль холостого хода

(цепь не должна вращаться)

++

Настройка холостого хода +

Проверка состояния электродов +

Свеча зажигания

Крепежные винты

и гайки

Уловитель пильной

цепи

Искрогасящая сетка

в глушителе

Замена ++

Проверка

+

Подтягивание +

Контроль ++

Замена +

Контроль +

Замена +

100

часов

рабо-

ты

Изготовитель: BORT GLOBAL LIMITED

20

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

Page 21

Работы по техническому обслуживанию

ВНИМАНИЕ! Никогда не выполняйте об-

служивание на горячем двигателе. Это

может привести к ожогу рук или пальцев.

Воздушный фильтр

ВНИМАНИЕ! Никогда не работайте пи-

лой без воздушного фильтра, с грязным

или поврежденным воздушным фильтром. Пыль и грязь будут попадать в

двигатель, что приведет к его поломке.

Выход из строя двигателя по этой причине не подлежит гарантийному ремонту.

Держите воздушный фильтр чистым!

Проверка и чистка (рисунок 9):

Рисунок 9

1. Открутите барашковую гайку и снимите крышку

воздушного фильтра.

2. Снимите воздушный фильтр с корпуса и проверьте на отсутствие повреждений.

3. Очистите воздушный фильтр. Вымойте фильтр

чистой, теплой мыльной водой. Промойте в чистой, холодной воде. Просушите. Сильно загрязненный фильтр необходимо заменить.

4. Установите воздушный фильтр. Установите верхнюю крышку воздушного

дежно гайку крепления крышки.

фильтра. Затяните на-

Топливный фильтр

ВНИМАНИЕ! Никогда не работайте пи-

лой с отсутствующим топливным фильтром. Топливный фильтр необходимо

заменять по мере необходимости, но не

реже одного раза в год.

1. Снимите крышку топливного бака.

2. Согните кусок мягкого провода в виде небольшо-

го крючка.

3. Зацепите крючком топливный шланг с фильтром

и вытяните

через заливную горловину.

ВНИМАНИЕ! Не вытягивайте топливный

шланг полностью из бак а. Достаточно

вытащить наружу часть шланга с фильтром.

Изготовитель: BORT GLOBAL LIMITED

SUITES 3009-12 SHUI ON CTR 6-8, HARBOUR RD WAN CHAI HONG KONG

Тел/Факс +85 258 194 891

4. Отделите фильтр скручивающим движением.

5. Уст

ановите новый фильтр. Вверните топливный

шланг в бак. Убедитесь, что фильтр лежит на дне

топливного бака.

6. Заполните бензобак новым топливом.

ановите крышку топливного бака.

7. Уст

ВНИМАНИЕ! Топливный фильтр не под-

лежит очистке. Только замена.

ВНИМАНИЕ! Для эффективной работы

двигателя пилы, свеча зажигания должна

быть исправной и иметь соответствующий зазор.

Рекомендованная свеча зажигания L7T. Использование для работы двигателя свечи зажигания, отличной по своим параметрам от рекомендованной,

может привести к выходу двигателя из строя и не

подлежит ремонту по гарантии

единить колпачок свечи зажигания и уда-

1. Отсо

лить грязь вокруг свечи зажигания.

2. Открутить свечу зажигания свечным ключом.

ВНИМАНИЕ! Никогда не выкручивай-

те свечу, пока двигатель полностью не

остыл - опасность повреждения резьбовой части головки цилиндра.

3. Проверить свечу зажигания. Если электроды из-

ношены или повреждена изоляция, замените ее.

4. Измерьте зазор между электродами свечи зажи-

гания специальным щупом. Зазор должен быть

0,6-0,65 мм. При увеличении или уменьшении

требуемого зазора рекомендуется заменить свечу, так как регулировка зазора может привести к

изменению качества искрообразования.

5. Аккуратно закрутите свечу руками

6. После того , как свеча зажигания установлена на

место, затяните ее свечным ключом.

7. Установит

е свечу на колпачок.

.

ВНИМАНИЕ! При установке новой свечи

зажигания, для обеспечения требуемой

затяжки, заверните свечу ключом на

1/2оборота после посадки буртика свечи

на уплотнительную шайбу. При установке

бывшей в эксплуатации свечи зажигания,

для обеспечения требуемой затяжки заверните свечу ключом на 1/4- 1/8 часть

оборота после посадки буртика свечи на

уплотнительную шайбу.

ВНИМАНИЕ! Свеча зажигания должна

быть надежно затянута. Не завернутая

должным образом свеча зажигания сильно нагревается при работе двигателя

и может привести к его повреждению.

Большое усилие затяжки свечи зажигания может повредить резьбу головки цилиндра.

Уполномоченное изготовителем лицо: ООО «СБМ ГРУП»

445024, Самарская обл., г. Тольятти, Дзержинского ул.,

д. 98, оф. 337 т +7 (499) 700-10-34

21

Page 22

Настройка карбюратора

Карбюратор был оптимально настроен на заводе.

Если необходима регулировка карбюратора, обращайтесь, пожалуйста, в ближайший авторизированный сервисный центр.

Обслуживание шины

Требуется частое смазывание ведомой звездочки на конце шины, который поддерживает и несет

пильную цепь. Надлежащее обслуживание шины,

как объяснено

димым для содержания пилы в хорошем состоянии.

в этом параграфе, является необхо-