Boomerang RC Jets, LLC.

Website www.Boomerang-RC-Jets.com

Boomerang RC Jets, LLC.

2

Some of the additional items required to complete this kit:-

Extension leads to servos

2 X 1.5 metres (along booms to elevators)

8 X 1 metre from RX to outlet ribs of centre wing

2 X 1 metre along booms to rudders

2 X 300 mm from ailerons in outer wings

2 X 100 mm. from flaps in outer wings

1 X 300mm for steering servo

1 set heavy duty retracts, (Boomerang Jets option available)

1 set of wheels and brakes, (Boomerang Jets option available)

1 set wire legs, (5/6mm) or oleos (Boomerang Jets option available)

1 X electronic air valve for retracts,

1 X electronic air valve for brakes,

8 servos for control surfaces (5 to 8K torque digitals suggested)

1 servo for nose leg steering.

Many modellers prefer to choose commercially available control

horns, so these are not included in the kit. Optional Boomerang

Jets custom pushrod/clevis/ horns pack is available.

A

B

2mm

Warning!

Note the Symbols used throughout these

L

R

Assemble left and right sides

the same way.

Not supplied

Drill holes to the specified

diameter (here: 2mm. shown).

Cut off shaded portion.

Apply epoxy glue.

Pay close attention here!

Ensure smooth non-binding

movement while assembling.

Apply instant glue (CA glue, super glue).

Do not overlook this symbol!

3

2

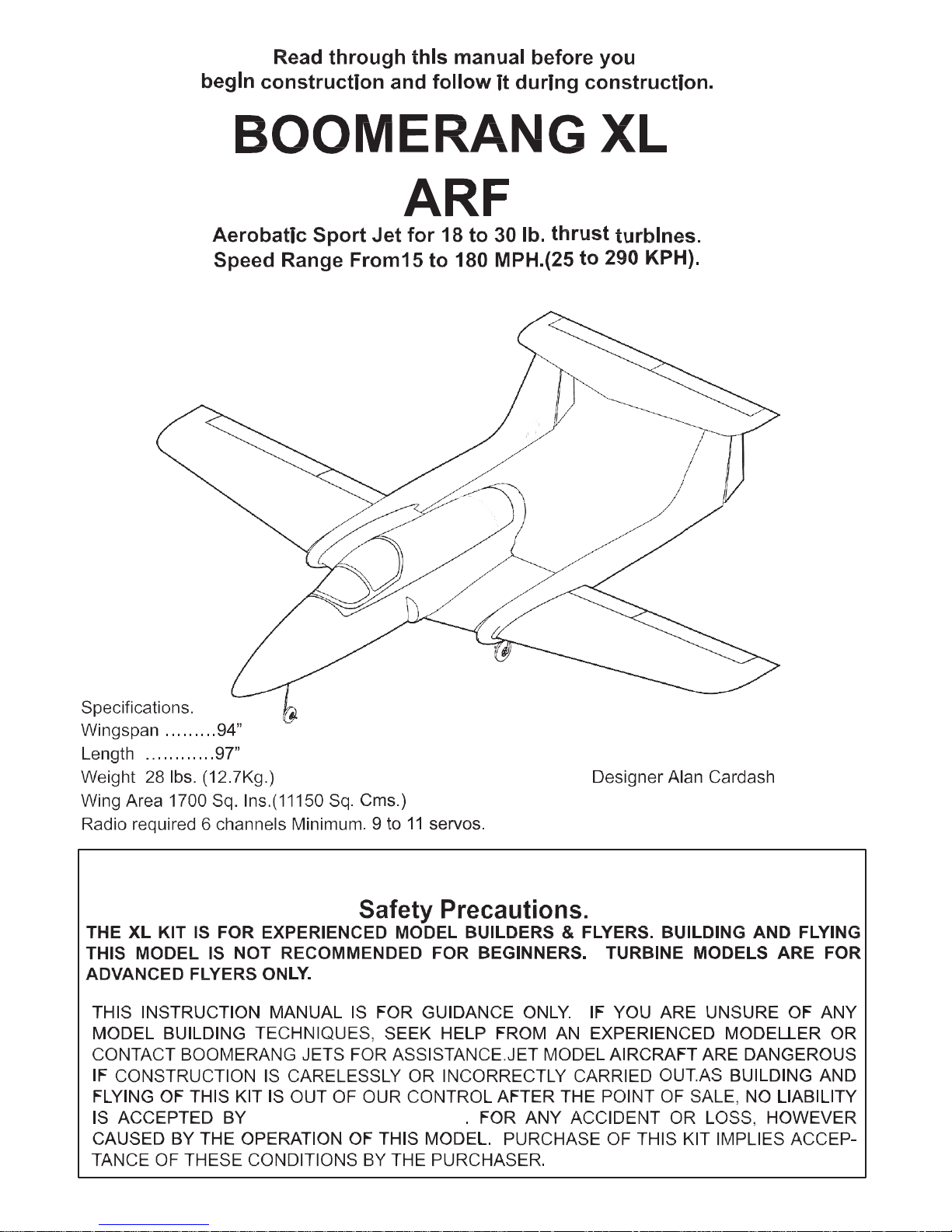

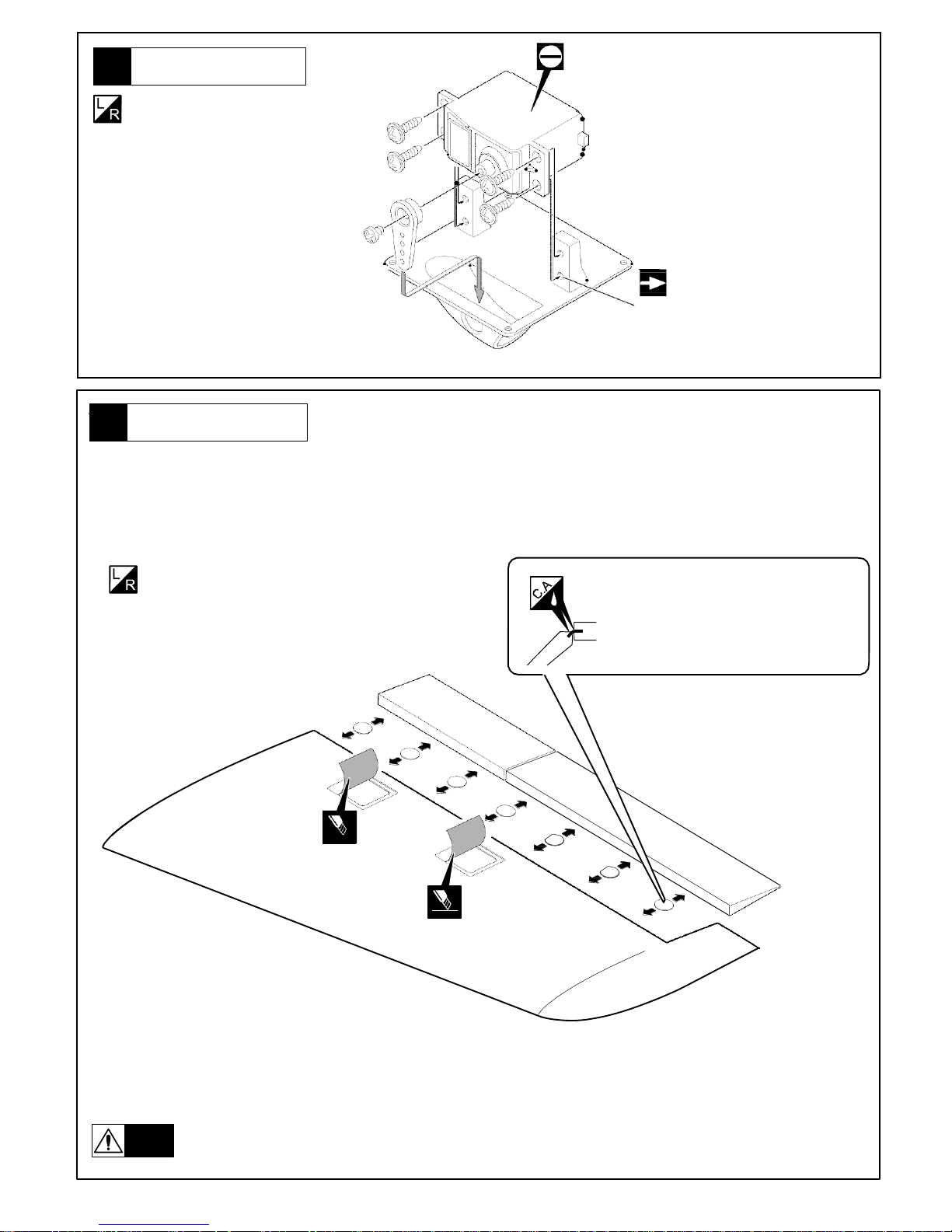

Centre Wing Underside

Iron the main landing gear area lightly through a cloth with a warm

iron before cutting away the covering film.

Take care not to damage the painted surfaces.

Cut away covering film.

For Main Landing Gear

Self-adhesive

4

1

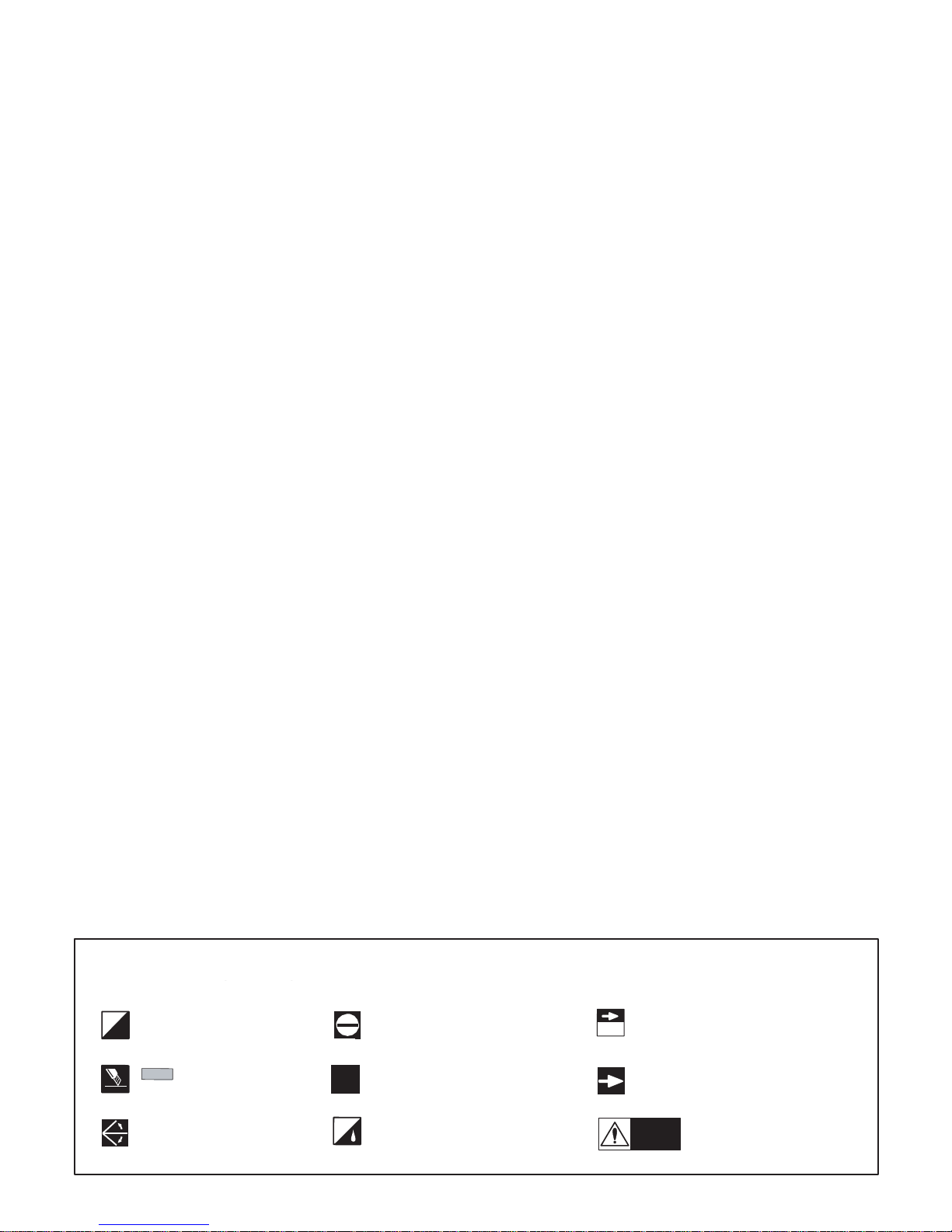

Centre Wing Topside

Iron the area lightly through a cloth with a warm

iron before cutting away the covering film from the exit

Self-adhesive

Wing Top

Self-adhesive

Cut away covering film.

Warning!

Be sure to glue securely.

This is Vital for safe flying!

4

5

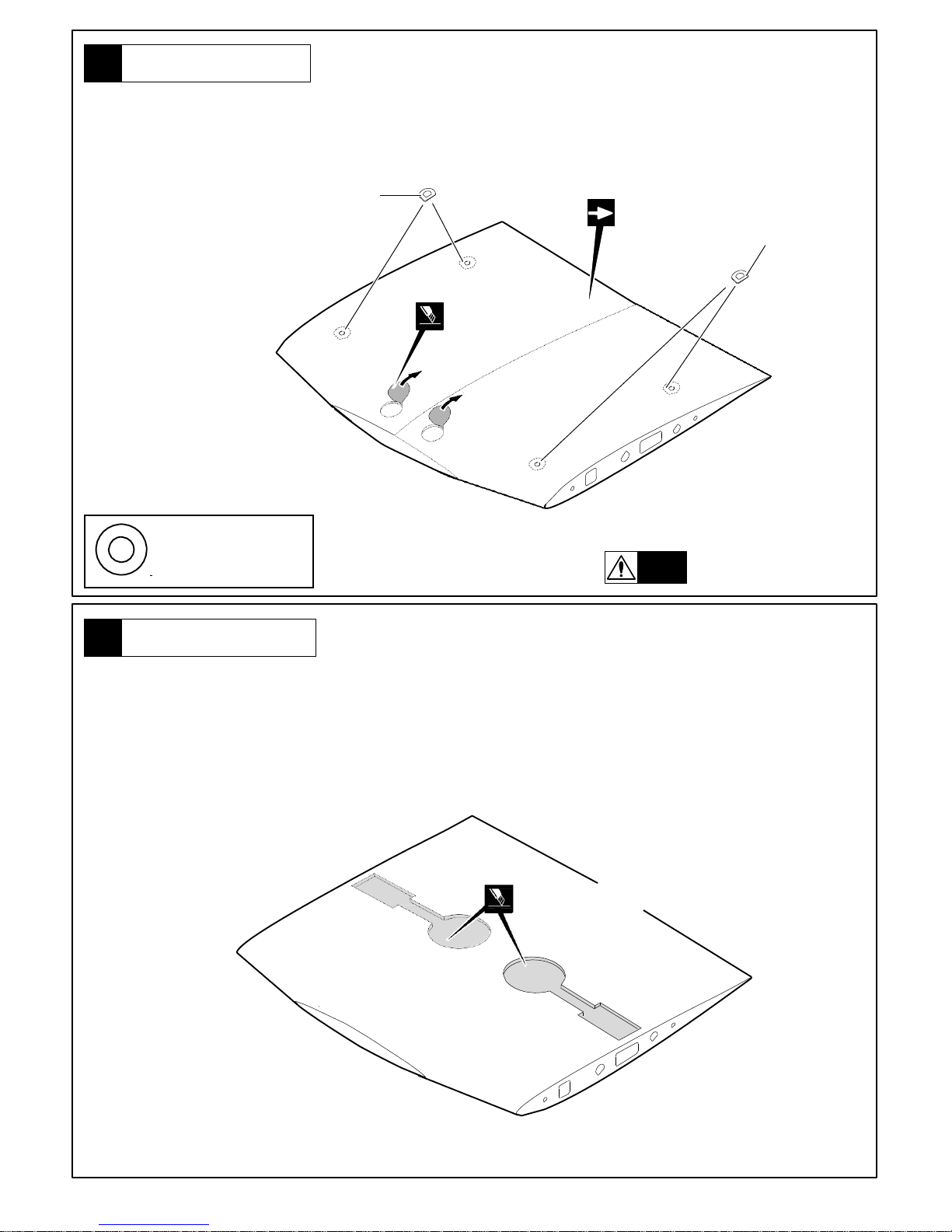

Mounting Retracts

Not Supplied.

Up to 2.75 inches

Not Supplied.

Not Supplied.

4

Cut off shaded portion.

Wheel Wells

Pass all 8 servo wires and air lines through the

centre wing before you trim the whe.el wells to

fit. Do not fix the vacformed wheel wells u.ntil

the servo wires and air lines are all in

place.Then trim the wheel wells to fit leaving

approx. 3mm.flat surface on top and fit and glue

them under the balsa wing surface.

NOTE;

Do not fix plastic wheel wells until the

servo wires and air lines are in place.

Cut off shaded portion.

2.6 x12mm TP Screw

8

3

Requires some modification

Main Retracts

2.6 x12mm

TP Screw

on main gear cover.

.

Not Supplied.

Not Supplied.

Not Supplied.

2.6 x12mm

TP Screw

Not Supplied.

5

7

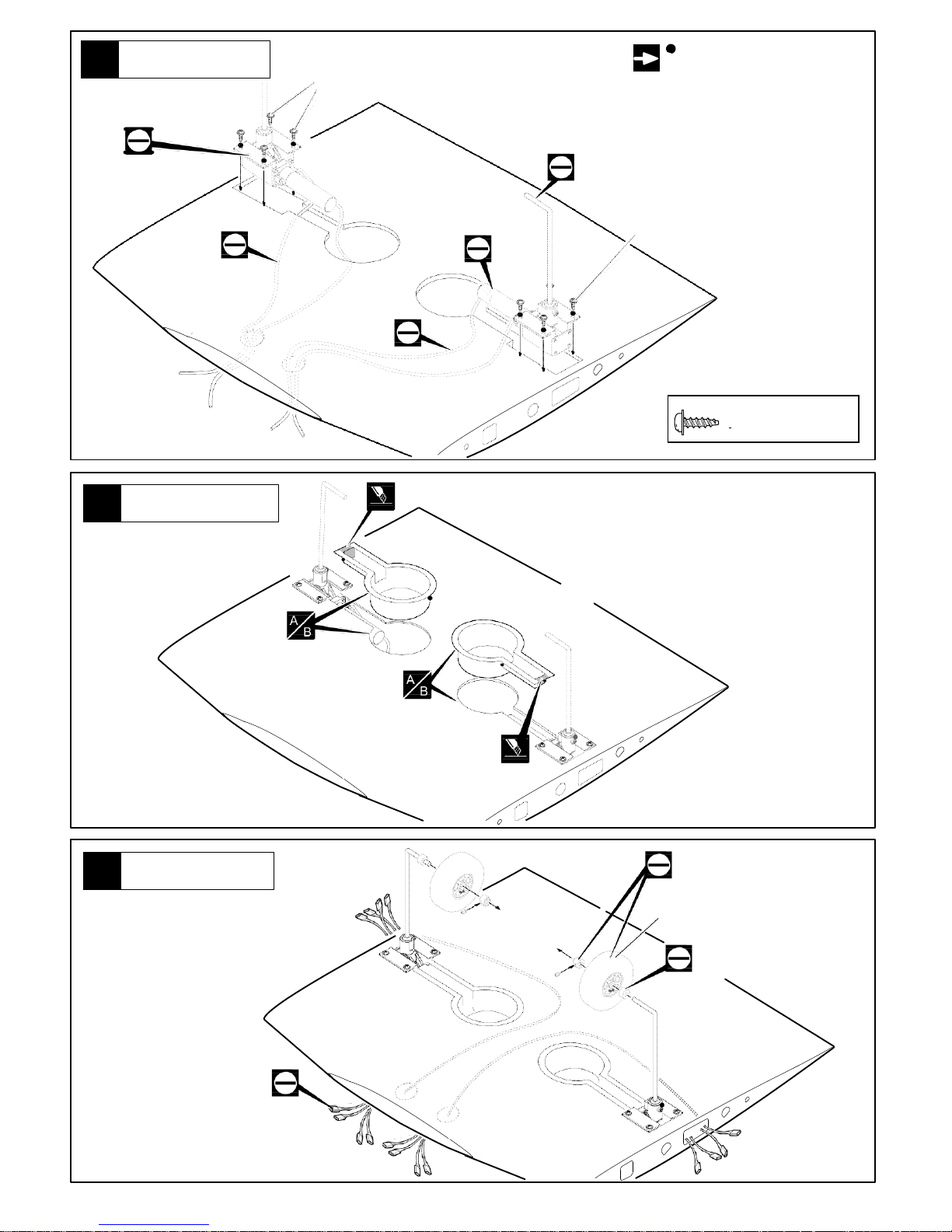

Wings

Lightly iron the covering film through a cloth and cut away allowing 3 mm overhang all

round.

Assemble left and right sides

the same wa.y

Be sure to apply instant type CA glue to

both sides of each hinges.

(low viscosity type)

Cut away covering film.

Cut away covering film.

Warning!

Be sure to glue securely

This is Vital for safe flying!

6

Servo Mounts

Assemble left and right sides

the same wa.y

Position of holes may need

adjustment depending on

servo brand used

6

2.6 x 12mm

TP Screw

8

2.6 x 12mm

TP Screw

8

9

Servo Mounts

Note: - Both flap servos are the same hand to ensure identical movement.

Allow 120 mm (5”) overhang of servo leads.

2.6 x12mm TP Screw

Extension lead

300 mm from ailerons in outer wings

Not Supplied.

Not Supplied.

Not Supplied.

Not Supplied.

Not Supplied.

Extension lead

100 mm. from flaps in outer

8

Servo Mounts

Fix servos using servo mounts supplied.

2.6 x12mm TP Screw

Not Supplied.

Not Supplied.

Not Supplied.

7

2.6 x12mm TP Screw

8

11

Rudder Servo

Extension lead

1 metre along booms to rudders

2.6 x12mm TP Screw

10

Alloy dowels

9x285mm

9x285mm

Screw in the 9 X 285 mm alloy dowels.

Ensure at least 120 mm (5”) servo wire minimum overhang

(to pass through the booms when field assembling)

8

13

Tailplane/Stab

Lightly iron covering through a cloth with warm

iron before cutting away covering film,

(leaving 3 mm. overhang all round the servo mounts as per the

Be sure to apply

instant

type CA glue to both

sides of each hinges.

Cut away covering film.

12

Rudders

Assemble left and right sides

the same way.

Use thin cyano both sides of each hinge

not supplied

3mm. or 4/40 pushrod and

clevises (not supplied).

not supplied

Assemble left and right sides

the same way.

Not Supplied

Right boom shown.

Heat Gun Be careflul not to

scorch the

heat-shr1n

J)I

W)n

·

k Tube

2m x 40mm

Heat-shrink Tube

10

Self adhesive

4

3 x 30mm Bolt

4

17 Tail Assembly

Self adhesive

3 x 30mm Bolt

3 x 30mm Bolt

Decrease size of top

exit hole after wires

are through to prevent

the connector falling

inside the fin.

16

Wing Locking

Lock

Wing Top

2.5mm Hex Wrench

3x6mm Bolt

3x6mm Bolt

3 x 6mm Bolt

4

4mm Washer

2

4mm Lock Nut

2

4 x 15mm Screw

2

11

19

Nose gear

55mm

Not Supplied.

Not Supplied.

“Trim the Cover Plate to clear the leg.”

“Use plywood to pack up the retract

mount as necessary to clear the

bearers when retracted.”

Not Supplied.

Not Supplied.

3mm

18

Additional safety fitting to stabilisor

With tailplane (Stab.) firmly

screwed down, pass a 3.6mm

drill through the holes in the fins

and drill a hole through the metal

tongue projecting down from the

Stab. Remove the Stab and tap

the new hole in the tongue out to

4mm thread. Repeat the

process through the other fin.

During assembly apply the 4mm

X15mm bolt through the fins and

the tongues and lock in place

with the 4mm nylock nuts and

washers supplied. If a 4mm tap

is not available drill the hole in

the tongue out to 4mm and

assemble the same way.

12

21

Gluing fuselage to wing

20

Check belly pan for fit, mark, then lightly iron covering,

then cut away wing covering as you did with the fuselage,

to expose Balsa. Glue in place."

/

Fuel Tank etc

Suggested Fuel Tank 3 litre pop bottle

The tank mounting formers can be cut

away to accommodate a larger tank

if required.

Cockpit Canopy

"Cut away a section of the cockpit floor to

allow the vacuum formed seat unit to be

glued or screwed in place. Add fascia

decal. Add pilot (not supplied}. Mark

and drill canopy and screw in pl ace."

13

2.6 x12mm TP Screw

------------------------ 10

"Trim hatch latch and if necessary adjust the 6mm.

dowels to achieve a good fit."

4mm Blind Nut

---------------------------- 1

4mm Washer

-- ---- - ----------------------· 1

lf

necessary, the use of large nicad packs will give the correct

CG for the first trimming flights CG should be as shown. Later

you can move the CG back a small amount at a time to

increase sensitivity for aerobatics. Set the travel to the values

shown below for the first flight. You can increase these later for

aerobatics if desired. Mount the control horns so that the

hole for the clevis is at 5 mm. behind the hinge on ailerons (to

provide differential). 1Omm. behind the low hinge line for the

flaps (to maximise movement), and Close to the hinge line

for the rudders and elevators."

Set the travel to the values show below

for the first flights. You can increase

these later for aerobatics if desired.

Carefully install the receiver and

battery

pack to

ensure that they will not shift during flight.

Shift the location of the receiver and battery pack

as

needed to obtain the specified CG.

ELEVATOR

.-- 30mm

_,.,- 40mm

----::;:;

;.:-- -<-- t---- Omm

.::::_:oJ

----, 30mm

Maximum possible down.

FLAP

For

first

trimming flights CG should be as shown.

Later you can move the CG back a small amount

at a time to increase sensitivity for aerobatics.

220 mm from Leading edge

350 mm from Trailing edge

14

AILERON

RUDDER

e

@

CG

The Boomerang XL is capable of just about any

maneuver possible with a jet. Take off run even on grass

is about ten yards if desired, and landing similarly short.

All development and most testing was done flying from

a 75 yard square grass surfaced flying field, ensuring

that the concept of a low maintenance, low stress, easy to

fly jet model was achieved. You will find that there is

almost no trim change when using the flaps. The

original XL models all used crow braking. If you have a

suitable computer transmitter, have the ailerons on two

separate channels and the flaps on a single channel

using a Y lead. Mix the flap and aileron channels so that

from half flap onwards the ailerons both rise together

until at full flap deflection of between 80 and 90 degrees

down, both ailerons are approximately 25 degrees

deflected up. This will still allow good lateral control and

will allow amazing slow flight on about one third to a half

throttle with the nose high, including a virtually stationary

hover on a breezy day.

IMPORTANT WARNING.

READ THROUGH BEFORE ASSEMBLING OR FLYING YOUR KIT.

Just as in any full size aircraft, any RIC model aircraft can be made to fail, be

it

a wing folding or a fuselage breaking under too high a load. Model RIC aircraft have a maximum safe G limit. Because you are

not in the plane

it

is difficult to judge the G during flight, and it is very easy to exceed the limits of the

aircraft. This is particularly important

if

you install a turbine larger or more powerful than the power band

specified for that particular kit. This negates any airframe warranty straight away.

All our designs are thoroughly test flown before the kit is released for sale. Turbine powered RIC model

aircraft are not manufactured to withstand unlimited G forces. When flying your Boomerang Jet, be

aware of the high loads which can be in excess of the airframes capability to handle. Respect the

airframe as you would when flying a full size aircraft. Fit a turbine only up to the specified power.

Understand that if you perform a snap roll, wall, blender, knife edge loop or any similar maneuver, or

pull hard on the elevator, particularly at high speed, you can over stress the airframe by up to15 G or

more. At 15 G, the 27 lbs (12.2 Kilo) model effectively weighs over 400 lbs (184 kilo), and though it may

be for only a few seconds, the strain on the airframe is huge. Your model may survive those hard

maneuvers a few times, but eventually the cumulative damage will tell and airframe break up can

occur.

It is common practice for any manufacturer not to replace an airframe which breaks in the air or upon

landing. Manufacturers may replace airframes when they have noticed many incidences of the same

failure and it is determined that there was a design fault or repeated manufacturing error. If you break

an airframe, and you are the only one to do so, then it is highly unlikely to be the fault of the manufacturer. Fly safely, and avoid full throttle operation other than at low airspeeds.

RIC model jets are not toys! If misused, they can cause serious bodily harm and property damage. Fly

only in open areas, and AMA (Academy of Model Aeronautics) or BMFA (British Model Flying Association) or your country's approved flying sites. Follow all manufacturer instructions included with your

plane, radio, servo's, batteries and engine. Each kit is guaranteed to be free from defects in both material and workmanship at the date of purchase. Warranty does not cover any component assembled by

the customer. All parts of high stress must be inspected and reinforced if necessary by a competent

builder.

Some parts should be examined, and if necessary, glued again. High stress areas such as firewalls,

motor mounts, wing mounts, landing gear mounts, etc., are areas of high concern. Seek help if necessary.

In no case shall Boomerang RC Jets, LLC. warranty cover any product which is not manufactured

by Boomerang RC Jets, LLC. The liability to the manufacturer cannot exceed the original cost of

the purchased item.

Further, Boomerang RC Jets, LLC. reserves the right to change or modify this warranty without

notice. In that Boomerang RC Jets, LLC. has no control over the assembly or materials used by the

builder of the model during final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use of the final user-assembled product. By using the user assembled

product, the user accepts all resulting liability. The kits manufacturers have provided you with a top

quality, thoroughly tested kit and instructions, but ultimately the quality and flying ability of your finished

model depends on how you build it. Therefore, we cannot in any way guarantee the performance

of your completed model, and no representations are expressed or implied as to the performance or

safety of your completed model. It is the user’s responsibility to inspect each component for

airworthiness.

Loading...

Loading...