Gas spit ROASTING OVEN

BONNET CIDELCEM GRANDE CUISINE

Siége social:

Rue des Frères Lumière - Z.I Mitry Compans

77292 MITRY MORY Cedex

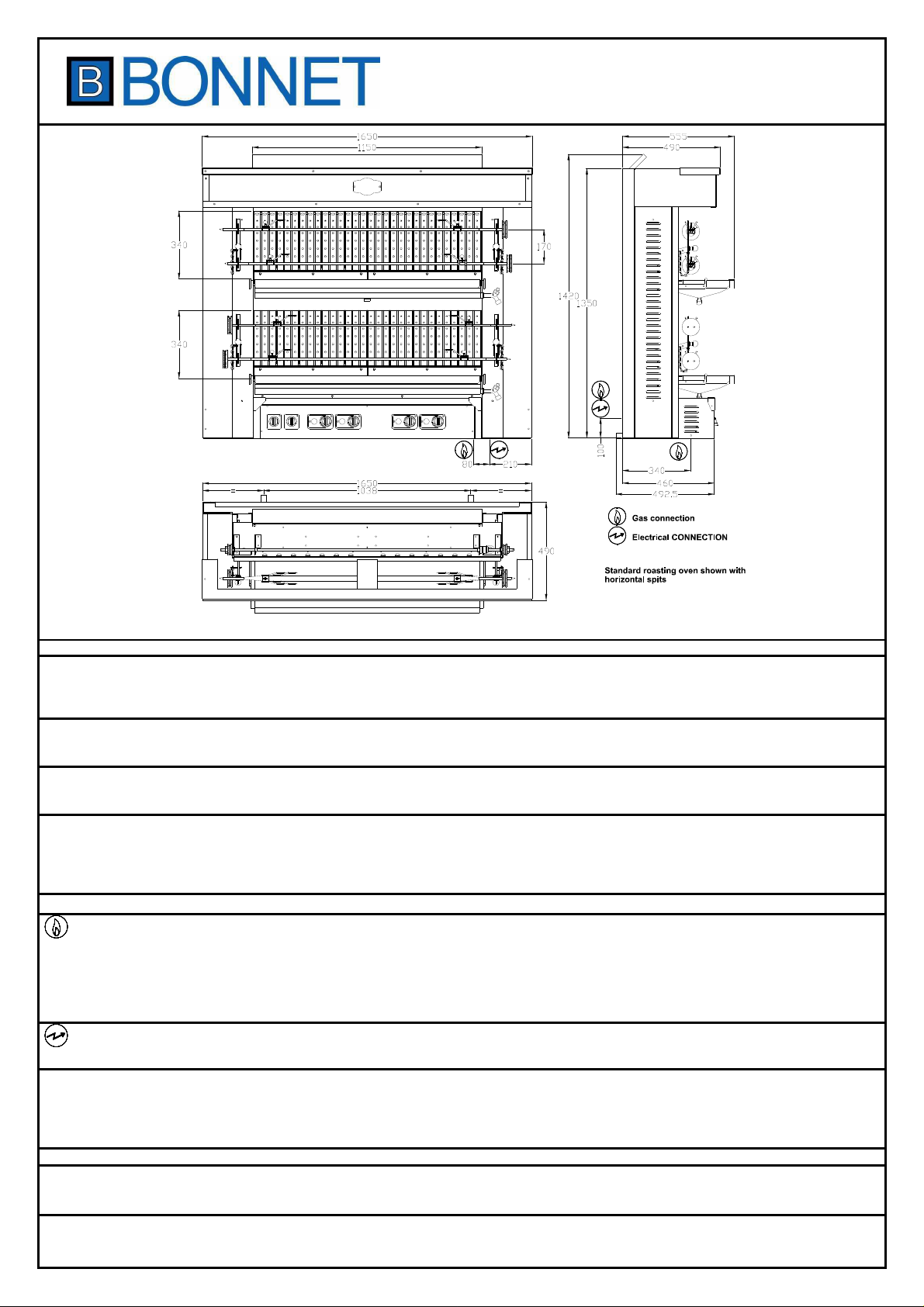

M642D142

Standard roasting oven shown with

GGEENNEERRAALLIITTIIEESS

• Spit roasting oven frame in 3 mm ferritic stainless steel with titanium coating.

• Trimming in black enamelled sheet, or 18-10 grade stainless steel.

• Trimming elements in nickeled plated coating brass.

• 18-10 grade stainless steel removable dripping-pan enabling cooking juice to be recuperated.

• Horizontal spits driven by a in nickeled plated coating brass chain for show cooking.

• Adjustable (6 positions) horizontal spit holder.

• Versatility of cooking provided by the number of motors (Separation of motorisation system between horizontal and vertical per vertical half-sides).

• Spits driven by electrical moto-reducers, supplied by energy regulator generating the possibility of a sequential operation.

- 3.3 revs/min horizontal spits.

- 5 revs/min vertical spits.

• Refractory cast-iron hearth fitted with ceramic fibre « bunches ».

• Heating and temperature distribution ensured by 15 flame solid stainless steel burner at the cast-iron foot base.

• Hand switching on.

• Thermocouple safety pilots.

• Equipment of provided pins (see tariff).

CCOONNTTRROOLL PPAANNEEL

• One control per gas ½ hearth.

• One control per vertical half-side for horizontal and vertical spits combined.

- Nickeled plated coating brass knob trimming plate on detachable front lid.

- Nickeled plated coating brass rotary knob.

OOPPTTIIOONNS

• Colour of enamelled coating as per the shade range.

S

AACCCCEESSSSOORRIIEESS ((NNOONN PPRROOVVIIDDEEDD)

• Horizontal spits (see tariff).

• Vertical spits (see tariff).

• Unheated and heated bases (see tariff).

L

)

horizontal spits

:

SSTTAANNDDAARRDDSS:

EN 203/1 : European standard relating to the safety of gas appliances.

EN 60335-2-36 : European standard relating to the safety of gas appliances.

IP 25 and IK9 : Index of protection.

Compliance with the standards

RT642G

DIMENSIONS

(mm)

RATED CAPACITY

DIMENSIONS OF PACKAGING

CONSTRUCTION

APPLIANCE TYPE

BONNET CIDELCEM GRANDE CUISINE

Siége social:

Rue des Frères Lumière - Z.I Mitry Compans

77292 MITRY MORY Cedex

LLAAYYOOUUTT

WWEEIIGGHHT

GGAASS CCOONNNNEECCTTIIOONN

Mounted against a wall, on a table or a specific support.

Leave at least 150 mm free space on each side of the roasting oven.

Also provide at least 1500 mm free space in front of the roasting oven.

External (Overall) 1650 590 1420

Heating hearth – Top / Bottom 1150 340 / 340

Capacity of horizontal spits 24 chickens

Capacity of vertical spits 14 portions

Dimensions of roasting oven packaging (LxDxH mm) 1720x560x1580

Volume of roasting oven packaging (m3) 1.52

Int. dimensions of accessory packaging (LxDxH mm) 1470x420x470

Volume of accessory packaging (m3) 0.29

T

(Kg)

S

GGAAS

Type Pressure Flow rate

G20 Natural gas 20 mbar 4.02 m3/h

G25 Natural gas 25 mbar 4.67 m3/h

G30 Butane 50 mbar 3 Kg/h

G31 Propane 50/37 mbar 2.95 Kg/h

EELLEECCTTRRIICCIITTYY

Mono 230V 230 V a.c. / 50hz

Welded/screwed frame Stainless steel F17 Th. 30/10

Trimming

Hearth Cast-iron FT25

(1 electrical outlet)

Length Depth Height

Packaging wrapped on wooden base

Gross

352

38 kW

Stainless steel 18-10 Th. 12/10

or EME enammelled sheet

Independent

Net

P (kW) = 0,1

Gas outlet at 100 mm above the base (20/27 mm thread)

The equipment is G 20/20 mbar (and G 25/25 mbar) fitted as standard or another gas on request

ELECTRICAL CONNECTION

Electrical outlet at 100 mm above the base.

This document is not contractual Edition 12/2009-MBE023FT

318

Loading...

Loading...