Bonis Machinery Corporation 3-6161-2-3 User Manual

BON

IS

SEWING

MACHINES

Bonis

Bros.

Locat

312

Machinery

ed

in

tlte

heart

SEVENTH

NEW YORK 1,

LOngacre 3-6161 -

Corporation

of

Manhattan

AVENUE

N.

Y.

2-3

USE

ONLY

NEEDLES

GENUINE

and

PARTS

BONIS

Bonis

models

the

needs

Model

wide

heavy

sewing

with

very

of

several

A is

throughout

fur

skins.

VARIOUS

BONIS

machines

fine

different

the

recognized

the

industry. It

SEWING

are

adjustments,

industries.

standard

is

TYPES

made

guides

used

OF

MACHINES

in

different

and gauges

fur

sewing

for

sewing

very

models and

to

accom

machine

fine

and

types

modate

used wor

medium

of

ld

It

is

imperative

by

inte ns

ive

especially

temper

perfect

fi

ne work. Th

breakage.

It

is

make

ulously

fully sk

agent

U. S.

and

or from

FOR

for

and

fit

to

GENUINE BONIS MACHINE PARTS

not

possi

it

work

manufactured

illed

mechanics

s. Th

ese

and

Europ

service.

one

WHEN ORDERING PARTS YOU

WHICH

THEY

to

use

Genuine

research,

Bonis

smoo

produce

ey eliminate skipping

ble

to

right.

agents are l

e.

BE

SURE

of

these

Machines;

th

eye. They

maximum

put

All Bonis

in

They

to

authent

ARE

TO

they

old

parts into

our

and sold

ocated

are

equipped

order

BE

Bonis

have

precis

are

efficiency

machines

own

plant

by

directly

ic

agents.

USED.

been

ion

also

of

stitches;

us

in

all

to

from

MUST

Needles

designed

made

the

in

need

are

equally

a n

ew

type

and their

under

or our

impor

give

you

our

STA

TE TYPE

ONLY

.

Perf

ected

and

made

with

the

prop

exact length and

sewing

the

authorized

tant cit

heavy

le

and

importa

mach

par

ts

are

supervision

ies

excellent sal

New

York

OF WORK

thread

ine

metic-

Bonis

of the

office

and

er

or

nt.

of

es

Model B comes

produces

and

millinery trade

duty

c

omes

pl

ush, plastics,

in

whip stitching

Model

B is

all

heavy pel

Equipped

Still

another

work

such

THEREFORE

WORK

AN

Model T machine

Model T for

In

automobiles,

TO

D NEEDLES.

in a

variety

different

in many di

also

used

ts

and

with various gauges,

to

insert

type

of

as:

sewing

IT

IS ABSOLUTELY NECESSARY

BE

DONE

has

of

types.

the toy

vinyl, terry cloth,

types,

it is

ear laps

used

on

for heavi

for

closing

wire

in

Mode

house

WHEN

been

market

used

on

caps

ffere

gloves

er

rims

l B

slippers,

ORDERING ANY

perfected

will

or

to

and

nt t

ypes.

and kidskin

work,

heavy

the Mod

of

ladies'

is

highly

taxidermy and

for

sew

any

other

sew

handles

on

many

One

with

such

as

type

furs.

el B mach

hats.

success

TO

MACHINE

extreme

beautifully

tough

on

sty

les

fine

products

moutons,

ine

ful

for

all

STATE

ly

coarse

and

fabric.

luggage,

of

house slippers.

adjustments

.

sheep

is

used

in

even

heavier

coarse

work.

THE

TYPE

OR ITS PAR

work and

efficie

ntly

robe

straps

skins

the

OF

TS

on

To

stand,

plate

which

attached

Place

the

right

base

plate.

base

plate

so

that

up

plate

inches

sewing

gloves,

When

and

remove

old

chain

plate

is

drainage

chain

drill

through

plate

and

wood

TO

set

up

remove

under

base

so

that

DO NOT

and

belt

and

back

toys,

it

is

lined

hole will

on

oil

hole

lever

table

screws.

any

Bonis

the

old

contains

the

plate

the

line

is

free

machine

from

front

the

plate

set

one

up

machine

drainage

must

on

the

table

correspond.

Now

SET

machine,

type

plate

an

oil

stand.

on

the

two

belt

PLACE

up

machine

from

table

to

favor

edge

is

set

inch back.

properly,

head.

correspond

hole.

be

drilled in

side.

Now

top.

Replace

place

machine

UP

and

reservoir

table

holes in

SCREWS

top

belt

for

sewing

flush

mark

Note

with

Mark

table

toke

plate

Fasten

MACHINE

whether

belt

that

on a power

replace

for

drainage

with

the

table

top

YET,

first,

with

slots

and

holes. Base

furs

with

front

position

there

new

one,

this

with

top.

Before drilling this hole,

plate

off

on

table

bose

plate

on

bose

it with a

large

motor. Put

of

ore

plate.

will

put

belt

and

of

plate

but

pencil

and

and

firmly

table

genuine

of

oil into

hole in

be

to

machine

will

move

plate

doth.

table;

on

two

holes in

at

upper

on

drill

see

to

or

base

the

right

in

place

belt

over

freely.

must

be

However,

and

for

table

with

left

old

table,

one

that

all

table

individual

Bonis

base

the

oil

plate

of

on

wheel

Line

set

two

when

sewing

pencil

plate;

corner

as

drop

inch

wood

holes in

with

four

jar

to

the

the

the

of

-CAUTION-

Sometimes a table

machine

see

if

the

four

under

four

binding;

spring

cause

at

foot

a

important

out

Moke

foot

stays

foot,

to

that

there

machine

wood

the

Now

machine

Put

toward

the

bottom

pedal

easily,

sure

The

pedal

open;

open

position

does

not

machine

is

any

play

head

screws a few

plate

so

put

chain

screws

now

put

jar

holder

bock

next

step

where

to

see

to

squeeze

because

there

is

best

way

and

wedge

then

arm,

very

slowly,

top

is slightly

bind

because

is

perfectly

in

and

that

through

and

on

belt.

into oil

of

is

it is

free

that

chain

chain

should

leverage

of

tightening

close hook into

then

remove

firm

the

corners, it is

mark

the

turns

and

base

plate

chain

turn

jar

the

stand

installation

from

works

link

this

in left foot

either a screw

wedge

or

you

warped.

of

this.

on

the

corner

force

is level. Replace

hole,

hand

wheel

hole

and

- this position is most

of

the

the

oil jar. Hook

properly

into

the

work

loose, it will

pedal

chain

to

driver

the

lever. Before

and,

will

break

To

base

certainly

where

two

fasten

so

screw

chain

without

lever

lever

or

by

wheel

Caution

guard

plate;

it is

or

three

head

that

into

lever

chain

so

to

work

...

piece

holding

discs.

must

against

if it rocks

advisable

not

steady.

thicknesses

machine

firmly

it is

free

plate.

important,

...

Set

into lever,

any

obstruction. It is

that

it will not

cause

wheel

machine

open

of

wood

removing

arm,

be

this

to

head.

to

plate

without

leave

chain

arm

arm

so

wedge,

let it

used

that

binding,

at

all,

remove

Loosen

of

paper

with

any

thumb

be-

lever

now

try

come

beokoge.

freely.

with left

that

arm

toke

return

or

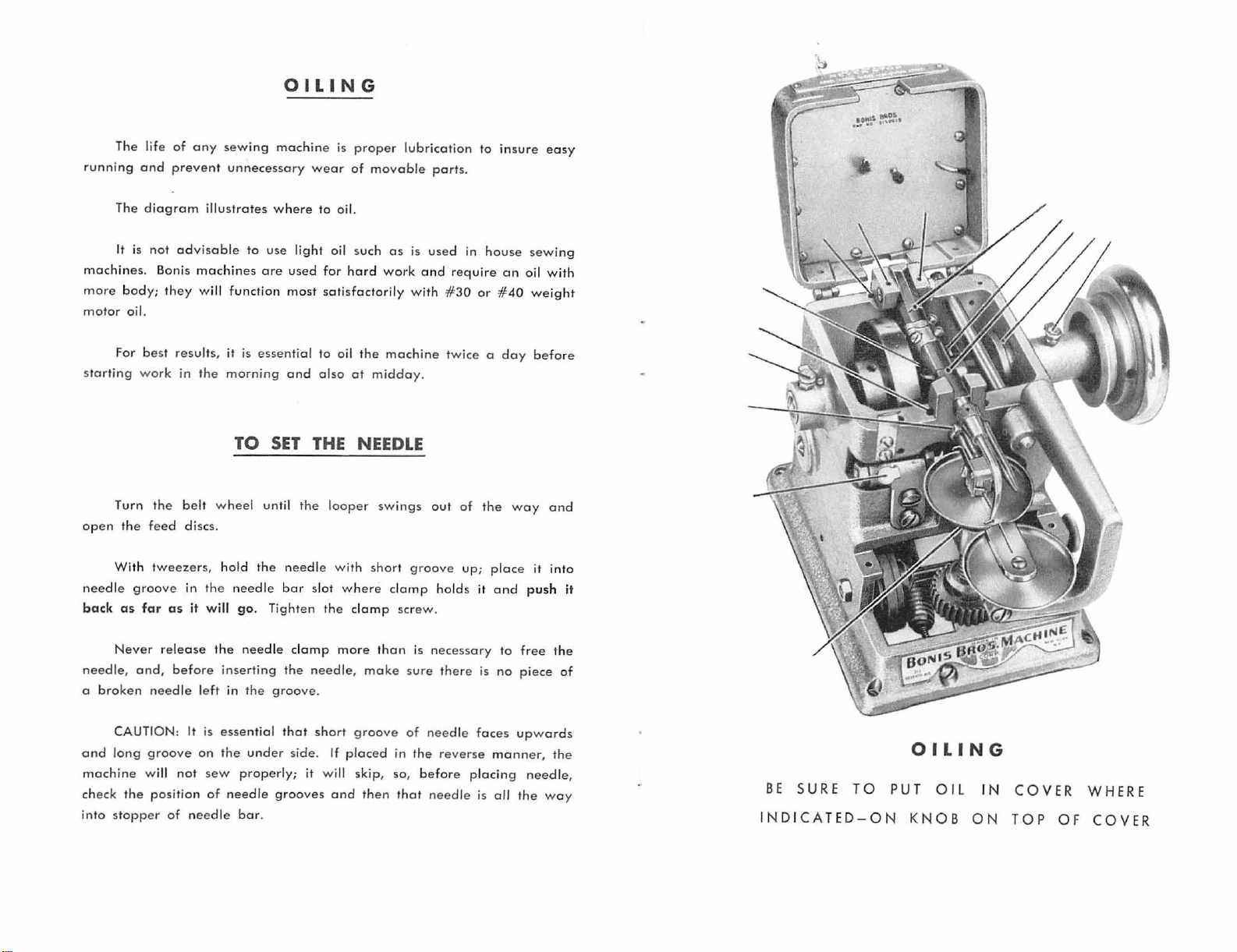

OILING

The life

running

The

It

is not

machines.

more

body; they will

motor

oil.

For best

star

ting work

Turn the

open

the

Wi

th

n

eed

le groove

back

as

of

any

sewing

and

prevent

diagram

advisable

Bonis

resul

in the

unnecessary

illustrates

machines

function

ts,

it

is

morning

TO

belt

wheel until

feed

disc

s.

twe

ezers, hold the needle

in the

needle ba

far

as

it

will

go. Tighten

machine

where

to

use

light

are

used

most

essential to

and also

SET

the

r sl

is

proper

wear

of

to

oil.

oil s

for

hard

satisfactorily w ith #

oil

at

THE

NEEDLE

looper

w ith

ot where

the clamp scr

movab

uch

work

the

midday.

swings

short

lubrication

le

as

is

machine

groove

clamp

ew.

part

s.

used

and

require

30

tw ice a day

out

of

up; place it

hold

s it a

to

in

house

or #40

the

insure

sew

an oil

weig

before

way

nd push

easy

ing

with

ht

and

into

it

Never relea

needle,

a

and

machin

check

into stopper

and,

brok

en needle

CAUTION:

lon

g g

e w

the

before inse

It

roo

ve

ill

not

position

of needle

se

left

on

the

is

sew

of

need

rting

in

the

esse

ntial

the

under side

properly;

needle

bar.

le

clamp mo

the needle,

groove.

that

short

. If

it w ill skip,

grooves

placed

and

re

than

make su

groove

so,

then that

is ne c

re there is

of

needle

in

the

befor

essa

ry

to

no

faces upwards

reverse

needle

manner, the

e placing needle

is a

ll the

free the

piece

of

way

,

BE SURE

I

NDICATED-ON

TO

OILING

PUT

KNOB

OI

L

IN

ON

COVER

TOP

OF

WHERE

COVER

To

ar

pig

re

# 3,

from

hole

# 5

the

needle

front

bar

into

cl

ose

through

thread

instr

uctions

When

s

kips,

which

1 -

Check

with

entire

results

and

thread the

tail (

thread

top

continue

in

the needle

bar

tension

disc

and pass

thread slot # 7. L

up

up

or

you

under

which

the

the

the

through

by

number.

operating

thread

can

very

front

disc

loose

fur,

wheel,

in

producing a proper even

thread

THREADING

machine; take

guide)

through

bar tension

plunger

thread

oop

needle

needle protrudes.

the nee

KEEP

d le

YOUR MACHINES CLEAN

for

ward and

front

#6

und

er

thread

bar

eye

thread

plate.

and

# 9.

for

# 1 s

over

between

pigtail

opens;

the nee

over tension plunger

into

Now, from

# 4,

Now

turn

holding

dle

and

hole # 8 in the

Make

sure you foll

MINOR ADJUSTMENTS

your

breaks

well

and

remove

rollers and

breakage.

machine,

often, it

do.

see

that

needle

stu

d.

if it

it is

may

running

plat

By

doing

seam.

does

not

need

smoo

e,

take wheel

this

It

pool

holder,

the

down

and

the

machine

the

thread

back under

# 6

the

un

derside,

ow

function

some

minor

thly and

apart, wipe

you will

also eli

minates

through

tension

through

pull

tight,

the

draw

forward,

tension

the

se simple

properly,

adjustment

not

get

exce

discs

ey

until

open

needle

plate

pass

if

clogged

llent

skipp

# 2

the

the

it

off

ing

2 -

Make

sure

Also

Take

See

that

3 - Loosen

back need

the

other

Ta

ke

maximum efficien

be

it

care

needle

sure

apart

thread

two

le

for

of

plate

needle

and

runs through

screws

bar

a little.

better

you

r Bonis

cy

slot

is

is not be nt,

clean

it.

in

needle bar

Sometime

sewing

Machine

under

severe

free

eye

results.

of ridges

see

that

of

needle freely.

yoke insi

s it

has

and

it w

tests.

and any

tension

de

machine

to

be moved one

ill

take

core

foreign

is

free

of

and

you

matter.

of

dirt

push

way

w ith

.

or

When ordering

to

be

done,

interchang

os the re

eable.

ports -spe

ore vari

ous

cify

mode

model of

ls

of

machines

machine

and

and

type

some

of

wor

ports ore

. . . .

·------

k

30

201

224

29

-

248

BONIS SEWING

Ports

Numb

er D

1-A

24 Belt W h

203 Belt

29

30

105

201

224 F

248

409

Main

Main Shaft

Main

Mai

P

ress

eed Shaft

Main Shaft

Sma

esc

ription

Frame

ee

l

Wheel Screw

Bushing

Shaft Bus

Shaft

n

ure L

ever

Screw

Bush ing

ll Oil

Cup

MACHINE

long

hing -short

Shaft

Screw

Nut

Screw

PARTS

24

I

203

409

105

• a

..........

ena&ae

Loading...

Loading...